Page 1

1/55 PAGE

Operating Manual

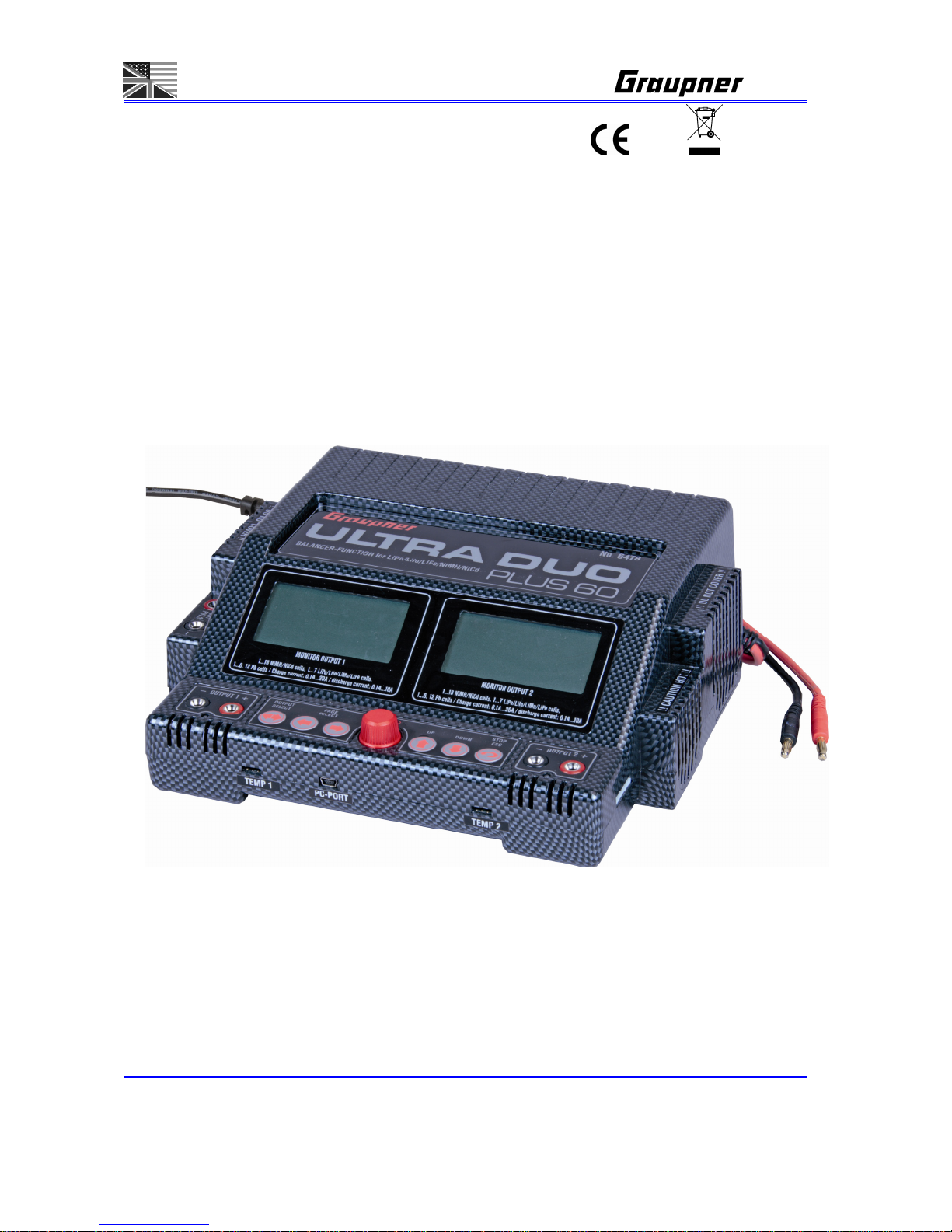

ULTRA DUO PLUS 60

Order-No. 6478

No liability for printing errors. Modifications reserved.

Page 2

2/55 PAGE

PN.OF-01

Contents Page

A-1 Introduction 3

A-2 Warnings and safety notes 4

A-3 General notes on using the charger 5

A-4 Recommended charge leads/polarity 7

A-5 Charger controls /connections 8

A-6 Using the charger for the first time 8

A-7 Cleaning and maintenance 9

A-8 Notes and handling of rechargeable batteries 9

A-9 PC-Interface 12

0-1 Features 14

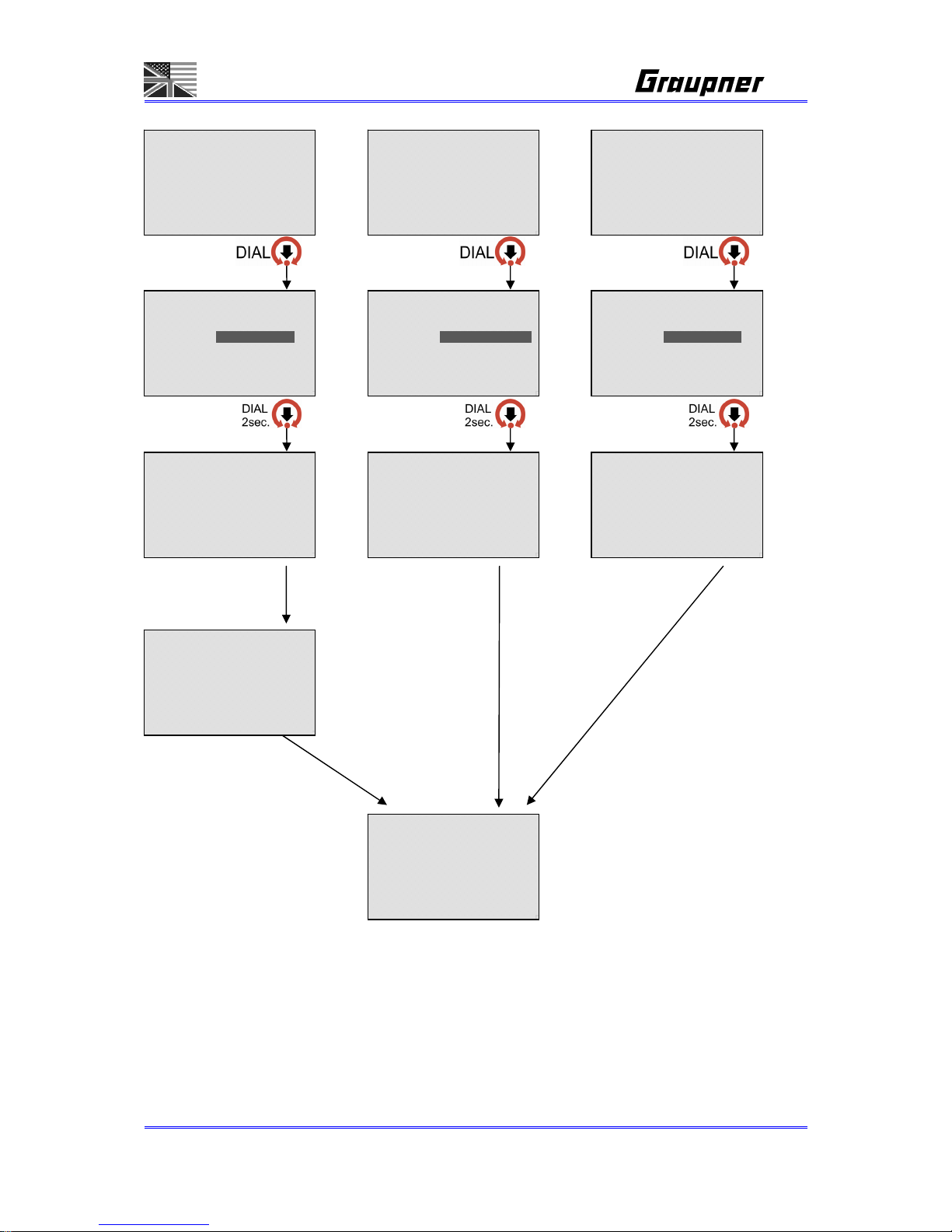

0-2 Main menu flow 15

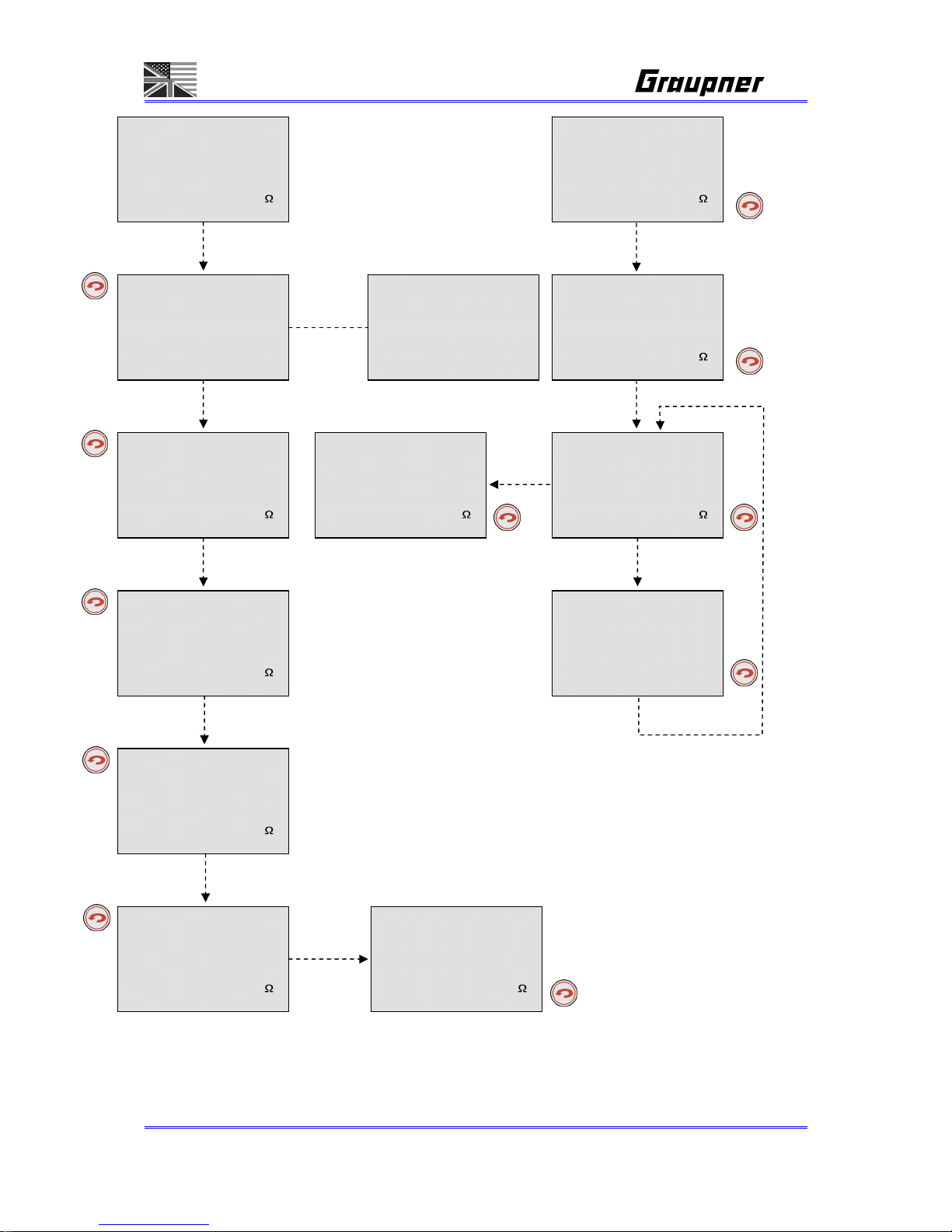

0-3 Control key select flow 16

1. Memory and battery setup menu screen 17

2. Charge setup menu flow 19

3. Discharge setup screen 22

4. Cycle menu screen 24

5. Step charge menu screen 25

6. Balancer Menü 27

7. Data view screen 29

8. Tyre, battery heater / battery heater screen / POWER SUPPLY 32

9. Motor run-in screen 34

10. Config setup screen 36

11. Start select menu screen 38

12. Battery select menu screen 45

13. Operation menu screen 46

14. Error message screen 52

15. Specification 53

16. Environnemental Protection Notes 54

17. EU Conformity Declaration 54

18. Warranty 55

Page 3

3/55 PAGE

A-1. INTRODUCTION

Please study these instructions, reading them completely and attentively, before using the unit for

the first time. This will guarantee that you will be able to exploit all the facilities of your new

battery charger. The warnings and safety notes are particularly important. Please store these

instructions in a safe place, and be sure to pass them on to the new owner if you ever dispose of

the charger.

In the CHARGER you have acquired a mature product with an excellent performance. It incorporates the

latest semi-conductor technology, controlled by a high-performance RISC micro-processor, to provide

superior charging characteristics combined with simple operation and optimum reliability. These features

can normally be expected only from much more expensive units. The CHARGER represents a reliable

method of charging sintered Nickel-Cadmium (NC, Ni-Cd) packs, Nickel-Metal-Hydride (Ni-MH) batteries,

Lithium-Polymer (Li-Po), Lithium-Manganese (Li-Mn), Lithium-Ion (Li-Io) and LiFePO4 (LiFe) batteries,

and also lead-gel and lead-acid (Plumbum: Pb) batteries These sealed, gas-tight batteries have proved

excellent for our purposes in RC models. They are mechanically robust, can be used in any attitude and

are generally highly reliable. They require no special measures for storage apart from protecting the cells

from becoming deep-discharged. The CHARGER can also be used to discharge your batteries and

balance the cells in a pack.

Note

It is important always to observe the charging instructions supplied by the battery manufacturer, and to

keep to the recommended charge currents and times Do not fast-charge batteries unless the

manufacturer states expressly that they are suitable for the high currents which flow during these

processes. When charging new batteries you may also encounter problems with premature charge

termination. Whenever you wish to use a new battery it therefore makes sense to carry out a series of

monitored test charges, so that you can check that the automatic charge termination circuit works

correctly and reliably with your packs, and charges them to full capacity.

Accessories

Order No. 6444.6 Battery holder for up to seven sub-C cells with individual cell terminals for side-by-

side soldered battery packs, as generally used in competition. Required for balancing cells, e.g. Order

No. 98947.6XXL

Replacement parts

Order No. Description

6444.1 Temperature sensor for sub-C batteries, with magnet

.2 Temperature sensor without magnet, e.g. for tyre heating covers

.USB Mini-USB / PC-USB interface cable

Page 4

Page 4/55

A-2. WARNINGS AND SAFETY NOTES

• The software does not take the output current of Output 3 into account when it calculates the charge

power. This means that the charger will re-boot if the internal mains PSU is overloaded. If devices with

a relatively high current drain (more than 1 A) - such as Peltier coolers or heating covers - are

connected to the unit, we therefore recommend that you use only one of the two charge outputs, and

set the power distribution to 50% / 50%, in order to prevent overloading the internal PSU.

In this case the second output can still be used for discharging and balancing a battery.

• This product isn‘t designed for use by children under the age of 14, it isn‘t a toy!

• Protect the charger from dust, damp, rain, heat (e.g. direct sunshine) and vibration. It should only be

operated in dry indoor conditions.

• The case slots serve to cool the charger, and must not be covered or enclosed; set up the charger

with space round it, so that cooling air can circulate unhindered.

• The charger is designed to be powered by a 12 V DC car battery or power supply or 100~240V AC

main socket only. It is not permissible to modify the charger in any way. You must not connect AC

power to the DC input.

