Page 1

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

1

Re: Order No.9355

9355.M

Instructions

BO 209 MONSUN

For internal combustion motors up to 33 cm³

and

electric motors

Requires a HoTT radio control system with 5 functions

Page 2

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

2

Specification

Wingspan about 2200 mm

Fuselage without spinner about 1660 mm

Wing area about 62 dm²

Tailplane area about 12 dm²

Wing area about 74 dm²

All-up weight depending on equipment about 7700 g

EWD 0-0.5 degrees

Centre of gravity about 100 -110 mm behind the leading

edge

Caution: This model is not a toy!

If you do not have experience with such motorised models, please ask experienced

model flyers for help. If the model is operated without the proper knowledge, injuries

can result. Think of your health and safety.

Important! Before you start the assembly!

Even if you have already built lots of RC models, read these instructions through

carefully and check the parts in the kit for completeness. A lot of effort was made to

keep things as simple as possible without neglecting safety.

Note on the covering sheet

Because of strong changes in the weather (temperature, humidity, et cetera), small

creases can form in the covering sheet. In rare cases, the components can even be

warped. This lies in the nature of wood construction with covering sheet. This can be

corrected as follows using a hair dryer like those available to model builders.

Creases: Blow with hot air and rub with a soft cloth.

Warped area: Gently twist the area against the direction of warping and smooth

it out again using hot air.

Caution! Never use more heat than is absolutely necessary. If the iron is too hot, the

covering sheet will melt and holes will form.

The extensively pre-fabricated model can be built in a very short time. However, the

remaining steps are important and have to be carried out with care. Doing this work

properly determines whether the model will have the prescribed rigidity and flight

characteristics; so please work slowly and precisely!

When putting screws into wood, secure them against loosening by using

casein glue: Squirt casein glue into the drill hole and screw in the screw.

Page 3

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

3

Tips on building the model

• Before assembling the model, it is essential to read the construction diagram and

the instructions all the way through. When using tools, be aware of the possible

dangers.

• Use only suitable cables that are adequate for the electrical currents that occur

during operation.

• Set up the receiver aerial as far as possible away from the cables carrying the

operating current (at least 3 cm).

• Clean residual grease from all connections that are to be glued. This can, for

example, be done through sanding and using a non-relubricating cleaning

solution. The same goes for the surfaces to be painted, in order to make sure that

the paint sticks. Before gluing parts, always roughen the corresponding surfaces

(especially for GRP fuselages) carefully with fine sandpaper and de-grease them

thoroughly, for example with acetone. Otherwise, adequate adhesion is not

assured.

Other required accessories

Internal combustion motor and accessories

Recommendations for internal combustion motor

Motor

Order No.

Capacity

cm³

Propeller

Order No.

Petrol motor

GT 33

2772

33

45x25 cm

1314.18x10"

Recommendations for electric motor

Electric

motor

Order No.

Propeller

Order No.

Drive battery

Order No.

Speed

controller

Order No.

COMPACT

740 Z

7780

45 x 25 cm

1326.22x10

LiPo 3/5200

18.5/5.2Ah

9752.5

COMPACT

CONTROL

90S

7228

Radio control system

It must have at least 5 control functions and 9 servos. Furthermore, the

transmitter must be capable of servo rotation reversal.

Particularly recommended: Computer-System from MX-20 to MC-24. Servos with

standard dimensions can be installed.

As receiver battery, we recommend: Receiver battery LiFe 2/2900 6.6V JR Order No.

7672.2, which has to be carefully serviced before and after all flight operations. The

Page 4

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

4

capacity of the rechargeable battery can be checked with Graupner Battery GUARD

Order No. 7599. See also the insert included with the battery.

For the connection of the two ailerons and the landing flap servos to the receiver,

extension cables Order No. 3935.18 are required.

Each of the two aileron servo cables needs an extension cable, Order No. 3935.50;

the two landing flap servo cables Order No. 3935.18; the elevator servos Order No.

3935.50; and the bow landing gear servo Order No. 3935.50 for extension.

Receiver and battery: Store in foam material.

Any servo of standard size and an adjusting power of about 50 Ncm can be installed.

