Page 1

1

For order nos. 41900

41910

Assembly Instructions

ALPINA 3001 CHAMP PRO

High Performance Model Glider

for

Flatfield, Slope and Aerotow

Minimum of a 5-channel radio control system is required!

#62624

Page 2

2

Technical Data

Wingspan 3001 mm

Fuselage length 1420 mm

Airfoil profile TA-30-Strak 8,3 %

Elevator profile 10 %

Wing area 48,2 dm²

Elevator area 4,2 dm²

Flight weight, from 2200 g

Longitudinal dihedral (deg) 1° - 1,3°

Centre of gravity (from root leading edge) 84-88 mm

Important Safety Advice

You have purchased a model aircrraft kit which can be used to build a fully functional

radio control model, together with the nessesary aditional parts and accessories. The

tit manufacturer GRAUPNER have no control over customer compliance with

assembly and operating instructions as well as the installation, operation, use and

maintenance of the components associated with the model. Therefore GRAUPNER

accept no liability for losses, damages or costs which arise from operational or

behavioural errors or which are in any other way connected with the aforementioned

kit. If not stipulated by law the company GRAUPNER is under no obligation to pay

compensation for whatever reason, including personal injuries, death, damage to

buildings as well as damages caused by loss of turnover or business, by interruption

of business or other indirect or direct consequential damages resulting from the

operation of the model aircraft. Under all circumstances and in any case the total

liability is limited to the amount that has actually been paid for this model.

The assembly and operation of the model is undertaken solely at the operator’s risk.

Cautious and considerate handling on the part of the user when operating the aircraft

is essential in order to prevent personal injuries and damage to property.

During the construction phase

Please observe the safety and handeling instructions of the manufacturers when

handling adhesives and solvents. Some adhesives and solvents can cause health

problems and material damage if not used correctly. Dispose of leftover glue and

paint safely by returning them to a specialist dealer or taking them your local waste

disposal collection site. Be aware that handling sharp balsa knives and pins can

easily lead to injuries. Ensure that children have no access to tools, glues or

varnishes.A generously sized clear working space is a particular advantage for all

handicrafts.

Please seek the advice of an experienced aero-modeller for assistance with

any aspect of the construction processes with which you are unfamiliar.

Flight Operations

Never fly your ALPINA 3001 CHAMP PRO in nature reserves or landscape

conservation areas. Always give due consideration to the habitats of animals and

plants as trees. Bushes and shrubs serve birds for nesting and bringing up their

young.

Page 3

3

You may want to consider taking out a special RC-model liability insurance if

applicable. These safety instructions must be kept safe for future reference and

handed to the buyer in case of the resale of this model aircraft.

Manufacturer’s Declaration:

Should any item sold by us in the Federal Republic of Germany and purchased by a

consumer (§ 13 BGB) found to be faulty with regards to material or workmanship, we,

the manufacturer Graupner GmbH & Co KG, D 73230 Kirchheim/Teck will take

responsiblity for the correction of faults of the item to the extent as described

hereafter. The consumer cannot assert rights from this declaration if the impairment

of the usability of the item results from natural wear and tear, use under competitive

conditions, improper use (including installation) or effects of external factors.

This manufacturer’s declaration does not affect the legally or contractually granted

claims for defects and statutory rights of the consumer towards the seller (dealer)

arising from the contract of purchase.

Extent of Warranty

In the event of a warranty we will at our discretion either repair or replace the faulty

goods. Further claims, especially claims for refunding costs in connection with the

defect (e.g. costs for installation or removal) and compensation for consequential

damages – where permitted by law – are excluded from warranty. Claims from legal

regulations, especially in accordance with the product liability law, are not affected by

this.

Conditions of Warranty

The buyer must claim under warranty in writing, enclosing the original proof of

purchase (e.g. invoice, receipt, delivery note) and this warranty card. In addition the

faulty goods must be posted to the above address at the buyer’s expense.

The buyer should describe the material or processing fault or the symptoms of the

fault as precisely as possible in order to enable us to check our duty of warranty.

The transport of the item from the consumer to us as well as its return are effected at

the consumer’s risk.

Period of Validity

This declaration is only valid for claims based on this declaration which are asserted

during the entitlement period. The entitlement period is 24 months from the date of

purchase of the model by the consumer when purchased from a dealer in the Federal

Republic of Germany. If faults are reported after the expiry of the entitlement period

or if the proofs or documents which are required in this declaration for the assertion

of claims due to faults are submitted after the expiry of the entitlement period, the

buyer is not entitled to any rights or claims specified in this declaration.

Limitation of claims

If we do not accept a claim stated in this declaration which has been asserted in due

form during the entitlement period, any claims based on this declaration lapse six

months from the date of assertion, but not before the end of the entitlement period.

Page 4

4

Applicable law

German material law applies exclusively to this declaration and the claims, rights and

duties arising from it, excluding the provisions of international private law and UN

Sales Law.

The following points must always be observed:

• Check before launching the model that the remote control system is functioning

correctly and that all mechanical and ellectrical connections are secure.

• The batteries are fully charged and the range of the remote control system is

checked. In particular the transmitter and and receiver batteries must be charged.

• Check that the radio control channel in use is free. Never fly your model if you are

unsure whether the channel is free.

• Follow the recommendations and instructions supplied with your remote control

system and accessories.

• Ensure that all control servos are operating freely and not mechanically restricted.

• Batteries must not be short-circuited.

• Remove the batteries for transport and whenever the model is not in use.

• Do not expose your model to extreme temperatures, high levels of humidity or

dirt.

• Secure the model and RC-components during transport against damage or

slipping.

• IMPORTANT: The model’s built-in battery must not be disposed of with

household waste. The battery must be disposed of in battery recycling containers.

• IMPORTANT: The model and the transmitter must not be disposed of with

household waste, but must be taken to a recycling depot for disposal as electronic

scrap. Contact your local council for further information.

Pre-Flight Checks

Before each flight check the correct function and range of the radio control system by

switching on the transmitter as well as the receiver, extend the transmitter antenn

and check from an appropriate distance that all control surfaces are operating

correctly, both in terms of magnitude and sense.

Depending on your level of experience and particularly in the case of the first flighgts,

it is advantageous to have an experienced helper by your side to offer assistance

with the pre-flight checks and first flights.

Care and Maintenance

• Clean the model after each flight. Only use suitable cleaning products for cleaning

the model and the RC-components. Contact your specialist dealer for information

about this.

• When cleaning decor print products (decor sheets, design foils) detergents which

contain solvents must not be used as they can damage or destroy prints. Please

use warm soapy water and a soft cloth for cleaning.

Page 5

5

Notes about the construction of the model

Before commencing the construction of the model you should take time to read

through these instructions in their entirety. Be particularly aware of potential dangers

when using sharp tools.

Remove any grease residue from each adhesive joint before bonding. This can for

example be achieved by sanding and treating with a non-relubricating detergent.

Before glueing together parts ensure that the relevant surfaces (especially with

regards to the fibreglass fuselage) are carefully roughened with a suitable grade

sandpaper and thoroughly degreased, e.g. with acetone. Otherwise sufficient

adhesion cannot be guaranteed.

Necessary tools for the construction of ALPINA 3001 CHAMP PRO

Pencil (lead grade HB), a set square as well as a tape measure or meter rule,

household scissors, a narrow sharp knife such as e.g. a balsa knife, order no. 980,

an electric miniture and assorted drill bits.

Glueing of materials

The following table lists some examples of adhesive connections. This list by no

means claims to be complete.

Material Usage (example) Adhesive Type

Order no.

_________________________________________________________________

Glass-fibre Canopy cover with fixing wire UHU plus endfest 300

reinforced polymers order no. 950.43

with steel

wire

Glass-fibre Fuselage with servo board UHU plus endfest 300

reinforced polymers order no. 950.43

with wood

Note:

Roughen the surfaces to be glued in the fuselage with fine-grained sandpaper to

remove any adhesive release agents. Wipe off any grinding dust. The glossy surface

of the fuselage must be rendered matt as otherwise good bonding of the adhesive

with the fuselage cannot be guaranteed. For information about bonding the

individual parts to one another follow the processing instructions of the adhesives.

