Page 1

CopperHead 3430AP

User Manual

4042-99M00-101

9 February 2015

Page 2

Copyright © 2015 by Grass Valley, A Belden Brand

All rights reserved. No part of this manual may be reproduced in any form by photocopy, microfilm, xerography or any other means, or incorporated into any information retrieval system,

electronic or mechanical, without the written permission of Grass Valley, A Belden Brand.

• Document revision: 101

• Document part number: 4042-99M00-101

Change History

Revision Published Description of Changes

4042-99M00-100 29 July 2014 Initial release

4042-99M00-101 9 February 2015 Correction of figure labels

Notice

Because of continued product development, the accuracy of the information in this document

may change without notice. The information and intellectual property contained herein is confidential between Grass Valley and the client and remains the exclusive property of Grass Valley. If

you find any problems in the documentation, please report them to us in writing. Grass Valley

does not warrant that this document is error-free.

Trademarks

Grass Valley is a registered trademark of Grass Valley, A Belden Brand.

Brand and product names mentioned in this manual may be trademarks, registered trademarks

or copyrights of their respective holders. All brand and product names mentioned in this

manual serve as comments or examples and are not to be understood as advertising for the

products or their manufacturers.

Software License Agreement and Warranty Information

Contact Grass Valley for details on the software license agreement and product warranty.

ii

Page 3

Safety Compliance

CopperHead 3430AP

User Manual

This equipment complies with:

• CSA/UL/IEC/EN 60950-1, 2nd Ed., for Information Technology Equipment -

Safety requirements

The power cord supplied with this equipment meets the appropriate national

standards for the country of destination.

WAR NIN G:

CAUTION:

An appropriately listed/certified mains power supply cord must be used

for the connection of the equipment to the mains voltage at either 120V~

or 240V~.

These servicing instructions are for use by qualified personnel only.

To reduce the risk of electric shock, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all

servicing to qualified service personnel.

Disconnect all power supplies before servicing.

Electromagnetic Compatibility

This equipment has been tested for verification of compliance with FCC Part 15,

Subpart B requirements for Class A digital devices.

NOTE: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

iii

Page 4

This equipment has been tested and found to comply with the requirements of the

EMC directive 2004/108/CE:

• EN 55022 Conducted emissions, Class A

• EN 55022 Radiated emissions, Class A

• EN 61000-3-2 Harmonic current emission limits

• EN 61000-3-3 Voltage fluctuation and flicker limitations

• EN 61000-4-2 Electrostatic discharge immunity

• EN 61000-4-3 Radiated electromagnetic field immunity - RF

• EN 61000-4-4 EFT immunity

• EN 61000-4-5 Surge immunity

• EN 61000-4-6 Conducted immunity

• EN 61000-4-8 Power frequency magnetic field immunity

• EN 61000-4-11 Voltage dips, short-interruption and voltage variation immunity

Important Safeguards and Notices

This section provides important safety guidelines for operators and service personnel. Specific

warnings and cautions appear throughout the manual where they apply. Please read and follow

this important information, especially those instructions related to the risk of electric shock or

injury to persons.

[fr] Mesures de sécurité et avis importants

La présente section fournit des consignes de sécurité importantes pour les opérateurs et le

personnel de service. Des avertissements ou mises en garde spécifiques figurent dans le

manuel, dans les sections où ils s’appliquent. Prenez le temps de bien lire les consignes et

assurez-vous de les respecter, en particulier celles qui sont destinées à prévenir les décharges

électriques ou les blessures.

Symbols and Their Meanings

The lightning flash with arrowhead symbol within an equilateral triangle alerts the

user to the presence of dangerous voltages within the product’s enclosure that

may be of sufficient magnitude to constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle alerts the user to the

presence of important operating and maintenance/service instructions.

iv

Page 5

CopperHead 3430AP

User Manual

The earth ground symbol represents a protective grounding terminal. Such a

minal must be connected to earth ground prior to making any other

ter

connections to the equipment.

The fuse symbol indicates that th

with one having the ratings indicated.

The presence of this symbol in or on Grass V

been designed, tested and certified as complying with applicable Canadian

Standard Association (CSA) regulations and recommendations for USA/Canada.

The presence of this symbol in or on Grass V

been designed, tested and certified as complying with applicable Underwriters

Laboratory (UL) regulations and recommendations for USA/Canada.

The presence of this symbol in or on Grass V

been designed, tested and certified as essentially complying with all applicable

European Union (CE) directives.

The presence of this symbol in or on Grass

with safety of laser product applicable standards.

Safety of Laser Modules

This equipment incorporates modules containing Class 1 lasers. These modules

are certified by the manufacturer to comply with:

– IEC/EN 60825-1 Safety of laser products

– IEC 60950-1 Safety of information technology equipment

e fuse referenced in the text must be replaced

alley equipment means that it has

alley equipment means that it has

alley equipment means that it has

Valley product means that it complies

[fr] Sécurité laser

L’appareil comprend des modules laser de classe 1. Ces modules sont certifiés conformes

aux normes suivantes par le fabricant :

– IEC/EN 60825-1 Sécurité des appareils à laser

– IEC 60950-1 Sécurité du matériel informatique

Warnings

A warning indicates a possible hazard to personnel, which may cause injury or death.

Observe the following general warnings when using or working on this equipment:

• Appropriately listed/certified mains supply pow

the equipment to the mains voltage at either 120 V AC or 240 V AC.

• This product relies on the building's installation for short-circuit (over-current) protection.

e that a fuse or circuit breaker for 120 V AC or 240 V AC is used on the phase

Ensur

nductors.

co

er cords must be used for the connection of

v

Page 6

• Any instructions in this manual that require opening the equipment cover or enclosure are

for use by qualified service personnel only.

• Heed all warnings on the unit and in the operating instructions.

• Do not use this equipment in or near water.

• This equipment is grounded through the grounding conductor of the power cords. To avoid

electrical shock, plug the power cords into a properly wired receptacle before connecting

the equipment inputs or outputs.

• Route power cords and other cables so they are not likely to be damaged.

• Disconnect power before cleaning the equipment. Do not use liquid or aerosol cleaners;

use only a damp cloth.

• Dangerous voltages may exist at several points in this equipment. To avoid injury, do not

touch exposed connections and components while power is on.

• Do not wear rings or wristwatches when troubleshooting high current circuits such as the

power supplies.

• To avoid fire hazard, use only the specified fuses with the correct type number, voltage and

current ratings as referenced in the appropriate locations in the service instructions or on

the equipment. Always refer fuse replacements to qualified service personnel.

• To avoid explosion, do not operate this equipment in an explosive atmosphere.

• This product includes a backup battery. There is a danger of explosion if the battery is

replaced incorrectly. Replace the battery only with the same or equivalent type

recommended by the manufacturer. Dispose of used batteries according to the

manufacturer’s instructions. Before disposing of your Grass Valley equipment, please review

the Disposal and Recycling Information appendix.

• Have qualified service personnel perform safety checks after any service.

[fr] Avertissements

• Un cordon d’alimentation dûment homologué doit être utilisé pour connecter l’appareil à

une tension de secteur de 120

V CA ou 240 V CA.

• La protection de ce produit contre les courts-circuits (surintensités) dépend de l’installation

électrique du bâtiment. Assurez-vous qu'un fusible ou un disjoncteur pour 120

240

V CA est utilisé sur les conducteurs de phase.

V CA ou

• Dans le présent manuel, toutes les instructions qui nécessitent d’ouvrir le couvercle de

l’équipement sont destinées exclusivement au personnel technique qualifié.

• Respectez tous les avertissements figurant sur l’appareil et dans les instructions

d’utilisation.

• Ne pas utiliser cet appareil dans l’eau ou à proximité d’un point d’eau.

• Cet équipement est mis à la terre par le conducteur de mise à la terre des cordons

d’alimentation. Pour éviter les chocs électriques, branchez les cordons d’alimentation sur

une prise correctement câblée avant de brancher les entrées et sorties de l’équipement.

• Acheminez les cordons d’alimentation et autres câbles de façon à ce qu’ils ne risquent pas

d’être endommagés.

• Coupez l’alimentation avant de nettoyer l’équipement. Ne pas utiliser de nettoyants

liquides ou en aérosol. Utilisez uniquement un chiffon humide.

• Des tensions dangereuses peuvent exister en plusieurs points dans cet équipement. Pour

éviter toute blessure, ne touchez pas aux connexions ou aux composants exposés lorsque

l’appareil est sous tension.

vi

Page 7

CopperHead 3430AP

User Manual

• Avant de procéder à toute opération d’entretien ou de dépannage visant des circuits à

courant élevé (e.g., les blocs d’alimentation), enlevez tous vos bijoux (notamment vos

bagues et votre montre).

• Pour éviter tout risque d’incendie, utilisez uniquement les fusibles du type et du calibre

indiqués dans la documentation ou sur l’équipement. Confiez le remplacement de fusibles

au personnel technique qualifié.

• Ne pas utiliser cet appareil dans une atmosphère explosive.

• L’appareil renferme une pile. Pour réduire le risque d’explosion, vérifiez la polarité et ne

remplacez la pile que par une pile du même type, recommandée par le fabricant. Mettez les

piles usagées au rebut conformément aux directives du fabricant. Avant de vous défaire de

l’équipement, assurez-vous d’avoir lu l’appendice

• Après tout travail d’entretien ou de réparation, faites effectuer des contrôles de sécurité par

le personnel technique qualifié.

Disposal and Recycling Information.

Cautions

A caution indicates a possible hazard to equipment that could result in equipment

damage. Observe the following cautions when operating or working on this

equipment:

• When installing this equipment, do not attach the power cord to building surfaces.

• To reduce the risk of electric shock, do not perform any servicing other than that contained

in the operating instructions unless you are qualified to do so. Refer all servicing to qualified

service personnel. Servicing should be done in a static-free environment.

• To prevent damage to equipment when replacing fuses, locate and correct the problem

that caused the fuse to blow before re-applying power.

• Use only the specified replacement parts.

• Follow static precautions at all times when handling this equipment.

• Products that have no on/off switch, and use an external power supply must be installed in

proximity to a main power outlet that is easily accessible.

[fr] Mises en garde

• Au moment d’installer l’équipement, ne fixez pas les cordons d’alimentation aux surfaces

intérieures de l’édifice.

• Pour réduire le risque de choc électrique, n'effectuez pas de réparations autres que celles

qui sont décrites dans le présent manuel, sauf si vous êtes qualifié pour le faire. Confiez les

réparations à un technicien qualifié. La maintenance doit se réaliser dans un milieu libre

d’électricité statique.

• Pour éviter d'endommager l'équipement lors du remplacement de fusibles, localisez la

source de la panne et corrigez la situation avant de rétablir le courant.

• Employez uniquement les pièces de rechange recommandées par le fabricant.

• Veillez à toujours prendre les mesures de protection antistatique appropriées quand vous

manipulez l’équipement.

• Les produits qui n'ont pas d’interrupteur marche-arrêt et qui disposent d’une source

d’alimentation externe doivent être installés à proximité d'une prise de courant facile

d’accès.

vii

Page 8

Electrostatic Discharge (ESD) Protection

Electrostatic discharge occurs when electronic components are improperly handled

and can result in intermittent failure or complete damage adversely affecting an

electrical circuit. When you remove and replace any card from a frame always follow

ESD-prevention procedures:

• Ensure that the frame is electrically connected to earth ground through the power cord or

any other means if available.

• Wear an ESD wrist strap ensuring that it makes good skin contact. Connect the grounding

clip to an unpainted surface of the chassis frame to safely ground unwanted ESD voltages. If

no wrist strap is available, ground yourself by touching the unpainted metal part of the

chassis.

• For safety, periodically check the resistance value of the antistatic strap, which should be

between

• When temporarily storing a card make sure it is placed in an ESD bag.

• Cards in an earth grounded metal frame or casing do not require any special ESD

protection.

[fr] Protection contre les décharges électrostatiques (DES)

Une décharge électrostatique peut se produire lorsque des composants électroniques ne sont

pas manipulés de manière adéquate, ce qui peut entraîner des défaillances intermittentes ou

endommager irrémédiablement un circuit électrique. Au moment de remplacer une carte dans

un châssis, prenez toujours les mesures de protection antistatique appropriées

• Assurez-vous que le châssis est relié électriquement à la terre par le cordon d'alimentation

ou tout autre moyen disponible.

• Portez un bracelet antistatique et assurez-vous qu'il est bien en contact avec la peau.

Connectez la pince de masse à une surface non peinte du châssis pour détourner à la terre

toute tension électrostatique indésirable. En l’absence de bracelet antistatique, déchargez

l’électricité statique de votre corps en touchant une surface métallique non peinte du

châssis.

• Pour plus de sécurité, vérifiez périodiquement la valeur de résistance du bracelet

antistatique. Elle doit se situer entre 1 et 10 mégohms.

• Si vous devez mettre une carte de côté, assurez-vous de la ranger dans un sac protecteur

antistatique.

