Page 1

Instruction Manual

071-0547-01

FIRST PRINTING: JANUARY 1999

REVISED PRINTING: APRIL 1999

8914

DUAL AES/EBU DELAY DISTRIBUTION AMPLIFIER

Page 2

Contacting Grass Valley Group

Region Voice Fax Address Web Site

North America (800) 547-8949

530-478-4148

Pacific Operations +852-2585-6688

Support: 852-2585-6579

U.K., Europe, Asia, Middle East +44 1753 218 777 +44 1753 218 757

France +33 1 45 29 73 00

Germany +49 221 1791 234 +49 221 1791 235

Copyright © Grass Valley Group. All rights reserved.

This document may not be copied, in whole or in part, or otherwise reproduced, except as specifically

permitted under U.S. copyright law, without the prior written consent of Grass Valley Group, P.O. Box

599000, Nevada City, CA 95959-7900 USA. GRASS VALLEY GROUP is a registered trademark and

Grass Valley is a trademark of Grass Valley Group. All registered trademarks and trademarks are property of their respective holders. Grass Valley Group products are covered by U.S. and foreign patents,

issued and pending. Product options and specifications subject to change without notice. The information in this manual is furnished for informational use only, is subject to change without notice, and

should not be construed as a commitment by Grass Valley Group. Grass Valley Group assumes no responsibility or liability for any errors or inaccuracies that may appear in this publication.

(530) 478-3347 Grass Valley Group

+852-2802-2996

P.O. Box 599000

Nevada City, CA 95959-7900

USA

www.grassvalleygroup.com

Page 3

Contents

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

8914 Dual AES/EBU Delay Distribution Amplifier

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Module Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Adjustments, Testpoints, and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Delay Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

48 KHz Input Signal Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Receive Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

FPGA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

FIFO Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Line Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Frequency Lock LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Index

8914 Instruction Manual iii

Page 4

Contents

iv 8914 Instruction Manual

Page 5

Preface

About This Manual

This manual describes the features of a specific module of the 8900 Series

Distribution Amplifier family. As part of this module family, it is subject to

Safety and Regulatory Compliance described in the 8900 Series frame and

power supply documentation (see the

8900 Series User’s Guide ).

8914 Instruction Manual v

Page 6

Preface

vi 8914 Instruction Manual

Page 7

8914 Dual AES/EBU Delay

Distribution Amplifier

Introduction

As the transition to digital video and audio accelerates, there is an

increased need to delay the audio associated with broadcast video. This is

due to the relatively large processing times associated with DVEs and

switchers. The 8914 provides a low cost and easy-to-use solution to the lip

sync errors associated with these large delays. Minimizing space requirements, the 8914 provides two fully controllable delay paths on a single

board, allowing up to 20 delays (ten modules) in a two rack unit frame. If

instead of two delays you require more distribution, the first channel can

be passively looped to the second channel to produce seven outputs. The

8914 is also a full-featured reclocking distribution amplifier that fits inthe

8900 series frame.

A clock referenced to the applied input reclocks all outputs in each section.

The delay is set using 16-position rotary switches on the front of the

module. There are fine and coarse rotary adjustment switches for each

delay channel.

The 8914 offers the following features:

■

Two full-function delays on a single board,

■

All outputs reclocked to reduce jitter,

■

Up to one half second delay in approximately 2 ms increments,

■

Support of 32, 44.1 and 48 KHz sample rates,

■

Four outputs on channel one, three outputs on channel two,

■

Loop-through input on channel one enables redundant system design,

■

Accepts input cable lengths of up to 1000m (Belden 8281 or equivalent),

and

Up to twenty AES/EBU delays in a 2 RU 8900 Frame.

