Page 1

7600 SD/HD/MHD-REF

REFERENCE GENERATOR

Instruction Manual

SOFTWARE VERSION 2.0.0.X

071860000

OCTOBER 2007

Page 2

Affiliate with the N.V. KEMA in The Netherlands

CERTIFICATE

Certificate Number: 510040.001

The Quality System of:

Grass Valley, Inc.

400 Providence Mine Road

Nevada City, CA 95945

United States

15655 SW Greystone Ct.

Beaverton, OR 97006

United States

10 Presidential Way

rd

Floor, Suite 300

3

Woburn, MA 01801

United States

Nederland B.V.

4800 RP BREDA

The Netherlands

Technopole Brest Iroise

CS 73808

29238 Brest Cedex 3

France

7140 Baymeadows Way

Suite 101

Jacksonville, FL 32256

United States

Weiterstadt, Germany

Brunnenweg 9

D-64331 Weiterstadt

Germany

17 rue du Petit Albi-BP 8244

95801 Cergy Pontoise

Cergy, France

Rennes, France

Rue du Clos Courtel

Cesson-Sevigne, Cedex

France

2300 South Decker Lake Blvd.

Salt Lake City, UT 84119

United States

Including its implementation, meets the requirements of the standard:

ISO 9001:2000

Scope:

The design, manufacture and support of video hardware and software products and

related systems.

This Certificate is valid until: June 14, 2009

This Certificate is valid as of: August 30, 2006

Certified for the first time: June 14, 2000

H. Pierre Sallé

President

KEMA-Registered Quality

The method of operation for quality certification is defined in the KEMA General Terms

And Conditions For Quality And Environmental Management Systems Certifications.

Integral publication of this certificate is allowed.

KEMA-Registered Quality, Inc.

4377 County Line Road

Chalfont, PA 18914

Ph: (215)997-4519

Fax: (215)997-3809

CRT 001 073004

Accredited By:

ANAB

Page 3

7600 SD/HD/MHD-REF

REFERENCE GENERATOR

Instruction Manual

SOFTWARE VERSION 2.0.0.X

071860000

OCTOBER 2007

Page 4

Contacting Grass Valley

International

Support Centers

Local Support

Centers

(available

during normal

business hours)

France

24 x 7

Australia and New Zealand: +61 1300 721 495 Central/South America: +55 11 5509 3443

Middle East: +971 4 299 64 40 Near East and Africa: +800 8080 2020 or +33 1 48 25 20 20

Europe

+800 8080 2020 or +33 1 48 25 20 20

+800 8080 2020 or +33 1 48 25 20 20

Hong Kong, Taiwan, Korea, Macau: +852 2531 3058 Indian Subcontinent: +91 22 24933476

Asia

Southeast Asia/Malaysia: +603 7805 3884 Southeast Asia/Singapore: +65 6379 1313

China: +861 0660 159 450 Japan: +81 3 5484 6868

Belarus, Russia, Tadzikistan, Ukraine, Uzbekistan: +7 095 2580924 225 Switzerland: +41 1 487 80 02

S. Europe/Italy-Roma: +39 06 87 20 35 28 -Milan: +39 02 48 41 46 58 S. Europe/Spain: +34 91 512 03 50

Benelux/Belgium: +32 (0) 2 334 90 30 Benelux/Netherlands: +31 (0) 35 62 38 42 1 N. Europe: +45 45 96 88 70

Germany, Austria, Eastern Europe: +49 6150 104 444 UK, Ireland, Israel: +44 118 923 0499

Copyright © Grass Valley. All rights reserved.

This product may be covered by one or more U.S. and foreign patents.

United States/Canada

24 x 7

+1 800 547 8949 or +1 530 478 4148

Grass Valley Web Site

The www.thomsongrassvalley.com web site offers the following:

Online User Documentation — Current versions of product catalogs, brochures,

data sheets, ordering guides, planning guides, manuals, and release notes

in .pdf format can be downloaded.

FAQ Database — Solutions to problems and troubleshooting efforts can be

found by searching our Frequently Asked Questions (FAQ) database.

Software Downloads — Download software updates, drivers, and patches.

4 7600 SD/HD/MHD-REF — Instruction Manual

Page 5

Contents

Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety Terms and Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Terms in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Terms on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Symbols on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Certifications and Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

FCC Emission Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Canadian EMC Notice of Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

EN55022 Class A Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Canadian Certified Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Canadian Certified AC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

FCC Emission Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7600 SD-/HD-/MHD-REF Reference Generator . . . . . . . . . . . . . . . . . . . . . . . . 17

Product Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7600REF Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7600 SD-REF Reference Signal Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7600 HD-REF Reference Signal Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7600 MHD-REF Master HD Reference Signal Generator. . . . . . . . . . . . . . . . . 18

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Module/Software Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Rack Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Rear Panel Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Grounding Lug. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Ethernet Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Tri-Level Sync Reference (7600 HD-REF and MHD-REF Models). . . . . . . . . 20

HD/SD SDI Test Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Analog Audio/Remotes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Analog BB Reference/Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

10/27/WC Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Genlock Loop Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5/10 Ref In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

AES 1/AES 2 and GPS BNCs (7600 MHD-REF Model) . . . . . . . . . . . . . . . . . . 24

AES Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

LTC Output (7600 MHD-REF Model). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

AC Mains Connection and Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Power Supply Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Front Panel Control Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7600 SD/HD/MHD-REF — Instruction Manual 5

Page 6

Contents

Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Selecting a Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Changing Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Leaving the Selected Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Menu Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Front Panel Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Top Level Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Digital Video Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Analog Video Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Audio Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Lock Mode Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Status Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Options Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Digital Video Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Digital Video – Video Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Digital Video – Test Patterns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Digital Video – Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Digital Video – AES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Digital Video – EDH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Analog Video Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Analog Video – All Black and Burst. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Analog Video – YUV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Analog Video – Composite/BB/BE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Analog Video – RGB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Analog Video – YC/BB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Audio Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Audio – AES 1 and AES 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Audio – Analog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Lock Mode Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Genlock – Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Genlock Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Genlock – Field Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Genlock – Input Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Setup – GPI Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Setup – More . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Setup – Comms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Status Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Option Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

GPS Setup (7600 MHD-REF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Timecode Functionality (7600 MHD-REF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Network Time Protocol (NTP) (7600 MHD-REF Model) . . . . . . . . . . . . . . . . 68

HD Tri-Level Sync (7600 HD-REF and 7600 MHD-REF Models) . . . . . . . . . 69

Using a TFTP Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Local Area Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Preparing a TFTP Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Preparing the 7600REF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Generating the Log File (Digital Signature) . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Updating 7600 Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparing to Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Preparing the 7600REF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Completing the Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

73

6 7600 SD/HD/MHD-REF — Instruction Manual

Page 7

Preface

About This Manual

This manual covers the complete details of the 7600REF Reference Generator, including installation, setup, operation, and specifications.

In addition to this manual, a 7600REF Installation and Safety Manual is

included with every frame to ensure that the required regulatory and safety

information for this product is available when the frame is received.

All documentation relating to this product and other Grass Valley Modular

products can be found on-line in PDF format at this URL:

www.thomsongrassvalley.com/docs/modular

7600 SD/HD/MHD-REF — Instruction Manual 7

Page 8

Preface

8 7600 SD/HD/MHD-REF — Instruction Manual

Page 9

Safety Summary

Read and follow the important safety information below, noting especially

those instructions related to risk of fire, electric shock or injury to persons.

Additional specific warnings not listed here may be found throughout the

manual.

WARNING Any instructions in this manual that require opening the equipment cover

or enclosure are for use by qualified service personnel only. To reduce the

risk of electric shock, do not perform any servicing other than that contained in the operating instructions unless you are qualified to do so.

Safety Terms and Symbols

Terms in This Manual

Safety-related statements may appear in this manual in the following form:

WARNING Warning statements identify conditions or practices that may result in per-

sonal injury or loss of life.

CAUTION Caution statements identify conditions or practices that may result in damage

to equipment or other property, or which may cause equipment crucial to

your business environment to become temporarily non-operational.

Terms on the Product

The following terms may appear on the product:

DANGER — A personal injury hazard is immediately accessible as you read

the marking.

WARNING — A personal injury hazard exists but is not immediately acces-

sible as you read the marking.

CAUTION — A hazard to property, product, and other equipment is present.

7600 SD/HD/MHD-REF — Instruction Manual 9

Page 10

Safety Summary

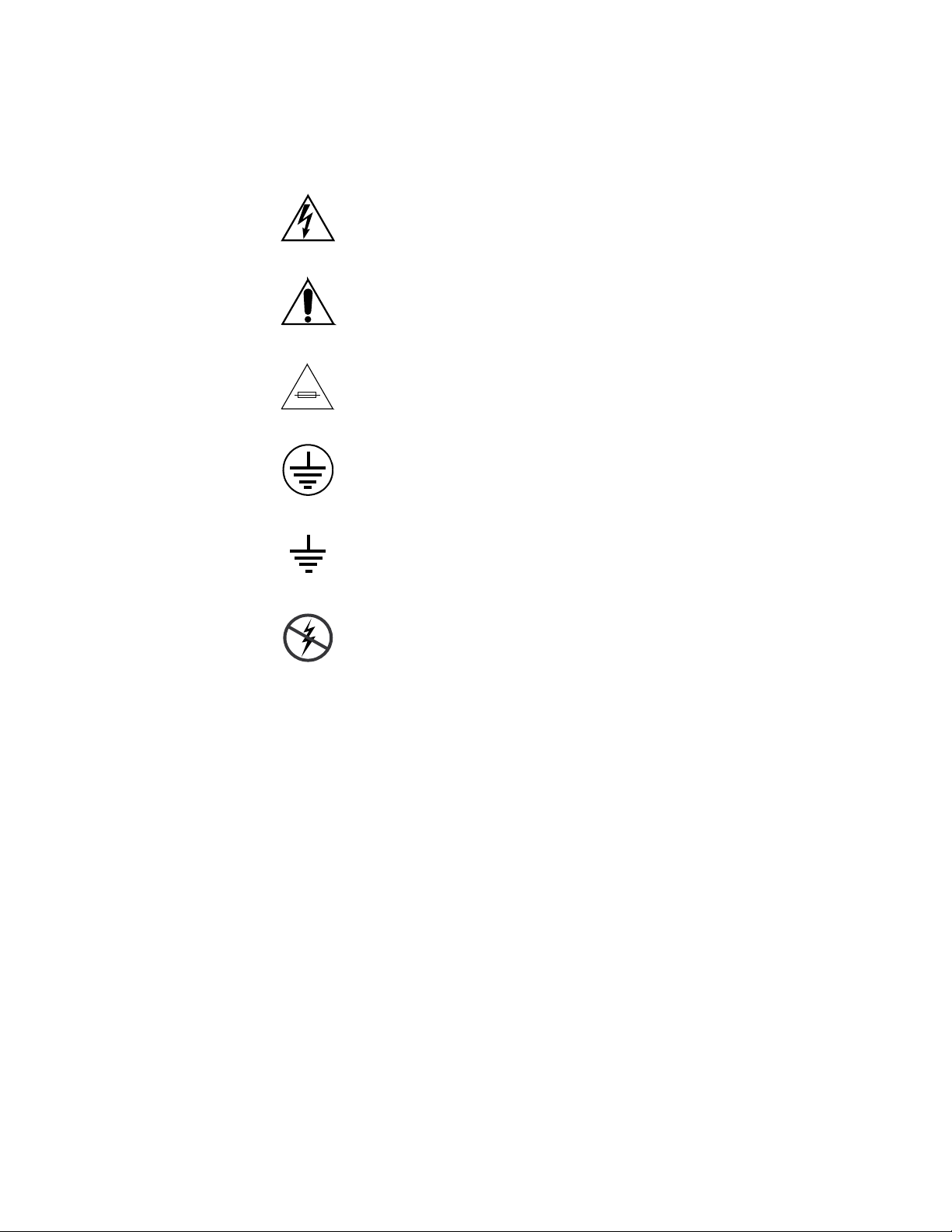

Symbols on the Product

The following symbols may appear on the product:

