Page 1

GRAUPNER/SJ GmbH D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. 3/2013

- 1 -

Order No. 9547

BUILDING INSTRUCTIONS

AMIGO IV

RC model glider of around 2000 mm wingspan

This model requires a two-function HoTT radio control system

Page 2

GRAUPNER/SJ GmbH D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. 3/2013

- 2 -

Please be sure to observe the safety notes included in the Appendix to these assembly instructions. If you ever dispose of the model, the complete operating instructions and safety notes

must also be passed on to the new owner.

Introduction

The AMIGO IV is a classic Graupner/SJ model aircraft which offers an exceptional

performance in the air. The outstanding features of the glider are its low airspeed and

excellent thermal flying qualities. In developing the new version we were determined

to emulate the original design as accurately as possible; for example, the wing and

tail airfoils are unchanged. The model can be launched by hand-tow or bungee, but

can also be flown as a powered glider with a motor pylon. Completing the aircraft

calls for manual modelling skills, and should therefore only be attempted by experienced modellers, or beginners with the assistance of a proficient model builder.

Additional items required (not included)

GRAUPNER HoTT MX-10 2.4 GHz COMPUTER SYSTEM Order No. 33110

DES 577 BB servo (2 required) Order No. 7944

Receiver battery Order No. 8716.4

ULTRAMAT 8 battery charger Order No. 6411

Receiver battery charge lead Order No. 3021

Additional items for motor pylon* (not included)

Motor pylon Order No. 2910

COMPACT 260Z 7.4 V electric motor Order No. 7731

COMPACT CONTROL 45 BEC G3.5 speed controller Order No. 7224

Propeller, ELEKTRO-PROP 8 x 5” Order No. 1326.8x5

Precision spinner, 38 mm Ø Order No. 1385.383

LiPo battery, 2/2500 7.4 V Order No. 7633.2

* The pack, Order No. 2910, contains the assembly instructions for this option.

Essential adhesives, tools and covering material (not included)

UHU ALLESKLEBER Kraft (general-purpose adhesive) Order No. 1096

Cyano-acrylate adhesive (“cyano”) Order No. 5821

Cyano-acrylate activator Order No. 953.150

Soft pencil (“B”-lead), set-square, balsa knife, miniature balsa plane, sanding block,

modelling pins, cross-point screwdriver, flat-nose pliers, scissors, 3 mm / 4 mm Ø

twist drills, paper towel, adhesive tape, clear plastic film, protective gloves, iron-on

film and film iron.

Building Instructions

Before you start building the model please study the building instructions and the

plan, so that you have a clear idea of the processes and sequence of assembly.

For each stage lay out the components, tools and adhesives required. Separate the

laser-cut wooden parts from the sheets using a balsa knife, trim them as required,

drill holes at the marked points and sand the edges smooth. Always work on a clean,

smooth surface when assembling components. The white glue supplied should be

used for all joints unless expressly stated otherwise; wipe off excess adhesive with

paper towel. Hold parts together with modelling pins or adhesive tape until the glued

joints have dried out thoroughly.

