Page 1

Page 2

Contents

General Notes

Safety Notes................................................................... 2

Introduction.................................................................... 3

Description of radio control system................................ 7

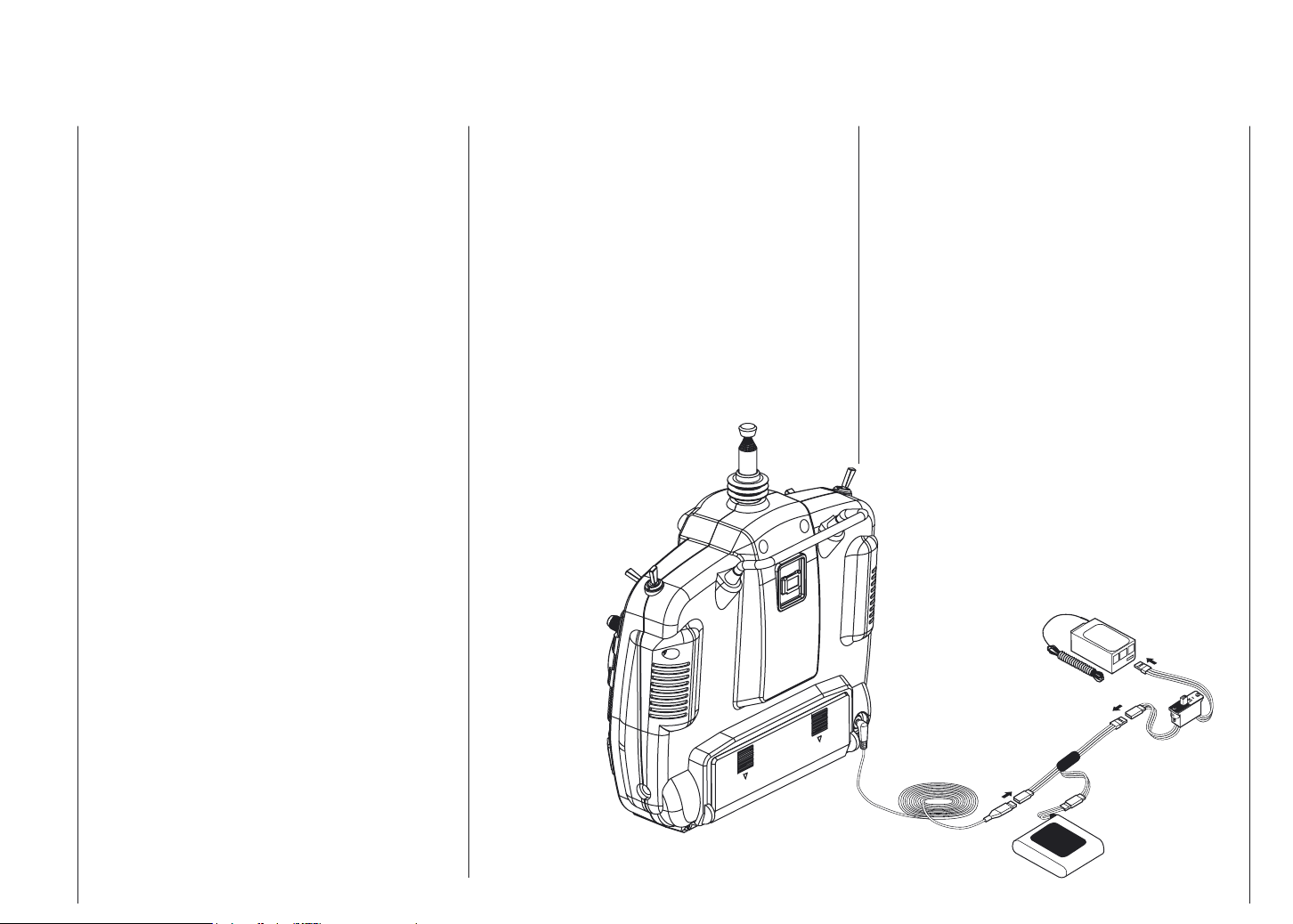

Charging the transmitter battery..................................... 8

Transmitter description................................................... 9

Direct servo control.......................................................11

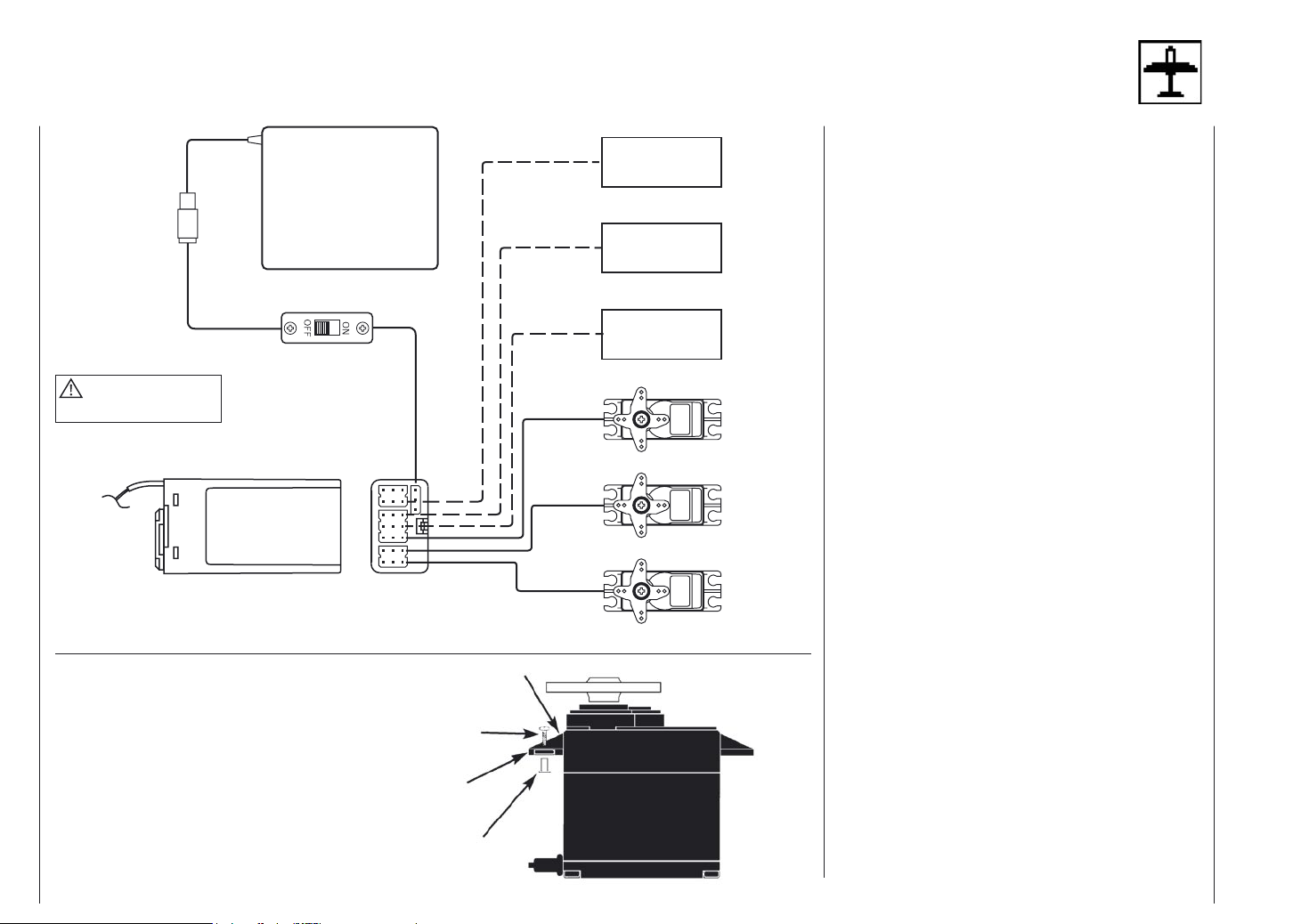

Connections and installations

-> For Airplane.............................................................. 12

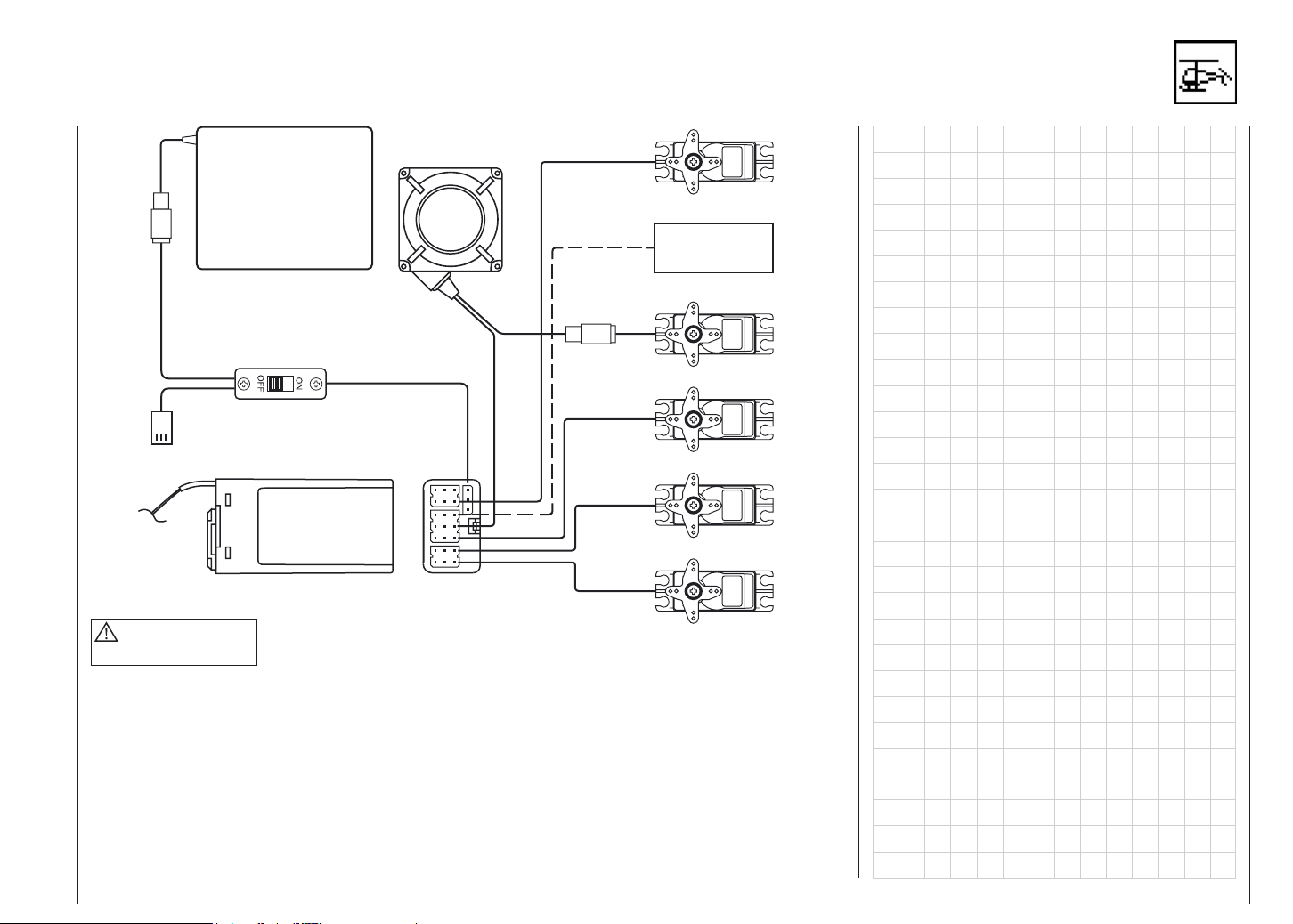

-> For Helicopter............................................................13

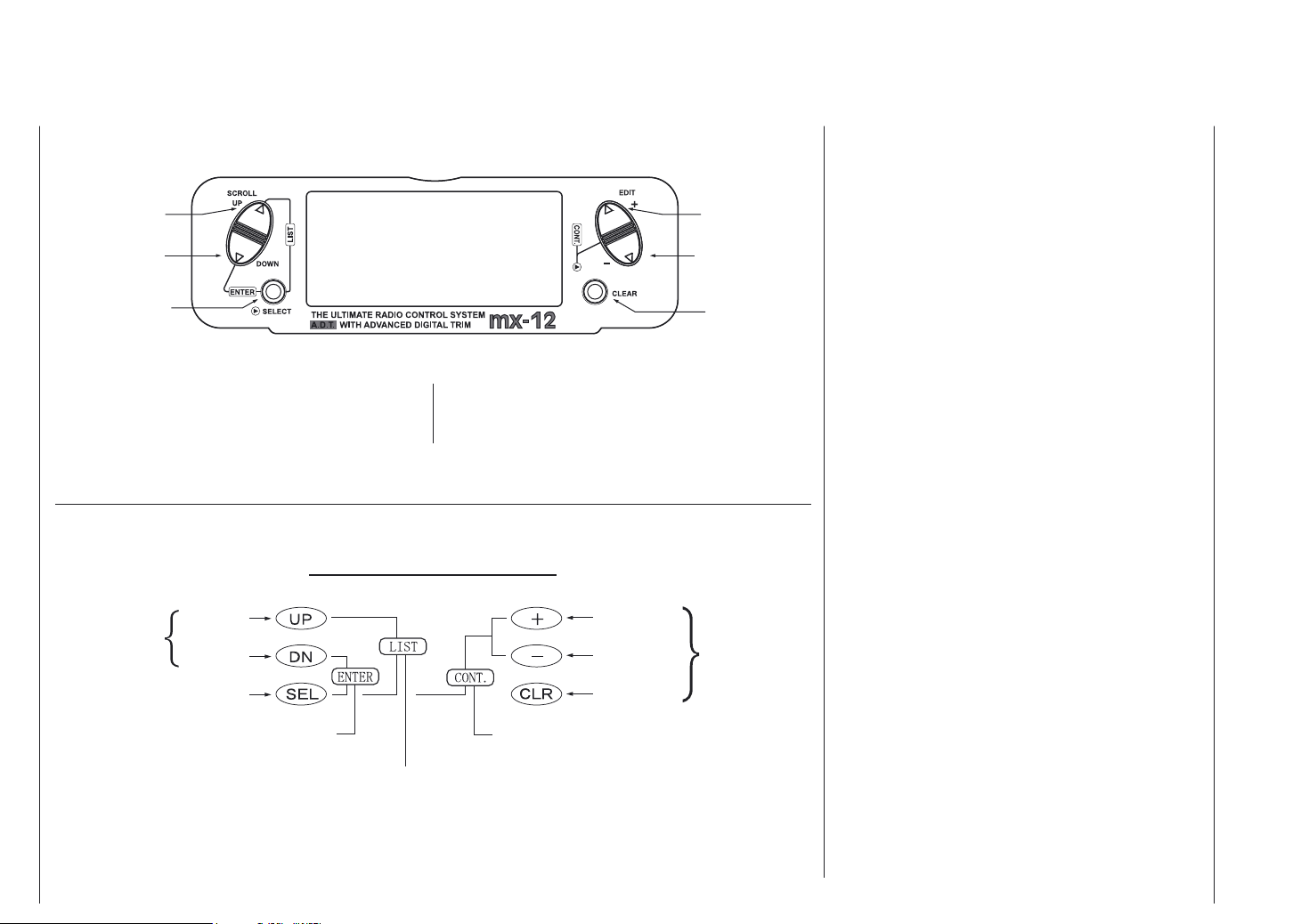

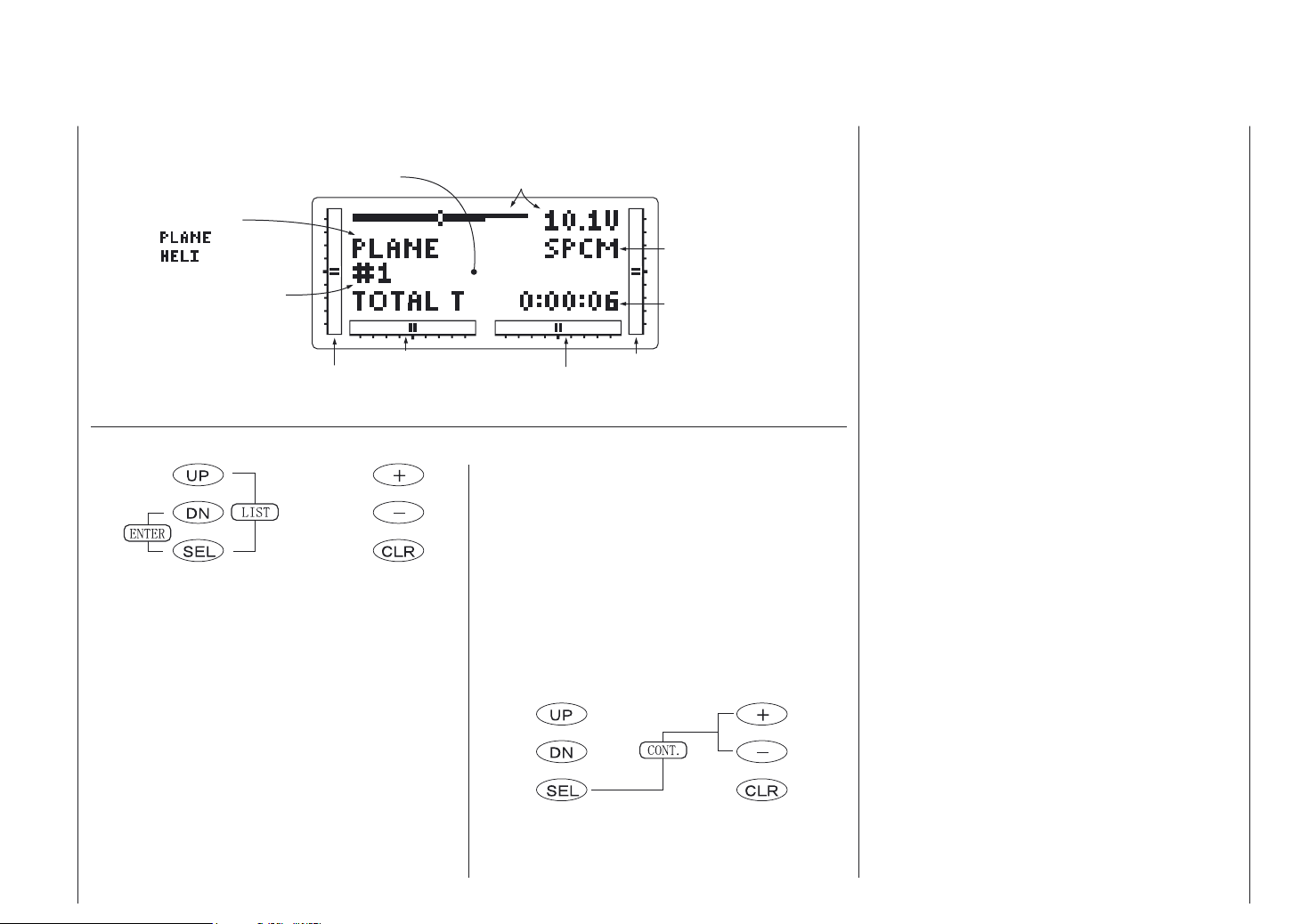

Key input and display.................................................... 14

Alarm and error display................................................. 14

Input mode and function............................................... 15

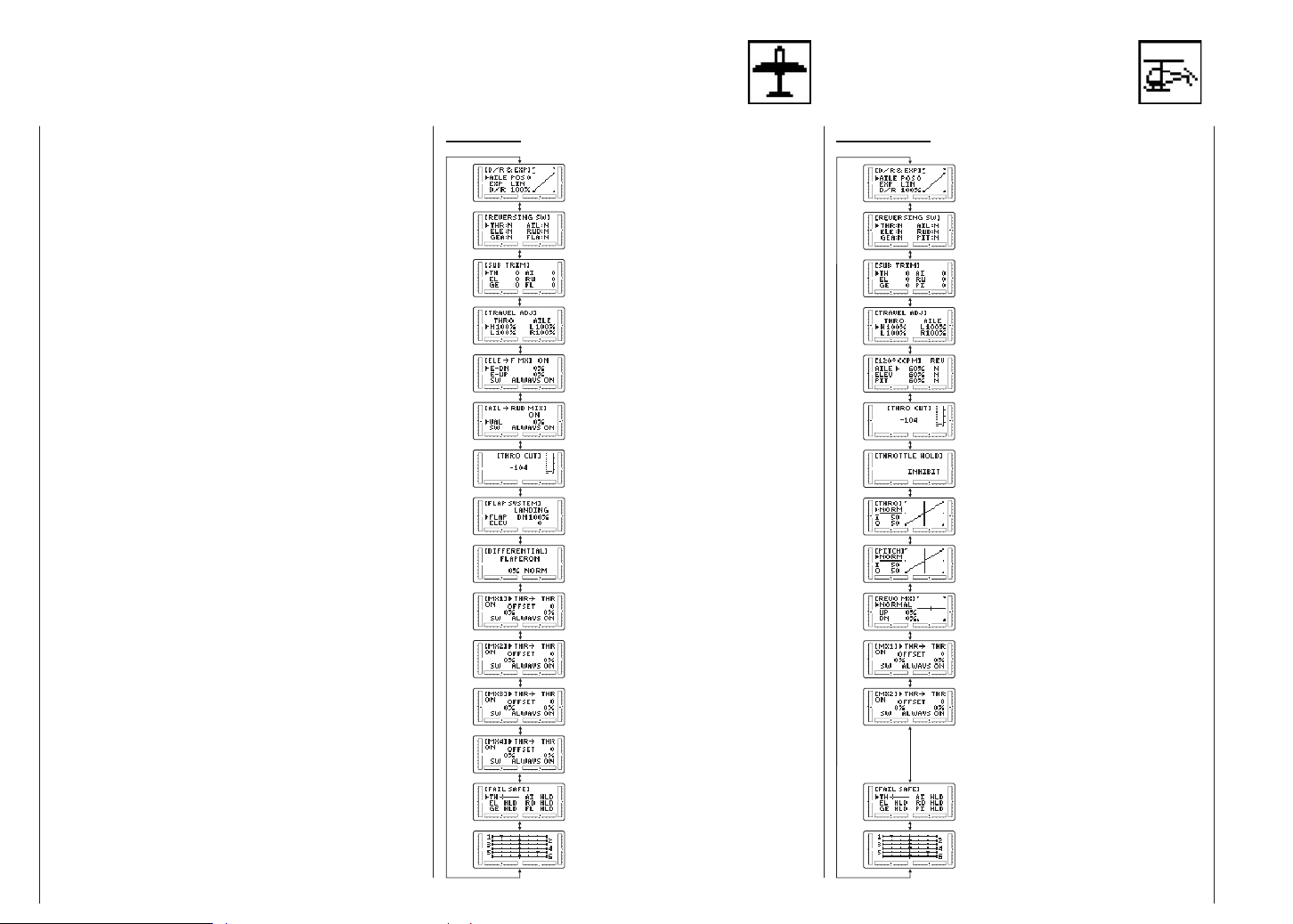

Program

Function mode.............................................................. 16

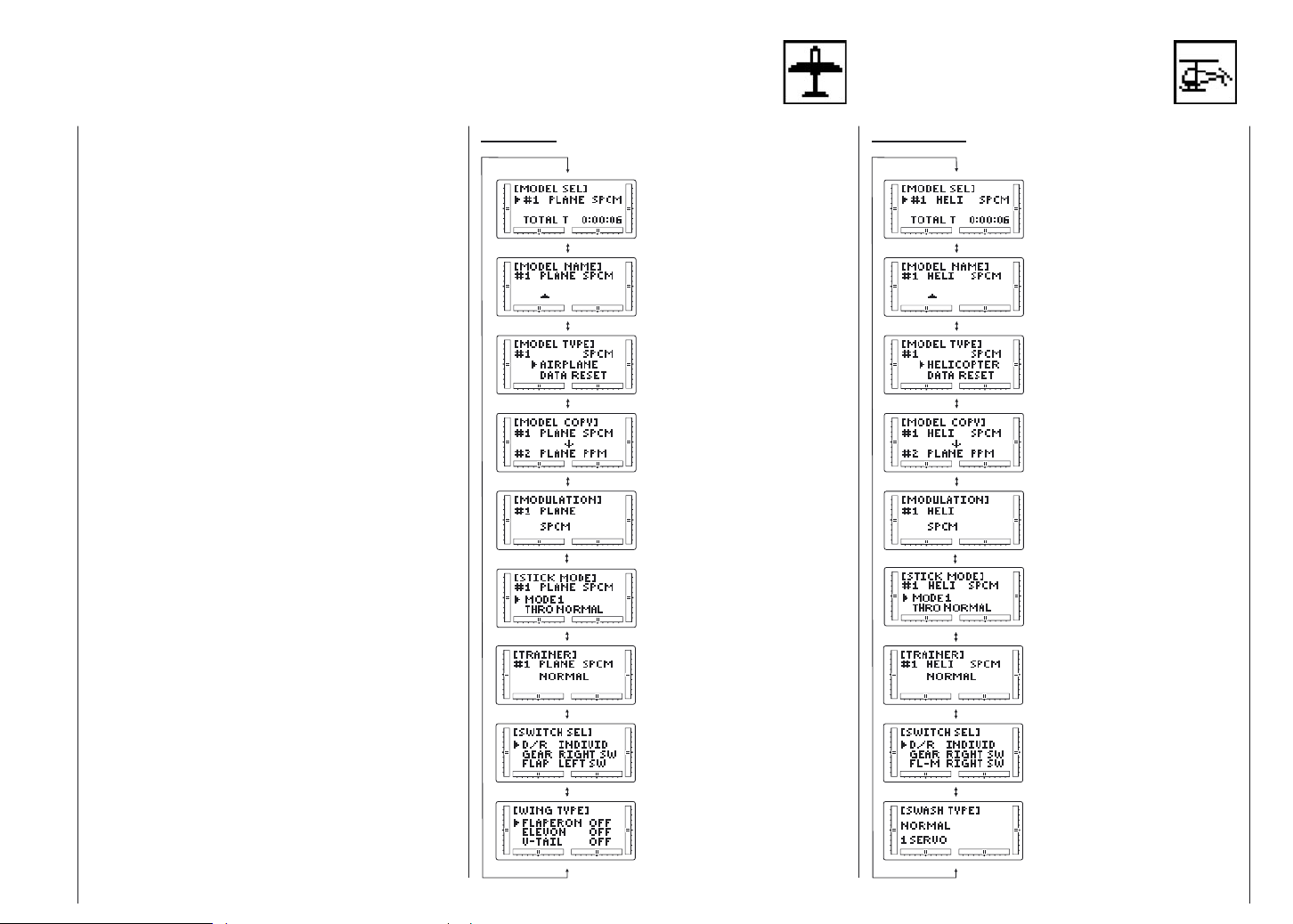

System mode................................................................17

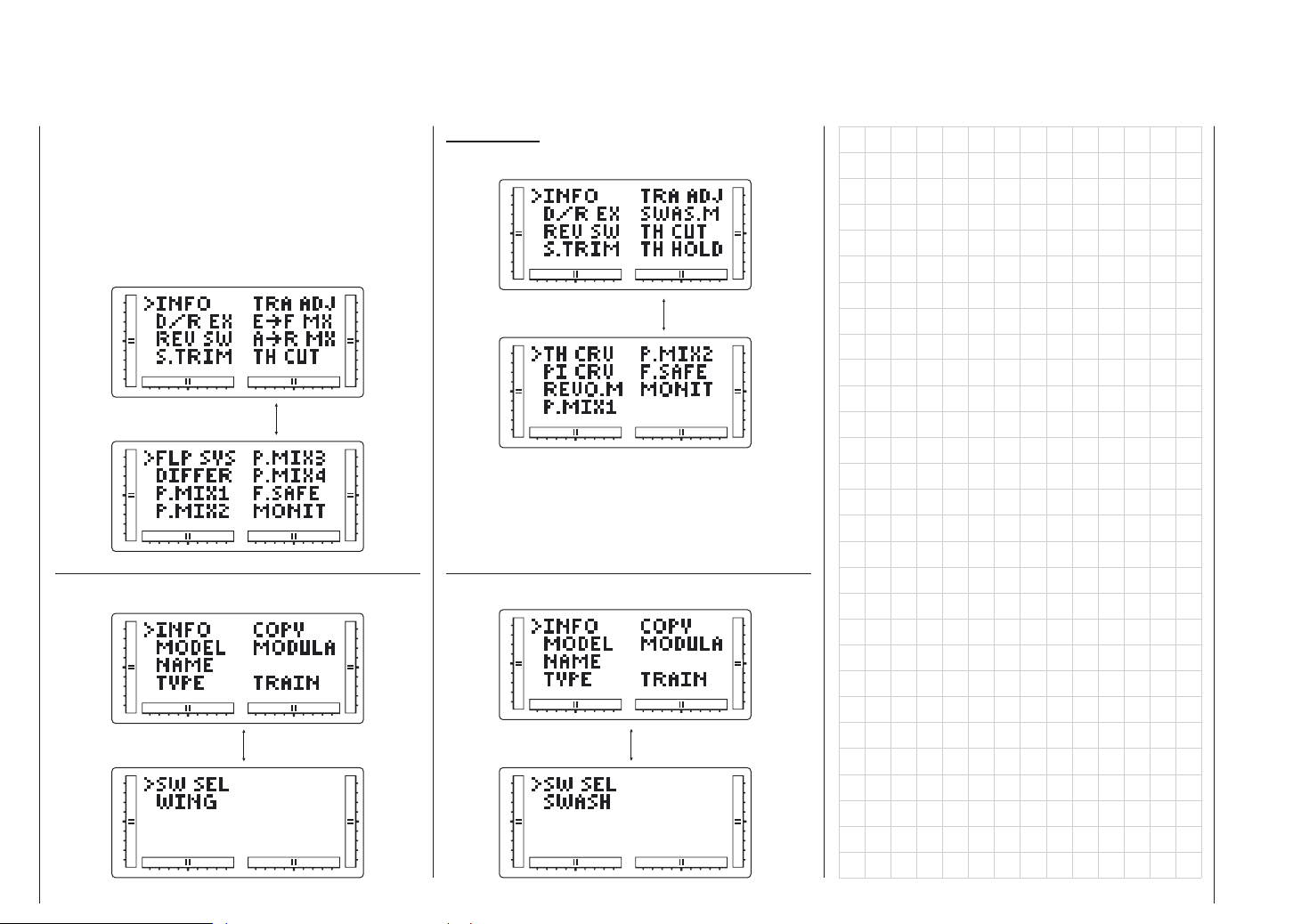

List mode...................................................................... 18

Function mode AIRPLANE

Dual Rates and Exponential......................................... 19

Servo Reversing........................................................... 19

Sub Trim....................................................................... 20

Travel Adjust................................................................. 20

Elevator to flap mixing.................................................. 21

Aileron to rudder mixing............................................... 21

Throttle Cut switch........................................................ 22

Flap System................................................................. 22

Differential aileron mixing............................................. 23

Programmable Mixing (1~4)......................................... 23

Fail Safe....................................................................... 24

Servo Travel Screen..................................................... 25

Function mode HELICOPTER

Dual Rates and Exponential.........................................26

Servo Reversing........................................................... 26

Sub Trim....................................................................... 27

2 Contents

Travel Adjust................................................................. 27

CCPM Swashplate Mixing............................................ 28

Throttle Cut Switch....................................................... 29

Throttle Hold................................................................. 29

Throttle Curves............................................................. 30

Pitch Curves................................................................. 31

Revolution Mixing (Non-heading lock Gyro only)......... 33

Programmable Mixing (1~2)......................................... 33

Fail Safe....................................................................... 34

Servo Travel Screen..................................................... 35

System Mode

Model Selection............................................................ 36

Model Name Entry........................................................ 36

Model Type Selection................................................... 37

Model Copy Function.................................................... 37

Modulation Selection.................................................... 38

Stick Mode.................................................................... 38

Trainer Function............................................................ 39

Switch Select................................................................ 40

Wing Type Selection..................................................... 41

Swashplate Selection................................................... 44

Appendix

Approved operating frequencies.................................. 45

Approval Certificate / Conformity.................................. 46

Guarantee certificate.................................................... 47

The sole purpose of this manual is to provide information. It is subject to modification at any time, and must

not be considered as any form of obligation on the part

of the GRAUPNER company. GRAUPNER accepts no

responsibility or liability for errors or inaccuracies which