1 and 10 megohms.

:

viii

Les cartes qui sont reliées à un châssis ou boîtier métallique mis à la terre ne nécessitent pas de

protection antistatique spéciale.

Restriction on Hazardous Substances (RoHS)

Grass Valley is in compliance with EU Directive RoHS 2002/95/EC governing the restricted use of

certain hazardous substances and materials in products and in our manufacturing processes.

Grass Valley has a substantial program in place for RoHS compliance that includes significant

investment in our manufacturing process, and a migration of Grass Valley product electronic

components and structural materials to RoHS compliance.

Page 9

CopperHead 3430AP

User Manual

It is our objective at Grass Valley to maintain compliance with all relevant environmental and

product regulatory requirements. Detailed information on specific products or on the RoHS

program at Grass Valley is available from Grass Valley Customer Support.

ix

Page 10

x

Page 11

Table of Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

The CopperHead 3430AP Fiber Optic Transceiver System . . . . . . . . . . . . . . . . . . . . . . . 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

System Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Detailed System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

CopperHead 3430AP Camera Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Connectors, Indicators and Controls - Back Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Connectors and Indicators - Front and Right Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Controls and Indicators - Left Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Copperhead 3400 Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

HDX-Plus Power Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

HDX-Plus Power Output and Derating Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3 Installation and Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Mounting the CopperHead 3430AP Camera Unit to the Camera. . . . . . . . . . . . . . . 27

Connecting the CopperHead 3430AP Transceiver System. . . . . . . . . . . . . . . . . . . . . 28

Connection Overview of the CopperHead 3430AP Transceiver System . . . . . . . . . . . . . 29

Connections to the CopperHead 3400 Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Connectors into and out of the CopperHead 3400 Base Station . . . . . . . . . . . . . . . . . . . 30

Connections to the CopperHead 3430AP Camera Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Set Up of the CopperHead 3430AP Transceiver System for Operation . . . . . . . . . 38

Connecting and Managing the Fiber Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Powering the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Powering the CopperHead 3400 Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Powering the CopperHead 3430AP Camera Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Intercom Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Using the Digital Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

A Brief Guide to Measurement of Fiber Optic Signal Strength . . . . . . . . . . . . . . . . . . . . . . 46

The CopperHead 3400 Base Station Digital Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

The CopperHead 3430AP Camera Unit Digital Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Standard Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Shutting Down the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

xi

Page 12

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Appendix A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Base Station Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Camera Unit Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Data 1 (Camera Control) Pinout Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Base Station Breakout Data/GPI Cable - typical configuration . . . . . . . . . . . . . . . . . 66

Appendix B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

CopperHead 3430AP Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Camera Signal Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Base Station Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Contact Us . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Grass Valley Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Corporate Head Office . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

xii

Page 13

Introduction

Chapter 1 is an introduction to the CopperHead 3430AP fiber optic transceiver system.

Topics

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1

System Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

The CopperHead 3430AP Fiber Optic Transceiver System

Overview

The CopperHead 3430AP Transceiver System is a camera video, audio and data multiplexing

system that installs the 3430 Camera Unit on the back of a professional camera with IDX or

Anton Bauer plate, and connects via a single hybrid fiber optic cable to the HDX-Plus power

supply. The HDX-Plus power supply then connects to a 3400 Base Station in a truck, studio or

other video production setup. The CopperHead 3430/3400 Transceiver System can accommodate both single video channel and Dual link/3D links to the base station.

The signals carried over the Fiber Optic cable are described in the next section. The Camera Unit

can be up to 2KM from the HDX-Plus power supply. The HDX-Plus power supply can be as much

10 kilometers from the 3400 base station.

The 3430 Camera Unit attaches to the professional camera battery mount. This battery mount is

either Anton-Bauer or the Sony V-Mount standard battery mount. The type of mount must be

specified at the time of purchase.

The CopperHead 3430AP Transceiver System consists of three main components:

1 The CopperHead 3430 Camera Unit – this unit has one option - the battery mount type.

2 The HDX-Plus power supply.

3 The CopperHead 3400 Base Station – this unit has three options:

a The base station can either be internally powered by AC or externally powered by a 12

VDC power supply

b The ST Fiber Connectors can be located on either the front or back panels of the Base

Station. The location will be determined by the physical setup of your particular system.

c The system can be equipped with the TRS, Clear-Com or Four-Wire intercom standard.

Options are determined at the time of product order and the units are delivered preconfigured.

1

Page 14

Introduction

System Concepts

The Copperhead 3430AP Transceiver System utilizes an optical fiber link between the Base

Station and the Camera Unit to carry all of the required signals necessary for operation of the

camera and associated production equipment. The Camera Unit multiplexes electrical signals

from the camera and other remote sources and converts them to an optical signal for transmission over the fiber. Simultaneously, an optical return signal is received at the Camera Unit from

the Base Station; this signal is then converted to electrical analog information for use by the

camera, camera operator, and auxiliary equipment at the camera location.

2

Page 15

Detailed System Description

Chapter 2 describes the three components of the CopperHead 3430AP system: (1) the camera

unit, (2) the base station and (3) the HDX-Plus power supply.

Topics

CopperHead 3430AP Camera Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Connectors, Indicators and Controls - Back Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Connectors and Indicators - Front and Right Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

Copperhead 3400 Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

HDX-Plus Power Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

Optical Power Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 23

HDX-Plus Power Output and Derating Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 25

CopperHead 3430AP Camera Unit

The camera unit has controls, connectors and indicators in a variety of locations. The following

diagrams and descriptions will assist you in locating those of interest.

Camera Unit Left Side & Back Side Camera Unit Right Side and Front Side

(attached to the camera)

Fig. 2-1: CopperHead 3430APCamera Unit

The actual appearance of your CopperHead 3430AP Camera Unit will vary depending on the

battery mount option specified at the time of purchase.

3

Page 16

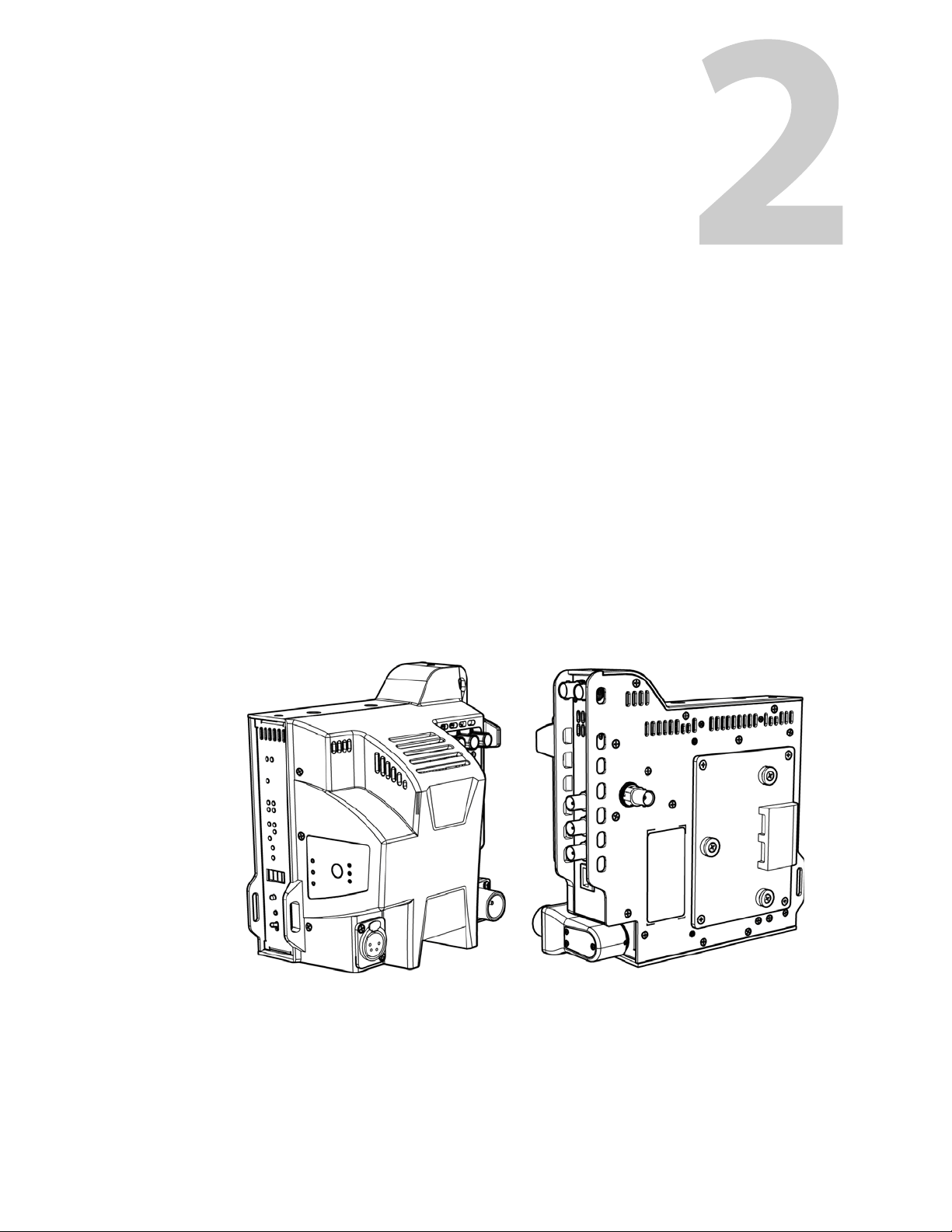

Detailed System Description

Connectors, Indicators and Controls - Back Side

Fig. 2-2: Back Side Connectors, Indicators and Contreols

There are four areas of interest in this view:

A) Audio/Intercom connector panel & controls

B) Miscellaneous connectors

C) Fiber connector

D) 12 - 17 VDC power output

Each of these areas of interest is described in detail below.

4

Page 17

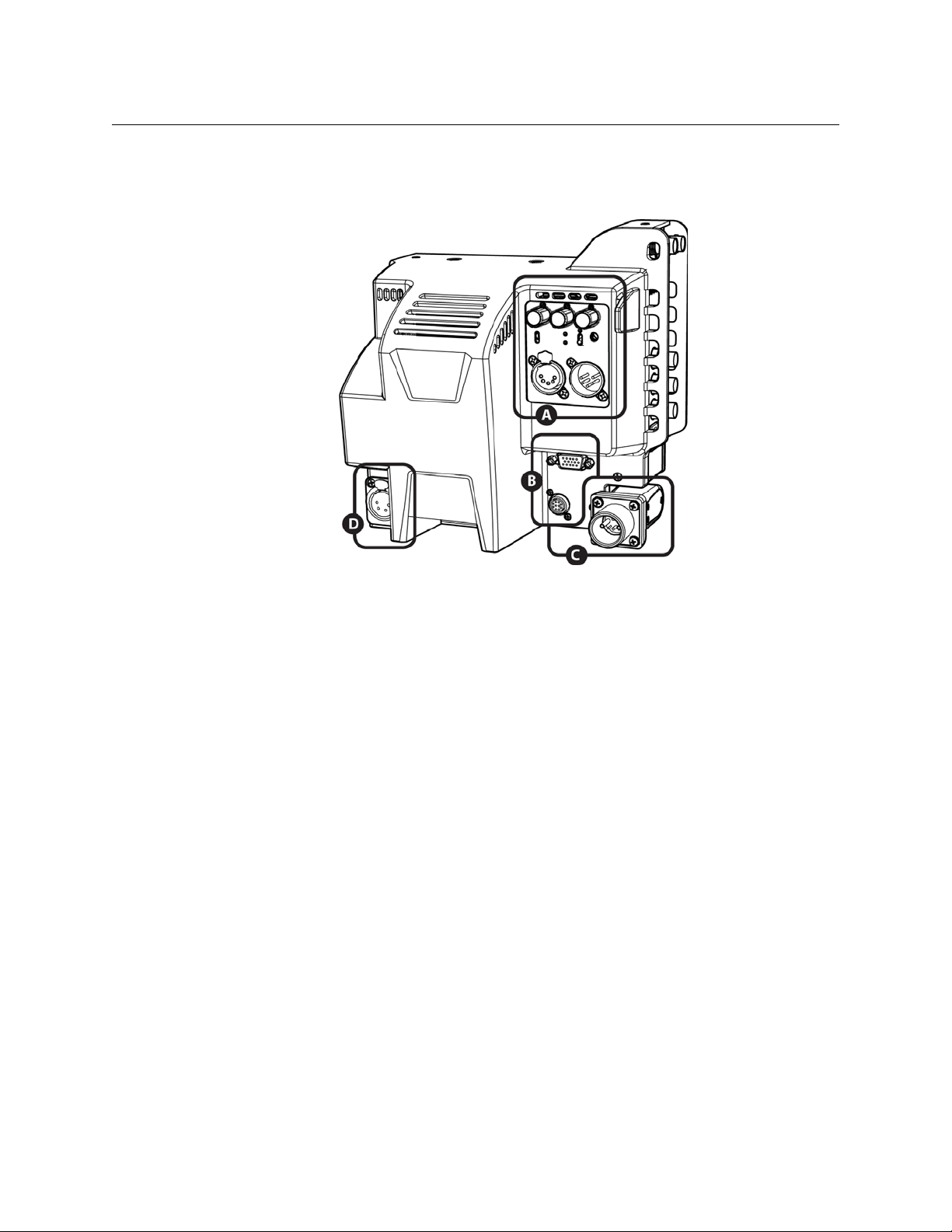

Area A - Audio/Intercom connector panel & controls

1 Intercom 1 Monitor Level Control and activity

indicator

2 Intercom 2 Monitor Level Control and activity

indicator

3 Return Program Monitor Level Control and

activity indicator

4 Intercom Local/Remore switch

5 Side tone control

6 Intercom talkback control

CopperHead 3430AP

User Manual

7 Intercom headset connector

8 Audio 1 & 2 Output Conncetor

For information on Audio/Intercom operation, please see Camera Unit Intercom Operation on

page 43.

