Page 1

EN

AIO Copter Flight Control with copter firmware Q06

AIO Copter Flight Control

Manual

Copyright © Graupner/SJ GmbH

No. S1038 with 5V SBEC, No. S1038.SW with 12V SBEC

Page 2

2 / 36 3 / 36

S1038_Q06_V2.0sh_en S1038_Q06_V2.0sh_en

Table of content

Introduction ......................................................................................4

Service centre ...................................................................................4

Intended use ....................................................................................5

Target group ....................................................................................5

Package content ................................................................................5

Technical data ...................................................................................6

Symbol description ...........................................................................6

Safety notes ......................................................................................6

For your safety by handling the transmitter and the receiver .......7

For your safety by handling the batteries ......................................8

Installing the Graupner S1038 AIO FC .............................................9

Connecting the RC components of the copter ...............................9

Connection socket J9 “FPV transmitter” .....................................9

Connection socket J10 "Telemetry/Update/Waypoints" ............9

Connection socket J11 - J14 "RGB-LEDs" .....................................9

connection socket J28 or Pin lines "ESC" .....................................9

Connection socket M27 and M28 “CAM POWER“ ......................9

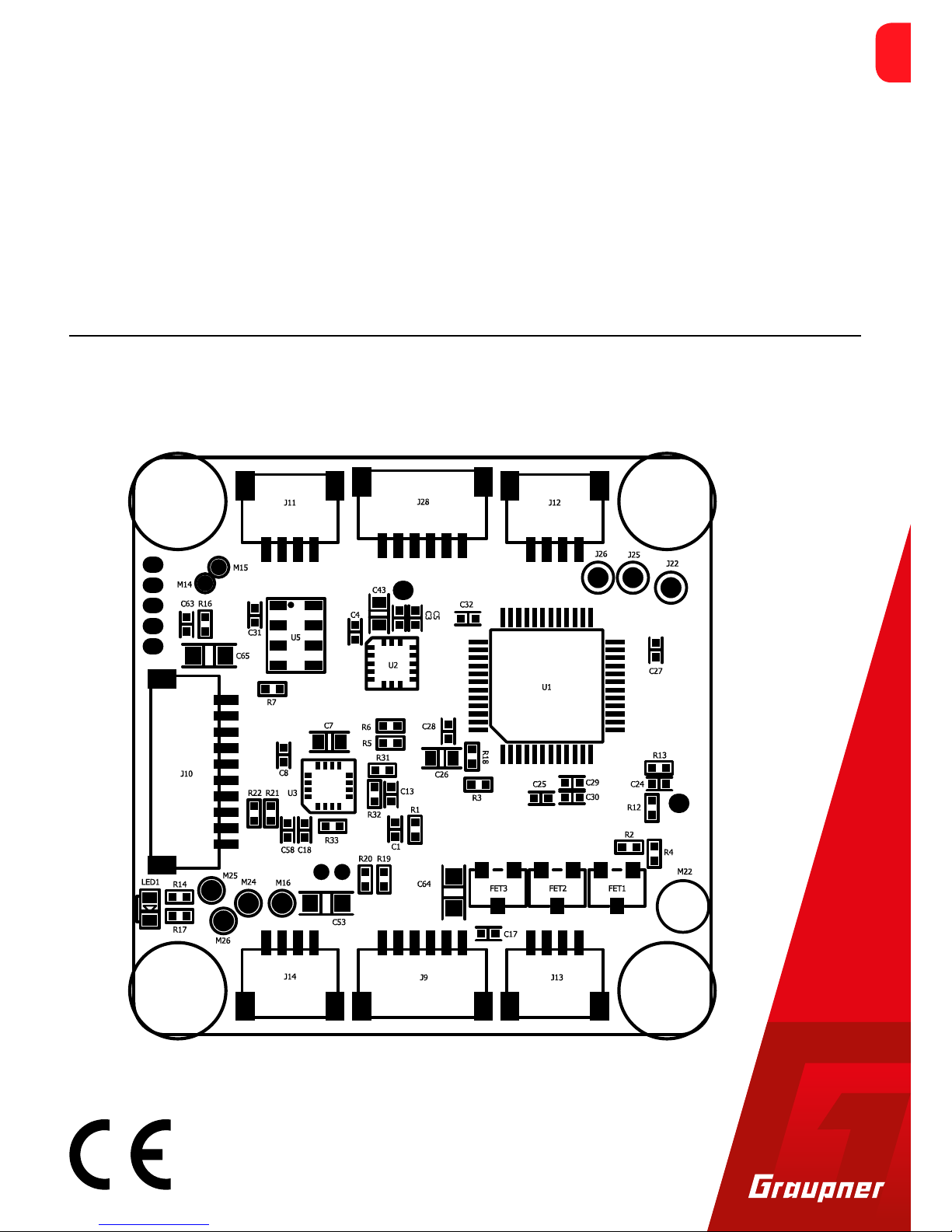

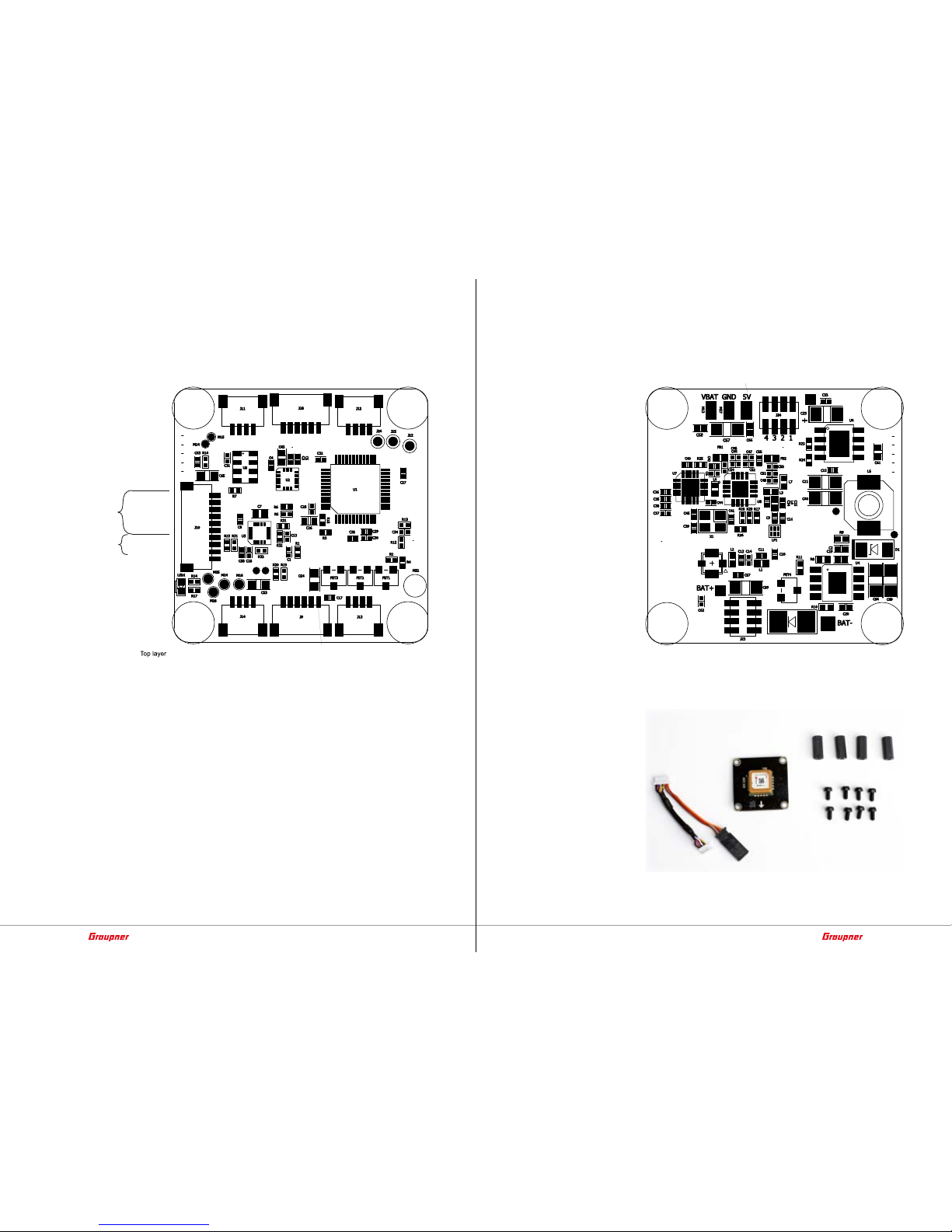

Top side of the Graupner S1038 AIO FC .......................................10

Bottom side of the Graupner S1038 AIO FC.................................11

Optional accessories ..................................................................11

