Page 1

User Manual

M3007-9900-102

2016-06-22

DENSITÉ 3+ FR4

HOUSING FRAME

All manuals and user guides at all-guides.com

Page 2

ii

Notices

Copyright and Trademark Notice

Copyright © 2015-2016, Grass Valley Canada. All rights reserved.

Belden, Belden Sending All The Right Signals, and the Belden logo are trademarks or

r

egistered trademarks of Belden Inc. or its affiliated companies in the United States and

other jurisdictions. Grass Valley Canada, Miranda, Densité 3+ FR4, iControl, and Densité are

trademarks or registered trademarks of Grass Valley Canada. Belden Inc., Grass Valley

Canada, and other parties may also have trademark rights in other terms used herein.

Terms and Conditions

Please read the following terms and conditions carefully. By using Densité 3+ FR4

documentation, you agree to the following terms and conditions.

Grass Valley hereby grants permission and license

to owners of Densité 3+ FR4 to use their

product manuals for their own internal business use. Manuals for Grass Valley products may

not be reproduced or transmitted in any form or by any means, electronic or mechanical,

including photocopying and recording, for any purpose unless specifically authorized in

writing by Grass Valley.

A Grass Valley manual may have been revised to reflect changes made to the product

during its manufac

turing life. Thus, different versions of a manual may exist for any given

product. Care should be taken to ensure that one obtains the proper manual version for a

specific product serial number.

Information in this document is subject to change without

notice and does not represent a

commitment on the part of Grass Valley.

Warranty information is available in the Support section of the Grass Valley Web site

(w

ww.grassvalley.com).

Title Densité 3+ FR4 User Manual

Part Number M3007-9900-102

Revision 2016-06-22, 15:35

All manuals and user guides at all-guides.com

Page 3

iii

Densité 3+ FR4

User Manual

Important Safeguards and Notices

Symbols and Their Meanings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . iv

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . v

This section provides important safety guidelines f

or operators and service personnel.

Specific warnings and cautions appear throughout the manual where they apply. Please

read and follow this important information, especially those instructions related to the risk

of electric shock or injury to persons.

Symbols and Their Meanings

Indicates that dangerous high voltage is present within the equipment

enclosure that may be of sufficient magnitude to constitute a risk of electric

shock.

Indicates that the user, operator or service technician should refer to the product

manuals for important operating, maintenance, or service instructions.

This is a prompt to note the fuse rating when replacing fuses. The fuse

referenced in the text must be replaced with one having the ratings indicated.

Identifies a protective grounding terminal which must be connected to earth

ground prior to making any other equipment connections.

Identifies an external protective grounding terminal which may be connected to

earth ground as a supplement to an internal grounding terminal.

Indicates that static sensitive components are present, which may be damaged

by electrostatic discharge. Use anti-static procedures, equipment and surfaces

during servicing.

Indicates that the equipment has more than one power supply cord, and that all

power supply cords must be disconnected before servicing to avoid electric

shock.

The presence of this symbol in or on Grass Valley equipment means that it has

been tested and certified as complying with applicable Canadian Standard

Association (CSA) regulations and recommendations for USA/Canada.

The presence of this symbol in or on Grass Valley equipment means that it has

been tested and certified as complying with applicable Underwriters Laboratory

(UL) regulations and recommendations for USA/Canada.

All manuals and user guides at all-guides.com

Page 4

iv

Notices

Warnings

A warning indicates a possible hazard to personnel, which may cause injury or

death. Observe the following general warnings when using or w

orking on this

equipment:

• Appropriately listed/certified mains sup

ply power cords must be used for the

connection of the equipment to the mains voltage at either 120 V AC or 240 V AC.

• This product relies on the building's installation for short-circuit (over-current)

pr

otection. Ensure that a fuse or circuit breaker for 120 V AC or 240 V AC is used on the

ph

ase conductors.

• Any instructions in this manual that requir

e opening the equipment cover or enclosure

are for use by qualified service personnel only.

• Do not operate the equipment in wet or damp conditions.

• This equipment is grounded through the grounding conductor of the power cords. To

a

void electrical shock, plug the power cords into a properly wired receptacle before

connecting the equipment inputs or outputs.

• Route power cords and other cables so they a

re not likely to be damaged. Properly

support heavy cable bundles to avoid connector damage.

• Disconnect power before cleaning the equipment. Do not use liquid or aerosol

cl

eaners; use only a damp cloth.

• Dangerous voltages may exist at several points in this equipment. To avoid injury, do

not touch exposed connec

tions and components while power is on.

• High leakage current may be present. Earth connection of product is essential before

c

onnecting power.

• Prior to servicing, remove jewelry such as r

ings, watches, and other metallic objects.

• To avoid fire hazard, use only the fuse type and rating specified in the service

instruc

tions for this product, or on the equipment.

• To avoid explosion, do not operate this equipment in an explosive atmosphere.

• Use proper lift points. Do not use door

latches to lift or move equipment.

• Avoid mechanical hazards. Allow all rotating devices to come to a stop before servicing.

• Have qualified service personnel perform saf

ety checks after any service.

The presence of this symbol in or on Grass Valley equipment means that it has

been tested and certified as complying with applicable Intertek Testing Services

regulations and recommendations for USA/Canada.

The presence of this symbol in or on Grass Valley product means that it complies

with all applicable European Union (CE) directives.

The presence of this symbol in or on Grass Valley product means that it complies

with safety of laser product applicable standards.

All manuals and user guides at all-guides.com

Page 5

v

Densité 3+ FR4

User Manual

Cautions

A caution indicates a possible hazard to equipment that could result in equipment

damage. Observe the following cautions when operating or working on this

equip

ment:

• This equipment is meant to be installed in a restricted access location.

• When installing this equipment, do not attach the power cord to building surfaces.

• Products that have no on/off switch, and use an external power supply must be

installed in pr

oximity to a main power outlet that is easily accessible.

• Use the correct voltage setting. If this product lacks auto-ranging power supplies,

b

efore applying power ensure that each power supply is set to match the power

source.

• Provide proper ventilation. To prevent product overheating, provide equipment

v

entilation in accordance with the installation instructions.

• Do not operate with suspected equipment failur

e. If you suspect product damage or

equipment failure, have the equipment inspected by qualified service personnel.

• To reduce the risk of electric shock, do not per

form any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all

servicing to qualified service personnel. Servicing should be done in a static-free

environment.

• This unit may have more than one power supply cord. Disconnect all power supply

c

ords before servicing to avoid electric shock.

• Follow static precautions at all times when handling this equipment.

Electrostatic Discharge (ESD) Protection

Electrostatic discharge occurs when electronic components are improperly

handled and can result in intermittent failur

e or complete damage adversely

affecting an electrical circuit. When you remove and replace any card from a frame

always follow ESD-prevention procedures:

• Ensure that the frame is electrically connected

to earth ground through the power cord

or any other means if available.

• Wear an ESD wrist strap ensuring that it makes good skin contact. Connect the

gr

ounding clip to an unpainted surface of the chassis frame to safely ground unwanted

ESD voltages. If no wrist strap is available, ground yourself by touching the unpainted

metal part of the chassis.

• For safety, periodically check the resistance value of the antistatic strap, which should

be

between 1 and 10 megohms.

• When temporarily storing a car

d make sure it is placed in an ESD bag.

• Cards in an earth grounded metal frame or casing do not require any special ESD

pr

otection.

Mesures de sécurité et avis importants

Signification des symboles utilisés . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Avertissements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . vii

All manuals and user guides at all-guides.com

Page 6

vi

Notices

Mises en gardeLes mises en garde signalent des conditions ou des pratiques susceptibles

d’endommager l’équipement. Veuillez vous famili

ariser avec les mises en garde ci-dessous :

viiiLa présente section fournit des consignes de sécurité importantes pour les opérateurs et

le personnel de service. Des avertissements ou mises en gar

de spécifiques figurent dans le

manuel, dans les sections où ils s’appliquent. Prenez le temps de bien lire les consignes et

assurez-vous de les respecter, en particulier celles qui sont destinées à prévenir les

décharges électriques ou les blessures.

Signification des symboles utilisés

Signale la présence d’une tension élevée et dangereuse dans le boîtier de

l’équipement ; cette tension peut être suffisante pour constituer un risque de

déchar

ge électrique.

Avertit l'utilisateur, l’opérateur ou le technicien de maintenance que des

instructions importantes relatives à l'utilisation et à l'entretien se trouvent dans

la documentation accompagnant l’équipement.

Invite l'utilisateur, l’opérateur ou le technicien de maintenance à prendre note du

calibre du fusible lors du remplacement de ce dernier. Le fusible auquel il est fait

référence dans le texte doit être remplacé par un fusible du même calibre.

Identifie une borne de mise à la terre de protection. Il faut relier cette borne à la

terre avant d’effectuer toute autre connexion à l’équipement.

Identifie une borne de mise à la terre externe qui peut être connectée en tant

que borne de mise à la terre supplémentaire.

Signale la présence de composants sensibles à l’électricité statique et qui sont

susceptibles d’être endommagés par une décharge électrostatique. Utilisez des

procédures, des équipements et des surfaces antistatiques durant les

interventions d’entretien.

Le symbole ci-contre signifie que l’appareil comporte plus d’un cordon

d'alimentation et qu’il faut débrancher tous les cordons d'alimentation avant

toute opération d’entretien, afin de prévenir les chocs électriques.

La marque C-CSA-US certifie que l’appareil visé a été testé par l'Association

canadienne de normalisation (CSA) et reconnu conforme aux exigences

applicables en matière de sécurité électrique en vigueur au Canada et aux États-

Unis.