Area B - Miscellaneous connectors

For information regarding available cables and customer-furnished cables please see the

Appendices.

9 Camera Remote Connector (for optional Camera

Remote Control unit). This connector also carries a Data

Signal for Serial Communication (RS232/422/485)

(see Appendix A for wiring information)

10 Production DB15HD Connector for Tally, Intercom

Trigger, 2

485)

nd

GPI and Serial Communication (RS232/422/

(see Appendix A for wiring information)

5

Page 18

Detailed System Description

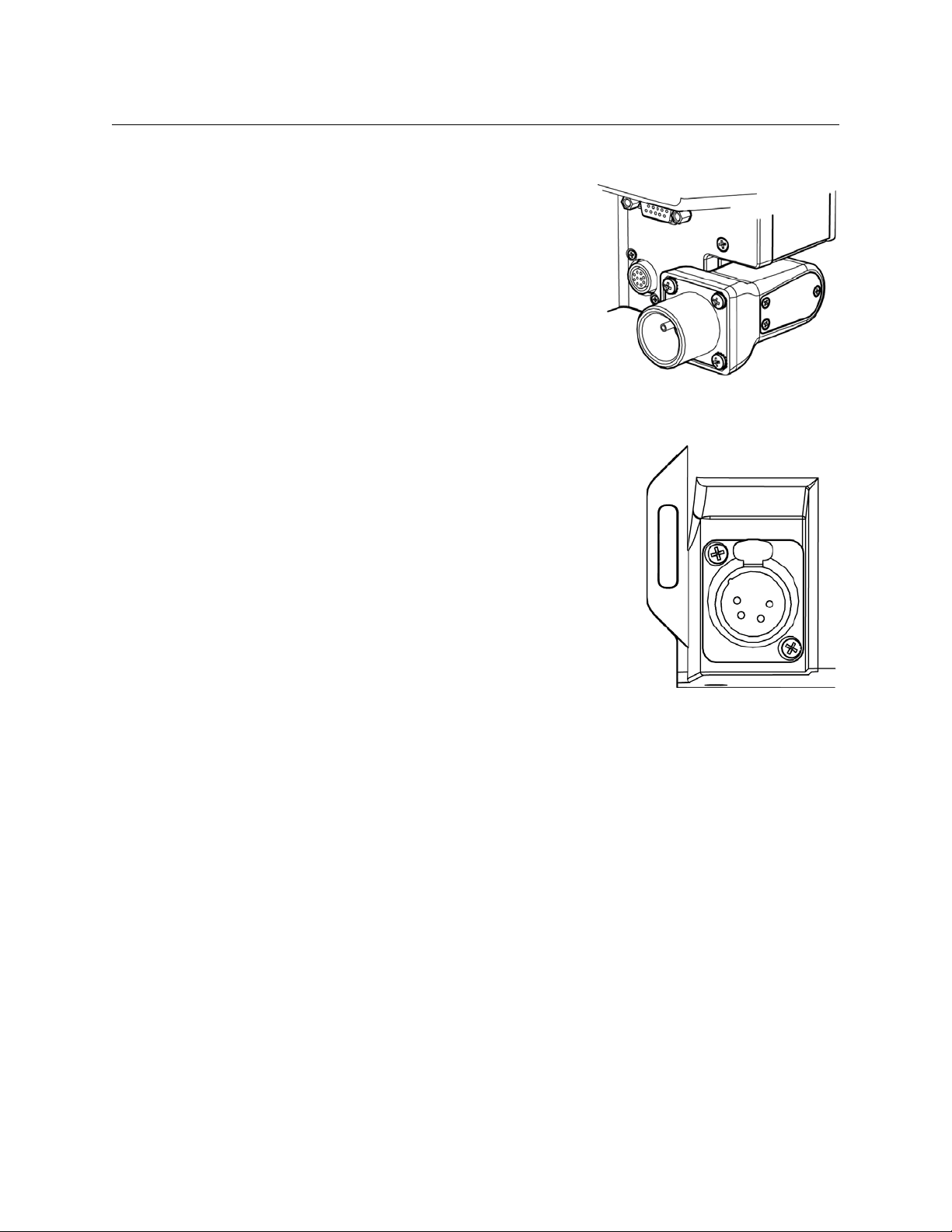

Area C– Fiber Connector

The CopperHead 3430AP Camera Unit is available

only with the SMPTE 304M Hybrid Optical Connector.

Area D - Power Output

The 4-Pin 17 VDC Power Plug can provide up to 30 Watts of

DC power to accessories attached to or near the camera

position.

For information regarding available cables and customerfurnished cables, please see Appendix B.

6

Page 19

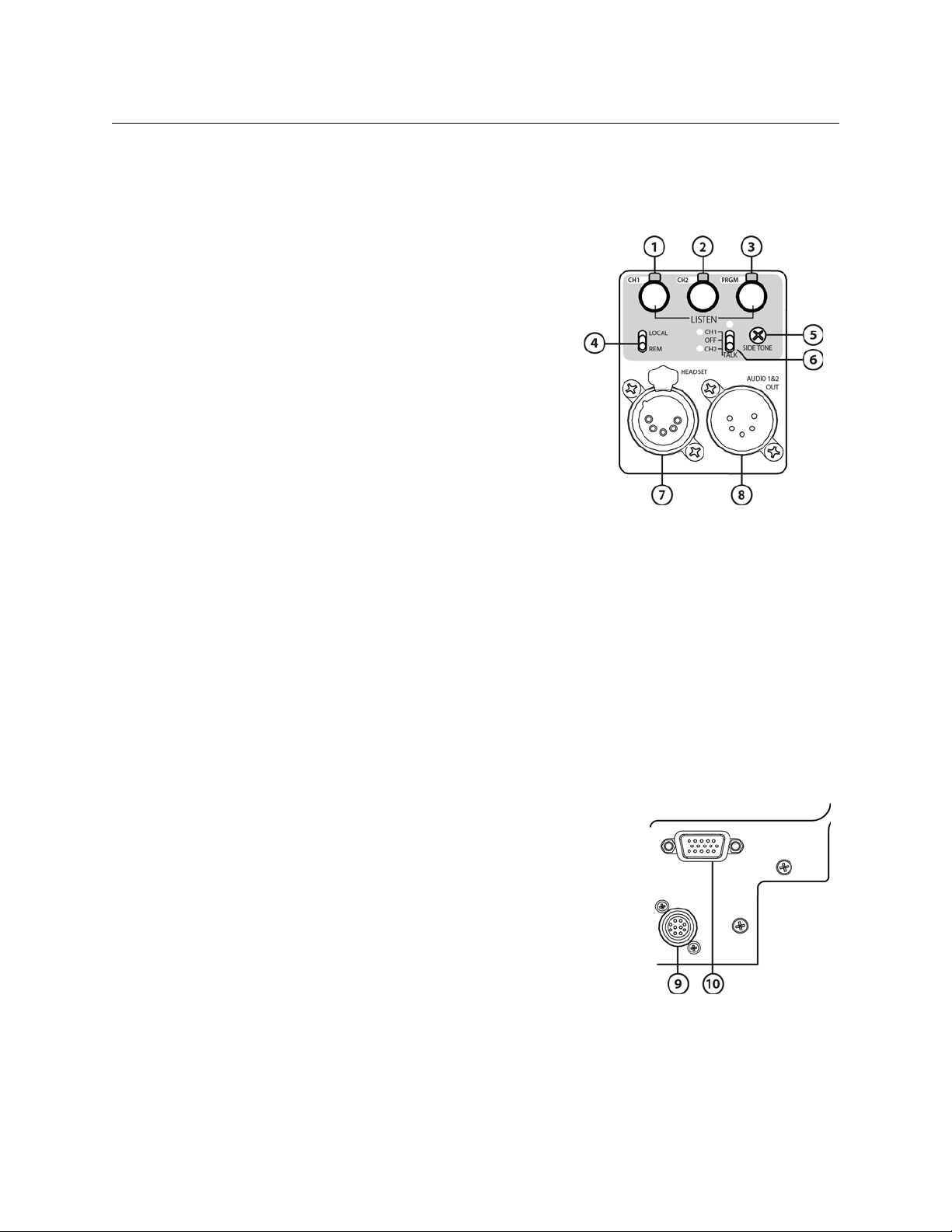

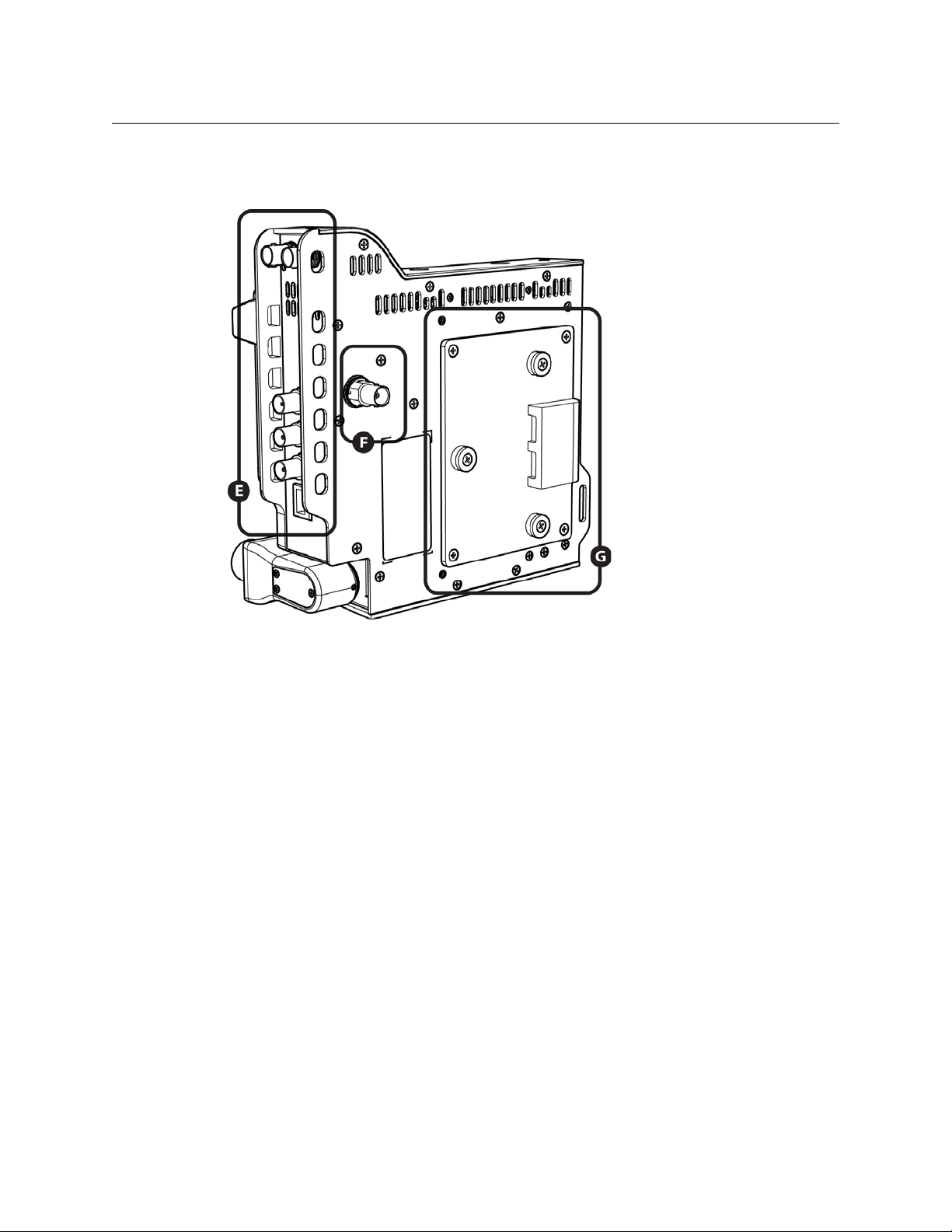

Connectors and Indicators - Front and Right Side

CopperHead 3430AP

User Manual

Fig. 2-3: Front and Right Side Connectors and Indicators

There are three areas of interest on the front and right sides of the CopperHead 3430AP

Camera Unit:

E) Connector panel (right side)

F) Time code output connector (front side).