Adhesives

Epoxy glue, for example UHU plus schnellfest, Order No. 962

Epoxy glue, for example UHU plus endfest 300, Order No. 950.43

"UHU Holzleim express" casein glue, Order No. 958.60

UHU hart, for example Order No. 534.35

Fast setting glue, for example Order No. 5821

Fast-setting (cyano-acrylate) glue, such as Order No. 5822

Thread lock fluid, for example Order No. 952

Accessories for operation (not included)

Fuel, depending on the motor petrol/oil mixture (see instructions for the motor used)

Fuel hose, for example Order No. 1325.2

Manual fuel pump, for example Order No. 6870

Ignition battery, Order No. 8716.5

Charger cables and chargers for electric aircraft

Required tools (not included)

Various (Phillips) screwdrivers, needle-nose pliers, flat-nose pliers, wire cutter, balsa

knife or razor blade, various drills, pencil, felt marker, soldering iron with fine tip.

Assembly of the BO 209 MONSUN

Page 5

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

5

Wings - tailplane and rudder

Do not begin the assembly until you have familiarised yourself with the components

and the individual construction stages. If you are not satisfied with any component,

report it to your retailer before you start the construction process.

Using sandpaper or sanding block, sand the control horns on the surfaces to be

glued in order to achieve an adequate connection when gluing.

As seen in the photos, unstick the slots in the ailerons, landing flaps, rudder, and

elevators for the GRP control horns; put a dab of glue into the slot, and push the

control horn in until it stops.

Wipe off any excess glue.

Page 6

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

6

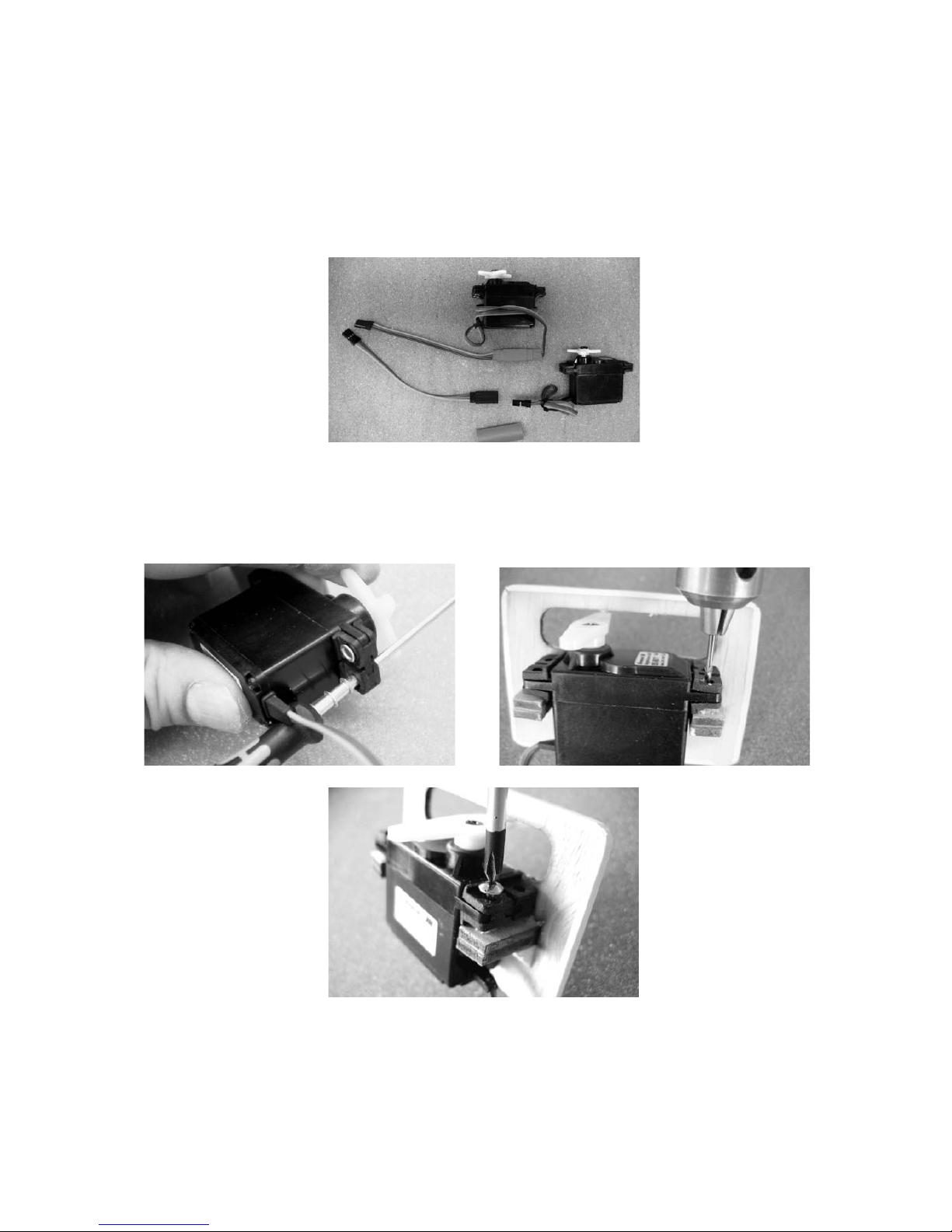

Until the glue hardens, the servos are installed in the corresponding mounts and

fastened into the wing or tailplane.