Page 3

GRAUPNER/SJ GmbH D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. 3/2013

- 3 -

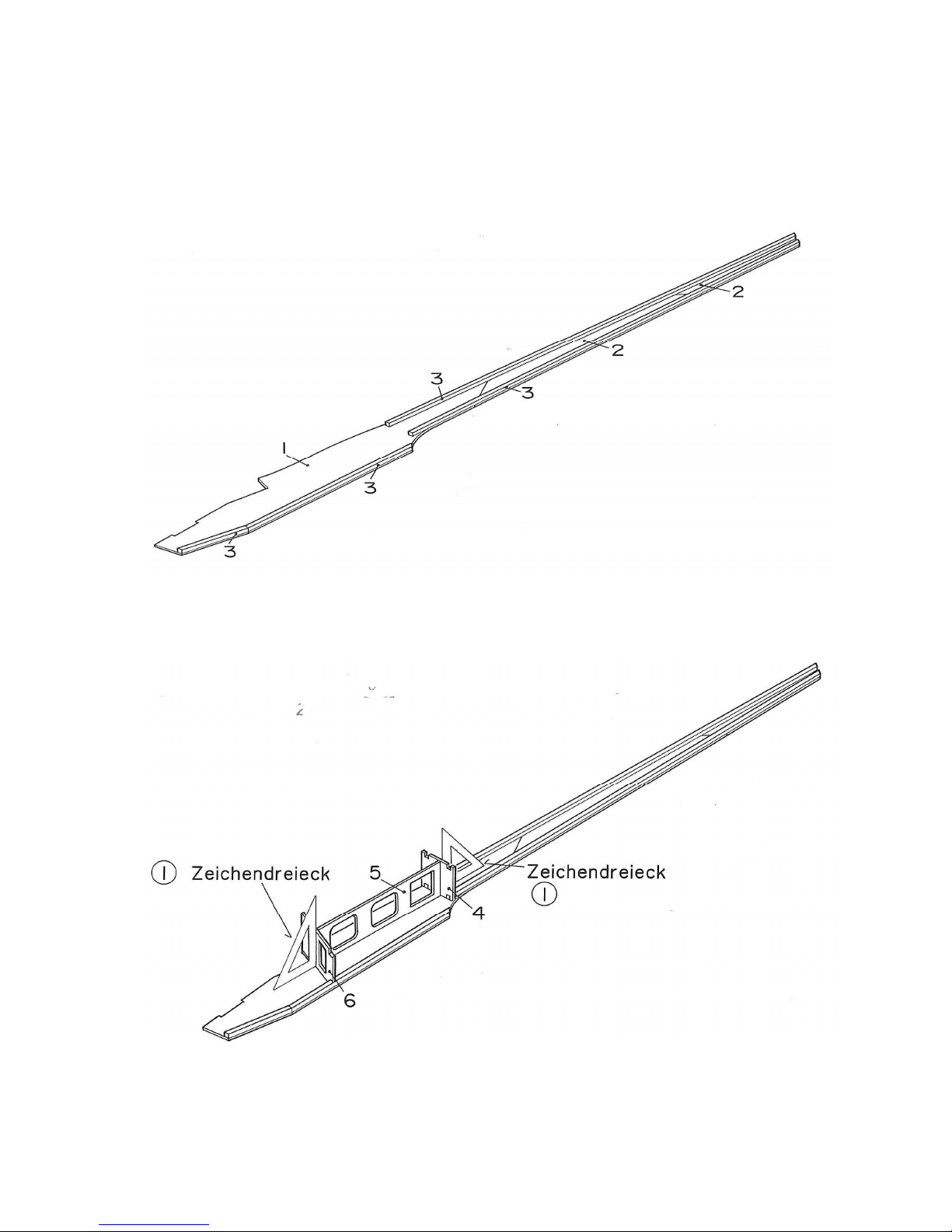

Fuselage and fin

Lay plan sheet 1 down on the building board, locate the area showing the fuselage

side, and cover it with clear plastic film to prevent the parts sticking to the paper later.

Glue together the right-hand fuselage side components (parts 1 and 2), and pin them

down accurately over the drawing on the plan. Glue the fuselage longerons (3) to

parts (1) and (2) exactly flush with the outside edges.

Assemble the left-hand fuselage side, working directly over the plan in the same way.

It is essential to note that the left-hand fuselage side needs to be removed from

the building board and turned over before the longerons are fitted; this produces a “handed pair” of sides.

Glue the formers (4) and (6) and the servo plate (5) to one fuselage side, and set

them exactly upright using a set-square. Pin them in place until the glue has set hard.