may be found in the information section of this manual.

Environ mental Protection Notes

When this product comes to the end of its useful life,

you must not dispose of it in the ordinary domestic waste. The correct method of disposal is to take it to your

local collection point for recycling electrical and electronic equipment. The symbol shown here, which may be

found on the product itself, in the operating instructions

or on the packaging, indicates that this is the case.

Individual markings indicate which materials can be

recycled and re-used. You can make an important contribution to the protection of our common environment

by re-using the product, recycling the basic materials or

recycling redundant equipment in other ways.

Remove batteries from your device and dispose of them

at your local collection point for batteries.

If you don’t know the location of your nearest

disposal centre, please enquire at your local

council office.

Page 3

Safety notes

Please read carefully!

We all want you to have many hours of pleasure in our

mutual hobby of modelling, and safety is an important

aspect of this. It is absolutely essential that you read

right through these instructions and take careful note of

all our safety recommendations. If you are a beginner to

the world of radio-controlled model aircraft, boats and

cars, we strongly advise that you seek out an experienced modeller in your field and ask him for help and

advice. These instructions must be handed on to the

new owner if you ever sell the transmitter.

Application

This radio control system may only be used for the

purpose for which the manufacturer designed it, i.e. for

operating radio-controlled models which do not carry humans. No other type of use is approved or permissible.

Safety notes

SAFETY IS NO ACCIDENT

and …

RADIO-CONTROLLED MODELS ARE NOT

PLAYTHINGS

Even small models can cause serious personal injury

and damage to property if they are handled incompetently.

Technical problems in electrical and mechanical systems

can cause motors to rev up or burst into life unexpectedly, with the result that parts may fly off at great speed,

causing considerable injury.

Short-circuits of all kinds must be avoided at all times.

Short-circuits can easily destroy parts of the radio control system, but even more dangerous is the acute risk of

fire and explosion, depending on the circumstances and

the energy content of the batteries.

The circumstances and the energy content of the

batteries.

Aircraft and boat propellers, helicopter rotors, open

gearboxes and all other rotating parts which are driven

by a motor or engine represent a constant injury hazard.

Do not touch these items with any object or part of your

body. Remember that a propeller spinning at high

speed can easily slice off a finger! Ensure that no

other object can make contact with the driven components.

Protect all electronic equipment from dust, dirt, damp,

and foreign bodies. Avoid subjecting the equipment

to vibration and excessive heat or cold. Radio control

equipment should only be used in „normal“ ambient temperatures, i.e. within the range -15°C to +55°C. Avoid

subjecting the equipment to shock and pressure.

Check the units at regular intervals for damage to cases

and leads. Do not re-use any item which is damaged

or has become wet, even after you have dried it out

thoroughly. Use only those components and accessories

which we expressly recommend. Be sure to use only

genuine matching GRAUPNER connectors of the same

design with contacts of the same material. Use only

genuine GRAUPNER plug-in crystals on the appropriate frequency band. When deploying cables note

that they must not be under tension, and should never

be bent tightly or kinked, otherwise they may fracture.

Avoid sharp edges which could wear through the cable

insulation.

Check that all connectors are pushed home firmly

before using the system. When disconnecting components, pull on the connectors themselves - not on the

wires.

It is not permissible to carry out any modifications to

the RC system components. Avoid reverse polarity

and short-circuits of all kinds, as the equipment is not

protected against such errors.

Installing the receiving system and deploying the

receiver aerial

In a model aircraft the receiver must be packed in soft

foam and stowed behind a stout bulkhead, and in a

model boat or car should be protected effectively from

dust and spray.

The receiver must not make contact with the fuselage,

hull or chassis at any point, otherwise motor vibration

and landing shocks will be transmitted directly to it.

When installing the receiving system in a model with a

glowplug or petrol engine, be sure to install all the components in well protected positions so that no exhaust

