Page 1

CopperHead PowerWafer User

Guide

M4002-9900-102

21 March 2014

Page 2

Notices

Copyright & Trademark Notice

Copyright © 2014, Miranda Technologies Partnership. All rights reserved.

Belden, Belden Sending All The Right Signals, and the Belden logo are trademarks or

registered trademarks of Belden Inc. or its affiliated companies in the United States and

other jurisdictions. Miranda, CopperHead PowerWafer are trademarks or registered

trademarks of Miranda Technologies Partnership. Belden Inc., Miranda Technologies

Partnership, and other parties may also have trademark rights in other terms used herein.

Terms and Conditions

Please read the following terms and conditions carefully. By using CopperHead PowerWafer

documentation, you agree to the following terms and conditions.

Miranda Technologies Partnership (“Miranda”) hereby grants permission and license to

owners of CopperHead PowerWafer to use their product manuals for their own internal

business use. Manuals for Miranda products may not be reproduced or transmitted in any

form or by any means, electronic or mechanical, including photocopying and recording, for

any purpose unless specifically authorized in writing by Miranda.

A Miranda manual may have been revised to reflect changes made to the product during its

manufacturing life. Thus, different versions of a manual may exist for any given product.

Care should be taken to ensure that one obtains the proper manual version for a specific

product serial number.

Information in this document is subject to change without notice and does not represent a

commitment on the part of Miranda.

Warranty information is available in the Support section of the Miranda Web site

(www.miranda.com).

Title CopperHead PowerWafer User Guide

Part Number M4002-9900-102

Revision 21 March 2014

ii

Page 3

Table of Contents

1 About CopperHead PowerWafer. . . . . . . . . . . . . . . . . . . . . . . . . 1

About CopperHead PowerWafer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

CopperHead System Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Unpacking the CopperHead PowerWafer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Product Returns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

About this User Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety and Fiber Optic Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Optical Fiber Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Power Fuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CopperHead System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Powered Systems using the PowerWafer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

PowerWafer, Direct to Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Power Wafer, Remote Panel-Mounted Fiber Connector . . . . . . . . . . . . . . . . . . . . . . . . 9

PowerWafer, with MPS Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CopperHead Transceiver System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Base Station Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Types of Base Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3 CopperHead System Components . . . . . . . . . . . . . . . . . . . . . . 15

Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Base Station Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Front Panel Section A - Signal Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Front Panel Section B- Power Switch and Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Front Panel Section C- Hybrid Power Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . 18

Base Station Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Rear Panel Section A - Power Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Rear Panel Section B - Optical Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Rear Panel Section C - Signal Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

PowerWafer Camera Adaptor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

MPS External PowerWafer Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

HDX Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

HDX Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

4 Camera Unit and Power Supply Installation . . . . . . . . . . . . . 27

Mounting the Copperhead Camera Unit with the PowerWafer . . . . . . . . . . . . . . . . . . . . .28

SMPTE Hybrid Fiber between Base Station (powered) and Camera Unit . . . . . . . .29

Hybrid Fiber between Base Station and Camera Unit (Infrastructure Wiring) . . . .30

Hybrid Fiber Cable between MPS Power Unit and Camera Unit. . . . . . . . . . . . . . . . .30

iii

Page 4

Table of Contents

Deployment of the CopperHead System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Insuring a Positive Fiber Link. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

5 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6 Contact Us . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Related documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Customer service and sales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Miranda’s corporate headquarters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

A Connectors and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

MPS Power Supply Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Parts and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

7 Intercom Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4-Wire Intercom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Clear-Com Intercom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

iv

Page 5

About CopperHead PowerWafer

This chapter provides an overview of the CopperHead PowerWafer and includes the safety

and warranty information about it.

About CopperHead PowerWafer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Unpacking the CopperHead PowerWafer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety and Fiber Optic Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1

Page 6

About CopperHead PowerWafer

About CopperHead PowerWafer

About CopperHead PowerWafer

The CopperHead System is a fiber optic transmission system that enables camcorders to be

used in live, multi-camera production environments.

The system uses a fiber optic cable to transport a variety of signals between a Camera Unit

and a Base Station.

The CopperHead Camera Unit is typically mounted to a camera that is placed in a studio,

theatre, sports venue, or other live-event location. The system's Base Station is usually

located in a truck, control room or other video production control area.

When "dry" fiber is used (typically lightweight "tactical" fiber cable), the signals are

transmitted bi-directionally, over distances as long as 5 km or more.

When hybrid fiber cable is used, the link powers the Camera Unit and the camera itself.

CopperHead System Features

• The system makes any camcorder practical for multi-camera production.

• All camera signals are carried on one lightweight fiber cable.

• Can be run through building or campus infrastructure on two strands of Single Mode

fiber.*

• Thin, lightweight, modular design.

• Studio quality uncompressed HD/SDI video up to 3 Gb/s.

• Multi-kilometer distance capability

• Anton/Bauer® Gold Mount and "V-Mount" battery options

• Wide temp range, low power consumption

• Durable, high reliability design

• Two fiber cable options

• Tactical Fiber: Military Spec, battery/local power, 10+km

•SMPTE Hybrid Fiber

• Low voltage camera-mounted "PowerWafer": 95 watts to 300m (984 ft.)

• High-voltage camera-mounted "PowerPlus": up to 150 watts to 2 km (1.2 miles)

Fig. 1-1: CopperHead Signal Paths

2

Page 7

Note: The CopperHead System is not readily compatible with active

or passive CWDM multiplexing technologies, including Teleport or

TeleThon systems.

Unpacking the CopperHead PowerWafer

Please consult your packing slip and purchase order to insure that you have received all of

the expected components.

Inspect all components for scratches and other mechanical damage, and inspect the

electrical connectors for bent or damaged pins and latches. Report any missing or

damaged components to Miranda (see Contact Us on page 35). See Product Returns on

page 3.

Leave the protective caps on the optical connectors whenever the fiber is disconnected.

Product Returns

In the unlikely event of damage to your CopperHead PowerWafer during shipping or

delivery please note the damage with the delivery or shipping service and document the

packaging and product where you see damage. If any component does not work correctly

out of the box please contact Miranda (see Contact Us on page 35).

CopperHead PowerWafer

User Guide

If the problem cannot be remedied through a service telephone call an RMA (Return of

Merchandise Authorization) will be issued and you will receive an RMA number. Please

note this RMA number inside and outside of all shipping boxes and on all documentation

provided with the items to be returned.

About this User Guide

This CopperHead Fiber Optic Transceiver System can be delivered in a number of

configurations depending on the Power and Battery Mount options selected. This user

guide is designed to cover all of the various options and so not every page in this guide will

apply to your specific system.

Throughout this guide a number of informational pointers are used to mark important or

useful information.

3

Page 8

About CopperHead PowerWafer

Safety and Fiber Optic Systems

Safety and Fiber Optic Systems

Optical Fiber Safety

Never look directly into the end of the optic fiber while either end of the system is

operating.

Always use cable connector caps when the cables are not connected. This protects the

connector from damage and the unlikely event of exposure to an operating optical link.