Indicates that dangerous high voltage is present within the

equipment enclosure that may be of sufficient magnitude to

constitute a risk of electric shock.

Indicates that user, operator or service technician should refer

to product manual(s) for important operating, maintenance,

or service instructions.

This is a prompt to note fuse rating when replacing fuse(s).

The fuse referenced in the text must be replaced with one

having the ratings indicated.

Identifies a protective grounding terminal which must be connected to earth ground prior to making any other equipment

connections.

Warnings

Identifies an external protective grounding terminal which

may be connected to earth ground as a supplement to an

internal grounding terminal.

Indicates that static sensitive components are present which

may be damaged by electrostatic discharge. Use anti-static

procedures, equipment and surfaces during servicing.

The following warning statements identify conditions or practices that can

result in personal injury or loss of life.

Dangerous voltage or current may be present — Disconnect power and remove

battery (if applicable) before removing protective panels, soldering, or

replacing components.

Do not service alone — Do not internally service this product unless another

person capable of rendering first aid and resuscitation is present.

Remove jewelry — Prior to servicing, remove jewelry such as rings, watches,

and other metallic objects.

Avoid exposed circuitry — Do not touch exposed connections, components or

circuitry when power is present.

10 7600 SD/HD/MHD-REF — Instruction Manual

Page 11

Safety Summary

Use proper power cord — Use only the power cord supplied or specified for

this product.

Ground product — Connect the grounding conductor of the power cord to

earth ground.

Operate only with covers and enclosure panels in place — Do not operate this

product when covers or enclosure panels are removed.

Use correct fuse — Use only the fuse type and rating specified for this

product.

Use only in dry environment — Do not operate in wet or damp conditions.

Use only in non-explosive environment — Do not operate this product in an

explosive atmosphere.

High leakage current may be present — Earth connection of product is essential

before connecting power.

Dual power supplies may be present — Be certain to plug each power supply

cord into a separate branch circuit employing a separate service ground.

Disconnect both power supply cords prior to servicing.

Cautions

Double pole neutral fusing — Disconnect mains power prior to servicing.

Use proper lift points — Do not use door latches to lift or move equipment.

Avoid mechanical hazards — Allow all rotating devices to come to a stop before

servicing.

The following caution statements identify conditions or practices that can

result in damage to equipment or other property

Use correct power source — Do not operate this product from a power source

that applies more than the voltage specified for the product.

Use correct voltage setting — If this product lacks auto-ranging power sup-

plies, before applying power ensure that the each power supply is set to

match the power source.

Provide proper ventilation — To prevent product overheating, provide equip-

ment ventilation in accordance with installation instructions.

Use anti-static procedures — Static sensitive components are present which

may be damaged by electrostatic discharge. Use anti-static procedures,

equipment and surfaces during servicing.

7600 SD/HD/MHD-REF — Instruction Manual 11

Page 12

Safety Summary

Do not operate with suspected equipment failure — If you suspect product damage

or equipment failure, have the equipment inspected by qualified service

personnel.

Ensure mains disconnect — If mains switch is not provided, the power cord(s)

of this equipment provide the means of disconnection. The socket outlet

must be installed near the equipment and must be easily accessible. Verify

that all mains power is disconnected before installing or removing power

supplies and/or options.

Route cable properly — Route power cords and other cables so that they ar not

likely to be damaged. Properly support heavy cable bundles to avoid connector damage.

Use correct power supply cords — Power cords for this equipment, if provided,

meet all North American electrical codes. Operation of this equipment at

voltages exceeding 130 VAC requires power supply cords which comply

with NEMA configurations. International power cords, if provided, have

the approval of the country of use.

Use correct replacement battery — This product may contain batteries. To

reduce the risk of explosion, check polarity and replace only with the same

or equivalent type recommended by manufacturer. Dispose of used batteries according to the manufacturer’s instructions.

Troubleshoot only to board level — Circuit boards in this product are densely

populated with surface mount technology (SMT) components and application specific integrated circuits (ASICS). As a result, circuit board repair at

the component level is very difficult in the field, if not impossible. For warranty compliance, do not troubleshoot systems beyond the board level.

12 7600 SD/HD/MHD-REF — Instruction Manual

Page 13

Regulatory Notices

Certifications and Compliances

FCC Emission Control

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equip

ment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equip

ment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

Changes or modifications not expressly approved by Grass Valley Group

can affect emission compliance and could void the user’s authority to

operate this equipment.

-

-

Canadian EMC Notice of Compliance

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference Regula

tions of the Canadian Department of Communications.

Le présent appareil numérique n’emet pas de bruits radioélectriques

dépassant les limites applicables aux appareils numeriques de la classe. A

préscrites dans le Règlement sur le brouillage radioélectrique édicte par le

ministère des Communications du Canada.

EN55022 Class A Warning

In a domestic environment, products that comply with Class A may cause

radio interference in which case the user may be required to take adequate

measures.

-

7600 SD/HD/MHD-REF — Instruction Manual 13

Page 14

Regulatory Notices

Canadian Certified Power Cords

Canadian Certified AC Adapter

FCC Emission Limits

Canadian approval includes the products and power cords appropriate for

use in the North America power network. All other power cords supplied

are approved for the country of use.

Canadian approval includes the AC adapters appropriate for use in the

North America power network. All other AC adapters supplied are

approved for the country of use.

This device complies with Part 15 of the FCC rules.Operation is subject to

the following two conditions: (1) This device must cause not interference,

and (2) this device must accept any interference received, including inter

-

ference that may cause undesirable operation.

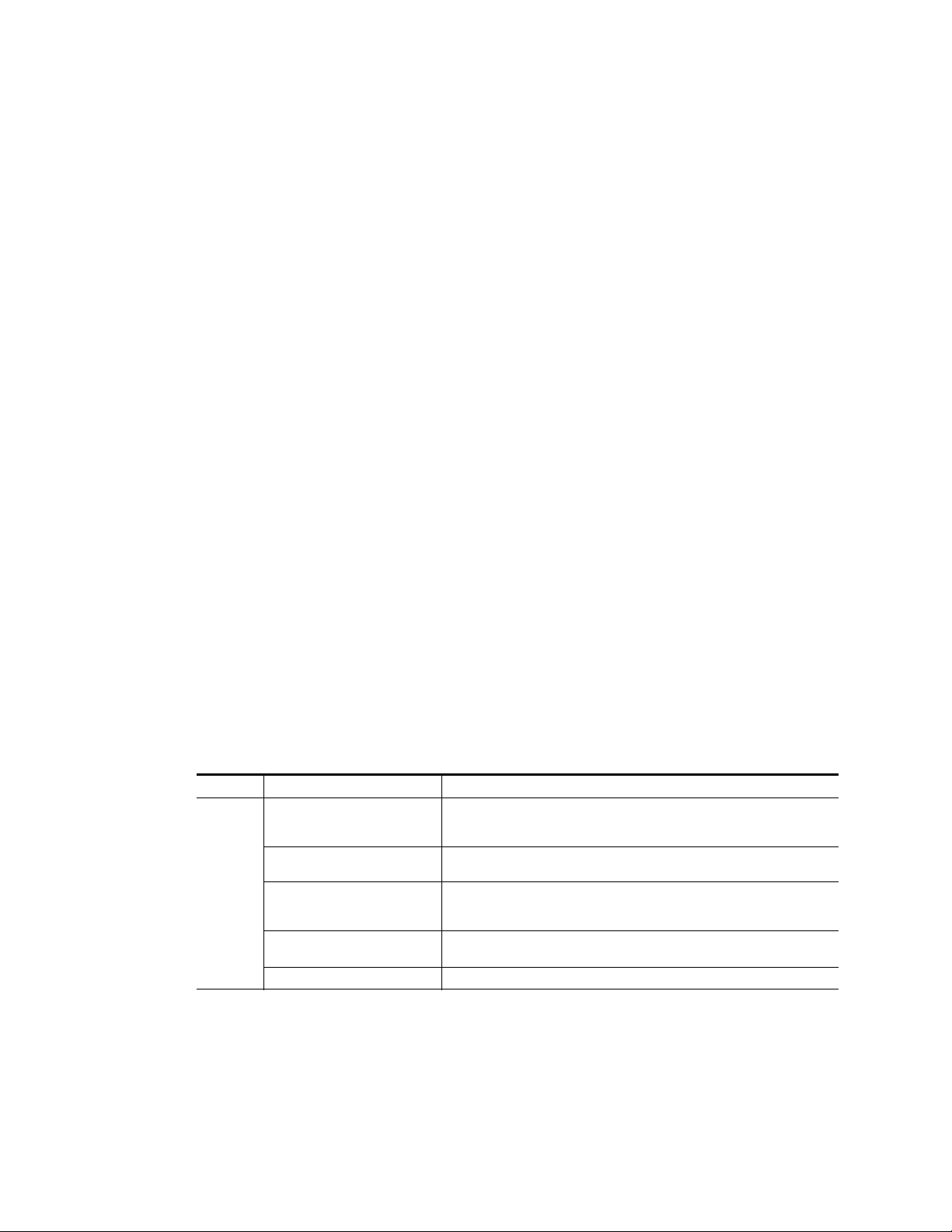

Certifications

Category Standard Designed/tested for compliance with:

Safety

Safety – This product has been evaluated and meets the following Safety

Certification Standards listed under the Safety category in the table below.

