Page 1

Manual

PEP

R/C electric airplane

No. 4318

EN

Copyright © Graupner/SJ GmbH

Page 2

Page 3

Index

Introduction ............................................................................. 5

Service centre ........................................................................... 5

Intended use ........................................................................... 6

Glue .......................................................................................... 6

Parts list No. 4318 .................................................................... 6

Technical data .......................................................................... 8

Required tools and facilities (not included) ............................ 8

Recommended accessories (not included) .............................. 8

Assembly step 1 ....................................................................... 9

Assembly step 2 ....................................................................... 9

Assembly step 3 ....................................................................... 9

Assembly step 4 ..................................................................... 10

Assembly step 5 ..................................................................... 10

Assembly step 6 ..................................................................... 11

Assembly step 7 ..................................................................... 11

Assembly step 8 ..................................................................... 11

Assembly step 9 ..................................................................... 12

Assembly step 10 ................................................................... 12

Assembly step 11 ................................................................... 13

Assembly step 12 ................................................................... 14

Assembly step 13 ................................................................... 14

Assembly step 14 ................................................................... 14

Assembly step 15 ................................................................... 15

Assembly step 16 ................................................................... 15

Assembly step 17 ................................................................... 15

4318_PN_V1

4318_PN_V1

Assembly step 18 ................................................................... 15

Assembly step 19 ................................................................... 15

Assembly step 20 ................................................................... 16

Assembly step 21 ................................................................... 16

Assembly step 22 ................................................................... 16

3 / 20

Page 4

Assembly step 23 ................................................................... 16

Assembly step 24 ................................................................... 17

Assembly step 25 ................................................................... 17

Assembly step 26 ................................................................... 17

Symbol description ................................................................ 18

Safety notes............................................................................ 18

Package content ..................................................................... 19

Care and maintenance ........................................................... 19

Warranty conditions .............................................................. 19

Page 5

Introduction

Thank you very much for purchasing the Graupner PEP. This 4318 is

extremely versatile. This manual is valid for all the models listed on

the cover sheet.

Read this manual carefully to achieve the best results with your 4318

and first of all to safely control your models. If you experience any

trouble during operation, take the instructions to help or ask your

dealer or

Due to technical changes, the information may be changed in this

manual without prior notice. Be always updated by checking periodically on our website,

the products and firmwares.

This product complies with national and European legal requirements.

To maintain this condition and to ensure safe operation, you must

read and follow this user manual and the safety notes before using

the product!

NOTE

This manual is part of that product. It contains important information concerning operation and handling. Keep these instructions

for future reference and give it to third person in case you gave the

product.

Graupner Service Centre.

www.graupner.de to be always uptodate with

Service centre

Graupner Central Service

Graupner/SJ GmbH

Henriettenstraße 96

D-73230 Kirchheim/Teck

Graupner USA

3941 Park Dr Suite 20-571

El Dorado Hills, CA 95762

Graupner in Internet For the service centers outside Germany please refer to our web site

www.graupner.de

Servicehotline

(+49) (0)7021/722-130

Monday - Thursday:

9:15 am - 4:00 pm

Friday:

9:15 am - 1:00 pm

service@graupner.de

Website: www.graupnerusa.com

Phone: +1 855-572-4746

Email:service@graupnerusa.com

4318_PN_V1

5 / 20

Page 6

Intended use

PEP is an electric airplane model for advanced beginners. It is suitable for 2S lipo batteries up to max. 2200 mAh. The flight characteristics and look of the model depend directly on the quality of the

bodywork, so the assembly of the model requires a precise and considered approach.

PEP is designed exclusively to be used in battery-powered, radio con-

trolled models, any other use is not allowed. For any improper use

no guarantee or liability is assumed.

Read through this entire manual before you attempt to install or use

the PEP.

Graupner/SJ constantly works on the development of all products;

we reserve the right to change the item, its technology and equipment.

Target group

The item is not a toy. It is not suitable for children under 14. Young

people should be overwied and helped by experienced model makers while assembling and flying this model. The assembly steps are

described as follows and illustrated with assembly photos and

sketches.

Glue

Parts list No. 4318

If you do not have sufficient knowledge about assembling and dealing with aircraft models, please contact an experienced modeler or

a model club.

UHU-Holzleim is suitable for almost all of the required gluing processes. For some adhesive joints, however, superglue is prescribed,

as indicated in the instructions below.

