Page 1

2031RDA-SM/-MM

SINGLE/MULTI MODE SD RECLOCKING REAR DA

Instruction Manual

SOFTWARE VERSION 1.0.0

071831800

SEPTEMBER 2005

Page 2

Contacting Grass Valley

Region Voice Fax Address Web Site

North America (800) 547-8949

Support: 530-478-4148

Pacific Operations +852-2585-6688

Support: 852-2585-6579

U.K., Asia, Middle East +44 1753 218 777 +44 1753 218 757

France +33 1 45 29 73 00

Germany, Europe +49 6150 104 782 +49 6150 104 223

Copyright © Thomson Broadcast and Media Solutions All rights reserved.

Grass Valley Web Site

Sales: (530) 478-3347

Support: (530) 478-3181

+852-2802-2996

Grass Valley

P.O. Box 599000

Nevada City, CA 959597900 USA

www.thomsongrassvalley.com

The www

Online User Documentation

.thomsongrassvalley.com web site offers the following:

— Current versions of product catalogs, brochures,

data sheets, ordering guides, planning guides, manuals, and release notes

in .pdf format can be downloaded.

FAQ Database

— Solutions to problems and troubleshooting efforts can be

found by searching our Frequently Asked Questions (FAQ) database.

Software Downloads

— Software updates, drivers, and patches can be down-

loaded.

2 2031RDA-SM/-MM Instruction Manual

Page 3

Contents

Preface

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2031RDA-SM/-MM Single/Multi Mode Fiber SD Reclocking Rear DA

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Module Placement in the Kameleon Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Electrical Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Electrical Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fiber Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fiber Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation Indicator LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Configuration and Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Configuration Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Local On-board Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Local or Local/Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Auto/270 Mb/Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Fiber TX Enable/Disable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Fiber or Electrical Input Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Remote Configuration and Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2000NET Module Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Newton Control Panel Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Web Browser Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2031RDA-SM/-MM Links and Web Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Status Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Settings Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Recall Factory Defaults Web Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Slot Config Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Software Update Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Status Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Frame Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Web Browser Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

SNMP Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Power-up Diagnostics Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Module Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Input Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2031RDA-SM/-MM Instruction Manual 3

Page 4

Contents

Microprocessor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Output Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4 2031RDA-SM/-MM Instruction Manual

Page 5

Preface

About This Manual

This manual describes the features of a specific 2000 Series module in the

Kameleon Media Processing System. As part of this module family, it is

subject to Safety and Regulatory Compliance described in the 2000 Series

frame and power supply documentation (see the Kameleon 2000 Series

Frames Instruction Manual ).

2031RDA-SM/-MM Instruction Manual 5

Page 6

Preface

6 2031RDA-SM/-MM Instruction Manual

Page 7

2031RDA-SM/-MM Single/Multi Mode Fiber SD Reclocking Rear DA

Introduction

The 2031RDA-SM (Single)/-MM (Multi) Mode SD Reclocking Rear DA

provides reclocking and distribution of one electrical or optical SDI input

to eight electrical outputs and one optical output. Two module versions are

available supporting either a single or multimode fiber input and output.

The single module resides in any rear slot of a Kameleon 2000 Series frame

and is independent of any front card for operation.

The module is designed to be used as an optical to electrical converter, an

electrical to optical converter, or a distribution amplifier for standard definition serial digital video.

The features of the 2031RDA-SM/-MM include:

• Eight reclocked electrical BNC outputs,

• Single or multi-mode fiber input and output interface,

• Hot-swappable in the Kameleon 2000 frame,

• Ideal for monitoring or distributing reclocked signals from adjacent

2000 modules, and

• NetConfig and NetCentral support, and

• Remote control and monitoring support including the Newton Control

Panel interface.

2031RDA-SM/-MM Instruction Manual 7

Page 8

Installation

Installation

Module Placement in the Kameleon Frame

1.

Installation of the 2031RDA-SM/-MM module is a process of:

• Placing the module in a rear frame slot, and

• Cabling signal ports.

The 2031RDA-SM/-MM module can be plugged in and removed from a

Kameleon 2000 Series frame with power on. When power is applied to the

module, LED indicators reflect the initialization process (see Power Up on

page 11).