• The charger and the battery to be charged should be set up on a heat-resistant, non-inflammable

and non-conductive surface before use. Never place the charger directly on a car seat, carpet or

similar. Keep all inflammable and volatile materials well away from the charging area. Provide good

ventilation. Defective batteries can explode or burn!

• Connect the charger 12DC input directly to the car battery using the original cables and connectors

supplied. The car’s engine must be stopped all the time the CHARGER is connected to the car’s

battery. Do not recharge the car battery at any time when the CHARGER is connected to it.

• The charge output sockets and connecting leads must not be modified, and must not be inter-

connected in any way. There is a danger of short-circuit between the charge outputs and the

vehicle’s bodywork when the charger is connected to the car battery. The charge leads and

connecting leads must not be coiled up when the charger is in use. Avoid short-circuiting the charge

output or the model battery with the car bodywork. For this reason the charger must never be placed

directly on the vehicle’s bodywork.

• Never leave the charger running or connected to the car battery unsupervised.

• Only one battery may be connected to the unit for charging at any one time.

• The following types of battery must not

be connected to the charger:

- Ni-Cd / Ni-MH batteries consisting of more than 18 cells, Lithium-Ion / Li-Mn / Lithium-Polymer /

LiFePO4 (LiFe) batteries of more than 7 cells, or lead-acid batteries with a nominal voltage of more

than 12V or 24V.

- Batteries which require a different charge method from Ni-Cd, Ni-MH, Lithium or lead-acid types.

- Faulty or damaged cells or batteries.

- Batteries consisting of parallel-wired cells, or cells of different types.

- Batteries consisting of old and new cells, or cells of different makes.

Page 5

Page 5/55

- Non-rechargeable batteries (dry cells). Caution: explosion hazard!

- Batteries which are not expressly stated by the manufacturer to be suitable for the currents which

this unit delivers during the charge process.

- Packs which are already fully charged or hot, or only partially discharged.

- Batteries or cells fitted with an integral charge circuit or charge termination circuit.

- Batteries installed in a device, or which are electrically connected to other components.

• To avoid short-circuits between the banana plugs fitted to the charge leads, please always connect

the charge leads to the charger first, and only then to the battery to be charged. Reverse the

sequence when disconnecting.

• As a basic rule always check that the charge quantity is approximately the same as you expected

after

the charger has indicated that the pack is fully charged. This is a simple method of detecting a

problem reliably and in good time, should the charge process be terminated prematurely for any

reason. The likelihood of premature termination varies according to many factors, but is at its highest

with deep-discharged packs, low cell counts and particular cell types which are known to cause

problems.

• We recommend that you carry out a series of test charges to satisfy yourself that the automatic

termination circuit is working perfectly. This applies in particular when you are charging packs

consisting of a small number of cells. If the cells feature has a poorly defined voltage peak, the

charger may fail to detect the fully charged state.

• Before charging please check: have you selected the appropriate charge program for the battery?

Have you set the correct charge or discharge current? Have you set the important cut-off voltage

when charging Ni-Cd and Ni-MH packs? Are all connections firm, or is there an intermittent contact

at any point in the circuit? Please bear in mind that it can be dangerous to fast-charge batteries. For

example, if there is a brief interruption due to an intermittent contact, the result is inevitably a

malfunction such as a restart of the charge process, which would result in the pack being massively

overcharged.

• Be careful! A battery could explode or burn, if the charger does have a fault or if the user

does choose the wrong charging program and parameters.

A-3. GENERAL NOTES ON USING THE CHARGER

Charging batteries

When a battery is charged, a particular quantity of electrical energy is fed into it. The charge quantity is

calculated by multiplying charge current by charge time. The maximum permissible charge current

varies according to the battery type, and can be found in the information provided by the battery

manufacturer.

It is only permissible to charge batteries at rates higher than the standard (slow) current if they are

expressly

stated to be rapid-charge capable. The STANDARD CHARGE CURRENT is 1/10 (one

tenth) of the cells’ nominal capacity (e.g. for a 1.7 Ah pack the standard charge current is 170 mA).

Page 6

Page 6/55

• Connect the battery to be charged to the charger output sockets using a suitable charge lead (red =

positive terminal, black = negative terminal).

• Be sure to read the information provided by the battery manufacturer regarding charging methods,

and observe the recommended charge currents and charge times. Do not attempt to fast-charge

batteries unless they are expressly stated to be suitable for the high currents which this charger

delivers.

• Please bear in mind that new batteries do not reach their full capacity until they have undergone

several charge / discharge cycles. You should also be aware that the charger may terminate the

charge process prematurely when connected to new packs, and batteries which have been deep-

discharged.

• A Ni-Cd pack will normally be warm at the end of a rapid-charge process, but if you notice that one

cell of the pack is much hotter than the others, this may well indicate a fault in that cell. Such packs

could fail completely without warning, and should not be used again. Dispose of the battery safely,

preferably taking it to a toxic waste disposal centre.

• Ensure that all connectors and terminal clamps make good, sound contact. For example, if there is a

brief interruption due to an intermittent contact, the result is inevitably a malfunction such as a restart

of the charge process, which would result in the pack being massively overcharged.

• A common cause of malfunctions is the use of unsuitable charge leads. Since the charger is

incapable

of detecting the difference between a pack’s internal resistance, cable resistance and

connector transfer resistance, the first requirement if the charger is to work perfectly is that the

charge lead should be of adequate conductor cross-section and should be not be more than

30 cm long Good-quality connectors (gold-contact types) must be fitted to both ends.

• Charging transmitter batteries

A battery installed in a radio control transmitter can usually be recharged via the integral charge

socket which is fitted to the transmitter itself. Transmitter charge sockets generally include a diode

which prevents reverse current flow. This prevents damage to the transmitter electronics should the

charger be connected with reverse polarity, or if a short-circuit occurs between the bare ends of the

charge lead connectors. However, a transmitter battery protected in this way can only be charged by

the CHARGER if the diode is by-passed. Please read your transmitter operating instructions for

information on how to do this. The stated maximum charge current for the transmitter battery must

never

be exceeded. To avoid possible damage to the internal transmitter components due to

overheating and heat build-up, we recommend that the battery should be removed from the

transmitter’s battery compartment prior to charging. The transmitter must be set to „OFF“ and left in

that state for the whole period of the charge process.

Never

switch a radio control transmitter on when it is still connected to the battery charger. The

slightest interruption in the charge process may allow the charge voltage to rise to the point where it

immediately ruins the transmitter.

Never

attempt to carry out any battery discharge or battery maintenance programs via the

Page 7

Page 7/55

transmitter’s integral charge socket. The charge socket is not

suitable for this purpose.

When you set a particular current for charging, the charger only supplies that current if the value does

not exceed the unit’s technical capacity. If you set a charge current which the CHARGER cannot

deliver because it falls outside its technical limits, the unit automatically reduces the current to the

maximum possible value.

LIABILITY EXCLUSION

As manufacturers, we at GRAUPNER are not in a position to ensure that you observe the correct

methods of operation when installing, using and maintaining this charger. For this reason we are

obliged to deny all liability for loss, damage or costs which are incurred due to the incompetent or

incorrect use and operation of our products, or which are connected with such operation in any way.

Use only GRAUPNER or GM-Racing charge leads, batteries and accessories.

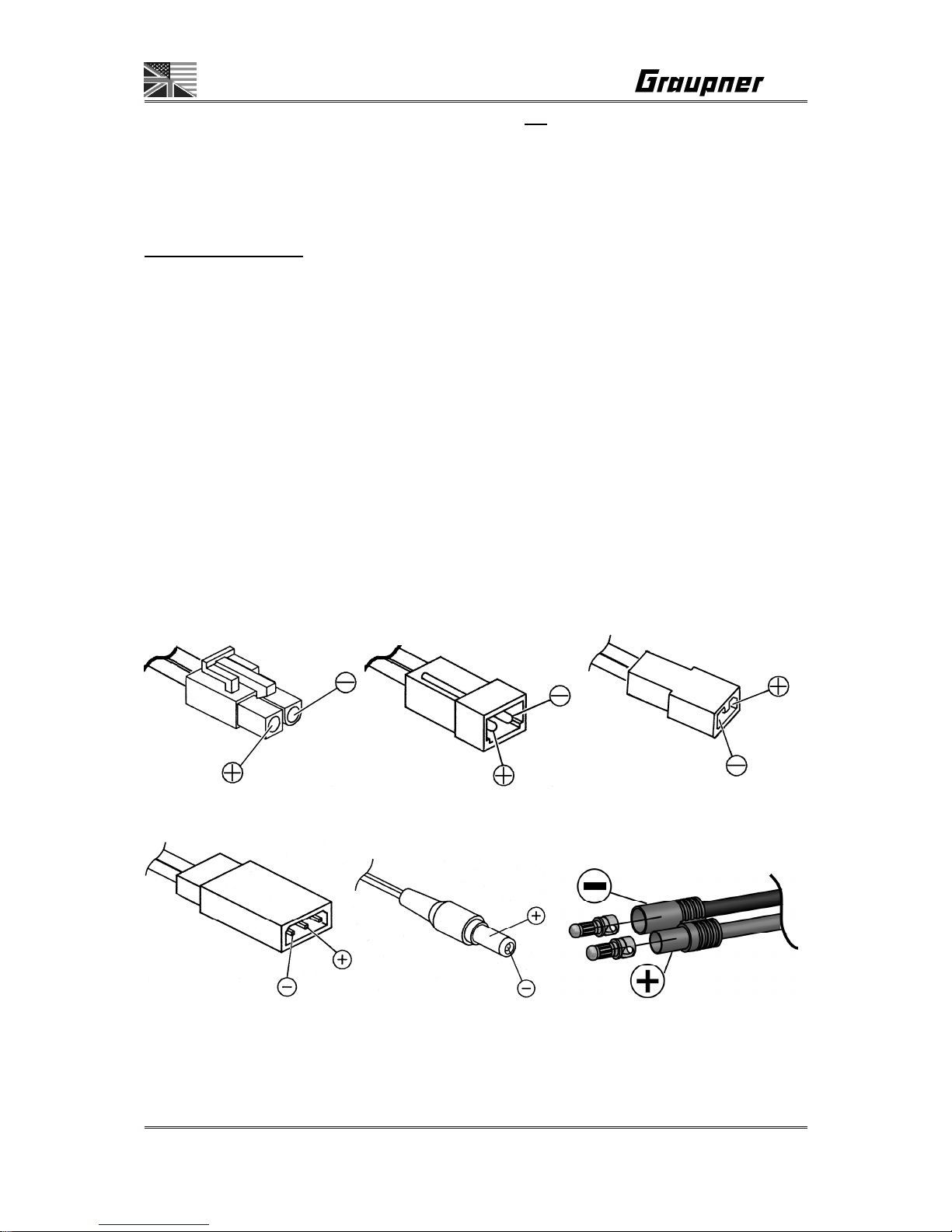

A-4. RECOMMENDED CHARGE LEADS/POLARITY

The requirements made on rechargeable batteries vary greatly according to their particular application,

and this in turn calls for different types of battery connector. Please note that connectors, connector

names and polarities may vary from one manufacturer to another. For this reason we recommend that

you always use genuine matching connectors of identical construction. The following charge leads are

suitable for battery charging with this unit:

:

JAPAN charging cable G2 charging cable BEC charging cable

Order-No. 3371 Order-No. 3011 Order-No. 3037

JR-receiver charging cable GRAUPNER/JR-transmitter charging cable G3,5 charging cable

Order-No. 3021 Order-No. 3022 Order-No. 2970.L

Be sure to use genuine charge leads fitted with cable of adequate conductor cross-section.

Page 8

Page 8/55

A-5. CHARGER CONTROLS / CONNECTIONS

BALANCERSTECKER:

A-6. USING THE CHARGER FOR THE FIRST TIME

Connect the charger INPUT 12V DC to a 12 V DC car battery min. 50Ah or power supply 5A-40A or

the INPUT 100~240V AC to a 100~240V AC mains socket.

Warning:

The software does not take the output current of Output 3 into account when it calculates the charge

Plug in the GRAUPNER-

BALANCER CONNECTOR

of your battery with 3-8 poles

right handed into the

BALANCER CONNECTOR of

the used OUTPUT.

Input 11…15V DC 5-40A

Input 100~240V AC Graph-LCDisplay 1

Balancer connector 2

Temperature sensor 2 PC-mini USB Interface

Temperature sensor 1

Balancer

connector 1

Fan

Fan Graph-LCDisplay 2

Output 2

Output 1

+ -

Control keys

LED

Output 1

LED

Output 2

GRAUPNER- BALANCER CONNECTOR TYPE EHR-8

PIN

1 = 0V = Ground = battery - = GND

2 = 3,7V = + cell 1

3 = 7,4V = + cell 2

4 = 11,1V = + cell 3

5 = 14,8V = + cell 4

6 = 18,5V = + cell 5

7 = 22,2V = + cell 6

8 = 25,9V = + cell 7

Output 3:

12V DC max. 5A

Page 9

Page 9/55

power. This means that the charger will re-boot if the internal mains PSU is overloaded. If devices with

a relatively high current drain (more than 1 A) - such as Peltier coolers or heating covers - are

connected to the unit, we therefore recommend that you use only one of the two charge outputs, and

set the power distribution to 50% / 50%, in order to prevent overloading the internal PSU.

In this case the second output can still be used for discharging and balancing a battery.

A-7. CLEANING AND MAINTENANCE

The charger is entirely maintenance-free in use, and requires no servicing of any kind. However, it is in

your own interests to protect the unit from dust, dirt and damp.

To clean the charger, disconnect it from the car battery and any other battery, and wipe it clean with a

dry cloth (don’t use cleaning agents!).

A-8. NOTES AND HANDLING OF RECHARGABLE BATTERIES

• Charging single Ni-Cd or Ni-MH cells, and packs consisting of 1 ... 4 cells, presents the automatic

charge termination circuit with a difficult task. The voltage peak is quite small in such cases, and it

cannot be guaranteed that the cut-off circuit will work reliably. In such conditions the automatic circuit

may not be triggered, or may not terminate the charge at the correct time. For this reason it is

important to carry out a series of monitored test charge processes with your packs in order to

establish whether the charge process is terminated reliably.

• Warm batteries offer much higher performance than cold ones, so don’t be surprised if your batteries

don’t seem so effective in the winter.

• Overcharging and deep-discharging batteries lead to irreparable damage to the cells, and

permanently reduces their maximum performance and effective capacity.

• Never store batteries for a long time in an uncharged, discharged or partially charged state. Charge

your batteries before storing them, and check their state of charge from time to time.

• When purchasing batteries we recommend that you buy good quality products exclusively. Start by

charging new packs at low rates, and work up gradually towards higher currents.

• Batteries should not be charged until shortly before use, as they are then able to deliver their best

performance.

• Do not solder directly to battery cells. The temperatures which occur during soldering can easily

damage the seals and safety valves of the cells. If this should happen, the battery may lose

electrolyte or dry out, and some of its potential performance will be lost.

• Charging any battery at high currents shortens the life expectancy of the pack. Don’t exceed the

maximum values stated by the manufacturer.

• Overcharging inevitably reduces the capacity of the battery, so do not recharge a hot pack, or one

which has already been charged.

• Charging and discharging any battery at a high current shortens the life expectancy of the pack.

Don’t exceed the maximum values stated by the manufacturer.