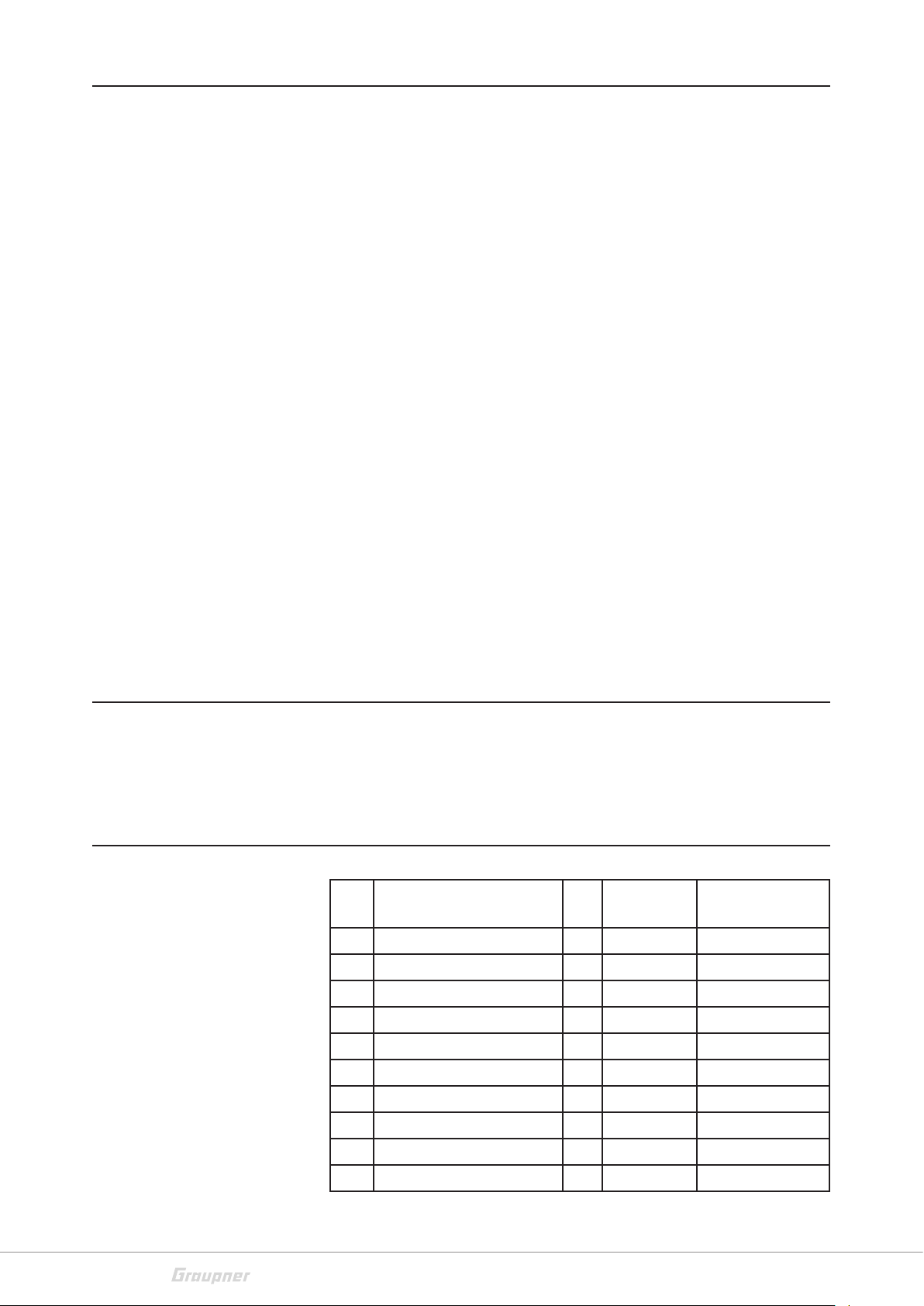

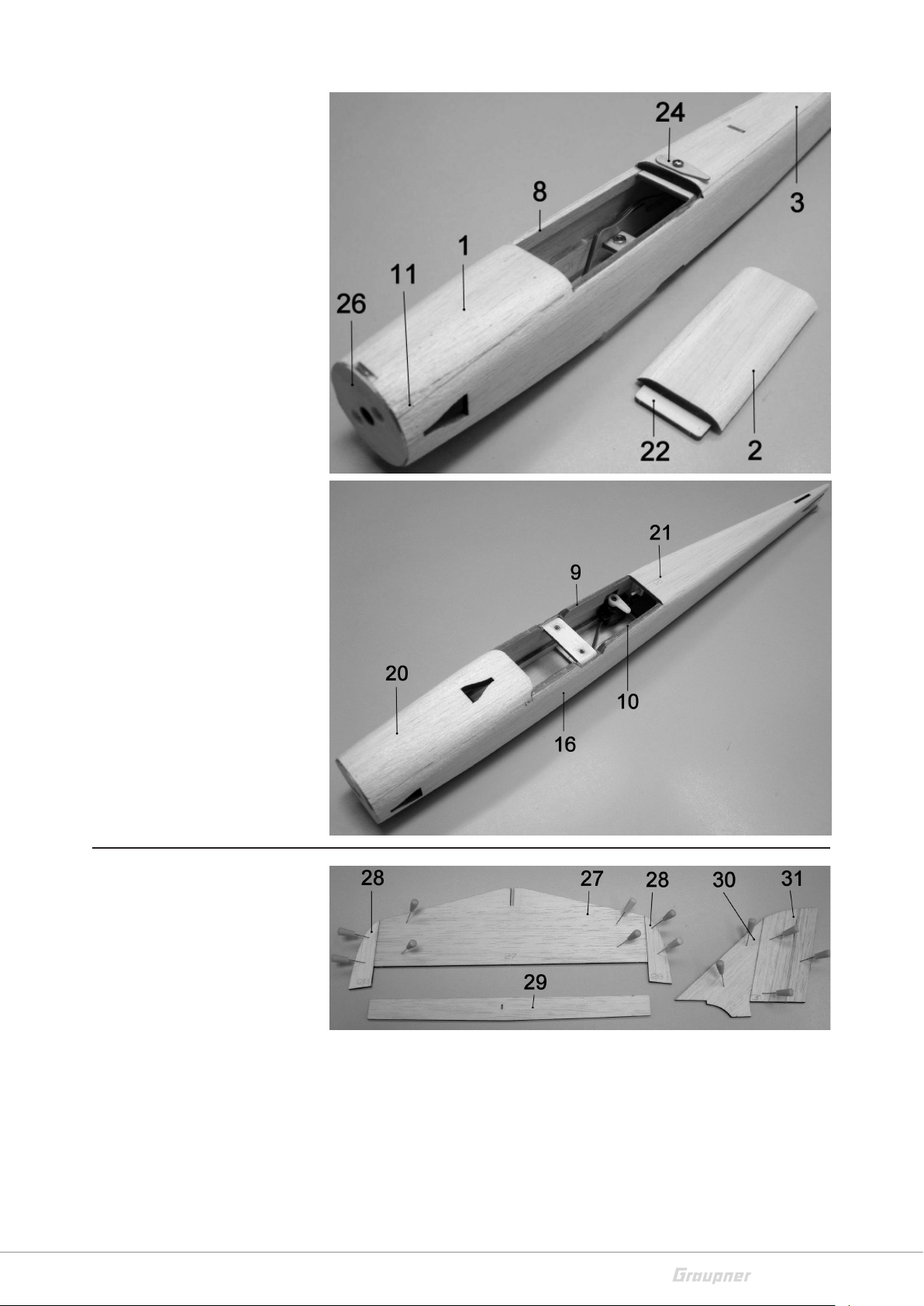

Nr. Name Pcs Material Dimension

in mm

1 Fuselage lower part 1 Balsa Laser part 6

2 Cover 1 Balsa Laser part 6

3 Fuselage lower part 1 Balsa Laser part 6

4 Bulkhead 1 Plywood Laser part 3

5 Bulkhead 1 Plywood Laser part 3

6 / 20

6 Bulkhead 1 Plywood Laser part 3

7 Bulkhead 1 Plywood Laser part 3

8 Reinforcement 2 Balsa Laser part 3

9 Reinforcement right 1 Balsa Laser part 3

10 Reinforcement left 1 Balsa Laser part 3

4318_PN_V1

Page 7

11 Triangle stick 4 Balsa 60 x 7 x7

12 Support 1 Plywood Laser part 3

13 Captive nut 2 Steel M3

14 Polyester band 1 Polyester 80 x 15 x 0,2

15 Fuselage side part right 1 Balsa Laser part 3

16 Fuselage side part left 1 Balsa Laser part 3

17 Pushrod tube 1 Plastic Ø 1,85/0,9

x 330

18 Sunk-head screw 2 Steel M3x6

19 Holder 1 Plywood Laser part 3

20 Cover part 1 Balsa Laser part 6

21 Cover part 1 Balsa Laser part 3

22 Cover fixation 1 Plywood Laser part 3

23 Reinforcement 1 Plywood Laser part 3

24 Cover lock 1 Plywood Laser part 1

25 Tapping screw 1 Steel Ø 2,9 x 9

26 Cover disc 1 Plywood Laser part 1

27 Elevator 1 Balsa Laser part 3

28 Conjunction part 2 Balsa Laser part 3

29 Elevator 1 Balsa Laser part 3

30 Rudder 1 Balsa Laser part 3

31 Rudder 1 Balsa Laser part 3

32 Elevator pushrod 1 Steel Ø 0,5 x 370

33 Rudder horn 3 Plywood Laser part 1

34 Rudder hinge

(not included)

