Page 1

Náv od V1.0

Neručím e za tiskové chyby! Zm ěny vyhrazeny !

We are not responsible for any printing bugs! Modications reserved!

Revize: D ecember 2013

PŘIJÍMAČ GR-18 3xG+3A+Vario & GR-24PRO 3xG+3A+3M+Vario

RECEIVER GR-18 3xG+3A+Vario & GR-24PRO 3xG+3A+3M+Vario

NÁVOD K POUŽITÍ

MANUAL

Obj. číslo: 33579

Order No: 33579

www.modellmarkt24.ch; www.modellmarkt24.de

Obj. číslo: 33583

Order No: 33583

Page 2

CHAPTER PAGE

Safety Notes

1

Functions

2

2.1. Binding

2.1.1. Binding Multiple Receivers

2.2. Fail-Safe Function

2.3. Range-checking

2.4. Installation in the model (airplane)

2.5. Installation in the model (heli)

Receiver

3

3.1. Connections

3.2. Receive r set-up menu

3.3. Free mixe rs

3.4. Assignin g the gyro axes

3.5. Adjust S ervolimit for chann els

Programming the gyro settings

4

4.1. Programming PID correction

4.2. Program ming the factors

4.2.1. Programming, transmi tter with proporti onal controls

4.2.2. Programming, transmitter without proportional controls

4.3. Initialising the gyro

Firmware Update

5

Declaration of Conformity

6

Manufacturer’s declaration

7

Environmental protection notes

8

Warranty

CONTENTS

39

42

42

43

43

44

45

46

47

47

48

51

56

60

60

61

63

63

64

65

66

70

71

72

73

37

Page 3

Thank you for purchasing the Graupner HoTT 2.4 System Please read through

this entire manual before you attempt the installation

and usage of your Graupner HoTT 2.4 System!

These operating instructions are part of this product. They contains important notes to the operation and handling. Please

take this into consideration when you pass on the product to third parties. Neglect of the operating instructions and the safety

instructions lead to expiring the warranty. Graupner constantly work on the advancement of all remote control systems;

changes of the s cope of delive ry in form, te chnology an d equipment we m ust reserve o urselves the refore. Please h ave understan ding

for the fact that from data and illustrations of this operating instructions no requirements can be derived.

Please keep the se instructions for fur ther reference!

APPROVED USAGE

The receiver is intended exclusively for use in radio -controlled models. Any other usage is prohibited, and may result in

damage to the receiver or model, and serious personal injury. We grant no guarantee and accept no liability for any t ype

of use outside the stipulated range.

Not suitable for children under fourteen years. This receiver is not a toy!

The receiver is also equipped with a telemetry function which is only available in combination with a Graupner/SJ HoTT

2.4 system. If you do not own a Graupner/SJ HoTT 2.4 system, the receiver will not work.

Please start by reading through the whole instructions before you attempt to install and operate the receiver.

38

Page 4

These operating instructions are an integral part of the product. They contain important notes on operating and handling

the receiver. For this reason please store the operating instructions in a safe place, and pass them on to the new owner

if you ever dispose of the product. Failure to observe the operating instructions and safet y notes invalidates

the guarantee.

Here at Graupner we are constantly working on the fur ther development of all our products; for this reason we are obliged

to reserve the right to introduce changes to the set contents in form, technology and features.

Please understand that we will not countenance claims resulting from information and illustrations in these operating

instructions.

Please store the operating instructions in a safe place for future reference!

1. SAFETY NOTES

KEY TO THE SYM BOLS

Caution!

This symbol alerts you to prohibited actions which must be observed at all times. Any failure to observe the prohibited

action indicated in this way may prevent the equipment working, and endanger the safety of the operator.

Caution!

This symbol alerts you to information which must be observed at all times. Any failure to observe the information

indicated in this way may prevent the equipment working properly, and endanger the safety of the operator.

This symbol indicates information which should always be observed in order to ensure that the equipment operates

reliably.

39

Page 5

SAFETY NOTES

40

Warning!

The receiver must never be operated under the inuence of medication, alcohol, drugs etc.

Caution!

Any deviation from the instructions may have an adverse eect on the function and operational security of the receiver,

and must be avoided under all circumstances.

Caution!

The operator bears full responsibility for using the receiver. The only way to guard against

personal injury and property damage is to handle the equipment carefully and use it exactly as recommended.

Caution!

Not suitable for children under fourteen years.

Caution!

Protect the receiver from dust, soiling, damp and foreign bodies. Never subject the receiver to excessive vibration, heat

or cold.

Caution!

During the programming process you must bear in mind that an internal combustion engine or electric motor could

unexpectedly burst into life at any time.

Caution!

Avoid subjecting the receiver to shocks and pressure. Check the receiver regularly for damage to the case and cables.

Do not re-use a receiver which is damaged or has become wet, even after it has dried out again.

Caution!

When deploying the cables ensure that they are not under tension, not tightly bent (kinked) or fractured. Avoid sharp

edges which could damage cable insulation.

Page 6

Caution!

Ensure that all plug-in connections are rmly seated. Do not pull on the wires when disconnecting plugs and sockets.

Caution!

The receiver must not make physical contact with the model’s fuselage, hull or chassis, as this would allow motor

vibration and landing shocks to be transferred directly to it.

Caution!

It is not permissible to carry out modications of any kind to the receiver. Any changes invalidate product approval, and

you forfeit any insurance protection.

Caution!

Ensure that the equipment is working correctly and at full range before every ight. Check the state of the batteries at

regular intervals.

Note!

Ensure that all your HoTT components are loaded with the current version of the software at all times.

Note!

Safety is no accident, and radio-controlled models are not playthings!

