Page 1

GRAUPNER/SJ GmbH. Henriettenstr.96, KG D-73230 KIRCHHEIM/TECK GERMANY

English

INNOVATION & TECHNOLOGY

HoTTrigger

Manual

2014/04/10

No.:13401

No.:13401.SD

Page 2

English

2

Contents

Foreword ......................................................................3

Model summary description..........................................3

Approved usage ...........................................................3

Specication .................................................................3

Parts List ......................................................................4

Kit contents ...................................................................5

Recommended accessories .........................................6

Recommended accessories - electric motor ................6

Adhesive .......................................................................6

Tools required ............................................................... 6

Symbols and their meaning ..........................................7

Warnings and safety notes ...........................................8

Manufacturer‘s declaration on behalf of GRAUPNER/

SJ GmbH ....................................................................12

Assembling the model ................................................13

Removing covering lm ..............................................13

Servo installation - general .........................................14

1. Information on installing servos ................................. 14

2. Servo installation ....................................................... 14

3. Fitting the rubber grommets ...................................... 14

4. Fitting the tubular brass spacers ............................... 14

5. Extending the servo lead ........................................... 15

6. Parking the servo leads ............................................. 15

Canopy .......................................................................16

Gluing the point-hinges ..............................................16

1. Information on gluing the point-hinges ...................... 16

2. Preparing the point-hinges ........................................ 16

3. Applying glue to the hinge holes ................................ 17

4. Inserting the point-hinges .......................................... 17

Installing the tailplane .................................................19

1. Aligning the tailplane ................................................. 19

2. Removing the lm from the joint surfaces ................. 20

3. Removing the lm from the joint surfaces ................. 21

4. Gluing the tailplane in place ...................................... 21

5. Preparing the elevator joiners ................................... 22

6. Gluing the elevator joiners ......................................... 22

7. Attaching the elevators .............................................. 23

Attaching the rudder to the n ....................................25

Attaching the rudder .................................................25

Installing the tailwheel assembly ................................26

Tailwheel bracket assembly ........................................... 26

4. Installing the tailwheel ............................................... 27

Installing the tailwheel bracket ...................................... 28

Tailwheel steering system ............................................. 28

Installing the undercarriage ........................................29

1. Installing the main undercarriage units ...................... 29

2. Preparing the wheel spats ......................................... 30

2. Fitting the wheel axles ............................................... 30

Installing the horns .....................................................32

Preparing the control horns ........................................... 32

Preparing the pushrods ................................................. 33

Preparing the servo output arms ................................... 34

Attaching the pushrods to the servo output arms .......... 34

Aileron and elevator ...................................................36

Installing the servos ....................................................... 36

Installing the servo output arms .................................... 37

Adjusting the pushrods .................................................. 37

Gluing the control surface horns ................................... 38

Rudder linkage ..........................................................39

Attaching the rudder cables ........................................... 39

Installing the rudder output arm ..................................... 41

Installing and replacing the batteries ..........................46

Installing the receiver..................................................47

General information ....................................................... 47

Wing root connection ..................................................... 47

Securing the receiver .................................................... 47

Aerial deployment .......................................................... 47

Installing the electric motor .........................................48

Preparing the cruciform motor mount ............................ 48

Fitting the stand-off pillars ............................................. 49

Installing the motor ........................................................ 49

Soldering the sockets to the speed controller ............... 50

Installing the speed controller .....................................51

Installing the spinner OMA-5020-490 .........................52

Installing the Cowl ......................................................54

Drilling the holes for the cowl retaining screws ............. 54

Applying the decals ....................................................56

Information on applying decals ...................................... 56

Slitting the decals over a hinge line ............................... 57

Model settings ............................................................58

Centre of Gravity: .......................................................... 58

Basic control surface travels: ........................................ 58

Attaching the wings to the fuselage ............................58

Using Planejama (aeroplane nightshirt) .....................59

Care and maintenance ...............................................60

Environmental protection notes ..................................60

Maiden ight ...............................................................60

Notes ..........................................................................61

Page 3

English

3

INNOVATION & TECHNOLOGY

Foreword

Many thanks for your decision to purchase the HoTTrigger, which is an aerobatic model of conventional all-wood construction. The HoTTrigger is a great aeroplane for modellers who already

have experience with powered models and wish to expand their skills, but it is also ideal for

more advanced pilots. The model is easily capable of standard and 3D aerobatics, and offers an

excellent performance. This means that you have acquired an aircraft which is ideal for practi-

sing aerobatic manoeuvres as well as simple fun ying, and all with ease of handling and little

effort. The model is very easy to rig: all you have to do is attach the wings to the fuselage using

two screws. The generous canopy opening ensures easy handling, and makes the model very

practical for everyday ying. The HoTTrigger can be completed with an electric power system

or a glow motor, and is prepared as standard for both versions. All you have to do is decide on

your preferred type of power, and acquire the appropriate accessories.

Attention!

It is essential to read right through the instructions before assembling and ying the model.

!

Approved usage

The HoTTrigger 1500 is designed to be used as a model aircraft. It is not suitable for any other

purpose.

This aerobatic machine is part of the new range of GRAUPNER/SJ all-wood model aircraft. These models are of particularly high quality, and have been developed and tested for you in-house.

Installation of the airborne RC components is simple and quick thanks to the very large fuselage

opening. To prepare the model for the air all you have to do is install the RC components and

power system, and carry out a few minor gluing and assembly procedures.

Model summary description

Wingspan approx. 1500 mm

Length approx. 1430 mm

Overall height approx. 360 mm

All-up weight approx. 3200 g

Specication

Page 4

English

4

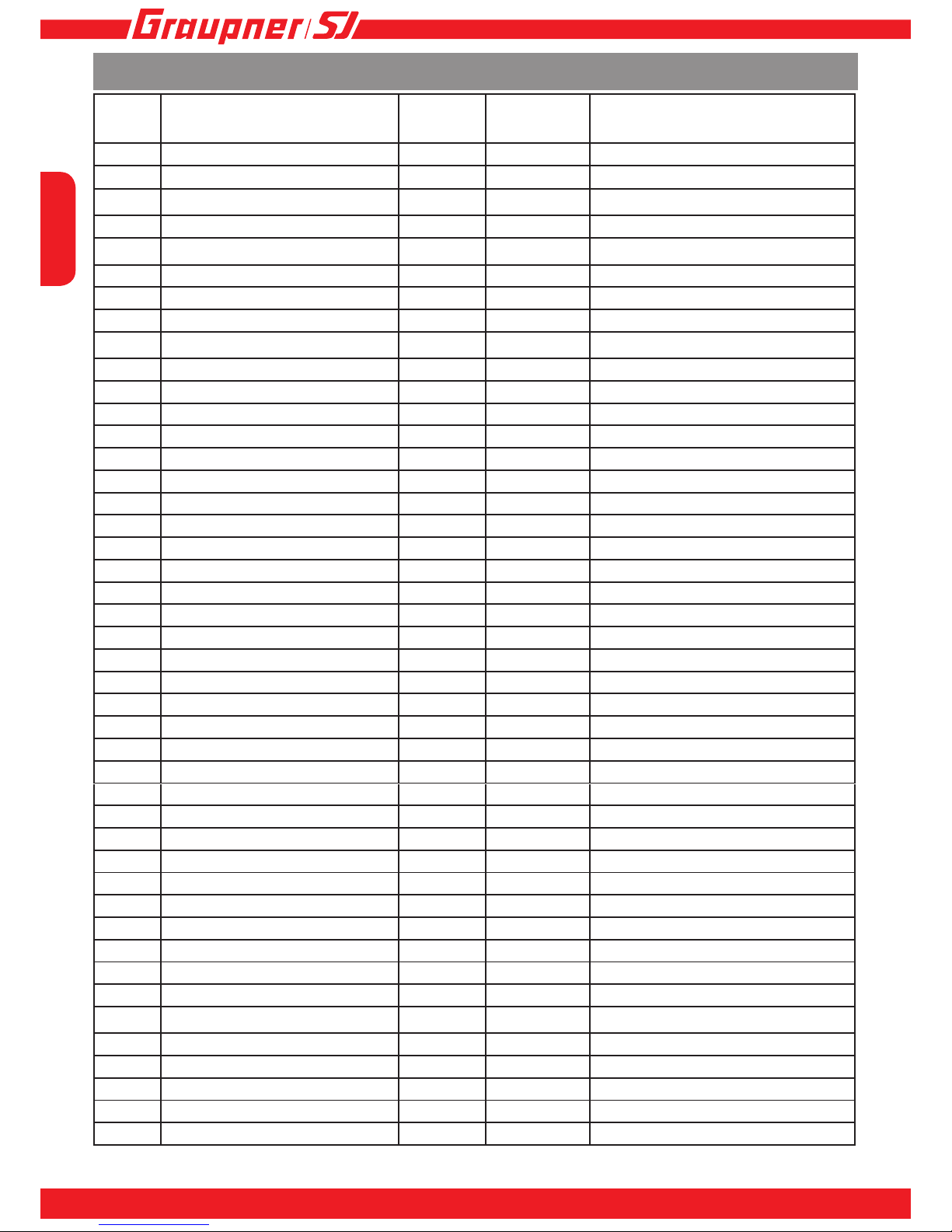

Parts List

Pos. Description Quant. Material Dimensions in mm

1

Point-hinge 19 Plastic Ø 3 x 49

2

Fuselage 1 Wood

3

Tailplane 1 Wood

4

Elevator joiner 2 GRP 120 x 10 x 2

5

R.H. elevator 1 Wood

6

L.H. elevator 1 Wood

7

Rudder 1 Wood

8

R.H. wing panel 1 Wood

9

L.H. wing panel 1 Wood

10

R.H. aileron 1 Wood

11

L.H. aileron 1 Wood

12

Grubscrew 2 Steel M 3 x 3

13

Collet 1 Steel Ø 8 x 5,5 x Ø 2,5

14

Wire tailwheel unit 1 Steel Ø 2,5

15

Tailwheel bracket 1 Steel ca. 50 x 10 x 2

16

Tailwheel steering rod 1 Steel/alum.

