Page 1

Manual

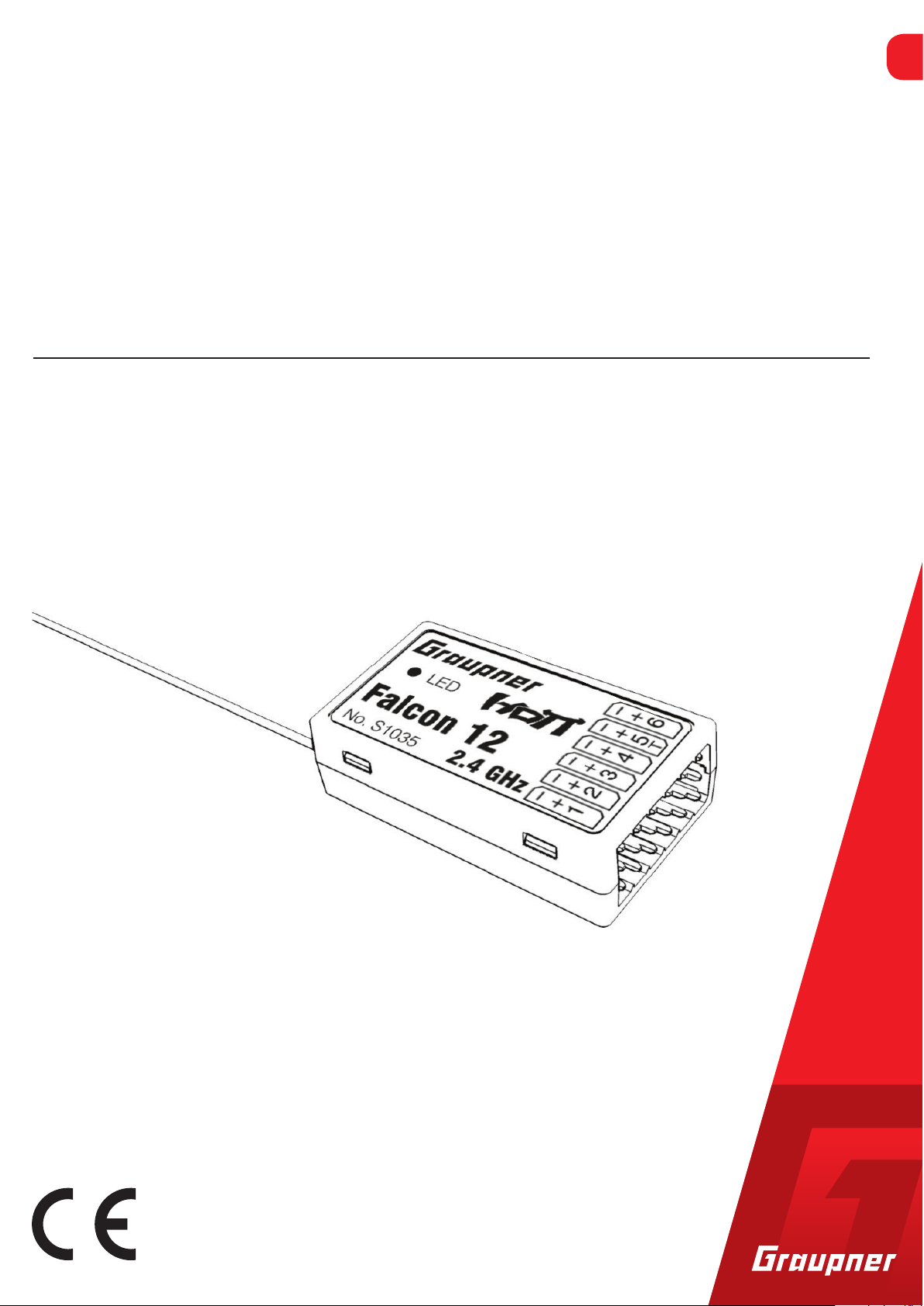

Falcon 12

HoTT 2.4 GHz receiver with 3 axis gyro

No. S1035

EN

Copyright © Graupner/SJ GmbH

Page 2

Index

Introduction ............................................................................. 4

Service Centre .......................................................................... 4

Intended use ............................................................................ 5

Target group ...................................................................................5

Package content ....................................................................... 5

Technical data .......................................................................... 5

Symbols explication ................................................................. 6

Safety notes.............................................................................. 6

Installation ............................................................................... 8

Fixed-wing model ...........................................................................8

Helicopter model ...........................................................................8

Binding ..................................................................................... 9

Interfaces ................................................................................. 9

Power supply ................................................................................10

Programming the receiver settings ....................................... 10

Receiver settings menu ...............................................................10

Programming a fixed-wing model ......................................... 12

Free mixers ...................................................................................12

Gyro assignment .................................................................... 14

Programming the regulation .................................................. 16

Gyro setting display .....................................................................16

Programming the axes sensitivity ................................................18

Initialization of the gyro ........................................................ 19

Adjust servolimit for channels ............................................... 19

Programming a helicopter model .......................................... 20

Preparing the helicopter ..............................................................20

2 / 36

Transmitter presettings ................................................................20

Initializing the gyro (helicopter) ..................................................20

Basic settings ......................................................................... 21

Axis assignment ..................................................................... 25

DO SETUP ....................................................................................25

Swashplate setting without Expertmode .............................. 26

S1035_Falcon_12_jh_V1

Page 3

Swashplate setting with Expertmode .................................... 27

Tail rotor setting without Expertmode .................................. 29

Tail rotor setting with Expertmode ....................................... 30

Firmware update .................................................................... 32

Declaration of conformity ...................................................... 33

Notes on environmental protection ...................................... 34

Care and maintenance ........................................................... 34

Warranty ................................................................................ 34

S1035_Falcon_12_jh_V1

3 / 36

Page 4

Introduction

Thank you very much for purchasing the Graupner Receiver

Falcon 12 HoTT 2.4 GHz 3 axis gyro. This receiver is extremely ver-

satile.

Read this manual carefully to achieve the best results with your

receiver and first of all to safely control your models. If you experience any trouble during operation, take the instructions to help or

ask your dealer or Graupner Service Centre.

Due to technical changes, the information may be changed in this

manual without prior notice. Keep updated by regularly checking

our own website,

www.graupner.de to be always updated with the

products and firmware.

This product complies with national and European legal requirements.

To maintain this condition and to ensure safe operation, you must

read and follow this user manual and the safety notes before using

the product!

Note

This manual is part of that product. It contains important information concerning operation and handling. Keep these instructions for

future reference and give it to third person in case you gave the

product.

Service Centre

Graupner Central Service

Graupner/SJ GmbH

Henriettenstrasse 96

D-73230 Kirchheim / Teck

Graupner USA

3941 Park Dr Suite 20-571

El Dorado Hills, CA 95762

Graupner in Internet For the service centers outside Germany please refer to our web site

www.graupner.de

Servicehotline

(+49) (0)7021/722-130

Monday - Thursday:

9:15 am - 4:00 pm

Friday:

9:15 am - 1:00 pm

service@graupner.de

Website: www.graupnerusa.com

Phone: +1 855-572-4746

Email:service@graupnerusa.com

4 / 36

S1035_Falcon_12_jh_V1

Page 5

Intended use

Target group

More punctual information about receiver can be found in the Technical data section.

The receiver is designed exclusively to be used in battery-powered,

radio controlled models, any other use is not allowed. For any

improper use no warranty or liability is accepted.

Read through this entire manual before you attempt to install or use

the receiver.

Graupner/SJ constantly works on the development of all products;

we reserve the right to change the item, its technology and equipment.

The product is not a toy. It is not suitable for children under 14 years.

The installation and operation of the receiver must be performed by

experienced RC models enthusiasts. If you do not have sufficient

knowledge about dealing with radio-controlled models, please contact an experienced model builder or a model club.