35 Wing central part 1 Balsa Formed part 6

36 Reinforcement 1 Pine 750x6x6

37 Winglet 2 Balsa Formed part 6

38 Edge profile 1 Balsa 200x25x6

39 Edge profile 2 Balsa 135x25x6

40 Aileron 2 Balsa 273x25x6

41 Reinforcement 1 Plywood Laser part 1.4

42 Servo cover back 4 Balsa Laser part 6

43 Rudder linkage 2 Steel Ø 0,5 x 50

44 Reinforcement 2 Plastic Ø 1,85/0,9

1 Plastic 240x20x0.1

x 30

45 Servo cover front 4 Balsa Laser part 6

46 Reinforcement 1 Pine 220x7x1.5

47 Cable tray 1 Balsa Laser part 2

48 Cover

(not included)

2 Plastic 75x20x0.1

Page 8

49 Rudder hinge

(not included)

50 Sunk-head screw 2 Polyamide M3x16

2 Plastic 270 x 20 x

0,1

51 Decals sheet 1 Self-

52 Angle template 88° 1 Plywood Laser part 3

53 Support 1 Balsa Laser part 3

54 Sanding block 1 Hardwood 120x40x20

Technical data

Wingspan approx. 1000 mm

Length o.a. approx. 625 mm

Wing area approx. 10,8 dm²

Tailplane area approx. 2,2 dm²

Total surface area approx. 13 dm²

Flight weight approx. 365 g

Wing loading approx. 28 g/dm²

Current consumption approx. 10 A

Required tools and facilities (not included)

No. 958.60 UHU-Holzleim express

gluing film

180 x 65 x

0,1

No. 5821 Cyano glue

No. 953.150 Activator for cyano glue

No. 504.C.10,0 Building board appr. 1000 x 100x 10 mm

No. 980 Balsa cutter

No. 737 Balsa plane

No. 717 Fixing needles

No. 5779.2 Phillips screwdriver PH2

No. 693.1 Hinges tape

Small flat-nose pliers, side cutters, hand-operated saw, fibre pen, triangle ruler, ruler, soft pencil, scissors, transparent film

Recommended accessories (not included)

No. S1002.PRO.DE Transmitter mz-12 PRO HoTT.DE

No. 4318.90 RC conversion kit

No. 6464 Battery charger ULTRAMAT 14plus

No. 3037 Charge cable BEC

No. 207 Glattfix pore filler

8 / 20

No. 208 Brush

No. 1409 Spannfix-thinner

No. 700.1 Sanding paper

4318_PN_V1

Page 9

Assembly step 1

First mark a straight line in

the middle of the construction board, then cover the

construction board with

transparent film so that no

parts stick to it. Fasten the

fuselage bottom (1) and (3)

as well as the cover (2) congruently. Insert the cover (2)

loosely, do not glue it. Glue

the bulk (4) inclined by 2 °

forward using the angle template (52). This results in a

motor inclination of 2 °. Glue

the other bulks (5) to (7) ver-

tically.

Assembly step 2

Remove the cover (2). Chamfer the triangular strips (11)

at the back over a length of 2

cm, then glue them together

with the reinforcements (8)

and secure them. Make sure

that both reinforcements (8)

are exactly flush with the

outer edge of the fuselage

bottom parts (1) and (3).

Only when the adhesive has

dried out well, detach the

fuselage from the construction board and grind it sides

with the sanding block.