Keeping the caps in place when the connectors are not in use will prevent dirt and dust

from entering the connector and degrading the performance of the optical link.

Power Fuses

The CopperHead PowerWafer Base Stations CHG3-BS-3050-95VD-xxx-xxx are equipped

with two fuses located next to the AC Power receptacle at the left rear of the unit. Refer to

Connectors and Accessories on page 37 for specific fuse and location information.

NEVERoperatetheCopperHeadCHG3‐BS‐3050‐95VD‐xxx‐xxxBaseStationwithout

properlyinstalledandratedfuses.Severeelectricalandheatdamagecouldresultaswell

aspersonalinjuryordeath.

4

Page 9

System Overview

This chapter provides a system overview about the Fiber Cables and the Transceiver

System.

CopperHead System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CopperHead Transceiver System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5

Page 10

System Overview

CopperHead System Configurations

CopperHead System Configurations

The CopperHead system is available in a variety of configurations that maximize the

advantages of either "dry" fiber cable, "hybrid" fiber cable, or a combination of the two.

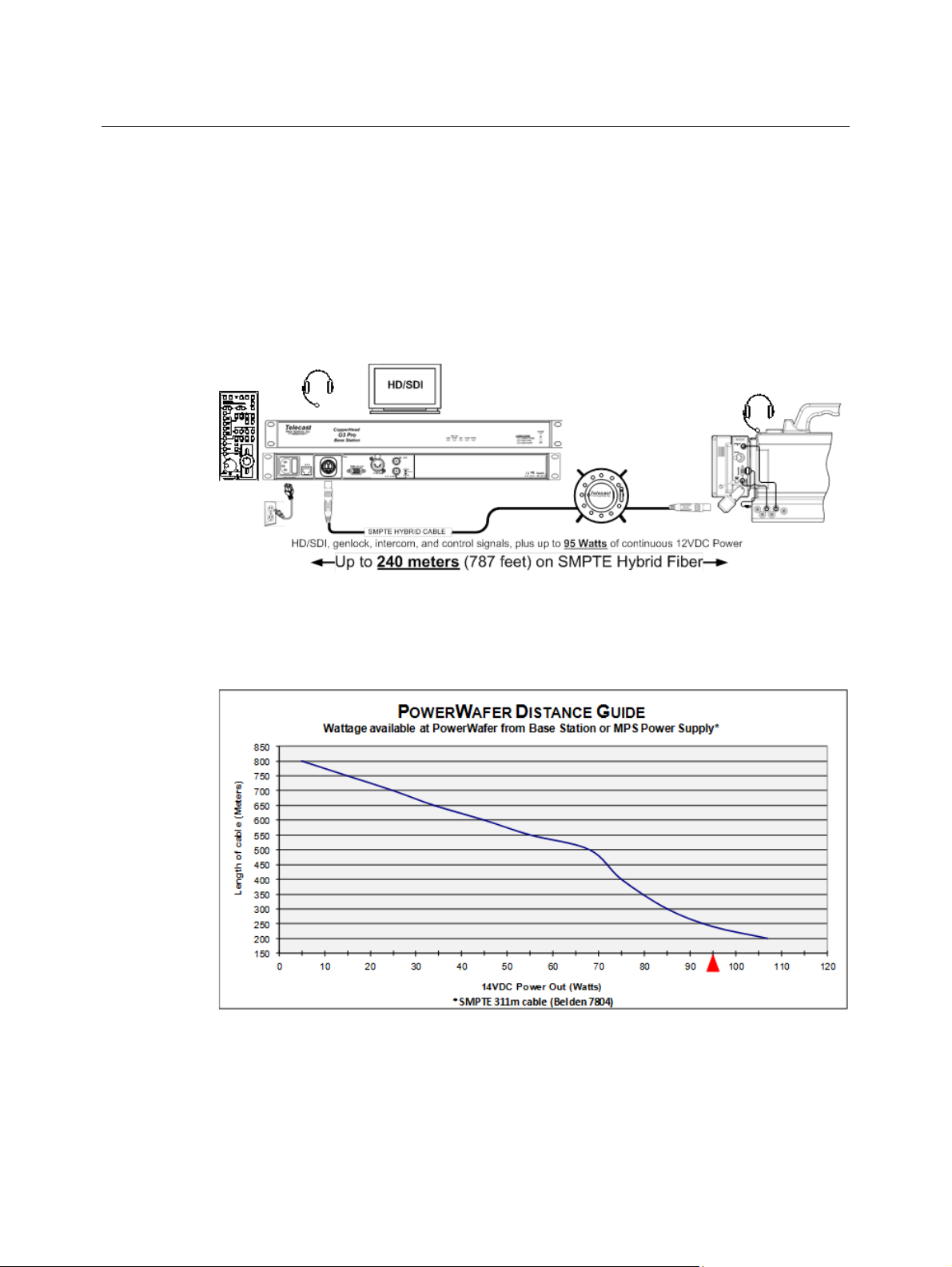

Powered Systems using the PowerWafer

CopperHead Base Stations can be equipped with an internal power supply that, when used

with SMPTE hybrid fiber cable and a PowerWafer at the Camera Unit, will deliver

approximately 95 Watts of power to the camera and related accessories.