41

Page 7

GENERAL NOTES

• The receiver’s integral gyros are very fast, high -resolution components. This means that you should always use

high-speed digital servos wherever possible, so that the gyro’s corrective signals are converted directly and accurately

into servo movement; this helps to prevent the model oscillating.

• Keep all servo extension leads as short as possible.

• When switching on or adjusting the radio control system, it is essential to keep the transmitter aerial at least 15 cm

from the receiver aerial(s). If the transmitter aerial is too close to the receiver aerials, the receiver will be swamped

and the red LED on the receiver will light up. The transmitter responds with a ashing red LED and repeated beeps at

approximately one-second inter vals, i.e. the radio control system reverts to fail-safe mode. If this should happen,

increase the distance until the audible warning ceases, and the blue transmitter LED lights up constantly once more.

The red LED on the receiver should now be o.

2. FUNCTIONS

2.1. BINDING

The Graupner/SJ HoTT 2.4 receiver must be “bound” to “its” Graupner/SJ HoTT 2.4 RF module (transmitter) before a radio

link can be created between them; this process is known as “binding”.

Binding is only necessar y once for each combination of receiver / RF module, so the binding procedure described below

only needs to be repeated if you add more receivers. However, binding can be repeated at any time if you wish;

for example, if you switch transmitters.

This is the procedure in detail

• Binding is only possible if the receiver has not been linked with a bound transmitter since being switched on (red LED

lights); press the SET button to set the receiver to BIND mode.

• If you have already bound a receiver to the transmitter, and wish to bind the receiver to a new model memory, this is

the procedure:

42

Page 8

• Switch the transmitter’s RF section o in the “Basic model settings” menu.

• Switch the receiver on, and press the SET but ton to set it to Bind mode.

• Initiate binding in the transmitter’s “Basic model settings” menu.

• The red receiver LED should go out within about ten seconds. If it does, the binding process has been completed

suc cessf ully.

• Your transmitter / receiver combination is now ready for use.

• However, if the red LED continues to glow, then the binding process has failed. If this should happen, repeat the whole

procedure.

2.1.1. BINDING MULTIPLE RECEIVERS PER MODEL

If necessary it is also possible to bind more than one receiver to a par ticular model. First bind each receiver individually as

described earlier.

When the system is actually in use, the receiver which was last bound acts as the Master unit, and any telemetr y sensors

installed in the model must be connected to this receiver, as only the Master receiver transmits the data to the ground

using the downlink channel. The second - and any other - receivers operate in Slave mode, in parallel with the Master

receiver, with the downlink channel switched o.

The channel mapping function of HoTT telemetr y also allows the control functions to b e divided up amongst multiple

receivers, or alternatively the same control func tion to be assigned to multiple receiver outputs. For example, this is useful

if you wish to actuate each aileron with two servos instead of just one.

2.2. Fail-Safe FUNCTION

In the receiver’s default state, all connected ser vos remain in their last valid position (“Hold” mode) if a fail-safe situation

should arise. In fail-safe mode the red LED on the receiver lights up, and the transmitter generates an audible alert by

beeping at a rate of around one per second.

You can exploit the safety potential of this option by at least setting the throttle position (for internalcombustion

43

Page 9

powered models) to Idle, or the motor function (electric-powered models) to “Stop”, or “Hold” for a model helicopter,

if a fail-safe event should occur. These settings ensure that the model is less likely to y out of control if interference

should occur, thereby helping to avoid property damage or even personal injury.

Read the operating instructions supplied with your radio control system for more details.

The gyro system remains active in a fail-safe situation.

2.3. RANGE-CHECKING

The range of your Graupner/SJ HoTT 2.4 system can be checked as described in the following instructions. We recommend

that you ask a friend to help you with the procedure.

Ideally the receiver should already be bound to the transmitter. Install it in the model in its nal p osition.

• Switch the radio control system on, and wait until the red LED on the receiver goes out. The servo movements can now

be observed.

• Place the model on a at surface (pavement, close-mown grass, earth), and ensure that the receiver aerials are at least

15 cm above the ground. It may be necessary to pack up the model to achieve this for the period of the range-check.

• Hold the transmitter away from your body at hip-level. Don’t point the transmitter aerial straight at the model; instead

rotate or angle the aerial tip in such a way that it is vertical when you operate the transmit ter controls.

• Select range-check mode, as described in the transmitter instructions.

• Walk away from the model, moving the transmitter stick s. If you detect an interruption in the radio link at any time

within a distance of about 50 m, see if you can reproduce the problem.

• If your model is tted with a motor or engine, switch it on or start it, so that you can check eective range when

potential interference is present.

• Walk further away from the model to the point where full control is no longer possible.

• At this point you should manually switch o range-check mode.

44

Page 10

The model should now respond to the controls again. If this is not 100% the case, do not use the system. Contact the

Graupner/SJ Service Centre in your locality and ask their advice.

We recommend that you carry out a range -check before every ight, simulating all the servo movements which occur in

ight. To guarantee reliable model operation, radio range must always be at least 50 m on the ground.

