Page 1

8949MDA-CFR/-SFR

SD/HD MONITORING DA

Instruction Manual

Software Version 2.6.0

071843404

OCTOBER 2011

Page 2

CERTIFICATE

Certificate Number: 510040.001

The Quality System of:

Grass Valley USA, LLC and its Grass Valley Affiliates

Headquarters:

400 Providence Mine Road

Nevada City, CA 95945

United States

15655 SW Greystone Ct.

Beaverton, OR 97006

United States

Brunnenweg 9

D-64331 Weiterstadt

Germany

Kapittelweg 10

4827 HG Breda

The Nederlands

2300 So. Decker Lake Blvd.

Salt Lake City, UT 84119

United States

Including its implementation, meets the requirements of the standard:

ISO 9001:2008

Scope:

The design, manufacture and support of video and audio hardware and software products and related

systems.

This Certificate is valid until: June 14, 2012

This Certificate is valid as of: December 23, 2010

Certified for the first time: June 14, 2000

H. Pierre Sallé

President

KEMA-Registered Quality

The method of operation for quality certification is defined in the KEMA General Terms And Conditions For

Quality And Environmental Management Systems Certifications. Integral publication of this certificate is allowed.

KEMA-Registered Quality, Inc.

4377 County Line Road

Chalfont, PA 18914

Ph: (215)997-4519

Fax: (215)997-3809

CRT 001 042108

ccredited By:

ANAB

A

Page 3

8949MDA-CFR/-SFR

SD/HD MONITORING DA

Instruction Manual

Software Version 2.6.0

071843404

OCTOBER 2011

Page 4

Contacting Grass Valley

International

Support Centers

Local Support

Centers

(available

during normal

business hours)

France

24 x 7

Australia and New Zealand: +61 1300 721 495 Central/South America: +55 11 5509 3443

Middle East: +971 4 299 64 40 Near East and Africa: +800 8080 2020 or +33 1 48 25 20 20

Europe

+800 8080 2020 or +33 1 48 25 20 20

Hong Kong, Taiwan, Korea, Macau: +852 2531 3058 Indian Subcontinent: +91 22 24933476

Asia

Southeast Asia/Malaysia: +603 7805 3884 Southeast Asia/Singapore: +65 6379 1313

China: +861 0660 159 450 Japan: +81 3 5484 6868

Belarus, Russia, Tadzikistan, Ukraine, Uzbekistan: +7 095 2580924 225 Switzerland: +41 1 487 80 02

S. Europe/Italy-Roma: +39 06 87 20 35 28 -Milan: +39 02 48 41 46 58 S. Europe/Spain: +34 91 512 03 50

Benelux/Belgium: +32 (0) 2 334 90 30 Benelux/Netherlands: +31 (0) 35 62 38 42 1 N. Europe: +45 45 96 88 70

Germany, Austria, Eastern Europe: +49 6150 104 444 UK, Ireland, Israel: +44 118 923 0499

Copyright © Grass Valley USA, LLC. All rights reserved.

This product may be covered by one or more U.S. and foreign patents.

United States/Canada

24 x 7

+1 800 547 8949 or +1 530 478 4148

Grass Valley Web Site

The www.grassvalley.com web site offers the following:

Online User Documentation — Current versions of product catalogs, brochures,

data sheets, ordering guides, planning guides, manuals, and release notes

in .pdf format can be downloaded.

FAQ Database — Solutions to problems and troubleshooting efforts can be

found by searching our Frequently Asked Questions (FAQ) database.

Software Downloads — Download software updates, drivers, and patches.

4 8949MDA-CFR/-SFR — Instruction Manual

Page 5

Preface

About This Manual

This manual describes the features of a specific 8900 module in the

GeckoFlex Signal Processing System family. As part of this module family,

it is subject to Safety and Regulatory Compliance described in the

GeckoFlex 8900 Series frame documentation (see the GeckoFlex Frames

8900FX/FF/FFN Signal Processing System Instruction Manual).

All Modular product documentation can be found on-line in PDF format at

this link:

www.grassvalley.com/docs/modular

8949MDA-CFR/-SFR — Instruction Manual 5

Page 6

Preface

6 8949MDA-CFR/-SFR — Instruction Manual

Page 7

Contents

Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

8949MDA-CFR and 8949MDA-SFR Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Module Placement in the GeckoFlex Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Module Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Local Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Configuration Switches S1 and S2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Rear Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Front Module Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Optional Fiber Optic SFP Device Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Fiber Optic Cleaning Requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Video Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Video Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8949MDA-CFR Module Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8949MDA-SFR Module Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Operation Indicator LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Remote Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8900NET Module Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Newton Control Panel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Web Browser Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8949MDA-CFR and 8949MDA-SFR Links and Web Pages . . . . . . . . . . . . . . . . . 27

Status Web Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Settings Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Slot Config Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Software Updating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Status Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

External Frame Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

LED Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Web Browser Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

SNMP Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Power-up Diagnostics Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Electronic Circuit Breaker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Module Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table of Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8949MDA-CFR/-SFR — Instruction Manual 7

Page 8

Contents

Configuration Summary Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8 8949MDA-CFR/-SFR — Instruction Manual

Page 9

8949MDA-CFR and 8949MDA-SFR Modules

Introduction

The 8949MDA-CFR or 8949MDA-SFR performs SD/HD equalization, and

reclocking for distribution of SD/HD signals among electrical connectors

and/or a fiber optic SFP device and downscaling of HD video signals to

SD- SDI video (-SFR) or analog video signals (-CFR) for monitoring appli

cations.

On the 8949MDA-SFR module with an SD-SDI video input, the module

will distribute the SD-SDI signal (including embedded audio) on all

outputs (distribution and monitoring). With an HD-SDI video input, the

module distributes the HD-SDI signal on the HD-SDI distribution outputs

(including embedded audio and HANC data – horizontal ancillary); the

downscaled monitoring SDI outputs do not pass embedded audio or

HANC data from the HD video input.

-

Features

The two models, 8949MDA-CFR (composite downscaler outputs) and

8949MDA-SFR (serial data interface downscaler outputs) must be installed

in a GeckoFlex frame and require the presence of an 8900WFR-R rear

module. Optical interface requires the presence of an optional fiber optic

SFP plug-in device.

The 8949MDA module features include:

• Multi-format HD/SD video on one electrical input and/or up to two

optical input/outputs (refer to Cabling on page 19),

• In HD input mode:

• Up to four reclocked HD electrical outputs and up to two reclocked

HD optical outputs,

• Up to four downscaled HD to SD or composite (SDI signals in the

case of 8949MDA-SFR or composite signals in the case of

8949MDA-CFR) electrical outputs,

8949MDA-CFR/-SFR — Instruction Manual 9

Page 10

Introduction

•In SD input mode:

• Up to eight reclocked SD-SDI electrical outputs and up to two

reclocked SD optical outputs in the case of 8949MDA-SFR,

• Up to four reclocked SD-SDI outputs and up to two reclocked

SD-SDI optical outputs and up to four composite outputs in the case

of 8949MDA-CFR,

• Auto cable equalization for up to 330m of cable in the case of SD-SDI

signals and for up to 125m of cable in the case of HD-SDI signals,

• A range of standard definition or high definition input signal on one

electrical input or optical inputs,

• Downscaled signals with monitoring quality (embedded audio and

HANC data will be passed on all SDI outputs except for downscaled

HD monitoring outputs),

• Alarm (signal presence detection) and status management,

• SNMP and product health monitoring is supported through the

8900NET (Net Card) module with applications such as NetCentral,

• A fiber optic SFP device option can be installed to provide optical video

input/output interfaces for both models depending on the SFP device

type. Refer to Table 2 on page 17 for the options available.

• Remote control and monitoring support with the 8900NET (Net Card)

installed in the frame: web browser and Newton Control Panel.

10 8949MDA-CFR/-SFR — Instruction Manual

Page 11

Installation

Module Placement in the GeckoFlex Frame

Installation

The front and the rear modules are delivered together as a set:

8949MDA-CFR front module or 8949MDA-SFR front module with the

8900WFR-R rear module. Optional fiber optic SFP devices must be ordered

separately. The types of optional fiber optic SFP devices available are listed

in

Tab le 2 on page 17.

The 8949MDA-CFR and 8949MDA-SFR front modules can be plugged in

and removed from a GeckoFlex frame with power on. When power is

applied to the module, LED indicators reflect the initialization process (see

Power Up on page 22).

CAUTION Use anti-static precautions when installing and removing the optional fiber

optic SFP devices, see Optional Fiber Optic SFP Device Installation on

page 17.

