Page 1

Manual

Alpha 150Q / 170Q / 220Q

Quadcopter

16570.RTF (Racecopter with FPV micro camera and transmitter)

16570.FPV (Racecopter with FPV micro camera)

16570.HoTT (3D copter)

16572.RTF (Racecopter with FPV micro camera and transmitter)

16572.FPV (Racecopter with FPV micro camera)

EN

Copyright © Graupner/SJ GmbH

Page 2

2 / 44

16570.16572_Alpha150Q/170Q /220Q_V1

Page 3

Inhaltsverzeichnis

Introduction ......................................................................................5

Service centre ...................................................................................5

Intended use ....................................................................................6

Package content and technical data ................................................7

16570.RTF .......................................................................................7

16570.FPV .......................................................................................7

16570.HoTT ....................................................................................8

16572.RTF .......................................................................................9

16572.FPV .......................................................................................9

Symbol description .........................................................................12

Safety notes ....................................................................................12

Safety notes for battery ................................................................13

Battery storage..............................................................................13

Charge the LiPo battery ................................................................14

First use ...........................................................................................14

Receiver.........................................................................................14

Installing the LiPo battery in the copter .......................................14

Connecting the LiPo battery .........................................................14

Determining the centre of gravity ................................................14

Default model memory ................................................................15

Binding the receiver .......................................................................16

Range test ........................................................................................17

Flight control ...................................................................................18

MODE 1 .........................................................................................18

MODE 2 .........................................................................................20

MODE 3 .........................................................................................22

MODE 4 .........................................................................................24

Installing the propellers .................................................................26

First flight ........................................................................................26

Camera function .............................................................................27

HoTT transmitter presettings .........................................................27

Control mode ................................................................................28

Flight mode ...................................................................................28

Fail-Safe setting .............................................................................28

Throttle Cut ...................................................................................29

Special functions on channel 6 .....................................................29

"Telemetry" menu ..........................................................................31

SETTING & DATA VIEW ..................................................................31

Receiver display ............................................................................31

ROLL/NICK Display ........................................................................32

16570.16572_Alpha150Q/170Q /220Q_V1

3 / 44

Page 4

YAW Display ...................................................................................33

Multicopter Basis display ..............................................................34

Axis assignment ............................................................................36

Firmware updates ...........................................................................40

SIMPLIFIED DECLARATION OF CONFORMITY ................................42

Notes on environmental protection ..............................................43

Care and maintenance ...................................................................43

Warranty conditions .......................................................................43

4 / 44

16570.16572_Alpha150Q/170Q /220Q_V1

Page 5

Introduction

Thank you very much for purchasing the Graupner 3D or Race cop-

ter Alpha 150Q, Alpha 170Q or Alpha 220Q. These copters are

extremely versatile. This manual is valid for all the copter sets listed

on the cover sheet. The package content changes depending on the

version.

Read this manual carefully to achieve the best results with your

Alpha 150Q, 170Q or 220Q and first of all to safely control your

models. If you experience any trouble during operation, take the

instructions to help or ask your dealer or Graupner Service Centre.

Due to technical changes, the information may be changed in this

manual without prior notice. Be always updated by checking periodically on our website, www.graupner.de to be always uptodate with

the products and firmwares.

This product complies with national and European legal requirements.

To maintain this condition and to ensure safe operation, you must

read and follow this user manual and the safety notes before using

the product!

Service centre

Note

This manual is part of that product. It contains important information concerning operation and handling. Keep these instructions for

future reference and give it to third person in case you gave the

product.

Graupner Central Service

Graupner/SJ GmbH

Henriettenstraße 96

D-73230 Kirchheim/Teck

Servicehotline

(+49) (0)7021/722-130

Monday - Thursday:

9:15 am - 4:00 pm

Friday:

9:15 am - 1:00 pm

service@graupner.de

Graupner USA

3941 Park Dr Suite 20-571

El Dorado Hills, CA 95762

Website: www.graupnerusa.com

Phone: +1 855-572-4746

Email:service@graupnerusa.com

Graupner in Internet For the service centres outside Germany please refer to our web site

www.graupner.de.

16570.16572_Alpha150Q/170Q /220Q_V1

5 / 44

Page 6

Intended use

Target group

The quadcopters Alpha 150Q, 170Q and 220Q are remote controlled quadcopters. Other components are required, depending on

the version, to be able to use one of these copters. Punctual technical information about the components can be found in the Technical

data section.

The quadcopters Alpha 150Q, 170Q or 220Q are designed exclusively to be used as a battery-powered, radio controlled model, any

other use is not allowed. For any improper use no guarantee or liability is assumed.

Read the entire manual in advance before attempting to assemble

and operate one of these copters.

Graupner/SJ constantly works on the development of all products;

we reserve the right to change the item, its technology and equipment.

A quadcopter of the series Alpha 150Q, 170Q or Alpha 220Q is not

a toy. These components are not suitable for children under 14. For

questions about radio-controlled models, please contact an experienced RC model expert or a RC model club.

In addition, it is explicitly pointed out that you must inform yourself

about the laws and regulations applicable at your respective starting

point before starting the remote control operation. Such conditions

may differ from state to state, but this must be followed in every

case. Read through this entire manual before you attempt to install

or use the transmitter.

Note

• After purchase always check the content of the packaging for

integrity or damages.

6 / 44

16570.16572_Alpha150Q/170Q /220Q_V1

Page 7

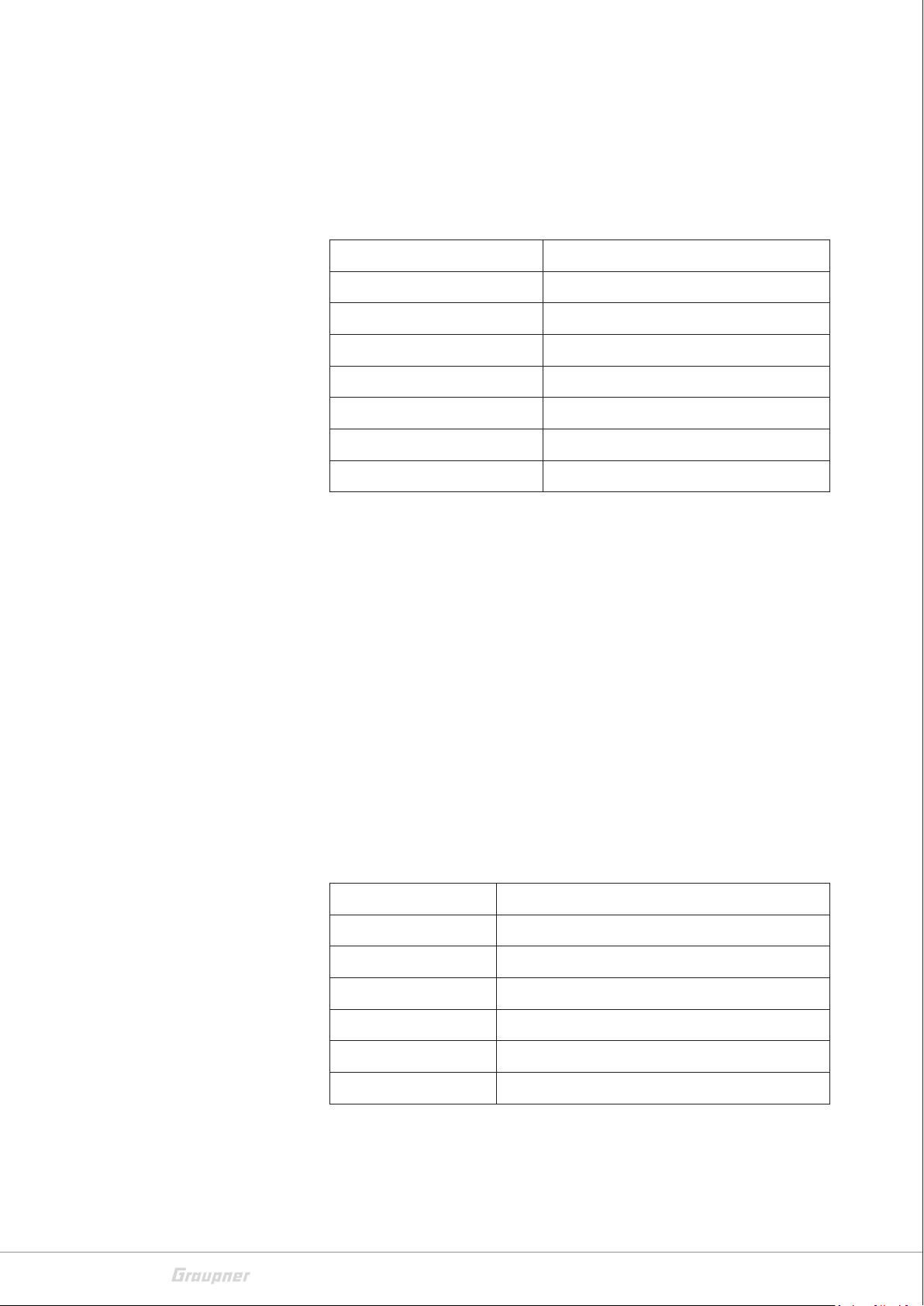

Package content and technical data

16570.RTF

already assembled Race copter Alpha 170Q

Propellers size 4 x 4,5 inches

Ultra PRO brushless motors 1306

(No. 16570.2300L and No. 16570.2300R)