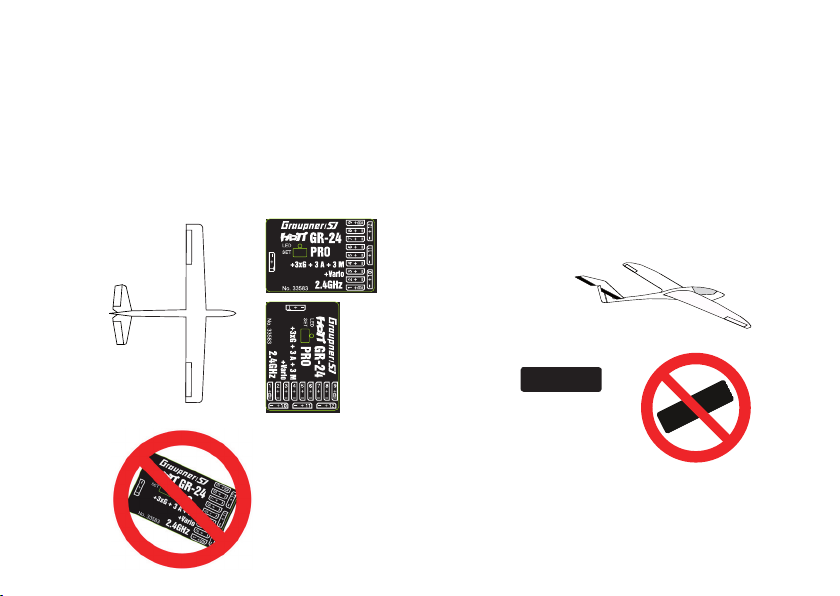

2.4. INSTALLATION IN THE MODEL (AIRPL ANE)

The gyro receiver must be installed straight and at right angles to aircraft longitudinal axis, so that the rotors can work as

intended, because of the accelerometer in addition also horizontal to the longitudinal axis.

OK

OK

45

Page 11

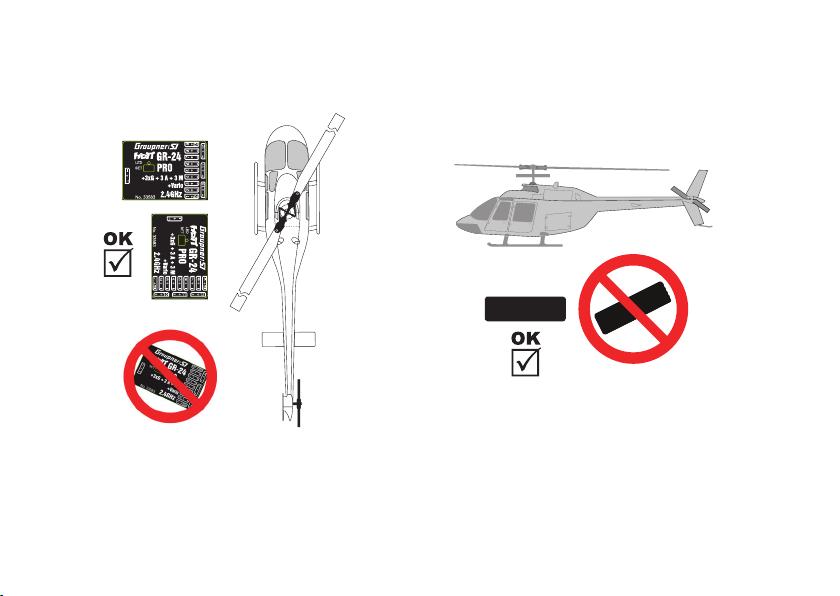

2.5 INSTALLATION IN THE MODEL (Heli)

The receiver has to be aligned strictly at right angles and parallel to the oor on the receiver platform on the helicopter.

46

Page 12

3. RECEIVER

3.1. CONNECTIONS

Connect the servos to the row of sockets on one end of the receiver. The connectors are polarised: note the small chamfers

on one side. Never use force - the connectors should engage easily. The polarity is also printed on the receiver;

the negative wire (-) is brown, the positive (+) red and the signal orange.

The servo sockets of Graupner/SJ HoTT 2.4 receivers are numbered sequentially. The socket for channel 6 can also be

programmed to deliver a (digital) sum signal (see section 3.2: Receiver set-up).

I²C (Inter-Integrated Circuit) - socket currently not active; for servicing purposes only!

Power supply

47

Page 13

Power supply

The receiver does not feature specic sockets for connecting the battery. We recommend that you connec t the power

supply to the socket(s) close to the servos already connec ted to the receiver. If you wish to connect multiple separate

batteries, the batteries must be of the same nominal voltage and capacit y. Never connect batteries of dierent type, or

packs of greatly diering states of charge, as this can cause eects similar to a short-circuit. If you encounter this problem,

we recommend the use of a voltage stabiliser unit (e.g. PRX-5A receiver power supply, Order No. 4136) between

the batteries and the receiver.

Telemetry (T/9 at GR-18)

The optional telemetry sensors are connected to the socket marked “T” (T/9)- Telemetry. In addition, the update is

performed on this socket (see point 5). At the GR-18, the socket can be used optionally for K9.

PROGRAMMING THE GENERAL RECEIVER SETTINGS

The receiver can be programmed using a suitable HoTT transmitter or the SMART-BOX (Order No. 33700).

3.2 RECEIVER SET-UP MENU GR-24

48

The receiver set-up menu

appears in the “Telemetr y” menu

under SET TINGS / DISPLAYS;

alternatively - if you are using a

SMARTBOX - under SETTING &

DATAVIEW. The method of

accessing this menu is

described in the operating

instructions supplied with your

transmitter or the Smar t-Box.

RECEIVE R SET-UP MENU GR-18

Page 14

Display Explanation Settings

REC EIVE R 1.0 1.0 indicates the version of the receiver’s rmware -

TYPE OF M ODEL Selection of modeltype Plane, Heli

ALARM VOLT. Alarm threshold for the receiver’s low voltage

ALARM TEMP.

Max. altitude

PERIOD Cycle time (frame rate) in ms 10 / 20 ms

SUMD at CH 8 (6) Digital sum signal at channel 8 (6) Yes / No

Sensor a t CH 9 Telemetr y-Sensor at channel 9 (only at GR-18) Yes / No

LANGUAGE

warning

Receiver overheating warning

Maximum altitude

Select menu language

Model type selection (Type of model)

here you can choose the model type.