17

Tailwheel 1 Plastic Ø 27 x 13 x 2,5

18

Mushroom-head allen screw 6 Steel M 3 x 12

19

Ball-link 11 Plastic M 2

20

Main undercarriage unit 1 Aluminium

21

Cheesehead allen screw 2 Steel M 3 x 12

22

R.H. wheel spat 1 GRP

23

L.H. wheel spat 1 GRP

24

Cheesehead allen screw 2 Steel M 4 x 40

25

Spacer ring 2 Wood Ø 16 x 5 x 2

26

Main wheel 2 Plastic Ø 50 x 19 x 4

27

Self-locking nut 4 Steel M 4

28

Washer 2 Steel Ø 16 x 5 x 1

29

Control surface horn 10 GRP

30

Cheesehead allen screw 13 Steel M 2 x 10

31

Self-locking nut 13 Steel M 2

32

Aileron pushrod 2 Steel M 2 x 70

33

Elevator pushrod 1 Steel M 2 x 85

34

Ring-screw 4 Brass M 2 x 20

35

Rudder servo output arm 1 GRP

36

Crimp sleeve 4 Aluminium 5 x 3 x 4

37

Linkage cable 1 Steel Ø 0,5 x 1500

38

Cheesehead allen screw 4 Steel M 5 x 15

39

Drilling template 4 Felt 100 x 15 x 0,2

40

Cowl 1 GRP

41

Canopy 1 Plastic

42

Wing joiner tube 1 CFRP Ø 15 x 550

43

Retaining screw 1 Plastic 1/4“ x 50

44

Planejama (protective bags) 1 set Textile

Page 5

English

5

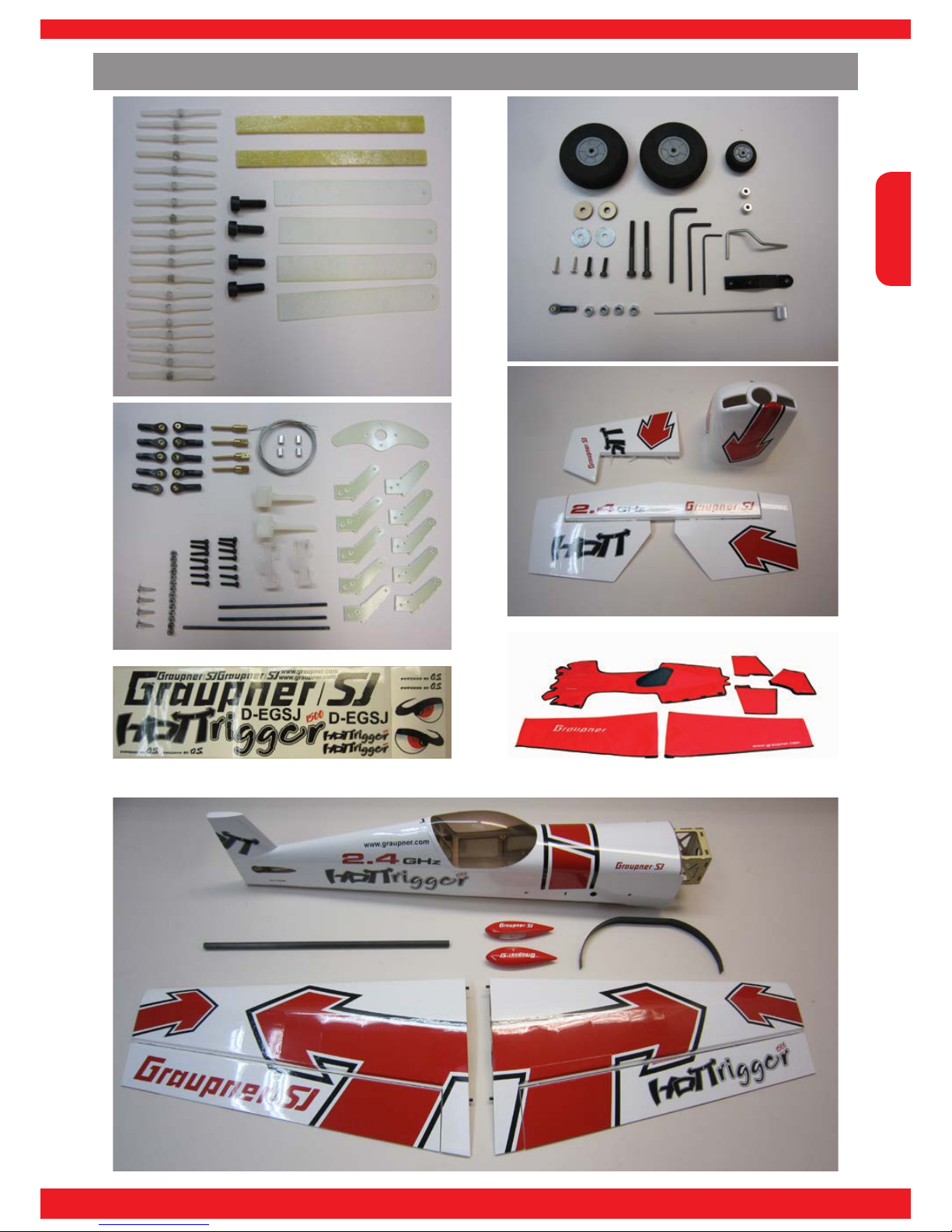

INNOVATION & TECHNOLOGY

Kit contents

Page 6

English

6

Recommended accessories

Adhesive

Tools required

Quant. Description No.

1 Gr. HoTT mx-16 8-channel computer system 33116

4

DES 708 BB MG servo 7946

1 GR 16 receiver 33508

2 100 mm extension lead 3935.11

1 320 mm extension lead 3935.32

1 White plastic spinner, 57 mm Ø 1112.57

1 Hook-and-loop strap, length 320 mm 1587

1

DES CFRP heavy-duty servo output arm 7907.2

1 Low-viscosity cyano-acrylate (thin cyano) 5822

1 Activator spray 953.150

1 UHU-Schraubensicher (thread-lock uid) 952

1 UHU-Plus endfest 300 (slow-setting epoxy) 950.43

1 UHU-schnellfest (fast-setting epoxy) 962

1 Silicone damper oil, 150 cps / 60 ml 95401

Description No.

Scalpel 982

Water pump pliers

Scissors

Cross-point screwdriver

1.2 / 1.9 / 5 / 6.4 mm drill bits

14 mm A/F open-ended spanner

4.5 mm socket spanner

1 O.S. OMA-5020-490 6626

1 Brushless Control +T 70 G 3,5 33770

1 V-MAXX 5/4200 18.5 V G3.5 LiPo, 45C 9740.5

1 Electric propeller, 15 x 8” 1326.15x8

2 Hook-and-loop tape, 100 mm 3368.1

1 Stand-off pillar, length 44.5 mm 2269.44,5

Recommended accessories - electric motor

Page 7

English

7

INNOVATION & TECHNOLOGY

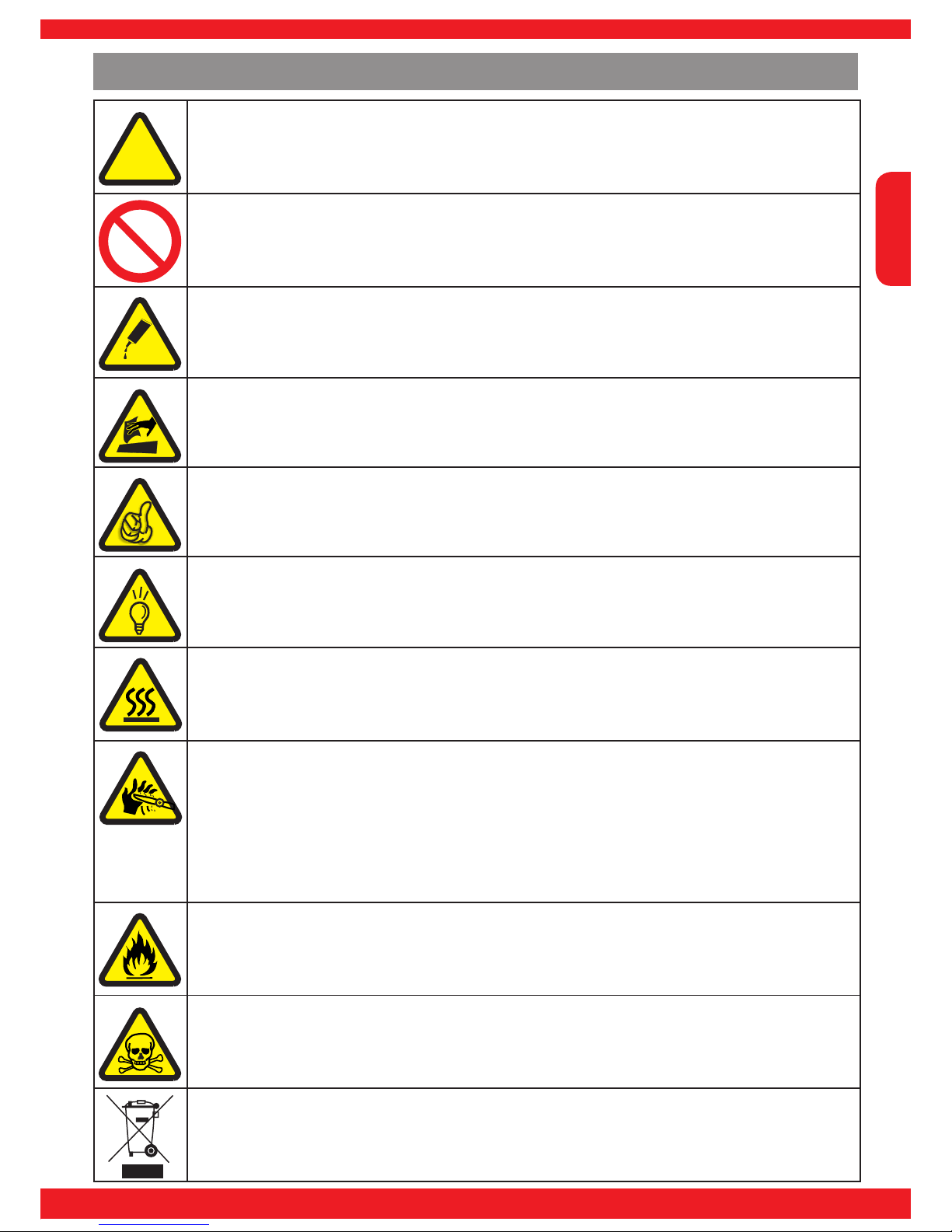

Symbols and their meaning

Attention!

This symbol alerts you to the following notes which the user must observe. Neglecting this

information may have an adverse effect on the system’s proper function and the safety of the

operator.

Warning!

This symbol alerts you to prohibited actions which the user must always observe. Neglecting

these warnings may have an adverse effect on the system’s proper function and the safety of

the operator.

Note regarding adhesives!

This symbol calls attention to the particular adhesive which is to be used in the following procedure in order to obtain a sound joint, or to secure the components or screws.

Care and maintenance!

This symbol calls attention to notices about care of the model which must absolutely be observed to ensure its long service life.

Note!

This symbol alerts the user to information which must always be observed in order to ensure

the safe operation of the device.

Tip!

This symbol alerts you to hints and tips during the model’s construction which help to avoid

problems and potential damage, and provide information on solving possible problems.

Warning: hot surfaces!

This symbol calls attention to injury risks which arise if you touch hot surfaces. Neglecting

these warnings may lead to serious injury.

Rotating power unit!

This symbol calls attention to the injury risks associated with operating a propeller which must

absolutely be observed by the user! Any disregard for the adjacent notices can lead to imbalance of the propeller, can se-verely damage the model and can produce most severe injuries

for persons in the vicinity as a consequence of hurled parts.

This symbol calls attention to the injury risks associated with operating a propeller which must

absolutely be observed by the user! Any disregard for the adjacent notices can lead to severe

injuries for the operator.

Inammable!

This symbol calls attention to the following information, which the user must always observe.

Neglecting these warnings incurs a risk of explosion and re.

Warning: toxic substances!

This symbol calls attention to the following information, which the user must always observe.

Neglecting these warnings incurs a risk of poisoning.

Disposal notes

This symbol calls attention to information regarding specic materials or products, which

must be observed when disposing of these items.

!

Page 8

English

8

Warnings and safety notes

Attention!

Never reach into a running propeller or attempt to hold the propeller by hand when it is operating. This leads to hand injuries. Rotational forces can readily cause the propeller to get out of

control.

Attention!

Never put objects/foreign materials into a running propeller. Always ensure that objects/foreign

materials can-not get into the propeller when it is running. If this does happen, the propeller‘s

sudden imbalance can cause heavy damage to the model. Persons in the vicinity can be severely injured by parts hurled through the air.

Attention!

Never dwell in front or back of a propeller. Improper assembly or unforeseen circumstances

can cause the propeller to come off of its shaft. Stop the propeller if unusual noises are heard.

Warning!

The propeller must be securely attached. Do not direct the propeller toward persons or animals, do not test the propeller in the hand. Never dwell in front of a propeller. Unforeseen

circumstances can cause the propeller to come off of its shaft. Persons in the vicinity can be

severely injured by parts hurled through the air.

