Page 1

8920ADC

AUDIO A-TO-D CONVERTER

Instruction Manual

SOFTWARE VERSION 2.0.1A

071059503

JUNE 2005

Page 2

Contacting Grass Valley

Region Voice Fax Address Web Site

North America (800) 547-8949

Support: 530-478-4148

Pacific Operations +852-2585-6688

Support: 852-2585-6579

U.K., Asia, Middle East +44 1753 218 777 +44 1753 218 757

France +33 1 45 29 73 00

Germany, Europe +49 6150 104 782 +49 6150 104 223

Copyright © Thomson Broadcast and Media Solutions All rights reserved.

Grass Valley Web Site

Sales: (530) 478-3347

Support: (530) 478-3181

+852-2802-2996

Grass Valley

P.O. Box 599000

Nevada City, CA 959597900 USA

www.thomsongrassvalley.com

The www

Online User Documentation

.thomsongrassvalley.com web site offers the following:

— Current versions of product catalogs, brochures,

data sheets, ordering guides, planning guides, manuals, and release notes

in .pdf format can be downloaded.

FAQ Database

— Solutions to problems and troubleshooting efforts can be

found by searching our Frequently Asked Questions (FAQ) database.

Software Downloads

— Software updates, drivers, and patches can be down-

loaded.

2 8920ADC Instruction Manual

Page 3

Contents

Preface

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

8920ADC Analog Audio to AES/EBU Converter

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Frame Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Module Placement in the 8900 Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Reference Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation Indicator LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Configuration Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Output Level Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Configuring Output Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Remote Control Lockout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Local Onboard Module Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Remote Configuration and Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8900NET Module Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Newton Control Panel Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Web Browser Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8920DAC Links and Web Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

User Settings Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Slot Config Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Software Update Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Status Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Frame Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Web Browser Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

SNMP Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Differential Input, Analog Gain and A/D Converters . . . . . . . . . . . . . . . . . . . . 35

Digital Reference Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Routing and Control FPGA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Index

8920ADC Instruction Manual 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Page 4

Contents

4 8920ADC Instruction Manual

Page 5

Preface

About This Manual

This manual describes the features of a specific module of the Gecko 8900

Signal Processing System. As part of this module family, it is subject to

Safety and Regulatory Compliance described in the Gecko 8900 Series

frame and power supply documentation (see the 8900TX/8900TF/8900TFN

Frames Instruction Manual

).

8920ADC Instruction Manual 5

Page 6

Preface

6 8920ADC Instruction Manual

Page 7

8920ADC Analog Audio to AES/EBU Converter

Introduction

The 8920ADC converts analog audio to digital audio. The right and left

channel audio inputs enter via a terminal block-to-BNC adapter on the rear

panel. A 48 kHz AES/EBU reference is required to lock the module, which

is connected to the loop through input BNCs. The module outputs 4

AES/EBU 75

Ω signals through BNCs on the rear panel.

The 8920ADC can modify the outgoing signal to provide channel swapping, channel summing, tone and phase inversion. The remote control

capability supports mode selection and input gain control.

The 8920ADC features:

• 24-bit resolution,

•AES/EBU loop-through reference input,

• 48 kHz sampling rate,

•Terminal block input via adapter,

• Independent input level control from +12 dBu to +28 dBu,

• 8900 Series Frame compatibility,

•Remote control via ethernet frame I/F,

•Newton Control Panel,

•SNMP monitoring, and

•Remote control lockout via onboard jumper.

8920ADC Instruction Manual 7

Page 8

Installation

Installation

Frame Capacity

1.

2.

3.

Installation of the 8920ADC module is a process of:

Placing the module in the desired frame slot,

Cabling and terminating signal ports, and

Configuring the module.

The 8920ADC module can be plugged in and removed from an 8900 Series

frame with power on. When power is applied to the module, LED indicators reflect the initialization process (see Power Up on page 11).

The 8920ADC module can be installed in all 8900 Series frames but with

varying maximum quantities determined by frame cooling capacity.

Table 1 provides the power capacity, cooling capacity, and maximum

module count for each frame type.

Table 1. Power, Cooling, and Module Capacity of 8900 Frames

Capacity Calculated

Power (W) 100 100 100

Recommended Module Cooling (W) 30 90 90

8920ADC Modules 7 10 10

Note

Module capacity figures assume no other modules are in the frame.

8900TX

Frame

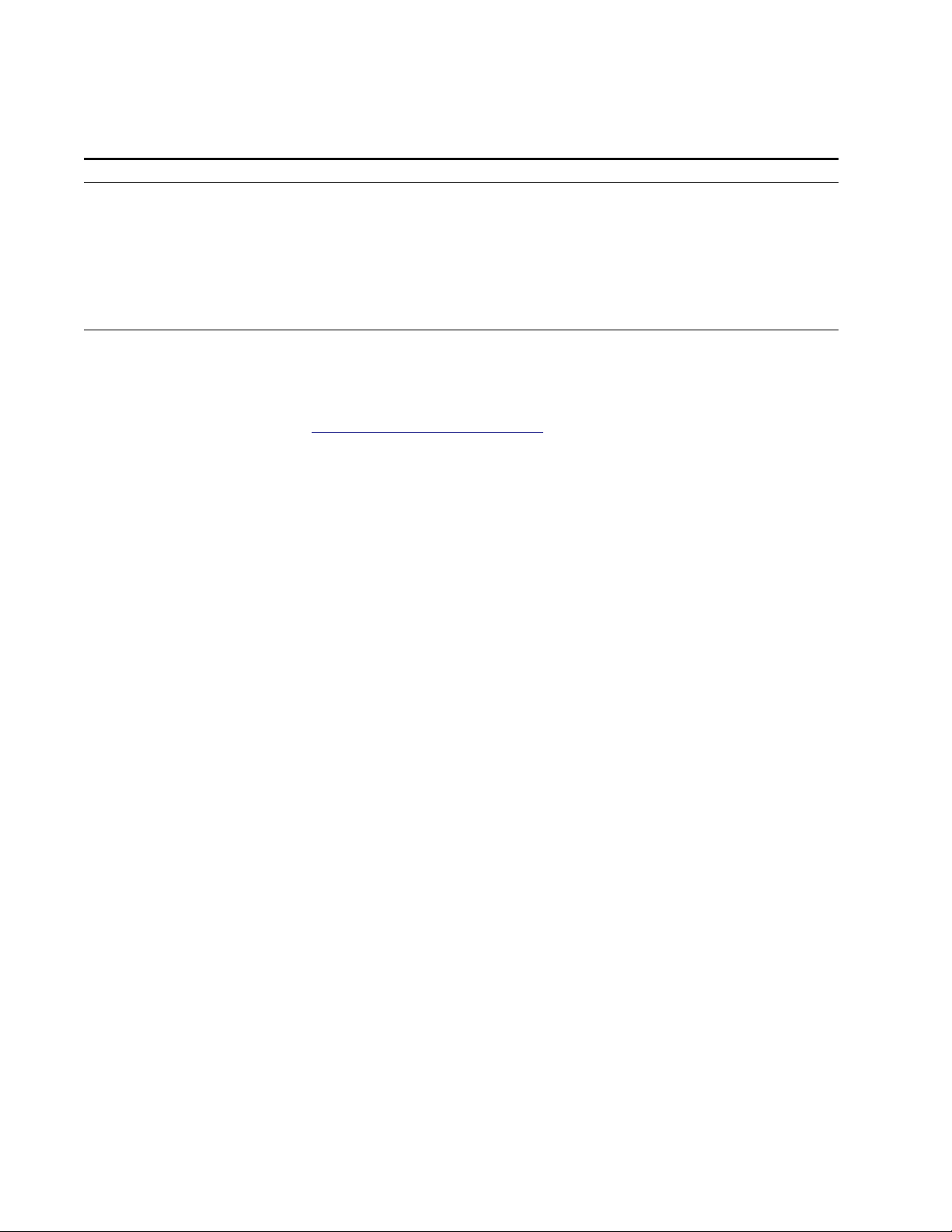

Module Placement in the 8900 Frame

There are ten cell locations in the frame to accommodate either analog or

digital modules. These are the left ten locations. Refer to Figure 1 on page 9.