When using adhesives containing solvents ensure that your work area is well

ventilated. Follow the instructions provided by the manufacturers.

Page 6

6

Important Note

No adhesives which contain solvents, in particular no superglue, must be used

for any glueing which comes into contact with the polystyrene in the wings

cores. These adhesives lead to the large-scale destruction of the styrofoam; the

part consequently becomes unusable. Always use solvent-free adhesives for

this process. We recommend glueing with UHU-Endfest or epoxy resin

thickened with cotton flocks. However, do avoid using 5 min Epoxy for

bondings which are relevant for statics or control technology!

Tip: Using with Epoxy Resins

Epoxy alone is not a viable adhesive! However, the addition of appropriate

additives turns laminating resin into a variety of excellent adhesives. Choose

the appropriate additive to create an adhesive which perfectly matches the job

requirements:

1. Chopped cotton fibre flocks produce a tough, but flexible bond.

2. Superfine glass fibres produce a very hard, but well grindable bond.

3. Micro-balloons produce a highly effective, lightweight filler.

Radio Control System

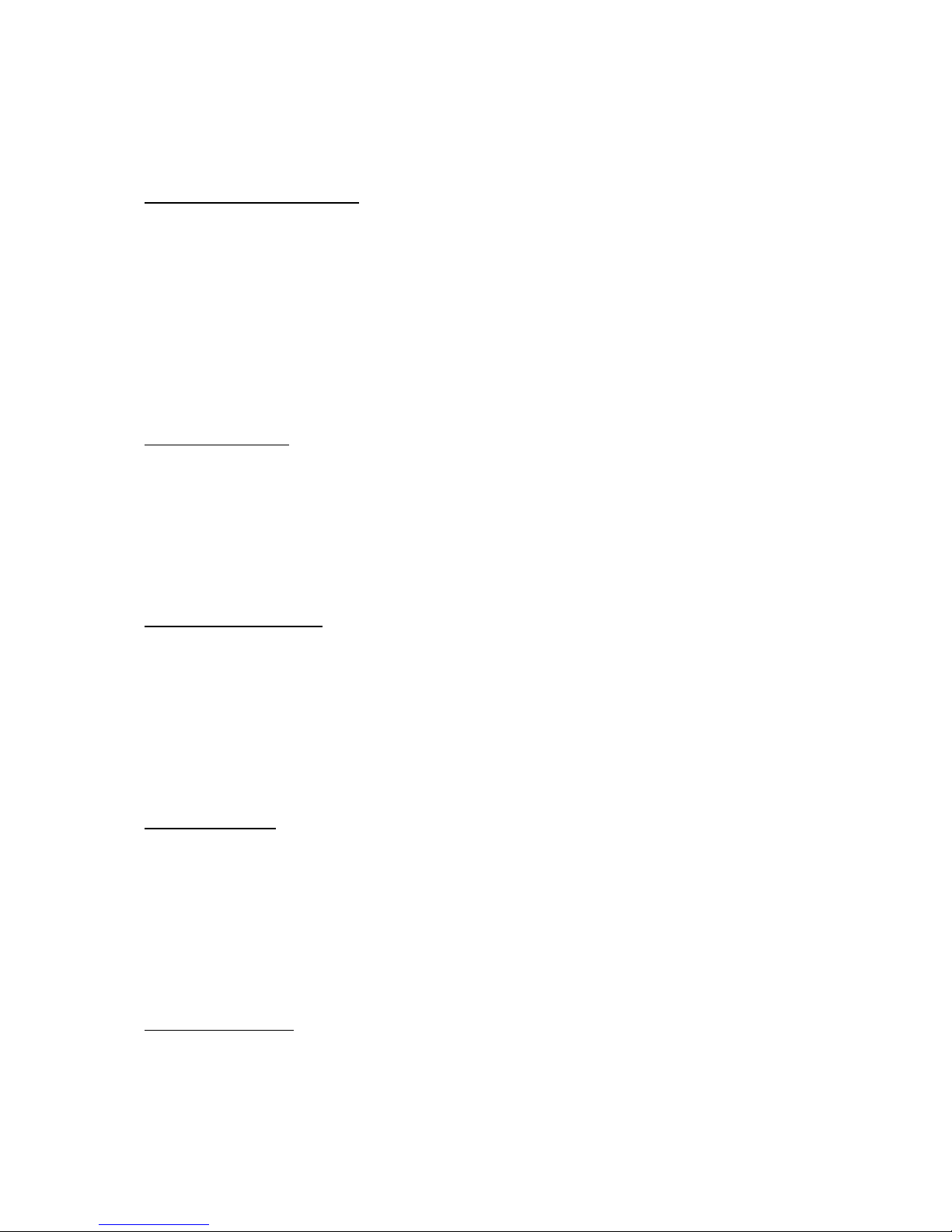

Especially recommended: Computer system from mc-12 to mc-24

or

Page 7

7

Recommended servos for:

Rudder and DES 678 BB,MG order no. 7943

Elevator

Ailerons and DES 448 BB,MG order no. 7914

Wing flaps

Receiver power supply PRX-3A order no. 4135

As receiver a DS 19 or SMC 19 or SMC 14 can be used

Required servo extension cables

Order no. 3935.18 for connection to receiver (4 pieces)

For the receiver battery we recommend: Order no. 7674.2 which must always be

properly maintained and charged before and after each flight, i.e. the battery ought to

be be discharged and re-charged several times until it reaches the full specified

capacity.

Re-chargeable batteries are recommended for the receiver and transmitter as they

provide the highest level of safety. For suitable battery chargers see our catalogue.

Assembling the ALPINA 3001 CHAMP PRO

Only begin the assembly after you have familiarised yourself with the individual

components and construction stages. In the event that a component should give

reason for complaint this should be communicated to your specialist dealer prior to

the start of construction.