Warning!

Do not touch any part of the drive train (i.e. motor + propeller + shaft) while it is operating as

this can lead to injuries. Allow the motor, shaft, regulator and battery time to cool off after operation before touching any of these parts!

Warning!

Operating the model while under the inuence of medication, alcohol, drugs, etc. is forbidden.

Attention!

Any deviation from the model‘s instructions can have an effect on the model‘s functionality

and operational safety. This must be avoided under all circumstances.

Attention!

The operator of a RC model must be aware of the legal stipulations before putting a RC model

into operation because a RC model is subject to applicable laws. Applicable laws are always

to be followed in every case. In this respect, pay attention to the laws applicable in the given

country. Before operating the model for the rst time, check if your private liability insurance

provides coverage for RC models of this type. If this is not the case, obtain special liability

insurance coverage for RC models.

!

!

!

This is a model that – together with appropriate accessories – can become a functional RC

model. GRAUPNER/SJ cannot monitor adherence to the assembly and operating instructions

for the model nor can GRAUPNER/SJ supervise the installation, operation or maintenance of

the model and its components. There-fore GRAUPNER/SJ accepts no liability whatsoever for

losses, damage or costs that arise from improper op-eration, improper behavior or which are

associated with same in any manner. Unless mandated by prevail-ing law, the obligation of the

GRAUPNER/SJ company to provide damage compensation arising from the use of the model,

regardless of the grounds, is excluded (this exclusion includes personal injury, death, damage to

buildings or structures as well as sales and business losses, consequential damage for busi-

ness inter-ruption or other direct and indirect consequential damages).

Total liability under all circumstances and in each case is limited to the amount actually paid for

this model.

Page 9

English

9

INNOVATION & TECHNOLOGY

Attention!

RC models are very demanding and potentially dangerous objects, and call for a high level of

knowledge and expertise from the operator, together with a sense of responsibility.

Attention!

Adhesives and paints contain solvents which can be injurious to health. It is important to heed

the manufacturer’s instructions and warnings.

Attention!

The model may only be operated with accessories which we recommend as otherwise functionality cannot be guaranteed.

Attention!

The commissioning and operation of the model is solely at the risk of the operator. Only cautious, considered handling during operation of the model will prevent personal injuries and

property damage.

Attention!

This model is not suitable for children under 16 years of age.

Attention!

Pay attention to the potential dangers associated with the tools that are used.

Attention!

Comply with the recommendations and notices associated with the remote control set and

accessories.

Attention!

Before operating the model, check it for reliable response to the remote control unit and all

plug-in connections for secure connection.

Attention!

Never attempt to recharge any primary cell batteries used as a power supply. Only rechargeable (i.e. secondary cell) batteries may be charged.

Attention!

The remote control unit‘s effective range must be checked prior to operation of the model. To

check this, switch the model on then walk with it away from the transmitter as far as about 100

m while a helper operates various controls on the transmitter. At this distance it must be possible to operate all model functions without any problem.

Attention!

Pay attention to radio devices or transmitters which could substantially affect the model‘s

functionality. Try to ensure that such devices are not operated in the vicinity while the model is

being operated.

Attention!

Batteries must never be short-circuited or come into direct contact with water.

Attention!

Never endanger yourself or others in an attempt to recover the model.

!

!

!

!

!

!

!

!

!

!

!

!

!

Page 10

English

10

Attention!

Take care with loose clothing such as scarves, loose shirts etc. Flapping cloth can easily be

sucked into the area of the propeller and then get tangled in the blades.

Attention!

If there are passers-by or spectators at your ying site, make sure that they are aware of the

dangers inherent in your activity, and insist that they keep a safe distance away (at least 5 m

behind the plane of the propeller).

Attention!

Model aircraft should only be own in “normal” weather conditions, i.e. a temperature range

of -5° to +35° C. More extreme temperatures can lead to changes in battery capacity, material

characteristics and other unwanted effects.

Attention!

If your model is powered by a motor or engine, it is important to observe the safety notes provided by the manufacturer of the power plant.

Attention!

Before and after every ight check the model and all parts attached to it - e.g. propellers, control surface linkages, control surfaces etc.) for possible damage. Do not y the model again

until you have corrected any defects.

Attention!

Adhesives and paints contain solvents which may be hazardous to health under certain circumstances. Read and observe the notes and warnings supplied by the manufacturer of these

materials.

Attention!

Never y over or towards other people.

Attention!

During take-off and landing procedures the runway must be free of unauthorised persons and

movable obstacles.

Attention!

Watch the aeroplane constantly while it is in the air. Models must always give way to full-size

aircraft.

Attention!

Never y the model from public roads, squares, schoolyards, parks and public playing elds. It

is your responsibility to keep the model under full control at all times.

Attention!

All model yers should behave in a manner which avoids endangering or interfering with public safety and order. Never act in any way which will disturb other yers and jeopardise safe,

orderly ying at the site.

Attention!

As operator of this model aircraft you bear sole responsibility for its safe operation, The only

way to avoid personal injury and property damage is to operate your model cautiously and

conscientiously.

!

!

!

!

!

!

!

!

!!!

!

Page 11

English

11

INNOVATION & TECHNOLOGY

Attention!

If there are passers-by or spectators at your ying site, make sure that they are aware of the

dangers inherent in your activity, and insist that they keep a safe distance away (at least 5 m

behind the plane of the propeller).

Attention!

This aeroplane is highly pre-fabricated and can be completed in a very short time. However,

the work which you have to carry out is important and must be done carefully. The model will

only be strong and y well if you complete your tasks competently - so please work slowly and

accurately.

Attention!

If your model is powered by a motor or engine, it is important to observe the safety notes provided by the manufacturer of the power plant.

Attention!

Before and after every ight check the model and all parts attached to it - e.g. propellers, control surface linkages, control surfaces etc.) for possible damage. Do not y the model again

until you have corrected any defects.

Attention!

Adhesives and paints contain solvents which may be hazardous to health under certain circumstances. Read and observe the notes and warnings supplied by the manufacturer of these

materials.

Attention!

Please don’t misunderstand the purpose of these notes. All we want to do is bring to your attention the many dangers and hazards which can arise if you lack knowledge and experience,

or work carelessly or irresponsibly. If you take reasonable care, model ying is a highly creative, instructive, enjoyable and relaxing pastime.

Attention!

It is important that your shoes should not slip when you are dealing with the motor or engine.

The model must also be rmly secured.

Note!

When the model is not in use, remove the ight battery from the model, and the dry or rechargeable cells from the transmitter.

Note!

Do not subject the model to severe humidity, heat, cold or dirt.

Note!

Secure the model and transmitter when transporting them, otherwise they could slide about

and be damaged.

Care!

Clean the model and the transmitter using suitable cleaning materials only; we recommend a

lint-free cloth. Never use chemical cleaning agents, solvents, methylated spirit, white spirit or

similar.

Attention!

According to the new regulation of §103 Paragraph 3 of the LuftVZO (German Aviation Approvals Ofce), all model aircraft - whether slow-yer, park-yer, glider, or model aircraft propelled

by any form of power plant - must be insured before the model is operated. If you are not sure

about this, please ask at your local model shop where the staff will be glad to advise you.

These safety notes must be kept in a safe place. If you ever dispose of the model, be sure to

pass them on to the new owner.

!

!

!

!

!

!

!

!

Page 12

English

12

Contents of the manufacturer’s declaration:

If material defects or manufacturing faults should arise in a product distributed by us in the Fe-

deral Republic of Germany and purchased by a consumer (§ 13 BGB), we, Graupner/SJ GmbH

D-73230 Kirchheim/Teck, Germany, acknowledge the obligation to correct those defects within the

limitations described below.

The consumer is not entitled to exploit this manufacturer’s declaration if the failure in the usability

of the product is due to natural wear, use under competition conditions, incompetent or improper

use (including incorrect installation) or external inuences.

This manufacturer’s declaration does not affect the consumer’s legal or contractual rights regar-

ding defects arising from the purchase contract between the consumer and the vendor (dealer).

Extent of the guarantee

If a claim is made under guarantee, we undertake at our discretion to repair or replace the defective goods. We will not consider supplementary claims, especially for reimbursement of costs

relating to the defect (e.g. installation / removal costs) and compensation for consequent damages

unless they are allowed by statute. This does not affect claims based on legal regulations, especially according to product liability law.

Guarantee requirements

The purchaser is required to make the guarantee claim in writing, and must enclose original proof

of purchase (e.g. invoice, receipt, delivery note) and this guarantee card. He must send the defective goods to us at his own cost, using the following address:

Graupner/SJ GmbH, Serviceabteilung,

Henriettenstr.96, D 73230 Kirchheim/Teck

The purchaser should state the material defect or manufacturing fault, or the symptoms of the

fault, in as accurate a manner as possible, so that we can check if our guarantee obligation is

applicable.

The goods are transported from the consumer to us and from us to the consumer at the risk of the

consumer.

Duration of validity

This declaration only applies to claims made to us during the claim period as stated in this declaration. The claim period is 24 months from the date of purchase of the product by the consumer from

a dealer in the Federal Republic of Germany (date of purchase). If a defect arises after the end of

the claim period, or if the evidence or documents required according to this declaration in order to

make the claim valid are not presented until after this period, then the consumer forfeits any rights

or claims from this declaration.

Limitation by lapse of time

If we do not acknowledge the validity of a claim based on this declaration within the claim period,

all claims based on this declaration are barred by the statute of limitations after six months from

the time of implementation; however, this cannot occur before the end of the claim period.

Applicable law

This declaration, and the claims, rights and obligations arising from it, are based exclusively on the

pertinent German Law, without the norms of international private law, and excluding UN retail law.

Manufacturer‘s declaration on behalf of GRAUPNER/SJ GmbH

Page 13

English

13

INNOVATION & TECHNOLOGY

Assembling the model

Attention!

It is important to observe the sequence of procedures described in these building instructions.

Attention!

Before you start assembling the model we recommend that you run a lm iron over the covering lm to ensure that it is taut, as uctuations in temperature and humidity may have

caused creases, and the lm may have come loose from the wood in places. This is important,

because in some areas the lm has to be removed, and the remaining lm would then shrink

uncontrollably when ironed down again.

!

!