The two cells on the right are allocated for the power supplies. For additional information concerning the Power Supply module, refer to the

8900 Frame Instruction Manual

The third cell from the right is allocated for the Frame Monitor or 8900NET

Network Interface controller modules. These modules provide health monitoring and control options.

.

8900TF

Frame

8900TFN

Frame

Gecko

8 8920ADC Instruction Manual

Page 9

Frame Monitor Module or

Network Interface Module

Any 8900 Module

Power

Supplies

(only)

0595-04r1

0595-03

J1 J2

J3 J4

J5 J6

J7 J8

J9 J10

IN

DA1

J2

J4

J6

J8

J1 J2

J3 J4

J5 J6

J7 J8

J9 J10

IN

DA3

J1 J2

J3 J4

J5 J6

J7 J8

J9 J10

IN

DA5

J1 J2

J3 J4

J5 J6

J7 J8

J9 J10

IN

DA2

J1 J2

J3 J4

J5 J6

J7 J8

J9 J10

IN

DA7

J1 J2

J3 J4

J5 J6

J7 J8

J9 J10

IN

DA9

J1 J2

J3 J4

J5 J6

J7 J8

J9 J10

IN

DA4

J2

J4

J6

J8

J1 J2

J3 J4

J5 J6

J7 J8

J9 J10

IN

DA6

J2

J4

J6

J8

J1 J2

J3 J4

J5 J6

J7 J8

J9 J10

IN

DA8

J2

J4

J6

J8

J1 J2

J3 J4

J5 J6

J7 J8

J9 J10

IN

DA10

O

U

T

O

U

T

O

U

T

O

U

T

O

U

T

O

U

T

O

U

T

O

U

T

O

U

T

O

U

T

1.

2.

3.

Figure 1. 8900 Series Frame

Installation

8900 modules are interchangeable within the module cells. There are 10

BNC connectors in each cell’s I/O group. The functional assignment of

each connector in a group is determined by the module that is placed in

that cell. The maximum number of modules an 8900 frame can accept is ten.

Figure 2 illustrates the rear connector plate for an 8900 Series frame.

Figure 2. 8900 Series Frame Rear Connector

To install a module in the frame:

Insert the module, connector end first, with the component side of the

module facing to the right and the ejector tab to the top.

Verify that the module connector seats properly against the backplane.

Press the ejector tab in to seat the module in place.

8920ADC Instruction Manual 9

Page 10

Installation

Cabling

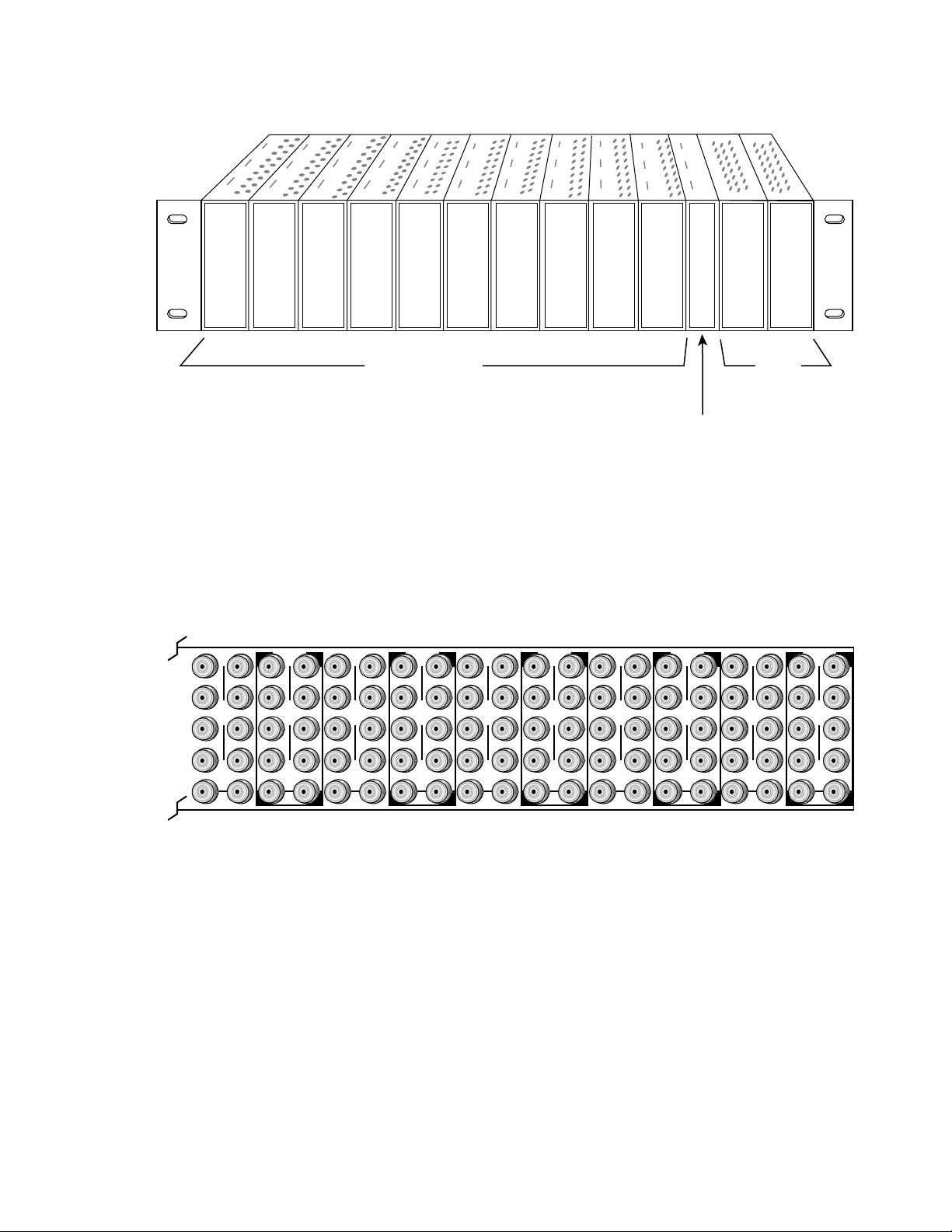

Input

Note

At the back of this manual are overlay cards that can be placed over the rear

connector BNCs to identify the specific 8920ADC connector functions.

Connect a balanced input source to the stereo pair input terminal block (see

Figure 3).

CAUTION The input signal must be balanced. Connecting an un-balanced input signal

at high signal levels may damage the input receivers.