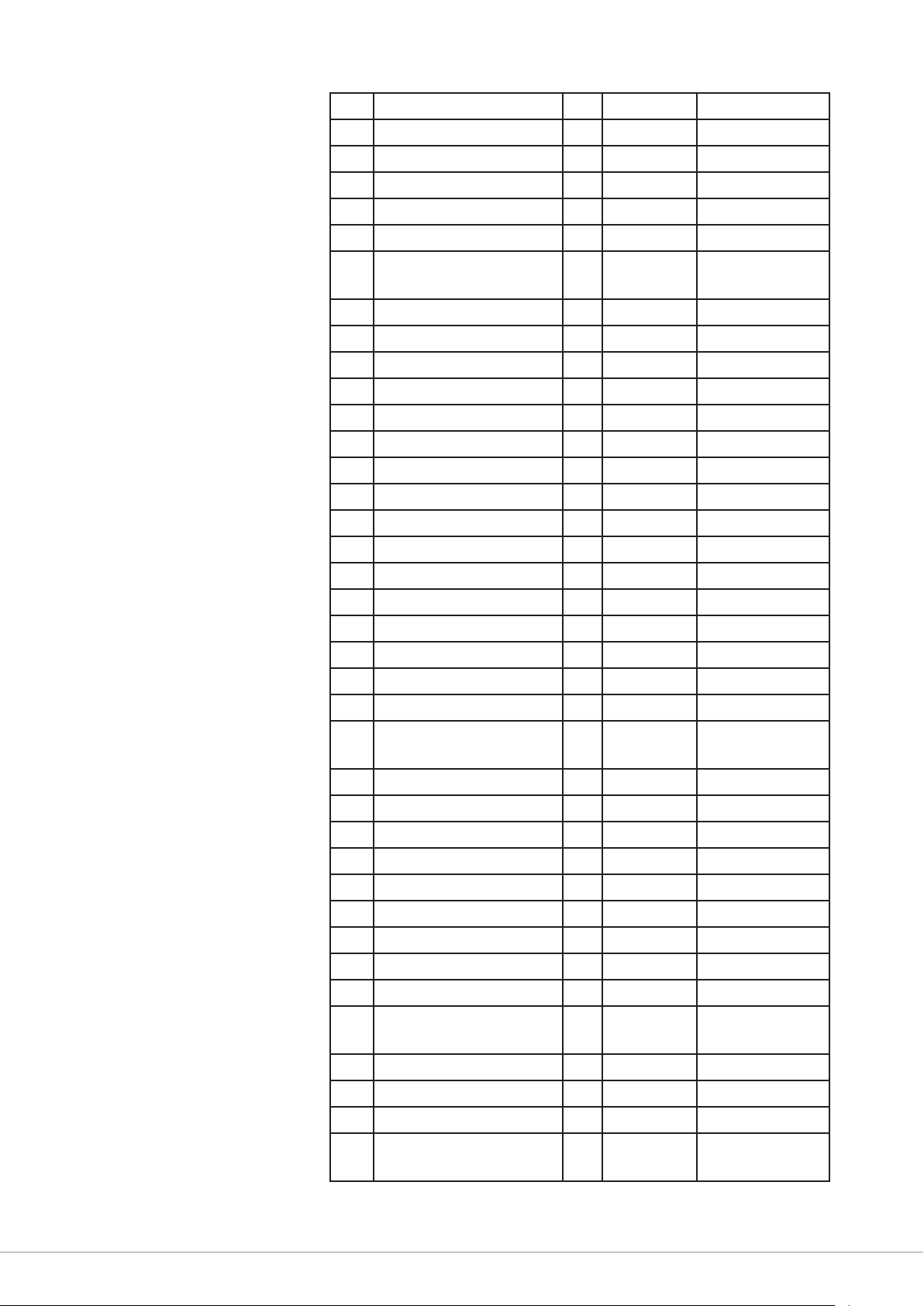

Assembly step 3

Glue the part (23), the hole

must match the one in the

fuselage bottom (3). Glue

the reinforcements (9) and

(10) with the triangular strips

(11) and secure them. Glue

the part (53). Press the nuts

(13) into the support (12)

and glue them with instant

glue. Make sure that no glue

penetrates the threads of

the nuts. Round off the outer

side edges of the support

(12) on the top, then glue in

the support. The rounded

edges are required so that

later the band (14) fits well.

4318_PN_V1

9 / 20

Page 10

Assembly step 4

After hardening the wood

glue, carefully remove the

fuselage from the construction board. Sand the outer

sides of the fuselage with

the sanding block (54) using

the coarse grained side. Do

not sand off the protruding

noses of part (53). Please

note that this sanding work

is carried out thoroughly,

this is very important for the

further construction and is

the prerequisite for an optimally shaped model fuselage.

Assembly step 5

Stick the polyester tape (14)

with superglue as shown in

the picture on the left. Apply

the super glue to the support (12) and reinforcements (9) and (10) before

stretching the polyester

tape. Please make sure that

this bonding process is carried out exclusively with

instant adhesive, as no other

adhesive ensures a sufficiently good bond between

polyester and plywood or

balsa wood. During the later

flight maneuvers the multiple fly forces of the model

weight must be absorbed by

the support (12).

10 / 20

4318_PN_V1

Page 11

Assembly step 6

Cut off the ends of the polyester tape protruding below

and cut the tape over the

nuts (13). Try to install the

elevator servo from RC drive

set No. 4318.90 (No. 4318.90

is not included in the quickkit No. 4318). To do so, spare

the right-hand reinforcement (8) accordingly. This

process takes place only at

the present time, so that the

reinforcement (8) is rectilinear. The elevator servo can

already be fixed in the fuselage with a few drops of

instant glue. Make sure the

servo is flush with the outer

edge of the fuselage bottom.

Assembly step 7

Pin the fuselage back onto

the construction board with

fixing needles. Then glue

and fix the fuselage side

pieces (15) and (16). Make

absolutely sure that both

sides of the fuselage are

resting exactly on the construction board without any

gaps, and that super glue is

applied in the area of the

polyester tape (14). Insert

the pushrod outer tube (17)

and also glue in with the

instant adhesive.