Page 10

Page 10/55

• Lead-acid batteries are not capable of being charged at high currents. Never exceed the maximum

charge rate stated by the battery manufacturer.

• Protect batteries from vibration, and do not subject them to mechanical stress or shock.

• Batteries can generate explosive gas (hydrogen) when on charge and when being discharged, so it is

important to provide good ventilation.

• Do not allow batteries to come into contact with water - explosion hazard.

• Never short-circuit battery contacts - explosion hazard.

• Batteries can explode or burn, if they overheat. We suggest to use a LiPo-security hard case

Order-No. 8372 with all Li-battery types and with NiCd und NiMH-batteries for charging.

• Do not open battery cells - corrosion hazard.

• It is best to „balance“, or even up the cells in Ni-Cd and Ni-MH battery packs by first discharging all

the cells separately to 0.9...1.1V and then charging up the pack.

• Please don’t be surprised if your batteries are not as willing to accept charge in winter as in summer.

The ability of a cold cell to accept and store charge is much lower than that of a warm one.

• Battery disposal

: exhausted batteries are not ordinary household waste, and you must not dispose of

them in the domestic rubbish. The retail outlet where you purchase your batteries should have a

battery recycling container for proper disposal. Trade outlets are obliged by law to accept exhausted

batteries for disposal.

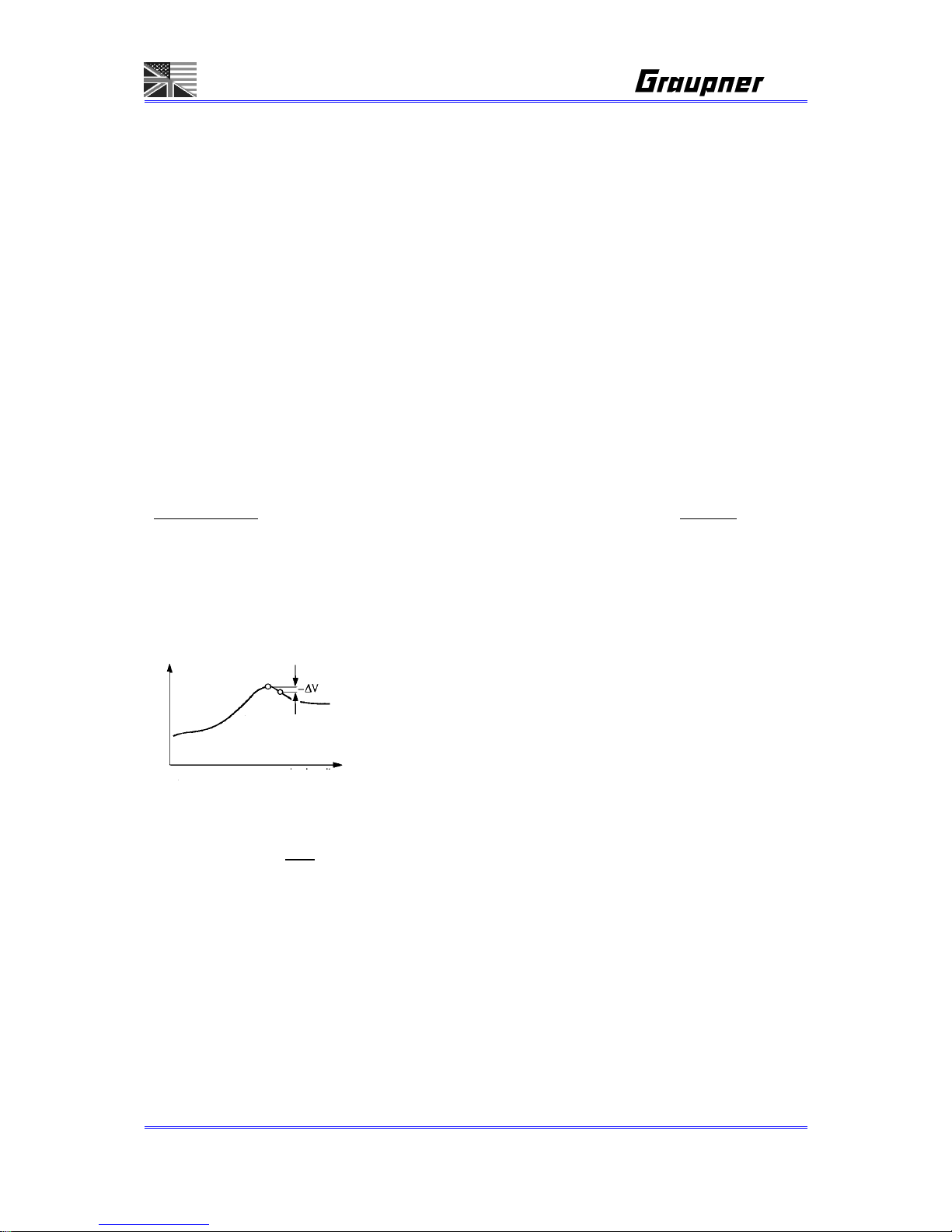

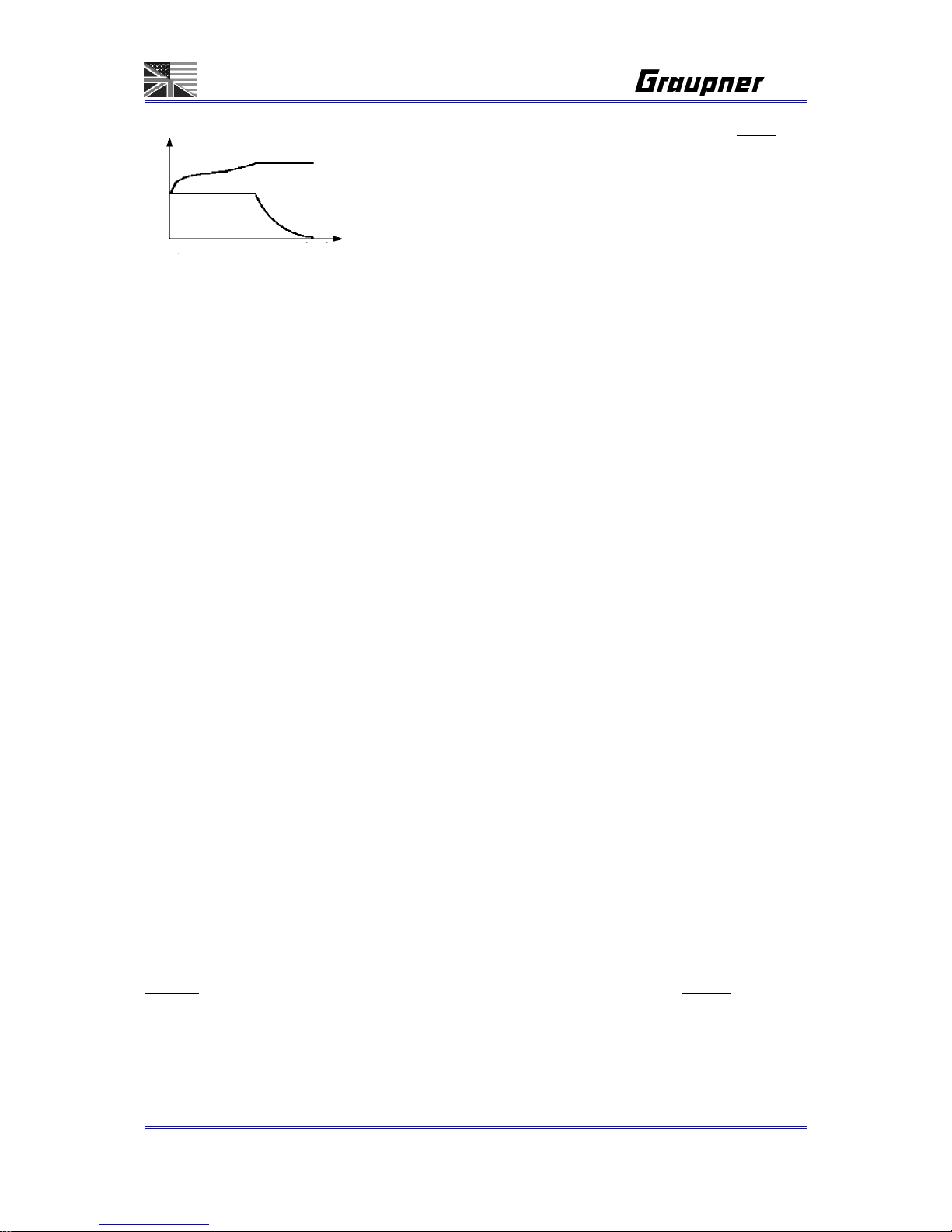

DELTA PEAK CHARGE TERMINATION for NiCd-/NiMH- Batteries:

CC-CV CHARGING METHOD FOR LiPo/LiIo/LiFe- Batteries

These programs are only suitable for charging and discharging LiFePO

4

batteries with a voltage of

3.3 V / Cell, Lithium-Ion batteries with a voltage of 3.6 V / cell, and Lithium-Polymer and Lithium-

Manganese batteries with a voltage of 3.7 V / cell. The outstanding feature of Lithium batteries is their

much higher capacity compared to other battery types. However, this important advantage is offset by

the need to adopt different handling strategies: they must be charged and discharged using specific

methods, otherwise they will be damaged, and can be dangerous. The directions in these instructions

must be observed at all times when handling these batteries. Specific information and safety notes will

also be found in the battery manufacturer’s technical information.

The automatic charge termination circuit (battery full detection)

works on the proven Delta Peak principle (also known as the

Delta-V process), which is already in use in millions of chargers.

The PEAK SENSITIVITY is shown as – delta V in the graph.

Charging Time

V

o

l

t

a

g

e

Page 11

Page 11/55

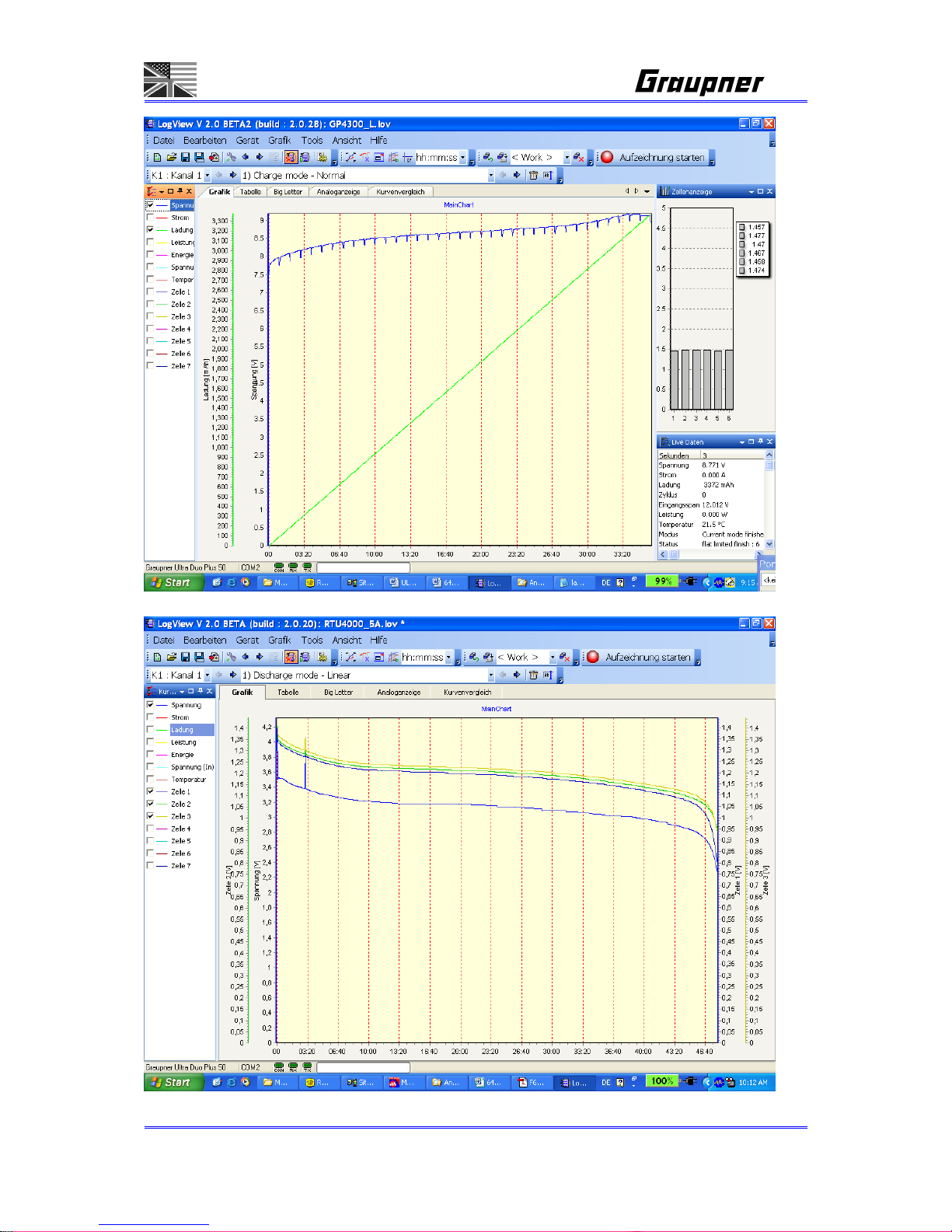

The charge process is fundamentally different to that required for Ni-Cd or Ni-MH batteries, and is

termed a constant current / constant voltage method. The charge current required varies according to

the battery capacity, and is set automatically by the charger. Lithium batteries are usually charged at

the 1C rate (1C charge rate = half capacity as charge current. Example: battery capacity 1500 mAh:

1C charge current = 1500 mA = 1.5 A).

Because some types can be charged with up to 2C or 4C charging current, the charging current and

the capacity of the battery must be set separately. When the battery on charge reaches the specific

final voltage which is appropriate to the battery type, the charger automatically reduces the charge

current in order to prevent the battery exceeding the final permissible voltage. If the battery

manufacturer states a charge current lower than the 1C rate, then the capacity (charge current) must

be reduced accordingly.

We recommend the use of the balancer connector, which ensures that your Lithium batteries

are charged optimally, and therefore increases safety and their useful life.

Problems caused by mistreating batteries:

It is very dangerous to overcharge Lithium-Ion batteries, as they tend to react by gassing, overheating

and even exploding. If the final charge voltage of 3.6 V / cell (LiFePO4), 4.1 V / cell (Lithium-Ion) or 4.2

V / cell (Lithium-Polymer and Lithium-Manganese) is exceeded by more than 1%, the lithium ions in

the cell start to change into metallic lithium. This material reacts very violently with the water in the

electrolyte, and this can result in the cell exploding. On the other hand it is also important to avoid

terminating the charge process before the final charge voltage is reached, since this reduces the

effective capacity of the Lithium-Ion cell markedly. Stopping the charge at just 0.1 V under the

threshold means a capacity loss of around 7%. Lithium batteries must not be deep-discharged, as this

leads to a rapid loss of capacity. This effect is irreversible; it is absolutely vital to avoid discharging the

batteries to below 2.5 V / cell.

Caution

: the cell type, cell capacity and cell count set on the charger must always be correct

for the battery to be charged; if you make a mistake, the battery could explode and burn! Never

connect a Lithium-based battery to the charger if it features an integral charge circuit! Always

place your Lithium batteries on a non-flammable surface for charging.

