Page 1

CopperHead Pro User Guide

M4013-9900-102

24 July 2014

Page 2

Notices

Copyright & Trademark Notice

Copyright © 2011–2014, Grass Valley. All rights reserved.

Belden, Belden Sending All The Right Signals, and the Belden logo are trademarks or

registered trademarks of Belden Inc. or its affiliated companies in the United States and

other jurisdictions. Grass Valley, CopperHead Pro are trademarks or registered trademarks

of Grass Valley. Belden Inc., Grass Valley, and other parties may also have trademark rights

in other terms used herein.

Terms and Conditions

Please read the following terms and conditions carefully. By using CopperHead Pro

documentation, you agree to the following terms and conditions.

Grass Valley, a Belden Brand (“Grass Valley”) hereby grants permission and license to owners

of CopperHead Pro to use their product manuals for their own internal business use.

Manuals for Grass Valley products may not be reproduced or transmitted in any form or by

any means, electronic or mechanical, including photocopying and recording, for any

purpose unless specifically authorized in writing by Grass Valley.

A Grass Valley manual may have been revised to reflect changes made to the product

during its manufacturing life. Thus, different versions of a manual may exist for any given

product. Care should be taken to ensure that one obtains the proper manual version for a

specific product serial number.

Information in this document is subject to change without notice and does not represent a

commitment on the part of Grass Valley.

Warranty information is available in the Support section of the Grass Valley Web site

(www.miranda.com).

Title CopperHead Pro User Guide

Part Number M4013-9900-102

Revision 24 July 2014

ii

Page 3

Table of Contents

1 About CopperHead Pro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About CopperHead Pro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CopperHead System Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Unpacking the CopperHead Pro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Product Returns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

About this User Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety and Fiber Optic Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Optical Fiber Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Power Fuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CopperHead Pro System Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Dry Fiber Systems - Locally powered cameras . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

PowerWafer, Direct to Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power Wafer, Remote Panel-Mounted Fiber Connector . . . . . . . . . . . . . . . . . . . . . . . . 7

PowerWafer, with MPS Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

PowerPlus - High Power/Long Distance with HDX Power Supply . . . . . . . . . . . . . . . 9

CopperHead Pro Transceiver System Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Base Station Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Types of Base Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Single “Dry” Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Dual Unpowered Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Powered Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 CopperHead System Components . . . . . . . . . . . . . . . . . . . . . . 13

Camera Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Camera Unit - Front Side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Camera Unit - Signal Status Panel (Section A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Camera Unit - Intercom Controls (Section B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Camera Unit - Power Switch & Indicator (Section C) . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Camera Unit - Camera Mounting Plate (Section D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Camera Unit - Rear Side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Camera Unit - Connectors (Section A). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Camera Unit - Fiber Connector/Swivel (Section B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Camera Unit - Battery Mount (Section C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Base Station Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Front Panel Section A - Signal Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Front Panel Section B- Power Switch and Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Front Panel Section C- Hybrid Power Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . 23

Base Station Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

iii

Page 4

Table of Contents

Rear Panel Section A - Power Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Rear Panel Section B - Optical Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Rear Panel Section C - Signal Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

PowerWafer Camera Adaptor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

MPS External PowerWafer Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

PowerPlus 3000 - Camera Power Adaptor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

HDX Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

HDX Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

4 Camera Unit and Power Supply Installation . . . . . . . . . . . . . 35

Mounting the Copperhead Camera Unit with the PowerWafer . . . . . . . . . . . . . . . . . . . . .36

Mounting the CopperHead Pro Camera Unit with a battery . . . . . . . . . . . . . . . . . . . .36

Mounting the CopperHead Pro Camera Unit with the PowerWafer . . . . . . . . . . . . .37

Mounting the CopperHead Pro Camera Unit with the PowerPlus. . . . . . . . . . . . . . .38

Connecting the CopperHead Pro System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Connecting Camera Unit to a Camera or Camcorder . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Connecting Base Station to Studio Infrastructure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Intercom connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Fiber Connections between the Base Station and Camera Unit . . . . . . . . . . . . . . . . .44

Tactical Fiber between Base Station (powered) and Camera Unit. . . . . . . . . . . . . . .45

SMPTE Hybrid Fiber between Base Station (powered) and Camera Unit . . . . . . . .45

Hybrid Fiber between Base Station (powered) and Camera Unit. . . . . . . . . . . . . . . .46

Hybrid Fiber Cable between MPS Power Unit and Camera Unit. . . . . . . . . . . . . . . . .46

SMPTE Hybrid Fiber between HDX Power Supply and Camera Unit. . . . . . . . . . . . .48

Deployment of the CopperHead System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Insuring a Positive Fiber Link. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Intercom Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Shutting Down the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

5 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

A Fiber Optic Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Basic Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Fiber Optic Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Fiber Optic Connector Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

A Brief Guide to Measurement of Fiber Optic Signal Strength . . . . . . . . . . . . . . . . . . . . . .61

B CopperHead Pro System Connectors . . . . . . . . . . . . . . . . . . . . 62

Camera Unit Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Camera Remote and Tally. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Camera Headset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

PowerWafer Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Base Station Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

AC Power Input Connector- Models CHG3-BS-Pro-95VD-xxx-xxx . . . . . . . . . . . . . . .65

12VDC Input Power Connectors - Models CHG3-BS-Pro-2ST/2MX/NEU . . . . . . . . .65

iv

Page 5

System Monitor (future use) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

95VDC output: Model CHG3-BS-PRO-95VD-STM-xxx . . . . . . . . . . . . . . . . . . . . . . . . . .66

Base Station Remote/Tally Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

4-Wire Intercom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Clear-Com Intercom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

RTS Intercom. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

PowerWafer Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

PowerPlus Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

PowerPlus 12VDC Output Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

PowerPlus 24VDC Output Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

MPS Power Supply Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

AC Power Input Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

C Cables, Parts, and Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Camera Unit & Base Station Interface Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

CHCR-PRO Camera Unit Remote Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

CHBR-PRO Base Station Remote Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Parts & Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

CopperHead Pro

User Guide

D Overview Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Camera Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Base Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Base Station: 12Volt DC (single/dual) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Base Station: 120/200 Volt AC (single only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

v

Page 6

Table of Contents

vi

Page 7

About CopperHead Pro

This chapter provides an overview of the CopperHead Pro and includes the safety and

warranty information about it.

About CopperHead Pro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Unpacking the CopperHead Pro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety and Fiber Optic Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1

Page 8

About CopperHead Pro

About CopperHead Pro

About CopperHead Pro

The CopperHead System is a fiber optic transmission system that enables camcorders to be

used in live, multi-camera production environments.

The system uses a fiber optic cable to transport a variety of signals between a Camera Unit

and a Base Station.

The CopperHead Pro Camera Unit is typically mounted to a camera that is placed in a

studio, theatre, sports venue, or other live-event location. The system's Base Station is

usually located in a truck, control room, or other video production control area.

When "dry" fiber is used (typically lightweight "tactical" fiber cable), the signals are

transmitted bi-directionally over distances as long as 5 km or more.

When you use a hybrid fiber cable, the link also provides power to the Camera Unit and the

camera itself.

CopperHead System Features

• Makes any camcorder practical for multi-camera production

• All camera signals are carried on one lightweight fiber cable

• Can be run through building or campus infrastructure on two strands of Single Mode

fiber*

• Thin, lightweight, modular design

• Studio quality uncompressed HD/SDI video up to 3 Gb/s

• Multi-kilometer distance capability

• Anton/Bauer® Gold Mount and "V-Mount" battery options

• Wide temp range, low power consumption

• Durable, high reliability design

• Two fiber cable options

• Tactical Fiber: Military Spec, battery/local power, 10+km

•SMPTE Hybrid Fiber

• Low voltage camera-mounted "PowerWafer": 95 watts to 300m (984 ft.)

Fig. 1-1: CopperHead Pro Signal Paths

2

Page 9

• High-voltage camera-mounted "PowerPlus": Up to 150 watts to 2 km (1.2

miles)

Note: The CopperHead ProSystem is not readily compatible with active

or passive CWDM multiplexing technologies, including Teleport or

TeleThon systems.

Unpacking the CopperHead Pro

Individual items shipped with a CopperHead Pro system depend on the particular

configuration.

.

Item Description Part Code CopperHead System Type

Tac tical Fib er

(local power

at camera)

Hybrid Fiber Standard Power

(PowerWafer)

CopperHead Pro

User Guide

Hybrid Fiber High Power

(PowerPlus)

CopperHead Camera Unit CHG3-CAM

CopperHead Base Station CHG3-BS

AC-to-DC Power Supply ADAP-AC No No

Panel-Mountable Fiber Extension CH3BFC

Camera Remote cable CHCR

Camera Signal cable CH3CS

Base Station Remote cable CHBR

PowerWafer w/jumper cable CHG3-PW No No

Eternal PowerWafer Supply CH3-MPS No

PowerPlus PWRPLS No No

HDX Power Supply HDX No No

Fiber jumper(s) various No No

Reel or coil of Tactical Fiber CA No No

Reel or coil of Hybrid Fiber CA No

Operations Manual CA

No

No

Standard Optional

Consult your packing slip and purchase order to ensure that you have received all of the

expected Fiber Systems components. Inspect all components for scratches and other

mechanical damage, and inspect the electrical connectors for bent or damaged pins and

latches. Report any missing or damaged components to Grass Valley (see Product Returns

on page 4).

You must use your own video and audio cables to make connections for Video, Tally, Black

Burst/Genlock, Base Station monitor, intercom, and other ancillary signals and equipment.

Suggestions for these cables are discussed later in this User Guide.

3

Page 10

About CopperHead Pro

Product Returns

Product Returns

In the unlikely event of damage to your CopperHead Pro during shipping or delivery, take

note of any damage with the delivery or shipping service and document the packaging and

product where you see this damage. If any component does not work correctly out of the

box, contact Grass Valley (see Contact Us on page 57).

If the problem cannot be remedied through a service telephone call,you will receive an

RMA number (Return of Merchandise Authorization). Take note this RMA number inside

and outside of all shipping boxes and on all documentation provided with the items to be

returned.

About this User Guide

This user guide is designed to cover all of the various options and so not every page in this

guide will apply to your specific system.

Safety and Fiber Optic Systems

Optical Fiber Safety

Never look directly into the end of the optic fiber while either end of the system is

operating.

Always use cable connector caps when the cables are not connected. This protects the

connector from damage and the unlikely event of exposure to an operating optical link.

Keeping the caps in place when the connectors are not in use will prevent dirt and dust

from entering the connector and degrading the performance of the optical link.

Power Fuses

The CopperHead Pro Base Stations CHG3‐BS‐PRO‐95VD‐XXX‐XXX are equipped with two

fuses located next to the AC Power receptacle at the left rear of the unit. Refer to AC Power

Input Connector- Models CHG3-BS-Pro-95VD-xxx-xxx on page 65 for specific fuse and

location information.

NEVER operate the CopperHead CHG3-BS-PRO-95VD-XXX-XXX Base Station without

properly installed and rated fuses. Severe electrical and heat damage could result as well as

personal injury or death.

4

Page 11

System Overview

This chapter provides a system overview about the Fiber Cables and the Transceiver

System.

CopperHead Pro System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CopperHead Pro Transceiver System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5

Page 12

System Overview

CopperHead Pro System Configurations

CopperHead Pro System Configurations

The CopperHead Pro system is available in a variety of configurations that maximize the

advantages of either "dry" fiber cable, "hybrid" fiber cable, or a combination of the two.

Dry Fiber Systems - Locally powered cameras

CopperHead Pro systems can be run on "dry" fiber optic cable, typically tactical fiber optic

cable or infrastructure fiber. These "dry" cable runs do not provide power from Base Station

to Camera Unit, so the camera and CopperHead Pro Camera Unit must be powered locally,

typically by a battery.

In "Dry" fiber configurations, Camera Unit, Base Station, and Tactical Fiber cable can be

equipped with one of two types of fiber connectors:

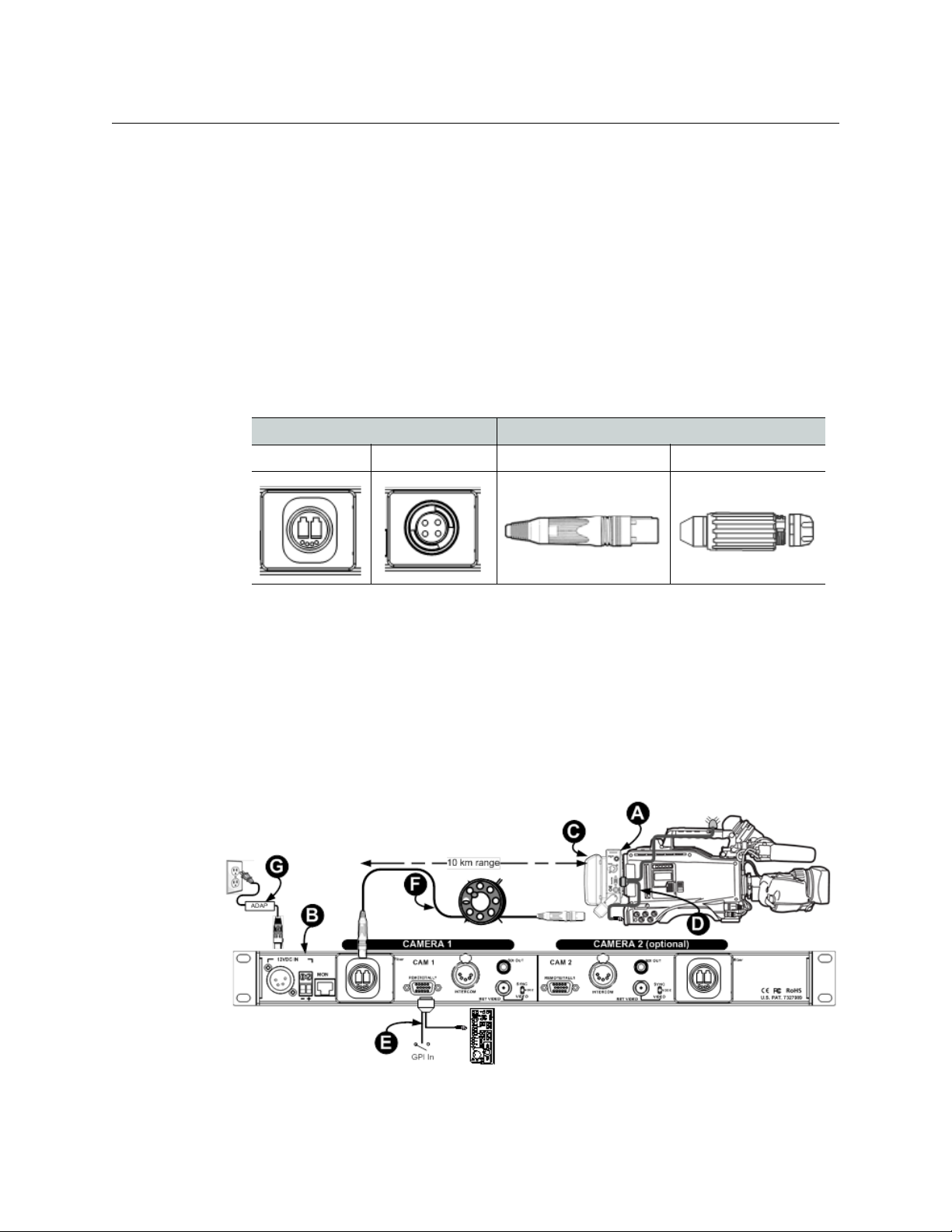

Panel Connectors Cable Plugs

OpticalCON (dry) MX OpticalCON (dry) MX

PowerWafer, Direct to Base Station

When connected directly to a Base Station using tactical fiber, the system is typically

