Page 1

8916

AES/EBU AUTO-TRACKING DELAY DA

Instruction Manual

071-0585-01

FIRST PRINTING: JULY 1999

REVISED PRINTING: JUNE 2000

Page 2

Contacting Grass Valley Group

Region Voice Fax Address Web Site

North America (800) 547-8949

530-478-4148

Pacific Operations +852-2585-6688

Support: 852-2585-6579

U.K., Europe, Asia, Middle East +44 1753 218 777 +44 1753 218 757

France +33 1 45 29 73 00

Germany +49 221 1791 234 +49 221 1791 235

Copyright © Grass Valley Group. All rights reserved.

This document may not be copied, in whole or in part, or otherwise reproduced, except as specifically

permitted under U.S. copyright law, without the prior written consent of Grass Valley Group, P.O. Box

599000, Nevada City, CA 95959-7900 USA. GRASS VALLEY GROUP is a registered trademark and

Grass Valley is a trademark of Grass Valley Group. All registered trademarks and trademarks are property of their respective holders. Grass Valley Group products are covered by U.S. and foreign patents,

issued and pending. Product options and specifications subject to change without notice. The information in this manual is furnished for informational use only, is subject to change without notice, and

should not be construed as a commitment by Grass Valley Group. Grass Valley Group assumes no responsibility or liability for any errors or inaccuracies that may appear in this publication.

(530) 478-3347 Grass Valley Group

+852-2802-2996

P.O. Box 599000

Nevada City, CA 95959-7900

USA

www.grassvalleygroup.com

Page 3

Contents

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Frame Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Module Placement in the 8900 Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Loop-through Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Delay Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operation Indicator LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Onboard Module Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Delay Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Remote Control Lockout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Remote Configuration and Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Module Configuration Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Signal Configuration Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Input Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

FPGA Delay Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Delay FIFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Transmitter/Multiplexer Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Line Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Delay Adjustment Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Audio Delay Control Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8916 Instruction Manual iii

Page 4

Contents

iv 8916 Instruction Manual

Page 5

Preface

About This Manual

This manual describes the features of a specific module of the 8900 Series

Modular Products family. As part of this module family, it is subject to

Safety and Regulatory Compliance described in the 8900 Series frame and

power supply documentation (see the 8900TX/8900TF/8900TFN Frames

Instruction Manual ).

8916 Instruction Manual v

Page 6

Preface

vi 8916 Instruction Manual

Page 7

8916 AES/EBU Auto-Tracking Delay DA

Introduction

The 8916 Auto-Tracking DA is a 1 x 7 distribution amplifier for AES/EBU

serial digital audio. It delays digital audio to correct lip-sync errors. The

8916 offers two forms of delay, which are summed:

■

A fixed delay up to 0.5 seconds

A variable delay based on the signal input from a Grass Valley video

■

frame synchronizer

The 8916 can correct a large, fixed lip-sync error while continuously

adjusting audio delay to match video delay created by a frame sync’s asynchronous video input.

The 8916 offers the following features:

Up to 0.5 second delay in 2 ms increments

■

■

Auto-tracks Grass Valley video frame sync delays (models 8900FSS,

SMS 8121-FS, 8981FS, VFS211, and 8960DEC)

Note

■

■

■

■

Early versions of the 8960DEC did not support the export of the auto-track

signal. Contact Grass Valley customer service for more information regarding

8960DEC frame sync.

Seven 75

Module is part of the 8900 family of audio and video modules

Supports remote control in 8900 networking frames

Offers remote control lockout using an on-board jumper

Ω

outputs

8916 Instruction Manual 1

Page 8

8916 AES/EBU Auto-Tracking Delay DA

Installation

Installation of the 8916 module is a process of:

Placing the module in the proper frame slot, and

■

■

Cabling and terminating signal ports.

The 8916 module can be plugged in and removed from an 8900 Series frame

with power on. When power is applied to the module, LED indicators

reflect the initialization process (see Power Up on page 5 ).