Page 4

GRAUPNER/SJ GmbH D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. 3/2013

- 4 -

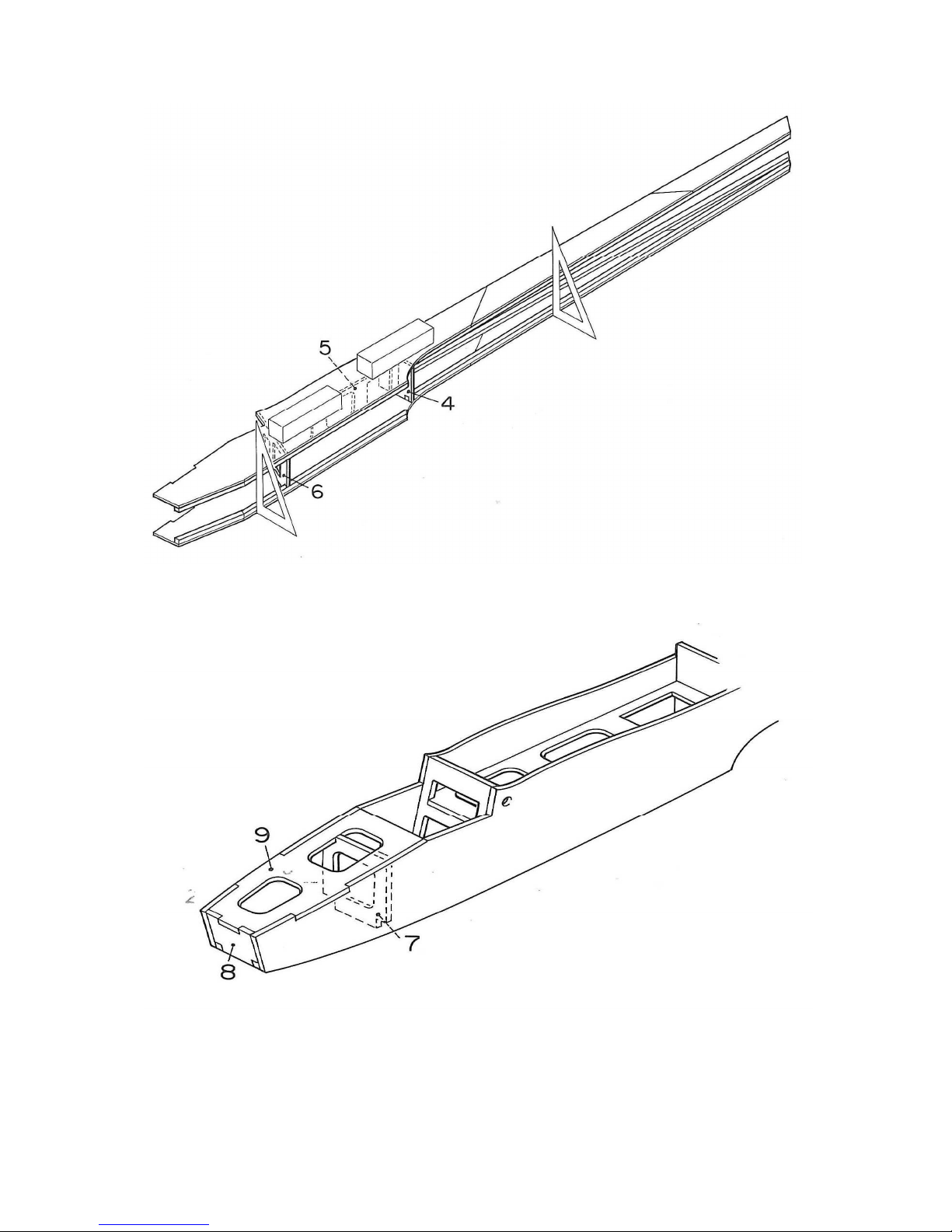

The prepared left-hand fuselage side can now be trial-fitted and glued to the fuselage

framework. It is essential to check that the two fuselage sides line up accurately.

Weight the second side down as shown in the sketch until the glue has set hard.

The drawing shows the nose area of the fuselage. The next step is to glue the formers (7) and (8) and the nose reinforcement (9) in place as shown. Caution: the

fuselage must be straight and symmetrical. You can check this by placing the

fuselage over the plan (fuselage plan view). Fix the parts together with modelling pins

or tape until the glue has set hard.