G) Camera mounting plate (front side)

7

Page 20

Detailed System Description

Area E - Connector panel

11 3D – Dual Link SDI Connectors A & B – Activity

indicators are below each SDI connector (to

Base Station). System can be used as single or

dual link

12 SD-HD/SDI Digital Video Output (from Base Sta-

tion)

13 VBS In (to Base Station). VBS signal paths typi-

cally carry analog video

14 VBS Out (from Base Station)

15 Ethernet (100Mbs)

Area F - Time code output

Time Code Out (from Base Station)

For time code synchronization of multi-camera productions,

and/or video/audio synchronization.

8

Page 21

CopperHead 3430AP

User Manual

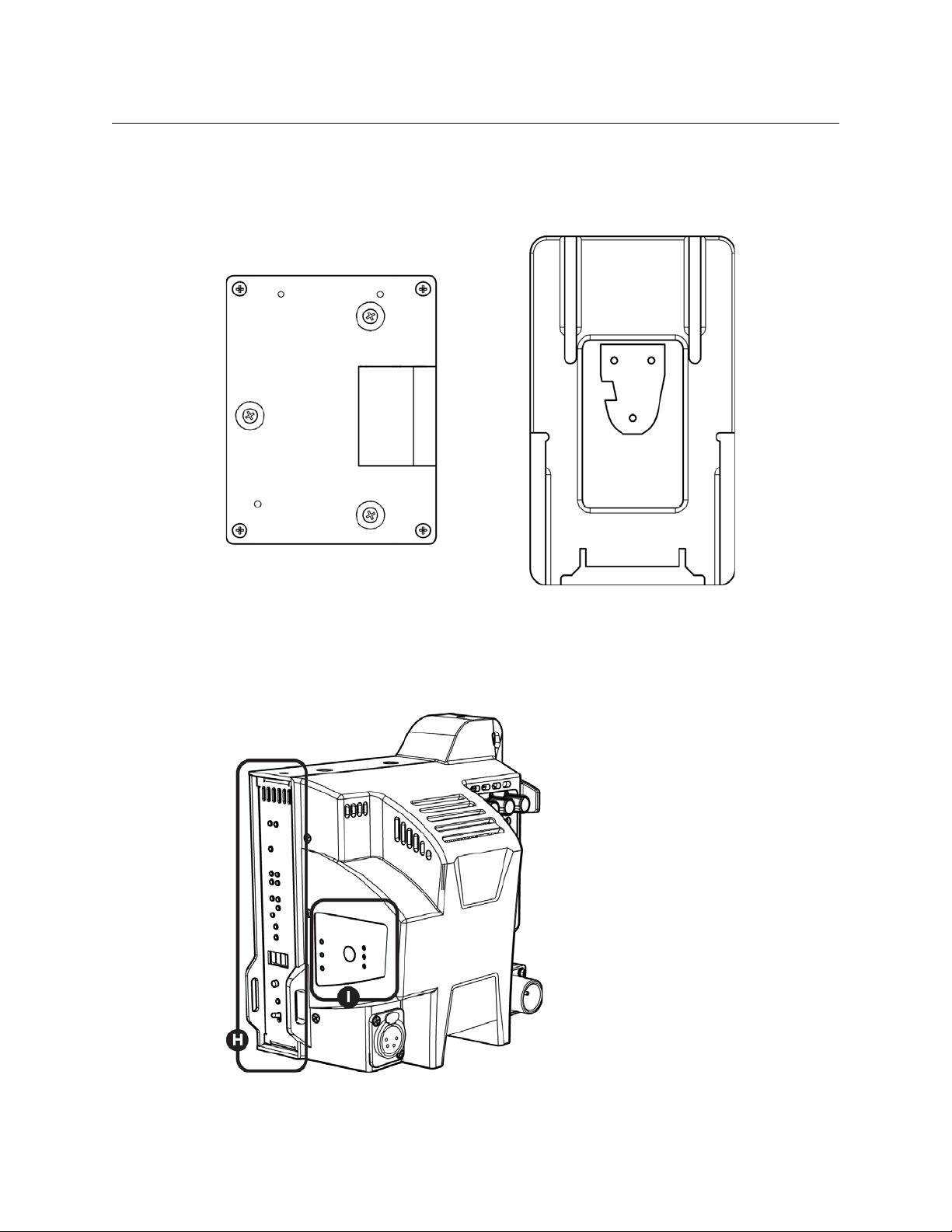

Area G - Camera mounting plate

The CopperHead 3430AP is shipped with either the Anton Bauer mount or the Sony V-mount.

