Page 1

Copyright © Graupner/SJ GmbH

Part 2

Programming manual

Manual

No. S1006.PRO

12 channel HoTT 2,4 GHz transmitter

mz-24 Pro

Page 2

General operating instructions

Before use ................................................................ 3

Warning and advisory symbolsand their meaning ..... 3

Starting up the transmitter ....................................... 4

Operating the display .......................................... 6

Warnings ............................................................. 8

DSCsocket ....................................................... 10

Data socket ....................................................... 10

Ear phones port ................................................. 11

Card slot ............................................................ 11

Mini-USB connection ........................................ 12

Starting up the receiver .......................................... 14

Installation notices .................................................. 16

Safety and handling

instructions for Lith. Batteries ........................... 22

Definition of terms .................................................. 24

Control and switch assignment ............................... 26

Receiver configuration

Vehicles, boats and copters ............................... 30

Helicopter models .............................................. 31

Fixed-wing models ............................................. 32

Program description

Program description ............................................... 34

Base menu

Model selection ...................................................... 38

HoTT synchronization methods setting ............. 39

Model name ............................................................. 42

Manually programming the basic settings of a

new model .......................................................... 42

Entering the basic settings of a new model with

an assistant ........................................................ 44

Index

Model type ............................................................. 60

E.P.A ....................................................................... 62

REV/SUB ................................................................ 64

Throttle Cut ............................................................. 66

Transmitter setting .................................................. 68

Timers ..................................................................... 74

Fail Safe .................................................................. 80

Trim settings ............................................................ 82

Servo monitor ......................................................... 86

Base menu - Control/switch setting ....................... 90

Throttle limit function ......................................... 94

Transmitter output .................................................. 96

Telemetry ................................................................ 98

Announces ............................................................ 118

Function menu

Phase .................................................................... 120

D/R,EXP ................................................................ 124

THR.CRV .............................................................. 128

What is a mixer? ................................................... 132

General information on

programmable mixers ........................................... 133

Free mixer .............................................................. 134

Trainer ................................................................... 141

Connecting scheme ........................................ 144

Wireless HoTT system ..................................... 145

Logical switch ........................................................ 148

Sequencer ............................................................. 150

Phase .................................................................... 120

D/R,EXP ................................................................ 124

Pitch curve ........................................................... 154

Throttle curve ....................................................... 160

Gyro/governor ...................................................... 166

THR.HOLD ............................................................ 170

Swashplate mixer ................................................. 172

Swashplate limiter ................................................ 173

Heli mixer .............................................................. 174

Throttle mixer ....................................................... 176

What is a mixer? ................................................... 132

General information on

programmable mixers ........................................... 133

Free mixer .............................................................. 134

Trainer ................................................................... 141

Connecting scheme ........................................ 144

Wireless HoTT system ..................................... 145

PIT>>TAIL ............................................................. 178

Logical switch ........................................................ 148

Sequencer ............................................................. 150

Phase .................................................................... 120

D/R,EXP ................................................................ 124

THR.CRV .............................................................. 128

Idle LOW ............................................................... 180

What is a mixer? ................................................... 132

General information on

programmable mixers ........................................... 133

Free mixer .............................................................. 134

Snap roll ............................................................... 181

AILE differentiation (motor airplane) ...................... 182

AILE differentiation (glider) .................................... 184

Wing Mix ............................................................... 188

Flap mixer ............................................................. 192

Flap Sett ............................................................... 196

Airbrake ................................................................ 200

Butterfly ................................................................ 202

Trainer ................................................................... 141

Connecting scheme ........................................ 144

Wireless HoTT system ..................................... 145

Logical switch ........................................................ 148

Sequencer ............................................................. 150

V-Tail ..................................................................... 206

2 Index

Page 3

Before use

Thank you very much for purchasing the Graupner

mz-24 HoTT Pro transmitter.

The manual of this transmitter is made of two parts:

The one named Part 1 quick guide is included in the

package of the transmitter and this Part 2 in form of

programming manual is always updated and is available as download in the web page of the related item

on www.graupner.de.

Read both manuals carefully to use the transmitter

optimally und first of all to safely control your models.

If you experience any trouble during operation, take

the instructions to help or ask your dealer or Graupner

Service Centre.

To make the research of important information easier, the single paragraphs in this manual are marked

with model type symbols. They are the same as the

ones used in the transmitter and they show you which

paragraph is related to your model type.

Furthermore you can find in many places in the manual numbers (page number) or strings in blue characters, for example www.graupner.de. Clicking or tap-

ping on brings you directly to the related target.

System menu

Control mode ........................................................ 208

Warning ................................................................ 210

Etc. Set ................................................................. 212

Display .................................................................. 216

Stick calibration .................................................... 220

MP3 Player ........................................................... 222

Telemetry

Telemetry data display .......................................... 225

Programming examples

Phase specific flaps trimming ............................... 230

Phase specific pitch trimming ............................... 232

Phase specific trimming

"RPM setting" ........................................................ 233

Appendix

Appendix .............................................................. 234

Warning and advisory symbolsand their meaning

Always observe the information indicated by

this warning sign. Particularly those which

are additionally marked with the CAUTION

or WARNING.

The signal word WARNING indicates the

potential for serious injury, the signal word

CAUTION indicates possibility of lighter injuries.

The signal word Note indicates potential malfunctions.

Attention warns you against

potential damages to objects.

This symbol indicates instructions on the

care of the device that the user must follow

to ensure that the device remains useful over

a long period.

3

Before use

Page 4

Starting up the transmitter

Preliminary remarks

Theoretically, the Graupner-HoTT system allows more

than 200 models or remote-control systems to be operated at the same time. This number will be significantly less in practice since permits are required for

combined remote operation within the 2.4 GHz ISM

band. The ultimate limiting factor should be overall the

dimension of the available field.

Battery charged?

Since the transmitter is delivered with a partially

charged battery, you will need to charge it observing

the charge instructions included in the Part 1 of the

manual. Otherwise, a warning signal will sound after a short time, and a related message will appear

in the basic display after the voltage drops below a

certain threshold which can be changed in the line

"Batt warning" in the sub-menu "ETC. SET", within

the system menu.

Transmitter startup

After the transmitter is switched on by a motor powered fixed wing model the actual control impulse of

the output 1 or by helicopter model the throttle servo or rpm controller connected to the output 6 are

checked. If this impulse is outside a specifically selected band width for idle and then there is the danger

that the motor can start, the RF module remains off for

safety reasons.

In all other cases by switching on the transmitter the

RF module will be switched on too and in the center

of the display it will appear the message:

At the same time, audible warning signals sound for

a few seconds.

You now have the option of waiting a few seconds

until the display disappears automatically or maintaining the HF transmissions by manually tapping the ON

button, or switching them off by tapping the OFF

button.

You can turn off a receiver that is on and then first

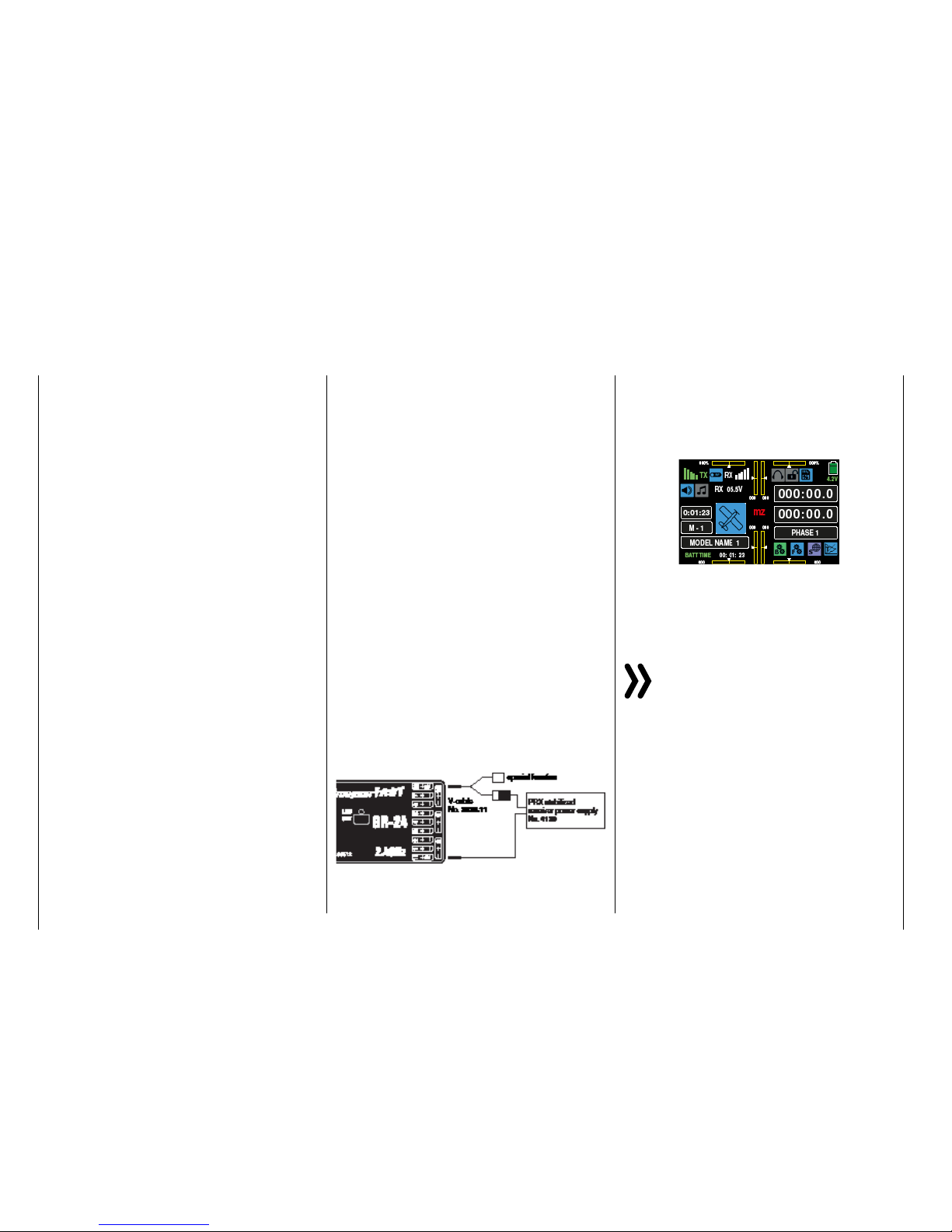

touch ON for demonstration purposes. You are then in

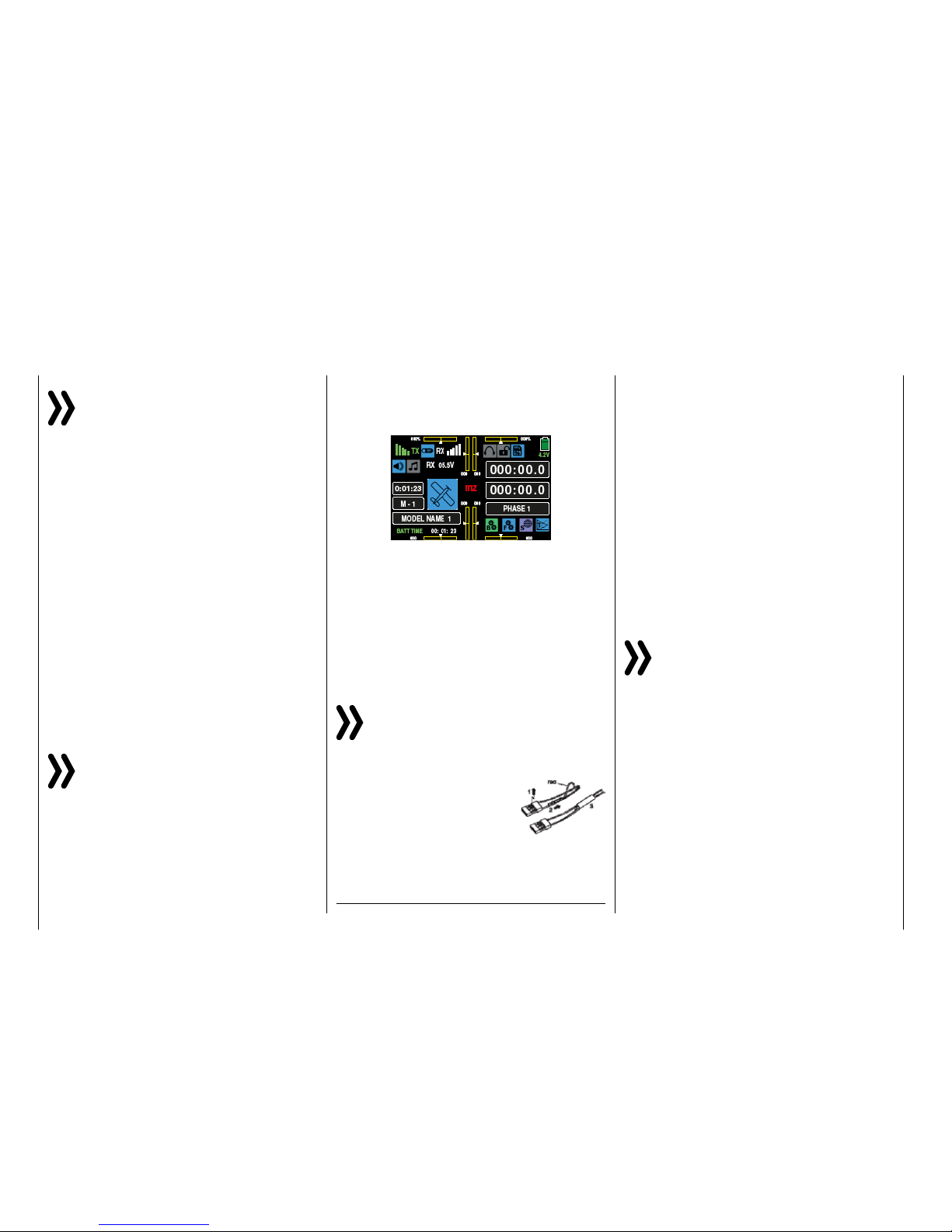

the basic display of the mz-24 HoTT Pro transmitter:

The blue switch symbol at the top left between the

green "TX" and the white "RX" means that the RF

transmission of the transmitter is on. (Otherwise the

symbol would be gray.)

The green "TX" and white "RX" on the left and right

of this switch symbol mean that the currently active

model memory has once been linked to a Graupner-

HoTT receiver but is presently not linked.

Once this link exists, the field strength display appears to the left of the green "TX" and to the right of

the white "RX", and the numeric display underneath

shows the current voltage of the receiver power supply, for example:

If the transmitter is turned on while the RF transmission is off, all of this information is not displayed, and

the RF switch symbol is gray.