Page 5

GRAUPNER/SJ GmbH D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. 3/2013

- 5 -

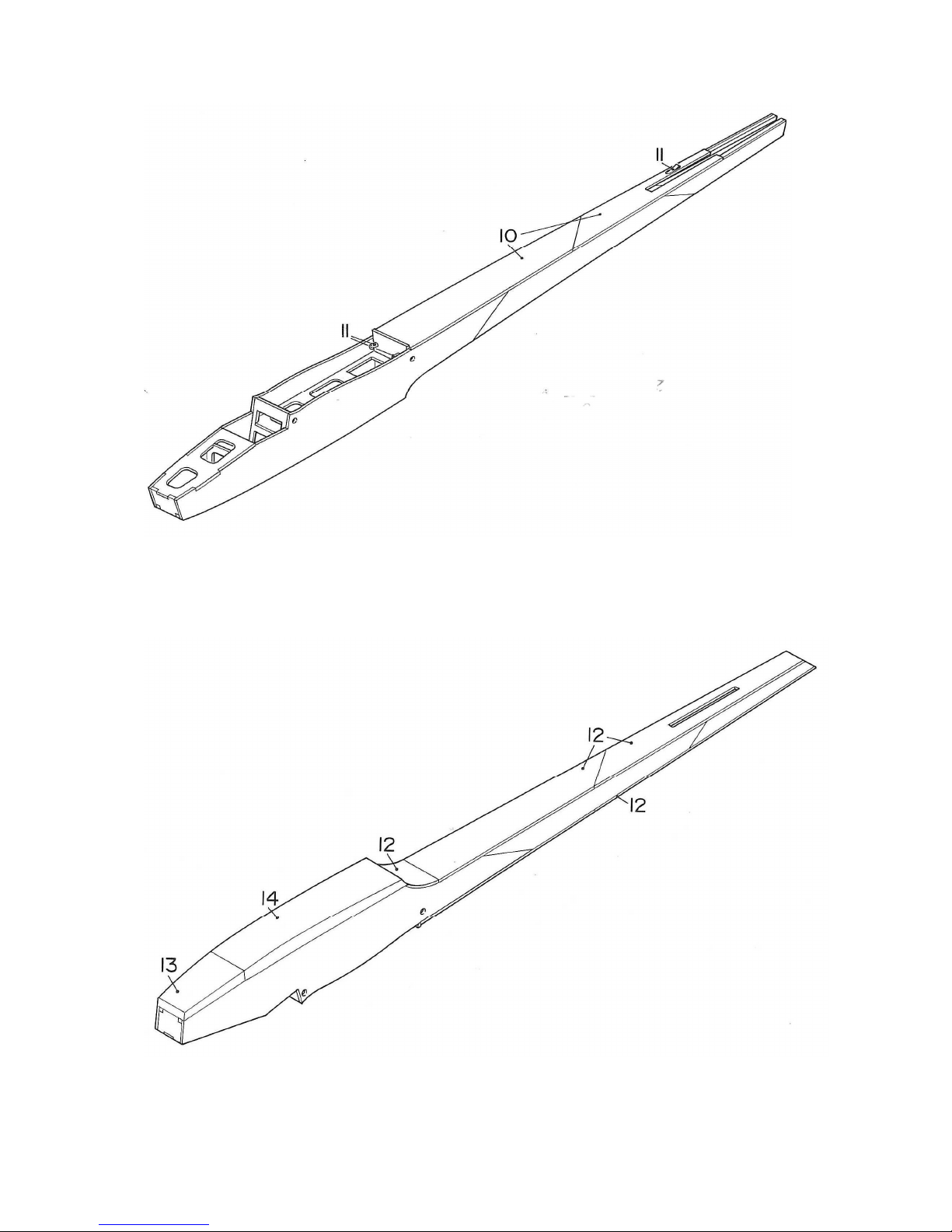

Carefully sand the top of the fuselage using a sanding block before gluing the top

decking panels (10) in place. Temporarily fit the “snake” outer sleeves (11) and trim

the exit slots if necessary. Fit an inner tube in each sleeve to check that they move

smoothly. When you are satisfied, glue the snake outers to the fuselage using UHU

ALLESKLEBER Kraft or cyano.

The sketch shows the bottom fuselage panels (12) to (14) glued in place; sand the

underside using a sanding block beforehand, as described earlier.

Page 6

GRAUPNER/SJ GmbH D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. 3/2013

- 6 -

Glue the shaped upper nose panel (15) in place. Sand the front face of the fuselage

flat before gluing the noseblock (16) in place. Glue the flanged nut (17) to the tailplane support (18) and glue it to the fuselage as shown.

Assemble the fin and rudder from parts (19) to (21) using cyano. Refer to section D-D

on plan sheet 1; do not use activator spray for these joints. Sand the fin to the profile

shown in section D-D, and check that the rudder deflects freely to both sides. Trial-fit

the fin assembly in the slot in the fuselage. Check from the nose of the fuselage that

the fin is exactly vertical, then glue it in place permanently.

Page 7

GRAUPNER/SJ GmbH D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. 3/2013

- 7 -

Trim parts (22) and (23) to fit on the fuselage, and trial-fit the locating pieces (23) and

(23a). Glue the parts together, and tape them to the fuselage while the glue is drying;

take care not to glue them to the fuselage itself. Carefully trim the moulded canopy to

final size, and glue it to the canopy frame using UHU ALLESKLEBER Kraft.

Allow all the glued joints to set hard before rounding off the fuselage to the profile

shown in sections E-E and F-F, using a balsa plane and sanding block. This process

produces a good-looking, streamlined fuselage, and also saves considerable weight.