Binding .............................................................................................12

Transmitter presettings ..................................................................13

Flight mode ...................................................................................13

Auto-flip function on channel 6 ....................................................15

Advancing the FPV transmit channel ...........................................15

"Telemetry" menu ..........................................................................17

SETTING & DATA VIEW ..................................................................17

Receiver display .........................................................................17

ROLL/NICK Display .....................................................................18

YAW Display ................................................................................20

MULTIC. AUTOPILOT ..................................................................20

BASIC Display ..............................................................................22

AXIS ASSIGNMENT .....................................................................28

Firmware update ............................................................................31

SIMPLIFIED DECLARATION OF CONFORMITY ................................34

Manufactured by ..........................................................................34

Notes on environmental protection ..............................................35

Care and maintenance ...................................................................35

Warranty certificate........................................................................35

Page 3

4 / 36 5 / 36

S1038_Q06_V2.0sh_en S1038_Q06_V2.0sh_en

Intended use

The Graupner S1038 AIO Flight Control should only be used for the

purpose specified by the manufacturer for operation of remote controlled UAVs and other unmanned RC-models. Any other type of use

is impermissible and may cause significant property damage and/or

personal injury. No warranty or liability is therefore offered for any

improper use not covered by these provisions.

In addition, it is explicitly pointed out that you must inform yourself

about the laws and regulations applicable at your respective starting

point before starting the remote control operation. Such conditions

may differ from state to state, but this must be followed in every

case.

Notes

• In general, it should forbidden to fly over airfields, factories,

nature reserves, built-up areas, etc.

• Where designated no-fly zones are located, and which in no way

affect them, it can be determined, for example, using the "AirMap" app.

Read through this entire manual before you attempt to install or use

the receiver.

Target group

The item is not a toy. It is not suitable for children under 14. The

installation and operation of the receiver must be performed by

experienced modellers. If you do not have sufficient knowledge

about dealing with radio-controlled models, please contact an experienced modeller or a model club.

Package content

• S1038 or S1038.SW AIO Copter Flight Control

• Manual

Introduction

Thank you very much for purchasing a S1038 Graupner AIO FC.

Read this manual carefully to achieve the best results with your HoTT

system and first of all to safely control your models. If you experience

any trouble during operation, take the instructions to help or ask

your dealer or Graupner Service Centre.

Due to technical changes, the information may be changed in this

manual without prior notice. Be always updated by checking periodically on our website, www.graupner.de to be always uptodate with

the products and firmwares.

This product complies with national and European legal requirements.

To maintain this condition and to ensure safe operation, you must

read and follow this user manual and all the safety notes before

using the product and you have to respect those notes also for future

use!

Note

This manual is part of that product. It contains important information concerning operation and handling. Keep these instructions for

future reference and give it to third person in case you gave the

product.

Service centre

Graupner Central Service

Graupner/SJ GmbH

Henriettenstraße 96

D-73230 Kirchheim/Teck

Servicehotline

(+49) (0)7021/722-130

Monday - Thursday:

9:15 am - 4:00 pm

Friday:

9:15 am - 1:00 pm

service@graupner.de

Graupner USA

3941 Park Dr Suite 20-571

El Dorado Hills, CA 95762

Website: www.graupnerusa.com

Phone: +1 855-572-4746

Email:service@graupnerusa.com

Graupner in Internet For the service centers outside Germany please refer to our web site

www.graupner.de.

Page 4

6 / 36 7 / 36

S1038_Q06_V2.0sh_en S1038_Q06_V2.0sh_en

Technical data

Antenna

1x 145 mm,

of which the last 30 mm active

Operating voltage 7.4 ... 15,2 V

Frequency range 2400 ... 2483.5 MHz

Modulation 2.4 GHz FHSS

Current consumption approx.

70 mA

Temperature range -15 … +70°C

Dimensions approx. 36 x 36 x 10 mm

Weight approx. 9 g

Symbol description

Always observe the information indicated by these warning signs.

Particularly those which are additionally marked with the words

CAUTION or WARNING.

!

The signal word WARNING indicates the potential for serious injury,

the signal word CAUTION indicates possibility of lighter injuries.

The signal word Note indicates potential malfunctions.

Attention indicates potential damages to objects.

Safety notes

!

These safety instructions are intended not only to protect the product, but also for your own and other people’s safety. Therefore please

read this section very carefully before using the product!

• Do not leave the packaging material lying around, this could be a

dangerous toy for children.

• Persons, including children, with reduced physical, sensory or

mental capabilities, or lack of experience or knowledge, or not

capable to use safely the receiver must not use the receiver without supervision or instruction by a responsible person.

• Operation and use of radio-controlled models needs to be learnt!

If you have never driven such a model, then start extra carefully

and make sure to be familiar with the reactions of the model to

the remote control commands. Proceed responsibly.

• First, always perform a range and function test on the ground (to

do so, hold your model tight), before you use your model. Repeat

the test with running motor and with short throttle bursts.

• Only use the components and spare parts that we recommend.

Always use matching, original Graupner plug-in connections of

the same design and material.

• Make sure that all of the plug-in connections are tight. When disconnecting the plug-in connections, do not pull the cables.

• Protect the AIO FC from dust, dirt, moisture and foreign parts. Do

not expose it to vibrations or to extreme heath or cold. The models may only be operated remotely in normal outside temperatures such as from -10°C to +55°C.

• Always use all your HoTT components only with the latest firmware version.

• If you have questions which cannot be answered by the operating manual, please contact us or another expert in the field.

For your safety by handling the transmitter and the receiver

!

WARNING

Also while programming the transmitter, make sure that a connected motor cannot accidentally start. Disconnect the fuel supply or drive battery beforehand.

!

CAUTION

Avoid every kind of short-circuit in all sockets of the transmitter!

Risk of fire! Use only the suitable connectors. In no case the electronic component of the transmitter or of the receiver may be

changed or modified. Due to licensing reasons, any reconstruction

and/or modification of the product is prohibited.

Note

During transport protect the model and the transmitter from damages.

Page 5

8 / 36 9 / 36

S1038_Q06_V2.0sh_en S1038_Q06_V2.0sh_en

For your safety by handling the batteries

!

CAUTION

• Protect the batteries from dust, dirt, moisture, heat and vibrations. Only use in dry locations.

• Do not use any damaged battery.

• Batteries may not be heated, burned, short-circuited.

• If handled improperly, there is a danger of fire, explosion, irritation and burns.

• Leaked electrolyte is caustic and should not be touched or

come into contact with your eyes. In case of emergency, rinse

with a large quantity of water and consult a Med. Doctor.

• Stock the batteries in dry and fresh conditions.

• Dispose of the battery in the proper disposal centers.

Installing the Graupner S1038 AIO FC

The Graupner S1038 AIO FC must be mounted with its lower surface

parallel to the chassis using the rubber buffers and M3 screws.

The Graupner S1038 AIO FC must be protected against dust, splash

water, etc. in the model. But do not pack your AIO FC too airtight so

that it does not overheat during operation.

The cables may not be wound around antenna or run next to it. Make

sure that the cables cannot shift to lie directly adjacent to antenna

during flight.

In the case of carbon fibre chassis, at least the last 35 mm of the

antennas shall be routed outside.

Connecting the RC components of the copter

Insert the connection cable of the ESCs of the copter, which must be

connected to the receiver, with the black or brown cable upwards

into the connector strip of the receiver, as shown in the illustration

on the left. The polarity of the plug-in system cannot be reversed. Do

not apply force. The servo connections of the Graupner-HoTT

receiver are numbered. Only use speed controllers that are multi-

shot capable to connect the motors.

Connection socket J9 “FPV transmitter”

If necessary, the FPV transmitter # 16570.123 is connected to the

socket labelled “J9”. For S1038.SW Voltage reduction 12V to 5V PDB

#8474 is needed.