If the following warning appears in the display after

the transmitter is turned on, ...

4 Starting up the transmitter

Page 5

... the currently active model memory is not linked to

any receiver. Tapping on the SET button you accede

immediately the under-menu »Transmitter setting«,

…

... where you can bind your receiver or, tapping on the

BACK button at the top left of the display to terminate

the procedure.

Tip

The basic procedure for initially programming a new

model memory starts on page 42.

Notices

• With this mz-24 HoTT Pro transmitter it is

possible to control up to 12 functions. Any

servos which are connected to connections

13 and higher remain in their middle position

by default and cannot be actuated by the

transmitter as standard.

• For the sake of maximum flexibility and to prevent unintentional misuse, control channels

5-12 are initially not assigned to any control elements, and the servos linked to these channels first remain in their middle position until

an operating element has been assigned. For

the same reason, nearly all mixers are inactive.

Similarly you will find at the begin of the paragraph's description "CTL Set".

• When training, linking or adjusting the remote

control, make sure that the transmitter antenna is always far enough from the receiver antennas. If the transmitter antenna is too close

to the receiver antennas, the receiver will

overdrive, and the red LED on the receiver will

shine to indicate that no signal is received. At

the same time, the feedback channel will stop

working, the field strength bar in the transmitter display will disappear, and the current receiver battery voltage will be displayed as 0.0

V. In this moment the transmitter is in the so

called Fail safe mode. That is, due to the loss

of reception, the servos remain in the last correctly received positions or after a short time

in the preset Fail-Safe positions, until a new

valid signal is received. In this case, move the

two antennas away until the displays return to

normal.

CAUTION

Never turn off the transmitter while operating the model! If this nonetheless acci-

dentally happens, do not panic, and wait

until the transmitter display goes dark which indicates that the transmitter is completely off. This

will take at least four seconds. After this time, turn

the transmitter on again. Otherwise, the transmitter may freeze directly after being turned on, and

you will be unable to control the model any more.

The transmitter may only be turned on again after

it has been turned off and the described procedure

has been correctly repeated.

5

Starting up the transmitter

Page 6

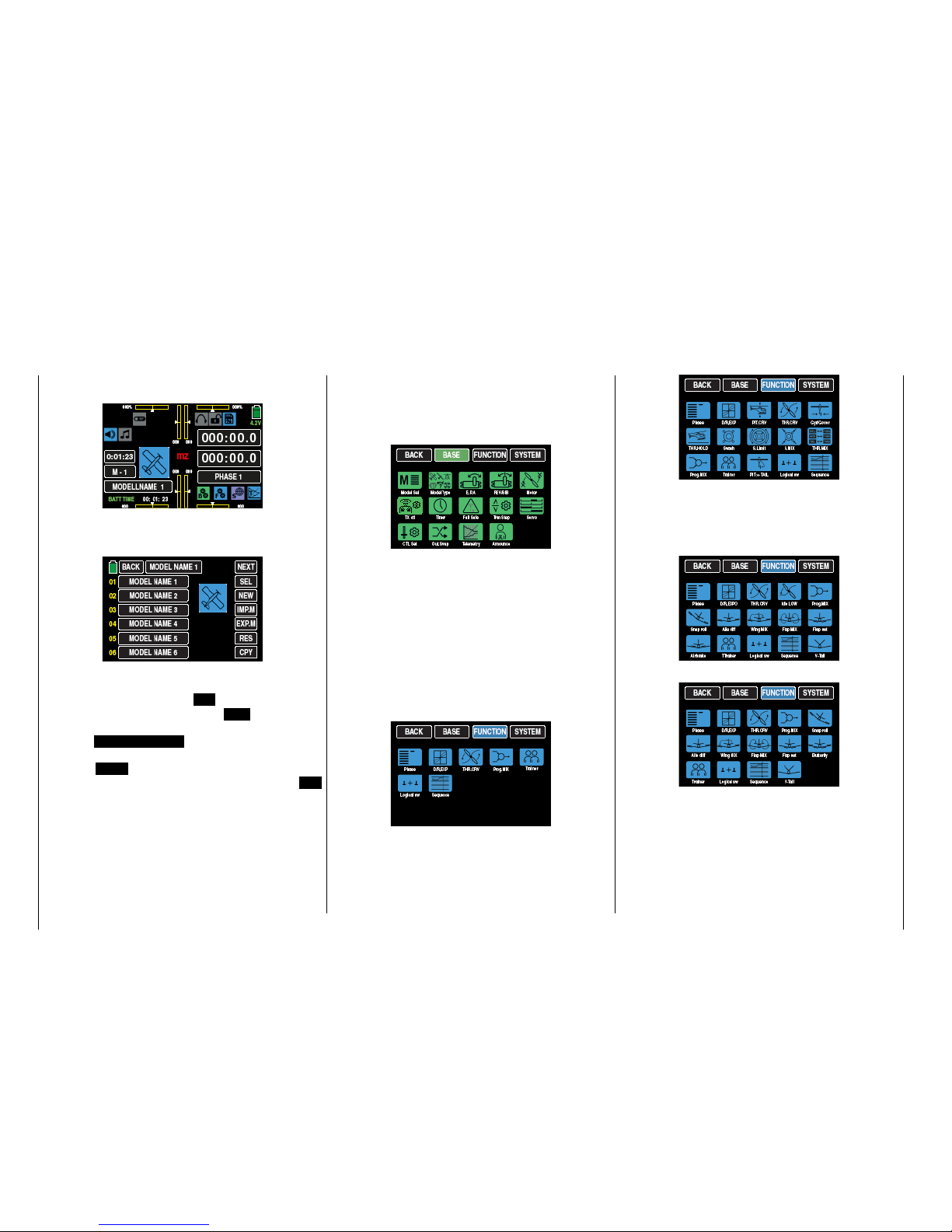

The display is basically operated by touching the desired field with a finger or the provided stylus:

By touching the model memory field labeled "M 1" in

the above display with a finger or the provided stylus,

the "Model memory" selection menu opens.

In this sub-menu, you have the possibility for example

to change the model memory by touching the desired

model memory and then the SEL button.

Just as described on page , touch NEWto start programming a Programming a new model , or touch

the field MODEL NAME 1 at the upper edge of the

display to switch to the "Model name" entry menu,

or touch BACK at the top left to return to the previous menu item. In contrast, touch the button SW

[Change page] (generally using the rotation method)

which is also available in several menus to go to the

next page. In the above display of the model memory,

this would be to the display of model memories 07 …

12, etc.

Operating the display

Touching one of the three gear icons identified with

"B", "F", and "S", special selection menus open on

the bottom right from which you can switch to other

sub-menus. Starting with the green BASE menu, the

selection displaysappear as follows, ...

... it should be noted that the blue function menu described from page 120, Function menu contains

model-type-specific sub-menus and for this reason in

divided into a total of three paragraphs.

In the first paragraph starting on page 120 only the

sub-menus for "Vehicles", "Copters" and "Boats"

model types will be described. Because the same

sub-menus are also included in the "blue" menus of

the model type "Helicopter" and "Fixed-wing" models, their description is valid for all the model types

and for space reasons they will not be repeated in

both other paragraphs:

In the second paragraph, beginning on page 154,

exclusively the sub-menus related to the model type

"Helicopter" will be described excluding the above

mentioned "general menus":

And in the third paragraph, beginning on page 182

also excluding the previously described "general

menus", exclusively the sub-menus related to the

"fixed-wing" model type, in which the menus of a

"motor powered model" …

... distinguishes from the menus of a "Glider" model:

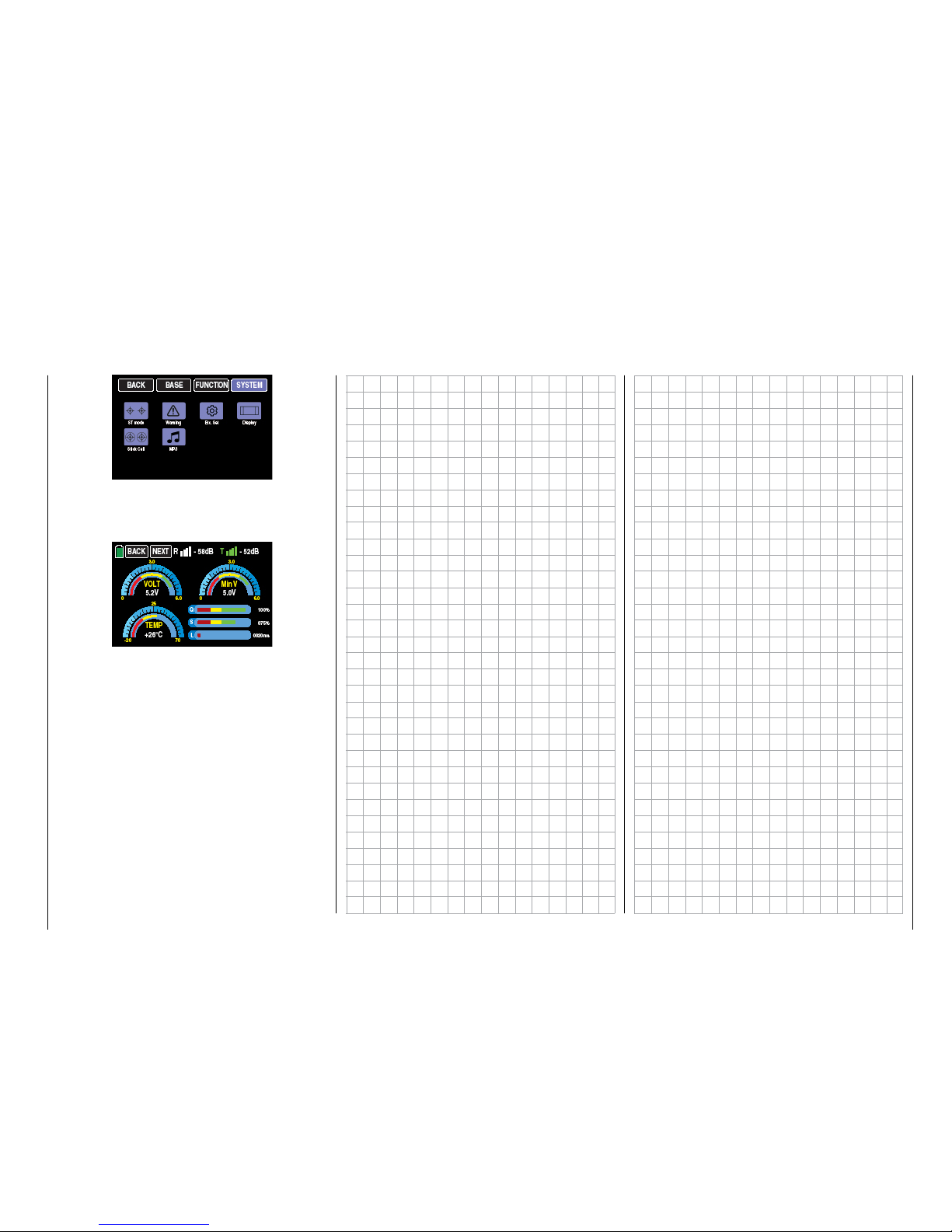

The purple System menu which can be accessed

tapping on "S" and whose description begins on page

220, is displayed as follows …

6 Operating the displays

Page 7

... and the display which can be accessed by tapping on "T" and detailed described from page 225 is

displayed for graphic representation of the telemetry

data e.g. so:

7

Operating the displays

Page 8

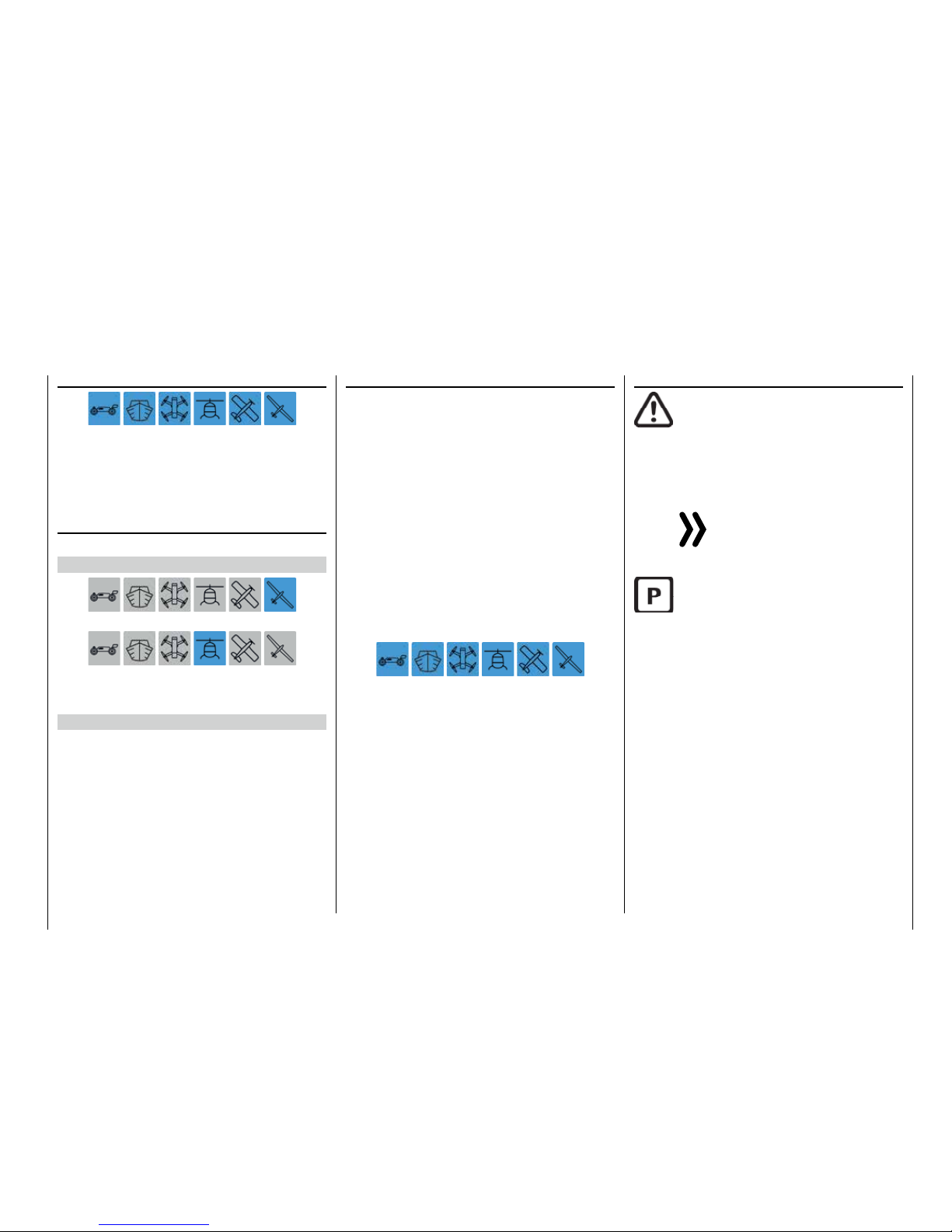

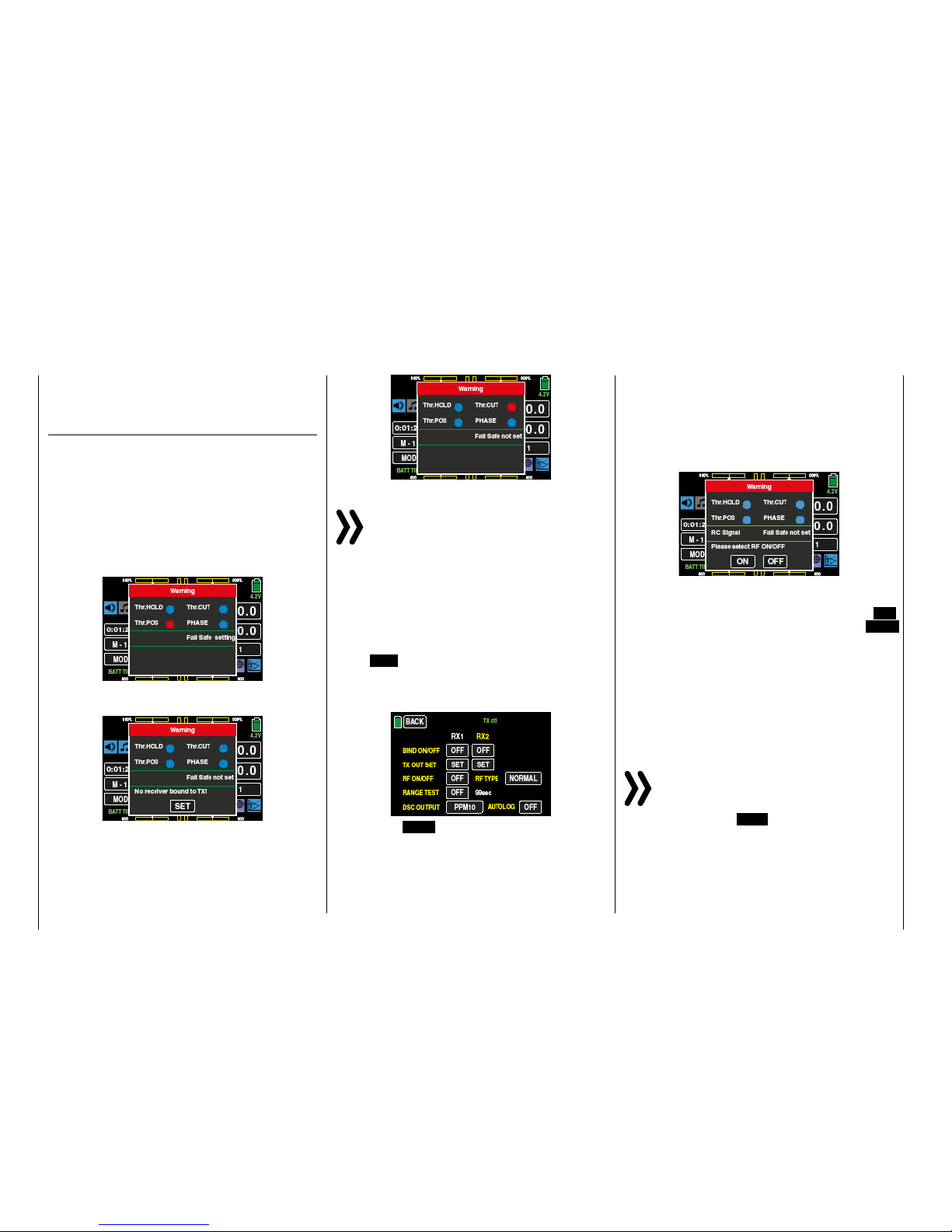

Warnings

In the display of the mz-24 HoTT Pro transmitter appear different warning windows. These can be divided

into two groups:

"Warning" display

These warning windows primarily appear after the

transmitter is turned on and indicate certain operating

states. In the following illustration, for instance, the

red dot after "CH1-POS" indicates that the throttle

servo connected to the output 1 in fixed-wing models,

or the throttle servo and to output 6 on an helicopter

model, is not in the idle position and there is the risk

of a runaway engine. Until this state persists, the content of the underneath field are obscured for safety

reasons ...

... until the Throttle/Pitch control stick is not in the idle

area:

Basically the it is the same for the warning option "Thr.

HOLD", with the difference that the sub-men "WARN-

ING" of the system menu it can be selected, depend-

ing on the model, if the motor stop function on/off

must be worn:

Notice

In no case you should use the possibility of the

servo reverse of the channel 6 for helicopters and

channel 1 for other model types to reverse the

direction in which the related control stick works. Because the switch-on warning "CH1-Pos" as the "Thr.

HOLD" function do not follow this kind of reverse control

direction. To reverse the control direction use exclusively

the possibility offered by the "Pitch curve" menu for

helicopters models and "Throttle curve" for all the other model types.

Touch SET with a finger or the provided stylus to go

directly to the »TX ctl« display (Transmitter setting) in

which you can link the receiver to the model memory

as described in the related paragraph ...

Or touch the BACK button at the top left to terminate

the procedure.

If instead by switching the transmitter, there is already

a receiver bound to the model memory and inactive

Thr.POS warning, the transmitter will switch on and

the RF module will also be active. Otherwise in the

middle of the display it will standardly appear the following page and at the same time an acoustic warning will be emitted.

You now have the option of waiting a few seconds

until the display disappears automatically or maintaining the HF transmissions by manually tapping the ON

button, or switching them off by tapping the OFF

button.

In the field between the two green lines, the message

"RC signal" indicates that the transmitter is set to normal remote control. Alternately, messages such as

"TEACH signal" or "PUPIL signal" can appear here.

Another – possible – variant is to display "SET F/S" as

an indication that no fail-safe settings have yet been

made.

Notices

• By default,only the monitoring of the "Warn -

ing" sub-menu is activated in the display of

the sub-menu "Warning"of the system menu.

• By selecting REV in the "Thr.HOLD" line of

the "Warning" sub-menu the transmitter can

remind you to switch this function safely on.

8 Warnings

Page 9

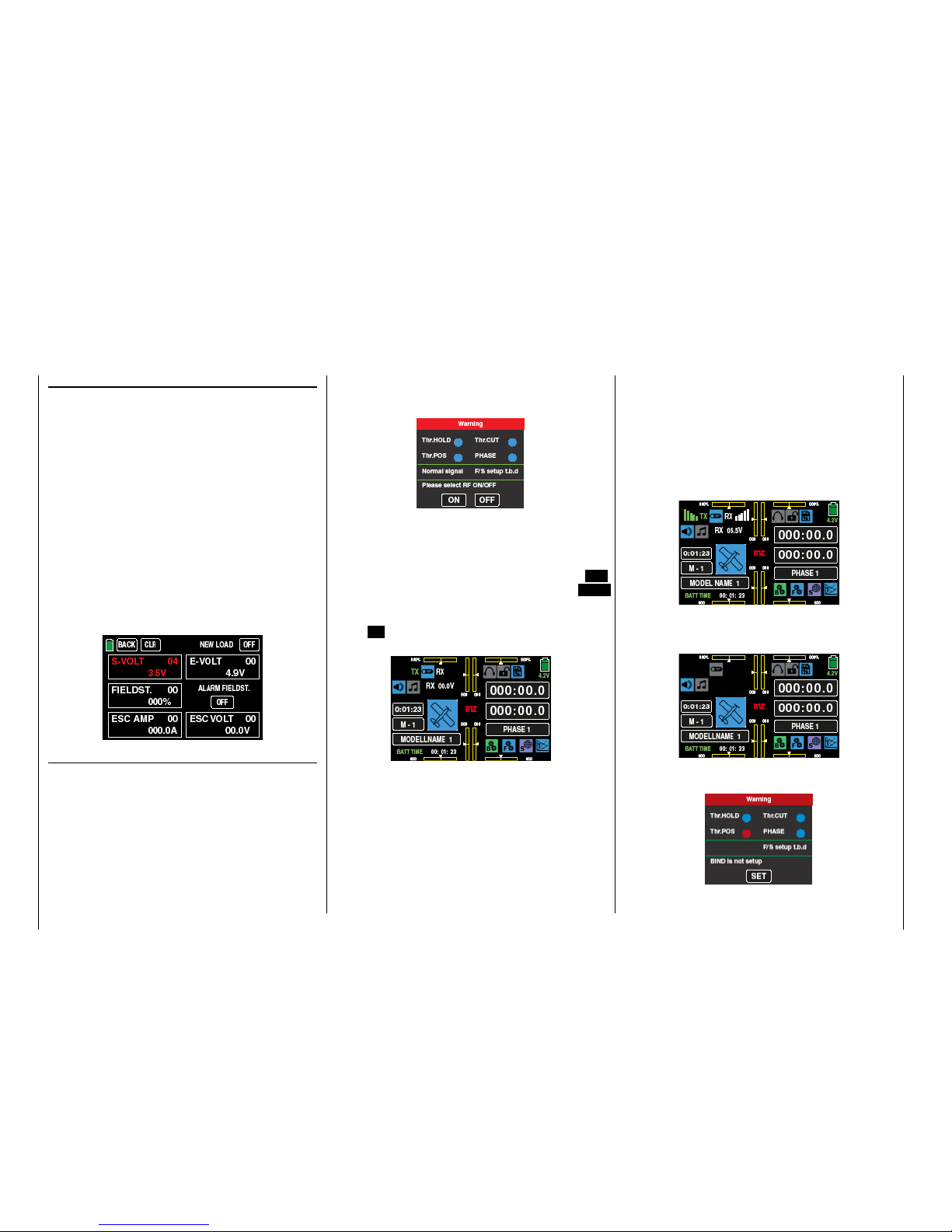

"Acute warning" display

You can open this display by touching mz in the middle of the transmitter's basic display ...

Touch

... and touch the BACK button at the top left to close

the display.

If acoustic warnings sound and the normal transmitter display is covered by this display, take note of the

message in red. An example would be because the

transmitter's supply voltage has reached the warning

threshold set in the sub-menu "»ETC. SET" of the

SYSTEM menu:

At the same time, the display contrast is reduced to

05 to save power.

This warning can be kept from reappearing by touching the ON button at the top right then deleted by

touching the BACK button at the top left in the display. (In specific cases, stop operating the model as

soon as possible and charge the transmitter).

The red number at the top right of each warning field

shows the number of current warnings; in the above

example, the warning is the fourth one. This count can

be deleted by touching the CLR button at the top left.

All other warnings in this display can be handled in

the same way. However, in the case of a field strength

alarm, you can also suppress other alarms triggered

by the low field strength by touching the ON button

under "STRENGTH ALARM" and switch it to OFF.

CAUTION

A switched OFF "Strength alarm" will not

automatically be set to the "ON" position

when the transmitter will be switched on

the next time.

9

Warnings

Page 10

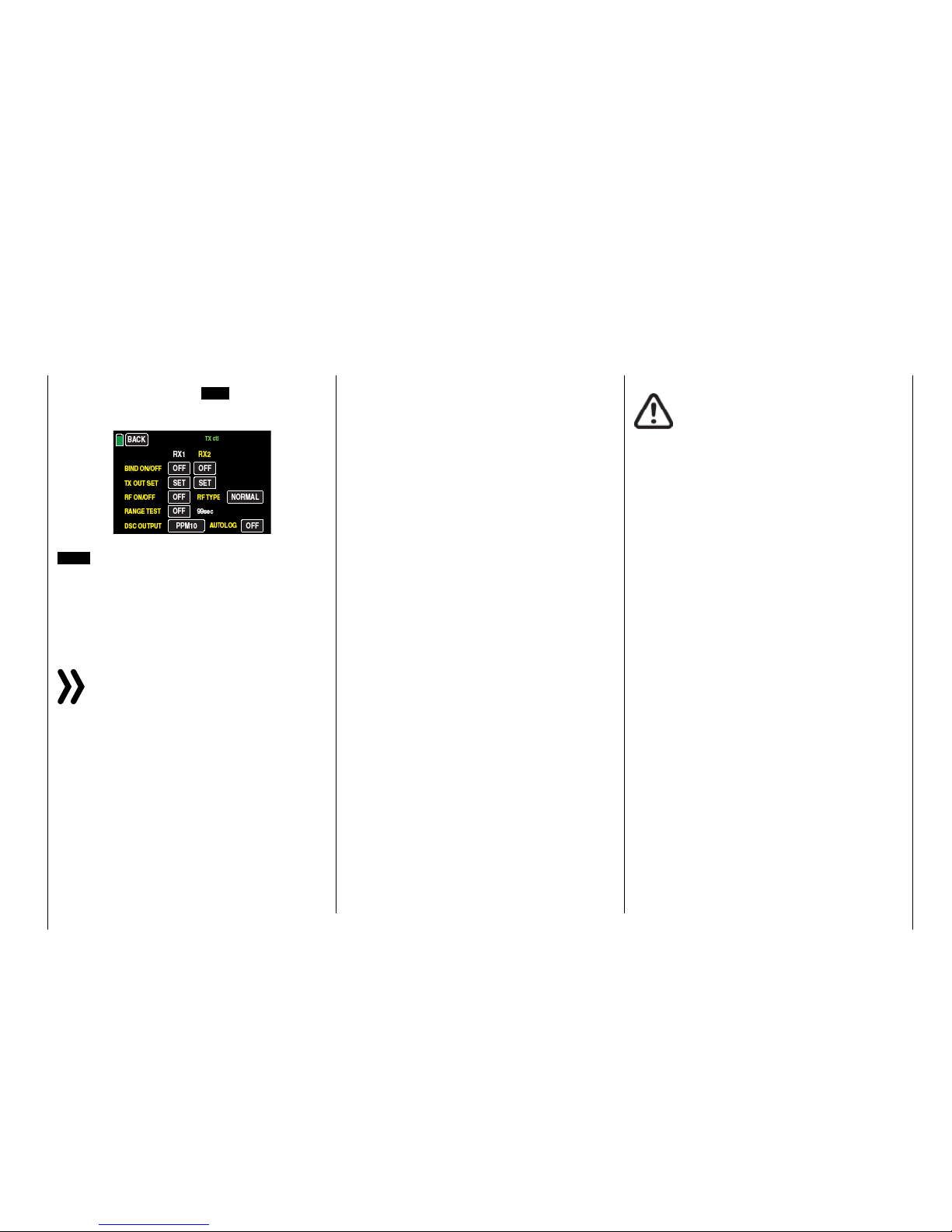

3. In the sub-menu »TX ctl«, depending on the number of channels used for the connected flight simulator or for the Training mode, you can select in

the line "DSC output" one of the following modes:

PPM10, PPM16, PPM18 und PPM24. Default setting: PPM10.