Anton Bauer Camera Mounting Plate V-type Camera Momunting Plate

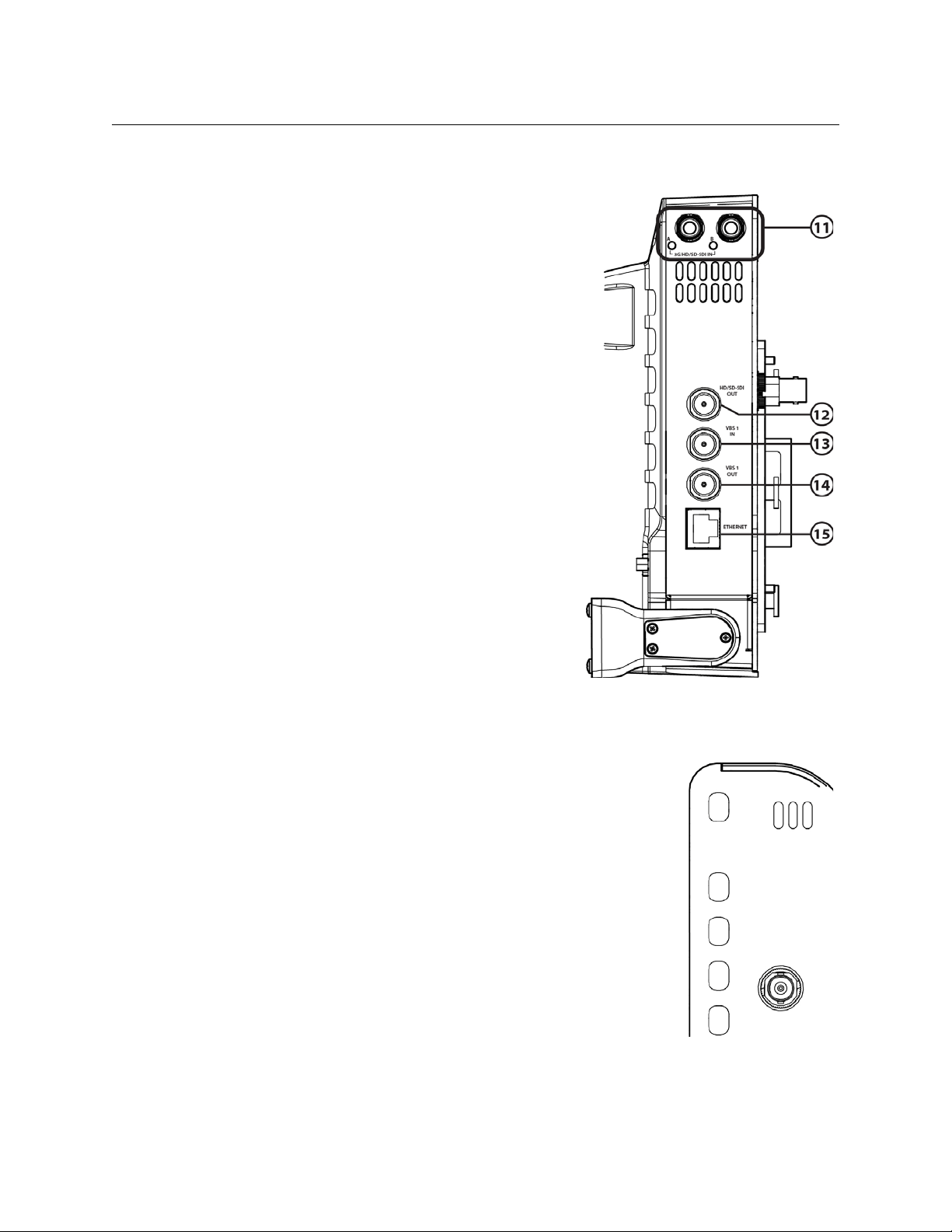

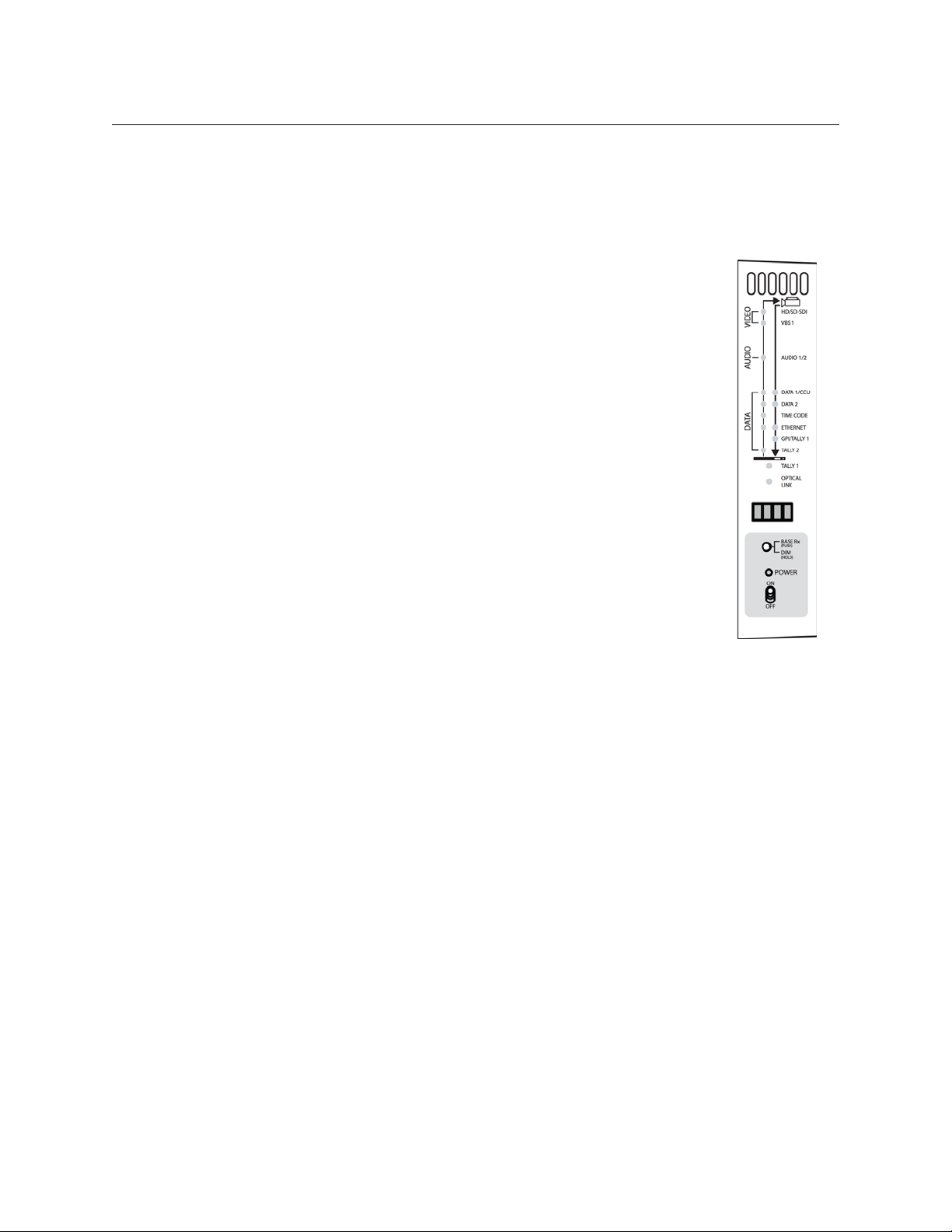

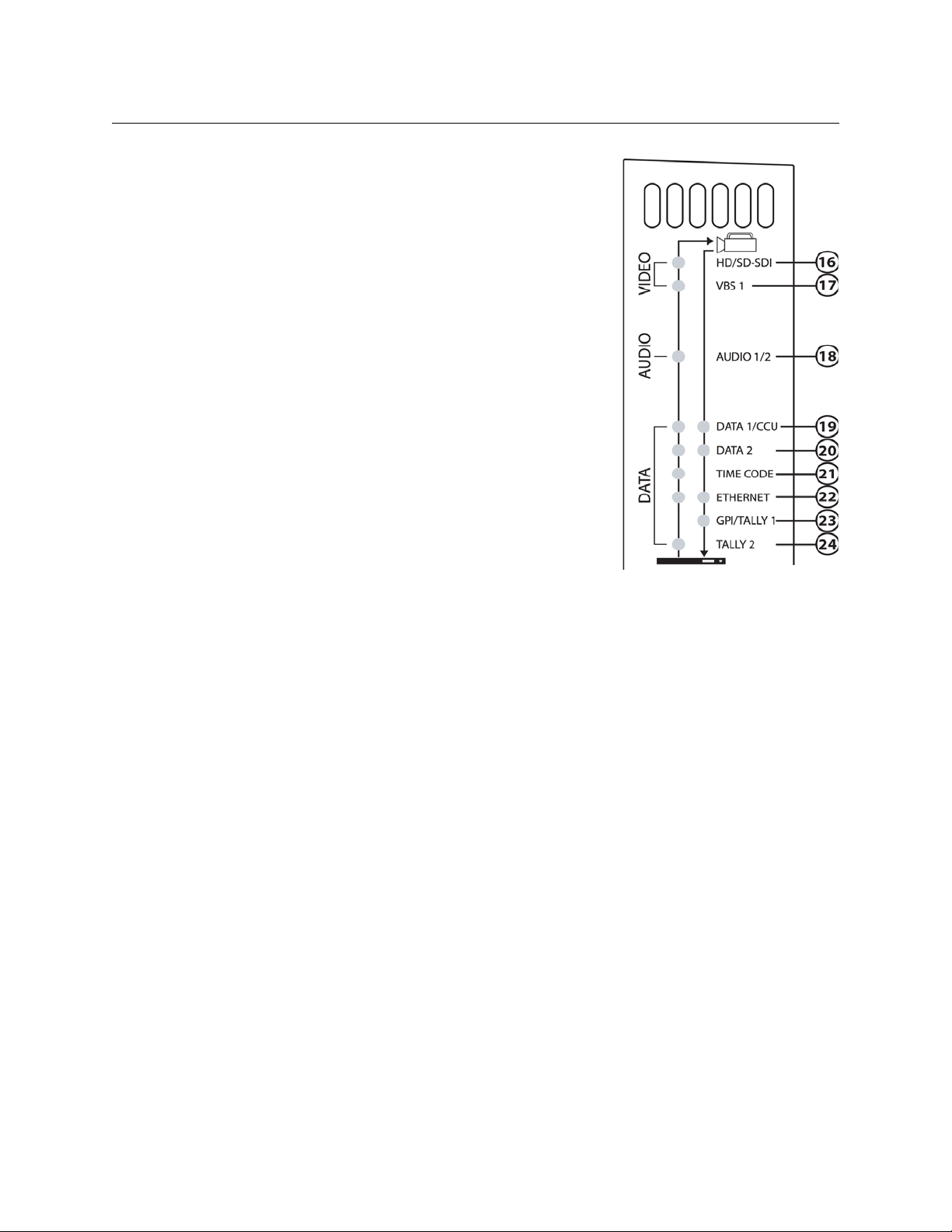

Controls and Indicators - Left Side

Fig. 2-4: Left Side Controls and Indicators

9

Page 22

Detailed System Description

The left side of the camera unit has two areas of interest:

H) Signal/Data indicators

I) Fan Control switch and indicators

Area H - Signal/Data LED activity indicators

The CopperHead 3430AP Camera Unit Indicator Panel has a series of LED

displays that monitor the various signal paths between the Camera Unit and

the Base Station.

For signals remain constant such as time code and video the LED remains

on as a steady green. For signals that fluctuate such as audio, the LED will

reflect the varying signal activity. If the LED is off either the signal has been

lost or it is not in use.

The LED indicators on the left side of the panel indicate signal paths from

the Base Station to the Camera Unit. Right side LEDs indicate signal paths

from the Camera Unit to the Base Station. Note: the 3G/HD/SD-Dual Link

Indicators are located on the opposite (left) side of the Camera Unit adjacent to the 3G/HD/SD-Dual Link SDI Connectors.

The arrow on the panel graphic indicates the direction of the signal - either

to or from the camera unit.

10

Page 23

CopperHead 3430AP

User Manual

16 H D/ SD -SDI Digital Video

Signal

Monitors camera SDI Video to Base Station and SDI

return video to the Camera Unit (this is not the 3DDLink signal)

17 VBS 1 – Analog Video Signal

VBS 1 is used for Return Video from the Camera Unit

to the Base Station and Return Video from the Base

Station to the Camera Unit

Program Audio Channels 1/2

18

Monitors return audio from Base Station to Camera

Unit.

19 Data 1 / CCU

Data 1 - used for a serial control device (RS232, 422,

485)

CCU – used for Camera Control Unit

20 Data 2

Data 2 is typically used for an auxiliary device such as a

robotic pan & tilt head. or a serial control device

(RS232, 422, 485)

21 TC – Time Code

Signal

Monitors Time Code to Camera

22 Ethernet Signal

Monitors Ethernet to Base Station and return from

Camera

23 GPI/Tally 1

Monitors GPI/TRIG Signal or TALLY 1 from camera.

24 Tally 2

Monitors TALLY 2 signal to camera unit.

11

Page 24

Detailed System Description

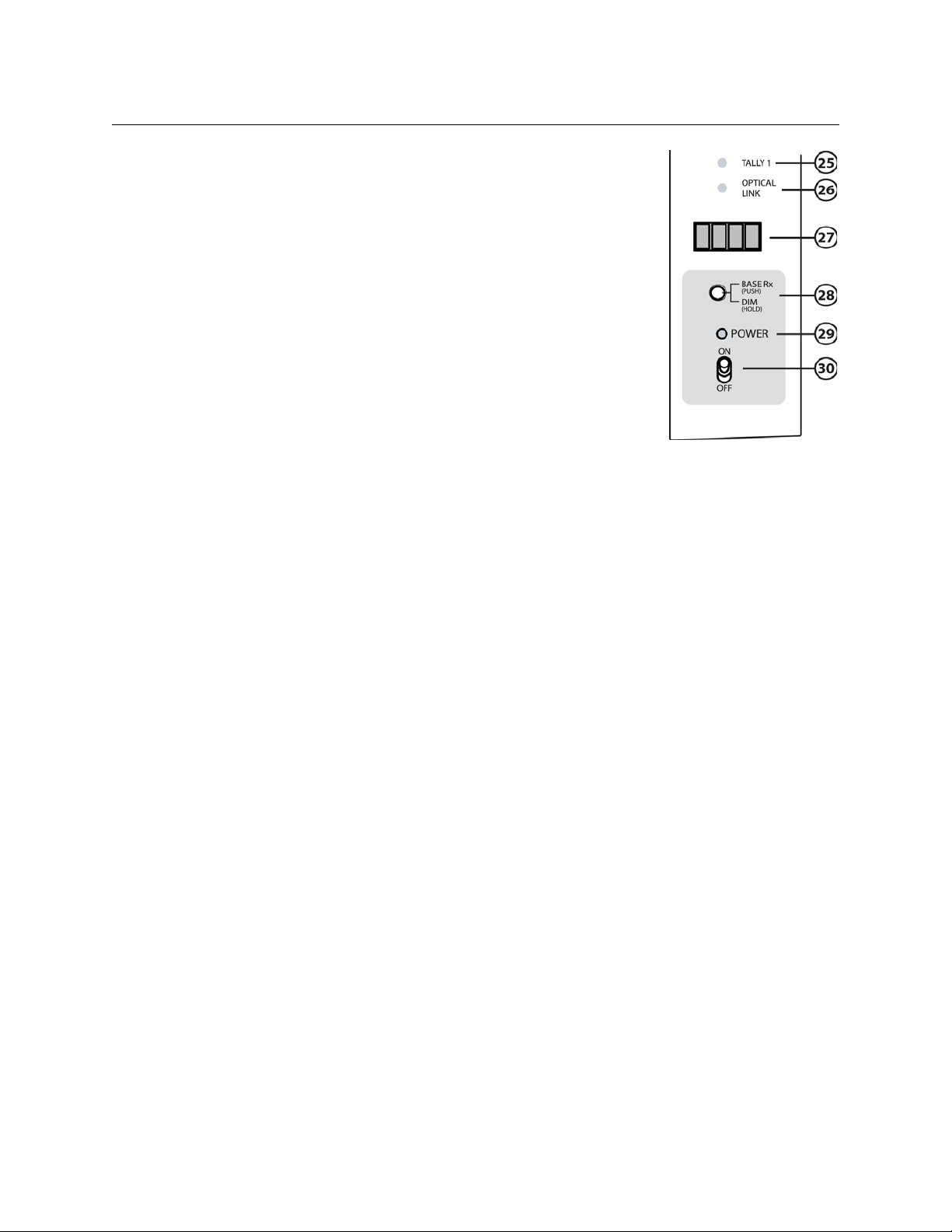

25 Tally 1 Indicator Light

Indicates the status of the GPI/Tally 1 signal

• Off when the signal is not present

• Bright Red when the signal is present

26 Optical Link Indicator

Indicates the status of the optical connection from base to

camera and camera to base

• Green when both the Base Station and camera control unit

have optical power within normal range.

• Red when either the Base Station or camera control unit

optical power is not within normal range.

27 Rx Optical Display (Digital Status Display)

Four character display in one of five modes. See The CopperHead 3430AP Camera Unit Dig-

ital Display on page 51 for use of this Digital Status Display

28 Base Rx/Dim Push Button

Change four character display mode. Push and release changes display mode. Push and

hold adjusts LED indicator brightness

29 Power Indicator LED

• Green indicates power is applied to the camera control unit.

• Blinking Green indicates a camera control unit error. Refer to DIAG display mode for

details – page 52

30 Power On/Off Switch

Toggle switch controls power to the CopperHead 3430AP Camera Unit, the 12 VDC output

and the camera when using the Sony-V Mount (Camera power control is not available with

the Anton-Bauer mount)

12

Page 25

CopperHead 3430AP

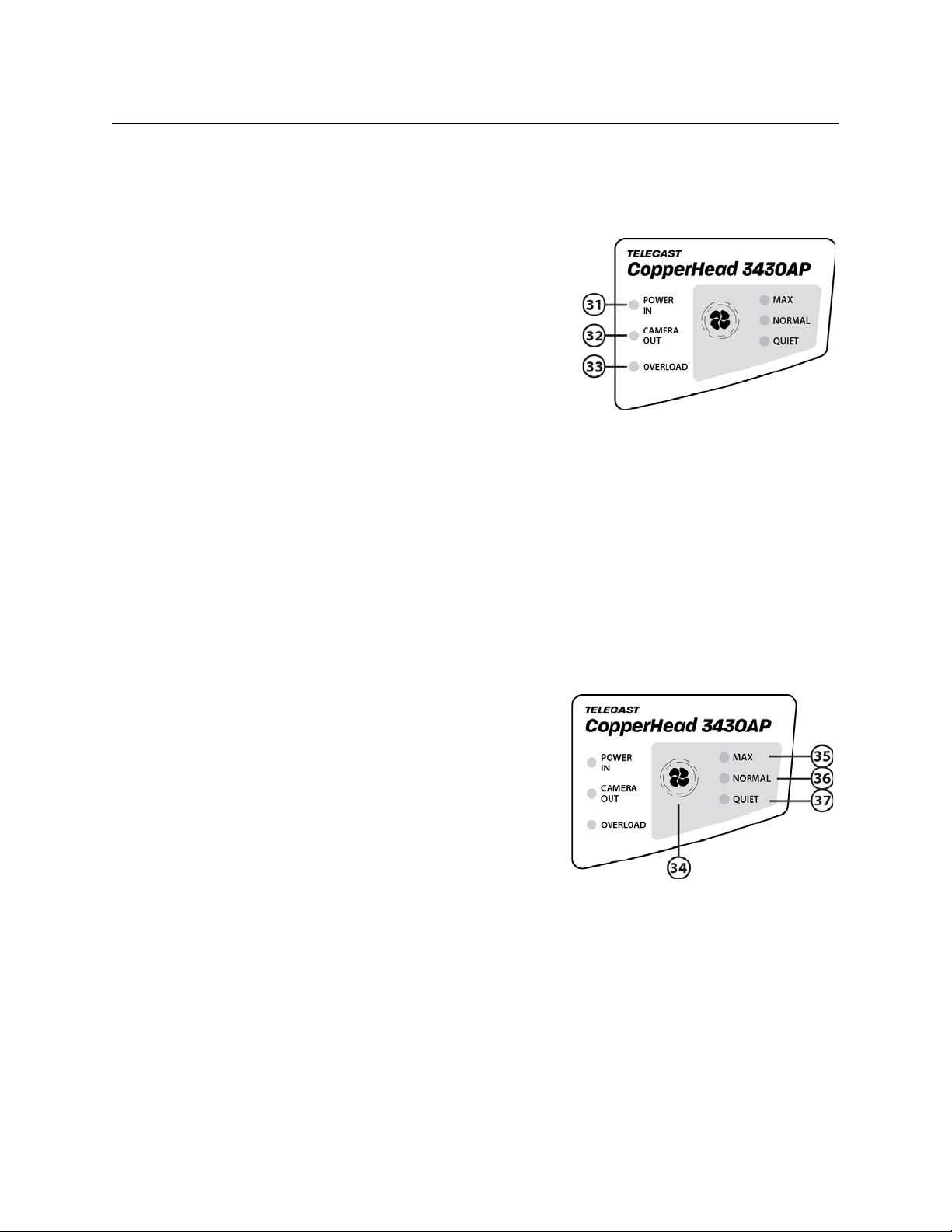

Area I – Power Indicators, and Fan Control Switch and Indicators

Power Indicators

31 POWER IN

• BRIGHT GREEN – CopperHead 3430AP Cam-

era Unit is switched on and the HDX-Plus is

operating at normal voltage

• DIMLY LIT GREEN – CopperHead 3430AP

Camera Unit is switched off and the HDX-Plus

is operating at standby voltage

32 CAMERA OUT

• BRIGHT GREEN – CopperHead 3430AP Cam-

era Unit is switched on and the HDX-Plus is operating at normal voltage. The camera is

receiving normal voltage.

