7500 SERIES

7500NB/7500WB ROUTERS

Instruction Manual

071810700

FIRST PRINTING: JULY 2001

Contacting Grass Valley Group

Region Voice Fax Address Web Site

North America (800) 547-8949

530-478-4148

Pacific Operations +852-2585-6688

Support: 852-2585-6579

U.K., Europe, Asia, Middle East +44 1753 218 777 +44 1753 218 757

France +33 1 45 29 73 00

Germany +49 221 1791 234 +49 221 1791 235

Copyright © Grass Valley Group. All rights reserved.

This document may not be copied, in whole or in part, or otherwise reproduced, except as specifically

permitted under U.S. copyright law, without the prior written consent of Grass Valley Group, P.O. Box

599000, Nevada City, CA 95959-7900 USA. GRASS VALLEY GROUP is a registered trademark and

Grass Valley is a trademark of Grass Valley Group. All registered trademarks and trademarks are property of their respective holders. Grass Valley Group products are covered by U.S. and foreign patents,

issued and pending. Product options and specifications subject to change without notice. The information in this manual is furnished for informational use only, is subject to change without notice, and

should not be construed as a commitment by Grass Valley Group. Grass Valley Group assumes no responsibility or liability for any errors or inaccuracies that may appear in this publication.

Online User Documentation

(530) 478-3347 Grass Valley Group

+852-2802-2996

P.O. Box 599000

Nevada City, CA 95959-7900

USA

www.grassvalleygroup.com

Current versions of product catalogs, brochures, data sheets, ordering

guides, planning guides, manuals, and release notes may be downloaded

via the Product Documentation link on the Grass Valley Group home page:

FAQ Database

Many solutions to problems and troubleshooting efforts can be found by

searching our Frequently Asked Questions (FAQ) database. To access:

Select the Service/Support link on the Grass Valley Group home page.

1.

Select the Online Support & FAQ link on the Service/Support page.

2.

Follow the directions provided to access the FAQ database and other

3.

online support services.

Software Downloads

Software updates, drivers and patches may be downloaded via the

Download link on the Grass Valley Group home page:

Contents

Preface

About This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Additional Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Safety Summary

Safety Terms and Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Terms in This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Terms on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Symbols on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Regulatory Notices

Certifications and Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

FCC Emission Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Canadian EMC Notice of Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

EN55022 Class A Warning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Canadian Certified Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Canadian Certified AC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Laser Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Laser Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Laser Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

FCC Emission Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Section 1 — Overview

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Level Architecture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

7500NB Architecture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

7500WB Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Section 2 — Installation

Frame Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

7500 NB Frame Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

7500 WB Frame Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Module Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

7500NB Module Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

7500WB Module Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

7500 Series Instruction Manual iii

Contents

7500NB Backplane Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

7500NB Backplane Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

7500NB Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

7500WB Ethernet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Global Serial Channel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

7500NB AES Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

7500NB Video Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

7500WB Video Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

AC Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

48V DC Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

7500NB 48V DC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

7500WB 48V DC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Section 3 — Configuration

7500NB Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Series 7000 Control of 7500NB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

New AES Configured Node Controller Settings . . . . . . . . . . . . . . . . . . . . . . . 3-2

AES Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Physical Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

7500WB Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Series 7000 Control of 7500WB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

New 7500WB Configured Node Controller Settings. . . . . . . . . . . . . . . . . . . . 3-7

VRef Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Section 4 — Functional Description

Matrix Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Matrix Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

7500WB Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

7500NB Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Section 5 — Maintenance and Troubleshooting

Field Replaceable Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

To Remove Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

To Insert Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Air Filter 7500WB 256x256. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Fan Assembly 7500WB 256x256 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

To Replace a Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Service and Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Matrix Controller LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Matrix Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Power Supply Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

7500NB Power Supply Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

7500WB Power Supply Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Thermal Control Module Reset 7500WB 256x256 . . . . . . . . . . . . . . . . . . . . . . . . 5-8

iv 7500 Series Instruction Manual

Contents

To Reset the Thermal Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Appendix — Specifications

Mechanical and Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Performance and Environmental Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

7500NB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

7500WB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Glossary

Index

7500 Series Instruction Manual v

Contents

vi 7500 Series Instruction Manual

Preface

About This Manual

This manual provides installation, operation, and service information specific to the 7500 Series Routing frames.

Additional Documentation

The 7500 Series Routing frames can be controlled by either the Series 7000

Signal Management System or the Encore Control System. Configuration

information required for using the 7500 Series frames with either of these

systems is contained in the control system’s documentation set.

Electronic copies of all routing documentation is available on the documentation CD that came with your frame. A printed copy of the documentation

set was provided with the system. Individual manuals may be ordered by

contacting Customer Service.

7500 Series Instruction Manual vii

Preface

viii 7500 Series Instruction Manual

Safety Summary

Read and follow the important safety information below , noting especially

those instructions related to risk of fire, electric shock or injury to persons.

Additional specific warnings not listed here may be found throughout the

manual.

WARNING Any instructions in this manual that require opening the equipment cover

or enclosure are for use by qualified service personnel only. T o reduce the

risk of electric shock, do not perform any servicing other than that contained in the operating instructions unless you are qualified to do so.

Safety Terms and Symbols

Terms in This Manual

Safety-related statements may appear in this manual in the following form:

WARNING Warning statements identify conditions or practices that may result in per-

sonal injury or loss of life.

CAUTION Caution statements identify conditions or practices that may result in damage

to equipment or other property.

Terms on the Product

The following terms may appear on the product:

DANGER

the marking.

WARNING

sible as you read the marking.

— A personal injury hazard is immediately accessible as you read

— A personal injury hazard exists but is not immediately acces-

CAUTION

7500 Series Instruction Manual ix

— A hazard to property, product, and other equipment is present.

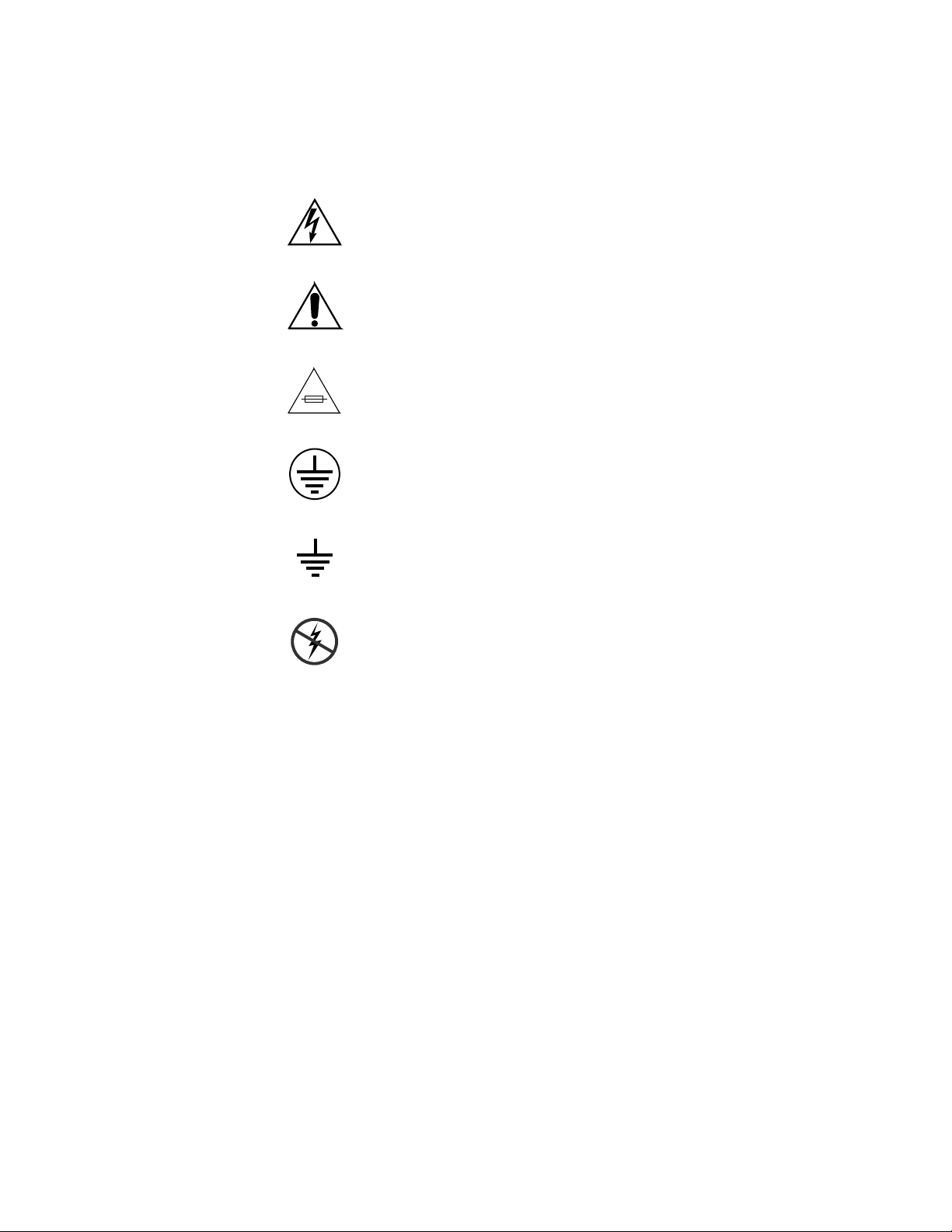

Symbols on the Product

The following symbols may appear on the product:

Indicates that dangerous high voltage is present within the

equipment enclosure that may be of sufficient magnitude to

constitute a risk of electric shock.

Indicates that user, operator or service technician should

refer to product manual(s) for important operating, maintenance, or service instructions.

This is a prompt to note fuse rating when replacing fuse(s).

The fuse referenced in the text must be replaced with one

having the ratings indicated.

Warnings

Identifies a protective grounding terminal which must be

connected to earth ground prior to making any other equipment connections.

Identifies an external protective grounding terminal which

may be connected to earth ground as a supplement to an

internal grounding terminal.