Notice

Given the numerous flight simulators on the market, it is possible that the contacts on the jack

plug or DSC module may have to be adapted by

Graupner Service.

Attention

When your transmitter is directly connected to a

desktop computer or laptop by a connecting ca-

ble (DSC cable) and/or a computer interface is

connected to your simulator, the transmitter may be destroyed byelectrostatic discharge. This type of connection should therefore only be used if you protect yourself

from electrostatic discharge while operating the simulator by wearing a commercially available grounding armband. Graupner therefore strongly recommends only

using wireless simulators.

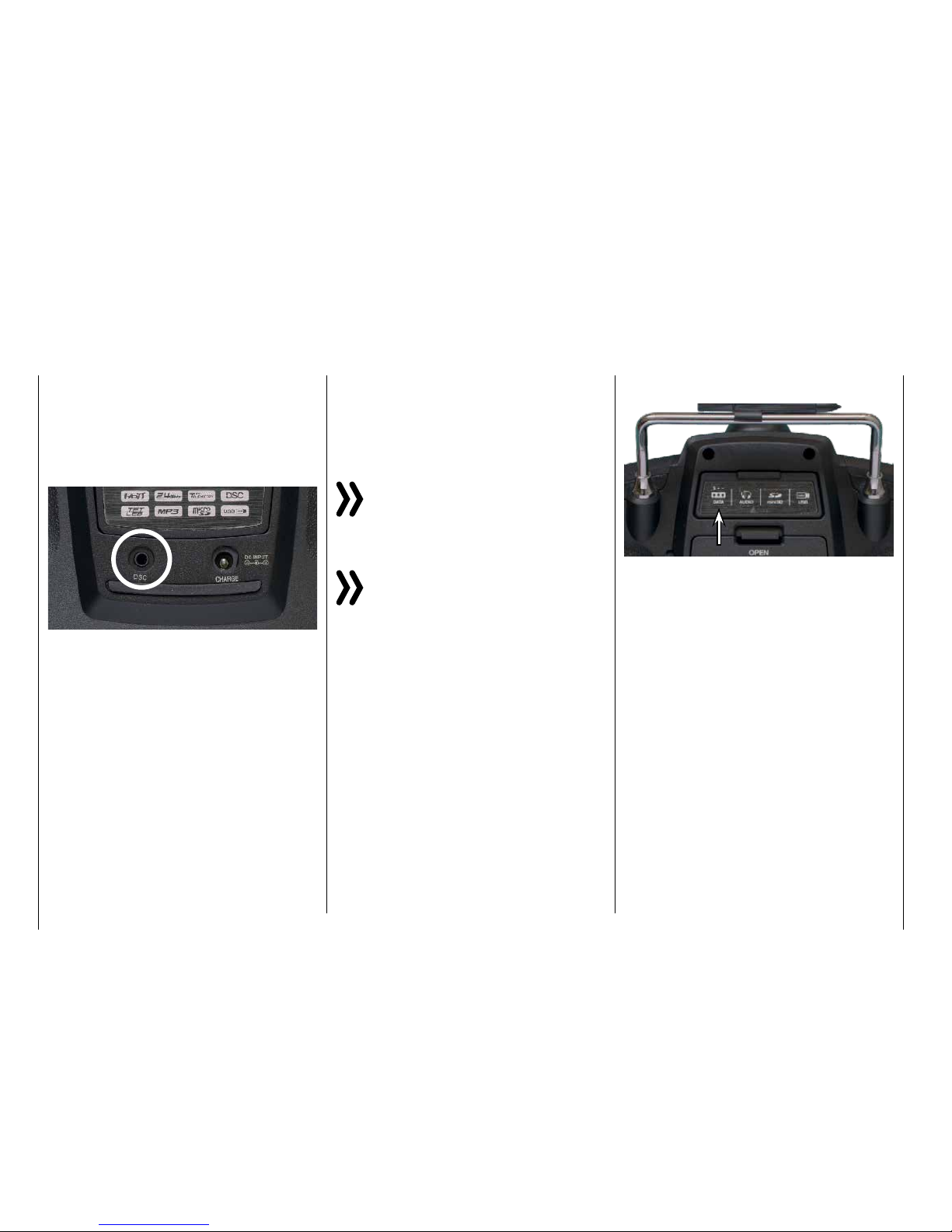

DSCsocket

The abbreviation "DSC" is from the initial letters of the

original function, "direct servo control". With the HoTT

system, "direct servo control" using a diagnostic cable is not possible for technical reasons.

The standard two-pin DSC socket on the back of the

mz-24 HoTT Pro transmitters functions as a TRAINER

or PUPIL socket as well as an interface for flight simulators or other external devices.

To ensure a correct DSC connection, observe the

following:

1. Perform any necessary adaptations in the menu.

To adapt to the transmitter to a trainer system,see

the description of the "Trainer" menu.

2. Connect the other end of the connecting cable to

the desireddevice while observing the relevant operating instructions.

Tip

Make sure that all the plugs are securely inserted in

the respective sockets, and only use the provided

plug-in connections with a 2-pin jack plug on the

DSC side.

The so-called DATA socket is found under the back

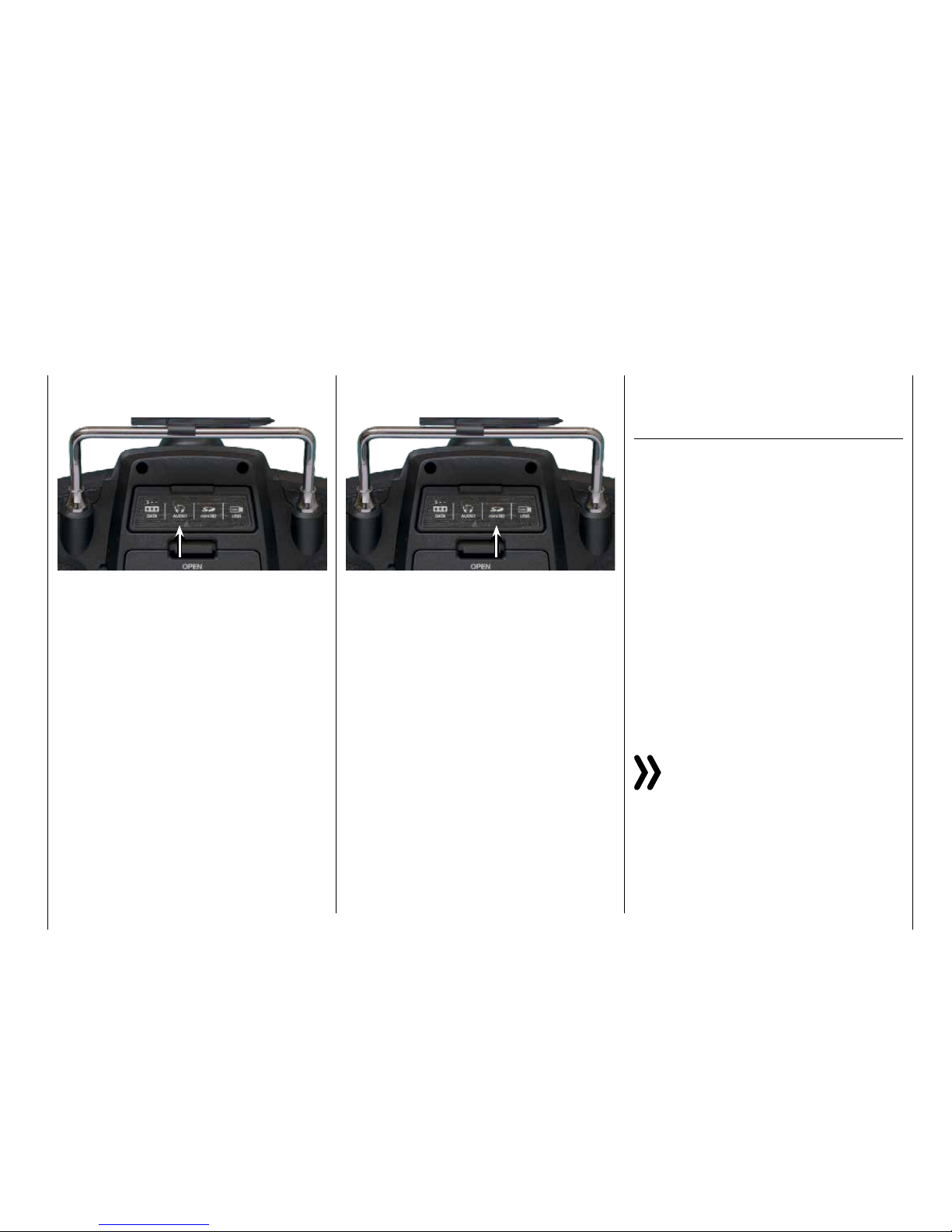

cover of the mz-24 HoTT Pro transmitters:

This is for connecting the optional Smart Box ( order

No. 33700) or alternatively for an external Bluetooth

module (No. S8351).

Further information on the Smart Box and the Bluetooth module can be found in the main Graupner FS

catalogue and on the Internet at www.graupner.de for

the respective product.

Data socket

10 Connection on the back side

Page 11

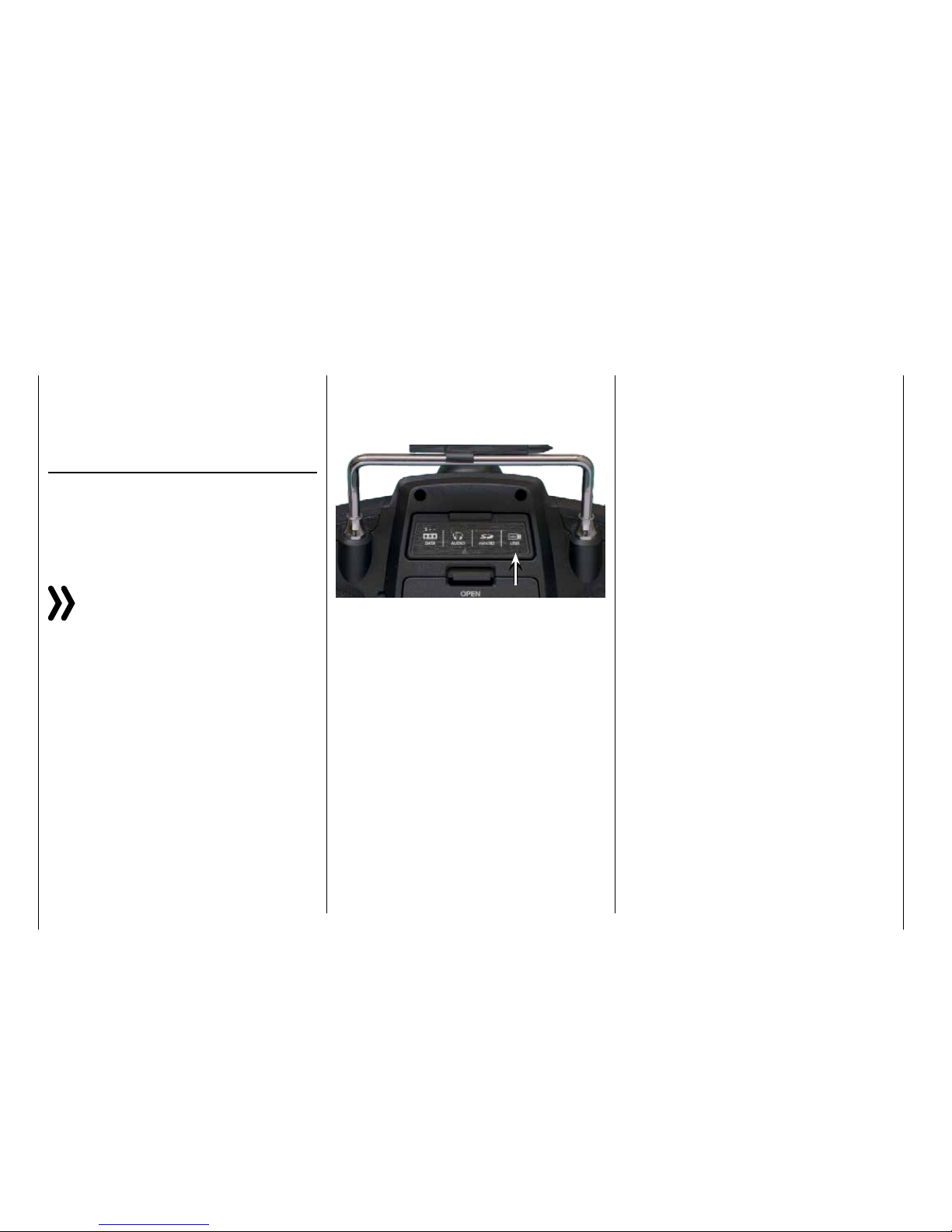

The headphone connection is found left of center under the back cover of the mz-24 HoTT Pro transmitter:

The socket is for connecting commercially available

ear buds or headphones with a 3.5 mmstereo jack.

(Not included in the set.)

When headphones are plugged in, the transmitter's

speaker is turned off and the stylized icon of a headphone is depicted in color and not gray in the basic

display.

In addition to acoustic signals from the transmitter,

signals and messages associated with the "Teleme-

try" menu are output via this connection. These messages are in German by default. Further information

can be found under "Announces" in the ""Teleme-

try"" section.

Ear phones port

Card slot

Micro-SD and micro-SDHC

Thecard slot for micro-SD und micro-SDHC memory

cards is found on the right of center under the back

cover of the mz-24 HoTT Pro transmitters:

In addition to the micro-SD memory cards that come

standard with the mz-24 HoTT Pro, all conventional micro-SD memory cards with up to 2 GB and micro-SDHC cards with up to 32 GB memory can be

used. The manufacturer recommends using memory

cards with a maximum of 4 GB since this capacity is

normally sufficient.

The memory card that is provided for the transmitter is inserted into the slot behind the cover with the

contacts facing up and then locked in place. After the

memory card is inserted, the transmitter cover can be

closed.

After the provided memory card included in the mz-

24 HoTT Pro set or another memory card has been

inserted in the transmitter at least once, the card is

ready for use directly after the transmitter is turned on.

If the transmitter is turned on after the memory card

is inserted, the stylized memory card icon is displayed

in color and not gray in the basic display. Otherwise, a

few folders are first created on the memory card.