By selec ting “Plane” you will be able to access the gyrosettings for surface models, as described in chapter 4.

The selection “Heli” will be made available through a future software update. It will enable a receiverintegrated ybarless

system, which can be adjusted inside the transmitters telemetry settings.

2.5 - 24.0 V

Default setting: 3.8 V

50 - 80° C

Default setting: +70° C

0 - 2500 m

in 25 m increments

German, English, French,

Italian, Spanish

49

Page 15

Low-voltage warning (ALARM VOLT )

if the receiver voltage falls below the set value, a low-voltage warning is generated by the transmitter’s RF module in

the form of the “general alarm tone”: a regular beeping at a rate of about one per second; alternatively the speech output

message “Receiver voltage”.

Temperature warning (AL ARM TEMP)

if the receiver temperature exceeds the set temperature threshold, a warning is generated by the transmitter’s RF module

in the form of the “general alarm tone”: a regular beeping at a rate of about one per second; alternatively the speech

output message “Receiver temperature”.

Maximum altitude (Max. altitude)

at this point you can enter a maximum altitude, at which an alarm is triggered, either via the transmitter’s RF module in

the form of the “general alarm tone”: a regular beeping at a rate of about one per second; alternatively the speech output

message “Height”. Note: the model’s actual height is adopted as zero when the receiver is switched on; the indicated

height is therefore the altitude relative to the launch point.

Cycle time (PERIOD):

if your system is used exclusively with digital servos, you can set a cycle time (frame rate) of 10 ms at this point. If your

system includes some or all analogue servos, you should always select 20 ms, as many analogue servos cannot process

the higher frame rate, and may respond by “jittering” or “growling”.

HoTT sum signal (SUMD)

if you activate the digital sum signal at channel 8, a sum signal containing eight channels is present at this socket, instead

of a servo signal. The HoTT receiver congured as SUMD constantly generates a digital sum signal from 8 control signals

from the transmitter and makes this signal available at the appropriate servo socket, which is receiver-specic.

At the time these instructions were revised, this type of signal is used by several of the latest electronic developments in

the area of ybarless systems, heavy-duty airborne power supplies, etc.

50

Page 16

WARNING: if you wish to use this facility, it is essential to observe

the set-up information supplied with the devices connected to the receiver,

otherwise there is a risk that your model may be uncontrollable!

Menu item only at 33579 GR-18 PRO 3XG +3 A + Vario

Telemetry sensor (sensor at K9): This jack allows you to use either for telemetry or for an extra channel (9). (Note: Both

together is not possible!) Switching is done in this menu item. If you select „Yes“, the socket is connected to the connection

of a sensor. If you select „No“ a jack is connected to the control channel 9.

3.3. FREE MIXERS

Impor tant note: If you w ish to use the gyr os, you must alwa ys set the tail

type to ‘n ormal’ in the t ransmitte r’s model typ e menu. If your mo del

is a delt a, features a V-ta il, or has two e levator servos ,

you must u se the receiver m ixer - not the tran smitter mix er - to

contro l these contro l surfaces, s ince the gyro st abilisati on system will

The four r eceiver mixer s work ‘downstrea m’ of the gyros . If you have

already programmed mixer functions in the “Wing mixers” or

“Free mi xers” menu of you r HoTT transmit ter, you must ensu re

that tho se mixers do not o verlap with thos e available in t his menu!

have no eect on these servos otherwise.

51

Page 17

SCREEN DISPLAY KEY SETTINGS

MIXER Mixer select 1, 2,....., 4

FROM CHANNEL Signal source / source channel 0,1,2,...6

TO CHANNEL Target channel 0,1,2,...6

TRIM Trim position in % -15 - + 15%

TRAV EL - Travel limit at % Servo travel -150 bis +150 %

TRAV EL + Travel limit at % Servo travel -150 b is +150%

Mixer

up to four mixers can be programmed simultaneously. You can switch between Mixer 1, Mixer 2, … and mixer 4 in the

“Mixer” line. The following settings only aect the mixer selected in this line.

From channel

the signal present at the signal source (or source channel) is mixed in to the target channel (TO CHANNEL) to an ex tent

which can be set by the user. The method of set ting up the values is analogous to the “Free mixers” menu in HoTT

transmitters.

To channel

part of the source channel signal (FROM CHANNEL) is mixed into the target channel (TO CHANNEL). The mixer ratio is

determined by the percentage values entered in the “ TRAVEL-“ and “TRAVEL+” lines. Select “0” if you do not require

the mixer.

52

Page 18

Mixer ratio (TRAVEL-/+)

in these two lines you can dene the mixer ratio in relation to the source channel (FROM CHANNEL); the value is set

separately for both directions.

PROGRAMMING EXAMPLES

V-tail with rudder dierential

Dierential is not normally necessar y with this tail type. Mixer 3 is not required if you do not need rudder dierential, and

TRAVEL- for mixer 2 must then be set to -100%. Alternatively you may prefer to carry out the programming using

the transmitter menu. A ‘Rudder elevator’ mixer can be set up at the transmitter instead of ‘Free mixer 3’ at the receiver;

the mixer should be set up asymmetrically, e.g. +30%, -30%. This option frees up one mixer at the receiver.

53

Page 19

Delta with aileron dierential (1 aileron)

In this example aileron dierential is set to 40%. Alternatively you may prefer to carry out the programming using

the transmitter menu. An ‘Aileron elevator’ mixer can be set up at the transmitter instead of ‘Free mixer 3’ at

the receiver; the mixer should be set up asymmetrically, e.g. +30%, -30%. This option frees up one mixer at the receiver.