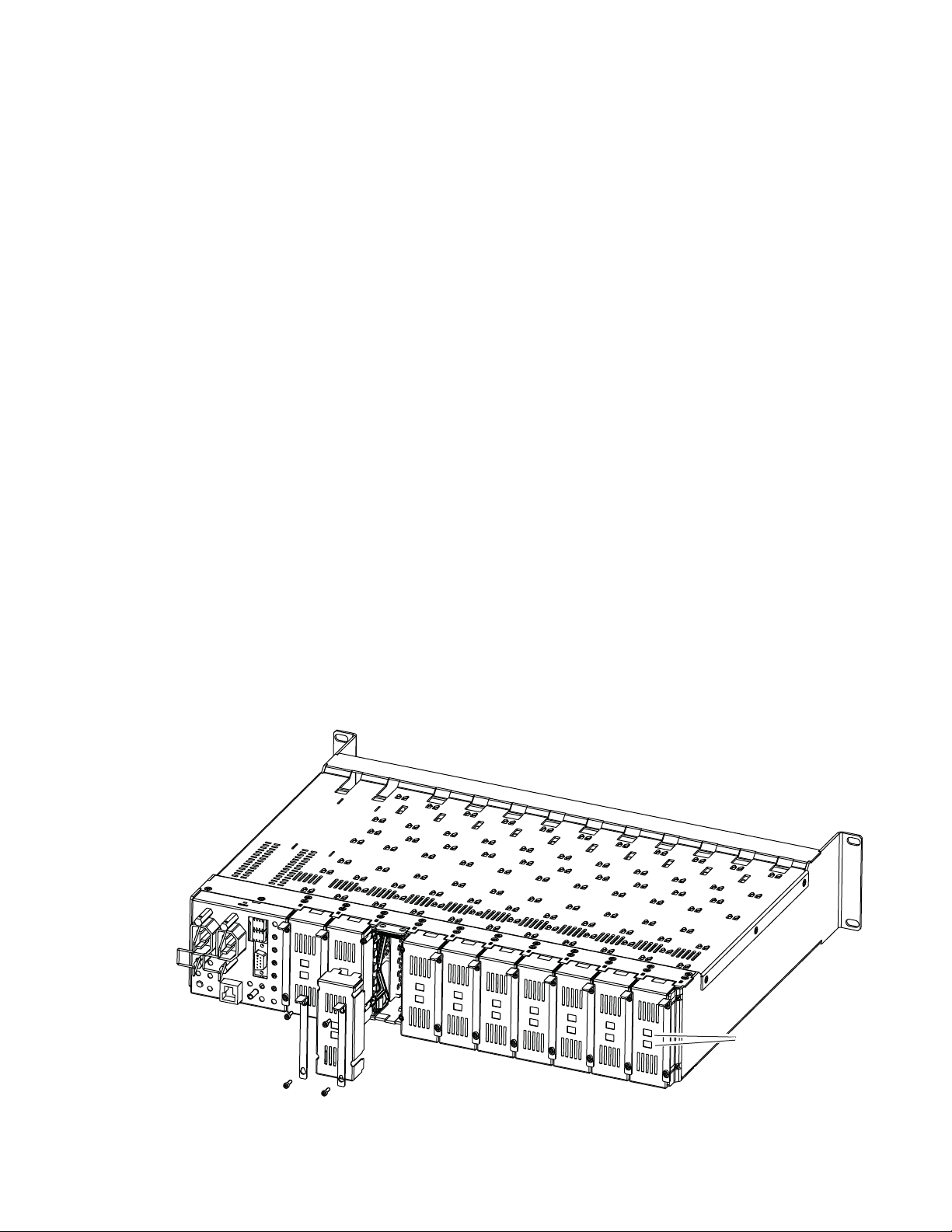

There are ten rear and front slot locations in the 2 RU frame to accommodate

either audio or video modules (

into any one of the available GeckoFlex frame slots. The 8949MDA

modules require a single rear and corresponding front slot.

Note Use anti-static precautions when handling the module. As the module can be

changed when the GeckoFlex is powered on, before removing the cover,

please put an anti-static bracelet tied to a metal part of the frame.

Figure 1. GeckoFlex Frame

Figure 1). The module set may be plugged

8949MDA-CFR/-SFR — Instruction Manual 11

Page 12

Installation

Module Installation Precautions

Please read and follow the precautions listed below before installing the

front and rear modules and any fiber optic option SFP device:

• Use standard anti-static procedures during installation. As modules

can be installed or removed when the GeckoFlex frame is powered up,

before removing the cover, please use an anti-static bracelet tied to a

metal part of the frame.

• Install the rear module first, then the front module, then the fiber optic

SFP device option if used on the module.

• When installing or removing a rear module, loosen or tighten the

screws holding the retainer clips to the frame manually with the

retainer clip tool provided inside the front cover of the frame or use a

2 mm (5/64”) hex screwdriver. Please do not use an electric screwdriver.

Note On newer 751- version GeckoFlex frames, a Rear Retainer Clip removal tool

and 2 extra retainer clips and screws for installing them are provided on the

inside of the frame cover.

• Make every effort to leave the screws holding the retainer clips in place

(do not remove them completely). They are very small and can easily

drop into other equipment causing a shorting hazard. (Two turns of the

screw should be enough to loosen the screws, 3 turns or more will

remove it.)

• When installing a rear module, tighten the screws on the retainer clips

just until snug. Do not apply more force than is necessary to seat the

rear module. Refer to the

page 43.

• If using a fiber optic SFP device on the fiber-ready module, handle it

carefully, use anti-static precautions, and read the Fiber Optic Cleaning

Requirement on page 17 before cabling.

Mechanical specifications given in Tab le 6 on

12 8949MDA-CFR/-SFR — Instruction Manual

Page 13

Local Configuration

See Table 1 on page 14

If you do not have an 8900NET module in the GeckoFlex frame for remote

monitoring and configuration, you will need to configure the module using

the local onboard controls before installing the front module.

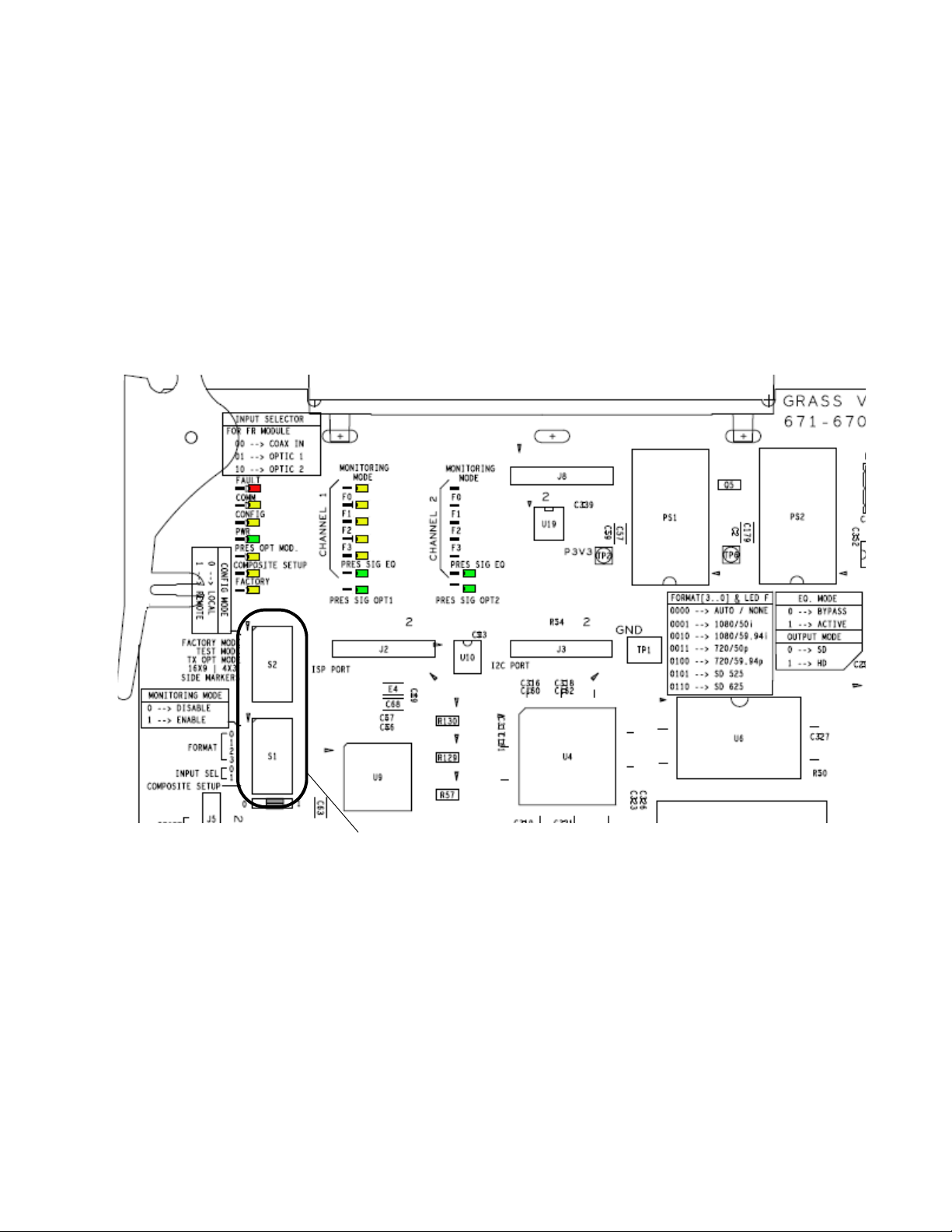

Local configuration of the 8949MDA-CFR and 8949MDA-SFR consists of

two DIP switches (S1 and S2) outlined in the lower left corner of

Refer to Ta bl e 1 on page 14 for setting S1 and S2. A summary of Local and

Remote (web page and Newton Control Panel) parameters is provided in

Ta bl e 10 on page 49.

Figure 2. Configuration Switches on 8949MDA Module

Installation

Figure 2.