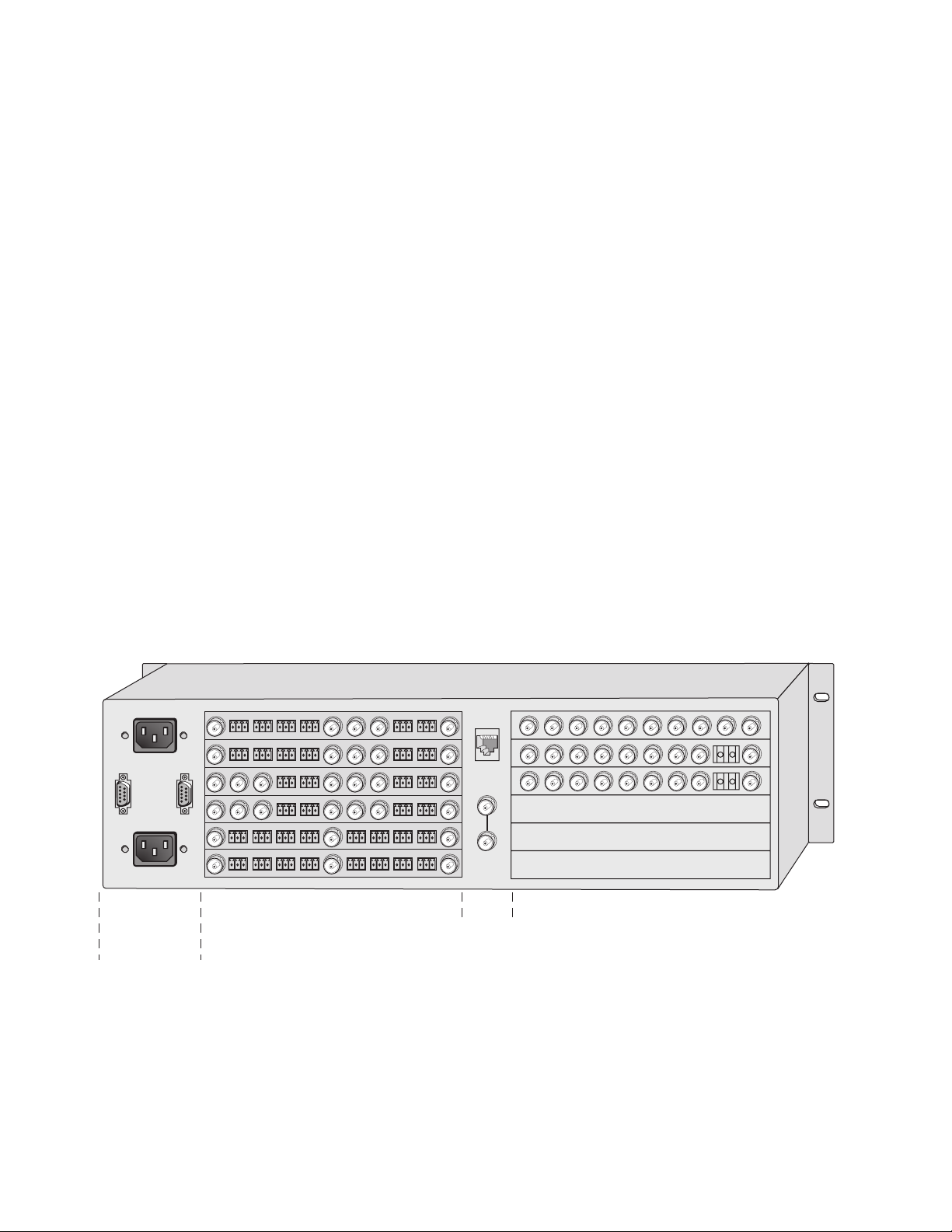

There are twelve slot locations in the both the front and rear of a 3 RU frame

and four slot locations in a 1 RU frame to accommodate 2000 and Kameleon

Series media modules (audio/video signal handling modules).

The 2031RDA-SM/-MM rear module plugs into any one of the rear slots of

the Kameleon 2000 frame.