La marque C-UL-US certifie que l’appareil visé a été testé par Underwriters

Laboratory (UL) et reconnu conforme aux exigences applicables en matière de

sécurité électrique en vigueur au Canada et aux États-Unis.

All manuals and user guides at all-guides.com

Page 7

vii

Densité 3+ FR4

User Manual

Avertissements

Les avertissements signalent des conditions ou des pratiques susceptibles

d’occasionner des blessures graves, voire fatales

. Veuillez vous familiariser avec les

avertissements d’ordre général ci-dessous :

• Un cordon d’alimentation dûment homologué doit être utilisé pour connecter

l’

appareil à une tension de secteur de 120 V CA ou 240 V CA.

• La protection de ce produit contre les cour

ts-circuits (surintensités) dépend de

l’installation électrique du bâtiment. Assurez-vous qu'un fusible ou un disjoncteur pour

120 V CA ou 240 V CA est utilisé sur les conducteurs de phase.

• Dans le présent manuel, toutes les instructions qui néc

essitent d’ouvrir le couvercle de

l’équipement sont destinées exclusivement au personnel technique qualifié.

• N’utilisez pas cet appareil dan

s un environnement humide.

• Cet équipement est mis à la terre par le conducteur de mise à la terre des cordons

d

’alimentation. Pour éviter les chocs électriques, branchez les cordons d’alimentation

sur une prise correctement câblée avant de brancher les entrées et sorties de

l’équipement.

• Acheminez les cordons d’alimentation et autres câbles de faç

on à ce qu’ils ne risquent

pas d’être endommagés. Supportez correctement les enroulements de câbles afin de

ne pas endommager les connecteurs.

• Coupez l’alimentation avant de nettoyer l’équipemen

t. Ne pas utiliser de nettoyants

liquides ou en aérosol. Utilisez uniquement un chiffon humide.

• Des tensions dangereuses peuvent exister en plusie

urs points dans cet équipement.

Pour éviter toute blessure, ne touchez pas aux connexions ou aux composants exposés

lorsque l’appareil est sous tension.

• Avant de procéder à toute opération d’entretien ou de dépannage, enlevez tous vos

b

ijoux (notamment vos bagues, votre montre et autres objets métalliques).

• Pour éviter tout risque d’incendie, utilisez uniquement les fusibl

es du type et du calibre

indiqués sur l’équipement ou dans la documentation qui l’accompagne.

• Ne pas utiliser cet appareil dans une atmosphèr

e explosive.

• Présence possible de courants de fuite. Un raccordement à la masse est indispensable

avant la mise sous tension.

La marque ETL Listed d’Intertek pour le marché Nord-Américain certifie que

l’appareil visé a été testé par Intertek et reconnu conforme aux exigences

applicables en matière de sécurité électrique en vigueur au Canada et aux États-

Unis.

Le marquage CE indique que l’appareil visé est conforme aux exigences

essentielles des directives applicables de l’Union européenne en matière de

sécurité électrique, de compatibilité électromagnétique et de conformité

environnementale.

Le symbole ci-contre sur un appareil Grass Valley ou à l’intérieur de l’appareil

indique qu’il est conforme aux normes applicables en matière de sécurité laser.

All manuals and user guides at all-guides.com

Page 8

viii

Notices

• Après tout travail d’entretien ou de réparation, faites effectuer des contrôles de sécurité

par le personnel technique qualifié.

Mises en gardeLes mises en garde signalent des conditions ou des pratiques

susceptibles d’endommager l’équipement. Veuillez v

ous familiariser avec les mises

en garde ci-dessous :

• L’appareil est conçu pour être installé dans un endroit à accès restreint.

• Au moment d’installer l’équipement, ne fix

ez pas les cordons d’alimentation aux

surfaces intérieures de l’édifice.

• Les produits qui n'ont pas d’interrupteur mar

che-arrêt et qui disposent d’une source

d’alimentation externe doivent être installés à proximité d'une prise de courant facile

d’accès.

• Si l’équipement n’est pas pourvu d’un modules d

’alimentation auto-adaptables, vérifiez

la configuration de chacun des modules d'alimentation avant de les mettre sous

tension.

• Assurez une ventilation adéquate. Pour éviter toute su

rchauffe du produit, assurez une

ventilation de l’équipement conformément aux instructions d’installation.

• N’utilisez pas l’équipement si vous suspectez un dy

sfonctionnement du produit. Faites-

le inspecter par un technicien qualifié.

• Pour réduire le risque de choc électrique, n

'effectuez pas de réparations autres que

celles qui sont décrites dans le présent manuel, sauf si vous êtes qualifié pour le faire.

Confiez les réparations à un technicien qualifié. La maintenance doit se réaliser dans un

milieu libre d’électricité statique.

• L’appareil peut comporter plus d’un cordon d'alimenta

tion. Afin de prévenir les chocs

électriques, débrancher tous les cordons d'alimentation avant toute opération

d’entretien.

• Veillez à toujours prendre les mesures de protection antistatique appropriées quand

v

ous manipulez l’équipement.

Protection contre les décharges électrostatiques (DES)

Une décharge électrostatique peut se produire lorsque des composants

électroniques ne sont pas manipulés de manière adéquate, ce qui peut entraîner

des défaillanc

es intermittentes ou endommager irrémédiablement un circuit

électrique. Au moment de remplacer une carte dans un châssis, prenez toujours les

mesures de protection antistatique appropriées :

• Assurez-vous que le châssis est relié électriquement à la terre par le cordon

d'

alimentation ou tout autre moyen disponible.

• Portez un bracelet antistatique et assur

ez-vous qu'il est bien en contact avec la peau.

Connectez la pince de masse à une surface non peinte du châssis pour détourner à la

terre toute tension électrostatique indésirable. En l’absence de bracelet antistatique,

déchargez l’électricité statique de votre corps en touchant une surface métallique non

peinte du châssis.

• Pour plus de sécurité, vérifiez périodiquement la valeur de résistance du bracelet

antistatique. Elle doit se situer entre 1 et 10 mégohms.

• Si vous devez mettre une carte de côté, assur

ez-vous de la ranger dans un sac

protecteur antistatique.

All manuals and user guides at all-guides.com

Page 9

ix

Densité 3+ FR4

User Manual

• Les cartes qui sont reliées à un châssis ou boîtier métallique mis à la terre ne

nécessitent pas de protection antistatique spéciale.

Recycling

Visit www.grassvalley.com for recycling information.

Certification and Compliance

Safety Compliance

This equipment complies with the requirements of CSA/UL/IEC/EN 60950-1, 2nd

Ed. + AM1, Safety of information technology equipment.

The power cords supplied with this equipment meet the appropriate national

st

andards for the country of destination.

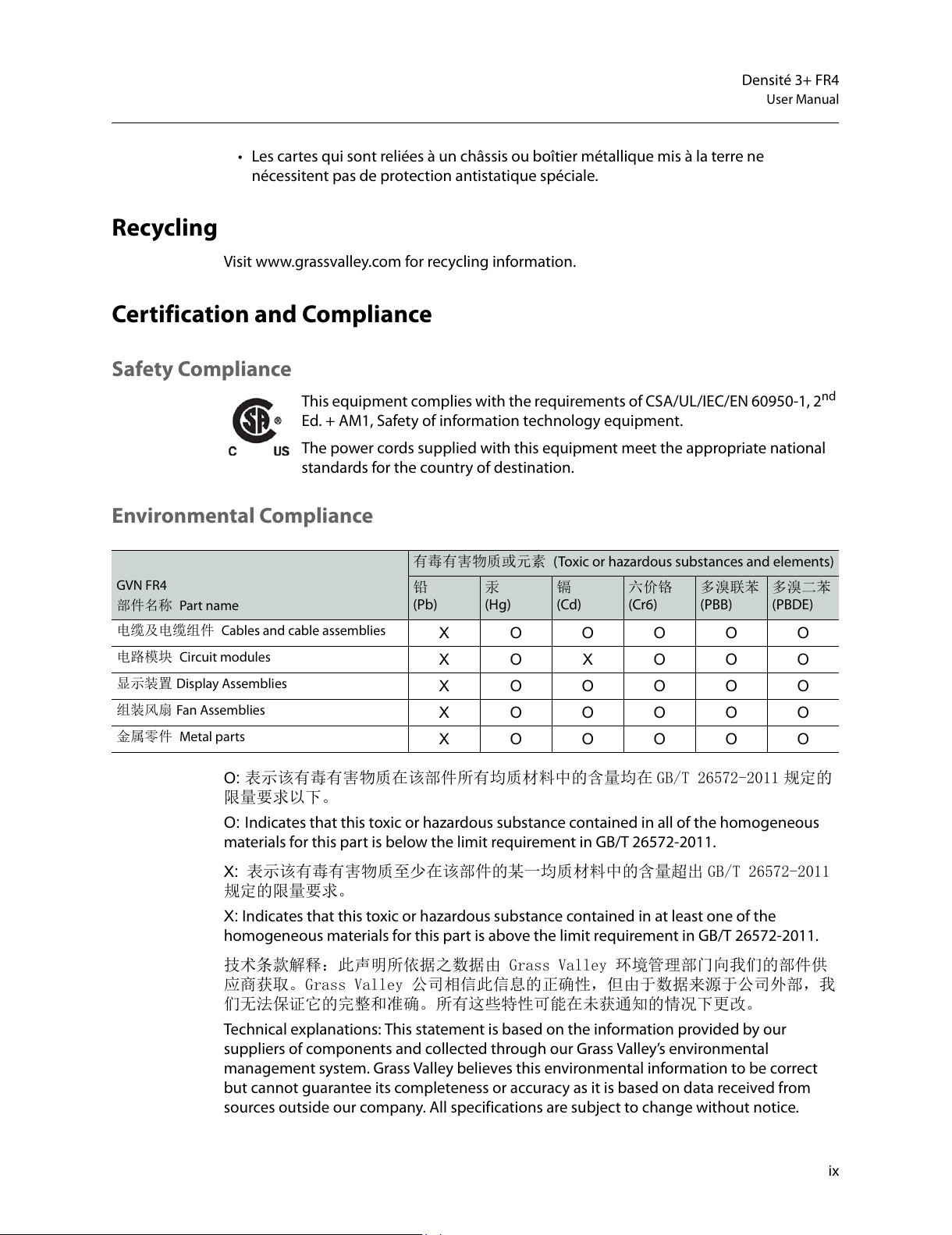

Environmental Compliance

GVN FR4

部件名称

Part name

有毒有害物质或元素 (Toxic or hazardous substances and elements)