■

8914 Instruction Manual 1

Page 8

8914 Dual AES/EBU Delay Distribution Amplifier

Module Installation

There are ten cell locations in the frame to accommodate either analog or

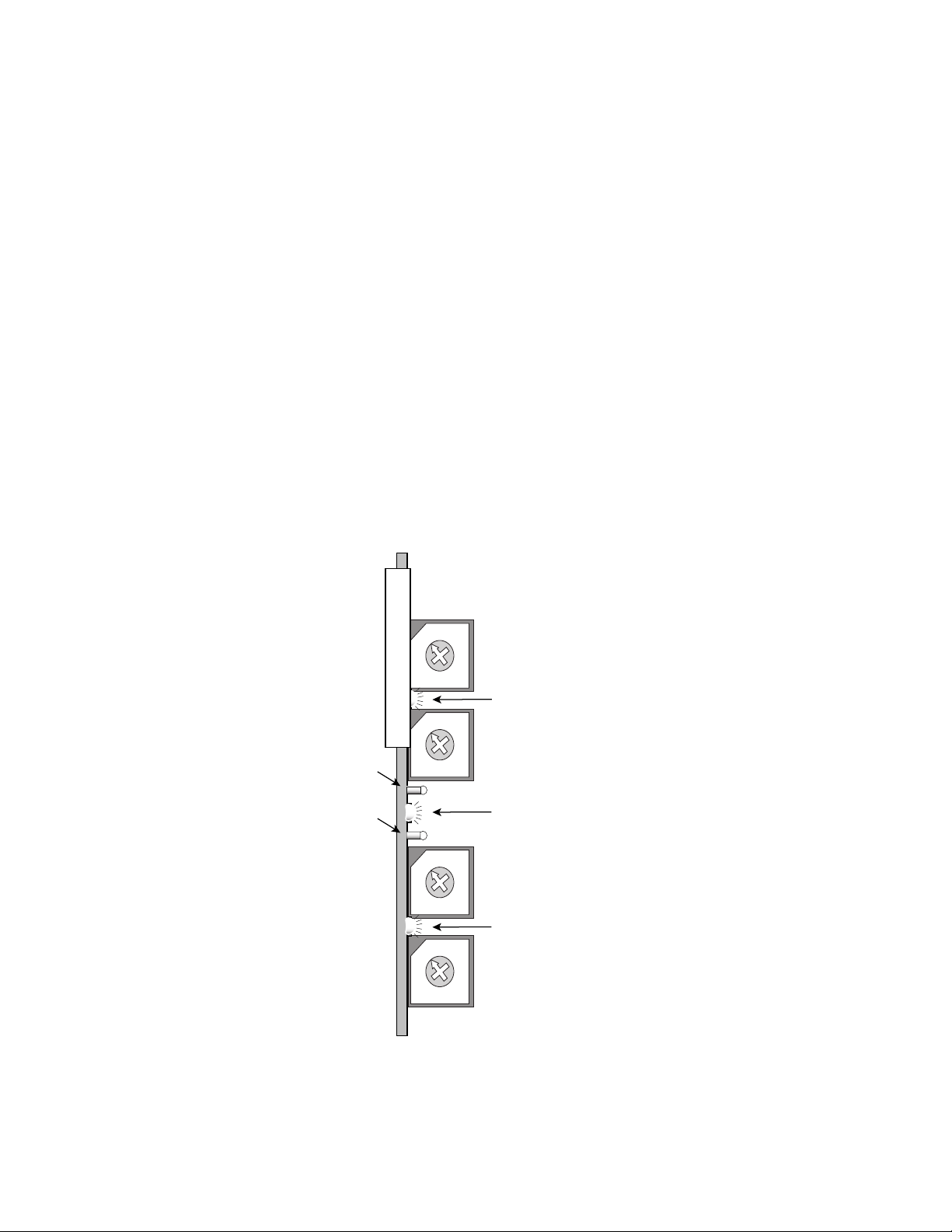

digital modules. These are the left ten slots. Refer to Figure 1.

The two cells on the right are allocated for the power supplies. For addi-

tional information concerning the Power Supply module, refer to the

Power Supply manual.