Package content

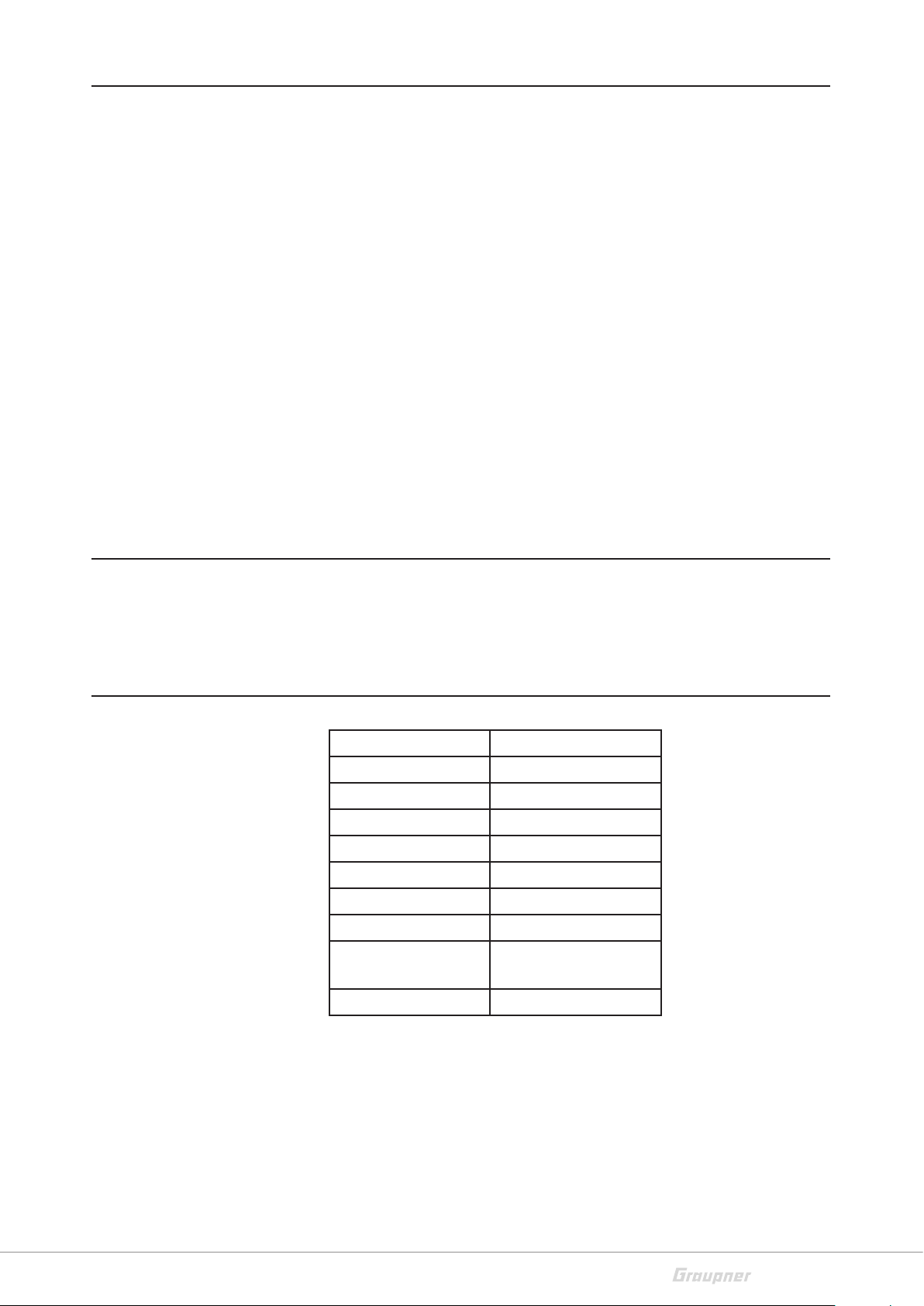

Technical data

Falcon 12 HoTT 2.4 GHz 3 axis gyro receiver

Manual

Falcon 12

Temperature range - 15...+70 °C

Antenna length 1 x wire 145 mm

Total weight approx.: 7 g

Frequency 2400 ... 2483.5 MHz

Range approx. 2000 m

Dimensions approx. 36 x 21 x 10 mm

Modulation 2.4 GHz FHSS

Power

consumption

Operating voltage (2,5) 3,6 ... 8,4 V

70 mA

S1035_Falcon_12_jh_V1

5 / 36

Page 6

Symbols explication

!

!

Safety notes

Always observe the information indicated by this warning sign. Par-

ticularly those which are additionally marked with the

WARNING. The signal word WARNING indicates the poten-

or

tial for serious injury, the signal word

of lighter injuries.

The signal word Note indicates potential malfunctions.

Attention indicates potential damages to objects.

These safety instructions are intended not only to protect the prod-

uct, but also for your own and other people’s safety. Therefore please

read this section very carefully before using the product!

Do not carelessly leave the packaging material lying around, since it

might become a dangerous toy for children.

Persons, including children, with reduced physical, sensory or

mental capabilities, or lack of experience or knowledge, or not

capable to use safely the receiver must not use the receiver without supervision or instruction by a responsible person.

CAUTION indicates possibility

CAUTION

Operation and use of radio-controlled models needs to be

learned! If you have never operated a model of this type before,

start carefully and make yourself familiar with the model's reactions to the remote control commands. Proceed responsibly.

First, always perform a range and function test on the ground (to

do so, hold your model tight), before you use your model. Repeat

the test with running motor and with short throttle bursts.

Before you start using the remote control model, you have to

check the further relevant laws and regulations. These laws you

must obey in every case. Pay attention to the possibly different

laws of the countries.

The insurance is mandatory for all kinds of model operation. If

you already have one, please inform yourself if the operation of

the respective model is covered by your insurance. If this is not

the case, conclude a special liability insurance policy for models.

We recommend to provide your model with a label, where your

personal data are indicated. So that the model can be clearly

assigned in the event of a crash.

6 / 36

33576_jp_V1

Page 7

Due to safety and licensing reasons (CE), any reconstruction and/

!

or modification of the product is prohibited.

Only use the components and spare parts that we recommend.

Always use matching, original Graupner plug-in connections of

the same design and material.

Make sure that all of the plug-in connections are tight. When dis-

connecting the plug-in connections, do not pull the cables.

Protect the receiver from dust, dirt, moisture and foreign parts.

It must be protected from vibration as well as excessive heat or

cold. The models may only be operated remotely in normal outside temperatures such as from -10°C to +55°C.

Only operate all your components using the current software

version.

If you have questions which cannot be answered by the operat-

ing manual, please contact us or another expert in the field.

WARNING

Also while programming, make sure that a connected electric

motor cannot accidentally start. Risk of injury by rotating propellers or rotor!

Avoid shock and pressure. Check the receiver regularly for damages to the housings and cables, specially after model crashes.

Damaged or wet receiver, even if re-dried, should no longer be

used!

33576_jp_V1

7 / 36

Page 8

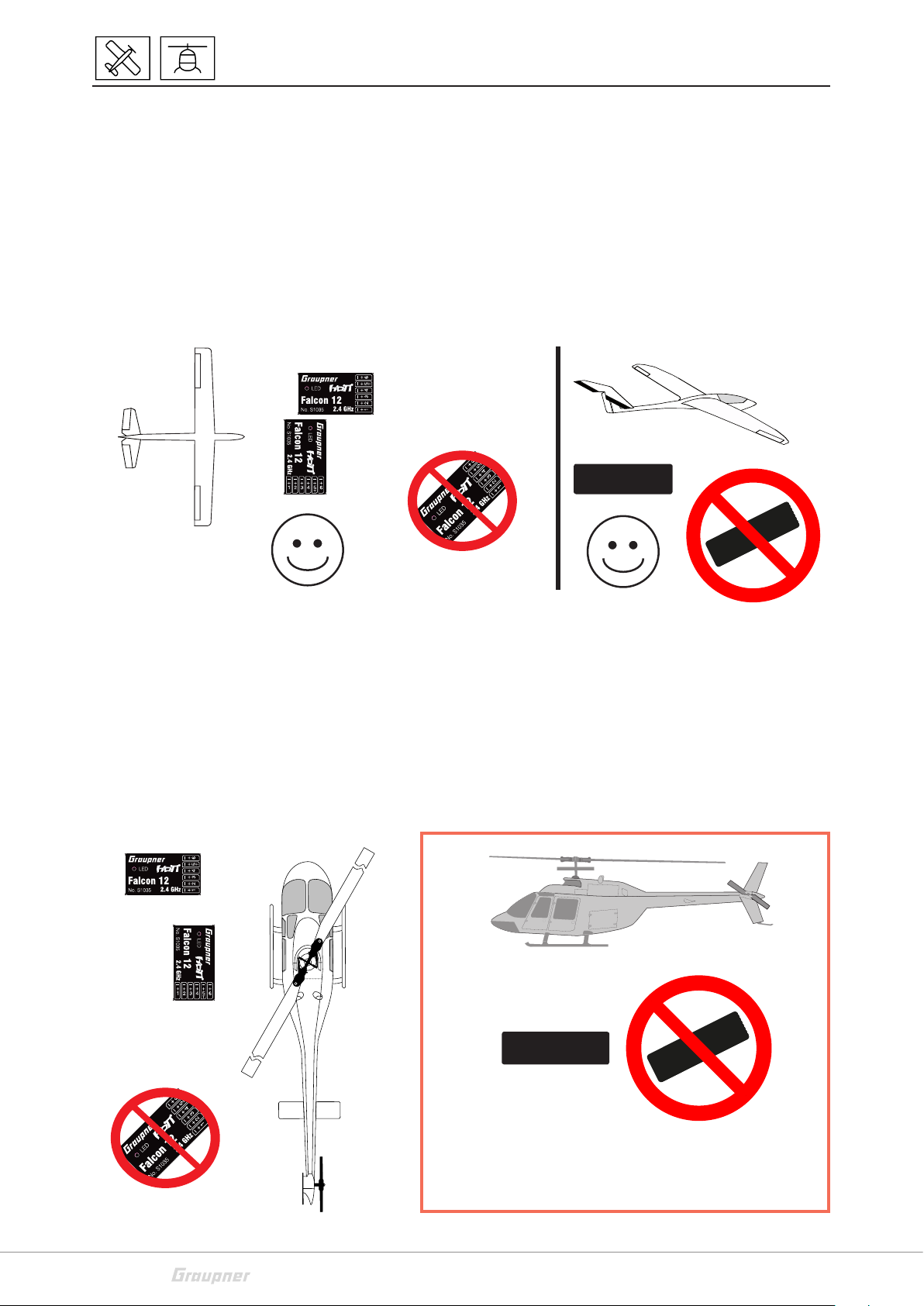

Installation

Fixed-wing model

The receiver must be aligned at right angles to the model on the

receiver platform.