Power, frame

configuration,

& frame health

connections

To install a 2031RDA-SM/-MM rear module in a 2000 Series frame:

Locate a vacant slot in the rear of the 3 RU frame (Figure 1) or the

2000T1DNG frame (Figure 2 on page 9).

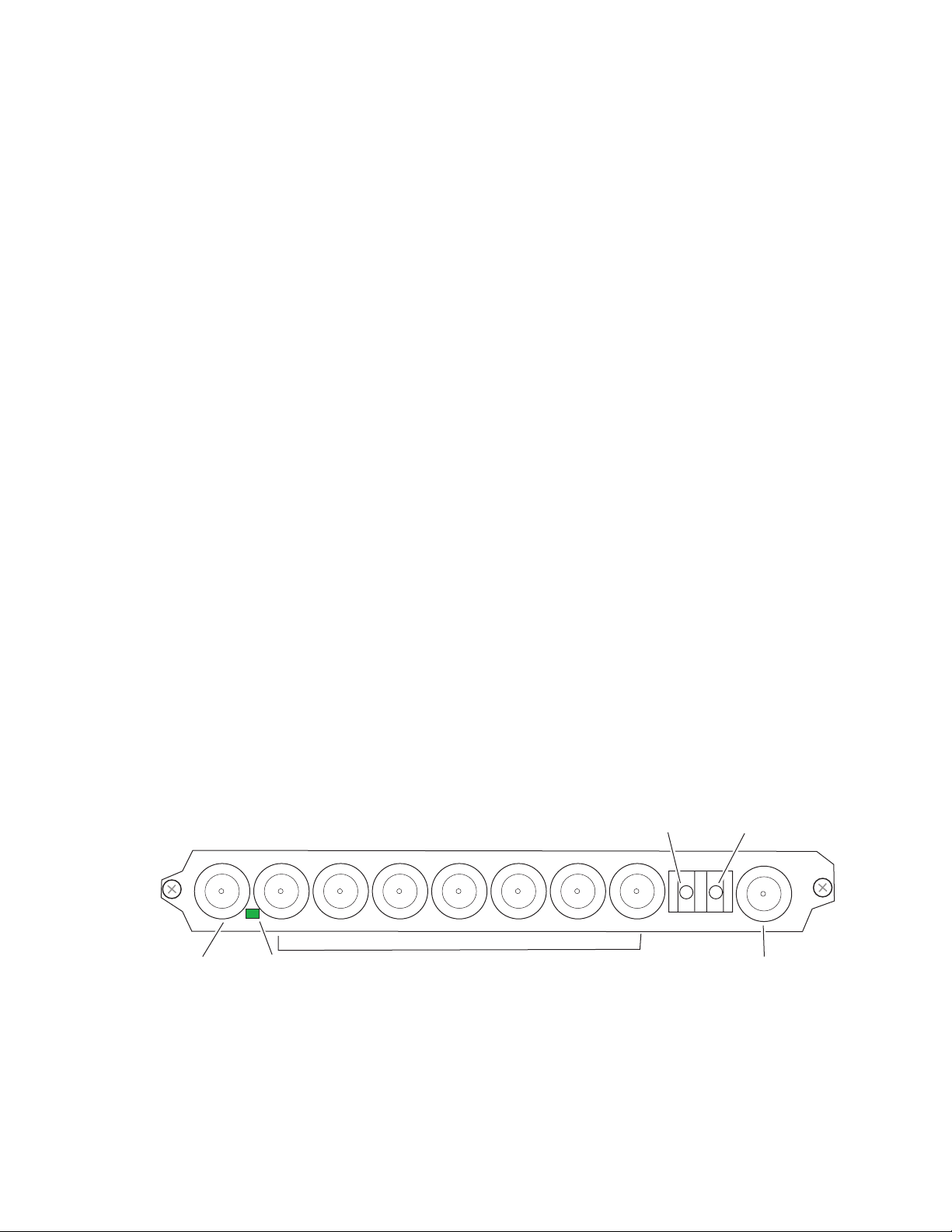

Figure 1. 2000T3NG Frame, Rear View

Media section

rear slots 7-12

Network

and reference

input connections

Media section

rear slots 1-6

(with three 2000EMI blanks)