Two elevator servos (channel 6 for the second elevator servo)

54

Page 20

Only for transmitters without a buttery (crow) mixer (e.g. mx-10 HoTT)

If a buttery (crow) mixer is required, you will not be able to use one of the t wo functions ‘dierential’ or ‘landing ap’

adjustment, as two mixers are needed for this.

Programming example

Programming example

55

Page 21

3.4. ASSIGNING THE GYRO AXES

Aileron servos

You should enter the value 2 in this line if your model has two aileron servos; in this case the gyro for channel (servo) 2 also

acts on servo 5. If the ailerons are also used as aperons or speedbrakes, gyro suppression is based on the sum of both

channels.

CAUTIO N: the servo reve rse setting m ust be the same fo r both aileron s ervos, i.e. e ither both

‘normal ’ or both ‘rever se’. If this is not po ssible, on no ac count should y ou reverse one se rvo in

the tran smitter men u. The only opti on is to re-ins tall it in the mod el by turning it ro und physicall y.

However, if yo ur model is tt ed with progra mmable servo s (e.g. Graupne r DES, HVS or HBS t ypes

- see the i nstruction s for the update p rogram ‘Firmwa re_Upgrad e_grStudio - t hen it is possi ble to

Please read the installation notes on page 5 of these instructions. The rst step is to dene the three gyro axes and the

orientation of the receiver. This is accomplished by switching on the transmitter and model, and selecting ‘New setting:

yes’ in the receiver’s ‘Gyro settings’ menu.

56

reverse t he directio n of rotation at th e servo itsel f.

Page 22

• Now move the stick for any control surface to full travel in one direction; in the following example we use the aileron

channel.

• The detec ted axis (aileron) is highlighted (black background). (In the receiver’s default state the value for all axes is

shown as ‘+0’; the axes can also be set manually to ‘+0’. 0 = inaktiv).

• Now turn the model through at least 45° in the direction corresponding to the stick movement. For example, if you

moved the aileron stick to the left, you must simulate a left turn with the model move the left wing down through

at least 45°.

• This process denes the one axis and direction; now you must repeat the procedure for the other two axes.

• The gyro axis 1, 2 or 3 is now displayed in the ‘Aileron / Elevator / Rudder’ display; a negative prex will appear if servo

reverse is activated.

• Once all three axes are dened, the display automatically reverts to ‘New setting: no’.

WARNING : once you have com pleted this pro cedure, it is a bsolutely es sential to che ck that all

the gyro s are working in t he correct dir ection. This i s accomplis hed by moving

the mode l around all th ree axes in tur n, and checki ng the control su rface deec tions - see dia grams

below. You mus t not y the model b efore doing th is: crash haza rd!

57

Page 23

EL EVAT OR

Model movement Cont rol surfac e response (s een from the t ail)

RUDDER

Model movement Cont rol surfac e response (s een from the t ail)

58

Page 24

AILERON

Model movement Control sur face respo nse (seen fro m the tail)

59

Page 25

3.5. ADJUST SERVO LIMIT FOR CHANNELS

In this menu, you can limit the servo travel for all channels.

Limit the servo travel to the maximum possible deection, so

that the ser vos can not run in the stop in the gyro operation.

Move the cursor to the desired line (by further downward

move of the cursor will be displayed further channels),

here „1“ for channel 1 Pressing the SET button is

pressed the „SEL“ eld in „STO“.

Now move the stick of channel 1 in the desired direction

and position, while the corresponding

percentage display is shown inverted.

Now press the SET button again and the set value

is displayed and stored. Go through the procedure

for the other channels.

4. PROGRAMMING THE GYRO SETTINGS

PID (Proportional Integral Dierential) correction

The stabilising eec t of the gyro sensors is based fundamentally on three parameters

P factor: denes proportional correction

P = propor tional: if the intended value is not the same as the actual value, then the dierence is fed proportionally into

the correc tive signal; in simple terms, the input value (e) is multiplied by a xed value: u(t) = Kp*e(t).

Kp is termed the amplication value. The output value is therefore propor tional to the gyro’s input value. Propor tional

60

Page 26

correction cannot occur until a deviation from the intended value is present; if the deviation is 0, then the product is also

zero. If the amplication value is set too high, the P factor causes the model to oscillate and become unstable.

I factor: integral correction (not currently implemented)

D factor: denes dierential correction

D = dierential: in this case the corrective output value is aected by the rate of change of the input value, i.e. the faster

the model tilts around the axis, the more pronounced the correc tive response of the gyro. If the model changes attitude

very gently, then the D factor causes hardly any corrective action. It also makes absolutely no dierence how far the model

has already changed attitude; the crucial value is only the speed or rate of the movement.

The rate of change is again multiplied by a factor (as with P correction) to produce the output value. For this reason pure

D correction is not used; it must always be employed in combination with P correction.

4.1. PROGRAMMI NG PID CORRECTION - GYRO SETTINGS DISPLAY

CAUTIO N: before you sta rt entering s ettings for a ne w model, it is es sential to sel ect the numbe r of

ailer on servos in the A ileron ser vos menu point , and to dene the g yro axes and orie ntation in th e New

settings menu point.

Aileron / Elevator / Rudder

Shows the programmable P factors for the corresponding control surface.

Note: the gyro axes must rst be dened under New settings (see section 3.4).

If you wish to disable the gyro, enter the value OFF in the appropriate control function.

61

Page 27

P factor

The P factor should always be set rst, followed by the D factor (adjustment range in each case 0 to 10). A general rule is

that the larger the control surface, the smaller the P factor required. Start with a factor of 2 (default set ting), and do not

exceed 4 - 5 as maximum value for the normal ight phase, 2 - 3 for speed, 3 - 6 for landing; the maximum value of

10 should be reserved for torque-rolls only.