铅

(Pb)

汞

(Hg)

镉

(Cd)

六价铬

(Cr6)

多溴联苯

(PBB)

多溴二苯

(PBDE)

电缆及电缆组件 Cables and cable assemblies

X O O O O O

电路模块 Circuit modules

X O X O O O

显示装置 Display Assemblies

X O O O O O

组装风扇 Fan Assemblies

X O O O O O

金属零件 Metal parts

X O O O O O

O

: 表示该有毒有害物质在该部件所有均质材料中的含量均在 GB/T 26572-2011 规定的

限量要求以下。

O: Indicates that this toxic or hazardous substance contained in all of the homogeneous

materials for this part is below the limit requirement in GB/T 26572-2011.

X: 表示该有毒有害物质至少在该部件的某一均质材料中的含量超出 GB/T 26572-2011

规定的限量要求。

X: Indicates that this toxic or hazardous substance contained in at least one of the

homogeneous materials for this part is above the limit requirement in GB/T 26572-2011.

技术条款解释:此声明所依据之数据由 Grass Valley 环境管理部门向我们的部件供

应商获取。Grass Valley 公司相信此信息的正确性,但由于数据来源于公司外部,我

们无法保证它的完整和准确。所有这些特性可能在未获通知的情况下更改。

Technical explanations: This statement is based on the inf

ormation provided by our

suppliers of components and collected through our Grass Valley’s environmental

management system. Grass Valley believes this environmental information to be correct

but cannot guarantee its completeness or accuracy as it is based on data received from

sources outside our company. All specifications are subject to change without notice.

All manuals and user guides at all-guides.com

Page 10

x

Notices

Electromagnetic Compatibility

This equipment has been tested for verification of compliance with FCC Part 15,

Subpart B requirements for class A digital devices.

Note: This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to Part 15 of the FCC rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy, and, if

not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

This equipment has been tested and found to comply with the requirements of

the EMC directive 2004/108/EC:

• EN 55022 Class A Radiated and conducted emissions

• EN 61000-3-2 Limits for harmonic current emissions

• EN 61000-3-3 Limitation of voltage fluctuations and flicker

• EN 61000-4-2 Electrostatic discharge immunity

• EN 61000-4-3 Radiated, radio-frequency, electromagnetic field immunity

• EN 61000-4-4 Electrical fast transient immunity

• EN 61000-4-5 Surge transient immunity

• EN 61000-4-6 Conducted disturbances immunity

• EN 61000-4-8 Power frequency magnetic field immunity

• EN 61000-4-11 Voltage dips, short interruptions and voltage variations

immunit

y

All manuals and user guides at all-guides.com

Page 11

xi

Table of Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

The Densité 3+ FR4 Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Overview - Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Overview - Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Mechanical Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Controller Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Opening the Front Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing Cards in the Densité 3+ FR4 Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Installing the Power Cord Retaining Clips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Control Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Using the Ethernet interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Using the local control interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Using the Controller’s web page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Configuring the CPU-ETH3 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Status Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Link Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Data Restoration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Factory Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Time Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Local Control Panel Menu - CPU-ETH3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Upgrading the CPU-ETH3 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Configuring the Frame Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Reference Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

URS Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Timecode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

All manuals and user guides at all-guides.com

Page 12

xii

Table of Contents

Factory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Upgrading the Frame Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4 Service and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Changing the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Replacing the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Replacing the Frame Ventilation Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Cleaning and replacing the front-door air filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Contact Us . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Grass Valley Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Corporate Head Office . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

All manuals and user guides at all-guides.com

Page 13

1

Introduction

Summary

Overview - Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1

Overview - Controller

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

Mechanical Layout

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Controller Rear Panel

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

The Densité 3+ FR4 Frame

Overview - Frame

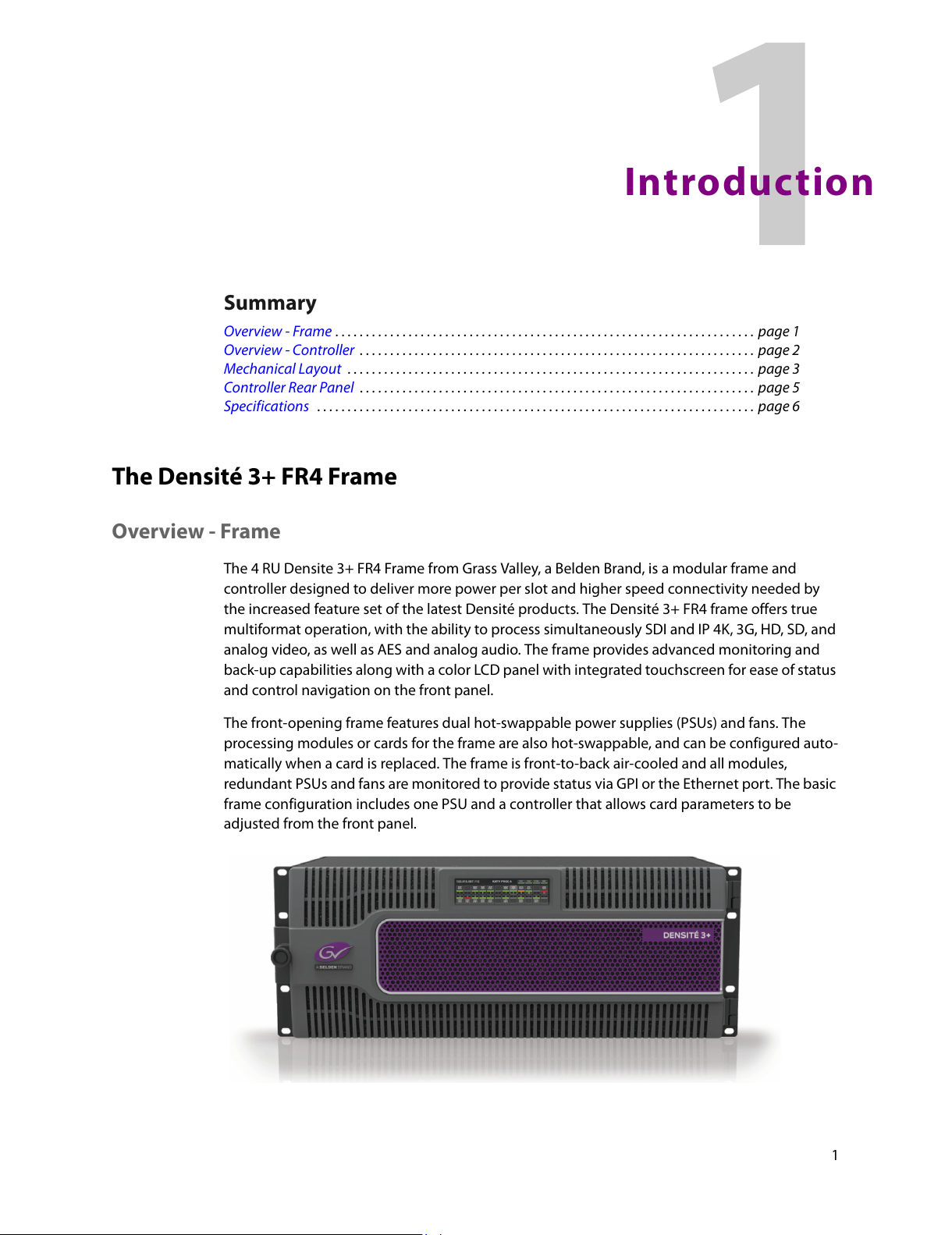

The 4 RU Densite 3+ FR4 Frame from Grass Valley, a Belden Brand, is a modular frame and

controller designed to deliver more power per slot and higher speed connectivity needed by

the increased feature set of the latest Densité products. The Densité 3+ FR4 frame offers true

multiformat operation, with the ability to process simultaneously SDI and IP 4K, 3G, HD, SD, and

analog video, as well as AES and analog audio. The frame provides advanced monitoring and

back-up capabilities along with a color LCD panel with integrated touchscreen for ease of status

and control navigation on the front panel.

The front-opening frame features dual hot-swappable power supplies (PSUs) and fans. The

pr

ocessing modules or cards for the frame are also hot-swappable, and can be configured auto-

matically when a card is replaced. The frame is fr

ont-to-back air-cooled and all modules,

redundant PSUs and fans are monitored to provide status via GPI or the Ethernet port. The basic

frame configuration includes one PSU and a controller that allows card parameters to be

adjusted from the front panel.

All manuals and user guides at all-guides.com

Page 14

2

Introduction

Key Product Capabilities

• Fully backwards compatible with Densité 2 and Densité 3 cards.

• 24 slots with a power budget of 25 watts per slots.