Indicates that static sensitive components are present which

may be damaged by electrostatic discharge. Use anti-static

procedures, equipment and surfaces during servicing.

The following warning statements identify conditions or practices that can

result in personal injury or loss of life.

Dangerous voltage or current may be present

battery (if applicable) before removing protective panels, soldering, or

replacing components.

— Disconnect power and remove

Do not service alone

person capable of rendering first aid and resuscitation is present.

Remove jewelry

and other metallic objects.

Avoid exposed circuitry

circuitry when power is present.

x 7500 Series Instruction Manual

— Do not internally service this product unless another

— Prior to servicing, remove jewelry such as rings, watches,

— Do not touch exposed connections, components or

Use proper power cord

— Use only the power cord supplied or specified for

this product.

Ground product

— Connect the grounding conductor of the power cord to

earth ground.

Operate only with covers and enclosure panels in place

— Do not operate this

product when covers or enclosure panels are removed.

Use correct fuse

— Use only the fuse type and rating specified for this

product.

Use only in dry environment

Use only in non-explosive environment

— Do not operate in wet or damp conditions.

— Do not operate this product in an

explosive atmosphere.

High leakage current may be present

— Earth connection of product is essential

before connecting power.

Dual power supplies may be present

— Be certain to plug each power supply

cord into a separate branch circuit employing a separate service ground.

Disconnect both power supply cords prior to servicing.

Double pole neutral fusing

— Disconnect mains power prior to servicing.

Cautions

Use proper lift points

Avoid mechanical hazards

— Do not use door latches to lift or move equipment.

— Allow all rotating devices to come to a stop before

servicing.

The following caution statements identify conditions or practices that can

result in damage to equipment or other property

Use correct power source

— Do not operate this product from a power sour ce

that applies more than the voltage specified for the product.

Use correct voltage setting

— If this product lacks auto-ranging power supplies, before applying power ensure that the each power supply is set to

match the power source.

Provide proper ventilation

— To prevent product overheating, provide equip-

ment ventilation in accordance with installation instructions.

Use anti-static procedures

— Static sensitive components are present which

may be damaged by electrostatic discharge. Use anti-static procedures,

equipment and surfaces during servicing.

7500 Series Instruction Manual xi

Do not operate with suspected equipment failure

— If you suspect product

damage or equipment failure, have the equipment inspected by qualified

service personnel.

Ensure mains disconnect

— If mains switch is not provided, the power cor d(s)

of this equipment provide the means of disconnection. The socket outlet

must be installed near the equipment and must be easily accessible. Verify

that all mains power is disconnected before installing or removing power

supplies and/or options.

Route cable properly

— Route power cor ds and other cables so that they ar not

likely to be damaged. Properly support heavy cable bundles to avoid connector damage.

Use correct power supply cords

— Power cords for this equipment, if pr ovided,

meet all North American electrical codes. Operation of this equipment at

voltages exceeding 130 VAC requires power supply cords which comply

with NEMA configurations. International power cords, if provided, have

the approval of the country of use.

Use correct replacement battery

— This product may contain batteries. To

reduce the risk of explosion, check polarity and replace only with the same

or equivalent type recommended by manufacturer. Dispose of used batteries according to the manufacturer’s instructions.

Troubleshoot only to board level

— Circuit boards in this product are densely

populated with surface mount technology (SMT) components and application specific integrated circuits (ASICS). As a result, circuit board repair at

the component level is very difficult in the field, if not impossible. For warranty compliance, do not troubleshoot systems beyond the board level.

xii 7500 Series Instruction Manual

Regulatory Notices

Certifications and Compliances

FCC Emission Control

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable pr otection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interfer ence at his own expense.

Changes or modifications not expressly approved by Grass Valley Group

can affect emission compliance and could void the user’s authority to

operate this equipment.

Canadian EMC Notice of Compliance

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’emet pas de bruits radioélectriques

dépassant les limites applicables aux appareils numeriques de la classe A

préscrites dans le Règlement sur le brouillage radioélectrique édicte par le

ministère des Communications du Canada.

EN55022 Class A Warning

For products that comply with Class A. In a domestic environment this

product may cause radio interference in which case the user may be

required to take adequate measures.

7500 Series Instruction Manual xiii

Canadian Certified Power Cords

Canadian approval includes the products and power cords appr opriate for

use in the North America power network. All other power cords supplied

are approved for the country of use.

Canadian Certified AC Adapter

Canadian approval includes the AC adapters appropriate for use in the

North America power network. All other AC adapters supplied are

approved for the country of use.

Laser Compliance

Laser Safety Requirements

The device used in this product is a Class 1 certified laser product. Operating this product outside specifications or altering from its original design

may result in hazardous radiation exposure, and may be consider ed an act

of modifying or new manufacturing of a laser product under U.S. regulations contained in 21CFR Chapter1, subchapter J or CENELEC regulations

in HD 482 S1. People performing such an act are required by law to recertify and reidentify this product in accordance with provisions of 21CFR

subchapter J for distribution within the U.S.A., and in accordance with

CENELEC HD 482 S1 for distribution within countries using the IEC 825

standard.

Laser Safety

Laser safety in the United States is regulated by the Center for Devices and

Radiological Health (CDRH). The laser safety regulations are published in

the “Laser Product Performance Standard,” Code of Federal Regulation

(CFR), Title 21, Subchapter J.

The international Electrotechnical Commission (IEC) Standard 825, “Radiation of Laser Products, Equipment Classification, Requirements and

User’s Guide,” governs laser products outside the United States. Europe

and member nations of the European Free trade Association fall under the

jurisdiction of the Comite European de Normalization Electrotechnique

(CENELEC).

For the CDRH: The radiant power is detected trough a 7 mm aperture at a

distance of 200 mm from the source focused through a lens with a focal

length of 100 mm.

For IEC compliance: The radiant power is detected trough a 7 mm aperture

at a distance of 100 mm from the source focused through a lens with a focal

length of 100 mm.

xiv 7500 Series Instruction Manual

FCC Emission Limits

Certification

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) This device may no cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesirable operation. This device

has been tested and found to comply with FCC Part 15 Class B limits for a

digital device when tested with a representative laser-based fiber optical

system that complies with ANSI X3T11 Fiber Channel Standard.

Category Standard Designed/tested for compliance with:

Safety UL1419 Professional Video and Audio Equipment

7500 Series Instruction Manual xv

xvi 7500 Series Instruction Manual

Overview

Introduction

The 7500 Series Routing frames can be controlled by either the Series 7000

Signal Management System or the Encore Control System. The 7500 Series

Routing frames expand the multiformat routing capability of the Series

7000 Signal Management System and are compatible with existing Series

7000 matrices and control panels.

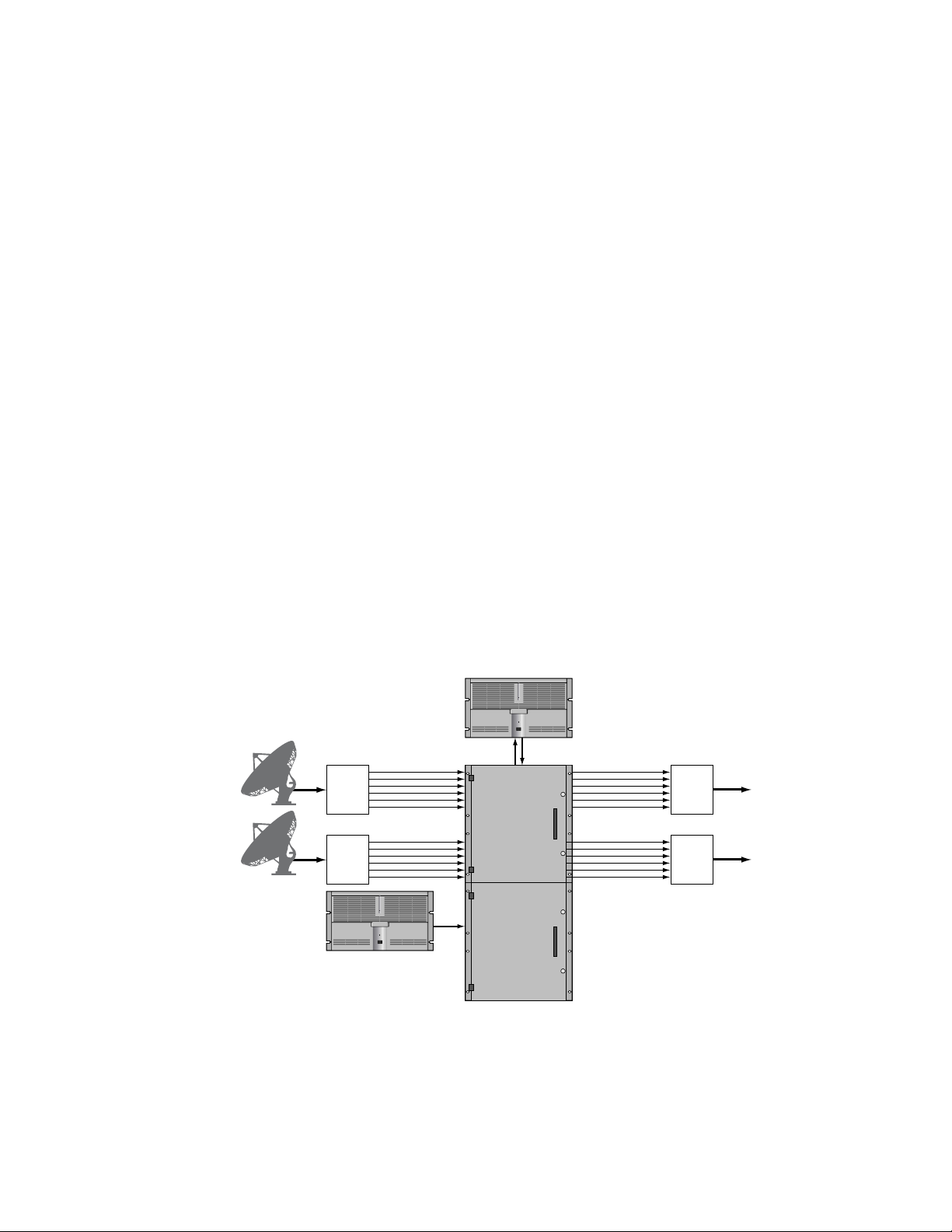

The 7500NB frame is designed to switch digital signals up to 50 Mbps.