EMI – TThis product has been evaluated for Electromagnetic Compatibility

under the EN 55022 / EN 55024 standards for Emissions and Immunity and

meets the requirements listed under the EMI Category in the table below.

This product complies with Class A. In a domestic environment this

product may cause radio interference in which case the user may be

required to take adequate measures.

ANSI / UL60950 “Standard for Safety of Information Technology Equipment - Safety - Part 1: General

Requirements”, (ANSI/UL 60950-1, First Edition, Dated April 1, 2003, with revision

through and including November 26, 2003.)

IEC 60950 “Standard for Safety for Information Technology Equipment - Safety - Part 1: General

Requirements”, (IEC 60950-1, First Edition, 2001, Corrigendum 1:10-2002)

CAN/CSA C22.2, No. 60950 “Standard for Safety of Information Technology Equipment - Safety - Part 1: General

Requirements”, (CAN/CSA-C22.2 No. 60950-1-03. First Edition Dated April 1,

2003, with revisions through and including November 26, 2003)

EN60950 Safety of Information Technology Equipment, including Electrical Business Equip-

ment.

73/23/EEC Low Voltage Directive

14 7600 SD/HD/MHD-REF — Instruction Manual

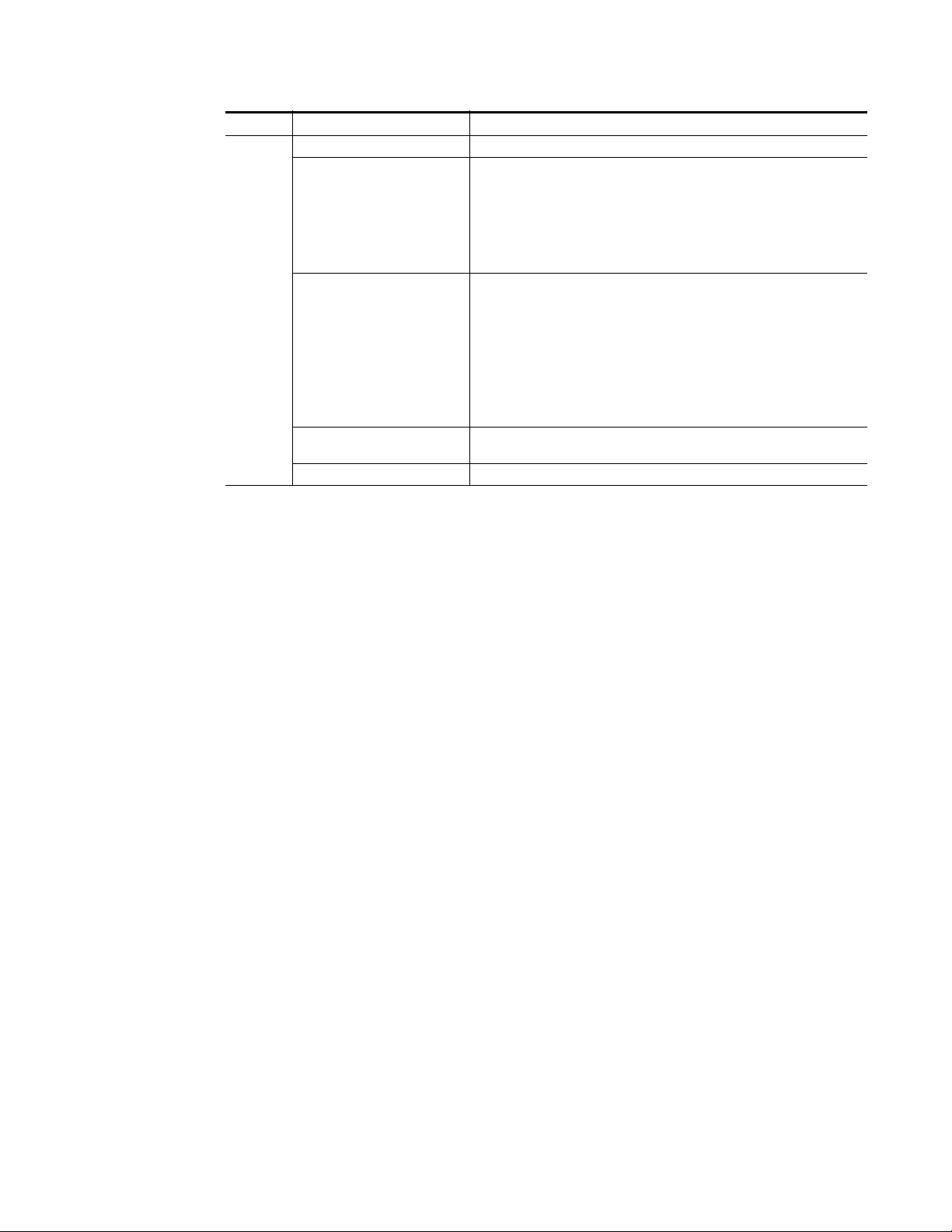

Page 15

Category Standard Designed/tested for compliance with:

EMC Directive 89/336/EEC Information and Technology Equipment

EMI

EN 55022: 1998, Inc.

A1:2000 & A2:2003

Radio Disturbance Characteristics

EN 55024:1998, Inc.

A1:2000 & A2:2003

Immunity Characteristics

US FCC Class A

Canada FCC Industry Canada

Australia & New Zealand: AS/NZS 3548

Electromagnetic compatibility.

Product family standard for Information and Technology equipment for professional

use.

Emissions, Class A

EN 61000-3-2: Power Line Harmonic Emissions, Radiated Magnetic Field Emissions, Peak Inrush Current

EN61000-3-3: Mains voltage flicker and manual switching (Dmax = 4%)

Electromagnetic compatibility--Product family standard for Information and Technology equipment for professional use.

EN 61000-4-2:

Electrostatic Discharge “ESD” Immunity

EN 61000-4-3:

Radiated RF Electromagnetic Field Immunity

EN 61000-4-4:

Electrical Fast Transient/Burst “EFT” Immunity

EN 61000-4-5: Surge Immunity

EN 61000-4-6: Conducted RF Immunity

EN 61000-4-11: Voltage Dips, Short Interruptions and Voltage Variations

CISPR Pub. 22 (1997 Class A)

Regulatory Notices

7600 SD/HD/MHD-REF — Instruction Manual 15

Page 16

Regulatory Notices

16 7600 SD/HD/MHD-REF — Instruction Manual

Page 17

7600 SD-/HD-/MHD-REF Reference Generator

Product Overview

The 7600REF Synchronizing Pulse Generator is one of the most flexible SPG

units available on the market today. It is suitable for any digital or mixed

format environment where a high quality digital SPG is required. This

manual covers the installation and operation of the three available models

along with full technical specifications.

Refer to 7600REF Models on page 18 for specific functionality available for

each of the model types: 7600 SD-REF, 7600 HD-REF, and 7600 MHD-REF.

Each 7600REF model has the following basic functionality:

• Oven-controlled reference oscillator allowing the unit to be used either

as a master reference, or to follow another unit,

• Five analog outputs,

• Three SD SDI black outputs with four channels of embedded AES

silence and EDH,

• Two AES silence outputs,

• Each output selectable to either 525 or 625 operation,

• Each input individually timed,

• Dual power supplies that auto-sense line rates with separate mains

connections for power backup in the case of one power supply failure,

• Selectable clock output of 10 MHz/27 MHz/Word Clock,

• Looping Genlock input,

• 10 MHz Reference input

• ANALOG AUDIO/REMOTES connector that provides:

• A serial communication port,

• Analog audio output test tones,

• Power fail output status,

• Fan failure status, and GPI input output control connections.

7600 SD/HD/MHD-REF — Instruction Manual 17

Page 18

Product Overview

7600REF Models

7600 SD-REF Reference Signal Generator

7600 HD-REF Reference Signal Generator

Functionality specific to the three different 7600REF models is described

below.

This model features the following functionality:

• SD-SDI and analog video test signal patterns,

• Analog and AES audio test tones (including GLITS), and

• Full-field test patterns.

This model provides the same features as the SD version in addition to the

following:

• HD-SDI video test patterns, and

• A one slot HD Tri-level sync module provides 4 tri-level sync outputs,

each output individually configured from the front panel.

7600 MHD-REF Master HD Reference Signal Generator

This module expands the 7600 HD-REF model to include the following:

• A one slot GPS receiver module with a GPS antenna input and a

GPS 1 PPS output allows for locking to a high stability time and oscillator reference,

• Two LTC timecode outputs available on the LTC D-25 connector and

the addition of VITC timecode to the SDI signal, and

• Network Time Protocol (NTP) with both Client and Server modes. NTP

is intended for synchronizing function for changeover units (such as

the 7620PX) to keep them both in sync.

18 7600 SD/HD/MHD-REF — Instruction Manual

Page 19

Installation

Unpacking

Module/Software Installation

Installation

Follow the instructions below to unpack, install, and cable the 7600REF

frame.

Carefully unpack the unit from its packing box and check for signs of

damage. Check the contents of the box against the packing list and your

original order to ensure that you have received the correct parts.

In the event the unit has been damaged or does not match your order,

contact the Thomson Grass Valley Sales office listed on Contacting Grass

Valley on page 4.

All hardware modules are installed at the factory and shipped inside the

unit. Module functionality included in the model configuration depends

on the model type (see

ality included with the model is already installed and enabled.

7600REF Models on page 18). Any software function-

Rack Mounting

The 1 RU rack frame has integral rack mounting ears on the frame front

cover for direct mounting into a standard 19 inch rack. Carefully place the

unit in your rack and firmly attach it to the rack using four standard rack

screws (not provided).

CAUTION This unit has air intakes on one side of the unit and fan-assisted exhaust vents

on the other side of the unit. Ensure that these have an unobstructed air flow,

otherwise the unit will overheat. Pay particular attention to ensure that any

rack wiring or cable trays do not obstruct the vent. 60 mm (2.36 in.) of clear

space should be allowed between the vents and any potential obstruction.

7600 SD/HD/MHD-REF — Instruction Manual 19

Page 20

Installation

Rear Panel Connections

Grounding Lug Tri-level Sync Outputs

The rear connectors for the 7600REF frame are shown in Figure 1. Presence

of hardware and software functionality depends on the model you have

purchased (see

7600REF Models on page 18). Cabling instructions for each

of the connectors are explained in detail in this section.

