Page 1

MINI MASTER CONTROL PANEL

M-2100 DIGITAL MASTER CONTROL SYSTEM

Installation and Operation

071812900

5.0software release

FIRST PRINTING: JULY 2001

Page 2

Contacting Grass Valley Group

Region Voice Fax Address Web Site

North America (800) 547-8949

530-478-4148

Pacific Operations +852-2585-6688

Support: 852-2585-6579

U.K., Europe, Asia, Middle East +44 1753 218 777 +44 1753 218 757

France +33 1 45 29 73 00

Germany +49 221 1791 234 +49 221 1791 235

Copyright © Grass Valley Group. All rights reserved.

This document may not be copied, in whole or in part, or otherwise reproduced, except as specifically

permitted under U.S. copyright law, without the prior written consent of Grass Valley Group, P.O. Box

599000, Nevada City, CA 95959-7900 USA. GRASS VALLEY GROUP is a registered trademark and

Grass Valley is a trademark of Grass Valley Group. All registered trademarks and trademarks are property of their respective holders. Grass Valley Group products are covered by U.S. and foreign patents,

issued and pending. Product options and specifications subject to change without notice. The information in this manual is furnished for informational use only, is subject to change without notice, and

should not be construed as a commitment by Grass Valley Group. Grass Valley Group assumes no responsibility or liability for any errors or inaccuracies that may appear in this publication.

Online User Documentation

(530) 478-3347 Grass Valley Group

+852-2802-2996

P.O. Box 599000

Nevada City, CA 95959-7900

USA

www.grassvalleygroup.com

Current versions of product catalogs, brochures, data sheets, ordering

guides, planning guides, manuals, and release notes may be downloaded

via the Product Documentation link on the Grass Valley Group home page:

FAQ Database

Many solutions to problems and troubleshooting efforts can be found by

searching our Frequently Asked Questions (FAQ) database. To access:

Select the Service/Support link on the Grass Valley Group home page.

1.

Select the Online Support & FAQ link on the Service/Support page.

2.

Follow the directions provided to access the FAQ database and other

3.

online support services.

Software Downloads

Software updates, drivers and patches may be downloaded via the

Download link on the Grass Valley Group home page:

Page 3

Contents

Preface

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Documentation Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Other Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Section 1 — Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Control Panel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Control Panel Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Tabletop Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Console Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Rack Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Control Panel Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Powering On. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Power Supply Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Setting MCP Net IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Control Panel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Control Panel Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Software Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Section 2 — System Operations

About this Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Using Multichannel Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Channel Control Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Assigning Channels to Channel Control Buttons. . . . . . . . . . . . . . . . . . . . . . . . 2-4

Assigning Primaries and Secondaries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Automation Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Program and Preset Bus Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Preset Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Selecting Preset Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Backup Preset Sources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Program Bus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Source Names Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Non-Sync Source Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Transition Controls and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

MMCP Installation/Operation Manual iii

Page 4

Contents

Transition Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Transition Rates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Hot Switching (Hot Program Cuts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Custom Transitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Using Custom Transitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Audio/Video Breakaways. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Breakaway Selection Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Next Transition Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Preroll Transitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

First Press Transitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Second Press (and Subsequent) Transitions . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Hold Transitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Preroll Transitions Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

GPI Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Mode/Function Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Keyer Controls and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Keying Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

SD Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

HD Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Selecting and Transitioning Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Cutting Keys On or Off Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Previewing the Key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Non-Synchronous Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Modifying Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Key Modifier Mode Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Matte Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Border (Brdr) Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

SELF/EXT and LIN/LUM Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Key Modifier Button Tally Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Key Modifier Knobs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Recalling and Initializing Key Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Key Recall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Keyer Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Linear/Luminance Key Unity Clip and Gain Default. . . . . . . . . . . . . . . . . . 2-32

Reset Key Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Setting Matte Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

Configuring Matte Crosspoints. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

Configuring the Transition Matte. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

Configuring the Loss Of Signal (LOS) Matte . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

Using SqueezeBack and Crop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Defining SqueezeBack and Crop Effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Viewing the Current SqueezeBack Effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

Selecting and Displaying SqueezeBack Effects. . . . . . . . . . . . . . . . . . . . . . . . 2-37

Making SqueezeBack Transitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

Creating Chroma Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

Chroma Key Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

Auto Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Using Auto Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

Audio Controls and Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Audio Control Subpanel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Audio Processor Delegation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

Audio Only PST Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

Audio Only PGM Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

iv MMCP Installation/Operation Manual

Page 5

Contents

Audio Breakaway Audio (ABA) Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

Left and Right (Audio) Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

Stereo, L-Mono and R-Mono Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

Phase Inversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

PGM Level and PST Level Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

Audio Ratio Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

Audio Ratio Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

Audio Monitor Subpanel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

PST, PGM, and AIR Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

Monitor Volume Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

DIM Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

Index

MMCP Installation/Operation Manual v

Page 6

Contents

vi MMCP Installation/Operation Manual

Page 7

Preface

About This Manual

This manual provides control panel installation and operating information

for the Grass Valley Group M–2100 Mini Master Control Panel (MMCP) for

use with the M–2100 Digital Master Control system. This manual is

designed for personnel responsible for installing or operating MMCP systems.

Documentation Set

The standard M–2100 user documentation set consists of a:

■

User Manual,

■

Installation and Service Manual, and

■

Release Notes.

The User Manual contains background information about the M–2100, and

describes operating procedures. This manual can be used while learning

about the M–2100, and for enhancing your basic knowledge of the system.

The

Installation and Service Manual

configuring, and maintaining the system.

The

Release Notes

enhancements for a specific software version, and also includes software

installation procedures. Always check the release notes for your current

system software before operating your system.

Other Documentation

A separate Automation Interface Protocol Technical Reference Manual is also

available for installation and operation of an external device to control the

M–2100.

contains information about installing,

contain information about new features and system

MMCP Installation/Operation Manual vii

Page 8

Preface

viii MMCP Installation/Operation Manual

Page 9

Channel Control

Transition Rate

Mode

Slow Med Fast

Keyer Control

Mon

Lvl

PreRoll

Transition

BKGD KEY

Next Transition

Audio Monitor

Mode

Func

PGM

PST DIM

AIR

Hue

Clip

Sat

Gain

Bright

Opacity

Key 1

On/Off

Brdr

Key 2

On/off

Key 3

On/off

Key 4

On/off

PGM

PST

Ratio

PGM Level

PST Level

Left Right

Left Right

AP2 AP3 AP4

1

Primary

Over

PROGSRC1

PROGSRC3 PROGSRC5

PROGSRC7

PROGSRC2 PROGSRC4

PROGSRC6

PROGSRC8

2 3 4 5 6 7 8 1 2

1 2

V

A

V

A

User

GP1 GP2

Video

Only

Audio

Only

Non Sync

Non Sync

MINI MASTER CONTROL

Audio

Video

Transition

VIDEO

Matte

SELF

EXT

Lin

Lum

SQB

Ch 1

Ch 5

Ch 2

Ch 6 Ch 7 Ch 8

Ch 3 Ch 4

12345678

8129_01

Installation

Introduction

This section gives installation and configuration instructions for the Grass

Valley Group M–2100 Mini Master Control Panel (MMCP).