4in1 ULTRA brushless speed controller BL Heli S (No. S3087)

FPV micro camera V2 (No. 48341)

25 mW 5,8 GHz video transmitter raceband (No. 16570.123)

LiPo battery V-Maxx 3s/850 mAh (No. 78108.3XT30)

Battery charger (No. S2015.XH or 6454.XH)

mz-12PRO HoTT transmitter (No. S1002.PRO77DE)

Assembly material and manual

Recommended accessories

FPV goggle (No. 48354)

Graupner 7“ FPV monitor (No. S8405)

Technical data

16570.FPV

Length excl. rotors 140 mm

Width excl. rotors 140 mm

Axial distance 122 mm

Propellers 3 blades 4 x 4,5 inches

Chassis material Carbon fibre

Chassis height 30 mm

Weight <250 g w/out battery protection

Video channels in Europe R 3 … 6

already assembled Race copter Alpha 150Q

Propellers size 3 x 5,2 inches

Ultra PRO brushless motors 1306

(No. 16570.3500L and No. 16570.3500R)

Recommended accessories

16570.16572_Alpha150Q/170Q /220Q_V1

4in1 ULTRA brushless speed controller BL Heli S (No. S3087)

FPV micro camera V2 (No. 48341)

25 mW 5,8 GHz video transmitter race band (No. 16570.123)

Assembly material and manual

mz-12PRO HoTT transmitter (No. S1002.PRO77DE)

7 / 44

Page 8

Technical data

16570.HoTT

LiPo battery V-Maxx 3s/850 mAh (No. 78108.3XT30)

Battery charger (No. S2015.XH or 6454.XH)

FPV goggle (No. 48354)

Graupner 7“ FPV monitor (No. S8405)

Length excl. rotors 126 mm

Width excl. rotors 126 mm

Axial distance 106 mm

Propellers 3 blades 3 x 5,2 inches

Chassis material Carbon fibre

Chassis height 30 mm

Weight <250 g w/out battery protection

Video channels in Europe R 3 … 6

Recommended accessories

Technical data

already assembled 3D copter Alpha 170Q

3D propellers size 3,8 x 3,5 inches

Ultra PRO brushless motors 1306

(No. 16570.2300L and No. 16570.2300R)

4in1 ULTRA brushless speed controller BL Heli S (No. S3087)

Assembly material and manual

mz-12PRO HoTT transmitter (No. S1002.PRO77DE)

LiPo battery V-Maxx 3s/850 mAh (No. 78108.3XT30)

Battery charger (No. S2015.XH or 6454.XH)

Length excl. rotors 140 mm

Width excl. rotors 140 mm

Axial distance 122 mm

Propellers 3S 3 blades 3,8 x 3,5 inches

8 / 44

Chassis material Carbon fibre

Chassis height 30 mm

Weight <250 g w/out battery protection

16570.16572_Alpha150Q/170Q /220Q_V1

Page 9

16572.RTF

Recommended accessories

Technical data

already assembled Race copter Alpha 220Q

Propellers size 5 x 4,6 inches

Ultra PRO brushless motors 2206 (No. S7118 + S7119)

4in1 ULTRA brushless speed controller BL Heli S (No. S3088)

FPV micro camera V2 (No. 48341)

25 mW 5,8 GHz video transmitter raceband (No. 16570.123)

LiPo battery V-Maxx 3s/1300 mAh (No. 78113.3)

Battery charger (No. S2015.XH or 6454.XH)

mz-12PRO HoTT transmitter (No. S1002.PRO77DE)

Assembly material and manual

LiPo V-Maxx 4s/1800 mAh (No. 78118.4FPV)

FPV goggle (No. 48354)

Graupner 7“ FPV monitor (No. S8405)

16572.FPV

Length excl. rotors 185 mm

Width excl. rotors 185 mm

Axial distance 156 mm

Propellers 3 blades 5 x 4,6 inches

Chassis material Carbon fibre

Chassis height 30 mm

Weight <500 g

Video channels in Europe R 3 … 6

already assembled Race copter Alpha 220Q

Propellers size 5 x 4,6 inches

Ultra PRO brushless motors 2206 (No. S7118 + S7119)

4in1 ULTRA brushless speed controller BL Heli S (No. S3088)

FPV micro camera V2 (No. 48341)

25 mW 5,8 GHz video transmitter raceband (No. 16570.123)

Recommended accessories

16570.16572_Alpha150Q/170Q /220Q_V1

Assembly material and manual

mz-12PRO HoTT transmitter (No. S1002.PRO77DE)

LiPo battery V-Maxx 4s/1800 mAh (No. 78118.4FPV)

Battery charger Ultramat 14 plus (No. 6464)

FPV goggle (No. 48354)

9 / 44

Page 10

Technical data

Graupner 7“ FPV monitor (No. S8405)

Length excl. rotors 185 mm

Width excl. rotors 185 mm

Axial distance 156 mm

Propellers 3 blades 5 x 4,6 inches

Chassis material Carbon fibre

Chassis height 30 mm

Weight <500 g

Video channels in Europe R 3 … 6

10 / 44

16570.16572_Alpha150Q/170Q /220Q_V1

Page 11

16570.16572_Alpha150Q/170Q /220Q_V1

11 / 44

Page 12

Symbol description

!

!

Safety notes

Always observe the information indicated by these warning signs.

Particularly those which are additionally marked with the words

CAUTION or WARNING.

The signal word WARNING indicates the potential for serious injury,

the signal word CAUTION indicates possibility of lighter injuries.

The signal word Note indicates potential malfunctions.

Attention indicates potential damages to objects.

This safety notes are intended to protect you and other people. They

are also used for safe handling the product. Therefore please read

this section very carefully before using the product!

• Do not leave the packaging material lying around, this could be

a dangerous toy for children.

• Persons, including children, with reduced physical, sensory or

mental capabilities, or lack of experience or knowledge, or not

capable to assemble and use safely one of these 3D or Race

copter Alpha 150Q, 170Q or Alpha 220Q must not use it without supervision or instruction by a responsible person.

• Operation and use of radio-controlled models needs to be

learnt! If you have never operated a model of this type before,

start carefully and make yourself familiar with the model's

reactions to the remote control commands. Proceed responsibly.

• First, always perform a range and function test on the ground

according to the manual of your transmitter (to do so, hold

your model tight), before you use your model. Repeat the test

with running motor and with short throttle bursts.

• Due to safety and licensing reasons (CE), any unauthorized

reconstruction and/or modification of the product is prohibited.

• Only use the components and spare parts that we recommend.

Always use matching, original Graupner plug-in connections of

the same design and material.

• Make sure that all of the plug-in connections are tight. When

disconnecting the plug-in connections, do not pull the cables.

12 / 44

16570.16572_Alpha150Q/170Q /220Q_V1

Page 13

• Protect your copter from dust, dirty, humidity and other small

!

!

parts. Do not expose it to vibrations or to extreme heath or

cold. The models may only be operated remotely in normal

outside temperatures such as from -10°C to +55°C.

• Always use all your Graupner HoTT components only with the

latest firmware version.

• If you have questions which cannot be answered by the operating manual, please contact us (contact information see page

5) or another expert in the field.

WARNING

• During programming, make sure that connected electric motors

do not start unintentionally. Injury risk by the turning propellers! For safety reasons always remove the propellers when

programming. Always activate the Motor Stop function according to the instructions of your transmitter.

• Avoid impacts and crushing. Check the copter regularly for

damages to the housings and cables, specially after model

crashes. Damaged or wet electronic components, even if

re-dried, should no longer be used!

Safety notes for battery

• Never touch the turning propellers, this can cause serious

injury.

• The propellers must be mounted securely, thrown parts can

cause serious injury.

• Never stay in the danger area of running propellers! Long hair,

loose clothing such as scarves, loose shirts or similar, can be

sucked in by the propeller, flying parts can lead to serious injuries.

• Observe the safety notes of the required components.

CAUTION

• LiPo batteries are not a toy. Persons, including children, with

reduced physical, sensory or mental capabilities, or lack of

experience or knowledge, or not capable to use safely the battery must not use the battery without supervision or instruction by a responsible person.

16570.16572_Alpha150Q/170Q /220Q_V1

13 / 44

Page 14

Battery storage

• Any alterations to the battery, charger or charging cables can

cause serious injury. Risk of fire and explosions! Risk of burns!

• Do not use any damaged battery or charger, risk of short-circuit

and fire!

LiPo batteries should be stored with a voltage of about 3,8V per cell.

If the cell voltage falls below 3 V, then the battery must be necessarily charged. Deep discharge and storage in discharge status (cell voltage < 3V) make the battery useless. For transport and storage the

LiPo batteries should be placed in a safety bag e.g. No. 8373.

Notes

• Remove the battery from the model when transporting or when

not in use.

• During transport protect the model and the transmitter from

damages.

