GRAUPNER CHIP Building Instructions

Order No. 4564

BUILDING INSTRUCTIONS

CHIP

For electric motor and three 850 mAh LiPo cells

The model requires a three-function HoTT radio control system

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. Id.-Nr. 0062414 3/2011

- 1 -

Please be sure to observe the Safety Notes in the Appendix of these operating instructions. If

you ever pass the model on to another person, the complete operating instructions must be

included with it.

Introduction

The CHIP is an ideal beginner’s hotline model, which offers maximum flying pleasure

for minimum building effort. The model is highly pre-fabricated, but the procedures

described in the following instructions must be carried out with the greatest care to

ensure that the model flies safely and well. The aircraft’s all-up weight must not

exceed 600 g.

RC system accessories

The following items are required in order to operate the model.

MX-12 2.4 GRAUPNER HoTT COMPUTER SYSTEM Order No. 4754

DES 261 BB servo (two required) Order No. 7903

ULTRAMAT 8 Order No. 6411

Transmitter charge lead Order No. 3022

Charge lead with BEC connector Order No. 3037

COMPACT FLY 15 BEC speed controller Order No. 7220

GRAUPNER LiPo flight battery, 3/850 11.1 V / 850 mAh Order No. 7621.3BEC

Essential tools and adhesives

Balsa knife Order No. 980

Screwdriver

Abrasive paper, 320-grit

Side-cutters

Mini flat-nose pliers

Open-ended spanner, 8 mm A/F, allen key, 1.5 mm A/F, allen key, 2 mm A/F

Paper scissors

Adhesive tape

Soldering iron, solder, heat-gun

Cyano-acrylate glue (“cyano”) Order No. 5821

Cyano activator Order No. 953.150

Building instructions

Please read right through these building instructions before you start construction, to

ensure that you have a clear understanding of the sequence of operations required.

Lay out all the components, tools and adhesives for each stage before you start

work, and prepare the model parts as described in the building instructions. When

assembling the components always work on a clean, smooth surface, or cover the

workbench with a layer of soft foam. Use cyano-acrylate and activator as adhesive.

We recommend that you apply the glue to one joint surface, and spray activator on

the mating surface. Take particular care to avoid adhesive running onto your hands

or the model’s surface; immediately wipe off any excess glue using paper towel.

Caution: cyano-acrylate must never come into contact with body parts. Take

particular care to avoid it getting in your eyes; we therefore recommend that

you wear goggles when handling cyano. Store the adhesive well out of the

reach of children. For safety reasons we recommend that you only use the

adhesive stated above.