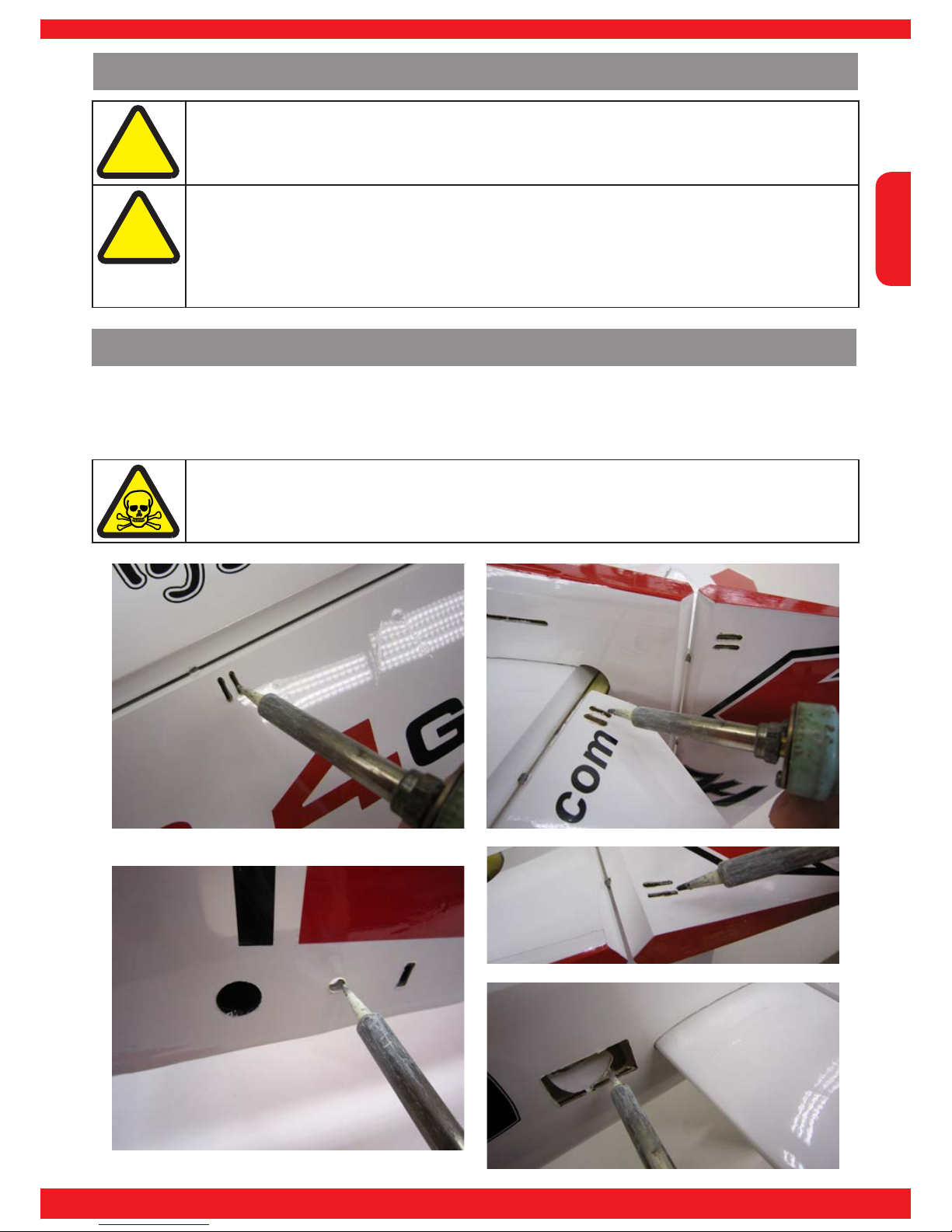

Use a hot soldering iron to melt away the covering lm over the holes for the wing joiner tube, incidence pegs,

retaining screws, control surface horns and servo leads. Use your ngertips to locate the openings under the lm.

Removing covering lm

Attention!

This stage should be carried out in a well ventilated room, to avoid directly breathing in fumes.

Page 14

English

14

Attention!

Avoid damaging the raised ange of the servo output arm, otherwise the arm could fail in

ight, leaving the model uncontrollable.

!

2. Servo installation

Cut down the servo output lever as shown in the photo. Centre the servo from the transmitter using a new model

memory. Push the lever onto the output shaft.

3. Fitting the rubber grommets

Push the rubber grommets into the servo mounting lugs.

Servo installation - general

1. Information on installing servos

The same procedure is employed for preparing and tting all the servos. The following steps should be carried

out for each servo which is to be installed, using the parts supplied in the servo’s accessory pack. Variations from

the standard procedure - such as tting different servo output arms, and changing the position of the arms on the

servos - are explained in the relevant stages, and shown in the pictures of the installed servos.

4. Fitting the tubular brass

spacers

Push the brass spacers into the rubber grommets from

underneath.

Page 15

English

15

INNOVATION & TECHNOLOGY

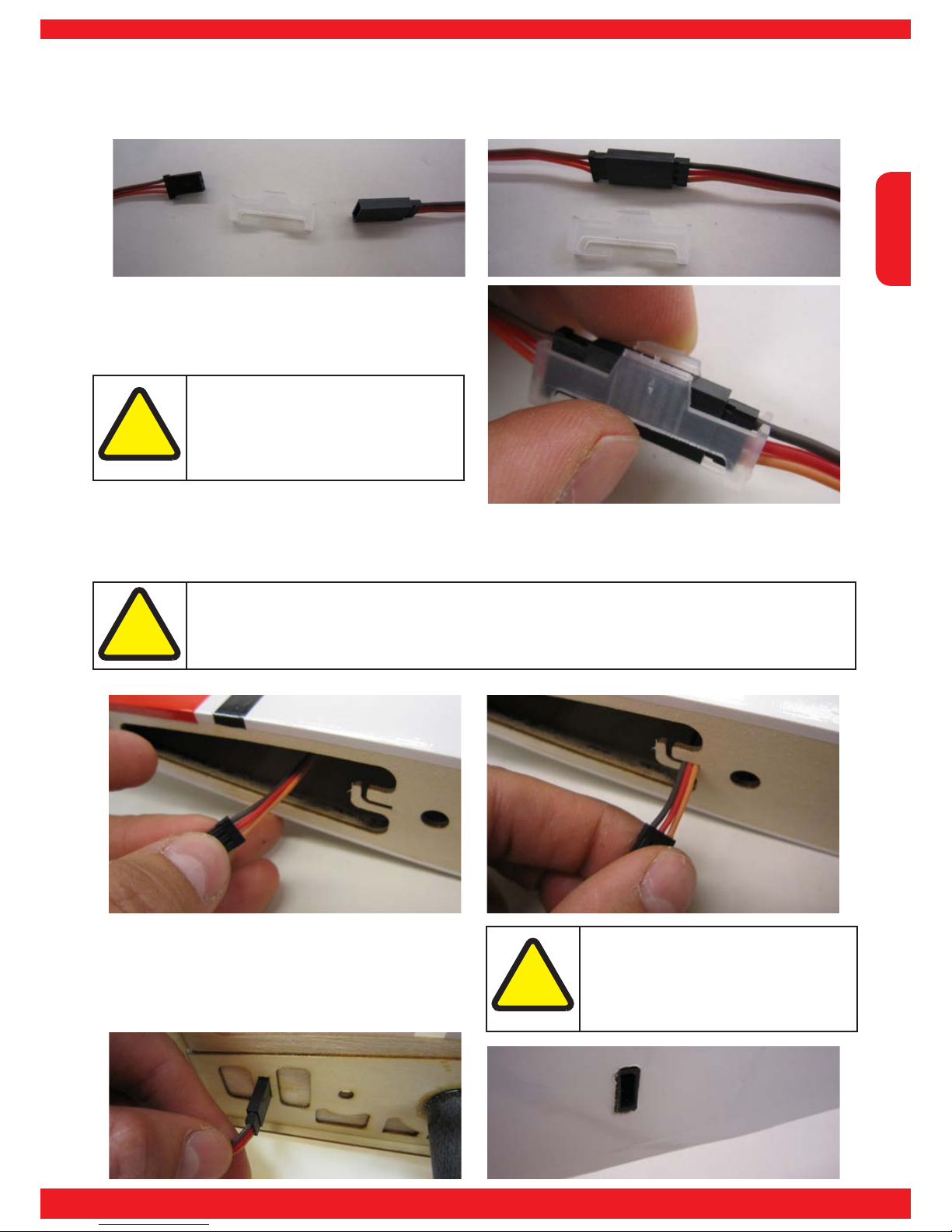

5. Extending the servo lead

If a servo extension lead is used, it must be secured using one of the clips supplied. First insert the servo lead

plug into the socket on the extension lead.

Attention!

Check that the clip engages fully,

otherwise the servo could become

disconnected in ight, leaving the

model uncontrollable.

!

Push the clip over the plastic plug / socket housings.

6. Parking the servo leads

The aileron servo leads can be ‘parked’ in slots in the wing root; this prevents the nuisance of the leads falling

inside the wing.

Attention!

The slots are only intended for use when the wings are in storage. Disengage the leads from

the slots before assembling the model, otherwise the wings will not t correctly against the

fuselage; using force could damage the slotted ribs.

!

The socket is tted in the slot in the fuselage side,

working from the inside, and glued in place using

thick cyano; it must nish ush with the outside of the

fuselage.

Attention!

Don’t allow glue to run inside the

socket, as this will soil the contacts,

and the connector will have to be

replaced.

!

Page 16

English

16

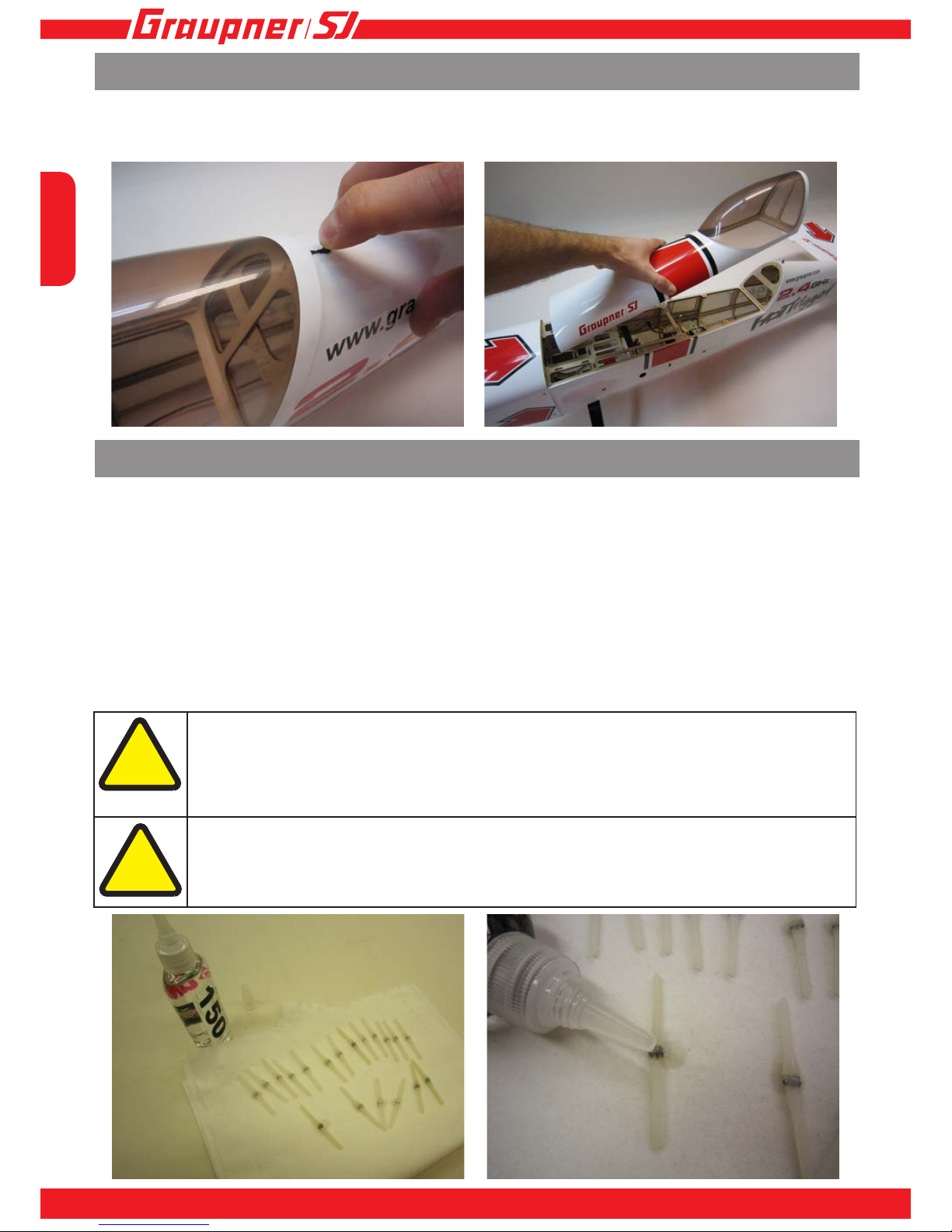

Canopy

Slide the canopy latch towards the tail and hold it in that position while you raise the rear end of the canopy and lift

it off.