The 8920ADC can produce a full-scale output from an analog audio input

signal level of +12 dBu to +28 dBu.

Figure 3. 8920ADC Input/Output Connectors

Grass Valley

DAx

Adaptor

R+

J2

J2

GND

R–

J4

J4

T

J4

Analog balanced

input adapter

J1

J1

J3

L+

GND

L–

O

U

AES reference

loop-through input

Outputs

Reference Inputs

J5

J7

J9 J10

IN

J6

J8

J6

J8

AES outputs

0595-02

The 8920ADC has four AES/EBU serial digital outputs—J5 through J8. The

Ω

destination equipment should have a 75

through inputs that are terminated into 75

input impedance or loop

Ω .

Loop-through input BNCs are provided for the required 48 kHz AES/EBU

reference signals. Terminate the looping BNC into 75

Ω if not used.

10 8920ADC Instruction Manual

Page 11

Power Up

Operation Indicator LEDs

Power Up

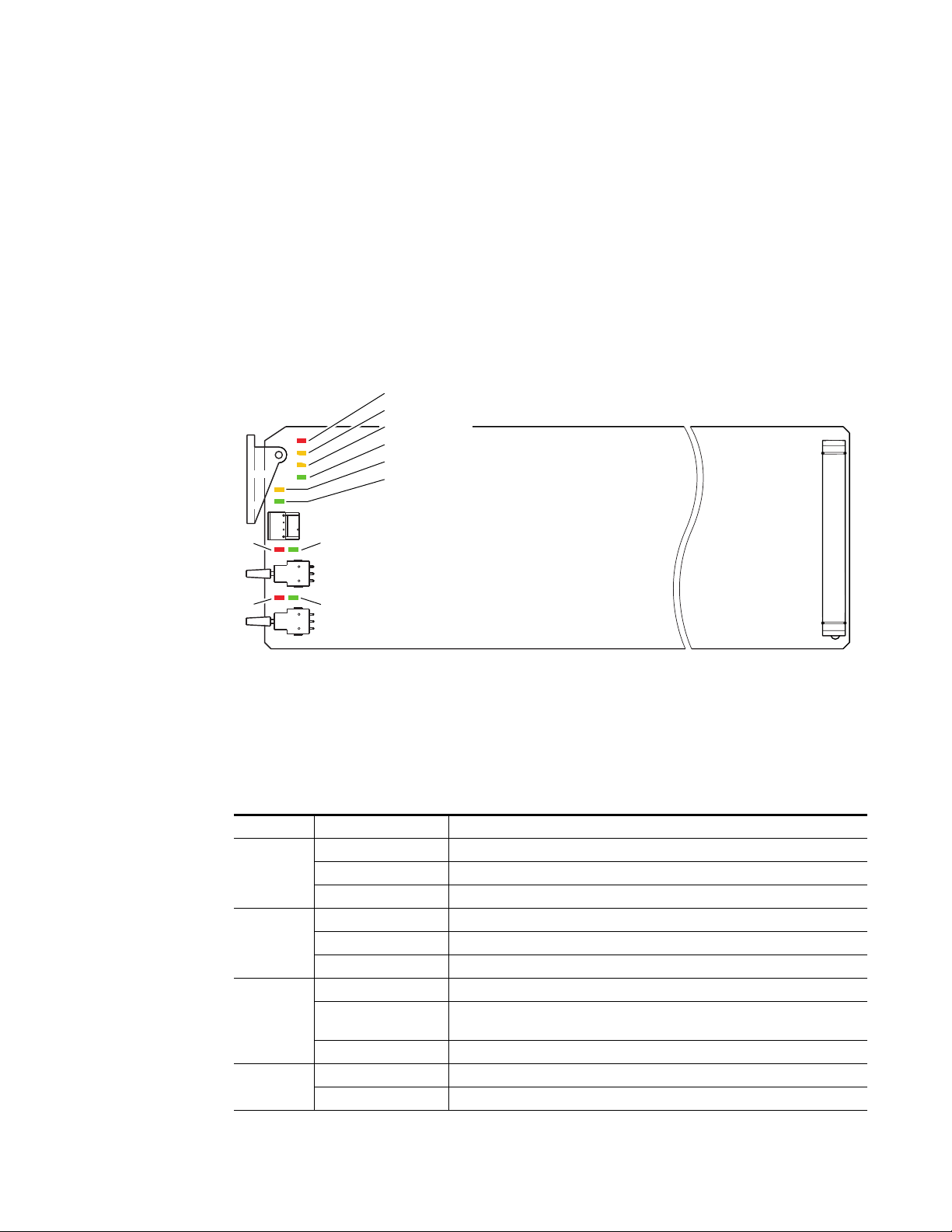

The front LED indicators and configuration switches are illustrated in

Figure 4. Upon power-up, the green PWR LED should light and the yellow

CONF LED should illuminate for the duration of module initialization.

With factory default configuration and valid input and reference signals

connected, the green PWR LED and the green LOCK LED should be on.

Figure 4. Operation Indicator LEDs

FAULT (red)

COMM (yellow)

CONF (yellow)

PWR (green)

REM OVER (yellow)

LOCK (green)

Left In

Clip (red)

Right In

Clip (red)

Left In > -20dBFS (green)

Right In > -20dBFS (green)

A red FAULT LED indicates an error situation and, with the other LEDs,

can indicate the operational conditions presented in Table 2. The table

describes signal output and LED indications for various input/reference

combinations and user settings.

Table 2. Indicator LEDs and Conditions Indicated

LED Indication Condition

FAULT

(red)

COMM

(yellow)

CONF

(yellow)

PWR

(green)

Off Normal operation.

On continuously Module has detected an internal fault.

Flashing Reference input is faulty or not present.

Off No activity on frame communication bus.

Long flash Location Command received by the module from a remote control system.

Short flash Activity present on the frame communication bus.

Off Module is in normal operating mode.

On continuously

Flashing Indicates rate of change of paddle-controlled analog setting.

Off No power to module or module’s DC/DC converter failed.

On continuously Normal operation, module is powered.

Module is initializing, changing operating modes or updating firmware. Simultaneous CONF and FAULT LEDs on indicate FPGA load error.

0595_06

8920ADC Instruction Manual 11

Page 12

Power Up

Table 2. Indicator LEDs and Conditions Indicated - (continued)

LED Indication Condition

REM OVER

(yellow)

LOCK

(green)

LEFT IN

(green)

RIGHT IN

(green)

LEFT IN

CLIP

(red)

RIGHT IN

CLIP

(red)

Off Module configuration matches switch and jumper settings.

On continuously

Off Module does not detect a valid AES in reference signal.

On continuously Valid AES in reference signal is present and module is locked to it.

Off Left channel level is less than -20 dBFS.

On continuously Left channel level is greater than -20 dBFS.

Flashing Left channel level is transitioning through -20 dBFS

Off Right channel level is less than -20 dBFS.

On continuously Right channel level is greater than -20 dBFS.

Flashing Right channel level is transitioning through -20 dBFS

Off Left channel digitized signal level is less than -0.5 dBFS.

On continuously Left channel digitized signal level is greater than -0.5 dBFS.

Flashing Left channel digitized signal level is transitioning through -0.5 dBFS.

Off Right channel digitized signal level is less than -0.5 dBFS.

On continuously Right channel digitized signal level is greater than -0.5 dBFS.