gas or oil residues can reach the units and get inside

them. This applies above all to the ON / OFF switch,

which is usually installed in the outer skin of the model.

Secure the receiver in such a way that the aerial, servo

leads and switch harness are not under any strain.

The receiver aerial is permanently attached to the receiver. It is about 100 cm long and must not be shortened

or extended. The aerial should be routed as far away

as possible from electric motors, servos, metal pushrods and high-current cables. However, it is best not to

deploy the aerial in an exactly straight line, but to angle

it: e.g. run it straight to the tailplane, then leave the final

10 - 15 cm trailing down, as this avoids reception „blind

spots“ when the model is in the air. If this is not possible

we recommend that you lay out part of the aerial wire

in an S-shape inside the model, close to the receiver if

possible.

Safety notes 3

Page 4

Safety notes

Installing the servos

Always install servos using the vibration-damping

grommets supplied. The rubber grommets provide

some degree of protection from mechanical shocks and

severe vibration.

Installing control linkages

The basic rule is that all linkages should be installed in

such a way that the pushrods move accurately, smoothly and freely. It is particularly important that all servo

output arms can move to their full extent without fouling

or rubbing on anything, or being obstructed mechanically at any point in their travel.It is important that you

should be able to stop your motor at any time. With a

glow motor this is achieved by adjusting the throttle so

that the barrel closes completely when you move the

throttle stick and trim to their end-points.Ensure that no

metal parts are able to rub against each other, e.g. when

controls are operated, when parts rotate, or when motor

vibration affects the model. Metal-to-metal contact causes electrical „noise“ which can interfere with the correct

working of the receiver.

Always extend the transmitter aerial fully before

operating your model.

Transmitter field strength is at a minimum in an imaginary line extending straight out from the transmitter aerial.

It is therefore fundamentally misguided to „point“ the

transmitter aerial at the model with the idea of obtaining

good reception.

When several radio control systems are in use on adjacent channels, the pilots should always stand together

in a loose group. Pilots who insist on standing away

from the group endanger their own models as well as

those of the other pilots.

Pre-flight checking

If there are several modellers at the site, check carefully

with all of them that you are the only one on „your“

channel before you switch on your own transmitter.If two

modellers switch on transmitters on the same channel,

the result is interference to one or both models, and the

usual result is at least one wrecked model.

Before you switch on the receiver, ensure that the throttle stick is at the stop / idle end-point.

Always switch on the transmitter first, and only then

the receiver.

Always switch off the receiver first, and only then

the transmitter.

If you do not keep to this sequence, i.e. if the receiver

is at any time switched on when „its“ transmitter is

switched off, then the receiver is wide open to signals

from other transmitters and any interference, and may

respond. The model could then carry out uncontrolled

movements, which could easily result in personal injury

or damage to property. The servos may run to their

end-stops and damage the gearbox, linkage, control

surface etc. Please take particular care if your model

is fitted with a mechanical gyro: Before you switch your

receiver off, disconnect the power supply to ensure that

the motor cannot run up to high speed accidentally. The

gyro can generate such a high voltage as it runs down

that the receiver picks up apparently valid throttle commands, and the motor could respond by unexpectedly

bursting into life.

Range checking

Before every session check that the system works

properly in every respect, and has adequate range. This

means checking that all the control surfaces respond

correctly and in the appropriate direction to the transmitter commands at a suitable ground range.

Repeat this check with the motor running, while a friend

holds the model securely for you.

Operating your model aircraft, helicopter, boat or car

Never fly directly over spectators or other pilots, and

take care at all times not to endanger people or animals.

Keep well clear of high-tension overhead cables. Never

operate your model boat close to locks and full-size vessels. Model cars should never be run on public streets

or motorways, footpaths, public squares etc.