WARNING : if you program s eparate igh t phases, it is e ssential to se lect the appr opriate igh t phase

when the m odel is in the ai r, as inapprop riate gyro sett ings may cause t he control sur faces to osci llate,

possibly resulting in the loss of the model!

Note: the higher the model’s speed, the more quickly oscillation may set in.

D factor

For a given P factor setting, the model’s tendenc y to oscillate can be reduced by setting a lower D factor. However, if

you selec t a lower setting for the P factor, then you may be able to set a higher D factor value before the onset of control

surface oscillation. The gyro eect can be optimised by netuning the D factor.

Note: the standard P and D values should cause the gyros to correct the model’s attitude quickly when

it is upset by an outside inuence, without causing oscillation, but in practice the optimum values

for a particular model can only be found by ight-testing. If the model displays little or no automatic

stabilisation with the default settings, the value should be raised; on the other hand, if the model

oscillates (wave-like movements in ight), the value should be reduced.

If your transmitter has spare propor tional controls, you can use them to adjust the values while the model is ying.

Some transmitters allow the correc tive factors to be altered during a ight using the proportional controls, whereas

others allow xed values only.

62

Page 28

4.2. PROGRAMMING THE FACTORS

4.2.1. Programming, transmitter with proportional controls

If your HoTT transmitter is equipped with propor tional controls, it is also possible to adjust the P and D factors for each

axis during a ight: what you might call ‘ying the settings’.

You need to assign proportional controls (e.g. the sliders on the mc-20) to any channel in the range 5 to 16 (in this example

channel 9); now you can alter the P factor (and the D factor) using these controls. In each case the current values are shown

in brackets.

Procedure, using the ailerons as an example

• Move the cursor to the appropriate line, in this case “Ail” for aileron.

• Press the SET button to activate the Channel eld.

• Select the appropriate channel, and save the setting with pressing

the SET but ton again

• Move the corresponding proportional control to alter the factor

(adjustment range 0 - 10; 0 means no gyro correction for that axis).

• You can also adopt this factor directly by pressing the left button < or

the right button >. This frees up the channel previously occupied by

the proportional control, so that it can be used for some other purpose,

e.g. for elevator or rudder.

• Move on to elevator and / or rudder, and select the channel and factor (you can either select the same channel, in order

to alter all the axes simultaneously, or dierent channels, allowing you to program the axes individually).

• Move the cursor to the Factor line, where you can also change the P factor for aileron, elevator and rudder with priority

(adjustment range up to 200%).

• Move the cursor to the D factor line, where you can alter the D factor for aileron, elevator and rudder with priority using

a propor tional control (adjustment range up to 200%; channel value -100% equates to a factor of 0%, channel value 0%

equates to 100%, and +100% equates to 200%). This makes it a very easy matter to match the gyro’s corrective eect to

the model ’s airspeed. In particular, higher gyro gain can be used for the landing approach - without the need to switch

ight phases.

63

Page 29

• Now test-y your model and ne-tune the values one by one until your preferred stabilising eect is achieved without

the model oscillating.

• It may be sensible or easier to activate the gyro for one axis only at rst, and then to establish the optimum setting for

that axis, rather than for several axes simultaneously.

4.2.2. Programming, transmitter without proportional controls

• Move the cursor to the appropriate line, in this case “Ail” for aileron.

• Press the SET button to activate the Channel eld, select the appropriate

value (1 - 10 of OFF), then press the SET button to save it.

• First select a low value (see P factor section for starting points) and carry

out a test- ight. If gyro stabilisation is not su ciently pronounced,

increase the value step by step until the level of correction is as required;

if the model already oscillates, reduce the value step by step.

• Do not select a channel (Ch5 - Ch16); this function is only relevant to

transmitters with proportional controls.

• Move on to elevator or rudder and select the desired value (or OFF).

• Leave the settings for “Factor” and “Factor D” at OFF.

• It may be sensible or easier to activate the gyro for one axis only at rst, and then to establish the optimum setting for

that axis, rather than for several axes simultaneously.

Once you have found the optimum settings, you can set up a transmitter switch to control the gyro, i.e. for switching

between gain settings. For example, you could assign a three-position switch to “Factor” and “Factor D”, and then use it to

switch the values between 0% (OFF), 100% and 200%.

Flight phase specic settings

It is possible to use a channel to control the fac tor value by setting up ight phase speci c transmitter control settings,

but only if the transmitter is an MX20 / MC20 or MC32; please see the instructions supplied with your transmitter and refer

to the “Transmit ter control settings” and “Flight phase settings” menu points for more information.

64

Page 30

4.3. INITIALISING THE GYRO

After switching on the model of the gyroscope is immediately ac tive but not yet initialized. To initialize it, you keep your

model when switching quiet and straight in level ight - the best place it on the at ground or a at table.

After about 2 seconds, the ailerons move up and down just once. This “wiggle” signaled the successful initialization,

the end of the calibration, only then the model may be moved again.

All sticks are to be kept strictly in neutral!

WARNING : during the ini tialisati on phase the gyr o detects the mo del’s neutral a ttitude, an d for this

reason i t is absolutel y essential t o leave the model i n its ‘normal igh t attitude’ d uring the act ivation

phase , and avoid moving i t! If you neglec t this, the gyr o may detect an in correct ight a ttitude, wi th

the resu lt that the mod el will not y as you e xpect it to. It ma y be di cult to con trol, and coul d even

crash!

Durin g the initiali sation phase t he receiver al so detects the c entre points o f the individu al control

channels; this information is used for gyro suppression. Gyro suppression reduces the stabilising

actio n progressive ly as the trans mitter contr ols are de ect ed away from cent re; at +/- 100% the gyro

is completely disabled.