Figure 1. 7600REF Rear Backplane

GPS Option/AES Unbalanced Audio

AES Audio Out (Balanced)

4321 432 1

TRI-

LEVEL SYNC

321

ETHERNET

Ethernet Port Analog Audio and Remote Control

SD/HD SDI Outputs

SD/HD SDI

ANALOG AUDIO/REMOTES

54321

Analog BB Reference/Test Outputs

Grounding Lug

The unit is provided with a single 4 mm (0.16 in.) ground lug on the far left

of the rear panel. Incoming mains ground from the IEC connector is inter

nally bonded to both the chassis and technical 0V to meet safety requirements and performance specifications. The stud allows the addition of an

ground strap, if required, for rack installations.

Ethernet Port

Each 7600REF model is equipped with a 10/100 base-T Ethernet port. This

port may be configured for either dynamic (DHCP) address mode or static

address mode. Configuration is done in the Setup menu (see

page 47). The 7600REF should be connected to the network in the same way

as other networked devices (such as a computer or printer) with a 1:1 CAT 5

RJ-45 cable.

TEST

SIGNALS

TEST

BB/ANALOG

AES 2GPS 1 PPS

AES 1

10/27/WC OUT

10/27/WC Out

Genlock Loop input

LOOP

GENLOCK

5/10 REF IN

5/10 Ref In

AES

LTC Out

47-63Hz

AC ONLY

AC/Mains InAC/Mains In

90-260V

2A-1A

47-63Hz

AC ONLY

90-260V

2A-1A

LTC

-

Setup Menu on

Tri-Level Sync Reference (7600 HD-REF and MHD-REF Models)

The TRI-LEVEL SYNC REFERENCE BNCs will output four independently

configured tri-level sync outputs. Setup is done in the Options menu (

HD

Tri-Level Sync (7600 HD-REF and 7600 MHD-REF Models) on page 69).

HD/SD SDI Test Outputs

The outputs from the SD/HD SDI TEST BNCs 1, 2, and 3, provide three

independently configured test signals. If the HD video capability is

present, further HD video formats are available. The three outputs are con

figured in the Digital Video menu (Digital Video Menu on page 33).

20 7600 SD/HD/MHD-REF — Instruction Manual

-

Page 21

These outputs also offer a combination of the following LTC (Longitudinal

Timecode) features with LTC capability (7600 MHD-REF model):

• Digital VITC (SMPTE S266) for standard definition signals only, and

• ATC (SMPTE RP188) for standard definition or high definition SD sig-

nals.

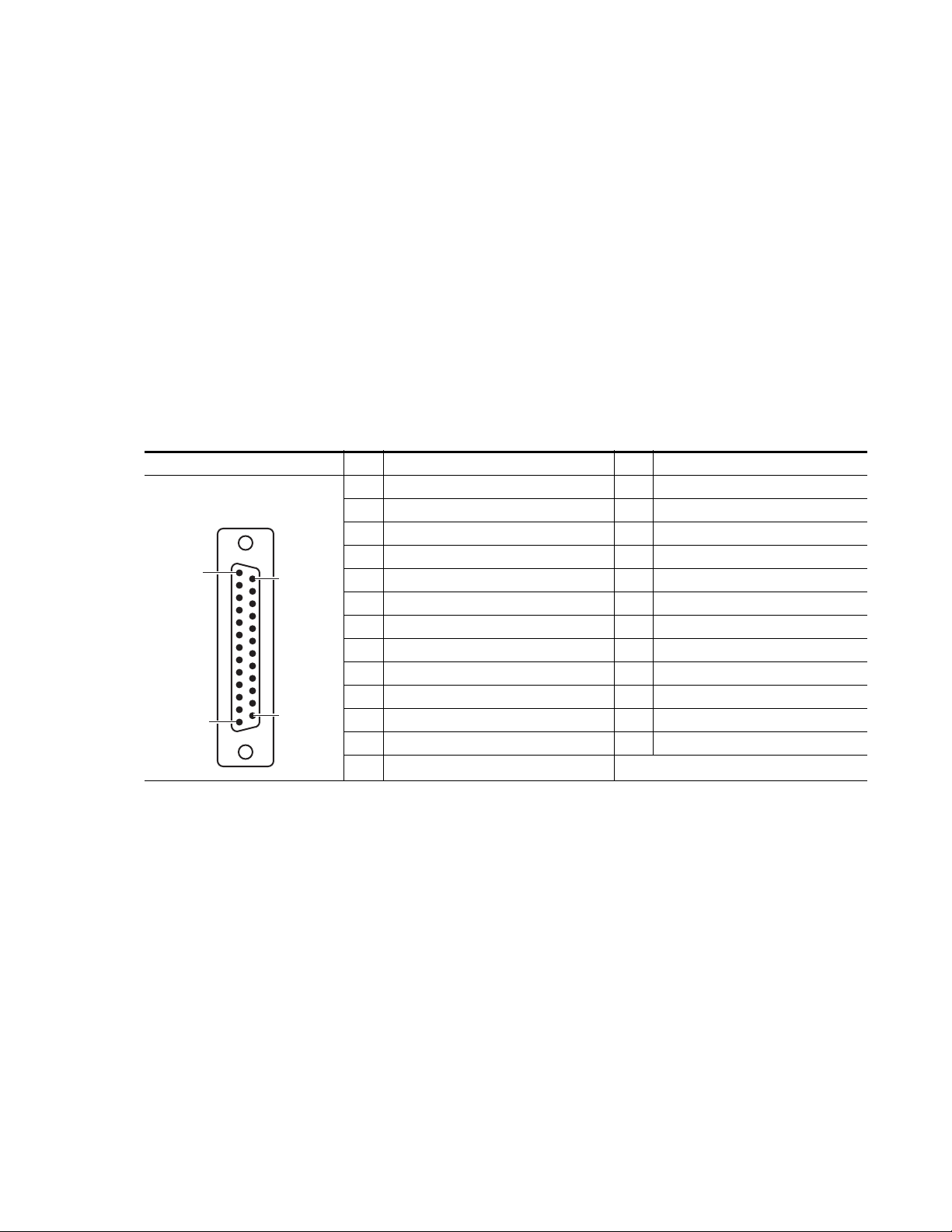

Analog Audio/Remotes

The 25 pin Sub-D connector labeled ANALOG AUDIO/REMOTES provides a serial communication port, the analog audio output tones, power

fail output status, fan failure status, and the GPI connections.

Pinouts for the ANALOG AUDIO/REMOTES connector are given in

Ta bl e 1. Each of the connector function is described in detail in this section.

Table 1. ANALOG AUDIO/REMOTES Connector Pinouts

ANALOG AUDIO/REMOTES Pin Function Pin Function

Power OK 1

Power OK 2

Fan OK - 2

GPIO - Input 2

GPIO - Input 1

RS422 CTS + (plus)

GPIO - Output 2

RS422 RTS + (plus)

Analog Audio Out 1 – (minus)

Analog Audio Out 2 – (minus)

Pin 1

Pin 13

D-25 Female

Pin 14

Pin 25

1 Fan OK -1 (Pair with pin 16. Closed if OK) 14

2 RS422 CTS – (minus) 15

3 RS422 RXD + (plus) 16

4 RS422 TSD + (plus) 17 GPIO - Output 1

5 RS422 RTS – (minus) 18

6 RS422 TXD – (minus) 19

7GND 20

8 RS422 RXD – (minus) 21

9GND 22

10 + 12V DC / 0.3A 23

11 Analog Audio Out 1 + (plus) 24

12 Analog audio Out 2 + (plus) 25 GND

13 GND

Installation

Fan Failure Output

This open collector output senses the current drawn by the cooling fans

fitted to the enclosure. The detector indicates a failure if a fan is stuck

and/or an open circuit is detected.

7600 SD/HD/MHD-REF — Instruction Manual 21

Page 22

Installation

GPI Inputs 1 and 2

The General Purpose Interface (GPI) inputs 1 and 2 are configured in software using the menus described in GPI Inputs 1 and 2 on page 22 to provide

any of the following functions:

•Force freerun mode

•Force Genlock mode

• Force external 10MHz lock mode

• Step through SDI output 1 test patterns

• Step through SDI output 2 test patterns

• Step through SDI output 3 test patterns

• Step through setup memories

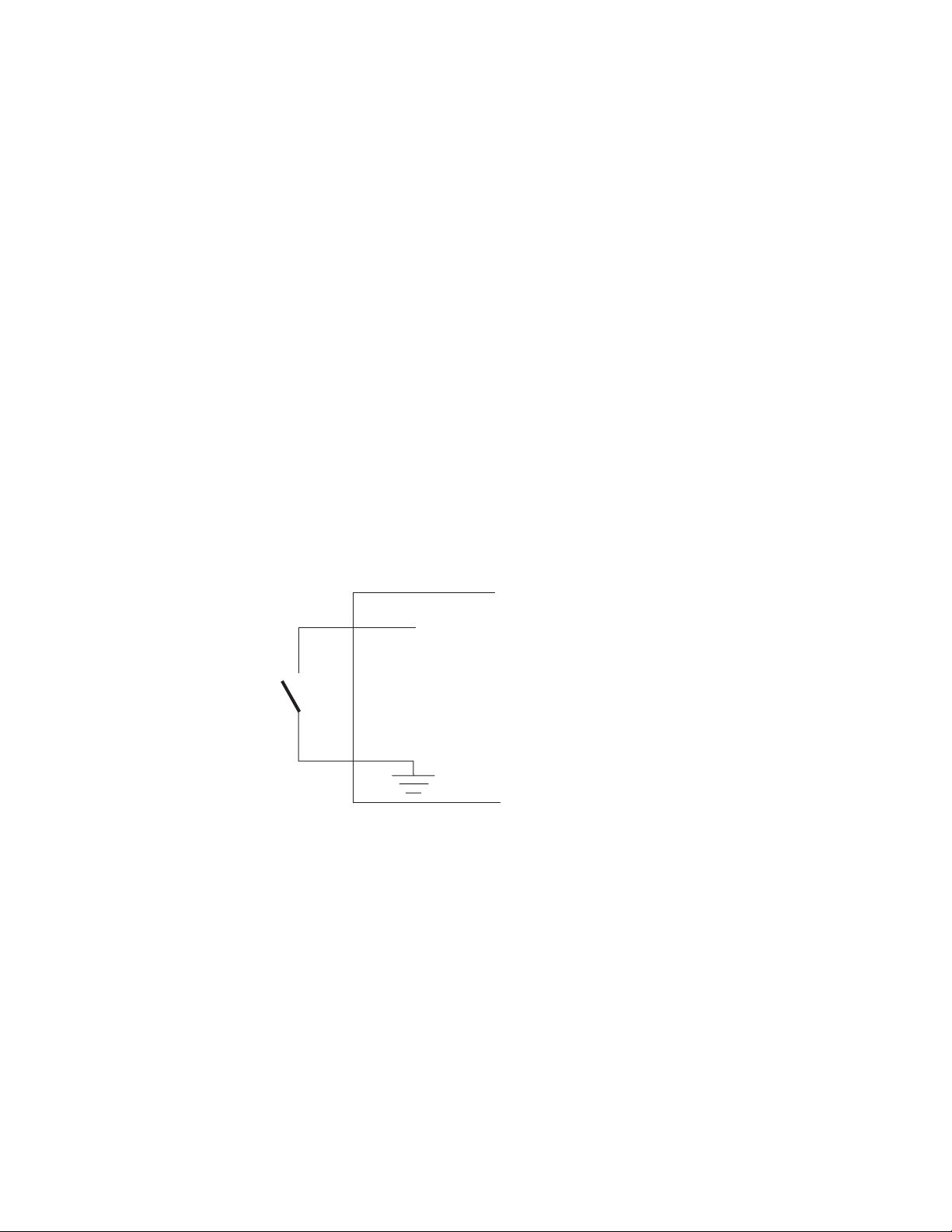

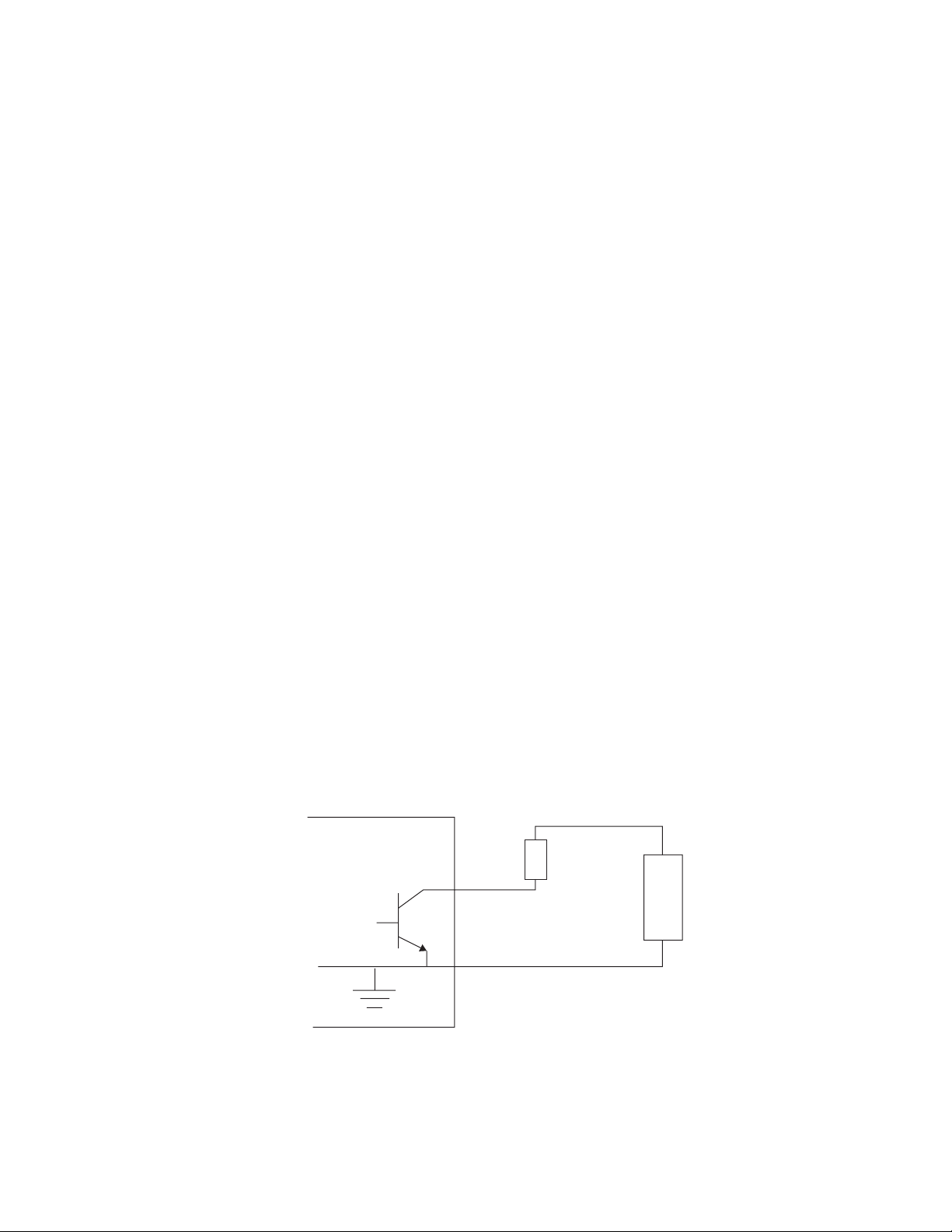

The single-ended 7600 GPI inputs are activated when connected to a

ground connection on the 25 pin Sub-D connector as shown in

The two GPI inputs are pin 18 and pin 19 as listed in Tab le 1 on page 21. The

inputs can withstand +/- 20V and draw approximately 600uA when activated.

Figure 2.

Figure 2. Connection to GPI Inputs

7600Ref

GPI In

22 7600 SD/HD/MHD-REF — Instruction Manual

Page 23

Installation

GPI Outputs 1 and 2

The General Purpose Interface (GPI) outputs 1 and 2 are configured in software using the menus described in GPI Outputs 1 and 2 on page 23 to

provide any of the following functions:

• Loss of genlock input

• Loss of external 10MHz reference

• Line lock error

• Field lock error

• Subcarrier lock error

• Illegal input ScH

• Diagnostic state alert

• Currently locked to external 10MHz

• Currently locked to external genlock

• Currently internal/freerun mode

The GPI outputs are single-ended open collector outputs with a

50V/200mA rating not to exceed 600 mW. The two GPI outputs are pin 17

and pin 21 as listed in

activated when one or more of the above conditions is true (for example,

loss of genlock input and/or line lock error).

To use an output, a load should be connected between the output and an

external power supply, with the negative end of the power supply connected back to the ground pin on the 25 pin Sub-D connector.

As an alternate to an external power supply, a +12V, 300mA feed is available on pin 10 of the Sub-D connector.

Figure 3. Connection to GPI Outputs

7600REF

GPO

Tab le 1 on page 21. It is intended that the GPO be

+

Load

Power Supply

_

7600 SD/HD/MHD-REF — Instruction Manual 23

Page 24

Installation

Analog BB Reference/Test

The five ANALOG BB REFERENCE/TEST BNCs provide independent

black burst reference signals and/or video test signal outputs as configured

in the Analog Video menus (see

10/27/WC Output

The 10/27/WC BNC provides either a 10MHz, 27MHz, or Word Clock

output. The output type is configured in the Setup/Clock Output menu

(

Setup Menu on page 47).

Genlock Loop Input

The GENLOCK LOOP BNCs provide an external genlock reference input

to the device. Genlock configuration is done in the Lock menu (

Menu on page 44).

5/10 Ref In

Analog Video Menu on page 36).

Lock Mode

The 5/10 REF IN BNC accepts either a 5MHz or 10MHz reference input.

AES 1/AES 2 and GPS BNCs (7600 MHD-REF Model)

The blanks for AES 1 and AES 2 unbalanced outputs and the GPS and 1PPS

BNCs shown in

Figure 8 on page 35 are present with the 7600 MHD-REF

model. Setup for AES outputs is described in Digital Video – AES on

page 35. GPS setup is described in GPS Setup (7600 MHD-REF) on page 52.

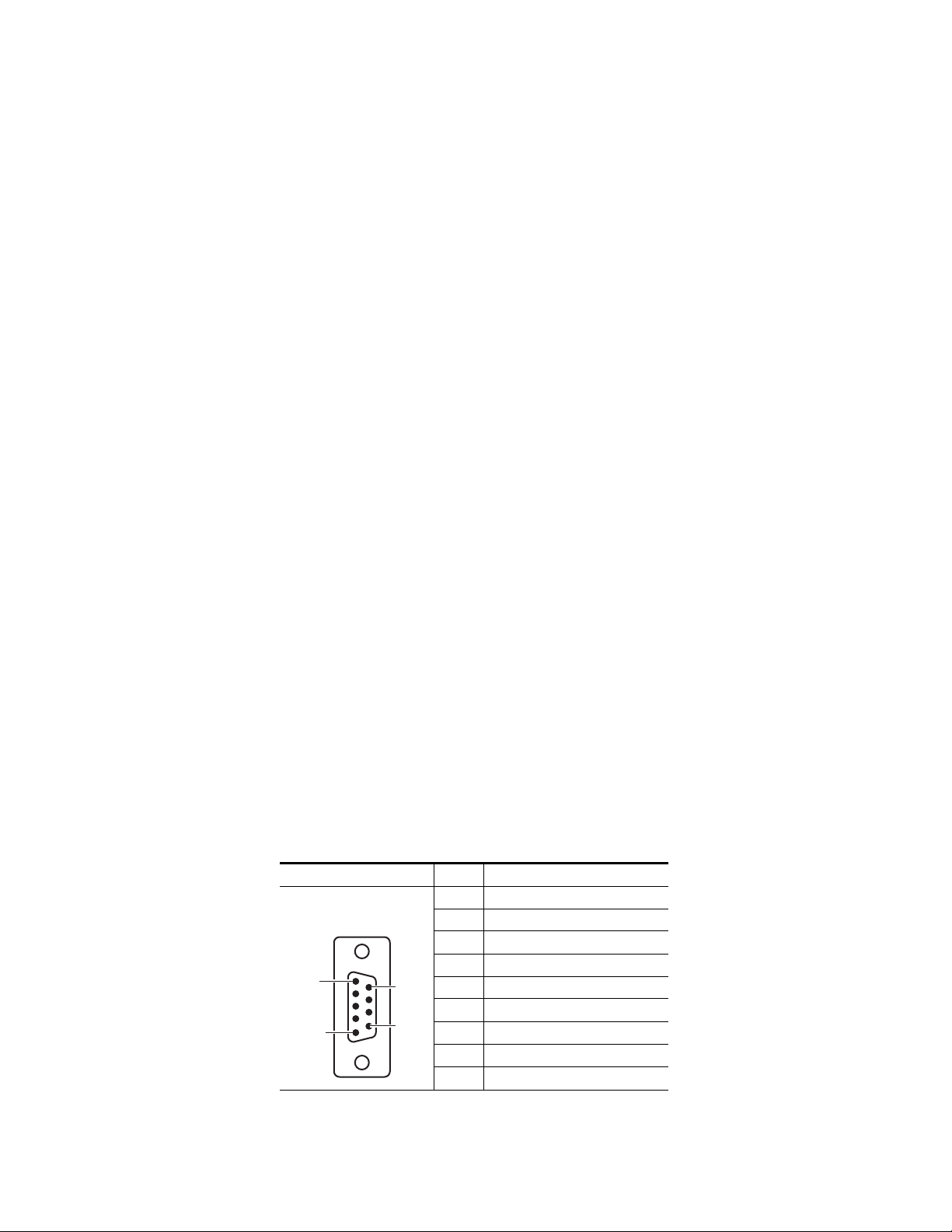

AES Outputs

The AES 9 pin Sub-D female connector provides balanced AES audio 1 and

2 outputs. The pinouts and their functions for this connector are

AES

shown in

described in Digital Video – AES on page 35.