Tailplane

Lay plan sheet 1 on the building board, and cover the tailplane area with clear plastic

film to avoid the components sticking to the plan later. Assemble parts (26) to (42) as

Page 8

GRAUPNER/SJ GmbH D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. 3/2013

- 8 -

shown on the plan and in the drawing, and glue all the joints, referring to sections AA and C-C. When the glue is dry, sand the tailplane framework, round off the tip

blocks (42) and shape the elevator (43) as shown on the plan using a sanding block.

When the tailplane has been covered, the elevator can be attached using a fulllength tape hinge, as shown in the sketch.

Wings

The first stage here is to assemble the right-hand inboard wing panel: cover the appropriate area of the plan with clear plastic film as already described, then pin down

the leading edge (44), spar (50) and trailing edge (45). Fit the 0.8 mm packing strip

under the trailing edge as shown in section H-H. Glue the wing ribs (46) to (49) in

place. Note that the ribs (46) have to be set at an angle using the template (98).

Allow the glue to set hard, then remove the wing panel from the building board and

glue the bottom spar (50) to the structure.

Roughen (sand) the outside of the brass tube (51) and glue it in place using cyano.

Fit the in-fill pieces (52) using plenty of glue, followed by the reinforcements (53) and

the spar webs (54).

The outboard wing panel is constructed on the same principle.

Before building the left wing panel rub a little thin plant oil into the plan to render it

translucent; see the note on the plan. The left-hand wing panels can then be assembled on the back of the plan using the familiar procedure.

Page 9

GRAUPNER/SJ GmbH D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. 3/2013

- 9 -

The inboard and outboard wing panels can now be joined: first trial-fit the parts, then

glue them together using the reinforcements (68) to (73). Glue the incidence pegs

(74) in the root ribs. Allow the glue to set hard, then carefully sand the whole wing

before gluing the sheet panels (75) to (78) to the structure.

When fitting the sheet panels it is essential to keep the wing flat on the building board

to avoid warps. It is best to glue the sheeting in place using cyano sparingly, and

then to apply more glue to the joints, working from the underside. Sand the joined

wing overall as shown in section H-H, and round off the wingtips (79). Finally check

that the two wings fit together snugly at the root. Glue the trailing edge reinforcement

rods (81) in place, and secure them with nylon tape (21), again fixed using cyano.

Covering

The whole model can now be covered with iron-on film (not included). The fuselage

requires several sections of film: start with the underside, then the nose area and the

turtle deck, and finish with the fuselage sides. Each wing is covered with four film

panels, always starting with the underside. Cover each panel of the tail group individually. It is important to avoid warps creeping into the structure when the film is

applied and shrunk. The final part of the covering procedure is to apply the selfadhesive name placards.

RC installation

Screw the tailplane to the fuselage using parts (92) and (93).

Fit the servos in the fuselage and screw them in place (the retaining screws and

output devices are included in the servo accessory packs). Install the two horns using

parts (87) to (90). Connect the control snakes, install the remaining receiving system

components, and check the working systems from the transmitter. If the control surfaces are not central, screw the clevises in or out on the threaded couplers to correct.

Attach the wing to the fuselage using the four rubber bands (99).

Page 10

GRAUPNER/SJ GmbH D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. 3/2013

- 10 -

Balancing

Assemble the model completely for balancing, i.e. with the whole RC system fitted.

The correct Centre of Gravity is at a point 115 mm from the wing leading edge,

measured at the root.

Check the C.G. by supporting the model under the wing on two fingertips at the point

indicated: the model should now balance level. Add lead ballast to the extreme nose

until the model remains horizontal. Note: the C.G. of the AMIGO IV is further aft than

normal due to the lifting airfoil of the tailplane.

Longitudinal dihedral

The longitudinal dihedral, i.e. the difference in incidence between the wing datum and

the tailplane datum, should be 1.5° to 2°. If you h ave built the model accurately and

in accordance with the plan, this will automatically be correct. If you are not sure of

this, or if the model needs to be checked after a repair, simply refer to the sketch

below.

Flying

Assemble the model completely, charge all the batteries, and check that the control

surfaces are properly centred before undertaking the first flight. Wait for a day with

little or no breeze. A good flying site is a flat grassy field, ideally with a gentle slope

facing into wind.

Note: for the initial test-glide push the model forward directly into any wind; the

fuselage nose should be angled down slightly (by about 10°). If necessary apply

very slight rudder and elevator commands to keep the model gliding straight and flat.

Fine-tuning is carried out using the trim sliders below and adjacent to the transmitter

sticks. Always land the model directly into wind.