Connection socket J10 "Telemetry/Update/Waypoints"

Connector J10 “Telemetry / Update / Waypoints”

If required, the optional GPS module, order no. 33602 connected. In

addition, receiver updates are performed through this jack.

The Smart Audio connector can be used to connect an FPV video

transmitter with the Smart Audio function. If required, the power

supply of the video transmitter can be made via the 5V / .SW 12V

connection and GND.

With the help of the adapter cable S1038.2 software updates or waypoints can be loaded. Optionally, a receiver can be connected to

SBUS to operate the flight control with an SBUS receiver.

The SBUS signal is detected automatically after switching on the

Flight control.

Connection socket J11 - J14 "RGB-LEDs"

If required, the optional RGB LED PCBs are connected to sockets

labelled "J11 - J14".

connection socket J28 or Pin lines "ESC"

The 4in1 ESC # 7242.4 is connected to the sockets labelled "J?". The

4in1 ESCs # S3087 or # S3088 are connected to the double row pin

headers J23 / 24.

Connection socket M27 and M28 “CAM POWER“

The FPV camera is connect to the sockets “M27” (GND) and “M28”

(5 V) (S1038.SW 12V).

Page 6

10 / 36 11 / 36

S1038_Q06_V2.0sh_en S1038_Q06_V2.0sh_en

Top side of the Graupner S1038 AIO FC

RGB-LEDs

RGB-LEDs

B

G

R

+ 5V

/12V

B

G

R

+ 5V

/12V

RGB-LEDs

RGB-LEDs

B

G

R

+5V

/12V

B

G

R

+5V

/12V

CH8_TIM2_CH2

CH7_TIM2_CH1

CH6_TX3_TIM2_CH3

CH5_RX3_TIM2_CH4

GND

S1038 +5V,

S1038.SW 12V

FPV-TX

GND

+5V/ .SW +12V

USART1_TX

USART1_RX

I2C_SCL

I2C_SDA

GND

+5V/ .SW 12V

Telemetr./SBUS

SMART-AUDIO

+5V

+3V3

CURRENT

SENSE

USART2_RX

LED4

BAT+

GND

CURRENT SENSE

GND

PWM MOTOR 4

PWM MOTOR 3

PWM MOTOR 2

PWM MOTOR 1

GPS

S1038 5V

S1038.SW 12V

Bottom side of the Graupner S1038 AIO FC

BAT+

GND

CURRENT SENSE

S3087/S3088

PWM MOTOR1-4

GND

BAT+

S1038 5V

S1038.SW 12V

Optional accessories

GPS-Module 33602

Page 7

12 / 36 13 / 36

S1038_Q06_V2.0sh_en S1038_Q06_V2.0sh_en

Binding

To establish a connection with the transmitter, the Graupner HoTT

receiver must first be "bound" to at least one model memory in "its"

Graupner HoTT transmitter. This process is generally called "binding". However, the available methods to be used are not always the

same, so the following step-by-step instructions apply only to binding a HoTT AIO FC to any transmitter:

Binding step-by-step

• If the Graupner S1038 AIO FC is already bound to a specific trans-

mitter and this binding should be maintained, the transmitter

should ideally be switched on before the receiver. At the latest,

however, within approximately 15 seconds from the moment

when the receiver is switched on, the red LED of the receiver is

constantly on.

Attention

As soon as the LED starts to flash, the AIO FC is in bind mode.

From this point on there is the risk that the AIO FC unintentionally binds to a transmitter, which is casually in bind mode at the

same time, whereupon the model can run uncontrolled at any

time. The distance between transmitter and AIO FC should be at

least 0.5 m, otherwise the receiver of the AIO FC can be overdriven.

• If the Graupner S1038 AIO FC is unbound or it should be bound

to another transmitter or only the model memory has to be

changed than the previous one, proceed as follows:

1. Prepare the transmitter or model memory to be bound according to the instructions for binding.

2. Switch on the copter power supply.

3. The LED of the AIO FC lights constantly red.

4. Approximately 15 seconds after the AIO FC is switched on, its

red LED starts to flash, indicating that the AIO FC is now in

bind mode.

5. Start the transmitter-side binding according to the instructions of the transmitter.

6. If the red LED of the AIO FC goes out within about three seconds, the binding process has been completed successfully.

7. Your transmitter/AIO FC combination is ready for operation.

If the LED on the Graupner S1038 AIO FC remains still red, the

"binding" has failed. Change the positions of the associated

antennas and try the entire procedure again.

Transmitter presettings

Depending on the bandwidth of the model type selection of the

transmitter used, either the model type "Copter" or alternatively a

"Fixed-wing model" should be selected. Some of the current HoTT

transmitters are even shipped with preconfigured model memory.

According to the transmitter instructions, the appropriate control

mode and, if necessary, "motor front / rear" must be set. Usually

"backwards" so that the channel 1 indicator in the servo display indicates -100% in the "motor off" position of the "motor / pitch control

stick".

Flight mode

Flight mode has to be set to channel 5. To do this, according to the

transmitter instructions program a 3-way switch in the »Transmitter

setting« menu on channel 5 as follows on the next page:

Attitude mode

The stick movements acts directly proportionally to Roll and Nick. In

the attitude mode, the maximum inclination angle is limited to

approx. 50° at 100% of the stick travel.

The attitude mode is active as long as the bar of channel 5 is on the

left of +49 % in the »Servo display«.

(The 0 % shown on the left are based on the switch programming

above.)

Flight mode suggested for beginners.

Rate mode

In this mode, the rate is determined by the rash of the stick without

inclination limit. In this aerobatic mode rolls and loops are possible.

The rate mode is active as soon as the bar of channel 5 in the display

»Servo Display« is +50% or higher.

(The +100% shown on the left are based on the switch programming

above.)

Not suitable for beginners.

Note

The third switch position is required for the autopilot mode described

below and it is available only after the connection of the optional

GPS module No. 33602.