The wings

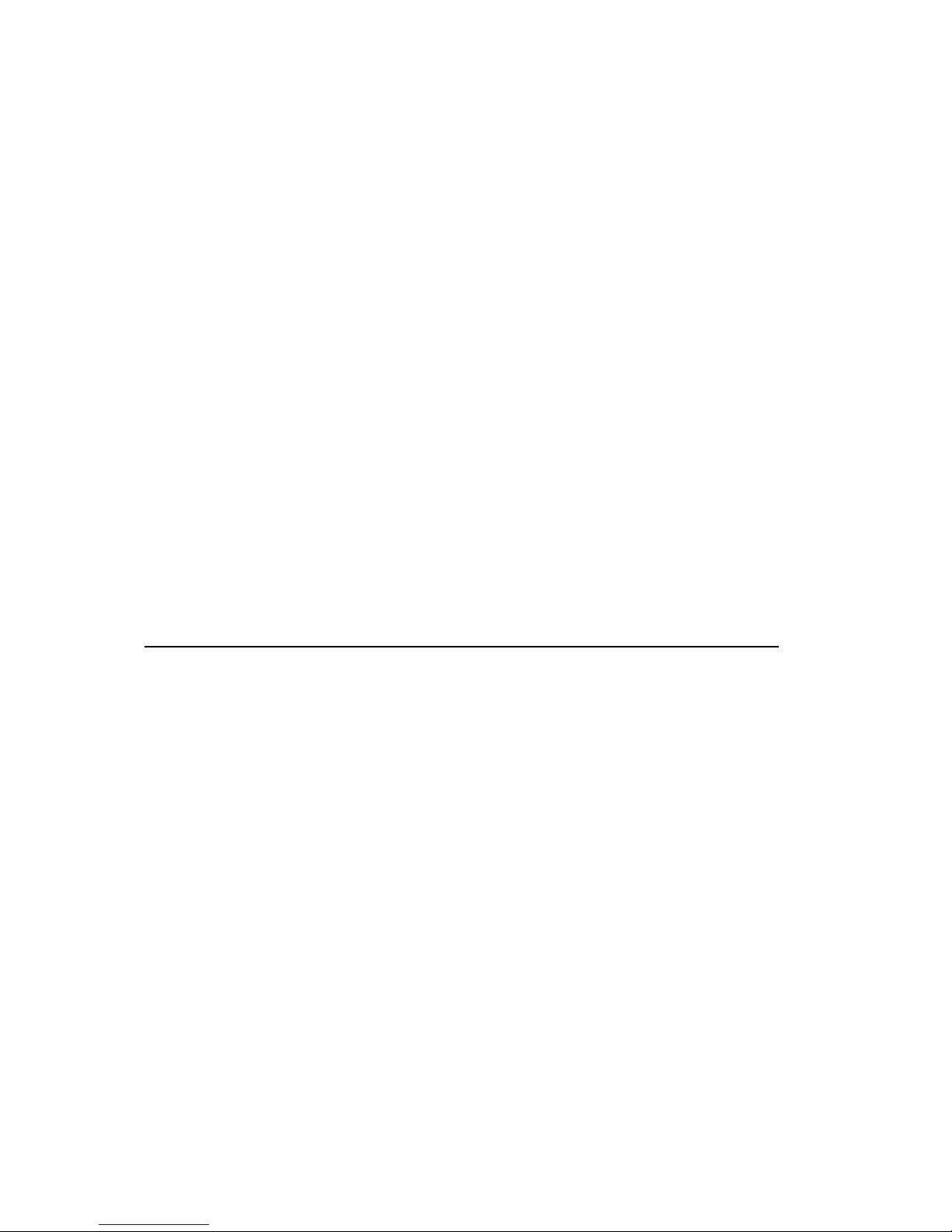

Feel with your fingertips for the servo openings for the aileron and flaps servos, then

melt them free with a hot soldering iron or cut free with a sharp balsa knife and adjust

to accomodate the control horns as nesssary. As shown in both photos glue in the

GRP control horns using suitably thickened epoxy resin.

Page 8

8

The depth of the servo openings is mechanically prefabricated; it may, however, be

necessary to adjust the depth of the openings by removing further Styrofoam (as

much as possible, until veneer with a fibre orientation transverse to the wingspan

becomes visible).

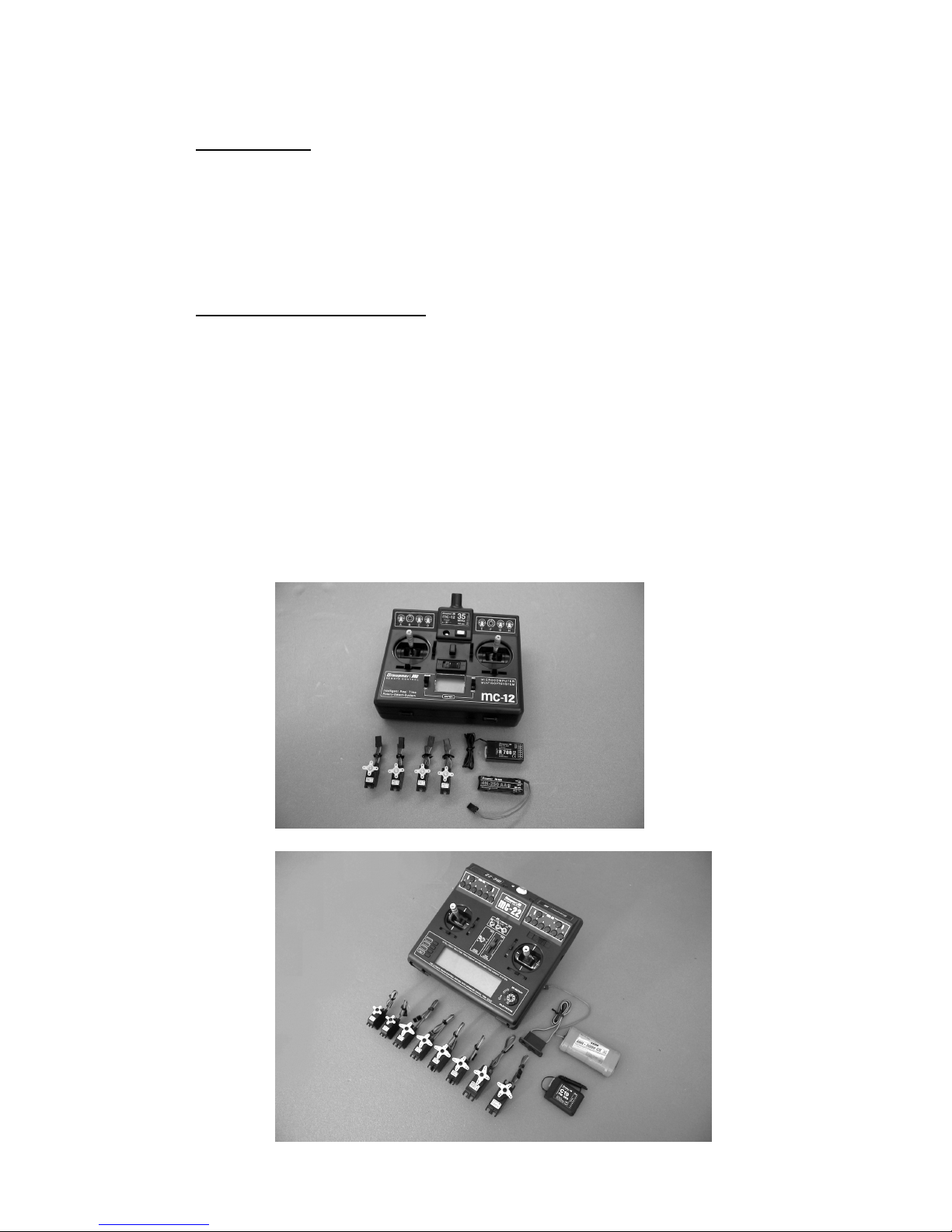

While waiting for the the adhesive to cure, prepare the servo control horns as shown

in the photo. The outer hole may need to be drilled open to a diameter of 1,6 mm to

accomodate the push-rod.