Gluing the point-hinges

Attention!

Ensure that the oil only contacts the pivot of the point-hinge (1), and that no oil gets onto the

part of the hinge which is to be glued, otherwise the hinge might not be securely xed in the

hole. In this case the control surface could come loose in ight and render the model uncontrollable.

Attention!

Take care to keep the oil off your ngers, as this could transfer it to the joint areas of the hinge. Wash your hands after handling the oil to prevent unwanted transfer.

!

!

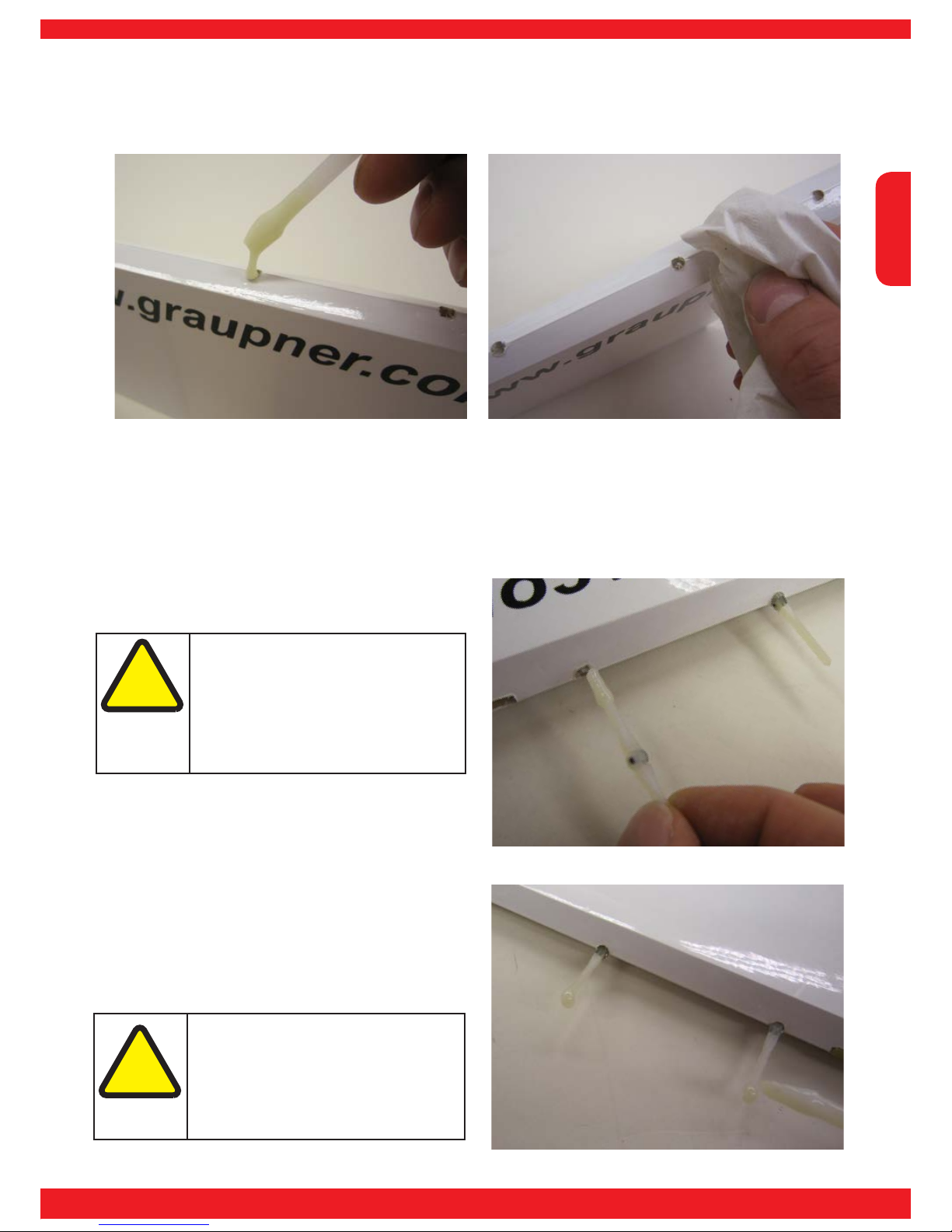

2. Preparing the point-hinges

Apply a drop of 150 cps silicone damper oil or similar to the pivot of the point-hinge (1) to protect it from excess

glue. Lay a strip of paper towel (kitchen paper) under the point-hinge (1) to absorb any excess oil.

1. Information on gluing the point-hinges

All the point-hinges (1) should be prepared and installed in the same manner. Follow the procedure described for

each hinge at the appropriate juncture. Complete the task for one sub-assembly at a time, e.g. rst one wing and

aileron, then the next, and so on. Any deviations from the standard procedure (e.g. for the elevators) are

explained at the appropriate point in the instructions, or are shown in the pictures of the point-hinges (1) when they

are tted.

Page 17

English

17

INNOVATION & TECHNOLOGY

3. Applying glue to the hinge holes

The point-hinges (1) are glued in place using UHU-Plus Endfest 300 (slow-setting epoxy). Apply a little glue to each

hole in the control surface. If glue gets onto the surface adjacent to the hole, it can be removed by wiping with a

piece of kitchen paper dipped in methylated spirit.

4. Inserting the point-hinges

Apply a little adhesive to the rst third of the point-hinge (1), and twist the hinge into the hole. If you have used

the correct quantity of glue, the adhesive will be distributed along the length of the hinge and glue it to the control

surface over the full length of the hole. Push the point-hinge (1) into the hole to the point where the pivot axis is

located about 1 mm outside the leading edge of the control surface.

Attention!

Take care that no glue gets into the

pivot and jams the point-hinge (1), as

this might prevent the hinge rotating

when the glue has cured; the control

surface would then no longer move in

either direction.

!

Attention!

Take care not to apply too much glue,

as this would cause the excess to be

forced out of the hole and into the

pivot area of the point-hinge (1).

!

Apply a little adhesive to the rst third of the point-hinge

(1) and the hole in the mating part of the xed panel, as

described in section 3. Applying glue to the hinge

holes.

Page 18

English

18

Push the point-hinges (1) attached to the control surface into the holes in the xed panel or wing - depending on

the sub-assembly you are currently working on. Ensure that the colour scheme on the two panels

lines up correctly. Offer up the control surface, holding it at an angle at the pivot axis, and push the point-

hinges (1) one by one into the holes in the xed panel.

Attention!

This procedure is very important, and must be carried out with the greatest care, because there is a real risk of epoxy running into the pivot points and jamming the hinges. When the glue

has cured, the hinges will then be impossible to move, and the control surface will not deect.

Attention!

Dip a piece of kitchen paper into methylated spirit and use it to wipe away excess epoxy from

the surface of the components.

!

Now push the control surface towards the xed panel until the hinge pivots are just visible. Repeatedly move the

control surface to both extremes of travel to allow the point-hinges to settle themselves into the correct position.

Temporarily x the control surface to the xed panel

with paper masking tape to ensure that it cannot shift.

Allow the epoxy to set hard, then remove the tape and

move the control surface in both directions. You may

hear a slight cracking sound as any excess glue at the

hinge pivots fractures; this is not a problem, unless the

hinge is completely jammed with glue.

!

Page 19

English

19

INNOVATION & TECHNOLOGY

Installing the tailplane

1. Aligning the tailplane

Apply a strip of paper masking tape to the underside of the fuselage (2) to protect the underlying lm. Draw a

centreline on the tape, on which a setsquare can be placed in order to help you align the tailplane (3). First mark

the end of the tailplane (3) at which the setsquare will be positioned later.

Attention!

This procedure must be carried out with the greatest care, otherwise the tailplane may be installed at an angle. This will cause the model to veer off to one side when you apply an elevator

command, and it will be difcult to y in a straight line.

!

Page 20

English

20

Attention!

Take care to set the tailplane (3) exactly ‘square’ in the fuselage before marking the surfaces,

otherwise you could easily remove too much lm and leave the wood exposed, where it would

be subject to weathering. This could lead to material fatigue and structural failure, leaving the

model uncontrollable.

!

2. Removing the lm from the joint surfaces

The covering lm over the joint surfaces of the tailplane (3) must rst be removed: slide the tailplane (3) through

the slots in the fuselage (2), and set it central; it must also be at 90° to the fuselage centreline. Draw a line on the

tailplane on both sides of the fuselage (2), top and bottom, to mark the area of lm to be removed.

Page 21

English

21

INNOVATION & TECHNOLOGY

4. Gluing the tailplane in place

Slide the tailplane (3) into the slot in the fuselage (2), and set it exactly central. It must project by the same

dimension on both sides, and be at an angle of 90° to the fuselage centreline, so that the area from which the lm

has been removed is completely hidden inside the fuselage (2).

Attention!

Ensure that the tailplane (3) is the right way up in the slots in the fuselage (2), as shown in the

picture.

Note!

Use thin cyano, No. 5822, for this joint. Fitting a syringe needle allows you to apply the glue

directly to the wood and the joint lines to ensure a sound joint.

!

3. Removing the lm from the joint surfaces

Run the tip of a soldering iron along the marked lines, using a steel ruler as a guide, and remove the lm between

the two cuts.

Attention!

Just allow the tip of the soldering iron to glide over the lm. Don’t apply excessive pressure,

as this could damage the wood underneath; the tailplane could then snap off at the fuselage,

leaving the model uncontrollable.

Attention!

Carry out this procedure in a well ventilated room to avoid directly breathing in the fumes.

!

Page 22

English

22

5. Preparing the elevator joiners

Sand both sides of the elevator joiner (4) using 100-grit abrasive paper, to ensure that the glue adheres strongly

to the surfaces.

6. Gluing the elevator joiners

The elevator joiners (4) must be glued together before the elevators (5) are attached by their hinges. This is

important, as the joiners and hinges must be aligned while the glue is soft, to ensure that

the elevators work correctly. Use the same adhesive as specied for the hinges.

Attention!

Ensure that the larger faces of the elevator joiners (4) are glued together, as the angled edge of

the joiner forms an extension of the elevator leading edge.

!

Apply a thin, even layer of epoxy to one of the

mating faces, and place the two joiners (4) together.

Press them together lightly, and check that their

edges line up ush.

Place the elevator joiner (4) to one side for a

moment, and continue with point 6. Attaching

the elevators.

Page 23

English

23

INNOVATION & TECHNOLOGY

7. Attaching the elevators

Glue the point-hinges (1) in one of the elevators (5 or 6) as described in the section entitled Gluing the pointhinges (1). Apply epoxy to the slot for the elevator joiner (4). Wipe off excess resin using kitchen paper and

methylated spirit.

Push the elevator joiner (4) into the slot. Wipe off

excess glue using paper towel and methylated spirit.

Apply glue to the point-hinges (1) and the hinge holes in the tailplane (3).

Attention!

It is important to t the tailplane (3)

in the slot with the top surface facing

up, as shown in the picture.

!

Page 24

English

24

Attach one elevator (5 or 6) to the tailplane by means

of the point-hinges (1) and the elevator joiner (4).

Repeat the procedure for the second elevator panel

(5 or 6).

Attach the second elevator (5 or 6) to the tailplane (3)

using the point-hinges (1) and the elevator joiner (4).