Extend the servo cables with the corresponding extension cables and secure them

against loosening, for example using a piece of heat-shrink sleeve or a drop of fastsetting glue. Using the RC system, bring the servos in the middle position and install

the servo levers.

Fasten the servo to the attachment block using the screws included with the servos.

To do so, insert the rubber grommets with the brass hollow rivets, collar downward,

into the servo flange. For drilling Ø 1.5 mm holes for the screws, the hollow rivets can

be used as a drilling template. To make it easier to push them in,

the hollow rivets can be placed onto a screwdriver of the proper size.

Now the servo cables are pulled into the wing halves and tailplane halves using a

thin string. Just behind the connector, tie the string to the cable and pull it in so that it

comes out the wing root.

Page 7

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

7

With servo and rudder in neutral position, screw together the lengths of the rods for

the ailerons, landing flaps, and elevators, adjust them, and use thread lock fluid (such

as UHU schraubensicher) and lock nuts to secure them against loosening.

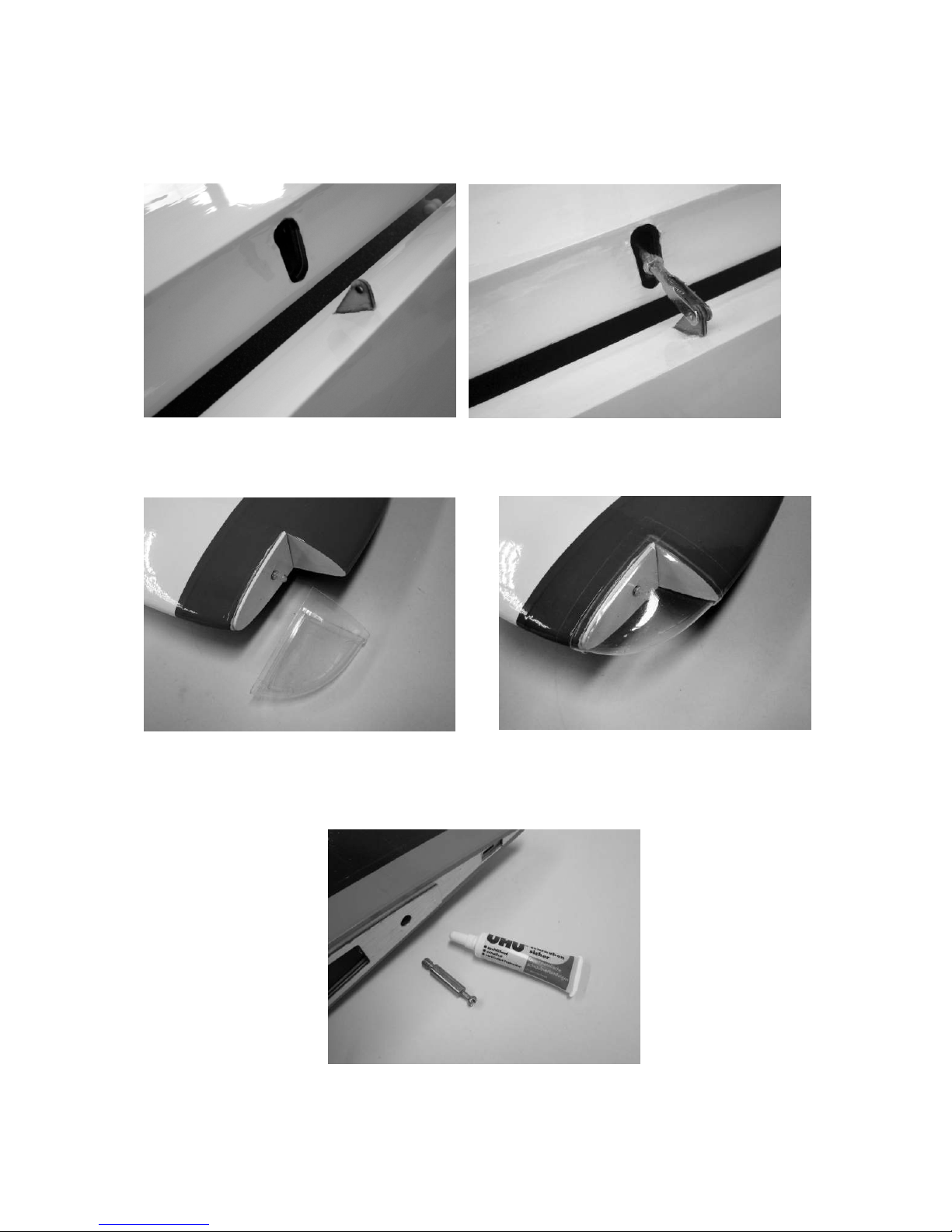

As shown in the photo, secure the hinges for the landing flaps using heat-shrink

tubing.

On the underside of the wings, there are markings indicating where the flap hinges

can be screwed in. Make sure that the axes of rotation of the hinges are all the same

distance from the trailing edge of the wing.

As shown in the photo at the left, a screw is used to fix the hinges in place; then use

an engineer's square or geometric protractor for alignment with the trailing edge, and

fasten the hinges with two more screws. Now push the landing flaps up against the

wings and tape them in place temporarily; align them, and fasten them with screws.

Page 8

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

8

Screw the pushrods together as shown in the following photos.

Adjust the transparent covers of the wing tip lights and use transparent adhesive film

to attach them to the wings.

The bolts used to secure the wing are screwed into the corresponding holes in the

wing roots. Use UHU schraubensicher thread lock fluid to secure the bolts against

loosening.

Page 9

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

9

As shown in the photos, glue the boarding steps together and fasten them to the

wing halves using the plywood tabs.

Later, the boarding steps can be removed in order to transport the wings by pulling

out the plywood tabs.

Fuselage with vertical stabiliser and undercarriage

The vertical stabiliser can either be glued permanently to the fuselage or fastened

removably using two screws.

Page 10

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

10

The tailplane is installed to the fuselage from underneath using three Allen screws.