The fundamental rule is that Lithium-based batteries may ONLY

be

charged using special chargers, and the charge program must be

set up correctly in terms of final charge voltage and capacity for the

battery type in use.

Charging Time

Voltage

current

Page 12

Page 12/55

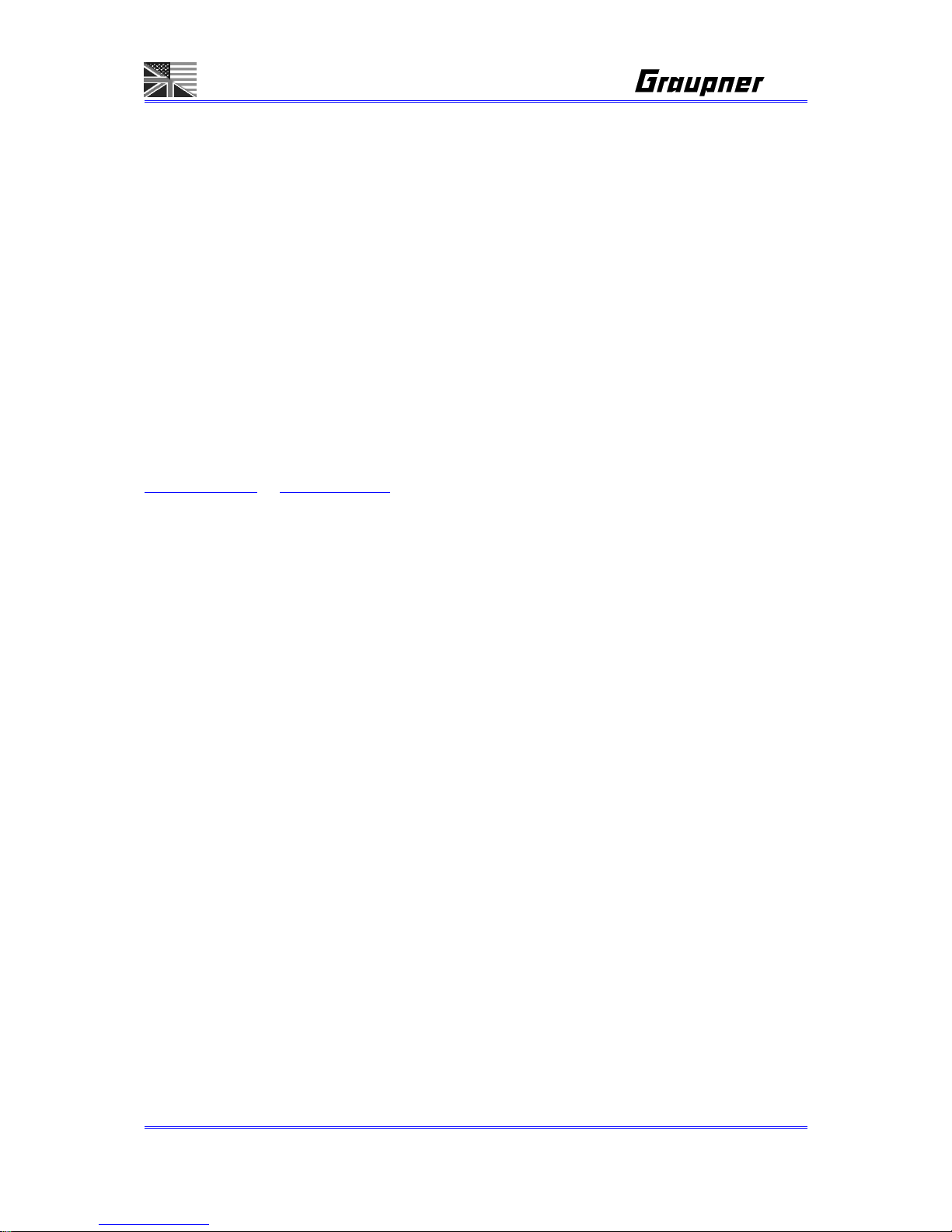

A-9. PC-INTERFACE

You can download the appropriate USB serial driver CP210x_Drivers.exe for this battery charger from

the Software Download area of www.graupner.de or www.gm-racing.de.

Install this driver first.

Connect the USB lead to the charger and to a free USB port on your PC.

PC software can be downloaded at www.graupner.de, www.gm-racing.de our www.logview.info.

This software enables you to display battery curves and much more.

LogView - displays your serial data ...

We have been working closely with the manufacturer of the software ‘LogView’, in order to provide

optimum facilities for evaluating the data generated by our ULTRA DUO PLUS 60 battery charger.

With the help of LogView, which we recommend and support, it is possible to visualise and analyse the

serial data delivered by these chargers, and if necessary to export the data in a wide variety of forms.

The software is Donationware, and can be downloaded from the following web addresses:

www.graupner.de

or www.logview.info. If you enjoy using the software, there is a method of sending a

monetary contribution to the developer, but otherwise the program can be used free of charge.

In addition to an intuitive user-friendly interface, LogView offers the opportunity to use a wide range of

different equipment. The data received from the devices is always displayed in the same way, which

makes it much easier for the user to handle his equipment. The files generated by LogView can also

be used directly by any other user, even if he does not have actual physical access to the device in

question.

Additional software features include:

High-performance graphics engine with numerous analysis and measurement functions. Wide-

ranging options are available for adjusting the display of the curves to suit individual requirements.

Analysis functions help to investigate rechargeable batteries more thoroughly.

The curve comparison functions enable the user to display different charge and discharge processes

in graphic form. In this way it is possible in particular to assess the quality and ageing effects of

rechargeable batteries very accurately, and to compare them with other rechargeable batteries.

The object management function provides a means of storing and managing recorded data and

information relating to specific batteries.

Numerous export functions for graphs and tables allow other applications to use the data.

The label printing function provides a means of printing out labels for applying to individual battery

packs.

The integral Help system is a fast, straightforward method of obtaining information relating to the

program’s functions. If particular questions arise concerning the use of the software, or if you have

suggestions for further improvements to the LogView program, it is possible to contact the developer

directly via the LogView forum, or to exchange ideas and experiences with other users.

Page 13

Page 13/55

Page 14

Page 14/55

0-1. Features

Computer-controlled universal fast charger

With integral lightweight switch-mode mains PSU for 100 ... 240 V and 12 DC inputs. This means that the

charger is the perfect choice for all mobile applications, and also for use abroad (USA / Japan).

Two equal-value independent or dependent (CV-link mode) charge outputs

Graupner Balancer socket for 2 x 1 ... 7 NiCd / NiMH / LiPo / LiIo / LiFe cells

Sixty memories for storing all essential battery parameters

Automatic charge, discharge, capacity measurement, battery maintenance and conditioning programs for all

NiMH, NiCd, LiPo, LiIo, LiFe batteries used in modelling

Ultra-simple to operate, with clearly arranged program structure, six buttons and rotary knob button

Two high-contrast LCD screens (128 x 62) with blue backlighting: 21 x 8 characters for displaying all relevant

parameters or charge / discharge curves

Charge / discharge facilities for NiMH, NiCd, LiPo, LiIo, LiMn, LiFe or Pb (lead-acid) batteries

Delta-Peak cut-off detector for NiMH and NiCd cells with variable Delta-Peak voltage, ensuring 100% full

battery charging

Capable of charging single cells, therefore ideal for glow energizer batteries and for cell selection processes

Charges LiPo, LiIo, LiFe and lead-acid cells using constant current / constant voltage method. Declining current

curve after final charge voltage, with automatic charge termination.

Charge processes:

NiCd / NiMH: Automatic, normal, linear, GMVIS, IMPULSE, REFLEX, RE-PEAK, staged charging

LiPo / LiIo / LiFe: Automatic, CC / CV, FAST-CHG, CV-link, STORE

Special charge facility for battery storage

Balancer program

Data memory for comparing all important battery data.

Lead-acid battery charge programs with optimised charge curve, discharge facility, variable discharge current

for determining battery capacity and residual capacity.

Program for tyre heating covers

Order No. 94711 with temperature control

Motor run-in and test functions for brushed electric motors

Protected against short-circuit, overload and reversed polarity

Switchable buzzer, selectable melody

Variable safety timer

Variable max. charge capacity

Selectable language: English / German / French / Italian

Internal battery resistance display

Individual cell voltage display for 2 x 2 - 7 cells in NiCd / NiMH / Li modes

PC-USB interface for displaying battery curves on the PC screen

Ready to connect

Page 15

Page 15/55

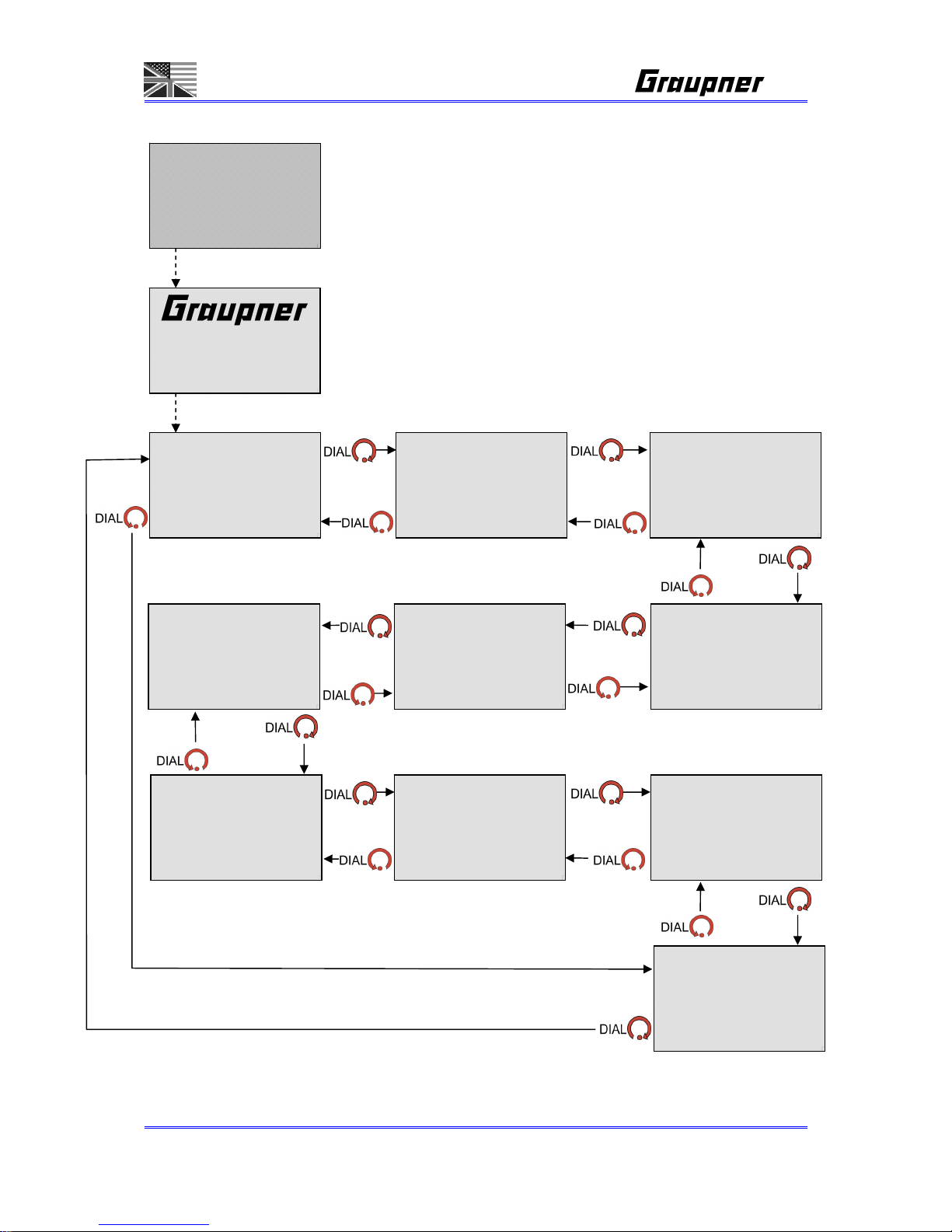

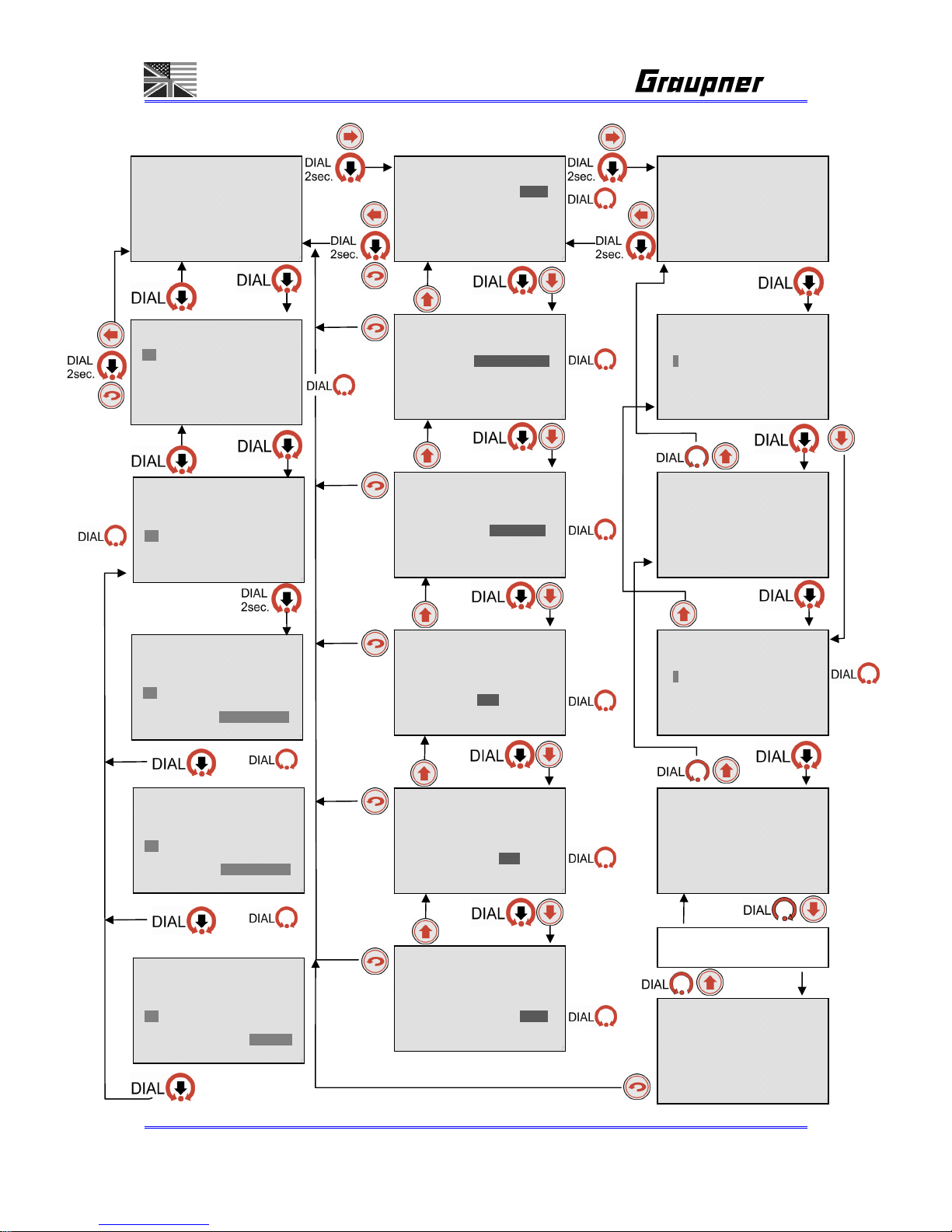

0-2. MAIN MENU FLOW

Easy to scroll up and down using the dial.