Push both elevators (5 and 6) towards the tailplane as far as the pivot axis of the point-hinges (1). Repeatedly

move the elevators up and down to allow the point-hinges (1) to settle in the correct position.

Attention!

Deect both elevators up and down and check that they move simultaneously and evenly, to

ensure that the hinges in both panels (5 and 6) are positioned equally; if the pivot axes are

different, the elevators will not be able to deect accurately.

!

Page 25

English

25

INNOVATION & TECHNOLOGY

Temporarily x the elevators (5 and 6) to the tailplane with paper masking tape to prevent them shifting, then use

a screwdriver to push the elevator joiner into the elevators (5 and 6) as far as it will go. Wipe off excess epoxy

using methylated spirit on a piece of paper towel.

Attaching the rudder to the n

Glue the point-hinges (1) into the rudder (7) as described in the section entitled Gluing the point-hinges

(1). Wipe off excess glue with paper towel and methylated spirit.

Attaching the rudder

Glue the point-hinges (1) into the wings (8 and 9) and the ailerons (10 and 11) as described in the section

entitled Gluing the point-hinges (1). Wipe off excess glue with paper towel and methylated spirit.

Page 26

English

26

Installing the tailwheel assembly

Remove the grubscrew (12) from the tailwheel steering

rod (16), and slip the steering rod (16) onto the wire

tailwheel unit (14).

Slip the tailwheel bracket (15) onto the wire tailwheel

unit (14).

Tailwheel bracket assembly

Remove the grubscrew (12) from the collet (13), then t

the collet (13) on the wire tailwheel unit (14).

Page 27

English

27

INNOVATION & TECHNOLOGY

4. Installing the tailwheel

Slip the tailwheel (17) onto the wire unit (14), and secure it with the collet (13) and grubscrew (12).

Note!

Use UHU thread-lock uid, No. 952, to prevent the grubscrew (12) working loose.

Position the tailwheel steering rod (16) on the wire

tailwheel unit (14) in such a way that part (14) is

exactly at 90° to the steering rod (16). Tighten the

grubscrew (12) in the collet.

Note!

Use UHU thread-lock uid, No. 952, to

prevent the grubscrew (12) working

loose.

Locate the collet (13) which you tted rst, and slide

it along the wire until it rests against the tailwheel

bracket (15). Tighten the grubscrew (12).

Note!

Use UHU thread-lock uid, No. 952, to

prevent the grubscrew (12) working

loose.

Page 28

English

28

Installing the tailwheel bracket

Fix the tailwheel bracket (15) to the fuselage using the retaining screws (18).

Glue the ball-link (19) into the rudder (7) using thick

cyano-acrylate.

Tailwheel steering system

Mark a point about 20 mm from the end of the tailwheel steering rod (16) on the centreline of the rudder (7).

Use a 5 mm bit to drill a hole for the ball-link (19) which acts as a link between the rudder and the tailwheel.

Note!

Use UHU Schraubensicher (thread-lock uid) No. 952 to secure the screws (18).

Slip the ball-link (19) onto the tailwheel steering rod (16) and push it into the hole in the rudder (7).

Page 29

English

29

INNOVATION & TECHNOLOGY

1. Installing the main undercarriage units

Invert the fuselage (2) and lay it on the bench prior to attaching the undercarriage.

Installing the undercarriage

Place the main undercarriage unit (20) in the recess in

the fuselage, and secure it with the retaining screws

(21).

Note!

Use UHU Schraubensicher (threadlock uid) No. 952 to secure the

screws (21).

Page 30

English

30

2. Fitting the wheel axles

Fit the screw through the enlarged hole in the wheel

spat (22, 23), then slip the spacer ring (25) on the screw

(24) inside the spat.

Fit the wheel (26) onto the screw (24).

Screw the self-locking nut (27) onto the screw (24) to

the point where the screw (24) projects out of the selflocking nut (27) by about 2 mm.

2. Preparing the wheel

spats

Open up the hole in the outside of the wheel spats (22,

23) using a 6.4 mm Ø drill, then use a round le to open

up the hole slightly to clear the head of the screw (24);

the screw-head should be a close t in the hole.

Attention!

Take care to produce one left-hand

and one right-hand wheel spat.

!

Page 31

English

31

INNOVATION & TECHNOLOGY

Slip the washer (28) onto the projecting end of the

screw.

Tighten the screw fully into the self-locking nut (27),

ensuring that the wheel (26) still rotates. The head of

the screw should now be located in the enlarged hole in

the wheel spat (22, 23).

The wheel spat (22, 23) is xed to the main

undercarriage unit (20) using the installed screw

(24): slip the screw (24) through the hole in the main

undercarriage unit (20).

Fit a further self-locking nut (27) on the screw so

that the spat (22, 23) can be xed to the main

undercarriage unit (20) using the screw. Lock the two

self-locking nuts (27) against each other.

Attention!

Ensure that both wheels (26) rotate

smoothly, otherwise the model will

not run straight on the runway.

!

Page 32

English

32

Installing the horns

Preparing the control horns

All the control surface horns (29) are prepared and

glued in place using the same procedure. Follow these

steps for each horn (29) which has to be installed on the

model. Any variations from this procedure are explained

in the instructions at the appropriate point, or can be

seen in the pictures.

Sand the joint areas on both sides of the horns (29)

using 100-grit abrasive paper, to ensure that the glue

adheres strongly to the components.

Slip the screw (30) through the horn.

Fit the ball-link (19) onto the screw (30).

Page 33

English

33

INNOVATION & TECHNOLOGY

Attach the second horn (29) to the screw (30).

Tighten the self-locking nut (31) on the screw (30).

Prepare a total of ve control surface horn assemblies

using this procedure. For aesthetic reasons it is best

to prepare two right-hand and three left-hand horn

assemblies; this is accomplished by tting the retaining

screws through the control surface horns (29) from

left or right as appropriate. The horns should then be

installed with the screw-head facing out. This also

makes maintenance easier, e.g. at the elevators.

Preparing the pushrods

Screw the pushrods (32, 33) and ring-screws (34) into the ball-links (19) by about 5 - 10 full turns, as shown in

the picture. The nal length of the pushrods (32, 33) is adjusted individually once they have been installed.

Page 34

English

34

Preparing the servo output

arms

For aesthetic reasons it is best to shorten the three

servo output arms by one hole. Alternatively you can

simply screw the ball-links (19) to the second hole from

the outside.

Snip off the end of the servo outputs using side-cutters, removing one linkage hole, and round off the cut end

using a sanding block to produce a neat radius round the next hole.

Use a 1.9 mm Ø bit to open up the linkage hole in the

servo output arm to take the screws (30).

Attaching the pushrods to

the servo output arms

Page 35

English

35

INNOVATION & TECHNOLOGY

Slip the screw (30) through the linkage ball in the balllink (19).

Tighten the screw (30) in the servo output arm.

Repeat the procedure to connect the ball-links to the

rudder servo output arm (35). The result of your work

should now look as shown in the photo.

Fit the self-locking nut (31) and tighten it on the

screw (30).

Page 36

English

36

Installing the servos

The servos should be installed in the appropriate apertures in the wings (8, 9) and fuselage (2) as shown in the

pictures, using the retaining screws supplied with the servos. Connect a 320 mm extension lead to the rudder servo

following the procedure described n the section General servo installation.

Aileron and elevator

Pass the elevator servo lead through the opening in the

receiver platform.

Page 37

English

37

INNOVATION & TECHNOLOGY

Installing the servo output arms

Install the output arms (with the linkages attached) on the servos as described n the section General servo

installation.

Adjusting the pushrods

Switch the RC system on and set all the servos to neutral (centre) from the transmitter prior to adjusting the

pushrods (32, 33). Temporarily insert the horns in the slots in the control surfaces (5, 10, 11), and adjust the length

of the pushrods until the control surfaces are also at neutral. Screw the ball-links evenly onto the pushrods until the

bottom of the horns (29) lies at on the control surface, and the control surface / horn pivot axis is offset slightly to

the rear as shown in the diagram.

Attention!

Ensure that the servo output arms are at 90° to the servo case, so that the control surface deections are mechanically identical in both directions. If the servo output arm is not at 90°, the

minor discrepancy can be adjusted and corrected at the transmitter.

!

Page 38

English

38

Gluing the control surface horns

Apply plenty of epoxy to the slots for the control surface

horns (29). The RC system should be left switched on

so that the horns (29) can be glued in place with the

control surfaces accurately at neutral.

Push the horn assembly (29) into the slots, so that

excess epoxy is forced out. Withdraw the horn (29)

again, and force glue into the holes in the horn bases to

ensure sound joints.

Note!

The control surface horns (29) should

be glued in place using UHU

schnellfest No. 962, with the addition

of about 1% chopped cotton strands.

Wipe off excess adhesive using methylated spirit on a

piece of paper towel.

Push the horn (29) back into the slots in the control

surface, then x the control surface in the neutral

position using paper masking tape.

Page 39

English

39

INNOVATION & TECHNOLOGY

Rudder linkage

Attaching the rudder cables

Slip a crimp sleeve (36) onto the linkage cable (37),

which will be cut in half later.

Thread the cable (37) through the hole in the ring-screw

(34).

Slip the cable (37) back through the crimp sleeve (36).

Page 40

English

40

Loop the cable (37) back through the crimp sleeve (36).

Compress the crimp sleeve rmly using a pair of pliers, so that the cable (37) cannot possibly slip out again.

Complete the other end of the cable (37) as described in the section Attaching the cables, and then cut the cable

(37) exactly in half. This is accomplished by placing the two horn assemblies (29) together, and stretching the cable

(37) out evenly. Cut the cable in the centre of the resultant loop .

Temporarily x the rudder in place with paper masking

tape to prevent it shifting.

Page 41

English

41

INNOVATION & TECHNOLOGY

Glue the horn assemblies (29) in the rudder as described in the section Gluing the control surface horns.

Attention!

Ensure that both horns (29) are

located in the same position relative

to the hinge pivot axis, otherwise the

cables (37) may not remain taut when

the rudder deects.

!

Thread the cables (37) through the slots in the sides of

the fuselage (2), and deploy them towards the servo.

Installing the rudder output arm

Remove the servo output arm screw as described in

the section General servo installation 3. / 4., and set the

servo to centre from the transmitter.

Page 42

English

42

Place the rudder output arm (35) on the servo output

disc; the central hole will automatically centre itself over

the raised ring of the output disc.

With the RC system switched on and the servo at

centre, rotate the rudder output arm (35) until it is at an

angle of 90° to the servo case sides.

Remove the rudder servo output arm (35) and the

output disc from the servo, and t the retaining screws

(30) through the holes.

Continue the four holes in the servo output arm through

the servo output disc.

Attention!

Ensure that the rudder output arm (35)

does not shift when you use the drill,

and that the servo remains at neutral.

!

Page 43

English

43

INNOVATION & TECHNOLOGY

Place the rudder servo output arm (35) on the output

disc, and t the self-locking nuts (31) on the screws.

Tighten the nuts to x the output arm to the output disc.

Snip off the excess screw length (30) using side-cutters.

Fit the servo in the aperture in the servo platform, and

run the servo lead through the opening forward of the

receiver.

File back the cut screw-ends ush with the self-locking

nuts (31).

Page 44

English

44

The rudder cables (37) must cross over inside the

fuselage, so run the cable (37) from the right-hand horn

to the left-hand end of the servo output arm, and vice

versa. Now hold the cables taut, and use a ne felt-tip

pen to mark the points where they coincide with the

holes in the ring-screws (34).

Slip the crimp sleeve (36) onto the cable (37).