YOUR MODEL IS NOW READY TO FLY .. !

65

Page 31

5. FIRMWARE UPDATE - Graupner 33579 / 33583 HoTT Receivers

Firmware updates are loaded into the receiver via the Channel 5 output, using a PC running Windows XP, Vista or 7.

You will also need the separately available USB interface, Order No. 7168.6 and the adapter lead, Order No. 7168.6A or

7168.S (33575: additional adapter lead, Order No. 33565.1).

The programs and les required for this can be found in the Download area for the corresponding products at

www.graupner.de.

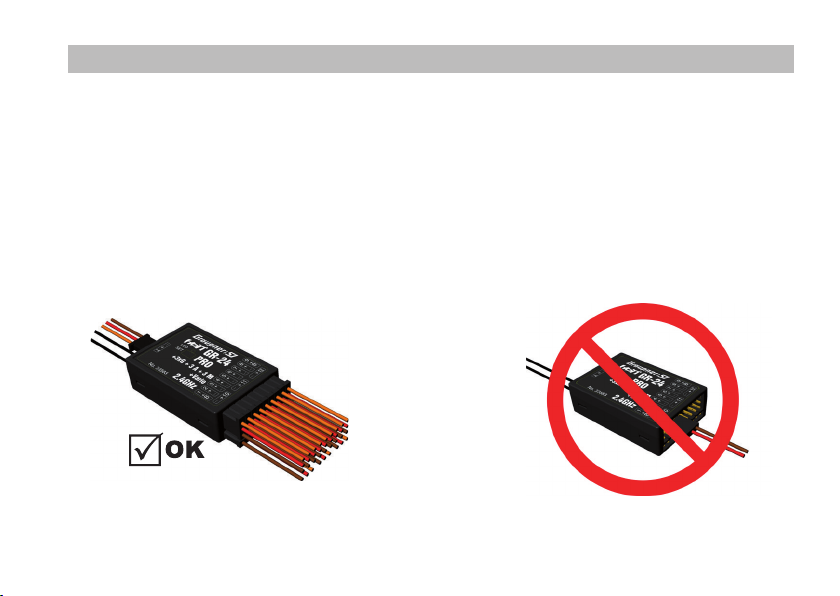

Connect the adapter lead to the USB interface,

Order No. 7168.6. The connec tors are polarised: note the small

chamfers on one side. Never use force - the connectors should

engage easily.

5.1. REC EIV ER

Connect the adapter lead to receiver as shown in the picture.

The connectors are polarised: note the small chamfers on one

side. Never use force - the connectors should engage easily.

The black wire must be at the top (-), the orange wire at

the bottom (T).

66

Page 32

5.2. UPDATE PROCEDURE

Start “Slow yer/Gyro receiver update”

The “Slow yer/Gyro receiver update” program is best called up from the “Firmware_Upgrade_grStudio” program. Click

on the “Slow yer/Gyro receiver update” point under “Link” in the left-hand function menu (alternatively selec t the appropriate entry “Micro Receiver Upgrade” under “Menu”).

It is also possible to start the associated application program directly by double- clicking on the le “micro_gyro_swloader.

exe”. You will nd this .exe le in the “Graupner_PCSoftware” folder of the “HoTT_Software VX” package.

A program window now appears in which you should rst set the “correct ” COM port for the USB interface,

Order No. 7168.6, in the Selec t window.

If you are not sure of this, check the COM port in the “Selec t Port ” window in the “Controller Menu” (see above), and note

down the COM port number at the “Silicon Labs CP210x USB to UART Bridge” entry – in this case “COM03” (if you select the

wrong por t, you will be alerted to this when you read out the receiver data).

Click on xx in order to load the corresponding rmware le named “MicroStabi7X_V_ XX.bin” from the hard disc (“XX”

stands for the version number.)

67

Page 33

When the le has loaded, click on Start …

… connect the receiver, and switch it on.

68

Page 34

The progress bar shows the transfer proceeding normally. The receiver LED is o during this period, then ashes as soon

as the le transfer is complete.

Please refer to th e detailed update instruc tions in the Download are a for the corresponding item a t http://www.graupner.de.

69

Page 35

6. DECLARATION OF CONFORMITY

Declaration of Conformity in accordiance with the Radio and Telecomunikations Terminal Equipment

Act (FTEG) and Directive 1999/5/EG (R&TTE)

Graupner/SJ GmbH, Service Department,

Henriettenstr. 96, D-73230 Kirchheim/Teck, Germany

declares that the product

GR-24 PRO +3xG + 3A + 3M HoTT

GR-18 PRO +3xG + 3A HoTT

Equipment class:

complies with the essential requirements of § 3 and the ot her relevant provisio ns of the FTEG (Articl e 3 of the R&TTE Directive).

Harmonised standards applied

EN 60950-1:2006+A11

EN 301 489-1 V1.9.2

EN 301 4 89-17 V2 .1.1

EN 300 328 V1.7.1

Kirchheim 17. April 2013

70

1

Health and safety requirements pursuant to § 3 (1) 1. (Article 3 (1) a))

Protection requirement concernig electromagnetic compatibility § 3 (1) 2, Artikel 3 (1) b))

Measures for the ecient use of the radio frequency spectrum § 3 (2) (Article 3 (2))

0678

Ralf Helbing

Managing Director

No. 33583

No. 33579

Page 36

7. MANUFACTURER’S DECLARATION

Content o f the manufact urer’s decla ration

If material defects or manufacturing faults should arise in a product distributed by us in the Federal Republic of Germany

and purchased by a consumer (§ 13 BGB), we, Graupner/SJ GmbH, D -73230 Kirchheim/Teck, Germany, acknowledge

the obligation to correc t those defects within the limitations described below.