Figure 1-1 shows an example of MPEG signal routing using a SMS-

NB512x512

Figure 1-1. 7500NB 512x512 MPEG Signal Routing

Section

1

Incoming

Satellite Feed

Incoming

Satellite Feed

PROFILE XP

Streaming Server

Multiple MPEG

Transport Streams

DMUX

DMUX

PROFILE XP

Time Delay Recorder

SMS-NB512x512

Matrix Frame

0723_00_01

MUX

MUX

Re-Transmission

via Cable or Satellite

Re-Transmission

via Cable or Satellite

7500 Series Instruction Manual 1-1

Section 1 — Overview

Analog

Inputs

SDI Inputs

8900 Series

A-to-D Converters

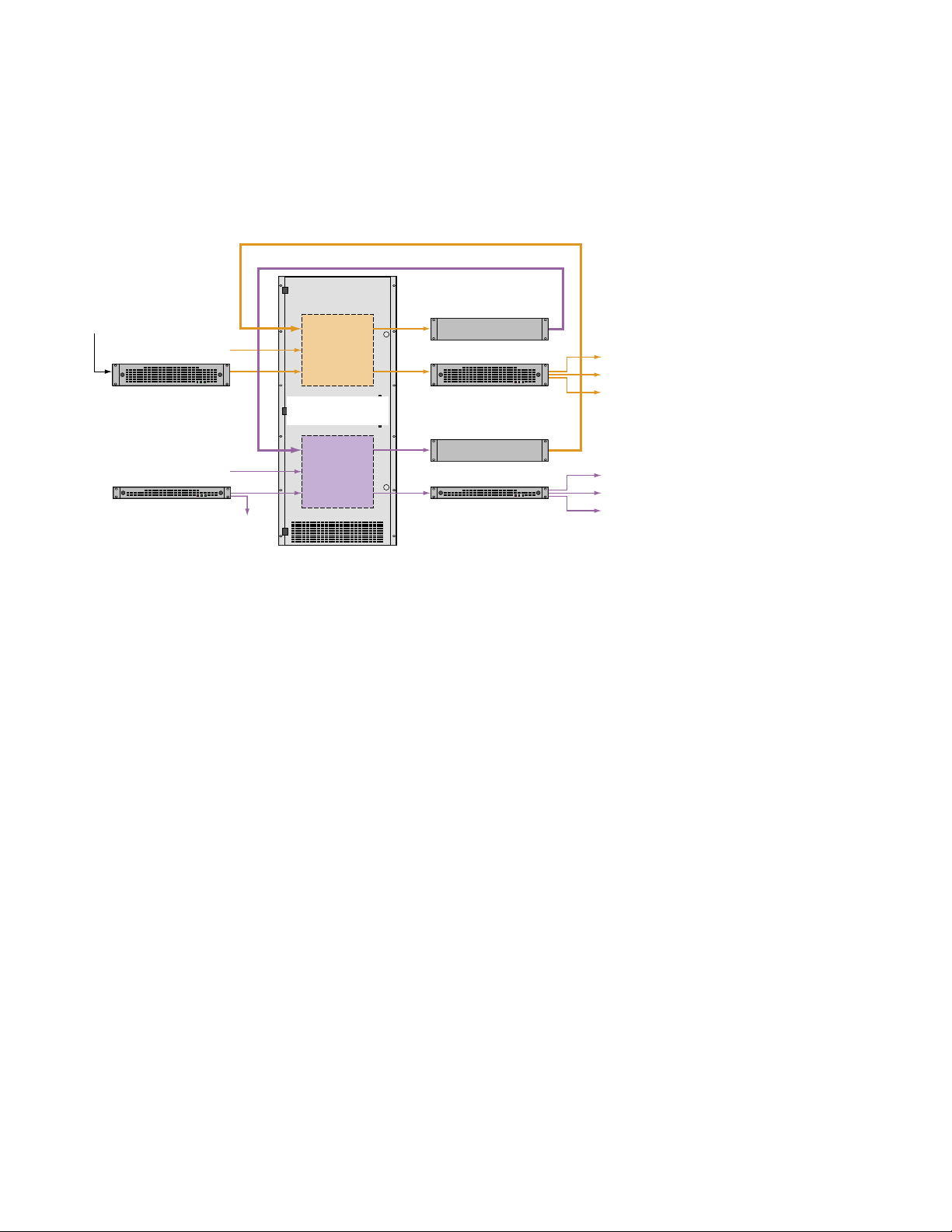

The 7500WB frame is designed to switch signals from 10 Mbps to 1.485

Gbps. Figure 1-2 shows an example of Standard Definition (SD) and High

Definition (HD) signal routing using a 7500WB 256x256.

Figure 1-2. 7500WB 256x256 HD and SD Signal Routing

SD Tie Lines

HD Tie Lines

SD

Operation

7500WB 256x256

Matrix Frame

Up Converter

8900 Series DAs

Profile® XP

Monitor

Master Control

HD Inputs

Monitor

HD

Operation

System Level Architecture

7500NB Architecture

7500NB AES Audio Systems are built around a 256x256, two bay, 12RU

matrix. The 7500NB 256x256 uses one matrix and the 7500NB 512x512 uses

two matrices connected together at the backplanes with expansion connector modules. The 7500NB 1024x1024 uses eight matrices connected

together.

Matrices are populated with crosspoint modules, input modules, output

modules, and matrix controller modules. synchronous and asynchronous

input and output modules are available. Both types of modules can be

placed in the same matrix. The synchronous modules can be configured to

allow an asynchronous signal to be passed through an input or an output.

Down Converter

0723_00_02

2000 Series DAs2000 Series DAs

Profile XP

Monitor

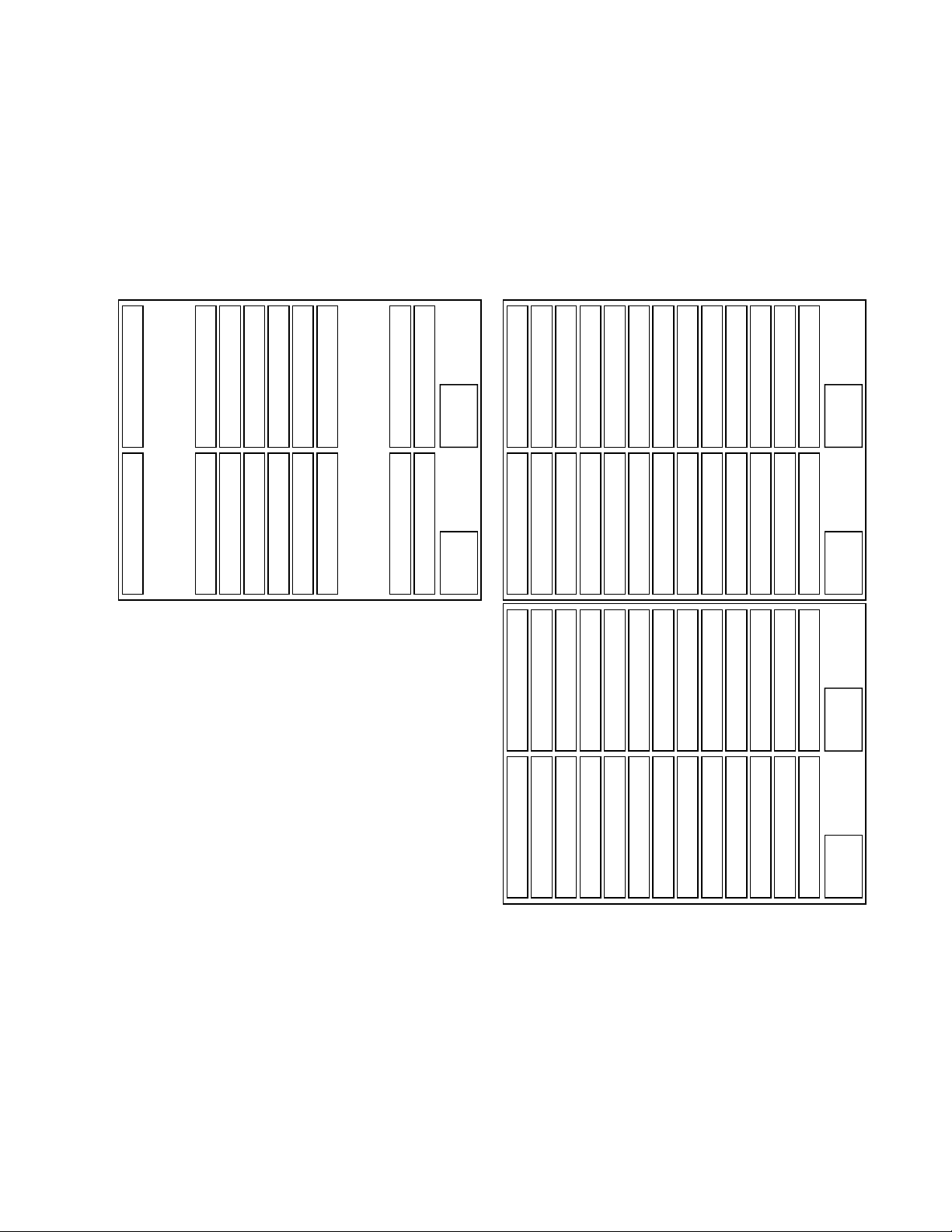

Master Control

The two bay, 12RU matrix uses four input modules, four output modules,

and eight crosspoint modules for a fully configured 256x256 system. Each

bay of the system contains a slot for a matrix controller and a power supply.

The slot locations for the modules are shown in Figure 1-3. The empty slots

are used for crosspoint modules in expansion systems larger than 256x256.