8318_08

8 2031RDA-SM/-MM Instruction Manual

Page 9

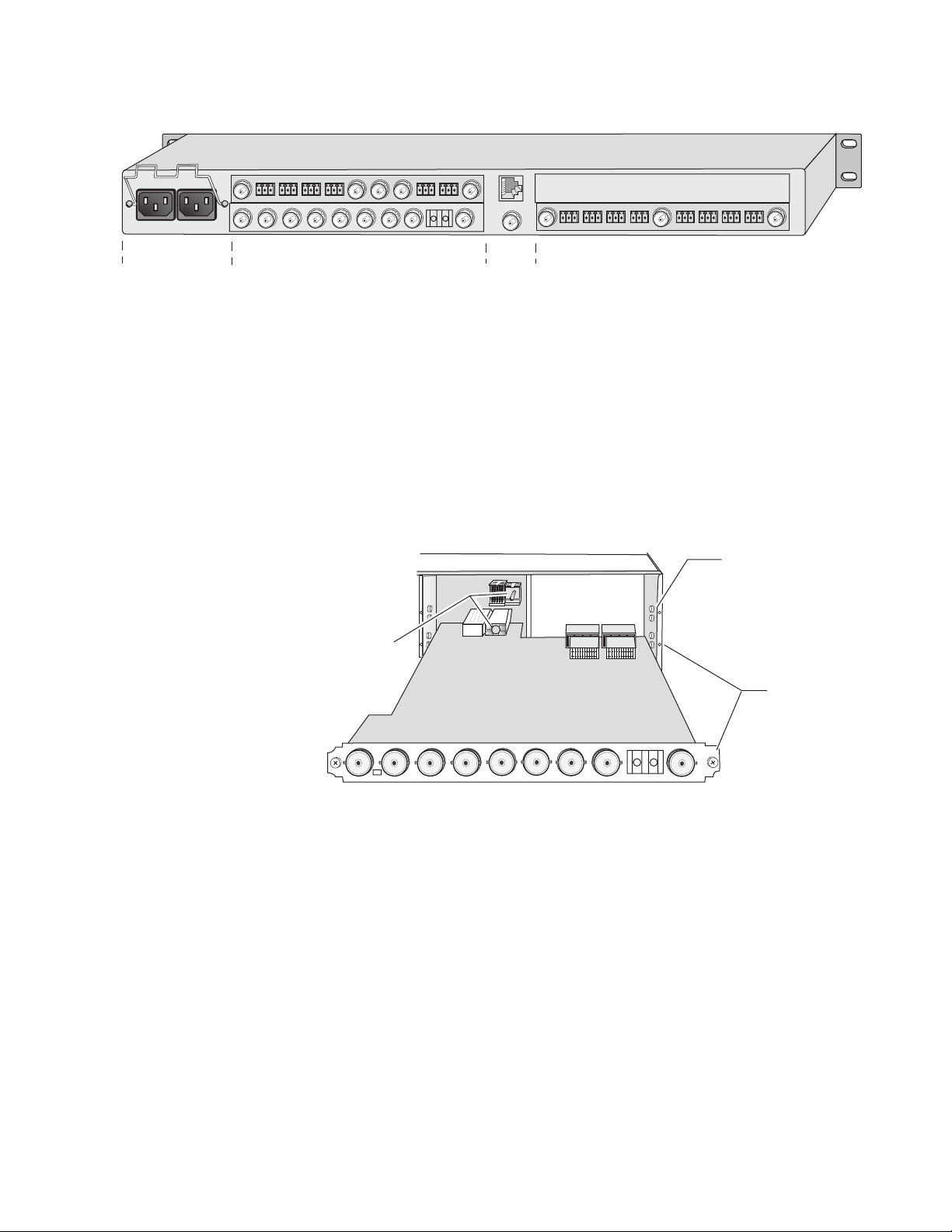

2.

Figure 2. 2000T1DNG Frame, Rear View

1

3

J101

J102

2

4

3.

4.

Installation

Power connections

Media section

rear slots 3-4

Network

and reference

Media section

rear slots 1-2

(with one 2000EMI blank)

input connections

Install the module by inserting it into any rear slot of the frame as

illustrated in Figure 3.

