Page 1

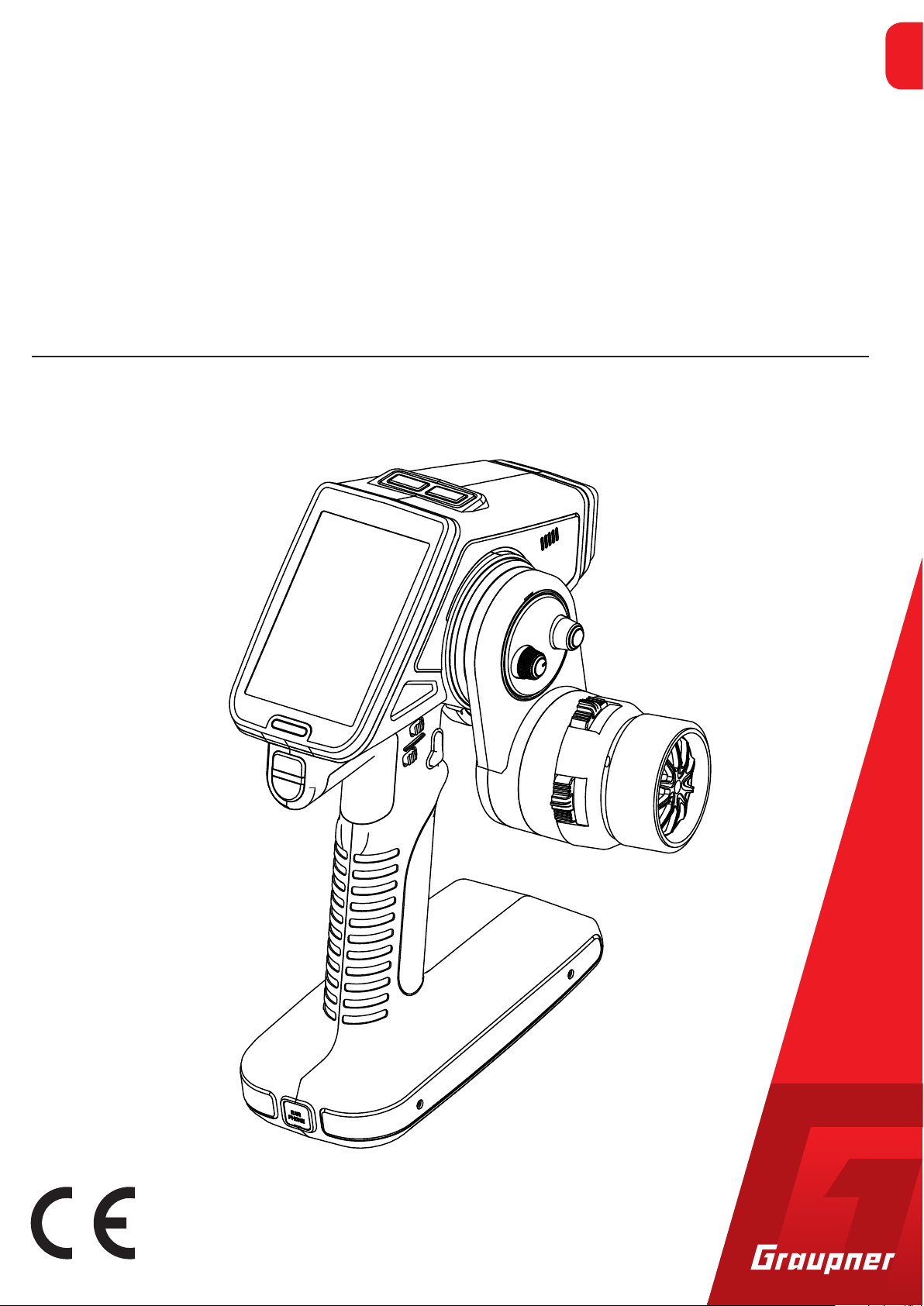

Manual

X-8E

4 channel HoTT 2.4 GHz transmitter

No. S1008

USA

Copyright © Graupner/SJ GmbH

Page 2

2 / 48

S1008_X-8E_jh_V1

Page 3

Index

Introduction ..........................................................................5

Service Center .....................................................................5

Intended Use ........................................................................6

Package Content .................................................................6

Technical Data .....................................................................7

Declaration of Conformity ..................................................7

Symbols Explication ............................................................8

Safety Notes .........................................................................8

For your safety by handling the battery ................................9

Control Elements and Connections .................................11

Buttons and Switches Layout ..........................................11

Commissioning ..................................................................12

Battery connection ............................................................12

Battery charging ................................................................12

Transmitter power switch ..................................................12

Tension Spring Adjustment ..............................................13

Adjusting Steering Wheel Position ..................................13

Converting the Steering Wheel for Left-Handers ...........14

Installing the Steering Wheel Adapter .............................15

RF SET ................................................................................16

Binding .............................................................................16

Channel features (CH FUNCTION) .....................................17

Range test ........................................................................18

Start Display .......................................................................19

Main Menu ..........................................................................21

H/W SET .............................................................................21

TELE. (Telemetry Menu) ....................................................22

Setting & Data View ..........................................................22

RF Status View..................................................................22

Voice Trigger .....................................................................23

S1008_X-8E_jh_V1

Device Management .........................................................23

Secret Mode .......................................................................24

Announcements (Voice Update) ........................................24

Language change .............................................................24

Steering wheel and throttle lever calibration .......................25

Interface (BT SPEED) ........................................................25

3 / 48

Page 4

Display Warnings ...............................................................26

Voltage Display Calibration ..............................................26

Change the Values in an Input Field ................................27

M-SEL (Model Selection) ..................................................27

REVERSE (Servo Reverse) ................................................27

TRIM ...................................................................................27

TRA ADJ (E.P.A.) ................................................................28

DR/EXP (Dual Rate/Exponential) .....................................28

B.R.A. ..................................................................................29

B-MIX ..................................................................................30

TH RESP (Throttle Response) ..........................................30

IDLEUP (Pumping) .............................................................30

PROFILE .............................................................................31

S/SPEED .............................................................................32

START .................................................................................32

TIMER .................................................................................33

SW SET ...............................................................................34

FAIL SAFE ...........................................................................36

SERVO (S View) ..................................................................36

P/MIX ..................................................................................37

AUX .....................................................................................38

S/MODE ..............................................................................38

A.B.S ...................................................................................40

Operating Receiver GR-8 ..................................................41

GR-8 Receiver Telemetry Menu .......................................42

Firmware Update - Transmitter ........................................ 43

Firmware Update - Receiver ............................................44

Battery Disposal ................................................................45

Care and Maintenance ......................................................45

Warranty .............................................................................45

4 / 48

S1008_X-8E_jh_V1

Page 5

Introduction

Thank you for purchasing the Graupner X-8E HoTT radio. This

radio will transform the way you have been experiencing surface

radios and add a new level of user experience between you and

your model. The X-8E is easy to use and setup using the TFT

color and touch screen. The voice notifications will even further

enhance your user experience.

You can get more out of your X-8E using our wide selection of

telemetry speed controllers and telemetry ESC’s. All HoTT compatible products can be setup and programmed directly wireless from the X-8E. No need for computers or programming

boxes!

Check us out regularly on the web for new changes and revisions of our manuals and firmware at www.graupnerusa.com.

This product complies with national and European legal requirements.

To maintain product condition and to ensure safe operation, you must

read and follow this user manual and the safety notes before use!

Note

This operating manual is part of the product. It contains important

information concerning operation and handling. Keep these instructions for future reference. Please pass this on to future owners or

third parties.

Service Center

Graupner USA – OPENHOBBY LLC

3941 Park Dr., Suite 20-571

El Dorado Hills, CA 95762

United States

Phone: (855) 572-4746 x2

Hours: Mon – Fri 9:00am – 4:00pm PST

Email: service@graupnerusa.com

Online Support: www.graupnerusa.com

Graupner Online For service centers, downloads, upgrades and product list, visit

our web site at www.graupnerusa.com.

S1008_X-8E_jh_V1

5 / 48

Page 6

Intended use

The X-8E HoTT transmitter is an ergonomically and technically

modern 8 function radio control system in 2.4GHzHoTT technology for ambitious and professional RC car and speedboat

drivers.

The X-8E HoTT transmitter is designed exclusively to be used in

battery-powered, unmanned radio controlled models; any other

use is not allowed. For any improper use no warranty or liability

is accepted.

Read through this entire manual before you attempt to use the

X-8E HoTT transmitter.

Graupner/SJ constantly works on the development of all products; we reserve the right to change the item, its technology and

equipment.

The product is not a toy. It is not suitable for children under

14 years. The operation of the X-8E HoTT transmitter must be performed by experienced modelers. If you do not have sufficient

knowledge about dealing with radio-controlled models, please

contact an experienced model builder or a model club.

Package content

X-8E transmitter

GR-8 Receiver

LiPo battery 1S 5000 mAh

USB update cable set (No.S8500, 7168.S)

Micro SD card

Steering wheel adapter 10 degree and cover

Manual

6 / 48

S1008_X-8E_jh_V1

Page 7

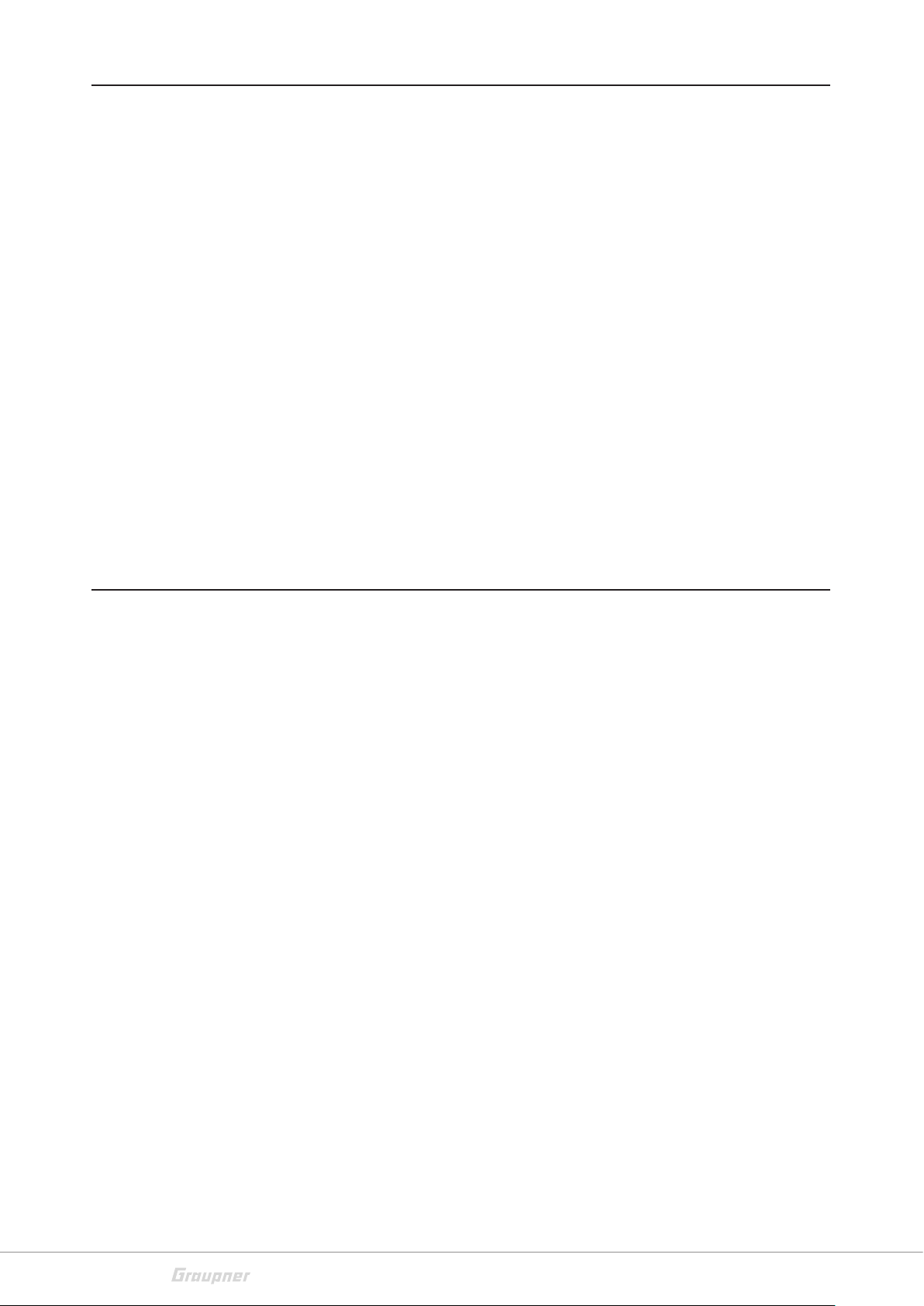

Technical Data

X-8E transmitter data

Operating voltage 3.4 to 6 V

Frequency 2.4 Ghz

Weight 1.44 lb (657 g)