Table 2. AES Pin Sub-D Pinout

Pin 1

Pin 5

Ta bl e 2. Setup of these outputs is done in the Audio/AES menu

AES Audio Out Pin Function

1 AES 1 + (plus)

D-9 Female

Pin 9

Pin6

2 AES 1 – (minus)

3Shield

4N/C

50V GND

6Shield

7 AES 2 + (plus)

8 AES 2 – (minus)

Shield

9

24 7600 SD/HD/MHD-REF — Instruction Manual

Page 25

AES audio may also be accessed through the unbalanced AES 1 and AES 2

BNCs when they are present. This requires the GPS function with the 7600

MHD-REF model. See GPS Setup (7600 MHD-REF) on page 52.

LTC Output (7600 MHD-REF Model)

The LTC (Longitudinal Timecode) 9 pin Sub-D female connector provides

LTC 1 and LTC 2 outputs with the 7600 MHD-REF model. The LTC function

provides the following:

• Two outputs of LTC

• Vertical Interval Timecode (VITC) superimposed on analog waveforms.

This is enabled or disabled in accordance with the current group

arrangement of the analog signal outputs.

• SDI outputs (see HD/SD SDI Test Outputs on page 20) will offer a com-

bination of Digital VITC (SMPTE S266) for standard definition signals

only and ATC (SMPTE RP188) for standard definition or high definition

SD signals.

The pinouts and their functions for this connector are shown in Table 3 .

Configuration is done from the Setup/LTC menu. Refer toTimecode Func-

tionality (7600 MHD-REF) on page 58.

Installation

Table 3. LTC Output Sub-D Pinout

LTC Out Pin Function

1 LTC 1 + (plus)

2 LTC 1 – (minus)

3Shield

4N/C

50V GND

6Shield

7 LTC 2 + (plus)

8 LTC 2 – (minus)

9

Pin 1

Pin 5

D-9 Female

Pin 9

Pin6

Shield

7600 SD/HD/MHD-REF — Instruction Manual 25

Page 26

Installation

AC Mains Connection and Fusing

CAUTION The power supply cord is used as the main power disconnection device.

Ensure that the socket outlet is located/installed near the equipment and is

easily accessible.

ATTENTION Le cordon d’alimentation est utilisé comme interrupteur général. La prise de

courant doit être située ou installée à proximité de l’équipement et être facile

d’accés.

Each 7600REF model is fitted with two independent AC mains power supplies. Each power supply has its own dedicated IEC mains plug on the rear

of the unit.

The correct power cords for the line standard of the region the product has

been shipped to are included in the shipping box. The power supplies used

in this the unit are a switch mode design and are auto-sensing to handle a

wide input voltage range. See Power (page 79) in the Specifications table

for the voltage and frequency ranges.

Power Supply Replacement

If one of the power supplies fails, a replacement unit can be acquired from

Customer Service and can be installed by the customer in the field.

To replace a 7600REF power supply:

CAUTION Make sure power to the unit is completely disconnected by removing both AC

cords from both power supply connections on the rear of the unit.

1. Remove the top cover of the frame by removing the 13 screws holding

the cover to the frame. Determine which power supply unit needs to be

replaced.

2. Tilt the frame up and on the bottom of the frame remove the two screws

holding the defective power supply unit to the frame chassis.

3. On the front of the power supply unit, remove the 2-pin connector

labeled J1 coming from the AC Main assembly. Note the orientation of

the connector when removing it.

4. On the rear of the power supply unit, remove the 4-pin rear connector

labeled J2 from the power supply attached to the cable coming from the

rear of the main circuit board. Note the orientation of the connector

when removing it.

5. Lift the defective power supply out of the chassis.

6. Install the new unit by reversing the steps above noting cable connector

orientation. These connectors are keyed so they cannot be installed

improperly.

26 7600 SD/HD/MHD-REF — Instruction Manual

Page 27

Operation

Front Panel Control Description

Operation

This section of the manual will cover using the front panel for configuration

and adjustments.

When the unit is powered up by connecting one or both of the AC Mains

connections, initialization messages will appear on the LCD display as the

unit configures the internal hardware.

Once initialization is complete, the following message indicating a normal

operational status will be displayed:

7600REF Main Menu

<Digital Video> Analogue Video Audio –>

The front panel is shown in Figure 4.

Figure 4. Front Panel Display

LCD Display

ADJUST knob

OK

Left Navigation Arrow Right Navigation Arrow

CANCEL

:Video buttons:

SDI and ANALOG

AUDIO

LOCK MODE

OPTIONS

STATUS

SETUP

The front panel has the following main functional areas (see Figure 4):

• A Liquid Crystal Display (LCD) used to show information to guide the

user through operating the various functions and to show status information.

• Front Panel Buttons

• Left and right arrow buttons for menu navigation

OK and CANCEL buttons to initiate or exit the currently selected func-

•

tion

ADJUST knob for parameter adjustment and/or left/right menu nav-

•

igation

•Video

SDI and ANALOG function buttons to access SDI or Analog

video menus

AUDIO function button to access menus for analog and AES audio

•

menus

7600 SD/HD/MHD-REF — Instruction Manual 27

Page 28

Operation

Basic Operation

• OPTIONS function button to access optional menus (options included

depend on model type, see 7600REF Models on page 18).

LOCK MODE function button to set up genlock modes

•

SETUP function button for miscellaneous configuration options

•

STATUS button for accessing diagnostic and status information

•

There are a number of basic concepts that once understood will simplify the

use of the unit as described below:

• Valid button pushes are indicated by a lamp lit inside a button. In most

cases, buttons without a lamp will not be prohibited, allowing rapid

changes between functions grouped on each button.

• Invalid button pushes will result in an informative message on the

LCD.

Selecting a Function

To change any parameter, the appropriate function button must first be

pushed. Once a function button is pushed, that button will remain illumi

nated and the others will turn off to provide a reminder of which function

is active.

Pushing a function button that has sub-functions under it will show the

name of the function and the first menu choice. For example, pushing the

SDI function button will bring you to the top of the SDI menu, SDI: Select

Channels

select the choices under this menu:

The selected choice will be surrounded by brackets < > indicating your

choice. Once you reach the desired choice, press the

menu. Depending on the sub-function chosen, either a further set of

sub-functions or the current value of the function is displayed. Where

appropriate, the currently selected option is indicated by asterisks, such as

* On * or * 1080p/23.98 * for example.

. Use either the ADJUST knob or the left or right arrow buttons to

-

SDI 1, SDI 2, or SDI 3.

OK button to enter that

28 7600 SD/HD/MHD-REF — Instruction Manual

Page 29

Changing Values

To change the value of a function, the ADJUST knob or the left or right arrow

buttons can be used.

In the case of numerical values, there are two functional modes:

Operation

• If the overall range of an adjustment is small the

alters the value by the smallest amount possible.

• If a wider range of adjustment is required, a Delta value system is used.

Use the right arrow button to select the Delta value in brackets and

adjust it to the desired resolution by turning the

press the left arrow button to select the value then adjust it with the

ADJUST knob.

An example of this would be setting the Line Offset for SDI 1. Scroll down

from Digital Video to SDI 1. Select Video Standard then Timing and scroll

to Line and press the OK button. The Line Offset menu will be present on

the LCD. Note the Delta value on the right of the LCD indicated by a triangle Delta symbol = 1. You may change the Delta resolution value to 10 or

100 with the knob.

Use the left arrow button to select the Pixel choice field and turn the knob

to change the values to 1, 10, or 100. Note that when the Delta value is 1, the

values change by steps of one pixel. With a Delta value of 10, the pixels

change by steps of 10, 20, 30 etc.). Selecting a Delta value of 100 allows you

to change the pixels by 100, 200, 300 etc. Change the Delta resolution if you

need a finer offset setting.

As the parameter is changed, the new value will be shown on the LCD. For

some functions, the unit responds by actually altering the value immediately. Otherwise the new value is applied when the

ADJUST knob always

ADJUST knob, then

OK button is pushed.

Leaving the Selected Function

Once the parameter has been set the unit can be returned to the normal

operating mode or another function chosen by one of the following

methods:

• Pressing the current (lit) function button will step up through the menu

structure until either the top (normal) level is reached or another menu

level of the same function is reached, at which point another menu can

be accessed by pressing the

•The

• At any time any other function key may be pressed causing the menu

7600 SD/HD/MHD-REF — Instruction Manual 29

OK button allow you to descend the menu structure and the current

function and the

structure to be traversed sideways. For example, having set an

CONTROL

back up through the menu first.

function, the SETUP key may be pushed without having to step

CANCEL key allows you to ascend the menu structure.

OK button.

OUTPUT

Page 30

Operation

Menu Timeout

In addition, there is a built-in timeout mechanism that will automatically

step back up through the menu structure until the top level is reached if a

key is not pressed within a preset time period. In any event, once the top

level is reached, the front porch will once again indicate valid functions by

lighting the relevant buttons.

The menu system may be set to auto-revert to the top level after a period of

inactivity. The option to enable/disable this feature is located in the

SETUP>>DISPLAY menu.

Front Panel Lock

Front panel controls may be locked to prevent inadvertent changing of settings. To lock or unlock the controls, press the Left and Right arrows simulaneously.