Checking the transmitter and receiver batteries

It is essential to stop using the radio control system and

recharge the batteries well before they are completely

discharged. In the case of the transmitter this means

- at the very latest - when the message „Battery must

be charged“ appears on the screen, and you hear an

audible warning signal. It is vital to check the state of the

receiver battery at regular intervals. When the battery

is almost flat you may notice the servos running more

slowly, but it is by no means safe to keep flying or running your model until this happens. Always replace or

recharge the batteries in good time. Keep to the battery

manufacturer’s instructions and don’t leave the batteries

on charge for longer than stated. Do not leave batteries

on charge unsupervised. Never attempt to recharge dry

cells, as they may explode.

Rechargeable batteries should always be recharged

before every session. When charging batteries it is important to avoid short-circuits. Do this by first connecting

the charge lead banana plugs to the charger, taking

care to maintain correct polarity. Only then connect the

charge lead to the transmitter or receiver battery.

4 Safety notes

Page 5

Safety notes

Disconnect all batteries and remove them from your model if you know you will not be using it in the near future.

Capacity and operating times

This rule applies to all forms of electrical power source:

battery capacity is reduced every time you charge it.

At low temperatures capacity is greatly reduced, i.e.

operating times are shorter in cold conditions.

Frequent charging, and / or the use of maintenance

programs, tends to cause a gradual reduction in battery

capacity. We recommend that you check the capacity of

all your rechargeable batteries at least every six months,

and replace them if their performance has fallen off

significantly.

Use only genuine GRAUPNER rechargeable batteries!

Suppressing electric motors

All conventional electric motors produce sparks between

commutator and brushes to a greater or lesser extent

depending on the motor type; the sparking generates

serious interference to the radio control system. In

electric-powered models every motor must therefore be

effectively suppressed.

Suppressor filters effectively eliminate such interference,

and should always be fitted. Please read the notes and

recommendations supplied by the motor manufacturer.

Refer to the main GRAUPNER FS catalogue for more

information on suppressor filters.

Servo suppressor filter for extension leads

Order No. 1040

Servo suppressor filters are required if you are obliged

to use long servo extension leads, as they eliminate the

danger of de-tuning the receiver. The filter is connected

directly to the receiver input.

In very difficult cases a second filter can be used, positioned close to the servo.

Using electronic speed controllers

Electronic speed controllers must be chosen to suit the

size of electric motor which they will control. There is

always a danger of overloading and possibly damaging

the speed controller, but you can avoid this by ensuring

that the controller’s current-handling capacity is at least

half the motor’s maximum stall current.

Particular care is called for if you are using a „hot“ (i.e.

upgrade) motor, as any low-turn motor (small number of

turns on the winding) can draw many times its nominal

current when stalled, and the high current will wreck the

speed controller.

Electrical ignition systems

Ignition systems for internal combustion engines can

also produce interference which has an adverse effect

on the working of the radio control system.

Electrical ignition systems should always be powered by

a separate battery - not the receiver battery.

Be sure to use effectively suppressed spark plugs and

plug caps, and shielded ignition leads.

Keep the receiving system an adequate distance away

from the ignition system.

Caution:

Radio control systems may only be operated on the

frequency bands and spot frequencies approved in each

EU country. You will find information on frequencies in

the section entitled „Approved operating frequencies“.

It is prohibited to operate radio control systems on any

other frequency, and such misuse will be punished by

the relevant authorities.

Static charges

Lightning causes magnetic shock waves which can

interfere with the operation of a radio control transmitter even if the thunderstorm actually occurs several

kilometres away. For this reason cease flying operations immediately when you notice an electrical storm

approaching.

Static charges through the transmitter aerial can be

life-threatening!

Care and maintenance

Don’t use cleaning agents, petrol, water or other

solvents to clean this equipment. If the case, the aerial

etc. gets dirty, simply wipe the surfaces clean with a soft

dry cloth.

Liability exclusion / Compensation

As manufacturers, we at GRAUPNER are not in a position to influence the way you install, operate and maintain

the radio control system components. For this reason

we are obliged to refute all liability for loss, damage

or costs which are incurred due to the incompetent or

incorrect use and operation of our products, or which

are connected with such operation in any way.

Unless otherwise prescribed by law, the obligation of the

GRAUPNER company to pay compensation is limited

to the invoice value of that quantity of GRAUPNER

products which was immediately and directly involved in

the event in which the damage occurred. This does not

apply if GRAUPNER is found to be subject to unlimited

liability according to binding legal regulation on account

of deliberate or gross negligence.

Safety notes 5

Page 6

Computer system mx-12

6 channel digital proportional radio control system

Computer radio control system with 10 model

memories, incorporating high-level technology. Modern computer system for excellent reliability and

security. Simplified rotary programming technology

for straightforward programming.

High-contrast graphic screen provides an accurate

display of the transmitter battery voltage, modulation, model type, model name, model memory

number, set-up data, throttle and collective pitch

curves and model operating time.

• All-purpose radio control system, fully expanded as

standard

• High-quality radio control system for F3A, F3B, F3C,

F3D, F3E model aircraft, deltas and V-tail models.

Fully expanded, offering 6 channels: 4 proportional

channels with trims, 2 switched channels

• Convenient mode selector for simple switching

between stick MODES 1 - 4 (throttle right / left).

All mixer, set-up and reverse memory data are

automatically converted if you switch modes

• Convenient wing mixer programs:

DIFFERENTIAL FLAPERON (aileron differential

mixer), ELEVON (deltas: aileron-elevator mixer),

V-TAIL (V-tail models: elevator - rudder mixer)

• Convenient swashplate programs:

SWASHPLATE TYPE (swashplate: 1 servo, 2 ser vos 180°, 3 servos 120°, 3 servos 90°)

• 10 model memories, with transfer of all essential

programming and set-up parameters

• Compatibility with FM and FMsss (PPM) receivers

as well as SPCM receiving systems

• High-contrast Multi-Data-Display LCD screen provi des accurate monitoring even in bright sunlight;

screen displays information such as mixer input

data, set-up values, directions of rotation, trim

values, programming information in multi-function

programs, and transmitter battery operating voltage

• Wide range of mixer system, plus precisely vari able end point and centre positions, making the

system suitable for the demanding operator of model

aircraft, boats and cars.

• REVERSE function, programmable for six servos

• MONIT: servo travel monitor for six servos

• MODEL NAME and model number programmable

separately

6 Introduction

Page 7

• MODULATION: switchable PPM / SPCM

• DUAL RATE / EXPO switchable to two positions and

programmable for three servo functions, available

range 5 to 125%.

• DIFFERENTIAL FLAPERON (differential aileron

mixer)

• SUB-trim memory system for offsetting all servo

centres; also for adjusting older servo types and

servos with no standard centre

• TRAVEL ADJUST: separate travel adjustment for

both end-points of all servos adjustment range 0 to

150%. New type of adjustment enables program ming of symmetrical and asymmetrical servi travels,

e.g. to compensate for one warped wing or special

applications.

• DSC socket for connection to flight simulator

• Integral visual and audible alarm system for trans-

mitter battery and Lithium back-up battery

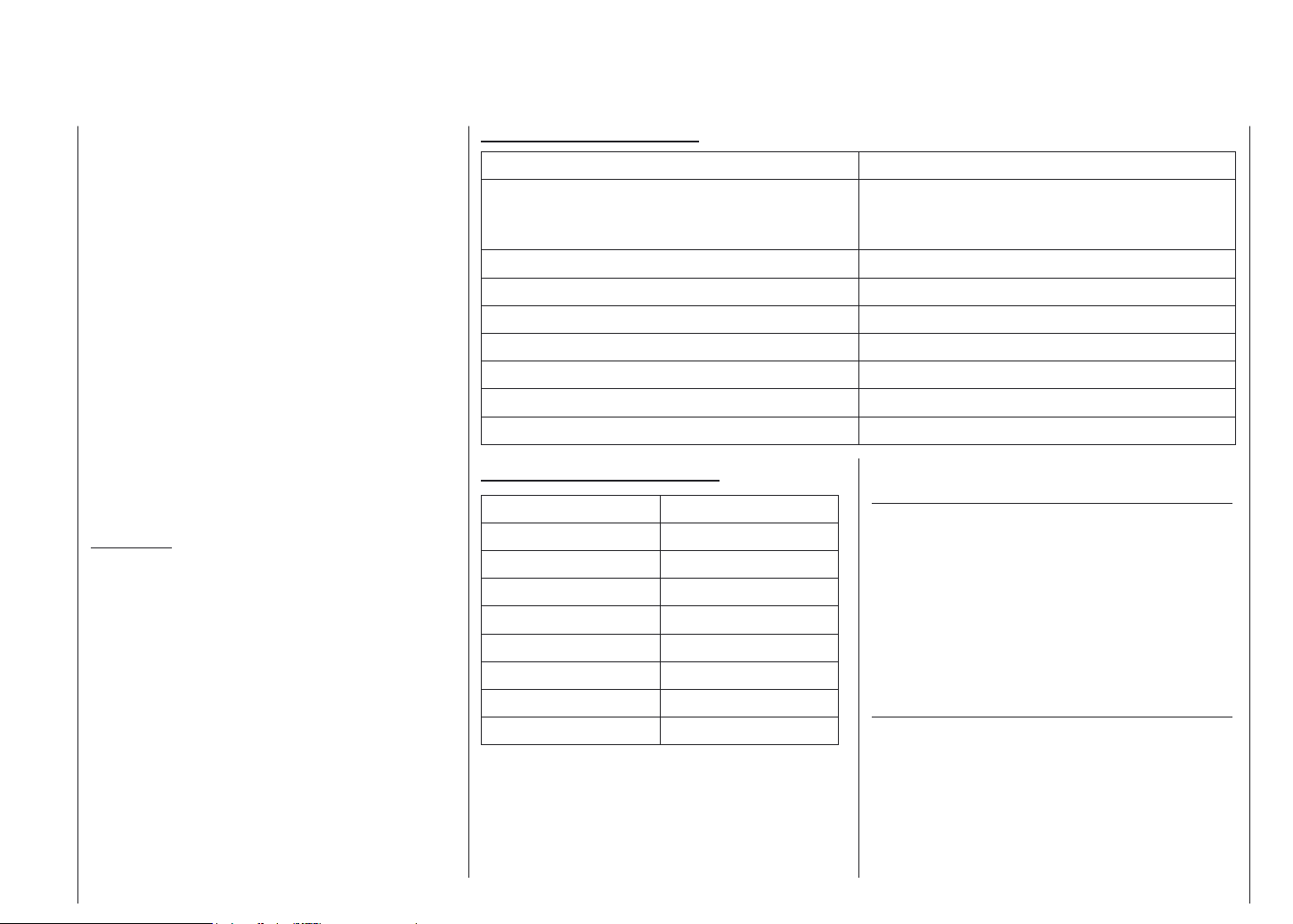

Set contents

mx-12 micro-computer transmitter with integral NiMH 8

NH-1700 TX battery, R 700 receiver on the appropriate

frequency, pair of crystals on the same frequency,

C 577 servo, switch harness, battery holder for receiving

system

Six-channel micro-computer radio control system,

fully expanded. Switchable PPM / SPCM modulation

(4 proportional functions with trims, 2 switched

functions)

Specification mx-12 transmitter

Transmission system FM / FMsss (PPM) and SPCM

FMsss crystals 35 MHz band; Order No. 3864.61 - .80

40 MHz band; Order No. 4064.50 - .92

41 MHz band; Order No. 4164.400 - .420

Channel spacing 10 kHz

Control functions max. 6

Channel pulse width 1,5ms +/- 0,5 mx, incl. trim

Aerial 9,6 ... 12 V

Current drain approx. 175 mA

Dimensions approx. 190 x 195 x 85 mm

Weight approx. 870 g incl. transmitter battery

Specification R 700 micro receiver

Accessoires

Order No. Description

Aerial 4,8 ... 6 V

Current drain approx. 13 mA

Channel spacing 10 kHz

Sensitivity approx. 10 µV

Servo functions 7

Temperature range -15° ... + 55° C

Aerial length approx. 950mm

Dimensions approx. 47 x 25 x16 mm

Weight approx. 16 g

1121 Neckstrap, 20mm wide

70 Neckstrap, 30mm wide

4179.1 Trainer lead for mx-12

For use with Graupner hand-held

transmitters with DSC sockets

3290.8 Trainer lead for mx-12

For use with Graupner mc-… trans mitters with trainer sockets

Spare Parts

Order No. Description

3100.6 Antenna for mx-12

Order No. 4722 35 MHz band

Order No. 4722.B 35 MHz-B-Band

Order No. 4723 40 MHz band

Order No. 4723.41* 41 MHz band

*For export only

Description of radio control system 7

Page 8

Charging the transmitter battery

Charging the transmitter battery

The rechargeable transmitter battery can be charged

via the charge socket fitted to the side of the case.

The transmitter must be switched „OFF“ for the whole

period of the charge process. Never switch on the

transmitter when it is still connected to the charger;

even a very brief interruption in the charge process

can cause the charge voltage to rise to the point where

the transmitter is immediately damaged by the excess

voltage. Alternatively the interruption may trigger a new

charge cycle, which means that the battery will possibly

be severely overcharged.

For this reason check carefully that all connectors

are secure, and making really good contact. Interruptions due to an intermittent contact, no matter

how brief, inevitably cause the charger to malfunction.