Modulation FHSS

Range 1640 ft (500 m)

Control functions 4

Power consumption max. 600 mA

Temperature range

14° to 130°F (-10 to +55 °C)

Antenna type Patch antenna

Dimensions

8.6 x 7.3 x 5.5 in

GR-8 receiver data

Operating voltage 3.6 to 8.4 V

Frequency 2.4 Ghz

Weight

Modulation FHSS

Range

Control functions 4

Power consumption

Temperature range

Aerial length

Dimensions

0.24 oz (6.9 g)

1640 ft (500 m)

80 mA

14° to 130°F (-10 to +55 °C)

4.3 in (110 mm)

1.18 x 0.82 x 0.56 in

Declaration of conformity

S1008 / X-8E

Graupner/SJ declares that the product is conform to EU norms.

EN 301 489-1 V1.9.2

EN 301 489-17 V2.2.1

EN 300 328 V1.8.1

EN 60950-1:2006 + A11:2009 + A1:2010 + A2:2013

EN 62311:2008

S1008_X-8E_jh_V1

7 / 48

Page 8

Symbols explication

!

!

WARNING indicates the potential for serious injury.

CAUTION indicates possibility of lighter injuries.

Safety notes

Always observe the information indicated by this warning sign.

Particularly those which are additionally marked with the signal

words CAUTION or WARNING.

Note indicates potential malfunctions.

Attention indicates potential damages to objects.

General

These safety instructions are intended to protect this product,

yourself and the safety of others. Please read this section very

carefully before using this product!

To avoid risk of suffocation, keep packaging materials away from

babies and small children.

Supervision by an experienced adult is required for chil-

dren, persons mentally or physically handicapped, novices, or anyone not capable of safely using this product.

Always perform a range and function test on the ground

before you use your model (hold your model tight). Repeat

the test with running motor and with short throttle bursts.

Check all relevant laws and regulations before using this

remote control model. These laws and regulations must

be observed in for the safety of yourself and others and

may vary by state, region, or country.

Special liability insurance policies are mandatory for all

device operations. If you already own a device, determine

if the respective model is covered by your insurance.

8 / 48

Page 9

Protect all equipment from dust, dirt, moisture, vibration and

!

excessive heat or cold. The models may only be operated

remotely in normal outside temperatures ranging from 14° to

130°F (-10°C to 55°C).

Maintain frequent updates of your HoTT components with

the latest firmware version.

For additional questions or support, contact the Graupner

USA Service Center, or an experienced user.

Battery Safety

CAUTION

Protect batteries from dust, moisture, heat and vibrations.

For use in dry locations only.

Do not use damaged batteries.

Batteries not handled properly may catch fire, explode, or

cause irritation and burns. To extinguish a battery fire use

either water, CO² or sand.

Batteries should not be heated, burned, short-circuited,

incorrectly inserted, modified, soldered or welded.

Charge batteries in a room outfitted with a smoke detec-

tor, on a non-flammable, heat-resistant and non-conductive surface. Keep away from combustible or highly flammable objects while charging. Always monitor batteries

during the charging process.

Do not exceed the maximum quick-charging current

specified for the respective cell type.

If a battery reaches temperatures above 140°F (60°C)

while it is being charged, immediately stop charging and

let the battery cool down to approximately 86 - 104°F (30

- 40°C).

S1008_X-8E_jh_V1

Never charge batteries that have already been charged,

are hot or are not fully discharged. If a cell in a battery pack

heats up following a quick-charge process, this may indicate a defective cell. Discard the battery immediately!

9 / 48

Page 10

Damaged or corroded batteries may leak an electrolyte

that is caustic and should not be touched or come into

contact with your skin or eyes. In case of emergency,

rinse thoroughly with water and seek immediate

medical attention.

Always fully recharge the battery.

Special instructions on charging LiPo batteries

To charge and discharge LiPo batteries, only use specifi-

cally designed chargers/dischargers with balancer connector.

The white connector (cell count + 1 pole) is designed for

the connection to a LiPo balancer or a battery charger as

a single cell charger with a manual cell balancer. Always

charge the battery with the balancer connector.

Safety notes for stocking LiPo batteries

LiPo batteries should be stored with a voltage of about

3.8V per cell. If the cell voltage falls below 3V, then the battery must be charged. Fully discharging or storing a battery with a cell voltage < 3V renders the battery useless.

Exersize safety procautions when charging and transport-

ing your LiPo batteries. Always use a safety bag.