• Optional frame reference on controller card.

• Fully modular I/O for the frame controller for “future readiness” of the controller I/O.

• Dual GigE port for system wide redundancy.

• Full touchscreen color LCD panel for module status and control.

Standard Densité capabilities

• Multiple video and audio formats can be fitted in a single frame.

• Densité 3 RU and Densité 2 RU modules can co-exist in the same frame.

• Easy configuration by front panel or remotely via the Ethernet frame controller.

• Choice of control panels, including the PC-based iControl Solo GUI.

• Hot-swappable power supply, with optional redundant power supply.

• Supports full range of Densité Series modules.

• Frame can be stacked without additional cooling spaces.

• Optional redundant Ethernet connection.

Available Options

• Second power supply for redundant power security

• Full link redundancy using Channel Bonding on the CPU-ETH3

• Frame reference integrated with controller

Cards (maximum 24 per frame)

The Densité 3+ FR4 housing frame supports all current Densité 3 series cards directly. Many

Densité 2 series cards can also be installed with the use of an adapter that fits on the card, plus

an additional adapter to extend the rear panel if a dedicated 3RU rear is not available..

Overview - Controller

The CPU-ETH3 controller installed in the Densité 3+ FR4 frame supports all on-frame communi-

cation between cards, and incorporates a touch-screen panel for local control and adjustment of

the frame and installed cards. The CPU-ETH3 controller serves as the communications port for

control and alarm information entering and leaving the frame. The CPU-ETH3 controller features

two Ethernet ports for system-wide monitoring and control of the frame, using Miranda’s

control solutions. This controller card is compatible with the TCP/IP protocol and can support

polling or report on error modes (unsolicited messaging).

All manuals and user guides at all-guides.com

Page 15

3

Densité 3+ FR4

User Manual

Features

• Dual Ethernet RJ-45 ports (100Base-T and Gigabit Ethernet) - the two ports can be config-

ured independently for full network redundancy

• Provides ultra-robust Ethernet connectivity for LAN/WAN

• Accelerated data throughput: allows video thumbnail and audio level meter and line scope

streaming from all installed modular cards

• Linux-based operating system for robust, mission-critical operations

• Removable SD memory card for portable and quickly-recoverable device and frame configu-

ration

• User-configurable GPI alarm port

• Features front display panel and push-buttons for local configuration of cards and frame

• Can be remotely configured via iControl

• Provides card and frame health monitoring and status reporting

• Provides extensive frame monitoring:

- Ethernet port monitoring, with communication settings and overall bit rate

- detailed bitrate and communication thoughput from individual cards

- self-monitoring with CPU load, memory usage

- Power Supply and GPI status reporting

• Individual Card parameter storage for easy card swapping

• optional integrated frame refrence module

Description

Mechanical Layout

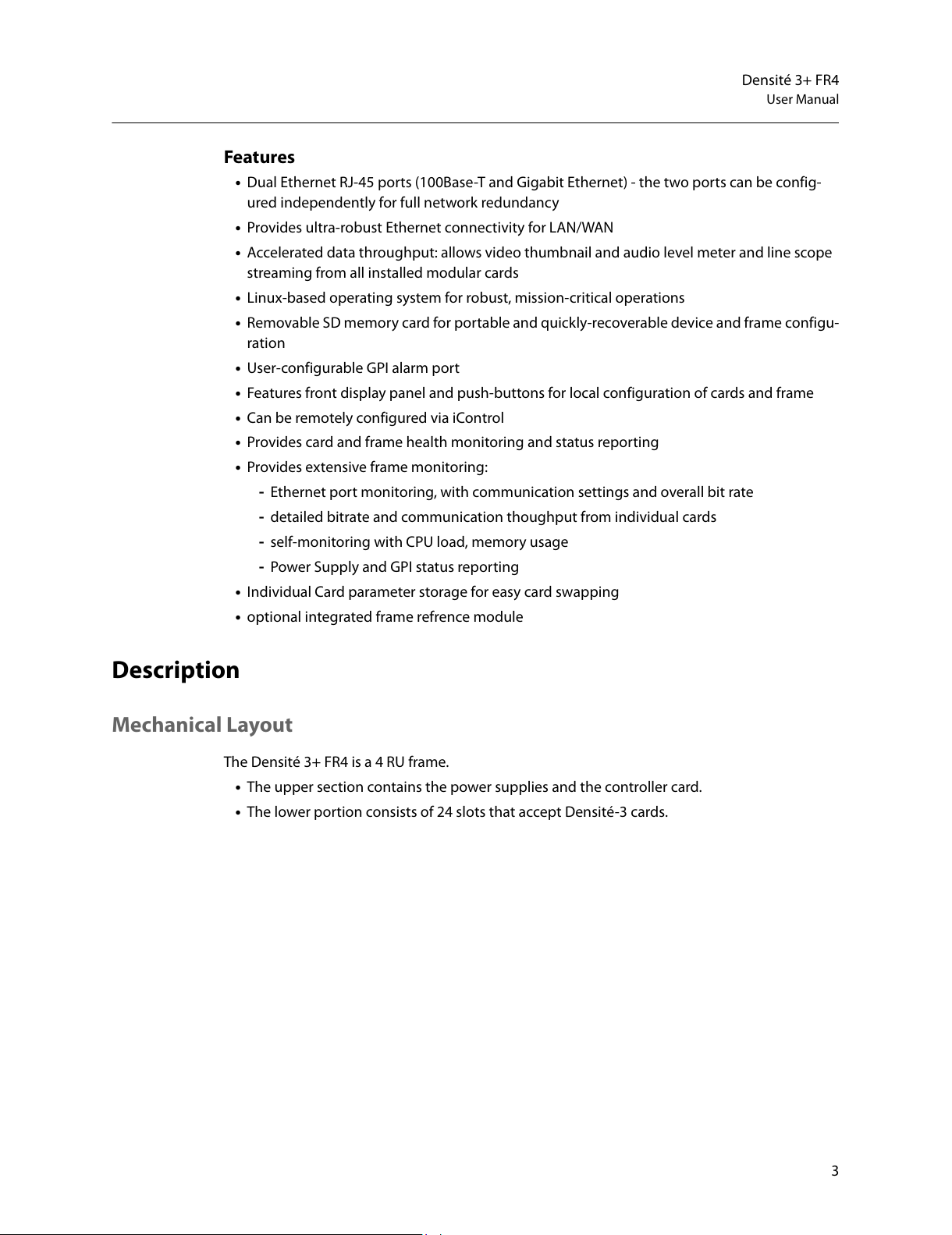

The Densité 3+ FR4 is a 4 RU frame.

• The upper section contains the power supplies and the controller card.

• The lower portion consists of 24 slots that accept Densité-3 cards.

All manuals and user guides at all-guides.com

Page 16

4

Introduction

Front of the frame

When the frame door is closed, the controller card touch screen is exposed through an opening

in the top center of the door. All other front elements are concealed by the door.