The lower surface of the receiver must always be parallel to one of

the model sides.

Prior to installation, remove the sticker on the back of the receiver.

We recommend using double-sided tape No.: S8376 for Gr-18 to fix

the receiver in place. Also the so-called mirror adhesive tape is suitable.

Helicopter model

OK

The receiver must be aligned at right angles to the helicopter on the

receiver platform. Prior to installation, remove the sticker on the

back of the receiver. We recommend using double-sided tape (No.

S8376 for Gr-18) to fix the receiver in place. The receiver must be

connected to a stable power supply with at least two power cables.

Comply with the maximum power consumption permitted by the

servos. All connections can be used for this purpose.

OK

8 / 36

This installaon posion is at the moment not yet relevant,

but in case of later use of the accelerometers (through so-

ware update) it will be important!

S1035_Falcon_12_jh_V1

Page 9

Binding

The binding is only possible if, since the switch-on of the receiver, it

has not been bound to any transmitter (red LED on).

If you want to bind the receiver to a new model memory, proceed as

follows:

Switch off the RF module in the transmitter’s “Model base set-

tings” (see transmitter’s manual)

Distance between transmitter and receiver, minimum 1 meter

Switch the receiver on (red LED on), wait about 15 seconds until

the red LED blinks, the receiver is now in binding mode

Start the binding in the transmitter’s “Model base settings”

menu

If the red LED of the receiver switches off within about 15 sec-

onds, the binding process has been concluded successfully. Your

transmitter/receiver combination is now ready for use.

If the red LED is still blinking, the binding has not been success-

ful. In this case please repeat the entire procedure.

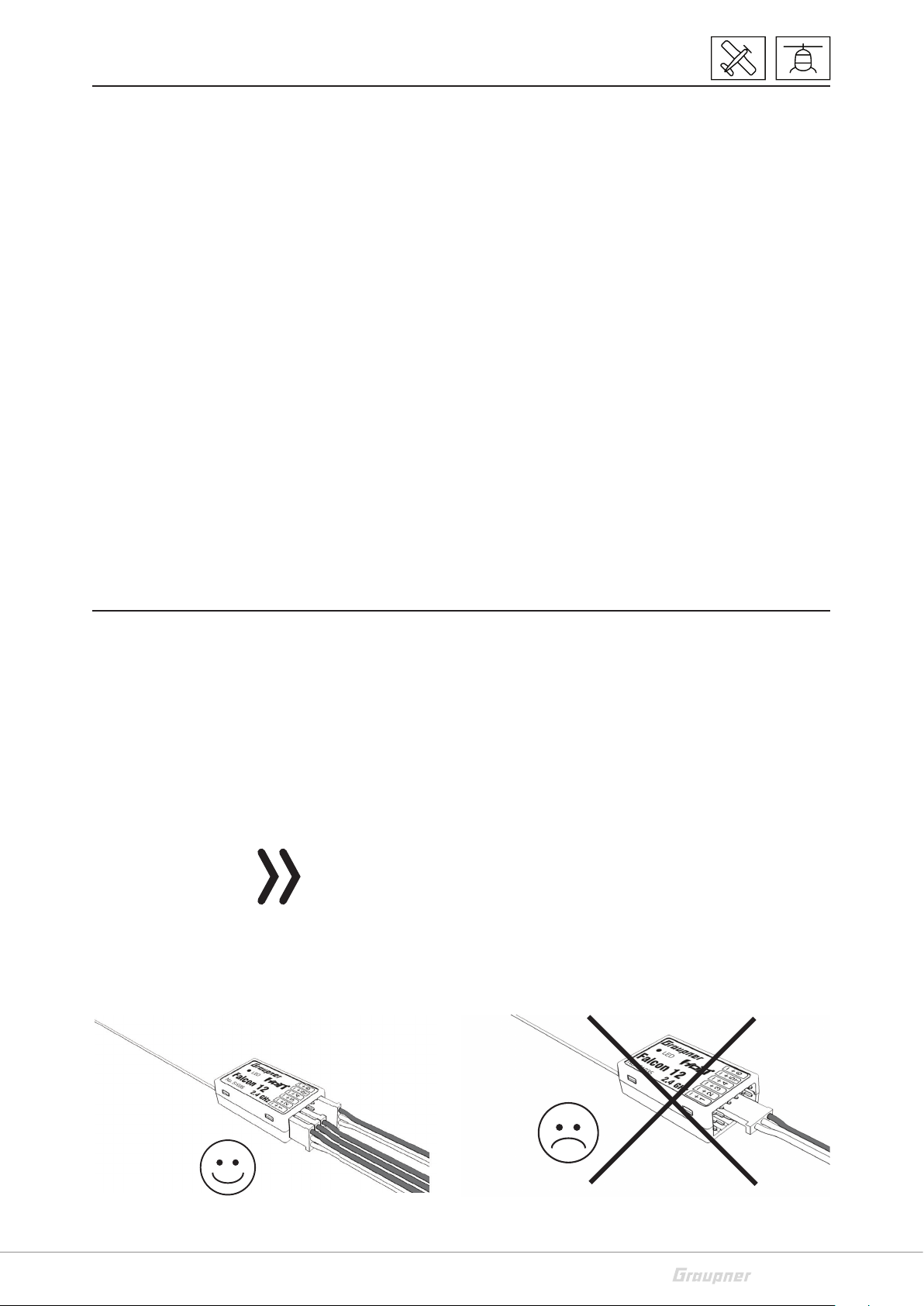

Interfaces

Connect the servos to the row of sockets on one end of the receiver.

The connectors are reverse polarity protected: note the small chamfers on the sides. Never use force – the connectors should engage

easily. The polarity is also printed on the receiver; the negative wire

(-) is brown, the positive (+) red and the signal orange. The servo

sockets of Graupner-HoTT 2.4 receivers are numbered sequentially.

The socket for channel 5 can also be programmed to deliver a (digital) sum signal (see receiver settings section).

Attention

Never connect a battery with voltage higher than 8,4V directly to

the receiver! The receiver and the connected servos would be

destroyed.

S1035_Falcon_12_jh_V1

9 / 36

Page 10

Power supply

The receiver does not feature specific sockets for connecting the

battery. We recommend that you connect the power supply to the

socket(s) close to the servos already connected to the receiver. If you

wish to connect multiple separate batteries, the batteries must be

of the same nominal voltage and capacity. Never connect different

battery types or batteries with strongly different charges since this

can cause an effect similar to a short circuit. In such cases for safety

reasons, insert voltage stabilizing elements such as PRX-5A (No.

4136) receiver power supplies between the batteries and receiver.

Programming the receiver settings

The receiver can be programmed with a suitable HoTT transmitter

or in connection with the SMART-BOX.

Receiver settings menu

RECEIVER 2.0 <

>LANGUAGE: English

Model type: HELI

ALARM VOLT 3,8V

ALARM TEMP: 70°C

CYCLE: 20ms

SUMD at C5: No

C5: Sensor

The receiver setup menu appears in the “Telemetry“ menu under

SETTINGS / DISPLAYS or if you are using a SMART-BOX under SETTING & DATAVIEW. How to access this menu is described in the operating instructions supplied with your transmitter or Smart-Box.

Model type

Setting "HELI" or "Fixed-wing". The following specific setting menus

will appear depending on the model type selected. Factory reset for

heli settings: Switch from heli to fixed-wing then disconnect the

power supply and reconnect it.

Then switch from fixed-wing to heli, disconnect the power supply

and reconnect it.

Low voltage warning (ALARM VOLT)

If the receiver voltage or the external voltage at channel 5 falls below

the set value, a low-voltage warning is generated by the transmitter's RF module in the form of a "general alarm tone" (regular beeping at a rate of approx. one beep per second) or the "receiver voltage" speech output message.

Temperature warning (ALARM TEMP)

If the receiver temperature exceeds the set temperature, a warning

is generated by the transmitter’s RF module in the form of a "general

alarm tone" (regular beeping at a rate of approx. one beep per second) or the "receiver temperature" speech output message.

10 / 36

S1035_Falcon_12_jh_V1

Page 11

Cycle time (CYCLE)

If your system is used exclusively with digital servos, you can set a

cycle time (frame rate) of 10 ms. If your system includes some or

uses exclusively analogue servos, you should always select 20 ms, as

many analogue servos cannot process the higher frame rate and

may respond by "jittering" or "growling".

SUMD (Sum signal) at channel 5

If you activate the digital sum signal at channel 5, a sum signal containing 8 channels is present at this socket, instead of a servo signal.

The HoTT receiver configured as SUMD constantly generates a digital sum signal from 8 control signals from the transmitter and makes

this signal available at the specified servo socket, which is receiver-specific. This type of signal was being used by some of the newest

flybarless systems and power supplies.