Removing the memory card

Open the cover on the back. Press the SD card slightly toward the card slot to unlock it and then remove it.

Capturing / saving data

The data memory on the SD card is linked to timer

1: Once this starts, data storage also starts assuming that an appropriate memory card is in the card

slot and there is a telemetry link with the receiver. Data

storage stops when the timer 1 is stopped. Timer 1

starts and stops as described in the section "Timer".

The data writing on the memory card is remarked by

an animation of the memory card symbol.

After data storage is finished, an (empty) "Models"

folder and "LogData" folder appear on the memory card. Finally, the log files are saved in subfolders

called "Modelname" named according to the structure

0001_year-month-day.bin, 0002_year-month-day.bin.

If in contrast a model memory is still nameless, the

corresponding log files are saved in a subfolder entitled "NoName" after the memory card is removed

from the transmitter and inserted in the card slot of

a desktop or laptop computer. The data can be evaluated on a compatible computer using the programs

found on the downloads page for the transmitter under www.graupner. de.

Notice

Please note that for technical reasons NO data

representation is possible during the reproduction of MP3 data.

11

Connection on the back side

Page 12

Mini-USB connection

Located under the rear cover of the mz-24 HoTT Pro

transmitter, there isa connection socket for software

updatesas well as the date andtime settingfrom a

desktop or laptop with one of the Windows operating

systems (XP, Vista, 7 ... 10):

The USB cable that comes with the set is plugged into

this socket. The procedure for obtaining software updates through a computer is described in the software

package instructions.

The software that the computer needs as well as the

appropriate USB driver can be found on the download

page at www.graupner.de for the respective product.

After the required driver and software are installed, the

transmitter can be updated as needed using this connection, or the date and time can be set.

Tip

In order to be aware of important software updates, you

should therefore register at https://www.graupner.de/

de/service/produktregistrierung.aspx. This will allow you

to automatically receive updates by e-mail.

Importing and exporting model memories

To exchange data between transmitters of the same

make or to backup data, model memories can be copied to the inserted memory card, or from the memory

card to the transmitter. More information can be found

in the section "Import from SD card" or "Export to SD

card"..

Notices

• Some of the special characters used in model names cannot be transferred to FAT and

FAT32file systemsdue to the specific restrictions of these file systems used by the memory cardand are therefore replaced by a tilde

(~) during the copying process.

• The model memories of the mz-24 and mz-

24 Pro transmittersare in principle compatible, BUT:

In order to import from an SD card in another

a transmitter type, the desired model memory

must be copied or moved to a corresponding

directory on a desktop or laptop. For example

from \\Models\mz-24 to \\Models\mz-24pro

or vice versa.

More information on "import from SD card"

After importing from an SD card,you always

need to check each and every model function and in particular adapt the control and

switch functionsto the respective transmitter.

12 Connection on the back side

Page 13

13

Personal notes

Page 14

Starting up the receiver

Preliminary remarks

Notice

With this mz-24 HoTT Pro transmitter it is possible to control up to 12 functions. Any servos

which are connected to the receiver outputs 13

and higher remain in their middle position by default and

cannot be actuated by the transmitter.

As described in the manual of the related receiver,

after switching it on a LED indicates the missing reception, so long as "its" transmitter is out of range or

switched off or simply the wrong model memory has

been selected in the transmitter. This means that a link

has not (yet) been established with a Graupner-HoTT

transmitter.

To establish a connection with the transmitter, first the

Graupner HoTT receiver must be "bound" to its model

memory in its Graupner HoTT transmitter. This process is known as "Binding". This "binding" is however

required only once for each receiver-model memory

combination or, after changes have been made to one

or more model memories (see page 39), only once

for each transmitter-receiver combination . Therefore

you need to perform a "binding" only after buying a

new transmitter or other receivers or for example if

you have changed model memory (and you can repeat it at any time).

Notice

If the LED of your receiver indicates that it is ready

for use and the receiver does not react to the SET

button and to the control movements, then you

would be better to check the polarity of your receiver

power supply.

On-board voltage display

When a telemetry link exists, the current voltage of

the receiver power supply appears in the transmitter

display in white.

Temperature warning

If the receiver temperature falls below a threshold

which can be set in the receiver (-10°C by default) or

exceeds a top warning threshold (+55°C by default)

which can also be set in the receiver, the receiver

emits a warning in the form of a beep that repeats

approximately once per second.

Note the installation instructions for the receiver, receiver antennas and servos on page 16.

Notice

If you are using a speed controller with an integrated BEC* in addition to the receiver battery,

the plus pole (red cable) may have to be removed

from the 3-pin plug depending on the speed controller.

In this regard, take note of the related information in the

speed controller instructions.

Use a short screwdriver to carefully lift the middle tab of the plug (1),

remove the red cable (2), and use

electrician's tape to protect against

shorts (3).

Reset

To reset the receiver, hold down the SET button on the

top of the receiver while turning on the power.

If the reset is performed while the transmitter is

switched off or with a not bound receiver, the LED on

the receiver indicates the actual status according to

the description included in the package. If there is no

different description, release the button after about 3

seconds.

If the reset is performed with a not bound receiver, you

can then start a binding process at any time.

If a linked receiver is reset and the associated model

memory is active in the turned-on transmitter, the LED

indicates for about 2-3 seconds, accordingly to the

description included in the package of the receiver, to

indicate that your transmitter/receiver system is ready

to use.

Note

Through a RESET ALL of the settingsin the receiver are brought to the factory settings with the

exception of the HoTT synchronization informa-

tion!

If a reset is performed accidentally, all of these settings

that were made using the "Telemetry" menu in the re-

ceiver should be restored.

Resetting is particularly recommendable when you want

to switch a receiver to a different model. This makes it

easy to keep settings which do not match from being

transferred.

* BEC = Battery Elimination Circuit

14 Starting up the receiver

Page 15

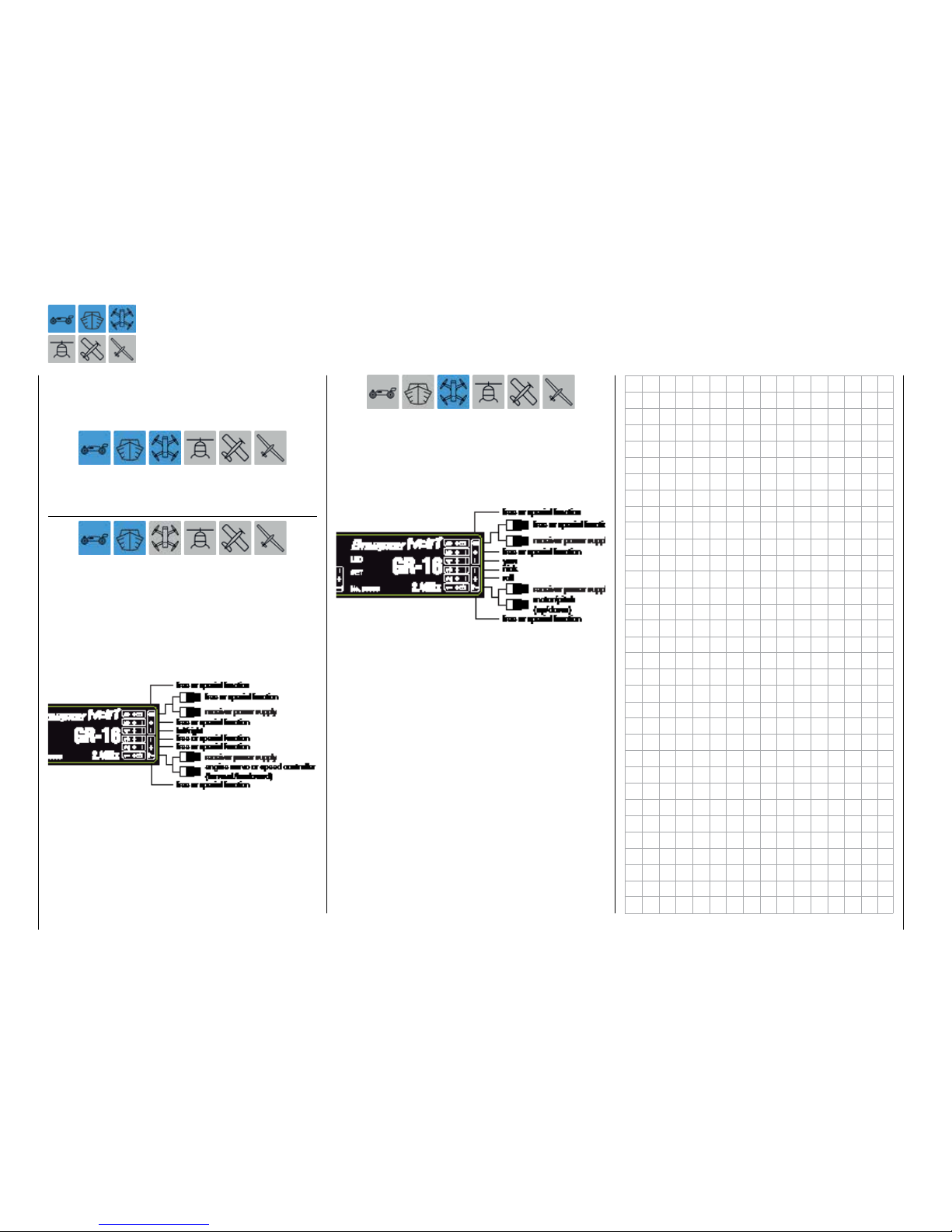

Channel mapping

The function of each channel is determined by the

transmitter and not the receiver. The channel mapping can be changed directly in the receiver programming the "Telemetry" menu and indirectly through the

menu point "Transmitter output" of the base menu.

Installing the receiver

WhateverGraupner receiver system you use, the

procedure is the same.

For aircraft models, the receiver is installed behind

a strongbulkhead or it is protected against dust and

splash waterincar and ship models. When you install

the receiver, make sure that it is not excessively airtight to prevent it from overheating during operation.

The receiver may not directly touch the fuselage or

chassis since they can directly transmit motor vibration or impact from landing. When installing the receiver in a model with a gas motor, all of the parts

must be protected to prevent exhaust or oil from penetrating. This holds true in particular for the ON/OFF

switch that is installed in the shell of the model in most

cases.

Install the receiver so that the connecting cables for

the servos and power supply remain loose, and so

that the receiving antennas are at least 5 cm from all

large metal parts or wires that do not directly originate

from the receiver. This includes carbon fiber parts,

servos, electric motors, fuel pumps, all types of cables, etc. in addition to steel parts.

It is preferable to install the receiver away from all other installed parts at an easily accessible location in

the model. Servo cables may not be wound around

antennas or run next to them.

Note that the cables can shift under the influence of

acceleration during flight. You therefore need to make

sure that the cables cannot move to be directly adjacent to antennas. Moving cables can interfere with

reception.

Installing the receiver

Installing the receiver antennas

In case of single antenna, the orientation is not crucial.

In the case of diversity antennas (two antennas), the

active end of the second antenna should be at a 90°

angle from the end of the first antenna, and the distance between the active ends should ideally be more

than 125 mm.

If the fuselages are made of carbon fiber, the ends

of the antennas should extend from the fuselage by

at least 35 mm. If necessary, exchange the approx.

145 mm standard antennas for HoTT receivers with

the 300 mm or 450 mm long antennas No. 33500.2

or 33500.3.

Servo connections and polarity

The servo connections of the Graupner-HoTT receiver are numbered. The supply voltage runs through all

the numbered connections. The polarity of the plug-in

system cannot be reversed. When inserting the plug,

note the small bevels on the side. Do not apply force.

Attention

Do not reverse the polarity of these connections!

This can destroy the receiver and connected devices.

Notice

In compact receivers like the GR-12L HoTT the

outputs 1 … 6 are reverse of 180° if compared to

bigger receivers, for this reason we recommend

to pay a very lot of attention while you connect any plug

to the receiver. If applicable, use a V or Y cable (No.

3936.11).

15

Installing the receiver

Page 16

Installation notices

Components and accessories

Attention

As the manufacturer, Graupner|SJ GmbH recommends only using components and accesso-

ries that have been tested and accepted by

Graupner|SJ GmbH for suitability, functioning and safety. If this is done, Graupner|SJ GmbH will assume responsibility for the product.

However, Graupner|SJ GmbH assumes no liability for

products or accessories by other manufacturers that

have not been approved, and is incapable of evaluating

every single third-party product to determine if it can be

used safely.

Installing the switch

All of the switches must be installed so that they are

not influenced by exhaust or vibration. The switch

knob must be freely accessible over its entire operating range.

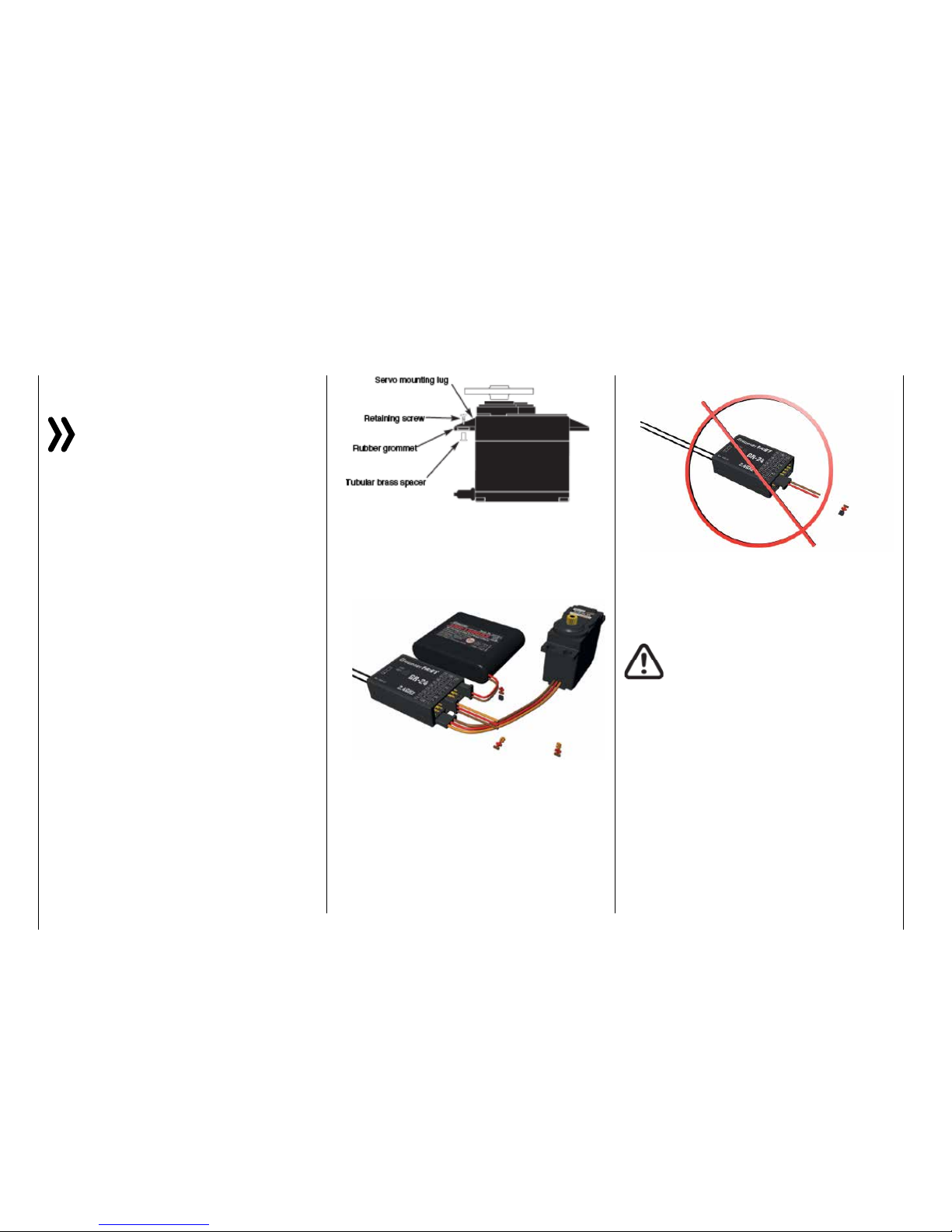

Installing the servos

Always install the servos with the provided rubber vibration damper, see the following installing notices.