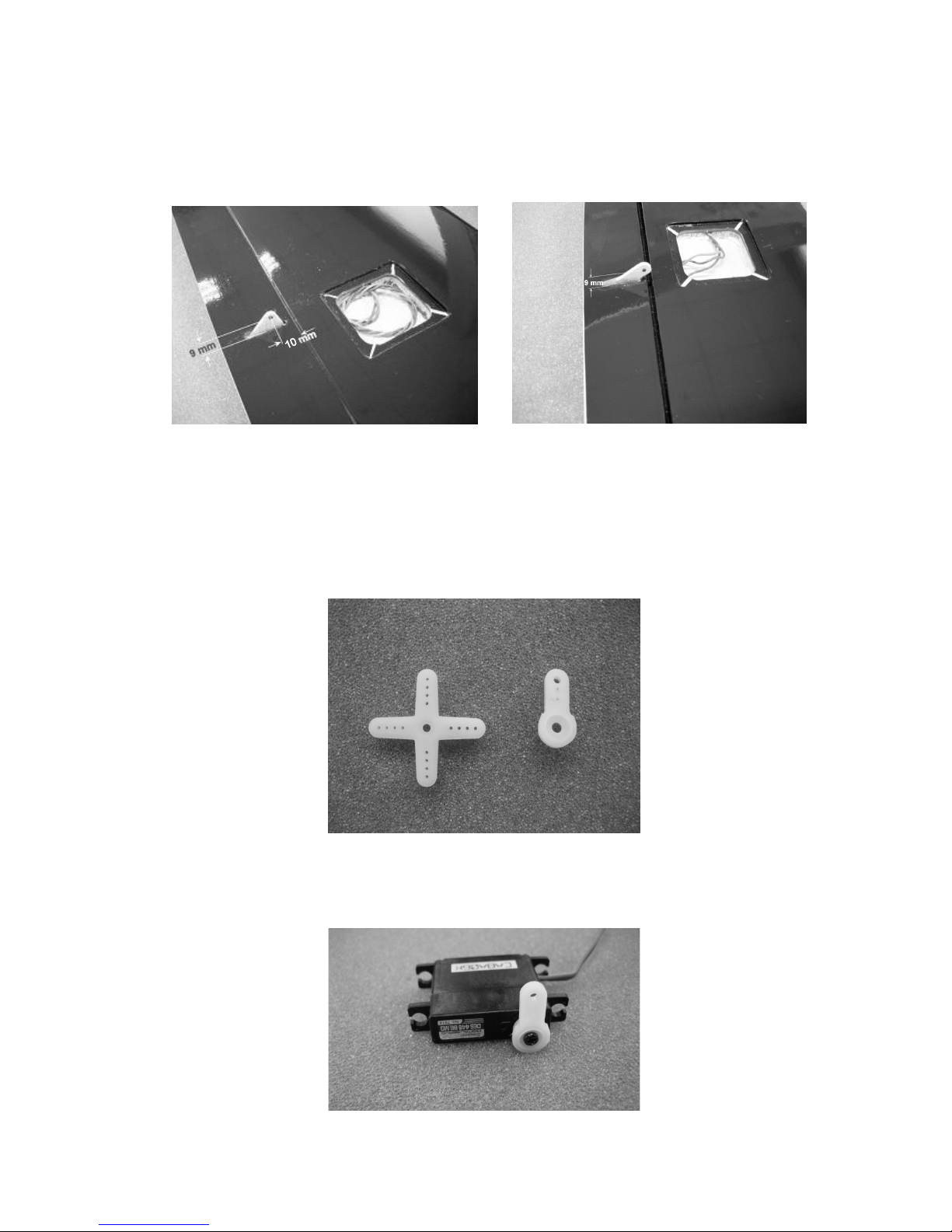

With servo in the centre (neutral) position the prepared servo levers are mounted on

each respective servo and tightly screwed down. In order to do this, place the servo

via the remote control in neutral position.

Page 9

9

Before glueing the servos on the covers the connection cables must be soldered onto

the extension cables which have already been pre-fitted into the wings and the

mounting links must be removed from the servos. When doing so ensure that the

correct polarity is applied, i.e. the correct colour-coded cables are soldered together.

As shown in the photo isolate the soldering joints with heat shrinkable tubing which

must be pushed onto the cables before soldering.

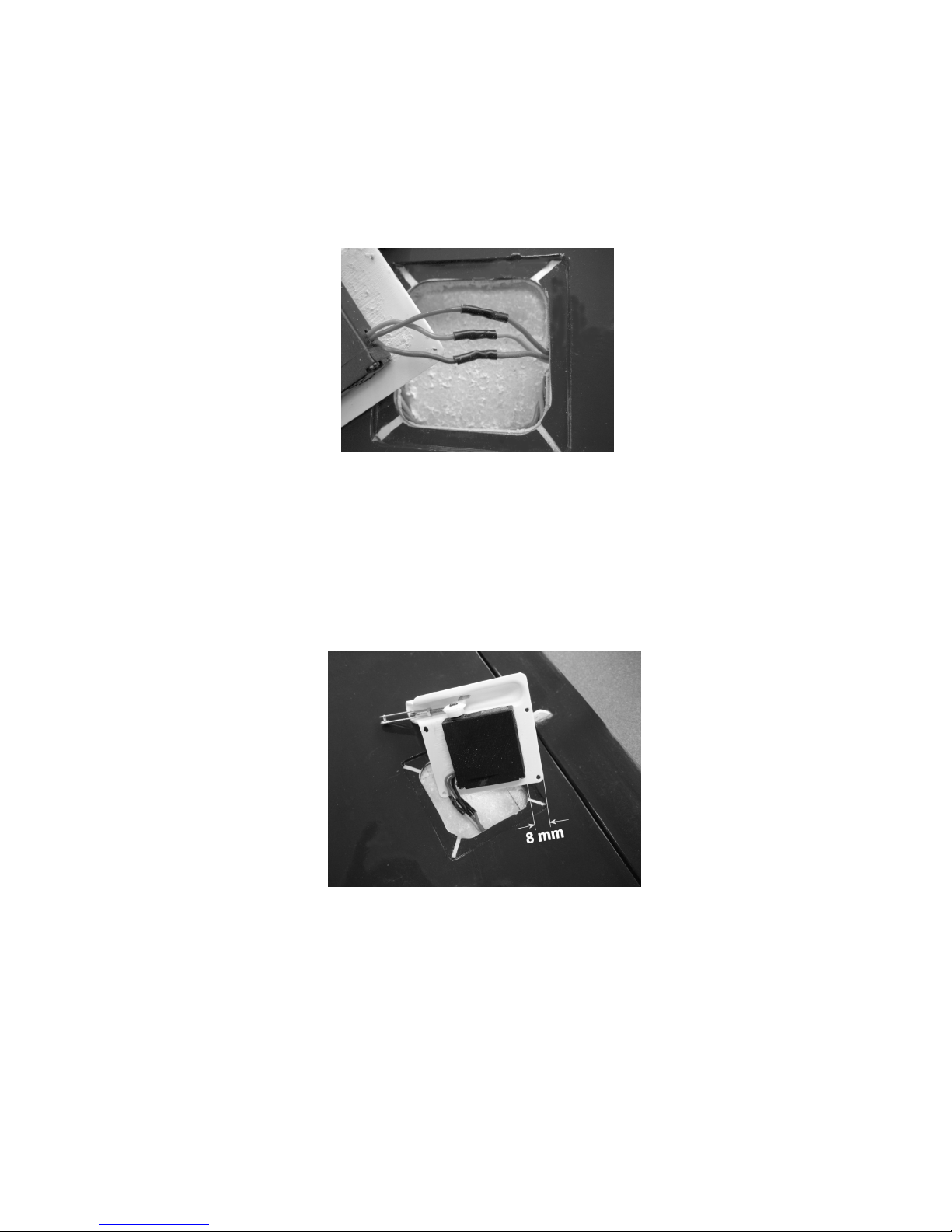

Now the servos are glued onto the servo covers; as shown in the photo. The servo

lever must be in the centre of the output fairing and the servo must be about 8 mm

from the edge. The servo cover and the servo casing itself must be well roughened

with sandpaper. Superglue (order no. 5821) can be used as adhesive here. Ensure

that the servo is placed in the correct position at the first attempt at assembly.

Note: When using superglue it is not possible to move the item at a later stage in

order to correct its position.

The push-rods for the ailerons and wing flaps are made from the M2 threaded rods

supplied in the hardware pack and are fitted with a M2 lock nut and a M2 clevis. The

aileron push-rods must be bent so as to measure 40 mm from the mount point on the

servo lever to the clevis pin. For the wing flaps the distance must be about 45 mm.

The exact length can be adjusted after screwing the covers is adjusted by turning the

clevis in or out.

Page 10

10

For extra security, the clevis and lock-nut ought to be secured with UHU screwsafe.

Now is the time to mount the clevises in the control horns and fasten the covers using

the flat-head screws supplied in the hardware pack.

Tip: Countersink the holes to achieve good aerodyamic performance!.

There are two ways to connect the servos to the receiver: The first option is to extract

the connection cables from the openings in the fuselage and then plug them together

with the extension cables. The second option is to solder onto the connection cables

using the wing servo quick connection order nos. 2972 and 2973 whereby the servos

are automatically connected when both wing halves are assembled.

Page 11

11

The openings in both sides of the fuselage wing fairing must be opened out at the

positions marked in the molding. Ensure that you leave about 1mm space arround

the larger rectangular opening for the wing joiner.