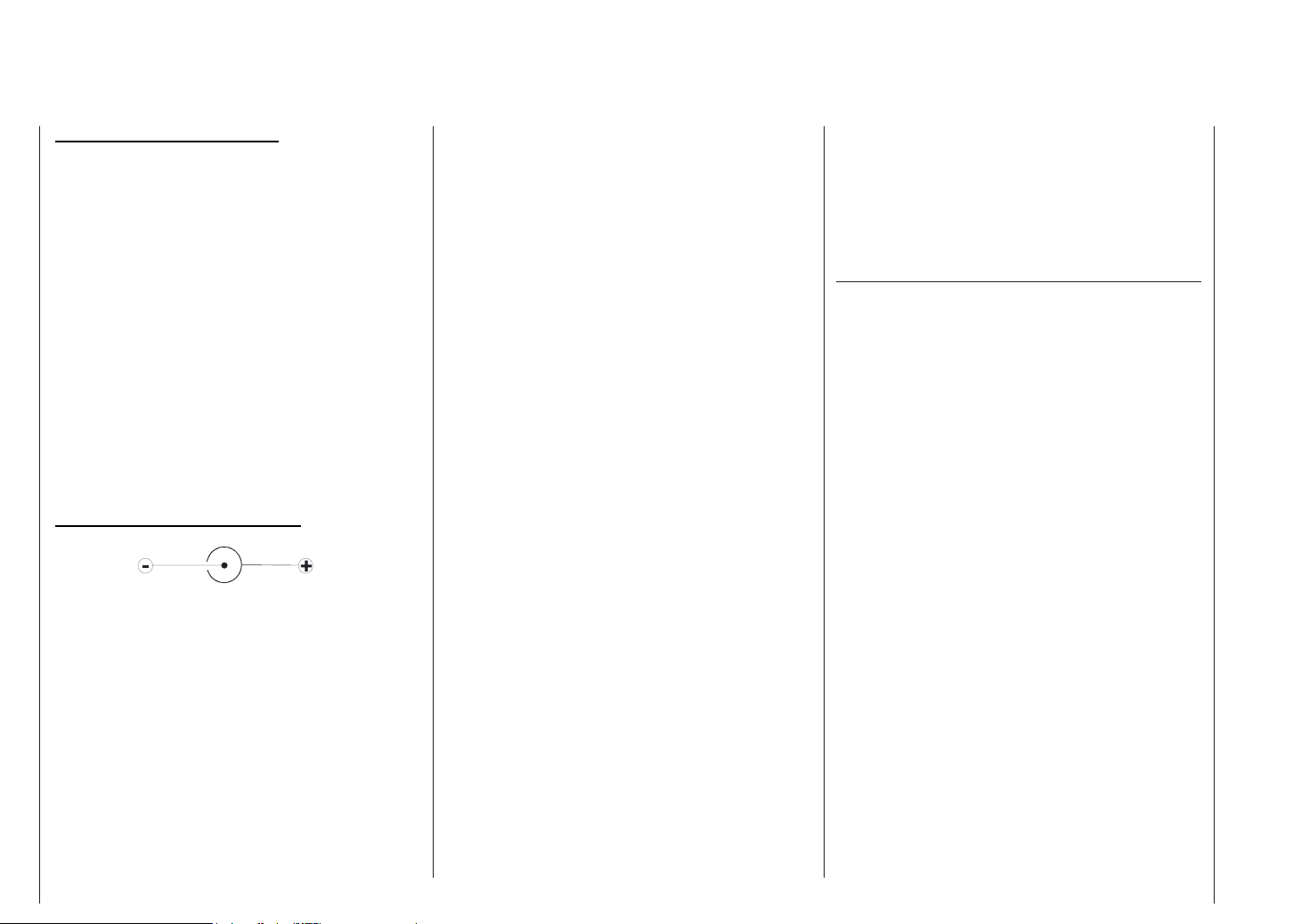

Polarity of the mx-12 charge socket

Commercially available battery charge leads produced

by other manufacturers are often made up with the opposite polarity. For this reason use genuine GRAUPNER

charge leads exclusively.

Notes on recharging transmitter batteries using an

automatic charger

· Observe the recommendations provided by the

charger manufacturer and the battery manufactu rer at all times.

· Carry out a series of test charges to ensure that

the automatic charge termination circuit works

correctly with your battery. This applies in parti cular if you are using an automatic charger desig ned for NiCd batteries to recharge the standard

NiMH battery. You may need to adjust the Delta Peak trigger voltage, if your charger provides this

option.

· The charge current must be set using the

charger’s „manual charge current select“ facility,

to ensure that the maximum charge current never

exceeds 1.5 A. Never allow the charger to set the

charge current automatically.

· Do not discharge the battery or carry out a

battery maintenance program via the integral

charge socket. The charge socket is not suitable

for this application.

· If you intend to charge the transmitter battery at

a current higher than 1.5 A, the battery must be

removed beforehand, otherwise the transmitter

could be damaged through overheating.

Automatic chargers with special NiMH charge

programs

Order-No. 6419 Ultramat 5*, **

Order-No. 6410 Ultramat 10*

Order-No. 6412 Ultramat 12*, **

Order-No. 6417 Ultramat 25*, **

Order-No. 6416 Ultra Duo Plus 30*, **

* To recharge the mx-12 system you will also need the transmitter

charge lead, Order No. 3022, and the receiver battery charge lead,

Order No. 3021.

** 12 V power source required.

Charge current

To avoid damage to the transmitter the maximum charge

current should not exceed 500 mA (0.5 A) with the charge circuit fuse out of circuit (not fitted); with the charge

circuit fuse in place: max. 1.5 A.

8 Charging the transmitter battery

Standard chargers

Order-No. 6422 Minilader 2

Order-No. 6427 Multilader 3

Order-No. 6426 Multilader 6E*

Order-No. 6428 Turbomat 6 Plus*

Order-No. 6429 Turbomat 7 Plus*

Page 9

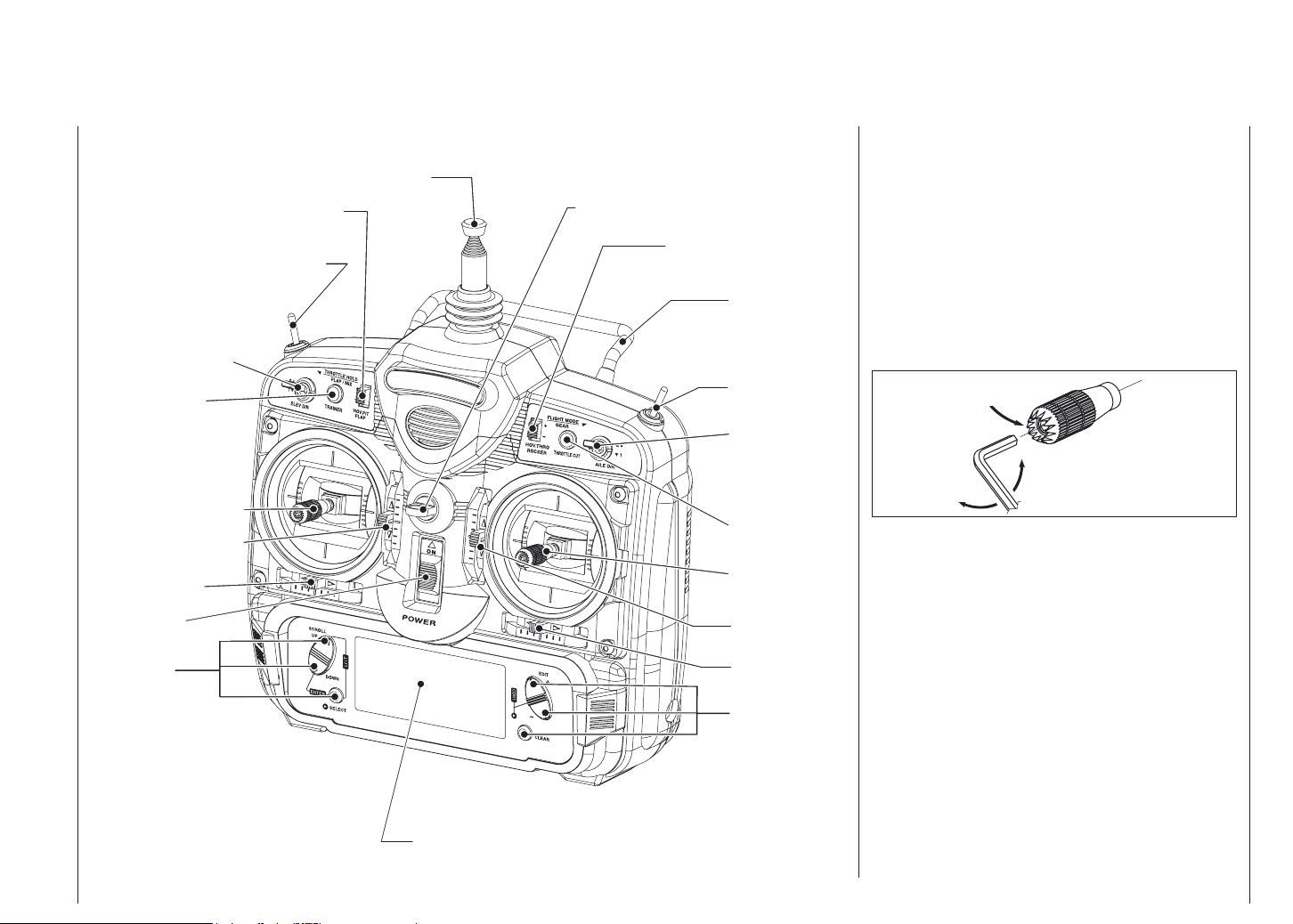

Transmitter description

Transmitter callouts

Antenna

Hovering Pitch Trim (For HELI)

Flap Trim (For AIRPLANE)

Throttle Hold SW (For HELI)

Flap Mixing SW (For AIRPLANE)

Elevator D/R SW

Trainer SW

Neck Strap

Eyelet

Hovering Throttle Trim

(for HELI)

Rocker SW

(for AIRPLANE)

Carrying Bar

Flight Mode SW

(for HELI)

Gear SW (for

HELI+AIRPLANE

Aileron D/R SW

Control stick length adjustment

To adjust the stick lenght, use the 2mm Allen wrench

(supplied with your mx-12 transmitter) to unlock the set

screw. Turn the wrench counterclockwise to loosen the

screw. Then turn the stick clockwise to shorten or counterclockwise to lenghten. After the control stick lenght

has been adjusted to suit your flying style, tighten the

2mm set screw. If you desire longer sticks, GRAUPNER

offers a stick that is approximately one inch longer than

standard. This stick, crafted from bar stock aluminum, is

available at your local GRAUPNER dealer.

SET SCREW

LOOSEN

Elevator Rudder Stick

Elevator Trim

Rudder Trim

On/Off SW

Entry Key

LCD Display

Throttle Cut SW

Throttle (Pitch)

-Aileron Stick

Throttle Trim

Aileron Trim

Entry Key

TIGHTEN

Neck strap attachment

An eyelet is provided on the face of the mx-12 transmitter that allows you to connect a Neck Strap. This hook

has been positioned so that your transmitter has the

best possible balance when you use the neck strap.

Transmitter description 9

Page 10

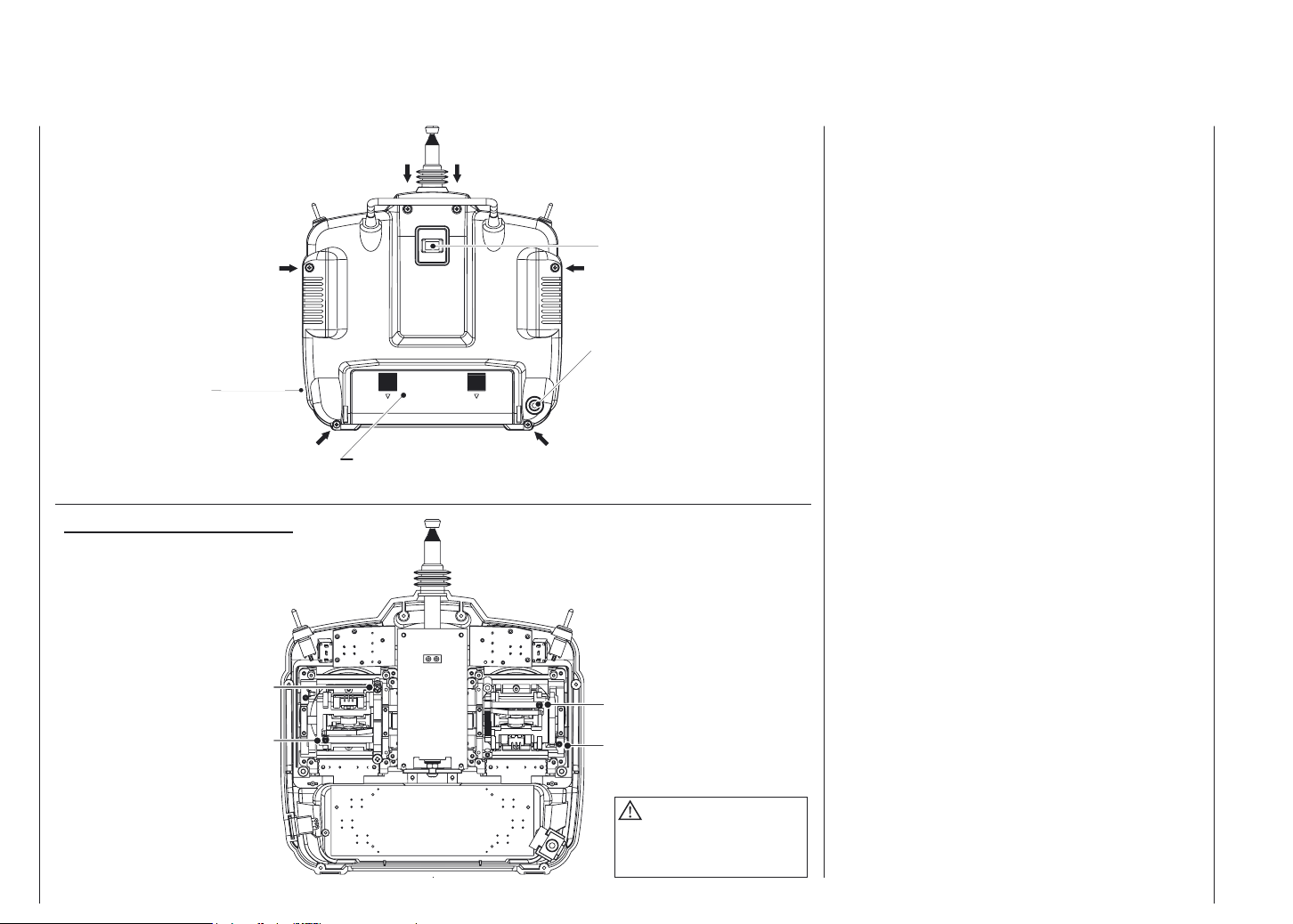

Transmitter description

Transmitter Rear

Transmitter Crystal

Control Stick tension adjustment

Remove the battery and six transmitter back screws as

shown on the previous page. Remove the transmitter

back, being careful not to cause damage to any components. Adjust each screw for desired tension (counterclockwise to loosen stick feel; clockwise to tighten stick