1-2 7500 Series Instruction Manual

System Level Architecture

Two of the two bay, 12RU matrices are connected using expansion connectors to create a fully configured 512x512 system. The system uses eight

input modules, eight output modules, and thirty-two crosspoint modules

as shown in Figure 1-3. The top bay is always used for inputs 1-128, the

second one for inputs 129-256, the third for 255-384, and the fourth bay is

used for inputs 385-512.

Figure 1-3. 7500NB Module Placement

7500NB 256x256

Inputs 1-64

Inputs 129-192

Xpt Expansion Slot

Xpt Expansion Slot

Xpt Expansion Slot

Xpt Expansion Slot

Outputs 1-64

Xpt (In=1-128, Out=1-64)

Xpt (In=129-256, Out=1-64)

Xpt (In=1-128, Out=129-192)

Outputs 129-192

Xpt (In=129-256, Out=129-192)

Outputs 65-128

Xpt (In=1-128, Out=193-256)

Xpt (In=129-256, Out=193-256)

Xpt (In=1-128, Out=65-128)

Outputs 193-256

Xpt (In=129-256, Out=65-128)

Inputs 65-128

Xpt Expansion Slot

Xpt Expansion Slot

Xpt Expansion Slot

Xpt Expansion Slot

Matrix Controller 1

Inputs 193-256

Matrix Controller 2

Power

Supply

1

Power

Supply

2

7500NB 512x512

Inputs 1-64

Xpt (In=1-128, Out=257-320)

Inputs 129-192

Xpt (In=129-256, Out=257-320)

Inputs 257-320

Xpt (In=257-384, Out=1-64)

Xpt (In=1-128, Out=1-64)

Xpt (In=1-128, Out=385-448)

Xpt (In=129-256, Out=1-64)

Xpt (In=129-256, Out=385-448)

Xpt (In=257-384, Out=129-192)

Xpt (In=257-384, Out=257-320)

Outputs 1-64

Xpt (In=1-128, Out=129-192)

Outputs 129-192

Xpt (In=129-256, Out=129-192)

Outputs 257-320

Xpt (In=257-384, Out=385-448)

Outputs 65-128

Xpt (In=1-128, Out=193-256)

Xpt (In=129-256, Out=193-256)

Xpt (In=257-384, Out=449-512)

Xpt (In=1-128, Out=65-128)

Outputs 193-256

Xpt (In=129-256, Out=65-128)

Outputs 321-384

Xpt (In=257-384, Out=321-384)

Inputs 65-128

Power

Matrix Controller 1

Xpt (In=1-128, Out=449-512)

Xpt (In=1-128, Out=321-384)

Xpt (In=129-256, Out=449-512)

Xpt (In=129-256, Out=321-384)

Xpt (In=257-384, Out=65-128)

Xpt (In=257-384, Out=193-256)

Supply

1

Inputs 193-256

Power

Matrix Controller 2

Supply

2

Inputs 321-384

Power

Matrix Controller 3

Supply

3

Inputs 385-448

Xpt (In=385-512, Out=1-64)

Xpt (In=385-512, Out=129-192)

Outputs 385-448

Xpt (In=385-512, Out=257-320)

Outputs 449-512

Xpt (In=385-512, Out=385-448)

Xpt (In=385-512, Out=449-512)

Xpt (In=385-512, Out=321-384)

Xpt (In=385-512, Out=193-256)

Inputs 449-512

Power

Matrix Controller 4

Xpt (In=385-512, Out=65-128)

Supply

4

7500 Series Instruction Manual 1-3

Section 1 — Overview

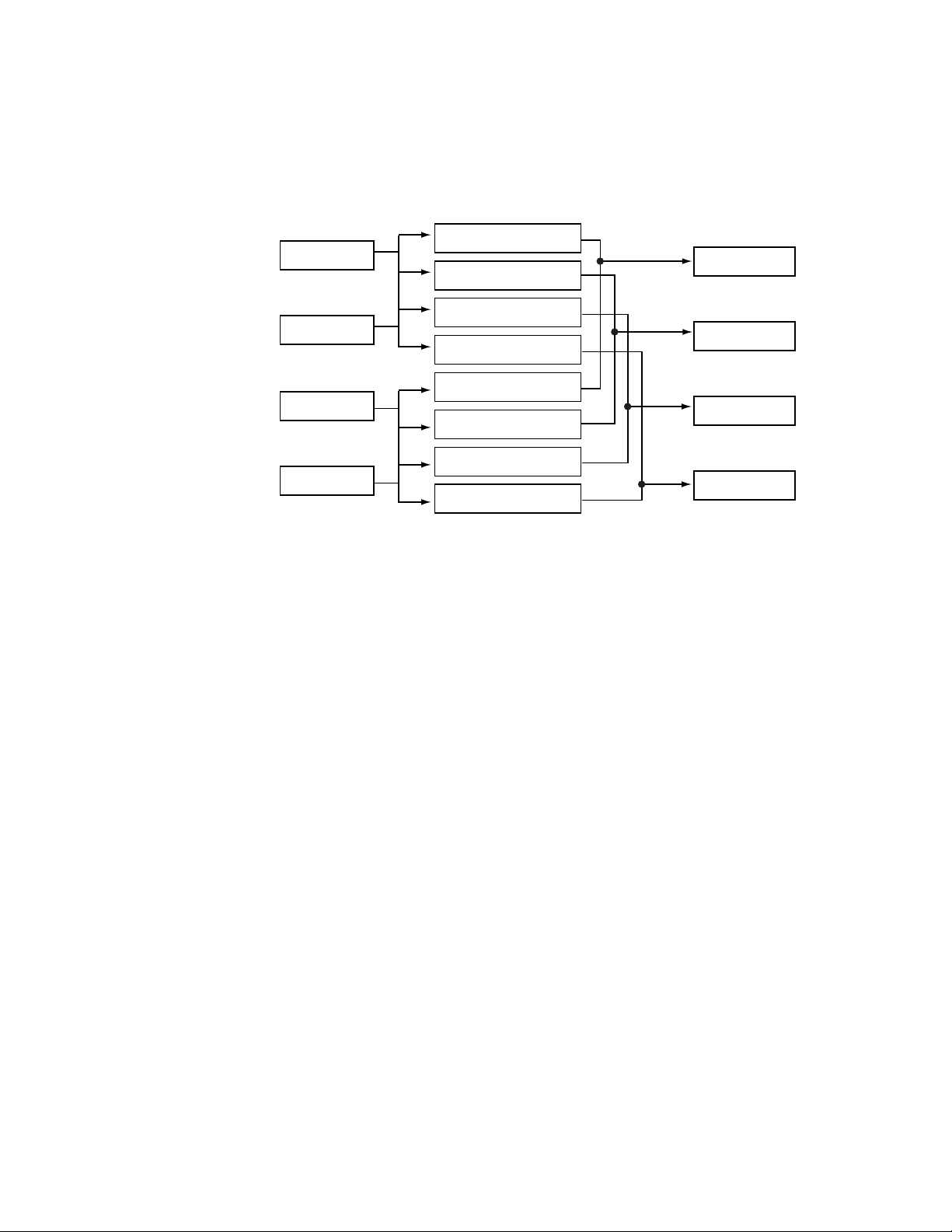

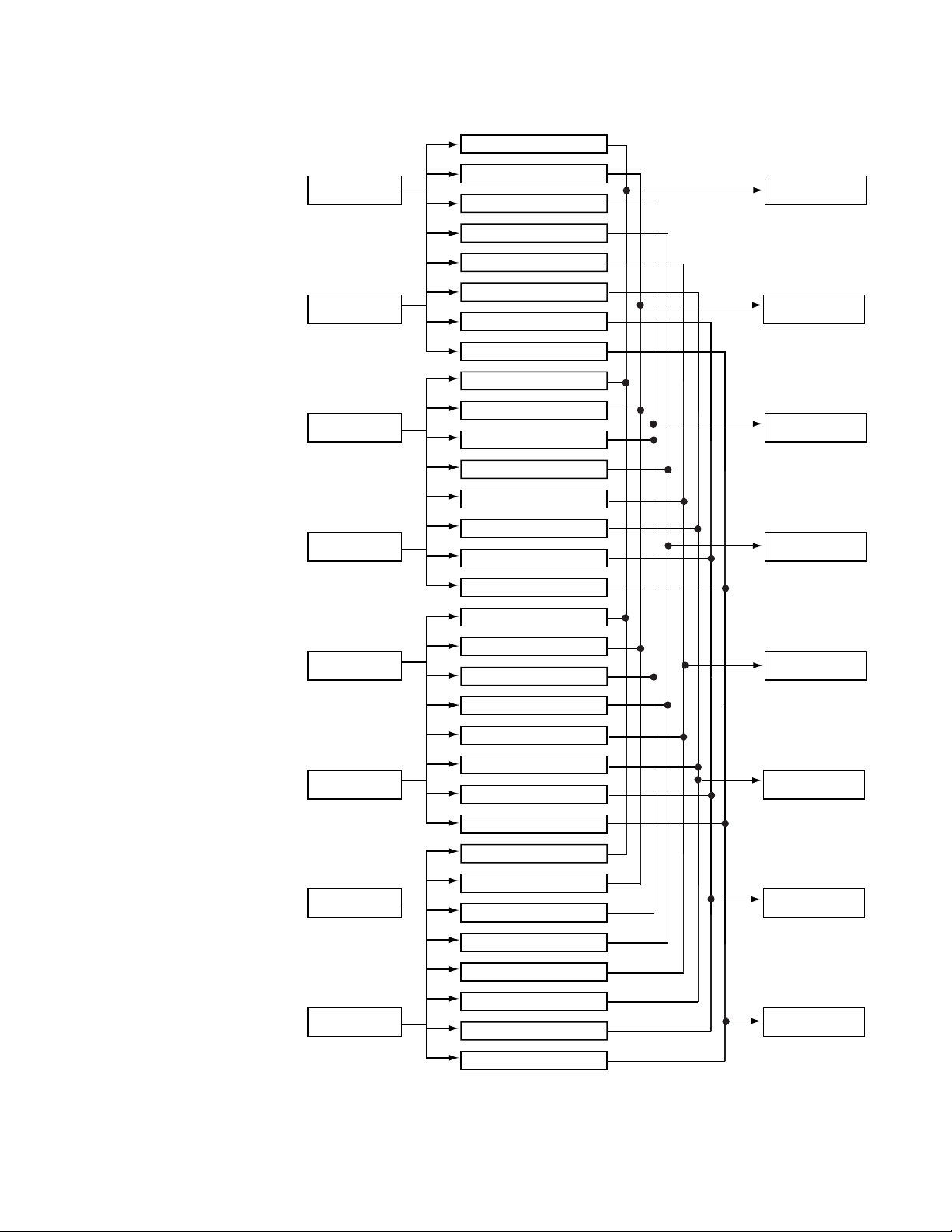

Inputs are routed by the Crosspoint modules to the Output modules to

ensure that all Inputs are available to all Outputs. See Figure 1-4 for the

256x256 signal flow and Figure 1-5 for the 512x512 signal flow.