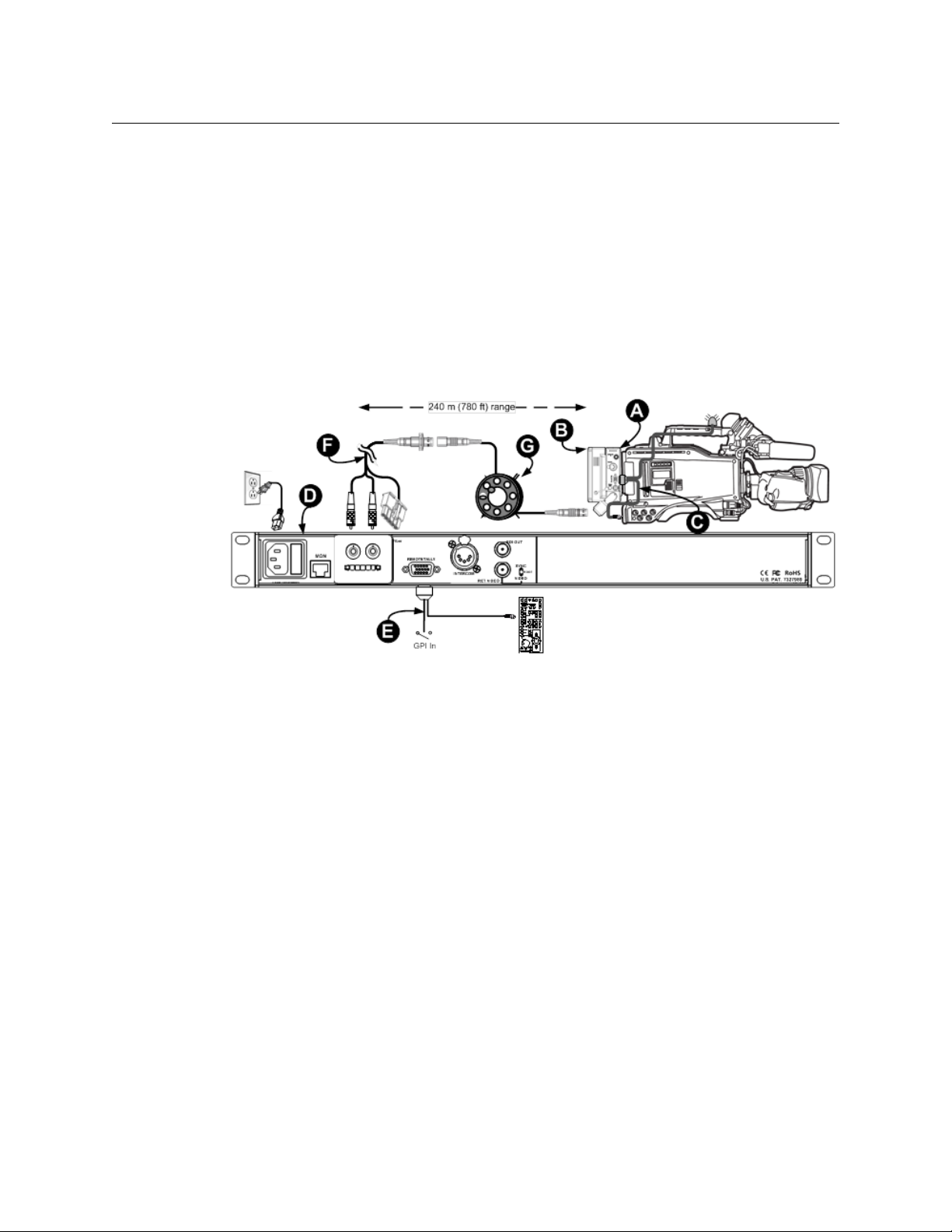

configured as shown in Figure 2-1, and uses the following components:

• A: Camera Unit

• B: DC-powered Base Station

• C: Battery or Local Power Source

• D: CHCR camera remote cable

• E: CHBR base remote cable

• F: Hybrid fiber optic cable

• G: ADAP 12VDC Power Supply

Fig. 2-1: Direct Connect to Base Station with Power Wafer

6

Page 13

CopperHead Pro

User Guide

Power Wafer, Remote Panel-Mounted Fiber Connector

The hybrid fiber receptacle may be mounted a distance from the Base Station if the station

is equipped with a pair of inexpensive ST fiber connectors and a Molex receptacle to carry

power (Figure 2-2).You can use a breakout cable or infrastructure wiringto connect the

hybrid fiber receptacle to Base Station.

• A: Camera Unit

• B: Power Wafer

• C: CHCR camera remote cable

• D:

AC-powered Base Station with internal

camera power supply

Fig. 2-2: Powered Base Station with Fiber Receptacle Extension

• E: CHBR base remote cable

• F:

ST & Molex breakout cable or

campus/building infrastructure

• G: Hybrid fiber optic cable

7

Page 14

System Overview

Dry Fiber Systems - Locally powered cameras

PowerWafer, with MPS Power Supply

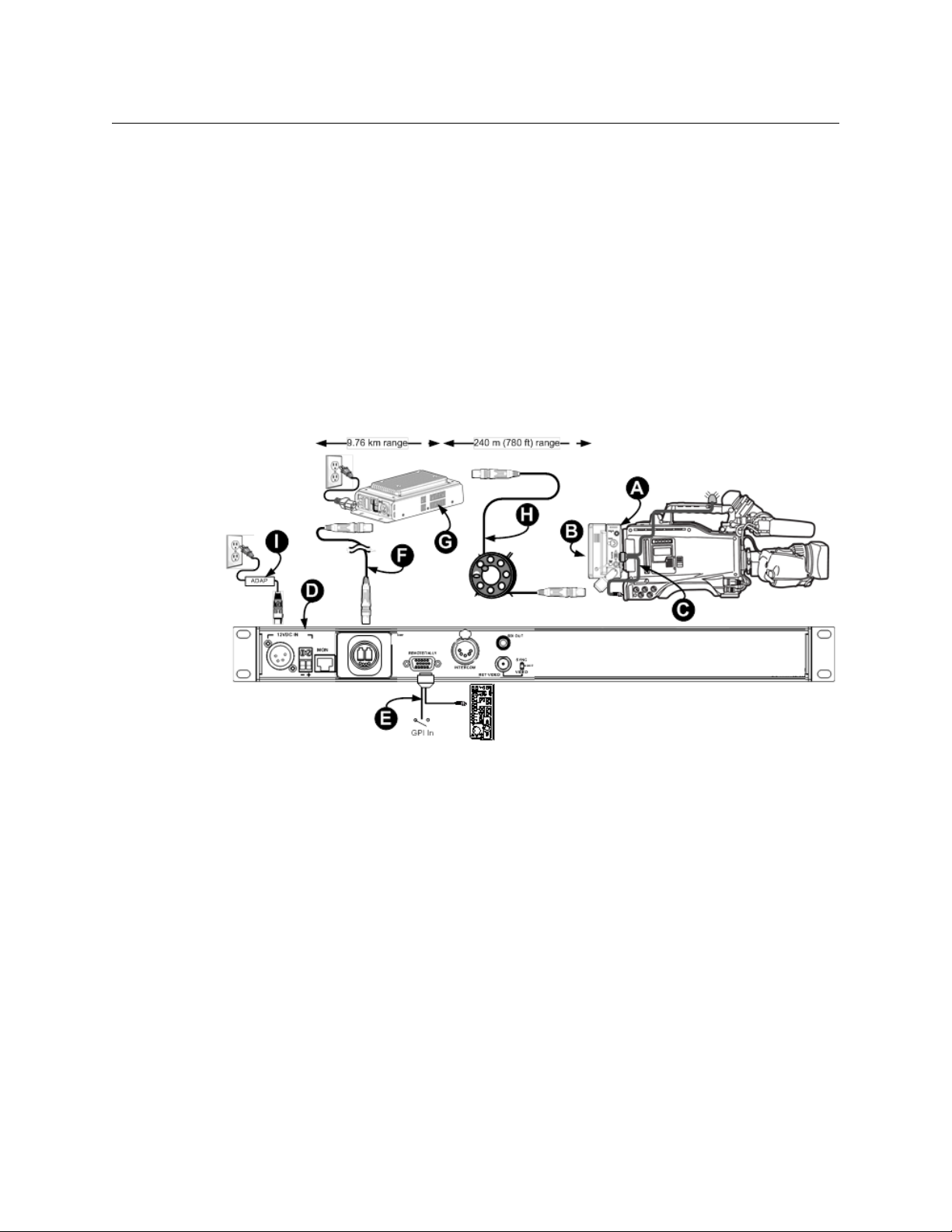

Systems can be configured so that the majority of the fiber run is made via "dry" tactical or

infrastructure fiber, after which a "throwdown" MPS Power Supply is placed in line to

provide powered SMPTE hybrid fiber cable to the camera. In this configuration, as shown in

Figure 2-3, the Base Station can be separated from the MPS power supply by more than

nine kilometers (5.6 miles), where powered cable can be run to the camera for 240 meters

(780 feet), providing up to 95 watts of power to the camera and accessories.

• A: Camera Unit

• B: Power Wafer

• C: CHCR camera remote cable

• D:

DC-powered Base Station

• E: CHBR base remote cable

• F:

Tactical fiber or Infrastructure fiber run

• G: MPS Power Supply

• H: Hybrid fiber optic cable

• I: ADAP 12VDC power supply

Fig. 2-3: System using MPS Power Supply

8

Page 15

CopperHead Pro

User Guide

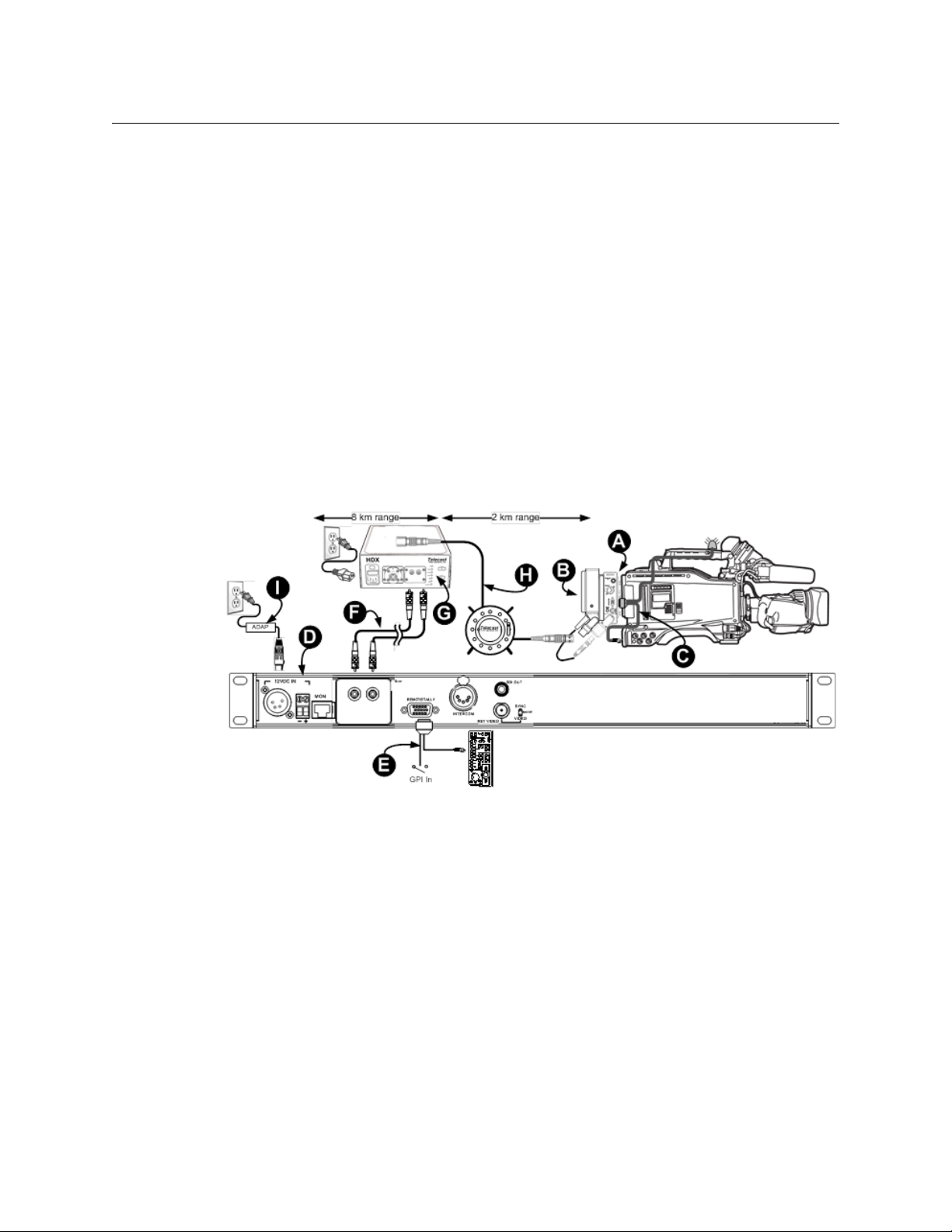

PowerPlus - High Power/Long Distance with HDX Power Supply

When power needs to be run for distances exceeding 240 meters or power requirements

exceed 95 watts for the camera and accessories, the external HDX power supply and

PowerPlus may be utilized. The PowerPlus can deliver up to 150 watts of power to the

camera and accessories.