30 7600 SD/HD/MHD-REF — Instruction Manual

Page 31

Top Level Menu

The top level menu has the menu branches shown in Figure 5.

Figure 5. Top Level Menu

The content and features of each top level choice are summarized below. A

more detailed description of each top level choice is given later in this

manual. Note that the Options branch (on the right side of Figure 5) is only

displayed if specific options are included in the model. For functionality for

each model, refer to 7600REF Models on page 18.

Operation

Digital Video Menu

The Digital Video (SDI) menu provides full control of the configuration of

the three SDI outputs. The video standard, timing and appearance of each

output are controlled from this sequence of menus. In addition, the

embedded AES audio is enabled and configured for each output. If high

definition (HD) is present, additional choices will appear on the menu. See

Digital Video Menu on page 33.

Analog Video Menu

The Analog Video menu controls the format of the five analog video signals

provided on the Analog BB/Test BNCs on the rear of the frame. These are

arranged as a group of three plus a second group of two outputs. This

allows the group of three to be set as RGB or YUV in a single operation. See

Analog Video Menu on page 36.

Audio Menu

The Audio menu controls both the AES and analog audio outputs. For all

outputs, control of frequency and amplitude is available. In addition, for

the AES outputs, the sample rate and source ident may also be set. See

Audio Menu on page 41.

Lock Mode Menu

The Lock Mode genlock input menu sets the required format of the

incoming video signal and defines the behavior of the 7600REF when the

genlock signal is applied or removed. See

7600 SD/HD/MHD-REF — Instruction Manual 31

Lock Mode Menu on page 44.

Page 32

Operation

Setup Menu

The system Setup menu provides control of the basic configuration of the

7600REF and will be used primarily during the installation phase. Refer to

Setup Menu on page 47 for details.

System setup includes:

• Configuration of the LTC function (7600 MDH-REF model)

• Configuration of the Clock Output

• Comprehensive control of General Purpose Inputs and Outputs,

including:

• the input signal response mode

• the action resulting from a GPI trigger

• the event causing a GPO state change

• Check and control of the internal memory

• Setup of the real-time clock (RTC)

• Configuration of the Network Time Protocol (NTP) (7600 MHD-REF)

• Functions under the COMMS menu, including:

• Functions under the DISPLAY menu, including:

• Configure the 7600REF as Slave, allowing settings to be received from

Status Menu

The Status menu provides, for information only, the current version of the

software, hardware and firmware of the 7600REF. These three values will

be required when speaking to Technical Support.

In addition, a series of status error messages may be enabled for display on

the LCD screen. The final option on this menu displays a summary of the

current configuration status. See Status Menu on page 51 for details.

• configuration of the Ethernet port

• configuration of the Serial port

• enable and control timing of the menu timeout

• set the display contrast

a Master

Options Menu

The Options menu (page 32) lists the type of module fitted in each of the

three option slots. Options installed depend on the model type. If no option

module is installed, the text OPTION will be displayed. The text TLS refers

to the Tri-Level Sync option module.

32 7600 SD/HD/MHD-REF — Instruction Manual

Page 33

Digital Video Menu

The Digital Video menu provides control and configuration of the three SDI

video outputs. In models with HD capability, the menu is extended to

include further options.

From the top level, the menu branches to three identical sections. for clarity,

only SDI 1 is shown below in Figure 6. SDI 2 and SDI 3 are identical.

The SDI 1 menu then has five menu branches. If the LTC capability is

present (7600 MHD-REF), an extra VITC entry is also present. Refer to VITC

Within SDI on page 66.

Figure 6. Digital Video – SDI 1 Menu

Operation

Digital Video – Video Standard

The currently available digital video standards are listed in Ta bl e 4.

Table 4. Current Digital Video Standards

Description Lines/Frames Frame Rate (Hz) Scan

525

625

1080i / 59.94 1080 59.94 Interlaced

1080i / 60 1080 60 Interlaced

1080i / 50 1080 50 Interlaced

1080p / 30 1080 30 Progressive

1080p / 29.97 1080 29.97 Progressive

1080p / 25 1080 25 Progressive

1080p / 24 1080 24 Progressive

1080p / 23.98 1080 23.98 Progressive

720p / 60 720 60 Progressive

720p / 59.94 720 59.94 Progressive

720p / 50 720 50 Progressive

720p / 30 720 30 Progressive

720p / 29.97 720 29.97 Progressive

720p / 25 720 25 Progressive

720p / 24 720 24 Progressive

720p / 23.98 720 23.98 Progressive

7600 SD/HD/MHD-REF — Instruction Manual 33

Page 34

Operation

Digital Video – Test Patterns

Select the SDI 1 test pattern parameters from the Test Pattern menu shown

Figure 7.

in

Figure 7. Digital Video – Test Patterns Menu

34 7600 SD/HD/MHD-REF — Instruction Manual

Page 35

Digital Video – Timing

Adjust the SDI 1 timing with the Timing menu shown in Figure 8.

Figure 8. Digital Video – Timing Menu

Digital Video – AES

Configure the AES audio outputs with the AES menu shown in Figure 9.

Operation

Figure 9. Digital Video – AES Menu

7600 SD/HD/MHD-REF — Instruction Manual 35

Page 36

Operation

Analog Video Menu

Digital Video – EDH

Enable (On) or disable (Off) EDH with the EDH menu shown in Figure 10.

Note This menu is only visible if the video output standard is set to a Standard Def-

inition signal.

Figure 10. Digital Video – EDH Menu

The top level menu is shown in Figure 11 on page 37. The five available

analog output connectors are arranged as follows:

• A group of three, configured as:

• All Black Burst (BB) (see Analog Video – All Black and Burst on

page 38)

• YUV test pattern (see Analog Video – YUV on page 39)

• A single composite video signal, plus two BB outputs (see Analog

Video – Composite/BB/BE on page 40)

• RGB test pattern (Analog Video – RGB on page 40)

• A YC test pattern plus a single BB output (see Analog Video – YC/BB

on page 40)

• A group of two, configured as:

• Both Black and Burst

• A single composite video signal, plus one BB Output

36 7600 SD/HD/MHD-REF — Instruction Manual

Page 37

Operation

The menus follow two common themes, either for the test pattern signals

or for Black Burst configuration as shown in

Figure 11. Analog Video – Top Level Menu

Figure 11.

7600 SD/HD/MHD-REF — Instruction Manual 37

Page 38

Operation

Analog Video – All Black and Burst

For configuring the analog outputs for all black burst refer to the menu

shown in

Figure 12. Analog Video – All Black Burst Menu

Figure 12.

38 7600 SD/HD/MHD-REF — Instruction Manual

Page 39

Analog Video – YUV

For configuring the analog outputs for YUV refer to the menu shown in

Figure 13.

Figure 13. Analog Video – Analog Outputs YUV

Operation

7600 SD/HD/MHD-REF — Instruction Manual 39

Page 40

Operation

Analog Video – Composite/BB/BE

For configuring the analog outputs for 1 composite output, and 2 Black

Burst outputs refer to the menu shown in

Figure 14. Analog Video – Composite and Black and Burst

Analog Video – RGB

For configuring the analog outputs for RGB, the menu is the same as Analog

Video – YUV on page 39.

Figure 14.

Analog Video – YC/BB

For configuring the analog output 1 and 2 for YC and 3 for Black Burst use

the menu shown in

Figure 15. Analog Video – Composite and Black and Burst

Figure 15.

40 7600 SD/HD/MHD-REF — Instruction Manual

Page 41

Audio Menu

Operation

The top level audio menu has two branches (Figure 16):

•AES

•Analog

Figure 16. Audio Top Level Menu

7600 SD/HD/MHD-REF — Instruction Manual 41

Page 42

Operation

Audio – AES 1 and AES 2

Use the menu shown in Figure 17 to set up the AES 1 audio outputs. The

menu for AES 2 is identical.

Figure 17. AES 1 Menu

42 7600 SD/HD/MHD-REF — Instruction Manual

Page 43

Audio – Analog

Use the menu shown in Figure 18 to set up the Analog audio outputs. The

menu for AES 2 is identical.

Figure 18. Analog Audio Menu

Operation

7600 SD/HD/MHD-REF — Instruction Manual 43

Page 44

Operation

Lock Mode Menu

The Lock Mode top level menu is shown in Figure 19.

Figure 19. Genlock Top Level Menu

The Lock Mode settings of the unit (for example, the current genlock mode

and timing offsets) may be changed by entering the Lock Mode top level

menu and setting the following:

Mode – changes the basic genlock mode from the mode selections (Gen-

•

lock – Mode on page 45).

Genlock Loss – sets the behavior of the unit following loss of the genlock

•

signal (Genlock Loss on page 45).

Field Lock – alters the field lock action – instantaneous or slow lock (Gen-

•

lock – Field Lock on page 46).

Input Standard – refer to Genlock – Input Standard on page 46.

•

To enter a sub-menu, scroll to the function and select the

OK button.

44 7600 SD/HD/MHD-REF — Instruction Manual

Page 45

Genlock – Mode

Select the Genlock mode required by using the Adjust knob or the Left and

Right arrow buttons. All available modes are discussed below.

Note Please be aware that the mode will change immediately when an option is

• Internal Free Run – sets the unit to be free running, relying on the internal

oven oscillator for stability. The ScH of the unit will be set to zero.

External 10MHz – sets the unit to genlock to the 10MHz input. There will

•

be no fixed phase relationship with any other units lock to this signal.

The ScH of the unit will be set to zero.

Manual SC Phasing – sets the unit to genlock to the video input. The sub-

•

carrier phase offset may be adjusted as required.

Force Strict ScH – sets the unit to genlock to the video input. The ScH of

•

the outputs of the unit is forced to zero regardless of the genlock input

ScH. This is achieved by moving the line timing with respect to the

genlock input until the correct ScH phase results.

Operation

selected.

•

•

Genlock Loss

Select the operational mode of the unit following loss of the genlock signal

from the following choices:

• Revert to Internal – if the external reference signal is removed, the unit will

•

•

Note Note that if the unit is powered up in this mode with no genlock input applied,

Follow External SC Phase – sets the unit to genlock to the video input. The

subcarrier output phase is set to be the same as the input genlock video.

Sync Lock Only – sets the unit to genlock to the video input. The system is

genlocked using only the sync information of the genlock video input.

the ScH phase of the output is forced to zero (correct).

use the internal oven maintained oscillator as its master oscillator.

External 10 MHz – if the genlock video input is removed, the unit will use

the 10MHz input as its master oscillator. if the 10Mhz input is not

present when the video input fails, the unit will use the internal oven

maintained oscillator as its master oscillator.