Carefully bend the cable (37) at the ring-screw so that

the marked point remains inside the ring-screw (34); the

cable should then not shift.

Thread the cable (37) through the hole in the ring-screw

(34) until the marked point disappears in the hole,

and does not project out of the other side. This small

difference between the marked point and the hole is

sufcient to ensure adequate tension in the cable for

initial test-ights

Attention!

The next few procedures must be

carried out with the greatest care to

ensure that the system works well

and efciently. Keep strictly to the

sequence described, as this makes

the linkage easier to install.

!

Attention!

You will need to check and adjust the

tension in the rudder cables after the

rst few ights.

!

Page 45

English

45

INNOVATION & TECHNOLOGY

Thread the cable (34) back through the crimp sleeve

(36) again.

Fit the prepared output arm on the servo. The cables should now be under light tension, and cross over inside

the fuselage. The tension in the cables (37) can be adjusted at any time by screwing the ring-screws (34) in or

out.

Snip off the excess cable (37) using side-cutters.

Firmly compress the crimp sleeve (36) using a pair

of pliers, so that the cable (37) cannot slip.

Attention!

Take care to cut only the excess cable

end (37), and not the part which belongs to the linkage, otherwise you will

ruin the system.

!

Page 46

English

46

The ight battery for the electric motor is located inside the model forward of the wing joiner tube using two hook-

and-loop straps No. 1587, and hook-and-loop tape No. 3368.1.

Installing and replacing the batteries

Page 47

English

47

INNOVATION & TECHNOLOGY

Installing the receiver

Wing root connection

The extension lead sockets are tted into the slots in the

fuselage sides, set ush with the outside surface, and

glued in place using thick cyano.

General information

Please refer to the instructions supplied with the receiver before installing the unit, connecting the servo and switch

leads, and deploying the aerial.

Securing the receiver

Locate all the cables attached to the RC system

components, connect them to the receiver, and secure

the receiver in the model using a hook-and-loop

strap No. 1587 and hook-and-loop tape No. 3368.1.

Alternatively the receiver can be retained with a

cabletie.

Aerial deployment

Fix the aerials to the fuselage side using strips of

adhesive tape as shown.

Attention!

This is only a recommendation. If you

nd that reception is poor with this

deployment, try a different location for

the aerials.

!

Page 48

English

48

Installing the electric motor

Preparing the cruciform motor mount

Locate the cruciform motor mount supplied with the motor and open up the outer holes in it using a 5 mm Ø bit.

Clean up the holes with a countersink bit.

Attention!

It is important to place the mount on a hardwood surface prior to drilling, to avoid damaging

the table or bench underneath.

!

Page 49

English

49

INNOVATION & TECHNOLOGY

Fitting the stand-off pillars

Fit the shakeproof washers on the M 5 x 15 retaining

screws.

Screw the stand-off pillars to the cruciform motor

mount

Installing the motor

Fix the motor to the cruciform mount using the M 4 x 5

countersunk screws supplied.

Note!

Use UHU Schraubensicher (thread-lock

uid) No. 952 to secure the screws.

Attach the motor assembly to the motor bulkhead

using the screws (38) and washers.

Note!

Use UHU Schraubensicher (thread-lock

uid) No. 952 to secure the screws.

Page 50

English

50

Soldering the sockets to the speed controller

Remove the heat-shrink sleeves from the sockets which are soldered to the speed controller by slitting the sleeves

lengthwise with a sharp knife.

Attention!

The sockets should be unsoldered from the cables. Do not just cut off the sockets with sidecutters, as the additional cable length is required in the model, otherwise the speed controller

will not be correctly positioned, and it will be difcult to secure it.

!

Unsolder the G3.5 sockets, and solder the G4 sockets to the cables; they are supplied with the motor.

Slip the pieces of heat-shrink sleeve (supplied with the motor) over the connectors and the cables, and shrink them

down onto the cables using a heat gun.

Page 51

English

51

INNOVATION & TECHNOLOGY

Installing the speed controller

Connect the speed controller to the motor, and route

the controller through the lower opening in the rewall

towards the receiver.

Attention!

Check that the motor spins in the correct direction.

!

Use a cable-tie to secure the cables between the

connectors and the speed controller to prevent it

shifting and coming unplugged.

Attention!

It is important that the motor wires

are not under tension, otherwise the

connectors could come adrift in ight,

causing the motor to stop; this could

result in a crash.

!

Secure the speed controller with a hook-and-loop

cable tie, and route the battery wires upwards through

the opening; the speed controller lead should be

routed towards the receiver.

Connect the speed controller lead to the receiver,

referring to the instructions supplied with the receiver

and the controller.

Page 52

English

52

Installing the spinner OMA-5020-490

Fit the spinner backplate onto the shaft of the taper

collet. Depending on the type of spinner you are

using, you may need to use the appropriate size of

drill to open up the central hole to match the diameter

of the shaft.

Slip the propeller onto the shaft of the taper collet.

Fit the spreader washer on the shaft of the taper

collet.

Fit the nut on the shaft of the taper collet, but do not

tighten it fully, as this would compress the taper collet

and prevent it tting onto the motor shaft.

Page 53

English

53

INNOVATION & TECHNOLOGY

Slide this assembly onto the motor shaft, leaving

about 2 mm clearance to the motor case where the

shaft enters the motor.

Tighten the propeller nut rmly.

Cut away the spinner cap to clear the propeller

blades.

Attach the spinner cap to the backplate using the

retaining screws supplied.

Attention!

The holes for the spinner cap retaining

screws must line up accurately with

those in the spinner backplate, so that

the spinner is correctly tted, and neit-

her propeller blade fouls the spinner

cap.

!

Page 54

English

54

Installing the Cowl

Drilling the holes for the cowl retaining screws

Use paper masking tape to attach the drilling templates (39) over the captive nuts in the fuselage (2).

Attention!

Ensure that the hole in the drilling template (39) is centred accurately on the captive nut, and

offset towards the cowl (40) by about 2 mm. This compensates for the thickness of the cowl

(40); the drilling template (39) will be positioned exactly over the captive nuts once the cowl

(40) is tted on the fuselage.

!

Place the canopy (41) on the fuselage (2) and lock it

in place using the spring latch. This is important, to

ensure that the cowl (40) is positioned correctly.

Page 55

English

55

INNOVATION & TECHNOLOGY

Fit the cowl (40) on the fuselage, slipping it under the

drilling templates (39) as shown.

Attach the spinner backplate / propeller assembly to

the motor, then align the cowl (40) with the spinner;

there should be about 2 - 3 mm clearance between

the spinner and the fairing at the front of the cowl. Fix

the cowl (40) to the fuselage (2) using paper masking

tape to prevent it shifting when you drill the holes.

Drill the rst hole in the cowl (40) for the retaining

screws (18) with the help of the drilling templates (39)

and a 3 mm drill bit.

Attention!

Be careful not to damage the threaded

part of the captive nut; use the drill

very carefully.

Tip!

It is a good idea to x a ‘stop’ to the

drill to avoid drilling too deep. This

takes the form of a 3 mm collet clamped at a point about 2 mm from the tip

of the drill.

!

Remove the drilling templates (39) from the fuselage.

Fit the rst cowl retaining screw (18) to help prevent

the cowl (40) shifting. Repeat these two steps until

you have tted all four retaining screws (18).

Note!

Use UHU Schraubensicher (thread-lock

uid) No. 952 to secure the screws (18).

Page 56

English

56

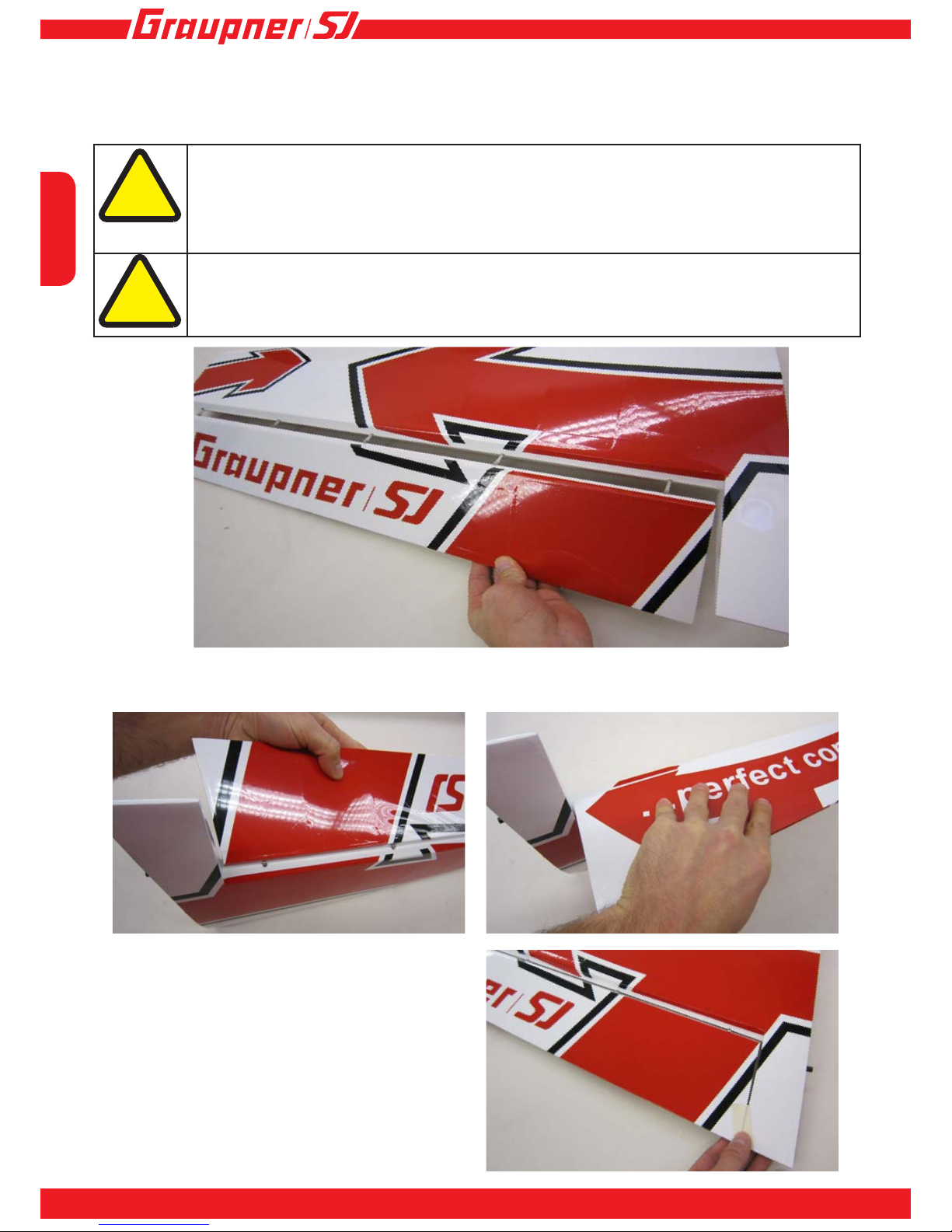

Applying the decals

Information on applying decals

Each decal is prepared and applied using the same procedure; simply follow the same steps for each one. The

decals can be arranged in any way you nd pleasing, but you are free to use the arrangement shown below.

Cut out the decal from the sheet, complete with

backing paper. Cut approximately along the edges of

the die-cut lines; where the die-cut line separates two

decals, cut exactly along the die-cut line.

Separate the backing paper at one end and peel it

back for a distance of about 5 cm.

Now use a pair of scissors to cut off a strip of backing

paper about 2 cm wide.

Place the decal on the model in its nal position.