This is the only way to protect them somewhat from

excessive vibration.

• Install the servos on rubber grommets with tubular

brass spacers to protect them from vibration. Do

not overtighten the fixing screws; this could counteract the vibration protection provided by the rubber grommets. The system offers both safety and

vibration protection for your servos when the servo

fixing screws are properly tightened. The following figure shows how to correctly mount a servo.

The brass spacers are inserted from below into the

rubber grommets:

... they should never be connected as follows:

• In contrast, the sequence for connecting the servosdepends on the model type. Refer to the connection assignments for Helicopter models and

Fixed-wing models.

WARNINGS

• Technical defects of an electrical or

mechanical naturemay cause motors

to start without warning,or may generate flying partswhich can cause significant injuryto you and others!

• Avoid every kind of short-circuit!

Short-circuits can destroy parts of the

remote control system and cause serious burns or explosions depending

on the circumstances and the battery

charge.

• All parts driven by the motor such as

air and water propellers as well as helicopter rotors, exposed gears, etc.

always pose an injury hazard. Never

touch these parts! A fast-rotating propeller can cut off a finger! Make sure

that no other objects come into contact with driven parts.

• The servo arms must be freely movable throughout

their operating range. Make sure that no linkage

parts block the free movement of the servo.

• Connect the receiver's power supply cable(s) or

the servo connecting cable to the receiver as follows ...

16 Installation instructions

Page 17

• Once the battery is connected or the

motor is running, always maintain a

safe distance from the hazard area

posed by the propulsion system!

• During the programming process,

make sure that a connected gas engine or electric motor cannot accidentally start. Disconnect the fuel supply

or drive battery beforehand.

Notices

• Protect all equipment from dust, dirt, moisture

and other foreign parts. All equipment must be

protected from vibration as well as excessive

heat or cold. The models may only be operated remotely in normal outside temperatures

such as from -10°C to +55°C.

• Avoid shock and pressure. Check for damage to the housing and cables. Devices that

become wet or damaged may not be used

anymore even if they dry out.

• Only use the components and spare parts

that we recommend. Always use matching,

original Graupner plug-in connections of the

same design and material.

• When running the cables, make sure that they

are not excessively tight, kinked, or severed. A

sharp edge can also damage insulation.

• Make sure that all of the plug-in connections

are tight. When disconnecting the plug-in

connections, do not pull the cables.

• No changes may be made to the devices. This

will void permission to use the device along

with the warranty. If appropriate, send the

relevant device to the responsible Graupner

Service Center

Range and function test

Before every use, check the range and functioning.

Firmly secure the model, and make sure that no one

is nearby.

Perform at least one complete function test on the

ground, and run through an entire flight simulation to

determine if there are any problems with the system

or the programming of the model. Always follow the

instructions under Range test.

WARNING

If the range and function test as well as

the flight simulation are not performed

completely and conscientiously, malfunctions may go unrecognized and reception may be

lost which could cause a loss of control or even

cause the model to crash. This canresult in major

property damage and/or personal injury.

17

Installation instructions

Servo noise filters for extension cables

No. 1040

The servo noise filter is required when using lon-

ger-than-usual servo cables. The filter is connected

directly to the receiver output. In critical cases, a second filter can be placed on the servo.

Electrical ignitions

Ignition systems of gas engines also generate interference that can impair the functioning of remote controls.

The power for electrical ignitions should always be

from a separate source.

Only use interference-suppressed spark plugs and

spark plug connectors and shielded ignition cables.

The receiver should be at a sufficient distance from

the ignition system.

Model function

WARNING

• Neverfly the model over observersor

other pilots. Never endanger people

or animals. Never fly close to power

lines. In addition, never operate your

model close to locks and open nautical traffic. Do not operate your model

on open roads, highways, paths, public walkways, etc.

• Never turn off the transmitter while

operating the model! If this nonetheless accidentally happens, do not panic, and wait until the transmitter display goes dark which indicates that

the transmitter is completely off. This

will take at least three seconds. After this time, turn the transmitter on

again.

Page 18

• Otherwise, the transmitter may freeze

directly after being turned on, and you

will be unable to control the model.

The transmitter may only be turned

on again after it has been turned off

and the described procedure has been

correctly repeated.

• When operating towed models, maintain a minimum distance of approximately 50 cm between the participating receivers or their antennas. Using

the satellite receiver is an option. Otherwise, malfunctions from the feedback channel are possible.

Checking the transmitter and receiver batteries

Stop operation and recharge the transmitter battery at

the latest when the transmitterbattery is running low,

the message "Charge the battery!" appears in the

display, andan acoustic warning sounds.

Regularly check the battery charge, especially of the

receiver battery. Do not wait until the movements of

the rudder are noticeably slower. Replace dead batteries in a timely manner.

Always follow the manufacturer's charging instructions, and charge the battery for the indicated time.

Do not charge the batteries without monitoring them.

Never attempt to charge dry batteries. An acute explosion hazard exists.

All batteries must be charged before each use. To prevent short-circuits, first plug the banana plugs of the

charging cable into the charger (make sure the poles

are correct). Then plug in the charging cable plugs into

the sockets of the transmitter and receiver battery.

If you are not going to use your model for a while,

disconnect all power sources.

Never use rechargeable or replaceable batteries with

damaged, defective or different cell types; that is, a

mixture of old and new cells, or cells by a different

manufacturer. Combinations of old and new cells or

cells from different manufacturers.

Capacity and operating time

The following applies to all power sources: The capacity decreases with each charge. At low temperatures,

the internal resistance increases while the capacity

decreases further. As a result, the battery's ability to

discharge and retain power is reduced.

Frequently charging and/or using battery care programs can also gradually reduce the capacity. Nevertheless, check the capacity of power sources at least

every 6 months, and replace them if their performance

is significantly low.

Only use original Graupner rechargeable batteries!

18 Installation instructions

Page 19

19

Personal notes

Page 20

To safely operate the model, a reliable power supply

is required. If the receiver voltage shown on the transmitter display always drops or is generally (too) low

even though the linkage moves freely, the battery is

full, the cross-section of the battery connecting cable

is sufficient, and the transition resistance at the plugin connections is minimal, etc., observe following:

First make sure that the battery remains fully charged

when initially operating the model. Make sure that the

resistance of the contacts and switches is low. Measure the voltage drop over the installed switch cables

under a load since even robust, new switches cause

a voltage drop of up to 0.2 V. This value can be several times higher due to aging and oxidation of the

contacts. In addition, constant vibration and shaking

of the contacts also gradually increase the transition

resistance.

Furthermore, even small servos such as a Graupner/

JR DS-281 draw stall current to 0.75 A when you stop

under a load. Four of these servos in a foam airplane

can hence draw up to 3 A from the on-board power

supply.

Furthermore, servos connected to a 2.4 GHz receiver

receive control pulses more frequently than comparable receivers in the classic frequency range. This affects the power consumption of the receiver system

as well as the characteristic of many modern digital

servos of maintaining the last position specified by

the last control pulse until the next pulse arrives.

You should not only therefore choose a power supply

that does not fail under a permanent high load and

always provides sufficient voltage. To calculate the required battery capacity, add at least 350 mAh for each

analog servo, and at least 500 mAh for each digital

servo.

Using this method, a battery with 1400 mAh represents the absolute minimum for supplying power to

a receiver with four analogue servos. In your calculation, also include the receiver which requires about

70 mA due to its bidirectional function.

Apart from the above considerations, it is generally

recommendable to connect the receiver to the power

supply using two cables. As usual, connect cable "1"

to the "6+B" or "12+B-" output of a GR-16 or GR24 receiver, and cable "2" to the opposite end of the

connector strip labeled "1+B-" or "11+B-" of the receiver. When, for example, using a switch or voltage

regulator with two power supply cables leading to the

receiver. Between the cable and receiver, you can use

a V or Y cable (No. 3936.11, see figure) if one or both

receiver connections also need to be connected to a

servo, speed controller, etc. With the double connection to the switch or voltage controller, you not only

reduce the risk of a cable rupture but also ensure an

even power supply to the connected servos.

If you connect a separate battery to each battery

connection, be sure that each of the batteries have

the same rated voltage and capacity. Never connect

different battery types or batteries with strongly different charges since this can cause an effect similar

to a short circuit. In such cases for safety reasons,

insert voltage stabilizing elements such as the PRX5A receiver power supplies between the batteries and

receiver:

For safety reasons, never used battery boxes or dry

batteries.

The voltage of the on-board power supply is graphically represented, when the model is in use, in the

upper right side of the display so as underneath in

green numerically:

If the voltage falls below the warning threshold (normally 3.8 V) which can be adjusted in the "RX SERVO

TEST" display of the "SETTING & DATA VIEW" of the

"Telemetry" menu, a visual and acoustic low-voltage

warnings are generated.

Attention

Thebattery level should be checked regularly. Do

not wait to charge the battery until the voltage

decreases enough for a warning signal to be

generated.

Tip

A summary of the batteries, chargers and measuring

devicesfor checkingthe power sources can be found

in the main Graupner FS catalogue as well as on the

Internet at www.graupner.de.

20 Installation notice - Receiver system power supply

Receiver system power supply

Page 21

Charging the receiver battery

The charging cable (No. 3021) can be connected directly to the receiver battery to charge it. If the battery

in the model is connected by a power supply cable

(No. 3046, 3934, 3934.1 or 3934.3), the battery is

charged via the charging socket integrated in the

switch, or a separate charging connection. The switch

for the power supply cable must be set to "OFF" for

charging

Polarity of the receiver battery plug

.

Receiver system power supply

NiMH battery packs with 4 cells

With a traditional 4-cell pack, you can reliably operate

your Graupner HoTT system providing that the above

conditions are observed, and assuming that the packs

have a sufficient capacity and charge.

NiMH battery packs with 5 cells

Battery packs with five cells offer greater leeway in

comparison to 4-cell packs.

You should note, however, that not every servo available on the market can handle the voltage from a

5-cell pack over the long term, especially when the

pack is freshly charged. Some of these servos audibly

"growl" when operated with a 5-pack.

Notice

You should therefore note the specifications for

your servo before you choose to use a 5-cell

pack.

LiFe packs with 2 cells

Given the above considerations, these cells are the

best choice.

LiFe cells are also available in a hard plastic housing

to protect against mechanical damage. Like lithium

polymer cells, LiFe cells can be charged quickly with

suitable chargers and are comparably robust.

In addition, this type of cell can undergo significantly

more charging/discharging cycles than conventional

LiPo batteries. The comparatively high rated voltage

of 6.6 V of two cell LiFe battery packs does not pose

any problems to Graupner HoTT receivers or the servos, speed controllers, gyros, etc. which are approved

for operation with this higher voltage.

Attention

However, practically all of the previously marketed servos, speed controllers, gyros, etc. as well

as many which are offered today have a permissible operating voltage range of 4.8 to 6 V. Stabilized

voltage control such as the PRX (No. 4136) is therefore

needed to connect them to the receiver. Otherwise, the

connected devices may quickly become damaged.

LiPo packs with 2 cells

LiPo batteries are lighter yet they offer the same capacity of NiMH batteries. LiPo batteries also come in

a hard plastic housing to protect against mechanical

damage.

The comparatively high rated voltage of 7.4 V of two

cell LiPo battery packs does not pose any problems

to Graupner HoTT receivers or the servos, speed controllers, gyros, etc. which are approved for operation

with this higher voltage.

Attention

However, practically all of the previously market-

ed servos, speed controllers, gyros, etc. as well

as many which are offered today have a permissible operating voltage range of 4.8 to 6 V. Stabilized

voltage control such as the PRX (No. 4136) is therefore

needed to connect them to the receiver. Otherwise, the

connected devices may quickly become damaged.

21

Installation notice - Receiver system power supply

Page 22

Lithium-ion (LiIo) and lithium polymer (LiPo) batteries

require special treatment. This is true when charging,

discharging, storing and all other types of handling.

Observe the following specifications:

Charging Graupner LiPo/LiIo batteries

• Since Graupner|SJ GmbH is unable to monitor

whether the batteries are correctly charged and

discharged, all warranties are voided upon incorrect charging or discharging.

• Only use the approved chargers with the associated charging cables to charge lithium ion/lithium

polymer batteries. Any alterations to the charger

and/or charging cables can cause serious damage.

• The maximum charging capacity must be limited

to a factor of 1.05 of the battery capacity.

Example: 700 mAh battery = 735 mAh max.

charging capacity

• To charge and discharge lithium-ion/lithium polymer batteries, only use the plug-in charger in the

set, or the specially designed charger/dischargers

by Graupner, see under www.graupner.de.

• Make sure that the number of cells, charging cutoff and discharging cutoff voltage are set correctly.

Refer to the operating instructions of your charger/

discharger.

• Under these prerequisites, Graupner lithium-ion/

lithium polymer batteries can be charged with a

maximum 2 C (1 C corresponds to the cell capacity) charging current. Starting at a maximum 4.2 V

per cell, continue charging at a constant 4.2 V per

cell until the charging current falls below 0.1... 0.2

A.