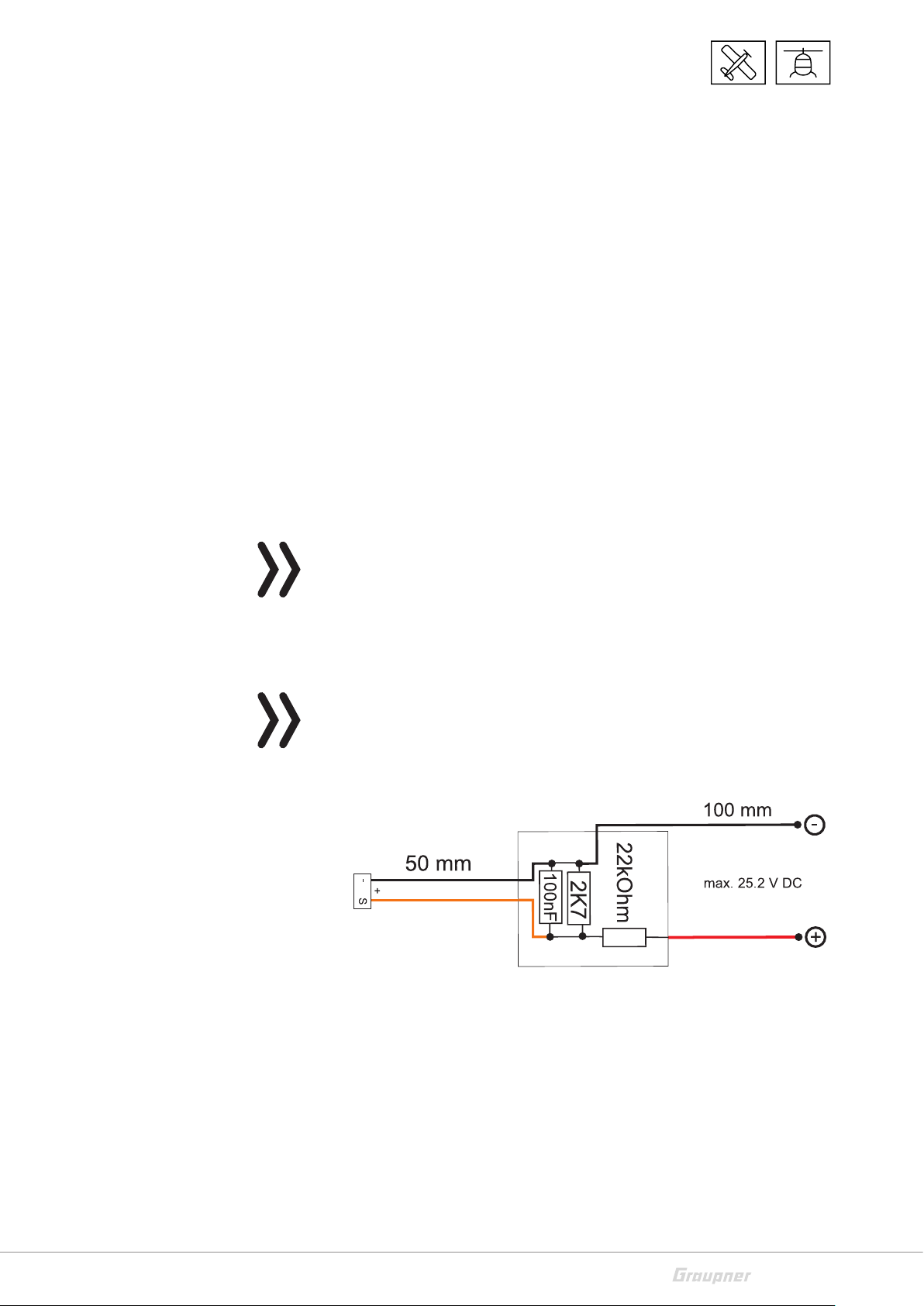

Channel 5 (C5)

This socket allows you to use either for telemetry "Sensor" or for an

extra channel servo 5 "Servo" or or for measuring the voltage "Voltage".

Attention! It is only possible one function at the same time!

Only through the unit described in the introduction it is possible to

measure a voltage up to max. 25.5 V DC. This voltage will be shown

in the display of the transmitter instead the receiver voltage. This

way it is possible to monitor the main battery voltage without using

external sensors.

Note

If the voltage measurement is active, the following described switch

(see sketch) must be used to measure a maximal voltage of 25.5 V

through this output. Never connect a battery to this telemetry port

without this switch!

<- Channel 9

This voltage distributor is included in the ESCs S3082 and S3083.

S1035_Falcon_12_jh_V1

11 / 36

Page 12

Programming a fixed-wing model

Free mixers

Note

If you wish to use the gyros, you must always set the tail type to

‘normal’ in the transmitter’s model type menu.

FREE MIXER < >

>MIXER: 1

FROM CHANNEL: 1

>TO CHANNEL: 6

>TRIM: +0%

TRV - : +100%

TRV + : +100%

If your model is a delta, features a V-tail, or has two elevator servos,

you must use the receiver mixer - not the transmitter mixer - to control these control surfaces, since the gyro stabilization system will

have no effect on these servos otherwise.

The four receiver mixers work ‘downstream’ of the gyros.

If you have already programmed mixer functions in the “Wing mixers” or “Free mixers” menu of your HoTT transmitter, you must

ensure that those mixers do not overlap with those available in this

menu!

Mixer

Up to four mixers can be contemporaneously programmed . You can

switch between Mixer 1, Mixer 2, … and mixer 4 in the “Mixer” line.

The following settings only affect the mixer selected in this line.

Programming examples

FREE MIXER < >

>MIXER: 1

FROM CHANNEL: 3

>TO CHNNEL: 4

>TRIM: +0%

TRV - : +100%

TRV + : +100%

From channel

The signal source (or source channel) is mixed in to the target channel (TO CHANNEL) with a programmable amount. The method of

setting up the values is analogous to the “Free mixers” menu in HoTT

transmitters.

To channel

TO CHANNEL: part of the source channel signal (FROM CHANNEL) is

mixed into the target channel (TO CHANNEL). The mixer ratio is

determined by the percentage values entered in the “TRAVEL-” and

“TRAVEL+” lines. Select "0" if you do not want to activate any mixer.

Mixer ratio (TRAVEL-/+): in these two lines you can define the mixer

ratio in relation to the source channel (FROM CHANNEL); the value

is set separately for both directions.

V-tail with rudder differential

FREE MIXER < >

>MIXER: 2

FROM CHANNEL: 4

>TO CHANNEL: 3

>TRIM: +0%

TRV - : -60%

TRV + : +100%

FREE MIXER < >

>MIXER: 3

FROM CHANNEL 4

>TO CHNNEL: 4

>TRIM: +0%

TRV - : +100%

TRV + : +60%

12 / 36

Differential is not normally necessary with this tail type. Mixer 3 is

not required if you do not need rudder differential, and TRAVEL for

mixer 2 must then be set to -100%.

Alternatively you may prefer to carry out the programming using the

transmitter menu.

S1035_Falcon_12_jh_V1

Page 13

A ‘Rudder / elevator’ mixer can be set up at the transmitter instead

of ‘Free mixer 3’ at the receiver; the mixer should be set up asymmetrically, e.g. +30%, -30%. This option frees up one mixer at the

receiver.

Delta with aileron differential (1 aileron)

FREE MIXER < >

>MIXER: 1

FROM CHANNEL: 2

>TO CHANNEL: 3

>TRIM: +0%

TRV - : +100%

TRV + : +60%

FREE MIXER < >

>MIXER: 2

FROM CHANNEL: 3

>TO CHANNEL: 2

>TRIM: +0%

TRV - : -100%

TRV + : -100%

FREE MIXER < >

>MIXER: 3

FROM CHANNEL: 2

>TO CHANNEL: 2

>TRIM: +0%

TRV - : +60%

TRV + : +100%

In this example aileron differential is set to 40%. Alternatively you

may prefer to carry out the programming using the transmitter

menu. A ‘Aileron -> elevator’ mixer can be set up at the transmitter

instead of ‘Free mixer 3’ at the receiver; the mixer should be set up

asymmetrically, e.g. +30%, -30%. This option frees up one mixer at

the receiver.

Two elevator servos

(channel 6 for the second elevator servo)

FREE MIXER < >

>MIXER: 1

FROM CHANNEL: 3

>TO CHANNEL: 6

>TRIM: +0%

TRV - : +100%

TRV + : +100%

Programming examples

Programming examples

Only for transmitters without a butterfly (crow) mixer

If a butterfly (crow) mixer is required, you will not be able to use one

of the two functions ‘differential’ or ‘landing flap’ adjustment, as 2

mixers are needed for this.

FREE MIXER < >

>MIXER: 1

FROM CHANNEL: 1

>TO CHANNEL: 2

>TRIM: +0%

TRV - : +100%

TRV + : +100%

FREE MIXER < >

>MIXER: 1

FROM CHANNEL: 1

>TO CHANNEL: 2

>TRIM: +0%

TRV - : +100%

TRV + : +100%

FREE MIXER < >

>MIXER: 2

FROM CHANNEL: 1

>TO CHANNEL: 5

>TRIM: +0%

TRV - : -100%

TRV + : -100%

FREE MIXER < >

>MIXER: 2

FROM CHANNEL: 1

>TO CHANNEL: 3

>TRIM: +0%

TRV - : -100%

TRV + : -100%

S1035_Falcon_12_jh_V1

13 / 36

Page 14

Gyro assignment

Axis assignment < >

>AILERON SERVOS: 2

DO SETUP: yes

AILE: (right) +2

ELEV:(push) +0

RUDD:(right) +0

Axis assignment < >

>AILERON SERVOS: 2

DO SETUP: No

AILE: (right) +2

ELEV:(push) +1

RUDD:(right) -3

Aileron servos:

You should enter the value 2 in this line if your model has two aileron servos. In this case the gyro for channel (servo) 2 also acts on

servo 5. If the ailerons are also used as flaperons or speedbrakes,

gyro suppression is based on the sum of both channels.