1

3

5

7

+

0%

0%

9

11

0%

0%

2

4

6

8

+

0%

0%

0%

0%

10

12

0%

0%

0%

0%

I5

I6

I7

+

trv

+100%

+100%

+100%

+100%

+100%

+100%

I8 +100%

+100%

free

free

free

SW4/5

I9

+100%

+100%

free

1

3

5

7

+

0%

0%

9

11

0%

2

4

6

8

+

0%

0%

0%

0%

10

12

0%

0%

0%

0%

+100%

I5

I6

I7

+

trv

+100%

+100%

+100%

+100%

+100%

+100%

I8 +100%

+100%

free

free

free

SW4/5

I9

+100%

+100%

free

Page 8

14 / 36 15 / 36

S1038_Q06_V2.0sh_en S1038_Q06_V2.0sh_en

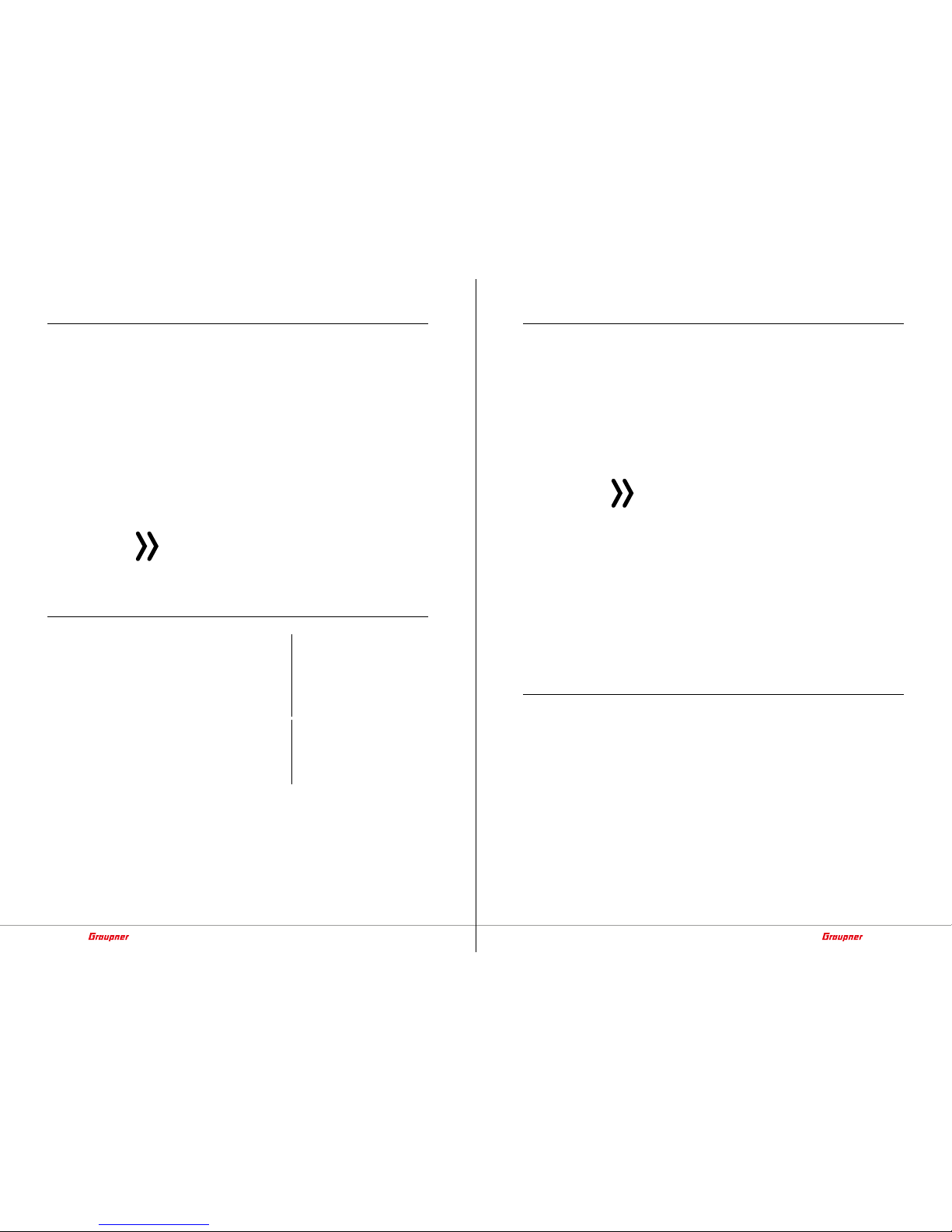

Fail-Safe settings

FAIL SAFE

Pos

Hold

1 2 34567 8

Delay 0.25s STO

We recommend to set Channel 1 and Channel 5 to "Pos" according

to the transmitter instructions and to put the pitch control stick in

the motor OFF position before storing the fail-safe settings and to

set the attitude / rate mode switch to the "Attitude mode" position

so that the attitude mode is active in fail-safe situations and the

motors stop. When using the # S1038 AIO FC together with the

optional GPS-module # 33602, it is recommended to set C1 on Hold

and C5 and 6 on Pos, in the Come back home position, so that the

copter will fly back to the starting position if there is a loss of signal.

Note

Please note that when the signal is received again, the set mode will

become active again and the pilot will have to take again the control.

Throttle Cut

raised min

timer

+6%

4:00

cut off

Race timer

–100% +150%

1

yes

1

=

For safety reasons, a motor stop switch must always be programmed

on the transmitter side according to the transmitter instructions.

Only when this is placed into the appropriate position, an undesired

start of the motors is reliably prevented.

But in order to be able to switch off the motors also in the Acro 3D

mode, another mixer has to be programmed. Namely, if the copter

is operated in the acro 3D mode with the rate mode enabled, the

motor stop function would not shut off the motors, but set them to

"full power backwards". To prevent this, the mixer must be programmed in such a way that switching the motor stop switch to the

motor OFF position also switches to the attitude mode, in which the

stop of all motors is ensured.

Programming step-by-step

1. Program a linear mixer of "S => 5" according to the transmitter

instructions.

2. Assign to this mixer the same switch with the same switching

direction, which switches to the attitude mode.

3. Change to the setting page of the mixer.

4. Set the "travel" symmetrically to +100%.

5. Change to the line "Offset".

6. Now either set the offset value manually to +100% or set the

motor stop switch to "motor ON" and then push the ENT key. In

both cases, however, the adjacent picture must arise.

fro

M1

M2

M3

S

5

??

??

M4

M5

??

??

??

??

??

??

1

=

to

L.MIX1

trv +100%+100%

offs

SEL

STO

S 5

+100%

Auto-flip function on channel 6

If the copter is in attitude mode, the automatic flip function can easily trigger a flip of the copter.

The auto-flip function is activated via a key switch assigned to channel 6. This has to be programmed on channel 6 in the "Control setting" menu of the transmitter and then, with the button held down,

the asymmetrical travel must be set to +125%.

If this button is pressed, the servo position of channel 6 exceeds the

value of 111% and the autoflip function is thus "armed" for 5 seconds. As soon as the roll or pitch control stick is moved over more

than 50% of the stick travel within this time, the copter will automatically flip in that direction.

Note

After the flip, position deviations in the range <10 ° are possible.

Advancing the FPV transmit channel

I5

I6

I7

+

trv

+100%

+100%

+100%

+100%

+100%

I8 +100%

+100%

free

free

SW6/7

+100%

I9

+100% +100%

free

SW4/5

If the Attitude mode and the motor stop function are active, with

each switching pulse of +100% on channel 6, the transmission channel of the FPV transmitter can be switched in rotation.

Only with the optional GPS module No. 33602

Autopilot mode

The combination of a control signal of -100 % on channel 5 and 0 %

on channel 6 switches to autopilot mode. Neutral stick position

means to hold GPS position and altitude.

If you start in autopilot mode, the height is maintained at the middle

of the stick (0%).

If you start in Rate or Attitude mode and then switch to the autopilot mode, the throttle position when switching the mode is the stick

position at which the altitude is maintained.

When starting in autopilot mode with a throttle position above the

center of the stick (0%), the copter automatically raises to a altitude

of approx. 1m so that it can hold the position.In autopilot mode, an

electronic grid at 500 m distance and the set max. altitude active.

When the limits are reached, a corresponding warning message is

transmitted to the transmitter.

• An additional value higher as +50 % on Channel 7 switches to the

“Carefree Autopilot mode“.

Come back home mode

The combination of a control signal of -100 % on channel 5 and -100 %

on channel 6 switches to come back home to the start point mode.

I5

I6

I7

+

trv

+100%

+100%

+100%

+100%

+100%

I8

+100%

+100%

free

free

SW6/7

+125%

I9

+100% +100%

free

SW4/5

1

3

5

7

+

0%

0%

9

11

0%

2

4

6

8

+

0%

0%

0%

0%

10

12

0%

0%

0%

0%

–100%

I5

I6

I7

+

trv

+100%

+100%

+100%

+100%

+100%

I8 +100%

+100%

free

free

SW6/7

+100%

I9

+100% +100%

free

SW4/5

Page 9

16 / 36 17 / 36

S1038_Q06_V2.0sh_en S1038_Q06_V2.0sh_en

Departure from previously programmed waypoints

The combination of a control signal of -100 % on channel 5 and +100 %

on channel 6 switches to departure from previously programmed

waypoints mode.

To create the waypoints you will need:

• A suitable mobile phone with Android operating system.

• The app “GraupnerSJHoTTViewer2” on the mobile phone.

For transfer to the Kopter you will need:

• “micro USB OTG to micro USB cable”, No. 33002.OTG0M5

• Update adapter, No. S8500

• Update cable, No. 7168.S

Notes

• When the GPS is connected, the copter only allows the motors

to be switched on if 6 GPS satellites or more are found.

• While searching for GPS satellites, an HD camera should be off.

If more than 8 satellites have been found, the HD camera can be

switched on. But then is to check if there still are more than 6

satellites in the GPS Copter telemetry display.

• The Autopilot and Come back home mode only work in the configuration of how the compass was calibrated (eg with HD camera on). If you change the airfield, the compass should be recalibrated.

• If the departure of the pre-programmed waypoints is interrupted and switched to “autopilot” mode, the copter will stop

at the point of interruption.

Carefree autopilot mode

The combination of a control signal of -100 % on channel 5, +0 % on

channel 6 and +100 % on channel 7 switches to the carefree control

mode.

In Carefree control mode, the flight direction is saved when activated, even if the Copter is then rotated by yaw command.

This facilitates the control of the copter in difficult visibility conditions.

The combination of a control signal of -100 % on channel 5, +0 % on

channel 6 and -100 % … +50 % on channel 7 switches to normal con-

trol mode.

• An additional value less than +50 % on Channel 7 switches to the

“Autopilot mode“.