Frame Capacity

The maximum number of 8900 modules allowed in a frame is determined

by frame cooling capacity. Table 1 provides the power capacity, cooling

capacity, and maximum module count for the 8916 in each frame type.

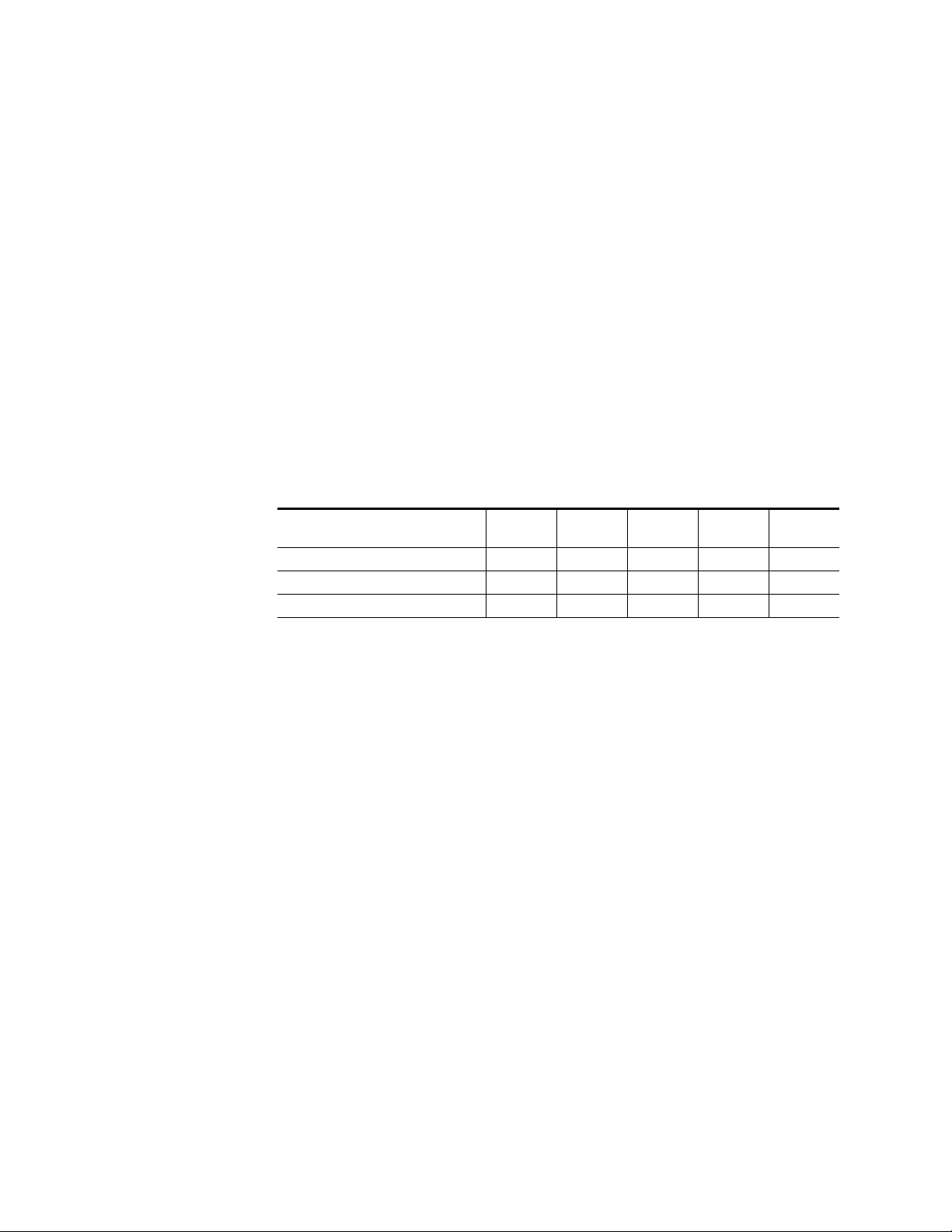

Table 1. Power, Cooling, and Module Capacity of 8900 Frames

Capacity Calculated

Power (W) 60 60 100 100 100

Recommended Module Cooling (W) 30 60 30 90 90

8916 Modules 8 10 8 10 10

Note

Module capacity figures assume no other modules are in the frame.

