Page 1

Order No. 4239

BUILDING INSTRUCTIONS

ELEKTRO-ROOKIE QR

RC electric-powered model for three LiPo cells of around 2500 mAh

This model requires a 3-function or 4-function HoTT radio control system

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. Id.-Nr. 0062273 3/2011

- 1 -

Page 2

Please be sure to read through the Safety Notes in the Appendix to these operating

instructions. If you ever dispose of the model, it is important to pass on the complete building

instructions to the new owner.

Introduction

The ELEKTRO-ROOKIE QR is an RC model aircraft designed expressly for the

newcomer to model flying, and offers a superb performance in the air. Either the

rudder or the ailerons can be set up as the primary directional control. If you intend

only to fit rudder control at first, it is nevertheless an easy job to fit working ailerons at

a later stage. For safety reasons the model’s all-up weight should not exceed 850 g.

RC system accessories (not included)

GRAUPNER MX-12 HoTT 2.4 COMPUTER SYSTEM Order No. 4754

ULTRAMAT 16S battery charger Order No. 6468

C231 servo (two to four required) Order No. 5109.LOSE

Servo extension lead, 100 mm (two required) Order No. 3935.11

Servo extension lead, 320 mm (two required) Order No. 3935.32

LiPo battery, 20C 3/2500, 11.1 V, G3.5 Order No. 7633.3

Essential tools and adhesives (not included)

Balsa knife Order No. 980

Cyano-acrylate (“cyano”) Order No. 5821

Cyano-acrylate activator (“kicker”) Order No. 953.150

You will also need the following items: cross-point screwdriver, flat-nose pliers, paper

scissors, 1.5 mm A/F allen key, adhesive tape, paper towel, protective gloves,

goggles.

Building instructions

Please start by reading right through these building instructions, so that you gain an

overall understanding of how the model goes together. Lay out the components

required for each stage of construction, together with the tools and adhesives. When

working on the model always keep the bench surface clean and smooth, or cover it

with a sheet of soft foam; this avoids damage to the model’s surfaces. Unless stated

otherwise, use cyano-acrylate glue (“cyano”) and activator (“kicker”) for all joints on

this model: the best method is to apply adhesive to one side of the joint, and spray

activator on the mating surface. Please take particular care to avoid adhesive getting

on your hands or the surface of the model: wipe off excess glue immediately using

kitchen paper (paper towel).

Caution: cyano-acrylate adhesives must not be allowed to come into contact

with any part of your body, and especially not your eyes. For this reason we

recommend that you wear goggles when building the model. Store all glues

well out of the reach of children. For safety reasons use the adhesive stated

above exclusively.

Please take the time to read through the operating instructions for the

BRUSHLESS CONTROL 18 speed controller, which is supplied in the motor set.