10 / 48

S1008_X-8E_jh_V1

Page 11

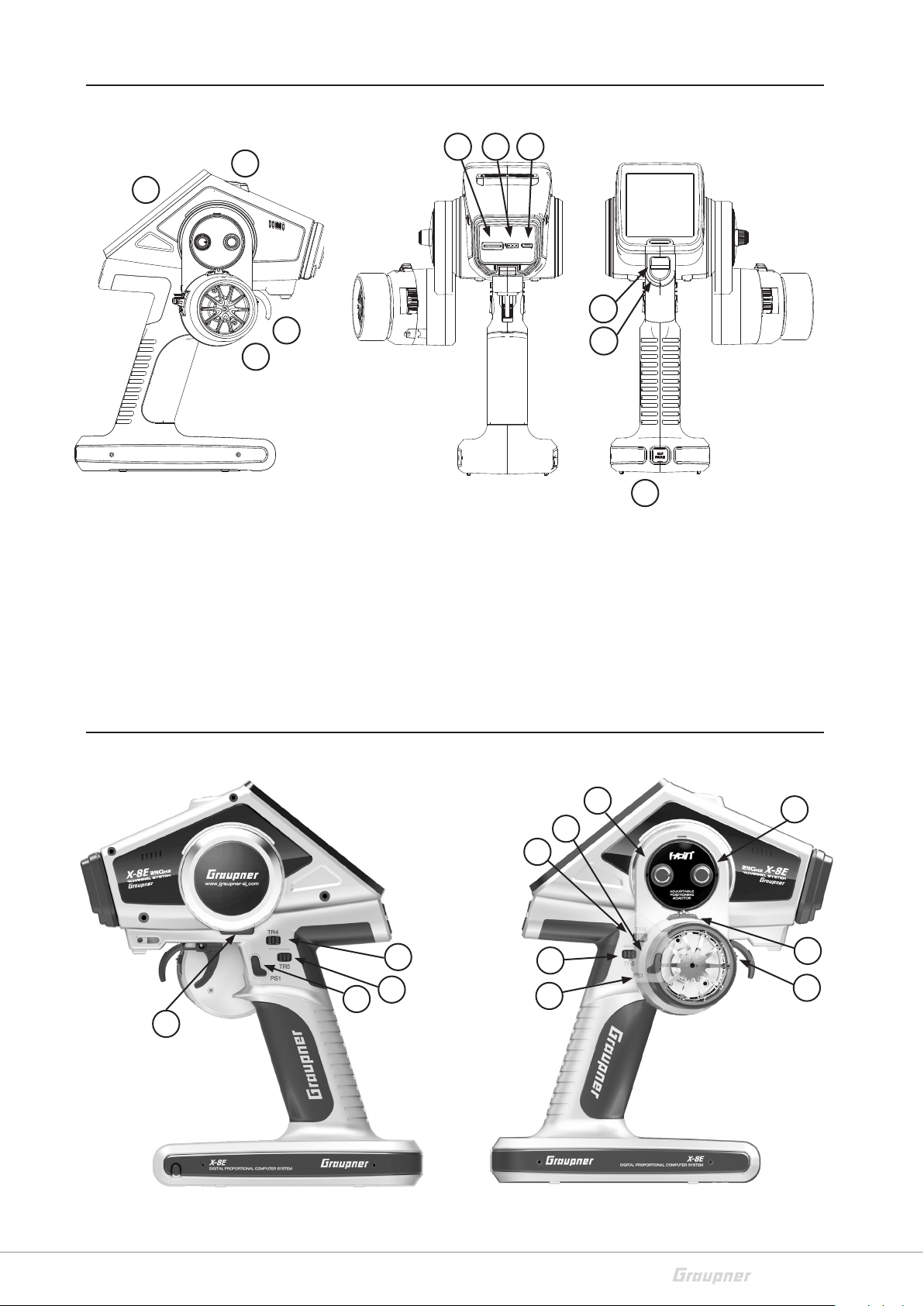

Control Elements and connections

8

1

3

2

5 6 7

9

10

4

1. Touch Display

2. Steering wheel

3. Throttle lever

4. Earphone socket

5. SD card slot

6. Data socket

Buttons and Switches Layout

3

7. Mini USB socket

8. On/off switches

9. Direct button S1 (see chapter SW SET)

10. Direct button S2 (see chapter SW SET)

1. PS 1

2. PS 2

4

2

6

3. PS 3

8

4. DV

5. TR 1

6. TR 2

8

7. TR 3

9

1

8. TR 4

9

1

5

7

9. TR 5

S1008_X-8E_jh_V1

11 / 48

Page 12

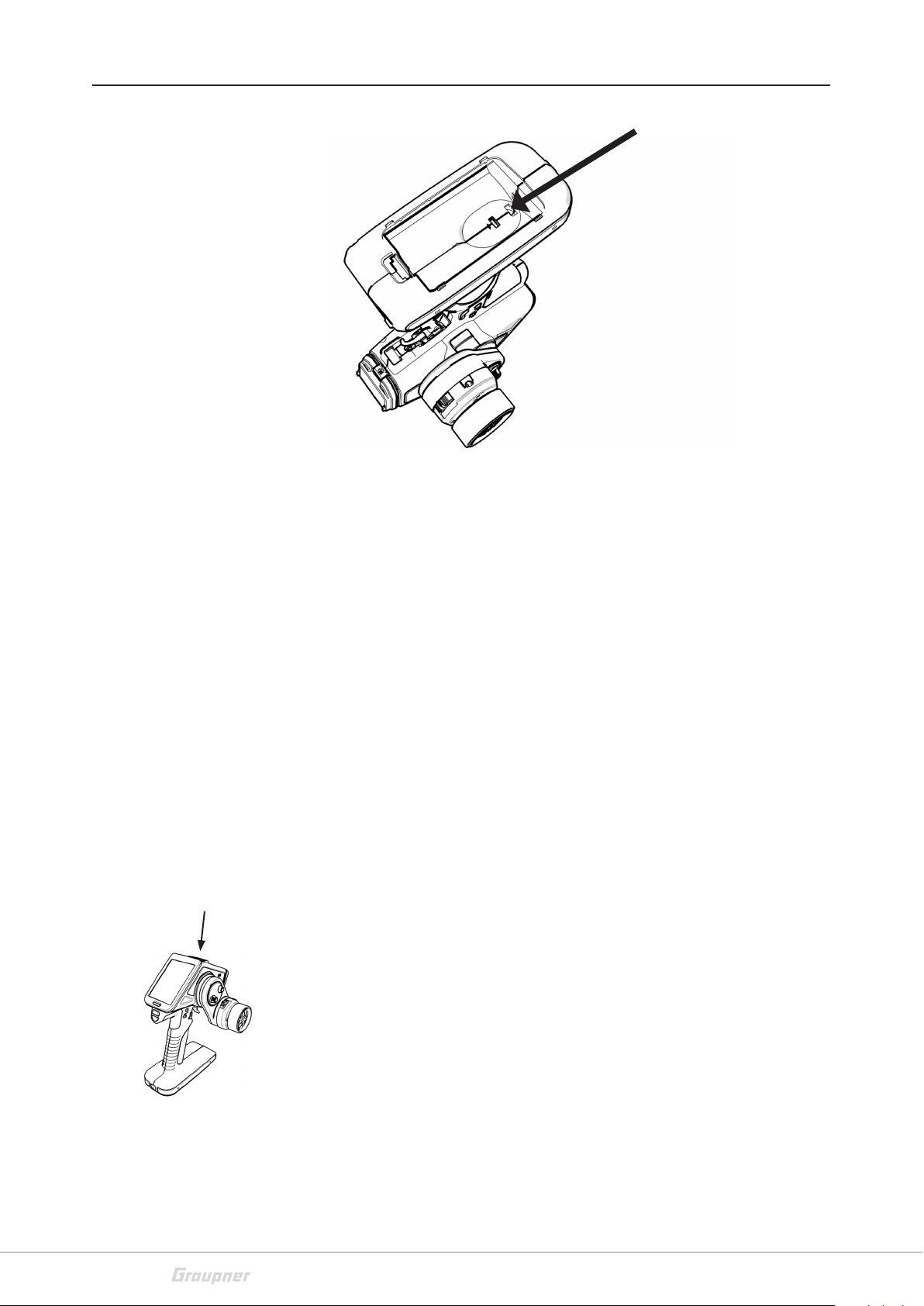

Commissioning

Battery socket

Battery connection

Remove the cover from the bottom of the transmitter and connect the battery, paying attention to the correct polarity. Shut

the cover and ensure it is securely closed.

On - Off

Switch

Set the the battery warning threshold in accordance with the

battery used. (see Chapter “SYS SET”)

If a voltage warning is triggered, charge the batteries.

Battery charging

Charge the LiPo batteries in the transmitter through the micro

USB socket using the USB cable provided. For all other battery

types, use an USB connection, e.g. a PC USB port or an USB

net adapter. During the charging process the LED under the display lights up red. When the battery is full the LED turns off.

Alternatively, you can charge the battery outside the transmitter

with an RC battery charger (not included).

Transmitter power switch

On the top of the transmitter there are two buttons. To turn on

the transmitter with RF off, push the right button for about 2 seconds. When the RF mode is off, a safety feature is activated that

prevents switched-on models from accidentally starting during

programming. Additionally, power consumption is reduced,

significantly conserving battery life.

12 / 48

To turn on the transmitter with RF on, push the left button.

S1008_X-8E_jh_V1

Page 13

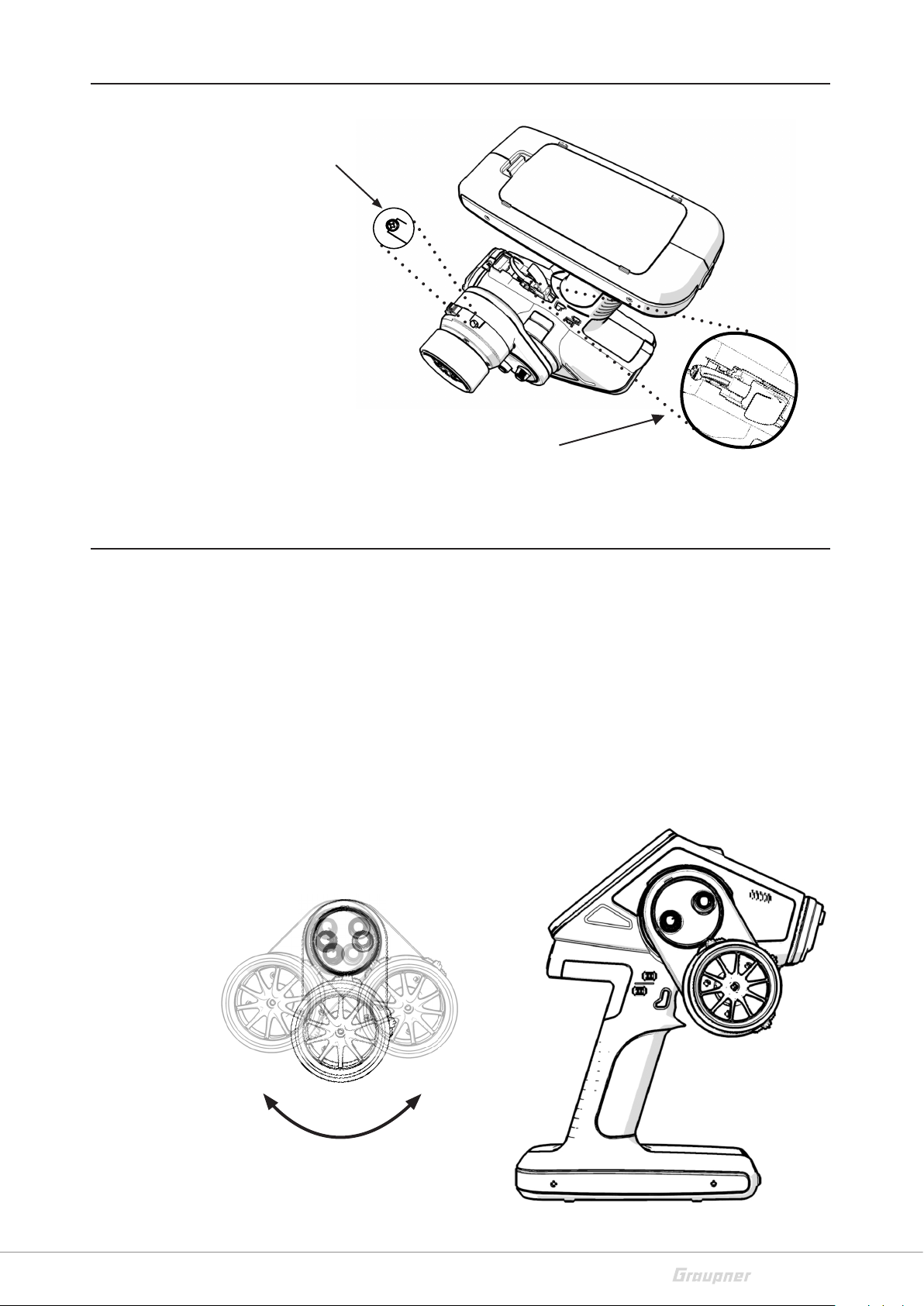

Tension spring adjustment

To adjust the steering wheel

tension spring, locate the

adjusting screw in the housing

below the wheel.

Using a hex key, turn the

screw left or right to increase

or decrease tension force.

To adjust the throttle lever tension spring, locate the adjusting

screw in the housing at the throttle lever.

Using a hex key, turn the screw left or right to increase or

decrease tension force.

Adjusting the steering wheel position

To adjust the steering wheel position forward or backward,

remove the X-8E logo cover, located above the steering wheel.

Loosen the two screws and maneuver the steering wheel into

desired position. Retighten the two screws to secure.

S1008_X-8E_jh_V1

13 / 48

Page 14

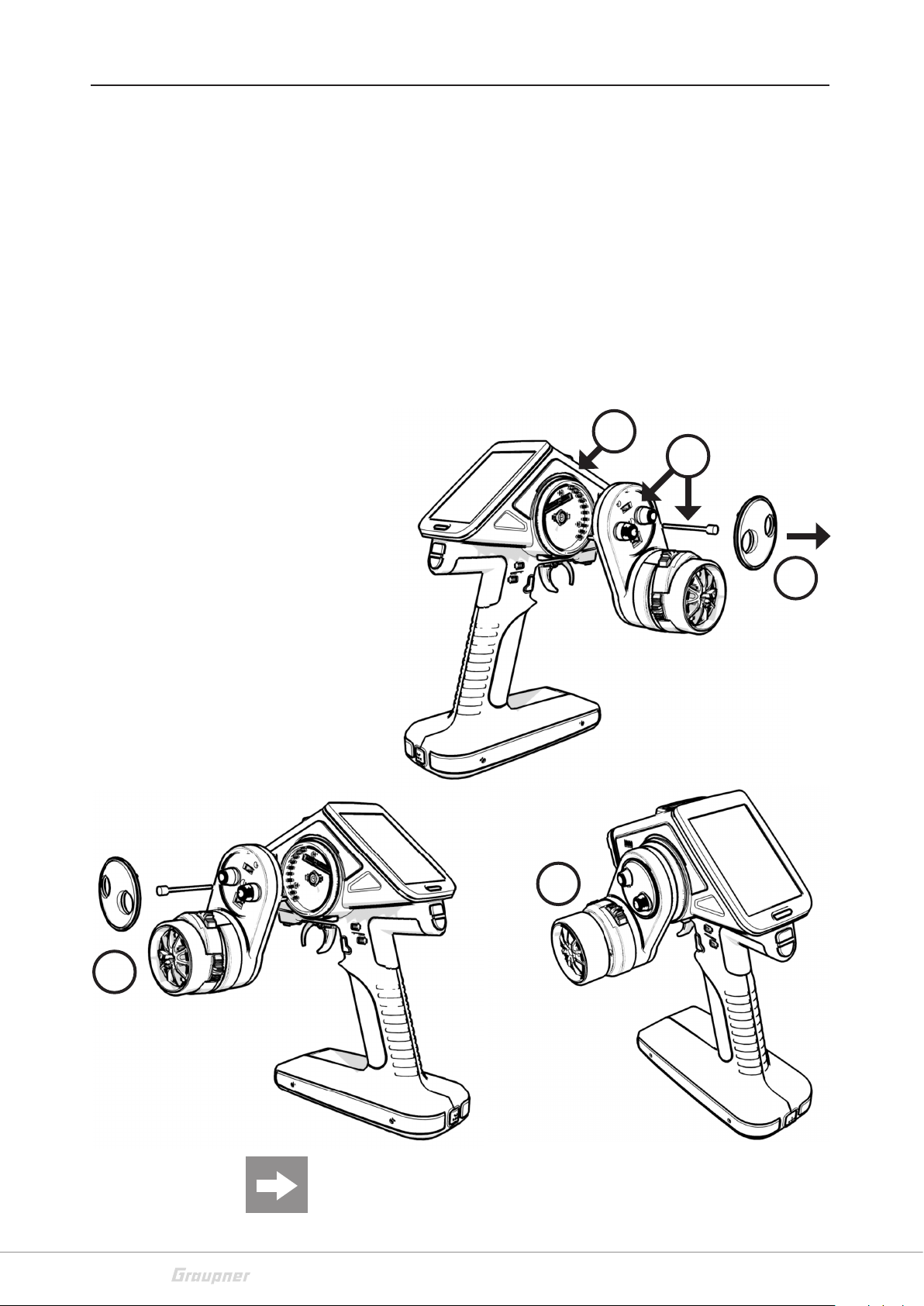

Converting the steering wheel for left-handers

The entire steering wheel can be converted to the left side for

operation by left-handers.