8949MDA-CFR/-SFR — Instruction Manual 13

Page 14

Installation

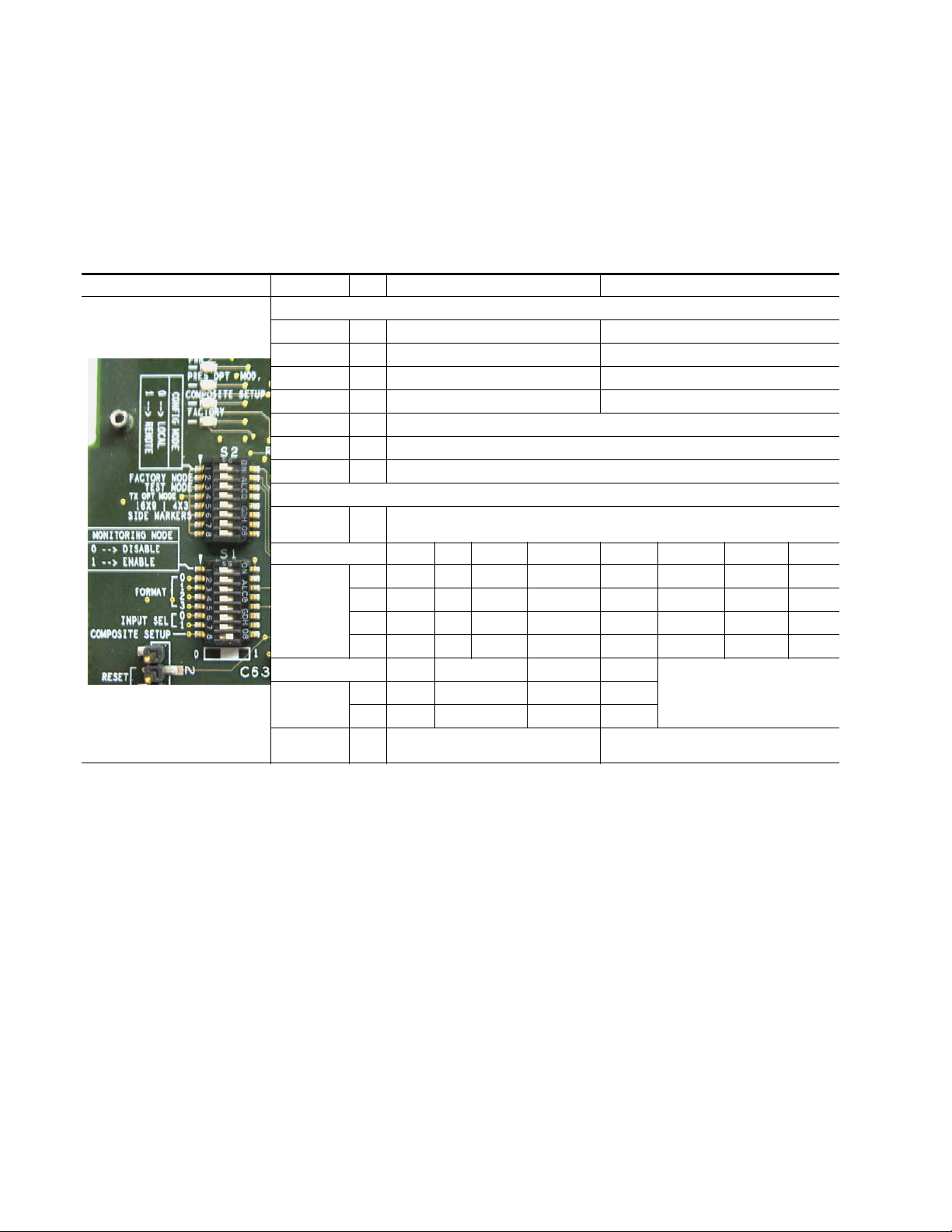

Configuration Switches S1 and S2

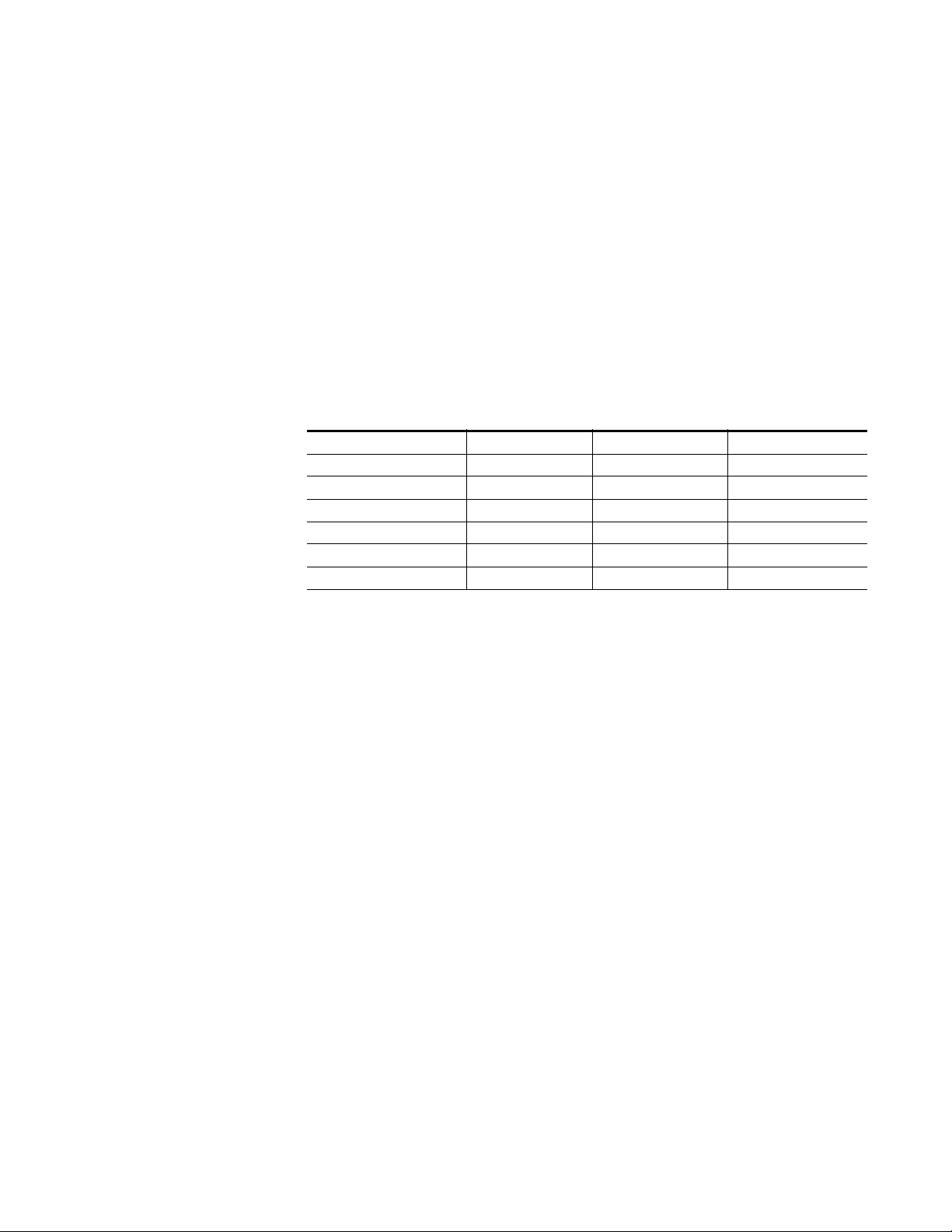

Ta bl e 1 gives the parameters set with the onboard switches S1 and S2 on the

8949MDA module circuit board.

Note To lock out remote control, set the Config Mode to Off.

Table 1. Switch S1 and S2 Settings

Switches S1 and S2 Function Pin 0 (Left/Off) 1 (Right/On)

Switch S2

Config Mode

Factory Mode

Test Mode

Tx Opt Mode

16X9 / 4X3

Side Markers

–

Switch S1

Monitoring

Mode

Format (Input) Setting Auto 1080i/50 1080i/59.94 720p/50 720p/59.94 480i/59.94 576i/50

Input Select Setting Coax In Optic 1 Optic 2

Composite

Setup

Local mode (Remote control locked out) Remote mode

1

2

3

4

5

6

7-8

1

2

3

4

5

6

7

8

Off (fiber optic outputs disabled) On (fiber optic outputs enabled)