The screws are screwed in only tight enough to pull the tailplane and vertical

stabiliser firmly against the fuselage.

Attach the pull cables to the control horn of the rudder as shown in the photo.

Then attach the rudder servo to the servo plate at the front of the fuselage.

As shown in the photo, install the pull cables to the servo lever and adjust them so

that the rudder is in the centre position when the servo is in the centre position.

Page 11

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

11

Screw the aero-tow mechanism into the hole just behind the canopy, and apply UHU

thread-lock fluid to prevent the coupling and nut from working loose.

The aluminium part must be shortened enough so that the clevis can move freely;

adjust the rods accordingly. It is best to operate the aero-tow release mechanism

using a momentary switch mounted on the joystick. The servo travel must be set

accordingly.

Fix the nose gear in the brackets by tightening the screw in the collet. Assemble the

pull cables as shown in the photo. As for the rudder, make sure that when the servo

is in the middle position, the nose gear is also in neutral position, meaning that the

model will later roll straight ahead.

Now the nose wheel is installed along with the cover. To do so, unscrew the fork and

re-install it together with the cover. To install the wheel, a hole of about Ø 9mm must

be drilled/filed into the left side of the cover about 5 mm from the underside.

Page 12

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

12

Later the nose gear steering servo and the rudder servo can be connected to the

same receiver socket either using a Y-lead or via a mixer at the transmitter.

The servo for the rudder control horn, as already described in the beginning, is

installed in the servo mount. Fasten it to the side wall of the fuselage with the four

pan-head self-tapping screws.

Prepare the rudder linkages and attach them to the control horn and servo levers as

shown in the photo. Here too, make sure that the elevator is in the neutral position

when the control servo is in the centre position.

Now, using two Allen screws each, the two main undercarriage components

are fastened to the bottom of the fuselage.

To install the two main wheels and covers, a hole must be drilled/filed in each of the

covers about 15 mm from the lower edge and centred with the cut-out. Remember

that a left and a right cover are needed. To reinforce the covers, one of the included

plywood reinforcements is glued to the inside of each cover. Make sure that the drill

holes of the reinforcements and covers line up. This can be done by inserting the

wheel axle.

Page 13

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

13

After the glue has set, the axles together with the wheels and collets are installed and

fastened to the undercarriage components.

Align the covers so that they are fastened parallel to the ground.