1. Remove the X-8E logo cover (see following figure).

2. Unscrew the steering wheel (2 screws).

3. Unplug the steering wheel cable.

4. Mount the steering wheel on the left side and re-plug the

cable.

5. Tighten the steering wheel and replace the X-8E logo

cover.

3.

2.

4.

1.

5.

14 / 48

Attention After the conversion, check all steering wheel func-

tions, buttons and rotary controls before operating the model

again!

S1008_X-8E_jh_V1

Page 15

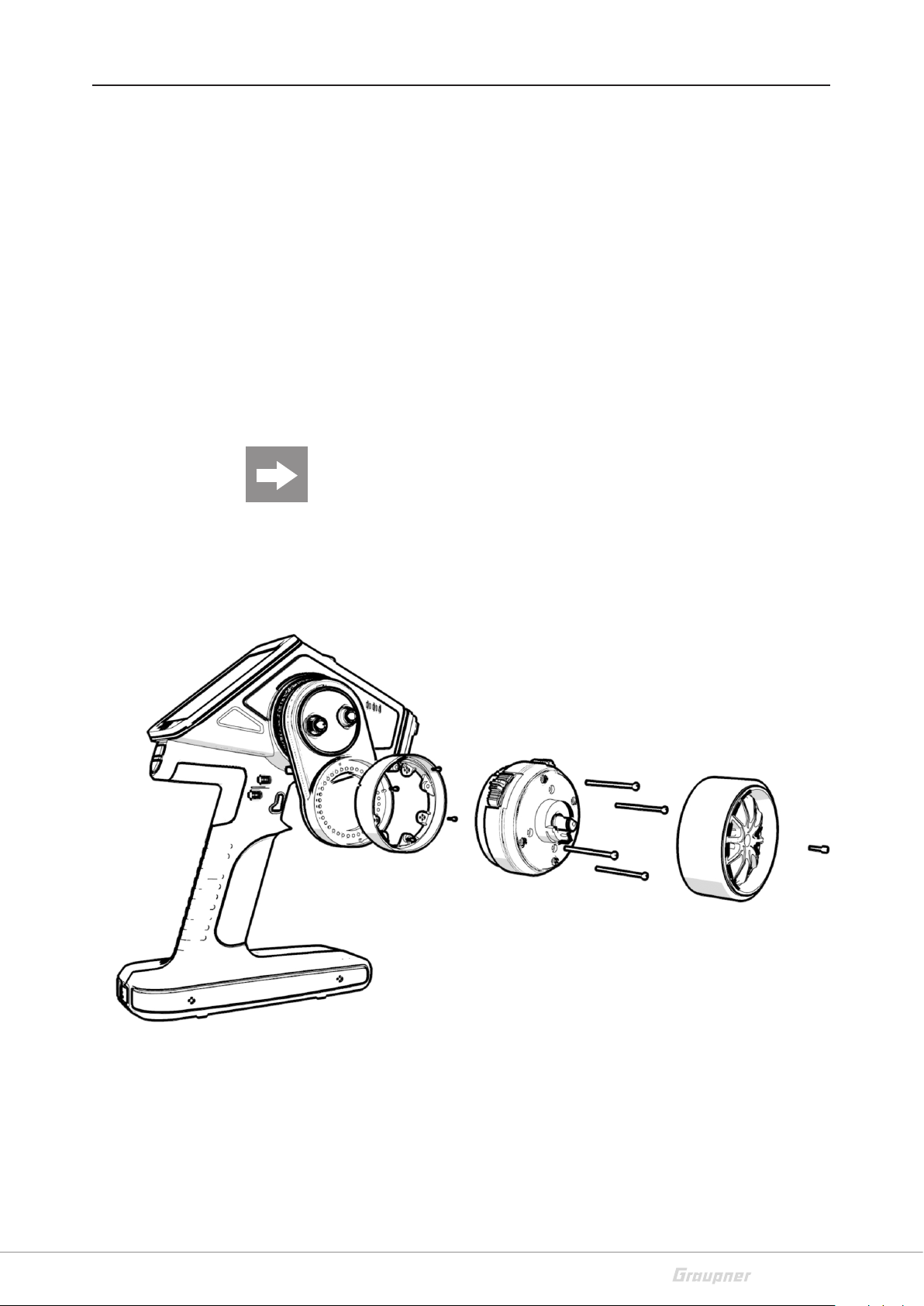

Installing the steering wheel adapter

The steering wheel position can be adjusted 10 degrees through

an adapter.

1. Remove the steering wheel.

2. Remove the four long screws under the wheel.

3. Remove the steering wheel mechanism and disconnect

the connector.

4. Adjust the adapter to preferred position and secure with

the four short screws.

5. Reconnect the connector

6. Install the steering wheel mechanism on the adapter part

and reattatch the steering wheel.

Attention After the conversion, check all steering wheel func-

tions, buttons and rotary controls before operating the model

again!

S1008_X-8E_jh_V1

15 / 48

Page 16

RF SET

Binding and range test

Binding

To establish a communication link, bind the Graupner-HoTT

receiver to the X-8E Graupner-HoTT transmitter. The binding

process has already been performed for the transmitter and the

receiver included. However, binding is required for each additional receiver added to this transmitter. To bind additional

receivers:

NOTE: The transmitter can be turned ON or OFF with one of

two buttons. When using the white button, the transmitter RF

functions are completely disabled and it will not be possible

to turn on the RF or bind a receiver.

1. Turn on the transmitter using the RED button. If no

receiver is bound to the model, select SET. Selecting SET

will bring up the bind finction of the RF SET menu.

2. Select the correct RF system. (HoTT V2 for the GR-8 or

HoTT for the GR-4.) GR-8: The red LED flashes slowly

when there is no communications link. GR-4: The red

LED glows solid red when there is no communications

link.

3. Press and hold the SET button on the receiver for about

3 seconds.

4. Press the BIND button on the transmitter.

5. The OFF will change to CHK momentarily.

6. If the bind is successful, the number of receiver channels

will be displayed. If not successful, the button will return

to OFF status.

Repeat the bind process until successful. It is all a matter of timing. (Counting "one thousand one, one thousand two, one

thousand three" will help with the timing.)

Receiver

Binding button

Transmitter display

NORMAL

BACK

RF SYSTEM

BIND

TELEMETRY

HOTT V2

OFF

ON

16 / 48

S1008_X-8E_jh_V1

Page 17

BACK

NORMAL

Meaning of the individual menu items

RF SYSTEM

BIND

RF ON/OFF

RANGE TEST

CH FUNCTION

NORMAL

BACK

CH

CH 1

CH 2

CH 3

CH 4

FUNCT

NSR12m0

NSR12m0

NSR12m0

NSR12m0

HOTT V2

R04

ON

OFF

99sec

>>

SERVO

RF SYSTEM = HoTT for receiver (GR-4/12/16/18/24/32)

HoTT V2 for receiver with SUMD-V2 (GR-8)

BIND = Displays bound receiver channels

RF ON/OFF = Displays if RF is switched on or off

RANGE TEST = Range test (see chapter “Range test”)

CH FUNCTION ==> (only available in HoTT V2 operation with

compatible receiver)

Channel features (CH FUNCTION)

Only available in HoTT V2 operation with compatible receiver!

Each channel is capable of the following signals:

USR1m50 : ULTRA SIGNAL 1.5msec

FSR3m00 : FAST SIGNAL 3.0msec

SUMD-V2 : FAST SIGNAL BUS 3.0msec

NSR6m00 : NORMAL SIGNAL 6.0msec

NORMAL

BACK

CH FUNCT

Reboot as follows:

1. Power rec eiver off

2. Switch transmitter off

3. Switch transmitter on

4. Power rec eiver on

OK

SERVO

NSR12m0 : NORMAL SIGNAL 12.0msec

NSR24m0 : NORMAL SIGNAL 24.0msec

Use this menu to adjust the servo properties by setting the individual channel properties. (For more information refer to the

servo’s user’s manual.)

Attention

The SUMD-V2 setting can only be used for Graupner servos,

sensors and controllers that support this function!

Notice: To save receiver settings, follow the instructions on the

screen in the following order:

1. Switch receiver off

2. Switch transmitter off

3. Switch transmitter on

4. Switch receiver on

To verify the receiver settings are displayed, check the telemetry

menu.

S1008_X-8E_jh_V1

17 / 48

Page 18

NORMAL

BACK

RF SYSTEM

HOTT V2

Range test

Always perform a range test before each operation. Have an

assistant to help with the range test. Range test instructions are

as follows:

BIND

RF ON/OFF

RANGE TEST

CH FUNCTION

R04

ON

ON

87sec

>>

1. Bind the receiver with the transmitter and insert into the

model. Switch on the transmitter first, then the receiver.

Servo movements can now be monitored.

2. Place the model on a flat surface (cement, mowed lawn

or level ground) with the receiver antennas at least 6 in (15

cm) above the ground. If necessary, place a support

underneath the model during the test. Hold the transmitter at waist-level at a comfortable distance from your

body. Do not point the aerial directly at the model.

Turn or angle the aerial tip so it stands vertical during operation. In the “RF SET” menu, press OFF in the “RANGE

TEST” line. This switches the option ON and begins the

range test. The test will ramian active for 99 seconds,

after which it will automatically switch off. (Quit the range

test at any time by pressing ON in the “RANGE TEST” line

to switch this option OFF.)

3. Walk away from the model and turn the wheel to simulate

all servo movements and normal operations. If at any time

you detect an interruption in the link within a range of

about 164 ft (50 m), attempt to reastablish the link.

4. To check interference resistance, switch on an existing

motor. Move away from the model until it no longer

responds. Manually terminate the range test mode.

5. The model should now respond again. If not, do not use

the system and contact the Graupner Service Center.

6. Ground range for safe operation and handling should be

within 164 ft (50 m).

18 / 48

S1008_X-8E_jh_V1

Page 19

Start display

Symbol explination

TX

RX

NORMAL

RX

3.9V

4.8V

M - 1

MODEL 1

000:00.0

ST

CH3 CH4

ST TRIM

CH3

+100%

100%

ST D/R

PS1

O.TIME 0 : 23 : 02 B.TIME 0 : 11 : 59

TH TRIM0%

BK D/R

CH4

PS2OFF OFF

Voice output (announce)

Blue = Active / Gray = Inactive

Earphones (announce)

Blue = Connected / Gray = Disconnected

Display rotation (function - press)

Normal = 1 / 90° right = 2 / 90° left = 3

TH

0%

100%

0%

1

SD card (indicator)

3.9 V

RX

TX

RX 4.8V

Blue = Inserted / Gray = Not Inserted

Display warnings (function - press)

Warnings display (see chapter “Warnings”)

Transmitter battery display (function - press)

Graphic representation of battery power level and green voltage information

(see chapter “Voltage indicator calibration”). Blinks while battery charging.