00 0 0 0 0 0 0

10 0 0 0 1 1 1

20 0 1 1 0 0 1

30 1 0 1 0 1 0

00 01

10 10

Off Factory use only

Off Factory use only

Not Used

Not Used

Not Used

Not Used

Off On

14 8949MDA-CFR/-SFR — Instruction Manual

Page 15

Rear Module Installation

8444_23r0

Use retainer clip or

needlenose pliers

to pull out blank after

removing retainer clips

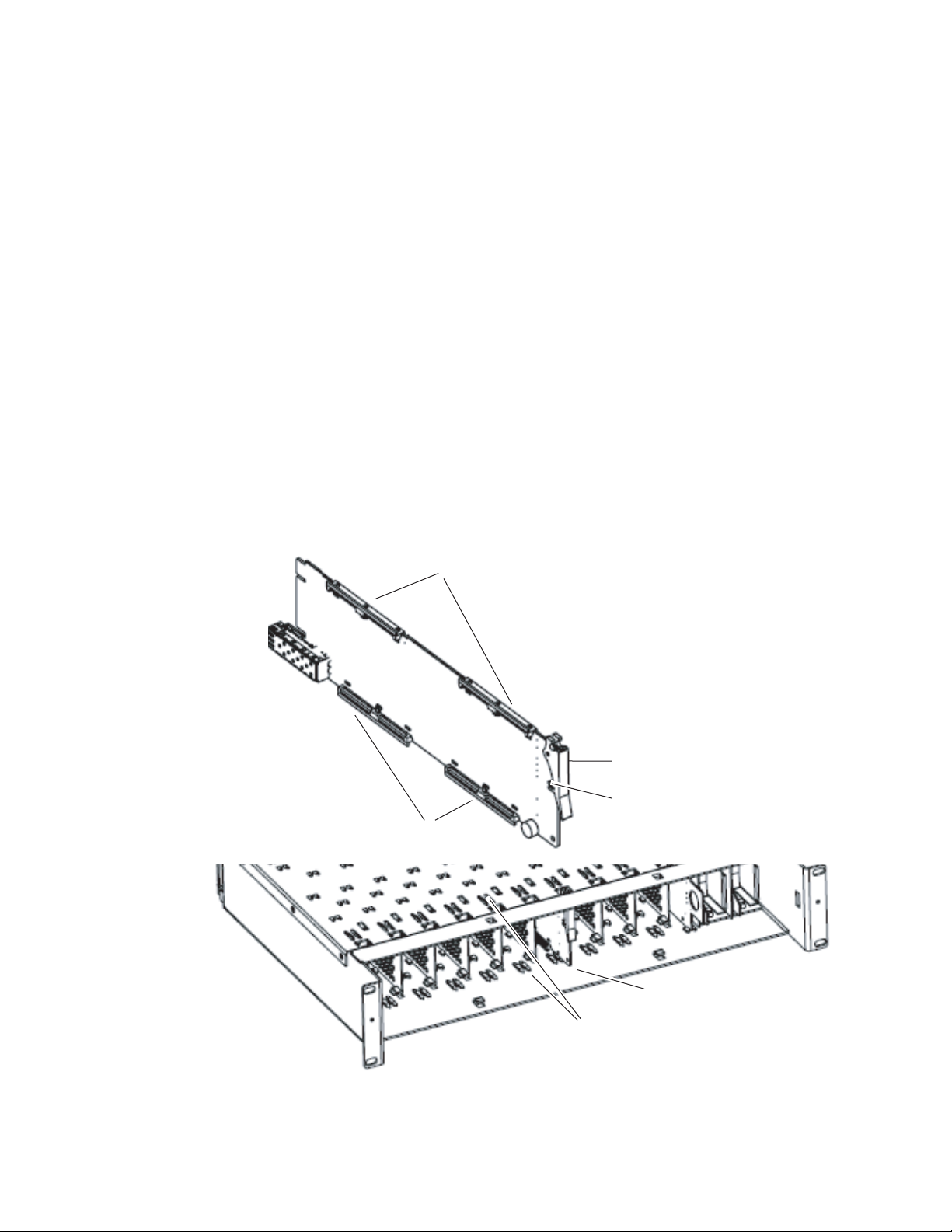

1. To remove a blank rear adapter cover (or a rear module already

present), manually loosen the two screws holding each retainer clip on

the rear adapter cover or rear module to the frame with the retainer clip

tool provided inside the front cover of the frame (751- model frames

only) or a 2 mm (5/64”) hex screwdriver.

Note To remove a rear module already installed, follow the same steps. It is helpful

to first remove the front module so the rear can be pulled out more easily.

1. After loosening the retainer clip screws, pull up on each retainer and

completely remove it, leaving the screws in place.

2. Remove the blank rear adapter cover by inserting the retainer clip tool

or needlenose pliers into the slots in the blank cover and pulling it off

(Figure 3).

3. Insert the rear module into the empty slot, guiding it into place.

4. Replace each retainer clip over the two screws on both sides of the

module and push down to seat the retainer clip.

Installation

5. Tighten the two screws on each retainer clip just until they come into

contract with the retainer clip then tighten about a 1/4 turn more

(maximum torque is 4-5 inch-lb/0.45-0.6Nm). Do not force or torque

the screws too tightly. The clips should not bend or be bowed.

Note All unused rear slots in a GeckoFlex frame should have a blank rear adapter

cover installed.

Figure 3. Installing Rear Module

8949MDA-CFR/-SFR — Instruction Manual 15

Page 16

Installation

8479_03

Slide top and bottom card carriers on module

over top and bottom guides on right of slot.

Module installed

Locking Pin

Card Carriers

Card Carriers

Front Module Side View

Ejector Tab

Front Module Installation

After installing the rear module and configuring the front module using

local controls if required, install the front module as follows:

1. Remove the front cover of the frame.

2. Locate the front slot corresponding to the rear module you have already

installed.

3. Insert the front module so that the plastic card guides on the module

top and bottom edges go over the upper and lower raised rail guides on

the right of the top and bottom of the slot (Figure 4).

4. Carefully slide the module into the rear connector, making sure the

fiber optic connector on the 8949MDA module fits into the rear module

properly.

5. Lock the front module ejector tab into the locking pin.

6. Replace the frame front cover during operation to maintain optimum

cooling conditions.

Figure 4. Front Module Installation

16 8949MDA-CFR/-SFR — Instruction Manual

Page 17

Optional Fiber Optic SFP Device Installation

After the front and rear modules have been installed, install the optional

fiber optic SFP device option if being used into the rear module metal cage

labeled FIBER (

may be installed or removed with power applied to the module.

CAUTION Use anti-static precautions and handle the SFP device carefully when

installing and the removing it.

to clean all fiber connections as described in Fiber Optic Cleaning Require-

ment below.

Refer to Tab le 2 for the correct model of SFP device to use with different

software versions.

Table 2. Fiber Optic SFP Device Summary

SFP Device Model Type SW 2.4.1 and later SW 2.4.1 and earlier

SFP-13103G-M2DRX Dual Receiver Yes No

SFP-13103G-M2DTX Dual Transmitter Yes No

SFP-13103G-M2TRX Transceiver Yes No

1310nm-DRL Dual Receiver Yes Yes

1310nm-DTL Dual Transmitter Yes Yes

1310nm-TRL Transceiver Yes Yes

Figure 5 on page 18). The SFP device is hot-pluggable and

Before inserting the fiber cable, it is important

Installation

Fiber Optic Cleaning Requirement

Before making any fiber optic cable mating connections, including installation, and after every de-mating cycle, use an industry standard fiber optic

cleaning kit, including oil-free compressed air, to clean the fiber connectors

and the connectorized fiber end faces. This helps ensure optimum perfor

mance of the fiber optic interface. Industry standard fiber optic cleaning

kits can be purchased on the web and in electronics stores.

-

8949MDA-CFR/-SFR — Instruction Manual 17

Page 18

Installation

FIBER

J7J9J8

8431_03r3

Label

Handle

Arrow Indicators:

Fiber Optic Receiver

Fiber Optic Transmitter

Fiber Optic Transceiver

To install the fiber optic SFP device:

1. Slide the fiber optic device into the metal fiber cage with the label and

handle to the right.

2. Push the device in as far as it will go without forcing it. It will not go

completely into the cage.

3. Cable the fiber optic connectors according to the instructions given in

8949MDA-CFR Module Cabling on page 20 or 8949MDA-SFR Module

Cabling on page 21 depending on the type of SFP device used.

Figure 5. Installing Fiber Optics SFP Device

To extract the fiber optic SFP device follow the steps below:

1. Remove the fiber cable first.

2. Unlock the module by flipping the handle to the left.

3. Remove the fiber optic SFP device by using its handle.

18 8949MDA-CFR/-SFR — Instruction Manual

Page 19

Cabling

Cabling

Cabling to the 8949MDA-CFR or 8949MDA-SFR module is done on the

BNCs and the fiber connector on the rear module when an optional fiber

optic SFP device is installed.

Cabling of the rear module depends on presence and type of fiber optic SFP

device option as listed below:

• 8949MDA-CFR/-SFR without fiber optic SFP device option (electrical

only),

• 8949MDA-CFR/-SFR with a Dual Receiver Fiber Optic

• 8949MDA-CFR/-SFR with a Dual Transmitter Fiber Optic and

• 8949MDA-CFR/-SFR with a Transceiver Fiber Optic.

Note Fiber input and output connections must be cleaned before cabling as

described in Fiber Optic Cleaning Requirement on page 17.

Video Input

The 8949MDA-CFR or 8949MDA-SFR will accept any of the video standards listed in the input specifications in Tab le 6 on page 43.

For both module types, the SD or HD video input to the module can be

selected from one of the following three sources, depending on the pres

ence and type of fiber optic SFP device option:

• Electrical BNC, J9 (always available)

• Fiber Input RX 1 or RX 2 (requires a Dual Receiver SFP device), or

• Fiber Input RX 1 (requires a Transceiver SFP device).

All three sources can be connected but only be one input can be active at

any time. The active input is configured with local onboard controls (

figuration Switches S1 and S2 on page 14) or using the Settings web page

(page 33). The video input type must also be selected in configuration.