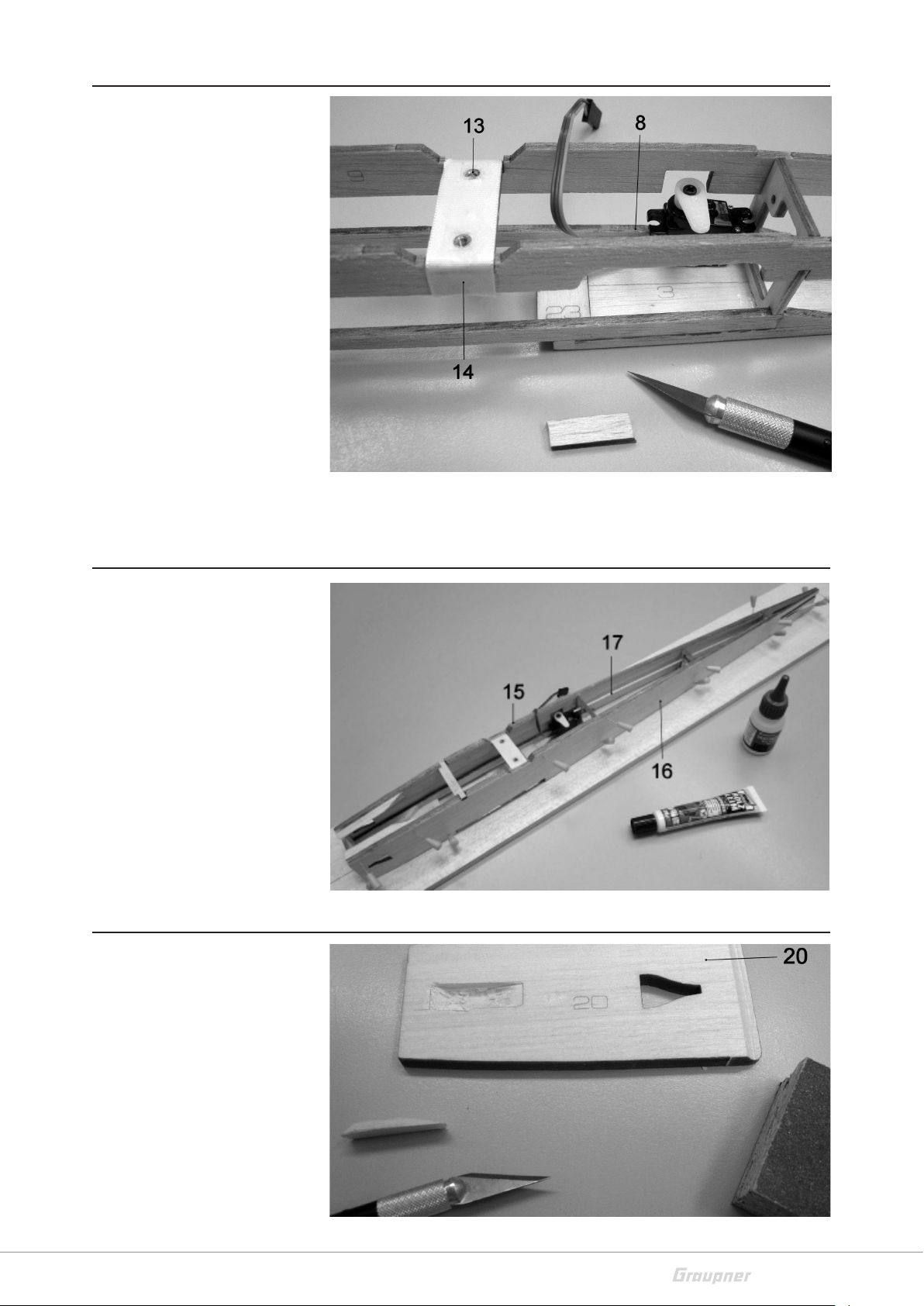

Assembly step 8

Prepare the fuselage nose

cover (20) for further assembly. To do this, cut out the

field engraved in front with

the balsa cutter according to

the illustration. The recess

should be 5 mm deep, so

that later the motor leads

can have space. Sand the

end edge according to the

leading edge of the wing

4318_PN_V1

11 / 20

Page 12

(35) with the sanding block.

To check, attach the wing to

the building board as shown

in the figure and place part

(20). Please note, the small

radius is on the underside of

the wing, the top is profiled

to a depth of about 15 mm

finished with a large radius.

Assembly step 9

Thoroughly sand the top of

the fuselage with the sanding block (54), then glue on

the hull covers (20) and (21)

and secure them. Make

absolutely sure that the elevator support cover (21) is

glued exactly in the middle,

because otherwise later the

rudder sits off-center or

diagonally. Glue the parts

(19) and (22) onto the

engraved fields of the cover

(2).