Reception strength (display)

Red bars representing receiver (RX) field strength.

RF switched on (display)

Blue = RF On / Gray = RF Off

Transmission strength (display)

Green bars representing transmitter (TX) field strength

Receiver (RX) input voltage.

S1008_X-8E_jh_V1

19 / 48

Page 20

M-1

M - 1

MODEL 1

NORMAL

Tap for model memory selection

Model 1

Tap to input the model name

Profile

Tap to switching between the five profiles.

Main menu

Tap to move to main menu

Telemetry menu

Tap to move to telemetry menu

Bar display (display only)

Steering

Throttle

Backdfgsd

BACK

BACK

TRIM ST

BK D/R

+100%

NORMAL

0%

CH3

0%

PS1

OFF

PS3

OFF

TH ST

Percent display / status display

Shows the position percentage of steering, throttle, dual-rate

and the switch state of PS1 and PS2.

Tap this display screen to access a detail screen for more information. (Display only.)

TRIM TH

0%

D/R ST L

-100%

CH4

0%

PS2

OFF

Model use time (see chapter “Timer”).

000:00.0

20 / 48

Battery use time (see chapter “Timer”).

Laps timer: Tapping opens the “Timer” menu.

S1008_X-8E_jh_V1

Page 21

Main Menu

Push the “F” icon in the main display to access the menu. The

menu system is comprised of 3 pages. Scroll between the

pages by tapping the <+ and -> directional buttons at the bottom of the screen. Tap the blue icons to access the related submenu screen.

H/W SET

H/W Type

Batt type LI-PO

Batt Warning

Startup tone

Voice v olume

Power saving

Secret Mode

BACK

NORMAL

SERVO

SYSTEM

3.4 V

ON

03

OFF

SET

3.9V

MODEL 1BACK

SERVO

MODEL 1BACK

M-SEL RF SET

TRA ADJ DR/EXP

B.R.A.

IDLE UP TIMER

3.9V

REVERSE

TRIM

MODEL 1BACK

PROFILE REVERSE

S/SPEED

P/MIX

A.B.S

B-MIX

3.9V

TH RESP

START

H/W SET

SW SET S/MODE

AUX

TELE.

The H/W SET menu controls system setup and display settings.

To switch between System and Display tap the button to the

right of H/W TYPE.

System settings (H/W TYPE = SYSTEM)

Battery type - This transmitter only works with a LiPo battery.

LiPo - The warning threshold is automatically set to 3.6V.

Battery warning - The battery warning threshold can be manually

adjusted by 0.1V incriments.

S1008_X-8E_jh_V1

Startup tone - Turn ON or OFF the startup melody.

Voice volume - Speaker volume control for voice announce-

ments. OFF = no sound / 05 = highest volume.

Power saving - Turns ON or OFF a power-saving mode that

begins a 1 minute countdown following a period of inactivity.

After the countdown the transmitter will automatically switch off.

Secret Mode - Refer to the Secret Mode chapter for additional

information on these settings.

21 / 48

Page 22

BACK

NORMAL

SERVO

Display settings (H/W TYPE = DISPLAY)

H/W TYPE

Brightness

Back light

Touch sense

LED control

Display mode

Display

15

OFF

1

SET

1

RFID 55555

NORMAL

BACK

LEFT

OFF

FRONT

SERVO

RIGHT

BLUE

RED

Brightness - Adjust brightness level from 1 - 20

Display light - Switching the backlight ON or OFF.

Touch sense - Adjust the touch screen sensitivity.

1 = very sensitive / 5 = reduced sensitivity.

LED control - Opens a separate page in where users can switch

on/off the transmitter's LED lights or change their colors.

Display mode - Change the display orientation.

1 = Normal. 2 = 90° right rotation. 3 = 90° left rotation.

RFID - Displays transmitter's identification number.

TELE. (Telemetry Menu)

NORMAL

BACK

SETTING & DATA VIEW

RF STA TUS VIEW

VOICE TRIGGER

DEVICE MANAGEMENT

NORMAL

BACK

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

QUA

96%

TD

- 56 dB

ERR

9ms

Vc

4.9

Vm

SERVO

>>

>>

>>

>>

SERVO

100%STR

RD

- 36 dB

4.9

Setting & Data View

This menu option allows setup of receiver's telemetry menu.

Refer to the receiver's user's manual for specific telemetry setup

information.

RF Status View

This display displays the frequency band and channel assignments.

22 / 48

S1008_X-8E_jh_V1

Page 23

NORMAL

BACK

REPEAT

FIXED VOICE

TRANSMITTER

PLA Y LIST

CAR ESC

GENERAL

VARIO

BACK

10s

NORMAL

Device List

LIST

New Device

FIND

Live Log Device

>>

SERVO

OFF

OFFTRIGGER

--

RECEIVER

SERVO

AIR ESC

ELECTRIC

GPS

SERVO

Voice Trigger

Only connected sensors and receivers are active.

REPEAT: If the REPEAT function is activated (via SW/FUN

menu, VOICE RPT button), set the repetition frequency of the

voice output here.

TRIGGER: Switch ON or OFF voice output from play list.

FIXED VOICE: Tap to open a drop-down menu of all voice

announcemnts available on the SUMD-V2 system.

Device Management

If the SUMD-V2 system's channels are set in the RF SET menu

at "CH FUNCTION", this menu manages the administration of

all devices connected to the receiver. (display only)

NORMAL

BACK

No

Device CH PORT

RECEIVER

00

01

02

03

04

05

NORMAL

BACK

Device List

FINDING

LIST

NO. 00

OK

New Device

FIND

Live Log Device

>>

-

SERVO

-

SERVO

Device List

This menu shows a list of all connected devices and to which

receiver port they are connected. Devices can be assigned to

channels here.

New Device

Plug in a new device and push FIND. A pop-up menu will appear

showing the device is being located and assigned to a device

list number. Once found, tap OK.

Repeat this process for each new device to be assigned to the

list.

S1008_X-8E_jh_V1

23 / 48

Page 24

BACK

01

02

03

04

05

Secret Mode

Secret Mode

BACK

NORMAL

Device

SERVO

Number

Live Log Device

If the device is equipped with the Bluetooth module S8351, realtime telemetry data can be logged and analyzed and transmitted via features available found in the Firmware Upgrade Studio.

This menu logs, lists and numbers all devices being tracked

through this option.

Refer to the Secret Settings chapter for additional information

on setting up this option.

The "Secret mode" option is the last item on the "H/W SET"

menu.

Voice U pdate

Stick Calibration

Interface

USB PORT

BT Speed

NORMAL

Voice File List

BACK

01

Voice2_German

02

Voice2_English

03

Voice2_France

04

Voice2_Italiano

05

Voice2_Spain

06

Voice2_Dutch

>>

>>

Announcements (Voice Update)

By default, all voice announcements are recorded in German

and are saved in a voice packet that is stored in the transmitter's

internal memory. They can be replaced by a voice packet of a

different language at any time.

On the micro SD card (included) choose from the following language options: German, English, French, Dutch, Italian and

Spanish.

You can also download additional language packets at

www.graupner.de.

Language change

Language change step by step:

1. Insert the included SD memory card in its slot.

2. Use the left switch to turn the transmitter on in RF mode.

3. Select the "Secret mode" menu in the H/W SET menu.

4. Tap the "Voice Update" button.

24 / 48

Load

5. Highlight the language from the list by tapping the appropriate button.

6. Tap the "Load" button. The selected language packet will be

stored in the transmitter memory.

7. The loading process is finished as soon as the progress bar

at the lower edge of the display disappears.

8. When this process is finished, switch the transmitter OFF.

S1008_X-8E_jh_V1

Page 25

Steering wheel and throttle lever calibration

If the center position of steering wheel or if the throttle lever does

not neutralize to 0%control travel, you can check and correct it

as follows.

Stick calibration step by step:

1. Go to the "M-SEL" menu and tap on an open model

memory slot to select.

BACK

L150%

F150%

CH3

CH3

BACK

NORMAL

0%

ST

0%

TH

0%

0%

Stick Calibration

0 %

LEFT

R150%

B150%

0%

0%

2. Move to the "SERVO" menu without changing any trim

settings or other program settings.

3. Center the steering wheel or the throttle lever by moving

the steering wheel and the throttle lever to the middle

position. If the throttle lever and the steering wheel are

correctly centered, the display should match the one

shown at left.

4. One at a time, move the steering wheel and throttle lever

as far as they will go in all directions without exerting force

at their position limits. The values should register between

-100% and +100%.

5. If the throttle lever or the steering wheel does not reach

the desired values, tap the "Stick Calibration" button in

the "Secret Mode" option in the "H/W SET" menu.

6. Follow the prompts on the screen by moving the steering

wheel and the throttle lever in the directions shown and

keep them still. Confirm the position by tapping on the

ENT button. Repeat this procedure for all of the indicated

positions. If you have correctly calibrated all positions, a

confirmation message will be displayed. Tap "OK" to save

the calibrations. Tapthe "BACK" button to quit the process and return to the submenu "Stick Calibration".

S1008_X-8E_jh_V1

ENT

Interface (BT SPEED)

Use this menu to assign transmitter ports for telemetry data

transmission.

DATA PORT

Plug in the external Bluetooth module S8351 to the DATA port

on the rear side of the transmitter. In the BT SPEED line, FAST

or NORMAL will automatically select depending on the transmission speed of the counterpart device.

USB PORT

Plug in the supplied connection cable 7168 to the micro USB

port on the rear side of the transmitter to establish a connection

with a PC.

25 / 48

Page 26

Display warnings

3.9V

RX

4.8V

M - 1

TX

RX

NORMAL

MODEL 1

000:00.0

ST

CH3 CH4

+100%

100%

TH TRIM0%

BK D/R

PS2OFF OFF

A-

ST TRIM

ST D/R

CH3

PS1

O.TIME 0 : 23 : 02 B.TIME 0 : 11 : 59

BACK CLR OFF

TX VOLT 3.9 V 0

RX VOLT 0.0 V 0

STRENGTH 0% 0

CH4

S-

100%

0%

ON

TH

0%

Tap the exclimation point symbol in the top line of the

Start Display to open the warnings display screenshowing the current values for transmitter voltage (TX

VOLT), receiver voltage (RX VOLT), signal strength

(STRENGTH), speed controller current (ESC CUR.)

and speed controller voltage (ESC VOLT).

Acoustic (A-) and optical (S-) warnings can be activated or

deactivated by tapping the ON or OFF buttons.

Resets the alarms by tapping Clear (CLR).

ESC CUR. 0.0A 0

ESC VOLT 0.0V 0

Voltage display calibration

NORMAL

BACK

Tx Volt

3.95V

+2

+10

Cali. Data

34814

-2

-10

SAVE

From the Main Menu, tap on the battery symbol to pull up

the voltage calibration display. Calibrate the voltage display as follows:

Voltage display calibration step by step:

1. Measure the battery voltage with a voltmeter.

2. Tap on the Cali. Data button.

3. Enter the data by changing the value by 2 or 10 unit

incriments.

4. To SAVE tap and confirm the safety query through

YES.

5. The new value is displayed under Tx Volt

26 / 48

S1008_X-8E_jh_V1

Page 27

Change the values in an input field

NORMAL

SERVO

NORMAL

ST

TH

Warning

The following three buttons are visable on the lower part of the

display of many of the following menus. To raise or lower a value

by pressing the <+ or -> buttons. Reset the default value

through the curved back-arrow button.