Flashing Right channel digitized signal level is transitioning through -0.5 dBFS.

Module configuration may not match switch and jumper settings. Control has been

remotely overridden.

Table 3 provides the possible input conditions and the output condition

that results.

Table 3. Possible Operating Conditions

Audio Input Condition Reference Input Condition Output Condition

Audio inputs present Valid reference input present AES/EBU serial digital output sampled at 48 kHz.

No audio input signal present Valid reference input present AES/EBU serial digital output sampled at 48 kHz. See S/N specification for level.

Audio inputs present Reference not present AES/EBU serial digital output sampled at approximately 47.992 kHz. Internal

freerun clock rate.

Audio inputs present Invalid reference input Invalid AES/EBU serial digital output.

12 8920ADC Instruction Manual

Page 13

Configuration

Configuration

The 8920ADC can be configured locally using onboard switches or

remotely using the 8900NET network interface GUI or a networked

Newton Control Panel.

Refer to the following sections for configuration instructions:

•Configuration Summary (page 13)

• Local Onboard Module Configuration (page 18)

•Remote Control and Monitoring (page 19)

Operation of these control types is explained in detail in their respective

sections of this manual.

Configuration Summary

This section provides a summary of all parameters that can be configured

on the 8920DAC module. Table 6 on page 17 provides a summary in table

format of all parameters and their ranges, default values, and remote, local,

and control panel function names and locations for setting each value.

The following parameters must be set on the 8920ADC module:

•Output level (Left and Right) – coarse and fine adjustment of analog

input levels for full scale digital outputs,

•Output mode – such as channel swapping, summing, tone and phase

inversion, and

8920ADC Instruction Manual 13

Page 14

Configuration

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

Default

Position

Output Level Adjustment

To correctly adjust the 8920ADC for your digital application, determine

your maximum operating level and set the Coarse Level gain jumpers on

the module circuit board as described below. This is the level above which

digital clipping occurs.

Example Maximum Operating Level Setting

A setting of +24 dBu is a common maximum level. Using +24 dBu as the

maximum level, refer to Table 4 to select the lowest input level range that

includes the maximum level of +24 dBu. Select the Coarse Level Setting pin

4 to 5 jumper setting (refer to Figure 5 on page 18) because it is the highest

level supported by that range and requires the least amount of gain to bring

+24 dBu up to 0.0 dBFS level. This will give the best signal-to-noise ratio

that the system can deliver.

1.

2.

Setting Maximum Operating Level

Once you have determined the proper coarse level jumper setting, perform

the following steps:

Set the Function Rotary Switch (SW1) on the front of the module circuit

board to the position marked 0 as shown at left.

Remove the module from the frame and set jumpers on JP5 and JP6 to

the jumper setting that you determine using Table 4.

Table 4. Jumper Coarse Level Settings for 0.0 dBFS Output

Input Level JP5/JP6 Jumper Position

12 to 16 dBu Pins 1 and 2

16 to 19 dBu Pins 2 and 3

19 to 25 dBu Pins 4 and 5

25 to 28 dBu Pins 5 and 6

Return the module to the frame.

3.

Using Level Gain Toggle Switches

Note

14 8920ADC Instruction Manual

The toggle switches change input levels by increments of approximately

0.1 dB when held momentarily. Holding the switch up or down for about 1

second activates a continuous change mode that ramps the change rate from

about 0.1 dB per second to 0.6 dB per second. The yellow CONF LED will

flash slow (0.1 dB rate) or fast (0.6 dB rate) to indicate the change rate.

Page 15

Configuration

There are three ways to adjust the onboard gain toggle switches to the

proper level:

•Apply the maximum level to the input (example +24 dBu) and monitor

the AES output with a meter that indicates digital level in dBFS and

adjust the toggle switch for each channel until the meter indicates

0.0 dBFS.

Because the toggle switches have a resolution of 0.1 dB, you may not be

able reach 0.0 dBFS exactly. Use the closest negative setting possible.

•Apply an audio level that is -20 dB below the maximum level, (+4 dBu

for the example, +24 dBu -20 dB = +4 dBu) and adjust the AES output

as indicated on a digital audio meter to -20 dBFS.

If you have no meters calibrated in dBFS you can use the tone output

position to compare with the output level. Tone output is position E on

the Function Switch and outputs a 1 kHz tone at -20 dBFS. Note the

internal tone level indication while monitoring the AES output and

switch back to 0 or F position on the Function Switch, then adjust the

gain toggle switch to the same level as the internal tone level.

•Apply the maximum level to the input (example +24 dBu) and adjust

the gain toggle switch for each channel until the clip LED comes on.

This is -0.5 dBFS, and by tapping the toggle switch four more times you

will be within 0.15 dB (worst case) of the correct gain setting.

CAUTION Using a maximum level that is larger than the high end of the range setting

jumper will result in a clipped waveform and high distortion. Use the next

higher jumper setting that includes the maximum level and readjust the gain

following the instructions above.

8920ADC Instruction Manual 15

Page 16

Configuration

Configuring Output Mode

The 8920ADC provides thirteen possible output configurations as shown

in Table 5. The module can be configured using the rotary switch shown in

Figure 5 on page 18. To make a configuration setting, rotate the switch to

the desired output configuration. The 16-position rotary switch selects one

of 13 possible output modes. Positions B and C are not used and positions

0 and F select the same mode—the factory default.

Table 5. 8920ADC Output Mode Configuration

Switch

Position

0 Factory default – No phase inversion, channel swapping or summing

1 Channel swap – Left and Right

2 Both channels phase inverted

3 Left channel phase inverted

4 Right channel phase inverted

5 Right channel to both channel outputs

6 Left channel to both channel outputs

7 Left + Right to both channel outputs (-6 dB mono sum)

8 Left - Right to both channel outputs

9 Left + Right to Left channel output and Left- Right to Right channel output

A Left + Right to both channel outputs and both channels phase inverted

B Not used (outputs AES silence)

C Not used (outputs AES silence)

DTone 1 to all channels (AES Silence)

ETone 2 to all channels (1 kHz, -20 dBFS)

F Factory default – No phase inversion, channel swapping or summing

Remote Control Lockout

Mode Description

When a jumper is placed across pins 1 and 2 of jumper block JP7 (see

Figure 5 on page 18), module output mode settings are adjustable from the

Local on-board switches only. To have both Local and Remote access, set

the jumper across pins 2 and 3.

16 8920ADC Instruction Manual

Page 17

Table 6 provides a complete summary of the 8920ADC processing func-

tions and a comparison of the functionality available with each control type

along with the ranges and default values for each parameter.

Table 6. Summary of 8920ADC Configuration Functions

Function

Type

Operational modes Default

Controls type Numeric Numeric or Sliders

Left Channel Level 0 dB ± 6 dB

Right Channel Level 0 dB ± 6 dB

Monitor Audio Outputs Disabled Enabled or Disabled

Default

Range/Choices

Resolution

Default

L/R Swap

L/R Invert

L Invert

R Invert

R Mono (R to L/R)

L Mono (L to L/R)

L plus R to L/R

L minus R to L/R

L plus R, L minus R

(L plus R) Inv to L/R

AES Silence

1K@ -20 dBFS

Web Page/

Function Name

Audio Control and Status/

Operational Modes pulldown

Refer to Table 7 on page 24

for a description of each

setting

Audio Control and Status/

Controls Type pulldown

Audio Control and Status/

Left Channel Level (dB)

Audio Control and Status/

Right Channel Level (dB)

User Settings/

Monitor Audio Outputs

pulldown

Configuration

Rotary Switch

Bank/Setting

Function Rotary

Switch SW1.