Charge the LiPo battery

First use

Receiver

Connect the LiPo battery to the supplied charger and charge it as

described in the corresponding manual.

The following optional components may be required to commission

the copter:

Remote control HoTT transmitter (mz-12 Pro or higher) and a matching charger.

For versions 16570.RTF, 16570.FPV and 16572.RTF and 16572.FPV,

optionally available video goggle (No. 48354) or an optionally available FPV monitor (No. S8405) are needed for the FPV flight.

The integrated HoTT receiver is optimally matched to the respective

copter at the factory. To program some parameters, refer to the section "Receiver settings".

Installing the LiPo battery in the copter

To compensate for the weight of the camera, place the LiPo battery

slightly backwards with a self-adhesive Velcro strip on the underside

14 / 44

16570.16572_Alpha150Q/170Q /220Q_V1

Page 15

Connecting the LiPo battery

Default model memory

of the frame and, after fine-tuning the centre of gravity, secure it

against falling with an additional Velcro strip.

To start up the copter, plug the connector of the main battery into

the corresponding socket on the back of the copter and remove it

again after setting the flight mode.

Determining the centre of gravity

Hold the copter in the middle of the upper frame with two fingers

and lift it up. The copter should take a horizontal position. Otherwise, move the battery accordingly.

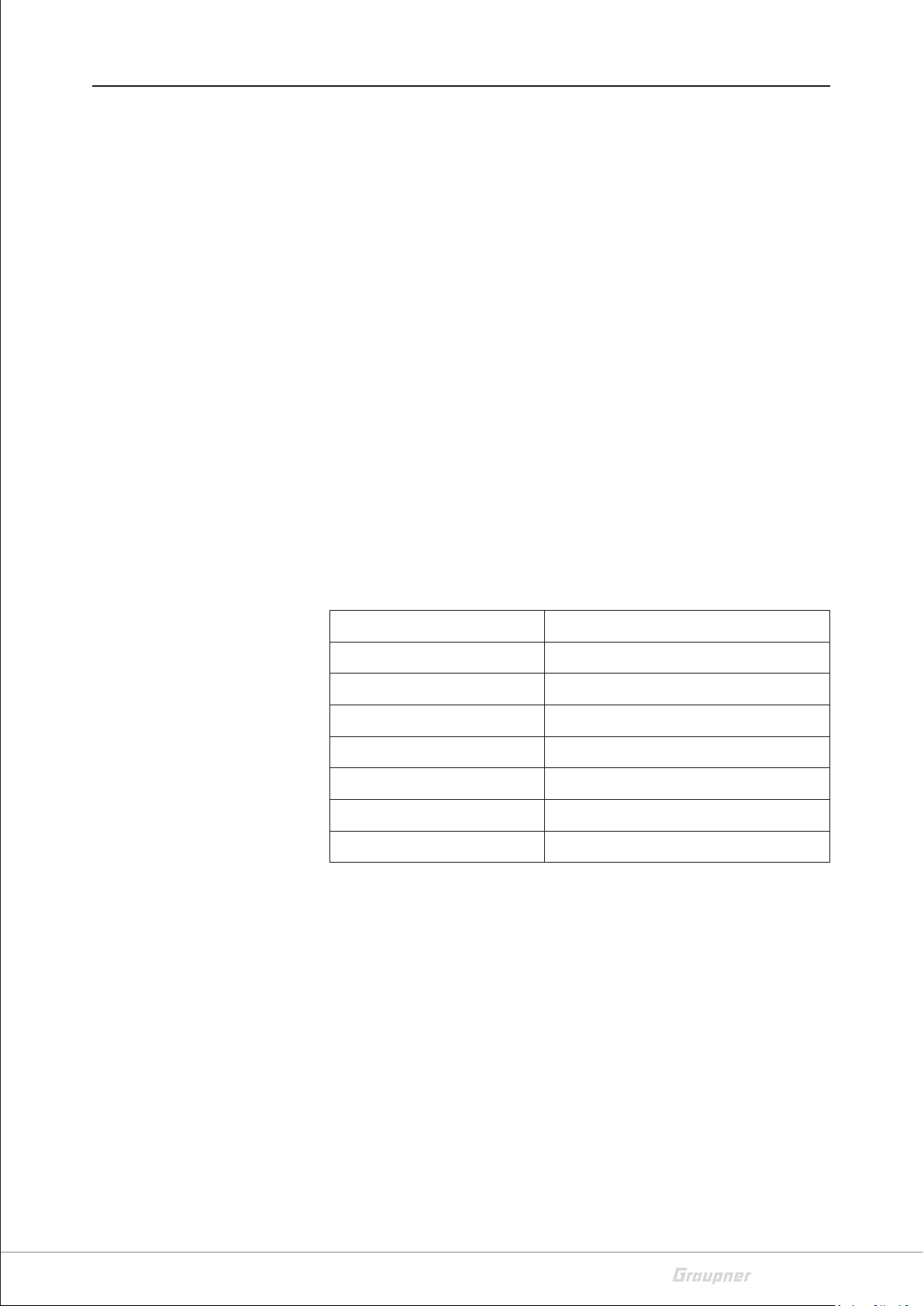

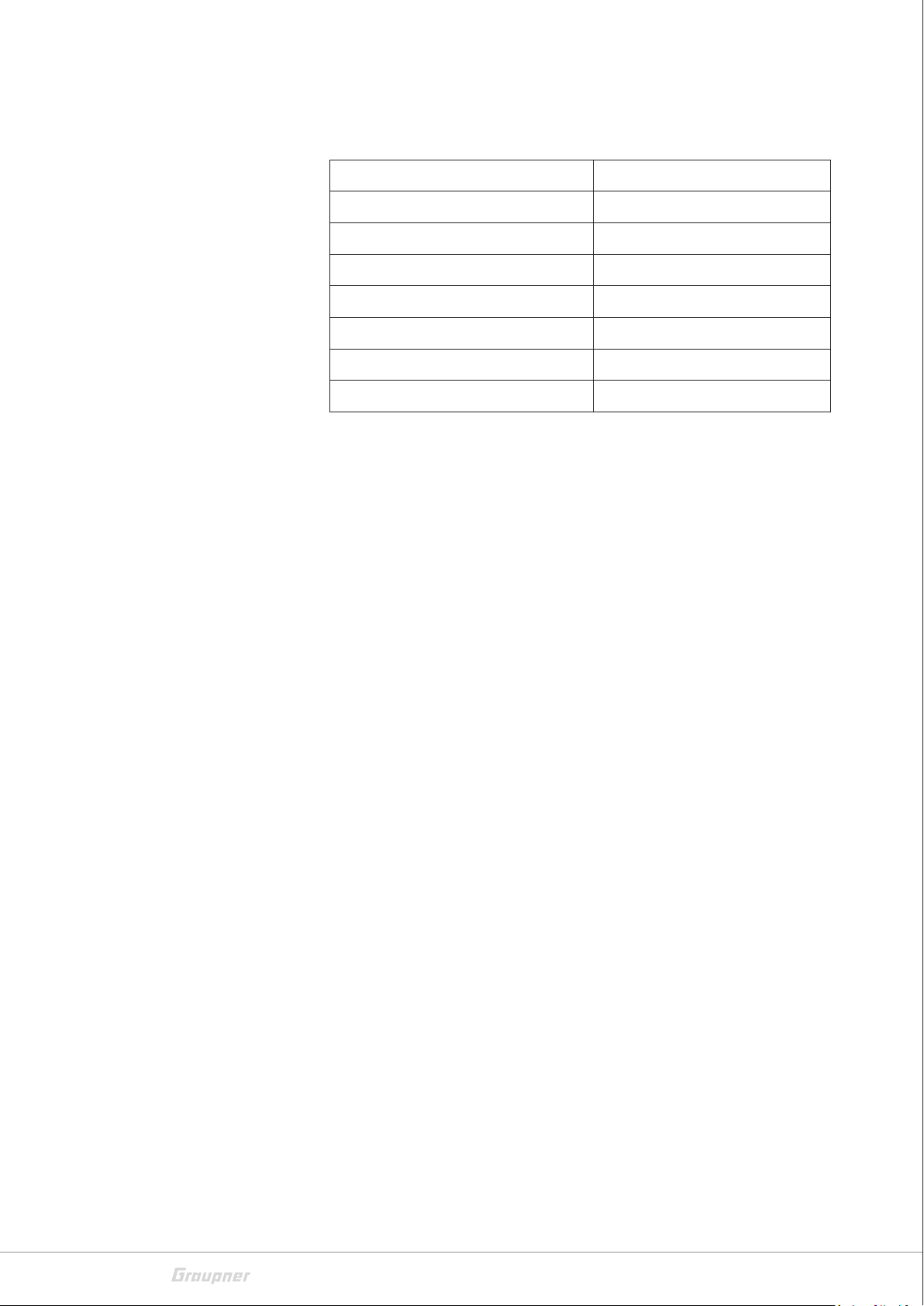

04

05

06

07

08

09 Alpha 1703D

01

02

03

04

05

06 VersaCopt

Hornet250

Xcell 220

VersaCopt

Alpha 150

Alpha 170

Alpha 110

Alpha 150

Hornet250

Alpha 300

Xcell 220

–––

–––

• The kits 16570.RTF and 16572.RTF are delivered with the transmitter Graupner mz-12 Pro HoTT.