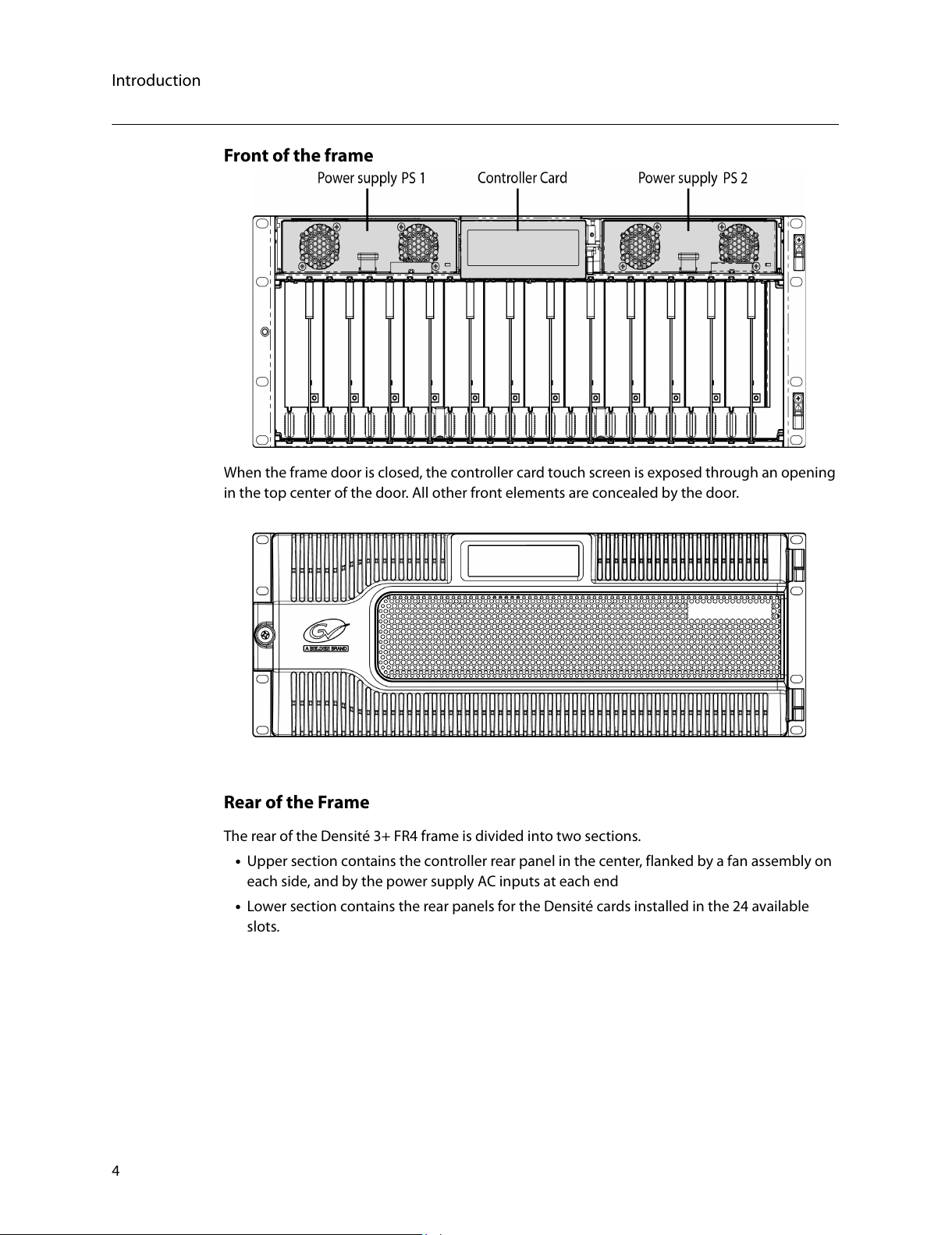

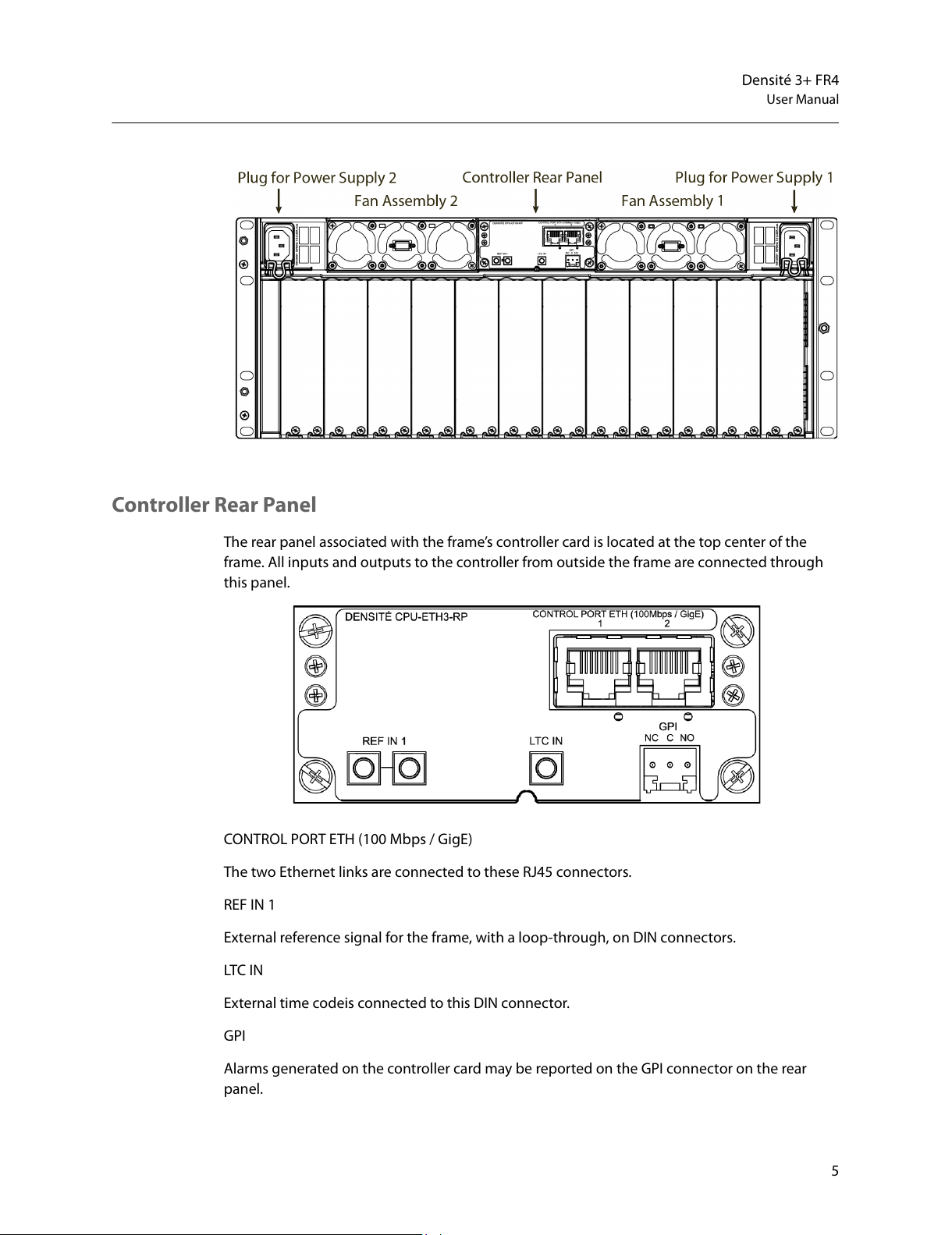

Rear of the Frame

The rear of the Densité 3+ FR4 frame is divided into two sections.

• Upper section contains the controller rear panel in the center, flanked by a fan assembly on

each side, and by the power supply AC inputs at each end

• Lower section contains the rear panels for the Densité cards installed in the 24 available

slots.

All manuals and user guides at all-guides.com

Page 17

5

Densité 3+ FR4

User Manual

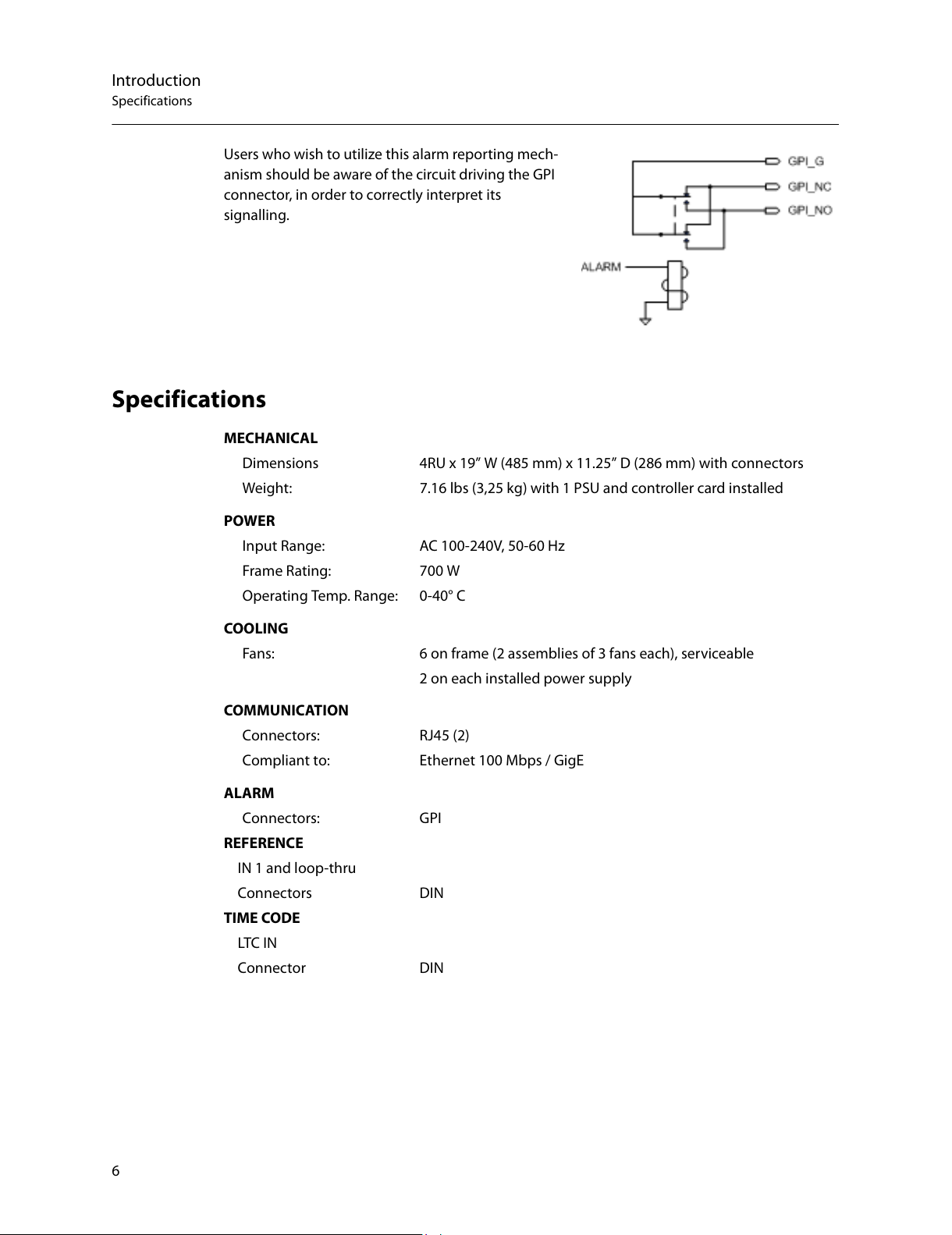

Controller Rear Panel

The rear panel associated with the frame’s controller card is located at the top center of the

frame. All inputs and outputs to the controller from outside the frame are connected through

this panel.

CONTROL PORT ETH (100 Mbps / GigE)

The two Ethernet links are connected to these RJ45 connectors.

REF IN 1

External reference signal for the frame, with a loop-through, on DIN connectors.

LTC IN

External time codeis connected to this DIN connector.

GPI

Alarms generated on the controller card may be

reported on the GPI connector on the rear

panel.