Refer to Table 5

on page 16 for

switch settings.

N/A Controls

Refer to

Using

Level Gain Toggle Switches

on

page 14

N/A Monitor

Newton

Control

Panel

Op Mode

Lt Level

Rt Level

8920ADC Instruction Manual 17

Page 18

Configuration

Local Onboard Module Configuration

The 8920ADC module can be configured locally to set parameters using the

jumpers, the rotary switch and two toggle switches shown in Figure 5. The

CONF LED indicates status of the configuration process.

These components perform the following:

• Jumper JP7 – sets control mode for Local only or Remote and Local.

• Jumpers JP5 and JP6 – set coarse input level adjustment for left and

right channels as explained in

Setting Maximum Operating Level

on

page 14).

•SW2 and SW3 (toggle) switches – provide fine adjustment of the left

and right channel input levels as described in Using Level Gain Toggle

Switches on page 14.

• Function (rotary) switch – selects a desired output configuration (0

through 9, A through F), although not all positions are used.

• CONF (configuring) LED – when on, indicates the module is initializing or processing configuration information.

Note Function switch positions 0 and F (Factory defaults) can be used to return the

module configuration to the original factory settings.

Figure 5. Module Configuration Switches and LEDs

Coarse Level Setting

Pins

1-2

2-3

5-6

4-5

JP5

Pins

CONF (yellow)

SW1 – Function Rotary Switch

JP7

SW2 – Left In Level

SW3 – Right In Level

LOCAL –

3

JP7

1

REMOTE –

2-3

4-5

5-6

JP6

1-2

jumper across these pins

(1 – 2) locks out remote control

jumper across these pins

(2 – 3) enables remote

and local control

JP5

JP6

0595_05r1

Remote Control Lockout

18 8920ADC Instruction Manual

Page 19

Remote Configuration and Monitoring

8920ADC configuration and monitoring can be performed using a web

browser GUI interface or a networked Newton Control Panel when the

8900NET Network Interface module is present in the video frame (Gecko

8900TFN-V frame). Each of these interfaces is described below.

Note For remote access, make sure the jumper block on the module is set for both

Local and Remote access (Figure 5 on page 18).

8900NET Module Information

Refer to the 8900NET Network Interface Module Instruction Manual for

information on the 8900NET Network Interface module and setting up and

operating the Gecko 8900 frame network.

Note The 8900NET module in the frame must be running software version 3.2.0 or

higher for proper remote and control panel operation. Upgrade software and

instructions for the 8900NET can be downloaded from the Grass Valley web

site.

Configuration

Newton Control Panel Configuration

A Newton Control Panel (hard or soft version) can be interfaced to the

Gecko 8900 Series frame over the local network. Refer to the documentation that accompanies the Newton Modular Control System for installation, configuration, and operation information.

Control panel access offers the following considerations for module configuration and monitoring:

•Ability to separate system level tasks from operation ones, minimizing

the potential for on-air mistakes.

•Ability to group modular products—regardless of their physical loca-

tions—into logical groups (channels) that you can easily manipulate

with user-configured knobs.

•Update software for applicable modules and assign frame and panel IP

addresses with the NetConfig Networking application.

•Recommended for real-time control of module configuration parame-

ters, providing the fastest response time.

Note Not all module functions are available with the control panel, such as E-MEM

and factory default recalls. The available control panel controls for the

8920ADC module are listed in Table 6 on page 17.

An example of the Newton Configurator is shown in Figure 6 on page 20.

8920ADC Instruction Manual 19

Page 20

Configuration

Figure 6. Newton Configurator Example

Web Browser Interface

The web browser interface provides a graphical representation of module

configuration and monitoring.

Use of the web interface offers the following considerations:

•Provides complete access to all module status and configuration functions, including naming of inputs and outputs, factory parameter and

name default recalls, E-MEM functions, slot configuration, and SNMP

monitoring controls.

•Web access will require some normal network time delays for processing of information.

•Configuration parameter changes may require pressing

Enter, upload processing time, and a manual screen refresh to become

effective.

•Web interface recommended for setting up module signal and slot

names, E-MEMS, and reporting status for SNMP and monitoring.

Refer to the Frame Status page shown in Figure 7 on page 21. The 8900

modules can be addressed by clicking either on a specific module icon in

the frame status display or on a module name or slot number in the link list

on the left.

Apply button or

20 8920ADC Instruction Manual

Page 21

Note The physical appearance of the web page displays on the web pages shown

in this manual represent the use of a particular platform, browser and version

of 8900NET module software. They are provided for reference only. Web page

displays will differ depending on the type of platform and browser you are

using and the version of the 8900NET software installed in your system. This

manual reflects 8900NET software version 4.0.0.

For information on status and fault monitoring and reporting shown on the

Status page, refer to Status Monitoring on page 32.

Figure 7. Gecko 8900 Frame Status Page

The Links section lists the frame and its current modules. The selected link's Status

page is first displayed and the sub-list of links for the selection is opened. The sub-list

allows you to select a particular information page for the selected device.

Content display section displays the information page

for the selected frame or module (frame slot icons are also

active links).