1

3

5

7

+

0%

9

11

–100%

0%

2

4

6

8

+

0%

0%

0%

0%

10

12

0%

0%

0%

0%

+100%

I5

I6

I7

+

trv

+100%

+100%

+100%

+100%

+100%

I8 +100%

+100%

free

SW6/7

3

SW4/5

+100%

I9

+100%

+100%

free

"Telemetry" menu

SETTING & DATA VIEW

The basic handling of the "Telemetry" menu is described in the

respective transmitter instructions or the instructions of the SmartBox. By way of derogation, only in certain receivers the menu structure is summarized under the generic term "setting & data view".

These instructions also provide information on how to access this

menu. Change accordingly to the first setting page of the Graupner

S1038 AIO FC.

Notes

• The setting values shown in the following display illustrations

always show the standard values.

• Some of the menu items shown in the following display illustrations are only displayed if the optional GPS module No. 33602 is

connected.

Receiver display

LANGUAGE

RECEIVER Q.06

ALARM VOLT: 10.2V

ALARM TEMP: 70°C

Altitude max: 100m

LANGUAGE: english

Video Channel R3

Alarm Capac. 400mAh

VTX-Power 0

In the "Language" line you can set the display language in the receiver

menu.

The choices are: German, English, French, Italian, Spanish

ALARM VOLT

If the receiver voltage falls below the set value, a low-voltage warning is generated by the transmitter in the form of a "sound-declining

alarm tone" or the "receiver voltage" speech output message.

ALARM TEMP

If the receiver temperature exceeds the set temperature, a warning

is generated by the transmitter in the form of a "3-step sound-climbing alarm tone" or the "receiver temperature" speech output message.

Max. altitude

Note

This menu item is only visible if the optional GPS module, No. 33602,

is connected.

If the optional GPS module No. 33602 is connected, this line is visible and in the autopilot mode, the altitude is limited to the set altitude value.

If the copter exceeds the set max. height, the transmitter will warn

you with "max. height"or, by transmitters without speech output,

with a corresponding tone sequence.

Telemetry

SETTING & DATA VIEW

SENSOR

RF STATUS VIEW

VOICE TRIGGER

RX DATA ON

ALARM SETTING

Page 10

18 / 36 19 / 36

S1038_Q06_V2.0sh_en S1038_Q06_V2.0sh_en

Video channel

If the video transmitter # 16570.123 is connected to the connector

J9, then the video channel can be set via this menu item.

In addition to what mentioned above, when the motor stop function

is active, the video channel can be further switched by a 2 second

switching pulse of +100% on control channel 6.

If a Smart Audio compatible FPV video transmitter with smart audio

is connected to port USART2_RX, then the Raceband channel 1-8

channel can be set via this menu item.

VTX-Power

If a Smart Audio compatible FPV video transmitter V2 or later with

Smart Audio is connected to port USART2_RX, the transmission

power can be set via this menu item. However, the setting only

applies to the current battery and will not be saved. After disconnecting the power supply and reconnecting the power supply, the

transmission power 0 is automatically active again until it is set differently again.

ALARM Capac.

If the used battery capacity exceeds the set value, a warning message "Capacity" is output in the transmitter or a corresponding

sequence of tones by transmitters without voice output. In this case

you should return to the starting point or, if this is no longer possible, land safely.

ROLL/NICK Display

The control is based on the PID principle, where the "P" stands for

"proportional", the "I" for "integral" and the "D" for "digital". In short

...

... the deviation from the setpoint proportional to the manipulated

variable has an effect at the P value.

... the existing control deviation is continuously summed up at the I

value and then acts on the manipulated variable via the I value.

... the differential component only takes into account the speed of

the control deviation and then acts on the control accordingly via the

D component.

ROLL/NICK P

This parameter determines the tilting behaviour of the copter during

the maximum climb.

In order to prevent tilting at full climbing power in the end, this

parameter must be increased in steps of 5 until a medium-fast tilting

occurs. Subsequently, this value is to be adjusted in individual steps

until the tilting has disappeared.

MULTICOPTER RO/NI

ROLL/NICK D 50

DAMPING 10

ROLL FACTOR % 95

POWER2SENS. 100

ROLL/NICK P 30

R/N DYNAMIC 70

––ATTITUDE MODE––

ROLL/NICK I 40

AGILITY 3

––RATE MODE––

R/N RATE I 10

RATE 70

ROLL/NICK D

This parameter determines the tilting behaviour of the roll / pitch

function of the copter.

As described above, this parameter must be adjusted until the Multicopter engages exactly over Roll and Nick. A too high value leads to

very rapid oscillations.

DAMPING

The damping factor should be set as low as possible, but as high as

necessary, so that the PID control can operate optimally. To prevent

oscillations or tilting, the damping should be <30. To dampen motor

or prop vibration and prevent motor noise, higher values may be

needed. These can be adjusted at the beginning in steps of 10 and

then finer.

ROLL FACTOR %

Set the Roll setting as percent value of the overall gain. For symmetrical copters, the value should normally be left at 100. If, because of

its gravity centre, the Copter is more agile on the Roll axis than on

the Nick axis, then you can change here the roll factor. In the Graupner

ALPHA RACE 250 Q this value is set about 65%.

POWER 2SENS.

Very strong drives can lead to oscillating at full throttle. This parameter allows you to set a kind of gyro suppression. Higher values result

in an increased suppression towards full throttle.

R/N DYNAMIC

Higher dynamic values provide a more direct feel for the flight (3D

flight 50 ... 100), lower dynamic values for smoother flight recordings, rounder freestyle flying and races (30 ... 50).

Note

If a channel is selected in the “R / N DYNAMIC” line, but no encoder

is assigned to it on the transmitter side, the value in brackets is

specified.

–– ATTITUDE MODE ––

ROLL/NICK I

Set the I component of the Attitude mode. At too low values of Copter tilts slowly. If it stops after a roll or pitch command and “oscillates”, the value must be reduced.

AGILITY

This value determines how fast a change of position is made.

Page 11

20 / 36 21 / 36

S1038_Q06_V2.0sh_en S1038_Q06_V2.0sh_en

–– RATE MODE ––

R/N RATE I

Sets the I component of the rotation in rate mode. At too low values

of Copter tilts slowly. If it stops after a roll or pitch command and

“oscillates”, the value must be reduced.

RATE

This value sets the maximum potential rate in Rate mode.

YAW Display

The general comments on PID control in the description of the roll /

pitch display are also applicable here.

YAW P

The P factor is responsible for the snap to yaw. Higher values result

in a faster stop. At too high P-values the copter starts to “swing”. In

such cases, the value must be reduced again.

YAW I

The I-factor ensures constant rotations. Start with low values and

only increase them until the rotations are constant. Too high value

cause an oscillation when you stop. Eventually, the motors can start

rotating and thus cause unwanted rising.

YAW D

The D-factor affects the stopping behaviour in Yaw. In most Copters

a hard D action is necessary. The D component must be set as low

as possible, since it affects the whole system.

RATE

For beginners we recommend a rate of about 50. For racers and freestyle pilots we recommend a value between 50 and 70.

YAW DYNAMIC

Higher dynamic values provide a more direct feel for the flight (3D

flight 80 ... 100), lower dynamic values for smoother flight recordings, rounder freestyle flying and races (30 ... 80).

MULTIC. AUTOPILOT

Note

This Displaypage is only visible if the optional GPS module, No.

33602, is connected.

GPS

YES: GPS features enabled. Starting the engines from 6 satellites.

NO: GPS features autopilot, come home and waypoints are disabled.

In autopilot mode, the attitude mode with altitude control active.

There is no need to wait for the engines to start until satellites are

found.

ALT HOLD P

The altitude hold P value compensates the climb and descent rate

and must be adjusted so that it is compensated as well as possible.

The copter must under no circumstances swing around the desired

height, otherwise the value must be reduced.

MULTICOPTER YAW

YAW I 10

YAW D 10

RATE 70

YAW DYNAMIC 75

YAW P 40

MULTIC. AUTOPILOT

ALT HOLD P 30

ALT HOLD I 10

ALT HOLD D 10

ALT HOLD II 5

GPS YES

POS HOLD P 40

POS HOLD I 15

POS HOLD D 10

POS HOLD II 50

ALT COMING HOME 25

Page 12

22 / 36 23 / 36

S1038_Q06_V2.0sh_en S1038_Q06_V2.0sh_en

ALT HOLD I

The altitude hold I value compensates for the height difference and

must be set so that it is compensated as well as possible. The copter

must under no circumstances swing around the desired height, otherwise the value must be reduced.