In accordance with the type of copter included in the set, the

supplied transmitter is already linked to a preprogrammed model

memory in both cases.

No. / Copter model Suitable sample memory

16570.RTF / Alpha 170Q Alpha 170 (Alpha 110)

16572.RTF / Alpha 220Q Alpha 170 (Alpha 110)

• The kits 16570.FPV, 16570.HoTT and 16572.FPV are delivered

without HoTT transmitter.

The optional Graupner mz-12 Pro HoTT transmitter already contains preprogrammed pattern memory. More are available for

download on the respective product page at www.graupner.de.

With the help of the option „Model memory“ of the PC program

„Firmware_Upgrade_gr_studio“ these sample programs can be

transferred to the transmitter.

No. / Copter model Suitable sample memory

16570.16572_Alpha150Q/170Q /220Q_V1

16570.FPV / Alpha 150Q Alpha 150 (Alpha 110)

16570.HoTT / Alpha 170Q 3D Alpha 1703D (Alpha 300)

16572.FPV / Alpha 220Q Alpha 110 / 150 / 170

Note

In both cases, it is recommended not to use the pre-programmed

model memory directly, but to copy it into a free model memory in

accordance with the transmitter manual and then rename it accordingly.

15 / 44

Page 16

Binding the receiver

Depending on the scope of delivery of your set, the receiver integrated in your 3D or Race copter Alpha 150Q, 170Q or Race copter

Alpha 220Q may already be bound to the transmitter Graupner

mz-12 Pro HoTT included in the set.

If you want to bind the copter to another transmitter or renew a

binding, proceed as follows:

Binding step-by-step

1. Switch on transmitter.

2. Start the copter by plugging in the drive battery.

On the left side of the copter, the status LED lights up red for

about 15 seconds: The copter waits exclusively for control signals

from "its" transmitter.

3. After the expiration of these approx. 15 seconds, the status LED

starts flashing rhythmically red: The receiver of the copter is now

in bind mode.

‖ If "his" previous HoTT transmitter is switched on, the existing

binding is retained.

‖ If a binding process is triggered on another HoTT transmitter

according to its description, the receiver of the copter binds

to this transmitter and the existing binding is lost.

4. If the binding process was successful, the red status LED on the

copter goes out and the green LEDs that may be present on the

arms of the copter light up constantly. Otherwise the process has

to be repeated.

Attention

As mentioned above, the receiver of a 3D or Race copter Alpha

150Q, 170Q and Race copter Alpha 220Q is in binding mode approx-

imately 15 seconds after the battery is plugged in. If the copter is

already bound to a specific transmitter and should this binding be

maintained, the transmitter must therefore be switched on for

safety reasons before the commissioning of the copter or at the latest within this period of 15 seconds. Otherwise, there is an acute

danger that the copter unintentionally binds to a foreigner Graupner

HoTT transmitter, which is eventually in binding mode at the same

time, and consequently goes into uncontrolled operation.

16 / 44

16570.16572_Alpha150Q/170Q /220Q_V1

Page 17

Range test

Carry out the range test of a Graupner HoTT remote control system

according to the instructions in your transmitter manual. It is useful

to have an assistant who helps you.

Attention

Never start a range test on the transmitter during normal model

operation!