All of us at Graupner/SJ Modellbau hope you enjoy many fine flights with your new

AMIGO IV

Page 11

GRAUPNER/SJ GmbH D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. 3/2013

- 11 -

Parts List

No.

Description

Quant.

Material

Dimensions

in mm

1 Front fuselage side 2 Plywood Laser-cut, 3

2 Rear fuselage side 2 x 1+1 Balsa Laser-cut, 3

3 Fuselage longeron 8 Balsa Oversize, 5 x 5

4 Fuselage former 1 Plywood Laser-cut, 3

5 Servo plate 1 Plywood Laser-cut, 3

6 Former 1 Plywood Laser-cut, 3

7 Former 1 Plywood Laser-cut, 3

8 Nose former 1 Plywood Laser-cut, 3

9 Nose reinforcement 1 Plywood Laser-cut, 3

10 Fuselage top decking 1+1 Balsa Laser-cut, 2

11 “Snake” outer sleeve 2 Plastic Overlength, 3.2 / 2.2 Ø

12 Rear fuselage bottom 3 x 1 Balsa Laser-cut, 2

13 Front fuselage bottom 1 Balsa Oversize, 10

14 Centre fuselage bottom 1 Balsa Oversize, 15

15 Shaped nose panel 1 Balsa Oversize, 17

16 Fuselage noseblock 1 Balsa Oversize, 46

17 Flanged nut 1 Steel Ready made, M 4

18 Tailplane support 2 Plywood Laser-cut, 2

19 Fin 1+1 Balsa Laser-cut, 2

20 Rudder 1+1 Balsa Laser-cut, 2

21 Nylon tape 1 Nylon Overlength, 20 wide

22 Canopy frame 1 Plywood Laser-cut, 2

23 Canopy frame 1 Plywood Laser-cut, 2

23a Canopy locating peg 2 Hardwood Oversize, 4 Ø

24 Canopy 1 Plastic Vac.-moulded

25 Wing band dowel 2 Hardwood Oversize, 5 Ø x 80

26 Tailplane spar 2 Balsa Oversize, 3 x 5 x 624

27 Tailplane sheet panel 1 Balsa Laser-cut, 1.5

28 Tailplane sheet panel 1 Balsa Laser-cut, 1.5

29 Tailplane leading edge 1 Balsa Oversize, 6.5 x 6 x 624

30 Tailplane false trailing edge 1 Balsa Oversize, 6 x 4 x 635

31 Rib 6 Balsa Laser-cut, 1.5

32 Rib 2 Balsa Laser-cut, 1.5

33 Rib 2 Balsa Laser-cut, 1.5

34 Rib 2 Balsa Laser-cut, 1.5

35 Rib 2 Balsa Laser-cut, 1.5

36 Rib 2 Balsa Laser-cut, 1.5

37 Rib 2 Balsa Laser-cut, 1.5

38 Rib 2 Balsa Laser-cut, 1.5

39 Rib 2 Balsa Laser-cut, 1.5

40 Rib 2 Balsa Laser-cut, 1.5

41 Sheet panel 1+1 Balsa Laser-cut, 1.5

42 Tailplane tip block 2 Balsa 10, length as plan

43 Elevator 1 Balsa 33 x 5 x 635

44 Wing leading edge 2 Balsa Oversize, 10 x 5 x 615

45 Wing trailing edge 2 Balsa 20 x 5 x 615

46 Rib 2 Balsa Laser-cut, 2

47 Rib 4 Plywood Laser-cut, 2

48 Rib 2 Balsa Laser-cut, 2

49 Rib 24 Balsa Laser-cut, 2

50 Main spar 8 Spruce 5 x 3, length as plan

51 Brass tube 2 Brass 5 / 4.2 Ø x 81

52 In-fill piece 8 Spruce 5 x 3 x 32

53 In-fill piece 2 Spruce 10 x 3 x 37

54 Spar web 16 Balsa 10 x 3 x 35

55 Wing leading edge 2 Balsa Oversize, 10 x 5 x 392

56 Wing trailing edge 2 Balsa Oversize, 20 x 5 x 395

57 Rib 2 Balsa Laser-cut, 2

58 Rib 2 Balsa Laser-cut, 2

59 Rib 2 Balsa Laser-cut, 2

60 Rib 2 Balsa Laser-cut, 2

Page 12

GRAUPNER/SJ GmbH D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. 3/2013

- 12 -

No.