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. Id.-Nr. 0062273 3/2011

- 2 -

Page 3

Fuselage and fin

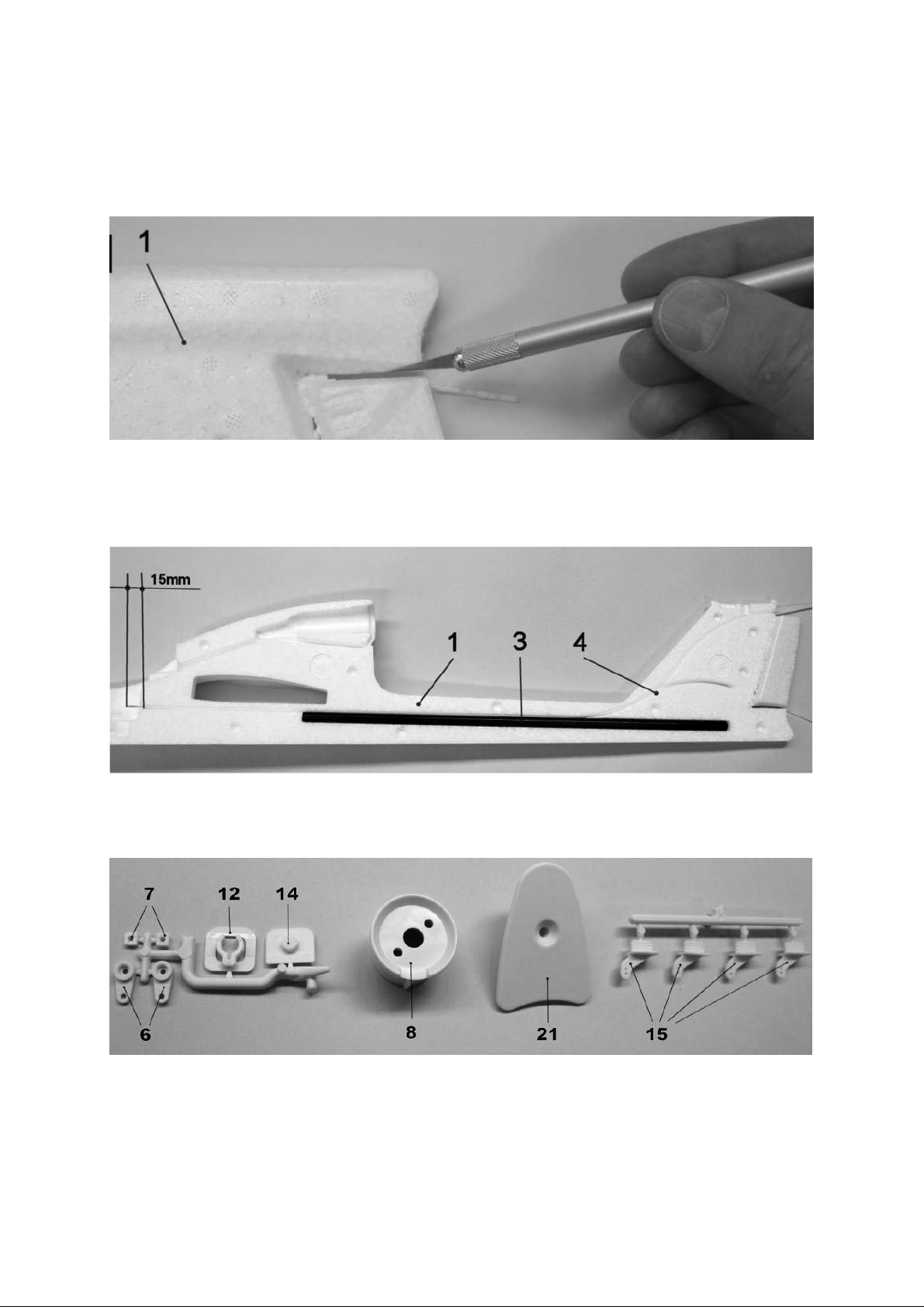

You will find a strip of foam linking the bottom edge of the rudder to the fuselage; cut

this away, and move the rudder repeatedly from side to side to free up the integral

hinge line.

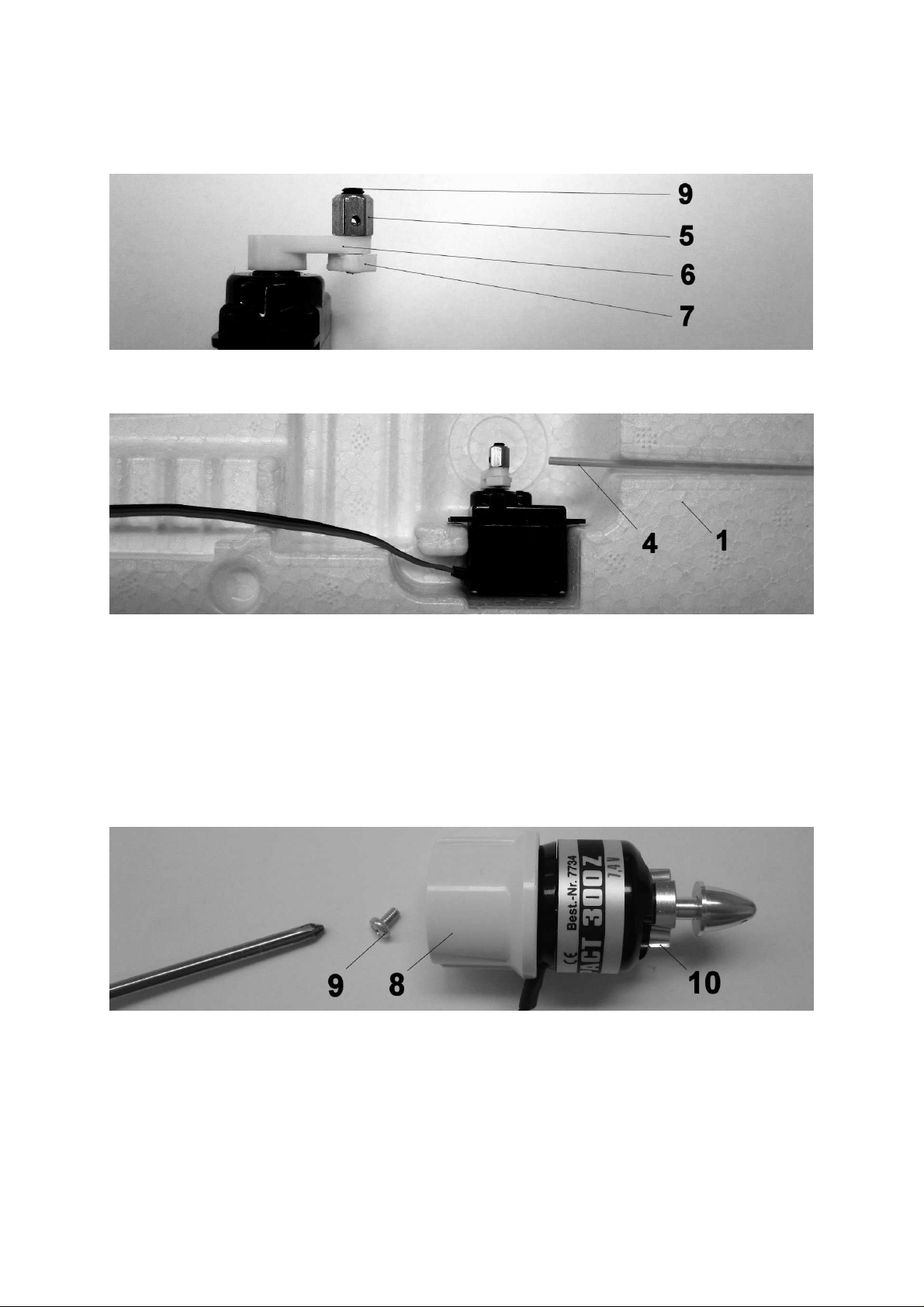

Glue the fuselage stiffening tube (3) in the right-hand fuselage side (1), followed by