16570.16572_Alpha150Q/170Q /220Q_V1

17 / 44

Page 18

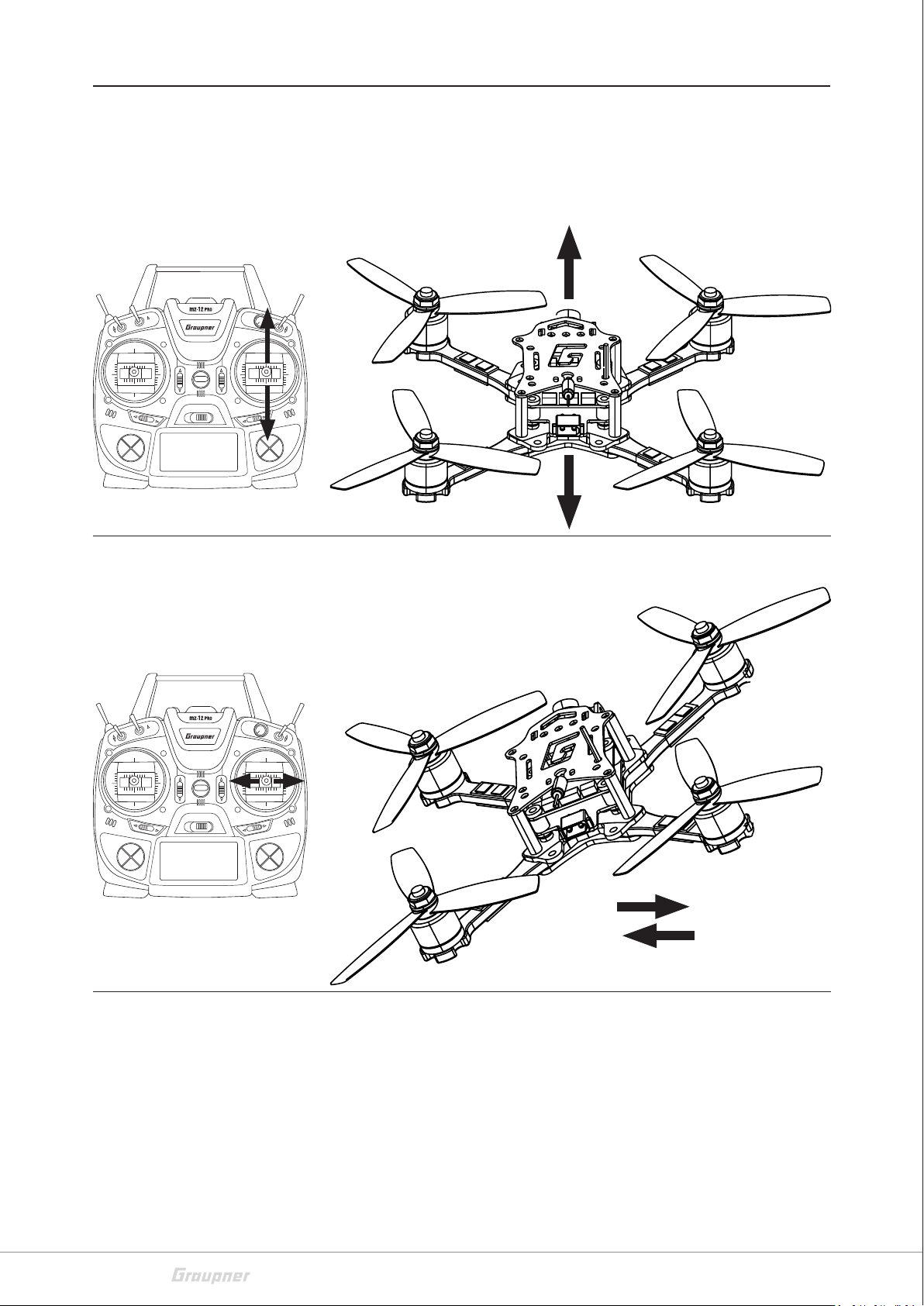

Flight control

MODE 1

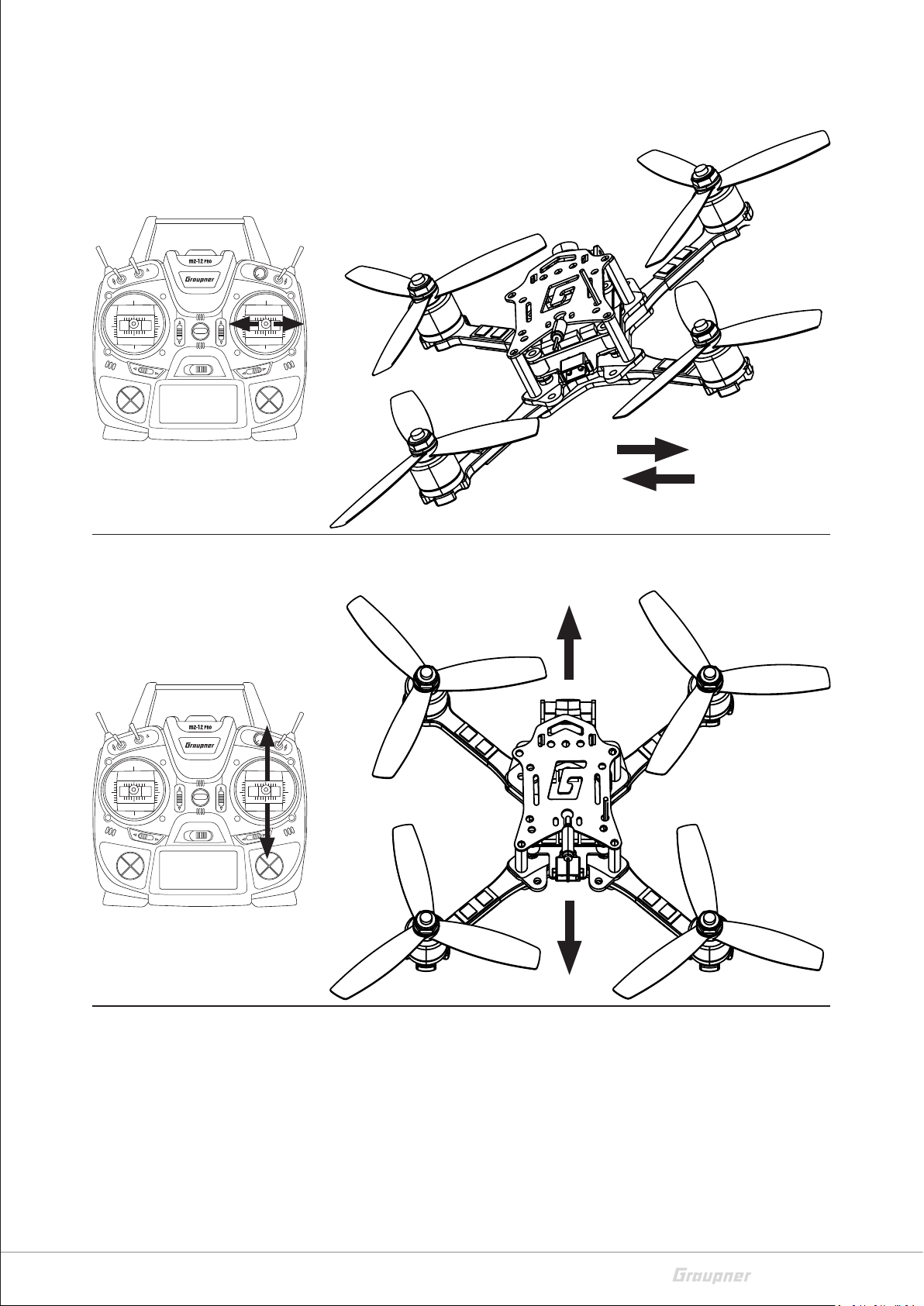

Climb and sink

Roll to the right and left

18 / 44

16570.16572_Alpha150Q/170Q /220Q_V1

Page 19

Turn (yaw)

Forward and backward (nick)

v

16570.16572_Alpha150Q/170Q /220Q_V1

19 / 44

Page 20

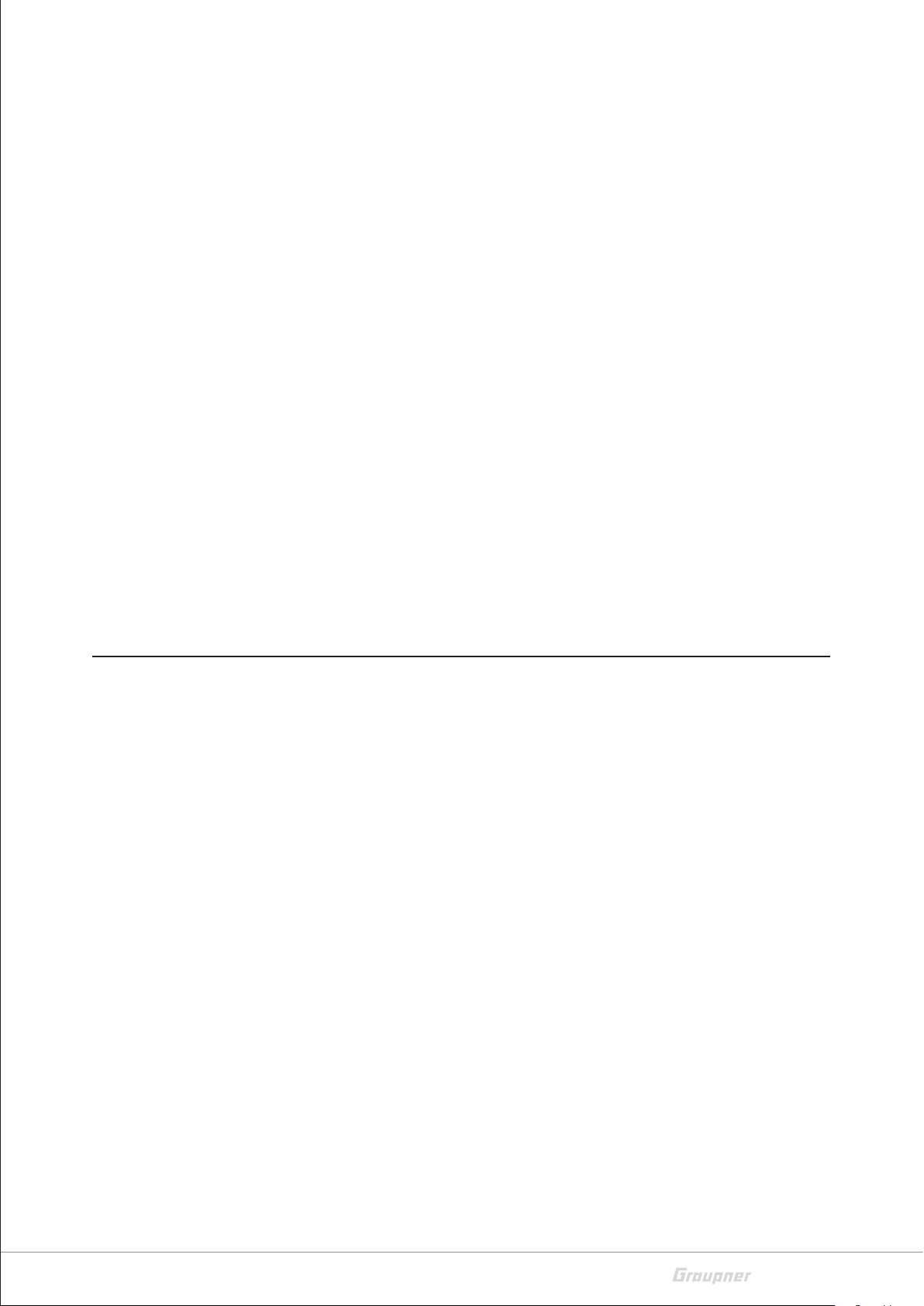

MODE 2

Climb and sink

Turn (yaw)

20 / 44

16570.16572_Alpha150Q/170Q /220Q_V1

Page 21

Roll to the right and left

Forward and backward (nick)

16570.16572_Alpha150Q/170Q /220Q_V1

21 / 44

Page 22

MODE 3

Climb and sink

Turn (yaw)

22 / 44

16570.16572_Alpha150Q/170Q /220Q_V1

Page 23

Roll to the right and left

Forward and backward (nick)

v

16570.16572_Alpha150Q/170Q /220Q_V1

23 / 44

Page 24

MODE 4

Climb and sink

Roll to the right and left

24 / 44

16570.16572_Alpha150Q/170Q /220Q_V1

Page 25

Turn (yaw)

Forward and backward (nick)

16570.16572_Alpha150Q/170Q /220Q_V1

25 / 44

Page 26

Installing the propellers

!

1R

2L

CAUTION

Risk of injury by rotating propellers in case the motors start.

Always unplug the connector to the battery before working on

the propellers.

Install the propellers as shown in the picture on the left. Be sure to

attach the right propeller to each motor. The propellers are marked

accordingly. If only one propeller is put on wrong, the copter is not

able to fly.

On the two, seen from above, running counterclockwise motors left

front (1) and right rear (3) you have to install the propellers marked

with an "R".

4L

First flight

3R

On the two, seen from above, clockwise running motors right front

(2) and left rear (4) you have to install the propellers marked with an

"L".

Another orientation option is: The outer propeller blades of the two

front propellers must be directed obliquely backwards at the top and

the two rear propellers diagonally forward at the top.

For the first flight, select a large, free flight surface with not too hard

ground. At least initially always start, fly and land in attitude mode

because the copter is easier to control. Familiarize yourself with the

flight behaviour of your copter before you switch to the Rate mode

for the first time. Proceed carefully and responsibly.

Commissioning the copter step-by-step

1. Switch on transmitter.

2. Activate the Motor Stop function by switching the corresponding

switch.

26 / 44

3. Start the copter by plugging in the battery.

‖ After commissioning of the copter, its position stabilization is

immediately active, but not yet initialized.

4. Place the copter horizontally on a suitable surface for about 3 sec

after switching on.

‖ The calibration process can only be performed when the

receiver is absolutely still. Always wait until the calibration

process has finished before starting to fly the model.

16570.16572_Alpha150Q/170Q /220Q_V1

Page 27

‖ If required, you can achieve the same effect with a corre-

spondingly long-lasting stopover on a suitable surface.

5. Move the throttle / pitch control stick to idle position.

This is usually the "back" end point.

6. Deactivate the Motor Stop function.

The propellers start to rotate at low speed.

7. Carefully move the throttle / pitch stick forward until the copter

is about one meter high and hold it at that height.

‖ Initially, move the control sticks slightly so that you have

enough time to familiarize yourself with the copter's reactions.

‖ If, especially when hovering, the copter always drifts in a cer-

tain direction, compensate the movement by tapping the corresponding trim button in the opposite direction. Alternatively, you can land and move the battery in the opposite

direction.