M-SEL (Model Selection)

Model settings can be managed and saved into memory slots

BACK

01

02

03

04

05

06

07

08

09

MODEL 1

MODEL 2

MODEL 3

MODEL 4

MODEL 5

MODEL 6

MODEL 7

MODEL 8

MODEL 9

NEXT

SEL

IMP.M

EXP.M

RES

CPY

by choosing from the following options:

SEL - Change active model memories.

IMP.M - Import model memories from the SD card.

EXP.M - Export model memories to the SD card.

RES - Reset a model memory to the factory presets.

Warning: All personal settings will be deleted!

CPY - Copy the actual model memory in a new model memory.

REVERSE (Servo Reverse)

NORMAL

BACK

ST

NORMAL

SERVO

TH

NORMAL

CH3 CH4

NORMAL NORMAL

TRIM

NORMAL

BACK

SV/TR

TX/TR

SV/TR

TX/TR

ST

0%

0% 0%

CH 3 CH 4

0%

0% 0%

SERVO

TH

0%

0%

The servo operates in two directions:

Normal - Reverse

To change servo directions, tap the NORMAL/REVERSE button of the related servo to toggle between options. If changing

the throttle direction, a safety warning will appear. Tap YES or

NO to verify the selection and the change will take effect.

Are you sure?

CH3 CH4

YES NO

This trim function allows for the entire servo travel to be moved,

i.e. full deflection position changes.

In the second line is displayed the respective trim value that has

been set through the buttons.

Tap on the related button. Change the values by pushing the <+

or -> keys. Press the curved arrow key to reset to the default

value (0%).

S1008_X-8E_jh_V1

27 / 48

Page 28

TRA ADJ (End Point Adjustment)

NORMAL

BACK

LEFT

100%

BRK FW

100%

UP DN

100%

UP DN

100%

ST

TH

CH3

CH4

RIGHT

100%

100%

100%

100%

SERVO

End Point Adjustment

DR/EXP (Dual Rate/Exponential)

BACK

CH

NORMAL

STEERING

SERVO

To set the DR (Dual Rate) and EXPO (Exponential) function for

the steering and throttle channel, press the STEERING or

THROTTLE button in the CH line. All setting changes are represented in the diagram.

BACK

This function sets the maximum

travel of the servo per channel.

The left and right deflection can be

set separately in the range from

0% - 150%. Press the related

button. Change the values by

pushing the <+ or -> keys. Press

the curved arrow key to reset to

the default value (100%).

BACK

CH

D/R

100%

NORMAL

THROTTLE

D/R

100%

Setting STEERING channel

D/R: 0% - 100% Limit the steering course. Press the <+ or ->

keys to raise or lower value. Press the curved arrow key to reset

0%EXP

to the default value (100%).

EXP: -100% to + 100% Exponentially change the steering

course. Press the <+ or -> keys to raise or lower value. Press

the curved arrow key to reset to the default value (0%).

SERVO

FWD

TYPE

EXP

Setting THROTTLE channel

D/R: 0% - 100% Limit the throttle course. Press the <+ or ->

keys to raise or lower value. Press the curved arrow key to reset

to the default value (100%).

EXP: -100% to + 100% Exponentially change the throttle

course. Press the <+ or -> keys to raise or lower value. Press

the curved arrow key to reset to the default value (0%).

0%EXP

FWD: Choose between forward and brake area. Refer to the

D/R and EXP settings described above and the FWD/BRK settings described on the following page.

28 / 48

TYPE: Select between EXPO or throttle CURVE

CURVE: Refer to the setting instructions on the following page.

S1008_X-8E_jh_V1

Page 29

NORMAL

BACK

THROTTLE

CH

POINT ? 0%

ST OFF

X-axis

+/-

SERVO

FWD

TYPE

Curve

TH.hold

OFF

Curve

ON

Y-axis

THROTTLE FWD point setting step by step:

1. Press the "ST OFF" button to switch to "ST ON".

2. Move the throttle lever.

3. A green line moves horizontally through the diagram.

4. Press the +/- key to create a new point. Multiple points

can be set by pressing the arrow key.

5. Delete highlighted points by pressing the +/- key.

THROTTLE FWD point moving step by step:

1. Press the "ST ON" button to switch to "ST OFF".

2. Press the <+ or -> keys to scroll through the points. Points

will highlight red when selected. Delete highlighted points

by pressing the +/- key.

3. Select the X-axis or the Y-axis button. Press the <+ or

-> keys to change axis curve or to reposition points along

the axis.

BACK

THROTTLE

CH

B.R.A. (ATL)

BACK

RATE

NORMAL

D/R +100%

EXP 0%

NORMAL

F50:B50

SERVO

BRK

SERVO

TH.hold

Use this option while programming a curve prevent the motor

from running. Tap the ON and OFF button to switch the throttle

channel on and off.

Brake force setting

1. Select the "THROTTLE" setting by pressing the "STEERING" button.

2. Select the "BRK" setting by tipping on the "FWD" button.

3. Moving the throttle lever. The green axis line moves in the

diaplay.

4. To adjust the force setting, select the percent button near

"D/R" or "EXP". Press the <+ or -> keys to raise or lower

value. Press the curved arrow key to reset the default

value.

Break rate and travel setting menu.

RATE: Factory default setting is F50:B:50. Press the button in

the RATE line to switch to F70:B:30 and move the servo center.

S1008_X-8E_jh_V1

B.R.A

BK

100%

0%

B.R.A: To adjust the travel, highlight the percent button in the

B.R.A. line. Press the <+ or -> keys to raise or lower value.

FW

Press the curved arrow key to reset to the default value (100%).

29 / 48

Page 30

B-MIX

BACK

ACT

RATE

DELAY

ABS

NORMAL

CH 3

INH

+100% +100%

0.00s 0.00s

INH INH

SERVO

CH 4

INH

Break mixer options menu, including mixer channel assignment,

mixer rate setting, delay time and ABS activation.

ACT: To activate the break secure function, press to change

INH (inhibit/off) to ON.

RATE: To set the break mixer part, press the percent button

on the RATE line. Press the <+ or -> keys to raise or lower value.

Press the curved arrow key to reset to the default value (100%).

DELAY: To set a delay time prior to activating the ABS, press

the percent button on the DELAY line. Press the <+ or -> keys

to raise or lower value. Press the curved arrow key to reset to

the default value (0.00s).

ABS: To activate the ABS function, press to change INH

(inhibit/off) to ON.

TH RESP (Throttle Response)

NORMAL

BACK

FW

BK

0%

BK

SERVO

0%

0%

FW

IDLE UP (Pumping)

NORMAL

BACK

ACT

ON

POS

0%

BK FW

PUMPING

SERVO

CTL

NONE

SET

Throttle response settings menu. The throttle and break travel

can be adjusted in one percent incriments, causing the servo to

automatically jump to the set value during operation. This setting

can compensate backlash of the throttle linkage or throttle

response weakness in lower ranges.

FW: 0% - 100% To set the throttle, press the percent button

on the RATE line. Press the <+ or -> keys to raise or lower value.

Press the curved arrow key to reset to the default value (0%).

BK: 0% - 100% To set the break, press the percent button

on the RATE line. Press the <+ or -> keys to raise or lower value.

Press the curved arrow key to reset to the default value (0%).

Motor start function settings menu. Holds the throttle to a specific value to enable a better start for cold combustion

engines.

POS: To adjust throttle position, press the percent button on

under POS. Press the <+ or -> keys to raise or lower value.

Press the curved arrow key to reset to the default value (0%).

NOTE: After starting the engine, this function must be deactivated;

the throttle lever has no effect during the IDLE UP function.

30 / 48

CTL: Assign this function to a switch. Refer to the SW SET

chapter for additional information on how to program switches.

S1008_X-8E_jh_V1

Page 31

PROFILE

NORMAL

BACK

ACT

INH

DELAY

0,5s

BK TH

NORMAL

BACK

1

NORMAL

2

PROFIL 1

3

PROFIL 2

4

PROFIL 3

5

PROFIL 4

NONE

POS

CTL

0%

SERVO

SERVO

ACTPROFILE

PUMPING

Automatic throttle activation menu. Set throttle strength and

delay time to protect motor during refueling.

POS: To set the strength of the throttle activation, select the percent button below POS. Press the <+ or -> keys to raise or

lower value. Press the curved arrow key to reset to the default

value (0%).

DELAY: To set delay time between throttle activations, select

the percent button below DELAY. Press the <+ or -> keys to

raise or lower value. Press the curved arrow key to reset to the

default value (0.5s).

ACT: Press ON or INH (inhibit/off) to switch the activation func-

tion on or off.

CTL: Assign this function to a switch. Refer to the SW SET

chapter for additional information on how to program switches.

Set up to five different profiles for the model memories. Create

names and assign settings to a programmable switch. (Refer to

the SW SET chapter for additional information on assigning

switches.)

Settings that have been changed in the other menus will be

automatically populated in the assigned profile.

NEW

CTL

BACK

A

G H

M N O P Q R

S

Y Z CL SP DE EN

CAPS NUM SPECIAL

COPY

FROM

NORMAL

TARGET

PROFIL 2

DEL

NAM

NONE

Current Profile Name

PHASE 1

New Profile Name

B C D E F

I J K L

U V

T

W X

CPY

Change profile name:

1. Select profile to be renamed by highlighting any line, 1 - 5.

2. Press the NAM button at the bottom of the screen.

3. The current name appears in a field at the top of a new

screen. Use the red keypad to input a new name.

4. To save, press EN in the lower right side of the keyboard.

5. Press the BACK button to return to the main menu.

Copy profile:

1. Select the profile to copy by highlighting the profile name.

2. Press CPY. A pop-up window will appear.

3. To select the target profile, tap to scroll through the saved

profiles. Press YES to confirm selection.

Delete profile:

1. Select the profile to delete by highlighting the profile name.

2. Press DEL. Settings will reset to factory default values.

WARNING: profile will be deleted without confirm query!

YES

S1008_X-8E_jh_V1

NO

31 / 48

Page 32

S/SPEED

BACK

NORMAL

SERVO

Steering and throttle servo speed settings menu.

CH

TURN

RETURN

BACK

CH

HIGH

100

POINT

50

STEERING

LEFT

100

100 100

NORMAL

THROTTLE

RIGHT

100

SERVO

NEUTRAL

100

For the steering servo, you can set the speed for left and right

and for forward and return travel separately.

For the throttle servo, a point can be set at which the speed is

set in two steps.

STEERING

Highlight the field to be adjusted by pressing the appriporiate

button in the LEFT or RIGHT columns and TURN or RETURN

lines. Press the <+ or -> keys to raise or lower value. Press the

curved arrow key to reset to the default value (100).

THROTTLE

HIGH or NEUTRAL: Select the field to be adjusted by pressing

the appriporiate button. Press the <+ or -> keys to raise or

lower value. Press the curved arrow key to reset to the default

value (100).

POINT: To set the switchover point between both ranges, highlight the button under POINT. Press the <+ or -> keys to raise

or lower value. Press the curved arrow key to reset to the default

value (50).

START

BACK

START

RATE

0%

NORMAL

T/POS TIME

0%

SERVO

OFF

0.0s

Automatic start function settings menu.

RATE: To allow a quick start without spinning the drive wheels

while the throttle is held on a specific value, press the percent

button below RATE. Press the <+ or -> keys to raise or lower

value. Press the curved arrow key to reset to the default value

(0%).