If the maximum number of modules a frame can handle is less than ten,

provide as much space between the modules as possible.

8900T2

Frame

8900T2-F

Frame

8900TX

Frame

8900TF

Frame

8900TFN

Frame

2 8916 Instruction Manual

Page 9

Module Placement in the 8900 Frame

There are ten slot locations in the frame to accommodate either analog or

digital modules. These are the left ten locations. Refer to Figure 1.

The two slots on the right are allocated for the power supplies. For additional information concerning the Power Supply module, refer to the 8900

Power Supply manual.

The third slot from the right is allocated for the Controller module. This

module provides an interface for the SMPTE 269M fault reporting (health

alarm). For additional information concerning the Controller module, refer

to the 8900 Controller manual.

Figure 1. 8900 Series Frame

Installation

Any 8900 Module

Controller

Module

(only)

Power

Supplies

(only)

8900 modules are interchangeable within the module slots. There are 10

BNC connectors in each slot’s I/O group. The functional assignment of

each connector in a group is determined by the module that is placed in

that slot. The maximum number of modules an 8900 frame can accept is

ten. Figure 2 illustrates the rear connectors for an 8900 Series frame.

0614-03

8916 Instruction Manual 3

Page 10

8916 AES/EBU Auto-Tracking Delay DA

Figure 2. 8900 Series Frame Rear Connector

1.

2.

3.

10

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

9

J1 J2

J2

O

J3 J4

J4

U

T

J5 J6

J6

J7 J8

J8

J9 J10

IN

8

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

Note

7

J1 J2

J2

O

J3 J4

J4

U

T

J5 J6

J6

J7 J8

J8

J9 J10

IN

6

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

5

J1 J2

J2

O

J3 J4

J4

U

T

J5 J6

J6

J7 J8

J8

J9 J10

IN

4

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

At the back of this manual are die-cut overlay cards that can be placed over

3

J2

J1 J2

O

J4

J3 J4

U

T

J6

J5 J6

J8

J7 J8

J9 J10

IN

2

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

J1 J2

J3 J4

J5 J6

J7 J8

the rear connector BNCs to identify the specific 8916 connector functions.

To install a module in the frame:

Insert the module, connector end first, with the component side of the

module facing to the right and the ejector tab to the top.

Verify that the module connector seats properly against the backplane.

Press the ejector tab in to seat the module in place.

1

O

U

T

J9 J10

IN

0585-03

Cabling

Loop-through Input

Connect an input source to one of the loop-through input connectors, J9 or

J10 (see Figure 3). The 8916 input will accept AES3id/EBU audio. Termi-

nate the unused connector into 75

Ω

if the signal is not looped to other

equipment.

4 8916 Instruction Manual

Page 11

Power Up

Outputs

Figure 3.

AES/EBUOutputs

Delay Input

from Frame Sync

AES/EBU

Loopthrough Input

Input/Output Connectors

8916

J3

J5

J7

DAx

O

U

T

J9 J10

IN

J2

J4

J6

J8

J2J1

AES/EBU

Outputs

J6

J8

0585-02

The 8916 has seven AES/EBU serial digital output connectors—J1 through

J6, and J8. The destination equipment should have a 75

or loop through inputs that are terminated into 75

Ω

input impedance

Ω

.

Power Up

Operation Indicator LEDs

Delay Input

A delay signal input BNC (J7) is provided for a reference signal from a

Grass Valley video sync generator (see Note page 1).

The various front LED indicators and configuration switches are illustrated

in Figure 4. Upon power-up, the green PWR LED should light and the

yellow CONF LED should illuminate for the duration of module initialization.