Installing the tank and motor

Assembling and installing the fuel tank

Slip a piece of plastic tubing onto the fuel tank clunk pick-up. Push the free end of the

fuel tubing onto one of the tubes in the fuel tank stopper so that the pick-up will be able

to move freely inside the tank later on without binding or jamming when the stopper is

in place. Use a heat-gun or lighter to gently heat the free plastic tubes so that they can

be bent easily. One tube should face down and will be used later to fill the tank; the

other one points upward and serves later as the overflow when the tank is filled. Use a

piece of tubing to extend the two tubes so that they reach to the top and bottom of the

tank.

Now push the tank stopper over the throat of the fuel tank, and tighten the Philips-head

screw to fasten the stopper in place. It is important to tighten the screw so that the tank

is completely sealed. This can be checked by holding the tank under water. Hold it

under water and blow air into it. If the tank is sealed, there will be no air bubbles.

To each stub tube projecting from the

fuel tank, a length of fuel tubing is

connected.

Mark the tubes with a felt marker to show

which runs to the motor, the overflow,

and the filler.

The tube from the clunk is then

connected to the carburettor, while the

overflow is run downward. The fuel filler tube can later be routed out through a drill

hole in the engine bonnet. After filling, it should be sealed with a plug.

Page 14

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

14

The attachment block is fastened with two screws.

The installation of the OS MAX GT 33 is described here, but the process

is the same for other motors.

To install the internal combustion engine, the fuselage is placed on the

undercarriage. Using the Allen screws and aluminium bushing provided, attach the

internal combustion engine to the bulkhead.

Attach the servo lever of the throttle servo to the linkage connector. Make sure that it

can turn without any noticeable play. Servo lever about 13 mm.

Fasten the servo to the board using the screws included with the servo.

The throttle linkage is attached to the carburettor lever using the double-cranked

section. With half open carburettor and servo in the middle position, the pushrod is

fixed to the linkage connector using the grub screw.

Page 15

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

15

The throttle rod is adjusted so that the carburettor is half open when the servo is in

centre position. The servo travel must be adjusted so that the engine stops when the

throttle stick and trim are at the full back position.

Install the rods for the choke flap as shown in the photo. The end is angled so that it

can be activated later through the opening in the engine bonnet. Do not let it get into

the propeller arc.

The silencer is attached to the motor using the included two bolts and seal.

Depending on the motor used - for the silencer outlet, spark plug, cylinder head, et

cetera - it is necessary to cut or file openings in the engine bonnet. Position the

engine bonnet on the fuselage in such a way that there is about 2 mm clearance

between the spinner base plate and the front edge of the bonnet.

To attach the engine bonnet to the fuselage, the four attachment points also have to

be marked on the engine bonnet. To do so, cut four strips of scrap wood and drill a Ø

3 mm hole in each one as shown in the photo.

Now each strip is fastened to the

fuselage using an M3 Allen screw and

taped in place as shown in the photo.

Page 16

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

16

Unscrew the Allen screws, then push up the engine bonnet so that it moves under

the strips and the spinner base plate is about 1.5-2 mm from the engine bonnet. In

this position, mark the four attachment points on the engine bonnet.

The engine bonnet is attached with four the Allen screws.

Installation of the electric motor

The electric motor is attached to the bulkhead using the included motor bulkhead,

bolts, nuts, cylindrical aluminium bushings, and sections of the aluminium pipe.

Page 17

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

17

The distance between bulkhead and spinner base plate should be the same as for

the internal combustion engine. Accordingly, four pieces of equal length must be cut

from the aluminium pipe.

As shown in the photo, the motor then rests upon four stilts. The four hexagonal bolts

must be cut off flush with the nuts.

Depending on the electric motor used, mark the fastening points on the motor

bulkhead and attach the electric motor.

The speed controller for the electric motor is fastened to the bulkhead as shown in

the photo.

Cockpit canopy

Glue the seat backs and pilot figure in the proper positions as shown in the following

photo.

The parts should be affixed using double-sided tape, such as Order No. 2904.

The cockpit canopy is attached using transparent tape all around.

The final work on the model consists of fitting and gluing the navigation lights and

decals. To position the individual name placards correctly, refer to the illustrations on

the carton.

Page 18

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

18

Balancing the BO 209 MONSUN

The completely equipped model, with the fuel tank empty, should balance level when

supported at a point about 100 - 110 mm aft of the leading edge of the wing, ideally

in inverted flight position. If the centre of gravity is correct, the model should balance

out horizontally or with the nose pointing slightly downward. If necessary, adjust the

centre of gravity by shifting the position of the receiver batteries. Before flying the

aircraft, set the transmitter trims to centre and ensure that all the control surfaces are

also exactly centred (in neutral position).