Note

The servo reverse setting must be the same for both aileron servos,

i.e. either both ‘normal’ or both ‘reverse’. If this is not possible, on

no account should you reverse one servo in the transmitter menu.

The only option is to re-install it in the model by turning it round

physically.

However, if your model is fitted with programmable servos (e.g.

Graupner DES, HVS or HBS types - see the instructions for the update

program ‘Firmware_Upgrade_grStudio - then it is possible to

reverse the direction of rotation at the servo itself.

Please read the installation notes on page 8 of these instructions.

The first step is to define the three gyro axes and the orientation of

the receiver. This is accomplished by switching on the transmitter

and model, and selecting ‘DO SETUP: yes’ in the receiver’s ‘Gyro settings’ menu.

Now move the stick for any control surface to full travel (in the

servo display at least 25%) in the indicated direction; in the following example we use the aileron channel.

The detected axis (aileron) is highlighted (black background). (In

the receiver’s default state the value for all axes is shown as ‘+0’;

the axes can also be set manually to ‘+0’. 0 = inactive)

Now turn the model through at least 45° in the direction corre-

sponding to the stick movement. For example, if you moved the

aileron stick to the left, you must simulate a left turn with the

model -> move the left wing down through at least 45°.

This process defines the one axis and direction; now you must

repeat the procedure for the other two axes.

The gyro axis 1, 2 or 3 is now displayed in the ‘Aileron / Elevator

/ Rudder’ display; a negative prefix will appear if servo reverse is

activated.

Once all three axes are defined, the display automatically reverts

to ‘New setting: no’.

14 / 36

S1035_Falcon_12_jh_V1

Page 15

Elevator

!

CAUTION

Check that all the gyros are

working in the correct

direction!

Move the model in all axes

directions. Check the movements and travels.

Now check the control

surface deflections - see

diagrams below.

You must not fly the model

before doing this: crash

hazard!

Movement of the model Control surface action (tail view)

Rudder

Movement of the model Control surface action (tail view)

Aileron

Movement of the model Control surface action (tail view)

S1035_Falcon_12_jh_V1

15 / 36

Page 16

Note

Before you start entering settings for a new model, it is essential to

select the number of aileron servos in the Aileron servos menu

point, and to define the gyro axes and orientation in the New settings menu point.

Programming the regulation

Gyro setting display

GYRO SETTINGS< >

MODE AIL/ELE (2) C H7

MODE RUDD (2)CH7

>Aileron: 0

>Elevator: 0

Rudder : 0

Factor : (44%)C10

MODE

In this point you can select the gyro correction mode (0-3):

0 - no gyro correction

1 - normal gyro correction (P and D parameter)

2 - heading lock mode (I parameter) with suppression

(Outside the suppression area the gyro control is active, in stick

center position acts the heading lock)

3 - Rate mode

(Heading lock acts in stick center position through the entire area)

Note

In Heading lock mode the servos are moved to the center position

if the factor is set to 0%.

Mode switching

The mode can be set separately for AILE/ELEV and RUDD. The mode

can be set permanently or it can be switched through an assigned

channel. Program the selected channel in your transmitter with a

switch, the following positions switch the related mode:

Mode 0 - 100%

Mode 1 - 50%

Mode 2 0%

Mode 3 ≥ 50%

Preparation step by step:

1. Trim the model with the gyro correction off

2. Switch the receiver off and on to save the values as standard

3. Activate the gyro correction

4. The phase trim should not be used!

5. Set the factor for gyro correction, eventually check the values for

the single control surfaces

16 / 36

S1035_Falcon_12_jh_V1

Page 17

Note

If the model is too agile in mode 3, it is then recommended to set

in the transmitter DUAL RATE and/or EXPO for this mode. Thus the

model will react in a more docile way. In the Rate mode the model

tries to reach the controlled rate. Also in mode 2 EXPO can be useful.

Aileron/elevator/rudder:

Shows the programmable factors for the corresponding control surface.

The gyro correction can also be disabled by setting the value to

"OFF". Do not exceed 4 - 5 as maximum value for the normal flight

phase, 2 - 3 for speed, 3 - 6 for landing. The maximum value of 10

should be reserved for torque-rolls only.

Factor (general sensitivity)

Setting this value the 3 parameters will be influenced contemporaneously.

General sensitivity for all gyros, action grade settable through a controller between 0 and 200%

Move the cursor to the Factor line. Move the cursor to reorder the

factor for aileron, elevator and rudder by using a proportional control (adjustment range up to 200%; channel value -100% means a

factor of 0%, channel value 0% means 100%, and +100% means

200%). This makes it a very easy matter to match the gyro’s corrective effect to the model’s airspeed. In particular, higher gyro gain can

be used for the landing approach - without the need to switch flight

phases.

Once you have found the optimum settings, you can set up a transmitter switch to control the gyro, i.e. for switching between gain settings. For example, you could assign a 3 position switch to “Factor”,

and then use it to switch the values between 0% and 100% (OFF) so

as 200%. In the transmitter the servo display for this 3 functions

switch must indicate -100, 0 and +100%.

Note

The OFF value means a gyro action of 100%!

Good to know!

The standard factor should cause the gyros to correct the model’s

attitude quickly when it is upset by an outside influence. Without

causing oscillation, but in practice the optimum values for a particular model can only be found by flight-testing. If the model shows little or no automatic stabilization with the default settings, the value

should be raised; on the other hand. If the model oscillates (wavelike movements in flight), the value should be reduced.

S1035_Falcon_12_jh_V1

Some transmitters allow the corrective factors to be altered during

a flight using the proportional controls, whereas others allow fixed

values only.

17 / 36

Page 18

Flight phase specific settings

It is possible to use a channel to control the factor value by setting

up flight phase specific transmitter control settings, but only with

some transmitters; please see the instructions supplied with your

transmitter and refer to the “Transmitter control settings” and “Flight

phase settings”.

Programming the axes sensitivity

GYRO SETTINGS< >

MODE AIL/ELE (2) C H7

MODE RUDD (2)CH7

>Aileron: (2)C9

>Elevator: (3)K8

Rudder : 6

Factor : (44%)C10

Programming through transmitter with proportional controls

If your HoTT transmitter is equipped with proportional controls, it is

also possible to adjust the value for each axis during a flight: what

you might call ‘flying the settings’. You need to assign proportional

controls to any channel in the range 5 to 16 (in this example channel

9); now you can alter the value using these controls. The current

value is shown in brackets.

Procedure, using the ailerons as an example: step by step:

1. Move the cursor to the appropriate line, in this case “Ail” for aileron.

2. Press the SET button to activate the "Channel" field.

3. Select the appropriate channel and save the setting with pressing the SET button again

4. Move the related proportional control to change the value (range

between 0 and 10, where 0 means no gyro correction for the

related axe).

5. This value can also be changed by pushing the left or the right

button. This frees up the channel previously occupied by the proportional control, So that it can be used for some other purpose,

e.g. for elevator or rudder.

GYRO SETTINGS< >

MODE AIL/ELE (2) C H7

MODE RUDD (2)CH7

>Aileron: 2

>Elevator: 4

Rudder : 6

Factor : Off

6. Move on to elevator and / or rudder, and select the channel and

value (you can either select the same channel, in order to alter

all the axes simultaneously, or different channels, allowing you

to program the axes individually).

7. Now test-fly your model and fine-tune the values one by one

until your preferred stabilising effect is achieved without the

model oscillating.

8. It may be sensible or easier to activate the gyro for one axis only

at first, and then to establish the optimum setting for that axis,

rather than for several axes simultaneously.

Programming by transmitter without proportional controls

1. Select by mode "0"; this function is only possible in case of transmitters with proportional controls.

2. Move the cursor to the appropriate line, in this case “Ail” for aileron.

3. Press the SET button to activate the input field. Select the appropriate value (1-10 or OFF) and save the setting with pressing the

SET button again.

18 / 36

S1035_Falcon_12_jh_V1

Page 19

Initialization of the gyro

4. First select a low value (see value section for starting points) and

carry out a test-flight. If gyro stabilization is not sufficiently pronounced, increase the value step by step until the level of correction is as required; if the model already oscillates, reduce the

value step by step.

5. Move on to "elevator" or "rudder" and select the desired value

(or OFF).

6. Leave the settings for “Factor” to OFF.

7. Activate the gyro for one axis only at first, and then to establish

the optimum setting for that axis, rather than for several axes

simultaneously.

Once the model has been switched on, the gyro immediately

becomes active but still needs to be initialized. To initialize the gyro,

keep your model still when you switch it on. After approx. 2 seconds

in still position, the ailerons move briefly in both directions. These

"wiggles" indicates that initialization has been successful and that

calibration is complete. Only now the model can be moved again.