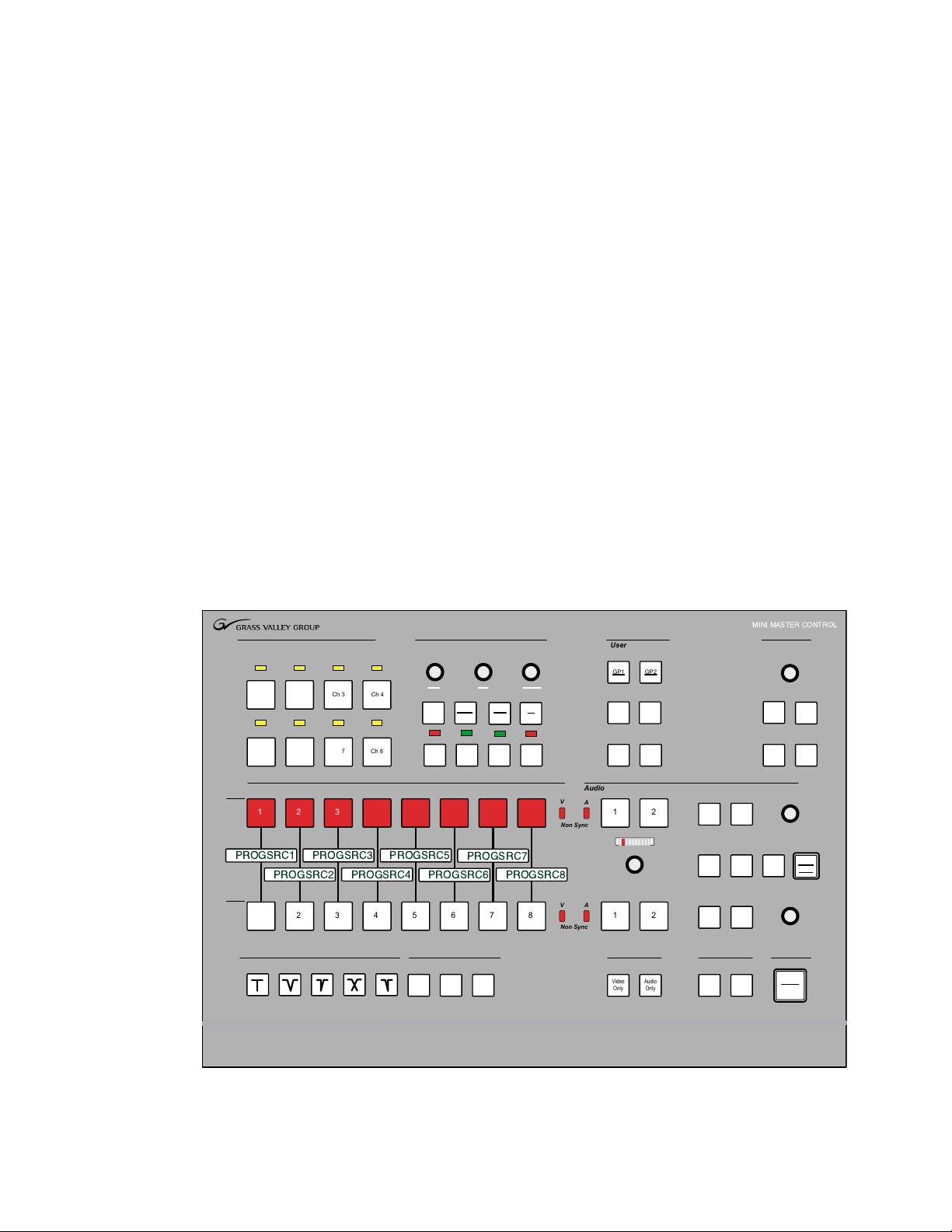

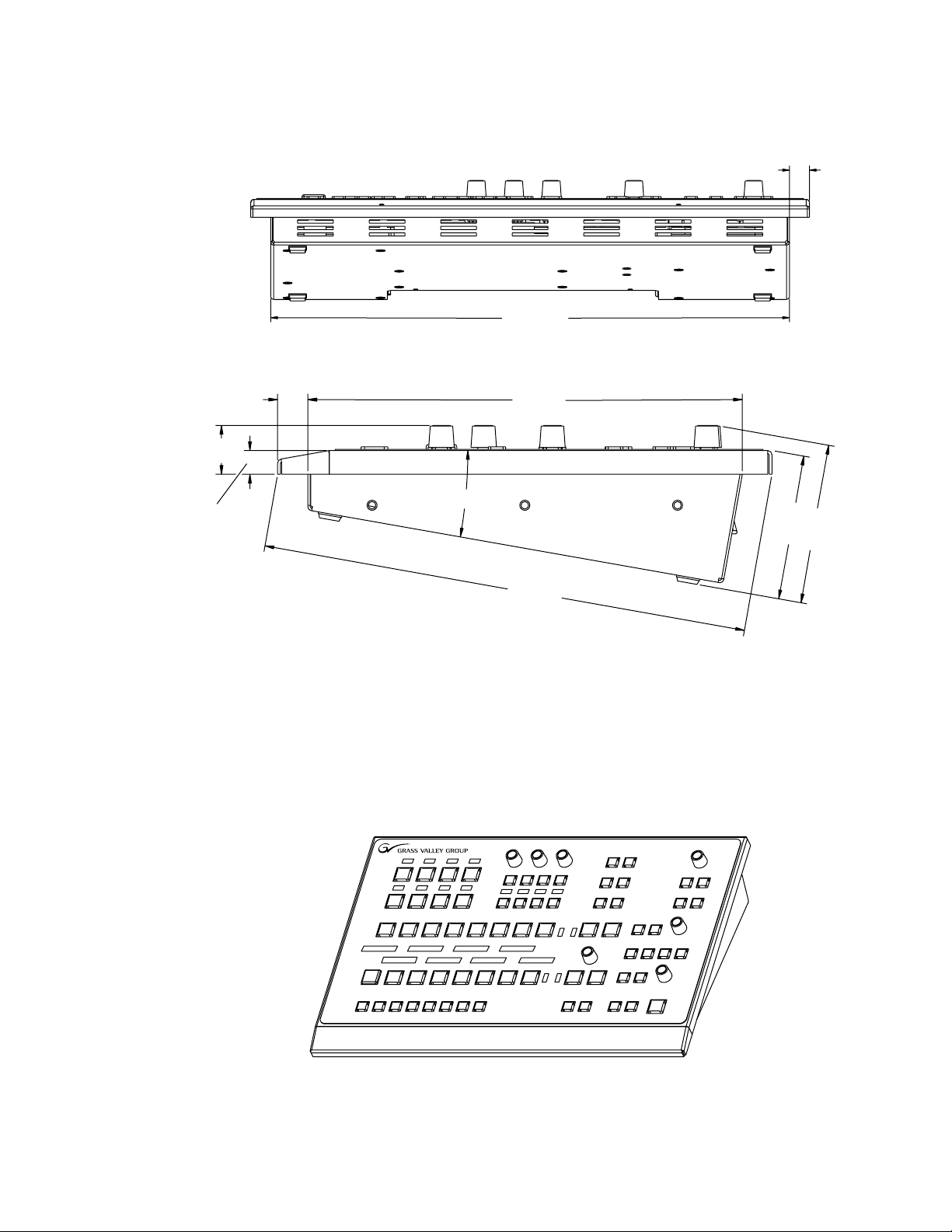

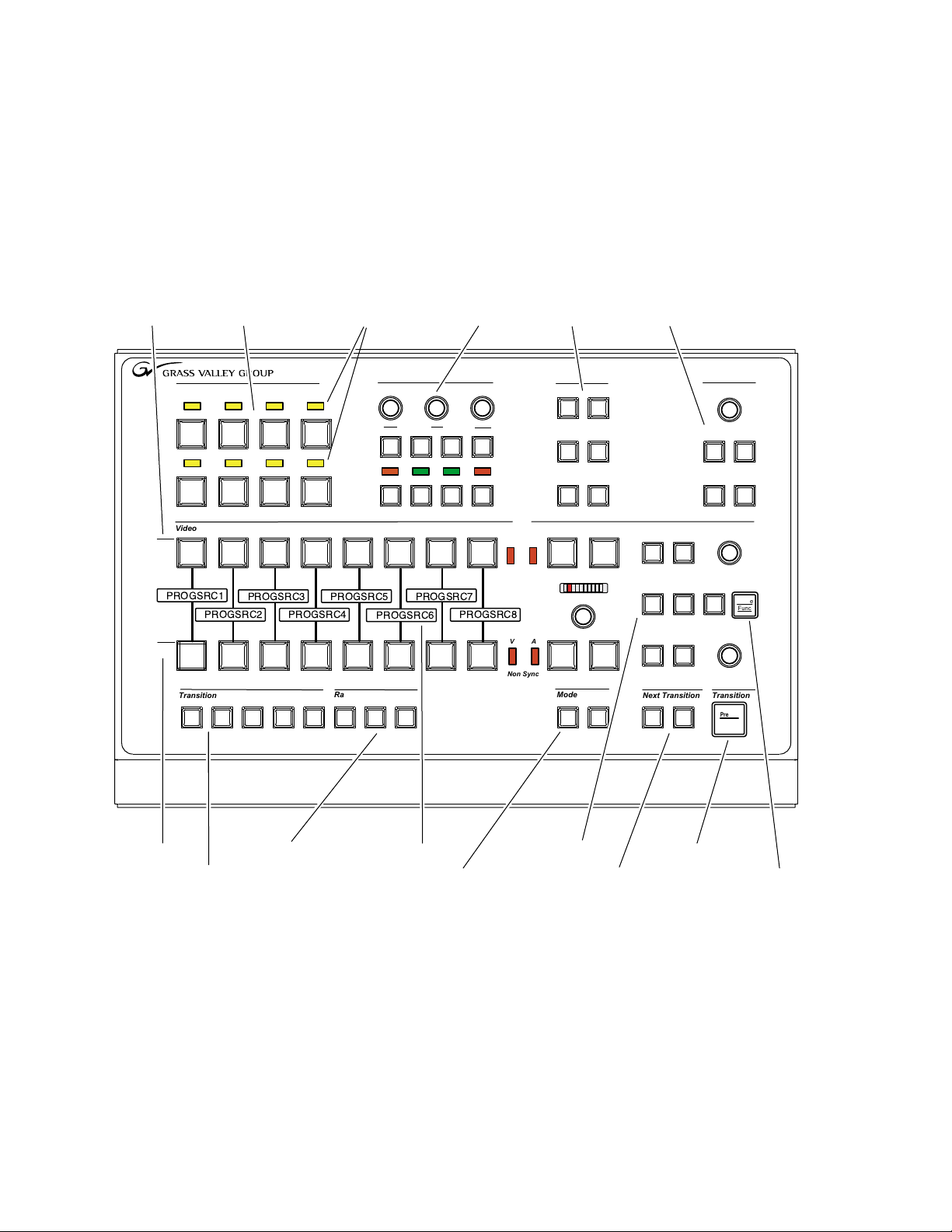

The MMCP (Figure 1-1) is a compact panel for controlling the M–2100

Digital Master Control system. It offers control of up to eight channels from

the panel, plus transition, key and audio functionality.

Note

Figure 1-1. Mini Master Control Panel

The M–2100 must be running v5.0 or later software for MMCP functionality.

Section

1

MMCP Installation/Operation Manual 1-1

Page 10

Section 1 — Installation

Control Panel Installation

The MMCP Control Panel can be installed in the following ways:

■

Tabletop mounting (page 1-3),

■

Console mounting (page 1-4), or

■

Rack mounting (page 1-5).

The kit for rack and console mounting is a separate option.

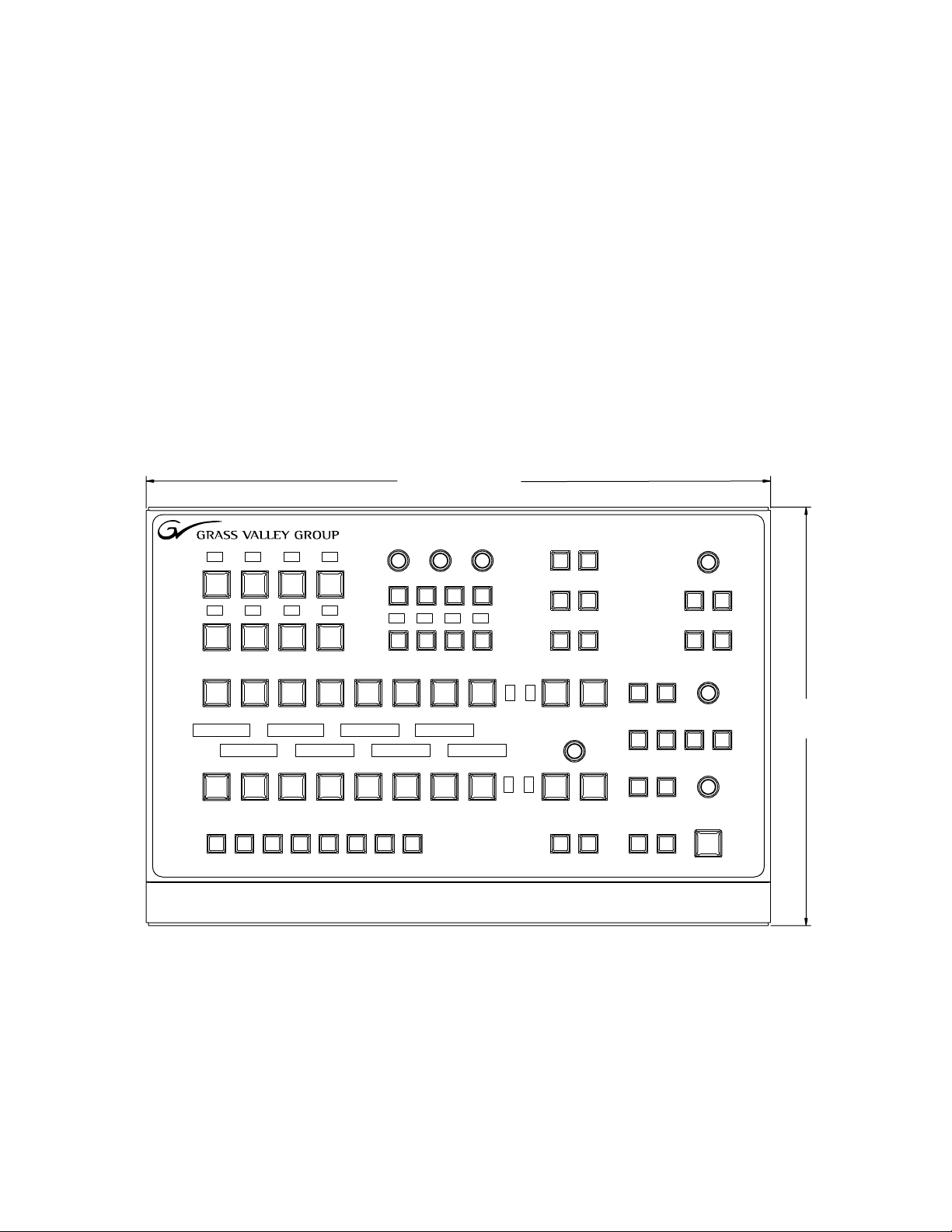

Control Panel Dimensions

The overall panel dimensions are illustrated in Figure 1-2 (top view) and

Figure 1-3 (front and right side views).

Figure 1-2. Top View Dimensions

15.62 in / 397 mm

10.47 in.

266 mm

8129_03

1-2 MMCP Installation/Operation Manual

Page 11

10.31 in.

262 mm

0.56 in.

14 mm

10°

9.20 in.

234 mm

14.50 in.

368 mm

0.64 in.

16 mm

1.03 in.

26 mm

0.5 in.

13 mm

3.39 in.

86 mm

3.07 in.

78 mm

Front view

Right side view

8129_04

Figure 1-3. Front and Right Side Panel Dimensions

Control Panel Installation

Tabletop Mounting

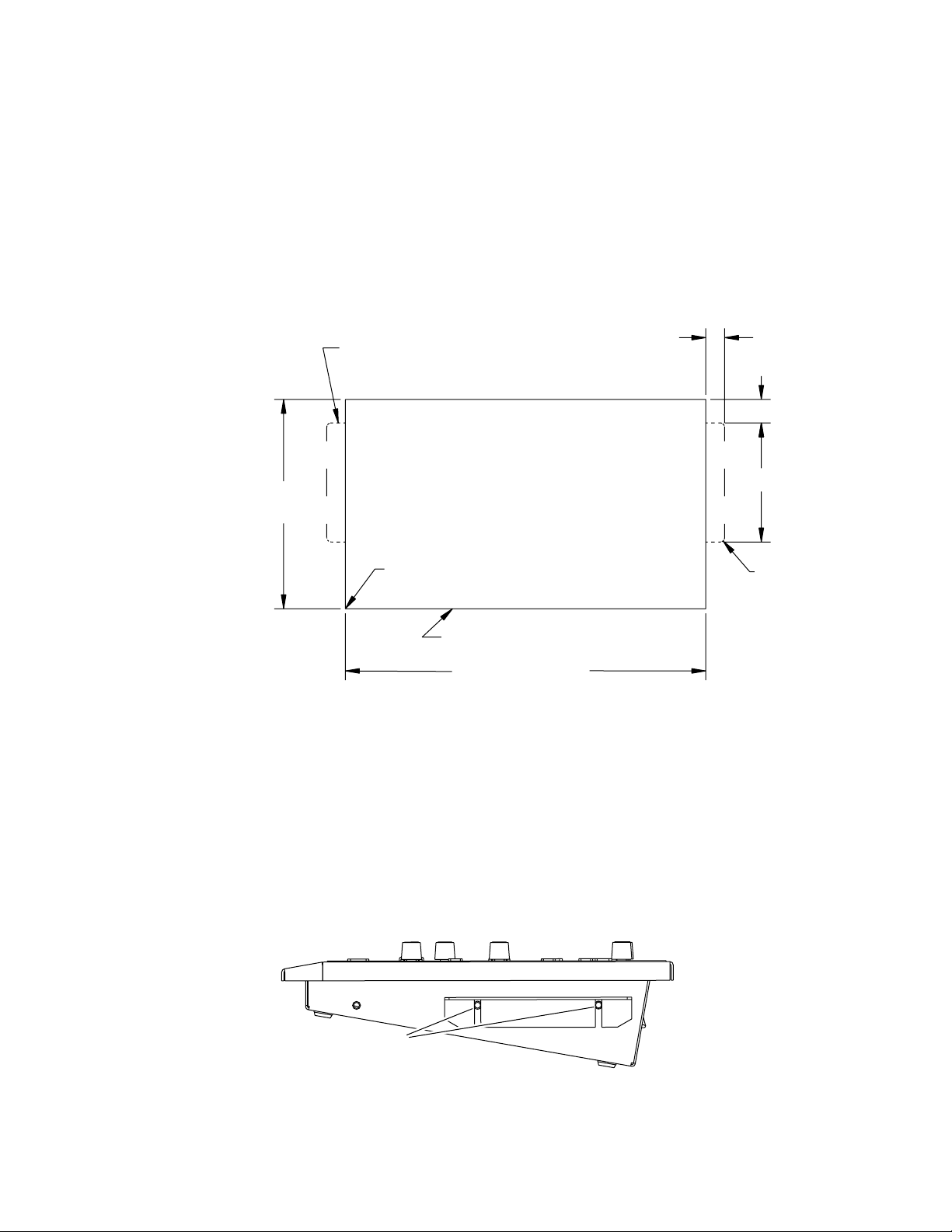

The MMCP panel can stand alone on a tabletop surface (Figure 1-4).