To ensure that the wings are held secure against twisting loads at the fuselage, four

steel wing incidence pins need to be securely bondede into the wing root ribs.

Open out the holes in the root ribs to accomodfate the wing incidence pins using a

Ø 3 mm drill to a depth of about 50 mm. The the wing halves can now be dry-rigged

against the fuselage using square CFK wing joiner and the wing panels may be dry

fitted to check for allignment. Tip: Take care to avoid that the wing incedence pins are

not pushed back into the holes in the wing roots!

The wing joiner.

The wing joiner for the ALPINA 3001 Champ PRO is in the form of a carbon square

joiner in a carbon composite sleve. The wing joiner itself a high-quality carbon fibre

laminate with in-built V-shaped profile which ensures excellent load bearing

properties. In spite of high levels of standardisation there can be small tolerances in

the fit due to limitations in the production process. This is NOT a quality defect – it

can be easily adjusted, if necessary, in a few seconds using 120-grain sandpaper.

Page 12

12

Now is a good time to install the compression strut, supplied as part of the wooden

parts kit. Carefully adjust the length of the hardwood piece to fit inside the width of

the fuselage, just aft of the trailing edge incidence pins. It is important that the strut

fit snugly, without distorting the shape of the fuselage, but correcting for any minor

manufacturing tollerence in respect of the wing/fuselage fairing. The strut is

bonded into place using suitably thickened epoxy resin.

Once satisfied with the fit and allignment of the wings on the fuselage, the wing

incidence pins may be bonded into the holes in the root ribs. The pins should

protrude about 7 – 10 mm from the wing roots. Be sure to make one pin in each wing

a little longer than the other, and round off the end of the pins to facilitate easier

assembly at the flying field. Once both wings have been marked and drilled, carefully

check the alignment before bonding the incidence pins into place. Apply a suitable

release agent to the holes in the fuselage fairing before applying a suitably thickened

epoxy. Then fit the wings to the fuselage, with the steel joiner installed to allow the

epoxy to cure overnight. Tip: Use a layer of kitchen film between the wing/fuselage

joint to avoid any excess epoxy from forming a permanent joint!

To complete the work on the wing halves glue the pressure pins (multilocks) into the

blind holes in the root ribs. In order to do this, press the pressure pins into their

counterparts in the fuselage. If necessary rework the blind-holes slightly to

accomdate the pressure pins. Apply a little adhesive in the blind-holes in the root ribs

and assemble the wing on the wing joiner and allow to cure.

TIP: Once again, use a layer of kitchen film between the wing/fuselage joint to avoid

any excess epoxy from forming a permanent joint!

Fuselage and Canopy

Fit the pin carrier strip (grooved strip) into the canopy. Then deburr the edges of the

pin and bond it securely into grooved strip. The pin should protrude about 22mm

beyond the end of the carrier strip. Glue the pin/carrier assembly such that that the

pin protrudes about 6 mm beyond the edge of the canopy and a distance of about 3

mm remains, measured on the inside of the canopy. Carefully file (not too much!)

with a round file a small groove into the fuselage in the centre of the front canopy

section, into which the canopy pin will lock. The canopy retainer consists of the GRPspring. The spring protrudes 10 mm beyond the rear canopy rim. The canopy spring

is fixed with superglue and subsequently laminated over with 1-2 layers of glass-

Page 13

13

fabric tape (160 g) and resin over a length of 50 – 60 mm. be sure to roughen the

joints with sandpaper (80 grain) before bonding with a suitably thickened epoxy resin

– as shown.

When mounting the canopy to the fuselage, place the canopy onto the fuselage so

that the GRP-tongue on the rear end can firstly be pushed so far into the fuselage

that the steel pin will be pushed under the fuselage section when the canopy is

pushed forward again.

When being pushed forward the canopy self-centres automatically in the canopy

frame on the fuselage.

To install the servo tray, start by tearing off the fabric tapes on the inside of the

fuselarge.

Page 14

14

The positioning of the components installed in the nose of the fuselage will depend to

some degree on your choice of battery pack and other RC components and all of

these will influence the balance point. Carefully check the physical layout of all the

components, bearing in mind the recommended centre of gravity.

The servo mounting tray is to be located within the cockpit opening leaving sufficient

space to accomodate the receiver battery. The servo mounting tray does fit in the

fuselage opening! Turn it around carefully and you will find that it will slip neatly into

place. Don’t be tempted to apply force, or to remove too much material which will

result in a poor fit. Mark the position carefully with a pencil and tack the servo tray in

place using an instant adhesive – before bonding the frame securely into the

fuselage with a generous bead of thickened epoxy. Allow to cure. Tip: Some may

wish to complete the job by adding a layer of wetted fibre glass cloth over the entire

servo frame allowing about 10mm extra on both sides to bond with the fuselage

sides.

Prepare the servo output arms with servo in the centre (neutral) position mount them

onto the servo output shaft. Mount the servos and the ON/OFF switch onto the servo

mountin tray.

The rudder and elevator push-rods will need to be shortened such that with the

servo in the centre (neutral) position the corresponding control surface is also

located in the neutral position. Both Bowden tubes used to support the rudder and

elevator control push-rods will naturaly also need to be shortened accordingly.

This is also a good time to install the aero-tow release (if required). There is a

good selection of purpose made model aero-tow release mechanisms available

commercially for which installation techniques vary, but the simplest form is

described below:

Carefully mark out and cut a 10mm slot about 2mm wide transversally about 5cm

from the nose and with the lower third of the fuselage diameter. Using thickened

epoxy, fix a length of PVC Bowden tube along the inside of the fuselage such that

it intersects the slot at 90 degrees. The slot should be positioned so as to allow at

least 5-10mm of the PVC tube in front of the slot. Once the resin has cured, cut

away the Bowden tube from inside the slot and insert a length of steel wire inside

the tube such that it engages both sides of the slot when closed and is clear of the

slot when open. Connect the free end of the steel wire to a suitable servo to

Page 15

15

operate the aero-tow release. You will require a simple loop, best made from

monofilament nylon to link up to the towline.

The winch hook

Measure and mark a point on the belly of the fuselage 55 mm from leading edge of

the wing fairing – as shown. Drill a 2.5mm hole to accommodate the winch hook.

Cover the hole on the outside with tape to protect the surface and roughen up the

inside of the fuselage in the area of the hole. Now glue the tow hook support block

into place centrally over the hole using thickened epoxy. Use a self tapping screw,

through the hole in the bottom of the fuselage to secure the support block while the

epoxy cures. Tip: for additional security, you may wish to finish the job by laminating

the support block to the fuselage bottom using 2-3 layers of suitably wetted 120g

fibreglass laminating cloth. Once the support block has thoroughly cured, drill a Ø 2

mm pilot hole to accommodate the supplied winch hook.

Page 16

16

The all-flying tailplane

The elevator bell-crank in this model is already pre-installed and ready for use. It may

only be necessary to slightly rework the groove milled onto the vertical stabiliser. The

tailplane halves are fitted using both Ø 3 mm steel wires. Push one steel wire through

the locating hole into the fin, the second through the milled groove in the fin and

bellcrank. Now both tailplane halves can be pressed fully home onto the steel wires.

CAUTION! Before pushing the tailplane halves onto the steel wires for the first time

these must by all means be checked for absence of burr. The tailplanes contain a

built-in locking system which may be damaged by burred edges on the wires and use

of excessive force.

CAUTION! With regard to the ARC-version of the model please ensure that the

tailplane is assembled with the correctly, with the upper-side of the elevator

uppermost. You can identify the upper-side by its dot marking at the root rib.

The Rudder

Locate and open-up the two hinge points along the leading edge of the rudder and

carefully mark the corresponding hinge points along the centre of the rudder post.