The first part of the fiber run can be made via "dry" tactical or infrastructure fiber, after

which the HDX power supply is placed in line to provide powered SMPTE hybrid fiber cable

for the camera.

Such a system is typically configured as shown in Figure 2-4 and includes the following

components:

• A: Camera Unit

• B: PowerPlus

• C: CHCR camera remote cable

• D:

DC-powered Base Station

• E: CHBR base remote cable

Fig. 2-4: System using PowerPlus and HDX

• F:

Tactical fiber or Infrastructure fiber run

• G: HDX Power Supply

• H: SMPTE 311M hybrid fiber optic cable*

• I: ADAP 12VDC power supply

The Base Station can be separated from the MPS power supply on "dry fiber" (F ) by more

than nine kilometers (5.6 miles) , where powered hybrid cable (H) can be run to the camera

for another two kilometers (1.2 miles).

9

Page 16

System Overview

Camera Unit Front

(attaches to the camera)

Camera Unit Rear (attaches to

battery or power supply)

CopperHead Pro Transceiver System Components

CopperHead Pro Transceiver System Components

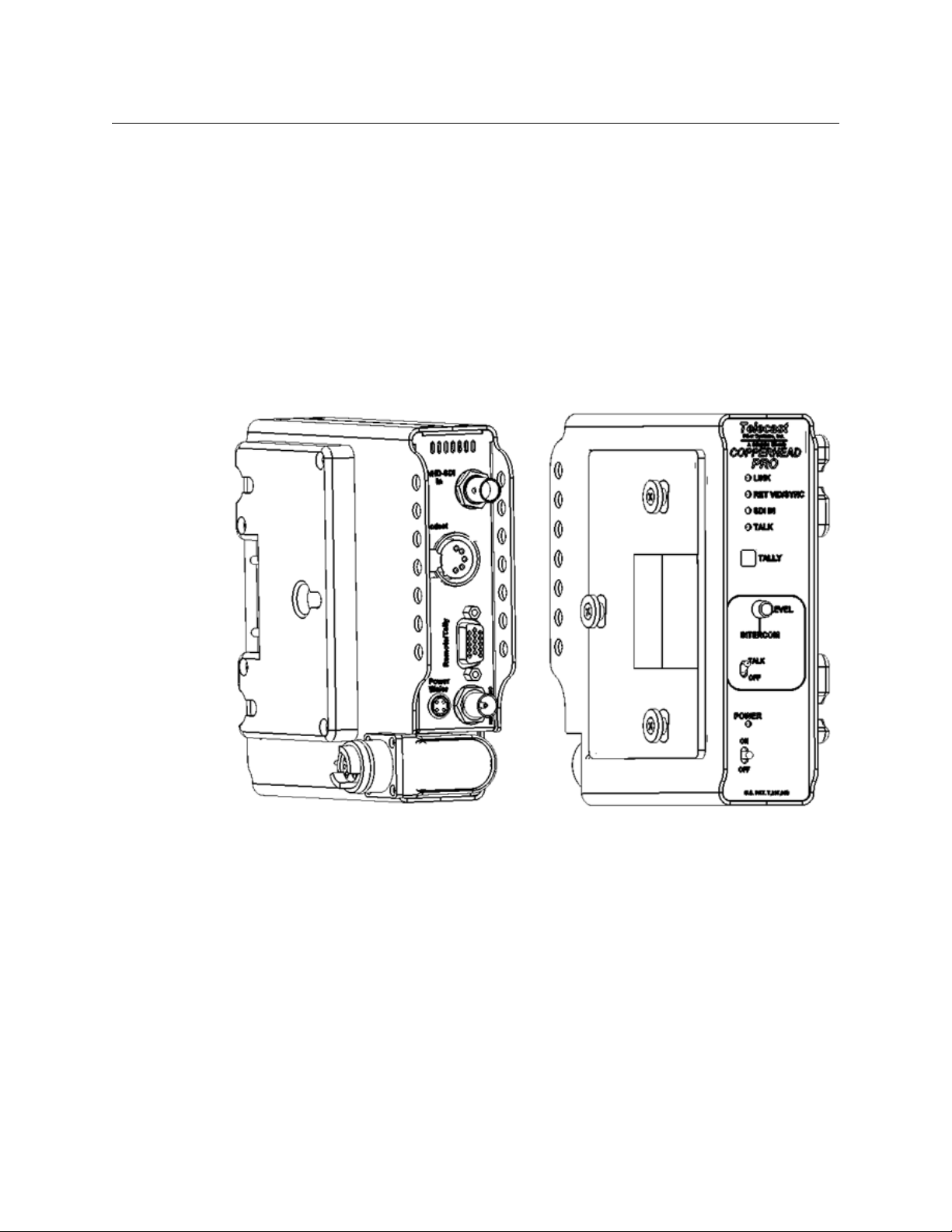

The CopperHead Pro Camera Unit fits between the battery or optional power supply and

the camera. The Camera Unit is configured at time of purchase with mounting plates to

accommodate the appropriate camera battery type.

The camera battery or optional power source attaches to Camera Unit, which in turn,

attaches to the video camera. Batteries accommodated are Anton/Bauer Gold Mount and

Sony "V" Mount. Other camera mounting plates may be available by special order. Contact

Grass Valley (see Contact Us on page 57) or your authorized dealer.

The Camera Unit is equipped with a swivel-mounted fiber optic connector, which can be

ordered with an OpticalCON, MX or SMPTE 304M connector. For more information, see

Parts & Accessories on page 75.

10

Fig. 2-5: Camera Unit Front and Rear

The actual appearance of your CopperHead Pro Camera Unit will vary depending on the

battery mount and fiber cable connector options specified at the time of purchase.

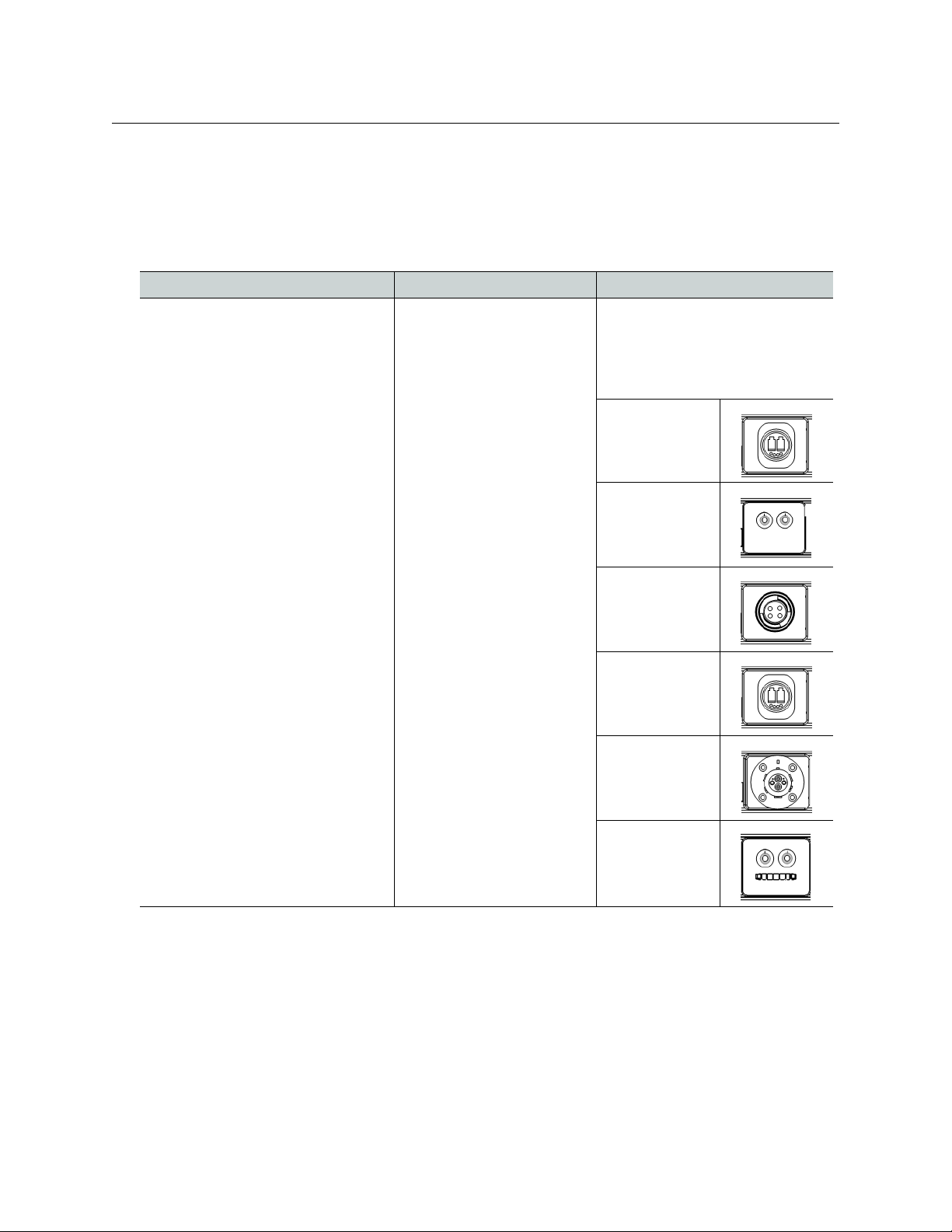

Page 17

Base Station Overview

The CopperHead Pro Base Station is a one rack-unit high device that provides all of the

inputs for signals going to the CopperHead Pro Camera Unit, as well as the outputs for the

signals coming from Camera Unit. Base Station is available in a variety of configurations.

The options are:

Power Supply Single or Double Fiber Connector

12 Volt DC Input: “Dry Fiber”

• No Internal camera power supply

• Does not supply power to Camera

Unit via SMPTE hybrid fiber cable

• Is typically used with Tactical fiber

cable and/or infrastructure cabling

• Available in “Dual” configuration for

interface and control of two Camera

Units in a single one RU device

120/220 Volt AC Input – “Powered

Fiber”

• Includes internal power supply for

Camera Unit

• Supplies power to Camera Unit via

SMPTE hybrid fiber cable

•Not available in “Dual”

configuration. Can only interface

and control a single Camera Unit

Single Configuration

• Interface and control a

single Camera Unit

• Available in 12 Volt DC and

120/220 VAC models

Dual Configuration

• Interface and control two

Camera Units in a one RU

device

• Available in 12 Volt DC only.

• Not available for 120/220

VAC mod els

Six different fiber connectors are

available for the

Base Station (see Rear Panel

Section B - Optical Connector on

page 25 for details).

•OpticalCON

(dry)

•Two STs

• MX (Expanded

Beam)

CopperHead Pro

User Guide

CopperHead Pro

•OpticalCON

(powered)

• SMPTE 304M

•Two STs and

Molex

11

Page 18

System Overview

Types of Base Stations

Types of Base Stations

The actual appearance of your CopperHead Pro Base Station will vary depending on the

fiber cable connectors and power option specified at the time of purchase.