The third cell from the right is allocated for the Controller module. This

module provides the interface for the forced air cover, as well as the SMPTE

269M fault reporting (health alarm) and the error detection. For additional

information concerning the Controller module, refer to the Controller

manual.

Any 8900 Module

Controller

Module

(only)

Figure 1. 8900 Series Frame

Power

Supplies

(only)

To install a module into the frame, follow these steps:

1.

Insert the module into the frame, connector end first, with component

side of the module facing to the right and ejector tab to the top.

2.

Verify that the module connector seats properly against the backplane.

3.

Press the ejector tab in to seat the module in place.

0547-04

2 8914 Instruction Manual

Page 9

Cabling

Ω

Ω

J2

J4

J6

J8

J1

J9 J10

IN

Four Delay 1

Outputs

DAx

O

U

T

J3

J5

J7

J2

J4

J6

J8

0547_03

Loopthrough

Delay 1 Input

Three Delay 2

Outputs

Terminated

Delay 2 Input

Module Installation

8900 module locations are interchangeable within the frame. The

maximum number of modules the frame will accept is ten. Figure 2 illustrates the rear connector plate for an 8900 Series frame.

DA10

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

DA9

J1 J2

J2

O

J3 J4

J4

U

T

J5 J6

J6

J7 J8

J8

J9 J10

IN

Inputs

DA8

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

DA7

J1 J2

J2

O

J3 J4

J4

U

T

J5 J6

J6

J7 J8

J8

J9 J10

IN

DA6

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

DA5

J1 J2

J2

O

J3 J4

J4

U

T

J5 J6

J6

J7 J8

J8

J9 J10

IN

DA4

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

DA3

J2

J1 J2

O

J4

J3 J4

U

T

J6

J5 J6

J8

J7 J8

J9 J10

IN

DA2

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

DA1

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

Figure 2. 8900 Series Frame Rear Connector

Note At the back of this manual are die-cut overlay cards that can be placed over the

rear connector BNCs to identify the specific 8914 connector functions.

The 8914 Dual AES/EBU Delay DA has two channels. Delay 1 is a 1x4 DA

with a looping input. Delay 2 is a 1x3 DA with a terminated input. Transformer coupling on the inputs eliminates common mode noise.

For a delay channel 1 signal, connect an input source to one of the

loopthrough input connectors, J9 or J10 (See Figure 3). Terminate the

unused connector into 75

nally terminated into 75

. Use J7 for input to delay channel 2. J7 is inter-

.

0547-05

8914 Instruction Manual 3

Figure 3. Typical Module Input and Outputs

Page 10

Ω

Ω

8914 Dual AES/EBU Delay Distribution Amplifier

Outputs

There are four identical outputs for delay channel 1— J2, J4, J6, and J8.

There are three identical outputs for delay channel 2 — J1, J3, and J5. The

destination equipment should have an input impedance of 75

has loopthrough inputs, in which case the unused loopthrough connector

must be terminated into 75

.

Adjustments, Testpoints, and Indicators

The 8914 DA has ground and +5V testpoints easily accessible on the front

edge of the module (see Figure 4).

Between the testpoints is a green Power On LED.

Each reclocking section is phase-locked to its AES input signal. The Lock

LEDs on the front of the module are on when the reclocking chip has locked

on the incoming AES data stream. There is one Lock LED for each channel

as shown.

unless it

5

6

4

7

3

8

2

9

Delay 1

A

Coarse increments

B

C

D

5

6

7

8

9

Delay 1

A

B

Fine increments

C

D

5

6

7

8

Delay 2

9

A

Coarse increments

B

C

D

5

6

7

8

Delay 2

9

A

Fine increments

B

C

D

Green LED indicates

Phase Lock Channel 1

Green LED indicates

Power On

Green LED indicates

Phase Lock Channel 2

+5V Testpoint

Ground Testpoint

0547_02

1

0

F

E

4

3

2

1

0

F

E

4

3

2

1

0

F

E

4

3

2

1

0

F

E

Figure 4. 8914 Adjustments, Testpoints, and Indicators

4 8914 Instruction Manual

Page 11

Delay Adjustments

Signal delay for each channel is set by two 16-position rotary switches that

provide additive coarse and fine adjustments. The amount of both the

inherent delay of the signal path and the increments of induced delay

varies according to signal data rate. Table 1 provides delay figures for the

three accepted AES data rates—48 KHz, 44.1 KHz, and 32 KHz.