- = - - - - - - - -

CHARGE

C:00.0A d00mV/C 00°C

- - = - - - - - - -

DISCHARGE

D:00.0A 1.0V/CL 00°C

ULTRA DUO PLUS 60

GRAUPNER #6478 V1.0

USER NAME

= - - - - - - - - -

MEMORY [01]

01] NEW BATTERY NAME

- - - = - - - - - -

CYCLE

D:C>D 00T C00/D00min

- - - - = - - - - -

STEP CHARGE

D: ON d00mV/C 00°C

- - - - - = - - - -

BALANCE

0CL 0.00Vpk 0.00Va

- - - - - - = - - -

DATA VIEW

0.0Vi 0.00Vo 0.0°C

Connect the charger main plug to the input 100…240V AC

or the 4mm banana plugs to 11…15V DC, see A-6

- - - - - - - = - -

HEATER & POWER

_

_0m __0°C

_

_0m __0°C

- - - - - - - - = -

MOTOR RUN

- - - - - - - - - =

CO N F I G

00/00/2000 am00:00:00

Page 16

Page 16/55

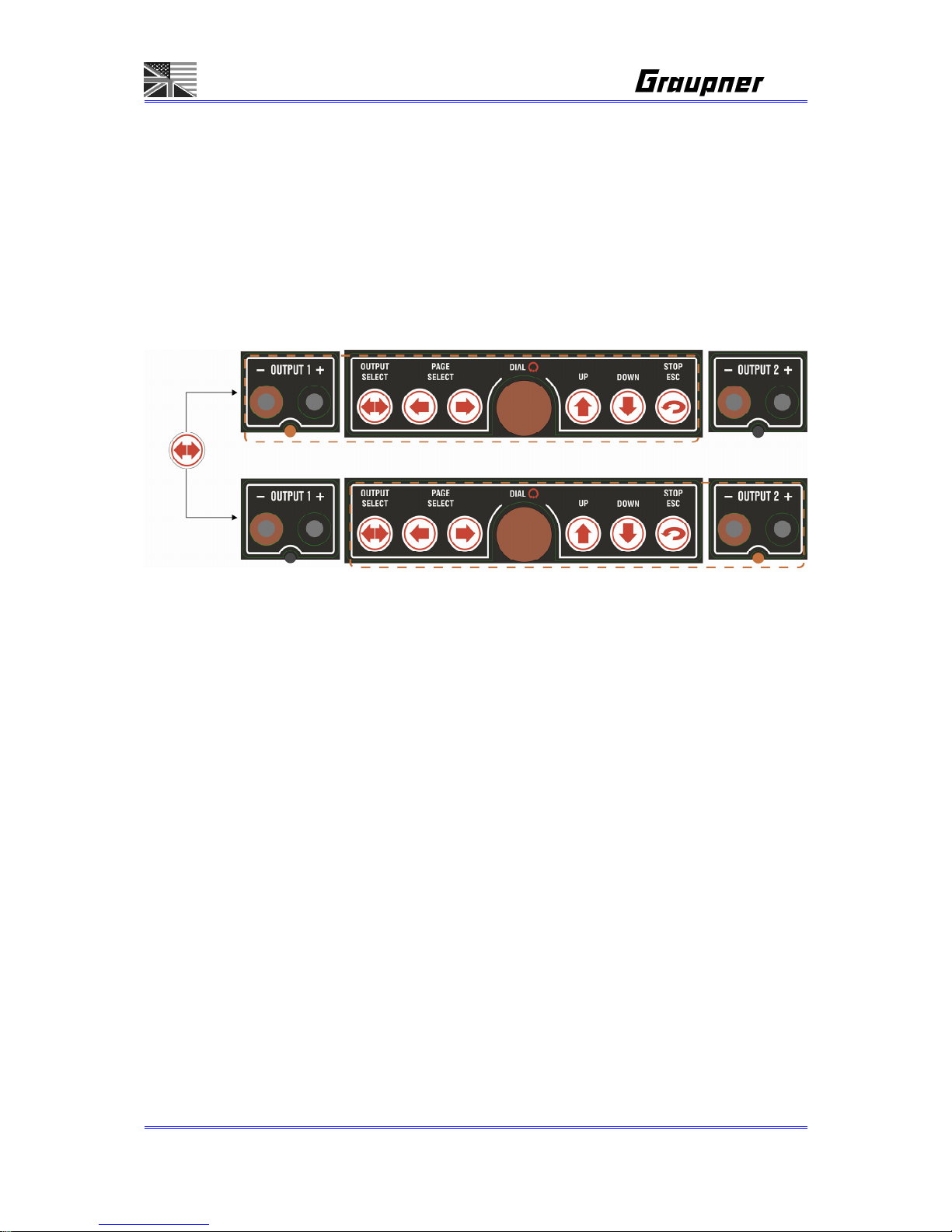

0-3. CONTROL KEY SELECT FLOW

Two LCD screens, but key control is possible for only one output.

The LCD where key control is possible is indicated by LED which flashes or is on.

In setting status, if ESC button is pressed, it directly moves to a higher menu.

In operating status, if the ESC button is pressed, operating should stop.

If OUTPUT SELECT button is pressed, OUTPUT-LED should be changed.

The OUTPUT LED is automatically changed in the following conditions.

When error occurs

If OUTPUT2 is now selected, and if error occurs in OUTPUT1, the output

should be automatically changed to OUTPUT1.

When operation is finished,

If OUTPUT2 is now selected, and if operation is finished in OUTPUT1, the

output should be automatically changed to OUTPUT1.

The function of the selected output LED.

LED should flash every one second indicating the menu status.

The LED should be ON during operating.

Page 17

Page 17/55

1. MEMORY AND BATTERY SETUP MENU SCREEN

= - - - - - - - - -

MEMORY [01]

01] NiMH GP 6N-4600

BATTERY SETUP <1/2>

TYPE NiMH

VOLTS _6CL _7.2V

CAPACITY _4600mAh

NEW 01/01/2008

BATTERY SETUP <1/2>

TYP E NiMH

VOLTS _6CL _7.2V

CAPACITY _4600mAh

NEW 01/01/2008

BATT NAME SETUP<2/2>

01] NiMH GP 6N-4600

^

ABCDEFGHIJKLMNOPQR

STUVWXYZabcdefghijk

lmnopqrstuvwxyz0123

456789 -.,'#_+/

ä ö ü é è

BATT NAME SETUP<2/2>

01] NiMH GP 6N-4600

^

ABCDEFGHIJKLMNOPQR

STUVWXYZabcdefghijk

lmnopqrstuvwxyz0123

456789 -.,'#_+/

ä ö ü é è

BATT NAME SETUP<2/2>

01] NiMH GP 6N-4600

^

ABCDEFGHIJKLMNOPQR

STUVWXYZabcdefghijk

lmnopqrstuvwxyz0123

456789 -.,'#_+/

ä ö ü é è

BATT NAME SETUP<2/2>

01] NiMH GP 6N-4600

^

ABCDEFGHIJKLMNOPQR

STUVWXYZabcdefghijk

lmnopqrstuvwxyz0123

456789 -.,'#_+/

ä ö ü é è

BATT NAME SETUP<2/2>

01] NiMH GP 6N-4600

^

ABCDEFGHIJKLMNOPQR

STUVWXYZabcdefghijk

lmnopqrstuvwxyz0123

456789 -.,'#_+/

ä ö ü é è

BATTERY SETUP <1/2>

TYPE NiMH

VOLTS _6CL _7.2V

CAPACITY _4600mAh

NEW 01/01/2008

...

BATTERY SETUP <1/2>

TYPE NiMH

VOLTS _6CL _7.2V

CAPACITY _4600mAh

NEW 01/01/2008

BATTERY SETUP <1/2>

TYPE NiMH

VOLTS _6CL _7.2V

CAPACITY _4600mAh

NEW 0 1 /01/2008

BATTERY SETUP <1/2>

TYPE NiMH

VOLTS _6CL _7.2V

CAPACITY _4600mAh

NEW 01/01/2008

BATT NAME SETUP<2/2>

01] NiMH GP 6N-4600

^

ABCDEFGHIJKLMNOPQR

STUVWXYZabcdefghijk

lmnopqrstuvwxyz0123

456789 -.,'#_+/

ä ö ü é è

MEMORY SELECT

01]NiMH _0.0V____0mAh

< >

01]NiMH _0.0V____0mAh

< >

MEMORY COPY

01]NiMH _0.0V____0mAh

< >

02]NiMH _0.0V____0mAh

< >

MEMORY COPY

01]NiMH _0.0V____0mAh

< >

02]NiMH _0.0V____0mAh

< >

Sure? SETUP ONLY

MEMORY COPY

01]NiMH _0.0V____0mAh

< >

02]NiMH _0.0V____0mAh

< >

Sure? SETUP+DATA

MEMORY COPY

01]NiMH _0.0V____0mAh

< >

02]NiMH _0.0V____0mAh

< >

Sure? CANCEL

Page 18

Page 18/55

1. MEMORY AND BATTERY SETUP MENU SCREEN

1-1. Memory selection

- Pressing the dial in Memory[00] then rotate the dial to select the wanted memory.

- Memory 0, 1-60 can be selected.

In any outputs, 0, 1-60 Memory can be selected and copied, but memory

room which is selected by counter output can not be selected.

- “0” Memory automatic mode can be selected at the same time in either channel 1

or channel 2.

The datas of Memory [0] are not stored into the data memory. Only the

battery type is stored.

In Automatic mode, main screens will be only shown as like order -

MEMORY CHARGE DISCHARGE DATA VIEW CONFIG

1-2. Battery selection

- In memory screen, select the memory and press “-> button”

- Set your wanted battery, cell or voltage, and capacity.

If battery type is changed, all setting parameters should be initialized, and TRACE

DAT in DAT VIEW mode is clear.

- Input the purchasing date of your battery (day/month/year)

If battery type is changed, the purchasing date on your battery should be

automatically changed to present date.

- In “0” memory, if battery type is changed then press the dial, it should move

“CHARGE SETUP”.

1-3. Battery Name Setting

- You can name your battery pack using up to total 16 letters.

1-4. Auto settings on parameters

- When battery type is changed

It should be clear to battery initial values.

- max. current:

The max. Charge or discharge current should be changed to 1C rate.

Safety timer value is automatically changed.

However, battery type and max. charge current MUST be set correctly.

Page 19

Page 19/55

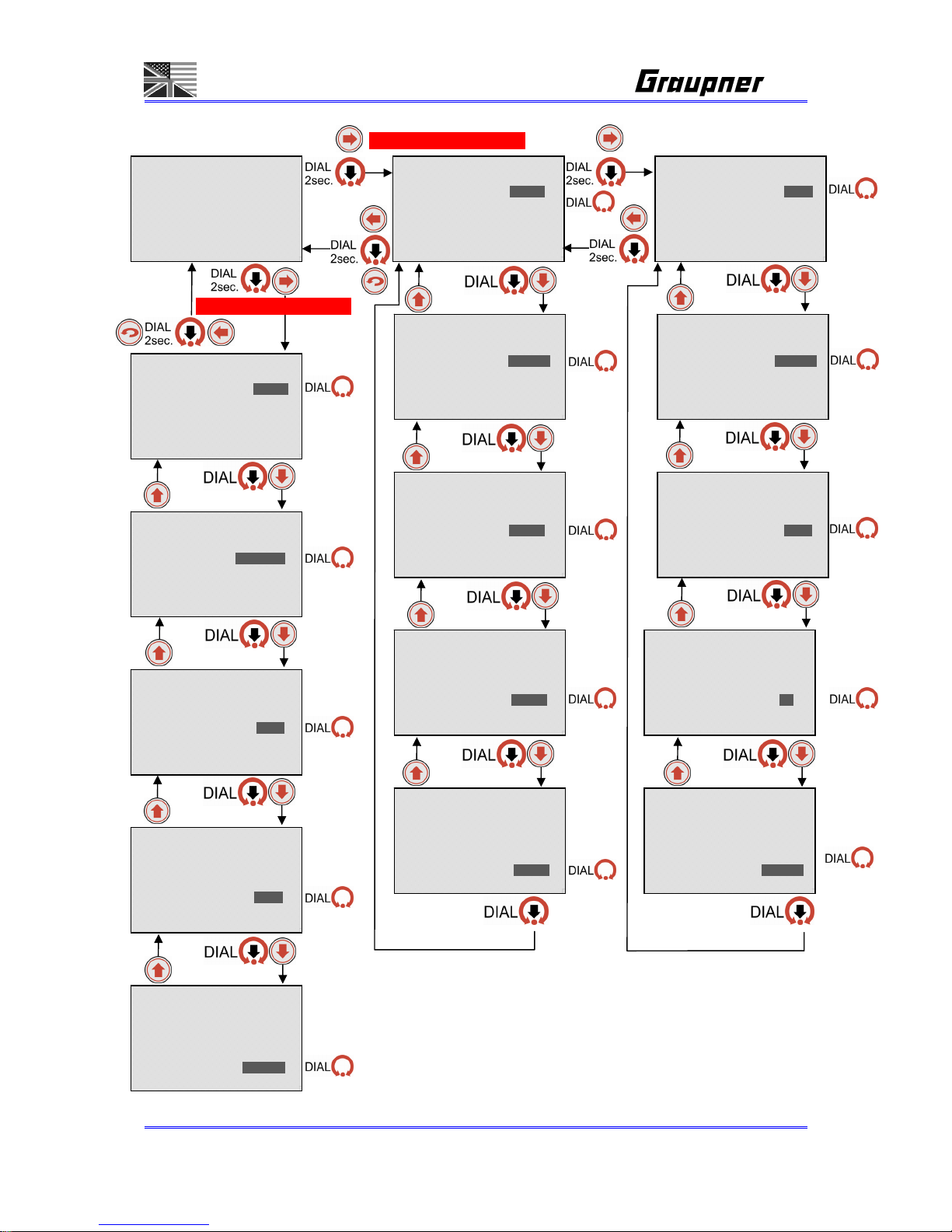

2. CHARGE SETUP MENU FLOW

- = - - - - - - - -

CHARGE

C: 4.6A ____V___ 50°C

CHARGE SETUP <1/2>

CHG CURRENT _4.6A

PEAK SENS _5mV/C

PEAK DELAY _3min

TRICKLE _AUTO

CUT-TEMP. _50°C

CHARGE SETUP <2/2>

MAX CAPACITY 125%

SAFETY TIMER _75min

FLAT CHECK _OFF

REPEAK CYCLE 1T

REPEAK DELAY _30min

CHARGE SETUP <1/1>

CHG CURRENT _2.1A

CHG VOLTAGE 4.20V/C

CUT-TEMP. 45°C

MAX CAPACITY 105%

SAFETY TIMER 140min

CHARGE SETUP <1/2>

CHG CURRENT _4.6A

PEAK SENS _5mV/C

PEAK DELAY _3min

TRICKLE _AUTO

CUT-TEMP. _50°C

CHARGE SETUP <1/2>

CHG CURRENT _4.6A

PEAK SENS _5mV/C

PEAK DELAY _3min

TRICKLE _AUTO

CUT-TEMP. _50°C

CHARGE SETUP <1/2>

CHG CURRENT _4.6A

PEAK SENS _5mV/C

PEAK DELAY _3min

TRICKLE _AUTO

CUT-TEMP. _50°C

CHARGE SETUP <1/2>

CHG CURRENT _4.6A

PEAK SENS _5mV/C

PEAK DELAY _3min

TRICKLE _AUTO

CUT-TEMP. _50°C

CHARGE SETUP <2/2>

MAX CAPACITY 125%

SAFETY TIMER _75min

FLAT CHECK _OFF

REPEAK CYCLE 1T

REPEAK DELAY _30min

CHARGE SETUP <2/2>

MAX CAPACITY 125%

SAFETY TIMER _75min

FLAT CHECK _OFF

REPEAK CYCLE 1T

REPEAK DELAY _30min

CHARGE SETUP <2/2>

MAX CAPACITY 125%

SAFETY TIMER _75min

FLAT CHECK _OFF

REPEAK CYCLE 1T

REPEAK DELAY _30min

CHARGE SETUP <1/1>

CHG CURRENT _2.1A

CHG VOLTAGE 4.20V/C

CUT-TEMP. 45°C

MAX CAPACITY 105%

SAFETY TIMER 140min

CHARGE SETUP <1/1>

CHG CURRENT _2.1A

CHG VOLTAGE 4.20V/C

CUT-TEMP. 45°C

MAX CAPACITY 105%

SAFETY TIMER 140min

CHARGE SETUP <1/1>

CHG CURRENT _2.1A

CHG VOLTAGE 4.20V/C

CUT-TEMP. 45°C

MAX CAPACITY 105%

SAFETY TIMER 140min

CHARGE SETUP <1/1>

CHG CURRENT _2.1A

CHG VOLTAGE 4.20V/C

CUT-TEMP. 45°C

MAX CAPACITY 105%

SAFETY TIMER 140min

NiMH CHARGE SETUP

LiPo CHARGE SETUP

CHARGE SETUP <2/2>

MAX CAPACITY 125%

SAFETY TIMER _75min

FLAT CHECK _OFF

REPEAK CYCLE 1T

REPEAK DELAY _30min

Page 20

Page 20/55

2. CHARGE SETUP MENU FLOW

Warning: To high settings of charging voltage (Li-batteries), charging current (all types)

or delta peak sensitivity (NiMH/NiCd) batteries can cause explosion and fire!