Rubber feet are installed on the bottom of the panel.

Figure 1-4. MMCP Tabletop Mounting

MMCP Installation/Operation Manual 1-3

8129_05

Page 12

Section 1 — Installation

Console Mounting

1.

2.

A mounting bracket option kit provides a console mounting bracket to

mount the control panel into a console cutout or rack ears to mount the

panel in a standard 19 in. rack.

To install the panel in a console cutout, perform the following steps:

Prepare the console cutout according to the dimensions in Figure 1-5.

Figure 1-5. MMCP Console Cutout Dimensions

2X If console thickness exceeds 0.375 in. / 10 mm

Route these areas from far side

9.37 in.

238 mm

4X R 0.125 in. / 3 mm permitted

This area through

14.62 in. / 371 mm

Console preparation as viewed from console top surface

Install the optional console mounting brackets to the right and left sides

of the panel using four of the #8 screws provided (Figure 1-6).

2X 0.75 in.

19 mm

2X 0.56 in.

14 mm

2X 5.25 in.

133 mm

4X 0.25 in.

6 mm

8129_06

Adjust the mounting bracket to position the panel in the console at the

desired height. Maximum console thickness is 0.375 in (10 mm). For a

console wider than this, route the areas from the far side as shown

above.

Figure 1-6. Attaching Console Mounting Brackets

2X

(right and left sides)

Right side view

8129_07

1-4 MMCP Installation/Operation Manual

Page 13

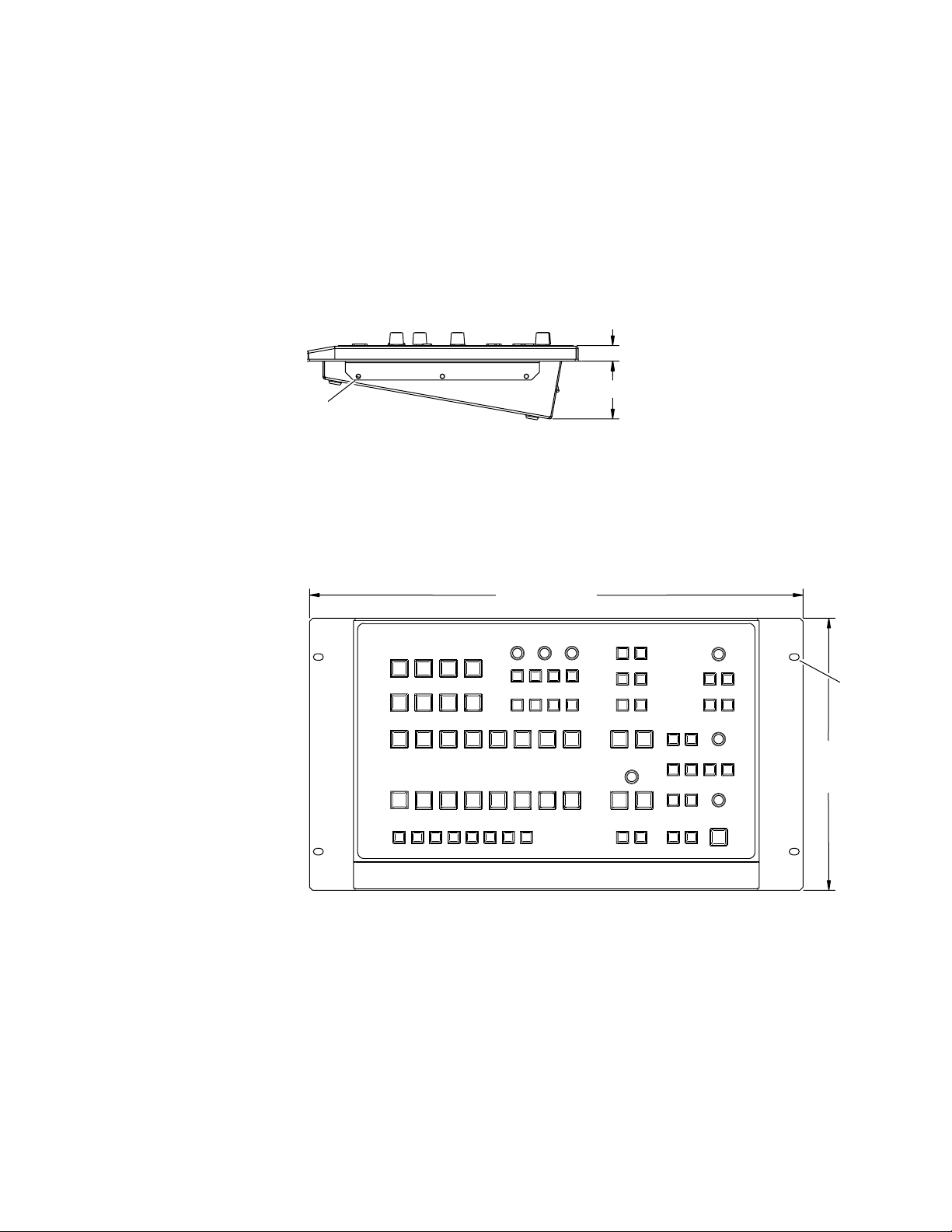

Rack Mounting

1.

2.

Control Panel Installation

To mount the control panel in a standard 19 in. (483 mm) rack, use the rack

ears provided with the mounting option.

To rack mount the panel, perform the following steps:

Install the rack ears to the right and left sides of the panel using the six

#8 screws provided as illustrated in Figure 1-7.

Figure 1-7. Install Rack Ears To Panel

0.6 in.

15.24 mm

2.22 in.

6X

(3 right and 3 left)

Right side view

56.38 mm

8129_08

Mount the assembly to a standard rack using four standard rack screws

and washers (not provided).

Figure 1-8. MMCP Rack Mounting

19 in. / 483 mm

Front view

4X

10.47 in.

266 mm

8129_09

MMCP Installation/Operation Manual 1-5

Page 14

Section 1 — Installation

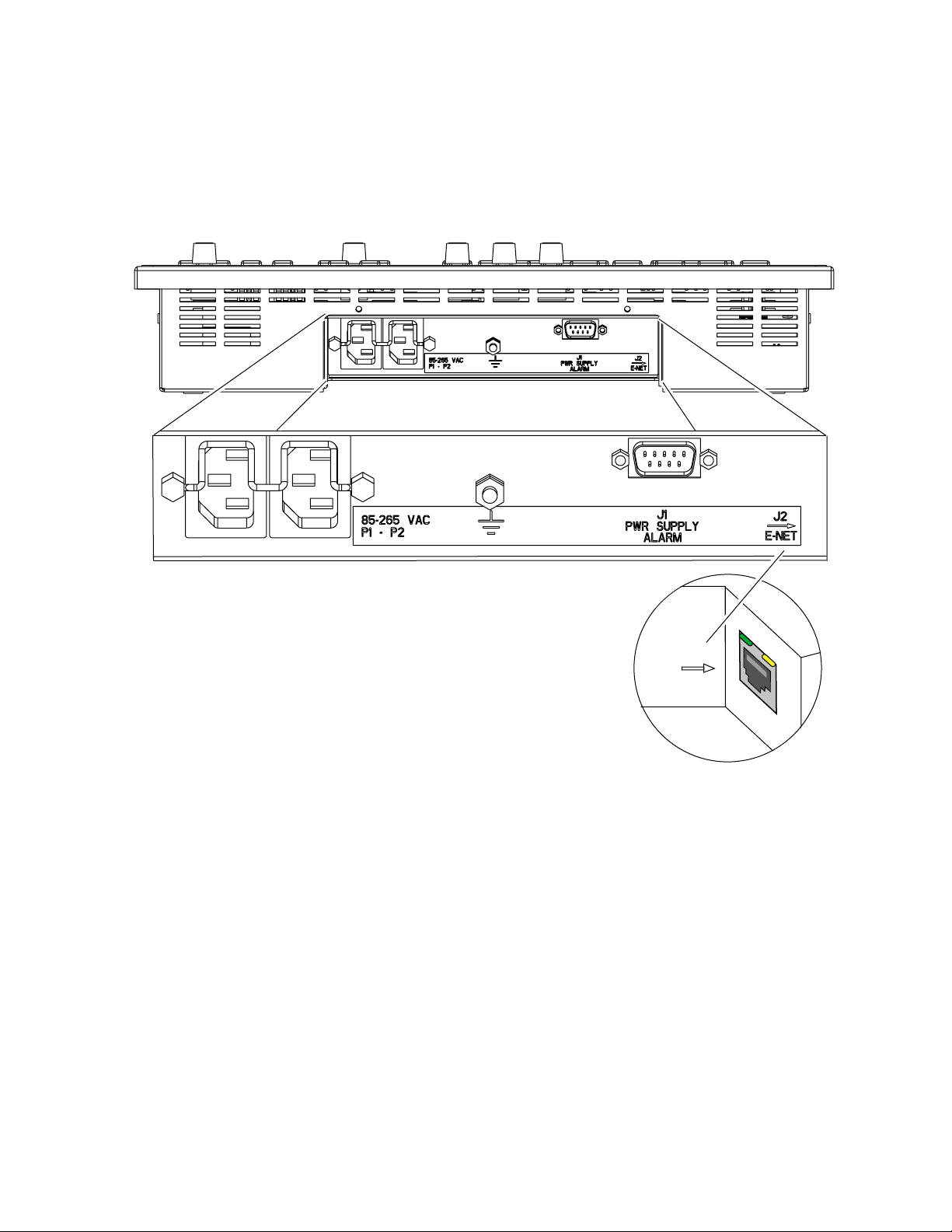

Control Panel Cabling

The connections to the MMCP panel are made at the rear of the panel in the

recessed area shown in Figure 1-9.

Figure 1-9. Control Panel Connections

Powering On

J2

ENET

8129_10

The MMCP has dual power supplies as standard features. The power supplies are installed inside the panel and are not accessible. There is no on/

off switch for either supply. To power on, connect the AC line cords to the

PS 1 and PS 2 AC connectors.

A chassis ground lug is provided at the rear of the panel.

1-6 MMCP Installation/Operation Manual

Page 15

Power Supply Alarms

A 9-pin male connector at J1 provides a power supply status reporting port.

An external device can be wired to this connector to indicate when one or

both of the power supplies fail.

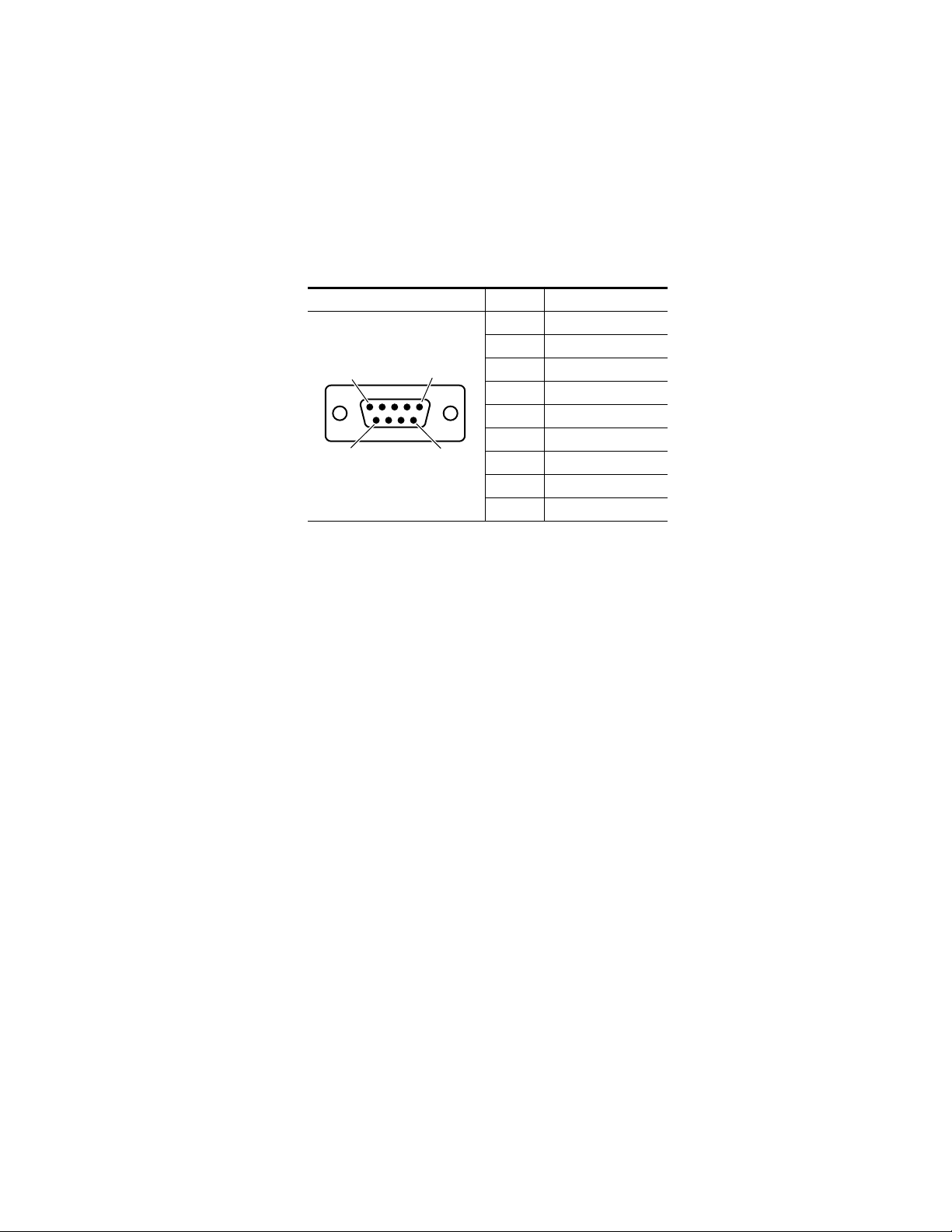

A pinout diagram for J1 is given in Table 1-1.