Verify that the module connector seats properly against the midplane.

Secure the module to the rear of the frame with the two screw locks on

either side of the back panel using a crossblade screwdriver.

Figure 3. Installing 2031RDA-SM/-MM Module

2000 frame (rear view)

Alignment post

and receptacle

Board edge guides

(both sides)

Screw lock

(both sides)

8318_09

IN

J9

J10

SIG

J8 J6J7 J5 J4

FIBER IF

J3

2031RDA

-MM

J2

J1

INOUT

8318_01

2031RDA-SM/-MM Instruction Manual 9

Page 10

Installation

Cabling

Cabling to the 2031RDA-SM/-MM module is done on the BNCs and the

fiber connector on the rear of the module. Refer to Figure 4 for a detailed

illustration of the rear connections referenced below.

The input can be either electrical or fiber optic and the desired input must

be enabled using an on-board jumper or with remote controls. The outputs

can be both electrical and fiber optic. The fiber optic output must be

enabled using an on-board jumper or remote controls.

For configuration, refer to Configuration and Monitoring on page 13.

Electrical Input

Connect an SDI electrical video input to BNC J10. This input must be

enabled for use during configuration.

Electrical Outputs

Fiber Input

Fiber Output

IN OUT

J10

SDI In

SIG

SIG LED

Connect electrical video destinations to any of the eight outputs at connectors J1, J3– J9. Terminate any unused outputs. These outputs are always

active and do not need to be enabled.

Connect a fiber input to the right side of the FIBER IF connector J2. This

input must be enabled for use in configuration.

The fiber output is available on the left side of the FIBER IF connector J2.

This output must be enabled for use in configuration.

Figure 4. 2031RDA-SM/-MM Input/Output Connectors

FIBER IF

INOUT

Fiber In

2031RDA

-MM

J2 J1

SDI Out 1

Fiber Out

OUT OUT OUT OUT OUT OUT OUT

J9

J8

J7

SDI Out 2-8

J6

J5

J4

J3

8318_02

10 2031RDA-SM/-MM Instruction Manual

Page 11

Power Up

Operation Indicator LEDs

(green on rear

The on-board LED indicators are illustrated in Figure 5 on page 12. Upon

power-up, the green PWR LED should light and the yellow CONF LED

should illuminate for the duration of module initialization.

With a valid input signal connected, the green on-board PWR LED and the

SIG LED (visible from the rear) should be on. A red FAULT LED indicates

an error situation and, when noted with the other indicator LEDs, can indicate a specific problem area. Table 1 describes signal output and LED indi-

cations for the various combinations.