The consumer is not entitled to exploit this manufacturer’s declaration if the failure in the usability of the product is due to

natural wear, use under competition conditions, incompetent or improper use (including incorrect installation) or external

inuences. This manufacturer’s declaration does not aect the consumer’s legal or contractual rights regarding defects

arising from the purchase contract between the consumer and the vendor (dealer).

Exte nt of the guaran tee

If a claim is made under guarantee, we under take at our discretion to repair or replace the defec tive goods. We will not

consider supplementary claims, especially for reimbursement of costs relating to the defect (e.g. installation / removal

costs) and compensation for consequent damages unless they are allowed by statute. This does not aect claims based on

legal regulations, especially according to product liability law.

Guarantee requirements

The purchaser is required to make the guarantee claim in writing, and must enclose original proof of purchase

(e.g. invoice, receipt, delivery note) and this guarantee card. The purchaser must send the defective goods to us at his own

cost, using the address stated below.

Graupner/SJ GmbH, Service Department,

Henriettenstr.96, D 73230 Kirchheim/Teck, Germany

Service Department: tel. [0049] 7021-722130

The purchaser should state the material defect or manufacturing fault, or the symptoms of the fault, in as accurate

a manner as possible, so that we can check if our guarantee obligation is applicable.

The goods are transpor ted from the consumer to us and from us to the consumer at the risk of the consumer.

71

Page 37

Duration of validity

This declaration only applies to claims made to us during the claim period as stated in this declaration. The claim period

is 24 months from the date of purchase of the produc t by the consumer from a dealer in the Federal Republic of Germany

(purchase date). If a defect arises after the end of the claim period, or if the evidence or documents required according to

this declaration in order to make the claim valid are not presented until af ter this period, then the consumer forfeits any

rights or claims from this declaration.

Limita tion by lapse of t ime

If we do not acknowledge the validity of a claim based on this declaration within the claim period, all claims based on this

declaration are barred by the statute of limitations after six months from the time of implementation; however, this cannot

occur before the end of the claim period.

Applicable law

This declaration, and the claims, rights and obligations arising from it, are based exclusively on the pertinent German Law,

excluding the norms of international private law, and excluding UN retail law.

8. ENVIRONNEMENTAL PROTECTION NOTES

When this product comes to the end of its useful life, you must not dispose of it in the ordinary domestic

waste.

The correct method of disposal is to take it to your local collection point for recycling electrical and

electronic equipment. The symbol shown here, which may be found on the product itself,

in the operating instructions or on the packaging, indicates that this is the case.

Individual markings indicate which materials can be recycled and re-used. You can make an important

contribution to the protection of our common environment by re-using the product, rec ycling the basic

materials or recycling redundant equipment in other ways.

Remove batteries from your device and dispo se of them at your local collection point for batteries.

In case of R/C models, you have to remove elec tronic parts like servos, receiver, or speed controller from the product in

question, and these parts must be disposed of with a corresponding collection point for electrical scrap.

If you don’t know the location of your nearest disposal centre, please enquire at your local council oce.

72

Page 38

ZÁRUKA / WARRANTY

Na tento výrobek je záruka

Warrantied for

Graupn er/SJ GmbH, Henrie ttenstraße 9 6, 73230 Kirchheim/ Teck, Německo

posky tuje na tento vý robek záruku p o dobu 24 měsíců od dat a nákupu.

Záruka s e vztahuje po uze na ty vady mate riálu nebo zpra cování, které byl y

přítomny u ž v době zakoupen í výrobku. Na p oškození způsob ené opotřeben ím,

přetížením, nevhodným zacházením nebo použitím nevhodného příslušenství se

záruka n evztahuje. Z ákonná záruka a p ráva spotřebite le nejsou těmito z áručními

podmín kami dotčena. Pečl ivě prosím výro bek zkontrolujt e předtím, než

uplatní te nárok na záruku n ebo nám výrob ek zašlete, jsme to tiž nuceni vám

naúčtovat naše náklady pokud se výrobek ukáže bezvadným.

Graupner/SJ GmbH, Henriettenstrasse 96, 73230 Kirchheim/Teck, Germany

guarante es this product f or a period of 24 month s from date of purchas e.

The guar antee applies onl y to such material or op erational def ects witch are

present a t the time of purchas e of the product.

Damage du e to wear, overloading , incompetent han dling or the use of inc orrect

accessor ies is not covered by th e guarantee. The us er´s legal r ights and claims

under gar antee are not aec ted by this guarant ee. Please check th e product

carefu lly for defect s before you are make a c laim or send the ite m to us, since we

are oblig ed to make a charge for o ur cost if the produ ct is found to be fre e

of faults.

Servis/Service

ČESKÁ REPUBLIKA

TRIVOX - Pat rik Dworsc hak

Do ub ra vi ce 11 0

533 53 Doub ravice

podpora@trivox.cz

www.trivox.c z

(+420) 226 519 671

Razítko a podpis prodejce

Stamp and signature of dealer

měsíců

months

Záruční list

Warranty certicate

33579 & 33583

GR-18PRO 3xG+3A+Vario

GR-2424PRO 3xG+3A+3M+Vario

Datum zakoupení

Date of purchase/delivery

Jméno majitele

Owner´s name

Adresa

Complete adress

73

Page 39

Specikace a dostupnost se mohou měnit. Dodáváno pouze sítí specializovaných modelářských prodejen.

Rádi vás budeme informovat o vašem nejbližším dodavateli.

Neodpovídáme za tiskové chyby.

Specications and availability subject to change. Supplied through specialist model shopsonly.

We will gladly inform you of your nearest supplier.

We accept no liability for printingerrors.

Loading...

Loading...