Con-

-

8949MDA-CFR/-SFR — Instruction Manual 19

Page 20

Cabling

Video Outputs

The 8949MDA-CFR or 8949MDA-SFR outputs conform to the video standards listed in the output specifications in Tab le 6 on page 43.

Electrical outputs are always enabled. Fiber optic outputs must be enabled

during configuration using the local onboard controls (

Switches S1 and S2 on page 14) or the Settings web page (page 33). Fiber

optic outputs available depend on the presence and type of fiber optic SFP

device installed.

8949MDA-CFR Module Cabling

Refer to Tab le 3 and Figure 6 for 8949MDA-CFR cabling information.

Table 3. Cabling Inputs and Outputs for 8949MDA-CFR Module

Fiber Optic SFP Device SDI Inputs Outputs

No fiber optic SFP device J9 BNC J1, J3, J5, J7: 4 HD-SDI electrical outputs

Dual Receiver J9 BNC,

Dual Transmitter J9 BNC J1, J3, J5, J7: 4 HD-SDI electrical outputs

Transceiver J9 BNC

Fiber 1,

or Fiber 2

or Fiber 1

Configuration

J2, J4, J6, J8: 4 downscaled PAL or NTSC electrical outputs

J1, J3, J5, J7: 4 HD-SDI electrical outputs

J2, J4, J6, J8: 4 downscaled PAL or NTSC electrical outputs

J2, J4, J6, J8: 4 downscaled PAL or NTSC electrical outputs

Fiber 1 and Fiber 2: 2 optical HD outputs

J1, J3, J5, J7: 4 HD -SDI electrical outputs

J2, J4, J6, J8: 4 downscaled PAL or NTSC electrical outputs

Fiber 2: 1 optical HD output

Figure 6. 8949MDA-CFR Cabling

8900WFR-R

J1

J2

HD/SD

SDI Out

J3

J4

HD/SD

SDI Out

J5

J6

HD/SD

SDI Out

J7

J8

HD/SD

SDI Out

J9

HD/SD

SDI In

Fiber

8434_02r1

PAL/NTSC

Monitoring Out

PAL/NTSC

Monitoring Out

PAL/NTSC

Monitoring Out

PAL/NTSC

Monitoring Out

Fiber 2 In/Out

Fiber 1 In/Out

Fiber Optic Cabling

Dual Receiver

Fiber Rx 2

Fiber Rx 1

Dual Transmitter

Fiber Tx 2

Fiber Tx 1

Transceiver

Fiber Tx 2

Fiber Rx 1

20 8949MDA-CFR/-SFR — Instruction Manual

Page 21

8949MDA-SFR Module Cabling

Refer to Tab le 4 and Figure 7 for 8949MDA-SFR cabling information.

Table 4. Cabling Inputs and Outputs for 8949MDA-SFR Module

Fiber Optic SFP Device SDI Inputs Outputs

No Fiber optic SFP device J9 BNC J1, J3, J5, J7: 4 HD-SDI electrical outputs

Dual Receiver J9 BNC,

Dual Transmitter J9 BNC J1, J3, J5, J7: 4 HD-SDI electrical outputs

Transceiver J9 BNC

Fiber 1,

or Fiber 2

or Fiber 1

Cabling

J2, J4, J6, J8: 4 downscaled SD SDI electrical outputs

J1, J3, J5, J7: 4 HD-SDI electrical outputs

J2, J4, J6, J8: 4 downscaled SD SDI electrical outputs

J2, J4, J6, J8: 4 downscaled SD SDI electrical outputs

Fiber 1 and Fiber 2: 2 optical HD outputs

J1, J3, J5, J7: 4 HD-SDI electrical outputs

J2, J4, J6, J8: 4 downscaled SD SDI electrical outputs

Fiber 2: 1 optical HD output

Figure 7. 8949MDA-SFR Cabling

8900WFR-R

J2

J1

HD/SD

SDI Out

J4

J3

HD/SD

SDI Out

J6

J5

HD/SD

SDI Out

J8

J7

HD/SD

SDI Out

J9

HD/SD

SDI In

Fiber

8434_01r1

SD SDI

Monitoring Out

SD SDI

Monitoring Out

SD SDI

Monitoring Out

SD SDI

Monitoring Out

Fiber 2 In/Out

Fiber 1 In/Out

Fiber Optic Cabling

Dual Receiver

Fiber Rx 2

Fiber Rx 1

Dual Transmitter

Fiber Tx 2

Fiber Tx 1

Transceiver

Fiber Tx 2

Fiber Rx 1

8949MDA-CFR/-SFR — Instruction Manual 21

Page 22

Power Up

Power Up

Operation Indicator LEDs

The on-board LED indicators are illustrated in Figure 8. Upon power-up,

the green PWR LED should light and the CONFIG, FAULT and COMM

LEDs should illuminate during the module initialization.

Note When a module is first plugged into a GeckoFlex frame, the 8900NET module

(if present) may report a momentary fault. This will clear once the module has

booted up.

With a valid input signal connected, the Channel 1 PRES SIG LED EQ

(input to BNC J9), OPT

fiber optic SFP device) should be on. Refer to

complete list of possible operating conditions and the resulting indicator

status.

Note Channel 2 Monitoring Mode LEDs are not used at this time.

1, and/or OPT 2 (depends on presence and type of

Tab le 5 on page 23 to see a

Figure 8. Front Module Indicator LED

22 8949MDA-CFR/-SFR — Instruction Manual

Page 23

A red FAULT LED indicates an error situation and, when noted with the

other indicator LEDs, can indicate a specific problem area.

signal output and LED indications for the various input/reference combinations.

Table 5. LED Indicators

LED Indication Condition

FAULT

(red)

COMM

(yellow)

CONFIG

(yellow)

PWR

(green)

PRES OPT MOD

(yellow)

COMPOSITE SETUP

(yellow)

FACTORY

(yellow)

MONITORING MODE

(Channel 1

F0, F1, F2 and F3)

(yellow)

Channel 1

PRES SIG EQ

(green)

PRES SIG OPT 1

(green)

PRES SIG OPT 2

(green)

Off Normal operation

On continuously Module has detected internal fault

Off No activity on frame communication bus

Long flash Location Command received by the module from a remote control system

Short flash Activity present on the frame communication bus

Off Module is in normal operating mode

On continuously Module is initializing, changing operating modes or updating firmware

Off No power to module or module’s DC/DC converter failed

On continuously Normal operation, module is powered

Off Fiber optic SFP device not installed

On Fiber optic SFP device installed

Off

On

Off Normal operation

On Test mode or factory mode

F0 F1 F2 F3

Off Off Off Off 0000 --> Auto

Off Off Off On 0001 --> 1080i/50

Off Off On Off 0010 --> 1080i/59.94

Off Off On On 0011 --> 720p/50

Off On Off Off 0100 --> 720p/59.94

Off On Off On 0101 --> 480i/59.94

Off On On Off 0110 --> 576i/50

Off No presence of signal on BNC J9 connector

On continuously Presence of signal on BNC on J9 connector

Off No presence of optical signal on Fiber optic input 1

On continuously Presence of optical signal on Fiber Optic input 1

Off No presence of optical signal on Fiber optic Input 2

On continuously Presence of optical signal on Fiber Optic Input 2

Setup disabled

Setup enabled

Power Up

Tab le 5 describes

8949MDA-CFR/-SFR — Instruction Manual 23

Page 24

Remote Configuration

Remote Configuration

The 8949MDA-CFR/8949MDA-SFR configuration and monitoring can also

be performed using a web browser GUI interface or a networked Newton

Control Panel when the 8900NET Network Interface module is present in

the GeckoFlex frame (8900FFN). Each of these interfaces is described below.

8900NET Module Information

Refer to the 8900NET Network Interface Module Instruction Manual available

online in PDF format for information on the 8900NET Network Interface

Module and setting up and operating the GeckoFlex 8900 frame network.

Note Upgrade software and instructions for the 8900NET can be downloaded from

the Grass Valley web site.

Newton Control Panel Configuration

A Newton Control Panel (hard and/or soft version) can be interfaced to the

GeckoFlex frame over the local network. Refer to the documentation that

accompanies the Newton Modular Control System for installation, config

uration, and operation information.

Control panel access offers the following considerations for module configuration and monitoring:

• Ability to separate system level tasks from operation ones, minimizing

the potential for on-air mistakes.

• Ability to group modular products—regardless of their physical locations—into logical groups (channels) that you can easily manipulate

with user-configured knobs.

• Update software for applicable modules and assign frame and panel IP

addresses with the NetConfig Networking application.

• Recommended for real-time control of module configuration parameters, providing the fastest response time.

Note Not all module functions are available with the control panel, such as factory

default recalls.

Newton Control Panel parameters are listed in Ta bl e 10 on page 49.

-

24 8949MDA-CFR/-SFR — Instruction Manual

Page 25

Remote Configuration

An example of the Newton Configurator is shown in Figure 9.

Figure 9. Newton Configurator Example

Web Browser Interface

The web browser interface provides a graphical representation of module

configuration and monitoring.

Use of the web interface offers the following considerations:

• Web access will require some normal network time delays for pro-

cessing of information.

• Configuration parameter changes may require pressing

Enter, upload processing time, and a manual screen refresh to become

effective.

• Web interface recommended for setting up module signal and slot

names, and reporting status for SNMP and monitoring.