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. Id.-Nr. 0062414 3/2011

- 2 -

Fuselage and tail

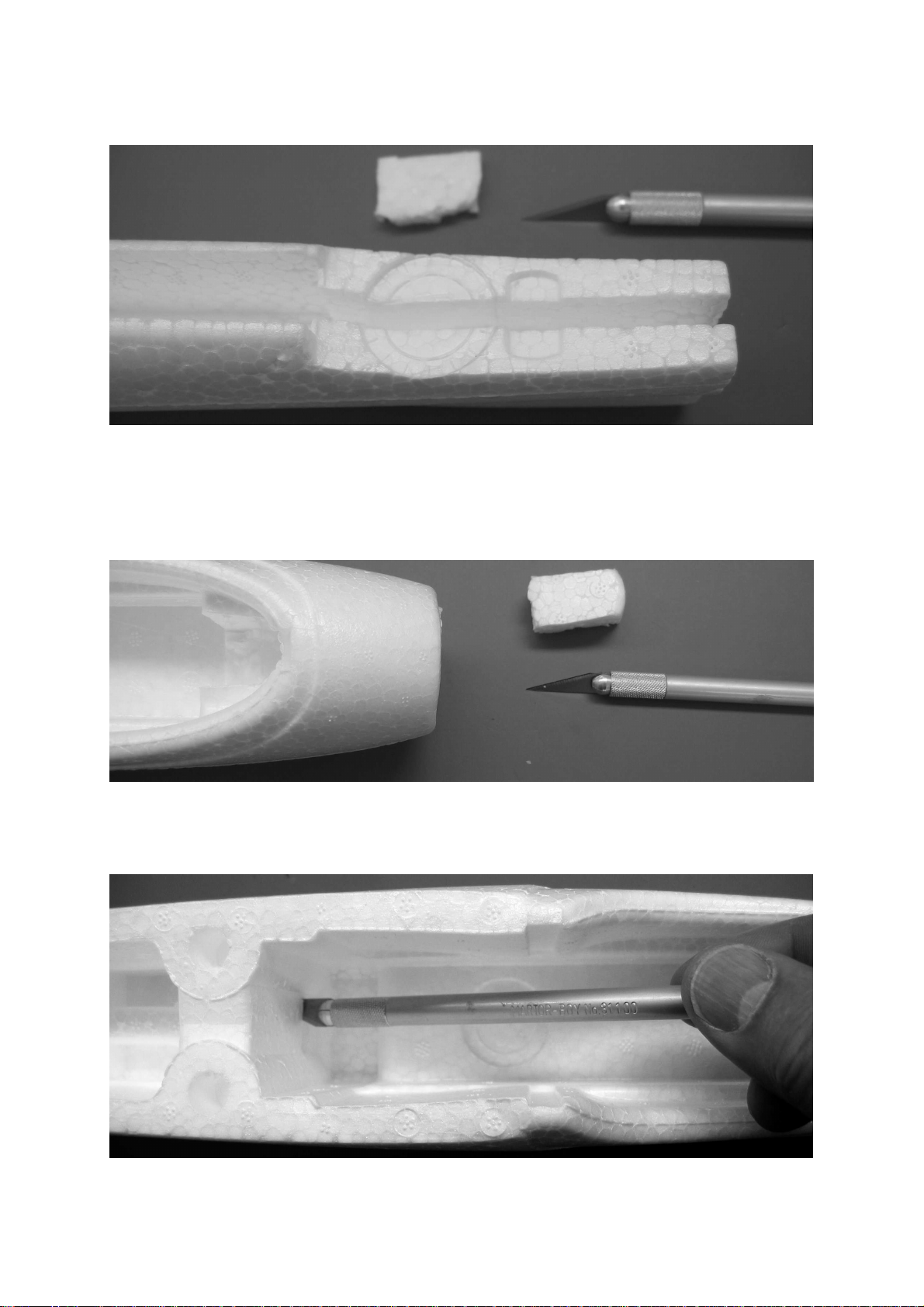

Use a balsa knife to continue the channel for the reinforcement (2) right through to

the end of the fuselage. Tip: use the balsa knife just to cut the side slits, then push

out the scrap SOLIDPOR foam using the strip of spruce (2). Fit the spruce strip and

ensure that it rests completely on the bottom of the fuselage. This is important,

otherwise it will not be possible to push the fin (4) fully into place.

Locate the lug at the front face of the fuselage produced by the moulding process.

Remove this to provide clearance for the power leads of the INLINE 400 electric

motor.