Table 1-1. Power Supply Alarm Connector Pinout

9-pin D Male Connector Pin Alarm Port (J1)

Pin

D-9 Male

1

Pin

6

J1

Pin

5

Pin

9

Control Panel Cabling

1 Normally Closed_1

2 Common

3 Normally Open

4 No Connection

5 No Connection

6 Normally Closed_2

7 No Connection

8 No Connection

9 No Connection

When both power supplies are working properly, Pin 3 (Normally Open) is

open with respect to Pin 2 (Common). If there is a power supply failure on

either AC circuit or power supply, Pin 2 and Pin 3 will close.

An external alarm may be attached to the connector to operate in one of the

following ways:

■

Connect an alarm between Pin 2 and Pin 3 to switch on when the AC

input or either power circuit fails or when either power supply fails.

■

Connect an alarm between either Pin 1 or Pin 6 and Pin 2 to open when

the AC input on either circuit fails or when either power supply fails.

Connect an alarm between Pin 1 and Pin 6 to open when the AC input

■

on either circuit fails or when either power supply fails.

Note

Connecting between Pin 1 and Pin 6 is recommended only when the alarm

relay is used to switch open an inductive load such as an AC-powered relay

that cannot otherwise be protected with an external shunt diode.

The alarm relay contacts should be rated for 100 mV to 28 V AC or DC at

100 to 500 mA.

MMCP Installation/Operation Manual 1-7

Page 16

Section 1 — Installation

Network Configuration

Setting MCP Net IP Address

The MMCP communicates with the M–2100 frames over a separate MCP

Net Ethernet network. The M–2100 frames communicate with other

external devices over the Facility LAN. The IP address of each panel must

be set to put it on the specific MCP Net where the frames it will control

reside. This must be done before you connect panels to the network.

If this is a new installation, you may use the default MCP Net IP addresses

of the panel and frame set at the factory. They should be on the same MCP

Net. If more than one panel or frame is present, you will need to change the

last octet of the MCP Net IP address of each of the additional devices. Each

device must have a unique IP address (first three octets are the same, the

last one different). The default IP address set at the factory for the MMCP

is 192.168.0.250.

If you are installing a panel into an existing network, you will need to

change the IP address of each panel so it is on the same MCP Net as the

frames it will be controlling (first three octets are the same, the last one different).

If you don’t know the MCP Net IP address of the existing network, you will

need to query your frame through Console Port J4 on the rear of the frame

to determine what MCP Net IP address has been assigned. Your network

administrator may also be able to tell you what IP addresses are used at

your facility.

There are two methods for setting the IP Address,

Using the Netburner PC Tool, or

■

■

Connecting a PC directly to the MMCP.

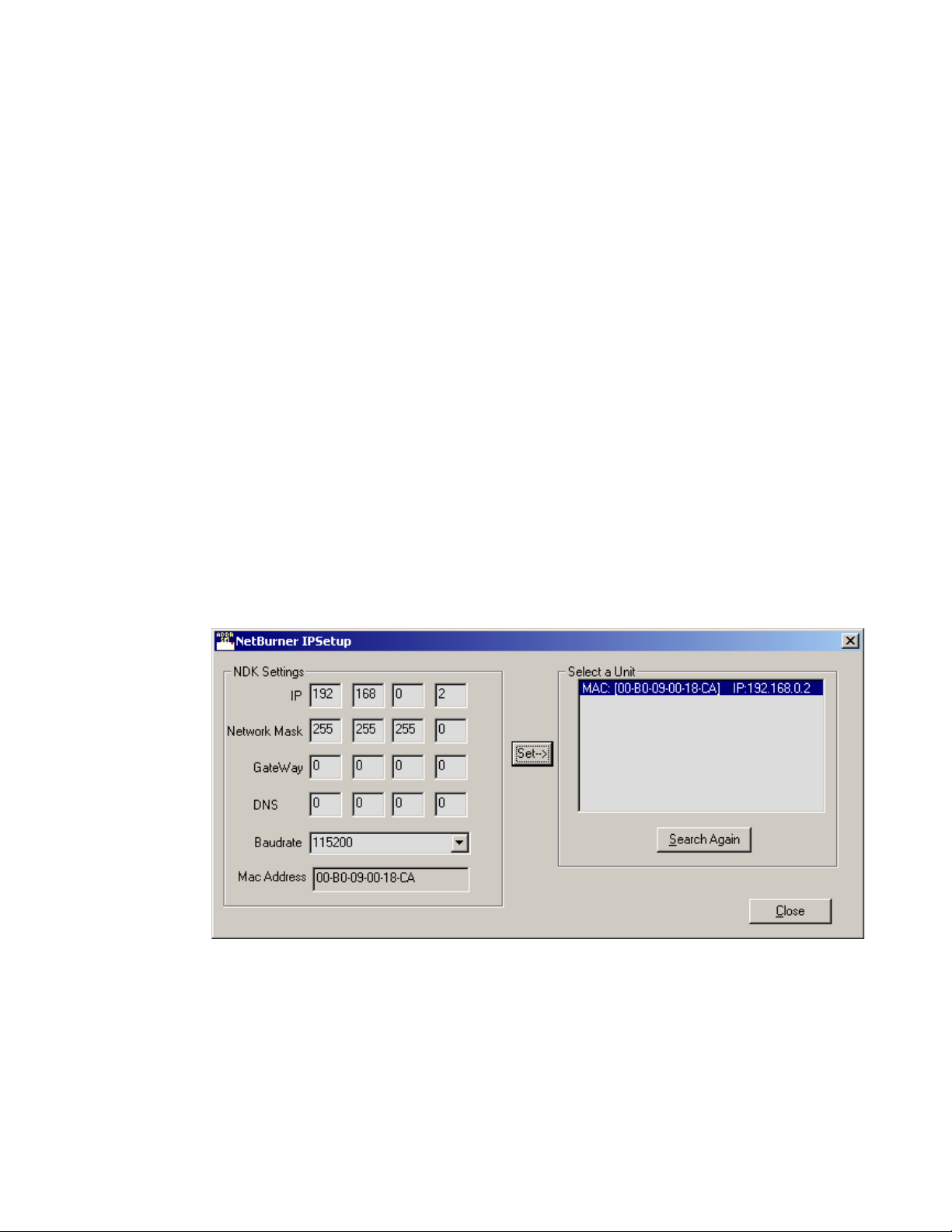

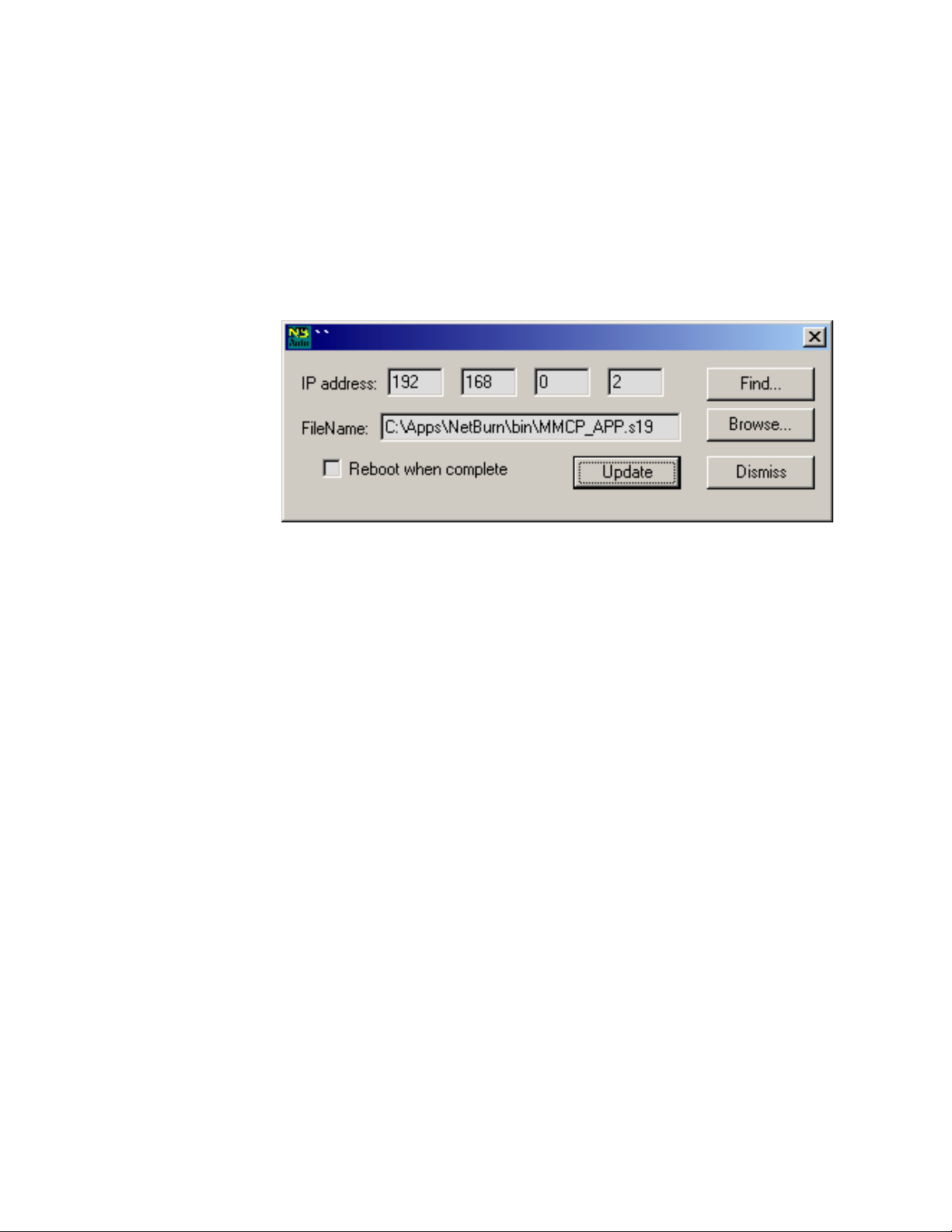

Netburner IPSetup PC Tool

The Ethernet card in the MMCP runs on the Netburner operating system.

You may use the Netburner IPSetup.exe PC tool included on the floppy

disk that accompanies the panel to set the IP address of the panel.

Note

This utility can also be downloaded free of charge from the Netburner.com

web site.

1-8 MMCP Installation/Operation Manual

Page 17

1.

2.

3.

4.

5.

6.

7.

8.

Control Panel Cabling

Use the following procedure to set the IP address using the Netburner PC

tool.

Connect a PC and one MMCP to the same 10 BaseT Ethernet network.

Note

Only one panel at a time should be connected to the PC to allow positive identification of the panel to be programmed.

Open the Netburner IPSetup.exe application and locate the panel on

the network as shown in Figure 1-10. The application will find

Netburner devices on the network and identify them by their MAC

addresses.

Type in the desired IP address in the

Set the Subnet Mask in the

Set the

Set the

GateWay

DNS

IP address to 0.0.0.0.

IP address to 0.0.0.0.

When finished, click on the

Network Mask

Close

IP

boxes.

boxes to 255.255.255.0.

button.

The panel must be rebooted for the new IP address to take effect.

Remove power momentarily to reboot.

Figure 1-10. Netburner IPSetup PC Tool

MMCP Installation/Operation Manual 1-9

Page 18

Section 1 — Installation

1.

2.