Refer to the Frame Status web page shown in Figure 10 on page 26. The

8900 modules can be addressed by clicking either on a specific module icon

in the frame status display or on a module name or slot number in the link

list on the left.

Apply button or

8949MDA-CFR/-SFR — Instruction Manual 25

Page 26

Remote Configuration

8480_02r0

The Links section lists the frame and its current modules. The selected link's Status

page is first displayed and the sub-list of links for the selection is opened. The sub-list

allows you to select a particular information page for the selected device.

Content display section

displays the information page

for the selected frame or module (frame slot icons are also

active links).

Refresh button for manual

update of page

Note The physical appearance of the graphics on the web pages shown in this

manual represent the use of a particular platform, browser and version of

8900NET module software. They are provided for reference only. Web pages

will differ depending on the type of platform and browser you are using and

the version of the 8900NET software installed in your system. This manual

reflects an 8900NET module with software version 4.3.0, using Internet

Explorer, the recommended web browser, and Windows XP operating

system.

For information on status, fault monitoring and reporting shown on the

Status web page, refer to

Figure 10. Main Menu – Frame Status Web Page

Status Web Page on page 28.

26 8949MDA-CFR/-SFR — Instruction Manual

Page 27

Remote Configuration

8949MDA-CFR and 8949MDA-SFR Links and Web Pages

The 8900 GUI provides the following links and web pages for the

8949MDA-CFR and 8949MDA-SFR modules (

• Status – reports input and output signals and frame bus communication status and module information (page 28),

• Settings – allows the configuration of the inputs and outputs (page 33),

• Slot Config – provides Locate Module and Slot Memory functions

along with links to the SNMP, LED Reporting, and Frame Alarm configuration web pages (page 37).

All parameters that can be set on the web pages are summarized in Ta bl e 10

on page 49.

Figure 11. 8949MDA Web Page Links

Figure 11):

8949MDA-CFR/-SFR — Instruction Manual 27

Page 28

Remote Configuration

Use

this

link

Status Web Page

The Status web page for 8949MDA-CFR for the 8949MDA-SFR) shows the

signal status of the input signal(s) and communicat

The Status page appearance will depend on the presence and type of fiber

optic SFP device installed.

ion with the frame bus.

Use the Status web page example appl

list below (the -CFR and -SFR are identical):

• 8949MDA-CFR/SFR without SFP device: Figur

• 8949MDA-CFR/SFR with Dual Receiver SFP device: Figure 13 on

page 30

• 8949MDA-CFR/SFR with Dual Transmitter SFP device: Figure 14 on

page 31

• 8949MDA-CFR/SFR with Dual Transceiver SFP device: Figure 15 on

page 32

Color coding of the display indicates the signal status. Refer to Web Browser

Interface on page 25 for an explanation of the color coding.

• Under the

location. Below, the graphic shows the input and output signals. If the

status of either input or output changes, it will be reflected in the color

status of the arrow (linked to the

status LED on the module web page.

• The presence and the type of

double bars area below the graphic depending on the fiber optic SFP

device installed.

Status title are given the model, the description and the frame

icable to your configuration from the

e 12 on page 29

Input Reporting parameter) and the

Optic Device installed will be reported in the

Other module warning

this area. If no SFP device is installed, it will report

Note Some modules may display a part number on the Status web page that is dif-

ferent from the one printed on the module circuit board. These part numbers

are completely compatible.

• Information about the module, such as Part Number, Serial Number,

Hardware Revision, Firmware Revision 1 (CPLD), Firmware Revision

2 (FPGA), Software Version, and Asset Tag number are given in a properties section at the bottom of the Status Web Page.

28 8949MDA-CFR/-SFR — Instruction Manual

messages from the module will also appear in

Optic Device: MISSING.

Page 29

Figure 12. Status Web Page without Fiber Optic SFP Device

Remote Configuration

8949MDA-CFR/-SFR — Instruction Manual 29

Page 30

Remote Configuration

Figure 13. Status Web Page with Dual Receiver SFP Device

30 8949MDA-CFR/-SFR — Instruction Manual

Page 31

Figure 14. Status Web Page with Dual Transmitter SFP Device

Remote Configuration

8949MDA-CFR/-SFR — Instruction Manual 31

Page 32

Remote Configuration

Figure 15. Status Web Page with Transceiver SFP Device

32 8949MDA-CFR/-SFR — Instruction Manual

Page 33

Settings Web Page

Use

this

link

The Settings web page for the 8949MDA-CFR and the 8949MDA-SFR

modules provide configuration and reporting of

provides controls to perform input configuration depending on the module

type and the presence and type of SFP device installed.

Remote Configuration

the DA output. This page

Use the Settings web page example applic

able to your configuration from

the list below:

• 8949MDA-CFR without SFP device: F

igure 16 on page 34

• 8949MDA-CFR/SFR with Dual Receiver SFP device: Figure 17 on

page 35

• 8949MDA-CFR/SFR with Dual Transmitter SFP device: Figure 18 on

page 36

• 8949MDA-CFR/SFR with Dual Transceiver SFP device: Figure 19 on

page 37

The parameters for configuration of a 8949MDA module are explained

below

. Controls act the same for the -CFR and -SFR unless otherwise noted.

•The

Routing Mode area will be different, depending on the presence and

type of fiber optic SFP devices. This area shows the available inputs.

Only one input can be selected.

•

Coax In 1 – selection of J9 BNC coax input (always available).

Optic 1 or/and 2 – selection of the available optical input when a Dual

•

Receiver fiber optic SFP device is installed (RX1 and RX2) or RX1

when a Transceiver is installed.

•

Optical Outputs – when a fiber optic dual transmitter SFP device is

installed, TX1 and TX2 outputs will be available or one TX2 output will

be available when a Transceiver is installed. You must

Enable or Disable

the transmitter outputs.

Note Make sure that the local control TX OPT MODE at Pin 4 of S2 (Table 1 on

page 14) is in the On position (to the right).

• Input Reporting – choose between Enable or Disable. The Enable parameter

sends alarms to the 8900NET module on the input signals (presence of

signal). The color of arrows on the module Status web page will report

status.

Disable parameter will change the color of arrows on the Status web

The

page to gray to show they are not being monitored or reported to upper

level control devices. This is the default setting.

Input Format – selection of the input format on the SD-SDI or HD-SDI

•

signal. Refer to Figure 16 on page 34 for formats available.

•

Carrier Detect – indicates the presence of valid input signal.

8949MDA-CFR/-SFR — Instruction Manual 33

Page 34

Remote Configuration

8949MDA-CFR only

• Locked Rate – this value is linked to the input bitstream rate detected.

Video Format – this value reports the input format detected.

•

Monitoring Format – this value indicates the downscaled output format.

•

Composite Color Bar – on the 8949MDA-CFR only, this parameter allows

•

the selection of a composite color bar test pattern on the downscaled

composite outputs.

Composite Setup – on the 8949MDA-CFR only, this parameter will appear

•

Monitoring Format is 480i/59.94 (NTSC). Configure as Setup or No

if the

Setup

on the composite outputs as shown in Figure 16.

Figure 16. Settings Web Page without SFP Device

34 8949MDA-CFR/-SFR — Instruction Manual

Page 35

Figure 17. Settings Web Page With Dual Receiver SFP Device

Select one input

Remote Configuration

8949MDA-CFR/-SFR — Instruction Manual 35

Page 36

Remote Configuration

Enable TX outputs

Figure 18. Settings Web Page with Dual Transmitter SFP Device

36 8949MDA-CFR/-SFR — Instruction Manual

Page 37

Figure 19. Settings Web Page with Transceiver SFP Device

Select one input

Enable TX2 output

Remote Configuration

8949MDA-CFR/-SFR — Instruction Manual 37

Page 38

Remote Configuration

Use

this

link

Slot Config Web Page

Use the Slot Config web page (Figure 20) to perform the following functions on the module:

•Locate Module

Slot Identification

•

•Slot Memory

• Frame Health Reports link

• LED Reports link

• SNMP Trap Reports link.

Figure 20. Slot Config Web Page

38 8949MDA-CFR/-SFR — Instruction Manual

Page 39

Remote Configuration

Locate Module

Selecting Flash from the Locate Module pulldown flashes the yellow COMM

and CONF LEDs on the front of the module so it can be located in the

frame.

Slot Identification

You may identify the module by typing a specific name in the Name field.

The assigned name is stored on the 8900NET module and travels with the

8900NET module if it is moved to another frame. Select

factory default module name.

An asset identification may be entered in the Asset Tag field. This will appear

on the module Status web page and in the NetConfig inventory report.

Default to enter the

Slot Memory

The slot configuration for each media module is automatically polled and

refreshed periodically (about every 50 minutes) by the 8900NET module

when the

page (with 4.3.0 software) and/or the

media module Slot Config web page is selected.

Always Slot Refresh checkbox on the 8900NET Configuration web

Restore upon Install checkbox on any

When the Restore upon Install checkbox on any media module Slot Config

web page has been selected, the current configuration from that module is

saved in slot memory on the 8900NET module. This allows the current

module to be removed and when another module of the same part number,

and software version is installed, the configuration saved to the 8900NET

module will be downloaded to the installed module. The

checkbox must be selected before the current module with the saved con

figuration is removed.

Note Make sure all modules of the same model type are running the same software

version and have the same part number silk-screened on the printed circuit

board. Downloading a configuration to a module with a different software

version or part number can produce unexpected results.