2-1. CHARGE CURRENT

- Set charge currents. Follow the instruction of the battery. Graupner batteries

should be charged with 0.5-1C (f. e. 6N-4200 should be charged with 4.2A).

Transmitter batteries must be charge with less then 2A. Follow the instruction of

the transmitter battery and transmitter.

2-2. PEAK SENS

WARNING! To high settings of the delta peak sensitivity can cause explosion and fire.

- Only for NiCd/NiMH. Follow the instruction of your battery or start with 3mV/Cell.

- If battery is 6cells and 3mV/C is set, the charger should finish as 3mV * 6cell =

18mV.

- In case of NIMH battery, charge can be also finished with Zero-peak.

- Set bigger peak sens values if delta-peak often happens.

- "END:DELTA-PEAK " should be shown if charge is finished with delta-peak.

- "END:ZERO-PEAK should be shown if charge is finished with ZERO-peak.

2-3. PEAK DELAY

- This function is not to detect delta peak which could happen at the initial stage of

charging and which could happen due to the chemical reaction internal battery.

Normal settings are 3-5min.

2-4. TRICKLE

- This current is to compensate battery self discharge after NICD/NiMH fast charging.

- As for Lithium battery, CV ( constant voltage ) is activated instead of trickle charge.

2-5. CUT-TEMP

- Connect the temp sensor to battery pack and when it reaches the selected temp,

charging should stop. Normal settings are 35-50°C.

- This function is likely to be used more to prevent battery pack from being

overheating rather than normal charge completion.

2-6. MAX CAPACITY

- This is to set your wanted charge percentage against the selected battery capacity.

- Set half of the battery capacity ( 50% ) for the purpose of the battery storage. Set

120-125% for fully charging of high current NiCd/NiMH batteries and 100-105% for

charging LiPo-, LiIo-, LiFe- batteries and NiMH RTU (Ready to use) batteries.

- If battery capacity is 3000mAh and if you set 10% out of the total max capacity, the

charger should stop charging at 300mAh.

- If “OFF” is set, this max capacity function is not activated.

- If charging is finished with MAX CAPACITY, “END:CAPACITY should be shown.

Page 21

Page 21/55

2-7. SAFETY TIMER

- If charging is not finished within charging time, this Safety Timer should stop

charging.

- When charge current is changed, the Safety Timer is also automatically changed.

Safety Timer per battery type is gained based on Linear charge mode

NiCd, NiMH = (Selected capacity * 60 / Selected current) * 1.5

LiIo, LiPo, LiFe, Pb = (Selected capacity * 60 / Selected current) * 2.0

Safety Timer should be “OFF” if the safety timer is bigger than 900minutes.

- Expected time can vary depending on input power or AC power (internal) in

CONFIG SETUP.

(Refer to the file “ watt limit & safe timer.xls” )

2-8. FLAT CHECK

- “END : FLAT CHECK “ : This message should be shown when the battery voltage

is not changed for a specific time during charging.

- Also, when a battery which has BIG capacity is being charged with smaller charge

current, this message could be also shown.

f. e. 4800mAh 0.1A Charge

- You can turn on or off for this FLAT CHECK function.

2-9. REPEAK CYCLE

- This is to recharge battery pack which is charged.

- This mode should be activated when it moves to “REPEAK” mode from CHARGE

PROCESS

- Since this function is to charge again the fully charged battery, this PEAK DELAY

should be automatically set to “0”. ( PEAK DELAY setting value is not charged )

- Set wanted repeak charge cycle number.

2-10. REPEAK DELAY

- Set the delay time between first repeak and second repeak.

2-11 . C HG-VO LTA G E

- This is only for lithium battery.

- Setting charging voltage can be used as battery storage.

Normally, LiPo battery is charged to 4.2V/cell, for the battery storage, it can

be charged to 3.7V/cell with CV charging.

- For charging range per battery type, please refer to “Setup Range sheet” and

battery instruction. Normal max. charging voltage settings are for:

LiFe: 3.6V/cell, LiIo: 4.1V/cell, LiMn = LiPo: 4.2V/cell. For higher cycle life

time, use 0.1V less. For storage use 0.4-0.5V less.

Page 22

Page 22/55

3. DISCHARGE MENU SCREEN

3. DISCHARGE MENU SCREEN

Warning: Deep discharging cells and too high discharge currents can destroy the

battery and can cause explosion and fire!

3-1. DSCH CURRENT

- Set wanted discharge currents. Check the battery instruction for the max.

discharge current.

3-2. DSCH CUTOFF

- Set discharge cutoff voltage per cell.

If it is set to 1.0V/Cell and its battery cell is 6cells, the discharge is finished

at 6.0V.

For NiCd/NiMH batteries the cells should be never discharged lower as

1.1V/cell.

LiFe cells should be never discharged lower as 2.5V/cell and LiPo/LiIo cells

should be never discharge lower as 3.0V/cell for the highest possible life

time.

Deep Discharge can cause capacity loss and in the worst case it can

destroy the battery and cause explosion and fire.

- Discharge is finished with smallest voltages with connecting the balancer cable the

balancing port of the charger.

Even if the cable is connected during discharging, discharge is not finished

with cell voltage.

3-3. CUT-TEMP

- Connect the temp sensor to battery, and discharge is finished when it reaches the

selected temp.

- - = - - - - - - -

DISCHARGE

D:00.0A 1.0V/CL 00°C

DISCHARGE SETUP<1/1>

DCHG CURRENT _0.0A

DCHG CUTOFF _0.0V/C

CUT-TEMP. __0°C

MAX CAPACITY __0%

MATCHED VOLT _0.00V

DISCHARGE SETUP<1/1>

DCHG CURRENT _0.0A

DCHG CUTOFF _0.0V/C

CUT-TEMP. __0°C

MAX CAPACITY __0%

MATCHED VOLT _0.00V

... 4x

Page 23

Page 23/55

- This function is likely to be used more to prevent battery pack from being

overheating rather than normal charge completion

3-4. MAX CAPACITY

- This is to set your wanted discharge percentage against the selected battery

capacity.

- If “OFF” is set, this max capacity function is not activated.

- If battery capacity is 3000mAh and if you set 10% out of the total max capacity, the

charger should stop discharging at 300mAh

3-5. MATCHED VOLT

- This is only for NICD and NIMH batteries.

- This mode should be activated when it moves to “MATCH” mode from

DISCHARGE PROCESS

- To activate this mode, balancing cable MUST be connected to the balancing port

of the charger.

- Discharge to selected voltages with selected discharge currents and match each

cell voltage.

- If the discharge cut-off voltage is set to the same voltage as the match voltage, the

discharge current will be reduced when the cut-off voltage

is reached, to hold the constant voltage at the match/cut-off voltage level.

High current competition NiMH batteries should be matched before charging.

Matching the batteries does increase the life time of the battery.

Page 24

Page 24/55

4. CYCLE MENU SCREEN

4. CYCLE MENU SCREEN

4-1. DIRECTION

- Set cycle direction.

- D:CD This mode is to first unconditionally discharge then charge to discharge

repeatedly.

4-2. CYCLE TIME

- Set the cycle repeat time number.

4-3. AF-CHG DELAY

- Set pause time before discharging after charging.

4-4. AF-DCH DELAY

- Set pause time before charging after discharging, so the battery can cool down

after discharging before the next charging starts.

- - - = - - - - - -

CYCLE

D:C>D 1T C00/D00min

CYCLE SETUP <1/1>

DIRECTION D:C>D

CYCLE TIME _0

AF-CHG DELAY _0min

AF-DCH DELAY _0min

CYCLE SETUP <1/1>

DIRECTION D:C>D

CYCLE TIME _0

AF-CHG DELAY _0min

AF-DCH DELAY _0min

CYCLE SETUP <1/1>

DIRECTION D:C>D

CYCLE TIME _0

AF-CHG DELAY _0min

AF-DCH DELAY _0min

CYCLE SETUP <1/1>

DIRECTION D:C>D

CYCLE TIME _0

AF-CHG DELAY _0min

AF-DCH DELAY _0min

Page 25

Page 25/55

5. STEP CHARGE MENU SCREEN

- - - - = - - - - -

STEP CHARGE

D: ON d00mV/C 00°C

STEP CHARGE <1/2>

D: ON d 3mV/C 50°C

400 1600 3800 4500

4.0A 8.0A 6.0A 4.0A

STEP CHARGE <2/2>

PEAK SENS _5mV/C

CUT-TEMP. _50°C

TRICKLE CHG __OFF

DISCHARGE _ON

IMPULSE CHG 1 2 3

REFLEX CHG 1 2 3

STEP CHARGE <1/2>

D: ON d 3mV/C 50°C

400 1600 3800 4500

4.0A 8.0A 6.0A 4.0A

STEP CHARGE <1/2>

D: ON d 3mV/C 50°C

400 1600 3800 4500

4.0A 8.0A 6.0A 4.0A

STEP CHARGE <1/2>

D: ON d 3mV/C 50°C

400 1600 3800 4500

4.0A 8.0A 6.0A 4.0A

STEP CHARGE <1/2>

D: ON d 3mV/C 50°C

400 1600 3800 4500

4.0A 8.0A 6.0A 4.0A

STEP CHARGE <1/2>

D: ON d 3mV/C 50°C

400 1600 3800 4500

4.0A 8.0A 6.0A 4.0A

STEP CHARGE <2/2>

PEAK SENS _5mV/C

CUT-TEMP. _50°C

TRICKLE CHG __OFF

DISCHARGE _ON

IMPULSE CHG 1 2 3

REFLEX CHG 1 2 3

STEP CHARGE <2/2>

PEAK SENS _5mV/C

CUT-TEMP. _50°C

TRICKLE CHG __OFF

DISCHARGE _ON

IMPULSE CHG 1 2 3

REFLEX CHG 1 2 3

STEP CHARGE <2/2>

PEAK SENS _5mV/C

CUT-TEMP. _50°C

TRICKLE CHG __OFF

DISCHARGE _ON

IMPULSE CHG 1 2 3

REFLEX CHG 1 2 3

STEP CHARGE <2/2>

PEAK SENS _5mV/C

CUT-TEMP. _50°C

TRICKLE CHG __OFF

DISCHARGE _ON

IMPULSE CHG 1 2 3

REFLEX CHG 1 2 3

STEP CHARGE <2/2>

PEAK SENS _5mV/C

CUT-TEMP. _50°C

TRICKLE CHG __OFF

DISCHARGE _ON

IMPULSE CHG 1 2 3

REFLEX CHG 1 2 3

... 5x

... 3x

Page 26

Page 26/55

5. STEP CHARGE MENU SCREEN

5-1. STEP CAPACITY

- This mode is only for NiMH battery, which are discharge before charging. Never charge full batteries in

this mode. Use the temperature sensor for safety reasons.

- Set wanted charge capacity in each step.

- Step charge should be finished at the fourth step based on the selected capacity in the fourth step.

Set max possible capacity which can be charged to battery.

If battery is 4300mAh and 4800mAh is charged, set 4900mAh ( 100mAh – tolerance ).

- If you want three step charging, make sure to set same capacity in 2

nd

step and 3rd step, then, it should

be jumped directly from 2

nd

step to 4th step.

- Value can be automatically set pressing the dial long as AUTO SETUP.

5-2. STEP CURRENT

- Set wanted charge current in each step.

- Value can be automatically set pressing the dial long as AUTO SETUP.

5-3. PEAK SENS

- Set peak sens voltage.

- The selected peak sens voltage is checked in each step.

5-4. CUT-TEMP

- Connect the temp sensor to battery, and charge is finished when it reaches the selected temp.

- This function is likely to be used more to prevent battery pack from being overheating rather than

normal charge completion

5-5. TRICKLE CHG

- Set additional current after fast charging.

5-6. DISCHARGE

- Set whether discharge is first activated before step charging.

- If “ON” is set, discharge is done based on selected capacity (max selected capacity) x 4C rate. It is

limited to 10.0A if X4C rate is over 10.0A.

- Step charge is basically to charge full discharged battery pack, please make sure to set “ON” always.

5-7. IMPULSE

- Set whether impulse operation is activated or no in 1

st

~ 3rd step.

- Impulse current : Selected current X 1.5 current should be delivered for 0.5 second every 3 seconds.

Ex) If 5A is set, 5.0A current for 2.5 seconds, and 7.5A for 0.5 second.

- This IMPUSE is to improve battery power.

- Battery could be damaged if excessive current with impulse operation is set.

5-8. REFLEX

- Set REFLEC operation in 1

st

step ~ 3rd step.

- REFLEX is to discharge for a very short time every one second.