Al the sticks must be left in the central position!

Note

During the initialization the neutral position will be detected, for

this reason it is very important that the model is not moved during

the activation!

In the same way during the gyro initialization also the central position of each control channel is saved. By gyro suppression the gyro

correction is reduced with increasing control deflection, at +/- 100%

of the gyro is deactivated.

Adjust servolimit for channels

SERVOLIMIT <

> 1: -150% +150% SEL

2: -150% +150% SEL

3: -150% +150% SEL

4: -150% +150% SEL

5: -150% +150% SEL

6: -150% +150% SEL

7: -150% +150% SEL

SERVOLIMIT <

> 1: -150% +83% STO

2: -150% +150% SEL

3: -150% +150% SEL

4: -150% +150% SEL

5: -150% +150% SEL

6: -150% +150% SEL

7: -150% +150% SEL

+83% STO

In this menu, you can limit the servo travel for all channels. Limit the

servo travel to the maximum possible deflection, so that the servos

can not run in the stop in the gyro operation. Move the cursor to the

desired line (by further downward move of the cursor will be displayed further channels), here “1” for channel 1 Pressing the SET

button is pressed the “SEL” field in “STO”.

Now move the stick of channel 1 in the desired direction and position, while the corresponding percentage display is shown inverted.

Now press the SET button again and the set value is displayed and

stored. Go through the procedure for the other channels.

S1035_Falcon_12_jh_V1

19 / 36

Page 20

Programming a helicopter model

Preparing the helicopter

Set all servos to neutral; the arms must be at right angles and the

swashplate must be in the neutral position (perpendicular to the

main rotor axis). The swashplate pushrods must be the same length.

Transmitter presettings

Select the free/deleted model memory and activate the helicopter

model. Set the pitch front/back according to your personal preferences and do not change it anymore.

All trims must be set to 0 (Servo display 0%) and must not be altered

in flight under any circumstances. If possible, trims should therefore

be deactivated in the transmitter (set the trim steps to 0).

• Activate or retain the servo for swashplate type 1 (the swashplate mixer is implemented in the FBL system of the receiver).

• The settings for the servo travel and direction remain at first to

standard, 100% and not reversed.

• Do not connect the tail servo if it does not have a mid-point of

1.5 ms (standard).

• Swashplate servo arrangement at 120/135/140°:

• front left = 1, front right = 2, back =3

2

• If the swash plate is turned of 180° and the nick servo is forward,

• Bind the receiver to the transmitter.

Initializing the gyro (helicopter)

Once the model has been switched on, the gyro immediately

becomes active but still needs to be initialized. To initialize the gyro,

keep your model still when you switch it on. The calibration process

can only be performed when the receiver is absolutely still. After

approx. 3 seconds in the idle position, the swashplate moves briefly

three times. These "wiggles" signal that initialization has been successful and that calibration is complete. Always wait until the calibration process has finished before starting to fly the model.

3

1

the connection sequence does not change. The left roll servo is

always 1.

20 / 36

S1035_Falcon_12_jh_V1

Page 21

Basic settings

Procedure

1. Once the transmitter and helicopter have successfully been prepared, call up the Telemetry menu in the transmitter (see transmitter instructions).

2. Set in the receiver the model type "Hely" (see section "Receiver

settings"). Then change to the menu "Base setup contr.".

3. Scroll past the swashplate/tail setup menus; these will be used

later on.

4. You must work through each item of this menu in order

from top to bottom:

Base setup controller

BASE SETUP CONTR.<v>

>Rotating dir right

Swp Type 120 deg.

Swp Frequency 200Hz

Swp direction +0

Swp Nick Trim +0

Swp Roll Trim +0

Swp Pitch Trim +0

Swp travel 8d +80

Collective_B +80

Cyclic max +80

Swp rotate +0

Tail servo 1.5ms

Tail frequency 333Hz

Tail mid +0

Tail limit B +50

Logging +3

Expertmode No

When a value is activated in the basic setting control, the gyro control and partly the control are deactivated! Therefore, settings must

not be carried out in the air, but must be carried out on the ground

without speed!

Rotation direction

Here you can set the direction of the rotor rotation, seen from above

the helicopter. Right or left

Swp type

Swashplate type: select the correct swashplate type. 90°, 120°, 135°,

140°.

S1035_Falcon_12_jh_V1

Default setting 120°

21 / 36

Page 22

Swp frequency

Swp frequency: frequency for the swashplate servos

50-200, default setting: 200 Hz

Warning: Analogue servos may only be operated at 50 Hz. If they are

not, the servos will be destroyed. Many digital servos can be operated at a higher frequency. (Use at your own risk). This allows the

model to be controlled more quickly. With HBS servos, we recommend setting the frequency to 200 Hz.

Swp direction

0-3, default setting: 0

Here, a fixed servo-combination of the Swp servos is selected, in

which the Swp does not tip during "pitching". (pitch direction is set

under C1 in the transmitter's servo menu with servo reverse, if

required).

Now check the direction of rotation of the swash plate for pitch, roll

and nick. If one of the control functions is reversed, the servo reversal must be performed as follows in the transmitter's servo settings:

Reverse for pitch = C1, for roll = C2 and for nick = C3.

Elev trim, Aile trim and Collective trim

-100 - +100, default setting: 0

The swashplate must be aligned as far as possible at right angles to

the main rotor axis and with 0° pitch. By activating one of these 3

values, the gyro control switches off and the servos move into their

neutral position. After that, the swash plate can be aligned optimally

with Elev trim, Aile trim and Collective trim. A perfect setting is

achieved when the rotor plane does not move in flight when the

pirouettes are performed.

Swp cyclic travel 8

50-125, default setting: +80

Set the Swp cyclic travel 8° if the menu value is activated so that the

rotor blade located above the tail tube is as accurate as 8° by full rollover stroke. To do this, the field must be selected (highlighted field)

so that the swashplate can be controlled and adjusted in direct mode

when gyro gain is switched off. This is the only mode in which the

travel can be set correctly.

It is very important that the travel is set correctly. It plays a major role

in terms of acquiring the correct gyro gain.

22 / 36

S1035_Falcon_12_jh_V1

Page 23

Collective_A/B

50-120, default setting: 80

It is selected automatically based on the pitch stick travel on the

transmitter. Use the pitch gauge to measure the required pitch travel

when the full commands are applied (+-100%) and set it in this menu.

All of the other settings can be made later on the transmitter for the

pitch curves in the respective flying phase.

Swp limit

50-200, default setting: +80

Swashplate limit. The swashplate limit must be set so that it is not

possible for a servo to reach its mechanical limits, while ensuring

that the servo's travel is as large as possible. No humming should

come from any of the servos when full travel commands are applied.

Swp rotate

-90-90, default setting: 0

"Swp rotate": a virtual Swp rotation (in degrees) can be set here (for

certain systems with several blades). Normally for rotor heads with

up to a 3 bladed no rotation is necessary.

The Swp (swashplate) is now fully set up and you can move on to the

tail:

Tail servo

Default setting: 1.5 ms

"Tail servo": select the correct mid-point for your tail servo here.

Mid pulse: 1,5ms, 760μs or 960µs.

Default setting: 1.5 ms. 1.5 ms is generally the default setting for tail

servos. Narrowband servos (generally special tail rotor servos) may

however require a different mid pulse width. You must locate this

value in the servo manual and set it correctly. If a value has not been

specified, it is probably a standard servo set at 1.5 ms. If you have a

DES, HVS or HBS servo, this value can sometimes be programmed.

However, we recommend sticking with the default setting.

The control direction of the tail rotor can now be checked. If it is

reversed, the servo reversal of channel 4 must be performed in the

transmitter's servo settings.

Tail frequency

"Tail frequency": the tail frequency can be set to between 50 and

333 Hz.

S1035_Falcon_12_jh_V1

Default setting: 333 Hz

Warning: Analogue servos may only be operated at 50 Hz. If they

are not, the servos will be destroyed.

Many digital servos can be operated at a higher frequency (use at

your own risk).

23 / 36

Page 24

This allows the model to be controlled more quickly. With HBS servos, we recommend setting the frequency to 333 Hz.

Tail center

-100 - +100, default setting: 0

If the value "Value tail center" (inverted field) is activated, the tail

servo moves to the neutral position. The tail servo arm should be at

a 90-degree angle to the tail linkage pushrod.

The fine trim is then adjusted based on the mid-point of the tail.

When the servo is set to neutral, the tail rotor should have a pitch

angle of approx. 2 to 3° against the torque. Check whether the control direction is correct, if not then reverse the servo channel of C4

in the transmitter.

Tail limit A/B

50-200, default setting: +50

Limits the tail servo travel. Select the direction by moving the tail

stick to its endpoint. The display shows the values for A and B for

both endpoints, which are set separately. It must be set so that it

does not reach its mechanical limits but so that the full travel can be

used. Values that are suitable in terms of aerodynamics should be

selected here. If the travel is too large, this may cause the servo to

stall.

Logging

Default setting: +3

logs the corresponding servo to SD card of the transmitter for later

evaluation and error analysis with active flight timer.

0 = no logging

1 = roll and nick logging

2 = roll logging

3 = nick logging

4 = tail logging

We recommend always logging at least one function.