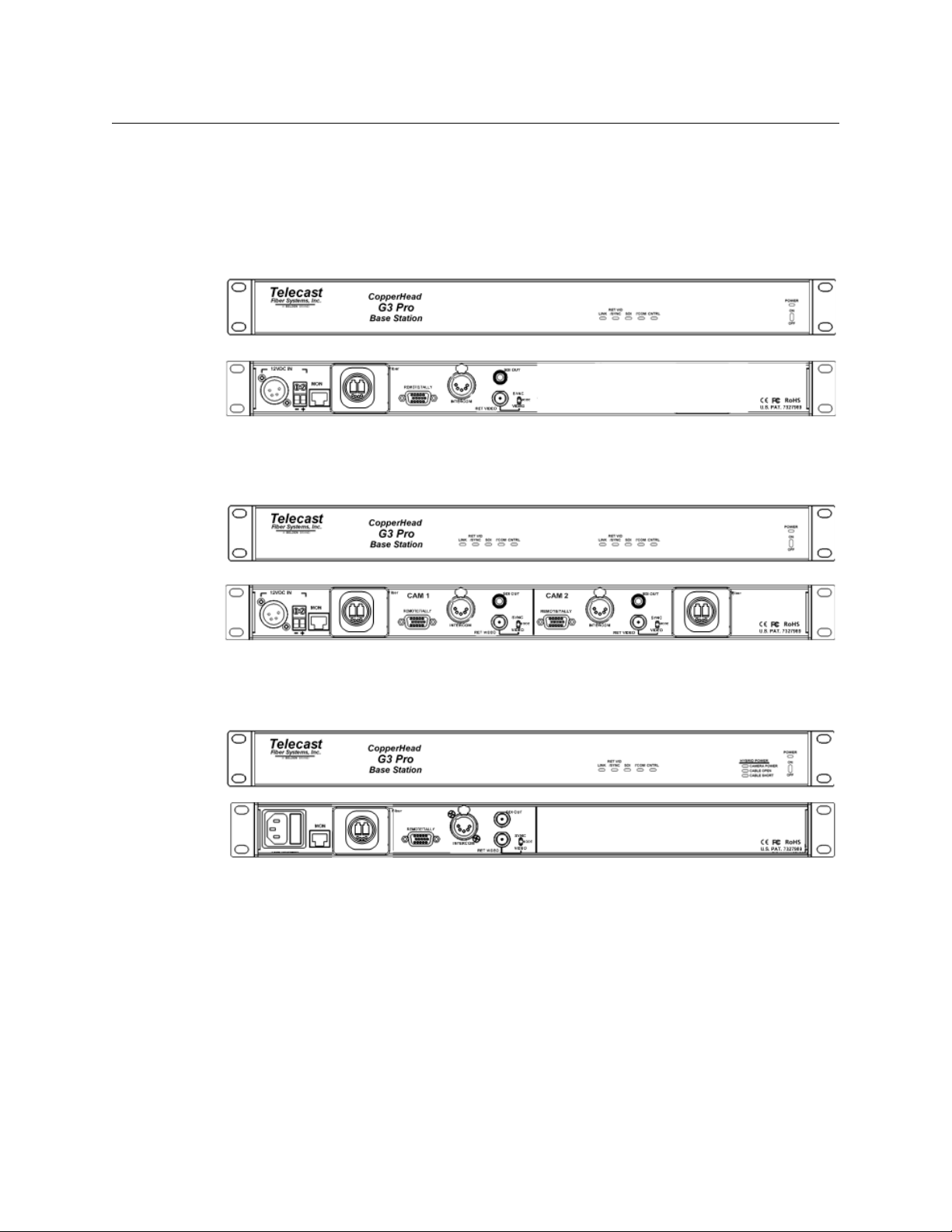

Single “Dry” Station

Fig. 2-6: Single "Dry" Base Station - Front Panel (top) and Rear Panel (bottom)

Dual Unpowered Base Station

Fig. 2-7: Dual Unpowered Base Station - Front Panel (top) and Rear Panel (bottom)

Powered Base Station

Fig. 2-8: Powered Base Station - Front Panel (top) and Rear Panel (bottom)

12

Page 19

CopperHead System Components

This chapter provides descriptive information for the CopperHead Pro system components.

Camera Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

PowerWafer Camera Adaptor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

MPS External PowerWafer Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

PowerPlus 3000 - Camera Power Adaptor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

HDX Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

13

Page 20

CopperHead System Components

Camera Unit

Camera Unit

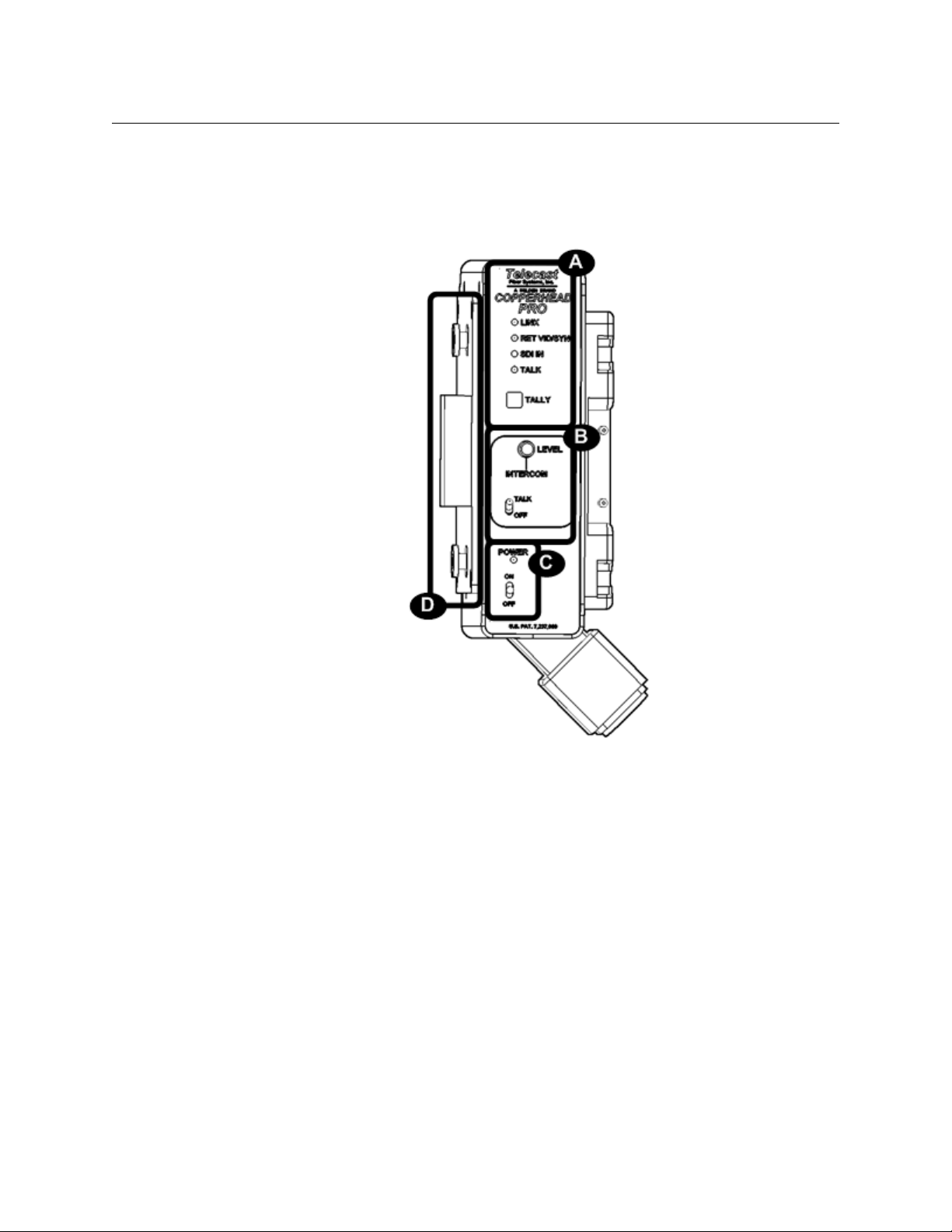

Camera Unit - Front Side

14

Fig. 3-1: Camera Unit - Front Side

The front of the CopperHead Pro Camera Unit has four features:

• A: Signal Status Panel: indicates the status of the various signals coming to and being

sent from the Camera Unit (see Camera Unit - Signal Status Panel (Section A) on

page 15).

• B: Intercom Controls: controls for intercom "talk" and "listen" functionality (see Camera

Unit - Intercom Controls (Section B) on page 16).

• C: Power Switch and Indicator: controls for power to the Camera Unit (see Camera Unit

- Power Switch & Indicator (Section C) on page 16).

• D: Camera Mounting Plate: mechanical mounting hardware for affixing CopperHead

Camera Unit to a camera or camcorder (see Camera Unit - Camera Mounting Plate

(Section D) on page 17).

Page 21

CopperHead Pro

User Guide

Camera Unit - Signal Status Panel (Section A)

Fig. 3-2: Camera Unit Signal Status Indicators

• 1: Link: indicates the status of the data link from Base Station to Camera Unit. This is a

good indicator of a valid optical link.

• Green when Camera Unit has a data "lock" with Base Station.

• Red when Camera Unit is not "locked" to Base Station.

A data lock means that the fiber link is valid and data can be exchanged securely.

• 2: Return Video/Sync: indicates the presence of the composite video signal (VBS) sent

from Base Station to Camera Unit. This VBS can be used for return "program" video or

for genlock to the camera.

• 3: SDI in: Green indicates the presence of digital SDI video at Camera Unit's input BNC.

• 4: Talk: lights Green to indicate that the intercom Tal k switch (see Camera Unit -

Intercom Controls (Section B) on page 16) is in the Ta lk position, and that the headset

mic is open.

• 5: Tally: lights Red when GPI/Tally signal is activated at Base Stations

For suggestions on connecting Tally in your system, see Connecting Base Station to

Studio Infrastructure on page 42.

15

Page 22

CopperHead System Components

Camera Unit - Front Side

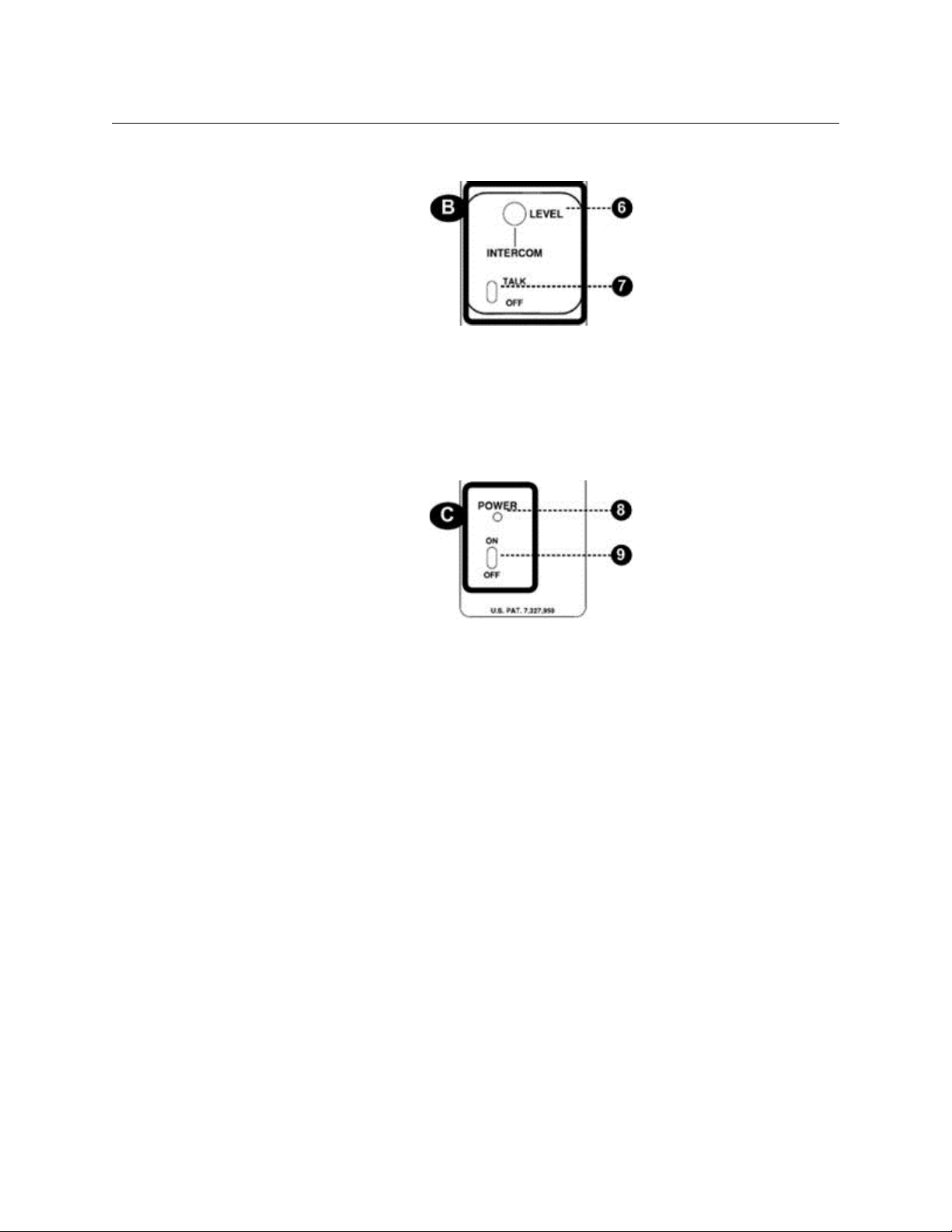

Camera Unit - Intercom Controls (Section B)

• Headset Level Knob: controls the volume of the intercom channel in the headset

•Intercom Talk Switch

• TA LK (up) opens the headset mic

• OFF (down) closes the headset mic

Camera Unit - Power Switch & Indicator (Section C)

• Power Indicator: lights Green to indicate main power is on

• Power On/Off: turns the main power supply on and off

16

Page 23

CopperHead Pro

Anton Bauer Camera

Mounting Plate

V-Mou nt Came ra

Mounting Plate

User Guide

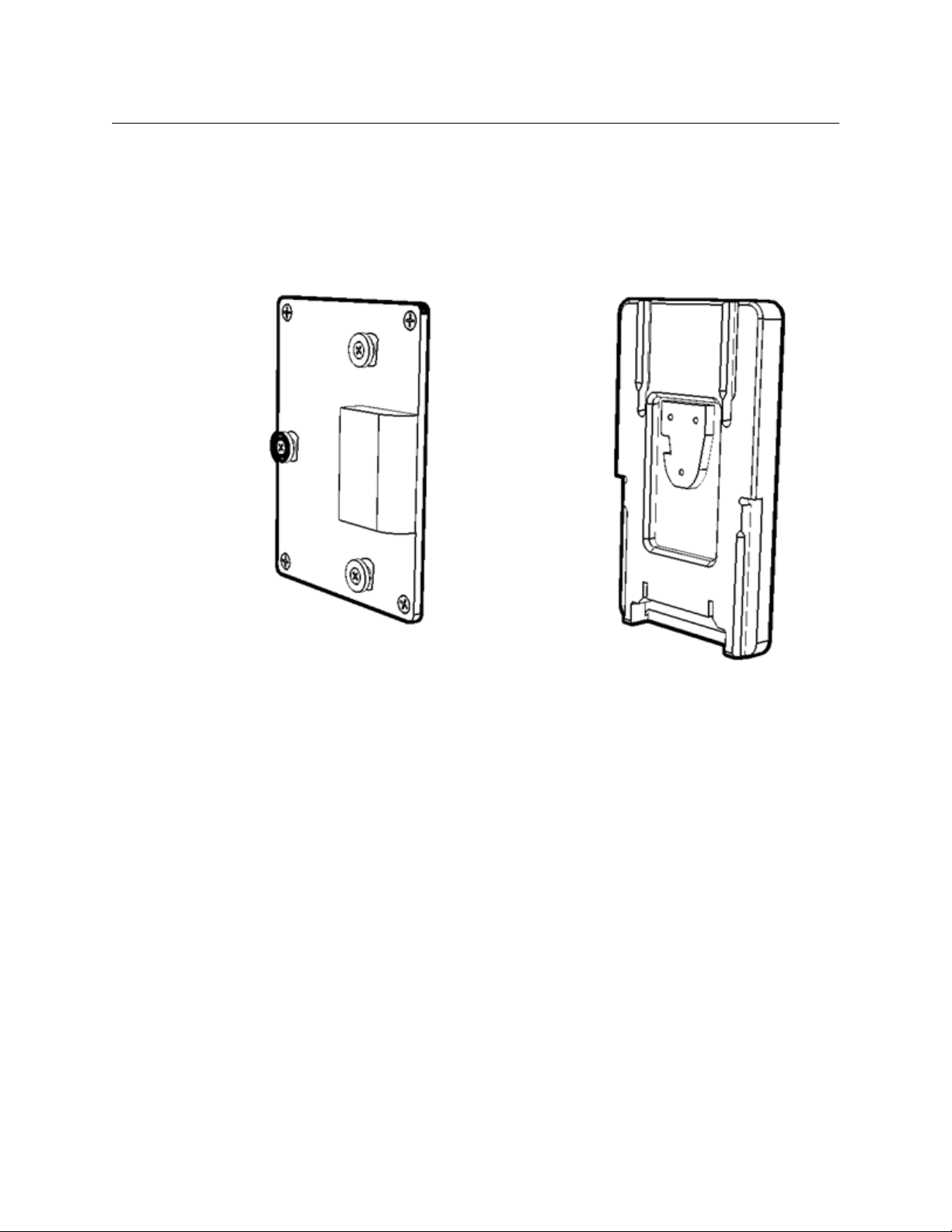

Camera Unit - Camera Mounting Plate (Section D)

This plate is used to mount the CopperHead Pro Camera Unit to a camera or camcorder.