T/POS: To use this function, first assign a switch that sets the

START function to READY. When the throttle lever exceeds the

set trigger point, the READY (standby) mode is activated. To

adjust the trigger position, press the percent button below T/

POS. Press the <+ or -> keys to raise or lower value. Press the

curved arrow key to reset to the default value (0%).

TIME: To delay the response of this function when exceeding

the trigger point, select the button below TIME. Press the <+ or

-> keys to raise or lower value. Press the curved arrow key to

reset to the default value (0.0s).

32 / 48

S1008_X-8E_jh_V1

Page 33

TIMER

NORMAL

BACK

SET TIMER

P.ALARM

MODE

STAR T SW

LAP SW

LAP List

Vibrator

TIME INFO

00

00

UP

NONE

NONE

>>

NONE

00

:

sec

:

NEXT

00

00

Timer and date settings menu. To toggle between the Timer

and Date display, press the NEXT button at the top of the

screen.

TIMER Display

P.ALARM: To set the time for a pre-alarm that will be active

before the main alarm, select the button in the P.ALARM line.

Press the <+ or -> keys to raise or lower value. Press the curved

arrow key to reset to the default value (00).

MODE: To toggle between mode options, press the button in

the MODE line. Choose UP for increasing count, DOWN for

countdown and LAP for lap timer. If LAP is selected, the START

SW function will automatically set to TH, allowing the timer to

start through the throttle lever.

START SW: This function is only available in UP or DOWN

mode. Pressing the button in the START SW line brings up the

SW SET menu. For additional information on these settings,

refer to the SW SET chapter.

LAP SW: To assign a start/stop function to the timer, press the

button in the LAP SW line. This brings up the SW SET menu.

For additional information on these settings, refer to the SW

SET chapter.

NORMAL

BACK

TIMER

LAP

BEST LAP

0 : 0 . 0

A VERAGE LAP

0 : 0 . 0

NORMAL

BACK

No

LAPTIME No LAPTIME

1

0 : 22.70

2

0 : 10.45

3

0 : 5. 9

4 B

0 : 0. 89

0 : 3. 94

5

6

7

8

9

10

11

12

13

14

15

<<

28

29

30

CLR >>

0

16

17

18

19

20

21

22

23

24

25

26

27

SERVO

LIST

CLR

SERVO

LAP List: To view total laps, best lap time and average lap time,

press the right-arrows button on the LAP List line to view the

statistics display. To reset to zero, press the CLR key.

LIST: The lap times list has 120 memory slots. To view a full

list of lap times, press the button at the top of the statistics

display. The best lap is alway marked in red and highlighted

with a B. Scroll through the list by pressing the << and >>

arrow keys at the bottom of the screen. Clear the list by

pressing the CLR key at the bottom of the screen.

Vibrator: To set or change alarm vibrations, press the button in

the Vibrator line. There are five different vibration options to

scroll through.

S1008_X-8E_jh_V1

33 / 48

Page 34

SW SET

NORMAL

BACK

DA TE

SET

2048

TIME

16

20 27

: :

BA TTERY TIME

1 : 19 : 33

MODEL TIME

1 : 02 : 52

NORMAL

BACK

Control Ke y

>>

Direct Button

>>

Menu Screen

>>

NORMAL

BACK

SW

FUNC

TR1

ST TRIM

TR2

TH TRIM

CH3

TR3

2

/

B.RES

M.RES

REV T/S

NOR

NOR

NOR

NEXT

11

/

SERVO

SERVO

DATE/TIME

Date/Time and Battery/Model Time settings menu.

From the TIMER menu, press the NEXT button at the top of the

screen.

DATE/TIME

To set the date and time, press the SET button under the DATE

line. This unlocks the Year, Month, Day, Hour, Minute and Second fields. Select to highlight and press the <+ or -> keys to

raise or lower value. To save and lock the fields, press SET

again.

BATTERY/MODEL TIME

To reset the battery or model times to zero, press the B.RES or

M.RES buttons.

Control Key

Use this menu to assign functions to trim buttons, switches and

rotary controls. Some buttons and switches have default functions assigned. All buttons, switches, controls and defaults can

be assigned as follows:

1. Press the Control Key arrow >> button to bring up the

Function screen.

2. Press the NEXT button to scroll through the screens.

3. Press the control button to select the desired function for

the control. Depending on the control there are different

functions available here. Assigned functions are greyed

out. (See list on the next page.)

1

1

1

4. Press the <+ or -> keys to select the function.

REV/NOR: To change between normal and reverse switch

function, press the button under REV to toggle between options.

34 / 48

TR4

ST D/R

NEXT

NORMAL

BACK

No Display

1.

2.

TELE.

SERVO

ACT

NOR

ON

SERVO

T/S: To set the increase number for each click or step, press

1

the <+ or -> keys to raise or lower value. Press the curved arrow

key to reset to the default value (1). Only available on trims and

rotary controls.

Direct Button

To assign a menu shortcut function to buttons S1, S2 (under the

display):

1. Press the button on line 1 to set S1; line 2 to set S2.

2. Press the <+ or -> keys to scroll through display options.

3. To activate settings press the ON or OFF button on the

ACT line.

S1008_X-8E_jh_V1

Page 35

Select 1 to 3 for TR 1 - 5 / DV

NORMAL

BACK

D/R ST L D/R ST P1

D/R ST P3

D/R ST H

D/R TH P3

D/R TH H

TRIM ST

TRIM CH4

S-TRIM C3

BX CH3 RT

D/R ST P4

D/R TH P1

D/R TH P4

BK D/R

TRIM TH

S-TRIM ST

S-TRIM C4

BX CH4 RT

NEXT

D/R ST P2

D/R ST P5

D/R TH P2

D/R TH P5

BK EXP

TRIM CH3

S-TRIM TH

ATL

G/B TH

NORMAL

BACK

G/B BS IDLE UP

SPD ST RT

SPD ST LR

SPD C3 RT

SPD C3 LR

START T/P

ABS MOV

FR MIX 1 A

FR MIX 1 Y FR MIX 2 A

SPD ST LT SPD ST RR

SPD TH HO

SPD C3 LT SPD C3 RR

SPD C4 HO SPD C4 NT

START RT

C3

FR MIX 1 B FR MIX 1 X

NEXT

PUMPING

SPD TH NT

ABS T/P

C4

FR MIX 2 B

BACK

P-MIX 2 X

P-MIX3 P1 P-MIX3 P2

P-MIX3 P4

P-MIX4 L

P-MIX4 P3 P-MIX4 P4

P-MIX4 H

P-MIX5 P2

P-MIX5 P5 P-MIX6 H CL SPD RT

CL SPD RT

Select for PS 1 + 3 Select for PS 2

NORMAL

BACK

START ABS CH2 ABS CH 3/4

IDLE UP PUMPING

CH4

CW MODE

VOICE RPT

TK MODE

FIX.VOICE T1 ST ART

T1 LAP

T2 START

T2 LAP

ESC MODE

VOICE TRG

T1 RESET

T2 RESET

Q.LINK

CH3

NORMAL

BACK

START ABS CH 2 ABS CH3/4

IDLE UP PUMPING

CH4

TK MODE

FIX.VOICE

CW MODE

VOICE RPT

ESC MODE

VOICE TRG

NORMAL

CH3

NEXT

P-MIX 2 Y P-MIX 3 L

P-MIX3 P3

P-MIX3 P5

P-MIX4 P1

P-MIX5 L

P-MIX5 P3

ST>> C3

P-MIX3 H

P-MIX4 P2

P-MIX4 P5

P-MIX5 P1

P-MIX5 P4

C3 >> ST

BACK

REVERSE

M-SEL

EPA DR/EXP

B-MIX TH RESP

Q.LINK TIMER S-VIEW

H/W SET TELE.

S/SPEED

A.B.S S/W SET FAIL SAFE

P/MIX

RF SET START

AUX S/MODE

M-SEL

REVERSE

M-SEL

EPA DR/EXP

B-MIX TH RESP

Q.LINK TIMER S-VIEW

H/W SET TELE.

S/SPEED

P/MIX AUX

RF SET START

A.B.S S/W SET FAIL SAFE

RES

SUB-TRIM

B. R. A

IDLE UP

BLANK

SUB-TRIM

B. R. A

IDLE UP

S/MODE

Menu Screen

The green marked area represent the first main menu page, the

yellow marked area indicates the second main menu page, the

blue marked area indicates the third main menu page (see Main

Menu section)

RES: Press the button at the top of the screen to return all func-

tions to default factory presets. A warning screen will pop-up to

verify this option. Press YES or NO to continue.

Change the display assignation:

1. Press on the field to be changed. The function name will

apper on the button in the upper left corner of the screen.

2. Available buttons for this field will appear crossed out in

green.

3. Select the desired function button. Confirm change by

pressing the button in the upper left corner of the display

screen.

4. To delete or unselect, tap the BLANK button in the upper

right corner of the display screen.

S1008_X-8E_jh_V1

35 / 48

Page 36

FAIL SAFE

BACK

ST

TH

CH3

CH4

DELAY

NORMAL

MODE POS

FREE

FREE

FREE

FREE

100ms

SERVO

Fail Safe settings menu. In case of receiver signal loss or interruption, assign the servo channel to a predefined position. For

example, set an engine-powered model to idle (or an electric-powered model to shut off), so the model does not move

uncontrollablly.

FREE: Channel is empty with no failsafe assigned.

HOLD: Holds the servo in the previous position.

F/S: The servo automatically moves to a defined position

STO

BACK

ST

TH

CH3

CH4

DELAY

STO

NORMAL

MODE POS

HOLD

F/S

FREE

FREE

100ms

SET

SET

SERVO

0%

To set the position: Press and change the channel line button

to F/S. A percent value button will appear to the right in the POS

column. Press the percent button to select and set servo position by moving the related control. Press the SET button to con-

firm. The POS button displays the assigned position of the

servo. Press the STO button to save all settings before exiting.

DELAY: To set the delay time between signal loss and failsafe

launch, press the button on the DELAY line to choose between:

50ms, 100ms, 250ms, 500ms, 750ms and 1.0s. Press the

STO button to save all settings before exiting.

Attention

To store settings, press the STO button on the bottom of the

screen before exiting this menu. Settings will not be saved until

the STO button is pressed and the "Position stored" confirma-

tion message appears.

SERVO (S View)

NORMAL

BACK

L150%

F150%

36 / 48

+100%

+100%

CH3

CH3

0%

ST

TH

0%

R150%

B150%

0%

0%

Servo monitor (display only).

This display shows the servo travels of all four control channels.

Access this display by pressing the Servo icon in the main menu,

or by pressing the Servo button in the upper right corner of most

submenu displays.

S1008_X-8E_jh_V1

Page 37

P/MIX

BACK

ACT

INH

1.

INH

2.

INH

3.

INH

4.

5.

ON

NORMAL

MST SLV SET

NONE

NONE

NONE

NONE

NONE

NONE

NONE

NONE

ST

CH4

SERVO

>>

Mixer setup menu. Assign linear mixers to line numbers 1 and

2; curves mixers to line numbers 3 through 5. Activate mixers

by pressing the first button in the number line to change from

INH (inhibit/off) to ON.

Pressing the buttons in the MST or SLV columns will open a

new display screen. To assign the origin (MST/master) and the

target (SLV/slave), highlight the appropriate button above the

blue line and select the applicable channel button below. To

clear the selection press the CLR button.