ALT HOLD D

The altitude hold D value compensates the acceleration (wind gusts)

in the height direction and it must be adjusted so that it is compensated as well as possible.

ALT HOLD II

The altitude hold II value compensates for the time-integrated height

difference, so that the desired height is kept as good as possible. This

does not usually have to be adjusted.

POS HOLD P

MULTIC. AUTOPILOT

ALT HOLD P 30

ALT HOLD I 10

ALT HOLD D 10

ALT HOLD II 5

GPS YES

POS HOLD P 40

POS HOLD I 15

POS HOLD D 10

POS HOLD II 50

ALT COMING HOME 25

The POS HOLD P value compensates for the position speed and must

be set to compensate as well as possible. The copter must never circling or overshooting the GPS target position, otherwise the value

must be reduced.

POS HOLD I

The POS HOLD I value compensates for the position difference and

must be set to compensate as well as possible. Under no circumstances the copter should oscillate around the GPS target position,

otherwise the value must be reduced or the compass calibration and

voltage calibration have to be repeated.

POS HOLD D

The POS HOLD D value compensates the acceleration (wind gusts) of

the GOS position and it must be adjusted so that it is compensated

as well as possible.

POS HOLD II

Currently without effect.

The POS HOLD II value compensates for the distance difference integrated on time so that the position setpoint is kept as good as possible. This does not usually have to be adjusted.

ALT COMING HOME

Determines the return altitude at Coming Home in meters.

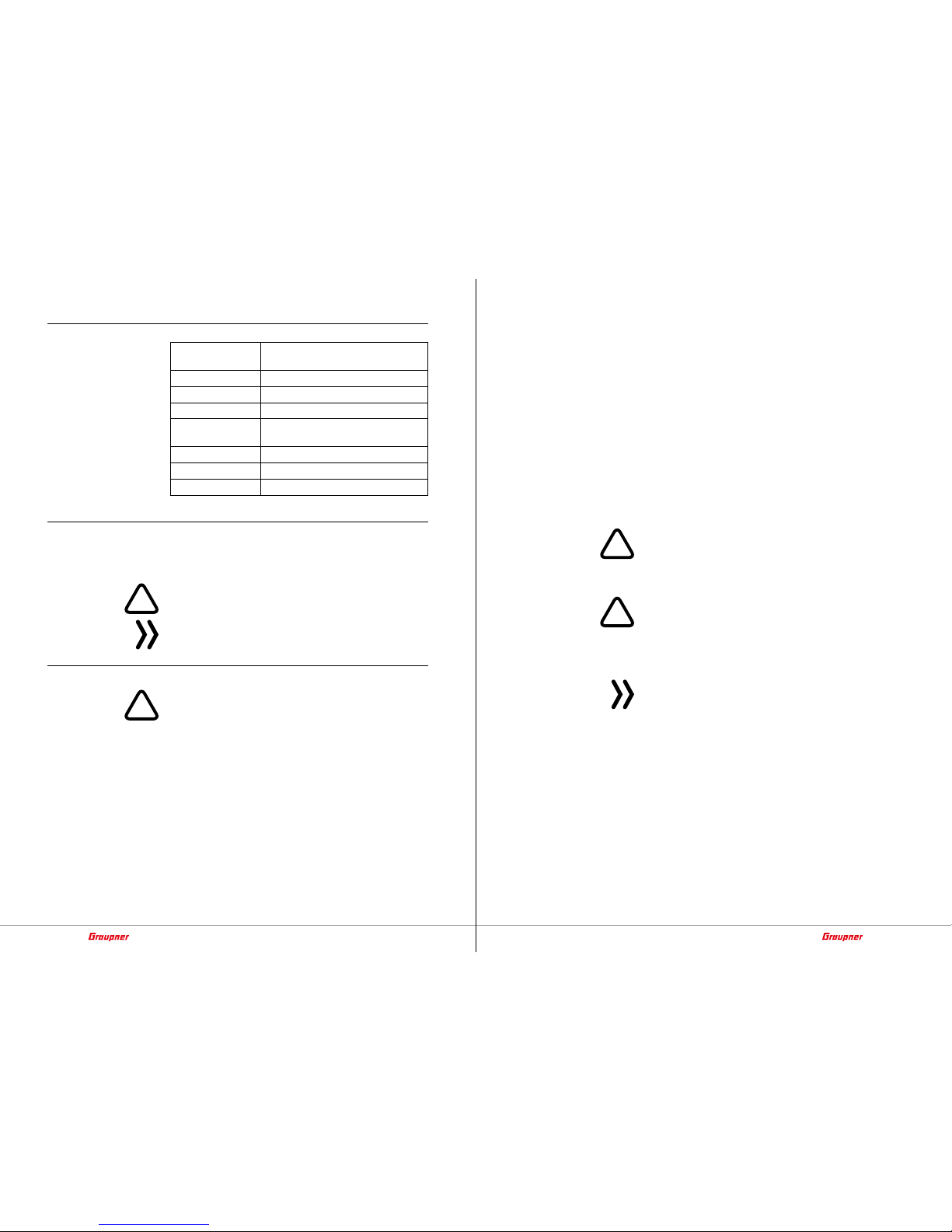

BASIC Display

TYPE

The "Type" line defines the basic configuration of the copter. The following selections are available:

QUADRO X QUADRO XI (invers)

1

2

3

4

1

2

3

4

QUADRO +

1

2

3

4

Connect the speed controllers of the motors to the receiver following the proper scheme. The represented motor direction is referred

to the copter seen from the top.

ESC

The 4in1 controllers No. S3087, S3088 and 7242.4 have a built-in

power shunt. For correct current indication, the current connection

of the 4in1 controller must be connected to the S1038 AIO FC and

the corresponding 4in1 controller must be selected.

CURRENT FACTOR

The current factor is set to 100 (%) by default. However, if the current display is not accurate enough, it can be adjusted in the range

of 75 ... 125%.

Note

If the current can not be measured directly, the current factor can

be readjusted as follows: charging capacity * 100 / consumed capacity.

ESC: factory setting Multishot8

ONESHOT, MULTISHOT8, MULTISHOT32 are faster communication

protocols between receiver and ESC. Please check which protocol

your ESC supports. It allows the commands to be passed much faster

to the controller. Thus, the engines respond faster to the commands

MULTICOPTER BASE

ESC S3088

MODE NORMAL

MINPOWER % 5

TYPE QUADRO XI

CURRENT FACTOR 100

COMPASS CALIBR No

FREESTYLE 1

VIBRATION FILTER 80

CURRENT CALIBR No

CALIBR. POSITION No

LOGGING 10

ESC MULTISHOT8

Page 13

24 / 36 25 / 36

S1038_Q06_V2.0sh_en S1038_Q06_V2.0sh_en

!

CAUTION

Since the power control operates differently in the rate mode, see

figure on the left, the motors may start rotating more or less when

switching from the attitude mode to the rate mode, depending on

the current position of the pitch stick. Therefore always mount the

propellers immediately before starting the flight operation and

start and land exclusively in "attitude mode".

During prolonged extreme aerobatics of the copter in Acro 3D

mode (e.g. , sequence> 1min), the receiver may lose its attitude

information and, as a result, the copter may move to an undesired

position when switching to attitude mode. In this situation, the

copter should be in the Rate mode and either it is left quiet for

about 30 seconds or it is landed for a short time, so that the

receiver can readjust the position information again.

Note

If the motors do not stop completely in the attitude mode, so that

the position control is still active and can also serve as a rescue

mode in an emergency, this can be remedied with the aid of a mixer:

Mixer programming step by step

1. Program a same-channel mixer "1 => 1" according to the transmitter instructions.

2. Assign to this mixer the same switch with the same switching

direction, which switches to the attitude mode.

3. Leave this switch in the ON position.

4. Change to the setting page of the mixer.

5. Change through "ASY" to the setting field of the "Travel" line.

6. Set the value in the active value field of the "Travel" line to -30%.

In the idle position of the throttle / pitch stick, the bar of channel

1 in the "servo display" should now be at about -66%.