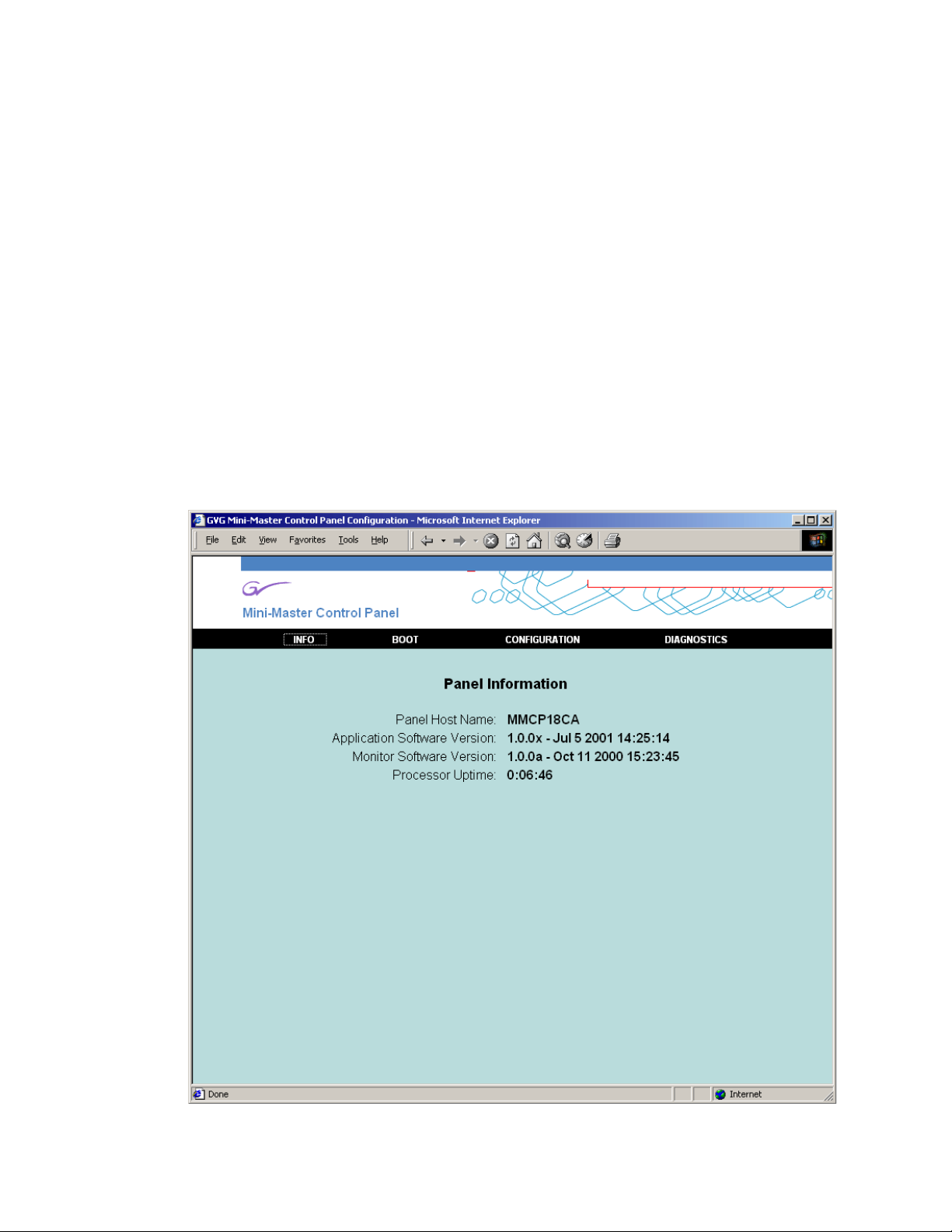

Direct PC Connection

You may use a PC equipped with an Ethernet interface and a web browser

to change the panel IP address as follows.

Connect the PC’s Ethernet port directly to the MMCP panel ENET RJ45

connector J2 (Figure 1-9 on page 1-6).

Note

A crossover Ethernet cable (Tx/Rx pair crossed) is needed when connecting

a PC directly to the panel without a hub intermediary.

Run the web browser and type in the default IP address of the MMCP

panel as http://192.168.0.250. The PC IP address must have a network

value (first three octets) that matches the default IP address.

If the address is found, a

Panel Information

screen similar to Figure 1-11

will appear.

3.

Click on the

Figure 1-11. Panel Information Screen

BOOT

link to go to the Boot Configuration screen.

1-10 MMCP Installation/Operation Manual

Page 19

4.

5.

7.

Control Panel Cabling

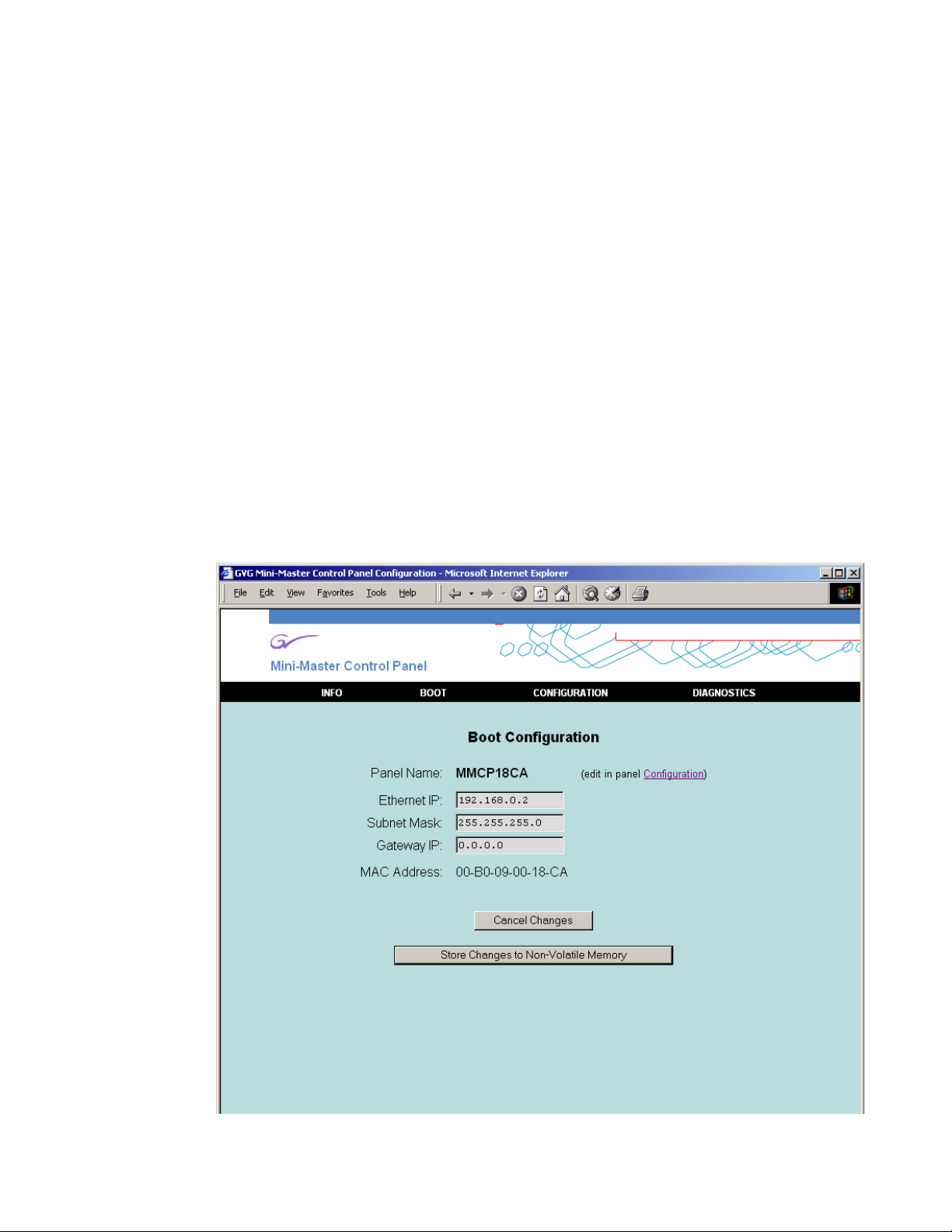

In the Boot Configuration screen (Figure 1-12 on page 1-11), enter the

Ethernet IP

address for this panel to put it on the MCP Net with the

frames it will be controlling.

8.

9.

The

Subnet Mask

should be 255.255.255.0 (the subnet mask for the

M–2100 network).

6.

Gateway IP

The

Select

should be set to 0.0.0.0.

Store Changes to Non-Volatile Memory

to store these values or

make no changes.

Note

The MAC address of the Ethernet card inside the panel is also given in readonly format.

Disconnect the panel from the PC and install it onto the MCP Net

Ethernet network.

Repeat this procedure on all the MMCP panels to be used with your

M–2100 system, entering unique MCP Net IP addresses (last octet

different) for each MMCP panel.

Figure 1-12. Boot Configuration Screen

Cancel

to

MMCP Installation/Operation Manual 1-11

Page 20

Section 1 — Installation

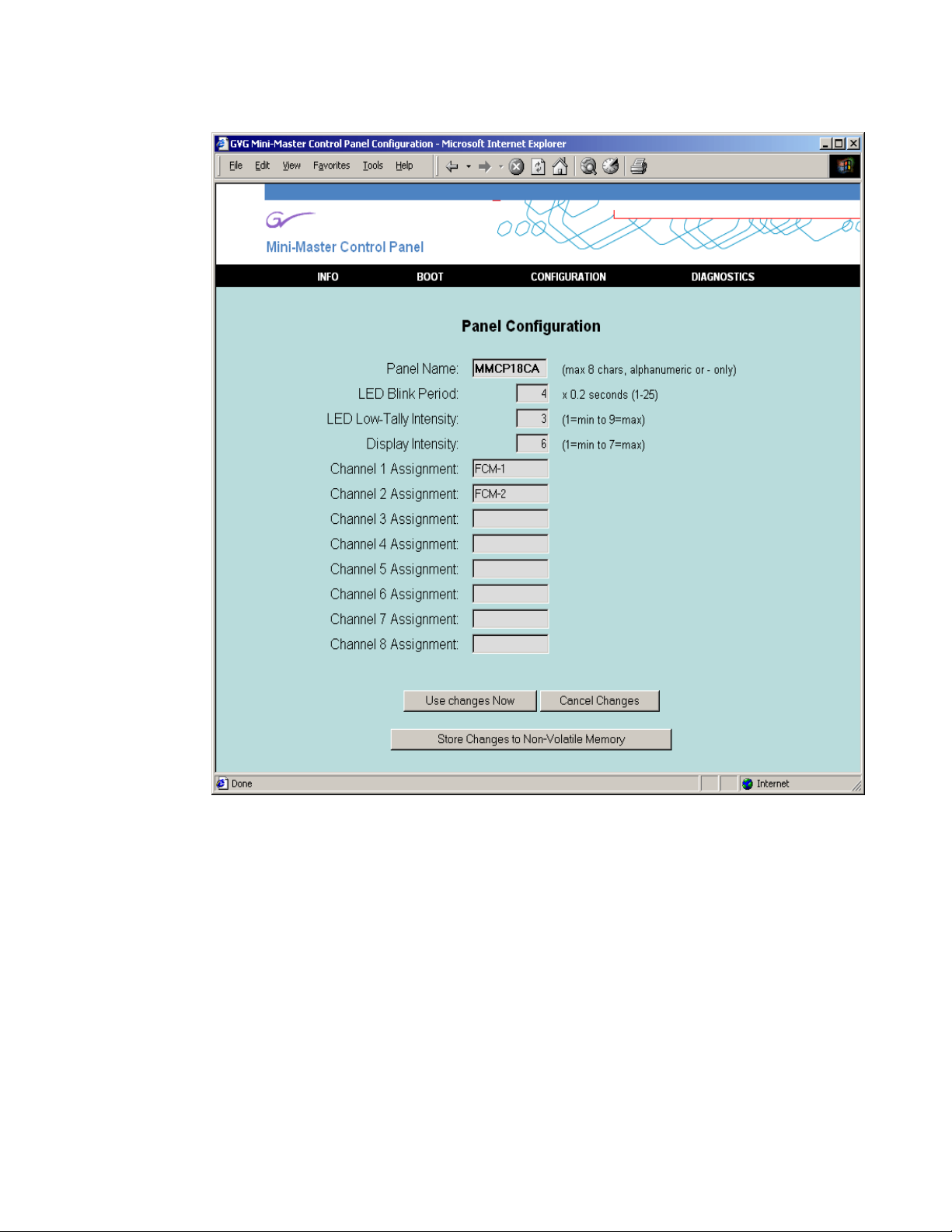

Control Panel Configuration

After installing the panel in the MCP Net and in its operating location you

may wish to adjust some of the operating parameters such as display and

low tally intensity and LED blink period. This can be done in the

figuration

menu also accessible through the web browser.

Panel

Con-

Return to the panel IP address location with the web browser by entering

the new IP address of the panel. From the

CONFIGURATION.

The

Panel

Configuration

screen will appear as shown in Figure 1-13 on

Panel Information

screen, click on

page 1-13.

You may set the following parameters from this screen:

■

Panel Name

■

LED Blink Period

— Enter a panel name of up to eight characters.

— Enter a number from 1–25 for a blink rate.

■

LED Low-Tally Intensity

— Enter a value from 1–9 (1=minimum to 9=max-

imum).

■

Display Intensity

— Enter a value from 1–7 (1=minimum to 7=maximum).

You may make channel assignments for each of the eight channel controls

on the panel from this menu. Enter the name of the channel (from the FCM

name assigned in M–2100 configuration). The name must be a valid FCM

name on the network. The preferred method of making channel assignments is by using the

Channel Control

Assigning Channels to Channel Control Buttons on page 2-4

When you have finished, click the

the intensity or blink rate parameters. Click the

Memory

to store these values or

buttons on the panel as described in

.

Use Changes Now

Cancel Changes

button to preview any of

Store Changes to Non-Volatile

to make no changes.