33 OVERLOAD

• BRIGHT RED – Maximum rated power output is reached

• FLASHING RED – Maximum rated power output is exceeded – the CopperHead 3430AP

unit will shut down to protect the system and must be power cycled either at the Camera

Unit or the HDX-Plus to restart the system.

User Manual

Fan Operations

34 Fan Control Switch

Push switch selects between three settings; the

LED corresponding to the selection is illumi

nated:

• MAX – Fan Speed is continuously at maxi-

mum speed

• NORMAL – Fan Speed initially set to lowest

speed and then adjusts based on unit internal temperature – the temperature is never

allowed to be close to the unit maximum

operating temperature.

• QUIET – Similar to NORMAL setting except that the temperature IS allowed to be close to

the unit maximum operating temperature.

35 MAX Indicator

Fan is operating at full speed.

36 NORMAL Indicator

-

Fan is operating in Normal mode and speed increases from minimum speed to full speed

13

Page 26

Detailed System Description

over a temperature range of 55 degrees centigrade to 70 degrees centigrade. Speed

increases more rapidly as unit first begins to increase in temperature.

37 QUIET Indicator

Similar to NORMAL mode except that fan speed increases slowly as unit increases temperature and then more rapidly as the unit approaches maximum allowable temperature.

Fan Diagnostic Mode

The fan switch allows entry into a LED test mode. Push and hold the FAN switch for about five

seconds and the test will begin. At this point all of the LEDs will blink indicating that the fan

system is functioning.

High Temperature Warning

If during regular operation (not the diagnostic mode described above) any of LEDs begin to

blink slowly then the CopperHead unit has reached a temperature of 65 degrees centigrade. If

during regular operation (not the diagnostic mode described above) any of LEDs begin to blink

quickly then the CopperHead unit has reached a temperature of at least 70 degrees centigrade.

If the temperature reaches 70 degrees centigrade confirm that the fan is working correctly in the

unit. If this high temperature is sustained for any period of time damage may occur to the

system. The unit should be turned off and allowed to cool before restarting and the unit should

be checked for malfunction as soon as possible.

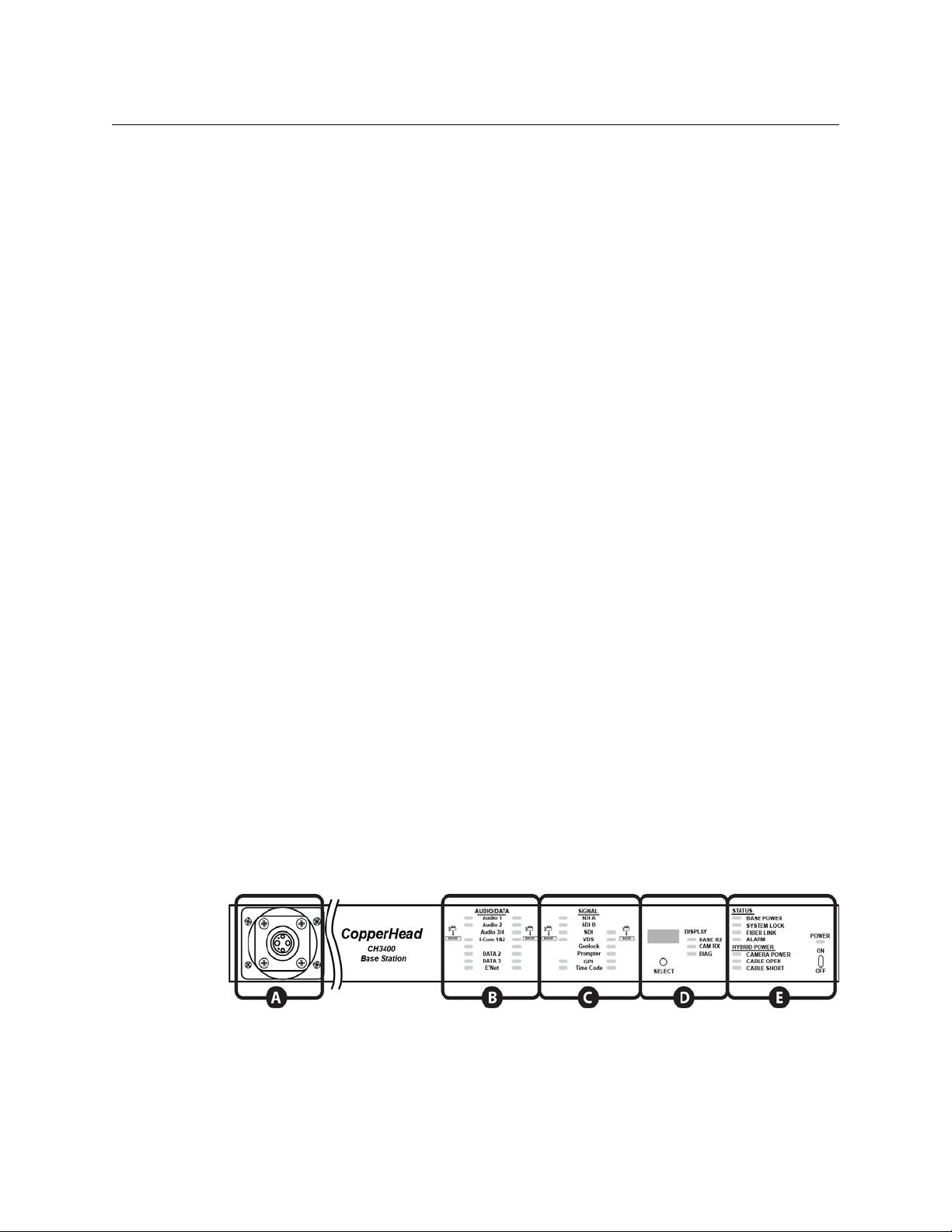

Copperhead 3400 Base Station

The Co pp er h ea d 340 0 Base Station is available with a number of options. The unit is

ordered with a specified Power Module, Audio/Intercom Module and Fiber Connector.

Front Panel

Fig. 2-5: Base Station Front Panel

14

The front panel of the Copperhead 3400 base station has five areas of interest:

Page 27

CopperHead 3430AP

aaaST/UPC

User Manual

A) Optical Connector

See this

Page

B) Audio/Data Indicators

See page 16

C) Video/Data Indicators

See page 16

D) Signal Strength Indicators/Setup

See page 17

E) Status/Power Indicators

See page 17

Area A – Front Panel Optical Connector (Optional)

Area A of the Copperhead 3400 Base Station provides for the optional mounting of the Fiber

Optical Connector on the front of the Base Station instead of the rear of the Base Station. Front

mounting of the optical connectors is normally specified at the time of ordering. Area A is

provided with a blank panel when the normal rear mounting of the fiber connectors is specified.

The Copperhead 3400 Base Station for use with the CopperHead

3430AP Camera Unit is normally delivered with two ST Fiber Optical

connectors for connection to the HDX-Plus power supply.

As noted above existing Copperhead 3400 Base Station units with

other types of connectors can be used with the 3430AP system with

the addition of Fiber Connector jumper cables connecting ST connectors to one of the panel mounted connector types shown below.

Please consult Grass Valleysupport for information regarding the

appropriate jumper cable.

The Copperhead 3400 Base Station may also be equipped with one of these other types of Fiber

Connector. These types of connector are not normally specified for a new CopperHead 3430AP

system.

Neutrik OpticalCOM SMPTE 304M ST/UPC with 5Pin Molex MX

Fig. 2-6: Fiber Connector

Types

15

Page 28

Detailed System Description

Area B – Audio Indicators

LED Indicators to the left side of the label indicate signal paths from the Camera Unit to the

Base Station and right side LEDs indicate signal paths from the Base Station to the Camera Unit.

1 Program Audio Channels

Monitors Return audio from Base Station to Camera

Unit. Channels 3/4 are n/a.

2 I‐Comm (Intercom) Channels 1‐2

Monitors Intercom audio from Camera Unit to

Base Station and from Base Station to Camera Unit

3 DATA 1‐2 Signal

Monitors the serial Data signals to and from Base Station to and from the Camera Unit,

DATA 3 is n/a.

4 E’Net (Ethernet) Signal

Indicates IP Data traffic to and from Camera Unit to and from Base Station

Area C – Video/Data Indicators

5 SDI A‐B

Monitors the 3G/HD/SD-0SDI Dual-Link signals

from the CopperHead 3430AP Camera Unit

6 SDI Digital Video Signal

Monitors SDI return video to the Camera Unit.

7 VBS– Analog Video Signal

Monitors analog Camera video from the Camera Unit to the Base Station and Return video

to the Camera Unit from the Base Station

8 Genlock

N/A for the CopperHead 3430AP system.

9 Prompter

Signals

16

N/A for the CopperHead 3430AP system.

10 GPI

Use the VBS signal path.

Page 29

CopperHead 3430AP

User Manual

Monitors the Tally/GPI signals to and from Base Station and Camera

11 Time

Code

Monitors the house time code from the Base Station to the Camera Unit

Area D – Signal Strength Indicators/Setup

12 Signal Strength Readout in dBm

This display changes between display modes when

selected

13 Readout Function Indicator

BASE RX – Optical Link signal strength received

at Base Station from Camera

CAM RX – Optical Link signal strength received at Camera from Base Station

DIAG – Digital display is in Diagnostic mode

14 Select

Button

Unit

Unit

Chooses between three modes of operation

For details on how the setup/diagnostic functions operate, please see The CopperHead

3400 Base Station Digital Display on page 47.

Area E – Status/Power Indicators

15 Power Switch & Power Indicator

Toggle switch to enable or disable Base Station

power.

LED turns Green when on/off switch is changed to

the ON position.

For an AC-powered base station to be properly powered, the AC Mains switch on the rear

of Base Station must be in the ON position.

16 Hybrid Power Indicators

The Hybrid Power indicators are N/A in the CopperHead 3430AP system

17

Page 30

Detailed System Description

17 Status

Indicators

BASE POWER - indicates the status of all power

levels in the Base

Station

• Green when all power levels are normal.

• Red when any power level is not normal.

SYSTEM LOCK - indicates that the Base

Station is communicating with the Camera Unit.

• Green when communicating with Camera Unit

• Red when it is not communicating with the Camera Unit

Note: Hybrid Power Indicators are present only on an AC-powered base station.

FIBER LINK - indicates the optical power status of the Base

Station and camera

• Green when both the Base Station and camera optical power are within a normal

range.

• Orange when either the Base Station or camera optical power is not within a normal

range

• Red when both the Base Station and camera optical power are not within a normal

range

ALARM - indicates that some error condition exists in either the Base Station or the camera.

• Red if there is a Base Station error. Refer to the Base Station DIAG for details on the

error.

• Orange if there is a camera error. Refer to CAM DIAG for details for the error.

18

Rear Panel

Fig. 2-7: Base Station Rear

The rear panel of the Copperhead 3400 base station has four areas of interest:

A) Power & Fiber Connectors

See page 19.

B) Sync/Data/Control Connectors

See page 20.

Panel

Page 31

CopperHead 3430AP

User Manual

C) Video/Ethernet Connectors

See page 20.

D) Audio/Intercom Connectors

See page 20.

Area A – Power & Fiber Connectors (Power Module)

The Copperhead 3400 Base Station for the CopperHead 3430AP system can be configured with

Internal AC Power or external 12 Volt power. Multi-pin connector wiring suggestions are

covered in the Appendix.