the two “snake” outer sleeves (4), noting that the sleeve for the rudder should be

fitted first; it must project by 15 mm at the front end.

Caution: do not cut off the excess length of the snake sleeves (4) at the tail end, as

this might allow excess cyano to run inside them.

The illustration shows the small ABS parts included in the kit.

Do not remove these components from the sprue until you actually need them.

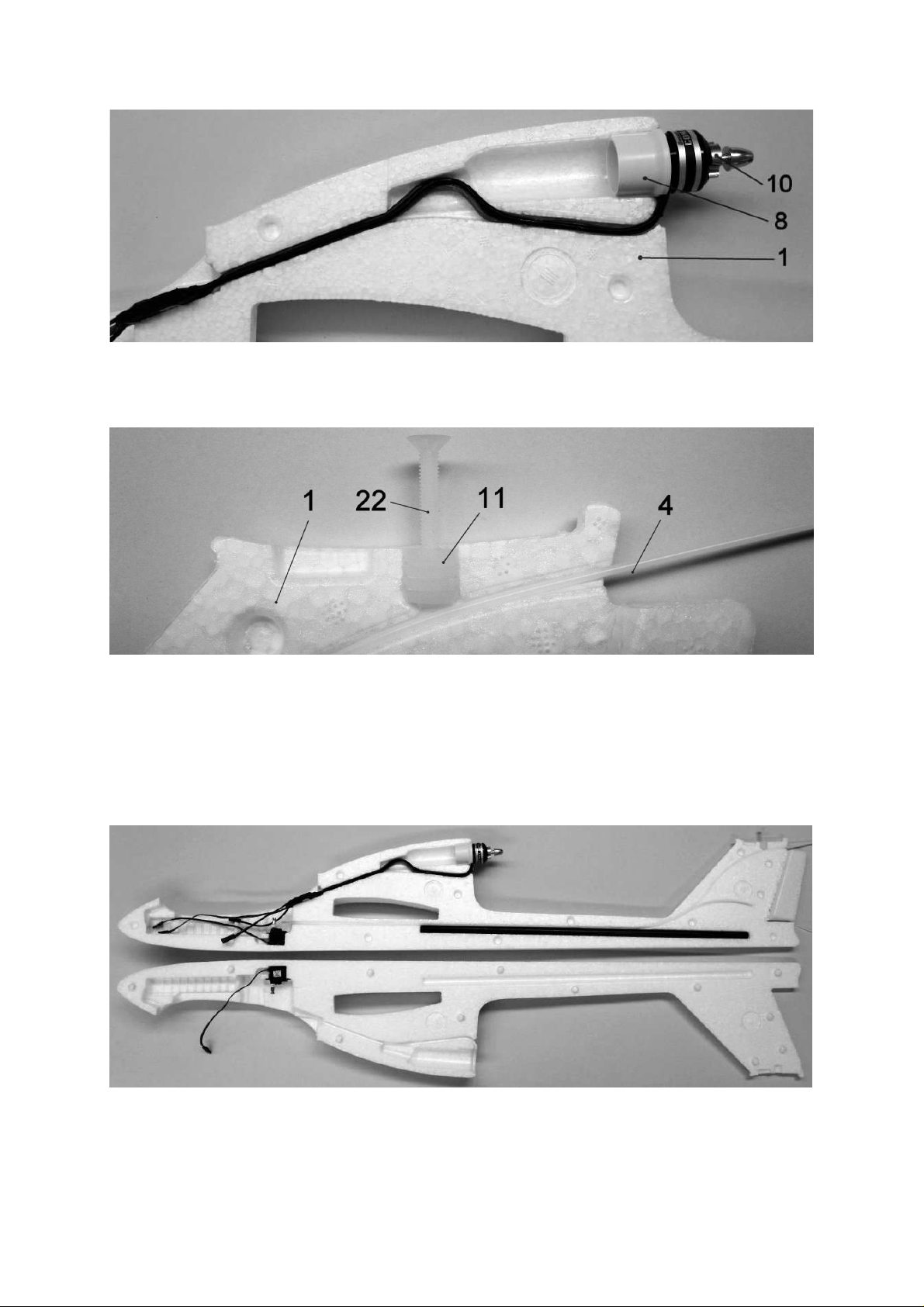

Unscrew the original output levers from the C231 servos, and set the servos to centre

(neutral) from the transmitter. Mount parts (5) to (9) on the servo output arms (6) as

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. Id.-Nr. 0062273 3/2011

- 3 -

Page 4

shown in the photo. Tighten the nuts just to the point where the swivel pushrod

connectors rotate smoothly, but without lost motion.