With factory default configuration and a valid input signal connected, the

green PWR LED, the yellow TRACK, and one of the green signal rate LEDs

should illuminate (refer to Table 2 on page 6 to see the possible operating

indicator combinations).

Audio input presence is indicated by the 32 kHz, 44.1 kHz, or 48 kHz LED

(indicating the module has locked to the indicated signal rate).

8916 Instruction Manual 5

Page 12

8916 AES/EBU Auto-Tracking Delay DA

Figure 4. LEDs and Configuration Switches

5

6

4

7

3

8

2

9

1

A

0

B

F

C

E

D

Ejector Tab

FAULT – Red diagnostic LED is off during normal operation

COMM – Yellow LED on during remote control communication

CONF – Yellow LED on when module is initializing or

processing control data

PWR – Green diagnostic LED on indicates power OK

32 kHz – Green LED on indicates lock to a 32 kHz signal

44.1 kHz – Green LED on indicates lock to a 44.1 kHz signal

48 kHz – Green LED on indicates lock to a 48 kHz signal

TRACK – Green LED on indicates auto delay is being added to the fixed delay

Coarse Delay Adjust

Rotary switch

5

6

4

7

3

8

2

1

0

F

E

D

9

A

B

C

Fine Delay Adjust

Rotary switch

REMOTE OVR – Yellow LED on indicates local switches and

0585_06

jumper settings are overridden by remote control

GND

A red FAULT LED indicates an error situation and, with the previously

described LEDs, can indicate the operational conditions presented in

Table 2. The table describes signal output and LED indications for various

input/reference combinations and user settings.

Table 2. Indicator LEDs and Conditions Indicated

LED Indication Condition

Off Normal operation

Fault

(red)

COMM

(yellow)

CONF

(yellow)

On continuously Module has detected internal fault

Long flash Configuration problem: Check inputs and settings

Short flash CRC (cyclic redundancy check) error detected

Off No activity on frame communication bus

Long flash Location Command received by the module from a remote control system

Short flash Activity present on the frame communication bus

Off Module is in normal operating mode

On continuously Module is initializing, changing operating modes or updating firmware

6 8916 Instruction Manual

Page 13

Table 2. Indicator LEDs and Conditions Indicated - (continued)

LED Indication Condition

PWR

(green)

32 kHz

(green)

44.1 kHz

(green)

48 kHz

(green)

REM OVR

(yellow)

Tracking

(yellow)

Off No power to module or module’s DC/DC converter failed

On continuously Normal operation, module is powered

Off Sample rate is not near 32 kHz

On Continuously Sample rate is 32 kHz ±400 ppm

Flashing Sample rate is 32 kHz ±4%

Off Sample rate is not near 44.1 kHz

On Continuously Sample rate is 44.1 kHz ±400 ppm

Flashing Sample rate is 44.1 kHz ±4%

Off Sample rate is not near 48 kHz

On Continuously Sample rate is 48 kHz ±400 ppm

Flashing Sample rate is 48 kHz ±4%

Off Module configuration is by the module’s on-board switches and jumpers

On continuously

Off Fixed delay only

On continuously

Module configuration is by remote control and on-board switches and jumpers are

overridden

Total operating delay is the sum of fixed and auto delay from frame sync delay input.

Front panel switches do not indicate total delay in this mode.

Power Up

8916 Instruction Manual 7

Page 14

8916 AES/EBU Auto-Tracking Delay DA

Configuration

The 8916 can be configured locally using onboard switches or remotely

using the 8900NET network interface. Configuration establishes:

■

Delay setting

■

Active or locked out remote control

Onboard Module Configuration

The 8916 can be configured using the rotary switches illustrated in Figure 5.

Delay Setting

For an AES/EBU signal the FINE switch delay increments are 2 ms (1/16

video frame), and the COARSE switch delay increments are 32 ms (one

video frame). Each switch can select up to 15 times its increment to create

a total delay of approximately 510 ms.

Remote Control Lockout

To make the 8916 module delay settings adjustable from the on-board

switches only, place a jumper across the Local Only pins on jumper block

JP3 illustrated in Figure 5. To have both Local and Remote access, set the

jumper on the two pins on the right side of the three-pin block.