Rudder deflection for normal flying

Ailerons 35 mm up and 15 mm down

Elevators 25 mm up and down

Rudder 75 mm left and right

Landing flaps Take-off 15 mm down

Landing 60 mm down

We recommend that you set exponential values of 30% at the transmitter.

Important:

When assembling the rods, always take care to ensure that they move freely and can

move through their entire controllable path - including trim travel - and are not

mechanically impeded.

When the joystick moves to the right, the rudder must turn to the right (left stick/left

rudder). When the elevator stick is pulled back, toward your stomach, the elevators

must deflect upward (stick forward = elevators down). If the aileron stick is moved to

the right, the right aileron should move upward; the left aileron downward. When the

throttle stick is pushed forward, the motor must run at full power; if the throttle stick

and trim are moved back to their end-points, the engine must stop. If the trim travel is

moved all the way back, the motor must stop. The landing flaps are best activated via

a three-position switch.

All that remains is to wish you many hours of happy flying with your BO 209

MONSUN.

Your Team !

Safety notes and warnings

Regarding motorized aircraft models with internal combustion engines

• Before you first attempt to fly the model, it is essential to carefully read all

the operating and assembly instructions.

• These safety notes are part of these instructions and must be stored

carefully with the operating instructions and, if the model is passed on to

others, they must also be passed on to the next user.

Page 19

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

19

• Motorised models are very demanding and dangerous objects and require

that the user have great expertise, skill, and a sense of responsibility.

• Motorised models are not suitable for persons under 18 years of age.

• They may be operated only under the instruction and supervision of an

adult who is familiar with the attendant hazards.

• The operator of the model must be in full possession of his or her bodily

and mental faculties. As with car driving, operating a model aircraft under

the influence of alcohol or drugs is not permissible under any

circumstances.

• Radio controlled aircraft models may be used only for the purpose intended

by the manufacturer; meaning not as a sporting device designed to carry

people. Any other use is forbidden.

• A model can only work properly and fulfil your expectations if it is built or

assembled with the greatest of care and in accordance with the assembly

instructions. Independent changes in design or materials are not permitted.

To avoid injuring people and damaging property, it is essential to be careful

and thoughtful when operating your model. Nobody would climb into a fullsize sports aircraft and attempt to fly it without undergoing training

beforehand. Model flying is also something that has to be learned! We

suggest that you ask an experienced model flyer for help, or join a model

club or model flight training school. Your local model shop and the

specialist magazines are excellent sources of information.

• Always observe the information on the centre of gravity and on control

surface deflection! The model must be adjusted accordingly.

• Radio control system: Make sure the frequency used is vacant. Do not

switch on until you are sure! Check the RC system frequently; it too is

subject to wear. Radio interference caused by unknown sources can occur

at any time without warning. Your model will then be uncontrollable and

completely unpredictable. Never leave your radio control system

unattended, as another person might pick it up and try to use it. To ensure

proper operation of your RC system, make sure that the batteries are kept

fully charged.

• Do not ignore warnings! They refer to materials and situations, which, if

ignored, can - in extreme cases - result in fatal injury or permanent damage.

• You alone are responsible for the safe operation of your model and motor.

• Questions regarding the safe operation of model and motor can be

answered by your retailer.

• Propellers and all rotating parts that are powered by a motor pose a

constant risk of injury. Do not touch them with any part of your body! For

example, a propeller spinning at high speed can cut off a finger!

• Always keep well clear of the rotational plane of the propeller! You never

know when some part may come loose and fly off at high speed and with

great energy, hitting you or a third party. Make sure that no other object can

come into contact with the rotating propeller.

• Be careful with loose clothing, such as scarves, loose shirts, et cetera: They

can be sucked in by the propeller stream and get in the way of the propeller

itself.

Page 20

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

20

• If there are passers-by or spectators at your flying site, make sure that they

are aware of the dangers inherent in your activity before you start the

motor, and insist that they keep a safe distance away (at least 5 m).

• Model aircraft may be flown only at "normal" outside temperatures,

meaning in a range of - 5º C to + 35º C; more extreme temperatures can lead

to changes, for example in battery capacity and material characteristics, et

cetera.

• Model fuel is poisonous! Do not let it come into contact with eyes or mouth!

Store only in clearly marked containers out of the reach of children.

• Never run the motor in closed rooms, such as basement, garage, et cetera.

Model motors also produce deadly carbon monoxide gas.

• Operate only outdoors!

• Adhesives and paints contain materials which may be hazardous to health

under certain circumstances. You should therefore observe the notes and

warnings supplied by the manufacturers of these materials.