All manuals and user guides at all-guides.com

Page 18

6

Introduction

Specifications

Users who wish to utilize this alarm reporting mech-

anism should be aware of the circuit driving the GPI

co

nnector, in order to correctly interpret its

signalling.

Specifications

MECHANICAL

Dimensions 4RU x 19” W (485 mm) x 11.25” D (286 mm) with connectors

W

eight: 7.16 lbs (3,25 kg) with 1 PSU and controller card installed

POWER

Input Range: AC 100-240V, 50-60 Hz

Fr

ame Rating: 700 W

Operating Temp. Range: 0-40° C

COOLING

Fans: 6 on frame (2 assemblies of 3 fans each), serviceable

2

on each installed power supply

COMMUNICATION

Connectors: RJ45 (2)

C

ompliant to: Ethernet 100 Mbps / GigE

ALARM

Connectors: GPI

REF

ERENCE

IN 1 and loop-thru

Connectors DIN

TIME CODE

LTC IN

Connector DIN

All manuals and user guides at all-guides.com

Page 19

7

Installation

Summary

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Opening the Front Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing Cards in the Densité 3+ FR4 Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Using Densité 2 cards in the Densité 3+ FR4 Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing the Power Cord Retaining Clips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installation

Unpacking

Make sure the following items have been shipped with your Densité 3+ FR4 frame:

• Densité 3+ FR4 frame, including 1 Power Supply unit (AC in) with power cord

• Frame controller (Densité 3+ CPU-ETH3)

• Power cord retaining clips (2)

• A second power supply and AC cord (optional)

• Densité-series cards (per order) with associated rear panels

Opening the Front Door

The front door of the Densité 3+ FR4 frame is hinged on the right-hand side, and latched by a

captive thumbscrew on the left-hand side. There are no electrical connections to the door.

To open the door

• Turn the thumbscrew clockwise until it releases, and pull the door open.

• The door can be removed completely after it is open by sliding it vertically off the hinge pins

on the right-hand side.

To install and close the door

• Slide the door down onto the hinge pins on the right-hand side

• Push the door into the closed position and turn the thumbscrew on the left-hand side coun-

terclockwise to latch the door in the closed position.

All manuals and user guides at all-guides.com

Page 20

8

Installation

Mounting

Mounting

The Densité 3+ FR4 housing frame occupies 4RU in a standard 19” rack.

To mount the frame

• Remove the front door to expose the rack mounting flanges at the ends of the chassis.

• Install the frame in the rack using 8 standard rack-mounting screws (not supplied) through

the eight holes in the mounting flanges.

Installing Cards in the Densité 3+ FR4 Frame

All Densité-series cards can be installed with the frame power on. Each card has a connector

which plugs into the frame’s backplane for distribution of power and connection to the

controller card, and a second connector that plugs into the associated rear panel for inputs and

outputs.

IMPORTANT - the rear panel must be installed bef

ore the card is inserted into the frame.

Note: If you need to install a Densité 2 series card in this frame

, which has Densité 3 slots, please

see Using Densité 2 cards in the Densité 3+ FR4 Frame, on page 9

To install the rear connector panel

1 If a card is installed in the slot whose rear panel is being changed, remove it as described

below.

2 Remove the existing panel (either blank or belonging to an existing card that is being

changed) by releasing the captive screw(s) on the bottom

3 Position the new panel and secure it in place with the captive screw(s) on the bottom.

All manuals and user guides at all-guides.com

Page 21

9

Densité 3+ FR4

User Manual

Card Installation and removal

1 Open the front door of the frame

2 To install a card into an empty slot, slide the card into the slot with the swivel handle to the

top, and push gently on the handle to seat the connectors. If the card requires a double-

width rear panel or larger to accommodate a large number of connectors, it should be

inserted into the right-hand slot. Inserting the card into the wrong slot will not damage the

card, and will be flagged by the on-card status LED flashing red to indicate that there is no

connection to the rear panel.

N.B. the rear panel must be installed before the card.

3 To remove a card from a slot, tilt the swivel handle on the front of the card to lever the con-

ne

ctors apart, then use the handle to pull the card straight out of the slot.

4 Close the front door of the frame

Note:

Detailed information about the rear panel connections is included in the user manual for the

card.

Using Densité 2 cards in the Densité 3+ FR4 Frame

The Densité 3+ FR4 frame supports Miranda Densité 2 series cards. Should you need to install a

Densité 2 card in your Densité 3+ FR4 frame, you will need two adapters – one for the card, and

one for the rear panel. These adapters extend the height of the Densité 2 devices so that they

will fit into the slots of the Densité 3+ FR4 frame. Note that some Densité 2 cards are available

with a 3 RU rear panel, and sold with the card adapter already attached.

All manuals and user guides at all-guides.com

Page 22

10

Installation

Mounting

Card adapters:

There are 3 different types of adapters that

can be used, depending on the Densité 2

ca

rd geometry:

o DENSITE 3-EXT-A

o

DENSITE 3-EXT-B

o DENSITE 3-EXT-C

Install these on the Densité 2

card as

follows:

1 Fit the top edge of the card into the

ho

lding slot along the bottom edge of

the adapter.

2 Align the holes in the top of the card with the holes on the adapter, and secure them

together with the two provided screws and lock washers, as shown in the figure.

Rear Adapters

3-RU rear panel adapters are available for Single and Double Densité 2 rear panels:

• DENSITE SRP-3RU for single sl

ot-width rear panels

• DENSITE DRP-3RU for double slot-width rear panels

To install the adapter and the rear panel

1 Position the adapter at the top of the empty slot(s) on the rear of the frame.

2 Use the captive screw in the adapter to fasten it securely in position.

3 Slip the top of the 2RU rear panel into the slot on the bott

om of the adapter, and secure the

panel to the frame using the captive screw at the bottom of the panel.

All manuals and user guides at all-guides.com

Page 23

11

Densité 3+ FR4

User Manual

Installing the Power Cord Retaining Clips

Each power supply is provided with a power cord retaining

clip that holds the power cord in

place to prevent inadver-

tent disconnections.

To install the power cord retaining clips

1 With the power cord removed, install the clip into the

pla

te that extends out beneath the power cord

socket on the rear of the frame, by slipping the two

ends of the clip into a pair of holes in the plate

Several pairs of holes are provided to accommodate

dif

ferent sizes of plugs. Use the holes that position

the clip closest to the body of the plug.

2 Position the clip horizontally and insert the plug into

the socket.

3 Rotate the clip up and press the cord into the gripping loop of the clip.

Ventilation

Ventilation for the frame is provided by two fan assemblies, each containing three fans, located

on each side in the top section of the rear panel. The fans draw air through the frame from the

front and exhaust it to the rear. Ventilation slots are provided in the front door of the frame to

allow air to flow into the frame.

An air filter is installed in the fr

ont door behind the slots.

• Ensure that the front door ventilation slots are not obstructed.

•

Check the air filter regularly to ensure that it is not plugged up with debris.

See Cleaning and replacing the front-door air filter, on page 44 for detailed instructions.

In addition to the main frame cooling fans, each installed power supply has its own fans that

pul

l air into the front of the supply. The fan speed is controlled in response to overall load and

frame temperature.

All manuals and user guides at all-guides.com

Page 24

12

Installation

Ventilation

All manuals and user guides at all-guides.com

Page 25

13

Configuration

Summary

Using the Ethernet interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Using the local control interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Using the Controller’s web page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Configuring the CPU-ETH3 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Upgrading the CPU-ETH3 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Configuring the Frame Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Control Interfaces

The CPU-ETH3 controller is the control point for the Densité 3+ FR4 frame and the Densité-series

cards installed in the frame. There are no separate operating controls on the frame or cards.

There are three ways to configure the controller, as explained below.

Using the Ethernet interface

The CPU-ETH3 controller supports remote operation through two rear-panel 100Mbps / GigE

ethernet ports, using Grass Valley’s iControl. The command set available for communicating

with a DENSITÉ frame permits more complex and comprehensive control, parameter storage,

and field upgrading than is supported by the local control panel.

The operation of the CPU-ETH3 card can be controlled using Grass Valley’s iControl system. This

manual describes the control panels associated with the CPU-ETH3 and their use.

Please consult the iControl User’s Guide for information about setting up and operating

iControl.

All manuals and user guides at all-guides.com

Page 26

14

Configuration

In iControl Navigator or iControl

Websites, double-click on the icon of

the controller to open its control panel.

• CPU-ETH3 controllers are identified

as Controller3 in the Type column

of the iControl Navigator window.

• For convenience, enter a descrip-

tive Label in the Info panel of the

card, to make it easy to locate this

specific frame controller amongst

those in the list. See Identification,

on page 18 for instructions.

.

The iControl panel for the CPU-ETH3 controller

displays a series of buttons down the left-hand

side

. Clicking a button changes the contents

of the main window to display status reports

and controls related to the topic named on the

button.

A full description of the use of the iControl

int

erface to configure the CPU-ETH3 card is

given below, beginning on page 17.

All manuals and user guides at all-guides.com

Page 27

15

Densité 3+ FR4

User Manual

Using the local control interface

The local control interface is fastened to the front of the CPU-ETH3 controller card, and when

installed is located in the top center of the frame.

The touch screen interface is accessed through an aperture in the frame door.

In its home state, it shows the contents of all 24 slots in the Densité 3+ FR4 frame:

•Card type (text)

•

Card status (colored outline)

The status of the controller itsef is shown in the

CTRL segment on the top right.

Touching a “slot” displays the local menu and navigation controls for the card occupying that

slot:

• Two lines of text, each 16 characters in length

•

Four virtual pushbuttons.