Now drill the holes using a Ø 3.5 mm drill to accommodate eye-bolts used to form the

hinge and screw these into the rudder post, but do not bond in place just yet. Insert

the GRP hinge pin through the guide tube located in the leading edge of the rudder

such that it passes through the three holes in the eye-bolts – to form an effective

hinge. Now carefully check the movement and throw of the rudder with respect to the

fin and adjust the depth of the hinge, by screwing in (or out) the three eye-bolts until

you find the optimum depth. Mark the position of the eye-bolts before bonding into

place using a suitably thickened epoxy, re-install the rudder and adjust as necessary

before finally allowing the hinge points to set. Tip: It is possible to unscrew the hinge

bolt and reset it with a little more adhesive should you find it necessary to make an

adjustment after the hinge bolts have been set into the fin post.

Page 17

17

Next, carefully mark out the position of the rudder control horn to align with the

shroud in the rear of the fuselage and the rudder control linkage. Try to locate the

horn as close as possible to the pivot line, and at exactly 90 degrees to the rudder

hinge line. Take care to avoid any restriction caused by the rudder horn touching the

shroud in the fuselage. Now drill a 4 mm hole at the point where the rudder horn is to

be installed. The hole should be as deep as possible but take care not to pierce the

skin on the other side of the rudder. Undermine the hole using a sharp tool so as to

increase area available to the adhesive and bond the rudder horn into place using

suitably thickened epoxy.

Assembly of the ALPINA 3001 CHAMP PRO

Insert the wing joiner through the fuselage opening and press the wings firmly onto

the joiner, ensuring that all four wing incedence pins and the pressure pins have fully

engaged and all wing servo connections have been secured. Insert both tailplane

halves on the steel wires and check that they are secure.

Important: The tailplane and wings must be fastened to the fuselage so they

are immoveable.

Finishing

Caution!!!

The Alpina – just like other models we produce - is manufactured using very

sophisticated Load Specific Covering Thickness Procedure (LTSCP)-technology in

order to achieve the desired optimal relationship between of weight and strength. In

this process, the thickness of wing skins are carefully reduced towards the tips which

means that the thermal diffusivity is considerably enhanced! Particular care must be

taken when using heat-shrink covering films to decorate your model. You should by

all means use covering films which have a low melting point so as not to destroy the

underlying polystyrene core (polystyrene melts at temperatures greater than 70°C).

When using heat-shrink covering films you should make every effort to avoid

prolonged exposure to heat.

We therefore recommend preferably low temperature covering films such as for

example adhesive foils.

Page 18

18

Balancing the ALPINA 3001 CHAMP PRO

Support the completely equipped, airworthy model, right and left next to the fuselage,

about 84 mm behind the root wing leading edge. The model should now balance

itself horizontally, or as the case may be, the nose pointing slightly downwards. If

additional nose weight is required, use a measured amount of Lead (Lead shot is the

most convenient form) and fix it into the nose with suitably thickened epoxy resin

.

The correct longitudinal dihedral (decelage) is +1 to +1,3°. This is the angle of the

elevator (at the neutral position) with respect to the wing and is best measured with

the aid of an incidence meter.

The following recommended control throws have been determined following several

test flights, confirmed by several different model pilots. We strongly recommend that

you begin with the recommended throws and only change them with experience

.

Control Throws:

Ailerons plus 25 mm up minus 10 mm down

Elevator plus 10 mm up minus 10 mm down

Rudder plus 10 mm left minus 10 mm right

Thermal Position

Ailerons minus 1,5 mm down

Flaps minus 3 mm down

Speed Position

Ailerons plus 2 mm up

Flaps plus 1,5 mm up

Butterfly Position

Ailerons plus 18 mm up

Flaps minus 65 mm down

Elevator minus 3 mm down

Tip: The specified control throws may be further adjusted via the Dual Rate function

of the transmitter.

Page 19

19

Important:

When installing the control push-rods always take great care that they run easily,

and to their full extent – including trimming – and are in no way mechanically

restricted.

When moving the rudder-control stick to the right, the rudder must swing to the right,

when moving it to the left, it must swing to the left. When moving the elevator control

stick back, both elevators must move upwards (pitch up). When moving the aileroncontrol stick to the right, the right aileron must move up, the left one downwards.

When moving the butterfly-control stick back the ailerons must swing upwards and

the flaps downwards. The flaps are best operated via a slider with an electronically

restricted path, so that for a full path of the slider the specified throws are achieved.

The First Flight

Experienced model flyers will now take the first opportunity to go to the model airfield

and test fly their model in the usual manner, make final corrections and then

hopefully have much fun and success flying their Alpina 3001 CHAMP PRO.

Some tips from the practice of modelflying should help you to make the most of the

wide variety of application possibilities for this model.

Test Flying

Every flying machine, from model aircraft to passenger carrying planes, must be test

flown after completion. This also applies to your Alpina 3001. The slightest deviation

in manufacture or construction can lead to minor variations in flying characteristics

and control responses. Test flying is the means to optimise the centre of gravity and

to generally fine-tune the control response.

Avoid by all means unnecessary low altitude hand launches on a flat site. While

doing so the model is flying close to the ground in the most dangerous zone as there

is little time to make adequate corrections and damages are most likely to occur.

The Range Test (also for experts!)

Ensure that both transmitter and receiver batteries are fully and properly charged.

Before switching on the transmitter ensure that the channel you are using is free. The

channel pennant on your antenna is obligatory and indicates your channel to other

pilots! If other pilots are present, announce your channel loudly and clearly.

Carry out a range test before the first flight. You should always carry out this test as a

matter of principle before commencing each days flying. Hold the model in a way that

the antenna is not affected – at the tip of the fuselage is best. An assistant walks

away with the transmitter. While doing so the antenna is fully pushed in. While

walking away operate a control function. Observe the other servos. The uncontrolled

servos should remain stationary up to a distance of at least 80 m and the controlled

servo must follow the controlled movements without delay. Should this not be the

case check again if your channel is free. If this is the case, return the entire system

(with battery, switch cable, servos etc.) to the service department of the manufacturer

for inspection.

Page 20

20

Faults do not cure themselves!

This test can only be carried out if the wireless band is undisturbed and no further

remote control transmitters are being operated, even on other channels! Such trials

are not advisable on high mountains due to the extremely strong field strengths and

overshoots by other transmitters. If you are unsure about anything do not under any

circumstance fly your model, even if you are very keen to try it out and the spectators

demand a first flight demonstration.

The First Start

The first flight can be carried out in different ways: at a slope site from a hand launch,

at a flat-field site or via an aero-tow.

Aerotow is the best (safest) method to launch your Alpina 3001 for the first time. Do

not forget the usual arrangements between you and your tug pilot!

At a slope site: Wait for a good upwind phase and throw the model diagonally

downwards. Let the model initially flop – gaining speed is half the battle! If necessary

adjust the trims to achieve straight and level flight and maintain speed. Then fly

control switch curves to test cornering characteristics, control throws (roll, pitch and

yaw). Be sure to extend the air breaks/flaps briefly at height to get to know the

behaviour of the model.

If there is sufficient height, check the centre of gravity at the same time. The

procedure for checking the centre of gravity described in the following is a fine-tuning

of the centre of gravity. This method requires gentle airflow and a precisely balanced

centre of gravity; it fails in strong winds or when severe balancing errors are made.

During strong winds it is very difficult to trim the normal speed as it is very hard to

estimate the actual speed in relation to the ambient air.

The model is being trimmed in normal speed; this is considerably higher than the

pitch speed. The model must not undulate or appear "spongy" and heavy to control.

The flaps are on "neutral".

Now – provided the model is flying at a safe height – briefly apply down elevator to

place the model in a steep dive. Then allow the elevator to return to neutral

immediately and observe the flight path. The centre of gravity can be considered to

be about right if the model recovers in a gentle upward arc (100 m) without any

further control inputs.

The centre of gravity is too far forward if the model bounces quickly out of the dive

and climbs steeply.