Screw the servo output arms to the servos in the arrangement shown in the picture.

Fix the rudder servo in the right-hand fuselage shell (1) with a single drop of cyano on

each mounting lug and one on the underside of the servo case.

Caution: do not use thin cyano to secure the servos, or too much cyano of any

type, as it could penetrate the case and jam the moving parts.

Use the same procedure to glue the elevator servo in the left-hand fuselage shell (2).

Check from the transmitter that both servos still work correctly.

Fix the motor (10) to the motor mount (8) using the two screws (9). Tighten the

screws fully, and secure each one with a drop of cyano.

The motor mount (8) can now be glued in the right-hand fuselage shell. Press the

cables into the channel, and secure them with a little glue. If necessary, shorten the

motor cables by deploying them in a curve - as shown in the photo - so that the

BRUSHLESS CONTROL 18 speed controller lies flat on the fuselage. Tack the

speed controller in place with a little adhesive.

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. Id.-Nr. 0062273 3/2011

- 4 -

Page 5

Connect the power system - but without fitting the propeller - and check that it

functions properly, referring to the instructions supplied with the power set.

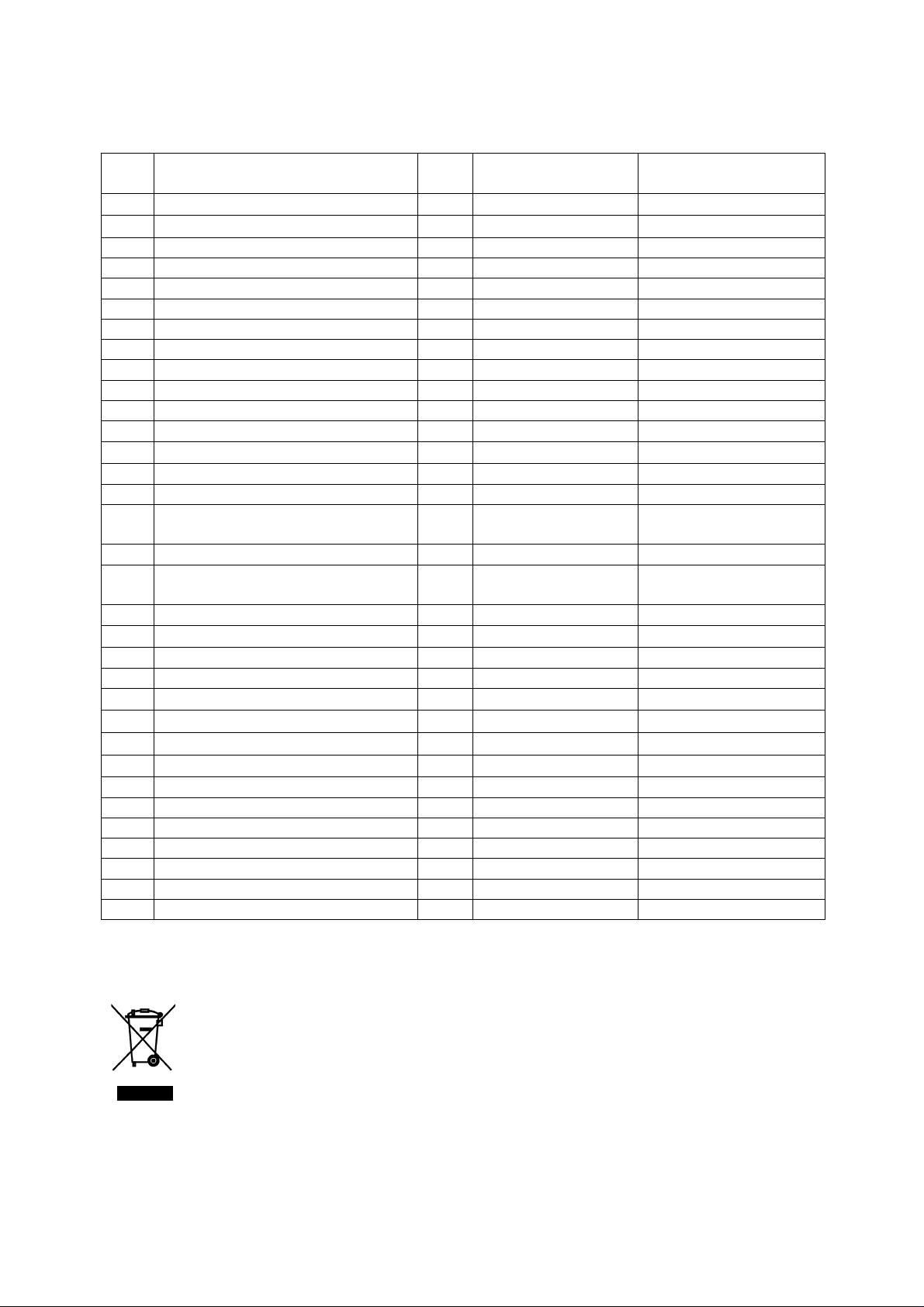

Fit the countersunk plastic screw (22) in the threaded insert (11), then glue the insert

in the top of the fin as shown, again using cyano. Remove the plastic screw. The

fuselage shells (1) and (2) are now ready for joining. To be on the safe side, repeat

the check of the servos and the motor (without propeller), and temporarily fit the

pushrods (16) and (18) in the outer sleeves to ensure that they slide smoothly.