Description

Quant.

Material

Dimensions

in mm

61 Rib 2 Balsa Laser-cut, 2

62 Rib 2 Balsa Laser-cut, 2

63 Rib 2 Balsa Laser-cut, 2

64 Rib 2 Balsa Laser-cut, 2

65 Rib 2 Balsa Laser-cut, 2

66 Rib 2 Balsa Laser-cut, 2

67 Spar web 18 Balsa 37 x 7 x 3

68 Dihedral brace 2 x 1+1 Plywood Laser-cut, 2

69 Dihedral brace 4 Plywood Laser-cut, 2

70 Rib 4 Balsa Laser-cut, 2

71 Half-rib 2 Balsa Laser-cut, 2

72 Gusset 6 Balsa Laser-cut, 3

73 Gusset 2 Balsa Laser-cut, 3

74 Incidence peg 2 Hardwood Overlength, 4 Ø x 85

75 Sheet panel 2 Balsa 615 x 85 x 1.5

76 Sheet panel 2 Balsa 390 x 85 x 1.5

77 Sheet panel 4 Balsa Laser-cut, 1.5

78 Sheet panel 2 Balsa Laser-cut, 1.5

79 Tip block 2 Balsa 10, length as plan

80 Root facing rib 2 Plywood Laser-cut, 2

81 Trailing edge reinforcement 2 Steel rod 1.5 Ø x 60

82 Wing joiner rod 1 Steel Ready made, 4 Ø

83 Snake inner tube 2 Plastic Overlength, 1.85 / 0.9 Ø

84 Threaded coupler 4 Plated brass Ready made, M 2

85 Nut 4 Steel Ready made, M 2

86 Clevis 4 Steel Ready made, M 2

87 Control surface horn 1 Plastic Ready made

88 Control surface horn 1 Plastic Ready made

89 Spreader plate 2 Plastic Ready made

90 Pan-head screw 4 Steel M2 x 10

91 Hinge tape (not included) 2 Plastic 620 x 15 x 0.1

92 Countersunk screw 1 Plastic M4 x 20

93 Spreader plate 1 Plastic Ready made

94 Towhook 1 Plastic Ready made

95 Spreader plate 1 Plastic Ready made

96 Pan-head screw 2 Steel M3 x 28

97 Reinforcement 1 Plywood Laser-cut, 3

98 Angle template 2 Plywood Laser-cut, 2

99 Rubber band 4 Rubber 40 Ø x 4 x 2

100 AMIGO IV name placard 4 Self-adhesive film 380 x 140 x 0.1

The picture shows the finished airframe in its uncovered state.

Page 13

GRAUPNER/SJ GmbH D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. 3/2013

- 13 -

Specification - AMIGO IV

Wingspan approx. 2000 mm

Overall length approx. 1115 mm

Wing airfoil NACA 4409

Wing area approx. 37.5 dm²

Tailplane area approx. 7.5 dm²

Total surface area approx. 45.0 dm²

All-up weight approx. 1100 g

Replacement part (not included)

AMIGO IV canopy Order No. 9546.1

Safety Notes

Caution: cyano-acrylate adhesive must never be allowed to contact any part of your body, and your eyes

in particular. For this reason we recommend the use of gloves and goggles when handling these

materials. The workshop should be effectively ventilated. Store the adhesive out of the reach of children.

It is a legal requirement to obtain third-party insurance before you operate any model aircraft.

Before attempting to operate the model for the first time it is essential to read right through the operating

instructions attentively. You alone are responsible for the safe operation of your RC model aircraft. Young

persons must be supervised by a responsible adult who is aware of the possible hazards involved in the

operation of model aeroplanes.

In legal terms our models are classed as aircraft, and as such are subject to legal regulations and

restrictions which must be observed at all times.

Avoid short-circuits at all times. The high energy density of the batteries used in modelling involves a

constant risk of explosion and fire.

A radio-controlled model aircraft can only work properly and fulfil your expectations if it is built very

carefully, and in accordance with the building instructions. Nobody would climb into a full-size sailplane

and try to fly it without first completing a course of training. Model flying is just such a skill, and has to be

learned in exactly the same way.

However, as manufacturers we have no means of influencing the way you build and operate your RC

model aircraft, and for this reason we can do no more than point out the hazards expressly. We accept no

further liability.

If you need help, please enlist the aid of an experienced modeller, join a model club or enrol at a model

flying training school. Model shops and the specialist model press are also good sources of information.