When you are satised with the position, press the

decal down where the adhesive is exposed, so that it

can no longer shift.

Page 57

English

57

INNOVATION & TECHNOLOGY

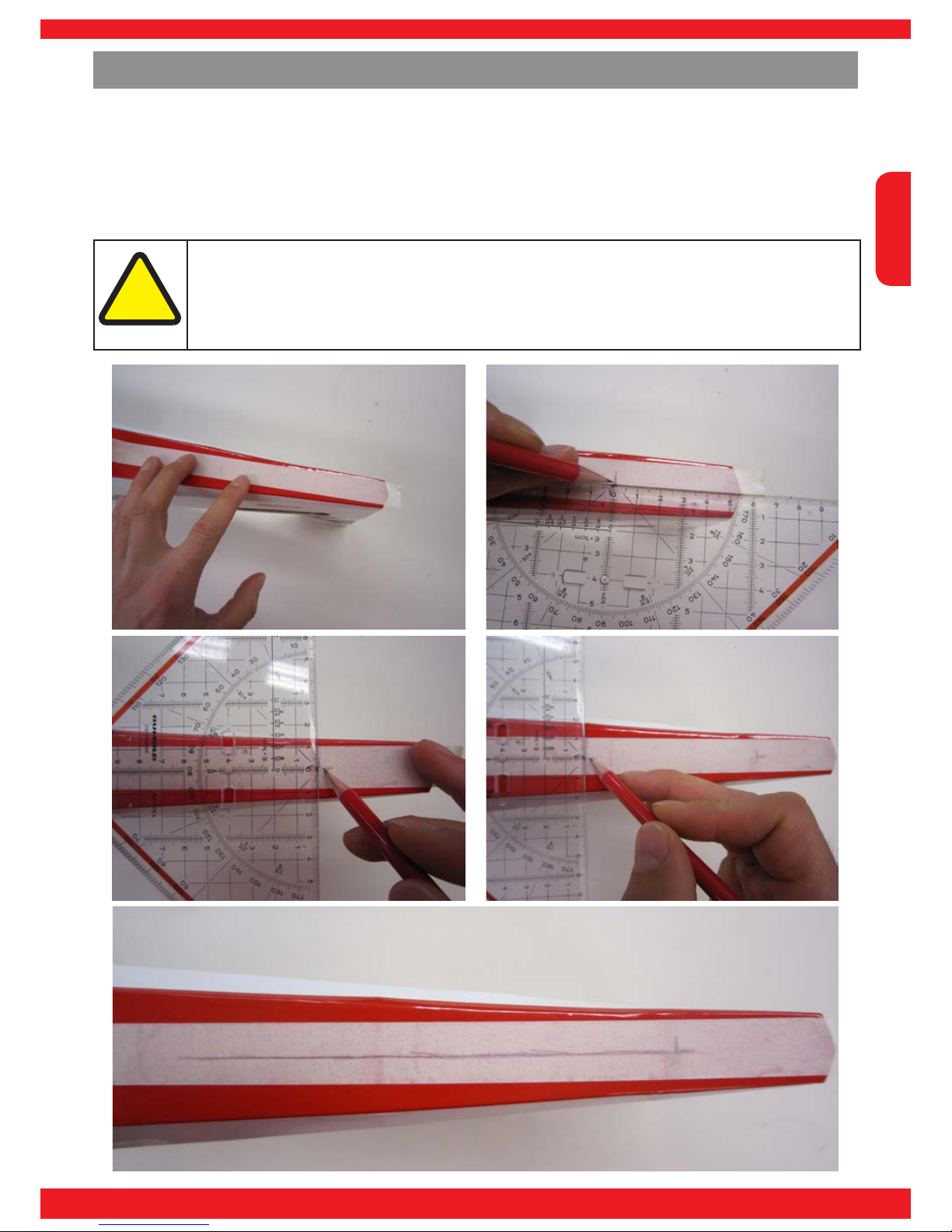

Slitting the decals over a hinge line

Apply the decal as described in the section above: Applying the decals. Now use a sharp knife to cut along

the edge of, say, the n (7), and rub the decal down over the edge.

Attention!

When slitting the decal take care not to damage the hinge or covering lm underneath.

!

Gradually peel off the backing paper, working from the

end already stuck down, and use the at of your hand

to rub the decal down and onto the model.

Work slowly and steadily to avoid trapping air bubbles under the decal.

All the decals can now be applied using this

procedure, until the model is completely decorated.

Page 58

English

58

Model settings

Centre of Gravity:

The model should balance at a point 115 mm aft

of the wing leading edge, measured at the root.

Attaching the wings to the fuselage

Slide the wing joiner tube (42) into the sleeve in the fuselage (2), and set it central (equal projection on both

sides). Now t one wing panel (8 or 9) onto the wing joiner tube (42), connecting the servo plug to the socket

at the same time. Repeat this procedure with the other wing panel (8 or 9). Secure the wings (8, 9) using the

retaining screws (43).

Attention!

It is important that no cables are caught or jammed between the wing panels (22 or 23) and

the fuselage (2), otherwise a wire could break, leaving the model uncontrollable; it could then

crash.

!

Basic control surface travels:

Before setting up the control surface travels, assemble the model completely, as if you were about to y it. Move

the throttle stick on the transmitter to the Stop position, then switch the receiving system on. In the transmitter’s

Servo Settings menu set all control surfaces to the centre (neutral) position. Now use a set-square to measure the

control surface travels: move the transmitter stick to full travel for each control surface individually, and use the

transmitter’s servo adjustment menu to set the travels stated in the table below.

Description

Deec-

tion in

mm

EXPO in %

Aileron travel

+70

30

-70

Rudder travel

+100

60

-100

Elevator travel

+110

60

-110

Page 59

English

59

INNOVATION & TECHNOLOGY

Using Planejama (aeroplane nightshirt)

The Planejama (aeroplane nightshirt) consists of protective bags with carefully sewn seams. The bags are made

of hard-wearing fabric, and protect your model from dents, scratches and other damage in transit. The Planejama

can also be used at the ying eld when the model is fully rigged. In this guise it protects the aircraft from the

effects of sunshine, and briey from rain while you move it under cover.

Slide the protective bags onto the wings and

tailplane of the assembled model.

Slip the protective bag over the n of the assembled

model, and x it to the tailplane bags.

Lay the fuselage bag over the fuselage and attach

it to the tailplane bags. Now wrap the bag under the

fuselage and then round the cowl at the nose.

Page 60

60

All that remains is to wish you many hours of happy ying with your HoTTrigger

Your team!

English

60

Graupner/SJ GmbH

Henriettenstrasse 96

73230 Kirchheim/Teck

Germany

No liability for printing errors. Technical changes reserved! Keine Haftung für Druckfehler.

Technische Änderungen vorbehalten!

• When you have completed the model in accordance with the instructions, pro-grammed the

radio control system as stated, and charged all the batteries, there is nothing to stop you

ying the model for the rst time.

• The maiden ight should be carried out in at calm conditions, or no more than the lightest of

breezes.

• A range check with the motor running is also recommended!

• Building the model is very simple; ying it represents a greater challenge.

Maiden ight

Attention!

This aircraft should only be own by experienced model pilots!

!

Environmental protection notes

After every ying session clean the model and the transmitter using a suitable cleaning agent

only: we recommend a lint-free cloth. Never use chemical cleaners, solvents, methylated spirit

(‘meths’), white spirit (‘turps’) or similar. After every ight check that all screwed joints are still

tight. If an area of covering lm should come loose or become wrinkled, re-attach it using a lm

iron set at no more than 100°C.

Care and maintenance

The presence of this symbol on a product, in the user instructions or the packaging,

means that you must not dispose of that item in the ordinary domestic waste when

the product comes to the end of its useful life. The correct method of disposal is to

take it to your local collection point for recycling electrical and electronic equipment.

Individual markings indicate which materials can be recycled and re-used. You can

make an important contribution to the protection of our shared environment by reusing the product, recycling the basic materials or re-processing redundant equipment in other ways. Dry cells and rechargeable batteries must be removed from the

device and taken separately to a suitable battery disposal centre. If you don’t know

the location of your nearest disposal centre, please enquire at your local council

ofce.

Page 61

English

61

INNOVATION & TECHNOLOGY

61

Notes

Page 62

English

62

Page 63

English

63

INNOVATION & TECHNOLOGY

Page 64

Die Fa.Graupner/SJ GmbH, Henriettenstrasse 96,

73230 Kirchheim/Teck gewährt ab dem Kaufdatum auf

dieses Produkt eine Garantie von 24 Monaten. Die

Garantie gilt nur für die bereits beim Kauf des Produktes

vorhandenen Material- oder Funktionsmängel. Schäden,

die auf Abnützung, Überlastung, falsches Zubehör oder

unsachgemäße Behandlung zurückzuführen sind, sind von

der Garantie ausgeschlossen. Die gesetzlichen Rechte und

Gewährleistu sansprüche des Verbrauchers werden durch

diese Garantie nicht berührt. Bitte überprüfen Sie vor einer

Reklamation oder Rücksendung das Produkt genau auf

Mängel, da wir Ihnen bei Mängelfreiheit die entstandenen

Unkosten in Rechnung stellen müssen.

Graupner/SJ GmbH, Henriettenstrasse 96, 73230

Kirchheim/Teck, Germany guarantees this product for a

period of 24 months from date of purchase. The guarantee

applies only to such material or operational defects witch

are present at the time of purchase of the product. Damage

due to wear, overloading, incompetent handling or the use

of incorrect accessories is not covered by the guaratee.

The user´s legal rights and claims under garantee are

not affected by this guarantee. Please check the product

carefully for defects before you are make a claim or send the

item to us, since we are obliged to make a charge for our

cost if the product is found to be free of faults.

La société Graupner/SJ GmbH, Henriettenstrasse 96,

73230 Kirchheim/Teck, Allemagne, accorde sur ce produit

une garantie de 24 mois à partir de la date d´achat. La

garantie prend effet uniquement sur les vices de fonctionnement et de matériel du produit acheté. Les dommages

dûs à de l´usure, à de la surcharge, à de mauvais

accessoires ou à d´une application inadaptée, sont exclus

de la garantie. Cette garantie ne remet pas en cause les

droits et prétentions légaux du consommateur. Avant toute

réclamation et tout retour du produit, veuillez s.v.p. contrôler

et noter exactement les défauts ou vices.

Garantie-Urkunde

Warranty certi cate / Certi cat de garantie

Übergabedatum

Date of purchase/delivery

Date de remise

Name des Käufers

Owner´s name

Nom de I`acheteur

Straße, Wohnort

Complete adress

Adresse complète

Wir gewähren auf dieses Erzeugnis eine / This product is / Sur ce produit nous accordons une

Garantie von

warrantied for

garantie de

24

Monaten

months

mois

Servicestellen / Service / Service après-vente

Graupner/SJ-Zentralservice

Graupner/SJ GmbH

Henriettenstrasse 96

D-73230 Kirchheim / Teck

Servicehotline

(+49) (0)7021/722-130

Montag - Donnerstag

7:30 -9:00 Uhr

9:15 -16:00 Uhr

Freitag

9:00 - 13:00 Uhr

Die Adressen der Servicestellen außerhalb Deutschlands

entnehmen Sie bitte unserer Webseite www.graupner.de.

For adresses of service points outside of germany please

refer to www.graupner.de/en/.

Pour adresses des points de service situés en dehors de

l‘Allemagne s‘il vous plaît se référer à www.graupner.de/fr/.

Firmenstempel und Unterschrift des Einzelhändlers

Stamp and signature of dealer

Cachet et signature du vendeur

64

Loading...

Loading...