The photo below shows the fuselage shells (1) and (2) ready for joining.

The first step in joining the shells is to offer them up “dry” (no glue). It is a good idea

to secure the loose cables temporarily with tape to avoid them getting caught in the

joint.

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. Id.-Nr. 0062273 3/2011

- 5 -

Page 6

Caution: the next procedure demands your full concentration. Take great care

to avoid glue getting onto the area of the rudder hinge. Keep some absorbent

kitchen paper to hand so that you can wipe away excess cyano immediately.

Tip: if you are not an experienced model builder, avoid using activator spray for this

procedure. Instead tape the fuselage shells together and leave the assembly while

the glue sets hard; this may take several hours.

The canopy

Glue the canopy retainer clip (12) in the fuselage as shown, and glue the mating

spigot (14) in the canopy (13).

Allow the glue to harden fully before fitting the canopy on the fuselage. Tip: if the

retainer clip (12) grips too strongly for comfort, bend the two claws outwards, working

gently and evenly.

The tailplane

Cut away the unwanted foam at both ends of the elevator, and move the control

surface repeatedly in both directions to free up the integral hinge. This procedure

should also be carried out with the wing-mounted ailerons.

Glue the spreader plate (21) to the top of the tailplane as shown, and glue the horn

(15) in the slot in the underside of the elevator.

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. Id.-Nr. 0062273 3/2011

- 6 -

Page 7

The control surface linkages

Cut off the excess length of the snake outer sleeves (4) at the tail end of the

fuselage. Slip the rudder pushrod (16) into the outer sleeve from the tail end, and slip

the front end through the swivel pushrod connector (5) mounted on the right-hand

servo. Connect the rudder horn (15) to the pre-formed end of the pushrod, then glue

the horn in the slot in the rudder. Install the elevator pushrod (18) in the same way.

Place the tailplane (20) on the fin and secure it with the countersunk plastic screw

(22). Tip: if you are a beginner to model flying, connect the pushrods to the outer

holes in the rudder and elevator horns in order to obtain small control surface travels.

If you prefer more marked control response, use the inner holes in the horns, as

shown in the photographs.

Set the rudder and elevator to centre, then tighten the clamping screws (9). Hold the

connector barrel tightly in a pair of flat-nose pliers while you do this, as shown in the

photograph.

The wing

Glue the spar channel covers (24) and (26) in the wing panels as shown, but do not

use activator spray for these joints. Spray cyano activator in the channel for the spar

(27) to eliminate any possibility that it might become stuck permanently in the wing.

If you do not intend to equip the model with aileron servos initially, apply adhesive

film (33) over the aileron servo openings and the aileron hinge line.

Please note that the following parts are not required for the rudder / elevator version:

four servo extension leads, two aileron pushrods (31), two aileron horns (15), and two

C 231 servos.

Please refer to the section entitled “Control surface checks” for information on

control surface travels.

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. Id.-Nr. 0062273 3/2011

- 7 -

Page 8

The picture shows the version of the wing without aileron servos.

Fit 14 mm long output arms (supplied with the servos) on the aileron servos. Set the

servos to centre from the transmitter, press them into the servo wells, and press the

servo leads in the channels. Check that the servos work properly before securing

them with a drop of glue on each mounting lug.

Installing the receiving system

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. Id.-Nr. 0062273 3/2011

- 8 -

Page 9

The illustration shows the HoTT receiver installed above the rudder servo using

Velcro tape (32). Route the receiver aerials through the fuselage opening above the

speed controller. We recommend the following receiver channel assignment:

Connect the speed controller to receiver socket I, the left aileron servo to socket II,

the elevator servo to socket III, the rudder to socket IV, the right-hand aileron servo to

socket V. Coil up the servo leads next to the receiver, so that they cannot obstruct

the servo output arms when they move. Connect the 100 mm servo extension leads

to sockets II and V.

Note: if the model is fitted with rudder and elevator controls only, the rudder servo

should be connected to socket II.

The receiving system is switched on by connecting the G3.5 plugs and sockets, as

shown in the photo. Bind the receiver to the transmitter using the procedure outlined

in the manual supplied with your RC system. Check the direction of motor rotation: if

the propeller spins clockwise when viewed from the tail, disconnect the push-button

(bottom of picture) from the speed controller.

Installing the wing

Push the right-hand wing panel into the side of the fuselage, then slide the CFRP

spar into place, followed by the left-hand wing panel. Tip: squeeze together the projecting lugs at the root of the left-hand wing panel, as this makes it easier to engage

the wing retainer system.