Touching the CTRL segment displays the local menu for the CPU-ETH3 controller itself.

The full CPU-ETH3 controller menu is shown beginning on page 31.

The functionality of the four virtual pushbuttons is as follows:

[+] [–] Move up and down the menu when a parameter name is shown

Change to the next or previous value whe

n a variable value is shown and change

has been enabled using the [SEL] button

[SEL] Gives access to the next menu level. When

a parameter value is shown, pushing this

button once enables modification of the value using the [+] and [–] buttons; a

second push confirms the new value

[ESC] Cancels the effect of parameter value changes that have not been confirmed;

pu

shing [ESC] causes the parameter to revert to its former value.

All manuals and user guides at all-guides.com

Page 28

16

Configuration

Pushing [ESC] moves the user back up to the previous menu level.

[HOME] Exits the current menu and returns the user to the HOME screen.

If no controls are operated for 30 seconds, the controller reverts to its normal operating status,

an

d the status display ceases flashing yellow and reverts to its normal operating mode.

Controller Status Indicator

The contoller status is displayed in the upper right side of the control panel, as a colored outilne

around the CTRL segment. The table shows how the various error conditions are flagged.

Alarm/Status Priority Display

Power supply failure 1 FLASHING RED

Fan failure 1 FLASHING RED

Internal error 2 RED

Normal (no errors) GREEN

LOCAL CONTROL SELECTED FLASHING YELLOW

The status display can show only one alarm/status, so it displays only the highest priority. For

example if there is an internal error, it should display RED. But if at the same time the chassis fan

has failed, then the LED will display FLASHING RED.

Be aware that a high priority alarm can

mask a lower priority one.

Using the Controller’s web page

The controller serves a web page from it’s ETH1 port. The web page provides complete configu-

ration utilities for the controller itself.

To use this resource, you must be able to connect to the controller. The controller is shipped

wit

h these default IP addresses on its ports:

ETH1 ETH2

IP address 192.168.3.3 192.168.4.3

Network Mask 255.255.255.0 255.255.255.0

Gateway 0.0.0.0 0.0.0.0

You will need to change these to fit your local network.

• You can change them from this web page, or

through the local control panel menu, but

not through the iControl interface.

To access the CPU-ETH3 controller web page

1 Open a Web browser window and enter your CPU-ETH3’s IP address in the address bar.

The home page of the CPU-ETH3 Web client appears.

All manuals and user guides at all-guides.com

Page 29

17

Densité 3+ FR4

User Manual

2 Select the topic area of interest from the index on the left, and click to open the

configuration page.

Configuring the CPU-ETH3 Controller

This section introduces the operating features of the CPU-ETH3 controller, and describes

how to access and control them using:

• The iControl interface

• The controller’s web page

• The local control panel and menu.

In general, the iControl interface will be used as the primar

y interface for purposes of

describing the configuration process.

The functionality of the web page interface follows the iControl model, and will not be

explained sepa

rately except as required.

In each case, the menu path which must be navigated on the local control panel to access

the c

onfiguration item under discussion will also be given.

Summary

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Status Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . 22

Link Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Data Restoration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Factory Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . 25

Time Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . 26

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . 27

All manuals and user guides at all-guides.com

Page 30

18

Configuration

Identification

iControl - click the Info button

The CPU-ETH3 controller is accessible on a

network, and must be identifiable in order to

fun

ction in the iControl environment. The

identification data is entered in the iControl

INFO control panel. This panel also shows

other data that is not user-adjustable.

You can enter the following information by

click

ing and typing in the data box:

Label: al

lows the user to define the label that

identifies this device when it appears in iCon-

trol applications

Short Label: a

llows the user to define the

short-form label for iControl (8 characters)

Source ID: t

ype a descriptive name for this

CPU-ETH3 controller

Comments: t

ype any desired text

The remaining data boxes show manufac-

turing information about this card.

Three buttons in the panel give access to other information:

Details:

Reports the Firmware version, service version, and panel version for this card

Advanced: Show

s the LongID for this card. The LongID is the address of this CPU-ETH3

controller in the iControl network.

Remote System Administration:.

Opens the Joining Locators

data box, which lists remote

lookup services to which this

CPU-ETH3 is registered.

Add: F

orce the iControl service for this CPU-ETH3 to regis-

ter itself on a user-specified Jini lookup service, using the

f

ollowing syntax in the data box:

jini://<ip_address>

where <ip_address> is the ip address of the server running the lookup service, e.g.:

All manuals and user guides at all-guides.com

Page 31

19

Densité 3+ FR4

User Manual

Remove: select one of the services listed in the window by clicking on it, and click Remove

to open a query box allowing you to delete it from the window.

Using the menu

None of this data can be accessed via the local control panel menu, except to read the Firmware

version.

Status Monitoring

The CPU-ETH3 controller continuously monitors the operating condition and status of the

housing frame’s power supplies and ventilating fans. It also monitors the status and usage of its

two ethernet ports, and the status of its on-board memory, as well as the data throughput of all

cards installed in the frame.

In addition to the information displayed on the Controller Status Indicator

(see page 16), status

information acquired by the control

ler can be viewed in the iControl interface, and on the local

controller display through the menu.

The iControl interface always displays two icons in the upper left of the window. These report

th

e status of the two power supplies.

Icon Messages

Power supply 1 voltage: OK

Power supply 2 voltage: OK

Power supply 1 voltage: Absent

Power supply 2 voltage: Absent

Power supply 1 voltage: Error

Power supply 2 voltage: Error

The table shows the possible icon displa

ys and the associated messages that appear below

them. Error messages are always displayed; other status messages appear only upon mouse-

over of the icon.

The Status panel shows status information in fou

r categories, each accessed by clicking the

appropriate tab.

All manuals and user guides at all-guides.com

Page 32

20

Configuration

iControl - click the Status button

Status - Frame

Select the Frame tab to see a report on the

status of the frame’s CPU, fans and power

supplies.

Status - Network

Select the Network tab to see a report on the

status of the two Ethernet ports on the CPU-

ETH3 card.

All manuals and user guides at all-guides.com

Page 33

21

Densité 3+ FR4

User Manual

Status - Cards

Select the Cards tab to see a chart of the

current send (Tx) and receive (Rx) data rates,

and speed, for all cards installed in the Densité

frame.

For a more detailed report on the status of a

specif

ic card, open that card’s control panel in

iControl.

Status - Advanced

Select the Advanced tab to view a report on the

usage of the card’s resources:

Using the Menu

Select STATUS and then [SEL] to cycle through the list of current faults. The information shown

on the Network, Cards and Advanced tabs is not available through the menu.

All manuals and user guides at all-guides.com

Page 34

22

Configuration

Network

iControl - click the Network button and select the ETH tab

Enter the HOSTNAME in the box at the top.

• The hostname is the unique name by

which this D

ensité CPU-ETH3 is known on

the network. The hostname should be 15

characters or less, and may contain only

the ASCII letters 'a' through 'z' (case-insen-

sitive), the digits '0' through '9', and the

hyphen.

You can see the IP address of the two ethernet

por

ts, but they can only be configured via the

menu or the web page.

Using the web page:

1 Select Setup-Ethernet from the index on the left.

2Enter a Ho

stname in the databox

3 Enter the IP address, Network Mask and Gateway for the two ethernet ports

4 Select AU

TONEGOTIATION in the MII Status pulldown for each port

5Click Ap

ply to save your changes

Using the Menu:

To change the IP address:

Link Redundancy

DENSITE 3+ CPU-ETH3-OPT-LINK is a software option that enables the Ethernet link

redundancy function on the Densite 3+ CPU-ETH3.

• Ethernet Link Redundancy is achieved

by using channel bonding.

All manuals and user guides at all-guides.com

Page 35

23

Densité 3+ FR4

User Manual

• Channel bonding is an arrangement in which the CPU-ETH3’s two network interfaces

are combined for redundancy.

The Densite 3+ CPU-ETH3 works in the Active-Backup bonding mode. Active-Backup

bonding provides fault tolerance.

• Only one slave in the bond is active.

•The slave eth1 is the primary device. The primary device will always be the active slave

while it’s available. Only when the primary is off-line will the alternate device eth2 be

used.

• The Link Redundancy option can only be activated via the web page.

To activate the Link Redundancy option

1 Purchase the option from Grass Valley - you will be given an activation key.

2Click the Options heading in the left index of the web page.

3 Enter the activation key into the web page data box.

4Click Enable.

5 Click the Ethernet heading under Setup in the left index of the web page.

6 Enable the Channel Bonding

7 Click Apply

8Click Reset

Data Restoration

Many of the Densité-series cards that can be installed in the Densité 3+ FR4 frame are complex

and have a lot of data stored on-board related to their configuration and parameter values. The

CPU-ETH3 controller provides a backup of this data, which can be restored to the card when

needed. This is valuable if the card is inadvertently reconfigured, or is replaced after failure with

a new card of the same type. The saving of the current data into the controller’s memory, and

restoring the data onto the Densité-series card, can be done manually or automatically.

All manuals and user guides at all-guides.com

Page 36

24

Configuration

For manual operation:

iControl - click the Restore Point button and view the Cards tab.

The tab show a list of the slots available in the

Densité frame, with a check box, name, and

statu

s box for each.

Click the check box to activate the Data

R

estore feature for the card in that slot,

-or-

Click the Select All box at the top to activate

the

feature for all slots in the frame.

Click S

ave to controller at the bottom to

copy all restorable data from the cards in the

selected slots into the memory on board the

CPU-ETH3 controller.

Click Lo

ad to cards to load the cards in the

selected slots with data from the controller’s

memory.