1-12 MMCP Installation/Operation Manual

Page 21

Figure 1-13. MMCP Configuration

Control Panel Cabling

MMCP Installation/Operation Manual 1-13

Page 22

Section 1 — Installation

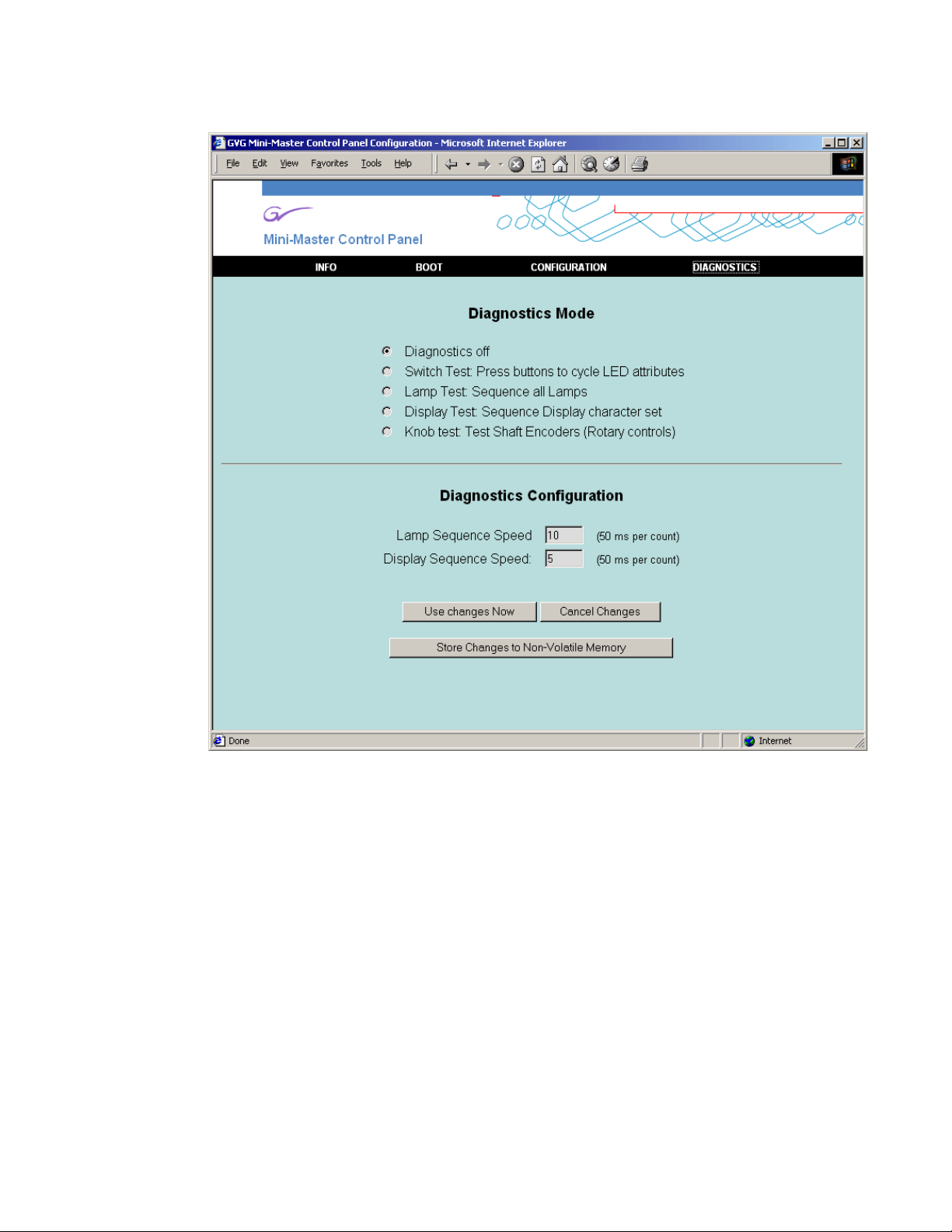

Control Panel Diagnostics

Some control panel diagnostics are available through the

Diagnostics Mode

menu and from button presses on the panel pushbuttons.

Note

Diagnostics may only be run when the system is off-air and no FCMs are

communicating. Release all connected FCMs or clear all FCM assignments

from

Channel Control

buttons.

To perform diagnostics from the web browser, click on DIAGNOSTICS from

the

Panel Information screen.

The Diagnostics Mode screen will appear as shown in Figure 1-14 on

page 1-15.

You may perform the following diagnostic tests from this screen:

■ Switch Test — The LED display behind each switch will be cycled

through bright, dim and off states. For switches with two LEDs, both

LEDs will be cycled though all combinations.

■ Lamp Test — All LEDs will be turned on in sequence. The current LED

number will be displayed.

■ Display Test — All displays are identified by number while the intensity

is cycled through all states. All possible ASCII characters are also

cycled.

■ Knob Test — An absolute signed value will be shown for each shaft

encoder. Turn knobs to send delta values to the frame. Press any button

to clear and reset the displayed values.

Click the

parameters. Click the

or

Cancel Changes to make no changes.

Use Changes Now button to preview any of the intensity or blink rate

Store Changes to Non-Volatile Memory to store these values

The panel diagnostics may also be initiated directly from the panel pushbuttons as follows:

1. Press and hold the unlabeled white button below the GPI 2 button in the

User control section of the panel.

2. Press one of the top four Channel Control buttons to run the

diagnostics. The four buttons correspond to the diagnostic tests above

(Channel 1=Switch Test, Channel 2=Lamp Test, Channel 3=Display

Test and Channel 4=Knob Test).

3. To turn diagnostics off, press and hold the unlabeled button and select

any one of the bottom four

Channel Control buttons.

1-14 MMCP Installation/Operation Manual

Page 23

Figure 1-14. MMCP Diagnostics Screen

Control Panel Cabling

MMCP Installation/Operation Manual 1-15

Page 24

Section 1 — Installation

Software Installation

The MMCP requires that the M–2100 is running v5.0 or later software.

When new system software is released, installation is done with the Netburner AutoUpdate PC Tool shown in Figure 1-15. Instructions for using

the tool are given in the Release Notes that accompany the upgrade. The

Release Notes will also cover new operating and configuration information.

Figure 1-15. Netburner AutoUpdate PC Tool

System Configuration

After installing new software, you will need to configure the system with

Configuration Manager. The

panel parameters. Refer to your M–2100 Installation and Service Manual

for complete instructions.

MCP form in this application is used to set the

1-16 MMCP Installation/Operation Manual

Page 25

System Operations

About this Section

This section of the Mini Master Control Panel Installation and Operation

manual describes the basic operation of the MMCP. The operations are

described using step-by-step procedures.

The topics covered in this section are:

■ Multichannel operations,

■ Program/Preset bus operations,

■ Transition controls and operation including Transition Type and Rate,

Breakaway Mode, Next Transition, and PreRoll/Transition button groups,

Section 2

■ GPI button operations,

■ Mode/Function button operations,

■ Keying controls and operations including keys and key modifiers,

Chroma keying, SqueezeBack and Crop, and

■ Audio Controls and operations including audio monitoring.

MMCP Installation/Operation Manual 2-1

Page 26

Section 2 — System Operations

Introduction

The Mini Manual Control Panel shown in Figure 2-1, provides an alternative to automated control of the M–2100 Serial Digital Master Control

System. A single MMCP can control up to sixteen channels (frames), eight

channels selectable at any given time. Automation can be disabled at the

MMCP for each of the Audio/Video/Control Processors.

Figure 2-1. Mini Master Control Panel

PGM Bus

PGM

PROGSRC1

PST

Channel Controls Automation Controls Keyer Controls GPI Buttons (2) Audio Monitor Controls

MINI MASTER CONTROL

Channel Control

Video

PROGSRC3 PROGSRC5 PROGSRC7

PROGSRC2 PROGSRC4

Transition

Rate

Keyer Control

Hue

Clip

PROGSRC6

Gain

Sat

Bright

Opacity

PROGSRC8

V

Non Sync

Non Sync

User

Audio

A

Primary

V

A

Mode

Over

Ratio

Next Transition

Audio Monitor

Monitor

Volume

PGM Level

PST Level

Transition

PreRoll

Transition

Mo de

Func

8129_12

Transition Rate Buttons (3)

Transition Type Buttons (5)

Source DisplaysPST Bus

Next Transition ButtonsAudio/Video Breakaway Mode

PreRoll/Transition Button Audio Controls

Mode/Function Button

2-2 MMCP Installation/Operation Manual

Page 27

Using Multichannel Control

A powerful feature of the M–2100 is the ability to control more than one

processing channel (FCM). A Channel Control subpanel (Figure 2-1 on

page 2-2) located in the top left corner of the panel, allows you to:

■ Enable/disable automation for each channel,

■ Assign Channel Control buttons to specific channel (Frame Controller

Modules or FCMs),

■ Control chosen FCMs using MMCP controls, and

■ Monitor channel status.

Channel Control Overview

The Channel Control subpanel (Figure 2-2) allows control of up to eight

channels from the panel. The panel will respond to the lamps and tallies for

only one panel at a time. This is the Primary channel. Up to seven Secondary channels can be assigned; one of which can be chosen to replace the

Primary fails for some reason. Assigned and connected channels do not

have to be selected as Primaries or Secondaries. The color and state (bright

or dim) of the

nected channel (see Table 2-1 on page 2-4).

Channel Control buttons will indicate the status of each con-

Using Multichannel Control

The

Channel Control buttons also enable and disable automation of any asso-

ciated assigned channel and show automation status with the yellow LED

above each button.

Figure 2-2. Channel Control Subpanel

Channel Control

Ch 1

Ch 5

Ch 2

Ch 6

Ch 3 Ch 4

Ch 7 Ch 8

8129_13

MMCP Installation/Operation Manual 2-3

Page 28

Section 2 — System Operations

The Channel Control button color, tally states and their meanings are summarized in Table 2-1.

Table 2-1. Channel Control Button Color and Tally States

Dim Red (blinking) Assigned pending connection

When assigning a channel, you may scroll through the available channels

with the

panel (Figure 2-1 on page 2-2).The scrolling channel names will appear in

a Source Name display (Figure 2-3) corresponding to the

button being pressed. Once channels are assigned to a button, the channel

names will be displayed in the Source Name displays corresponding to the

Channel Control buttons.Channel names will only display during the channel

assignment process.

Color/State Meaning

Off Not assigned

Dim Red Assigned but not available (Busy or No Comm)

Dim Green Assigned and connected

Bright Yellow Primary channel

Dim Yellow Secondary channel

Alternating Red Non-sync

Take and Fade/Fade Transition Type buttons in the lower left of the

Channel Control

Figure 2-3. Channel Names in Source Name Displays

Channel 1

Channel 5 Channel 6

Channel 2 Channel 3

Assigning Channels to Channel Control Buttons

Each frame (channel) must be currently configured as a valid Equipment

Type in Configuration Manager before it can be assigned to a

button.

Channel Control buttons can only be assigned when the panel is in a quiescent

state (no Primary active and all panel lights off).

To assign channels, do the following:

1. Press and hold down the Mode/Function button on the far right of the

panel between the PGM and PST Level audio controls (Figure 2-1 on

page 2-2).

Channel 7

Channel 4

Channel 8

8129_24

Channel Control

2-4 MMCP Installation/Operation Manual

Page 29

Using Multichannel Control

2. Press and hold down one unassigned Channel Control button whose

button state is off.

3. Release the Mode/Function button. Continue to hold down the Channel

Control button.

4. Use the first two buttons, Take and Fade/Fade, in the Transition Type

subpanel to scroll through the list of available valid channel names

displayed in the Source Name display corresponding to the selected

Channel Control button (Figure 2-3 on page 2-4).

Note Frame names already assigned will not appear in the list.

5. When the desired FCM name is found, and while continuing to hold

the

Channel Control button, press and release the Mode/Function button.

6. Release the Channel Control button. The FCM name is assigned to the

associated

Channel Control button and the button will light dim green to

indicate it is assigned and connected or dim red if it is assigned but not

available. Refer to Table 2-1 on page 2-4 for a summary of other status

states.

7. To delete an assignment, scroll through the list and assign None to the

button.

In addition to the above functionality, an assigned and connected (dim

green status) channel may be released to allow another control panel to

acquire it without changing the assigned FCM name stored in non-volatile

memory.

To release a channel for use by another MCP, do the following:

1. Press and hold the Mode/Function button.

2. Press and hold the appropriate Channel Control button.

3. Release the Mode/Function button and momentarily press it again.

MMCP Installation/Operation Manual 2-5

Page 30

Section 2 — System Operations

Assigning Primaries and Secondaries

Any button that is displaying dim green status may now be selected as a

Primary or Secondary channel.

A Primary channel is active and on-air. Any changes made on the panel

controls will affect this channel. Its status is indicated by the corresponding

Channel Control button tallying bright yellow. Only one Primary channel may

be selected at a time.

A Secondary channel can be selected but is not on-air. Its corresponding

Channel Control button will light dim yellow. If the Primary channel fails, the

operator can select the Secondary and it will be in the same panel state as

the Primary. Up to seven Secondaries can be selected.

Selecting a Primary or Secondary Channel

To select a Primary channel, press a Channel Control button with dim green

status. The button will now tally bright yellow indicating it is the active

Primary channel.

The following behavior applies to a selected Primary:

■ Pressing the button again will deselect it as the Primary.

■ Pressing and holding the Primary button and selecting and releasing

another button with dim green status will assign that button as a Secondary (dim yellow). The Primary button will not lose its status.

■ If no Secondary is selected, releasing the Primary button will result in

its de-selection as Primary. It will return to a dim green status. Select it

again to return it to the Primary channel.

■ Pressing another dim green or dim yellow (Secondary) tallied Channel

Control button will select the associated channel as the Primary. All other

previously selected channels (Primary and Secondary) will be deselected (return to dim green status).

Pressing an already selected Primary when there are Secondaries will have

the following affects:

■ While held down, Secondaries can be de-selected by pressing and

releasing their button. The Primary remains unaffected.

■ While held down, new Secondaries can be selected by pressing and

releasing their associated button. The Primary remains the Primary.

■ When the Primary button is released, and if no Secondaries have been

selected or de-selected, all Secondaries are de-selected. The Primary

remains selected.