Slip the servo leads through the appropriate channel in the left-hand fuselage side (2)

as shown in the picture; this is easier if you use a pair of tweezers or small pliers.

Checking the control surfaces

The stick mode at the transmitter should be set as shown in the photograph: throttle

(motor speed) and direction (aileron) on the right-hand stick. Stick back (towards you)

equates to motor off; stick forward means full power. Elevator control should be on

the left-hand stick: pulling the stick back deflects the elevator up; pushing it away

from you produces down-elevator.

The rudder is operated by moving the left-hand stick left and right. If any function

works the wrong way round, use your transmitter’s servo reverse facility to correct

that channel. If you want maximum possible control surface travels, connect the

pushrods to the innermost holes in the control surface horns (15). If you are a relative

beginner to model flying, we recommend that you connect the pushrods to the outer

holes.

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. Id.-Nr. 0062273 3/2011

- 9 -

Page 10

Fitting the propeller

Install the propeller on the motor as shown in the photo, using a 1.5 mm Ø steel rod

to tighten the spinner. Caution: fit the propeller with the lettering facing forward, i.e.

towards the model’s nose. If you fit it the other way round, motor power will be greatly

reduced.

Decals

It is not necessary to paint the model’s SOLIDPOR® components. If you wish to give

the aircraft a coloured finish, we recommend the use of GRAUPNER LEXACOLOR

spray paints, Order No. 945... Do not rub down the surfaces prior to painting; instead

wipe them with cellulose thinners, Order No. 1409, and a piece of absorbent paper

towel.

Cut out and apply the decals from the decal sheet (28) to complete the model.

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. Id.-Nr. 0062273 3/2011

- 10 -

Page 11

Balancing

Assemble the model completely, with all the RC and power system components in

place.

The Centre of Gravity range is 70 mm to 80 mm aft of the wing root leading edge

(see markings on the underside of the wing). Support the model at the stated CG

position with two fingers under the wing roots, and allow it to hang freely: when

balanced correctly, the fuselage will hang level.

Flying

For the initial test-flight wait for a day with little or no breeze. The ideal flying site is a

grassy field with a gentle slope facing into wind. Check that the control surfaces are

exactly at centre before flying.

Switch the motor on and give the aeroplane a hand-launch exactly into any

breeze; trotting forward for a few steps gains the necessary momentum. The

model’s nose should be angled up slightly (around 15°) for a launch under

power.

Initially use the rudder and elevator controls gently, just to correct any deviations from

a straight flight path. Fine-tuning can be carried out by adjusting the trim sliders

situated below and adjacent to the transmitter sticks. Always land the model directly

into wind, with the motor switched off. Just before touch-down, apply slight upelevator to flare out and slow the machine down further.

All of us at GRAUPNER Modellbau wish you many fine flights with your new

ELEKTRO-ROOKIE QR

Specification

Wingspan approx. 1400 mm

Overall length approx. 960 mm

Wing airfoil HQ 3.0/12

Tailplane airfoil NACA 009

Wing area approx. 23.4 dm²

Tailplane area approx. 3.9 dm²

Total surface area approx. 27.3 dm²

Total surface area loading approx. 30.0 g/dm²

All-up weight approx. 820 g

Replacement parts (not included)

Canopy Order No. 4218.1

Fuselage shells Order No. 4239.2

Wing panels Order No. 4239.3

Tailplane Order No. 4218.4

ABS small parts Order No. 4218.5

Decal sheet Order No. 4239.14

CFRP wing spar Order No. 4218.20

Propeller Order No. 2945.16.8

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. Id.-Nr. 0062273 3/2011

- 11 -

Page 12

Parts List - ELEKTRO-ROOKIE QR

Part

No.

1 R.H. fuselage shell 1

2 L.H. fuselage shell 1

3 Fuselage stiffening tube 1 CFRP 10 / 9 Ø x 450

4 Control “snake” outer sleeve 2 Nylon 1.9 Ø

5 Swivel pushrod connector 2 Steel M2, ready made

6 Servo output lever 2 ABS Ready made

7 Self-locking nut 2 ABS Ready made

8 Motor mount 1 ABS Ready made

9 Cheesehead screw 4 Steel M3 x 5

10 COMPACT 300 7.4 V power set 1 Steel / plastic Ready made

11 Threaded insert 1 Nylon M4, ready made

12 Canopy retainer clip 1 ABS Ready made

13 Canopy 1

14 Canopy retainer spigot 1 ABS Ready made

15 Control surface horn 4 ABS Ready made

16 Rudder pushrod 1 Steel 0.6 Ø x 708,

17 Spigot 1 ABS Ready made

18 Elevator pushrod 1 Steel 0.6 Ø x 774,

19 Rudder horn 1 ABS Ready made

20 Tailplane 1

21 Tailplane spreader plate 1 ABS Ready made

22 Countersunk screw 1 Nylon M4 x 25

23 L.H. wing panel 1

24 L.H. spar channel cover 1

25 R.H. wing panel 1

26 R.H. spar channel cover 1

27 CFRP wing spar 1 CFRP 10 / 8 Ø x 600

28 Decal 12 Self-adhesive film Sheet

29 Propeller 1 Plastic 160 x 80

30 Grubscrew 22 Steel M3 x 3

31 Aileron pushrod 2 Steel Ready made

32 Velcro tape 1+1 Plastic 33 x 25 x 3

33 Aileron servo / aileron gap cover L+R Adhesive film Oversize

Description No.