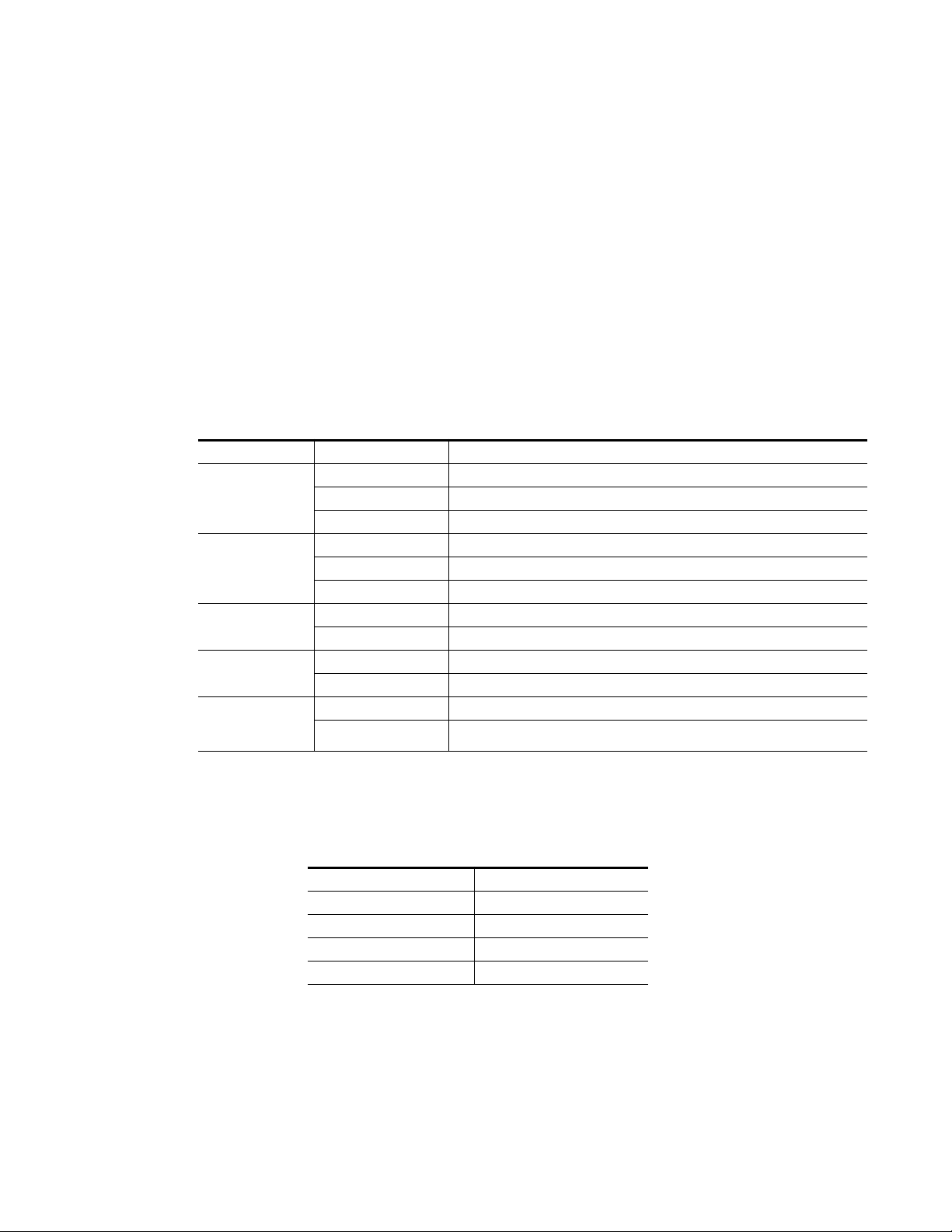

Table 1. Indicator LEDs and Conditions Indicated

LED Indication Condition

FAULT

(red)

COMM

(yellow)

CONF

(yellow)

PWR

(green)

SIG PRES

of module)

Off Normal operation

On continuously Module has detected internal fault.

Long flash No input signal or input signal does not meet selected standard.

Off No activity on frame communication bus.

Long flash Location command received by the module from a remote control system.

Short flash Activity present on the frame communication bus.

Off Module is in normal operating mode.

Short flash Module is initializing, changing operating modes or updating firmware.

Off No power to module or module’s DC/DC converter failed.

On Normal operation, module is powered.

Off Carrier input signal is present at either the coax or fiber optic input.

On No carrier input signal is present at either the coax or fiber optic input.

Power Up

Table 2 provides the possible input and output conditions that result from

different input signals and conditions.

Table 2. Input and Output Conditions

Input Condition Output Condition

Serial Digital Component (SDI) Serial Digital Component (SDI)