Return to the P/MIX menu screen by pressing the BACK button.

An arrow >> button will appear in the SET column.

NORMAL

BACK

>>

MST

ST

ST

CH3

CLR

NORMAL

BACK

ST >> CH3

0%A

0%

X Y

Img.1

NORMAL

BACK

ST>> CH3

POINT ? 0%

ST ON

X-axis

SLV

ACT

B

ACT

CH3

TH

CH4

0%

0%

-100%

OUT

-62%

T-OFF

Y-axis

SERVO

SERVO

INH

SERVO

INH

IN

Press the arrow >> button for the linear and curve settings

menu. The Linear menu is only accessable on lines 1 and 2;

the Curve menu is only accessable on lines 3 through 5.

Linear menu (Img.1)

Select the "A" percent button to set the left (red) line and

the "B" percent button to set the right (blue) line. Use the

<+ or -> keys or press the curved arrow key to reset to

the default value (0%).

Press the "X" or "Y" percent buttons to move the line on

the X or Y axis via the <+ or -> keys. Press the curved

arrow key to reset to the default value (0%).

Move the throttle lever or the steering wheel. The green

line moves horizontally through the diagram.

Curve menu (Img.2)

Point setting step by step:

1. Press the button "ST OFF" to switch to "ST ON".

2. Move the throttle lever or the steering wheel. A green line

moves horizontally through the diagram.

3. Press the +/- key to set a new point. To delete, press the

point to highlight it red and press the +/- key.

4. Set up to a maximum of 5 points.

Point moving step by step:

1. Press the button "ST OFF" to switch to "ST ON".

2. Select the point to be reallocated by moving the steering

wheel or the throttle lever until the point is highlighted red.

3. Select the X-axis or the Y-axis button. Reposition the

point using +/- key.

S1008_X-8E_jh_V1

Img.2

4. The mixer is not linear and follows the set curve.

37 / 48

Page 38

AUX

S/MODE

BACK

OFF

UP

DN

BACK

CRAW

TANK

BOAT

NORMAL

CH30%CH4

+100% +100%

+100% +100%

NORMAL

ACT

INH

INH

INH

SERVO

0%

SERVO

SET

Additional channel settings menu. Set the servo deflections to

OFF (center) and UP/DN on two additional control channels

(CH3 and CH4).

OFF: To set the central point, press the <+ or -> keys to raise

or lower value. Press the curved arrow key to reset to the default

value (0%).

UP: To set the upper end point, press the <+ or -> keys to raise

or lower value. Press the curved arrow key to reset to the default

value (0%).

DN: To set the lower end point, press the <+ or -> keys to raise

or lower value. Press the curved arrow key to reset to the default

value (0%).

Various model type setup menu. Preprogrammed mixers tuned

to the characteristics of model types crawler, track vehicle and

boat.

To activate the model function, press the INH (inhibit/off) button

to change to ON. An arrow >> button appears in the SET column.

Press the arrow >> button to bring up a settings menu specific

to the vehicle type.

NORMAL

BACK

S/MODE

4WS

DUAL ESC

ST MODE

ESC MODE

SPD RA TE

SERVO

CRAW

INH

INH

NORMAL

NORMAL

0%

CRAWLER

4WS: To use all wheel steering activation on Channels 1 and 3,

press INH (inhibit/off) button to change to ON.

DUAL ESC: To use two independent drive motors with 2 speed

controllers on channel 2 and 4, press INH (inhibit/off) button to

change to ON.

ST MODE: To adjust active 4WS steering, press to select the

button in the ST MODE line. Scroll between options by pressing the <+ or -> keys. Press the curved arrow key to reset to the

default (FRONT). (see image on next page).

ESC MODE: To adjust active DUAL ESC in 2 motors, press to

select the button in the ESC MODE line. Scroll between options

by pressing the <+ or -> keys. Press the curved arrow key to

reset to the default (FRONT). (See image on next page.)

SPD RATE: To set the maximum speed for both speed controllers in DUAL ESC mode, press to select the percent button

in the SPD RATE line. Press the <+ or -> keys to raise or lower

value. Press the curved arrow key to reset to the default value

(0%). (See image on next page.)

38 / 48

S1008_X-8E_jh_V1

Page 39

ST MODE (steering)

ESC MODE (2 drives)

NORMAL

BACK

S/MODE

ST MODE

SPD RA TE 0%

NORMAL

BACK

S/MODE

ST >> CH3

CH3 >> ST 0%

SERVO

TANK

TYPE1

SERVO

BOAT

0%

TANK

Use the ST MODE to mix the throttle and the steering on a

tracked vehicle and emit on Channel 1 and 2. Actuate steering

by adjusting SPD RATE of the left and right tracks speed.

ST MODE: Select the button to highlight and press to choose

between: TYPE 1 = standing rotation only, TYPE 2 = driving

rotation only. Press the curved arrow key to reset to the default

(TYPE1).

SPD RATE: To set the maximum speed of the drive, highlight

the percent button in the SPD RATE line and press the <+ or ->

keys to increase or decrease value. Press the curved arrow key

to reset to the default (100%).

BOAT

Use these mixers to actuate a second drive (ESC).

ST -> 3CH: To adjust the mixing rate from steering to Channel

3, press the <+ or -> keys to increase or decrease value. Press

the curved arrow key to reset to the default (0%).

S1008_X-8E_jh_V1

3CH -> ST: To adjust the mixing rate from Channel 3 to steering, press the <+ or -> keys to increase or decrease value. Press

the curved arrow key to reset to the default (0%).

39 / 48

Page 40

A.B.S

NORMAL

BACK

ACT

INH

T/POS MOV

30% 50%

CYC

120ms

SERVO

DUTY

0

DELAY

0.00s

A.B.S setup menu.

A.B.S. enables a better braking response, since the brake is

actuated in pulses.

ACT: Press the button under ACT to choose between INH

(inhibit/off) and ON.

DUTY: To set the atio between pulse and pulse pause (see

image below), press the <+ or -> keys to raise or lower value.

Press the curved arrow key to reset to the default value (0).

T/POS: To set the point on the brake lever path from which the

A.B.S. will become active, press the <+ or -> keys to raise or

lower value. Press the curved arrow key to reset to the default

value (30%).

MOV: To set the pulse height (see image below), press the <+

or -> keys to raise or lower value. Press the curved arrow key to

reset to the default value (50%).

CYC: To set the pulse length (see image below), press the <+

or -> keys to raise or lower value. Press the curved arrow key to

reset to the default value (240ms).

DELAY: To set the delay time of the A.B.S. response (0 - 1 s),

press the <+ or -> keys to raise or lower value. Press the curved

arrow key to reset to the default value (0.00s).

DUTY

MOVE

CYC

40 / 48

S1008_X-8E_jh_V1

Page 41

Operating receiver GR-8

10K/C

)

Description LED indicator

Red LED Green LED

Not bound Flashing Off

Bound Off On

Error Flashing On

Binding Flashing Flashing

Channels function

<T/V

<CH4

<CH3

<CH2

<CH1

Function Alternative

CH 1 Channel 1 signal

output

CH 2 Channel 2 signal

output

CH 3 Channel 3 signal

output

CH 4 Channel 4 signal

output

T/V Ext. temp./voltage

SUMD-V2 BUS system Battery plug

connection

SUMD-V2 BUS system Battery plug

connection

SUMD-V2 BUS system Battery plug

connection

SUMD-V2 BUS system Battery plug

connection

------

sensor

The power source for the receiver is connected through channel

1 to 4. If all of the channels are used, use a Y-cable on one channel.

CH 1+2: Connected the steering servo.

Channel 2: Connected with the throttle servo of engine-pow-

ered models or with the speed controller of electric-powered

models.

CH 3+4: Open channels freely assignable for special control

functions.

S1008_X-8E_jh_V1

T/V socket:

Used to connecting the optional external voltage and temperature sensor S8362. When reaching the warning thresholds, an

alarm is generated (set the warning thresholds via Telemetry

menu). Sensor and voltage of a battery must only be connected

according to the following scheme:

Ext.Spannung(+

T

V

G

(1 - 25,5V)

NTC TemperaturSensor

ATTENTION: The receiver will be destroyed if you connect a bat-

tery directly to this socket without a pre-resistance. This socket

is not suited for the power supply of the receiver.

41 / 48

Page 42

GR-8 Receiver Telemetry Menu

Display screen (display only)

Warning Thresholds and Telemetry Language Setting Screen

Channel Properties Setting Screen (refer to RF SET section)

S-QUA: transmission quality

S-STR: transmission power

S-dBm: transmission power in dBm

RX-TEMP: receiver temperature

LOSS PACK: lost data packets in milliseconds

BATT VOLT: receiver voltage

LOW VOLT: warning threshold for minimum receiver voltage

AL RX-V: receiver voltage warning threshold

AL RX-T: receiver temperature warning threshold

AL EX-V: ext. voltage sensor warning threshold

AL EX-T: ext. temperature sensor warning threshold

LANGUAGE: language setting (telemetry menu only)

The current value is shown in brackets

Settings:

USR1m50 - ULTRA SIGNAL 1.5msec

FSR3m00 - FAST SIGNAL 3.0msec

SUMD-V2 - FAST SIGNAL BUS 3.0msec

NSR6m00 - NORMAL SIGNAL 6.0msec

NSR12m0 - NORMAL SIGNAL 12.0msec

NSR24m0 - NORMAL SIGNAL 24.0msec

Connected Components Display (display only)

(Refer to Telemetry Menu section)

Fail Safe Setting Screen

F/S MEMORY: To save the data in the receiver, select "YES.

Press ENTER to confirm.

F/S DELAY: Fail Safe delay time

CH1(STR): FREE, HOLD, POSITION

CH2(TH): FREE, HOLD, POSITION

CH3(AUX): FREE, HOLD, POSITION

CH4(AUX): FREE, HOLD, POSITION

(Refer to Fail Safe section)

42 / 48

S1008_X-8E_jh_V1

Page 43

Firmware Update - Transmitter

NOTE

In case of transmitter firmware update, carefully observe the following instructions. Before every update it is recommend all model data

on the SD card be saved externally (refer to M-SEL section).

UPDATE USING THE BACK-SIDE USB SOCKET

Use a PC or laptop with the Windows XP, Vista, 7 or 8 OS.

Download an up-to-date software package from the Internet at

www.graupner.de and unpack it onto a PC or laptop. Connect

your switched-off transmitter with the PC or laptop by using the

USB cable (USB-A to mini-B-USB, 5 pole), which is supplied as

a standard accessory. Plug one end of the USB cable directly

into the 5 pole micro-USB port at the rear side of the transmitter

and the other end into a free USB port of the computer. For

more information, please refer to the update instructions PDF file

located in the respective software package.

S1008_X-8E_jh_V1

43 / 48

Page 44

Firmware Update - Receiver

<CH3

Updates to the receiver’s firmware are made via the telemetry

socket using a PC running Windows XP, Vista or 7 with the

included USB interface (order No. 7168.6), and adapter lead,

(order No. 7168.6A or 7168.S).

The programs and files required can be found in the Download

area for the corresponding products at:

www.graupner.de.

Connect the adapter lead to the USB interface. The connectors

are reverse polarity protected: note the small chamfers on the

sides. Never use force – the connectors should engage easily.

Connect the adapter lead to the receiver's socket 3 (CH 3). The

connectors are reverse polarity protected: note the small chamfers on the sides. Never use force – the connectors should

engage easily.

Update process