Figure 5. Delay Adjustment Switches and Remote Lockout Jumper

CONF – configuration processing LED

Coarse

Delay adjust

Fine

rotary switches

JP3

Local only,

jumper across these

pins locks out

remote control

JP3

Local &

remote

active

0585_05

Remote Control Lockout

8 8916 Instruction Manual

Page 15

Remote Configuration and Monitoring

8916 configuration and monitoring can be performed using the 8900NET

interface in 8900TF or TFN frames (see Figure 6). This section describes the

GUI access to the module configuration functions. Refer to the 8900NET

Network Interface Module Instruction Manual for information on setting

up and operating the 8900 frame network.

For remote access, make sure the jumper block on the module is set to the

pins on the right for both Local and Remote access (Figure 5).

Configuration

Note

Figure 6. 8900NET GUI

The physical appearance of the menu displays shown in this manual represent the use of a particular platform, browser and version of 8900NET

module software. They are provided for reference only. Displays will differ

depending on the type of platform and browser you are using and the version

of the 8900NET software installed in your system.

The links section lists the frame and its current modules. The selected link's Status

page is first displayed and the sub-list of links for the selection is opened. The sub-list

allows you to select a particular information page for the selected device.

Content display section displays information for the selected

frame or module (frame slot icons are also active links).

The 8900 modules can be addressed by clicking on a specific module icon

in the frame status display or on a module name or slot number in the link

list on the left.

8916 Instruction Manual 9

Page 16

8916 AES/EBU Auto-Tracking Delay DA

The 8916 will indicate a SMPTE Alarm fault on the Frame Status display for

the following alarms:

Lack of valid audio input,

■

■

Internal Fault, or

■

Board Failure.

Module Configuration Displays

The 8900 GUI provides the following links and displays for the 8916

module. The module name shown in Figure 7 is “AES Audio Delay 3” (slot

number and module type). The name is user determined and is assigned

using the module’s Configuration display. The four module configuration

displays provide:

■

Module operational status information,

■

Module properties (part and version numbers),

■

Module configuration information (location and user assigned names),

and

■

Software update (file transfer).

These displays are the same for all remote controllable 8900 modules. Refer

to the 8900NET manual for more information on these displays. Some functions listed may not be supported by a particular module. These will be

indicated as not supported.

Figure 7. 8960DEC Display Links

Module Configuration

Displays

Signal Configuration

Display

Signal Configuration Display

This section discusses the Audio Delay display in the Signal Configuration

Display section used to set the amount of audio delay required in the 8916

module. You may set the audio delay using either the Numeric (Figure 8)

or Slider (Figure 9) adjustment mode. In either display mode, the changes

do not take place until the Apply button is clicked and the display is

refreshed.

10 8916 Instruction Manual

Page 17

Indicates total

amount of delay

Configuration

For an AES/EBU signal the FINE delay increments are 2 ms (1/16 video

frame), and the COARSE delay increments are 32 ms (one video frame).

Any settings selected will default to the nearest 2 ms or 32 ms increment.

Each adjustment can select up to 15 times its increment to create a total

delay of approximately 510 ms.

Figure 8 illustrates the Audio Delay display in numeric adjustment mode.

Figure 8. Audio Delay Display, Numeric Mode

Coarse Adjust (10x)

Fine Adjust (1x)

Indicates amount of

auto tracking delay

from Delay Input (J7)

Indicates state of

auto tracking

Indicates input

audio error status

Indicates Incoming

Sample Rate

DISABLED

AUDIO OK

48K

Set the amount of delay in Numeric mode by entering a number in the

Coarse Adjust and Fine Adjust boxes or use the arrow keys to change the

values. The number will default to an increment of 2mS (Fine) or 32 mS

(Coarse). The single arrows will increment the value by 1x and the double

arrows will increment the value by 10x.