Action: Remove lead ballast from fuselage nose, trim depth a little.

The centre of gravity is too far back if the model shows no tendency to recover, or

indeed if it even begins a steeper nosedive.

Action: Intercept the model immediately. Add lead to the fuselage nose and secure,

trim height a little.

Page 21

21

Flight on a flat-field site

Flying on a flat-field site is relatively safe – without the risk of sinking which you may

experience when flying at a slope site.

It takes an experienced model pilot to be able to exploit thermal lift. Due to the higher

altitudes strong lift areas are harder to recognise by observing the flight

characteristics of the model on a flat-field site than at a slope site, where "beards"

can be found at eye level. Only the most skilled pilots are able to recognise a strong

lift area on a flat-field site directly "overhead" and fly it; therefore always and look for

it at a transve distance from your position.

The flight characteristics of your model allow you to recognise a strong lift areas. If

the thermal is good a strong climb is recognisable, weak lift areas require a trained

eye and a skilled pilot. After some practice you will be able to recognise the trigger

points for the thermals. The air warms up - depending on the reflective power of the

ground more or less strongly - and air flows driven by the wind closely above the

ground. The roughness of the terrain, a shrub, a tree, a fence, a forest edge, a hill, a

passing car, even on your landing model aircraft may cause warm air to lifted from

the ground and rise upwards. A fitting comparison in the reverse sense is the

travelling water drop on the ceiling which initially remains stuck to the ceiling, pushes

against some roughness and then falls down.

The most distinctive thermal triggers are sharply defined snow fields on mountain

slopes. Above the snow field the air is cooled down and flows downwards, on the

downhill side of the snowfield edge this meets the warm air flowing slopeside up and

replaces it abruptly. This results in strong climbs, but at the same time rough thermal

bubbles. The rising warm air is to be detected and "centred". When doing so the

model should by control corrections be kept in the centre of the lift area as the

strongest climb values are to be expected there. However, this requires some

practice.

Leave the climbing zone at the right time in order to avoid visibilty difficulties.

Remember that the model can be seen better under clouds than in the blue,

cloudfree areas. If height must be reduced consider the following:

The stability of the Alpina 3001 Champ is quite high, but there are limits. High speed

flights in the F3B-manner should only be attempted if the flaps are in neutral

position! A GRP-coating extends the speed range and the application possibilities of

the model.

Start the landing at a relatively high altitude and overcome the dangerous zone at low

altitude quickly and safely using the airbreaks/flaps. A correctly flown landing

approach – consisting of a parallel flight with the wind away from the pilot, a traversal

flight and a straight, butterfly-supported landing approach with subsequent catch for

landing – ensures the safety of the model, pilot and spectators.

Page 22

22

Flight at a slope site

Flights at a slope site are a particularly attractive type of model glider flying. Flying for

hours in the slope winds without external launching assistance is one of the most

enjoyable experiences. The highlight is the thermal flying from a slope. To launch the

model, fly out over the valley, seek thermal, find thermal, circle high up to the visibilty

limit, then bring down the model by acrobatics only to start the game over again is

model flying in perfection.

But beware, as slope flying can also harbour dangers for the model. Firstly, the

landing is in most cases considerably more difficult than on a flat-field site. Often the

landing must take place in the lee of a mountain, which requires concentration and a

spirited approach with crossing and subsequent air brake landing. A windward

landing, that is in the immediate upwind, is even more difficult; it should always be

carried out uphill, with crossing and timely catch shortly before landing.

Another danger is the lack of upwind or thermal at the most inconvenient moment,

which harbours the risk of a difficult landing in the valley. This risk can, however, be

reduced by obtaining information about a potentially necessary landing site in the

valley before the start of the flight and by personally inspecting this site in advance in

order to get to know any obstacles for the approach and local wind conditions. If the

landing cannot be avoided the landing should be carried out as in the flat field with a

landing approach and a short, straight end approach with air brake support. Always

fly the model in the visibility axis above the intended landing site. By doing so you will

avoid a too short landing and arrive safely at the landing site. If the sun shines you

can estimate the height from the early visible shadow of the model. With this

assistance even spot landings are possible in the valley.

Never give up!

Thermals can be found even at the lowest altitudes. Once the end approach has

been begun the landing should take place under any circumstance, as in this case

the altitude is really too low for thermals. Calmly memorise the landing site and how

to get there, maybe there are distinctive features in the terrain which you can aim for

in your later search.

The main thing about thermal search under launch height is, however, to "keep

calm". Realise that in most cases the pilot is the problem, not the model. Also reduce

any "helper" to silence who stands next to you and continuously and obtrusively

offers "good advice". A pilot who really wants to help you gives only very short and

really helpful hints, e.g. about other models whose pilots have found thermal, a

circling bird of prey or the safe approach to the intended landing site. Perhaps he

even launches his model, flies it down to the valley and helps with the thermal

search. The chances of success increase considerably if two models are being flown.

Page 23

23

Safety

Safety must always remain of paramount importance when flying model aircraft.

Liability insurance is obligatory. If you join a club or association you can take out

insurance there. Ensure that you get sufficient insurance cover. Always keep models

and remote controls in optimal working order. Familiarise yourself with the charging

technology of the batteries you use. Make use of all the sensible safety installations

which are on offer. Obtain information from different product catalogues and from

your local model-making specialist dealer.

Fly your model responsibly! To fly over other people’s heads is no sign of real skill.

The real expert won’t need such displays of vanity. Remind other pilots – in

everyone’s interest – about this fact. Always fly in a way that neither endangers you

nor others. Always remember that even the best remote control can be disturbed by

external influences. Even many years of accident-free flying experience are no

guarantee for what might happen in the next flight minute.

Fascination

Get to know your Alpina 3001 Champ PRO, its excellent performance, comfortable

flight characteristics and enormous range.Enjoy one of the few sports in which the

combination of technology coupled with your own skill – whether on your own or with

friends - and the conditions of Mother Nature are combined to provide enjoyable

experiences which have become rare in our present times.

We at GRAUPNER/TANGENT-model sport, wish you much pleasure and success

building and flying your new model!

GRAUPNER / TANGENT – Modellsport

Dieter Bär – Modellentwicklung

Page 24

24

Parts List

Qty Description Purpose Material Dimension

1 Assembly instructions Paper DIN A4

1 Epoxy Fuselage GRP white ready made

1 Canopy GRP ready made

1 Set wing panels Styro/Abachi ready made

1 Tailplane Styro/Balsa ready made

1 Rudder Balsa ready made

1 Wire set Metal/Plastic Parts list

1 Set wooden parts Wood Parts list

1 Accessory parts Miscell. Parts list

1 Set servo locks Plastic/wood Parts list

1 Wing Joiner CFC 20x12x227

Wire set

2* Steel wire Rudder/Elevator Spring Steel Ø 1,4x1200

1 Steel wire Aero-tow coupl. Spring Steel Ø 1,4x160

1 Bowden tube Aero-tow coupl. Plastic Ø3,2x350

1 Rudder bearings CFC Ø2,0y420

* Rudder/Elevator push-rods are pre-installed in the fuselage!

Wooden Parts

1 Servo mounting tray Fuselage Abachi 210x85x3 mm

1 Compression strut Fuselage Plywood 75x10x10 mm

1 Glider hook holder Fuselage Hardwood 50x15x15 mm

Accessories

3 Threaded bushing Rudder linkage Steel M2

7 Clevis Rudder linkage Steel M2

4 Threaded rods Rudder linkage Steel M2

2 Rudder horns aileron Rudder linkage GRP milled piece

2 Rudder horns Flap Rudder linkage GRP milled piece

1 Rudder horn Rudder linkage Alumin. M4/1,6

2 Eye bolt Rudder hinge Alumin. M4/2,05

6 Lock nuts Control linkages Brass M2

2 Pressure pin (multilock) Wing Plastic

1 Elevator joiner Elevator/Fuselage Steel Ø3x130

1 Elevator joiner Elevator/Fuselage Steel Ø3x100

4 Torsion pins Wing Steel Ø3x60

1 Glider hook Fuselage Steel Ready made

1 Self tapping screw Fuselage Steel M4x25

1 SPAX-screw Fuselage Steel Ø3x16

Note: Contents and technical details may be subject to change without notice

Page 25

25

Before the attempt of a first flight the entire operation and assembly

instructions must be read carefully. You alone are responsible for the safe

operation of your RC-model aircraft. The construction and operation of the

model must be supervised by a responsible adult who is familiar with the

conditions and potential dangers of a RC-model aircraft. Any questions relating

to safety issues when operating a RC-model aircraft will be happily answered

by specialist dealers.