feel.) When adjusting the throttle ratched tension, make

sure that the adjusting screw does not touch the PC

board after adjustment is complete.

Charging Jack

for transmitter batteries

(Graupner 8NH-1700 TX

Order No. 3414 included)

Control Stick tension adjustment

For Throttle

For Aileron

Battery Cover

PCB

Do not touch

PCB

DSC/Trainer Jack

For Rudder

For Elevator

CAUTION

The battery connector is keyed so

that you can only be plugged in one

direction. Do not force!

Throttle Stick

The initial setting for the throttle stick is ratched type.

If you don`t like this feeling, please follow the following

instruction to change it. You will be required a posidrive

screwdriver and a pair of tweezers;

1. Remove the model from back of the transmitter, by

squeezing the lugs and pulling it out.

2. Remove the battery cover by pushing it inwards and

downwards. Remove the battery.

3. Remove 4 screws from the rear 4 corners. Remove 2

screws, 1 from either side of the rear antenna base.

4. Carefully separate the 2 halves of the transmitter,

starting at the base.

5. Unplug the 2 multi pin connectors for ease of access.

6. The left side of left stick unit has a black plastic lever

and spring, which provide the centring action - move

the stick if you are in doubt. Using the tweezers,

remove the spring.

7. Slide the lever towards the center of the transmitter

in order to remove ir from its pivot (move the stick to

clear it if necessary).

8. Reverse the above process to fit the lever and spring

to the right-hand assembly (note; the pivot is at the

top of the right-hand stick assembly).

10 Transmitter description

Page 11

Direct servo control (DSC)

9. The left side of the right-hand assembly has a metal

strip which provides the ratched friction action. This

is held in place by two screws. Undo the screws and

transfer the metal strip to the left-hand assembly.

10. The mechanical conversion is now completed; check

the stick actions are as required and reassemble the

transmitter by reversing the above process, not for getting to plug in the multipin connectors.

Frequency notes

The mx-12 can transmit in either Pulse Code Modulation

(PCM) or Pulse Position Modulation (PPM, commonly

referred to as FM):

Be certain to observe the following guidelines:

Do not operate your transmitter when another transmitter is using the dame frequency, regardless of whether

the second transmitter is PCM, PPM (FM) or AM. You

can never operate two transmitters on the same frequency simultaneously without causinf interference.

For proper DSC hook-up and operation:

1. Leave the transmitter power switch in the OFF posi tion. The transmitter will not transmit any radio fre quency (RF) in this position.

2. Plug the (supplied) DSC cord into the DSC port in

the rear of the transmitter.

3. The encoder section of the transmitter will now be

operational and the LCD display will be lit.

4. Plug the other end of the DSC Cord into the receiver

charge receptacle. Turn the switch harness to the ON

position.

Note: When you install the charging jack, be sure to

hook the charging jack receptable securely into

the switch harness charge cord.

Why you should use the DSC function:

1. The DSC enables you to check the control surfaces

of your aircraft without drawing the fully operational

200mAh from your transmitter battery pack. Instead,

you will only draw approximately 70mAh when using

the DSC function.

2. The DSC function allows you to make final adjust ments to your airplane without transmitting any radio

signals. Therefore, if another pilot is flying on your

frequency, you can still adjust your aircraft and not

interfere with the other pilot`s aircraft.

Note: This function is for bench-checking your airplane

only.

TO BATT TERMINAL

DSC-CORD

Best.-Nr. 4178.1

V-CORD

Best.-Nr. 3936.11

BATTERY

BATTERY

SW HARNESS G

(OPTION)

Direct servo control 11

Page 12

Connections and installations

For Airplane

WARNING

Do not cut or fold the antenna!

ANTENNA

BATTERY

SWITCH HARNESS

RECEIVER

R700 RECEIVER

Servo Mounting Tab

Screw

FLAP

CHANNEL

GEAR

CHANNEL

RUDDER

CHANNEL

ELEVATOR SERVO

AILERON SERVO

THROTTLE SERVO

FLAP

(AUX1)

GEAR

RUDD

ELEV

AILE

THRO

Installation requirements

It is extremely important that your radio system be correctly installed in your model. Here a few suggestions

installing your GRAUPNER equipment:

1. Wrap the receiver in protective foam rubber that

is no less than 3/8 inch thick. Secure the foam to

the receiver with #64 rubber bands. This protects

the receiver in the event of a crash or a very hard

landing.

2. The servos should be mounted using rubber grom mets and brass eyelets to isolate them from vibrati on. Do not over-tighten the mounting screws; this will

negate the vibration absorption effect of the rubber

grommets. The following diagram will assist you in

properly mounting your servo. The brass eyelet are

pushed from the bottom up in the rubber grommets.

When the servo screw is tightened securely, it provi des the proper security as well as the proper vibrati on isolation for your servo.

3. The servos must be able to move freely over their

entire range of travel. Make sure that the control

linkages do not bind or impede the movement of any

of the servos.

4. Mount all switches away from the engine exhaust

and away from any high vibration areas. Make sure

the switch operates freely and is able to operate over

its full travel.

5. Mount the receiver antenna firmly to the airplane

to ensure that it will not become entangled on the

propeller or control surfaces.

12 Connections and installations

Rubber Grommet

Brass Eyelet

Page 13

Connections and installations

For Helicopter

AUX1

SWITCH HARNESS

CHARGING JACK

ANTENNA

WARNING

Do not cut or fold the antenna!

BATTERY

RECEIVER

R700 RECEIVER

GYRO

PITCH SERVO

GEAR

CHANNEL

RUDDER SERVO

ELEVATOR SERVO

AILERON SERVO

THROTTLE SERVO

GEAR

RUDD

ELEV

AILE

THRO

Connections and installations 13

Page 14

Key input and display; Alarm and error display

Up Key

Down Key

Select Key

The Function keys are used to move up and down through the functions. The Select key is used to advance

the channel or function selected. The increase and

The Key displays in this case

Decrease keys are used to make changes in the

selected functions.

Increase Key

Decrease Key

Clear/Store Key

Battery alarm and display

When the transmitter voltage drops below 9.0 volts DC,

the display flashes “BATT LOW“ and an alarm sounds.

If you are flying when this occurs, land immediately.

Backup error display

All preprogrammed data is protected by a five-year lithium battery that guards against main transmitter battery

failure. Should de lithium battery fail, the display will

indicate BACK ERROR. If this occurs it will be necessary to replace the lithium back-up battery, contact your

local dealer. Due to the possibility of extensive damage

caused by improper removal or replacement, only your

local dealeris authorized to make this change.

Up Key

Function Keys

Down Key

Select Key

Press both keys

to enter or exit

the function mode

Press both keys

to enter or exit

the list mode

14 Key input and display, Alarm and error display

Increase Key

Decrease Key

Clear Key

Press both keys

to control the brightness

Make changes

in the selected

functions.

Page 15

Input mode and function

Normal mode

Model Name

(If there is)

Model Type

: Airplane

: Helicopter

Model number

Rudder Trim Value

To Function mode

(press simultaneously)

To enter and exit the System

mode, press simultaneously

( )

then turn on the power switch

Elevator Trim Value

To List mode

(press simultaneously)

Transmitter voltage

Modulation Type

Transmitter “On Time“

Throttle Trim Value

Aileron Trim Value

Screen contrast adjustment

The screen conrast adjustment feature of the mx-12

allows the user to select the proper tint of the screen for

improved clarity and visibility in all weather conditions

and temperatures.

To increase the contrast (darken the screen), simply turn

the power switch ON and press the SEL and DATA +

keys simultaneously. To decrease the contrast (lighten

the screen), press the SEL and DATA - keys simultaneously.

Advanced Digital Trim (A.D.T.)

The mx-12 digital trims feature the Direct Access display

function. While at the Normal display screen, if a trim

lever is moved, the screen will automatically change to

display the graphic position for the trim being adjusted.

The mx-12 Aileron, Elevator, Throttle and Rudder trim

levers feature an audible center trim beep. This is

helpful in determining the trim levers center position

during flight. Please also note that unlike conventional

mechanical trim levers, when the mx-12 transmitter is

in the off position, no changes can be made to the trim

values during transportation.

Model operating time

The standard display shows the total model operating

time for the selected memory.

Selecting a new model, or erasing the memory and

saving new data in it, resets the model operating time to

the value “0:00:00”.

Screen brightness control

(press simultaneously)

Input mode and function 15

Page 16

Function mode

To enter the Function mode, switch the transmitter

power switch to the On position. Press the Down and

Select keys simultaneously, and the display will show

the last active program. Pressing either the Up or Down

key then scrolls through the functions one by one,

according to the Function Mode Flowchart shown below.

Once the appropriate function is displayed, changes can

be made by pressing the (+) or (-) keys. To select another channel of a particular function, press the Select

key. The Function mode is the most often used system

to input data.

Function Mode Flowchart

Information pertaining to each function is explained on

the page listed next to the function name. Functions will

appear in the same order they are shown on this chart.

Accessing the Mode Function

1. Move the power switch to the ON position.

2. Press the Down and Select keys simultaneously.

3. Use either the Up or Down to scroll through the

menu and access the applicable function.

AIRPLANE

1. Dual Rate & EXPonential

2. REVERSING SW

3. SUB TRIM

4. TRAVEL ADJust

5. ELEv Flap MIXing

6. AILe RUDd MIXing

7. THROttle CUT

8. FLAP SYSTEM

9. DIFFERENTIAL

(Only in Wing type)

10. Program MiXing 1

HELICOPTER

13. Dual Rate & EXPonential

14. REVERSING SW

15. SUB TRIM

16. TRAVEL ADJust

17. Swash Mixing

(Over 2 servos in Swashplate type

18. THROttle CUT

19. THROTTLE HOLD

20. THRO Curve

21. PITCH Curve

22. REVOlusion MiXing

16 Function mode

10. Program MiXing 2

10. Program MiXing 3

10. Program MiXing 4

11. FAIL SAFE

(Only in SPCM)

12. Servo Travel Screen

23. Program MiXing 1

23. Program MiXing 2

24. FAIL SAFE

(Only in SPCM)

25. Servo Travel Screen

Page 17

System mode

To enter the System mode, press the Down and

Select keys simultaneously, then turn the power switch

to the ON position. The display will show the last active

program. Pressing either the Up or Down key then

scrolls through the functions one by one, according to

the system mode flowchart is shown to the right. Once

the appropriate function is displayed, changes can be

made by pressing the (+) or (-) keys.

System Mode Flowchart

Information pertaining to each function is explained on

the page listed next to the function name. Functions will

appear in the same order they are shown on this chart.

Accessing the System Mode

1. Press the Down and Select keys simultaneously.

2. Move the power switch to the ON (upper) position.

3. Use either the Up or Down key to scroll through

the menu and access the applicable function.

AIRPLANE HELICOPTER

26. MODEL SELect

27. MODEL NAME

28. MODEL TYPE

& Data reset

29. MODEL COPY

30. MODULATION

31. STICK MODE

26. MODEL SELect

27. MODEL NAME

28. MODEL TYPE

& Data reset

29. MODEL COPY

30. MODULATION

31. STICK MODE

32. TRAINER

33. SWITCH SELect

34. WING TYPE

32. TRAINER

33. SWITCH SELect

34. SWASH TYPE

System mode 17

Page 18

List mode

To enter the Function List mode from the Function mode,

switch the transmitter power switch to the ON position.

Press the Up und Select keys simultaneously. To scroll

the functions, first press the Down and Select keys.