Figure 1-4. 7500NB 256x256 Signal Flow

Xpt (In=1-128, Out=1-64)

Inputs 1-64

Xpt (In=1-128, Out=65-128)

Xpt (In=1-128, Out=129-192)

Inputs 65-128

Xpt (In=1-128, Out=193-256)

Xpt (In=129-256, Out=1-64)

Inputs 129-192

Xpt (In=129-256, Out=65-128)

Outputs 1-64

Outputs 65-128

Outputs 129-192

Inputs 193-256

Xpt (In=129-256, Out=129-192)

Outputs 193-256

Xpt (In=129-256, Out=193-256)

1-4 7500 Series Instruction Manual

Figure 1-5. 7500NB 512x512Signal Flow

Xpt (In=1-128, Out=1-64)

Xpt (In=1-128, Out=65-128)

Inputs 1-64

Inputs 65-128

Inputs 129-192

Xpt (In=1-128, Out=129-192)

Xpt (In=1-128, Out=193-256)

Xpt (In=1-128, Out=257-320)

Xpt (In=1-128, Out=321-384)

Xpt (In=1-128, Out=385-448)

Xpt (In=1-128, Out=449-512)

Xpt (In=129-256, Out=1-64)

Xpt (In=129-256, Out=65-128)

Xpt (In=129-256, Out=129-192)

System Level Architecture

Outputs 1-64

Outputs 65-128

Outputs 129-192

Inputs 193-256

Inputs 257-320

Inputs 321-384

Inputs 385-448

Xpt (In=129-256, Out=193-256)

Xpt (In=129-256, Out=257-320)

Xpt (In=129-256, Out=321-384)

Xpt (In=129-256, Out=385-448)

Xpt (In=129-256, Out=449-512)

Xpt (In=257-384, Out=1-64)

Xpt (In=257-384, Out=65-128)

Xpt (In=257-384, Out=129-192)

Xpt (In=257-384, Out=193-256)

Xpt (In=257-384, Out=257-320)

Xpt (In=257-384, Out=321-384)

Xpt (In=257-384, Out=385-448)

Xpt (In=257-384, Out=449-512)

Xpt (In=385-512, Out=1-64)

Xpt (In=385-512, Out=65-128)

Xpt (In=385-512, Out=129-192)

Outputs 193-256

Outputs 257-320

Outputs 321-384

Outputs 385-448

Xpt (In=385-512, Out=193-256)

Xpt (In=385-512, Out=257-320)

Xpt (In=385-512, Out=321-384)

Inputs 449-512

Xpt (In=385-512, Out=385-448)

Xpt (In=385-512, Out=449-512)

Outputs 449-512

7500 Series Instruction Manual 1-5

Section 1 — Overview

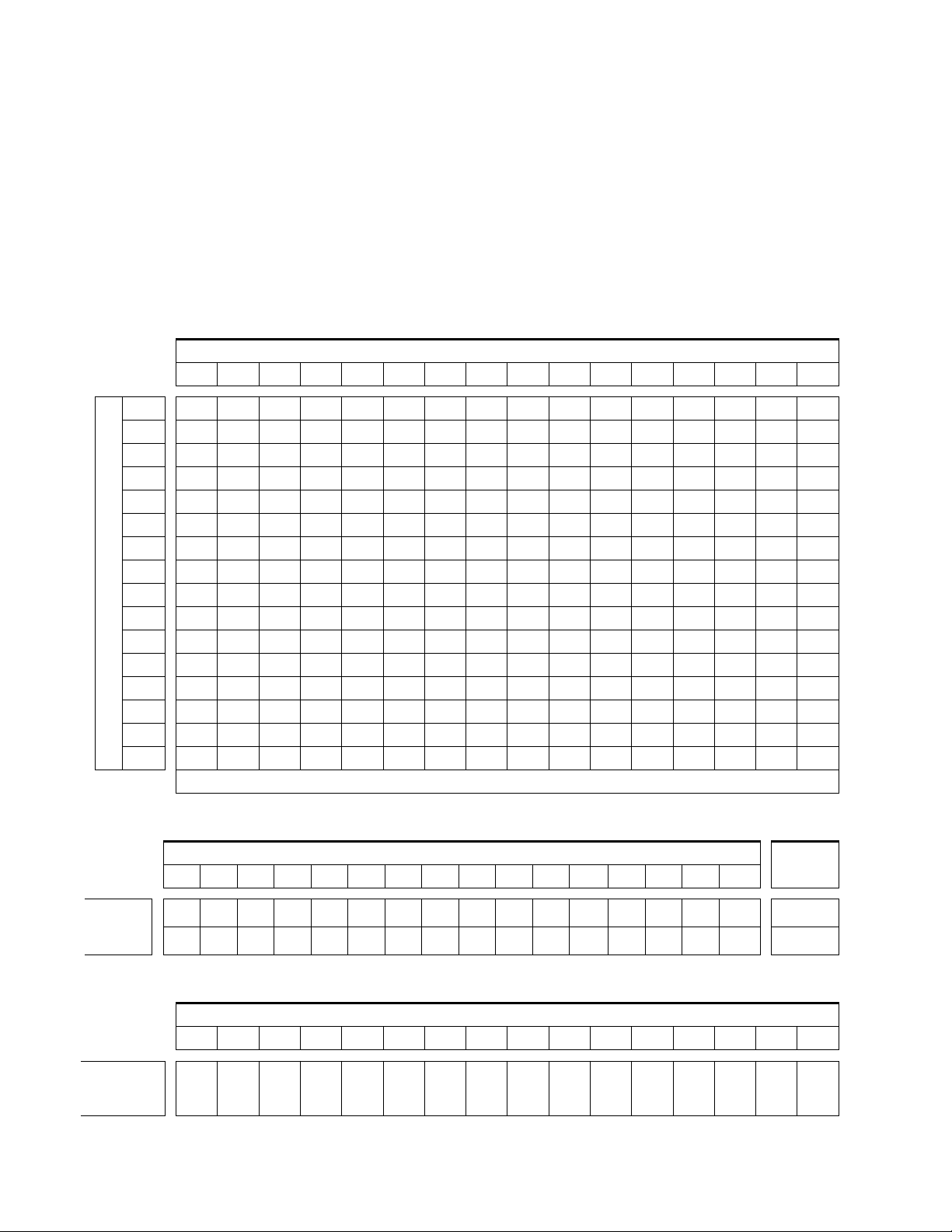

64 128 192 256 320 384 448 512 576 640 704 768 832 896 960 1024

7500NB systems can be expanded in increments of 64 inputs/outputs to as

large as 1024x1024. They are assembled using standard Grass Valley router

frames, distribution amplifiers, Ethernet switches, and in some cases

custom cables. Contact Customer Service for specifications and ordering

details. Table 1-1 shows the number of crosspoint modules required to

create configurations up to 1024x1024.Table 1-2 and Table 1-3 shows the

number of input and output modules needed to create configurations up to

1024x1024.The number of input modules needed is affected by how many

outputs the system contains.