Note

Numeric displays are for approximate values only. Calculation of displayed

values are subject to decimal place truncation. Variation from the absolute

value increases at higher values.

Use the Apply button to make the selections active.

8916 Instruction Manual 11

Page 18

8916 AES/EBU Auto-Tracking Delay DA

The sum of the Coarse, Fine and Auto Tracking delay will appear in the

Total Delay display above the Coarse and Fine Adjust.

Below the Coarse and Fine Adjust displays are the following indicators

giving module information:

■

Auto Tracking Delay: Amount of auto tracking delay in mS from the

Frame Sync Delay Input BNC (J7).

■

Auto Tracking State: Enabled or Disabled.

■

Input Audio Errors: Audio OK, Out of Range, GT (Greater Than) 4

Percent 48K, GT 4 Percent 44.1K, or GT 4 Percent 32K.

■ Incoming Sample Rate: 48K, 44.1K, 32K or Invalid.

Figure 9 shows the display for setting the delay in Slider mode.

Set Coarse and Fine delay using the arrow keys to increase or decrease the

delay. The settings will default to an increment of 2 mS (Fine) or 32 mS

(Coarse). The single arrows will change the value by 1x and the double

arrows will change the value by 10x.

Use the Apply button to make the selections active.

The sum of all delay is shown in the Total Delay slider display.

The module information below the Coarse and Fine Adjust displays is

identical to the information explained in the Numeric section above.

12 8916 Instruction Manual

Page 19

Indicates total

amount of delay

Coarse Adjust (10x)

Fine Adjust (1x)

Configuration

Figure 9. Audio Delay Display, Slider Mode

Indicates amount of

Auto Tracking

DISABLED

AUDIO OK

48K

8916 Instruction Manual 13

Page 20

8916 AES/EBU Auto-Tracking Delay DA

Specifications

Table 3. 8916 Specifications

Parameter Value

Digital Input

Signal type AES3id (1995)/EBU and SMPTE 276M - transformer coupled

Number of inputs 1 loop-through

Connector type 75 Ω BNC

Input return loss >25 dB (100 kHz-6 MHz)

Outputs

Number of outputs 7

Signal type AES3id (1995)/EBU and SMPTE 276M

Connector type 75 Ω BNC

Return loss >25 dB (100 kHz-6 MHz)

Intrinsic Jitter <6 ns

Performance

Sampling rates 32 kHz, 44.1 kHz, and 48 kHz

On-board delay adjustment Minimum 2 ms, Maximum 510 ms

Delay adjustment increments 2 ms

Tracking delay 20.8 µs to 30 ms

Environmental

Frame temperature range 0 to 45 degrees C

Operating humidity range 10 to 90% non-condensing

Non-operating temperature -10 to 70 degrees C

Mechanical

Frame type 8900 Series

Power Requirements

Supply voltage +12 V, -12V

Power consumption < 3.5 Watts

Minimum delay @ 32 kHz is 3 ms

14 8916 Instruction Manual

Page 21

Service

Service

The 8916 module makes extensive use of surface-mount technology and

programmed parts to achieve compact size and adherence to demanding

technical specifications. Circuit modules should not be serviced in the field.

If your module is not operating correctly, proceed as follows:

■ Check frame and module power and signal present LEDs.

■ Check for presence and quality of input signals.

■ Verify that source equipment is operating correctly.

■ Check cable connections.

■ Check output connections for correct I/O mapping (correct input con-

nector is used for the corresponding channel output).

Refer to Figure 4 for the location of PWR LED and Table 2 on page 6 for

proper LED indications.

If the module is still not operating correctly, replace it with a known good

spare and return the faulty module to a designated Tektronix repair depot.

Call your Tektronix representative for depot location.

Refer to the Contacting Grass Valley Group at the front of this document for

the Tektronix Customer Service Information number.

8916 Instruction Manual 15

Page 22

8916 AES/EBU Auto-Tracking Delay DA

Functional Description

Refer to the block diagram in Figure 10 while reading the following functional description.