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. Id.-Nr. 0062414 3/2011

- 3 -

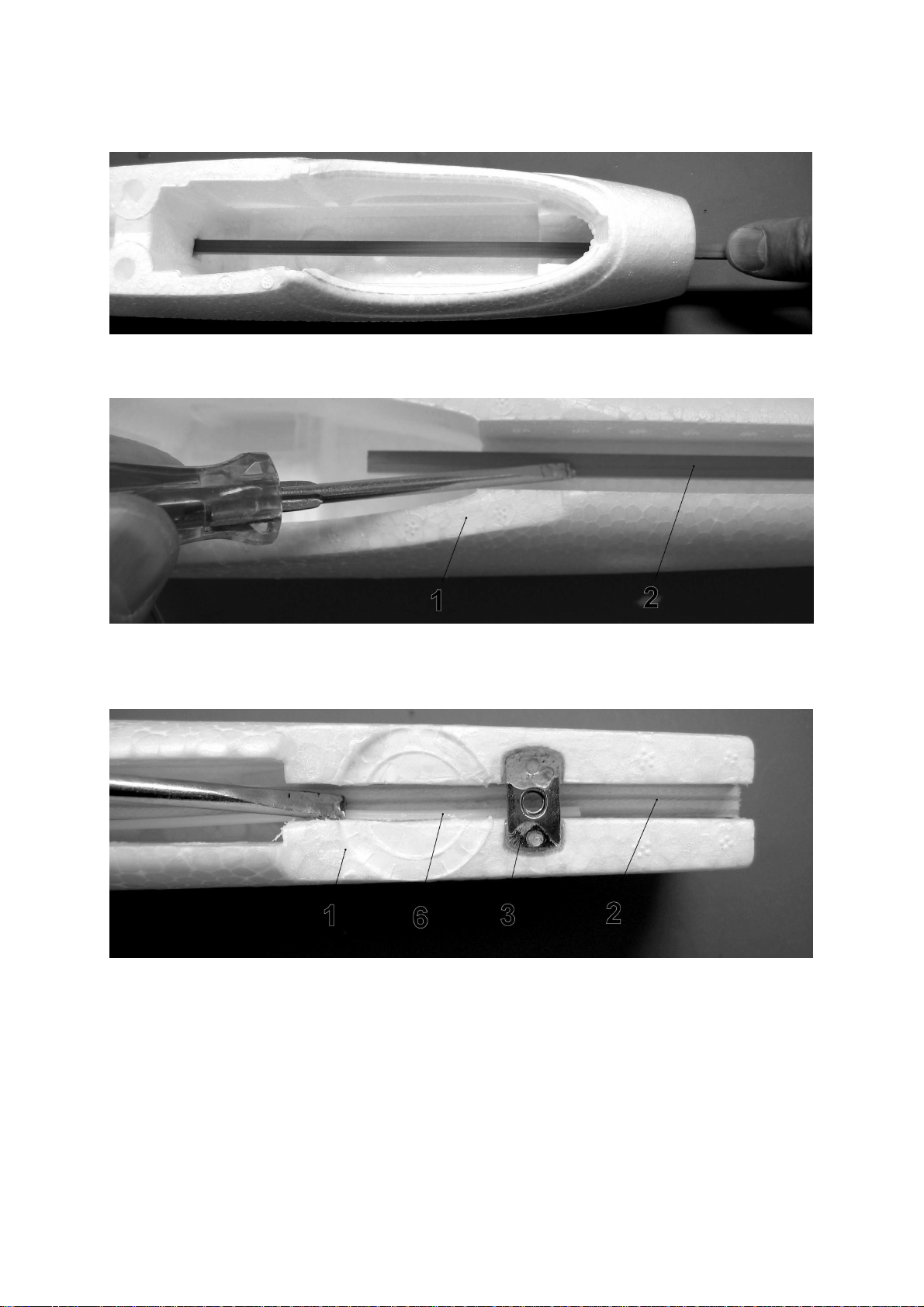

Cut a 10 x 6 mm opening at the bottom of the fuselage for the servo leads.

Push the strip of spruce (2) through to complete the opening.

Glue the fuselage reinforcement (2) exactly central in the fuselage (1), and press it

into place. Check carefully that the fuselage is not distorted when you do this.

Roughen the surface of the captive nut (3) using abrasive paper, then glue it in place

using plenty of adhesive. When the glue has set hard, fit the retaining screw (12) in

the nut and pull on it to check that the joint is strong enough.

Use the balsa knife to cut the elevator snake outer sleeve (6) to a length of 440 mm,

and press it into place as shown in the picture. Glue the elevator snake sleeve (6) to

the side of the fuselage reinforcement (2) at the front.