Camera Unit is typically shipped with an Anton/Bauer "Gold Mount" or Sony-style "VMount" camera mounting plate. Other camera mounting plates may be available by

special order. Formore information, contact Grass Valley (see Contact Us on page 57) or

your authorized dealer.

Fig. 3-3: Camera Unit: Camera-side mounting plates

17

Page 24

CopperHead System Components

Camera Unit - Rear Side

Camera Unit - Rear Side

18

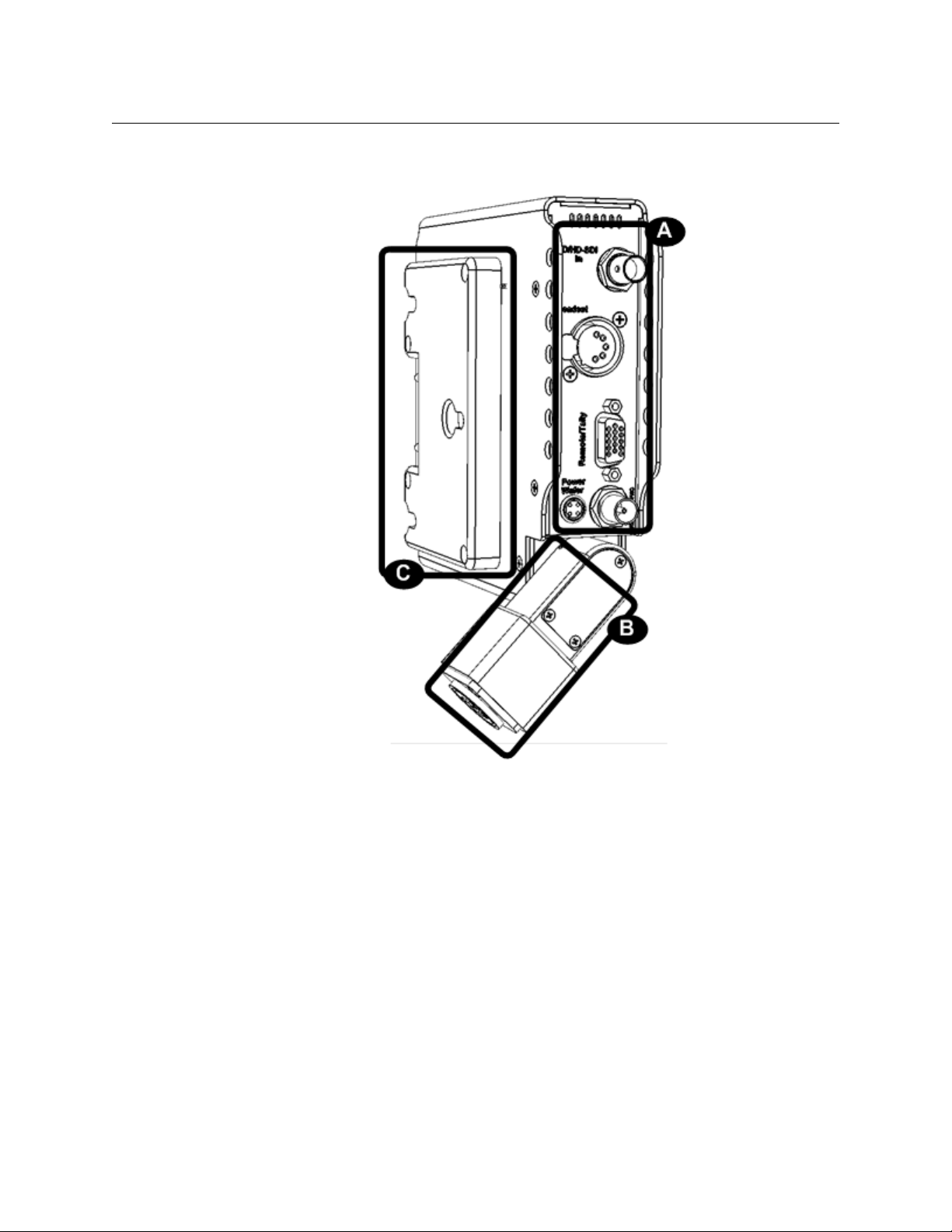

Fig. 3-4: Camera Unit Back Side

The back side of Camera Unit has three features:

• A: Connector Panel (see Camera Unit - Connectors (Section A) on page 19)

• B: Fiber Connector/Swivel (see Camera Unit - Fiber Connector/Swivel (Section B) on

page 20)

• C: Battery Mount (see Camera Unit - Battery Mount (Section C) on page 20)

Page 25

Camera Unit - Connectors (Section A)

CopperHead Pro

User Guide

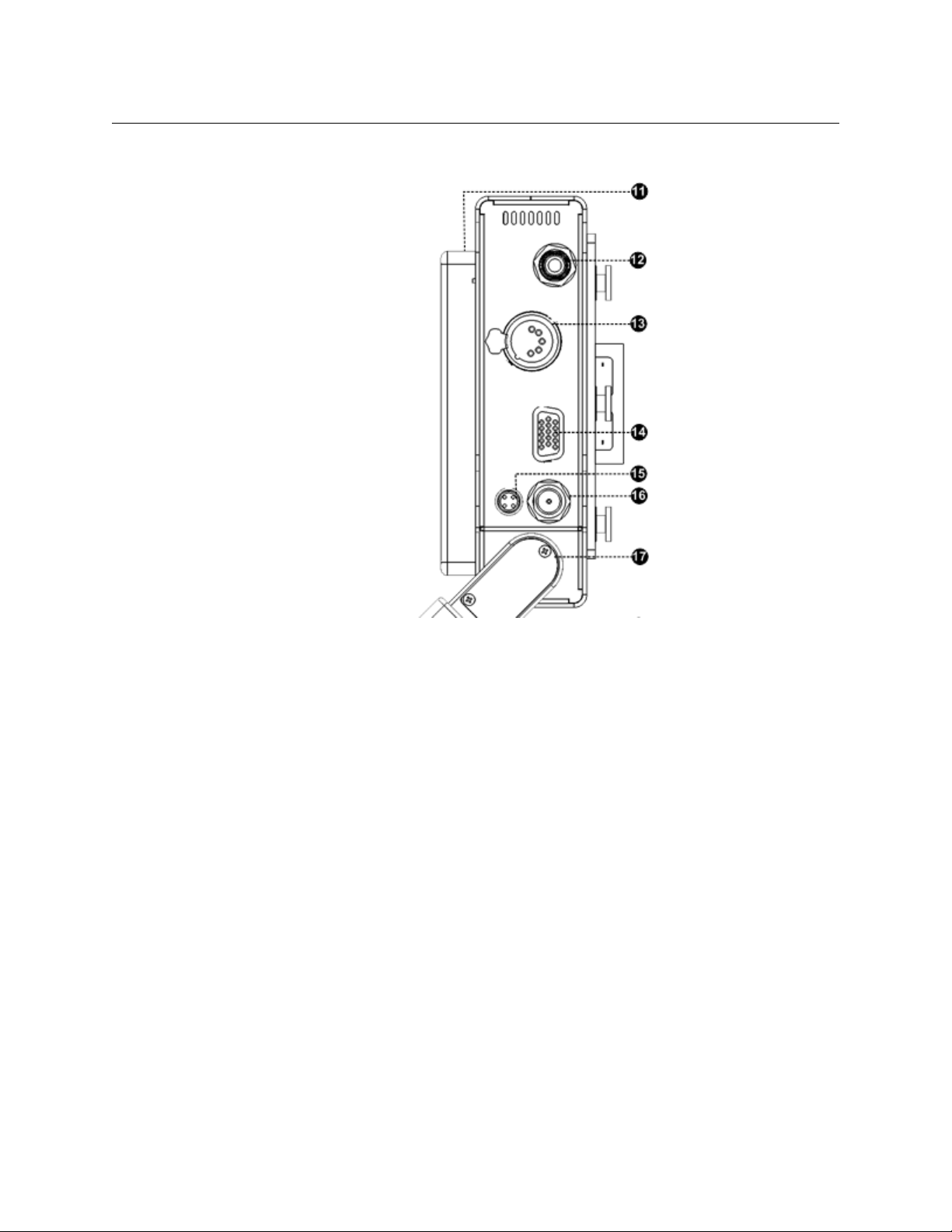

Fig. 3-5: Camera Unit Connectors

• 11: Battery Mounting Plate: typically equipped for with Anton/Bauer or V-Mount

batteries

• 12: SD/SDI or HD/SDI Input - to Base Station: digital video input connector from

camera's SDI output

• 13: Intercom Headset Jack: connect 5-pin XLR Male intercom headset connector

• 14: Connector for CHCR cable: Camera Remote Control, Tally: DB15HD connector for

Camera Remote Control, Tally input and output. See Camera Unit & Base Station

Interface Cables on page 73 for the correct cable for your camera.

• 15: PowerWafer Connector: for use with PowerWafer when used with the AC-powered

Base Station or the MPS power supply. Connect with CH3CP-INF-2FAG cable.

• 16: VBS (analog composite video) or Genlock Out - from Base Station: connect to

camera's Genlock/Sync input connector or to external VBS monitor

• 17: Fiber Connector Swivel: attach fiber cable to connector mounted here.

19

Page 26

CopperHead System Components

Anton Bauer Battery

Mounting Plate

V-Mount Battery

Mounting Plate

Camera Unit - Rear Side

Camera Unit - Fiber Connector/Swivel (Section B)

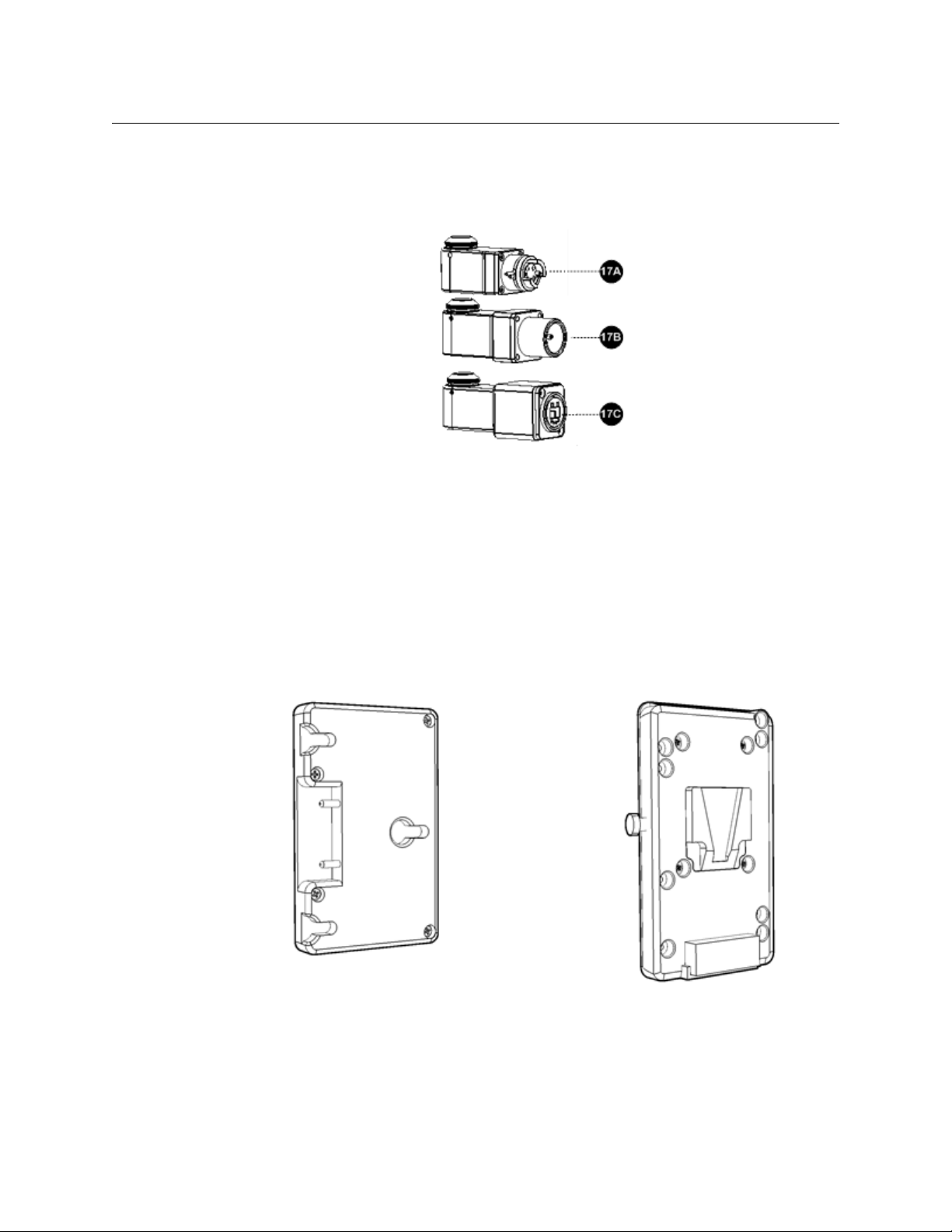

The CopperHead Pro Camera Unit is typically equipped with one of the three fiber

connectors shown in Figure 3-6:

• 17A: MX Expanded Beam (unpowered)

• 17B: SMPTE 304M (powered)

• 17C: OpticalCON (powered or unpowered)

Fig. 3-6: Camera Unit Fiber Connectors

Camera Unit - Battery Mount (Section C)

The CopperHead Pro Camera Unit can be shipped with a variety of plates to attach the unit

to your camera. The Anton Bauer mount and the "V"-mount are the most common,

although PAG and other battery mount systems are also available by special order. Formore

information, contact Grass Valley (see Contact Us on page 57) or your authorized dealer.