Assembly step 10

Insert the cover (2), screw

on the cap (24) with the

screw (25). Sand the front of

the fuselage and glue on the

front cover (26), use instant

adhesive; with wood glue

the thin plywood would

bend. Now give the hull its

shape by refining its aerodynamic shape.

12 / 20

4318_PN_V1

Page 13

The disc (26) serves as a

template. First round off the

fuselage edges with the

balsa plane, then with the

coarse-grained side of the

sanding block (54).

Make sure that the left and

right sides are evenly

rounded by removing the

cover (2). Lower the holes in

the bulkhead (4) and (26) for

the screws (18).

The figure on the left shows

the finished and sanded

upper side of the fuselage.

Please note that there is still

3 mm contact surface at the

tail end for the rudder. In the

area of the wing support,

grind the fuselage so far that

the upper edge of the fuselage side parts (15) and (16)

is only approx. 0.5 mm wide.

If the fuselage is optimally

shaped this has two positive

effects, on the one hand it

has a low air resistance and

on the other hand, the fuselage weight is reduced significantly. The fuselage

retains its good stability even

when rounded.

Assembly step 11

Glue and fix the tail parts as

shown. Bevel the front edge

of the elevator (29) at the

bottom by about 30 °, making sure that the slot for the

rudder horn (33) is on the

left side.

Round the front edges of

rudder and elevator using

the grinding block, not the

end edges.

4318_PN_V1

13 / 20

Page 14

Assembly step 12

Insert the prepared tail units

into the fuselage and align

them exactly, place the wing

(35) on the fuselage for control, sight from the front

whether the rudder is vertical and the elevator is parallel to the wing. If necessary,

check with a triangle ruler

placed on the wing. If all is

correct, as shown, apply a

few super glue in all corners

between the fuselage and

tail. The assembly of the

fuselage is complete.

Assembly step 13

Glue the reinforcement (36)

to the end edge of the wing

(35). Fix the strip (36) from

below with adhesive tape on

the wing without gaps. Then

tilt the bar slightly downwards and apply super glue

from the top, close it again

and immediately wipe off

the excess adhesive. Mark

the center line on the top

and bottom with a soft pencil, never press down firmly.

Assembly step 14

Place the wing centered on

the fuselage and align it at

right angles by means of a

square triangle. Then fix the

wing from the top with four

fixing needles. Open the flap

(2) and screw in the screws

(50) from below until they

impress a mark on the wing.

Remove the wing and

unscrew the screws (50).

14 / 20

4318_PN_V1

Page 15

Assembly step 15

Bevel the leading edge of

the reinforcement (41)

before sticking.

Then stick together with the

holes in the wing (35).

Check that the end edge is

parallel to the wing leading

edge and check the triangle

ruler.

Lower the holes for the screws (50) so that the screw heads do not protrude.

Assembly step 16

Cut off the end strips (38/39)

and glue them on, the underside should rest flat.

Then align the end strips

(39) to the contour of the

winglets.

Sand the top of the wing using the fine-grained side of the sanding block (54).

Assembly step 17

Glue the winglets (37) to the

wing by firmly attaching the

wing to the building board.

Loosely insert the ailerons

(40).

The V-shape of the winglets is 15 ° corresponding to 35 mm, measured at the end of the wing. When

the wood glue has hardened, sand the wing using the fine-grained side of the sanding block (54).

Assembly step 18

Glue the servo covers (42)

and (45) together and glue

them to the fastening straps

with a few instant glue.

Cover the servo housing

with adhesive tape so that it

will not be damaged when

sanding the balsa wood

parts. Unscrew the servo

lever. Streamline and sand

the panels.

Assembly step 19

Chamfer part (47) at the

back and glue on, put on

part (46) only loosely, as well

as the covered servos, mark

the contour of (45) on part

(46), saw it off, match the

front edge and stick on the parts (45) for part (46) below, then glue the servos.

4318_PN_V1

15 / 20

Page 16

Assembly step 20

The illustration shows the

fully installed aileron servos.

Insert the slots for the rudder horns (33) with the balsa

cutter into the ailerons (40).

Cut off the aileron linkage

(rest part of (32)) and trim

off with a pair of flat nose pliers at the end, first push on

the reinforcement (44) and

glue with superglue. Connect the ailerons to the wing

with hinge strap (49) (not

included). The assembly of

the wing is complete.

Assembly step 21

These parts of motor set No.

4318.90 are not needed, disassemble or remove. Note

that the motor set no.

4318.90 is not included in

the quick pack

No. 4318, it must be purchased separately as an accessory.

Assembly step 22

Install the CAM FOLDING

PROP according to instructions from No. 4318.90.

Insert the motor into the

fuselage and tighten with

the screws (18). The insertion of the motor is facilitated if an approximately 2

mm thick guide pin is

inserted from the front

through a hole in the associated mounting hole.