Expertmode

"Expertmode" is set to "No" by default. Even experts should stick

with this setting when carrying out the first steps with the new system. There are much fewer options in the Swp and tail menu and

they should only switch to Expertmode and its additional options if

they need to and when they have got used to the system.

24 / 36

S1035_Falcon_12_jh_V1

Page 25

Axis assignment

DO SETUP

Axis assignment <

>DO SETUP: Yes

Roll (right): +2

>Nick (push) +0

>Tail: (right +0

Axis assignment <

>DO SETUP No

Roll (right): +2

Nick: (push): +1

>Tail (right): -3

DO SETUP: Yes/No

Assignment of the gyros and their operating direction.

If you have not already done so, you must now set the C1-4 servo

directions so that everything works correctly.

In the receiver's "Axis assign" menu, go to the "Setup" option and set

it to "Setup: Yes". Now assign the axes as follows:

On the transmitter, briefly set the roll command fully to the right; the

roll axis is highlighted. You will then have both hands free again to

operate the helicopter.

Roll the helicopter more than 45° to the right → the identified axis

with the required prefix is displayed, the field is no longer highlighted

and identification of this axis is complete

Now do the same for nick: on the transmitter, briefly set the nick

command so that it is fully forward.

Roll the helicopter more than 45° forwards; the axis is displayed, the

field is no longer highlighted and identification of this axis is complete

Finally complete the procedure for the tail: on the transmitter, briefly

set the tail command fully to the right

S1035_Falcon_12_jh_V1

Turn the helicopter so that the nose turns more than 45° to the right;

the axis is displayed, the field is no longer highlighted and identification of this axis is complete.

The assignment of the axis assignment automatically adjusts the pirouette optimization. If the tail servo direction is subsequently

changed, the axis assignment must be performed again.

The gyros and operating directions have now been assigned. Now

check to make sure that the operating directions are correct. See the

illustrations below.

25 / 36

Page 26

Checking nick

Tilt the helicopter so that its nose is facing downwards; the swashplate moves consequently backwards.

Incorrect! Right!

Checking roll

Tilt the helicopter to the right; the swashplate moves consequently

to the left.

Checking the tail direction of operation

This effect depends by the helicopter, the left-hand or the right-hand

rotator, as well as the side and the direction of rotation of the tail

rotor. Refer to the heli's instructions for this information.

If one of the directions of operation is wrong, you must repeat the

axis assignment process. As a result of the control, the servos no longer return to their zero position or move slower. This is not a mistake

and it will not be noticeable in the air, since then the regulation can

work freely.

Note

However, we strongly recommend flying your model first using the

settings without Expertmode. If the directions are changed on the

transmitter due to any modifications being made to the helicopter

(e.g. new servos) or if the receiver is installed in a different position,

the axis assignment procedure must be fully repeated.

Swashplate setting without Expertmode

SWASHPLATE ADJUST<v>

Swp sense (5)C9

Swp rate +100%

Expo Swp +1

Direct stick R +100

Direct stick N +100

SWP sensitivity

1-100, min or C5…C16

Default setting: 70

The "SWP sensitivity" row allows you to specify a sensitivity setting

either using the values 1 to 100 or by assigning a channel (C5 to C16)

with a proportional control, which is used to control the value.

Different settings can then be used through the HoTT transmitters

to adjust the sensitivity based on specific flight phases, eg through

the control settings or the "Gyro" in the hely mix menu.

If the values are too high:

The heli oscillates around the rotor shaft. In this case, the sensitivity

should then be reduced somewhat until vibration-free flies are possible in all flight situations.

If the values are too low:

Helicopter no longer hovers in a stable manner, susceptible to wind.

26 / 36

S1035_Falcon_12_jh_V1

Page 27

Swp rate

Servo travel

Control travel

Expo = –100%

50 -120, default setting 85

Sets the max. potential rate of rotation in Rate mode for roll and nick.

Expo Swp

0 -50, default setting 15

You can set here an exponential curve (0 - 50%) for the rate of roll

and nick. Low percentages result in a linear increase in the rate of

rotation. High percentages a strong curve, the heli then no longer

reacts so sensitive to the center of the stick. We recommend to use

the Expo in the GR18 or in the transmitter. When using the expo in

the transmitter, the value here must be set to 0, otherwise the two

Expo settings overlap.

Expo = +100%

Servo travel

Control travel

Direct stick R (Roll), Direct stick N (Nick)

20 -150, default setting +115

The direct stick setting allows you to set the direct response of the

helicopter to the pilot's commands. If the nick command stops

abruptly, the helicopter will oscillate if the value is set too high.

Swashplate setting with Expertmode

SWASHPLATE ADJUST<v>

>SWP sensitivity(5)K9

Swp rate +85

EXPO Swp +15

Direct stick R +125

Direct stick N +125

P swp +100

(See above for swashplate sensitivity menu item)

(See above for Rate and Expo menu item)

(See above for direct stick menu item)

P swp (proportional) swashplate

Swashplate P-factor

Expo = +50%

Servo travel

Control travel

I Swp +70

D Swp +25

Speedflight +20

Stop optimizer +6

Anti-ballooning +0

S1035_Falcon_12_jh_V1

40 - 125, default setting: +90

The P swashplate option is responsible for effecting a harder stop

with the swashplate. Higher values result in a faster stop. If the P values are too high, the helicopter and/or the swashplate will start to

"oscillate". In such cases, the value must be reduced again.

I swp (integral) swashplate

Swashplate I-factor

30 - 125, default setting: +85

27 / 36

Page 28

The I-factor ensures constant rolling/nicking. Start with low values

and only increase them until the roll and nick rates are constant.

D swp (differential)

D-factor for swashplate

0 - 70, default setting: +40

The D swp D-factor influences the how the swashplate is stopped.

If the helicopter bounces somewhat when nick is stopped, this

parameter should first be increased in small increments to test the

nick stop. If the optimization was unsuccessful, return to the factory

defaults and continue with the Stop Optimizer setting.

Swp dynamic

10 -100, default setting: 90

Higher dynamic values provide a more direct control feeling, lower

values result in a smoother control feel. If the values are too high,

the swashplate does not stop and it can overflow. If the values are

too low, the control behavior becomes softer.

Speedflight optimisation

10 - 40, default setting: +15

When the helicopter is flying quickly in a straight line, it should fly

precisely in one line/at one altitude and not in a wave form. If the

helicopter flies in a wave form, the value can be increased until the

helicopter flies straight. This parameter should generally not be

changed.

Stop optimizer

0 - 10, default setting: 0

The value 0 means that the default stop optimizer is activated. The

values 1-10 are provided for the individual adjustment of the

extended stop optimizer. If the value is too low, the helicopter jerks

up during the fast pitch stop. If the value is too high, the system can

oscillate or the stop can be executed in two stages.

Anti-ballooning

0 - 50, default setting: 0

During an extreme fast flight, the heli can suddenly rebound without

control inputs. This is due to physical factors and depends on the

rotational speed of the main rotor and the pitch angle of the rotor

blades (pitch).

28 / 36

Pilots who want to fly safely in this border area can also activate this

parameter.

The default value is "0", the compensation is switched off by default.

The "Anti-ballooning" parameter can be adapted to each heli individually.

S1035_Falcon_12_jh_V1

Page 29

If you want to use the Anti-ballooning compensation, start with the

Servo travel

Control travel

Expo = –100%

value "30". A reduction of the parameter eg to the value "25"

increases the "rearing" tendency. An increase to, for example, "35"

reduces the tendency but can also adversely affect the final speed.

You need to find an optimal compromise between safe flight behavior without rearing and maximum speed. For this, first start in 5 steps

and then make the fine tuning in 1 steps.

Tail rotor setting without Expertmode

TAIL ADJUST<v>

>Tail sensitiv. 65

Tail rate +85

EXPO tail +40

Tail sensitivity

1-100, min or C5…C16

Default setting: 65

The "Tail sensitiv." row allows you to specify a sensitivity setting

either using the values 1 to 100 or by assigning a channel (C5 to C16)

with a proportional control, which is used to control the value.

The max. tail sensitivity is first determined at the highest speed and

it should be flown individually for each speed. It can be increased

until the tail begins to swing up. Afterwards, the tail sensitivity has

to be reduced a little, until in all flight positions no swinging of the

tail is recognizable anymore.

Different settings can then be used through the HoTT transmitters

to adjust the sensitivity based on specific flight phases, eg through

the control settings or the "Gyro" in the hely mix menu.

Tail rate

50 -120, default setting: 85

Sets the max. potential rate of rotation in Rate mode for the tail.

Expo = +100%

Servo travel

Control travel

S1035_Falcon_12_jh_V1

Servo travel

Expo = +50%

Control travel

Tail Expo

0 -50, default setting: 40

You can set here an exponential curve (0 - 50%) for the rate of the

tail. Low percentages result in a linear increase in the rate of rotation. High percentages produce a strong curve, the heli then no longer reacts so sensitive to the center of the stick. The Expo setting can

also be adjusted in a phase-related manner at the transmitter. But

avoid a overlapping of GR18 Expo and transmitter Expo.