Table 1. Delay Adjustment Settings

Adjustments, Testpoints, and Indicators

Input

Signal

48 KHz 1.2 ms

44.1 KHz 1.305 ms

32 KHz 1.799 ms

Minimum Delay

(switches @ 0,0)

48 KHz Input Signal Example

Inherent (minimum) circuit delay with no set delay adjustment (rotary

switches at 0, 0) is 1.2 ms. Any switch setting above 0,0 masks the inherent

delay and, starting at 2 ms, adds the selected number of delay increments.

For example, setting Coarse to 0 and Fine to 1 produces 2 ms of delay. Each

additional Fine switch increment adds 2 ms.

Setting Coarse to 1 and Fine to 0 produces 32 ms of delay. Each additional

Coarse switch increment adds 32 ms.

Adjustment

Fine 2 ms (96 frames)

Coarse 32 ms (8 blocks)

Fine 2.177 ms (96 frames)

Coarse 34.88 ms (8 blocks)

Fine 3 ms (96 frames)

Coarse 48 ms (8 blocks)

Adjustment

Increment

Incremental

Delay Range

2 ms to 510 ms

2.177 ms to 555.9 ms

3 ms to 765 ms

8914 Instruction Manual 5

Page 12

8914 Dual AES/EBU Delay Distribution Amplifier

Specifications

Table 2. 8914 Specifications

Parameter Value

Inputs

Number Two (1 loopthrough, 1 terminated)

Signal type AES/EBU digital audio, per AES3id:1995 and SMPTE 276M

Connector 75

Return loss > 25 dB, 0.1 to 6 MHz

Frame Rates 32, 44.1, or 48 KHz (Automatic selection)

Outputs

Number Seven (4 delay channel one, 3 delay channel two)

Signal type AES/EBU digital audio, per AES3id:1995 and SMPTE 276M

Connector 75

Return loss > 25 dB, 0.1 to 6 MHz

Intrinsic Jitter < 6 ns

Performance

Minimum Output Delay 1.2 ms

Maximum Output Delay 510 ms (127.5 AES/EBU blocks)

Environmental

Operating temperature range 0 to 45° C, noncondensing

Non-operating temperature range -10 to +70° C, noncondensing

Power Requirements

Supply Voltage +12 Volts

Power consumption 3.5 Watts

Physical

Frame Resides in standard 2 rack unit 8900 Series frame

Ω BNC

Ω BNC

6 8914 Instruction Manual

Page 13

Service

Service

The 8914 modules make extensive use of surface-mount technology and

programmed parts to achieve compact size and adherence to demanding

technical specifications. Circuit modules should not be serviced in the field.

If your module is not operating correctly, proceed as follows:

■

Check frame and module power and signal present LED.

■

Check for presence and quality of input signals.

■

Verify that source equipment is operating correctly.

■

Check cable connections.

■

Check output connections for correct I/O mapping (correct input is

used for the corresponding channel output).

Refer to Figure 4 for supply voltage test points on the 8914 module.

If the module is still not operating correctly, replace it with a known good

spare and return the faulty module to a designated Grass Valley repair

depot. Call your Grass Valley representative for depot location.

Refer to the

Contacting Grass Valley Group at the front of this document for

the Grass Valley Customer Service Information number.

8914 Instruction Manual 7

Page 14

8914 Dual AES/EBU Delay Distribution Amplifier

Functional Description

Refer to the block diagram in Figure 5 while reading the description.

There are 2 inputs for the module. One of these inputs is a loop-through

input. The data paths are otherwise conceptually identical for both inputs.