Table 1-1. Required AES 128x64 Crosspoint Modules

Outputs

128

192

256

320

384

448

512

576

Inputs

640

704

768

832

896

960

1024

64

12345678910111213141516

12345678910111213141516

2468101214161820222426283032

2468101214161820222426283032

3691215 18 21 24 27 30 33 36 39 42 45 48

3691215 18 21 24 27 30 33 36 39 42 45 48

481216 20 24 28 32 36 40 44 48 52 56 60 64

481216 20 24 28 32 36 40 44 48 52 56 60 64

5101520253035404550556065707580

5101520253035404550556065707580

6121824303642485460667278849096

6121824303642485460667278849096

714212835424956607077849198105112

714212835424956607077849198105112

81624324048566466808896104112120128

81624324048566466808896104112120128

Crosspoint Modules Required

Table 1-2. Required AES Input Modules

Inputs

64 128 192 256 320 384 448 512 576 640 704 768 832 896 960 1024

Outputs

# of Input

Boards

Required

# of Output

Boards

Required

12345678910111213141516

2468101214161820222426283032 >512

Table 1-3. Required AES Output Modules

Outputs

64 128 192 256 320 384 448 512 576 640 704 768 832 896 960 1024

12345678910111213141516

≤

512

1-6 7500 Series Instruction Manual

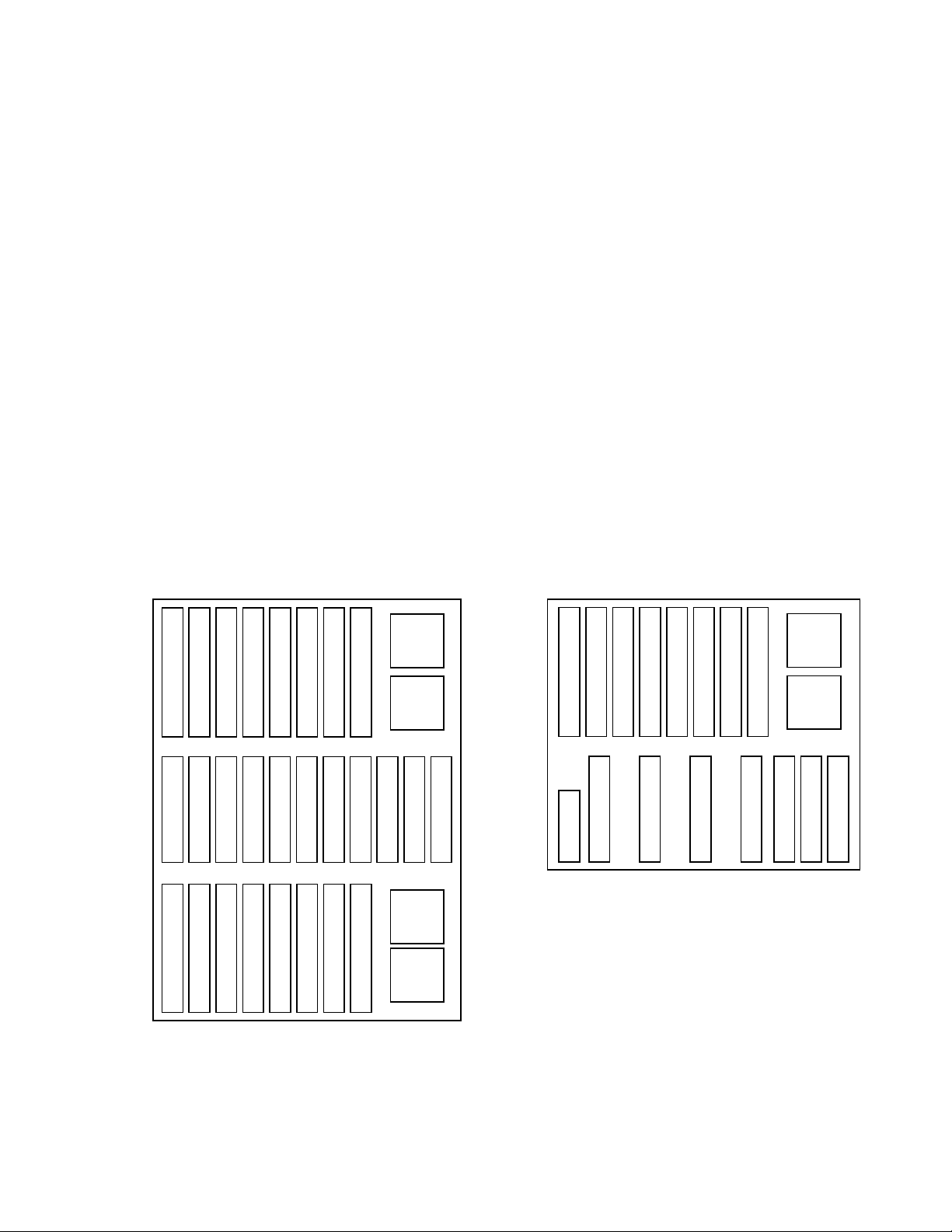

7500WB Architecture

The 7500WB 256x256 matrix frame is configured with a Controller module,

two Power Supply modules, eight Input modules, eight Crosspoint modules, eight Output modules, a two-piece backplane, an interconnect and an

optional monitor module. The router has two Controller module slots and

four Power Supply module slots to allow for redundancy. See Figure 1-6.

The 7500WB 128x128 matrix frame is configured with a Controller module,

one Power Supply module, four Input modules, four Crosspoint modules,

four Output modules, a backplane, an interconnect, a DC Distribution

module, and an optional monitor module. The router has two Controller

module slots and two Power Supply module slots to allow for redundancy.

See Figure 1-6.

Inputs are routed by the Crosspoint modules to the Output modules to

ensure that all Inputs are available to all Outputs. See Figure 1-7 and

Figure 1-8 for the signal flow. Table 1-4 shows how many Crosspoint,

Input, and Output modules are needed to create configurations in a

7500WB 256x256 from 32x32 to 256x256. Table 1-5 shows how many Cros-

spoint, Input, and Output modules are needed in a 7500WB 128x128 to

create configurations from 32x32 to 128x128.

System Level Architecture

7500WB 256x256

Input 1-32

Input 65-96

Output 1-32

Xpt (In=1-128, Out=1-64)

Xpt (In=1-128, Out=65-128)

Xpt (In=1-128, Out=129-192)

Input 33-64

Input 97-128

Output 33-64

Figure 1-6. 7500WB Module Placement

Output 65-96

Output 129-160

Xpt (In=129-256, Out=1-64)

Xpt (In=1-128, Out=193-256)

Output 97-128

Output 161-192

Input 129-160

Output 193-224

Xpt (In=129-256, Out=65-128)

Xpt (In=129-256, Out=129-192)

Input 161-192

Output 225-256

Power

Supply

1

Power

Input 193-224

Supply

2

Monitor

Controller

Controller

Xpt (In=129-256, Out=193-256)

Power

Supply

3

Power

Input 225-256

Supply

4

7500WB 128x128

Input 1-32

Input 33-64

Output 1-32

Xpt (In=1-64, Out=1-64)

DC Distribution

Output 33-64

Output 65-96

Xpt (In=1-64, Out=65-128)

Input 65-96

Output 97-128

Xpt (In=65-128, Out=1-64)

Power

Supply

1

Power

Input 97-128

Supply

2

Monitor

Controller

Controller

Xpt (In=65-128, Out=65-128)

7500 Series Instruction Manual 1-7

Section 1 — Overview

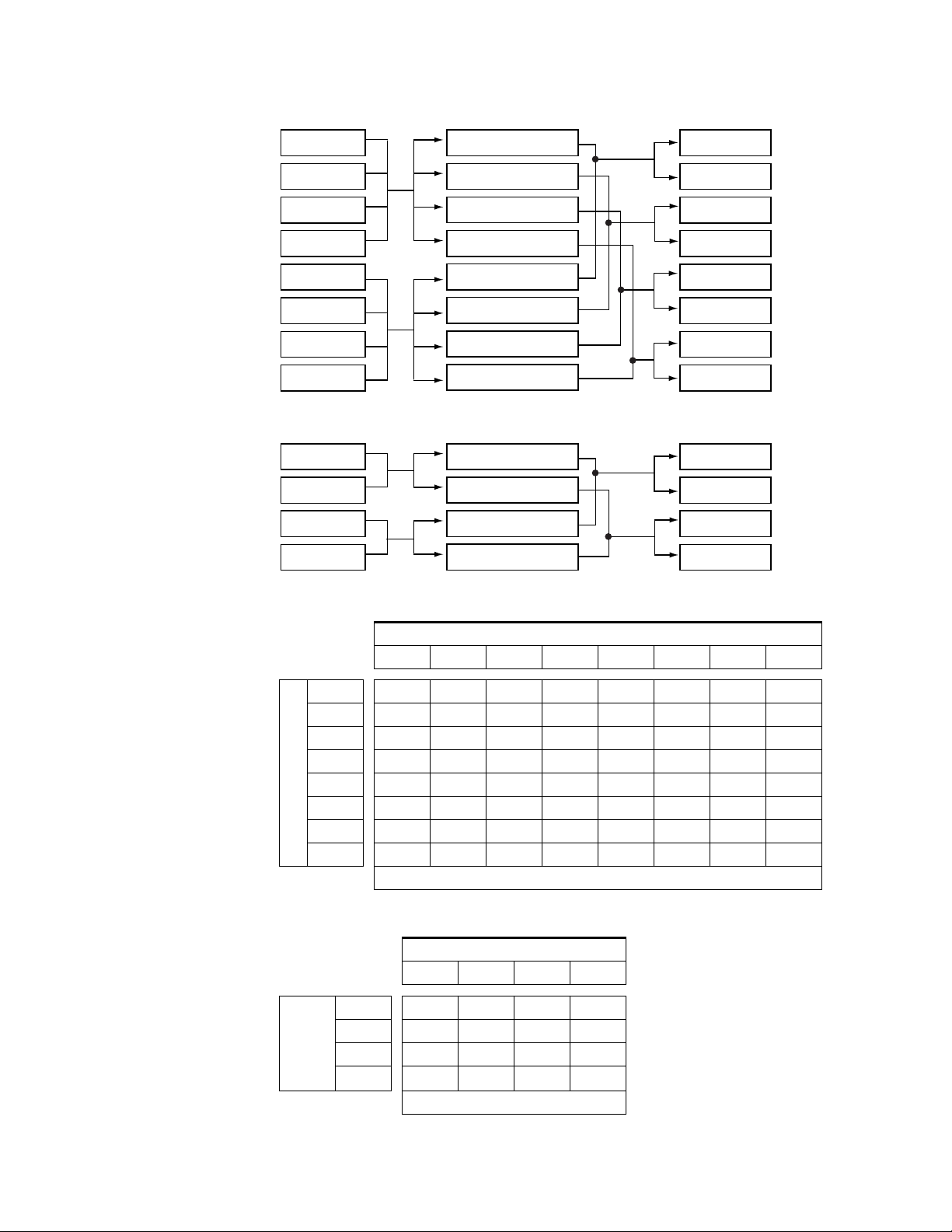

Figure 1-7. Signal Flow 7500WB 256x256

Inputs 1-32

Xpt (In=1-128, Out=1-64)

Outputs 1-32

Inputs 33-64

Inputs 65-96

Inputs 97-128

Inputs 129-160

Inputs 161-192

Inputs 193-224

Inputs 225-256

Xpt (In=1-128, Out=65-128)

Xpt (In=1-128, Out=129-192)

Xpt (In=1-128, Out=193-256)

Xpt (In=129-256, Out=1-64)

Xpt (In=129-256, Out=65-128)

Xpt (In=129-256, Out=129-192)

Xpt (In=129-256, Out=193-256)

Figure 1-8. Signal Flow 7500WB 128x128

Inputs 1-32

Inputs 33-64

Inputs 65-96

Inputs 97-128

Xpt (In=1-64, Out=1-64)

Xpt (In=1-64, Out=65-128)

Xpt (In=65-128, Out=1-64)

Xpt (In=65-128, Out=65-128)

Table 1-4. Crosspoint Modules Required for 7500WB 256x256

Outputs 33-64

Outputs 65-96

Outputs 97-128

Outputs 129-160

Outputs 161-192

Outputs 193-224

Outputs 224-256

Outputs 1-32

Outputs 33-64

Outputs 65-96

Outputs 97-128

Outputs (# of Modules)

32 (1) 64 (2) 96 (3) 128 (4) 160 (5) 196 (6) 224 (7) 256 (8)

32 (1)

64 (2)

96 (3)

128 (4)

160 (5)

196 (6)

Inputs (# of Modules)

224 (7)

256 (8)

11223344

11223344

11223344

11223344

22446688

22446688

22446688

22446688

Crosspoint Modules Required

Table 1-5. Crosspoint Modules Required for 7500WB 128x128

Outputs (# of Modules)

32 (1) 64 (2) 96 (3) 128 (4)

32 (1)

64 (2)

96 (3)

Inputs

128 (4)

(# of Modules)

1122

1122

2244

2244

Crosspoint Modules Required

1-8 7500 Series Instruction Manual

Installation

Frame Installation

The 7500 Series matrices are installed in a standard 483 mm (19-inch) rack.