FUNCTION LIST 1

FUNCTION LIST 2

SYSTEM LIST 1

HELICOPTER

FUNCTION LIST 1

FUNCTION LIST 2

SYSTEM LIST 1

SYSTEM LIST 2

18 List mode

SYSTEM LIST 2

Page 19

Function mode AIRPLANE

Dual Rates and Exponential; Servo Reversing

Dual Rates and Exponential

Channel

AILE: AILERON

ELEV: ELEVATOR

RUDD: RUDDER

Exponential Value

Dual Rate Value

D/R POSITION

Dual rates are available for the aileron, elevator and

rudder channels of yor R/C aircraft. The combined Dual

Rate Function is discussed at page XX. Dual rates may

be defined as the ability to vary the travel or throw rate

of a servo from a switch. Due to the differing travel rates, you will find that the sensitivity of the control either

increases or decreases accordingly. A higher rate, or

travel, yields a higher overall sensitivity. You may find it

easier to think of the Dual-Rate function as double-rates

or half-rates.

The amount of travel is adjustable from 0-125% in 1%

increments. The factory setting, or default value, for

both the 0 and 1 switch positions is 100%.

Exponential reduces the sensitivity in the middle portion

of stick movement, while still allowing full travel at the

end of the stick movement. The end result (travel)

remains the same, although exponential changes the

rate at which it achieves this travel. The adjustable

range is from 0-100%. Zero percent (0%) is linear stick

control, meaning the response rate is equal throughout

the stick control. 100% is full exponential. The larger the

exponential value, the less servo action or sensitivity

you will notice around the neutral setting.

Either switch position may be selected as the low or

high rate by placing the switch in the desired position

and adjusting the value accordingly.

Go to Reversing

SW menu

Go to Servo

Travel Screen

Select channel

EXP or D/R

Change channel

or value

Clear

(Lin or 100%)

Accessing the Dual-Rate and Exponential Function

1. Place the transmitter power switchin the ON positi on.

2. Access the Function mode by pressing the Down

and Select keys simultaneously.

3. Press either the Up or Down key until D/R EXP

appears in the upper left corner of the LCD.

4. Press the (+) ir (-) key until the desired channel

(aileron, elevator or rudder) appears.

5. Select the switch position for which you want to

adjust the rate. The number to the upper right of

the current rate value on the display indicates the

current position of the Dual-Rate switch for the

channel that you have selected. Either a 0 or a 1 will

be shown, corresponding to the position of the

switch. To select the opposite switch positio, move

the appropriate Dual Rate switch to the opposite

position. The number that appears above the current

rate value reflects the change.

6. Adjust the rate for the channel and the switch positi on just selected. To decrease the throw rate, move

the cursor to the D/R position using the Select key,

then press the (-) key. To increase the throw rate,

press the (+) key. As stated previously, the adjustab-

le rate is from 0-125% for each switch position and

channel.

7. Press the Up arrow key to access the REVERSING

SW menu.

8. Press the Down arrow key to access the SERVO

TRAVEL SCREEN.

9. Press the Down arrow and Select keys simultane ously to exit the DUAL RATE AND EXPONENTIAL

mode.

Servo Reversing

Channel being programmed THR 1: THROTTLE

AIL 2: AILERON

ELE 3: ELEVATOR

RUD 4: RUDDER

GEA 5: GEAR

FLA 6: FLAP

The Reverse Switch function is an electronic means of

reversing the throw of a given channel (servo). All six

channels of the mx-12 offer reversible servo direction.

This will ease setup during the servo installation into

your aircraft.

Go to Sub Trim menu

Go to D/R & Exp menu

Select channel to reverse

Change servo direction

(NR)

Reset direction to

normal (Adjust to N)

Accessing the Travel Adjust Function

1. Place the transmitter power switch in the ON positi on.

2. Access the Function mode by pressing the Down

and Select keys simultaneously.

Function mode AIRPLANE 19

Page 20

Function mode AIRPLANE

Sub Trim; Travel Adjust

3. Press either the Up or Down key until TRAVEL

ADJ appears in the upper portion of the LCD.

4. Using your transmitter`s control sticks, switches and

potentiometers, move the control surfaces of your

aircraft. Note the travel direction of each of the

corresponding control surfaces.

5. After you have determined which channel(s) need to

have the throw directions reversed, use the Select

key to call up the appropriate channel.

6. Press either the (+) or (-) keys to change the travel

directions of the servo. Pressing the Clear key re turns the travel direction to Normal.

7. You can observe the change in the travel direction

by moving the appropriate control at this time.

8. Access the D/R & EXP function by pressing the

Down key.

9. Access the SUB TRIM function by pressing the Up

key.

10. Exit the SERVO REVERSING function by pressing

the Down and Select keys simultaneously.

Sub Trim

Channel being programmed

THRO 1: THROTTLE

AIL 2: AILERON

ELE 3: ELEVATOR

RUD 4: RUDDER

GEA 5: GEAR

FLA 6: FLAP

Travel Value

(0~150%)

The Sub Trim Adjustment function allows you to electronically fine-tune the centering of your servos. Individual-

20 Function mode AIRPLANE

ly adjustable for all six channels with a range of +/125% (+/- 30 degrees servo travel).

The sub trim function provides precise servo arm neutral

positioning if rotating the servo arm will not allow the

desired servo arm position.

Go to Travel Adjust

menu

Go to reversing SW

menu

Select channel

Change value

Reset selection to

default (Adjust to 0)

Accessing the Sub Trim Function

1. Place the transmitter power switch in the ON positi on.

2. To Access the Function mode, press the Down and

Select keys simultaneously.

3. Press either the Up or Down key until SUB TRIM

appears in the upper middle portion of the LCD.

4. Press the Select key until the desired channel

appears.

5. Press the (+) or (-) key to establish the desired

amount and direction of Sub Trim.

Caution: Do not use excessive Sub Trim adjustments

since it is possible to overrun your servo`s

maximum Sub Trim. Remember that it is a trim

convenience function.

It is not intended to take the place of the

proper mechanical trim adjustments that are

necessary on any RC model.

6. Access the REVERSING SW function by pressing

the Down key.

7. Access the TRAVEL ADJ function by pressing the

Down key.

8. Exit the SUB TRIM function by pressing the Down

and Select keys simultaneously.

Travel Adjust

Channel being programmed

THRO 1: THROTTLE

AIL 2: AILERON

ELE 3: ELEVATOR

RUD 4: RUDDER

GEA 5: GEAR

FLA 6: FLAP

Travel Value

(0~150%)

The purpose of Travel Adjust is to offer you precise

servo control deflection in either direction of servo

operation. The mx-12 offers travel adjust for all six

channels. The Travel Adjust range is from 0-150% (0 degrees to 60 degrees) from neutral, or center, and it can

be adjusted for each direction inividually. The factory

default (Data Reset) value is 100% for each direction of

servo travel.

Go to Ele F MX menu

Go to Sub Trim menu

Select channel to

Adjust

Change value

Reset value to

Normal (Adjust to

100%)

Accessing the Travel Adjust Function

1. Place the transmitter power switch in the ON positi on.

2. Access the Function mode by pressing the Down

and Select keys simultaneously.

3. Press either the Up or Down key until TRAVEL

ADJ appears in the upper portion of the LCD.

4. Press the Select key until the desired channel is

Page 21

Function mode AIRPLANE

Elevator to flap mixing; Aileron to rudder mixing

highlighted.

5. Move the appropriate control stick (lever, switch,

etc.) to the right or left of center to the direction of

travel you want to adjust. An arrow to the left of the

travel adjust value will reflect the current position to

be adjusted.

6. After the control stick or switch is placed in the

direction of travel to be adjusted, press the (+) or

(-) key until the proper amount of servo travel is

shown on the LCD. Press the (+) key to increase the

amount of servo travel. Press the (-) key to decrease

the amount of servo travel.

7. Follow the same procedure for the remaining chan nels.

8. Access the SUB TRIM function by pressing the

Down key.

9. Access the ELE F MX function by pressing the

Up key.

10. Exit the TRAVEL ADJ function by pressing the

Down and Select keys simultaneously.

Elevator to flap mixing

When this system is active and a value of flaps is input,

the flaps will be deflected each time the elevator stick is

used. The actual flap movement is adjustable for both

up and down elevator. A switch can be assigned to turn

the elevator to flap mixing on or off.

MIXING VALUE (+/- 125%)

Elevator Operating Direction

E-DN: Down side

E-UP: Up side

Mixing SW Selection

SW Display

ALWAYS ON: Always Mixing In

RIGHT FWD: Gear SW Forward

side On

RIGHT REA: Gear SW Rear

sideOn

LEFT FWD: FLAP SW Forward sideOn

LEFT REA: FLAP SW Rear sideOn

AILE D/R: AILE D/R SW Position 1On

ELEV D/R: ELEV D/R SW Position 1On

Go to Ail

Rud Mix menu

Go to Travel

Adjust menu

Change selection

Change value/Select

switch

Reset selection to

Default (adjust to 0%

or ALWAYS ON)

Accessing the Elevator to Flap Function

1. Place the transmitter power switch on the ON positi on.

2. Access the Function mode. To do so, press the

Down and Select keys simultaneously.

3. Move the elevator stick in the direction you want to

mix with flaps.

Note: The position indicator will reflect this change by

highlighting the up or down arrow.

4. Press the (+) or (-) key to increase or decrease the

amount of flaps to be mixed. If you want to reverse

the flap travel, press the Clear key, bringing the

mixing value to the factory default (0%), and increa se the value using the opposite key (+) or (-) from

the key originally selected.

5. Once you have adjusted the first mixing position (up

or down), place the elevator stick in the opposite

direction and follow Step 5 above to adjust the

second elevator mixing value.

6. Access the switch position by pressing the Select

key. Use the (+) or (-) keys to select from the one of

six switches, or from always on.

7. Access the TRAVEL ADJ function by pressing the

Up key.

8. Access the AIL RUD MIX Mixing function by pres sing the Up key.

9. Exit the ELE F MX function by pressing the

Down

and Channel keys simultaneously.

Aileron to rudder mixing

This form of mixing is designed so that when input to the

aileron stick is given, the rudder servo will also move,

eliminating the need to coordinate these controls manually. When adjusting, if an opposite mixing direction of

the rudder servo is required, simply press the (+) or (-)

keys to change the mixing value from a (+) or (-). This

will reverse the mixing direction of the rudder from its

original direction. The switch used to activate this mix

can also be selected as explained below. The factory

default is a value of 0%

MIXING VALUE (+/- 125%)

Mixing SW Selection

SW Display

ALWAYS ON: Always Mixing In

RIGHT FWD: Gear SW Forward side On

RIGHT REA: Gear SW Rear sideOn

LEFT FWD: FLAP SW Rear sideOn

LEFT REA: FLAP SW Rear sideOn

AILE D/R: AILE D/R SW Position 1On

ELEV D/R: ELEV D/R SW Position 1On

Function mode AIRPLANE 21

Page 22

Function mode AIRPLANE

Throttle Cut switch; Flap System

Go to Throttle cut

menu

Go to Ele Flp

Mx menu

Change selection

Change value/Select

switch

Reset selection to

Default (Adjust to

0% or ALWAYS ON)

Accessing the Aileron to Rudder Mixing Function

1. Place the transmitter power switch in the ON positi on.

2. Access the Function mode. To do so, press the

Down and Select keys simultaneously. Press

either the Up or Down key until AILRUD MIX

appears in the center portion of your LCD.

3. Press the (+) or (-) key to increase or decrease the

amount of rudder to be mixed with aileron. If you

want to reverse the Rudder Mix direction, press the

Clear key, bringing the mixing value to the factory

default (0%), and increase the value using the oppo site key (+) ir (-) from the key originally selected.

4. Press the Select key to access the switch assign ment function.

5. Press the (+) or (-) key to select the desired switch/

function to activate the Aileron-to-Rudder Mixing

function.

6. Access the ELEFLP MX mixing function by pres sing the Down key.

7. Access the THRO CUT function by pressing the Up

key.

8. Exit the AILRUD MIX function by pressing the

Down and Select keys simultaneously.

22 Function mode AIRPLANE

Throttle Cut switch

This function assigns the Throttle Cut switch to the push

button located on upper right front of the transmitter.

The Throttle Cut function is designed to return the

throttle trim to the lowest position instantly and keep this

position while the button is pressed. This feature is used

to “cut“ or stop the engine without changing the position

of digital throttle trim.

Throttle cut operating position

(-32~-128)

Go to Flap System

menu

Go to AilRud

Mix menu

Change value

Set function to

Inhibit

Accessing the Throttle Cut Function

1. Place the transmitter power switch on the ON positi on.

2. Access the Function mode. To do so, press the

Down and Select keys simultaneously. Press

either the Up or Down key, until THRO CUT

appears in the upper portion of the LCD screen.

3. Use the (+) and (-) keys to change the value of the

Throttle cut function.

Note: Pressing the Clear key will Inhibit the Throttle

Cut, turning it off until it has been reactivated.

4. Access the FLAP SYSTEM mixing function by pres sing the Down key.

5. Access the AILRUD MIX function by pressing the

Up key.

6. Exit the THRO CUT function by pressing the Down

and Select keys simultaneously.

Flap System

The Flap System function provides elevator compensation to counteract any pitch tendencies when flaps are

deployed.