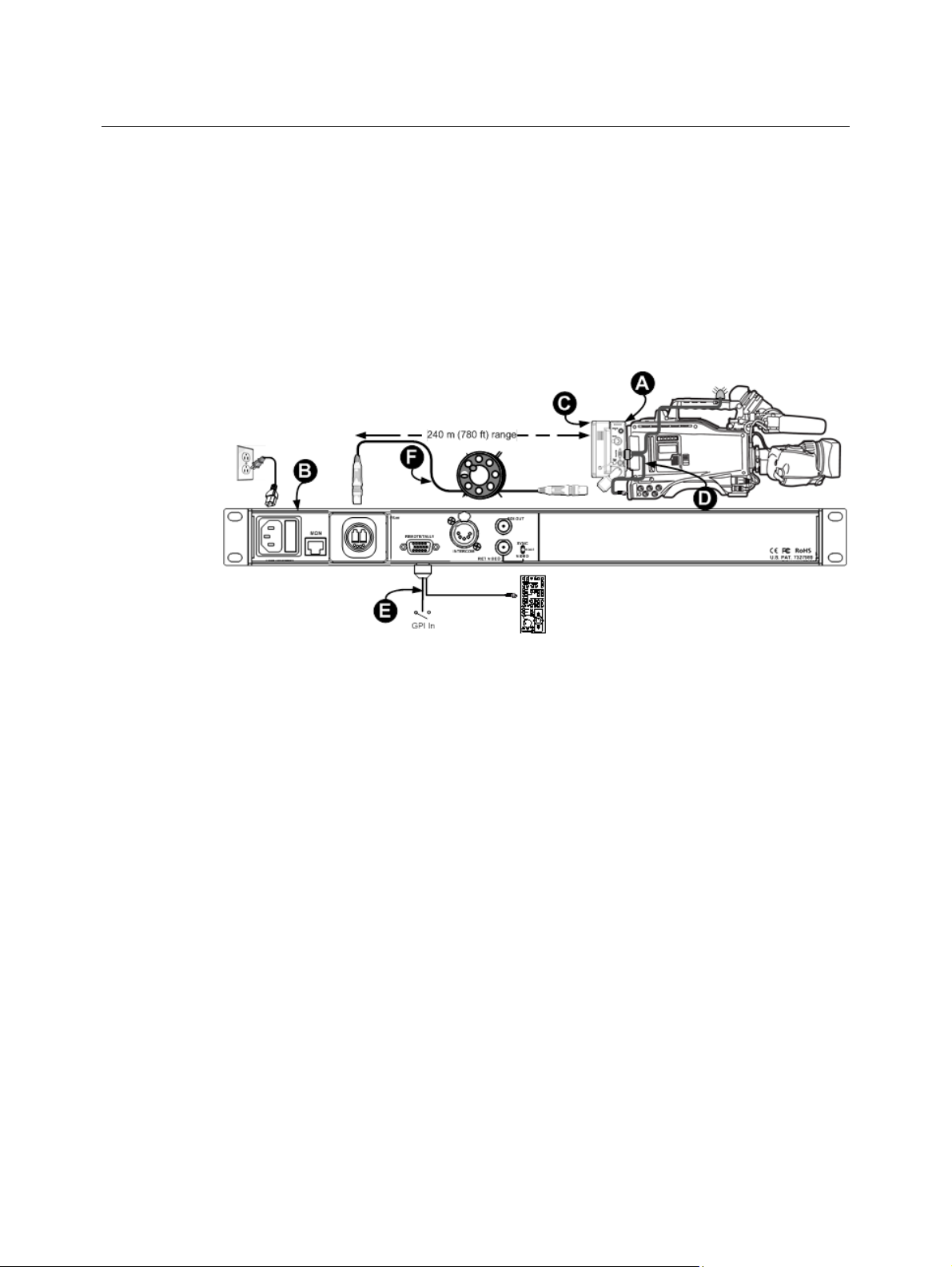

Fig. 2-1: Powered System Overview

The maximum range of the system is nominally 240 meters (787 feet)* when drawing 95

watts at the camera, but distances will vary depending on total power draw at the

PowerWafer, as shown in Figure 2-2.

Fig. 2-2: PowerWafer Distance Chart

* The maximum operational cable length varies due to optical loss that can depend on

cable quality, dirt/dust/contamination on connectors, and the number of cable connectors.

When using hybrid cables for camera power, the size of the hybrid cable, as well as the

power draw of the camera, lens, viewfinder, and other accessories are also factors.

6

Page 11

CopperHead PowerWafer

Female

Male

User Guide

In powered fiber configurations, the Camera Unit, Base Station and hybrid fiber cable can

be equipped with one of two types of fiber connectors:

Panel Connectors Cable Plugs

OpticalCON SMPTE 304M OpticalCON SMPTE 304M

7

Page 12

System Overview

Powered Systems using the PowerWafer

PowerWafer, Direct to Base Station

When connected directly to an AC-powered Base Station using SMPTE hybrid fiber cable,

the system delivers up to 95 watts of power to the camera and accessories. Such a system is

typically configured as shown in Figure 2-3, and includes the following components:

• A: Camera Unit

• B: AC-powered Base Station with

internal camera power supply

• C: PowerWafer

Fig. 2-3: Direct Connect to Base Station with Power Wafer

• D: CHCR camera remote cable

• E: CHBR base remote cable

• F: Hybrid fiber optic cable

8

Page 13

CopperHead PowerWafer

User Guide

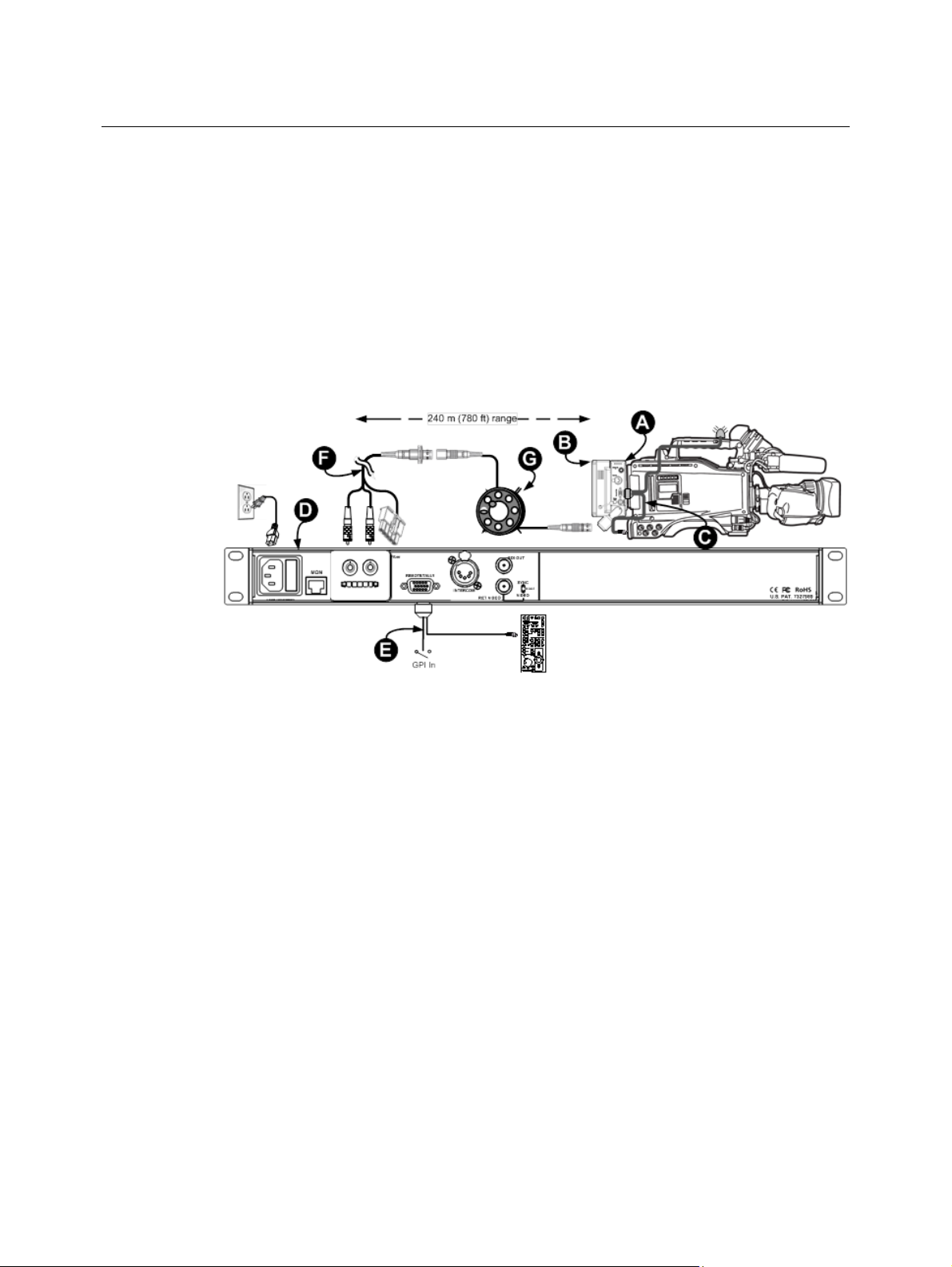

Power Wafer, Remote Panel-Mounted Fiber Connector

The hybrid fiber receptacle may be mounted a distance from the Base Station if the station

is equipped with a pair of inexpensive ST fiber connectors and a Molex receptacle to carry

power, as shown in Figure 2-4. A breakout cable can be used to connect the hybrid fiber

receptacle to Base Station, or infrastructure wiring can be used.