Rear frame support is not required.

7500 NB Frame Installation

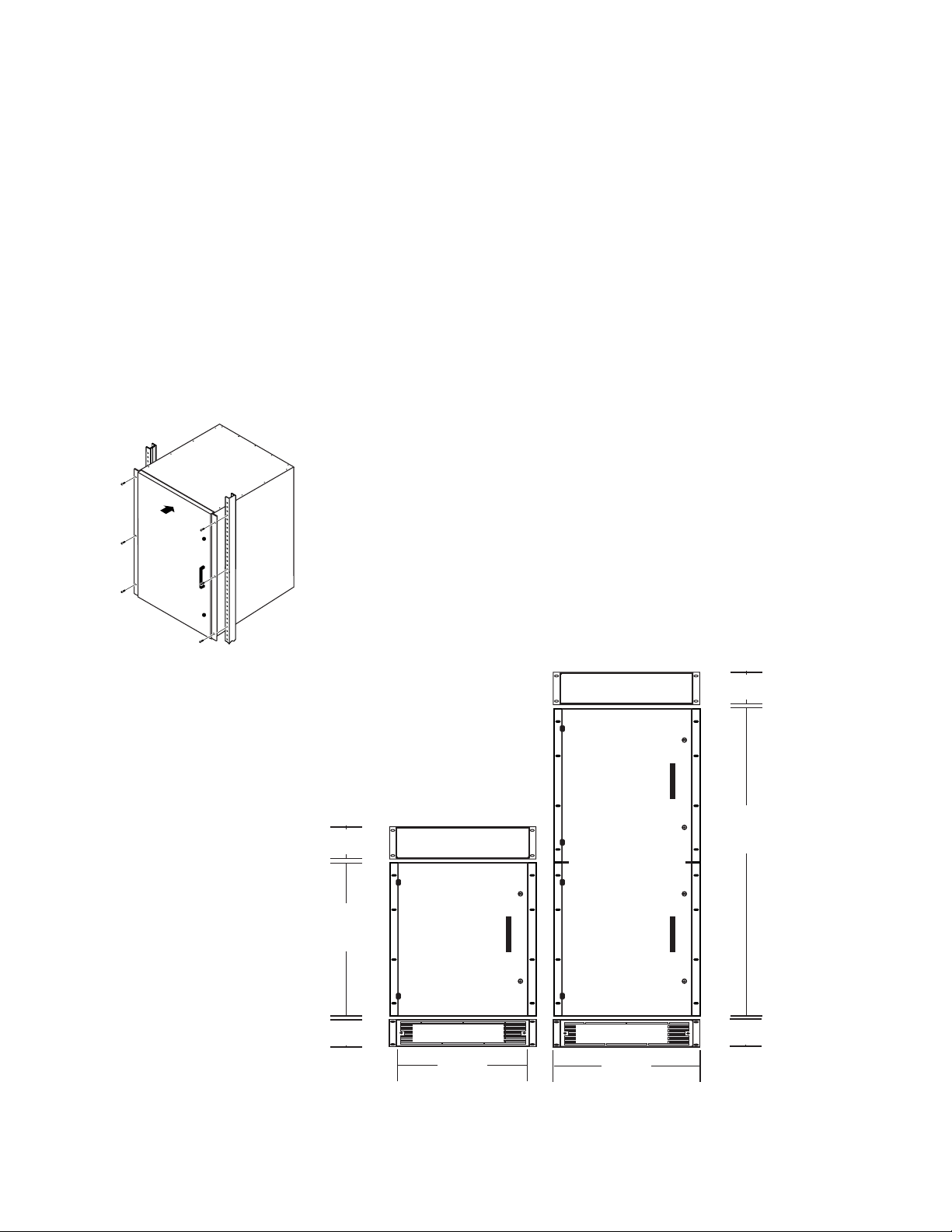

The 7500NB 256x256 occupies 12 rack-units. Cooling is by vertical airflow

using an external fan set. The 7500NB 512x512 is two 7500NB 256x256

frames connected by an Expansion module set. The 7500NB 512x512 occupies 24 rack-units. See Figure 2-2.

Section

2

Figure 2-1. Rack Mount

Figure 2-2. NB Rack Installation Front View

2 RU

89 mm/3.55 in.

12 RU

534 mm

21 in.

2 RU

89 mm/3.55 in.

Exhaust Unit

7500NB 256x256

Frame

Intake/Fan Unit

438 mm

17.25 in.

Exhaust Unit

7500NB 512x512

Frame

Intake/Fan Unit

483 mm

19 in.

2 RU

89 mm/3.55 in.

24 RU

1067 mm

42 in.

2 RU

89 mm/3.55 in.

7500 Series Instruction Manual 2-1

Section 2 — Installation

7500 WB Frame Installation

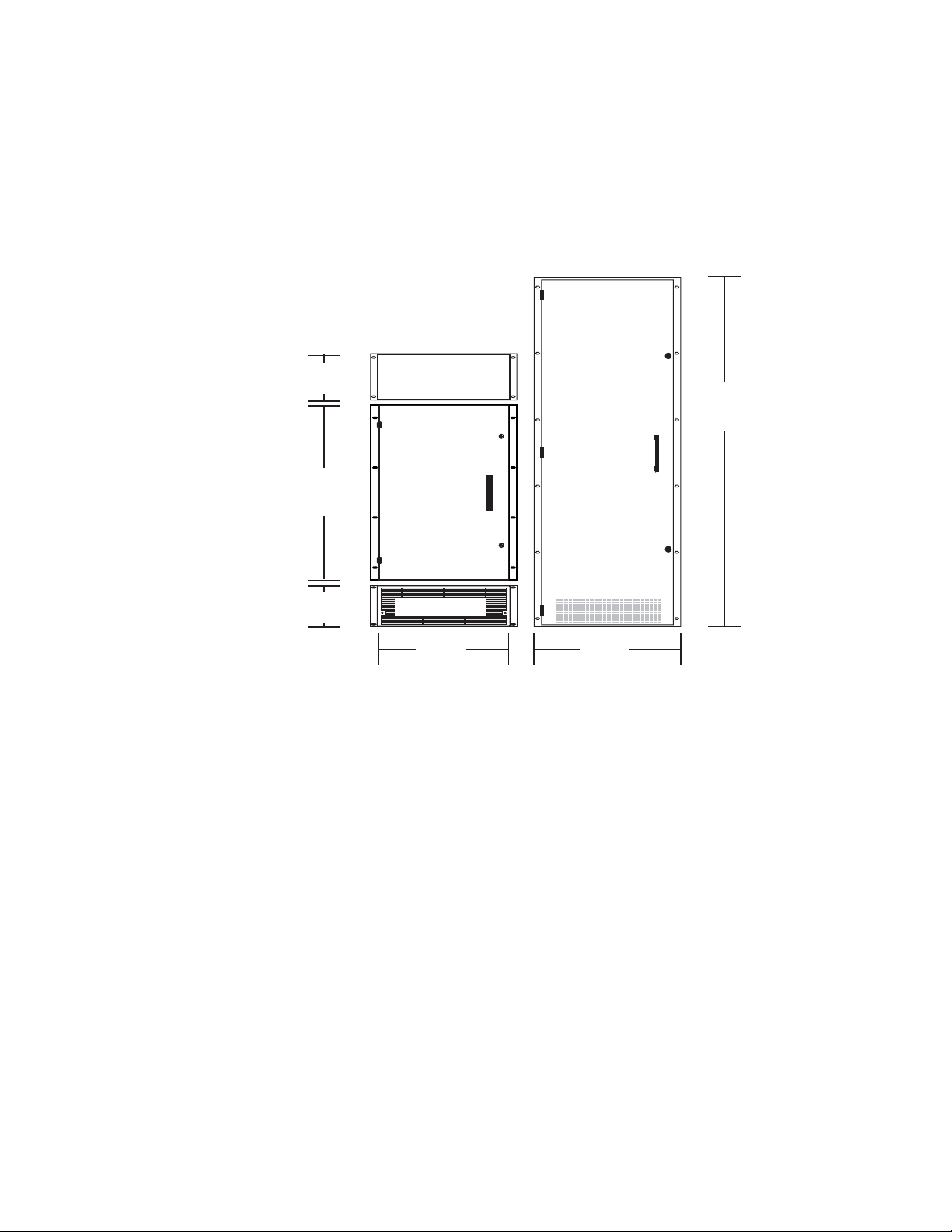

The 7500WB 256x256 router occupies 25 rack-units. Cooling is by vertical

airflow using a fan mounted inside the top of the frame and an air filter on

the front door . The 7500WB 128x128 r outer occupies 13 rack-units. Cooling

is by vertical airflow using an external fan set. See Figure 2-3.