Refresh button for manual

update of page

Configuration

0595_08

8920ADC Instruction Manual 21

Page 22

Configuration

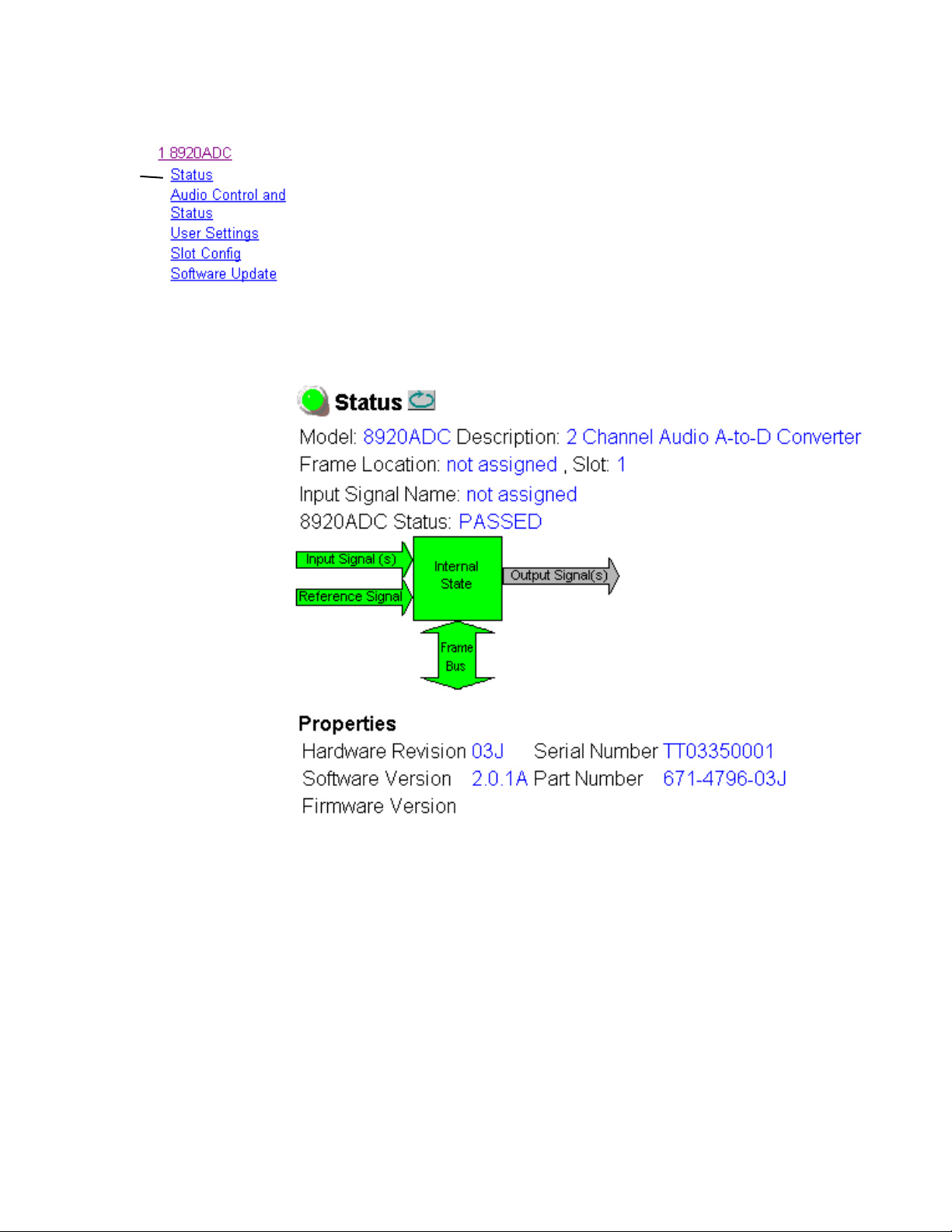

8920DAC Links and Web Pages

The 8900 GUI provides the following links and web pages for the 8920ADC

module (Figure 8):

• Status – reports input and reference signal status and module information (page 23),

•Audio Control and Status – select output format for module and adjust

the levels for video, composite sync and DC output, and video setup

amplitude (page 24),

•User Settings – select factory defaults and enable or disable status

reporting of audio inputs (page 26)

• Slot Config – provides a Locate Module function and Slot Memory and

SNMP reporting status information (page 27), and

• Software Update – provides information on software updating

(page 29).

Figure 8. 8920ADC Web Page Links

Refer to Table 6 on page 17 for a summary in table format of all parameters

and their ranges, and default values.

22 8920ADC Instruction Manual

Page 23

Status Web Page

Configuration

Use

this

link

The Status web page (Figure 9) shows the input signal status of the audio

input and the Reference Signal input. Color coding of the display indicated

the signal status. Audio input status monitoring can be disabled on the

User Settings webpage (page 26). If set to disabled, the Input Signal (s)

arrow will be gre yed out. Refer to Status Monitoring on page 32 for an

explanation of the color coding.

Information about the module, such as part number, serial number, hardware revision and software and firmware versions are given in a read-only

section at the bottom of the display.

Figure 9. 8920ADC Status Web Page (Monitor Audio Inputs Enabled)

8920ADC Instruction Manual 23

Page 24

Configuration

Use

this

link

Audio Control and Status Web Page

The Audio Control and Status web page (Figure 10 on page 25) provides

controls for setting the following audio parameters on the 8920ADC

module:

•Operational (output) mode, and

• Fine adjustment of left and right output channel levels.

The following audio status items are reported on this web page:

• Left and Right Ch > -20 dBFS – indicates whether the left and right

channel digital output levels are greater than -20 dBFS (True) or less

than -20 dBFS (False).

• Left and Right Ch > -0.5 dBFS Clip – indicates whether the digital

output clipping levels are greater than -0.5 dBFS (True) or less than -0.5

dBFS (False).

•Reference Signal – indicates whether the module is

reference signal is present and module is locked to it) or

Locked (valid AES in

Unlocked

(module does not detect a valid AES in reference signal).

Use the following controls to set the parameters for the 8920ADC:

•

Operational Modes – Set the operational mode pulldown for the desired

output of the module from the thirteen selections listed below in

Table 7 and shown in the web page in Figure 10 on page 25. After

making the selection, select the

Table 7. Audio Output Configuration Modes

Mode Name Mode Description

Default Factory default with no phase inversion, channel swapping or summing.

L/R Swap Swaps left and right channel outputs.

L/R Invert Both left and right channel outputs phase inverted.

L Invert Left channel output phase inverted.

R Invert Right channel output phase inverted.

R Mono (R to L/R) Right channel to both channel outputs.

L Mono (L to L/R) Left channel to both channel outputs.

L plus R to L/R Left plus right to both channel outputs.

L minus R to L/R Left minus right to both channel outputs

L plus R, L minus R Left plus right to left channel output and left minus right to right channel output.

(L plus R) Inv to L/R Left plus right to both channel outputs with both channel outputs phase inverted.

AES Silence AES silence on both left and right channel outputs.

1K@ -20dBFS Tone to both channel outputs.

Apply button to activate it.

24 8920ADC Instruction Manual

Page 25

Configuration

• Left and Right Channel Levels – fine gain adjustment of the module

output levels can be done with the

Coarse gain levels must first be set up using the on-board jumpers JP5

and JP6 as described in Remote Configuration and Monitoring on page 19.

Follow the procedures given there for adjusting the output levels using

the fine gain adjustments described below.

Left and Right Channel Level controls.

Adjust the fine gain in either

shown in Figure 10.) The single arrows increment the value by 1x and

the double arrow will increment the value by approximately 10x. These

controls will allow you ± 6.0 dB of fine adjustment range.

Note In Numeric mode only, values selected with the single or double arrow keys

will be enabled immediately. All other display entries, including typed in

values, require pressing Apply before the selection is enabled.

Figure 10. 8920ADC Audio Control and Status Display

Numeric or Sliders mode (Numeric mode

8920ADC Instruction Manual 25

Page 26

Configuration

User Settings Web Page

The User Settings web page (Figure 11) allows you to set the following

parameters:

Use

this

link

• Select the

tings (Operation output mode to default, all audio levels to 0 dB, and

Monitor Audio Input mode to disabled).

• Set Monitor Audio Inputs to enable or disable the status reporting of

the audio inputs. When set to disabled, the Input Signal(s) arrow on the

Status web page will be greyed out.

Figure 11. 8920ADC User Settings Web Page

Get Factory Defaults button to return the module to factory set-

26 8920ADC Instruction Manual

Page 27

Use

this

link

Slot Config Web Page

Use the Slot Config web page (Figure 12 on page 28) to perform the following functions on the 8920ADC module:

•

Locate Module – selecting the Flash radio button flashes the yellow

COMM and CONF LEDs on the front of the module so it can be located

in the frame.

•

Controls – the Controls status report will display either Normal or Remote

Override if a setting on the web pages is overriding that of the module

jumpers.

•

Slot Identification – You may identify the module by typing a specific

name in the

module and travels with the 8900NET module if it is moved to another

frame. Select

Configuration

Name field. The assigned name is stored on the 8900NET

Default to enter the factory default module name.