If a different type of module is installed in this slot, a warning message will

state that the original module type has been replaced with another module

type. In this case, a

configuration from the previous module.

Clear button will appear allowing you to clear the stored

Restore upon Install

-

8949MDA-CFR/-SFR — Instruction Manual 39

Page 40

Software Updating

You may also select the Learn Module Config button at any time to save the

current configuration for this slot. The configuration is saved on the

8900NET module. If the 8900NET module is removed or powered down,

the stored configurations are not saved.

When no Restore upon Install checkboxes on any of the media module Slot

Config web pages are selected and the

8900NET Configuration web page is unchecked, the slot refresh polling

function on the 8900NET module will be disabled. See the

checkbox description in the 8900NET (Net Card) Network Interface Module

Instruction Manual for more details.

Note Uncheck the Restore Upon Install button before downloading new software.

Software Updating

Software updating of the 8949MDA modules is done using the NetConfig

Networking Application PC option. The NetConfig application is available

free of charge from the Grass Valley web site. Check the Grass Valley web

site for update information. Refer to

more information.

Always Slot Refresh checkbox on the

Always Slot Refresh

Contacting Grass Valley on page 4 for

All modular product documentation can be found in PDF format on the

Grass Valley web site at this link:

www.grassvalley.com/docs/modular

40 8949MDA-CFR/-SFR — Instruction Manual

Page 41

Status Monitoring

There are a number of ways to monitor frame and module status. These

methods are summarized here. For more detailed information, refer to the

8900NET (Net Card) Network Interface Module Instruction Manual and the

8900 Gecko or 8900 GeckoFlex Frame Instruction Manuals.

All modular product documentation is available on-line in PDF format at

this link:

www.grassvalley.com/docs/modular

The main status monitoring methods include the following:

• External frame alarm output on the rear of the 8900 frame with

• LEDs on the Frame, 8900NET module, and individual frame media

• Web browser status reporting for each frame component, and

Status Monitoring

reporting from the Module Health Bus and other frame status alarm

reports,

modules,

• SNMP traps, captured by Grass Valley’s NetCentral or another SNMP

Manager Application.

Note SNMP trap information is only available when an SNMP Agent has been

installed and configured.

External Frame Alarm

An external Frame Alarm output is available on pins 8 and 9 of the RS-232

connector on the rear of the frame. The Frame Alarm outputs a voltage

level indicating there is an alarm condition on the Module Health Bus or

one of the other frame components reported to the Frame Monitor module

in a Gecko 8900TF or GeckoFlex 8900FF frame or the 8900NET module in

an 8900TFN and GeckoFlex 8900FFN frame.

• The Module Health bus is a separate line on the frame motherboard

that provides a means for older or less capable modules (such as DAs

with no microprocessor) that cannot communicate over the Frame

(serial) bus to report warning and alarm conditions to the external

Frame Alarm. All media modules in the frame report a voltage level to

this line when a warning condition occurs on the module. The specific

warning or module location is not reported, only an indication that an

warning condition has occurred.

• Frame alarm reporting from other frame components can be enabled

and disabled using DIP switches on the Frame Monitor and 8900NET

module. For frames with an 8900NET module, the Frame Alarm

Reporting web page allows configuration of the alarms and warnings

that are reported to this external Frame Health Alarm.

8949MDA-CFR/-SFR — Instruction Manual 41

Page 42

Status Monitoring

LED Reporting

Web Browser Interface

LEDs on the front of media modules, the Frame Monitor or 8900NET modules, and the front covers of the 8900TF/TFN and GeckoFlex FF/FFN

frames indicate status of the frame and the installed power supplies, fans

in the front covers, and module status. (The 8900TX-V/A and GeckoFlex

8900FX frames have no LED indicators on the front cover.)

• LED reporting from the modules in the frame to the 8900NET module

is configurable using the 8900NET LED Reporting web page.

• The Status LEDs for this module are described in Operation Indicator

LEDs on page 22. LEDs for the 8900NET module are described in the

8900NET (Net Card) Network Interface Instruction Manual.

The 8900NET module controls a web browser GUI that indicates frame and

module status on the following web pages:

• Frame Status web page – reports overall frame and module status in

•Module Status web page (Figure 12 on page 29) – shows specific input

• A Status LED icon on each web page reflects the module status on the

SNMP Reporting

The Gecko 8900 Series system uses the Simple Network Monitoring Protocol (SNMP) internet standard for reporting status information to remote

monitoring stations. When SNMP Agent software is installed on the

8900NET module, enabled status reports are sent to an SNMP Manager

such as the Grass Valley’s NetCentral application.

Status reporting for the frame is enabled or disabled with the configuration

DIP switches on the 8900NET module. Most module status reporting items

can be enabled or disabled on individual configuration web pages.

colored graphical and text formats. Refer to Figure 10 on page 26 for an

example.

and reference signal configuration error status to the module along

with module status and information (part number, serial number, hardware version, software/firmware/boot versions, and Asset number (as

assigned on the Slot Config web page).

module Status web page where warnings and faults are displayed and

is a link to the module Status web page.

42 8949MDA-CFR/-SFR — Instruction Manual

Page 43

Specifications

Specifications

Table 6. 8949MDA-CFR and 8949MDA-SFR Specifications

Parameter Value

Coax Input

Number and type of inputs 1 BNC

Input impedance 75 Ohm

Input signal type Serial digital component conforming to the following formats:

• SMPTE 292M for 1080i/50, 1080i/59.94, 720p/50 and 720p/59.94

• SMPTE 259M (270 Mb/s)

Signal level SDI 800 mV p-p ±10% max

Return loss >15 dB 0.004 to 1.50 GHz

Auto equalization • HD signals up to 125m of Belden 1694A

• SD signals up to 330m of Belden 1694A

Tolerated input jitter Compliant with the SMPTE 259M (270 Mb/s) and SMPTE 292M stan-

dards

DA Coax Outputs

Number and type of outputs 4 BNCs

Output impedance 75 Ohm

Signal type Serial digital component conforming to the following formats:

• 1080i/50, 1080i/59.94, 720p/50 and 720p/59.94

• SMPTE 259M (270 Mb/s)

Signal level SDI 800 mV p-p ±10%

Return loss • >15 dB 4 to 270 MHz

• >13 dB 0.27 to 1.50 GHz

Output jitter For input with < 0.1 UI jitter, the output jitter complies with the SMPTE

292M and SMPTE 259M standards

Downscaled Serial Outputs (8949MDA-SFR Module)

Number and type of outputs 4 BNCs

Signal type Conforming to the SMPTE 259M standard

SDI level 800 mV±10%

Return loss > 15 dB

Output jitter Conforming to the SMPTE 259M standard

Downscaler delay < 0.95 ms

Downscaler output 9 bits representation

Embedded audio and HANC passed to output SD SDI only

Downscaled Composite Outputs (8949MDA-CFR Module)

Number and type of outputs 4 BNCs

Signal type Conforming to the SMPTE 170M standard for NTSC and CCIR624 for

PAL-B

Return loss > 40 dB, 0 to 10 MHz

Output impedance 75 Ohm

Downscaler delay < 0.97 ms

Downscaler output 9 bits representation

8949MDA-CFR/-SFR — Instruction Manual 43

Page 44

Specifications

Table 6. 8949MDA-CFR and 8949MDA-SFR Specifications

Parameter Value

Power

Maximum Input power (with fiber optic SFP

device)

8949MDA-CFR

8949MDA-SFR

8.5 W

7.9 W

Mechanical

Number of frame slots 1 slot

Rear module type 8900WFR-R

Rear module retainer maximum screw torque 4-5 inch-lb./0.45-0.6Nm

Environmental

Frame temperature range

Operating humidity range

Non-operating temperature

Refer to GeckoFlex Frames 8900FX/FF/FFN Signal Processing Systems Instruction Manual at www.grassvalley.com/docs/modular

Table 7. Receiver/Transceiver Fiber Optic SFP Device Specifications

Model Number SFP-13103G-M2DRX SFP-13103G-M2TRX

Low wavelength 1270nm 1270nm

High wavelength 1610nm 1610nm

Receiver channels 2 1

Connector type LC

Fiber support Single mode

Data rate 143 Mb/s to 2.97 Gb/s

Maximum receive signal levels @2.97Gb/s,

360Mb/s, and 270Mb/s

Minimum receive signal levels @2.97Gb/s,

360Mb/s, and 270Mb/s

-3 dBm (0.501) mW

-23 dBm (0.500974 mW)

Table 8. Transmitter/Transceiver Fiber Optic SFP Device Specifications

Model Number SFP-13103G-M2DTX SFP-13103G-M2TRX

Wavelength 1 1310nm 1310nm

Wavelength 2 1310nm N/A

Transmit channels 2 1

Connector type LC

Fiber support Single-mode

Data rate 143 Mb/s to 2.97 Gb/s

Power output @2.97Gb/s, 360Mb/s, and

270Mb/s

Maximum distance 10 km

Maximum distance 20 km

1

The 1310 nm Dual Transmitter (SFP-13103G-M1DTX) and Transceiver (SFP-13103G-M1TRX) require no attenu-

ation between fiber transmitter and receiver connections at any length.