Figure 2-3. WB Rack Installation Front View

7500WB 256x256

Frame

3 RU

134 mm/5.25 in.

13 RU

578 mm

22.72 in.

Exhaust Unit

25 RU

1110 mm

43.75 in.

7500WB 128x128

Frame

3 RU

134 mm/5.25 in.

Intake/Fan Unit

438 mm

17.25 in.

483 mm

19 in.

2-2 7500 Series Instruction Manual

Module Installation

All the modules are vertically oriented in the frames, and edge guides aid

insertion and removal.

CAUTION It is critical that the modules be placed in the proper slot and oriented cor-

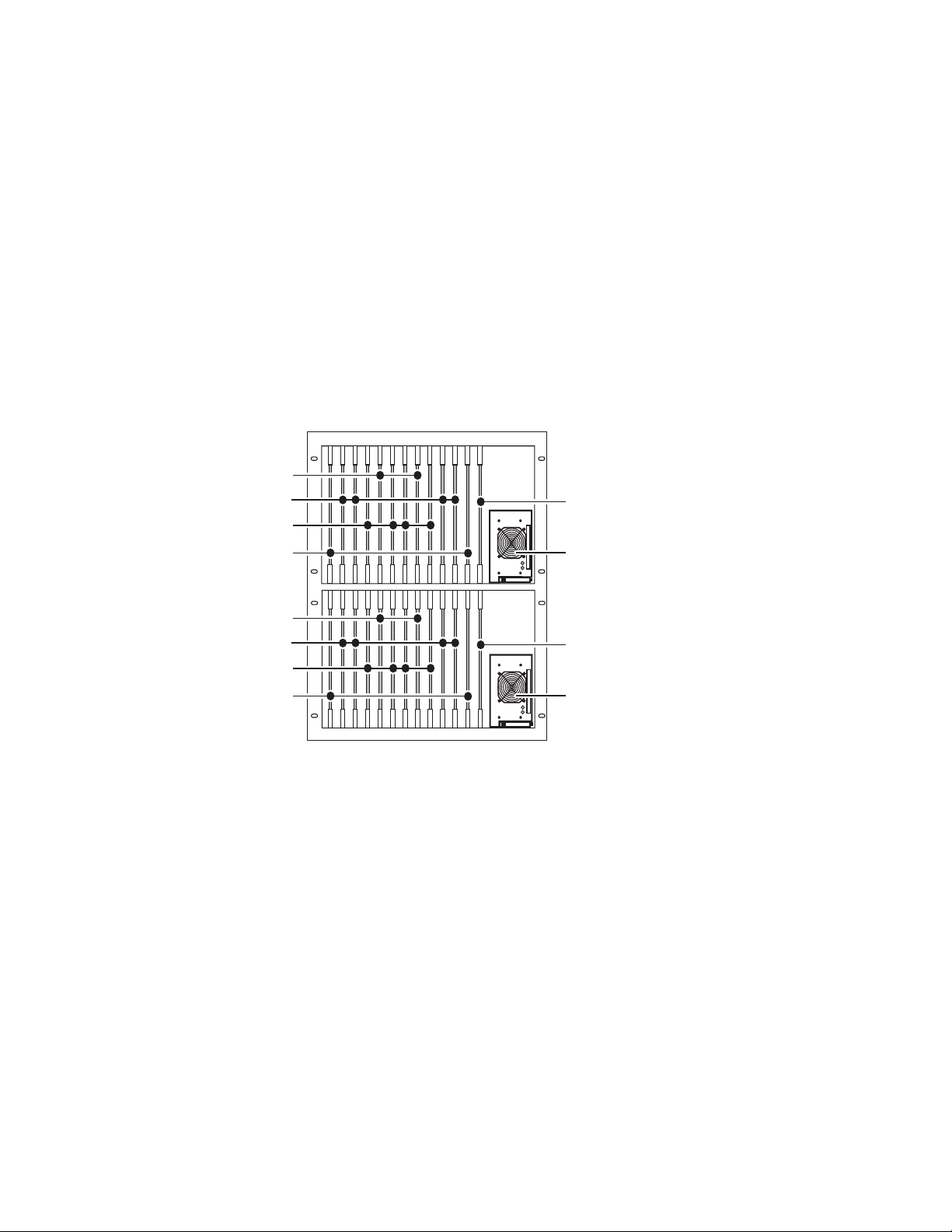

7500NB Module Placement

7500NB modules are oriented in the frame with the front (populated) side

facing to the right. See Figure 2-4.

Figure 2-4. 7500NB Module Configuration and Alignment

Output Modules

Crosspoint Expansion Modules

Crosspoint Modules

Input Modules

rectly to prevent bent pins.

DC OK

AC PRESENT

Module Installation

Controller Modules

Power Supply Modules

Output Modules

Crosspoint Expansion Modules

Crosspoint Modules

Input Modules

AC PRESENT

Controller Modules

DC OK

Power Supply Modules

7500 Series Instruction Manual 2-3

Section 2 — Installation

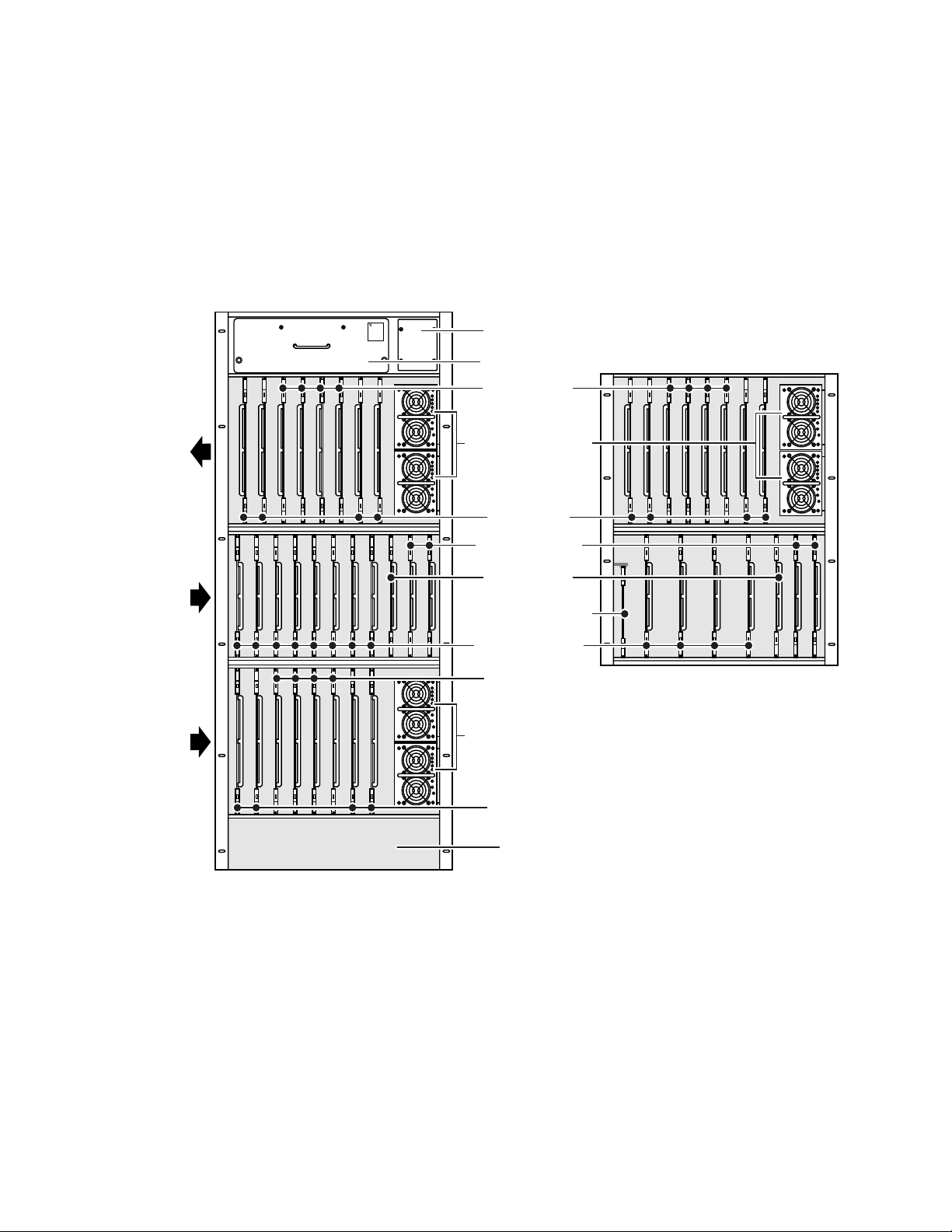

7500WB Module Placement

7500WB 256X256

In the top row of the 7500WB, Input and Output modules are oriented in

the frame with the front (populated) side facing to the left. The other rows

of modules are orientated in the frame with the front (populated) side

facing to the right. See Figure 2-5.

Figure 2-5. 7500WB Module Configuration and Alignment

WARNING

ROTATING

FAN BLADES

PULL OUT

1/2 INCH

AND WAIT

30 SECONDS

BEFORE

REMOVING

Thermal Control

Module Cover

Exhaust Fan Unit

7500WB 128X128

In this row all

Input and Output

modules are

orientated with

fronts to the left.

In this row all

modules are

orientated with

fronts to the right

In this row all

Input and Output

modules are

orientated with

fronts to the right.

All Power Supply

modules are

orientated with the

tops to the left.

100%

20 40 60 80

DCG

ACG

VADJ

100%

20 40 60 80

DCG

ACG

VADJ

Output Modules

Power Supply Modules

Input Modules

Controller Modules

Monitor Module

DC Distribution Module

Crosspoint Modules

100%

20 40 60 80

DCG

ACG

VADJ

100%

20 40 60 80

DCG

ACG

VADJ

Output Modules

Power Supply Modules

Input Modules

Air Intake

100%

20 40 60 80

DCG

ACG

VADJ

100%

20 40 60 80

DCG

ACG

VADJ

0528_01_16

2-4 7500 Series Instruction Manual

Loading...

Loading...