Assembly step 23

Lay the motor power line in

the fuselage as shown in the

picture, fix the speed controller and the power lines

to the fuselage wall with a

few superglue. Make sure

that the motor power lines

do not come into contact

with the rotating motor

housing.

16 / 20

4318_PN_V1

Page 17

Glue the rudder horn (33) in

the elevator (29), hook the

cranked end of the elevator

pushrod (32) into the rudder

horn, connect the elevator

(29) with hinged band to the

elevator.

Unhook the elevator pushrod at the front and attach it to the servo lever.

Assembly step 24

Mount the wing onto the

fuselage with the screws

(50). Install and tighten the

propeller. Connect the GR-12

HoTT receiver and insert it

behind the bulkhead (5).

Check all control functions

and bring all control surfaces

into neutral position. The

maximum control surface

excursions are 10 mm at the

aileron and 8 mm at the elevator, measured at the end

edge of the surface. I

t is not indispensable to

paint the model.

To protect the model against moisture, it can be painted 1 to 2 times with GLATTFIX pore filler. Before

and after the painting sand the surface with sanding paper No. 700.1.

Assembly step 25

Insert the battery as shown,

then balance the model. The

weighing takes place in ready

to fly state, ie with mounted

wing. The center of gravity is

measured at 50 mm from

the wing front edge. The

center of gravity is checked

by sustaining the model with

two fingers

at the center of gravity below the wing. The model should then be balanced and levelled. If necessary, move the battery.

Assembly step 26

Remove the individual writings (51) from the carrier foil and stick it to the desired position of the

model. The image on the packaging carton serves as a template. Paint the canopy with a black fiber

pen. Fly the model with neutral control surfaces in calm or light wind. An obstacle-free meadow is

ideally suited as a terrain. Start the model into the air by hand against the wind direction.

GRAUPNER Modellbau wishes many beautiful flights with the PEP model

4318_PN_V1

17 / 20

Page 18

Symbol description

!

!

!

Always observe the information indicated by this warning sign. Par-

ticularly those which are additionally marked with the words CAUTION or WARNING. The signal word WARNING indicates the

potential for serious injury, the signal word CAUTION indicates possibility of lighter injuries.

The signal word Note indicates potential malfunctions.

Attention indicates potential damages to objects.

Safety notes

General

These safety instructions are intended not only to protect your own

and other people’s safety, but also to protect the product. Therefore

please read this section very carefully before using the product!

Do not leave the packaging material lying around, this could be

a dangerous toy for children.

Persons, including children, with reduced physical, sensory or

mental capabilities, or lack of experience or knowledge, or not

capable to use safely the transmitter must not use the transmitter without supervision or instruction by a responsible person.

Operation and use of radio-controlled models needs to be learnt!

If you have never driven such a model, then start extra carefully

and make sure to be familiar with the reactions of the model to

the remote control commands. Proceed always responsibly. This

also means that you have for your own protection liability insurance.

Protect all equipment from dust, dirt, moisture. All equipment

must be protected from vibration as well as excessive heat or

cold. The models may only be operated remotely in normal outside temperatures such as from -10°C to +55°C.

For your safety by handling the transmitter

WARNING

Also while programming the transmitter, make sure that a connected motor cannot accidentally start. Disconnect the fuel supply or drive battery beforehand.

18 / 20

4318_PN_V1

Page 19

Package content

P

Care and maintenance

• Clear construction manual in German with detailed views.

• English, French and Italian manuals available for download.

• Laser cut boards made of balsa wood and plywood.

• Profile sawn end strips and ailerons made of balsa wood.

• Bowden cable pushrods for elevator.

• Fasteners for motor and wing.

• Decals with stamped lettering.

• Ready-to-use sanding block.

Notes on care

The product does not need any maintenance, it works so as it is without any special care. In your own interest please protect the model

from dust, dirty and humidity!

Warranty conditions

Graupner/SJ, Henriettenstrassee 96, 73230 Kirchheim/Teck grants

from the date of purchase of this product for a period of 24 months.

The warranty applies only to the material or operational defects

already existing when you purchased the item. Damage due to misuse, wear, overloading, incorrect accessories or improper handling

are excluded from the guarantee. The legal rights and claims are not

affected by this guarantee. Please check exactly defects before a

claim or send the product, because we have to ask you to pay shipping costs if the item is free from defects.

The present construction or user manual is for informational purposes only and may be changed without prior notice. The current

version can be found on the Internet at www.graupner.de on the relevant product page. In addition, the company

responsibility or liability for any errors or inaccuracies that may

appear in construction or operation manuals.

Not liable for printing errors.

Graupner/SJ has no

4318_PN_V1

19 / 20

Page 20

Loading...

Loading...