Fig. 3-7: Camera Unit - Battery side mounting plates

20

Page 27

Base Station

The CopperHead Base Station is available with a number of options. The unit is ordered

with a specified Power Module, Audio/Intercom Module, and Fiber Connector. For an

overall view of component location,see Overview Diagrams on page 78.

Base Station Front Panel

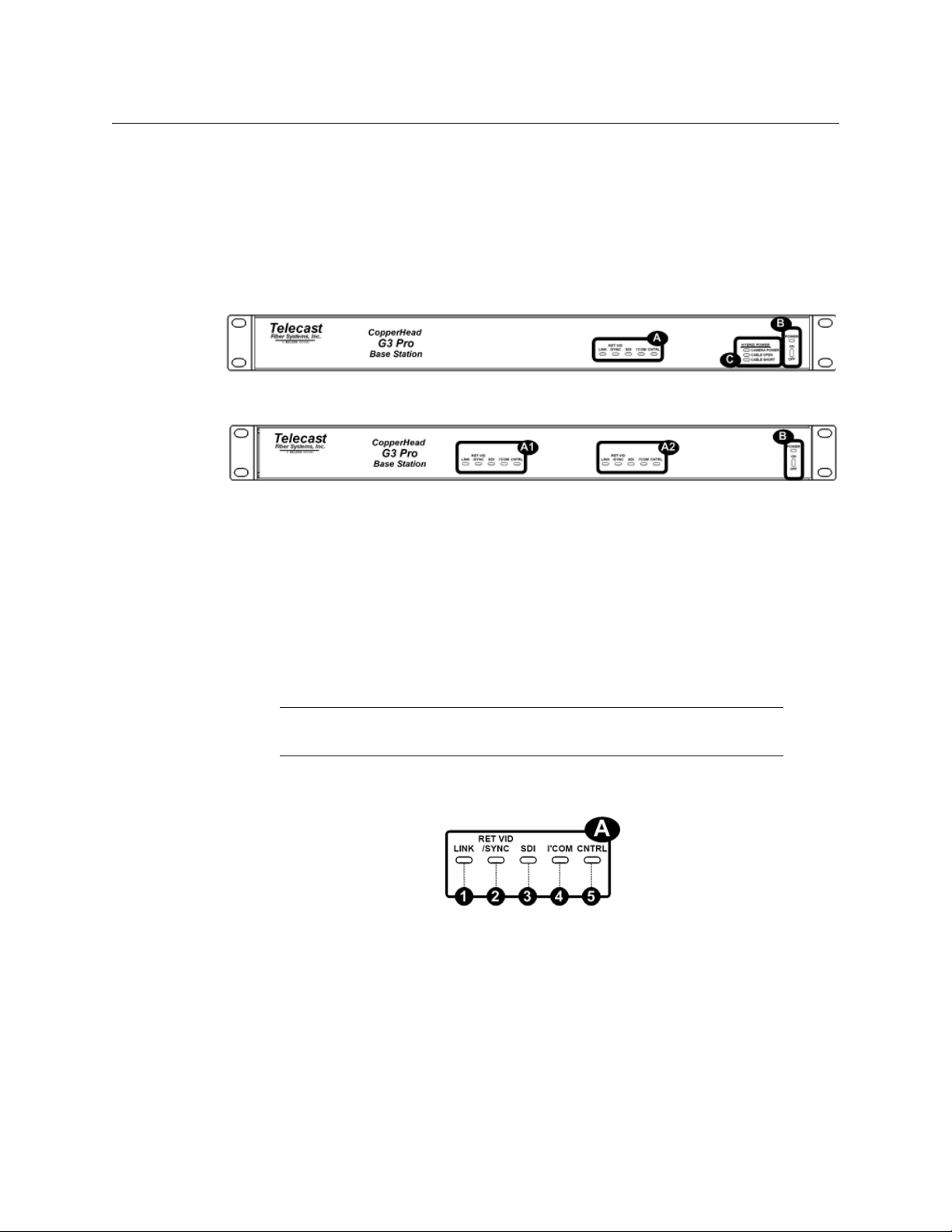

Fig. 3-8: Base Station Front Panel - single unit, 120/220 VAC power w/internal hybrid power supply

CopperHead Pro

User Guide

Fig. 3-9: Base Station Front Panel - dual unit, 12 VDC power

The front of Base Station has three features:

• A: Signal Status Indicators (see Front Panel Section A - Signal Status Indicators on

page 21)

Applies if Dual Base Station, A1 and A2. Otherwise, only A2 applies.

• B: Power Switch and Indicator (see Front Panel Section B- Power Switch and Indicator

on page 22)

• C: Hybrid Power Status Indicators (see Front Panel Section C- Hybrid Power Status

Indicators on page 23)

Note: These indicators only appears on Base Stations equipped with

internal hybrid power supply.

Front Panel Section A - Signal Status Indicators

Fig. 3-10: Base Station Status Indicators

• 1: Link: indicates the status of the data link from Camera Unit to Base Station. This is a

good indicator of adequate optical link.

• Green when Base Station has a data "lock" with Camera Unit.

• Red when Base Station is not "locked" to Camera Unit.

A data lock means that the fiber link is valid and data can be exchanged securely.

21

Page 28

CopperHead System Components

Base Station Front Panel

• 2: Return Video/Sync: indicates the presence of the analog video signal (VBS) at Base

Station's VBS In BNC. This VBS can be used for return "program" video or for genlock to

the camera.

• 3: SDI Presence: lights Green to indicate the presence of digital SDI video from Camera

Unit. This LED stays illuminated Green as long as the Base Station is receiving adequate

optical power. See A Brief Guide to Measurement of Fiber Optic Signal Strength on

page 61 for more information.

• 4: Intercom: lights Green to indicate audio activity on the Intercom channel.

• 5: Control: lights Green when camera control data is being transmitted between

Camera Unit and Base Station.

Front Panel Section B- Power Switch and Indicator

Fig. 3-11: Base Station Power Switch

• 6: Power: indicates that power is applied to Base Station.

• Green when Base Station is fully powered

• Red when there is power connected to Base Station, but Base Station is not turned

on

• 7: Power Switch: switchesthe Base Station on or off. With a hybrid power system

(power supplied by Base Station), this switch controls power to the camera and Camera

Unit.

22

Page 29

CopperHead Pro

User Guide

Front Panel Section C- Hybrid Power Status Indicators

This section is optional, and only appears on CopperHead Base Stations equipped with

internal power supplies designed to work with a CopperHead Camera Unit connected to a

PowerWafer.

Fig. 3-12: Base Station Hybrid Power Status Indicators

• 8: Camera Power: lights Green when high voltage is being supplied to Camera Unit.

• 9: Cable Open: lights Red when the SMPTE hybrid cable is open or when there is no

SMPTE hybrid cable connected.

High voltage will not be applied to the hybrid connector until the open condition is

corrected.

• 10: Cable Short: lights Red when the SMPTE hybrid cable has a short circuit in it.

High voltage will not be applied to the hybrid connector until the short-circuit is

corrected or the cable is replaced.

23

Page 30

CopperHead System Components

Base Station Rear Panel

Base Station Rear Panel

Fig. 3-13: CopperHead Pro Base Station Back Panel (Dual model shown)

• A: Power Connector (see Rear Panel Section A - Power Connector on page 24)

• B: Fiber Connectors (see Rear Panel Section B - Optical Connector on page 25 )

• C: Signal Connectors (see Rear Panel Section C - Signal Connectors on page 26)

Rear Panel Section A - Power Connector

The CopperHead Base Station can be configured for DC or AC power.

12VDC Power Interface

This power interface is used on CopperHead Base Stations that are not equipped with

internal power supplies. This type of Base Station is typically used with Camera Units

powered locally with a battery or a local power supply at the camera.

Fig. 3-14: 12VDC Power Connector

• 11: 12V DC Power input connector (XLR 4 Pin)

• 12: 12V DC Input - terminal block: can be used in lieu of the 4-pin XLR or in parallel as a

redundant input. See Base Station Connectors on page 65 for pin-out details.

• 13: For Future Use (RJ45)

24

Page 31

CopperHead Pro

User Guide

AC Power Connector Interface

This power interface is used on CopperHead Base Stations that are equipped with an

internal power supply. This type of Base Station is typically used with Camera Units

powered with a PowerWafer via SMPTE Hybrid cable

Fig. 3-15: AC Mains Connector

• 20: AC Power Receptacle 100-240V 50/60 Hz

• 21: 3.15 amp dual fuse assembly (see Base Station Connectors on page 65 for fuse

specification)

• 13: For Future Use (RJ45)

Rear Panel Section B - Optical Connector

The fiber optic connector is used to connect Base Station directly to Camera Unit or to the

external MPS or HDX power supply configured with your system. The type of fiber

connector will vary depending on your system configuration.

Six types of fiber optic connectors are available for use with the CopperHead Base Station.

"Dry" (unpowered) fiber connectors Fiber Connectors with Copper for Power

A: OpticalCON

(dry)

B: STs C: MX D: OpticalCON

(powered)

E. SMPTE 304M F. STs & Molex

25

Page 32

CopperHead System Components

Base Station Rear Panel

Rear Panel Section C - Signal Connectors

• 5: Connector for Camera Remote Control Panel and Tally input (DB15HD): connect

CHBR-PRO cable here, specified for your particular Camera Remote Control Panel.

See CHBR-PRO Base Station Remote Cable on page 74 to specify the correct cable for

your Camera Remote Control Panel.

• 6: Base Station Intercom Connector: connect your house intercom system here:

• XLR3: Two-wire (Clear-Com or RTS)

• XLR5M: Four-wire (matrix-style)

For more information, refer to Intercom connectivity on page 43.

• 7: SD/SDI or HD/SDI Output: digital video from camera's SDI output

• 8: VBS Return Input: analog composite video signal sent to Camera Unit

• 9: VBS Return Input Switch: switches the VBS Return Input connector to be optimized

for one of two uses:

• A: Sync In: Genlock/Sync/Tri-Level sync signal.

• B: Composite Video In: typically used to send analog VBS return video to the

camera or an external monitor.

Fig. 3-16: Rear Panel Signal Connectors

26

Page 33

PowerWafer Camera Adaptor

The CopperHead Camera Unit can be powered by the optional "PowerWafer" Camera

Adaptor. The PowerWafer replaces the local camera battery and any local AC power supply

adaptor. The PowerWafer gets its power from the use hybrid fiber cable and the

CopperHead Base Station equipped with the internal power supply or from the MPS

external power supply.

You can deliver up to 95 watts of power to the camera, Camera Unit, and camera-powered

accessories. You can use up to 780 feet (240 meters) of cable when the Camera Unit is

powered directly from Base Station.

The use of an external power supply can extend Base Station to Camera range and increase

camera power flexibility. The MPS Throw Down device or Wafer Power Adaptor provides

this functionality. This unit is described in MPS External PowerWafer Power Supply on

page 28.

The PowerWafer replaces the battery or local battery mountable AC adaptor (shown with

the Anton/Bauer "Gold Mount" option).

•1: Heat Sink

• 2: Battery Mounting Plate (Anton/Bauer Gold Mont or "V-Mount")

• 3: Power Input Connector

CopperHead Pro

User Guide

High voltage power is carried from Base Station to Camera Unit. A short jumper cable

(CH3CP-INF-2FAG) carries the high voltage power from Camera Unit to the PowerWafer's

power input connector (where it is converted to 12VDC power). The 12VDC power is

delivered back to the camera via the battery mounting plate.

Fig. 3-17: PowerWafer Power Adaptor and Jumper Cable

27

Page 34

CopperHead System Components

MPS External PowerWafer Power Supply

MPS External PowerWafer Power Supply

The CopperHead MPS external power supply provides 95 watts of 12VDC power and fiber

connectivity from Base Station to Camera Unit equipped with a CopperHead PowerWafer.

Connectivity between the MPS unit to the camera can be configured using either a Hybrid

OpticalCON connector or a SMPTE 304M connector. The nominal distance between them is

240 meters (780 feet).

Connectivity between the MPS unit and Base Station uses "dry" fiber and can be configured

with a "dry" OpticalCON connector or two ST connectors. The MPS is powered locally with

standard AC power. The unit is free-standing (see Hybrid Fiber Cable between MPS Power

Unit and Camera Unit on page 46 for system configuration with the MPS Power Supply and

PowerWafer).