• A: Camera Unit

• B: Power Wafer

• C: CHCR camera remote cable

• D:

AC-powered Base Station with internal

camera power supply

Fig. 2-4: Powered Base Station with Fiber Receptacle Extension

• E: CHBR base remote cable

• F:

ST & Molex breakout cable or

campus/building infrastructure

• G: Hybrid fiber optic cable

9

Page 14

System Overview

Powered Systems using the PowerWafer

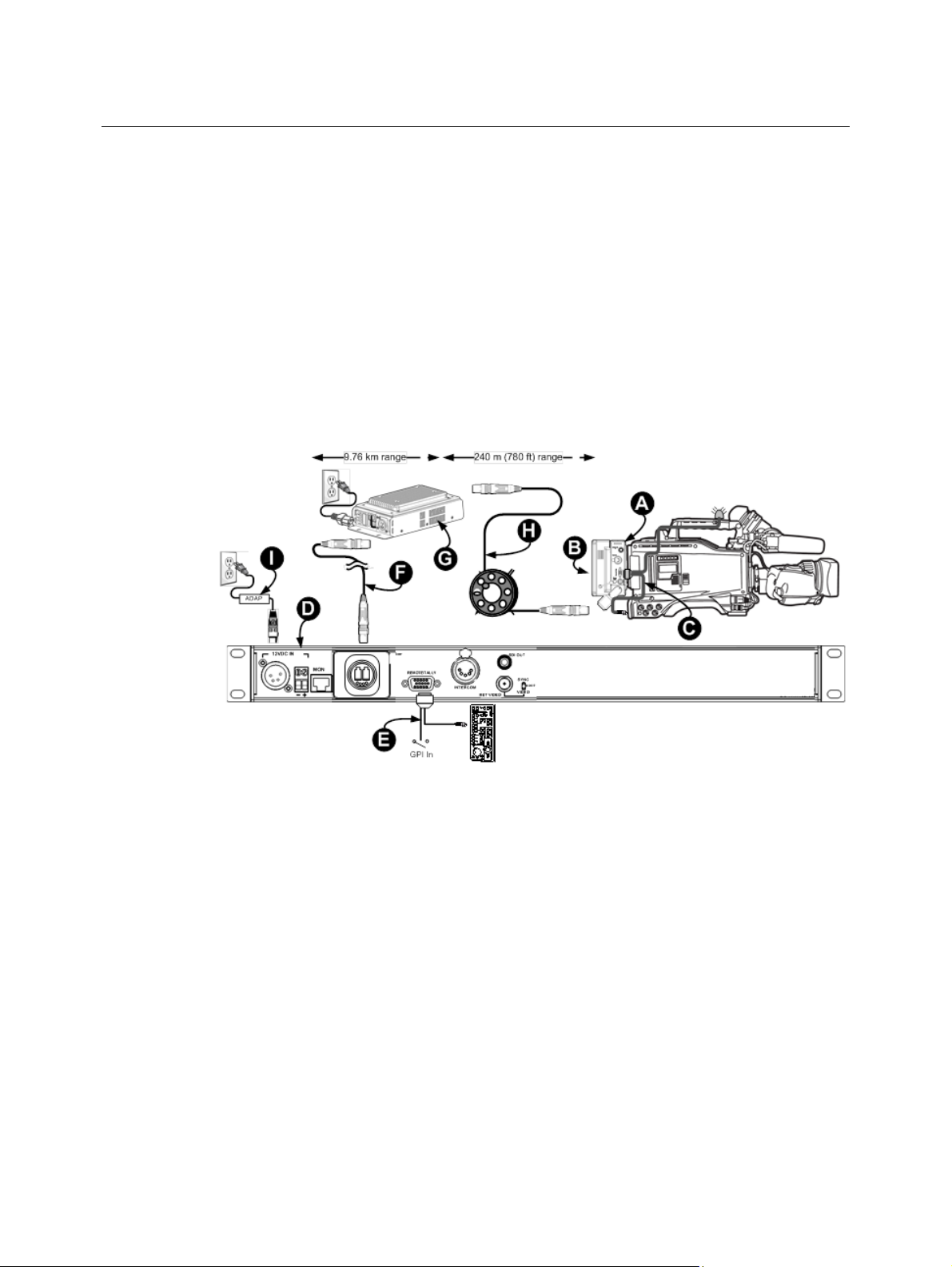

PowerWafer, with MPS Power Supply

Systems can be configured so that the majority of the fiber run is made via "dry" tactical or

infrastructure fiber, after which a "throwdown" MPS Power Supply is placed in line to

provide powered SMPTE hybrid fiber cable to the camera. In this configuration, as shown in

Figure 2-5, the Base Station can be separated from the MPS power supply by more than

nine kilometers (5.6 miles), where powered cable can be run to the camera for 240 meters

(780 feet), providing up to 95 watts of power to the camera and accessories.

• A: Camera Unit

• B: Power Wafer

• C: CHCR camera remote cable

• D:

DC-powered Base Station

• E: CHBR base remote cable

• F:

Tactical fiber or Infrastructure fiber run

• G: MPS Power Supply

• H: Hybrid fiber optic cable

• I: ADAP 12VDC power supply

10

Fig. 2-5: System using MPS Power Supply

Page 15

CopperHead Transceiver System Components

Camera Unit Front

(attaches to the camera)

Camera Unit Rear (attaches to

battery or power supply)

The CopperHead Camera Unit fits between the battery or optional power supply and the

camera. The Camera Unit is configured at time of purchase with mounting plates to

accommodate the appropriate camera battery type.

The camera battery or optional power source attaches to Camera Unit, which in turn,

attaches to the video camera. Batteries accommodated are Anton/Bauer Gold Mount and

Sony "V" Mount. Other camera mounting plates may be available by special order. Please

contact Miranda (see Contact Us on page 35) or your authorized dealer.

The Camera Unit is equipped with a swivel-mounted fiber optic connector, which can be

ordered with an OpticalCON, MX or SMPTE 304M connector. For more information, see

Parts and Accessories on page 38.

CopperHead PowerWafer

User Guide

Fig. 2-6: Camera Unit Front and Rear

The actual appearance of your CopperHead Camera Unit will vary depending on the

battery mount and fiber cable connector options specified at the time of purchase.