Flywheel – if the genlock video input is removed, the unit will continue

to operate - flywheel - at the same frequency as the genlock input just

removed.

the 7600REF outputs may not be within specification.

7600 SD/HD/MHD-REF — Instruction Manual 45

Page 46

Operation

Genlock – Field Lock

Select the mode required from the following choices:

• Crash – sets the unit to lock near instantaneously to the field information

of an applied genlock input. This is the normal state of operation.

Line Drop – sets the unit to lock to the field information of an applied

•

genlock video input by moving the outputs one line nearer the genlock

video input every 5 fields unit the unit is locked. This mode is useful if

the instant locking of the Crash mode is found to upset any downstream equipment.

Genlock – Input Standard

Select the video line standard of the input signal.

• 525

• 625

• Auto detect

46 7600 SD/HD/MHD-REF — Instruction Manual

Page 47

Setup Menu

Operation

The Setup top level menu is shown in Figure 20.

Figure 20. Setup Top Level Menu

The Setup menu has the following menu branches:

• Configuration of the Clock Output

• Comprehensive control of General Purpose Inputs and Outputs,

including:

• the input response mode

• the action resulting from a GPI trigger

• the event causing a GPO state change

The GPIO sub-menu for setting up GPI control is explained and shown in

Setup – GPI Control on page 48.

7600 SD/HD/MHD-REF — Instruction Manual 47

Page 48

Operation

Setup – GPI Control

The menu shown in Figure 21 shows the following:

• Configure GPI – the actions which the 7600REF will carry out when a

control signal is applied to GP Input 1 or 2.

• Configure GPO – the signal which will appear on the 7600REF output

when a defined condition occurs. As can be seen, this is normally an

error or alarm condition.

GPI wiring is described in GPI Inputs 1 and 2 on page 22 and GPI Outputs 1

and 2 on page 23.

Figure 21. GPIO Menu

48 7600 SD/HD/MHD-REF — Instruction Manual

Page 49

Setup – More

The Setup More menu is shown in Figure 22 and includes options to:

• Manage internal memory banks 1-4. A complete operational setup may

• Setup the real-time clock (RTC).

• Configure the Network Time (NTP) capability (7600 MHD-REF).

• Configure communication with the 7600REF by:

• Adjust the LCD display by:

• Configure the 7600REF as Client (Slave), allowing settings to be

Operation

be stored or retrieved at any time.

• Ethernet port

• Serial port (RS232 or RS422)

• Setting the display contrast

• Controlling the menu time-out

retrieved from a Server (Master). This is useful when configuring a pair

of units in fail-safe mode. Only the Master need be configured; the

Slave can request settings from a Master.

• Upgrade the 7600REF, including:

•Firmware updates

Figure 22. Setup More Menu

7600 SD/HD/MHD-REF — Instruction Manual 49

Page 50

Operation

Setup – Comms

The Comms menu (Figure 23) provides network and serial port setup.

The Ethernet Port is used to connect the 7600REF to a LAN, or to a laptop

PC when performing upgrades. The settings required are primarily governed by the network arrangements at the site and are explained in Local

Area Networks on page 70. A network connection will also be required if the

NTP function in the 7600 MHD-REF model is used.

The serial port is used primarily during the manufacturing process but in

RS422 mode if offers a range of functions. Contact Technical Support for

more information.

Figure 23. Comms Menu

50 7600 SD/HD/MHD-REF — Instruction Manual

Page 51

Status Menu

Operation

A dedicated STATUS button provides diagnostic and status information

(

Figure 24) in read-only format. Should an error condition such as loss of

genlock occur, the lamp in the STATUS button will flash to draw the attention

of the operator. The display text, which can be displayed by pressing the

STATUS button, will change to indicate that an error message is available.

Pressing the STATUS button at any time will display the unit’s current status.

Figure 24. Status Menu

7600 SD/HD/MHD-REF — Instruction Manual 51

Page 52

Operation

Option Menus

Available options on the different model types are enabled at the factory.

An option will appear in the menu trees if it is included in the model. Refer

to

7600REF Models on page 18 for the list of options included in each model.

GPS Setup (7600 MHD-REF)

The GPS module comes with the 7600-MHD-REF model and is installed in

Slot 1. The Global Positioning System (GPS) is currently the only fully-func

tional Global Navigation Satellite System. More than two dozen GPS satellites are in medium Earth orbit, transmitting signals allowing GPS receivers

to determine the receiver’s location, speed, and direction.

GPS also provides a precise time reference used in many applications

including synchronization of telecommunications networks.

The GPS BNCs (and the AES unbalanced outputs) active on the 7600

MHD-REF model are shown in Figure 25.

-

Figure 25. GPS BNCs

AES 1 and 2 Unbalanced

Audio Outputs

1

AES 1

10/27/WC OUT 5/10 REF IN

• The 1PPS (1 Pulse Per Second) output is a precise TTL level pulse which

may be terminated into 75 ohm when connected into external equipment.

• The GPS antenna input should be connected to a high quality 50R GPS

antenna.

• The AES 1 and 2 outputs provide an unbalanced duplicate of the

signals on the AES 9 pin Sub-D connector (Tab le 2 on p age 24). These

are not related GPS operation and are provided for convenience from

this module.

AES 2GPS 1 PPS

GPS Receiver

Antenna Input

LOOP

GENLOCK

GPS Receiver

1PPS Output

52 7600 SD/HD/MHD-REF — Instruction Manual

Page 53

Operation

GPS Antenna Requirements

The GPS module requires an external antenna with the following characteristics:

• Active single antenna is power from the 7600REF antenna connector

• 3V DC antenna is required

• Reception frequency optimized for 1575.42 MHz

• 10 dB to 50 dB gain as measured at receiver input (Antenna perfor-

mance dictated by antenna manufacturer)

• Connection by coaxial cable terminated in 50 ohm BNC male connector

• Maximum cable length controlled by signal strength and location.

Trimble cable is 25m/75ft (N.B. standard cable length is 5m or less on

some antennas.) Each extra interconnect will attenuate the signal and

could increase acquisition/response time.

• Mounting – ideally clear 360 degrees view of sky. Weatherproof mate-

rial for fixed installation.

Magnetic patch antennas suitable for vehicle mounting will also be satisfactory; the signal may be improved by mounting on minimum 3 inch/75mm

square steel plate.

Recommended antenna types See Disclaimer below):

• Trimble Bullet 3 with 75 ft cable. N or F to BNC adapter required. 3V or

as required.

TM

•Oncore

•Oncore

• Super Electronics Co.

• Gilsson

2000 (Matching connectors and cable will also be required)

TM

Hawk with BNC

TM

GA001D105001S (fit own male BNC)

TM

External GPD Antenna (specify male BNC and cable length)

Disclaimer

Thomson Grass Valley Inc. is not connected in any way with any of the

above companies. The information above is given in good faith from infor

mation in the public domain at the time of this manual release. Many

similar antennae are available and specifications change over time. Some

degree of experimentation may be required if the location is shrouded by

adjacent structures, buildings, etc. Excessive cable length will adversely

affect performance.

-

Thomson Grass Valley, Inc. has no control over the local conditions in

which the equipment is installed and the customer is expected to have

carried out a site survey to ensure that sufficient signal can be provided for

the equipment to work in a satisfactory manner. Thomson Grass Valley, Inc.

will not be held responsible for failures caused by poor installation, main-

7600 SD/HD/MHD-REF — Instruction Manual 53

Page 54

Operation

tenance, or changes in local conditions in which the required signals have

been degraded such that time synchronization is lost.

Acquisition Process

With satisfactory reception, the acquisition process commences automatically and takes around 15 minutes. An enhanced mode (Site Survey) is suitable for static installation and may be initiated from the Site Survey

selection on the GPS menu. A complete Site Survey can take around 2

hours. Once completed, it provides more accurate timing signals.

A 1 Pulse Per Second (1PPS) signal waveform is illustrated in

Figure 26. 1PPS Signal Waveform

The leading edge of the 6 ms wide, positive going pulse provides the timing

reference plane for locking external equipment.

Internally, this signal locks the 27MHz PLL Oscillator such that PAL output

signals are both frequency locked and phase locked. Any NTSC output

signals are frequency locked but cannot be phase locked.

54 7600 SD/HD/MHD-REF — Instruction Manual

Page 55

Operation

GPS Menu Structure

With the 7600 MHD-REF model, the GPS function will appear on the top

level menu. This opens the menu branch shown in

This menu is detailed below.

Status – see Status Menu on page 51.

•

PPS Lock – it the PPS Lock mode is set to On, it only affects the Internal

•

Free Run mode of genlock. The internal oscillator is then locked to the

GPS reference.

Crash Lock – if the Crash Lock mode is set to On, the output signal is

•

subject to a single large disturbance followed by a period of approximately 10 minutes for settling. If the Crash Lock is Off, convergence

may take many hours.

ATR Lock – ATR (Absolute Time Reference) is covered by SMPTE Pro-

•

posal 404 and is also known as SMPTE epoch. It defines a starting point

of midnight on January 1st, 1958, at which time all generating equipment is deemed to be phase locked By accurate determination of

current GPS time, any ATR equipment may be locked together again.

ATER also provides a time (and date) source for timecode generated by

the 7600 unit.

Figure 27 on page 56.

If ATR Lock mode is On, the unit will also perform a Crash Lock, independently of the Crash Lock mode described above.

• Site Survey – a site survey can take up to 2 hours to complete. It may be

initiated at any time, but would normally only be carried out when the

unit is in a fixed installation location with a high quality antenna. Status

of the Site Survey is shown in the Status sub-menu shown in Figure 28

on page 57.

Cable Length – provided compensation for the propagational delay of the

•

antenna cable.

7600 SD/HD/MHD-REF — Instruction Manual 55

Page 56

Operation

Figure 27. GPS Control.Menu

56 7600 SD/HD/MHD-REF — Instruction Manual

Page 57

GPS Status

The GPS Status menu shown in Figure 28 is a read-only menu.

Some information about this menu is listed below.

Satellites – the time taken to acquire satellites can be 10 or 15 minutes,

•

since the almanac data is broadcast fairly infrequently.

Current Mode – will be displayed as:

•

3D Fix Mode – when a standard lock has been achieved.

•

Position Hold – following a successful Site Survey

•

Site Survey – status is displayed as:

•

• In Progress

•Not In Progress

Figure 28. GPS Status Menu

Operation

7600 SD/HD/MHD-REF — Instruction Manual 57

Page 58

Operation

Timecode Functionality (7600 MHD-REF)