29 / 36

Page 30

Tail rotor setting with Expertmode

(See above for tail sensitivity menu item)

P tail

Tail rotor adj.<v>

>Tail sensitiv.(5)C9

Tail rate +85

EXPO tail +40

P tail +80

I tail +70

D tail +15

Pitch->Heck +25

Swp-> Tail +4

Swp dynamic +65

Anti ballooning. No

Stop damp. R +5

Stop damp. L +5

Tail P-factor

40-125, default setting: +80

The P tail option is responsible for effecting a harder stop with the

tail. Higher values result in a faster stop. If the P values are too high,

the tail will start to "oscillate". In such cases, the value must be

reduced again.

I tail

Tail I-factor

20-100, default setting: +70

The I-factor ensures constant pirouetting. Start with low values and

only increase them until the pirouettes are constant. If the values are

too high, this will cause the tail to oscillate slowly.

D tail

Tail D-factor

0 - 50, default setting: +15

The tail D-factor influences how the tail is stopped. If the tail bounces

somewhat when the tail is stopped, this parameter should first be

increased in 5-degree increments to test the tail stop.

Pitch->tail Swp->tail

Pitch->tail Swp->tail

0- 80, default setting: +25 0-40, default setting: +4

Static torque compensation for pitch and cyclic.

These two functions work best when they are set together.

Pitch>tail: In the event of fast pitch pumping and swashplate movements, the tail should remain stable even when load is applied. If the

tail swings out briefly, the "Collect. torque" setting can be increased

until the tail stops.

On the ground, you can easily check whether the tail is working

against the torque.

Swp->tail is useful with slow-speed tail rotor with less tail power and

is then set to 1/3 of the value of pitch-> tail. With high speeds and

good rear power the value can be set to 0.

30 / 36

S1035_Falcon_12_jh_V1

Page 31

Tail dynamic

10 -100, default setting: 65

Higher dynamic values provide a more direct control feeling, lower

values result in a smoother control feel. If the values are too high,

the tail does not stop and it can overflow. If the values are too low,

the control behavior becomes softer.

Vibration damping

YES-NO, default setting: NO

The vibration damping automatically detects emerging vibrations at

the tail rotor, e.g. at extreme speed flights (wind flag effect) or strong

speed changes in some 3D maneuvers (over-speed) and prevents an

extremely strong swing-up. The tail rotor should be set free of vibrations without active vibration damping in 3D and normal flight situations, only with a solid basic setting it makes sense to activate the

vibration damping.

Stop damping R / Stop damping L

0 -20, default setting: 5

The rear stop parameter on the right and left optimizes the stop

behavior after a yaw movement. The tail should stop as quickly as

possible without moving back. Select the value so low that the tail

does not move back at when stopping. The higher the value, the

more the stop is dampened. Determine the value in steps of 1.

S1035_Falcon_12_jh_V1

31 / 36

Page 32

Firmware update

Updates to the receiver’s firmware are made via the output channel

5 / telemetry socket using a PC running Windows. You will also need

a USB interface, order No. 7168.6, and adapter lead, order No.

7168.6A or 7168.S, which are available separately.

The programs and files required can be found in the Download area

for the corresponding products at:

www.graupner.de

Connect the adapter lead to the USB interface No. 7168.6. The connectors are reverse polarity protected: note the small chamfers on

the sides. Never use force – the connectors should engage easily.

Connect the adapter lead to the receiver's telemetry socket. The

connectors are reverse polarity protected: note the small chamfers

on the sides. Never use force – the connectors should engage easily.

Starting the "Slowflyer/Gyro receiver update"

We recommend accessing the "Slowflyer/Gyro receiver update" program from the "Firmware_Up-grade_grStudio" program. Click on

the "Receiver Downloader" item under "Link" in the left function

menu. (Alternatively, select the "Micro Receiver Upgrade" under

"Menu").

It is also possible to start the associated application program directly.

By double-clicking on the file “micro_gyro_swloader.

exe”. You will find this .exe file in the "Graupner_ PC Software" folder

of the "HoTT_Software VX" package.

A program window will now appear in which you should first set the

"correct" COM port for the USB interface No. 7168.6 in the selection

window. (See following picture)

If you are not sure which port to use, check the COM port in the

"Select Port" window in the "Menu" of the "Firmware_Up-grade_

grStudio" and note down the COM port number for the "Silicon Labs

CP210x USB to UART Bridge" entry – in this case "COM03". (If you

select the wrong port, you will be alerted to this when you read out

the receiver data). Click on "File" to load the corresponding firmware

file named e.g. "GR12_33577_V_XX.bin" from the hard disc ("XX"

stands for the version number).

32 / 36

S1035_Falcon_12_jh_V1

Page 33

When the file has loaded, click on start...

... connect the receiver and switch it on.

The progress bar shows that the transfer is running normally. The

receiver LED lights up red during this process and flashes once the

transfer is completed.

Declaration of conformity

Please refer to the detailed update instructions for the item in question in the Download area at www.graupner.de.

S1035 - Falcon 12 HoTT 2.4 GHz 3 axis gyro receiver

Graupner/SJ declares that the product is conform to EU norms.

EN 301 489-1 V1.9.2 EN 301 489-17 V2.2.1

EN 300 328 V2.1.1

EN 60950-1+A11+A1+A12+A2:2013

EN 62311:2008

S1035_Falcon_12_jh_V1

33 / 36

Page 34

Notes on environmental protection

P

Disposal notes

This symbol on the product, user manual or packaging indicates that

this product must not be disposed of with other household waste at

the end of its life. It must be handed over to the applicable collection

point for the recycling of electrical and electronic equipment.

The materials are recyclable as marked. By recycling, material reusing or other forms of scrap usage you are making an important contribution to environmental protection.

Care and maintenance

Notes on care

The product does not need any maintenance, it works so as it is without any special care. In your own interests protect it from dust, dirt

and moisture.

Clean the product only with a dry cloth (do not use detergent!) lightly

rub.

Warranty

The Graupner/SJ, Henriettenstrassee 96, 73230 Kirchheim/Teck

grants from the date of purchase of this product for a period of 24

months. The warranty applies only to the material or operational

defects already existing when you purchased the item. Damage due

to wear, overloading, incorrect accessories or improper handling are

excluded from the guarantee. The legal rights and claims are not

affected by this guarantee. Please check exactly defects before a

claim or send the product, because we have to ask you to pay shipping costs if the item is free from defects.

The present construction or user manual is for informational purposes only and may be changed without prior notice. The current

version can be found on the Internet at www.graupner.de on the

relevant product page. In addition, the company Graupner/SJ has

no responsibility or liability for any errors or inaccuracies that may

appear in construction or operation manuals.

No liability can be accepted for printing errors.

34 / 36

S1035_Falcon_12_jh_V1

Page 35

FCC Statement

1. This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference.

(2) This device must accept any interference received, including

interference that may cause undesired operation.

2. Changes or modifications not expressly approved by the party responsible for

compliance could void the users’ authority to operate the equipment.

3. To comply with FCC RF exposure compliance requirements, a separation distance of at least 20 cm must be maintained between the antenna of

this device and all persons.

4. This Transmitter must not be co-located or operating in conjunction with any other antenna or transmitter

FCC Caution

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

IC Statement

Under Industry Canada regulations, this radio transmitter may only operate using an antenna of a type and maximum (or lesser) gain approved for the

transmitter by Industry Canada.

To reduce potential radio interference to other users, the antenna type and its gain should be so chosen that the equivalent isotropically radiated power

(e.i.r.p.) is not more than that necessary for successful communication.

Conformément à la réglementation d'Industrie Canada, le présent émetteur radio peut fonctionner avec une antenne d'un type et d'un gain maximal (ou

inférieur) approuvé pour

l'émetteur par Industrie Canada. Dans le but de réduire les risques de brouillage radioélectrique à l'intention des autres utilisateurs, il faut choisir le type

d'antenne et son gain de sorte que la puissance isotrope rayonnée équivalente (p.i.r.e.) ne dépasse pas l'intensité nécessaire à l'établissement d'une

communication satisfaisante.

This radio transmitter (identify the device by certification number, or model number if Category II) has been approved by Industry Canada to operate with

the antenna types listed below with the maximum permissible gain and required antenna impedance for each antenna type indicated. Antenna types not

included in this list, having a gain greater than the maximum gain indicated for that type, are strictly prohibited for use with this device.

Le présent émetteur radio (identifier le dispositif par son numéro de certification ou son

numéro de modèle s'il fait partie du matériel de catégorie I) a été approuvé par Industrie

Canada pour fonctionner avec les types d'antenne énumérés ci-dessous et ayant un gain admissible maximal et l'impédance requise pour chaque type

d'antenne. Les types d'antenne non inclus dans cette liste, ou dont le gain est supérieur au gain maximal indiqué, sont strictement interdits pour

l'exploitation de l'émetteur.

IC Caution

The minimum separation generally be used is at least 20 cm, even if the calculations indicate that the MPE distance would be lesser.

This device complies with Industry Canada licence-exempt RSS standard(s).

Operation is subject to the following two conditions:

(1) This device may not cause interference and (2) this device must accept any interference,including interference that may cause undesired operation of

the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de licence.L'exploitation est autorisée aux deux

conditions suivantes :

(1) l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est

susceptible d'en compromettre le fonctionnement.

S1035_Falcon_12_jh_V1

35 / 36

Page 36

Loading...

Loading...