-5 to 0 dBm (-2dBm typical)

1

44 8949MDA-CFR/-SFR — Instruction Manual

Page 45

Service

Power-up Diagnostics Failure

Troubleshooting

The 8949MDA modules make extensive use of surface-mount technology

and programmed parts to achieve compact size and adherence to

demanding technical specifications. Circuit modules should not be ser

viced in the field unless otherwise directed by Customer Service.

If the module has not passed self-diagnostics, do not attempt to troubleshoot. Return the unit to Grass Valley (see Module Repair below).

Electronic Circuit Breaker

Service

-

The electronic circuit breaker works during a fault condition or an overcurrent which stops the module.

Remove the module and replace it in the frame. If the problem persists,

please refer to the Grass Valley Customer Service.

Module Repair

If the module is still not operating correctly, replace it with a known good

spare and return the faulty module to a designated Grass Valley repair

depot. Call your Grass Valley representative for depot location.

Refer to Contacting Grass Valley on page 4 at the front of this document for

information on contacting Grass Valley Customer Service.

8949MDA-CFR/-SFR — Instruction Manual 45

Page 46

Service

Table of Alarms

Ta bl e 9 below describes the different type of alarms that can occur on the

module.

Table 9. List of Alarms for 8949MDA module

Alarm

type

Fault Firmware failure If the firmware is wrong or after a bad download

Fault Optical failure Yes

Fault Optical SFP device communication error communication problem with the optical module Yes

Fault Software/Firmware version incompatible Yes

Warning Signal not Present on BNC Input PRES COAX IN

Warning Wrong Rear Module The rear module is not compatible with the front module

Warning Signal not Present on Optic Input 1 PRES OPT IN 1

Warning Signal not Present on Optic Input 2 PRES OPT IN 2

Warning Mismatch or unknown format Format detected different of format selected or unknown

Warning Module not locked No

Warning Incoming bit stream error Video input signal have a bit stream error No

Web Page Description LED Comments

STATUS PAGE:

The color of the front module becomes red

(green)

(orange)

(orange)

STATUS PAGE:

The electrical input arrow is yellow

SETTING PAGE:

The carrier detect option is not present

8949MDA-CFR or 8949MDA-SFR

STATUS PAGE:

Optic input arrow is yellow

STATUS PAGE:

Optic input arrow is yellow

format detected

Net Card&SNMP

Query status

towards

Yes

Yes

Yes

Yes

Yes

No

46 8949MDA-CFR/-SFR — Instruction Manual

Page 47

Functional Description

A block diagram of the 8949MDA-CFR is shown in Figure 21.

Figure 21. 8949MDA-CFR Block Diagram

Functional Description

HD/SD

SDI In

HD/SD

Optical In

Equalizer and

Re-clocker

Only one fiber

option may be

selected

Fiber RX

Fiber RX

Fiber RX

Down-

converter

Option

Encoder

OptionOption

A block diagram of the 8949MDA-SFR is shown in Figure 22.

Figure 22. 8949MDA-SFR Block Diagram

4X HD/

SD-SDI

Out

4X

PAL/NTSC

Out

Fiber TX

Fiber TX

HD/SD

Optical Out

Fiber TX

HD/SD

SDI In

HD/SD

Optical In

Only one fiber

option may be

selected

Fiber RX

Fiber RX

Fiber RX

Option

Option

Equalizer and

Re-clocker

Down-

converter

4X HD/

SD-SDI

Out

4X

SD-SDI

Out

Fiber TX

Option

Fiber TX

HD/SD

Optical Out

Fiber TX

8949MDA-CFR/-SFR — Instruction Manual 47

Page 48

Functional Description

48 8949MDA-CFR/-SFR — Instruction Manual

Page 49

Configuration Summary Table

Ta bl e 10 provides a complete summary of the module functions and a com-

parison of the functionality available with each control type along with the

ranges and default values for each parameter and notes on each control.

Table 10. Summary of Configuration Functions

Local Controls

Switches

S1 and S2

S2: Pin 1

Off = Local Only

On = Local&Remote

S1: Pins 6 and 7

Input Select

Coax In: 0 0

Optic 1: 0 1, or

Optic 2: 1 0

S2: Pin 4

Off = Disabled

On = Enabled

N/A N/A

S1: Pins 2, 3, 4,5

Auto: 0 0 0 0

1080i/50: 0 0 0 1

1080i/59.94: 0 0 1 0

720p/50: 0 0 1 1

720p/59.94: 0 1 0 0

480i/59.94: 0 1 0 1

576i/50: 0 1 1 0

N/A ColorBar

S1: Pin 8

Off = No Setup

On = Setup

Function

Type

Config mode Local&Remote

Routing mode

(Up to three inputs depending on

type of fiber optic SFP device

installed.) Only one input can be

active at a time.

Optic outputs enable

(Up to two outputs depending on

type of fiber optic SFP device

installed.) All fiber outputs can be

active at the same time.

Input reporting enable Enable Disable or Enable

Input Format selection Auto

Composite Color Bars test signal

(8949MDA-CFR only)

Composite Setup

(8949MDA-CFR only)

Default

Coax In J9

Disable Disable or Enable

Disable Enable or Disable

Setup Setup or No Setup

Range/Choices

Resolution

Local or

Local&Remote

Coax In J9,

Optic 1 (In), or

Optic 2 (In)

Auto,

1080i/50,

1080i/5994

720p/50,

720p/59.94,

480i/59.94, or

576i/50

Web Page/

Function Name

Access to web pages can be

locked out by Local controls

Settings/

Routing Mode

Coax In J9, Optic 1 (In), or

Optic 2 (In) radio button

Settings/

Optic Outputs pulldown

Settings/

Input Reporting pulldown

Settings/

Input Standard Selection

pulldown

Settings/

Composite Color Bar

pulldown

Settings/

Composite Setup pulldown

Newton

Control

Panel

N/A

Rout Mode

Optic Out

N/A

CompSetup

8949MDA-CFR/-SFR — Instruction Manual 49

Page 50

Configuration Summary Table

50 8949MDA-CFR/-SFR — Instruction Manual

Page 51

Index

Numerics

8900NET (Net Card) module 26

8900WFR-R rear module

installation

overview 11

8949MDA-CFR

cabling

features 9

installation 16

8949MDA-SFR

cabling

features 9

installation 16

15

20

21

A

Auto cable equalization 10

B

block diagrams 47

C

cabling

8949MDA-CFR module

8949MDA-SFR module 21

fiber optic SFP devices 20, 21

overview 19

Carrier Detect reporting 33

Clear button 39

Coax 1 and 2 inputs 33

COMM LED 23

Composite Color Bar test pattern 34

Composite Setup

local configuration

remote configuration 34

COMPOSITE SETUP LED 23

CONF (configuring) LED 23

configuration

local controls

14

13

20

summary table 49

with remote controls 24

control panel 24

D

documentation online 4

downscaled composite outputs

specifications

downscaled serial outputs

embedded audio

43

9, 10

E

embedded audio

overview

specification 43

9

F

factory defaults

summary table

FACTORY LED 23

FAQ database 4

FAULT LED 23

fiber optic

cabling

enabling inputs/outputs 33

options overview 10

fiber optic cleaning kit 17

fiber optic SFP device

installation

Frame Status web page 42

frequently asked questions 4

front module

installation

20, 21

49

17

16

G

GeckoFlex frame

frame alarm

41

8949MDA-CFR/-SFR — Instruction Manual 51

Page 52

Index

graphical user interface (GUI) 27

Grass Valley web site 4

H

HANC data

in downscaled outputs

9, 10, 43

I

Input Format selection 33

Input power 44

Input Reporting 33

installation

front module

precautions 12

rear module 15

Internet Explorer

recommended web browser

16

26

L

LEDs

front edge illustration

overview 23

Locate Module function 39

Locked rate reporting 34

22

O

online documentation 4

operating system 26

P

power specifications 44

PRES OPT MOD LED 23

PRES SIG EQ LED 23

PRES SIG OPT 1 LED 23

PRES SIG OPT 2 LED 23

PWR LED 22, 23

R

rear module

installation

installation precautions 12

type 9, 44

rear module retainer clip

installing

torque specification 44

Remote control 10

Restore upon Install checkbox 39

retainer clip tool 15

15

15

M

Module Health Bus 41

module installation precautions 12

Module Status web page 42

Monitoring Format of downscaled output 34

MONITORING MODE LEDs 23

N

NetConfig PC application

required for updating software

Newton Control Panel

overview

summary table 49

24

40

S

Settings web page 33

SFP Fiber Optic devices

options available

SIG_PRES LED 22

Slot Config web page 38

slot memory 39

SNMP reporting

overview

software download from web 4

software updating 40

specifications

8949MDA-CFR/-SFR

SFP devices 44

status monitoring 41

Status web page 28

42

10

43

52 8949MDA-CFR/-SFR — Instruction Manual

Page 53

V

Video Format reporting 34

video input(s)

8949MDA-CFR

8949MDA-SFR 21

specifications 43

video outputs

8949MDA-CFR

8949MDA-SFR 21

specifications 43

20

20

W

web browser

overview

recommended 26

web site

documentation

FAQ database 4

Grass Valley 4

software download 4

25

4

Index

8949MDA-CFR/-SFR — Instruction Manual 53

Page 54

Index

54 8949MDA-CFR/-SFR — Instruction Manual

Loading...

Loading...