11

Page 16

System Overview

Base Station Overview

Base Station Overview

The CopperHead Base Station is a one rack-unit high device that provides all of the inputs

for signals going to the CopperHead Camera Unit, as well as the outputs for the signals

coming from Camera Unit. Base Station is available in a variety of configurations. The

options are:

Power Supply Single or Double Fiber Connector

12 Volt DC Input: “Dry Fiber”

No Internal camera power supply

Does not supply power to Camera

Unit via SMPTE hybrid fiber cable

Is typically used with Tactical fiber

cable and/or infrastructure cabling

Available in “Dual” configuration for

interface and control of two Camera

Units in a single one RU device.

120/220 Volt AC Input – “Powered

Fiber”

Includes internal power supply for

Camera Unit.

Supplies power to Camera Unit via

SMPTE hybrid fiber cable

Not available in “Dual” configuration.

Can only interface and control a

single Camera Unit.

Single Configuration

Interface and control a single

Camera Unit.

Available in 12 Volt DC and

120/220 VAC models

Dual Configuration

Interface and control two

Camera Units in a one RU

device.

Available in 12 Volt DC only.

Not available for 120/220 VAC

models

Six different fiber connectors are

available for the CopperHead Base

Station. See Rear Panel Section B -

Optical Connector on page 20 for

details

OpticalCON (dry)

Two STs

MX (Expanded

Beam)

OpticalCON

(powered)

12

SMPTE 304M

Two STs and

Molex

Page 17

Types of Base Stations

The actual appearance of your CopperHead Base Station will vary depending on the fiber

cable connectors and power option specified at the time of purchase.

Single “Dry” Station

Fig. 2-7: Single "Dry" Base Station - Front Panel (top) and Rear Panel (bottom)

Dual Unpowered Base Station

CopperHead PowerWafer

User Guide

Fig. 2-8: Dual Unpowered Base Station - Front Panel (top) and Rear Panel (bottom)

Powered Base Station

Fig. 2-9: Powered Base Station - Front Panel (top) and Rear Panel (bottom)

13

Page 18

System Overview

Types of Base Stations

14

Page 19

CopperHead System Components

This chapter describes the main system components in the CopperHead PowerWafer

system.

Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

PowerWafer Camera Adaptor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

MPS External PowerWafer Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

HDX Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

15

Page 20

CopperHead System Components

Base Station

Base Station

The CopperHead Base Station is available with a number of options. The unit is ordered

with a specified Power Module, Audio/Intercom Module and Fiber Connector. For an overall

view of component location please see the overall diagrams in Error! Reference source not

found..

Base Station Front Panel

Fig. 3-1: Base Station Front Panel - single unit, 120/220 VAC power w/internal hybrid power supply

Fig. 3-2: Base Station Front Panel - dual unit, 12 VDC power

The front of Base Station has three areas of interest:

• A: Signal Status Indicators (see Front Panel Section A - Signal Status Indicators on

page 16)

If Dual Base Station, A1 and A2. Otherwise, A2 only.

• B: Power Switch and Indicator (see Front Panel Section B- Power Switch and Indicator

on page 17)

• C: Hybrid Power Status Indicators (see Front Panel Section C- Hybrid Power Status

Indicators on page 18)

Note: These indicators only appears on Base Stations equipped with

internal hybrid power supply.

Front Panel Section A - Signal Status Indicators

Fig. 3-3: Base Station Status Indicators

16

•1: Link

Indicates the status of the data link from Camera Unit to Base Station. This is a good

indicator of adequate optical link.

• GREEN when Base Station has a data "lock" with Camera Unit.

Page 21

CopperHead PowerWafer

• RED when Base Station is not "locked" to Camera Unit.

• 2: Return Video/Sync

Indicates the presence of the analog video signal (VBS) at Base Station's "VBS In" BNC.

This VBS can be used for return "program" video or for genlock to the camera.

• 3: SDI Presence

Illuminates GREEN to indicate the presence of digital SDI video from Camera Unit. This

will stay illuminated GREEN as long as there is adequate optical power being received

at Base Station. See Error! Reference source not found. for more information.

•4: Intercom

Illuminates GREEN to indicate audio activity on the Intercom channel.

•5: Control

Illuminates GREEN when camera control data is being transmitted between Camera

Unit and Base Station.

Front Panel Section B- Power Switch and Indicator

User Guide

Fig. 3-4: Base Station Power Switch

•6: Power

Indicates that power is applied to Base Station.

• GREEN when Base Station is fully powered.

• RED when there is power connected to Base Station, but Base Station is not turned

on.

• 7: Power Switch

Used to turn Base Station on and off. With a hybrid power system (power supplied by

Base Station) this switch will control power to the camera and Camera Unit.

17

Page 22

CopperHead System Components

Base Station Front Panel

Front Panel Section C- Hybrid Power Status Indicators

This section is optional, and only appears on CopperHead Base Stations equipped with

internal power supplies designed to work with a CopperHead Camera Unit connected to a

PowerWafer.

•8: Camera Power

Illuminates GREEN when high voltage is being supplied to Camera Unit.

• 9: Cable Open

Illuminates RED to indicate that the SMPTE hybrid cable is open or there is no SMPTE

hybrid cable connected.

High voltage will not be applied to the hybrid connector until the open condition is

corrected.

•10: Cable Short

Illuminates RED to indicate that the SMPTE hybrid cable has a short circuit in it.

High voltage will not be applied to the hybrid connector until the "short" condition is

corrected or the cable is replaced.

Fig. 3-5: Base Station Hybrid Power Status Indicators

18

Page 23

Base Station Rear Panel

• A: Power Connector (see Rear Panel Section A - Power Connector on page 19)

• B: Optical Connectors (seeRear Panel Section B - Optical Connector on page 20 )

• C: Signal Connectors (see Rear Panel Section C - Signal Connectors on page 20)

Rear Panel Section A - Power Connector

The CopperHead Base Station can be configured for DC or AC power.

12VDC Power Interface

This power interface is used on CopperHead Base Stations that are not equipped with

internal power supplies. This type of Base Station is typically used with Camera Units

powered locally with a battery or a local power supply at the camera.

CopperHead PowerWafer

User Guide

Fig. 3-6: CopperHead Base Station Back Panel (Dual model shown)

Fig. 3-7: 12VDC Power Connector

• 11: 12V DC Power input connector (XLR 4 Pin).

• 12: 12V DC Input - terminal block

This can be used in lieu of the 4-pin XLR or in parallel as a redundant input. See Error!

Reference source not found.for pin-out details

• 13: For Future Use (RJ45)

AC Power Connector Interface

This power interface is used on CopperHead Base Stations that are equipped with an

internal power supply. This type of Base Station is typically used with Camera Units

powered with a PowerWafer via SMPTE Hybrid cable

19

Page 24

CopperHead System Components

Base Station Rear Panel

• 20: AC Power Receptacle 100-240V 50/60 Hz

• 21: 3.15 amp dual fuse assembly

Two 4 amp fuses (5 x 20mm).fuses are in operation at all times – both the AC Line Hot

and the AC Line Neutral are fused.

• 13: For Future Use (RJ45)

Rear Panel Section B - Optical Connector

Fig. 3-8: AC Mains Connector

The fiber optic connector is used to connect Base Station directly to Camera Unit or to the

external MPS or HDX power supply configured with your system. The type of fiber

connector will vary depending on your system configuration. Six types of fiber optic

connectors are available for use with the CopperHead Base Station.