Power

Internal Power

18 AC Power Receptacle and 4AMP Dual Fuse

19 For Future Use3

20 AC Mains Switch

21 ST Connectors & Molex power connector

External Power

22 12V DC External Power Supply input connector

23 12V DC Input – terminal block

Options:

Assembly

100-240V 50/60 Hz

See Page nnn for the Fuse Specification

(XLR 4

Pin)

19

Page 32

Detailed System Description

Area B – Sync/Data/Control Connectors

24 Sync/Black Burst input connector & Loop through

25 Video Prompter input to Camera (N/A for 3430AP)

26 Camera Remote Control Panel Connector

27 Data/GPI Multi‐Pin Connector

28 Time Code In to Camera

29 Time Code Out from Camera (N/A for 3430AP)

Area C - Video/Ethernet Connectors

30 Ethernet connector – 10BaseT/100BaseT

31 VBS Output from Camera

32 VBS Return Video source Input to Camera

33 SDI Program from Camera Unit outputs 1‐2

(N/A for 3430AP)

34 SDI Return Video source Input to Camera

35 3D/HD/SD-SDI Dual‐Link from camera outputs A‐B

Area D – Audio/Intercom Connectors

The Copperhead 3400 Base Station can be configured with one of three different Intercom

options. The connection and practical use of each of these options is covered in Intercom

Usage beginning on page 42. Multi-pin connector wiring is covered in Appendix A.

Four Wire Intercom Module

36 Audio In Multi‐pin connector

37 Audio Out Multi‐pin connector

20

38 Ch‐1 Intercom connector

39 Ch‐2 Intercom connector

Page 33

RTS TW Intercom Module

CopperHead 3430AP

User Manual

40 Intercom

41 Intercom Loop Through

Clear‐Com Intercom Module

42 Ch‐A Intercom Connector

43 Ch‐B intercom Connector

Input

HDX-Plus Power Unit

The HDX-Plus Power Supply Unit is the required standard power supply for the CopperHead

3430AP Transceiver System. The HDX-Plus will supply up to 200 watts at 17 VDC to the CopperHead 3430AP Camera Unit.

Fig. 2-8: HDX-Plus Front Panel

The HDX-Plus has three areas of interest:

A) AC Power module - see page 22

B) Fiber optic connectors - see page 22

C) System indicators - see page 22

21

Page 34

Detailed System Description

Area A - AC Power Module

The HDX-Power Plus can utilize 100-240 VAC (50/60kHz) power. The

system will auto-detect the incoming voltage level

The power switch controls power on/off for the entire CopperHead

3430AP system.

Area B - Fiber Connectors

The HDX-Plus power supply connects to the

Copperhead 3400 base station with a pair of ST

Fiber connectors using Tactical Fiber Optic cable.

The HDX-Plus power supply connects to the

CopperHead 3430AP Camera Unit using SMPTE

304M Hybrid connectors over Hybrid Fiber Optic

cable.

Area C - System Indicators

The HDX-Plus power supply provides two types of

indicators:

• The first group is power and cable integrity

indicators.

• The second group is an Optical Power meter.

Power/Cable Integrity Indicators

This area provides the following LED indicators:

HIGH VOLTAGE

• Yellow when system High Voltage is present

OVER TEMP

• Orange if the HDX-Plus cooling fan fails

• Red if the HDX-Plus senses internal high temperature

• Flashing Red if the HDX-Plus has shut down because of

high temperature

22

Page 35

CopperHead 3430AP

User Manual

AC ON/OVERLOAD

• Green when system normal operations or when the HDX-Plus has AC Power

• Red when the HDX-Plus power supply is overloaded

• Off when switch is off, no AC power or fuse is blown

CABLE FAULT

• Red if a high voltage short or open condition is detected

CAMERA PSU

• Green if the Camera Unit power supply is detected

• Red if the 3430 Camera Unit power supply is shut down due to an overload.

Optical Power Monitoring

The HDX-Plus power supply provides Optical Power monitoring for both the Camera unit and

the Base unit. The metering uses Multi-Colored LEDs with indicators covering a range of -21dBm

to 0 dBm. The CopperHead 3430AP Transceiver system is specified to operate at Optical Power

levels above -22dBm.

The unit has two rows of LEDs:

• Top row indicates the optical power level at

the camera unit

• Bottom row indicate optical power level at

the base station

All of the indicator LEDs are multi-color:

• Green - good power

• Yellow Orange - Marginal power

• Red - Insufficient power.

Note: The CopperHead 3430AP system is, of course, a digital system and therefore the link will

operate properly at the lowest acceptable signal strength. If the signal strength dips

below the minimum acceptable level the link will not operate.

23

Page 36

Detailed System Description

Power Monitoring Scenarios

The following diagrams illustrate operational scenarios in which the Optical Power Indicator

LEDs provide a visual indication of the CopperHead 3430AP fiber optical status.

Thisscenarioisagoodoperationalsituation.The‐

6dBmreflectstypicalsignalstrengthacrossaFiber

Opticcablerun.TheCopperHead3430APsystem

willrunperfectlyatthissignalstrength.

ThisscenarioshowsabadFiberOpticlinkandno

OpticalPowerineitherdirection.Checktoseeif

there

isaproblemwiththeFiberOpticconnection

orcable.

ThisscenarioshowsjustenoughOpticalPower

presenttoprovideanoperationallink.Checkthe

FiberOpticcablerunforpossibledamageorphys‐

icalinterferencesuchassharpbendsinthecable.

AlsochecktheFiberOpticconnectorsfordust,

dirt

ordamage.

ThisscenarioshowslowOpticalPowerbutmore

thanadequateforausablelink.Keepaneyeon

thereadingtomakesureitisconsistent.Check

thecablerunasaboveandchecktheFiberOptic

connectorsfordust,dirtordamage.

24

Page 37

HDX-Plus Power Output and Derating Chart

CopperHead 3430AP

User Manual

25

Page 38

Detailed System Description

26

Page 39

Overview

Installation and Connection

Chapter 3 describes the installation and connection of the CopperHead 3430AP system,

including the Camera Unit and the base station.

Topics

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 27

Mounting the CopperHead 3430AP Camera Unit to the Camera . . . . . . . . . . . . . . . . . . . . . page 27

Connecting the CopperHead 3430AP Transceiver System . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 28

Connections to the CopperHead 3400 Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 30

Connections to the CopperHead 3430AP Camera Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 33

This chapter describes the physical installation of the CopperHead 3430AP Transceiver System.

The following areas are covered:

• Mounting of the CopperHead 3430AP Camera Unit to the camera

• Connecting the three components of the system – The Camera and Camera Unit, the HDX-

Plus Power Supply and the CopperHead 3400 Base Station

• Detailed information for all system connections

Mounting the CopperHead 3430AP Camera Unit to the Camera

This example illustrates the mounting of an Anton Bauer battery system. Your system may

differ.

Fig. 3-1: Mounting the CopperHead 3430AP Camera Unit to the Camera

27

Page 40

Installation and Connection

1 Position your camera so that you can easily access the battery mounting plate at the rear of

the camera. Ensure that the camera is well supported and stable.

2 Attach the CopperHead 3430AP Camera Unit to the camera battery mounting plate. The

mounting is mechanically identical to attaching a battery. See Camera Unit Connections

on page 35 for details of the camera unit-to-camera connections..

For configuration please see Chapter 4.

Connecting the CopperHead 3430AP Transceiver System

Prior to connecting your CopperHead 3430AP Transceiver System please ensure that each of the

required cables is available for use. This includes standard video, audio and data cables as well as

any custom multi‐pin cable sets required for your particular installation. Please see Appendix A

for information regarding cables, signals and custom multi‐pin cable fabrication.

Note that the use of any existing CopperHead 3400 Base Station without ST Fiber Connectors is

not covered in this user guide.

Covered in this chapter are:

1 Overview of connections between the three main system components.

2 Connections between the CopperHead 3400 Base Station and the base video infrastructure &

power components

3 Connections between the CopperHead 3430AP Camera Unit and the video camera & power

components.

Note: The following fiber connection scenario does not take into account any customized cable

and connector installations you may have at your facility. For assistance regarding more

complex connection situations please contact Grass Valley or your local authorized dealer.

28

Page 41

CopperHead 3430AP

User Manual

Connection Overview of the CopperHead 3430AP Transceiver

System

Fig. 3-2: Connection Overview of the CopperHead 3430AP Transceiver System

Between the Base Station (1) and the HDX-Plus Power Supply (4) connect a pair of ST Fiber

Cables (5).

Power the HDX-Plus Power Supply locally by connecting to AC Power. Between the HDX-Plus (4)

and the Camera Unit connect a length of SMPTE Hybrid Fiber Cable (6). Each end of the fiber

cable will have an SMPTE 304M Connector (3).

The Base Station connector (1) may be mounted either on the front or back of the Base Station.

The camera will be powered by the CopperHead 3430AP Camera Unit (2).

The Base Station will be powered by connection to local AC power either directly to the AC

Mains or by use of a 12 VDC external power supply depending on the model of CopperHead

3400 Base Station in use (7).

29

Page 42

Installation and Connection

Connections to the CopperHead 3400 Base Station

Fig. 3-3: CopperHead 3430AP Base Unit Connec

tions

Multi‐Pin Cable Assemblies Used with the CopperHead 3400 Base Station

A Camera Remote Control (Remote) Connector–

Connect either your Camera Remote Control or the Grass Valley Universal

CHRCP-2050A or CHRCP-2050-LCD.

See Appendix B for a list of Grass Valley-supplied cables

B Data/GPI Connector

Connect a Remote Pan/Tilt/Zoom Control Unit and connect to one GPI Out and two GPI

inputs. Usage of GPI/Os other than Tally and Intercom control is outside of the scope of this

User Guide.

Serial Control devices using RS232/422/485 can be controlled over this signal path. See

page 61 for wiring details

CAudio In Connector

Connect Intercom Program Audio and four Production Audio Channel outputs.

See page 61 for wiring details

Controller –

30

Connectors into and out of the CopperHead 3400 Base

This information duplicates some of that from above sections. It is presented here to provide a

single list of all Base Station connections. . Connectors that are present on the CopperHead 3400

Station

Page 43

CopperHead 3430AP

User Manual

Base Station but not used in the camera configuration are noted as Not Available (NA). Key

numbers refer to the diagram above.

1 & 21

Power In

Connect a standard 3 conductor AC Cable (IEC

Plug) 100-240V 50/60 Hz

standard or a 12V

DC ADAP power source (4 Pin)

4 Fiber Connector

(This connector can be mounted on the Base Station Front Panel – see page 15)

Connect the ST fiber connectors from the HDX-Plus power saupply.

5Sync In/Loop

BNC Connector – standard Genlock/Sync/Tri-Level sync signal. The loop-through is self-terminating.

6Prompter In

N/A in 3430AP configuration

7Time Code In

BNC Connector – Standard time code signal sent to camera – typically originating from a

“

house” time

primary camera may be used

base station via connector 8 and then be

ated Copperhead Base Stations

8Time Code Out

code generator feed available at the Base Station. On remote productions the

to originate the system time code feed (signal would return to

distributed to other cameras through the associ-

N/A in 3430AP configuration.

9Multi‐Pin Connector A

DB9 – 9 pin serial connector connected to an optional Camera Remote Control Panel

Power to the Base Unit (and the Camera Unit & Camera) must be turned

off when connecting the Camera Remote Control Panel – connecting with

th

e power on can seriously damage your equipment.

10 Multi‐Pin Connector B

DB15 – 15 pin serial connector connected to a breakout of Tally and GPI signal connectors.

T

ypically this connector will be connected to the Camera Tally system originating at the

Production Switcher or

ment. Additional custom GPI contact closures can be configured.

See page 66 for a typical configuration.

11 Ethernet Connector – 10Bt/100Bt capable

Designed to carry IP traffic data between the

PC or other

device such as a Wireless Access Point can be connected to the Production Envi-

the Tally Management system used in your production environ-

Base Station and the Camera Unit. A laptop

31

Page 44

Installation and Connection

ronment IP network.

12 VBS Out

BNC Connector -Typically used for SD Monitoring Video return from the Camera

13 VBS In

BNC Connector – Typically used to send SD return video to the camera – an example is

monitor out from the production switcher. Also used for Prompter feed.

14 SDI Out 1 & 2 (this carries the HD feed (not the 3D/Dual Link) from the camera)

N/A in 3430AP configuration.

15 SDI In

BNC Connector – Typically used to send HD return video to the camera – an example is program out

SDI Out A & B (this carries the dual 3D/Dual Link signals from the camera)

16

BNC Connectors

from the Production Switcher

17 Audio In ‐ Multi‐Pin Connector

DB25 – 25 pin Connector follows the Tascam TDIF standard. The CopperHead 3430AP

Transcei ver

handles return audio

Page 93 for sample wiring.

18 Audio Out ‐ Multi‐Pin Connector

DB25 – 25 pin Connector follows the Tascam TDIF standard. The CopperHead 3430AP

Transcei ver

nector handles return

19 & 20 Intercom Connectors #1 & #2

XLR 3 pin or 5 pin Connector depending on configuration. One of three options will be

installed

each

22 12V Termiinal Block

Terminal Block – bare wire connector. This can be used in place of the ADAP power connection in installations that have 12V power distributed as part of their infrastructure. Do not

use this at the same time as the ADAP power connection.