• Model fuel is highly flammable and combustible; keep away from open

flames, excessive heat, any sources of sparks or other things that could

lead to ignition. Do not smoke in the direct vicinity of fuel or fuel fumes.

• During operation, a model motor develops a great deal of heat. Motor and

shock absorbers are therefore very hot during operations and for a while

afterwards. Touching them can result in serious burns. Careful when

making adjustments! Wear protective gloves! In extreme cases, even fires

can be caused.

• While operating the motor, not only poisonous and hot exhaust emanates

from the exhaust pipe but also very hot liquid combustion residue, which

can result in burns.

• After operation, remove residual fuel from the tank and motor.

• Every time you intend to operate your model, check carefully it and

everything attached to it (for example propellers, control surface linkages,

rudders, et cetera) for possible damage. If you find a fault, do not fly the

model until you have corrected it.

• The motor is started with an electric starter, which may be equipped with an

adapter that fits the model. For fixed-wing aircraft, startup aid can also be

provided, for example, by a wooden rod with a piece of water hose attached.

• During operation, model motors may develop noise far greater than 85 dB

(A); always wear protection for your ears. Never start motors without a

silencer. However, even with a silencer, model motors can disturb

neighbours. Don’t run motors when people expect peace and quiet.

• If the propeller is turning while the model is standing on sandy ground, for

instance, the propeller can suck up sand and dust and hurl it around, and it

could get in people's eyes. Wear protective goggles!

• Take care that the spark plug clip and the lead can not get tangled in the

turning propeller or other rotating parts. Check the throttle linkage, too.

• Take particular care when carrying the model with the engine running. Hold

the rotating parts well away from you!

• Always keep an adequate supply of fuel in the tank. Never continue to fly

the model until all the fuel is used up.

• Never fly directly over people.

Page 21

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

21

• Never fly directly towards people.

• Make sure to keep a safe distance from residential areas: at least 1.5 km “as

the crow flies”. It is always best to join a club and fly at the approved model

flying site. Always keep well clear of high-tension overhead cables.

• Whenever working on the engine, make sure that you have secure footing,

and always hold the model securely.

• When starting and landing, the take-off and landing strips should be kept

free of unauthorised people and movable obstacles.

• The model aircraft must be kept constantly in sight during the entire flight. It

must always give way to manned aircraft.

• Never operate your aircraft from public roads, squares, squares, school

playgrounds, parks, or sports grounds, et cetera, and ensure that you are

always in full control of the model.

• To ensure that you can stop your engine at any time, the throttle must be

adjusted so that the carburettor barrel closes completely when the throttle

stick and trim are moved to their end points. If this does not work, pinch the

fuel line between your fingers or pull off the connecting tube to the tank.

Never try to stop the engine by grasping the flywheel, propeller, or spinner!

• All model fliers should take care to ensure that the public safety, especially

that of people and property, as well as orderly flying operations, are not

endangered or disturbed.

• In legal terms, model aircraft are classed as aircraft and as such are subject

to legal regulations and restrictions that must be observed.

• The brochure “Modellflugrecht, Paragrafen and mehr” (Model Aviation Law,

Legal Requirements and more), Order No. 8034.02 contains a summary of all

these rules, and your local model shop should also have a copy which you

can read. For models with internal combustion engines, it is necessary, for

example, to have the landowner's permission for flights, and insurance is

also mandatory. There are also regulations concerning your radio control

system that must be observed.

• These notes are intended only to make you aware of the many dangers and

hazards that can arise if you work carelessly or irresponsibly. If you take

reasonable care, model flying is a highly creative, instructive, and relaxing

pastime.

• The extensively pre-fabricated model can be built in a very short time.

However, the remaining steps are important and have to be carried out with

care. Doing this work properly determines whether the model will have the

prescribed rigidity and flight characteristics; so please work slowly and

precisely!

•

Important safety notes

You have acquired a kit that can be assembled into a fully working RC model when

fitted out with suitable accessories. However, GRAUPNER has no control over

whether you observe the instructions for the installation and operation of the model or

the use and maintenance of the associated components. For this reason

GRAUPNER assumes no liability for loss, damage, or costs, which are incurred due

to the incorrect use of our products or due to improper behaviour on the part of the

user, or which are connected with such operation in any way. Unless otherwise

Page 22

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

22

prescribed by binding law, the obligation of GRAUPNER to pay compensation for any

reason whatsoever (including personal injury, death, damage to buildings, damage

due to loss of business or turnover, interruption of business, or other direct or indirect

consequent damage) stemming from the operation of the model is excluded.

The total liability in all cases and under all circumstances is limited to the amount of

money that you actually paid for this model.