Camera function

8. After landing, first activate the motor stop function, then first put

the transmitter away and take the copter in hand to stake out the

battery.

With the exception of the 3D copter included in the set No. 16570.

HoTT, all other copter models have a factory-ready built-in micro-camera and a video transmitter. The transmission of the camera image

begins with the connection of a battery to the copter. Then, if necessary, scan the transmission channel of the copter on the video

goggle or on the video monitor.

The copter-side video channel switching is described in the next section under "Special functions on channel 6".

To align the camera unscrew the fixing screws of the red spacer and

loosen the camera; the spacer is then to move appropriately to align

the camera as desired. Finally, tighten all four screws again.

For sharpness adjustment loosen the ribbed ring on the camera

optics; turn this accordingly and finally secure the position found by

tightening the knurled ring again.

16570.16572_Alpha150Q/170Q /220Q_V1

27 / 44

Page 28

HoTT transmitter presettings

Depending on the bandwidth of the model type selection of the

HoTT transmitter used, either the model type "Copter" or alternatively a "Fixed-wing model" should be selected. Some of the current

HoTT transmitters are even shipped with preconfigured model memory, such as: for example, the transmitter mz-12 Pro HoTT included

in some sets. The following programming suggestions and display

illustrations are also based on this transmitter.

Control mode

According to the transmitter instructions, the appropriate control

mode and, if necessary, "motor front / rear" must be set. Usually

"backwards" so that the channel 1 indicator in the servo display indicates -100% in the "motor off" position of the "throttle / pitch control

stick".

Flight mode

Flight mode has to be set to channel 5. To do this, program a 2-way

switch in the "Control settings" menu on Channel 5 as follows:

I5

free

I6

I7 +100%

free

I8 +100%

I9 +100%

1

3

–100%

5

7

9

11

+

I5

free

I6

I7 +100%

free

I8 +100%

I9 +100%

1

3

+100%

5

7

9

11

+

3

0%

0%

0%

0%

0%

3

0%

0%

0%

0%

0%

+100%

+100%

10

12

+100%

+100%

10

12

• Attitude mode

+100%

+100%

+100%

+100%free

+100%free

trv

+

The stick movements act directly proportionally to Roll and Nick.

In the attitude mode, the maximum inclination angle is limited to

approx. 50° at 100% of the stick travel.

The attitude mode is active as long as the bar of channel 5 is on

the left of -50% in the »Servo display«. How far to the left is irrelevant.

2

4

6

8

+

+100%

+100%

+100%

+100%free

+100%free

trv

0%

0%

0%

0%

0%

0%

+

(The -100% shown on the left are based on the switch programming above.)

Flight mode suggested for beginners.

• Rate mode

In this mode, the rate is determined by the rash of the stick without inclination limit. In this aerobatic mode rolls and loops are

possible.

The Rate mode is active as soon as the bar of channel 5 is to the

right of +50% in the display "Servo display". How far to the right

is irrelevant.

2

4

6

8

0%

0%

0%

0%

0%

0%

+

(The -100% shown on the left are based on the switch programming above.)

Not suitable for beginners.

28 / 44

16570.16572_Alpha150Q/170Q /220Q_V1

Page 29

Fail-Safe setting

FAIL SAFE

Pos

Hold

1 2 3

Delay 0.25s STO

5

4

6

Throttle Cut

Mod.Name

Control mode

Motor on C1

M Stop

Timers 0:00 –––

ALPHA 110

–125% +100%

7 8

1

Idle B.

1

We recommend to set Channel 1 and Channel 5 to "Pos" according

to the transmitter instructions and, before saving the fail-safe settings, set the throttle / pitch control stick to the motor OFF position

and the Attitude / Rate mode switch to the "OFF" position Position

"Rate mode" to be active in fail-safe situations:

In such a case, a red LED will flash on the left side of the Alpha 150Q,

170Q or Alpha 220Q quadcopter. The motors run with the minimum

power set in the "MINPOWER%" line of the "Multicopter Basis" display described later and the position control of the copter is still

active.

This state continues until a correct transmitter signal is recognized

again by the receiver module.

For safety reasons, a motor stop switch must always be programmed

on the transmitter side according to the transmitter instructions.

Only when this is placed into the appropriate position, an undesired

start of the motors is reliably prevented.

Motor stop in Acro 3D mode

M1

M2

M3

M4

M5

MIX 1

trv +100%+100%

offs

STO

–100%

1

3

–100%

5

7

9

11

+

type

0%

0%

0%

0%

S

??

??

??

??

fro

+100%

SEL

S 5

2

4

6

8

10

12

5

??

??

??

??

to

+

1

=

0%

0%

0%

0%

0%

0%

When operating the copter in Acro 3D mode with the Rate mode

enabled, the motor stop function of the transmitter will not shut off

the motors, but set them to "full power backwards". To prevent this,

a mixer is to be programmed in such a way that switching the motor

stop switch to the motor OFF position also automatically switches

over to the position mode in which the stop of all motors is then

ensured.

Programming step-by-step

1. Program a linear mixer of "S => 5" according to the transmitter

instructions.

2. Give this mixer the same switch with the same switching direction

that activates the motor stop function.

Keep this switch in the motor OFF position while programming

the mixer.

3. Change to the setting page of the mixer.

4. Set the "travel" symmetrically to +100%.

5. Change to the line "Offset".

6. Now manually set the offset value to +100%, so as shown in the

picture on the left, see middle illustration on the left.

And in the servo display, the bars of channels 1 and 5 should be

set to -100% despite the Rate mode is activated, see the lower

figure on the left.

16570.16572_Alpha150Q/170Q /220Q_V1

29 / 44

Page 30

Special functions on channel 6

Through the channel 6 of the transmitter it is possible to switch up

to three special functions, but the auto-flip function additionally

requires a mixer.

• Video channel switching

I5

SW6/7

I6

I7 +100%

free

I8 +100%

I9 +100%

+100%

3

+100%

+100%

+100%

+100%

+100%free

+100%free

trv

There are four video channels available in Europe. Between them

is switched in rotation process, each with a short control pulse of

+100% to the control channel 6. In parallel, the colour of the LED

lighting of the copters changes.

+

• red = Video channel R3

• green = Video channel R4

• blue = Video channel R5

• white = Video channel R6

To toggle the video channels as well as the lighting of the copter,

in the menu "Control setting", program one of the self-resetting

switches on your transmitter to "input 6" and leave the rest at

their default values.

In the preprogrammed model memory "Alpha 110" of the optionally supplied transmitter mz-12 Pro HoTT is the right front

mounted switch "S6". From this three-stage switch, only the

self-resetting switch function is used.

• Auto-Flip

With the auto-flip function, it is easy to perform a flip in the Attitude mode with the copter.

M1

M2

M3

M4

M5

L.MIX1

trv

os

Typ

–125%

S

??

??

??

??

fro

0%

However, since the auto-flip function should only be activated in

"Attitude mode", the corresponding dependency is established

by setting a free mixer of "5 => 6" as follows:

Programming step-by-step

6

2

–––

??

–––

??

??

–––

??

–––

zu

6

5

0%

ASYSYM

1. Select "5" in the "from" column of a free linear mixer.

2. In the now accessible column "to",select "6" as target.

3. In the column above the switch symbol assign a self-resetting

switch, for example the switch 2 of the mz-12 Pro HoTT.

4. Change to the setting side of the mixer and hold down the

button just assigned to set the mixer.

5. According to the transmitter description, an asymmetrical

path of at least -110% has to be set. However, as shown in the

figure, a setting between -125% and -150% is recommended.

6. Recall the servo display for checking:

30 / 44

16570.16572_Alpha150Q/170Q /220Q_V1

Page 31

"Telemetry" menu

Copter Alpha 220Q

Copter Alpha 150Q/170Q

SETTING & DATA VIEW

ശ In Attitude mode, when the selected switch is activated,

the channel 6 bar must exceed the minimum value of

+110%.

ശ In the Rate mode, the bar of channel 6 must remain at 0%

even if the selected switch is pressed.

So programmed, the auto-flip function can be "armed" in the

Attitude mode with a short change of the self-resetting switch for

about 5 seconds. As soon as the roll or pitch control stick is moved

more than 50% of its way within this time, the copter will automatically flip to the appropriate direction.

Note

After the flip, position deviations in the range of <10 ° are possible.

Telemetry

SETTING & DATA VIEW

SENSOR

RF STATUS VIEW

VOICE TRIGGER

RX DATA ON

ALARM SETTING

Receiver display

RECEIVER Q.06

LANGUAGE: English

ALARM VOLT: 10.2V

ALARM TEMP: 70°C

VIDEO CHANNEL R3

ALARM CAPAC. 600mAh

K5: SERVO

RECEIVER Q.06

LANGUAGE: English

ALARM VOLT: 10.2V

ALARM TEMP: 70°C

VIDEO CHANNEL R3

ALARM CAPAC. 1200mAh

K5: SERVO

The basic handling of the "Telemetry" menu is described in the manual of the respective HoTT transmitter with display. By way of derogation, only in certain receivers the menu structure is summarized

under the generic term "setting & data view". These instructions

also provide information on how to access this menu. Change accordingly to the first setting page of the receiver module of the 3D or

Race copter Alpha 150Q, 170Q or Race copter Alpha 220Q.