SW Position

LANDING: (Flap SW forward side)

Elevator Offset value

Travel value (DN200~0~UP200)

Go to Differential

Go to Throttle Cut

Change selection

Flap operating value Travel value

(DN125%~0%~UP125%)

Change value

Reset to selection

to Default

Accessing the Flap System Function

1. Place the transmitter switch in the ON position.

2. Press the Down and Select keys simultanously to

enter the Function mode.

3. Press either the Up or Down key until FLAP SYS-

TEM appears in the top of the LCD.

4. Press the Select key to select the desired channels

to be adjusted.

5. Use the (+) or (-) keys to set the desired landing

mode surface positions.

6. Access the THRO CUT mixing function by pressing

Page 23

Function mode AIRPLANE

Differential aileron mixing; Programmable Mixing (1~4)

the Down key.

7. Access the MIX 1 function by pressing the Up key.

8. Exit the FLAP SYSTEM function by pressing the

Down and Select keys simultaneously.

Differential aileron mixing

In order to use the Differential Function, flaperon or elevon (Delta), wing mixing must be selected in the Model

Set-Up Mode and two servos must be used to operate

the ailerons (one on each). In the Function Mode, use

the UP or DN key to select Differential Aileron Mixing

and access by pressing the UP and DN keys simultanously.

Note: The Differential Aileron Mixing Function will

only be shown in the Function Model if either

Flaperon or Delta wing types have been pre viously selected in the System Mode.

Indicate present wing

type “FLAPERON“

DIFFERENTIAL VALUE

(NORM 0% - 100%)

To Program Mixing

To flap system

or “ELEVON“

Differential Value Increases or Decrease

Press to reset Differential

Value to factory preset. (NORM 100%)

Differential Value

NORM

(DIFF)

SPLIT

0%

50%

100%

Programmable Mixing (1~4)

The mx-12 offers four programmable mixes to be used

for any number of different purposes. This function allows mixing any one channel to any other channel. This

mix can remain on at all times or be switched on and off

in flight using a number of different switches.

Mix numbers 1-3 are of the standard variety, in that the

digital trim for the master channel only affect the master

channel, and not the slave channel. Mix number 4 is

of the “Trim Include“ variety. This mix is used any time

the mix requires the slave channels trim position to be

varied when the master channels digital trim position is

varied. An example for this type of mix would be when

dual elevator or dual aileron servos are used and connected to two separate channels of the system, rather

than using a single channel with a Y-harness.

Each channel of this radio is identified by an abbreviated name. The chart below indicates the channel

and its corresponding abbreviation. The channel name

apperaing first is known as the “master channel“ or the

channel to which you want to mix. The second number

is known as the “slave channel“ or the channel that is

being mixed into the master channel. For example,

AILRUD would indicate aileron-to-rudder mixing.

Each time the aileron stick is moved, the aileron will

deflect, and the rudder will automatically move in the

direction and to the value input. Mixing is proportional,

so small inputs of the master channel will produce small

outputs of the slave channel. Each programmable mix

has a mixing “offset“. The purpose of the mixing offset is

to re-define the neutral position of the slave channel.

Accessing the Programmable Mixing Function

Slave Channel

Offset Value

(+/- 125)

Change selected value

Reset selection to

default

Mixing percentages

(+/- 125)

Go to Fail Safe menu

Go to Differential

Change highlighted

selection

Master Channel

Mixing switch selection

SWITCH

ALWAYS ON: Always Mixing On

RIGHT FWD: Gear SW Forward sideOn

RIGHT REA: Gear SW Rear sideOn

LEFT FWD: FLAP SW Forward sideOn

LEFT REA: FLAP SW Rear sideOn

AILE D/R: AILE D/R SW Position 1On

ELEV D/R: ELEV D/R SW Position 1On

Function mode AIRPLANE 23

Page 24

Function mode AIRPLANE

Fail Safe

Accessing the Programmable Mixing Function

1. Place the transmitter switch in the ON position.

2. Press the Down and Select keys simultaneously

to enter the Function mode.

3. Press either the Up or Down key until MIX 1

appears in the LCD.

Selecting the Master and Slave Mixing Channels

4. Press the (+) or (-) keys to select the master chan nel.

5. Press the Select key to move the cursor to the

slave channel position.

6. Press the (+) or (-) keys to select the slave channel.

7. Press the Select key once. The display will conti nue to show the current mixing channels at the

top of the LCD, but now an arrow will indicate the

current stick position (master) to be adjusted.

Setting the Mixing Values

8. While holding the master stick in the direction you

want to mix, press the (+) or (-) keys to increase or

decrease the mixing value for the slave channel. The

value in the LCD will change to display the current

mix value selected. Next, hold the master stick to the

other side to adjust the mix for the other direction.

Setting the Mixing Switch Activation

9. Press the Select key until the SW is highlighted.

The LCD with “ALWAYS ON“ indicates the current

switch that this mix is currently selected to always be

active (ON).

Mixing Operation and Switches

Each mixing program can be turned on and off by a

lever or switch. The levers and switches that can be

selected for program mixing are tabulated at the right

with their abbreviations appearing on the displayand

their corresponding positions.

Setting the Mixing Channel Offset

1. Press the Select key until offset is highlighted. The

display will show the current mixing channels at the

top of the LCD, with the word “OFFSET“ in the

center of the LCD. The value to the right is the

mixing Offset neutral point, currently 0.

2. A new value for the offset can be selected using the

(+) or (-) keys. This is the new neutral point for the

slave channel (Point that the mix is activated). Press

the Clear key to reset the value back to 0.

3. Press the Down and Select keys simultaneously

to exit the Programmable Mix function.

With a little practice, programmable mixing will become

easier to understand. Mixing is inly limited by your

imagination.

Fail Safe

The Fail Safe/Hold function is available only when you

use the mx-12 transmitter in PCM modulations. This

function is designed to help minimize damage to your

aircraft during a loss of signal to the receiver. The servos either assume the fail-safe presets or hold their last

good signal position.

As noted earlier, if you are in the PPM modulation, the

Fail-Safe/Hold function is not applicable. Therefore,

the Fail-Safe/Hold function will not appear on your LCD

screen menu while in the PPM mode. Refer to the Modulation Selection section for more information pertaining to the broadcast signal of your mx-12 transmitter.

Note: The throttle fail safe position is defaulted to the

idle position for added safety.

Fail Safe Side Display

Channel being programmed

TH Throttle RU Rudder

AI Aileron GE Gear

EL Elevator FL Flap

Go to Servo Travel

Screen

Go to Programable Mixing menu

Change highlighted

selection

Hold Side Setup Display

Change from servo

hold to stick selection

(F.S.HOLD)

Invoke stick selection

Accessing the Fail Safe Function

1. Place the transmitter power switch in the ON positi on.

2. Access the Function mode. To do so, press the

Down and Select keys simultaneously. Press

either the Up or Down key until FAIL SAFE ap pears in the upper portion of the LCD screen.

3. Use the Select key to highlight the servo function to

set.

4. Use the (+) or (-) keys to toggle between servo hold

or setting the servo position.

5. When using the servo setting position, move the

corresponding control stick to the position where you

want the servo if the radio enters into the fail safe

mode. Press the Clear key to have the transmitter

memorize all stick position.

6. Repeat steps 4 and 5 intil all six controls have been

set.

7. Access the SERVO TRAVEL screen by pressing the

24 Function mode AIRPLANE

Page 25

Function mode AIRPLANE

Servo Travel Screen

Up key.

8. Access the MIXING FUNCTIONS function by pres sing the Up key.

9. Exit the FAIL SAFE function by pressing the Down

and Select keys simultaneously.

Servo Travel Screen

The Servo Travel Screen is used to verify the stick movements of the transmitter. It can also be used to verify

the mixing functions have been performed correctly

without the need to turn on the aircraft.

100%

50%

Neutral

Change D/R &

Exp menu

Go to Fail Safe menu

Accessing the Servo Travel Screen

1. Place the transmitter power switch in the ON positi on.

2. Access the Function mode. To do so, press the

Down and Select keys simultaneously. Press

either the Up or Down key until the SERVO

TRAVEL screen appears.

3. Move the sticks. The indicators correspond to the

following:

Indicator 1: Throttle

Indicator 2: Aileron

Indicator 3: Elevator

Indicator 4: Rudder

Indicator 5: Gear

Indicator 6: Flap

4. Access the D/R & EXP screen by pressing the Up

key.

5. Access the FAIL SAFE function by pressing the Up

key.

6. Exit the SERVO TRAVEL screen function by pres sing the Down and Select keys simultaneously.

Function mode AIRPLANE 25

Page 26

Function mode HELICOPTER

Dual Rate and Exponential; Servo Reversing

Dual Rates and Exponential

Channel

AILE: Aileron

ELEV: Elevator

RUDD: Rudder

Exponential value

Dual Rate value

Go to Reversing

SW menu

Go to Servo Travel

Screen

Select channel,

EXP or D/R

D/R POSITION

Change channel

or Value

Reset selection to

default

Dual rates are availabe for the aileron, elevator and

rudder channels of your RC aircraft.

Dual rates may be defined as the ability to vary the

travel or throw rate of a servo from a switch. Due to the

differing travel rates, you will find that the sensitivity of

the control either increases or decreases accordingly. A

higher rate, or travel, yields a higher overall sensitivity.

You may find it easier to think of the Dual-Rate function

as double-rates or half-rates.

The amount of travel is adjustable from 0-125% in 1%

increments. The factory setting, or default value, for

both the 0 and 1 switch positions is 100%.

Exponential reduces the sensitivity in the middle portion

of stick movement, while still allowing full travel at the

end of the stick movement. The end result (travel) remains the same, although exponential changes the rate

at which it achieves this travel. The adjustable range is

from 0-100%. Zero percent (0%) is linear stick control,

meaning the response rate is equal throughout the stick

control. 100% is full exponential. The larger the expon-

ential value, the less servo action or sensitivity you will

notice around the neutral setting.

Either switch position may be selected as the low or

high rate by placing the switch in the desired position

and adjusting the value accordingly.

Accessing the Dual Rate and Exponential Function

1. Place the transmitter power switch in the ON positi on.

2. Access the Function mode by pressing the Down

and Select keys simultaneously.

3. Press either the Up or Down key intil D/R & EXP

appears in the upper left corner of the LCD.

4. Press the (+) or (-) key until the desired channel

(aileron) elevator or rudder) appears.

5. Select the switch position for which you want to

adjust the rate. The number to the upper right of

the current rate value on the display indicates the

current position of the Dual-Rate switch for the

channel that you have selected. Either a 0 or a 1 will

be shown, corresponding to the position of the

switch. To select the opposite switch Rate switch to

the opposite position. The number that appears

above the current rate value reflects the change.

6. Adjust the rate for the channel and the switch positi on just selected. To decrease the throw rate, move

the cursor to the D/R position using the Select key,

then press the (-) key. To increase the throw rate,

press the (+) key. As stated previously, the adjustab le rate is from 0-125% for each switch position and

channel.

7. Press the Up arrow key to access the REVERSING

SW menu.

8. Press the Down arrow key to access the SERVO

TRAVEL SCREEN.

8. Press the Down arrow key to access the SERVO

TRAVEL SCREEN.

9. Press the Down arrow and Select keys simultane ously to exit the DUAL RATE AND EXPONENTIAL

mode.

Servo Reversing

The Reverse Switch function is an electronic means of

reversing the throw of a given channel (servo). All six

channels of the mx-12 offer reversible servo direction.

This will ease setup during the servo installation into

your helicopter.

Channel beeing programmed

Go to Sub Trim menu

Go to D/R & Exp

menu

Select channel,

to reverse

THR 1: Throttle

AIL 2: Aileron

ELE 3: Elevator

RUD 4: Rudder

GEA 5: Gear

PIT 6: Pitch

Change servo

direction

Reset direction to

normal

Accessing the Servo Reverse Function

1. Place the transmitter switch in the ON position.

2. Access the Function mode by pressing the Down

and Select keys simultaneously.

3. Press either the Up or Down key until the REVER-

SING SW appears in the upper portion of the LCD.

4. Using your transmitter`s control sticks, switches and

potentiometers, move the control surfaces on your

aircraft. Note the travel direction of each of the

26 Function mode HELICOPTER

Page 27

Function mode HELICOPTER

Sub Trim; Travel Adjust

corresponding control surfaces.

5. After determining which channel(s) need to have the

throw directions reversed, use the Select key to call

up the appropriate channel.

6. Press either the (+) or (-) keys to change the travel

direction of the servo. Pressing the Clear key returns

the travel direction to Normal.

7. You can observe the change in the travel direction

by moving the appropriate control at this time.

8. Access the D/R & EXP function by pressing the

Down key.

9. Access the SUB TRIM function by pressing the Up

key.

10. Exit the SERVO REVERSING function by pressing

the Down and Select keys simultaneously.

Sub Trim

The Sub Trim Adjustment function allows you to electronically fine-tune the centering of your servos. Individually adjustable for all six channels with a range of +/-125%

(+/- 30 degrees servo travel).

The sub trim functions provide precise servo arm neutral

positioning if rotating the servo arm will not allow the

desired servo arm position.

Channel beeing programmed

TH 1: Throttle

AI 2: Aileron

EL 3: Elevator

RU 4: Rudder

GE 5: Gear

PI 6: Pitch

Sub Trim Value

(0~+/-125)

Go to travel Adj

menu

Go to Reversing

SW menu

Select channel

Change value

Reset selection to

default

Accessing the Sub Trim Function

1. Place the transmitter power switch in the ON positi on.