"Dry" (unpowered) fiber connectors Fiber Connectors with Copper for Power

A: OpticalCON

(dry)

B: STs C: MX D: OpticalCON

(powered)

E. SMPTE 304M F. STs & Molex

Rear Panel Section C - Signal Connectors

20

Fig. 3-9: Rear Panel Signal Connectors

• 5: Connector for Camera Remote Control Panel and Tally input (DB15HD)

Connect CHBR-PRO cable here, specified for your particular Camera Remote Control

Panel.

Page 25

CopperHead PowerWafer

User Guide

See Error! Reference source not found.to specify the correct cable for your Camera

Remote Control Panel

• 6: Base Station Intercom Connector

Connect your house intercom system here:

• XLR3: Two-wire (Clear-Com or RTS)

• XLR5M: Four-wire (matrix-style)

Two 4 amp fuses (5 x 20mm).fuses are in operation at all times – both the AC Line Hot

and the AC Line Neutral are fused.

For more information, see Intercom Pinouts on page 41.

• 7: SD/SDI or HD/SDI Output

Digital video from camera's SDI output

•8: VBS Return Input

Analog composite video signal sent to Camera Unit.

•9: VBS Return Input Switch

Switches the VBS Return Input connector to be optimized for one of two uses:

• A: Sync In: Genlock/Sync/Tri-Level sync signal.

• B: Composite Video In: Typically used to send analog VBS return video to the

camera or an external monitor.

21

Page 26

CopperHead System Components

PowerWafer Camera Adaptor

PowerWafer Camera Adaptor

The CopperHead Camera Unit can be powered by the optional "PowerWafer" Camera

Adaptor. The PowerWafer replaces the local camera battery and any local AC power supply

adaptor. The PowerWafer gets its power from the use hybrid fiber cable and the

CopperHead Base Station equipped with the internal power supply or from the MPS

external power supply.

Up to 95 watts of power can be delivered to the camera, Camera Unit and camera powered

accessories. Up to 780 feet (240 meters) of cable can be used when Camera Unit is powered

directly from Base Station.

The use of an external power supply can extend Base Station to Camera range and increase

camera power flexibility. The MPS "Throw Down" device or Wafer Power Adaptor provides

this functionality. This unit is described in MPS External PowerWafer Power Supply on

page 23.

The PowerWafer replaces the battery or local battery mountable AC adaptor (shown with

the Anton/Bauer "Gold Mount" option).

•1: Heat Sink

• 2: Battery Mounting Plate (Anton/Bauer Gold Mont or "V-Mount")

• 3: Power Input Connector

High voltage power is carried from Base Station to Camera Unit. A short jumper cable

(CH3CP-INF-2FAG) carries the high voltage power from Camera Unit to the PowerWafer's

power input connector, where it is converted to 12VDC power. The 12VDC power is

delivered back to the camera via the battery mounting plate.

Fig. 3-10: PowerWafer Power Adaptor and Jumper Cable

22

Page 27

MPS External PowerWafer Power Supply

The CopperHead MPS external power supply provides 95 watts of 12VDC power and fiber

connectivity from Base Station to Camera Unit equipped with a CopperHead PowerWafer.

Connectivity between the MPS unit to the camera can be configured using either a Hybrid

OpticalCON connector or a SMPTE 304M connector. The nominal distance between them is

240 meters (780 feet).

Connectivity between the MPS unit and Base Station uses "dry" fiber and can be configured

with a "dry" OpticalCON connector or two ST connectors. The MPS is powered locally with

standard AC power. The unit is free standing (see MPS External PowerWafer Power Supply

on page 23).

CopperHead PowerWafer

User Guide

Fig. 3-11: MPS Power Supply, Front and Rear

• 1: AC Power Receptacle: 100-240V 50/60 Hz

•2: Fuse compartment

Two 4 amp fuses (5 x 20mm).fuses are in operation at all times – both the AC Line Hot

and the AC Line Neutral are fused.

For more information, see Intercom Pinouts on page 41.

• 3: Power Switch

• 4: For Future Use (RJ45)

• 5: "Dry" Fiber Optic Connection to CopperHead Base Station

This removable plate can be equipped with two ST connectors or a "dry" OpticalCON

connector. See Figure 3-12.

•6: Heat Sink

• 7: Powered Fiber Optic Connection to CopperHead Camera Unit

This removable plate can be equipped with a SMPTE 304M connector or a powered

OpticalCON connector. See Figure 3-13.

23

Page 28

CopperHead System Components

MPS External PowerWafer Power Supply

The "dry" connection y to the CopperHead Base Station can be equipped with two ST

connectors or a "dry" OpticalCON connector.

The powered connection V to the CopperHead Camera Unit can be equipped with a SMPTE

304M connector or a powered OpticalCON connector.

Fig. 3-12: MPS "dry" fiber connector options

Fig. 3-13: MPS powered fiber connector options

Dry Unpowered Fiber

Part Number

CH2-MPS-95VD-2ST-NEU 2 STs OpticalCON

CH2-MPS-95VD-2ST-304 2 STs SMPTE 304M

CH2-MPS-95VD-NEU-NEU OpticalCON OpticalCON

CH2-MPS-95VD-NEU-304 OpticalCON SMPTE 304

Connection to Base Station (y)

Powered Fiber Connection

to Camera (V)

24

Page 29

HDX Power Supply

The HDX Power Supply Unit is required when using the PowerPlus Camera Adaptor. The

HDX can be used as a free-standing unit or rack mounted, using the HDX-FR-2 for mounting

two HDX units. See PowerPlus 300 User Guide for details on connecting the HDX to a

CopperHead system.

The unit sends power via a SMPTE hybrid fiber cable to the PowerPlus, where it is converted

to 12VDC and optionally to 24VDC).

CopperHead PowerWafer

User Guide

Fig. 3-14: HDX device setups

The HDX has five features:

• A: AC Power Input Module and Switch

Power Switch and connector for AC Mains.

• B: "Wet" SMPTE 304M Hybrid Fiber Connector

The SMPTE hybrid cable is connected here. This cable connects to the PowerPlus at the

camera. This mating connector pair always uses SMPTE 304M connectors.

• C: "Dry" Fiber connector(s).

The CopperHead Base Station is connected here. This interface can be equipped with a

variety of fiber connectors:

• Two ST connectors

• MX connector

• OpticalCON connector

•D: Status Indicators

These indicators show the status of the HDX's power system (see HDX Status Indicators

on page 26).