• Do not charge with more than 4.20 V per cell.

This would permanently damage the cell and may

cause a fire.

To keep from overcharging individual cells within

the pack, set the cutoff voltage to between 4.10...

4.15 V per cell in order to extend the battery life.

• The permissible temperature range for charging

and discharging lithium ion/lithium polymer batteries is 0... +50°C.

• Batteries as well as individual cells are not toys

and must be kept from children. They must therefore be stored out of the reach of children.

• Keep batteries away from infants and small children. If a battery is swallowed, immediately consult a physician or go to an emergency room.

• Never place a battery in a microwave or under

pressure. This may cause smoke, fire or an explosion.

• Do not disassemble lithium ion/lithium polymer

batteries. Disassembling a battery can cause internal short-circuits. This can result in the release

of gas, fire and explosion, or other problems.

• The electrolyte and electrolyte vapors within lithium-ion/lithium polymer batteries are hazardous to

health. Avoid direct contact with electrolytes. If the

electrolyte comes into contact with your skin, eyes

or other body parts, use a large amount of fresh

water for rinsing and then consult a doctor.

• Before each use, make sure that the batteries are

in a satisfactory condition. Defective or damaged

cells or batteries may not be used.

• Cells and batteries may only be used in accordance with the technical specifications for the specific cell type.

• Batteries and cells may not be heated, burned,

short-circuited or charged with excessive current

or with reversed polarity.

Safety and handling instructions

for lithium-ion (LiIo) and lithium polymer (LiPo) rechargeable batteries

• If handled improperly, there is a danger of fire, explosion, irritation and burns. To extinguish a fire,

use a fire extinguishing blanket, CO2 extinguisher

or sand.

• If the batteries overheat, proceed as follows:

Disconnect the battery, and place it on a non-flam-

mable surface (such as concrete) until it cools

down. Never hold the battery in your hand due to

the risk of explosion.

• Batteries from parallel-connected cells, and combinations of old and new cells, cells of different

makes, sizes, capacities, manufacturers, brands

or type may not be used.

• Batteries which have been installed in a device

should always be removed when the device is

not being used. Always turn devices off after you

have finished using them to prevent battery drainage. Dead lithium-ion/lithium polymer batteries are

considered defective and may not be reused.

• Be sure to charge the batteries in a timely manner.

While they are being charged, the batteries must

be placed on a non-flammable, heat-resistant and

non-conductive surface. Combustible or highly

flammable objects are to be kept away from the

charging area.

• Batteries must be monitored while they are being

charged. The maximum charging current specified

for the respective cell type may not be exceeded.

• You may only charge a pack of series-connected

lithium-ion/lithium polymer batteries all at once as

long as the voltage of the individual cells does not

deviate by more than 0.05 V, or if the differences in

voltage are monitored and equalized by a balancer connection using a balancer or equalizer during

charging.

22 Safety and handling instructions for lithium-ion/lithium polymer batteries

Page 23

The 1s lithium-ion battery in the set comes with a

special safety shut off. The voltage differences between individual cells are therefore not balanced

by means of the usual balancer plug-in connection.

• If the battery heats up above 60°C while it is being charged, stop charging and let the battery cool

down to approximately 30°C.

• The batteries may not be modified. Do not directly

solder or weld the cells.

• To avoid deformation, avoid excessive mechanical

pressure.

• Make sure to observe the charging and discharging instructions.

Storage

LiIo/LiPo cells should be stocked with about 50% of

their nominal capacity. If the cell voltage falls below 3

V during the stocking, the lithium ion/lithium polymer

cells must be recharged to 50% of the full capacity.

Otherwise, the battery will die during storage and become useless.

Special instructions on discharging Graupner

LiIo/LiPo polymer batteries:

• A continuous current of approximately 1 C does

not pose a problem for Graupner lithium-ion/lithium polymer batteries. If the current is higher, refer

to the instructions in the catalogue. Bear in mind

the maximum load for the plug-in system (see the

maximum discharge current indicated on the battery label).

• Discharging below 2.5 V per cell will damage the

cells and should therefore be avoided at all costs.

• The batteries should never be short-circuited.

Short-circuits generate a very high current which

heats up the cells. This causes a loss of electrolyte, gas formation or even explosions. Graupner

LiIo/LiPo batteries should therefore be kept away

from and not touch conductive surfaces due to the

short-circuit hazard.

• The battery's temperature during discharging

should never exceed +70°C. If this occurs, make

sure that the battery is sufficiently cooled, or reduce the discharge current. The temperature can

be easily checked using the infrared thermometer

(No. 1963). However, the battery may not be discharged using the transmitter's charging socket.

This socket is not designed for this purpose.

Additional instructions on handling

• The battery capacity decreases each time it is

charged and discharged. Charging when the temperature is too high or too low can also gradually

reduce the battery's capacity. After 50 cycles, the

battery capacity of models is only 50-80% of that

of a new battery due to the occasionally high discharge current and induction current of the motor,

even when all charging and discharging instructions have been followed.

• Batteries may only be series-connected or parallel-connected in exceptions since the cell capacity

and charge can differ. The battery packs that we

supply are therefore preferable.

• The connections of lithium ion/lithium polymer

batteries are not as robust as other batteries. This

holds true particularly for the plus pole connection.

The connections can easily break.

Cells connection

Attention

Direct soldering on the battery cells is impermissible. The heat from direct soldering can damage

battery components such as the separator or

isolator.

Battery connections should only be created by spot

welding in the factory. If the cable is missing or severed, have it repaired professionally by the manufacturer or dealer.

Replacing individual battery cells

Attention

Individually battery cells may only be exchanged

by the manufacturer or dealer and not by the

user.

Do not use damaged cells

Damaged cells may not be used.

Indications of damaged cells include damaged hous-

ing packaging, deformed cells, the smell of electrolyte

or leaking electrolyte. The battery may not be used in

these cases.

Damaged or useless cells are considered hazardous

waste and must be disposed of properly.

Contact with liquids

Batteries may not be immersed in liquid such astap

water, sea water or beverages. Avoid all contact with

liquids of any kind.

23

Safety and handling instructions for lithium-ion/lithium polymer batteries

Page 24

Definition of terms

Control function, control, function input, control channel, mixer, switch, control and logical switch

To make it easier to use the Part 2 of the manual, we

offer a few definitions of terms that appear repeatedly

in the manual.

Control function

A control function is understood as the signal for a

specific control function independent of the signal

within the transmitter. In fixed-wing models set e.g.

the control signals would be throttle, rudder or aileron;

in helicopter models, these would be e.g. pitch, roll

or nick.

The signal of a control function can be transmitted

directly into one control channel or through a mixer

to several control channels. A typical example of the

latter are separate aileron servos, or the use of two roll

or elevation servos in helicopters. The control function

includes the influence of the mechanical control path

on the corresponding servo. This can be spread or

concentrated and modified from linear to highly exponential.

Controls

Controls are the control elements on the transmitter

that are activated directly by the pilot that control the

connected servos, speed controllers, etc. on the receiver. These include:

• The two control sticks for control functions 1 to

4, including the related trims. These four functions

in all the six model types (vehicle, boat, copter,

helicopter, motor airplane and glider) can be exchanged using the mode setting in the software,

such as throttle left or right. Throttle/brake or throttle/pitch left or right. The control stick function for

Throttle/brake flap control for fixed-wing models

or throttle/pitch control in helicopters is frequently

identified as the THR control (channel 1).

• the four proportional dials (DV1 … DV4)

• The two side proportional rotary controls SL1 and

SL2 mounted on the bottom.

• Switches S1 … S8

• the INC/DEC buttons DT1 and DT2

With the type DV and SL proportional controls as well

as the INC/DEC buttons, the servos directly follow the

control position, whereas only a two or three-stage

adjustment is possible with a switch.

The assignment of the controls and switches to the

servos 5 …12 is freely programmable.

Function input

This is an imaginary point in the signal flow and should

not be confused with the control connection on the

printed circuit board. The selected control mode and

the settings "TX OUT SET" line of the ""CTL Set""

sub-menu (transmitter setting) of the base menu influence the sequence beyond the physical connecting

points and this can generate differences between the

number of function inputs and the number of subsequent control channels.

Control channel

From the point at which a signal contains all control

information necessary for a particular servo, whether

directly from the control or indirectly via a mixer, the

term control channel is used.

For example, the "aileron" control function of a fixedwing model for the model type "2AILE" is divided into

control channels for the left and right aileron. Analogously,the "Roll" control function for the helicopter

model "3Sv(2Roll)" governs the controlchannels for

both the left and right roll servo.

This signal is only influenced by the settings made in

the sub-menus "E.P.A" (servo path/servo limit), "REV/

SUB" (servo direction reverse/delay) and "Sub-Trim"

(servo middle and neutral position) to adjust the servo, and possibly the settings in the sub-menu "Out.

Swap" (transmitter output) and is then transmitted by

the transmitter through the RF module. Once it arrives

in the receiver, this signal may be modified by settings

saved in the "Telemetry" menu, after which it controls

the associated servo.

Mixer

The transmitter program contains a variety of mixing

functions. These allow a control function to influence

several control channels and as final result several

servos or even many control functions to influence the

same one servo.

In this context, you can refer to the numerous mixing

functions.

Switch

The series of toggle switches S1 … S8 can also be included in the control programming. The switches are

however generally also intended to switch program

options such as to start and stop the timers, turn mixers on and off, as trainer switches etc. Each of the

switches can be assigned any number of functions.

Related examples are listed in the manual.

Control switch

Since it is occasionally practical to automatically

switch a timer or a function on or off when a control

is in a specific position (a stopwatch turns on/off to

measure engine operating times), the program for the

mz-24 HoTT Pro transmitter also allows you to program control switches.

24 Definition of terms

Page 25

With these program switches, all you have to do is

specify the switching point along the control path in

the direction of switching. More detailed information

are easily available in the paragraph "Controls and

switches assignment".

Logical switch

Through this option two switches, controls and/or

logical switches or the favorite combination of them,

can be interconnected in an "AND" or "OR" switch. A

total amount of 8 logical switches "L1 … L8" can be

programmed, see description in the "Logical switch"

menu.

25

Definition of terms

Page 26

Control and switch assignment

Basic procedure

In many places in the program, you can actuate a

control function with a freely selectable control (ST 1

… 4, DV1 … D4, DT1 and DT2, SL1 and SL2), switch

(S1 … 8), or switch between settings with a switch

(S1 … 8), control or logical switch (see below). In both

cases, multiple assignments are always possible. (The

distinction between a control and switch is explained

in the section "Definition of terms").

Notice

It should be noted however that incorrect responses may arise from functional overlaps such

as using the same physical switch as a switch to

switch between Phase switch and as a control for Phase

trimming. Change also your switch assignment.

Since the same method is used to assign the controls,

switches control and logical switches in all relevant

menus, the basic procedure will be explained at this

point which will allow you to focus on the specifics in

the detailed menu descriptions.

Control and switch assignment

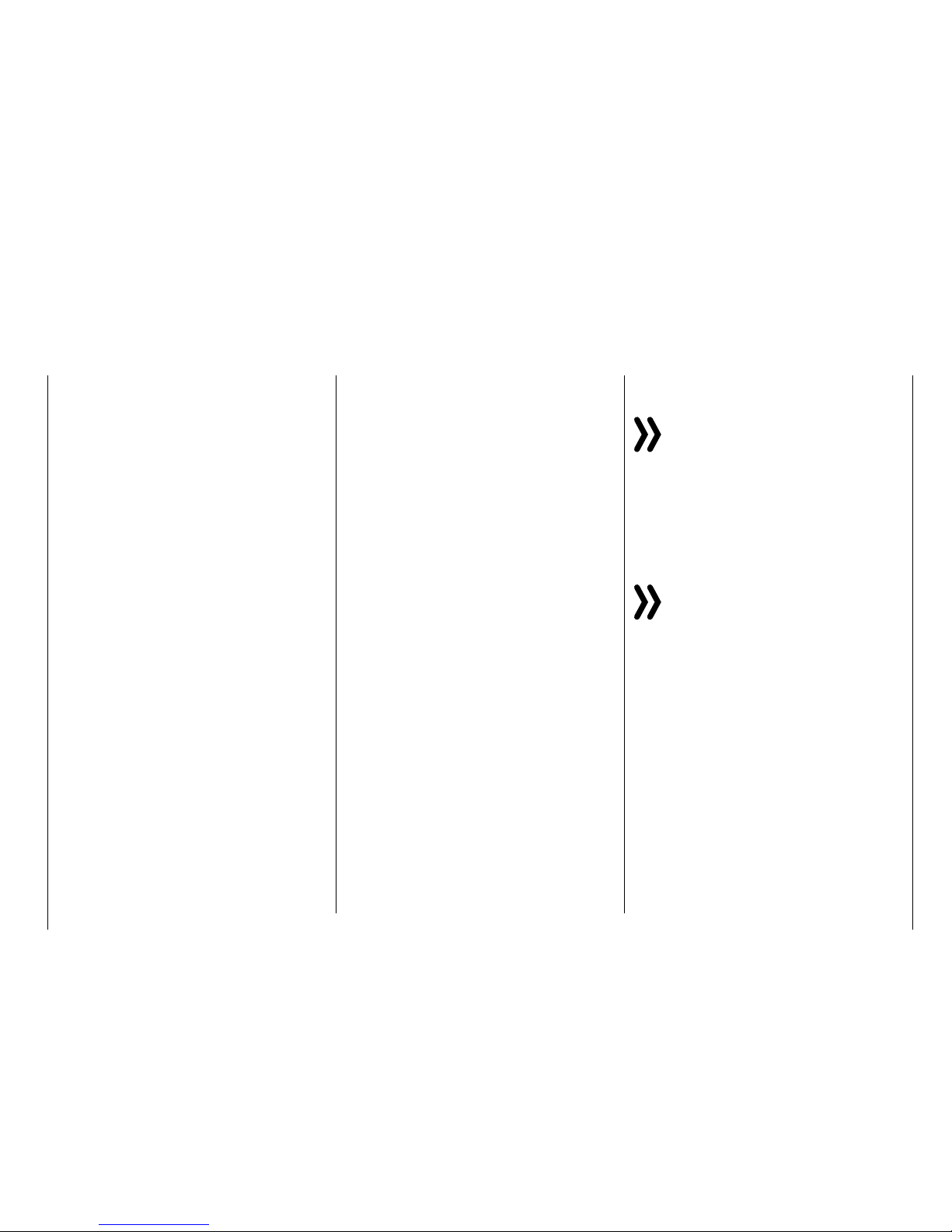

In the sub-menu "CTL Set" (control and switch assignment) you can …

… assign transmitter inputs 1 … 12 to operate servos of the mz-24 HoTT Pro transmitter as well as any

control stick (ST1 … ST4) and controls identified as

"DVx", "SLx" or "DTx", or any switch identified as "S1

… S8".