28

Fig. 3-18: MPS Power Supply, Front and Rear

• 1: AC Power Receptacle: 100-240V 50/60 Hz

• 2: Fuse compartment: see AC Power Input Connector- Models CHG3-BS-Pro-95VD-xxx-

xxx on page 65 for the fuse specification.

• 3: Power Switch

• 4: For Future Use (RJ45)

• 5: "Dry" Fiber Optic Connection to CopperHead Base Station: this removable plate

can be equipped with two ST connectors or a "dry" OpticalCON connector (see

Figure 3-19).

•6: Heat Sink

• 7: Powered Fiber Optic Connection to CopperHead Camera Unit: this removable

plate can be equipped with a SMPTE 304M connector or a powered OpticalCON

connector. See Figure 3-20.

Page 35

CopperHead Pro

User Guide

Fig. 3-19: MPS "dry" fiber connector options

The "dry" connection (#5 in Figure 3-18)to the CopperHead Base Station can be equipped

with two ST connectors or a "dry" OpticalCON connector.

Fig. 3-20: MPS powered fiber connector options

The powered connection (#7 in Figure 3-18) to the CopperHead Camera Unit can be

equipped with a SMPTE 304M connector or a powered OpticalCON connector.

Dry Unpowered Fiber

Connection to Base Station

Part Number

CH2-MPS-95VD-2ST-NEU 2 STs OpticalCON

CH2-MPS-95VD-2ST-304 2 STs SMPTE 304M

CH2-MPS-95VD-NEU-NEU OpticalCON OpticalCON

CH2-MPS-95VD-NEU-304 OpticalCON SMPTE 304

(#5 in Figure 3-18)

Powered Fiber Connection

to Camera

(#7 in Figure 3-18)

29

Page 36

CopperHead System Components

High Profile

Heat Sink

Low Profile

Heat Sink

PowerPlus 3000 - Camera Power Adaptor

PowerPlus 3000 - Camera Power Adaptor

The standard CopperHead PowerPlus 3000 power adaptor with standard (Low Profile) heat

sink (Figure 3-21) provides 100 watts of 12VDC power and fiber cable signal connectivity

from Base Station to the Camera. It also provides an external power feed of 12VDC and

optionally 24VDC for external accessories. The PowerPlus unit requires the use of the HDX

power supply.

The PowerPlus can be equipped with a "High Profile" heat sink (Figure 3-21) for power

requirements up to 150 Watts.

The PowerPlus unit is equipped with a fixed tactical fiber "dongle" that can be terminated

with either an OpticalCON plug, SMPTE 304M plug, or an MX plug. This dongle plugs into

the swivel of the CopperHead Camera Unit.

The PowerPlus is connected to the HDX power supply using Hybrid fiber cable with SMPTE

304 connectors. See Mounting the CopperHead Pro Camera Unit with the PowerPlus on

page 38 for details on connecting the PowerPlus.

The distance between the HDX power adaptor and the camera can be up to 2km (1.2 miles)

using Hybrid fiber cable and the distance between the HDX power adaptor and Base

Station can be up to 7km (4.3 miles).

Fig. 3-21: PowerPlus 3000 with Low and High Profile Heat Sink mounted to CopperHead Pro

30

Page 37

CopperHead Pro

User Guide

Fig. 3-22: PowerPlus 3000 LED Indicators

• 1: +24 Volt DC "A": lights up when 24 Volts is available on connector X

• 2: Power In: indicates that power is being received from the HDX power supply

• Red - initial safety handshaking in progress, full power not engaged.

• Green - safety handshaking completed, full power being received from HDX power

supply.

• 3: Camera Out: indicates that 12VDC is being supplied to the battery plate

• 4: Auxilliary +12 Volt Output: indicates 12 Volt is being supplied to the 4-pin XLR

connector(#7 on Figure 3-23)

• 5: +24 Volt DC "B": lights up when 24 Volts is available on connector(#10 on Figure 3-

23)

• 6: Battery Plate: used to mount the PowerPlus to the CopperHead Camera Unit

(Anton/Bauer or V-Mount)

31

Page 38

CopperHead System Components

PowerPlus 3000 - Camera Power Adaptor

Fig. 3-23: PowerPlus 3000 Connectors

•7: Heat Sink

• LP- Low Profile Heat Sink rated for 100 Watts (shown)

• HP - High Profile Heat Sink rated for 150 Watts

• 8: 12 Volt Auxiliary Output: 4-Pin XLR output connector for 12 Volt accessories

• 9: 24 Volt Auxiliary Output B: 3-pin connector for 24 Volt accessories.

• 10: 24 Volt Auxiliary Output A: 3-pin connector for 24 Volt accessories.

• 11: Tactical Fiber Dongle: fixed tactical fiber cable connects to the CopperHead

Camera Unit.

• 12: SMPTE Swivel: adjustable swivel for SMPTE 304M receptacle am.

• 13: SMPTE 304M Hybrid Fiber Receptacle: connect the SMPTE hybrid cable here. This

cable connects to the PowerPlus.

• 14: Tactical Fiber Connector (MX shown): dry fiber connector at the end of the

dongle. This should match the connector on the swivel of the mating CopperHead

Camera Unit. Available with the following termination:

• MX plug (shown)

• OpticalCON Connector ("dry")

• SMPTE 304M plug ("dry")

32

Page 39

HDX Power Supply

The HDX Power Supply Unit is required when using the PowerPlus Camera Adaptor. The

HDX can be used as a free-standing unit or rack mounted, using the HDX-FR-2 for mounting

two HDX units.

The unit sends power via a SMPTE hybrid fiber cable to the PowerPlus, where it is converted

to 12VDC and optionally to 24VDC). For details on connecting the HDX to a CopperHead

system, see @PowerPlus - High Power/Long Distance with HDX Power Supply on page 9 .

CopperHead Pro

User Guide

Fig. 3-24: HDX device setups

The HDX has five features:

• A: AC Power Input Module and Switch: power switch and connector for AC Mains

• B: "Wet" SMPTE 304M Hybrid Fiber Connector: the SMPTE hybrid cable is connected

here. This cable connects to the PowerPlus at the camera. This mating connector pair

always uses SMPTE 304M connectors.

• C: "Dry" Fiber connector(s): connect the CopperHead Base Station. This interface can

be equipped with a variety of fiber connectors:

• Two ST connectors

• MX connector

• OpticalCON connector

• D: Status Indicators: these indicators show the status of the HDX's power system (see

HDX Status Indicators on page 34 for more details)

• E: HDX Integrated Handle: stand-alone unit can be carried or hung from this robust

handle

33

Page 40

CopperHead System Components

HDX Status Indicators

HDX Status Indicators

Fig. 3-25: HDX Displays

• 1: AC IN - MAINS: AC Input power is present

• 2: DC HV ENABLE: DC "Sense" voltage from PowerPlus is present

• 3: AC HV ENABLE: AC "Sense" voltage from PowerPlus is present

• 4: HV Present: AC or DC voltage is available on Hybrid connector

• 5: CABLE OPEN: no camera cable connected

• 6: CABLE SHORT: camera cable non-functional due to a short

• 7: REMOTE PWR ENABLE

• Red: if local/remote sw in remote position and opt power <= -27 dBm

• Green: if local/remote sw in remote position and opt power >= -24 dBm gates HV

power

• 8: LOAD TYPE: indicates the type of load or camera being used:

• N/A - No load detected

• PWR+ - PowerPlus detected

• 9: Optical Power: not used with PowerPlus.

• 10: Local Remote: not Used With PowerPlus.

34

Page 41

Camera Unit and Power Supply Installation

This chapter explains how to install the Camera Unit and Power Supply components.

Mounting the Copperhead Camera Unit with the PowerWafer . . . . . . . . . . . . . . . . . . . . . . . . 36

Connecting the CopperHead Pro System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Deployment of the CopperHead System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Insuring a Positive Fiber Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Intercom Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Shutting Down the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

35

Page 42

Camera Unit and Power Supply Installation

Mounting the Copperhead Camera Unit with the PowerWafer

Mounting the Copperhead Camera Unit with the PowerWafer

When mounting the CopperHead Camera Unit, always position the camera so that the

battery mounting plate at the rear of the camera is easy to access. Ensure that the camera is

well-supported and stable. If a battery is mounted remove it and put it to one side.

Installing the CopperHead Camera Unit typically involves one of the following three

configurations.

• CopperHead Pro Camera Unit with a battery (see Mounting the CopperHead Pro

Camera Unit with a battery on page 36)

• CopperHead Pro Camera Unit with the PowerWafer (see Mounting the CopperHead Pro

Camera Unit with the PowerWafer on page 37)

• CopperHead Pro Camera Unit with the PowerPlus (see Mounting the CopperHead Pro

Camera Unit with the PowerPlus on page 38)

Mounting the CopperHead Pro Camera Unit with a battery

When the camera is powered locally at the camera position, either by a battery (as shown)

or by a local power source, tactical fiber is typically the preferred connection to Base

Station.

36

Fig. 4-1: Mounting the CopperHead Pro Camera Unit to the Camera

1 Attach the CopperHead Pro Camera Unit A to the camera battery mounting plate B. The

mounting is mechanically identical to attaching a battery.

2 Mount the battery C to the CopperHead Pro Camera Unit battery mounting plate D

exactly as you would mount the battery to the camera.

3 Instructions for attaching the required cables between the camera and Camera Unit

can be found in Connecting Camera Unit to a Camera or Camcorder on page 40 .

Page 43

Mounting the CopperHead Pro Camera Unit with the PowerWafer

The PowerWafer allows the camera and Camera Unit to be powered via hybrid fiber cable,

which is powered from the CopperHead Pro Base Station or MPS External Power Supply.

CopperHead Pro

User Guide

Fig. 4-2: Mounting the PowerWafer Unit to the CopperHead Pro Camera Unit

Fig. 4-3: Attaching the PowerWafer Cable

1 Attach the CopperHead Pro Camera Unit A to the camera battery mounting plate B.

The mounting is mechanically identical to attaching a battery. Instructions for

attaching the required cables between the camera and the Pro Camera Unit can be

found in Connecting Camera Unit to a Camera or Camcorder on page 40.

37

Page 44

Camera Unit and Power Supply Installation

Mounting the CopperHead Pro Camera Unit with the PowerPlus

2Mount the PowerWafer C to the CopperHead Pro Camera Unit battery mounting plate

D exactly as you would mount the battery to the camera.

3 Connect the supplied PowerWafer connector cable E. (model CH3CP-INF-FAG2)

between the PowerWafer C and the PowerWafer connector on Camera Unit A.

4 For best results, plug the straight connector F into the PowerWafer and the connector

with the Right Angle G into the Copperhead Camera Unit.

Mounting the CopperHead Pro Camera Unit with the PowerPlus

The PowerPlus allows the camera and Camera Unit to be powered via hybrid fiber cable for

extra-long distances at higher power than the PowerWafer. The PowerPlus is powered via

the hybrid fiber cable from the HDX Power Supply.

38

Fig. 4-4: Mounting the PowerPlus Unit to the CopperHead Pro Camera Unit

Fig. 4-5: PowerPlus on CopperHead Pro

Page 45

CopperHead Pro

User Guide

1 Attach the CopperHead Pro Camera Unit A to the camera's battery mounting plate B.

The mounting is mechanically identical to attaching a battery to the camera.

2 Mount the PowerPlus C to the CopperHead Pro Camera Unit battery mounting plate D

exactly as you would mount a battery to the camera.

3 Connect the PowerPlus "dongle" E to the fiber optic swivel F on Camera Unit A.

Connect the SMPTE hybrid cable connector G from the HDX to the SMPTE receptacle H

on the PowerPlus.

39

Page 46

Camera Unit and Power Supply Installation

Connecting the CopperHead Pro System

Connecting the CopperHead Pro System

The CopperHead Pro system is designed to integrate seamlessly into virtually any

production environment. Prior to connecting your system,ensure that each of the required

cables and accessories is available.

Connecting Camera Unit to a Camera or Camcorder

Fig. 4-6: Camera with CopperHead Pro and cables

Connecting the CopperHead Camera Unit requires the following:

• Two short BNC-terminated coax cables

•CHCS-Pro cable

• Headset

• External Tally light (optional)

•Fiber cable to Base Station

40

Page 47

CopperHead Pro

User Guide

Fig. 4-7: Camera Unit to Camera Connections

• 11: HD/SDI Input: connects to the camera's HD/SDI or SD/SDI output signal

• 12: Headset: receptacle for intercom headset

• 13: Remote/Tally: connect to CHCR-PRO cable. This cable connects to the Remote

connector of the camera, as well as to an external Tally light (customer supplied). See

Camera Unit on page 79 for details.

• 14: PowerWafer: connect to the PowerWafer using cable CH3CP-INF-2FAG. Powered

Base Station or MPS Power Supply required. See Parts & Accessories on page 75.

• 15: VBS Out: two options:

• Genlock: connect to the genlock input of your camera

• Return Video: connect to an external analog VBS monitor

• 16, 17: Fiber: swivel with fiber connector: MX, OpticalCON, or SMPTE 304M

41

Page 48

Camera Unit and Power Supply Installation

Connecting Base Station to Studio Infrastructure

Connecting Base Station to Studio Infrastructure

Connecting the CopperHead Base Station requires the following:

• Two BNC-terminated coax cables to connect to your infrastructure

•CHBR-Pro cable

•Camera Remote Panel

• XLR cable to connect to your intercom system (see Intercom connectivity on page 43)

• Access to your video switcher's tally outputs (optional)

• Fiber cable to Camera Unit

Fig. 4-8: CopperHead Pro Base Unit Connections

• 11: 12 VDC Input: connects to 12VDC power supply

• 20: 120/220 VAC Input: connects to AC mains

• 14: Fiber: connect fiber cable to CopperHead Camera Unit

• 15: Remote/Tally: connects to CHBS-PRO cable. This breakout cable connects to a

Camera Remote Control Panel. The pigtail connects to the tally output of a switcher or

to a studio Tally system. See CHBR-PRO Base Station Remote Cable on page 74 for

details.