Page 27

Page 27/55

6. BALANCER MENU SCREEN

- - - - - = - - - -

BALANCE

0C 0.00VPCK 0.00Va

BALANCE <1/4>

BATT CELLS _0CELL

PACK VOLTS _0.000V

AVG VOLTS _0.000V

GAP VOLTS _0.000V

MAX NO. 0 _0.000V

MIN NO. 0 _0.000V

BALANCER <2/4>

CELL NO. 1 _0.000V

CELL NO. 2 _0.000V

CELL NO. 3 _0.000V

CELL NO. 4 _0.000V

CELL NO. 5 _0.000V

CELL NO. 6 _0.000V

CELL NO. 7 _0.000V

BALANCER 0N=0.000V

0.000Vc 0.000Vy=A CL

BALANCER 0N=0.000V

0.000Vc 0.000Vy=A CL

BALANCER 0N=0.000V

0.000Vc 0.000Vy=M CL

BALANCER 0N=0.000V

0.000Vc 0.000Vy=M CL

BALANCER 0N=0.000V

0.000Vc 0.000Vy=M CL

RESISTANCE <3/4>

CELL NO. 1 __0.0m

CELL NO. 2 __0.0m

CELL NO. 3 __0.0m

CELL NO. 4 __0.0m

CELL NO. 5 __0.0m

CELL NO. 6 __0.0m

CELL NO. 7 __0.0m

Page 28

Page 28/55

6. BALANCER MENU SCREEN

6-1. BALANCE <1/4> SCREEN

- This is to show each cell information which is connected to the balancing port of

the charger.

BATTCELLS 0CELL - Connected cell number.

PACK VOLTS 0.000V – Overall cell voltage

AVG VOLTS 0.000V – Cell average voltage

GAP VOLTS 0.000V – Between max and min voltage

MAX NO. 0 0.000V - Max cell number and voltage

MIN NO. 0 0.000V - Min cell number and voltage

6-2. CELLS VOLTAGE <2/4>SCREEN

- Showing each cell voltage

6-3. CELLS RESISTANCE <3/4>SCREEN

- Showing each cell internal resistance

6-4. BALANCE GRAPHIC

- CL, 0N : Showing the selected cell voltage

- A, M : Select Auto or Manual for Y axis of the graph

A(Auto) : If Auto is set, Vy and Vc are automatically set.

M(Manual) : If Manual is set, Vy and Vc can be manually set.

- Vy : Vy means a scale of voltage in Y axis.

- Vc : Vc means voltage of center position of Y axis.

Page 29

Page 29/55

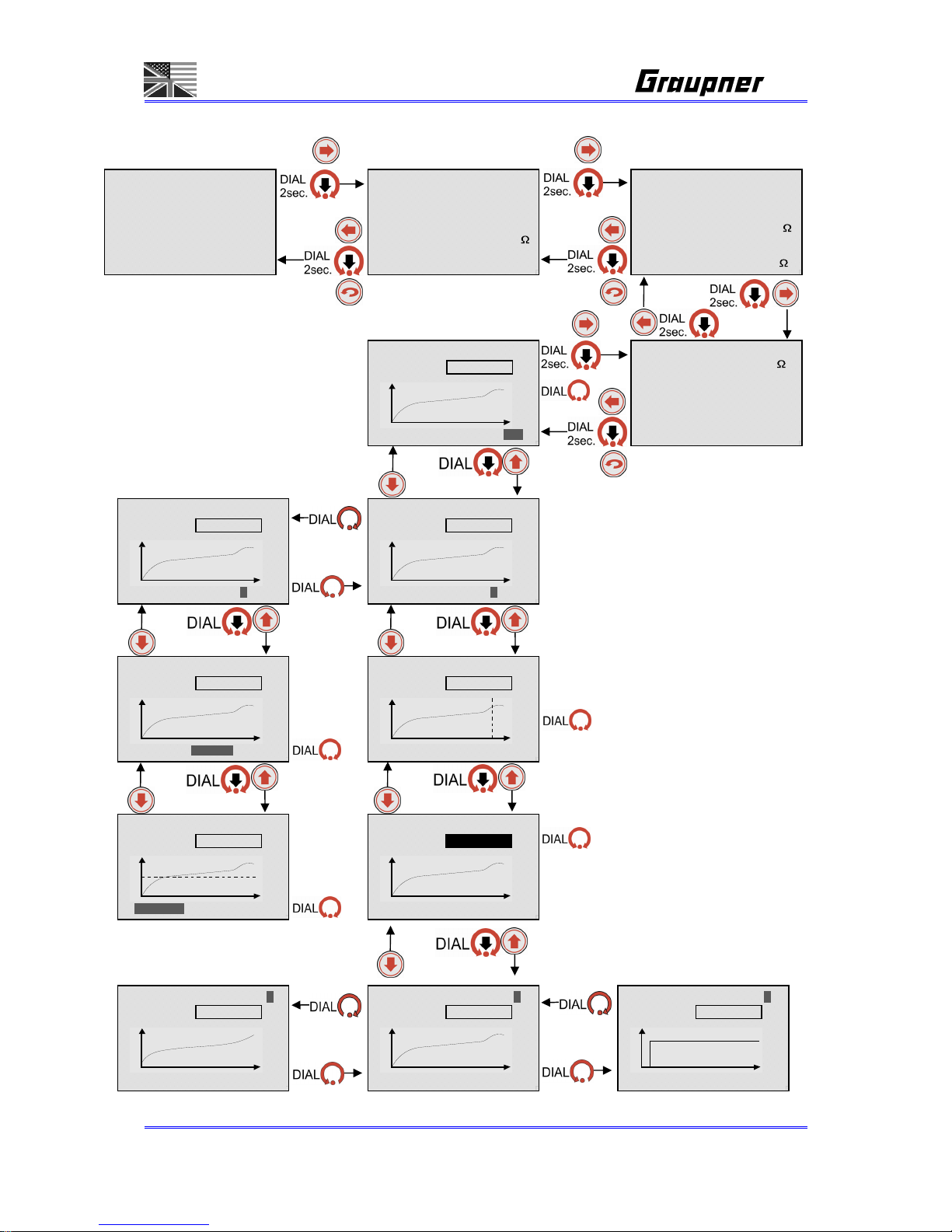

7. DATA VIEW SCREEN

- - - - - - = - - -

DATA VIEW

0.0Vi 0.00Vo 0.0°C

DATA VIEW <1/4>

INPUT _0.000V

OUTPUT _0.000V

TEMPERATURE __0.°C

HIGH TEMP __0.0°C

RESISTANCE _0.0m

CHG TIME _0:00:00

DCHG TIME _0:00:00

CYCLE DATA _0<2/4>

FIN.00/00/07 **--:- CHG CAP ____0mAh

PEAK VOLTS _0.000V

CHG RESITANCE _0.0m

DCHG CAP ____0mAh

AVG DCHG _0.000V

DISCHG RES. _0.0m

TRACE DATA <3/4>

MIN. RES. _0.0m

LAST CHG ____0mAh

LAST DCHG ____0mAh

MAX CHG ____0mAh

MAX DCHG ____0mAh

TOTAL CHARGES __0

NEW _0/_0/2000

0:00:00 0.00V GR=V

0.000Vc 0.000V=A 0x

0:00:00 0.00V GR=V

0.000Vc 0.000V=A 0x

zoom

auto

0:00:00 0.00V GR=V

0.000Vc 0.000V=M 0x

manual

0:00:00 0.00V GR=V

0.000Vc 0.000V=M 0x

Y axis value

0:00:00 0.00V GR=V

0.000Vc 0.000V=M 0x

center value

0:00:00 0.00V GR=V

0.000Vc 0.000V=A 0x

point value

0:00:00 0.00V GR=V

0.000Vc 0.000V=A 0x

position

0:00:00 0.00V GR=V

0.000Vc 0.000V=A 0x

0:00:00 0.00A GR=I

0.000Ac 0.000A=A 0x

0:00:00 0.00°C GR=T

0.00°Cc 0.00°C=A 0x

graph type

graph type

graph type

Page 30

Page 30/55

7. DATA VIEW SCREEN

7-1. DATA VIEW <1/4>

- This is to display charge status.

INPUT 0.000V -Input Voltage

OUTPUT 0.000V -Output Voltage

TEMPERATURE 0.0`F -Temp of the temp sensor

HIGH TEMP 0.0`F -Max temp of the temp sensor

RESISTANCE 0.0m

-Battery internal resistance after

operation

CHG TIME 0:00:00 -Charge time after charging

DSCH TIME 0:00:00 -Discharge time after discharging

7-2. CYCLE DATA <2/4>

- This is to store cycle operation and various status.

- Total 11 memories ( Memory 0~10)

- Memory consists of “ROM”, even if power is OFF, the data still leaves.

- Memory “0” is the latest data, and memory 10 is the oldest data.

Data which happens after 10 times should be removed in order.

CYCLE DATA 0<2/4> - Cycle number

END.00/00/00 10:00 - Date and Time for the cycle

CHG CAP 0mAh - Charged capacity

PEAK VOLTS 0.000V - Peak voltage during charging

CHG RESITANCE 0. 0m

- Battery internal resistance at charge

DSCH CAP 0mAh - Discharged capacity

AVG DSCH 0.000V - Average voltage during discharging

DISCHG RES. 0. 0m

- Battery internal resistance at

discharge

- Memory storage

- CHARGE, DISCHARGE MODE

Data is stored to “0” memory

- CYCLE MODE

If D:C->D mode is activated for 10 times, the first discharge is

stored to “10” memory and 1~10 cycles are stored to 9~0

memories.

If CD, DC mode is activated for 10 times, 1~10 cycles are

stored to 9~0 memories.

The latest data should be stored in Memory “0”.

- STEP CHARGE

Initial discharge “1” memory storage

1

st

~ 4th STEP “0” memory storage

- REPEAK CHARGE

Since this mode is to recharge charged battery, the previous

charged data is already stored to “0” memory.

Page 31

Page 31/55

7-3. TRACE DATA <3/4>

- This is to check battery condition.

- Memory consists of “ROM”, even if power is OFF, the data still leaves.

- MEMORY setting

MIN. RES. 0. 0

- min. internal battery resistance up to

now.

LAST CHG 0mAh - Last charged capacity

LAST DSCH 0mAh - Last discharged capacity

MAX CHG 0mAh - Biggest charged capacity up to now

MAX DSCH 0mAh - Biggest discharged capacity up to

now

TOTAL CHARGES 0 - Charged number up to now

NEW 00/00/2007 - Date of using battery for the first time

7-4. OPERATION GRAPHIC

- Graph does not exist in each memory. Instead, graph is shown for last operation.

- Check graph for voltage, current, and temperature in the graph.

- Memory consists of “ROM”, even if power is OFF, the data still leaves.

0x (zoom) - It means time of X axis and 1~43 can be set.

Ex) If one screen of X axis of 1X is 2minutes, if 10x is

set, 20minutes can be shown in the screen.

The more zoom is bigger, the less accuracy of the

graph becomes. AT = AUTOZOOM

A,M(auto,manual) - Select Auto or Manual for Y axis.

A(Auto) : If Auto is set, Vy and Vc are automatically set.

M(Manual) ; If Manual is set, Vy and Vc can be man.

set

Y axis value - One scale of voltage of Y axis

center value - Voltage of center position of Y axis

position - Location for graph moving

graph type -

V – Voltage graph with indication of Vc and V

I – Current graph with indication of AC and A

T – Temperature graph with indication of Fc and F

Page 32

Page 32/55

8. TYRE HEATER / BATTERY HEATER SCREEN AND POWER SUPPLY SCREEN

- - - - - - - = - -

POWER & HEATER

__0m _

_

0°C__0m __0°C

HEATER <1/1>

SET TIME 1 __0min

SET TEMP 1 __0°C

TIME DELAY __0min

SET TIME 2 __0min

SET TEMP 2 __0.0°C

CURRENT LIMIT _0.0A

HEATER <1/1>

SET TIME 1 __0min

SET TEMP 1 __0°C

TIME DELAY __0min

SET TIME 2 __0min

SET TEMP 2 __0.0°C

CURRENT LIMIT _0.0A

HEATER <1/1>

SET TIME 1 __0min

SET TEMP 1 __0°C

TIME DELAY __0min

SET TIME 2 __0min

SET TEMP 2 __0.0°C

CURRENT LIMIT _0.0A

... 4x

POWER SUPPLY <2/2>

VOLTAGE LIMIT 12.0V

CURRENT LIMIT 5.0A

POWER SUPPLY

VOLTAGE LIMIT 12.0V

CURRENT LIMIT 5.0A

POWER RATE 50%

AC POWER USED 60.0W

_0.00V _0.0A 0.0W

POWER & HEATER START5

PROCESS [ POWER-CTL]

HEAT T1: __0min _00°C

DELAY: __0min I:_0.0A

HEAT T2: __0min _00°C

POWER & HEATER START

-- CONNECT - __ CHECK __

POWER SUPPLY

VOLTAGE LIMIT 12.0V

CURRENT LIMIT 5.0A

POWER RATE 50%

AC POWER USED 60.0W

_0.00V _0.0A 0.0W

POWER SUPPLY

VOLTAGE LIMIT 12.0V

CURRENT LIMIT 5.0A

POWER RATE 50%

AC POWER USED 60.0W

_0.00V _0.0A 0.0W

POWER SUPPLY

VOLTAGE LIMIT 12.0V

CURRENT LIMIT 5.0A

POWER RATE 50%

AC POWER USED 60.0W

_0.00V _0.0A 0.0W

Page 33

Page 33/55

8. TYRE HEATER / BATTERY HEATER SCREEN AND POWER SUPPLY SCREEN

8-1. How to use

Using tyre warmer of GM-Racing #94711 or Much More or battery heater of Much

More. Never heat tyres over 80°C and never heat batteries over 50°C.

Insert the temp sensor into the tire warmer.

Select SETUP menu

Starting this mode.

Even changed values during operation should be also stored internal memory.

8-2. SETUP

- SET TIME 1

Set operation time 1.

When it reaches the selected operation time, operation should stop.

- SET TEMP 1

Set tire temperature 1 for the best tyre additive efficiency.

Control output in accordance with temperature.

- SET DELAY

Set the delay time between heating setting 1 and setting 2, if need for better

tyre performance.

- SET TIME 2

Set operation time 2.

When it reaches the selected operation time, operation should stop.

- SET TEMP 2

Set tire temperature 2 for the best racing temperature.

Control output in accordance with temperature.

- CURRENT LIMIT

Set max currents which is delivered to tire warmer. The max. current should

be limited to 3.0A. Current is not increased any more when it reaches max

currents even if tire temperature does not match.

8-3. POWER SUPPLY

Set the voltage limit and current limit.

Connect the user to the output and then start the power supply function

with the dial button. If you start the power supply and then connect a user,

It can happen, that the power supply will switch-off and cause a reset of the

charger.

Page 34

Page 34/55

9. MOTOR RUN-IN SCREEN (Warning: only use DC brushed motors or DC fans!)

9. MOTOR RUN-IN SCREEN (Warning: only use DC brushed motors or DC fans!)

9-1. MOTOR Break-In

- This is motor brake in mode.

- Rotate the motor keeping the selected voltage.

- Set voltage and operating time.

- Set 0.1V~24V

Make sure not to exceed 12V when breaking in motor used for electric power.

12~24V range is for operating range of fan.