off

Material Dimensions, mm

SOLIDPOR®

SOLIDPOR®

SOLIDPOR®

Ready made

Ready made

Ready made

ready made

ready made

SOLIDPOR®

SOLIDPOR®

SOLIDPOR®

SOLIDPOR®

SOLIDPOR®

Ready made

Ready made

Ready made

Ready made

Ready made

Environmental Protection Notes

The presence of this symbol on a product, in the user instructions or the packaging, means that you must not

dispose of that item, in the ordinary domestic waste when the product comes to the end of its useful life. The

correct method of disposal is to take it to your local collection point for recycling electrical and electronic

equipment.

Individual markings indicate which materials can be recycled and re-used. You can make an important

re-processing redundant equipment in other ways.

Dry cells and rechargeable batteries must be removed from the device and taken separately to a suitable battery disposal

centre.

contribution to the protection of our shared environment by re-using the product, recycling the basic materials or

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. Id.-Nr. 0062273 3/2011

- 12 -

Page 13

If you don’t know the location of your nearest disposal centre, please enquire at your local council office.

Safety Notes

Before you fly the model for the first time it is essential (and a legal requirement) to take out an

insurance policy designed to cover modelling risks.

Be sure to read right through the instructions covering assembly and operation of your model

before you attempt to operate it for the first time. You alone are responsible for the safe

operation of your radio-controlled model aeroplane. Young people should only be permitted to

build and fly this model under the instruction and supervision of an adult who is aware of the

hazards involved in this activity.

In legal terms our models are classed as aircraft, and as such are subject to statutory

regulations and restrictions which must be observed. Our brochure “Modellflugrecht,

Paragrafen und mehr” (Model Aviation Law, Legal Requirements and more) is available under

Order No. 8034.02, and contains a summary of all these rules; your local model shop should

have a copy which you can read. There are also Post Office regulations concerning your radio

control system, and these must always be observed. Refer to your RC system instructions for

more details.

It is important to use only those parts included in the kit, together with other genuine Graupner

accessories and replacement parts as recommended expressly by us. Even if you change a

single component, you can no longer be sure that the whole system will work reliably, and

such changes also invalidate your guarantee.

Avoid short circuits and reverse polarity at all times.

The high energy density of rechargeable batteries involves a constant risk of fire and even

explosion.

A radio-controlled model aircraft can only work properly and fulfil your expectations if it is built

very carefully, and in accordance with the building instructions. If you wish to avoid injuring

people and damaging property, it is essential to be cautious and painstaking at all stages of

building and operating your model. Nobody would climb into a full-size sailplane and try to fly

it without first completing a course of training. Model flying is just such a skill, and has to be

learned in exactly the same way.

However, as manufacturers we have no means of influencing the way you build and operate

your RC model aircraft, and for this reason we can do no more than point out the hazards

expressly. We accept no further liability.

If you need help, please enlist the aid of an experienced modeller, join a model club or enrol at

a model flying training school. Model shops and the specialist model press are also good

sources of information. The best course is always to join a club and fly at the approved model

flying site.

Adhesives and paints contain solvents which may be hazardous to health under certain

circumstances. Always read and observe the notes and warnings supplied by the manufacturer

of these materials.

The operator of the model must be in full possession of his or her bodily and mental faculties.

As with car driving, flying a model aircraft under the influence of alcohol or drugs is highly

dangerous and not permissible under any circumstances.

Make sure that all passers-by and onlookers are aware of the hazards involved in the operation

of your model. Remind spectators to keep a safe distance from the model.

Always maintain a safe distance between your model and other people or objects. Never fly low

over people or directly towards them.

Radio-controlled models should only be flown in “normal” weather conditions, i.e. a

temperature range of -5° to +35°C. More extreme temperatures can lead to changes in battery

capacity, material characteristics, the strength of glued joints and other unwanted effects.

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. Id.-Nr. 0062273 3/2011

- 13 -

Page 14

All model flyers should behave in a way which minimises the danger to people and property.

Never act in any manner which will disturb other pilots, or have an adverse effect on safe,

orderly flying at the site.

Don’t operate your model aeroplane in the vicinity of overhead power cables, industrial sites,

residential areas, public roads, school playgrounds or sports fields etc.

Pre-flight checks

Check that the radio control system works correctly and at full range before every flight: switch

on the transmitter and the receiving system, fit the transmitter aerial and extend it to its full

length; walk away from the model, and check that all the control surfaces work smoothly and

immediately at an appropriate distance; check also that they deflect in the correct “sense” in

relation to the stick movements. Repeat the check with the motor running, while a friend holds

the model securely for you.

If you are a relative beginner to this type of model flying, we recommend that you enlist an

experienced model pilot to help you check and test-fly the model.