23 12V Terminal Block

System accommodates up to two Audio Channels at Line Level. This connector

to the Camera location as well as intercom Program Audio. Please see

System accommodates up to two Audio Channels at Line Level. This con

audio to the Camera location. Please see Page 94 for sample wiring.

(4-wire intercom, RTS or Clear-Com). Please see Chapter 6 for information on using

of the Intercom Options

.

-

32

Terminal Block – bare wire connector. This can be used in place of the ADAP power connection in

not use this at the same

installations that have 12V power distributed as part of their infrastructure. Do

time as the ADAP power connection (21).

Page 45

CopperHead 3430AP

Connections to the CopperHead 3430AP Camera Unit

User Manual

Fig. 3-4: CopperHead 3430AP Camera Unit Back Side Connections

This information duplicates some of that from above sections. It is presented here to provide a

single list of all Camera Unit connections. Key numbers refer to the diagram above.

Multi‐Pin Cable Assemblies Used with the CopperHead 3430AP Camera Unit

A) Camera Remote Control (Remote) Connector

Connect this to the CCU input on your camera. The Grass Valley-supplied cable has a red

sleeve at the end to be connected to the CopperHead 3430AP Camera Unit.

See Appendix B for a list of Grass Valley supplied cables.

B) Data/GPI /Tally Connector

This connector carries a number of control, GPI and Tally signals.

See page 63 for wiring details

33

Page 46

Installation and Connection

Connectors into and out of the CopperHead 3430AP Camera Unit Back Side

1 3G/HD/SD Dual Link Inputs

BNC Connectors – Carries 3D/Dual Link camera video from the Camera(s) to the Camera

Unit. This requires BNC jumper cables between the Camera Unit and the Camera (s).

2 HD/SD - SDI Output

BNC Connector – Carries return video from the Base Station to the Camera Unit. Typically

this will feed a camera viewfinder or an HD viewing monitor at the camera location.

3 VBS In

BNC Connector – Carries SD Analog video from the Camera to the Camera Unit. This requires

a short BNC jumper cable between the Camera Unit and the Camera. Can be used to pro

vide technical monitoring from camera as with superimposed camera menus and other

information.

4 VBS Out

BNC Connector – Carries SD Analog video from the Base Station the Camera Unit. Typically

this will feed an analog viewing monitor or prompter at the camera location.

5 Ethernet Out

-

RJ45 Connector – Carries IP Data. Typically connects to a Laptop computer or perhaps a

wireless access point at the camera location. Any IP traffic controlled equipment can be han

dled through this signal path.

6 Fiber Connector

Swivel Mounted SMPTE 304M Fiber Optic Cable receptacle.

7 Time Code Out

BNC Connector – Carries Time Code signal from the Camera Unit to the Camera. This is master time code from the Base Station. This requires a short BNC jumper cable between the

Camera Unit and the Camera.

8 Aux Power Output

XLR 4 Pin Female Connector – Provides 17 VDC power to accessories on or near the camera.

Insure that the total power consumption of 30 watts is not exceeded.

9 Audio 1 & 2 Out

XLR 5 Pin Male Connector – Provides Return Audio Out from camera for Channels 1 & 2. Typically connected to a local monitor at the camera position.

10 Intercom Headset Out

XLR 5 Pin Female Connector – Provides two channels of two-way intercom and the Intercom

Program audio feed

11 Data Connector

-

34

Multi-Pin Connector B – DB15 15 Pin Serial Connector. This carries serial control signals for

lens and remote pan & tilt units as well as GPI, Intercom Trigger (GPI) and Tally signals.

Miranda Technologies Inc. supplies a number of pre-configured breakout cables for use

Page 47

CopperHead 3430AP

User Manual

with this connector. See Appendix B for details of available cables.

12 Camera Remote Connector

Multi-Pin Connector A– 10 Pin Hirose Connector. This is normally a Grass Valley supplied

ca

ble. It connects the Camera Unit to the Camera CCU in to allow operation of the Camera

Remote Control Panel. See Appendix B for details of available cables.

Power to the Camera Unit & Camera must be turned off when connecting the

Camera Remote Control Panel Cable– connecting with the power on can seriously damage your equipment.

Camera Unit Connections

The following diagrams show example connections between the CopperHead 3430AP Camera

Unit and the Camera. Your setup may not require all connections shown.

Camera Unit (Side and Front Panel Connectors) to Camera Connections

Fig. 3-5: CameraUnittoCameraConnections(SideandFrontPanelConnectors)

35

Page 48

Installation and Connection

Camera Unit (Rear Panel Connectors) to Camera Connections

Fig. 3-6: Camera Unit to Camera Connections (Rear Panel Connectors)

36

Page 49

Operation

Chapter 4 describes the set-up and operation of the CopperHead 3430AP transceiver system.

Topics

Operation of the CopperHead 3430AP Transceiver System . . . . . . . . . . . . . . . . . . . . . . . . . . . page 37

Set Up of the CopperHead 3430AP Transceiver System for Operation . . . . . . . . . . . . . . . . page 38

Connecting and Managing the Fiber Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 38

Powering the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 40

Intercom Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 42

Using the Digital Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 46

The CopperHead 3400 Base Station Digital Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 47

The CopperHead 3430AP Camera Unit Digital Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 51

Standard Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 53

Shutting Down the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 53

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 54

Operation of the CopperHead 3430AP Transceiver System

This chapter describes in detail the operation of CopperHead 3430AP Transceiver System.

Please keep in mind that a wide variety of options and variations are available in using this

product and so not every possible operational environment can be described.

The following topics are covered:

1 Set up of the CopperHead 3430AP Transceiver System

2 Connecting and Managing the Fiber Cable

3 Connecting the Fiber Cable

4 Powering the System

5 Understanding Intercom usage with the CopperHead 3430AP

6 Using the Digital Displays

7 Standard Operation

8 Shutting Down the System

9 Troubleshooting

37

Page 50

Operation

Operation of the CopperHead 3430AP Transceiver System

Set Up of the CopperHead 3430AP Transceiver System for Operation

This section provides an overview of setup of the CopperHead 3430AP Transceiver System for

operation. The following sections provide additional detail on each aspect of setup and

operation.

It is important that you do an initial setup and test of your CopperHead 3430AP Transceiver

System as soon as your receive it, in order to confirm proper operation and to provide training to

you and your team

Use the following list of items as an overall checklist for setup.

1 It is highly recommended that you do not attempt to power up the system until all con-

nections are made and in particular the Fiber Optic Cable has been connected at both

ends. If you need to power up either the CopperHead 3400 Base Station or the CopperHead 3430AP Camera Unit, make sure that the Fiber Connectors are securely capped. This

will protect them from damage or dirt and protect you from eye damage.

Make sure to connect the Camera Remote Control cable to the Base Station and Remote

Control Panel when the Base Station power is turned off.

2 When setting up the CopperHead 3430AP Camera Unit and associated Camera you will

need to do the following:

a. Make sure all cables running between the CopperHead 3400 base station and the HDX-

Plus power supply and local AC power cords are properly managed and secured..

b. Mount the camera and CopperHead 3430AP Camera Unit as shown on Page nnn

c. Connect all required cables according to Chapter 3. The order in which you connect

the cables makes no difference. BUT...

d. Turn OFF the camera power before connecting the camera remote control cable to the

camera unit and camera.

e. Set up the intercom talk back switches and level controls as desired. Please see Inter-

com Usage on page 42 for details on Intercom operation with the CopperHead 3430AP

Camera Unit.

3 Deploy the Fiber Cable (see the next section) – you are now ready to power up the system.

prior to

an actual production.

Connecting and Managing the Fiber Cable

Connecting and managing the Fiber Cable between the CopperHead 3430AP Camera Unit and

CopperHead 3400 base station or an intermediate power supply requires you to perform four

tasks:

1 Plan the route the Fiber Cable will take between the Camera Unit and HDX-Plus power sup-

ply, and the Base Station and power supply

2 Run the Fiber Cable along the planned route

3 Connect the Fiber Cable Connectors at each end

38

Page 51

CopperHead 3430AP

User Manual

4 Power up the HDX-plus power supply, the Camera Unit and the Base Station, and check the

Fiber Optic Cable Link and signal strength

Planning the Fiber Cable

Obviously the longer the planned cable run the more planning required. It also makes a difference whether you are running Tactical Fiber Cable or Hybrid Fiber Cable as these affect both the

length and the type of exposure the cable can endure.

When planning your cable route take into the consideration the following:

1 Possible obstacles that might cause you to run short of cable – you may need to take a

more indirect, but achievable route

2 Possible hazards to the cable – while tactical fiber is extremely durable it is not immune to

damage. An obvious hazard is running the cable across a lawn scheduled to be cut during

your live production. Make sure the empty roadway at 6AM will not be filled with heavy

equipment when it comes time to retrieve your cable

3 Possible interference (physical) with the cable that might cause it to bend or kink to an

extent that unacceptable signal loss occurs.

4 Safety hazards – make sure that the cable will not cause a tripping or tangling hazard

with people, animals or vehicles.

5 Decide whether the Fiber Cable is to be unspooled from the Base Station location or the

Camera location. Typically the reel is kept close to the base station. However if there is a

chance the Camera location may need to move further away from the Base Station after initial placement it makes sense to place the reel at the camera end. Make sure there is

enough free cable coming out of the stationary end of the cable reel to accommodate a

well‐managed connection to the camera.

Route

Planning the cable route requires common sense and the ability to foresee the unforeseen.

Running the Fiber

Do the following when running your Fiber Cable:

1 Make sure that both ends of the Fiber Cable are securely capped. In this case the concern is

dirt and damage. ANY dirt in the connector can adversely affect Fiber Optical performance

and potentially cause you to lose the use of your camera while the problem is diagnosed

and remedied.

2 If the cable run is long or if you will lose sight of the spooling out cable reel make sure you

have appropriate assistance in running out the cable. When retrieving the cable, assistance to prevent the cable end from being caught or tangled up could be critical. Don’t

start reeling in the cable on your own and assume the Connector end will make it back to

home base safely.

3 When unspooling the cable ALWAYS make sure the stationary end (the end that goes to

the Base Station or Power Supply) us securely contained within the reel. A loose Connector

can bang around and be damaged and NEVER connect the stationary end of the Fiber

Cable

39

Page 52

Operation

Operation of the CopperHead 3430AP Transceiver System

Cable to the Base Station or Power Supply and the start unspooling the Fiber Cable. Severe

damage to the cable could occur due to extreme spiraling of the connected portion of the

cable.

4 Prior to connecting the Fiber Connectors to the Base Station and Camera Unit inspect both

connectors. If required, clean with dry compressed air or with technical wipes that have

been moistened with isopropyl alcohol. Fingerprints or other dirt on the optical connector

end surfaces will reduce the optical signal level on the fiber. If the connectors have been

properly capped during storage and movement you will not likely have a problem.

However if a connector has been dropped or dragged through dirt or exposed to dust

cleaning is recommended.

5 Once the Fiber Cable has been connected it is time to secure the Fiber Cable run. Make

sure there are no cable hazards in the run. Secure the cable with cable guards and/or gaffers

tape to insure safety.

6 Now the system can be powered on. Plugging in Fiber Cable connectors with the power

on will not damage the system but is not recommended because of the chance of possible

eye damage.

7 When re‐spooling the Fiber Cable on to the spool, guide it across the entire width of the

spool so that it winds evenly and the possibility of cinching or kinks is greatly reduced.

Powering the System

The CopperHead 3400 Base Station and the CopperHead 3430AP Camera Unit each have

a power up routine which tests the equipment and performs a system diagnostic.

40

Page 53

CopperHead 3430AP

User Manual

Powering the CopperHead 3400 Base Station

Base Station Main Power 1 Turn on the Base Station Power Mains Switch located at the

rear left (when

overall diagram. This switch is only on Base Station units with

internal power. The front panel power light will come on and be

red until the next step.

facing the back of the Base Station) #3 on the

Base Station Power

Four Character Display

LED Indicator

progression

REV display

Scrolling

PAU S E

Diagnostics

Current Status Displayed

Turn on the Front Panel Power Switch located at the front

2

right. #15 on the

turns from red to green.

The 4 character display indicates TEST and all front panel

3

LEDs turn red, then green, then orange, then off.

The LED color test is followed by REV and the revision of

4

the display

The REV indication is followed by “miranda.com” scrolling

5

across

the 4 character display. If there's no scrolling, please

contact Grass Valley - A Belden Brand support for assistance.

The scroll is followed by about a 3 second interval used to

6

synchronize all

The front panel will cycle through the diagnostics displays –

7

See Section 6.5

After the 3 second pause, all the front panel displays update

8

with current

the camera- related status lights will show red.

overall diagram. The power monitor indicator

microcontroller firmware.

the microcontrollers in the base station

status. If the Camera Unit is not powered on

Powering the CopperHead 3430AP Camera Unit