• E: HDX Integrated Handle

Stand-alone unit can be carried or hung from this robust handle

25

Page 30

CopperHead System Components

HDX Status Indicators

HDX Status Indicators

• 1: AC IN - MAINS

AC Input power is present

• 2: DC HV ENABLE

DC "Sense" voltage from PowerPlus is present

•3: AC HV ENABLE

AC "Sense" voltage from PowerPlus is present

• 4: HV Present

AC or DC voltage is available on Hybrid connector

• 5: CABLE OPEN

No camera cable connected

•6: CABLE SHORT

Camera cable non-functional due to short

• 7: REMOTE PWR ENABLE

• Displays red if local/remote sw in remote position and opt power <= -27 dBm

• Displays green if local/remote sw in remote position and opt power >= -24 dBm

gates HV power

• 8: LOAD TYPE

Indicates the type of load or camera being used:

• N/A - No load detected

• PWR+ - PowerPlus detected

•9: Optical Power

Not used with PowerPlus.

• 10: Local Remote

Not Used With PowerPlus.

Fig. 3-15: HDX Displays

26

Page 31

Camera Unit and Power Supply Installation

This chapter explains how to mount the Camera Unit and deploy CopperHead PowerWafer

system.

Mounting the Copperhead Camera Unit with the PowerWafer . . . . . . . . . . . . . . . . . . . . . . . . 28

Deployment of the CopperHead System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Insuring a Positive Fiber Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

27

Page 32

Camera Unit and Power Supply Installation

Mounting the Copperhead Camera Unit with the PowerWafer

Mounting the Copperhead Camera Unit with the PowerWafer

When mounting the CopperHead Camera Unit, always position the camera so that the

battery mounting plate at the rear of the camera is easy to access. Insure that the camera is

well supported and stable. If a battery is mounted remove it and put it to one side. The

camera model shown here is for illustrative purposes only - your camera may differ.

The PowerWafer allows the camera and Camera Unit to be powered via hybrid fiber cable,

which is powered from the CopperHead Base Station or MPS External Power Supply.

Fig. 4-1: The PowerWafer Unit and the Cable

To attach the PowerWafer Cable

1 Attach the CopperHead Camera Unit A to the camera battery mounting plate B. The

mounting is mechanically identical to attaching a battery.

For instructions for attaching the required cables between the camera and the Camera

Unit, refer to any of the CopperHead User Guides.

2Mount the PowerWafer C to the CopperHead Camera Unit battery mounting plate D

exactly as you would mount the battery to the camera.

3 Connect the supplied PowerWafer connector cable E. (model CH3CP-INF-FAG2)

between the PowerWafer C and the PowerWafer connector on Camera Unit A.

4 For best results, plug the straight connector F into the PowerWafer and the connector

with the Right Angle G into the Copperhead Camera Unit.

The following table summarizes the various fiber cable connection options between the

Copperhead Base Station and Camera Unit.

Distance Range Between

Cable Type Base Station Power Camera Unit Power

Tactical Fiber 12VDC Local Battery or AC

Power

SMPTE Hybrid

Fiber

120/220VAC with

Internal Camera

Power Supply

PowerWafer

Adaptor

Camera and Base

Up to 10 KM

240 meters

28

Page 33

CopperHead PowerWafer

Distance Range Between

Cable Type Base Station Power Camera Unit Power

SMPTE Hybrid

Fiber

SMPTE Hybrid

Fiber

External MPS Power

Supply 95 Watts1

External HDX Power

Supply - 150 Watts2

PowerWafer

Adaptor

PowerPlus Adaptor 5 KM between base and

Camera and Base

5 KM between base and

power supply

240 meters between

power supply and

camera

power supply

3.2 KM between power

supply and camera

Note: The external MPS power supply must be equipped with the

required fiber cable connectors depending on your system

requirements. See MPS External PowerWafer Power Supply on

page 23 for a description of the various options

User Guide

SMPTE Hybrid Fiber between Base Station (powered) and Camera Unit

Fig. 4-2: SMPTE Hybrid Fiber between Base Station (powered) and Camera Unit

Connect a length of SMPTE Hybrid fiber cable A between Camera Unit B and the fiber

receptacle C on the back of Base Station D.

At each end of the fiber cable will be either an OpticalCON or SMPTE 304M Hybrid fiber

connector E and F.

The camera will be powered by the CopperHead PowerWafer Camera Power Supply G.

29

Page 34

Camera Unit and Power Supply Installation

Hybrid Fiber between Base Station and Camera Unit (Infrastructure Wiring)

Hybrid Fiber between Base Station and Camera Unit (Infrastructure Wiring)

Fig. 4-3: Hybrid Fiber between Base Station and Camera Unit (Infrastructure Wiring)

A remotely-mounted fiber connector can be used for permanent installations such as

communications closets, truck connector panels and within/between buildings. A panel

(D) with two STs (fiber) and a Molex connector (power) is mounted on Base Station (C).

Infrastructure fiber and copper wiring from Base Station connects to a remote panelmounted OpticalCON or SMPTE 304M receptacle (E). The standard hybrid fiber optic cable

(A) connects the panel- mounted receptacle and Camera Unit (B), equipped with a

PowerWafer (G).

Hybrid Fiber Cable between MPS Power Unit and Camera Unit

30

Fig. 4-4: Hybrid Fiber cable between the MPS Power Supply and Camera Unit

Dry fiber can be used between Base Station and the MPS External Power Unit, and the

camera can be powered by the MPS over powered hybrid fiber.

Connect "dry" (unpowered) single mode fiber cable (A) between the fiber connector(s) (B)

on Base Station (C) and the "dry" fiber connector(s) (D) on the MPS Power Supply (E).

Page 35

CopperHead PowerWafer

User Guide

Connect the MPS Power Supply (E) to AC Mains (F). Connect a length of hybrid fiber cable

(G) between the powered connector (H) on the MPS Power Supply (E) and the swiveled

fiber connector (I) on Camera Unit (J). The hybrid fiber cable can be equipped with either

OpticalCON or SMPTE 304M connectors (K). The camera and Camera Unit will be powered

via the hybrid cable by the PowerWafer (L).

The "dry" fiber connectors (D) on the MPS Power Supply (E) and the "dry" fiber connector(s)

(B) on Base Station (C) can equipped with one of two connector options:

• Two ST connectors (shown)

• OpticalCON connector

The powered fiber connectors (H) on the MPS Power Supply (E) and the fiber connector I on

Camera Unit (J) be equipped with one of two connector options:

• Two ST connectors (shown)

• OpticalCON connector

Other fiber optic connectors are available by special order. Contact Miranda (see Contact

Us on page 35) or your CopperHead dealer for more information.

31

Page 36

Camera Unit and Power Supply Installation

Deployment of the CopperHead System

Deployment of the CopperHead System

The CopperHead system is available with many different variations, including different

battery mounting plates, powering options, fiber cable connectors and intercom system

interfaces. This allows for many permutations that are all slightly different. Hence, not

every possible operational environment can be described.

However, the following steps are recommended:

1 Set up and test your Copperhead system immediately to confirm proper operation and

to provide training to you and your team prior to an actual production.

2 Do not attempt to power up the system until the fiber optic cable has been connected

at both ends.

3 Install Camera Unit and battery or power supply (see Mounting the Copperhead

Camera Unit with the PowerWafer on page 28).

4 Connect all Camera Unit and Base Station cables (see any of the CopperHead User

Guides).

The order in which you connect the cables makes no difference. However, to prevent

damage other sensitive electronics (such as camcorders and Remote Control Panels):

• Make sure to connect the CHCR Camera Remote Control cable to the camera when

the camera is powered off.