You may also enter a name in the

•

Slot Memory – the slot configuration for each media module is automati-

Input Signal Name field.

cally saved periodically (once an hour) to the 8900NET module in that

frame. You may also select the

Learn Module Config button at any time to

save the current configuration for this slot. The configuration is saved

on the 8900NET module. If the 8900NET module is removed or

powered down, the stored configurations are not saved.

When the

Restore upon Install box has been checked, the current configu-

ration saved to this slot is saved as slot memory. When the current

module is removed and another module of the same type is installed,

the configuration saved to the 8900NET module will be downloaded to

the new module. The box must be checked before the current module

with the saved configuration is removed.

•

Frame Heath Reporting – this function is not active with the latest version

of the 8900NET module that controls this page.

•

Hardware Switch Controls – a read-only status report of 8900NET module

switch settings for Module Status Reporting and Asynchronous Status

Reporting. These functions must be enabled for the following Slot

SNMP Trap Reports to function.

•

Slot SNMP Trap Reports – displayed only when the SNMP Agent software

has been installed on the 8900NET module. Slot SNMP traps can be

enabled only when the hardware switches for Module Fault reporting

and Asynchronous Status reporting are in enabled on the 8900NET

module (dipswitch S1 segment 5 and dipswitch S2 segment 1).

The enabled SNMP traps will be reported to any SNMP manager that

is identified as an SNMP Report Destination in 8900NET configuration.

Trap severity is read-only hard-coded information that is interpreted

and responded to by the SNMP Manager software configuration.

8920ADC Instruction Manual 27

Page 28

Configuration

Figure 12. 8920ADC Slot Config Web Page

28 8920ADC Instruction Manual

Page 29

Software Update Web Page

The Software Update page (Figure 13) is not used to update 8920ADC software. For instructions on updating to the latest software, refer first to the

8920ADC Release Notes that accompany the software update for complete

details.

Configuration

Use

this

link

Currently, the only recommended method of software updating is done

with a software kit (8900-FLOAD-CBL) that includes a CD-ROM with the

current software files and a serial cable assembly available from Grass

Valley.

Refer to the 8900-FLOAD-CBL Software Upgrade Instruction Manual in

PDF format on the CD-ROM for complete updating instructions and the

required software files for the module.

Figure 13. 8920ADC Software Update Web Page

8920ADC Instruction Manual 29

Page 30

Specifications

Specifications

Table 8. 8920ADC Specifications

Parameter Value

Analog Input

Number of inputs Balanced stereo pair

Connector type Terminal block

Input impedance > 20 kΩ differential

Input level range +12 to +28 dBu

Common mode rejection > 65 dB 50 Hz to 20 kHz

Differential DC 0.25 V maximum

Common mode input voltage 20 V maximum

AES Reference Input

Signal type AES3 ID (1992) transformer coupled

Number of inputs 1 Loop-through

Input return loss >15 dB (100 kHz-10 MHz)

Sampling rate 48 kHz

Maximum jitter < 200 ps RMS

Outputs

Number of outputs 4

Signal type SMPTE 276M, AES3 ID (1992)

Signal level +12 to +28 dBu input range adjustable to 0.0 dBFS

Output impedance 75 Ω

Connector type 75 Ω BNC

Coupling AC coupled

Performance (@ +28 dBU input and full scale output)

Sampling rate 48 kHz

Frequency response ± 0.05 dB relative to 1 kHz, 20 Hz to 20 kHz

Signal-to-noise ratio >102 dB unweighted, 20 Hz to 20 kHz

>105 dB “A” weighted, 20 Hz to 20 kHz

Interchannel crosstalk <-100 dB, 20 Hz - 20 kHz

Delay (input to output) 925 µS

Environmental

Frame temperature range See Gecko 8900 Frame specification

Operating humidity range 0 to 90% non-condensing

Non-operating temperature -10 to 70 degrees C

Mechanical

Frame type Gecko 8900 Series

Power Requirements

Supply voltage ±12 V

Power consumption < 4.2 Watts

30 8920ADC Instruction Manual

Page 31

Service

Service

The 8920ADC modules make extensive use of surface-mount technology

and programmed parts to achieve compact size and adherence to

demanding technical specifications. Circuit modules should not be serviced in the field.

If your module is not operating correctly, proceed as follows:

•Check frame and module power and signal present LEDs.

•Check for presence and quality of input signals.

•Verify that source equipment is operating correctly.

•Check cable connections.

•Check output connections for correct I/O mapping (correct input connector is used for the corresponding channel output).

Refer to Figure 4 for the location of PWR LED and Table 2 on page 11 for

proper LED indications.

If the module is still not operating correctly, replace it with a known good

spare and return the faulty module to a designated Grass Valley repair

depot. Call your Grass Valley representative for depot location.

Refer to the Contacting Grass Valley at the front of this document for the

Grass Valley Customer Support Information number.

8920ADC Instruction Manual 31

Page 32

Status Monitoring

Status Monitoring

This section provides a summary of status monitoring and reporting for a

Gecko 8900 Series system. It also summarizes what status items are

reported and how to enable/disable reporting of each item. There are a

number of ways to monitor status of modules, power supplies, fans and

other status items depending on the method of monitoring being used.

8900 Frame status will report the following items:

• Power supply health,

• Status of fans in the frame front cover,

•Temperature,

•Module health, and

• Frame bus status.

Module health status will report the following items:

• Internal module state (and state of submodule or options enabled)

including configuration errors (warning), internal faults, and normal

operation (Pass).

LEDs

• Signal input states including valid/present (pass), not present or

invalid (warning), not monitored, and not available (no signal inputs).

•Reference input states including locked/valid (pass), not

locked/invalid (warning), and not monitored.

• Signal output states with reporting functionality (reference output).

LEDs on modules in the frame and on the front of the 8900TF/TFN frames

indicate status of the frame and the installed power supplies, fans in the

front covers, and modules. (The 8900TX-V/A frames have no LED indicators on the front cover.)

When a red FAULT LED is lit on a frame front cover, the fault will also be

reported on the 8900NET or Frame Monitor module. The LEDs on the front

of these modules can then be read to determine the following fault conditions:

• Power Supply 1 and 2 health,

• Fan rotation status,

• Frame over-temperature condition,

• Frame Bus fault (8900NET only), and

•Module health bus.

32 8920ADC Instruction Manual

Page 33

Frame Alarm

Status Monitoring

In general, LED colors used on the frame and modules indicate:

•Green – normal operation, (Pass) or signal present, module locked.

•Red – On continuously = fault condition, flashing = configuration error.

•Yellow – On continuously = active condition (configuration mode or

communication), flashing in sequence = module locator function.

Status LEDs for this module are described in Indicator LEDs and Conditions

Indicated on page 11. LEDs for the 8900NET module are described in the

8900NET Network Interface Instruction Manual.

A Frame Alarm connection is available on pins 8 and 9 of the RS-232 connector on the rear of 8900 frame (Frame Monitor or 8900NET Network

Interface module required). This will report any of the status items enabled

with the 8900NET or Frame Monitor module configuration DIP switch.

Connection and use of the Frame Alarm is covered in detail in the 8900NET

Network Interface Instruction Manual.

Web Browser Interface

When the 8900NET module is installed in the frame, a web browser GUI

can indicate frame and module status on the following web pages:

• Frame Status web page – reports overall frame and module status in

graphical and text formats.

•Module Status web page – shows specific input and reference signal

status to the module along with enabled options and module versions.