Figure 10. 8916 Block Diagram

AES/EBU Input RX+

Loop-through

Delay Select Switches

Coarse

Fine

To Host

Delay Control I/F

RS 232

RX–

Controller

Receiver/

De-MUX

Power

Comm

Fault

Conf

Serial Data

SCK

F Sync

Error

Freq.

MCK

C

U

V

CBL

Field

Programmable

Gate Array

(FPGA)

Serial Data

SCK

F Sync

Parallel Data

Control

Parallel Data

32 kHz

44.1 kHz

48 kHz

Tracking

Remote Override

MUX

FIFO

AES/EBU

Serial

Data

Outputs

Line

Drivers

Input Receiver

AES/EBU audio data is fed into the 8916 through an isolation transformer

where it is received by the receiver chip. The receiver recovers the clock and

synchronization signals, and demultiplexes the audio and digital data.

FPGA Delay Section

The delay section receives the 12.29 MHz clock, synchronization information, frequency information, and error status information. It also receives

the switch position settings that determine the fixed length of delay.

16 8916 Instruction Manual

Page 23

Delay FIFO

The FIFO receives parallel data from the FPGA. The FPGA provides all

clock and control signals. The FIFO output is sent back to the FPGA.

The capacity of the FIFO is 262214 x 12 bits. A single audio sample is 48 bits

of data. With a sampling rate of 48 kHz the maximum delay of the card is

510 ms.

Transmitter/Multiplexer Circuit

The serial data, after being delayed, is routed to the Interface Transmitter

from the FPGA. The Transmitter multiplexes the channel, user, and validity

data from the receiver chip with the serial audio data from the FPGA.

Line Drivers

The line driver chip drives seven output lines. The outputs feed an RC

network that:

Functional Description

■ Attenuates the signal to one volt peak-to-peak

■ Limits the risetime to meet the AES specification, and

■ Creates a 75 Ω output resistance to match the cable impedance.

Delay Adjustment Switches

There are two rotary output timing adjustment switches:

■ A fine-step adjustment switch provides sixteen 2ms timing steps

■ A coarse-step adjustment switch provides sixteen 32ms timing steps

The switches provide output timing adjustable from 2ms to 510ms with

respect to the input.

Audio Delay Control Interface

The 8916 auto delay control input consists of a one wire serial signal using

RS232 voltage levels, input on a coaxial BNC connector (Delay Input).

Delay values can range from 0 to 3FF(hex).

8916 Instruction Manual 17

Page 24

8916 AES/EBU Auto-Tracking Delay DA

Controller

The controller provides the interface between the user and all the processing logic inside the 8916. It also supports communications between an

external host processor and the 8916.

18 8916 Instruction Manual

Page 25

Index

A

auto delay 17

frame status display 9

B

backplane 4

block diagram 16

C

clock 16

connector

delay signal

connectors 3

input 4

controller 18

controller module 3

5

D

delay 8

local adjustment 8, 17

remote adjustment 11

delay input 5

E

G

GUI 9

I

impedance 5

indicators 5, 6

input

loopthrough

receiver 16

termination 4

J

jumper 8

L

LEDs 5

line driver 17

links 10

local control 8

4

environmental 14

F

factory default 5

fault 6

fault report 10

features 1

FIFO 17

FPGA 16

frame 14

8916 Instruction Manual Index-1

M

module

controller

installation 3

power supply 3

slots 3

module name 10

multiplexer 17

3

Page 26

N

network 9

O

onboard module configuration 8

delay setting 8

remote control lockout 8

operational modes 6

outputs 14

connectors 5

termination 5

overlay 4

P

performance 14

power 14

power supply 3

power-up 5

processing logic 18

R

remote configuration and monitoring 9

audio delay display 10

remote lockout 8

repair depot 15

S

setting delay 8

SMPTE alarm 10

sync generator 5

T

termination 4

transmitter 17

troubleshooting 15

V

voltage 14

Index-2 8916 Instruction Manual

Loading...

Loading...