• 16: Intercom: connects to the house intercom system is connected here (see Intercom

connectivity on page 43)

• 17: SDI Out: connects to the digital video output (HD/SDI-SDI) from your camera is

found here

• 18: Return Video In: connects to the house genlock/sync or return VBS analog video

• 19: Return Video Mode Switch: switches to optimize the return video path (18) for

Genlock/Sync or analog return VBS video

42

Page 49

Intercom connectivity

The CopperHead Pro Base Station is delivered pre-configured for compatibility with either

"Two-Wire" or "Four-Wire" intercom systems, which can be identified by the XLR connector:

Intercom

Connector

Pin-outs See Camera Unit Connectors on page 63.

CopperHead Pro

User Guide

Two Wire Four Wire

RTS Clear-Com Universal/Matrix

(switchable: see below)

XLR3 Female XLR5 Male

• Four-Wire Interface: connects a Base Station to four-wire intercom systems (ex. matrixstyle systems).

• Two-Wire Interface - RTS or Clear-Com (switchable): connect the CopperHead Pro Base

Station to a two-wire intercom system like any other intercom component (such as a

belt pack or station). Internal dip switches (see Figure 4-9) are used to set the two-wire

intercom configuration.

The system is delivered from the factory configured as requested by the end-user or

dealer. An adhesive label on the rear of the unit identifies the factory setting (C-C, RTS1,

RTS2, 4W).

Two-Wire Intercom Configuration

SW1

Mode Intercom System A B

1 No Comms Off (0) Off (0)

2 RTS CH 1 Off (0) On (1)

3 RTS CH 2 On (1) Off (0)

4Clear-Com

5 Not Used On (1) On (1)

43

Page 50

Camera Unit and Power Supply Installation

Fiber Connections between the Base Station and Camera Unit

Fig. 4-9: Two-Wire Intercom Configuration Dip Switches

Fiber Connections between the Base Station and Camera Unit

The following table summarizes the various fiber cable connection options between the

CopperHead Pro Base Station and Camera Unit.

Distance Range Between

Cable Type Base Station Power Camera Unit Power

Tactical Fiber 12VDC Local Battery or AC

Power

SMPTE Hybrid

Fiber

120/220VAC with

Internal Camera

Power Supply

PowerWafer

Adaptor

Camera and Base

Up to 10 KM

240 meters

SMPTE Hybrid

Fiber

SMPTE Hybrid

Fiber

External MPS Power

Supply 95 Watts1

External HDX Power

Supply - 150 Watts2

PowerWafer

Adaptor

PowerPlus Adaptor 5 KM between base and

5 KM between base and

power supply

240 meters between power

supply and camera

power supply

3.2 KM between power

supply and camera

• The external MPS power supply must be equipped with the required fiber cable

connectors depending on your system requirements. See MPS External PowerWafer

Power Supply on page 28 for a description of the various options.

• The external HDX Power Supply provides two ST Fiber Connectors for connection

between the HDX and Base Station and a SMPTE 304M Connector for connection

between the HDX and Camera Unit.

The following fiber connection scenarios do not take into account any customized cable

and connector installations you may have at your facility. For assistance regarding more

complex connection situations, contact Grass Valley (see Contact Us on page 57) or your

local authorized dealer.

44

Page 51

Tactical Fiber between Base Station (powered) and Camera Unit

Fig. 4-10: SMPTE Hybrid Fiber between Base Station (powered) and Camera Unit

CopperHead Pro

User Guide

• Connect a length of tactical fiber cable A between Camera Unit B and Base Station C.

• At each end of the fiber cable will be either an OpticalCON or MX fiber connector

(F and G).

• Thecameramustbepoweredbylocalpower,suchasabatteryoralocalACpowersupply

H.

SMPTE Hybrid Fiber between Base Station (powered) and Camera Unit

Fig. 4-11: SMPTE Hybrid Fiber between Base Station (powered) and Camera Unit

Connect a length of SMPTE Hybrid fiber cable A between Camera Unit B and the fiber

receptacle C on the back of Base Station D.

At each end of the fiber cable will be either an OpticalCON or SMPTE 304M Hybrid fiber

connector E and F.

The camera will be powered by the CopperHead PowerWafer Camera Power Supply G.

45

Page 52

Camera Unit and Power Supply Installation

Hybrid Fiber between Base Station (powered) and Camera Unit

Hybrid Fiber between Base Station (powered) and Camera Unit

Fig. 4-12: Hybrid Fiber between Base Station and Camera Unit (Infrastructure Wiring)

A remotely-mounted fiber connector can be used for permanent installations such as

communications closets, truck connector panels and within/between buildings. A panel D

with two STs (fiber) and a Molex connector (power) is mounted on Base Station C.

Infrastructure fiber and copper wiring from Base Station connect to a remote panelmounted OpticalCON or SMPTE 304M receptacle E. A standard hybrid fiber optic cable A

connects the panel- mounted receptacle and Camera Unit B, equipped with a

PowerWafer G.

Hybrid Fiber Cable between MPS Power Unit and Camera Unit

46

Fig. 4-13: Hybrid Fiber cable between the MPS Power Supply and Camera Unit

Dry fiber can be used between Base Station and the MPS External Power Unit, and the

camera can be powered by the MPS over powered hybrid fiber.

Connect "dry" (unpowered) single mode fiber cable A between the fiber connector(s) B on

Base Station C and the "dry" fiber connector(s) D on the MPS Power Supply E. Connect the

Page 53

CopperHead Pro

User Guide

MPS Power Supply E to AC Mains F. Connect a length of hybrid fiber cable G between the

powered connector H on the MPS Power Supply E and the swiveled fiber connector I on

Camera Unit J. The hybrid fiber cable can be equipped with either OpticalCON or SMPTE

304M connectors K. The camera and Camera Unit will be powered via the hybrid cable by

the PowerWafer L.

The "dry" fiber connectors D on the MPS Power Supply E and the "dry" fiber connector(s) B

on Base Station C can equipped with one of two connector options:

• Two ST connectors (shown)

• OpticalCON connector

The powered fiber connectors H on the MPS Power Supply E and the fiber connector I on

Camera Unit J be equipped with one of two connector options:

• Two ST connectors (shown)

• OpticalCON connector

Other fiber optic connectors are available by special order. Contact Grass Valley (see

Contact Us on page 57) or your CopperHead dealer for more information.

47

Page 54

Camera Unit and Power Supply Installation

SMPTE Hybrid Fiber between HDX Power Supply and Camera Unit

SMPTE Hybrid Fiber between HDX Power Supply and Camera Unit

ST Fiber Connectors between Base Station and HDX Power Unit, camera powered by

Copperhead PowerPlus.

Fig. 4-14: SMPTE Hybrid Fiber between the HDX Power Supply and Camera Unit

Mount the PowerPlus J to the CopperHead Camera Unit K as shown in Mounting the

CopperHead Pro Camera Unit with the PowerPlus on page 38, being sure to plug the

PowerPlus' tactical fiber "dongle" X into the swivel-mounted fiber connector on Camera

Unit X.

Connect dry (unpowered) fiber cable A between the fiber connector(s) C on Base Station B

and the "dry" fiber connector(s) D on the HDX Power Supply E. Connect the HDX Power

Supply E to AC Mains F. Connect a length of hybrid fiber cable G between the HDX Power

Supply E and the swivel-mounted SMPTE 304M connector X on the PowerPlus J. The hybrid

fiber cable can be equipped with either OpticalCON or SMPTE 304M connectors I. The

camera and Camera Unit will be powered via the hybrid cable by the PowerPlus J.

Note: Connectors at each end of the fiber cable must be SMPTE 304M I.

OpticalCON connectors cannot be used in this configuration.

48

Page 55

Deployment of the CopperHead System

The CopperHead system features different battery mounting plates, powering options,

fiber cable connectors, and intercom system interfaces. This allows for many permutations

that are all slightly different. Hence, not every possible operational environment can be

described.

However, the following steps are recommended:

1 Set up and test your CopperHead Pro system immediately to confirm proper operation

and to provide training to you and your team prior to an actual production.

2 Do not attempt to power up the system until the fiber optic cable has been connected

at both ends.

3 Install Camera Unit and battery or power supply (see Mounting the CopperHead Pro

Camera Unit with a battery on page 36).

4 Connect all Camera Unit and Base Station cables as shown in Connecting the

CopperHead Pro System on page 40. The order in which you connect the cables makes

no difference. However, to prevent damage other sensitive electronics (such as

camcorders and Remote Control Panels):

• Make sure to connect the CHCR Camera Remote Control cable to the camera when

the camera is powered off.

• Make sure to connect the CHBR Base Remote Cable to the remote control panel

when Base Station power is turned off.

5 Deploy the fiber cable and connect it.

You should read the Using Fiber Optics Guide for information on how to manage and

deploy your fiber optics cabling, safety precautions, tips & tricks, and recommendations

for creating complex fiber optic networks. You can find a copy of this document on the

Support portal (see Contact Us on page 57).

CopperHead Pro

User Guide

Insuring a Positive Fiber Link

1 Connect the fiber cable connectors at each end.

2 Power up Camera Unit and Base Station or power supply and check the LED Link

indicators on each device.

3 Confirm that the LED Link indicators on Camera Unit and Base Station are both

illuminated Green. If so, all signals should now be passing between Camera Unit and

Base Station.

49

Page 56

Camera Unit and Power Supply Installation

Intercom Operation

Intercom Operation

Intercom controls and indicators are found on the control panel of the CopperHead Pro

Camera Unit:

Fig. 4-15: Camera Unit Intercom Controls

• 4: TALK: lights GREEN to indicate that the intercom TALK switch is in the "up" position,

and that the headset mic is open.

• 6: Headset Volume Control Knob: controls volume ("listen level") of the intercom

channel in the headset. Adjust it until the volume level is comfortable.

•7: Intercom Talk Switch

• TA LK (up) opens the headset mic

• OFF (down) closes the headset mic

To talk on the intercom line, toggle the TALK switch to the "up" position, which opens

the microphone, transmitting the voice to the intercom line. When the microphone is

open, the TALK indicator (x) will illuminate Green.

Note: Intercom beltpacks cannot be plugged into the CopperHead Pro

Camera Unit. Only an intercom headset can be plugged into Camera Unit.

The operation of your specific intercom system is beyond the scope of this User's Guide.

Please see the documentation provided with your intercom or consult your intercom

provider.

50

Page 57

Shutting Down the System

When shutting down the sytem, follow these guidelines:

• ,Take special care when handling the fiber cable and to the Camera Remote Control

Panel Cable.

• Power switches for the camera, Camera Unit, and Base Station may be turned off in any

order.

• To prevent looking directly into an active fiber optic port or cable, turn both Camera

Unit and Base Station off before disconnecting the fiber from either point.

• To prevent damaging the camera or camera remote control panel (RCP), turn both

Camera Unit and Base Station off before disconnecting the CHCR remote cable from

the camera or the CHBR remote cable from the RCP.

• Cap your fiber optic connectorsto keep them clean.

• Protect all cables from dirt, water entry, and from being dragged across the ground or

other surfaces.

• When re-spooling the cable, avoid cable snags and crimps, and take care not to

damage the connectors.

• When re-spooling the fiber cable on to the spool, guide it across the entire width of the

spool so that it winds evenly,reducing the possibility of cinching or kinks.

• If Base Station is a permanent or semi-permanent installation, power off and

disconnect and cap the fiber cable.

CopperHead Pro

User Guide

51

Page 58

Camera Unit and Power Supply Installation

Troubleshooting

Troubleshooting

Troubleshooting any technical issues with the CopperHead Prois similar to any piece of

television production gear with the obvious exception of the core Fiber Optic technology.

Keep the following tips in mind:

• Check the LINK indicators at each end of the system. They should be illuminated Green

if there is good fiber optic connectivity for the non-SDI signals (VBS/sync, camera

control, intercom, tally).

• Check the SDI indicator at the CopperHead Pro Base Station. It should be illuminated

Green if there is good fiber optic connectivity for the SDI signal.

• If the LINK or SDI indicators are not Green, there maybe low optical power between

Camera Unit and Base Station. Thefollowing are possible solutions:

• Ensure that all fiber optic connectors are clean. Clean fiber optic connectors are a

requirement for reliable connectivity between fiber optic components like your

CopperHead transceivers. Any contamination in the fiber connection, even

microscopic dust particles, can cause "link loss" and adversely affect the

operational functionality of your CopperHead equipment. For more information

on the care and maintenance of your fiber optic connectors, refer to

www.miranda.com.

• Examine the entire length of the fiber cable and see that it is in intact and has no

damage or severe bends or kinks.

• Confirm that all fiber optic connectors are connected securely.

• If optical power is good, but signals are not being received:

• Check all of your copper cables (coax) and connectors (BNC) for damage.

• Confirm signal type is on the proper signal path - It is possible to physically connect

analog signals to digital signal paths on the CopperHead Pro.

However, signals will not pass through the system unless they are the correct type.

An SDI signal will not pass through the Analog or VBS paths and an Analog signal

will not pass through an SDI path. If the wrong type of signal is incorrectly

connected, the signal LED indicator may illuminate, but no signal will pass through.

• Base Station power problems:

• 12VDC Base Station: Check that the DC power supply is functioning correctly and

connected securely.

• 110/220 VAC Base Station: Check the fuses. Do not try to multiplex the

CopperHead Pro with other fiber optic devices. The CopperHead Pro system is not

readily compatible with any active or passive CWDM technologies, including

TelePort and TeleThon systems.

52

Page 59

Specifications

Video, Digital (SDI)

Interface........................................................................................SMPTE 259M, 292M, 424M

Data Rate ...................................................................................... 270 Mb/s, 1.5 Gb/s, 3 Gb/s

Input Level. .................................................... 800 mV +/-10% (peak to peak, maximum)

Equalized cable lengths (Belden 1694A)................................................................................

270MB/s. .............................................................................................................................250m

1.5 Gb/s. .............................................................................................................................. 230m