•A Status LED icon on each web page to report communication status

for the frame slot and acts as a link to the Status web page where warnings and faults are displayed (8900NET version 3.0 or later).

In general, graphics and text colors used indicate the following:

•Green = Pass – signal or reference present, no problems detected.

•Red = Fault – fault condition.

•Yellow = Warning – signal is absent, has errors, or is mis-configured.

•grey = Not monitored (older 8900 module).

•White = Not present.

Status reporting for the frame is enabled or disabled with the configuration

DIP switches on the 8900NET module. Some module status reporting items

can also be enabled or disabled on individual configuration web pages.

8920ADC Instruction Manual 33

Page 34

Status Monitoring

SNMP Reporting

The Gecko 8900 Series system uses the Simple Network Monitoring Protocol (SNMP) internet standard for reporting status information to remote

monitoring stations. When SNMP Agent software is installed on the

8900NET module, enabled status reports are sent to an SNMP Manager

such as the Grass Valley’s NetCentral application.

There are both hardware and software report enable switches for each

report. Both must be enabled for the report to be sent. Software report

switches are set on the 8900NET Configuration web page for the Frame, the

8900NET module, and each module slot. Refer to the 8900NET Network

Interface Instruction Manual for installation instructions.

34 8920ADC Instruction Manual

Page 35

Functional Description

Differential

Input

Receivers

& Pad

Pad

+

Right In

Left In

AES Sync In

–

Pad

+

–

Functional Description

The 8920ADC Converts an analog audio stereo pair to a 48 KHz AES/EBU

signal. Refer to the block diagram in Figure 9 while reading the following

functional description.

Figure 9. 8920ADC Block Diagram

Control bus

from backplane

- 12 dB

- 8 dB

- 6 dB

- 12 dB

- 8 dB

- 6 dB

- 12 dB

- 12 dB

4-bit Rotary

CPU

(Controller)

- 15 dB- 9 dB

Audio

Stereo

- 15 dB- 9 dB

24-bit

ADC

Clocks

AES

Receiver

and PLL

Switch

FPGA

Routing and Control

Processor

Test

Tone

Option

Jumpers (4)

AES Out 1

AES Out 2

AES Out 3

AES Out 4

Level,

Clip,

Error,

PLL Lock,

Mode

LEDs

0595_01

Differential Input, Analog Gain and A/D Converters

The analog input is applied to a differential amplifier stage. This converts

the signal to single-ended and applies it to the coarse gain stage. Coarse

gain control pre-conditions the incoming signal before it is applied to the

A/D converters. For each channel, a six-position jumper sets the desired

coarse gain. This jumper controls the front-end pad of the unit in either a

-6 dB, -8 dB, or -12 dB mode and allows three 3 dB gain steps on the post

gain. This jumper allows input levels from +12 dBu to +28 dBu to be set to

0dBFS at the output.

The fine gain control is by two center-off toggle switches on the front of the

module. They provide a 6 dB range of fine gain adjustment in approximately 0.1 dB increments. The control takes approximately 6 to 10 seconds

to transition from minimum to maximum.

The signal is converted back to a differential signal and applied to the 24-bit

A/D converter, then to the Routing and Control FPGA (Field Programmable Gate Array).

8920ADC Instruction Manual 35

Page 36

Functional Description

Digital Reference Input

Routing and Control FPGA

The digital reference is applied via the loop-through input to the AES

receiver and phase-locked loop. This provides clock and data to the Control

and Routing FPGA and the A/D converters.

The signals from the A/D converters are applied to the Routing and

Control FPGA. The incoming signal processing and level is determined by

the setting of one of 16 possible mode commands from a four-bit rotary

encoder switch and four signals from the level toggle switches. After processing, the signals are embedded into an AES stream and applied to the

Output Drivers.

The Routing and Control section also drives the front panel LEDs and interfaces to the Controller section.

Controller

Power Supply

The Controller interfaces with the Routing and Control FPGA, the

EEPROM and the 8900 Frame Bus. The Controller also provides the FPGA

code that is downloaded to the FPGA during boot-up.

The Controller section handles local control and monitoring, as well as

remote control and monitoring via the frame bus (when an 8900NET

module is installed in the frame). Module settings are stored in the

EEPROM for power up recall.

Power is fed from ±12 V rails of the frame’s switching power supply. Each

stage of the module receives it’s own, separate, highly regulated and filtered power source. Two-stage regulation is used in the analog section of

the ADC to reduce switching noise.

36 8920ADC Instruction Manual

Page 37

Index

Numerics

20/24-bit DAC

remote indication

8900 frame

frame alarm

status reporting 32

8900-FLOAD-CBL option 29

8900NET module

required software version

8920ADC

features

functional description 35–36

specifications 30

7

24

33

A

Audio Control and Status web page 24

C

cabling 10

input 10

output 10

coarse level adjustment 14, 18, 25

COMM LED 11

CONF (configuring) LED 11, 18

configuration 16

factory default 11

jumpers 18

LEDs 18

local on-board 18

overview 13

Remote, GUI 19

summary table 17

switches 18

control panel

control summary table

overview 19

Controls status reporting 27

17

19

D

documentation online 2

E

enable SNMP 34

F

factory defaults

remote control

summary table 17

FAQ database 2

FAULT LED

description

troubleshooting 32

fine level adjustment

local on-board

remote 25

frame

cell locations

cooling capacity 8

module capacity 8

power capacity 8

Frame Status page 33

frequently asked questions 2

26

11

18

8

G

Get Factory Defaults button 26

graphical user interface (GUI) 22

Grass Valley web site 2

I

impedance 10

input

loopthrough

reference 10

specification 30

input signal name

10

8920ADC Instruction Manual 37

Page 38

Index

assigning 27

installation 8

L

left channel level

remote control

summary table 17

LEFT IN > -20 dBFS LED 12

LEFT IN CLIP LED 12

locate module 27

LOCK LED 12

25

M

maximum operating level 14

mode

output

module

block diagram

cells 9

install 9

placement 8

replacement 31

module health status 32

module name

assigning

Module Status page 33

monitor audio output control

remote control

summary table 17

16

35

27

26

output mode

rotary switch

outputs

configuration

connectors 10

level adjustments 19

local on-board 15

remote 25

specification 30

termination 10

overlay 10

16

16

P

power requirements 30

PWR LED 11

R

reference inputs 10

REM OVER (remote override) LED 12

remote control lockout

jumper

report enable switches 34

right channel level

remote control

summary table 17

RIGHT IN > -20 dBFS LED 12

RIGHT IN CLIP LED 12

rotary switch 16, 18

16, 18

25

S

N

Newton Control Panel

overview

summary table 17

19

O

online documentation 2

operational conditions

LED indications

operational mode

remote control

rotary switch 16

summary table 17

38 8920ADC Instruction Manual

11

24

Slot Config web page 27

slot memory 27

SNMP reporting

enabling

overview 34

software download from web 2

software update

8900-FLOAD-CBL

Software Update web page 29

status monitoring 32

Status web page 23

27

29

Page 39

T

termination 10

toggle switches 18

setting levels 14

troubleshooting 31

U

User Settings web page 26

W

web browser

overview

web site

documentation

FAQ database 2

Grass Valley 2

software download 2

20

2

Index

8920ADC Instruction Manual 39

Page 40

Index

40 8920ADC Instruction Manual

Loading...

Loading...