The best course is always to join a club and fly at the approved model flying site.

Adhesives contain substances which can be harmful to health under certain circumstances. It is therefore

important to read and observe the notes and warnings supplied by the glue manufacturer.

The operator must be in full possession of his bodily and mental capabilities. As with car driving, it is not

permissible to fly a model aircraft under the effect of alcohol or drugs.

Make sure that all passers-by and onlookers are aware of the hazards involved in the operation of your

model. Remind spectators to keep a safe distance from the model.

Always maintain a safe distance between your model and other people or objects. Never fly low over

people or directly towards them.

Radio-controlled models should only be flown in “normal” weather conditions, i.e. a temperature range of

-5° to +35°C. More extreme temperatures can lead to changes in battery capacity, material characteristics,

the strength of glued joints and other unwanted effects.

All model flyers should behave in a way which minimises the danger to people and property. Never act in

any manner which will disturb other pilots, or have an adverse effect on safe, orderly flying at the site.

Don’t operate your model aeroplane in the vicinity of overhead power cables, industrial sites, residential

areas, public roads, school playgrounds or sports fields etc.

Page 14

GRAUPNER/SJ GmbH D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors. 3/2013

- 14 -

Pre-flight checks

Check that the radio control system works correctly and at full range before every flight: switch on the

transmitter and receiving system, and ensure that all the control surfaces work smoothly, and deflect in

the correct “sense” in relation to the stick movements.

If you are a beginner to this type of model flying, we recommend that you enlist an experienced model

pilot to help you check and test-fly the model.

Please don’t ignore our warnings. They refer to hazardous materials and processes which, if ignored, can

result in fatal injury or serious damage to property.

If you are to fly your model safely and avoid problems, it is essential that you are aware of its position

and attitude throughout each flight - so don’t let it fly too far away. If you detect a control problem or

interference during a flight, immediately land the model to prevent a potential accident. Model aeroplanes

must always give way to full-size aircraft. Take-off and landing strips should be kept free of people and

other obstacles.

Your RC system can only work reliably if the batteries are kept fully charged.

Never use hot, faulty or damaged batteries. It is important to observe the instructions supplied by the

battery manufacturer.

Manufacturer’s declaration:

If material defects or manufacturing faults should arise in a product distributed by us in the Federal

Republic of Germany and purchased by a consumer (§ 13 BGB), we, Graupner/SJ GmbH, D-73230

Kirchheim/Teck, Germany, acknowledge the obligation to correct those defects within the limitations

described below.

The consumer is not entitled to exploit this manufacturer’s declaration if the failure in the usability of the

product is due to natural wear, use under competition conditions, incompetent or improper use (including

incorrect installation) or external influences.

This manufacturer’s declaration does not affect the consumer’s legal or contractual rights regarding

defects arising from the purchase contract between the consumer and the vendor (dealer).

Extent of the guarantee

If a claim is made under guarantee, we undertake at our discretion to repair or replace the defective

goods. We will not consider supplementary claims, especially for reimbursement of costs relating to the

defect (e.g. installation / removal costs) and compensation for consequent damages unless they are

allowed by statute. This does not affect claims based on legal regulations, especially according to

product liability law.

Guarantee requirements

The purchaser is required to make the guarantee claim in writing, and must enclose original proof of

purchase (e.g. invoice, receipt, delivery note) and this guarantee card. The purchaser must send the

defective goods to us at his own cost, using the address stated above.

The purchaser should state the material defect or manufacturing fault, or the symptoms of the fault, in as

accurate a manner as possible, so that we can check if our guarantee obligation is applicable.

The goods are transported from the consumer to us and from us to the consumer at the risk of the

consumer.

Duration of validity

This declaration only applies to claims made to us during the claim period as stated in this declaration.

The claim period is 24 months from the date of purchase of the product by the consumer from a dealer in

the Federal Republic of Germany (purchase date). If a defect arises after the end of the claim period, or if

the evidence or documents required according to this declaration in order to make the claim valid are not

presented until after this period, then the consumer forfeits any rights or claims from this declaration.

Limitation by lapse of time

If we do not acknowledge the validity of a claim based on this declaration within the claim period, all

claims based on this declaration are barred by the statute of limitations after six months from the time of

implementation; however, this cannot occur before the end of the claim period.

Applicable law

This declaration, and the claims, rights and obligations arising from it, are based exclusively on the

pertinent German Law, excluding the norms of international private law, and excluding UN retail law.

Loading...

Loading...