2-6 MMCP Installation/Operation Manual

Page 31

Automation Enable

The Channel Control buttons are also used to enable/disable automation

control for the corresponding channel.

Automation Control can be enabled/disabled for all eight channels independently of the

have to be chosen as a primary or secondary in order to enable/disable

automation.

To enable/disable automation on a channel, do the following:

1. Press and hold the Mode/Function button.

2. Press and release the Channel Control button corresponding to the

automation control you wish to enable or disable.

3. The corresponding yellow LED above the Channel Control button

(Figure 2-2 on page 2-3) will light when automation control of the

channel is enabled and go off when control is disabled.

Using Multichannel Control

Channel Control buttons status. That is, a channel does not

MMCP Installation/Operation Manual 2-7

Page 32

Section 2 — System Operations

Program and Preset Bus Operations

Preset Bus

The Preset bus (PST) (Figure 2-4) is a row of eight source select crosspoint

buttons. Each crosspoint button may be mapped to an input source from

the rear of the Processor frame. The crosspoint buttons are initially configured at the factory so that the sources are associated in ascending numeric

order from left to right. The left-most button corresponds to Source 1; the

right-most button corresponds to Source 8. This order may be changed in

the

Main Sources form, under PGM/PST/Aux Sources tab in Configuration Man-

ager.

The crosspoint buttons can be mapped to any input source desired. It is not

necessary to map Crosspoint 1 to Source 1, for example, it may be assigned

to any of the sources. Each source consists of video and like-numbered

audio inputs. For instance, video at input 1, and all audio connections to

input 1 (from one to four channels), are all part of the same source, Source 1.

Figure 2-4. Program (PGM) and Preset (PST) Buses

Video

PGM

PST

1

PROGSRC1

PROGSRC2 PROGSRC4

1

2 3 4 5 6 7 8

PROGSRC3 PROGSRC5

2 3 4 5 6 7 8

Selecting Preset Sources

PST buttons can select main audio/video (married) sources and/or sources

for Audio Processor Modules 1–4. To select a Preset source, do the following:

1. Press the PST button corresponding to the desired source.

PROGSRC7

PROGSRC6

PROGSRC8

V

A

Non Sync

V

A

Non Sync

8129_20

The selected

source of both video and audio signals. All other

PST button lights at high tally, indicating that it is the

PST buttons go dark.

2. If Next transition Bkgd tallies high, the selected Preset source will be output

on the Look Ahead Preview (LAP) output.

2-8 MMCP Installation/Operation Manual

Page 33

If video and audio monitors have been connected, you can view, hear,

and adjust the Preset source prior to taking it to the Program bus.

The audio level and trim settings that existed on the selected source when

last placed on the Program bus are recalled.

Backup Preset Sources

The M–2100 has the ability to maintain a backup source. A backup source

can be taken to air on the Program bus if the primary source fails.

You may enable another Preset source to act as a backup if you have

checked the

ration Manager. If backup capability has not been enabled, simultaneous

pressing of more than one

any effect.

If a backup source has been enabled in Configuration Manager, enable a

backup source as follows:

1. Press and hold a PST button (which will tally high) to select the primary

source.

Enable Backup Input Select check box in the MCP form in Configu-

Program and Preset Bus Operations

PST button results in only the leftmost having

Program Bus

2. Press and release a second PST button to select a backup source (which

will tally high/blinking). If this was the incorrect backup selection,

change the backup crosspoint by holding down the Primary

and pressing and releasing another

be replaced by the second.

Pressing and releasing the

swapped with the primary married source — the backup source becomes

the primary married source and the previous primary married source

becomes the backup source.

Pressing and releasing the

cause the backup source to be dropped.

When the Preset source is transitioned to the Program bus (on-air), the

backup source will follow and may be selected manually as a backup if the

original source fails. This is normally done with two identical sources

rolling the same tape or clip.

The Program bus (PGM) is a row of eight source select crosspoint buttons

(Figure 2-4 on page 2-8). Crosspoints assignments are made as described in

Preset Bus on page 2-8 and follow the Preset bus.

PST button of a backup source will cause it to be

PST button of the primary married source will

PST button. The first selection will

PST button,

MMCP Installation/Operation Manual 2-9

Page 34

Section 2 — System Operations

Sources active on the Program bus are sent to the Program output. This is

typically the output being supplied to the station transmitter. In routine

operation, sources are preset on the Preset bus, then transitioned to the

Program bus.

When a transition is made with the

PreRoll/Transition button, or automation,

sources selected on the Preset bus are transitioned to the Program bus, and

PGM button tally changes accordingly. For fade-type transitions, PGM button

tally changes in the frame during which new video first appears on the

Program output bus. For mixes,

PGM button tally changes when the transi-

tion is complete.

If more than one

PGM buttons can select main audio/video (married) sources and/or

PGM button is pressed, only the left-most has an effect.

sources for Audio Processor Modules 1–4.

Backup sources cannot be chosen on the Program bus, only the Preset bus,

as explained above.

Backups can be transitioned to the Program bus, but cannot be Tally

Summary for Program and Preset buses. A summary of the

PGM button

tally states is given in Table 2-2.

Table 2-2. PGM Button Tally

Button Tally Indication

Off Not selected

Low Audio breakaway

High

High/blinking Married backup source

Initialize

Primary married source

Primary video source

Left-most button (Source

#1) tallies high

Source Names Display

The Source Name displays are located directly above the Program bus

buttons (Figure 2-4 on page 2-8). They display an 8-character name for each

source. Source Names are defined in Configuration Manager,

form,

PGM/PST/AUX Sources tab.

The names displayed are usually those associated with the main sources,

but may be used to display names for optional Audio Processing Channels

2, 3, and 4.

The Source Name displays will also report the assigned channel names corresponding to the

Channel Control buttons when the panel is in a quiescent

state, as when channels are being assigned (Figure 2-3 on page 2-4).

2-10 MMCP Installation/Operation Manual

Main Sources

Page 35

If a particular input has been configured as a Router Linked Destination,

the name displayed is one of the following:

■ If SMS7000 communications are active, the name displayed will be the

source name provided by the SMS7000 (in software v5.1 or later).

■ If SMS7000 communications are not active for a set time, the name dis-

played will be *NOLINK*.

■ If the proper SMS7000 destination name has not been entered into Con-

figuration Manager, the name displayed will be *NODEST*.

Non-Sync Source Indicators

Two sets of indicators for non-synchronous sources video (V) and audio

(A) are located at the end of the Program and Preset rows (Figure 2-4 on

page 2-8). The video non-sync indicators display status on the corre-

sponding Program and Preset bus. The two audio non-sync lamps are tied

together. When either bus has an audio non-sync condition, both lights will

indicate non-sync.

Program and Preset Bus Operations

Non-sync conditions for audio and video are defined in Table 2-3.

Table 2-3. Non-sync Conditions

AUDIO buttons high tallies

PGM VIDEO button high tallies

PST VIDEO button high tallies

Note Non-sync backup sources are not reported.

Some aspect of audio for a selected source (primary, breakaway, Over)

on the Program or Preset bus is not in sync.

Some aspect of video for a selected source (primary, breakaway) on the

Program bus is not in sync.

Some aspect of video for a selected source (primary, breakaway) on the

Preset bus is not in sync.

If a Program source goes non-sync, the selected Transition Type button will go

low tally and the

Take button will go high tally.

MMCP Installation/Operation Manual 2-11

Page 36

Section 2 — System Operations

Transition Controls and Operation

A transition is a change from one combination of video and audio elements

(or sources) to another combination. These elements can be any of the following:

■ Married — video and audio supplied on the same crosspoint.

■ Video Only — video only signal supplied on this crosspoint.

■ Audio Only — there are four Audio Only PGM/PST crosspoint but-

tons, located on the Audio Control portion of the Manual Control

Panel.

■ Custom Transitions — split audio/video transitions by assigning them

different parameters in the Configuration Manager. You can configure

separate transition types, transition durations, and other associated

parameters. This is a software enabled option.

The following transition control buttons are explained in this section:

■ Transition Type

■ Transition Rate

■ Audio/Video Breakaway (Mode)

■ Next Transition

■ PreRoll/Transition

The following transition types are also explained in this section:

■ Custom transitions

■ Hot switching on the Program bus (Take)

Transition Type

In normal operation, Preset sources are transferred to the Program bus

through a transition. Transitions allow you to replace the current Program

output with the Preset source at a selected transition rate. There are five

standard transition types. The

MMCP are shown in Figure 2-5.

Figure 2-5. Transition and Rate Buttons

Transition and Rate pushbuttons on the

Transition Rate

Slow Med Fast

8129_22

2-12 MMCP Installation/Operation Manual

Page 37

From left to right, the Transition Type buttons select:

■ Take — provides a clean, abrupt switch from Preset to Program. Not

■ Fade/Fade — causes the current on-air source to fade down to transition

■ Take/Fade — causes the current on-air source to go abruptly to transition

■ Mix — causes the current on-air source to dissolve to the new source

■ Fade/Take — causes the current on-air source to fade down to transition

Transition Rates

Transition Controls and Operation

affected by transition rate selection.

matte/silent, at which point, the Preset source will fade up (to on-air)

from transition matte/silent.

matte/silent, at which point, the Preset source fades up (to on-air) from

transition matte/silent.

selected on the Preset bus.

matte/silent, at which point, the Preset source switches cleanly and

abruptly to on-air.

There is a Transition rate associated with each transition type. When a transition type is selected, the rate in effect when that transition type was last

used will be recalled. A

Take transition has no rate associated with it.

The transition rate applies the next time the

pressed, and is defined as the interval from the time the on-air video begins

to be modified to the time the preset audio and video is on-air at full gain.

Transition Rate buttons (Figure 2-5 on page 2-12) are labeled Slow, Medium, and

Fast.

The transition rates are set at the factory to the default values below:

■ Slow — default is 2.0 seconds

■ Medium — default is 1.0 second

■ Fast — default is 0.5 second

Transitions rates are set in the

M–2100 Configuration Manager. You may enter the desired transition rate

for each

Transition Rate button.

Hot Switching (Hot Program Cuts)

PreRoll Transition button is

Transition Rates section of the MCP form in the

A hot cut (also called hot punching) is a method used to select a source

directly on the Program bus. A hot cut always initiates a

Take transition. If

the selected video source is not present, the LOS (Loss Of Signal) Matte is

placed on-air. When LOS Matte is active, a continuous high/low tally

flashing occurs on the active

PGM button.

MMCP Installation/Operation Manual 2-13

Page 38

Section 2 — System Operations

If the hot cut is performed on a crosspoint configured with a preroll

enabled, the hot cut initiates the preroll sequence.

If the crosspoint is configured with a machine start or relay enabled, the hot

cut triggers the configured device.

The following hot cut actions will apply to transitions on the M–2100:

■ Hot cuts from the Program bus will take precedence over any transition

■ Hot cuts from automation will not be accepted if any transition (from

■ Hot cuts from the Preset bus will take precedence if the Enable Transition

■ Hot cuts will remove any selected keys or SqueezeBack selections if

Hot Cut Transition Interrupts

in progress, either from the MMCP or automation.

the MMCP or automation) is in progress.

Interrupt check box has been selected in the MMCP form in Configura-

tion Manager.

they are on-air.

A transition interrupt situation occurs when a new Program source is

selected during a transition in progress. The following functions take place:

■ Any Preroll/Transition is canceled.

■ Any Program bus Audio Overs are cancelled.

Selection of a Program audio source will recall the audio level and trim settings in effect when that source was last selected on the Program bus.

Custom Transitions

You can customize audio/video transitions by assigning them different

parameters in Configuration Manager. Custom separate transition types,

transition durations, and other associated parameters can be configured. A

combination of custom transitions and standard transitions is available.

Note This feature, called the 2100-SAV (Split Audio Video) is a software enabled

Refer to the Installation and Service Manual for complete configuration

instructions. Custom transitions are configured in the

Custom Transitions menu.

option and must be purchased.

MCP form, in the

2-14 MMCP Installation/Operation Manual

Page 39

Using Custom Transitions

Having previously defined your custom transitions using the Configuration Manager, you select a custom transition type as you would a standard

transition type. For example, if you set up a custom transition for Button

Type

Custom2, selecting the Mix transition button on the MMCP invokes that

custom transition.

Transition Rates

The transition rate is established by the parameters set up in the Custom Tran-

sition Configuration form. All of the Transition Rate buttons will low tally to

indicate that a custom transition is selected.

When a custom transition is active, and a Take transition occurs, the three

Transition Rate buttons tally off to indicate that the take is in progress.

Transition Rate Button Tally

The Transition Rate buttons (all three) display low tally when a custom tran-

sition is selected and active on the MMCP.

Transition Controls and Operation

Matte Duration

Any matte duration times are considered part of the New video.

When using SqueezeBack with matte transitions, the matte is disabled.

Changing from Custom to Standard Transition Types

To revert to standard transition types from Custom Transition types, do the

following:

1. In Configuration Manager, click on the Custom Transition button on the

MCP form.

2. In the Custom Transition form, uncheck the Enable Custom Transition check

box for each

3. Download the named configuration to the FCM.

Button Type that was customized.

Transition Interrupts

When custom transitions are selected and active, you can only make a hot

cut on the Program bus.

Transition Logging Tool

The Transition Logging Tool will accommodate custom transition types.

Custom transitions types may be logged with the Transition Logging Tool,

similar to the standard transition types.