The following window appears in the display after touching the corresponding button, such as

the NONE button to the right of "CH 5" in the second

page of the display of this menu, with a finger or the

provide stylus, and the following window will appear:

Actuate the desired control (control stick 1 … 4, DV1

… DV4, SL1 … SL2, or DT1 … DT2) or switch (S1 …

S8), such as the right proportional rotary control SL1:

Note

The controls are only recognized after a specific

path. Therefore move the control to the left or

right, forward or backward until the assignment

appears on the display. If the length of travel is insufficient, move the control in the opposite direction.

Deleting controls or switches

After the switching or control assignment has been

activated as described, touch the CLR button.

touch

Control or switch assignment interruption

After the switching or control assignment has been

activated as described, touch the N button.

Notice

In few menu positions you can assign only physical controls or switches, that is the reason why in

the pop-up windows that appear in those posi-

tions the LOGIC button is not available, for example:

This is not an error.

26 Control and switch assignment

Page 27

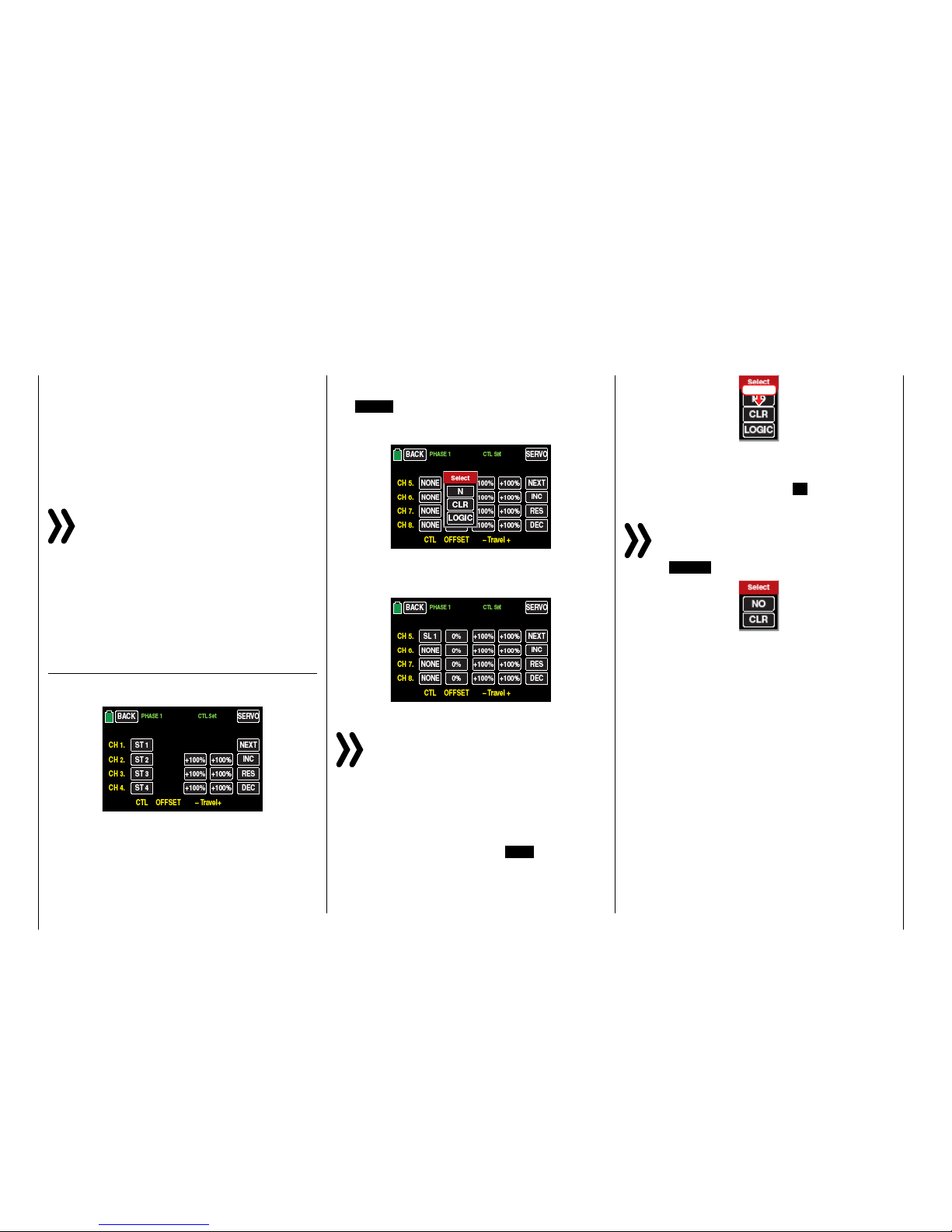

Assigning logical switch or control

• Switch assignment

The places in the program where a switch, a logical

control or switch can be assigned are marked with

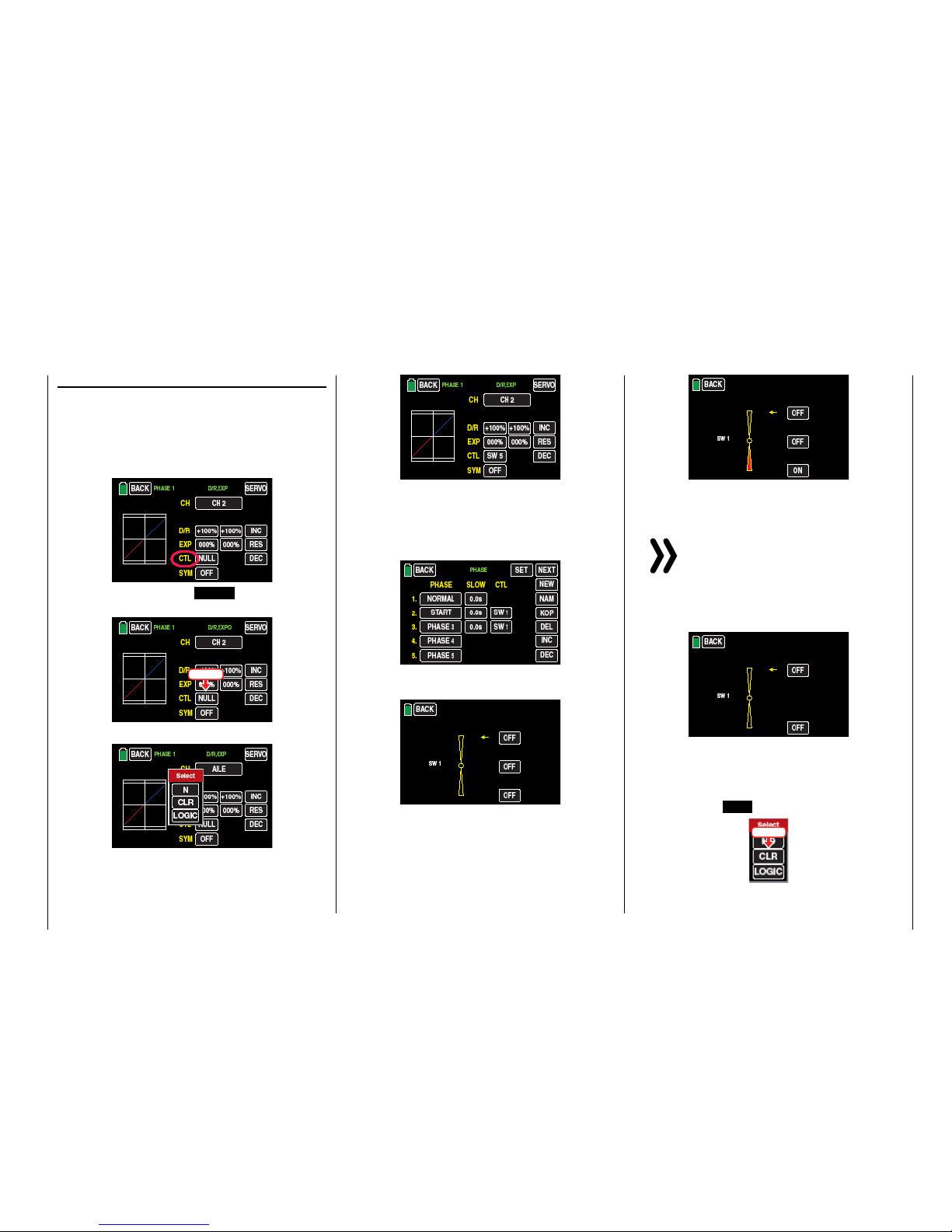

"CTL". So as for example as marked with a red circle in the penultimate line of the following picture

of the Dual Rate / Expo displays:

As soon as you tap on NONE , on the right near

CTL …

touch

... the window in the display will ...

... appear. Actuate the desired switch, for example

the front left 3-way switch S5:

Thus completes the assignation of the switch for

this menu.

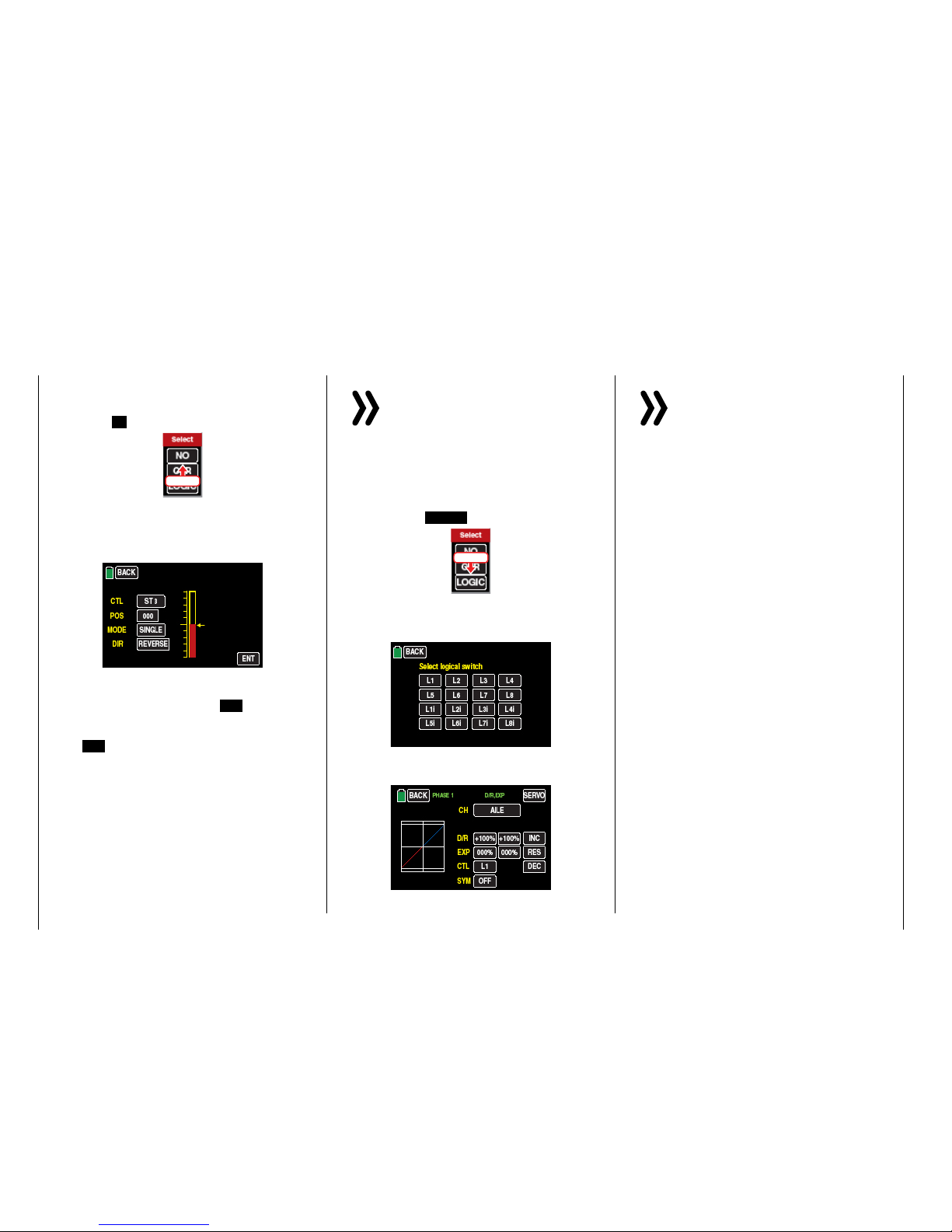

• Switch setup

In other menus, in which the switches can be assigned, for example the "PHASE" menu, …

... an accessory display will appear immediately after the switch assignation.

Completely independently from the yellow arrow,

which only indicates the actual position, you can

confirm in this display by touching the related button, in which position di selected phase should be

"ON", for example:

It has to be logically matched with the other switch

positions.

Notice

The phase 1, the "normal phase", is then always active when none of the assigned phase

switch is on the "ON" position.

If you choose the 2-stage switch SW 6 instead of

the 3-stage switch SW 1, the display appears as

follows:

Select the desired switching direction as above.

• Deleting switches

After the switching or control assignment has been

activated as described at the beginning of this section, touch the CLR button.

touch

27

Control and switch assignment

Page 28

Canceling the switch assignment

After the switching assignment has been activated as described at the beginning of this section,

touch the N button.

touch

• Control switch assignment

Move the control that you want to use to activate

the switching function, for example the control

function 3, indicated with "SL2":

The yellow arrow to the right of the bar diagram

illustrates the current control position which can

be accepted by touching the ENT button as the

switching point in the value field to the right of

"POS". Reverse the switching direction by touching REV in the line "DIR(ection)".

In the "MODE" line, the switching function of the

control switch can be changed from on/off like

a 2-stage switch to the switching behavior of a

3-stage switch.

Notice

In this case, be sure to specify a switching position that is not "000". Otherwise, you risk

switching continuously back-and-forth between the two switching states while the relevant

control is in the middle control position.

• Assigning logical switch

After the switching or control assignment has been

activated as described at the beginning of this section, touch the LOGIC button:

touch

In the new window appears a list with the eight

logical switches "L1 ... L8" so as 8 inverted logical switches.

As soon as you tap on the desired switch, it will be

assumed in the output menu, for example:

Notice

Therefore do not forget to program the related

selected logical switch in the "Logical sw"

sub-menu!

Tips

Through the logical switches, see sub-menu "Logi-

cal sw", you can logically interconnect two switch-

es and/or also control switch in a "AND" or "OR"

switch.. A total amount of 8 logical switches "L1 ...

L8" (so as 8 accessory logical switches with reversed

switch direction) are available.

The result of one of these logical switch functions