Note

The setting values shown in the following display illustrations show

the respective default values of the copters mentioned above.

LANGUAGE

In the "Language" line you can set the display language in the receiver

menu.

The choices are: German, English, French, Italian, Spanish

ALARM VOLT

If the receiver voltage falls below the set value, a low-voltage warning is generated by the transmitter in the form of a "sound-declining

16570.16572_Alpha150Q/170Q /220Q_V1

31 / 44

Page 32

alarm tone" or the "receiver voltage" speech output message.

Copter Alpha 150Q/170Q

3D Copter Alpha 170Q

ALARM TEMP

If the receiver temperature exceeds the set temperature, a warning

is generated by the transmitter in the form of a "3-step sound-climbing alarm tone" or the "receiver temperature" speech output message.

The adjustment range is 5 ° increments from 50 to 80 °C.

Video channel

If necessary, select the desired video channel in this line. Their selection depends on the region and its regulations.

Note

As described under "Special functions on channel 6" described

above, it is possible to change in rotation between the available

video channels through a push button.

ALARM CAPACITY

In this line, to be on the safe side, select a value that is approximately

10 to 15% lower than the nominal capacity of the battery used, so

that enough time and power remain for a safe landing.

ROLL/NICK Display

MULTICOPTER RO/NI

ROLL/NICK P 40

ROLL/NICK D 40

DAMPING 9

ROLL FACTOR % 95

POWER2SENS. 100

R/N DYNAMIC 70

––ATTITUDE MODE––

ROLL/NICK I 40

AGILITY 8

––RATE MODE––

R/N RATE I 17

RATE 70

MULTICOPTER RO/NI

ROLL/NICK P 30

ROLL/NICK D 40

DAMPING 30

ROLL FACTOR % 95

POWER2SENS. 80

R/N DYNAMIC 70

––ATTITUDE MODE––

ROLL/NICK I 40

AGILITY 8

––RATE MODE––

R/N RATE I 15

RATE 70

The control is based on the PID principle, where the "P" stands for

"proportional", the "I" for "integral" and the "D" for "digital". In short

...

... the deviation from the setpoint proportional to the manipulated

variable has an effect at the P value.

... the existing control deviation is continuously summed up at the I

value and then acts on the manipulated variable via the I value.

... the differential component only takes into account the speed of

the control deviation and then acts on the control accordingly via the

D component.

ROLL/NICK P

This parameter determines the tilting behaviour of the copter during

the maximum climb.

In order to prevent tilting at full climbing power in the end, this

parameter must be increased in steps of 5 until a medium-fast tilting

occurs. Subsequently, this value is to be adjusted in individual steps

until the tilting has disappeared.

32 / 44

16570.16572_Alpha150Q/170Q /220Q_V1

Page 33

MULTICOPTER RO/NI

Race Copter Alpha 220Q

ROLL/NICK P 25

ROLL/NICK D 35

DAMPING 30

ROLL FACTOR % 95

POWER2SENS. 100

R/N DYNAMIC 70

––ATTITUDE MODE––

ROLL/NICK I 40

AGILITY 8

––RATE MODE––

R/N RATE I 15

RATE 70

ROLL/NICK D

This parameter determines the tilting behaviour of the roll / pitch

function of the copter.

As described above, this parameter must be adjusted until the Multicopter engages exactly over Roll and Nick. A too high value leads to

very rapid oscillations.

DAMPING

The damping factor should be set as low as possible, but as high as

necessary, so that the PID control can operate optimally. If you do

not get vibrations away with the PID settings , then change the damping of 1 step and test whether the setting works better or worse.

ROLL FACTOR %

Set the Roll setting as percent value of the overall gain. For symmetrical copters, the value should normally be left at 100. If, because of

its gravity centre, the Copter is more agile on the Roll axis than on

the Nick axis, then you can change here the roll factor.

POWER 2SENS.

This parameter allows you to set a kind of gyro suppression. Higher

values result in an increased suppression towards full throttle.

R/N DYNAMIC

Higher dynamic values provide a more direct feel for the flight (3D

flight 50 ... 100), lower dynamic values for smoother flight recordings, rounder freestyle flying and races (30 ... 50).

Adjustment range: MIN (deactivated), 1 …100, (0)C5, (50)C6 … (50)

C16

Alternatively, the effect on the R/N Dynamic value can also be

adjusted by the transmitter. To do this, a rotary or slider control is

assigned to one of the control channels 5 ... 16 and the remaining

settings are left at the default values. In the value field of the "R/N

Dynamic" line, the corresponding channel is then merely to be

selected instead of a fixed value.

Note

If a channel is selected in the "R / N DYNAMIC" line, but no encoder

is assigned to it on the transmitter side, the value in brackets is

specified.

–– ATTITUDE MODE ––

16570.16572_Alpha150Q/170Q /220Q_V1

ROLL/NICK I

Set the I component of the Attitude mode. At too low values of Copter tilts slowly.

33 / 44

Page 34

–– Rate mode ––

Copter Alpha 150Q/170Q

3D Copter Alpha 170Q

YAW Display

If it stops after a roll or pitch command and “oscillates”, the value

must be reduced.

AGILITY

This value determines how fast a change of position is made.

R/N RATE I

Sets the I component of the rotation in rate mode. At too low values

of Copter tilts slowly. If it stops after a roll or pitch command and

“oscillates”, the value must be reduced.

RATE

This value sets the maximum potential rate in Rate mode.

The general comments on PID control in the description of the roll /

pitch display are also applicable here.

MULTICOPTER GIER

YAW P 40

YAW I 12

YAW D 10

RATE 70

YAW DYNAMIC 75

Race Copter Alpha 220Q

MULTICOPTER YAW

YAW P 25

YAW I 12

YAW D 10

RATE 70

YAW DYNAMIC 75

YAW P

The P factor is responsible for the snap to yaw. Higher values result

in a faster stop. At too high P-values the copter starts to “swing”. In

such cases, the value must be reduced again.

YAW I

The I-factor ensures constant rotations. Start with low values and

only increase them until the rotations are constant. Too high value

cause an oscillation when you stop. Eventually, the motors can start

rotating and thus cause unwanted rising.

YAW D

The D-factor affects the stopping behaviour in Yaw. Normally a hard

D action is necessary. The D component must be set as low as possible, since it affects the whole system.

RATE

For beginners a rate value of approx. 50, for racers and freestyle

pilots between 50 and 70 are recommended.

34 / 44

16570.16572_Alpha150Q/170Q /220Q_V1

Page 35

Multicopter Basis display

Copter Alpha 150Q/170Q

Race Copter Alpha 220Q

3D Copter Alpha 170Q

MULTICOPTER BASIC

TYPE QUADRO XI

ESC S3087

MODE NORMAL

MINPOWER % 10

FREESTYLE 1

CALIBR.POSITION NO

KALIBR.LAGE NEIN

MULTICOPTER BASIC

TYPE QUADRO XI

ESC S3088

MODE NORMAL

MINPOWER % 5

FREESTYLE 1

CALIBR.POSITION NO

KALIBR.LAGE NEIN

YAW DYNAMIC

Higher dynamic values provide a more direct feel for the flight (3D

flight 80 ... 100), lower dynamic values for smoother flight recordings, rounder freestyle flying and races (30 ... 80).

TYPE

The "Type" line defines the basic configuration of the copter. The fol-

lowing selections are available: "Quadro X", "Quadro XI" and "Quadro

+". The default setting "Quadro XI" is, however, to be maintained,

otherwise the copter will become uncontrollable.

ESC

This term is composed of the first letters of the English term "Electronic Speed Control" as a synonym for "motor control". In this line,

therefore, the type of the installed motor control must be entered

de facto. This value is, like the previous "type", given by the facto-

ry-installed technique of the copter and therefore may not be

changed at will.

MODE

MULTICOPTER BASIC

TYPE QUADRO XI

ESC S3087

MODE ACRO 3D

MINPOWER % 15

FREESTYLE 1

CALIBR.POSITION NO

KALIBR.LAGE NEIN

NORMAL

This setting must be used for copters with speed controller without

reverse of the direction of rotation.

ACRO 3D

This setting is reserved for copters whose speed controllers are

equipped with direction reverse.

Attention

The setting ACRO 3D is reserved for the 3D copter Alpha 170Q No.

16570.HoTT.

Note

For safety reason the "Type" and "Mode" changes take effect after

switching off and on the receiver system.

16570.16572_Alpha150Q/170Q /220Q_V1

35 / 44

Page 36

!

positive full throttle

negative full throttle

linear to full throttle

linear

MINIPOWER %

Travel Throle/Pitch control sck

idle

linear

CAUTION

• Since after changing to ACRO 3D the power control in Rate

mode is different, as shown in the figure on the left, the motors,

depending on the current position of the throttle / pitch control stick, can change more or less when switching from the

Attitude mode to the Rate mode or Acro 3D mode. Therefore

always mount the propellers immediately before starting the

flight operation and start and land exclusively in "attitude

mode".

motor idle

• During prolonged extreme aerobatics of the copter in Acro 3D

mode (e.g. , sequence> 1min), the receiver may lose its attitude information and, as a result, the copter may move to an

undesired position when switching to attitude mode. In this

situation, the copter should be in the Rate mode and either it

is left quiet for about 30 seconds or it is landed for a short time,

so that the receiver can readjust the position information

again.