MINPOWER %

MULTICOPTER BASE

ESC S3088

MODE NORMAL

MINPOWER % 5

TYPE QUADRO XI

CURRENT FACTOR 100

FREESTYLE 1

ESC MULTISHOT8

If the throttle / pitch control stick is moved past its stop on the idleside stopper of the copter speed controller, the motors will start to

run. The setting value of this option determines the minimum power

to be provided at the switch-on point so that the position control can

continue to operate in the Attitude mode and it can also serve as a

rescue mode in an emergency. But do not set a too high value here

in order not to restrict too much the control range of the speed controller.

The adjustment range is 5 ... 35%.

Vollgas positiv

Vollgas negativ

Min. Gas

linear bis Vollgas

Gasweg

Drehratenmodus

Gasweg

Lagemodus

linear

linear

Motor Min. Gas

L.MIX2

off

ASY

SYM

C1 C1

0%

trv –30% 0%

fro

zu

M1

M2

M3

S

5

C1

C1

M4

M5

??

??

??

??

??

??

1

=

to

3

=

MINIPOWER %

Travel Throle/Pitch control sck

of the receiver. The Motor Output Signal is now shorter, for oneshot

125μs-250μs, even faster with MULITISHOT with 5-25µs. MULTISHOT8 is the default. Faster protocols improve flight behavior, as

long as the ESC can process the protocol without errors.

MULTISHOT32 must not be used in 3D Mode, because most of the

ESCs could not handle this.

MODE

CONTROLLER SETTING

To initialize the controller, the signal of the motor / pitch control stick

of the transmitter is transmitted directly to the speed controller of

the copter.

Setting the speed controllers step-by-step

1. Remove rotors for safety reasons

2. Make sure that the transmitter-side pitch signal reaches ± 100%.

3. In the telemetry menu of the transmitter, change the value field

of the “MODE” line to “CONTROLLER SETTING” and confirm with

ENTER.

4. Switch off the copter or unplug the battery plug.

5. Switch off the motor stop function of the transmitter.

6. Move the pitch control stick of the transmitter to the full throttle

position.

7. Switch on the copter or connect the battery.

8. Wait for the confirmation melody or, if no sound is heard, alternatively switch on the motor stop function after approx. 15 seconds.

9. After approx. 15 additional seconds, check the function.

10. In the telemetry menu of the transmitter, reset the value field of

the “MODE” line to the original setting and confirm with ENTER.

11. Switch off the copter or unplug the battery plug.

12. If the motors do not start after completion of this process despite

active binding, the copter must be bound again.

NORMAL

This setting must be used for copters with speed controller without

reverse of the direction of rotation.

ACRO 3D

This setting is reserved for copters whose speed controllers are

equipped with direction reverse.

Note

For safety reason the "Type" and "Mode" changes take effect after

switching off and on again the receiver system.

Page 14

26 / 36 27 / 36

S1038_Q06_V2.0sh_en S1038_Q06_V2.0sh_en

Note

If a channel is selected in this line, but no control is assigned in the

transmitter or otherwise it influences its neutral position, the value

“50” in parenthesis is predefined.

COMPASS CALIBR

Note

This menu item is only visible after connecting the optional GPS

module, No. 33602.

After each change of the airfield the compass has to be recalibrated.

In contrast, the current calibration described below does not have

to be repeated every time.

Notes

• When using an HD camera, it must be turned on when calibrating the compass. Otherwise, the autopilot mode and the come

back home function only work when the HD camera is switched

off!

• If the autopilot and come back home function is used, the HD

camera may also have to be switched on, as its power requirement influences the compass calibration.

• Avoid calibrating the compass near magnetic fields, powered-on

cell phones, or other objects that may be interfering with the

natural magnetic field.

Compass calibration step by step

1. Bring the angle „ “ on the left edge of the display to the „COMPASS CALIBR.“ line.

2. Push the ENT key to activate the value field.

The value field is displayed inverted.

3. Change the value field to „Yes“.

4. Push again the ENT key.

The value field is again displayed as „normal“.

5. Slowly rotate the multicopter twice in a circle around all three

axes and then randomly in different directions until „NO“ appears

in the display.

2x

2x 2x

Otherwise the process has to be repeated.

MULTICOPTER BASE

MINPOWER % 5

COMPASS CALIBR No

FREESTYLE 1

VIBRATION FILTER 80

CURRENT CALIBR No

CALIBR. POSITION No

LOGGING 10

FREESTYLE

The setting basically serves to prevent the I-factor from generating

a vibration.

The higher the value, the more I-vibrations are prevented, but also

the straight-ahead flight is degraded. Values up to max. 20 recommended.

The adjustment range is from 1 ... 100

MIN = disabled

Alternatively, the effect on the I value can also be adjusted by the

transmitter. To do this, a rotary or slider control is assigned to one of

the control channels 5 ... 16 and the remaining settings are left at the

default values. In the value field of the "Freestyle" line, the corresponding channel is then merely to be selected instead of a fixed

value.

Note

If a channel is selected in this line, but no control is assigned in the

transmitter or otherwise it influences its neutral position, the value

"50" in parenthesis is predefined.

VIBRATION FILTER

MULTICOPTER BASE

ESC S3088

MODE NORMAL

MINPOWER % 5

CURRENT FACTOR 100

FREESTYLE 1

VIBRATION FILTER 80

ESC MULTISHOT8

If you hear , for example, “clicking” noises in the motors by widely

fluctuating speeds or vibrations during the flight, such as in low

throttle or under hover conditions, these vibrations can be filtered

out with the options “damping” and “vibration filter”. Preferably,

start with the “vibration filter”:

Configure vibration filter step-by-step

1. In the transmitter assign a rotary or slider to a free control channel, e.g. channel 8

2. Select this channel in the value field of the “VIBRATION FILTER”

line.

3. In flight, adjust the “VIBRATION FILTER” with the selected controller until the motor noises disappear or at least cannot be further

reduced and the rotor speeds are as constant as possible.

4. Leave the control in this position.

5. After landing, read out the set value found in the “VIBRATION FILTER” line of the telemetry menu and then set it manually in the

value field, see “67” in the two examples on the left.

6. If vibrations still occur during the flight at a different speed, the

filter may need to be adjusted slightly or even adjusted according

to gas.

Adjustment range: 100 … 1, MIN, (0)C5, (50)C6 … (50)C16

The usual adjustment range of the vibration filter is between “65”

with 4 ... 5 inch rotors and 80 with 3 inch rotors.

Extremely low values should be avoided as these will worsen the

flight behaviour.

MULTICOPTER BASE

ESC S3088

MODE NORMAL

MINPOWER % 5

CURRENT FACTOR 100

FREESTYLE 1

VIBRATION FIL(67)CH8

ESC MULTISHOT8

MULTICOPTER BASE

ESC S3088

MODE NORMAL

MINPOWER % 5

CURRENT FACTOR 100

FREESTYLE 1

VIBRATION FILTER 67

ESC MULTISHOT8

Page 15

28 / 36 29 / 36

S1038_Q06_V2.0sh_en S1038_Q06_V2.0sh_en

CURRENT CALIBR.

Notes

• This menu item is only visible after connecting the optional GPS

module, No. 33602.

• With active current calibration, the attitude control is inactive,

which is why this process must be done on the ground or with

appropriately secured copter.

• The current calibration should be done in calm wind conditions,

otherwise the current will fluctuate too much and make the calibration more difficult.

• The current calibration becomes most accurate when the nose

of the copter points either the west or east direction, because

then slight deviations can better detected.

• Furthermore, the suspension position must first be determined

and remembered before, if necessary, the propellers are

reversed and mounted vice versa, so that the copter is pressed

to the ground instead of lifting.

• During the current calibration, the copter must not move and no

other control sticks may be moved during the calibration except

for the throttle stick.

Current calibration step by step

1. Move the throttle / pitch control stick to the idle position and the

motor ON / OFF switch to the motor OFF position.

2. Bring the angle „

“ on the left edge of the display to the “CUR-

RENT CALIBR.” line.

3. Push the ENT key to activate the value field.

The value field is displayed inverted:

4. Change the value field to “Yes”.

5. Push again the ENT key.

The value field is again displayed as “normal”.

6. If “CURRENT CALIBR.” is displayed in the value field of the “CURRENT CALIBR.” line, the switch must be brought to the motor OFF

position if necessary.