• Make sure to connect the CHBR Base Remote Cable to the remote control panel

when Base Station power is turned off.

5 Deploy the fiber cable.

Read the Using Fiber Optics Guide for information on how to manage and deploy your

fiber optics cabling, safety precautions, tips & tricks, and recommendations for creating

complex fiber optic networks. You can find a copy of this document on the Support

portal (see Contact Us on page 35).

Insuring a Positive Fiber Link

To insure a positive Fiber Link

1 Connect the fiber cable connectors at each end.

2 Power up Camera Unit and Base Station or power supply and check the LED "Link"

indicators on each device.

3 Confirm that the LED "Link" indicators on Camera Unit and Base Station are both

illuminated GREEN. If so, all signals should now be passing between Camera Unit and

Base Station.

32

Page 37

Specifications

Distance Limit *see note below

Tactical Fiber (Local Power at Camera):

“Dry” fiber (1.5Gb/s) ............................................................ 16 db optical loss (≈ 30 km*)

SMPTE 311M Hybrid Fiber...........................................................................................................

Standard Internal Power Supply w/PowerWafer

.............................................................................................. 240m (787 ft): 95W @ 12VDC*

Long Range: HDX w/PowerPlus .............2km (6562 ft.): 100W Cont./150W Peak*

Mechanical/Environmental

Dimensions (WxLxD)

PowerWafer ............................................................................................... 5" x 6.12" x 2.2"

MPS Power Supply.................................................................................. 9.7" x 2.5" x 4.5"

Weight

PowerWafer ..................................................................................................................1.5 lb.

MPS Power Supply................................................................................................... 3.0 lb.

Power Consumption

Base Station (Hybrid Fiber):

Power Req................................................................ 110-120/220-240 VAC, 50 to 60Hz

Power Consumption ................................................................ 250 watts max @120VAC

Temperature Range ............................................................................................ -25° to +55°C

Humidity Range ................................................................... 0 to 95% RH, Noncondensing

* The maximum cable length varies due to optical loss that can depend on cable quality,

dirt/dust/contamination on connectors, and the number of cable connectors. When using

hybrid cable for camera power, the size of the hybrid cable, as well as the power draw of the

camera, lens, viewfinder, and other accessories are also factors

33

Page 38

Specifications

34

Page 39

Technical Suppor t

For technical assistance, please contact the Miranda Technical support centre nearest you:

Americas

Office hours: 9:00 a.m. - 9:00 p.m. (EST)

Telephone: +1-800-224-7882

Fax: +1-514-335-1614

e-mail: support@miranda.com

Asia

Office hours: 9:00 am - 5:00 pm (GMT+8)

Telephone: +852-2539-6987

Fax: +852-2539-0804

e-mail: asiatech@miranda.com

China

Telephone: +86-10-5873-1814

e-mail: asiatech@miranda.com

Europe, Middle East, Africa, UK

Office hours: 9:00 a.m. - 6:00 p.m. (GMT)

Telephone: +44 118 952 3444

Fax: +44 118 952 3401

e-mail: eurotech@miranda.com

France (only)

Office hours: 9:00 a.m. - 6:00 p.m. (GMT + 1)

Telephone: +33 (0) 1 55 86 87 88

Fax: +33 1 55 86 00 29

e-mail: eurotech@miranda.com

Contact Us

Related documentation

To access the most recent updates to this document, or to access other Miranda user

documentation, please visit the Miranda Support Portal:

http://www.miranda.com/support/

35

Page 40

Contact Us

Customer service and sales

Customer service and sales

For customer service or sales information, please contact a Miranda Technologies

Partnership’s sales office. Visit our web site at

http://www.miranda.com/contact.php?link=worldwide

Miranda’s corporate headquarters

You can also contact Miranda’s corporate headquarters at:

Miranda Technologies Partnership

3499 Douglas-B.-Floreani

St-Laurent, Quebec, Canada H4S 2C6

Tel. 514-333-1772

Fax. 514-333-9828

Visit our web site at www.miranda.com

to find office nearest to you.

36

Page 41

Connectors and Accessories

This appendix lists the specification for the CopperHead PowerWafer parts and accessories.

MPS Power Supply Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Parts and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

37

Page 42

MPS Power Supply Connector

MPS Power Supply Connector

Fig. A-1: MPS Power Interface IEC C14 Receptacle

• Panel Mounted AC Power Receptacle: 110/220 VAC

• Fuses: Two 3.15 amp slo-blo fuses (5 x 20mm). Littlefuse Series 218, part #02183.15 or

equivalent.

Parts and Accessories

Graphic Description Graphic Description

PWRWFR-95VD

Power Wafer Camera

Adaptor (for use with CH

Series Pro-BS-95VD)

CH3CP-INF-2FAG

PowerWafer-to-Camera

Unit jumper cable

CASM/MD/XL

Tac tica l Fiber on Reel :

Small (SM), Medium

(MD), or Large (XL)

CH2-MPS-95VD

External Power Supply for

PowerWafer

CHRCP-2050A

Universal Camera Control

Panel

38

Page 43

CopperHead PowerWafer

Graphic Description Graphic Description

CAXX-MX

Tactical Fiber Assembly,

MX Connectors

CAXX-XT2S-NOC

Tactical Fiber Cable

Assembly, OpticalCON

Connectors

User Guide

CAXX-XSM311-NOC

SMPTE 311M Hybrid

Fiber Cable Assembly,

OpticalCON connectors

MXRE

MX Receptacle Flange

Mount Assembly

Breakout to STs

CH3BFC-NOC-2ST/MOL

OpticalCON receptacle

to STs and Molex

39-01-4051

CH3BFC-304M-2ST

SMPTE Hybrid 304M

plug to STs and Molex

39-01-4051

CAXX-XSM311-SMPTE

SMPTE 311M Hybrid Fiber

Cable Assembly, SMPTE

304M connectors

MXRV

MX Receptacle Jam Nut

Assembly Breakout to STs

CH3BFC-NOC-NOC

OpticalCON receptacle to

OpticalCON Plug

CH3BFC-304M-NOC

SMPTE Hybrid 304M plug

to OpticalCON Plug

39

Page 44

Parts and Accessories

40

Page 45

Intercom Pinouts

This appendix lists the pinouts for the 4-Wire and Clear-Com Intercoms.

4-Wire Intercom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Clear-Com Intercom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

41

Page 46

Intercom Pinouts

4-Wire Intercom

4-Wire Intercom

This cable is end-user supplied.

Base Station Four Wire

Intercom Output Wiring

Base Station #16 & #17

XLR5 Male

Clear-Com Intercom

Pin Function Impedance Signal

1Ground

2 + Input 600 Ohm

3- Input Mic: -32 dBm

4 + Output >=600 Ohm

5- Output

Input

Load

Line: +8 dBm

+8 dBm

Base Station Clear-Com

Intercom Output Wiring

Base Station #16 & #17

XLR3 Female (x2)

Pin Signal

1Ground

2+ VDC Power

3Power

42

Loading...

Loading...