- - - - - - - - = -

MOTOR RUN

MOTOR BREAK-IN <1/3>

SET VOLT _0.0V

SET TIME __0m _0s

RUNTIME 000m 00s

VOLTAGE _0.00V

CURRENT _0.00A

Program Mode <2/3>

1st 2nd 3rd 4th

V>_0.0 _0.0 _0.0 _0.0

T> _0m _0m _0m _0m

D> _0m _0m _0m _0m

SPEED:0 CYCLE: _0

_0.00V _0.00A _0CYCLE

__0m00s -00000s

MOTOR Test <3/3>

Test voltage 0.0V

1st _0.0Aavg _0.0Apk

2nd _0.0Aavg _0.0Apk

3rd _0.0Aavg _0.0Apk

4th _0.0Aavg _0.0Apk

5th _0.0Aavg _0.0Apk

6th _0.0Aavg _0.0Apk

MOTOR BREAK-IN <1/3>

SET VOLT _0.0V

SET TIME __0m _0s

RUNTIME 000m 00s

VOLTAGE _0.00V

CURRENT _0.00A

MOTOR BREAK-IN <1/3>

SET VOLT _0.0V

SET TIME __0m _0s

RUNTIME 000m 00s

VOLTAGE _0.00V

CURRENT _0.00A

Program Mode <2/3>

1st 2nd 3rd 4th

V>_0.0 _0.0 _0.0 _0.0

T> _0m _0m _0m _0m

D> _0m _0m _0m _0m

SPEED:0 CYCLE: _0

_0.00V _0.00A _0CYCLE

__0m00s -00000s

Program Mode <2/3>

1st 2nd 3rd 4th

V>_0.0 _0.0 _0.0 _0.0

T> _0m _0m _0m _0m

D> _0m _0m _0m _0m

SPEED:0 CYCLE: _0

_0.00V _0.00A _0CYCLE

__0m00s -00000s

Program Mode <2/3>

1st 2nd 3rd 4th

V>_0.0 _0.0 _0.0 _0.0

T> _0m _0m _0m _0m

D> _0m _0m _0m _0m

SPEED:0 CYCLE: _0

_0.00V _0.00A _0CYCLE

__0m00s -00000s

... 11x

Page 35

Page 35/55

The motor function can only be started, if the other output is not in use!

For racing brushed motors and using the internal power supply, we

recommend to use a 1-2 Ohm resistor in series of the motor to reduce the max.

current flow.

Use voltages of max. 7.2V for 7.2V motors. Never use a higher voltage as the

motor is build for.

Higher voltages can destroy the motor and the charger. Never run brushless

motors!

9-2. Program Mode

- This mode is to program motor voltages.

- It consists of 4 steps, and user can set operation voltage, operating time and

pause time in each step.

- The meaning of “SPEED” is speed which reaches the selected voltage when step

is changed.

SPEED can be set to 1~5 and 1 is slowest and 5 is fastest. The slowest

speed is recommended for motors.

- Cycle can be set and it can be repeated in 1~4 step.

Cycle can be set to 1~10 times.

9-3. MOTOR Test

- Rotate the motor at 4.8V or 7.2V.

- Showing average currents and peak currents in each step.

- Step operation voltage

1st - 1.2V

2nd - 2.4V

3rd - 3.6V

4th - 4.8V

5th - 6.0V

6th - 7.2V

Page 36

Page 36/55

10. CONFIG SETUP SCREEN

- - - - - - - - - =

CO N F I G

00/00/2000 am00:00:00

CONFIG SETUP <2/4>

TEMP SCALE °C

BUTTON SOUND __ON

LANGUAGES _ENGLISH

PC SETUP DISABLE

SUPPLY _0.0V _0.0A

INPUT POWER [__0.0W]

TIME SETUP <3/4>

SET DATE 17/05/2007

SET TIME am11:20

SET TIME FORMAT 12h

17/05/2007 am11:20:00

USER NAME <4/4>

01] GRAUPNER GmbH

^

ABCDEFGHIJKLMNOPQR

STUVWXYZabcdefghijk

lmnopqrstuvwxyz0123

456789 -.,'#_+/

ä ö ü é è

TIME SETUP <3/4>

SET DATE 17/05/2007

SET TIME am11:20

SET TIME FORMAT 12h

17/05/2007 am11:20:00

TIME SETUP <3/4>

SET DATE 17/05/2007

SET TIME am11:20

SET TIME FORMAT 12h

17/05/2007 am11:20:00

TIME SETUP <3/4>

SET DATE 17/05/2007

SET TIME 11:20

SET TIME FORMAT 12h

17/05/2007 am11:20:00

TIME SETUP <3/4>

SET DATE 17/05/2007

SET TIME am11:20

SET TIME FORMAT 12h

17/05/2007 am11:20:00

CONFIG SETUP <2/4>

TEMP SCALE °C

BUTTON SOUND __ON

LANGUAGES _ENGLISH

PC SETUP DISABLE

SUPPLY _0.0V _0.0A

INPUT POWER [__0.0W]

CONFIG SETUP <2/4>

TEMP SCALE °C

BUTTON SOUND __ON

LANGUAGES _ENGLISH

PC SETUP DISABLE

SUPPLY _0.0V _0.0A

INPUT POWER [__0.0W]

CONFIG SETUP <2/4>

TEMP SCALE °C

BUTTON SOUND __ON

LANGUAGES _ENGLISH

PC SETUP DISABLE

SUPPLY _0.0V _0.0A

INPUT POWER [__0.0W]

CONFIG SETUP <2/4>

TEMP SCALE °C

BUTTON SOUND __ON

LANGUAGES _ENGLISH

PC SETUP DISABLE

SUPPLY _0.0V _0.0A

INPUT POWER [__0.0W]

USER NAME <4/4>

01] GRAUPNER GmbH

^

ABCDEFGHIJKLMNOPQR

STUVWXYZabcdefghijk

lmnopqrstuvwxyz0123

456789 -.,'#_+/

ä ö ü é è

...

CONFIG SETUP <1/1>

FINISH SOUND _0sec

FINISH MELODY _0

LCD CONTRAST _0

DISPLAY MOVE

MENU OUTPUT 2:

MENU OUTPUT 1:

CONFIG SETUP <1/1>

FINISH SOUND _0sec

FINISH MELODY _0

LCD CONTRAST _0

DISPLAY MOVE

... 4x

... 2x

... 2x

CONFIG SETUP <1/4>

FINISH SOUND _0sec

FINISH MELODY _0

LCD CONTRAST _0

DISPLAY MOVE

CONFIG SETUP <1/4>

FINISH SOUND _0sec

FINISH MELODY _0

LCD CONTRAST _0

DISPLAY LAST

... 3x

ZEIT KONFIG. <3/4>

DATUM 17.05.2007

UHRZEIT 17:20

ANZEIGE 24h

17.05.2007 17:20:00

Page 37

Page 37/55

10. CONFIG SETUP SCREEN

10-1. CONFIG SETUP <1/4> and <2/4>

- TEMP SCALE Can be set to either “C” or “F”

- BOTTON SOUND Button can be set to ON or OFF

Even if the button sound is OFF, the charger should beep when error occurs.

- FINISH SOUND Set operating time for finish sound.

- FINISH MELODY Select melody for finish sound.

- LCD CONTRAST Set LCD contrast

- LANGUAGES set wanted language to be operated.

- DISPLAY MOVE or LAST. Choose, if you want the moving menu or the last one

after power on.

- PC SETUP DISABLE / ACTIV = read and programm the battery memories with

the PC software.

- SUPPLY

Set power voltage and current in case of using outside DC power.

If voltage and current are set, input power is automatically calculated.

Output is limited in accordance with input power (refer to page 13 on

operation description)

10-3. TIME SETUP

- Set the Date, use the DOWN button to apply the setting. If dial is used and moved,

this should be not applied.

- Select RTC (Real Time Clock) and press the down button to confirm. This is ONLY

applied when DOWN button is pressed. If dial is used and moved, this should be not

applied.

- Time can be formatted as 12h or 24h.

Present time is shown at the bottom line.

10-4. USER NAME SETUP

- Write user name using up to 16 letters.

- This user name is shown at the initial display when the charger is connected to the

power.

Page 38

Page 38/55

11. START SELECT MENU SCREEN

without bal. con. in Li-Mode

3sec.

5 sec. or

5 sec. or

- = - - - - - - - -

CHARGE

C: 4.6A d 5mV/C 50°C

CHARGE START 5

PROCESS [ NORMAL ]

01]NiMH 7.2V 4600mAh

C: 4.6A d 5mV/C 50°C

with bal. con.

CHARGE START

[ NiMH ] BATTERY

-- CONNECT --

__ CHECK __

- - = - - - - - - -

DISCHARGE

D:00.0A 1.0Vc/CL 00°C

- - - = - - - - - -

CYCLE

D:C>D 1T C00/D00min

- - - - = - - - - -

STEP CHARGE

D: ON d00mV/C 00°C

CHARGE START 5

DELAY TIME ____OFF

EXPECT TIME __72min

EXP.FINISH am11:12:00

01/01/2008 am10:00:00

DISCHARGE START 5

PROCESS [ NORMAL ]

01]NiMH 7.2V 4600mAh

D:10.0A 1.1Vc/CL 50°C

STEP-CHG START 5

PROCESS [STEP-CHG ]

01]NiMH 7.2V 4600mAh

___0 ___0 ___0 ___0

CYCLE START 5

CHARGE [ NORMAL ]

DISCHG [ NORMAL ]

01]NiMH 7.2V 4600mAh

D:C>D _1T C_0/D_0min

DISCHARGE START 5

DELAY TIME ____OFF

EXPECT TIME __72min

EXP.FINISH am11:12:00

01/01/2008 am10:00:00

STEP-CHG START 5

DELAY TIME ____OFF

EXPECT TIME __72min

EXP.FINISH am11:12:00

01/01/2008 am10:00:00

DISCHARGE START

[ NiMH ] BATTERY

-- CONNECT --

__ CHECK __

STEP-CHG START

[ NiMH ] BATTERY

-- CONNECT --

__ CHECK __

CYCLE START

[ NiMH ] BATTERY

-- CONNECT --

__ CHECK __

*CONNECTED CHECK* 5

[0] cells are now

Connected at the

Balancing port

.......Right?

OUTPUT [ _0.000V ]

** BALANCER **

** CONNECTION **

** ADVISED! **

*SELECT CELLS*

Select [0] cells

to be charged or

discharged.

OUTPUT [ _0.000V ]

[ NORMAL ] CHARGE

TIME _0:00:00

CAPACITY _____0mAh

VOLTAGE _0.000V

CURRENT +_0.00A

RESISTANCE __0.0m

BATT TEMP __0.0°C

3 sec.

5 sec. or

[ NORMAL ]DISCHARGE

TIME _0:00:00

CAPACITY _____0mAh

VOLTAGE _0.000V

CURRENT +_0.00A

RESISTANCE __0.0m

BATT TEMP __0.0°C

[ 4 STEP ]-CHARGE

STEP=1 [i] [r]

TIME _0:00:00

CAPACITY _____0mAh

VOLTAGE _0.000V

CURRENT +_0.00A

RESISTANCE __0.0m

BATT TEMP __0.0°C

[ NORMAL ] CHARGE

CYCLE D:C>D 0/10

TIME _0:00:00

CAPACITY _____0mAh

VOLTAGE _0.000V

CURRENT +_0.00A

RESISTANCE __0.0m

BATT TEMP __0.0°C

Page 39

Page 39/55

- - - - - = - - - -

BALANCER

0CL 0.00Vpk 0.00Va

- - - - - - - = - -

POWER & HEATER

__0m

__

0°C

_

_0m __0°C

- - - - - - - - = -

MOTOR RUN

BALANCE START 5

PROCESS [ ALONE ]

02]LiPo _0.0V ___0mAh

_0CL _0.00Vpk _0.00Va

POWER & HEATER START5

PROCESS [ POWER-CTL ]

HEAT T1: __0min _00°C

DELAY: __0min I:_0.0A

HEAT T2: __0min _00°C

MOTOR START 5

PROCESS [BREAK-IN ]

BALANCE START

[ LiPo ] BATTERY

-- CONNECT - __ CHECK __

POWER & HEATER START

-- CONNECT - __ CHECK __

MOTOR START

-- CONNECT - __ CHECK __

OPERATION SCREEN

*CONNECTED CHECK* 5

[0] cells are now

Connected at the

Balancing port

.......Right?

OUTPUT [ _0.000V ]

3 sec. 3 sec. 3 sec.

5 sec.

Page 40

Page 40/55

11. START SELECT MENU SCREEN

11-1. CHARGE START

- CHARGE FLOW

a. Pressing the dial moves to the Start mode from Charge screen.

b. Select charge process.

c. Under RESEVE TIMER “OFF”, press the dial in Reserve charge screen.

d. Check battery and cell connection.

e. Charge starts.

- CHARGE PROCESS

Make sure to select right battery type before operation.

Battery would be damaged and cause explosion and fire, if lithium

battery is charged in NiCd/NiMH mode.

If balancing cable is connected to the balancing port of the charger in

NiCD/NiMH mode, it just shows cell voltages, but it should have no

influence on charging.

The only difference is, the delta peak detection does cut-off charging,

after the first cell reaches the delta peak voltage.

a. NiCd/NiMh Battery AUTOMATIC

Battery cell and charge current are automatically gained.

Check battery internal resistance every specific time to calculate

charge current and continue to charge.

Delta-peak value is NiCd = 8mV/cell and NiMh = 6mV/cell.

Cutoff temp which is applied in charge is used.

b. LiIo/Po/Fe Battery AUTOMATIC

Battery cell and charge current are automatically gained.

For safety purpose, make sure to connect the balancing cable to

the balancing port of the charger.

Current will be fixed when it reaches constant voltage or when

auto measured current becomes smaller.

c. NORMAL

This is only for NiCD/NiMH battery.

Charge is off every one minute and measure charge voltage and

finished by delta peak.

This charge mode is good to charge old battery or when charging

cable is not stably connected

Detect charge completion every one minute and delta peak could

be slightly delayed.

d. LINEAR

Page 41

Page 41/55

This is only for NiCD/NiMH battery.

Charging has to be NOT “OFF” during charging, this charge has

to be continued.

This charge mode is very sensitive to charge cable connection,

so if connected cable is touched, charging could be finished.

Since delta peak is detected every second, it is possible to check

delta peak accurately.

It is possible to finish charging without increasing battery

temperature as ZEROpeak can be detected in this charge mode.

Charging is off 10 minutes after charging and gain battery internal

resistance.

e. GMVIS

This is only for NiCd/NiMH battery.

Charging every 6 seconds and pause every 2 seconds at the

intervals of 8 seconds.

Charging every 2 seconds and pause every 6 seconds at the final

stage of charging to prevent battery from being overheated or

venting.

f. IMPULSE

This is only for NiCd/NiMH battery. Battery power could be

improved, mainly with old batteries.

Refer to IMPULSE 5-7 above.

g. REPLEX

This is only for NiCd/NiMH battery. Battery power could be

improved, mainly with old batteries, but the life time could be

reduced.

Refer to REFLEX 5-8 above.

h. REPEAK

This is only for NiCd/NiMH battery. REPEAKING can be

dangerous, if the battery is still warm.

Refer to REPEAK CYCLE 2-8 above.

i. CC/CV

This is only for Lilo/LiPo/LiFe/Pb battery

CC to CV method. (CC = constant current, CV = constant voltage)

If balancing cable is connected to the balancing port of the

charger, charging can be very stably proceeded and finished as

the charger can use voltage measured at the balancing cable.

Page 42

Page 42/55

j. FAST-CHG

This is only for Lilo/LiPo/LiFe battery:

CC to CV method. (CC = constant current, CV = constant voltage)

Charge finished at 20% of the adjusted charge current.

Connect the balancer wires for safety reasons.

k. CV-LINK

This is only for Lilo/LiPo/LiFe.

Same capacity batteries should be used in this mode.

CV-LINK PROCESS can be selected only after balancing cable is

connected to the balancing port of the charger.

CV-LINK is to charge simultaneously, so the counterpart output

should be not being operated.