MINPOWER %

If the throttle / pitch control stick is moved past its stop on the idleside stopper of the copter speed controller, the motors will start to

run. The setting value of this option determines the minimum power

to be provided at the switch-on point so that the position control can

continue to operate in the Attitude mode and it can also serve as a

rescue mode in an emergency. But do not set a too high value here

in order not to restrict too much the control range of the speed controller.

The adjustment range is 5 ... 35%.

FREESTYLE

36 / 44

The setting basically serves to prevent the I-factor from generating

a vibration.

The higher the value, the more I-vibrations are prevented, but also

the straight-ahead flight is degraded. Values up to max. 20 recommended.

Adjustment range: MIN (deactivated), 1 …100, (0)C5, (50)C6 … (50)

C16

Alternatively, the effect on the I value can also be adjusted by the

transmitter. To do this, a rotary or slider control is assigned to one of

the control channels 5 ... 16 and the remaining settings are left at the

default values. In the value field of the "Freestyle" line, the corresponding channel is then merely to be selected instead of a fixed

value.

Note

If a channel is selected in the "FREESTYLE" line, but no encoder is

assigned to it on the transmitter side, the value in brackets is specified.

16570.16572_Alpha150Q/170Q /220Q_V1

Page 37

Axis assignment

CALIBR.POSITION

With this option, if necessary, the basic calibration of the acceleration sensors can be readjusted, so that the copter hovers with the

control stick and trim to neutral, in attitude mode, precisely horizontally.

To recalibrate, place the copter on an absolutely horizontal surface

and then set the value field to "YES".

As soon as the calibration is completed, the display changes back to

"NO". To accept the calibration that has just been carried out in the

non-volatile memory of the receiver, it is essential to push or tap on

the ENT key.

Note

The gyroscope calibration, required each time the copter is switched

on, takes place as soon as the copter or its receiver is absolutely

quiet. The motors will not start until the calibration is completed.

AXIS ASSIGNMENT

DO SETUP No

ROLL +2

NICK +1

YAW –3

In this display, the gyros and their effective direction can be determined. A readjustment is normally not necessary with the quadcopter Alpha 150Q, 170Q or Alpha 220Q.

DO SETUP

After selecting the line "do setup" and changing the value field to

"yes", assign the axes as follows:

Do setup step by step

1. Push or tap on the ENT key

"NO" is displayed inverted.

2. Change the value field to "YES".

3. Push or tap on the ENT key

4. At the transmitter briefly bring the roll control stick to the right

stop.

The display shows the roll axis inverted.

5. Tilt the copter more than 45 degrees to the right.

As soon as the detected axis with the required sign is displayed in

"normal" representation, the axis assignation is completed.

16570.16572_Alpha150Q/170Q /220Q_V1

6. At the transmitter briefly bring the nick control stick to the front

stop.

The display shows the nick axis inverted.

7. Tilt the copter more than 45 degrees to the front.

As soon as the detected axis with the required sign is displayed in

"normal" representation, the axis assignation is completed.

37 / 44

Page 38

8. At the transmitter briefly bring the yaw control stick to the right

stop.

9. Turn the copter clockwise by more than 45 degrees to the right.

As soon as the detected axis with the required sign is displayed in

"normal" representation, the axis assignation is completed.

The gyros and their operating directions have now been assigned.

Attention

To be on the safe side, the directions of action of the gyroscope settings must be checked.

Check step by step

1. Remove the rotors of the copter.

2. Use the pitch control stick to give approx. 25% "throttle".

All motors run at the same speed.

3. Switch to the attitude mode.

4. Tilt the copter forward.

The front motors must turn faster than back ones.

5. Tilt the copter to one side.

The motors of the side, the "hanging" side must turn faster than

those of the opposite, higher side.

‖ If this is not the case, the entire gyro assignment must be

repeated.

38 / 44

16570.16572_Alpha150Q/170Q /220Q_V1

Page 39

16570.16572_Alpha150Q/170Q /220Q_V1

39 / 44

Page 40

Firmware updates

The required programs and files are enclosed in a software pack and

can be found for the corresponding product at www.graupner.de.

Download this software package from the Internet, and unpack it on

your Windows PC or laptop.

The procedure is also described in detail in the manual contained in

the data package. You can also singularly download these from the

download page of the product at www.graupner.de.

Notes

• Please note that compatible firmware is required for reliable

communication between the HoTT components. The programs

and files that are required for updates are therefore combined

into a single pack that is currently named "HoTT_Software_

V4.zip".

• Always use all your RC components only with the latest firmware version. The current firmware version can be found on the

Internet at www.graupner.de.

Firmware updates of a 3D or Race Copter Alpha 150Q, 170Q or

Alpha 220Q are performed via the connector on the left side of the

copter using a laptop or PC running Windows 7 ... 10. You will need

the optionally available USB interface, No. 7168.6, as well as the

adapter cables No. 7168.S and S1038.2.

Connect the adapter lead to the USB interface. The polarity of the

plug-in system cannot be reversed. Note the small chamfers on the

sides. Do not use force, the plug should click into place easily. Finally,

connect the adapter cable S1038.2 with the correct polarity to the

corresponding end of the adapter cable 7168.S.

Now push the narrow white plug all the way into the side connector.

But do not apply force.

The update takes place via the program part "Slowflyer / Gyro

Receiver Downloader" of the program "Firmware_Upgrade_gr_Studio" available under "Links". Please follow the notes of the software.

Firmware update step-by-step

1. Download the required firmware file from the product page to

your PC and unzip it if necessary.

2. Be sure to check the charge level of the battery to be used as the

power source before each firmware update.

3. When switched off, connect the device to be powered up to a PC

or laptop using the aforementioned cables and adapters.

40 / 44

16570.16572_Alpha150Q/170Q /220Q_V1

Page 41

ശ Do not interrupt this connection during an update! Therefore,

it is essential to ensure trouble-free contact between transmitter and computer, and later, after plugging in the power

source, between copter and power source.

4. Start the program "Firmware_Upgrade_gr_Studio".

5. Select the correct COM port in the program part "Port select" of

the "Firmware_Upgrade_gr_Studio".

6. Open the program part "Slowflyer, Gyro Receiver Downloader" of

the "Firmware_Upgrade_gr_Studio".

7. Click on "File" in the upper left corner and change to the location

of the previously downloaded upgrade file in the following "Open

File" dialog.

8. Select the ".bin" file matching your copter.

9. Click on "Start".

10. Now connect the battery, previously checked for its charge status,

to the copter.

The firmware upgrade process starts.

11. The end of the data transfer will be indicated by the update program.

12. Disconnect the battery from the copter and then disconnect the

PC or laptop.

13. Be sure to check the copter for correctness after each update.

16570.16572_Alpha150Q/170Q /220Q_V1

41 / 44

Page 42

SIMPLIFIED DECLARATION OF CONFORMITY

Graupner/SJ hereby declares that the radio systems 16570.RTF,

16570.FPV, 16570.HoTT, 16572.RTF and 16572.FPV comply with

Directive 2014/53/EU.

The full text of the EU Declaration of Conformity is available at the

following Internet address: www.graupner.de.

42 / 44

16570.16572_Alpha150Q/170Q /220Q_V1

Page 43

Notes on environmental protection

P

If this symbol is on the product, instructions for use or packaging, it

indicates that the product may not be disposed with normal household waste once it has reached the end of its service life. It must be

turned over to a recycling collection point for electric and electronic

apparatus.

Individual markings indicate which materials can be recycled. You

make an important contribution to protection of the environment by

utilizing facilities for reuse, material recycling or other means of

exploiting obsolete equipment.

Batteries must be removed from the unit and disposed of separately

at an appropriate collection point. Please inquire if necessary from

the local authority for the appropriate disposal site.

Care and maintenance

The product does not need any maintenance. Always protect it

against dust, dirt and moisture.

Clean the product only with a dry cloth (do not use detergent!) lightly

rub.

Warranty conditions

Graupner/SJ GmbH, Henriettenstrassee 96, 73230 Kirchheim/Teck

grants from the date of purchase of this product for a period of 24

months. The warranty applies only to the material or operational

defects already existing when you purchased the item. Damage due

to misuse, wear, overloading, incorrect accessories or improper handling are excluded from the guarantee. The legal rights and claims

are not affected by this guarantee. Please check exactly defects

before a claim or send the product, because we have to ask you to

pay shipping costs if the item is free from defects.

These operating instruction are exclusively for information purposes

and are subject to change without prior notification. The current

version can be found on the Internet at www.graupner.de on the

relevant product page. In addition, the company Graupner/SJ has

no responsibility or liability for any errors or inaccuracies that may

appear in construction or operation manuals.

Not liable for printing errors.

16570.16572_Alpha150Q/170Q /220Q_V1

43 / 44

Page 44

Loading...

Loading...