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. Id.-Nr. 0062414 3/2011

- 4 -

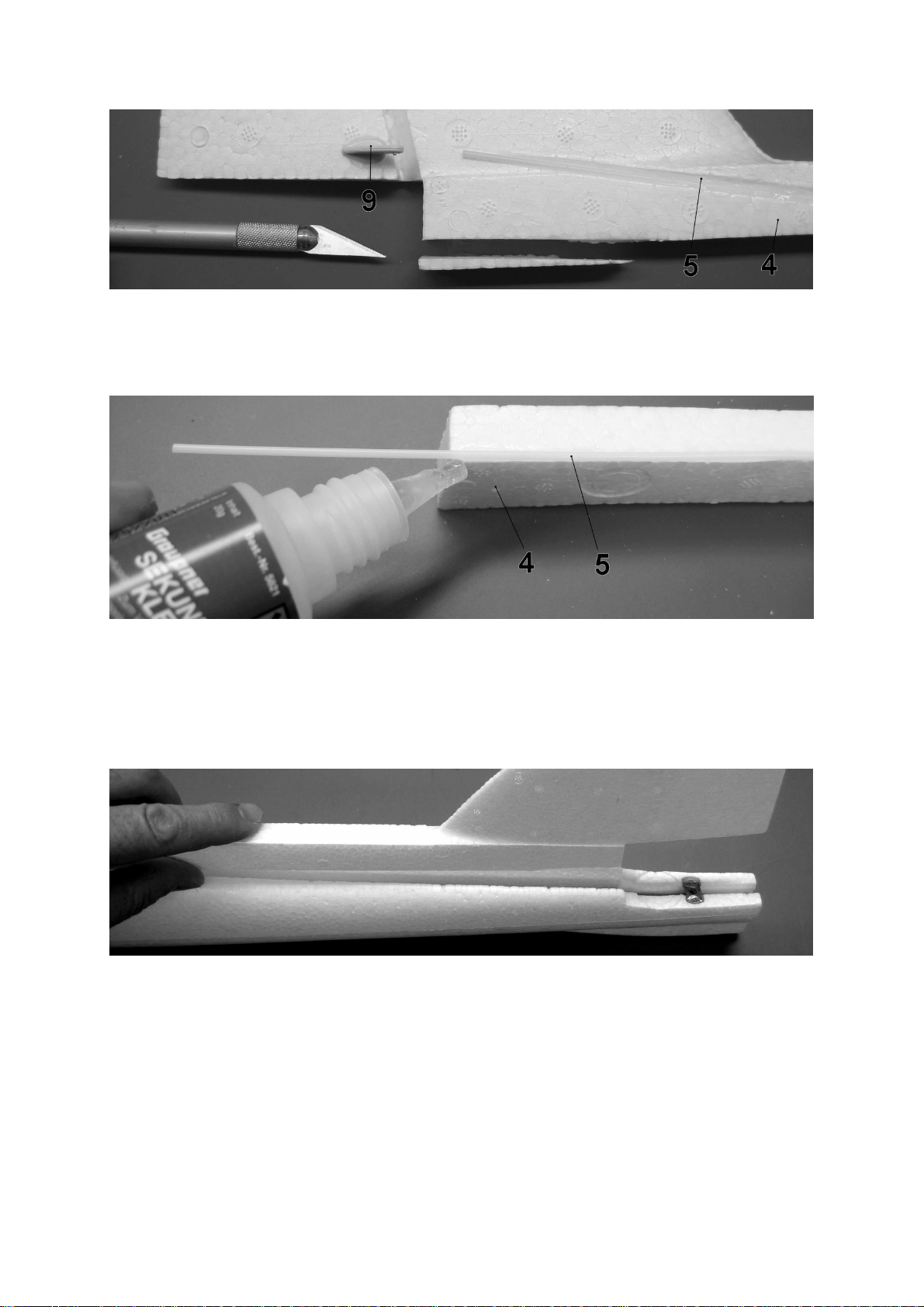

Cut off a 2 mm wide wedge from the fin (4), sand the joint surface of the rudder

snake outer sleeve (5) and glue it in place. Take care to glue the snake sleeve inside

its channel only. Don’t glue the horn (9) in place at this stage.

Glue the snake sleeve (5) to the underside of the fin at the front. Ensure that it ends

flush with the fin; it must not overlap the fuselage reinforcement (2) later, as this

would make it impossible to insert the fin (4) completely.

Temporarily slide the prepared fin into the fuselage; if there is a gap between the

fuselage and the fin, squeeze the fuselage sides together at the top.

The fin can now be glued in place. Caution: don’t use activator for this joint,

otherwise the parts will stick together before you have a chance to position

them correctly.

Apply cyano to the spruce strip (2) and the inside of the fuselage, then slide the fin

briskly into place. Ensure that it ends flush with the top of the fuselage, and makes

contact at the tail end.

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. Id.-Nr. 0062414 3/2011

- 5 -

Loading...

Loading...