Please don’t ignore our warnings. They refer to hazardous materials and processes which, if

ignored, can result in fatal injury or serious damage to property.

Propellers powered by a motor constitute a permanent hazard and represent a real risk of

injury. Don’t touch them with any part of your body. For example, a propeller spinning at high

speed can easily cut your finger badly.

Keep well clear of the rotational plane of the propeller. You never know when some part may

come loose and fly off at high speed, hitting you or anybody else in the vicinity. In

unfavourable circumstances this could result in serious injury. Ensure that the revolving

propeller never comes into contact with any object.

Make sure that it is impossible for any object to stall or block the propeller.

Every time you intend to operate your model, check carefully that it and everything attached to

it (e.g. propeller, RC components etc.) is in good condition and undamaged. If you find a fault,

do not fly the model until you have corrected it.

Satisfy yourself that your frequency is unoccupied before you switch on. Radio interference

caused by unknown sources can occur at any time without warning. If this should happen,

your model will be uncontrollable and completely unpredictable. Never leave your radio control

system unguarded, as other people might pick it up and try to use it.

Do not switch the electric motor on unless you have checked that there is nothing in the

rotational plane of the propeller. Never attempt to stop the propeller when it is spinning.

Electric motors with propellers fitted must only be run when firmly mounted.

If you are to fly your model safely and avoid problems, it is essential that you are aware of its

position and attitude throughout each flight - so don’t let it fly too far away. If you detect a

control problem or interference during a flight, immediately land the model to prevent a

potential accident. Model aeroplanes must always give way to full-size aircraft. Take-off and

landing strips should be kept free of people and other obstacles.

Your RC system can only work reliably if the batteries are kept fully charged.

Never use hot, faulty or damaged batteries. It is important to observe the instructions supplied

by the battery manufacturer.

Before every flight ensure that all functions are working correctly, and carry out a range check.

Always ensure that the throttle stick (or other throttle control) is at the motor OFF position

before switching the transmitter on. To avoid the electric motor bursting into life unexpectedly,

always switch the transmitter on first, followed by the receiving system. When switching off,

reverse the order: receiving system first, then the transmitter.

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. Id.-Nr. 0062273 3/2011

- 14 -

Page 15

Check that the control surfaces work in the correct “sense”, i.e. that they deflect in the

direction which corresponds to the movement of the stick.

After each session remove all the batteries from the model and store them in a discharged

state at a temperature of about +5° to +25°C. They must be k ept out of the reach of children.

Please don’t misunderstand the purpose of these notes. We only want to make you aware of

the many dangers and hazards which can arise if you lack knowledge and experience, or work

carelessly or irresponsibly. Provided that you take reasonable care, model flying is a highly

creative, instructive, enjoyable and relaxing pastime.

Manufacturer’s declaration:

If material defects or manufacturing faults should arise in a product distributed by us in the

Federal Republic of Germany and purchased by a consumer (§ 13 BGB), we, Graupner GmbH &

Co. KG, D-73230 Kirchheim/Teck, Germany, acknowledge the obligation to correct those

defects within the limitations described below.

The consumer is not entitled to exploit this manufacturer’s declaration if the failure in the

usability of the product is due to natural wear, use under competition conditions, incompetent

or improper use (including incorrect installation) or external influences.

This manufacturer’s declaration does not affect the consumer’s legal or contractual rights

regarding defects arising from the purchase contract between the consumer and the vendor

(dealer).

Extent of the guarantee

If a claim is made under guarantee, we undertake at our discretion to repair or replace the

defective goods. We will not consider supplementary claims, especially for reimbursement of

costs relating to the defect (e.g. installation / removal costs) and compensation for consequent

damages unless they are allowed by statute. This does not affect claims based on legal

regulations, especially according to product liability law.

Guarantee requirements

The purchaser is required to make the guarantee claim in writing, and must enclose original

proof of purchase (e.g. invoice, receipt, delivery note) and this guarantee card. The purchaser

must send the defective goods to us at his own cost, using the address stated above.

The purchaser should state the material defect or manufacturing fault, or the symptoms of the

fault, in as accurate a manner as possible, so that we can check if our guarantee obligation is

applicable.

The goods are transported from the consumer to us and from us to the consumer at the risk of

the consumer.

Duration of validity

This declaration only applies to claims made to us during the claim period as stated in this

declaration. The claim period is 24 months from the date of purchase of the product by the

consumer from a dealer in the Federal Republic of Germany (purchase date). If a defect arises

after the end of the claim period, or if the evidence or documents required according to this

declaration in order to make the claim valid are not presented until after this period, then the

consumer forfeits any rights or claims from this declaration.

Limitation by lapse of time

If we do not acknowledge the validity of a claim based on this declaration within the claim

period, all claims based on this declaration are barred by the statute of limitations after six

months from the time of implementation; however, this cannot occur before the end of the

claim period.

Applicable law

This declaration, and the claims, rights and obligations arising from it, are based exclusively

on the pertinent German Law, excluding the norms of international private law, and excluding

UN retail law.

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. Id.-Nr. 0062273 3/2011

- 15 -

Loading...

Loading...