Note that a data restore will only work if the

c

ard in the slot is the same type as the card that was there when the data was saved.

For automatic restore and save:

iControl - click the Re

store Point button and view the Config tab.

Restore: The CPU-ETH3 card can be set up to automatically update a card when it is inserted in

a slot previously occupied by a card of the same type whose data was saved. Thus, a new card

can be configured automatically to replace the card that was removed, saving a lot of time when

cards are swapped.

Click the D

efault Action box to enable the auto restore function for all the cards in the frame.

All manuals and user guides at all-guides.com

Page 37

25

Densité 3+ FR4

User Manual

Save: The CPU-ETH3 card can be configured to

automatically back up the data on the cards in

its slots ac

cording to a set schedule.

Click the Au

to Save box to enable the auto-

matic save function.

Set up the schedule for data b

ackup using the

controls provided.

Schedule: Daily, Weekly, Monthly

Start Time (UTC): Time in hours (24-hour clock)

an

d minutes

The label and function of the pulldown at the bottom changes to follow the Schedule selection:

Schedule Label Pulldown Options

Daily Freq Every day, Weekdays

Weekly Day Sunday, Monday, Tuesday, Wednesday, Thursday, Friday, Saturday

Monthly Week Week1, Week2, Week3, Week4, Last Week

Day Sunday, Monday, Tuesday, Wednesday, Thursday, Friday, Saturday

Using the menu:

Configure the data restoration functions, including default action and auto save, from the

Restore Points menu item.

Factory Alignment

There may be times when the CPU-ETH3 settings have been adjusted and it is useful to restore

them to a normalized condition. The CPU-ETH3 controller maintains a “Factory Default”

All manuals and user guides at all-guides.com

Page 38

Note: Ethernet settings are not included in the Factory data set, and are not

changed when the Factory Default alignment is installed.

26

Configuration

alignment in its memory, to which it can be restored at any time.

iControl - click the Factor y Control button

Click the Load Factory button to restore the

card to the Factory default alignment.

Click the L

oad Factory button to restore the

card to the Factory default alignment.

Using the menu

The factory default values can be loaded from the FACTORY DEFAULT menu item.

The default values are shown underlined in the menu listing beginning on page 31.

Time Management.

The CPU-ETH3 controller is time-aware, and its internal clock can be updated manually or via

NTP.

All manuals and user guides at all-guides.com

Page 39

27

Densité 3+ FR4

User Manual

iControl - click the Time button

Time (UTC)

The data boxes in this section display the

time

and date currently held in the card.

Enter new values in these boxes to change

the curr

ent setting. If an automatic update via

NTP is not enabled, the clock will continue to

run using an on-board reference, but preci-

sion is not guaranteed.

NTP IP address

Click the Enable NTP bo

x to use an NTP

(Network Time Protocol) source. Enter up to

three IP addresses of NTP servers. The CPU-

ETH3 card will use the first source of valid

time it finds in this list.

Using the menu

You can enter the current time and date, and

activate the NTP time sourcing through the TIME OPTIONS menu item.

Note that the NPT REFRESH item, setting the interval at which the local clock is refreshed from

the NTP server, is ONLY available from the menu and the web page, and does not appear on the

iControl interface.

Alarms

The CPU-ETH3 controller generates alarms for the frame in which it is installed when error

conditions are detected. These alarms are used to set the card-front Status LED and the status

icon in the top left of the iControl window.

The alarms are reported to the iControl network, and can be reported locally on the frame’s GPI

por

t.

• GPI reporting can only be accessed from the menu, as described at the end of this section

(page

32).

All manuals and user guides at all-guides.com

Page 40

28

Configuration

iControl - click the Alarm Config button

The iControl Alarm Configuration panel opens in a new window when the Alarm Config button

is clicked, and can be resized if needed. It allows the alarm reporting of the CPU-ETH3 to be

configured. The panel is organized in columns.

Status/Name

This contains an expandable tree listing all the alarms reported by this CPU-ETH3 controller.

Each alarm name includes an icon

that shows its current status

The O

verall alarm and GSM contribution columns contain pulldown lists that allow the level

of contribution of each individual alarm to the alarm named in the column heading to be set.

Click on the alarm status in either of these columns to show the status options that are available,

then click on one to select it. If no options appear, the alarm is not user-configurable

Overall Alarm

This column allows configuration of the contribution

of each individual alarm to the Overall

Alarm associated with this card. The Overall Alarm is shown in the upper left corner of the iCon-

trol panel, and also appears at the bottom of the Status/Name column.

GSM Contribution

This column allows configuration of the contribution of each individual alarm to the GSM Alarm

St

atus associated with this card. GSM is a dynamic register of all iControl system alarms, and is

also an alarm provider for external applications. The possible values for this contribution are

related to the Overall alarm contribution:

• If the Overall alarm contribution is selected as Disabled, the GSM alarm contribution can be

set to an

y available value

• If the Overall alarm contribution is selected as any level other than disabled, the GSM contri-

bution is forced to follow the Overall Alarm.

Levels associated with these alarms:

All manuals and user guides at all-guides.com

Page 41

29

Densité 3+ FR4

User Manual

The alarm status list may contain some or all of the following options:

Alarm status Significance

The alarm makes no contribution (black icon)

The alarm is of minor importance (yellow icon)

The alarm is of major importance (orange icon)

The alarm is of critical importance (red icon)

The alarm exists but has no effect (used for text and composite alarms)

Shortcut: if y

ou click on “Set All” at the top of one of these columns, you will open a pulldown

list that lets you assign a level to all alarms in that column simultaneously.

Once the alarms are configured, you may accept the changes or discard them:

Log Events

iControl maintains a log of alarm events associated with the card. The log is useful for trouble-

shooting and identifying event sequences. Click in the checkbox to enable logging of alarm

ev

ents for each individual alarm.

At the bottom of the window are several other controls:

Copy to other cards

Click this button to open a panel that

allows the alarm configuration set for

this ca

rd to be copied into other CPU-

ETH3 controllers in other frames.

Select one or more destination

c

ontrollers from the list in the window

by clicking in the checkboxes, or all of

them by clicking in the All checkbox

All manuals and user guides at all-guides.com

Page 42

30

Configuration

Get alarm keys

Click this button to open a save dialog

where you can save a file containing a

list of

all alarms on this controller and

their current values, along with an

Alarm Key for each. The alarm keys are

useful for system integration and

troubleshooting.

The file is saved in .csv format

OK, Apply, Cancel

• OK acc

epts the settings and closes the window once the controller confirms that there are

no errors.

• Apply accepts the settings, but leaves the window open

• Cancel closes the window without applying any changes, and leaves the previous settings

intact.

Using the Menu

Access the Alarm Report menu item, and scroll through the list of available alarms, setting each

to OFF or to report through GPI. Use the GPI Report item to turn GPI reporting on or off.

All manuals and user guides at all-guides.com

Page 43

31

Densité 3+ FR4

User Manual

Local Control Panel Menu - CPU-ETH3

Here is the complete on-board menu for the CPU-ETH3 controller, accessed through its local

control panel.

(continued)

All manuals and user guides at all-guides.com

Page 44

32

Configuration

Upgrading the CPU-ETH3 Controller

Upgrading the CPU-ETH3 firmware must be accomplished via a web page served by the

controller, and accessed through its ethernet port using a browser.

To upgrade the CPU-ETH3 controller

1 Obtain an upgrade file from Grass Valley.

The file will be named 3034-01P80-###

_CPU-ETH3-BASIC-Firmware_v#.#.#.zip, where

### is the firmware release version number.

2 Unzip the file, and save the expanded file, which will be named cpu

eth3-upgrade-

#.#.#.bbb.tar.gz

This file is the file you will need to up

grade the CPU-ETH3 card in step 7 below.

3 Using a browser on your network, browse to the IP address of the CPU-ETH3card.

If you are using iControl, double-click the controller in the iNavigator page, and select

NE

TWORK | ETH to see the IP address.

4 You will be asked for a username and password - the default values are:

• "Username = admin

• "Password = (leave blank)

The CPU-ETH3 web page will open in your browser.

5 In the left-side menu, select Tools | Upgrade Firmware.

All manuals and user guides at all-guides.com

Page 45

33

Densité 3+ FR4

User Manual

The current firmware version is shown at the top of the window

6Click Choose File.

7In the Op

en window, browse to the upgrade file you obtained in Step 1, select it and

click Open.

In the Tools | Upgrade Frame Controller windo

w, the upgrade firmware version will be

shown at the top of the page, and the Upgrade button will be enabled.

8Click Upgr

ade.

The window will show the status of the upgrade process.

The CPU-ETH3 card will reboot once the upgrade is complete.

9Click Lo

g Out at the bottom left of the window to exit the CPU-ETH3 web page.

Configuring the Frame Reference

Summary

Reference Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

URS Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . 34

Timecode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . 35

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . 36

Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . 37

Factory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . 39

The optional frame reference module is physically

integrated into the CPU-ETH3 module,

but it presents its own interface to the user.

All manuals and user guides at all-guides.com

Page 46

34

Configuration

• The frame reference distributes a Universal Reference Signal (URS) to all modular cards

in the frame.

• If the option has not been purchased, individual modular cards in the frame must be

connected to their own reference signals via their rear panels.

To open the Frame Reference control panel

Double-click on the Fr

ame Reference icon In iControl Navigator to open the service panel.

Reference Source

To select the reference source

1 Select the Inp

ut tab.

2Click the Reference Source pulldown.

3 Click to select the reference source:

Selection Detail

Auto Use the External reference; if it’s not available, use the Internal reference.

External Use the signal on the REF connector on the controller rear panel.