This model is started up and operated at the sole and exclusive risk of the

operator. To avoid injuring people and damaging property, it is essential to be

careful and thoughtful when operating your model.

According to the new regulation of §103 paragraph 3 of the LuftVZO (German

Aviation Approvals Office), all model aircraft - whether slow flyer, park flyer, glider, or

model aircraft propelled by any form of power plant - must be insured before the

model is operated. Therefore, you should purchase special RC model liability

insurance. Your local model shop will be glad to advise you.

These safety notes must be kept in a safe place, and, if you ever sell the model, must

be passed on to the buyer.

Manufacturer’s declaration:

If material defects or manufacturing faults should arise in a product distributed by us

in the Federal Republic of Germany and purchased by a consumer (§ 13 BGB), we,

Graupner GmbH & Co. KG, Kirchheim/Teck, Henriettenstraße 94-96, Germany,

acknowledge the obligation to correct those defects within the limitations described

below.

The consumer is not entitled to make claims under this manufacturer’s declaration if

the failure in the usability of the product is due to natural wear, use under competition

conditions, incompetent or improper use (including incorrect installation), or external

influences.

This manufacturer’s declaration does not affect the consumer’s legal or contractual

rights regarding defects arising from the purchase contract between the consumer

and the vendor (dealer).

Extent of the guarantee

If a claim is made under guarantee, we undertake at our discretion to repair or

replace the defective goods. We will not consider further claims, especially for

reimbursement of costs relating to the defect (such as installation / removal costs)

and compensation for consequent damages unless they are allowed by statute. This

does not affect claims based on legal regulations, especially according to product

liability law.

Guarantee requirements

The purchaser is required to make the guarantee claim in writing and must enclose

original proof of purchase (such as invoice, receipt, delivery note) and this guarantee

card. The purchaser must send the defective goods to us at his own cost, to the

above-mentioned address.

Page 23

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

23

The purchaser should state the material defect or manufacturing fault or the

symptoms of the fault in as accurate a manner as possible so that we can check

whether our guarantee obligation is applicable.

The goods are transported from the consumer to us and from us to the consumer at

the risk of the consumer.

Duration of validity

This declaration only applies to claims made to us during the claim period as stated

in this declaration. The claim period is 24 months from the date of purchase of the

product by the consumer from a dealer in the Federal Republic of Germany (date of

purchase). If a defect arises after the end of the claim period, or if the evidence or

documents required according to this declaration in order to make the claim valid are

not presented until after this period, then the consumer forfeits any rights or claims

from this declaration.

Limitation by lapse of time

If we do not acknowledge the validity of a claim that is properly made under this

declaration within the claim period, all claims based on this declaration expire after

six months from the time of claim, but not before the end of the claim period.

Applicable law

This declaration, and the claims, rights and obligations arising from it, are based

exclusively on the applicable German Law, without the norms of international private

law, and excluding UN retail law.

The following items must be observed:

• Before you fly the model, check that the radio control system is working reliably,

and that all connections are secure.

• If you intend to use dry cells as a power supply, please note that they must never

be recharged. Only rechargeable batteries can be re-charged.

• The batteries must be charged, and the range of the radio control system must

have been checked. In particular, the transmitter and receiver batteries must be

charged before each take-off.

• Ensure that the channel you intend to use is not already in use. Never fly the

model if you are not certain that your channel is free.

• Observe the instructions and information regarding your radio control system and

accessories.

• Ensure that the servos are not mechanically obstructed at any point in their travel.

• Dry cells and rechargeable batteries must never be short-circuited.

• Remove all batteries before transporting and storing the model.

• Do not subject the model to intense humidity, heat, cold, or to dirt.

• Protect the model and RC equipment against damage during transport.

Page 24

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. Not liable for printing errors!

12/2011

24

Pre-flight check

Check for correct functioning and range before every flight. To do so, screw in the

transmitter aerial and extend it fully. Then switch on the transmitter, followed by the

receiver. At an appropriate distance, make sure that all the control surfaces are

working properly and deflecting in the correct direction.

Repeat the check with the motor running, while someone holds the model securely

for you.

The first time you control a model aircraft, it is best to ask an experienced person to

help you with the pre-flight check and during the first few flights.

Care and maintenance

• Clean the model carefully after each use. Also remove any dirt from the propeller.

Clean the model and the RC components using suitable cleaning agents only.

Ask your model shop for information.

• If the model is not to be operated for a considerable time, all the moving parts

must be cleaned and re-lubricated.

Loading...

Loading...