MMCP Installation/Operation Manual 2-15

Page 40

Section 2 — System Operations

If a selected Transition Type has been defined as custom, the following data

will be displayed in the left pane of the main application window:

■ The TranType column displays the custom transition type, for example;

■ The (transition) Rate column displays the rate set for the selected

Custom1, Custom2, Custom3, etc.

custom transition based on the parameters set in the Configuration

Manager,

MCP form in the Custom Transition section.

2-16 MMCP Installation/Operation Manual

Page 41

Audio/Video Breakaways

Transitions can be tailored to change only selected signals using the Mode

(Audio and Video Breakaway) transition selections (Figure 2-6). Normally,

audio and video signals are transitioned simultaneously. The

Video Only buttons are used to perform program and preset bus breakaway

source selection. These buttons transition audio only or video only signals

as described below:

■ Audio Only—when selected, the next transition will change only the

audio portions of the on-air signal.

■ Video Only—when selected, the next transition will change only the back-

ground video portions of the on-air signal.

Figure 2-6. Audio and Video Breakaway Mode Buttons

Mode

Transition Controls and Operation

Audio Only and

Video

Only

Audio

Only

8128_18

Pressing either the Audio Only or Video Only button causes it to toggle between

its active and inactive state. Preset selections made while the

Video Only button is in the active state (lighted), unless the button is held,

will be restricted as indicated. If an

when a Preset selection is made, the

Audio Only or Video Only button is active

Audio Only or Video Only button will

Audio Only or

toggle to its inactive state automatically.

A typical

Video Only breakaway operation would be:

1. Press and release Video Only, then,

2. Press the desired Preset video source.

A typical

Audio Only breakaway operation would be:

1. Press and release Audio Only, then

2. Press the desired Preset audio source.

Note You cannot have a Backup set while performing Breakaways.

Breakaway Program or Preset bus selections (no Backup Presets) tally as

follows:

■ Video — high, steady

■ Audio — low, steady

MMCP Installation/Operation Manual 2-17

Page 42

Section 2 — System Operations

Breakaway Selection Examples

Audio Only Breakaway Example #1

1. Select VTR2 on Preset. Tallies high.

2. Select Breakaway Audio Only. Tallies high.

3. Select RS3 on Preset. Tallies low. Audio Only tallies off.

The next transition will take video from

1. Press the Preroll/Transition button.

2. On Program bus, VTR2 tallies high and RS3 tallies low.

VTR2 and audio from RS3.

Video Only Breakaway — Example #2

1. Select RS3 on Preset. Tallies high.

2. Select Breakaway Video Only. (tallies high).

3. Select VTR2 on Preset. Tallies high. RS3 on Preset changes to tally low.

Video Only tallies off.

The next

Program bus,

Preroll Transition takes video from VTR2 and audio from RS3. On

VTR2 tallies high and RS3 tallies low.

2-18 MMCP Installation/Operation Manual

Page 43

Next Transition Buttons

The Next Transition buttons (Figure 2-7) select whether the next transition will

consist of Background only, Key only, or both. The two buttons are:

■ Next Transition BKGD (Background) — when selected, the next transition

will change only the Background video portions of the on-air signal,

and

■ Next Transition KEY — when selected, the next transition will change only

the Key video portions of the on-air signal.

Both buttons may be selected simultaneously.

Figure 2-7. Next Transition Buttons

Next Transition

BKGD KEY

Transition Controls and Operation

8129_19

If an attempt is made to setup a Key-only transition while Audio Only is

active, there will be a beep audio warning and the setup is ignored.

If an attempt is made to press the

BKGD button during preroll, it will be

beeped and ignored.

If an attempt is made to press the

KEY button during preroll, it will be

ignored (that is, it will not change its state) but not beeped. This button

press is allowed since key cuts are allowed during preroll.

If one of the buttons tallies high and the other tallies off, the buttons will act

as follows:

■ Pressing and releasing the high tallied button has no effect. It stays high

tally.

■ Pressing and releasing the off tallied button will cause it to tally high.

The other button tallies off.

■ Pressing and releasing both buttons simultaneously results in both tal-

lying high.

If both switches tally high, the buttons will act as follows:

■ Pressing and releasing either will leave that button’s tally high and turn

the non-pressed button’s tally off.

■ Pressing and releasing both buttons simultaneously will have no effect

— both continue to tally high.

If

KEY tallies high, and there are no Key Select buttons in the active state (that

is, with high tally) the next transition will have no effect.

MMCP Installation/Operation Manual 2-19

Page 44

Section 2 — System Operations

Holding the Key button down can have special effects, as described in

Cutting Keys On or Off Air on page 2-26. (If a Key-cut occurs, releasing the

button does not change its tally.)

Preroll Transitions

A preroll transition causes Preset sources to begin prerolls (if configured),

then transition to the Program bus. Preroll transitions can be triggered by

pressing the

that has been configured with a preroll enable.

Figure 2-8. PreRoll/TransitionButton

Transition

Key

PreRoll/Transition button (Figure 2-8) or by selecting a crosspoint

PreRoll

Transition

8129_21

The PreRoll Transition button tallies three conditions:

■ Full brightness — Transition in progress,

■ Half brightness — One of the selected Preset sources has been config-

ured with a preroll time, and

■ Off — No selected Preset source has been configured with a preroll

time.

There are several scenarios involving the use of the

and the transition type selected as described in the following headings:

First Press Transitions

■ Begins a preroll (if any).

■ Makes a Preset bus-to-Program bus transition (no preroll), or at the end

of the preroll interval.

PreRoll/Transition button

2-20 MMCP Installation/Operation Manual

Page 45

Second Press (and Subsequent) Transitions

During a preroll, a repeat press of the PreRoll/Transition button forces the

Preset bus to begin the transition.

■ First half of Fade transition: Pressing the PreRoll/Transition button again

forces the first half of the transition to complete. The Program output is

held in transition matte/silent until the newly transitioned source is

ready to air, and the

■ Second half of a Fade transition: Completes second half of the Fade.

■ Mix transition: Pressing the PreRoll/Transition button again forces com-

PreRoll/Transition button is released.

pletion of the transition.

Hold Transitions

During a Fade type transition, you can hold a transition in transition

matte/silent by pressing and not releasing the

Program bus is set to transition matte/silent and is held there until you

release the button.

Transition Controls and Operation

Preroll/Transition button. The

Preroll Transitions Summary

Pressing the PreRoll/Transition button again after the actual video/audio

transition has started (regardless of how Transition Now is configured) has

the following effects:

■ For fade-fade (while fading down), cut to matte/silent. Hold in matte

until the

Program bus, then cut the Program bus to on-air.

■ For fade-take (while fading down), cut to matte/silent. Hold in matte

until the

Program bus, then cut the Program bus to on-air.

■ For fade-fade and cut-fade (while in fade up mode), immediately set

the Program bus to full gain.

■ For mix transitions, immediately complete the transfer of Preset

sources to the Program bus at full gain.

If flip/flop operation has been configured as enabled:

■ For mix transitions, Preset bus output cuts to the previous Program

output when the transition is complete.

■ For all other transition types, Preset bus output cuts to the previous

Program output as soon as Preset video/audio first appears on

Program output.

PreRoll/Transition button is released, switch Preset sources to the

PreRoll/Transition button is released, switch Preset sources to the

Preroll/Transition can affect main audio/video sources and/or AP 2–4

sources delegated for AFA operation. AP 2–4 details are described in the

Installation and Service Manual.

MMCP Installation/Operation Manual 2-21

Page 46

Section 2 — System Operations

GPI Buttons

Two user-configurable buttons, GP I1 and GPI 2, (Figure 2-9) allow control of

MMCP functions and output relays and responses to opto-isolator inputs.

The buttons and functions are associated with the 12 GPI relays on the rear

of the M–2100 frame. Four GPI input relays are also provided on the rear of

the frame and can be configured as opto-inputs to trigger an M–2100 action

such as a cut or transition.

When pressed, the

GPI button high tallies. If a GPI button is not configured

for one of the activities described below, pressing it has no effect, and

results in a warning beep.

GPI button presses are ignored unless in the qui-

escent state.

Figure 2-9. GPI Buttons

User

GP1 GP2

SQB

The GPI buttons can be configured to perform one of the following actions

when the assigned button is pressed:

■ Assign an output relay (GPI Outputs 1–12) to perform a programmed

action, or

■ Arm opto-inputs (trigger a programmed M–2100 action from GPI Opto-

inputs 1–4).

These parameters are configured in the

GPI form in the Configuration

Manager application described in the Installation and Service Manual.

2-22 MMCP Installation/Operation Manual

Page 47

Mode/Function Button

The Mode/Function button (Figure 2-10) is a multi-purpose control used in

conjunction with other controls on the MMCP to perform the following

functions:

■ Select SqueezeBack patterns,

■ Enable audio functions (set PST unity gain, invert audio phase),

■ Recall default key parameters and perform auto-setup, and

■ Make Channel Control assignments.

Figure 2-10. Mode/Function Button

Mode

Func

Refer to the specific section in this manual for using the Mode/Function button

with each of the above operations.

Mode/Function Button

8129_16

MMCP Installation/Operation Manual 2-23

Page 48

Section 2 — System Operations

Keyer Controls and Operation

The Keyer Control subpanel (Figure 2-11) offers control of the following

keying functions covered in this section:

■ Using Keys, including selecting key sources, previewing keys, modi-

fying keys, and setting key parameters.

■ Using Squeezeback and Crop functions.

■ Creating Chroma Keys (SD only).

The Keyer Control subpanel also provides controls for setting the following

matte configurations:

■ Matte crosspoints,

■ Transition matte,

■ Custom key fill matte defaults, and

■ Loss of Signal (LOS) matte.

Figure 2-11. Keyer Control Subpanel

Keying Overview

Video keyers allow you to insert additional video into the video background. They are commonly used to insert station logos, or text from character generators, or picture-in-picture feeds from still stores, production

switchers, or digital video effects equipment.

Keyer Control

Hue

Clip

Brdr

Key 1

On/Off

Saturation

VIDEO

Matte

Key 2

On/off

Gain

SELF

EXT

Key 3

On/off

Brightness

Opacity

Lin

Lum

Key 4

On/off

User

GP1

SQB

GP2

8129_17

Keys can be configured from an external source or be a self-key. They can

be filled with matte if desired and the matte parameters adjusted with controls on the Keyer Control subpanel. Linear or luminance type keys can

also be defined.

2-24 MMCP Installation/Operation Manual

Page 49

Key modifiers are available to add borders whose luminance parameter

can be adjusted. The clip and gain key parameters can be set and are used

in conjunction with the optional Chroma Keyer (SD only).

SqueezeBack, a special type of key, is offered as an option on the M–2100

for both SD and HD systems.

Note All video sources to the M–2100, including primary video and key inputs,

SD Systems

Keys are installed in pairs — you can have 2 or 4. Each keyer module can

contain 2 Linear Keyers, or 1 Chroma Keyer and 1 Linear Keyer. Modules

can be installed in either or both of slots 5 and 6 of the A/V/C Processor

Frame. Chroma Keyers (if present) are controlled by

and/or 3.

HD Systems

Keyer Controls and Operation

must be timed within +/– 1/2 line (+1/4, –3/4 for HD) relative to the reference

input to be synchronous.

Key Select buttons 1

HD systems can be configured with the same Linear Keyers modules as the

SD systems, or a combination of Framestore and Single Luminance/Linear

Keyer module(s) and Linear Keyer module(s). Modules can be installed in

either or both of slots 6 and 7 of the A/V/C Processor Frame.

Note The M–2100 HD system does not have Chroma Key, Borderline, or Drop

Shadow capability.

MMCP Installation/Operation Manual 2-25

Page 50

Section 2 — System Operations

Selecting and Transitioning Keys

Any combination of keyers (from 1 to all 4 keyers) can be selected at a time,

to appear on either, or both, the Program and Preset buses. Select a key by

pressing and releasing a

Off, Key 4 On/Off shown in Figure 2-11 on page 2-24) whose previous tally was

off. Switch tally goes low (selected but not active) or high (selected and

active), depending on the state of the

releasing the same

be selected/deselected independently of each other.

During the next transition, a key that is selected and active will be transitioned to on-air (if currently off-air), or to off-air (if currently on-air).

Note If the Next Transition Key button is not enabled (tallies off), key transitions

To select a Key, press one of the Key Select buttons.

■ If the key signal is set to be changed by the next transition (Next Transition

Key Select button (Key 1 On/Off, Key 2 On/Off, Key 3 On/

Next Transition Key button. Pressing and

Key Select button again toggles it off. Multiple keys can

will not occur, and all selected Key Select buttons tally low.

Key button active), the Key Select button lights at high tally.

■ If the key signal is not set to be changed by the next transition (Next Tran-

sition Key button inactive), the Keyer Select button lights at low tally.

■ After a key signal has been transitioned to the Program bus, the Keyer

Select button remains lighted at high tally and the associated LED indi-

cator (just above the button) lights green.

Keys which are on-air will be removed by the next transition unless:

■ The Next Transition Key button is inactive, or

■ You press the Keyer Select button so that it is tallied off before the next

transition occurs.

Note The key is dropped if either the background source or the key source

becomes non-sync while transitioning to air or when a hot cut is performed.

If configured, selecting a key automatically recalls associated key modifier

settings (

Border, Clip, Gain, and Matte values) previously used for that key

selection.