The inputs are first received by the receive circuit. Next, the Field Program-

mable Gate Array (FPGA) sends the data to the FIFO, which returns the

data to the FPGA. Finally, the data is passed to the transmit circuit.

Fine

Fine

Serial Data

Clock

Control

Serial Data

Clock

Control

Programmable

AES Input 1

Loop-through

AES Input 2

AES/EBU

Receiver

AES/EBU

Receiver

Delay Select Switches

Delay 1

Delay 2

Coarse

Coarse

Field

Gate Array

(FPGA)

Parallel Data

Control

Parallel Data

Parallel Data

Control

Parallel Data

AES Outputs

Delay

1

Line

Drivers

FIFO

FIFO

(Transmit)

Lock Ch. 1

Lock Ch. 2

Delay

2

0547-01

Figure 5. 8914 Dual AES/EBU Delay DA Block Diagram

Receive Circuit

This circuit features a digital audio transformer conforming to EBU stan-

dards.

The AES/EBU receiver recovers audio data and low jitter clocks from the

digital audio input transmission line. The data is reclocked, and then sent

to the FPGA. A special mode allows the preamble and bi-phase mark data

to pass through in its entirety. The 6.144 MHz clock signal is also sent to the

FPGA.

FPGA

The FPGA is a field programmable gate array containing proprietary Grass

Valley control circuitry. The FPGA converts the serial AES/EBU stream to

12-bit parallel data. The width of the data corresponds to the width of the

8 8914 Instruction Manual

Page 15

FIFO Circuits

Functional Description

FIFO (First In First Out) delay circuit. A small delay is introduced by the

nature of the serial to parallel circuit. The output goes to the external FIFO

chip.

The FIFO circuits are used to create various amounts signal delay. In the

FPGA, a separate controller is provided for each data stream to the FIFOs.

The two controllers perform the same functions. The controller outputs the

following signals: read reset, write reset, read clock, and write clock. The

read and write clocks are the same signal, and its frequency is determined

by the width of the parallel data.

The amount of delay is determined by two 16-position rotary switches.

Depending on input signal rate, the Fine switch delays the data by 2 to 3 ms

increments. The Coarse switch delays the data by 30 to 48 ms increments.

There is a minimum circuit delay of from 1.2 to 1.799 ms (for precise adjustment details, see

Adjustments, Testpoints, and Indicators on page 4 ).

The FIFO circuits create the signal delay. The FIFO receives parallel data

from the FPGA. All clock and control signals are provided by the FPGA.

The FIFO output is sent back to the FPGA.

Line Drivers

The delayed serial data is passed to the Line Driver (transmit) circuit.

Frequency Lock LEDs

The logic to turn on and off the Signal Lock LEDs is provided by the three

Error pins from the AES/EBU receiver. A no lock error condition (Lock

LED off) indicates that the phase-lock loop in the receiver is not locked to

the incoming data stream or the input signal is not present.

8914 Instruction Manual 9

Page 16

8914 Dual AES/EBU Delay Distribution Amplifier

10 8914 Instruction Manual

Page 17

Index

A

adjustments

1, 4

B

block diagram

8

C

cabling

circuit diagram

connections

controller module

input

output

3

8

3

3

3

D

delay adjustments

2

1, 4, 5

specification 6

L

LEDs 4

lock 4

M

module

controller

installation 2

power supply 2

2

O

outputs 6

connectors 4

specification 6

termination 3, 4

E

environmental specifications

F

frame

2, 3, 6

6

P

performance 6

phase lock 5

power requirements 6

power supply 2

R

G

repair depot 7

ground

I

impedance

indicator

input

8914 Instruction Manual Index-1

4

4

4

3, 6

loopthrough 3

rotary switch 1, 4

S

specifications 6

switch 4

delay 1

rotary 1

Page 18

T

termination 3

testpoints 4, 7

troubleshooting 7

Index-2 8914 Instruction Manual

Loading...

Loading...