7. If “Min” is displayed in the value field of the line CURRENT CALIBR, switch must be switched to the motor ON position.

8. If in the value field of the line “CURRENT CALIBR.” “hover” is displayed, the throttle / pitch control stick must be brought into the

hover position. If the display changes to Min, then please switch

the motors to the Mingas throttle position.

Note

If the copter has rotated by mistake or by a command during the

current calibration, the calibration must be repeated.

MULTICOPTER BASE

MINPOWER % 5

COMPASS CALIBR No

FREESTYLE 1

VIBRATION FILTER 80

CURRENT CALIBR No

CALIBR. POSITION No

LOGGING 10

CALIBR. POSITION

With this option, if necessary, the basic calibration of the acceleration sensors can be readjusted, so that the copter hovers with the

stick and trim to neutral, in attitude mode, precisely horizontally.

To recalibrate, place the copter on an absolutely horizontal surface

and then set the value field to "YES".

As soon as the calibration is completed, the display changes back to

"NO". To accept the calibration that has just been carried out in the

non-volatile memory of the receiver, it is essential to push or tap on

the ENT key.

LOGGING

Note

This menu item is only visible after connecting the optional GPS

module, No. 33602.

Logging 0 displays the Euler angles in the Copter telemetry display

and also allows the position display using the Graupner HoTT OSD #

33641 on the FPV screen or in the FPV video goggles.

10mAh I 0A

0:00 Dir: 0°

11.6V Alt: 0m

0km/h 0°

0 0m

C+00016 +00060 -00011

The default value “10” indicates the compass direction in degrees in

the bottom line of the Copterdisplays right of the “ ”, so that it can

be checked, for example after a recalibration of the compass. The

characters 2 … 14 before show raw values and the “C” at the beginning of the line stands for “Compasslogging”. In addition, this display

can be used to check the Power calibration: If the Copter is fixed to

the west or east, the degree indicator on the right may only change

slightly if the motors are off, or rotate driven by minimal power or

hover power. Otherwise, a calibration should be performed.

The other logging functions are exclusively intended for the service.

AXIS ASSIGNMENT

Note

The gyroscope calibration, required each time the copter is switched

on, takes place as soon as the copter or its receiver is absolutely

quiet. The motors will not start until the calibration is completed.

After approx. 3 seconds in the rest position, several beeps can be

heard from all motors. The number of beeps varies depending on

the speed controller used. These "wiggles" signal that initialisation

has been successful and that calibration is complete.

!

CAUTION

If the copter is used for long time (>1min) in Acro 3D mode the

receiver can loose its position information and the copter can

move itself out of control. In this case the copter should be left in

the rate mode and hover or land calmly for approx. 30 s, so that

the receiver can track the position again.

MULTICOPTER BASE

MINPOWER % 5

COMPASS CALIBR No

FREESTYLE 1

VIBRATION FILTER 80

CURRENT CALIBR No

CALIBR. POSITION No

LOGGING 10

Page 16

30 / 36 31 / 36

S1038_Q06_V2.0sh_en S1038_Q06_V2.0sh_en

In this display, the gyros and their effective direction are to be determined.

NEW SETUP

After selecting the line "do setup" and changing the value field to

"yes", assign the axes as follows:

Do setup step by step

1. Push or tap on the ENT key

"NO" is displayed inverted.

2. Change the value field to "YES".

3. Push or tap on the ENT key

4. At the transmitter briefly bring the roll control stick to the right

stop.

The display shows the roll axis inverted.

5. Tilt the copter more than 45 degrees to the right.

As soon as the detected axis with the required sign is displayed in

"normal" representation, the axis assignation is completed.

6. At the transmitter briefly bring the nick control stick to the front

stop.

The display shows the nick axis inverted.

7. Tilt the copter more than 45 degrees to the front.

As soon as the detected axis with the required sign is displayed in

"normal" representation, the axis assignation is completed.

8. At the transmitter briefly bring the yaw control stick to the right

stop.

9. Turn the copter clockwise by more than 45 degrees to the right.

As soon as the detected axis with the required sign is displayed in

"normal" representation, the axis assignation is completed.

The gyros and their operating directions have now been assigned.

Attention

To be on the safe side, the directions of action of the gyroscope settings must be checked.

Check step by step

1. Remove the rotors of the copter.

2. Use the pitch control stick to give approx. 25% "throttle".

All motors run at the same speed.

3. Switch to the attitude mode.

4. Tilt the copter forward.

The front motors must turn faster than back ones.

5. Tilt the copter to one side.

The motors of the side, the "hanging" side must turn faster than

those of the opposite, higher side.

GYRO ASSIGNMENT

do setup NO

ROLL +2

NICK +1

YAW –3

Firmware update

Firmware updates of the Graupner S1038 AIO FC are performed via

the J10 connector on its side, using a laptop or PC running Windows

7 ... 10. You will also need a USB interface, No. 7168.6, so as the

adapter lead, 7168.6S, which are available separately. Furthermore,

either the adapter cable No. 33602.1 included in the package of the

GPS module, No. 33602, or the optionally available adapter cable

No. S1038.2 are required.

The programs and files required can be found in the Download area

for the corresponding products at www.graupner.de.

One of the last two mentioned adapter cables must be connected to

the 7168.6S cable and this combination must then be connected to

the USB interface, No. 7168.6. The plug-in system is correspondingly

protected against reverse polarity. Never use force, the plugs should

click easily into place.

Insert the free end of one of the two adapter cables with the plug

side facing upwards into the socket of the Graupner S1038 AIO FC

marked “J10”. Under no circumstances you should use force here.

The update takes place via the program part “Slowflyer / Gyro

Receiver Downloads” of the program “Firmware_Upgrade_gr_Studio” available under “Links”. Please follow the notes of the software.

The further procedure is also described in detail in the manual contained in the data package. You can also download these from the

download page of the product at www.graupner.de.

7168.6

7168.S

33602.1

S1038.2

OR

+

Page 17

32 / 36 33 / 36

S1038_Q06_V2.0sh_en S1038_Q06_V2.0sh_en

Page 18

34 / 36 35 / 36

S1038_Q06_V2.0sh_en S1038_Q06_V2.0sh_en

‖ If this is not the case, the entire gyro assignment must be

repeated.

SIMPLIFIED DECLARATION OF CONFORMITY

Graupner/SJ hereby declares that the Graupner S1038 AIO FC com-

plies with the Directive 2014/53/EU.

The full text of the EU Declaration of Conformity is available at the

following Internet address: www.graupner.deNotes on environ-

mental protection

Manufactured by

Graupner Co., Ltd

Post Code: 14557

8th F, 202 Dong, Chunui Techno-Park II, 18, 198 Street

Bucheon-ro, Wonmi-Gu, Bucheon-Shi, Gyeonggi-do

South Korea

Notes on environmental protection

If this symbol is on the product, instructions for use or packaging, it

indicates that the product may not be disposed with normal household waste once it has reached the end of its service life. It must be

turned over to a recycling collection point for electric and electronic

apparatus.

Individual markings indicate which materials can be recycled. You

make an important contribution to protection of the environment by

utilizing facilities for reuse, material recycling or other means of

exploiting obsolete equipment.

Batteries must be removed from the unit and disposed of separately

at an appropriate collection point. Please inquire if necessary from

the local authority for the appropriate disposal site.

Care and maintenance

The product does not need any maintenance. Always protect it

against dust, dirt and moisture.

Clean the product only with a dry cloth (do not use detergent!) lightly

rub.

Warranty certificate

Graupner/SJ GmbH, Henriettenstrassee 96, 73230 Kirchheim/Teck

grants from the date of purchase of this product for a period of 24

months. The warranty applies only to the material or operational

defects already existing when you purchased the item. Damage due

to misuse, wear, overloading, incorrect accessories or improper handling are excluded from the guarantee. The legal rights and claims

are not affected by this guarantee.

Please check exactly defects before a claim or send the product,

because we have to ask you to pay shipping costs if the item is free

from defects.

These operating instruction are exclusively for information purposes

and are subject to change without prior notification. The current

version can be found on the Internet at www.graupner.de on the

relevant product page. In addition, the company Graupner/SJ has

no responsibility or liability for any errors or inaccuracies that may

appear in construction or operation manuals.

Not liable for printing errors.

P

Page 19

Loading...

Loading...