Remote control model aircraft are very sophisticated and dangerous objects

and require high levels of expertise, skill and responsibility on the part of their

operators.

Legally, a model aircraft is an aircraft and subject to the relevant laws and

regulations which must by all means be complied with. The brochure

»

Model

flight law, clauses and more«, order no. 8034.02 is a summary of these laws

and regulations; it can also be viewed at specialist dealers. Furthermore, postal

restraints which relate to remote control systems must be observed. Relevant

advice can be found in the operating instructions of your remote control

system.

Only parts supplied in the construction kit as well as genuine Graupner

accessories and parts which are expressly recommended by us are to be used.

If only one component of the drive unit is changed a safe operation cannot be

guaranteed and any potential claim under warranty is invalidated. Only use

fitting, reverse polarity protected plugs. Avoid short-circuits and incorrect

polarity. Due to the high energy of the NiMH-batteries there is a risk of

explosions and fires.

A RC-model aircraft can only be functional and meet your high expectations if

it has been carefully built according to the assembly instructions. Only

cautious and thoughtful handling when operating the model protects against

personal injury and damage to property. Nobody would try to fly a glider plane

without previous training. This also applies to model flying. However, the

manufacturer has no means to influence the construction and the operation of

a RC-model aircraft. We therefore emphasise strongly the dangers and hereby

reject any liability for this.

Please seek assistance and advice from experienced model flyers, clubs or

model flight schools. Furthermore we would like to refer you to specialist

dealers and relevant publications for additional information. It is best to fly as a

member of a club on a licensed model airfield.

Adhesives and varnishes contain solvents which may damage your health.

Always observe the relevant notes and warnings of the manufacturers.

The operator must be in full possession of his or her physical and mental

abilities. Just as with driving a car the operation of a model aircraft under the

influence of alcohol or drugs is prohibited by law.

Before operation inform all passers-by and spectators about any potential

dangers which may originate from your model.

Page 26

26

Always keep the necessary safe distance to people or objects; never fly low

over people’s heads or directly towards people!

Model flying must only be carried out at outside temperatures of between - 5º C

and + 35º C. More extreme temperatures can lead to changes of material

properties such as the battery capacity and defective adhesive connections.

Every model flyer must conduct him-/herself in such a way that public safety

and order, especially regarding other people and objects, as well as the order

of the model flight operation are not endangered or disturbed.

Never fly the model aircraft near high-voltage power lines, industrial estates,

in residential areas, public streets and places, school yards, parks and

playgrounds etc.

Warnings must always be observed. They refer to things and processes which

can lead to severe damage or injuries which in extreme cases can be fatal.

Prior to each operation of the model check that all plugged-in connections

such as e.g. radio control components, rudder horns etc. are secured tightly

and examine them for potential damage. Only after the elimination of all

defects is the model to be operated.

Ensure sufficient stability when holding the model in your hand. Wear suitable

sturdy shoes, e.g. trainers.

Only switch on the remote control after you have made sure that the used

frequency is free! Radio interference caused by unknown people can always

occur without warning. This can result in the model being out of control and

unpredictable! Never leave the remote control system unattended to avoid it

being operated by a third party.

The flight position of the model must always be clearly identifiable throughout

the entire flight in order to guarantee safe control. If malfunction or

disturbances are noticed during the flight the landing must be initiated

immediately for safety reasons. You must always give way to other aircraft.

Launching and landing areas must always be clear of people or other

obstacles.

Always ensure that the batteries are fully charged as otherwise faultless

functioning of the RC-system cannot be guaranteed. Never use hot, faulty or

damaged batteries. Always follow the instructions for use of the battery

manufacturers.

Before each flight check the complete RC-system as well as the model aircraft

for full operational reliability and carry out range checks.First switch on the

transmitter and then the receiver system. Equally, first switch off the receiver

system, then the transmitter. Check that the control surfaces move correctly,

according to the operation of the controller.

Page 27

27

Take all batteries out of the model after use and store only in discharged mode

(ca. 0,9 V pro cell) at temperatures between + 5º and + 25º C. Keep batteries

out of the reach of children.

These notes are meant to alert you to the many dangers which can result from

incorrect and irresponsible handling. When practised properly and

conscientiously model flying is a creative, educational and relaxing leisure

activity.

Notes regarding the use of NiMH-batteries

Application area

All Graupner NiMH-batteries as well as NiMH-individual cells are exclusively suited

for model-making purposes such as for model aircraft, ships or cars.

Charging

1. Charge the NiMH-battery with a suitable charger or fast charger (see chargers in

the Graupner- main catalogue FS).

2. Before charging the battery must have cooled down to a temperature of around

20° C. If necessary use the cooling appliance BATTERY COOLER, order no.

2882 for cooling down the battery.

3. Charge the battery only immediately before use. Each NiMH-battery is subject to

a slight auto-discharge for technical reasons.

4. Warning:

The charging process must be supervised even with fully automatic chargers.

Observe the maximum permissible charging current displayed on each battery or

individual cell. If the charging current is too high the NiMH-cells overheat. If the

battery heats up to 50° C during the charging process the charging current must

be interrupted immediately. By overheating of the NiMH-cells the overpressure in

the cell casing increases considerably. Each individual NiMH-cell of a battery is

equipped with an overpressure valve which protects the cell in emergencies from

a dangerous explosion. It is, however, possible that due to unpredictable

circumstances a valve will not function correctly so that an explosion may happen

in case of excessive overheating of the cell.

5. Warning:

Do not touch accidentally overcharged NiMH-batteries, but interrupt the

charging current and allow the battery to cool down.

6. Warning:

Avoid short-circuits by all means as the battery heats up immediately in the case

of an extremely fast discharge such as a short-circuit which can cause a cell

explosion just as in the case of overcharging. There is the risk of injury by

explosion and cauterisation from the electrolyte in the cell.

Avoid any skin or eye contact with leaked electrolyte. In an emergency rinse with

plenty of water and seek medical help.

7. Never solder cables or any similar objects directly onto the cell casing as this may

damage the overpressure valve.

8 Warning:

Never throw faulty or old NiMH-batteries into the fire.

Page 28

28

Do not throw away batteries in your household waste, but dispose of them safely

in the appropriate recycling containers. This is free and protects the environment

as most of the battery components can be recycled.

Notes regarding the construction and operation of the ALPINA 3001 Champ

PRO Before commencing the construction process:

Radio Controlled parts as well as controll push-rods are installed during assembly

according to the relevant construction stage. The installation at a later stage is either

not possible at all, or only with great difficulty.

When buying a radio remote control ensure that the transmitter and receiver

appliances are suitable for model aircraft, are licensed by the Deutsche

Bundespost-Telekom and have a Foreign Trade Zone (FTZ)-serial test number.

Other radio installations and high frequency appliances are also operated in the

frequency ranges for radio remote controls. Therefore no protection against

disturbances by such appliances can be granted.

The operation of radio remote controls for model aircraft on the authorised channels

in the 35 MHz-band is chargeable, i.e. the radio remote control must be registered

with the Deutsche Bundespost-Telekom.

Further information about this topic is available from your local Telecom-branch or at

your model-making specialist dealer.

Loading...

Loading...