Other carrier Other carrier

No input Muted

Cable exceeding 200 meters Muted

2031RDA-SM/-MM Instruction Manual 11

Page 12

Power Up

FAULT COMM CONF PWR

OVER

SEL

REM

FIBER

CD

M1

SEE TABLE 1

SEE TABLE 2

DR2 DR0

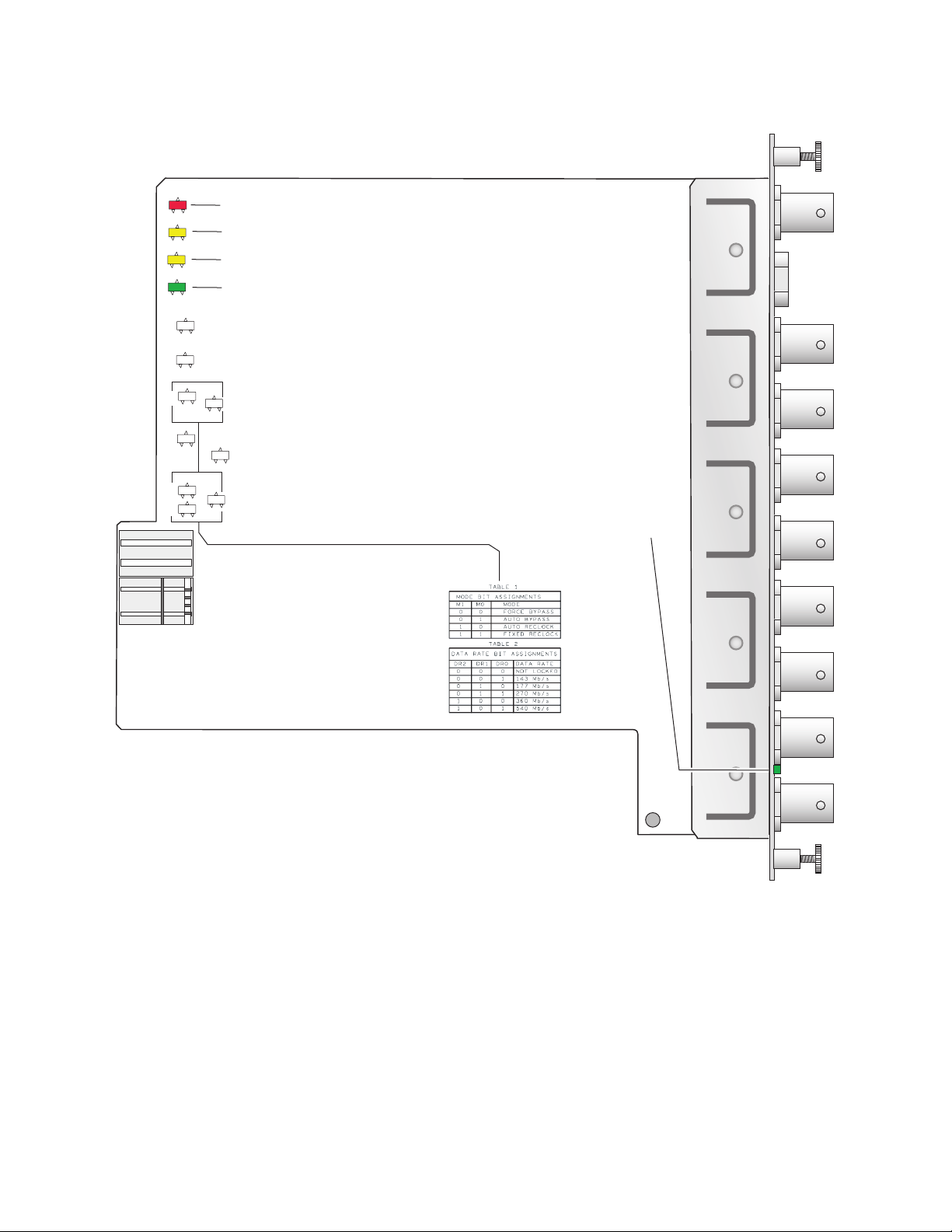

Figure 5. LEDs and Configuration Switches

FAULT– (red) off during normal operation

COMM – (yellow)

CONF – (yellow)

PWR – (green) on during normal operation

M0

LD

DR1

Signal present – (green) on rear connector plate

8318_04

12 2031RDA-SM/-MM Instruction Manual

Page 13

Configuration and Monitoring

The 2031RDA-SM/-MM can be configured locally using on-board switches

or remotely using the 2000NET network interface GUI or a Newton Control

Panel. Operation of these control types is explained in detail in their respective sections of this manual.

Configuration and Monitoring

Note

Not all available functions are configurable with the local on-board controls.

Refer to the following sections for configuration instructions:

• Configuration Summary (page 13)

• Local On-board Configuration (page 14)

• Remote Configuration and Monitoring (page 16)

Configuration Summary

The configuration parameters and monitoring functions available with the

local on-board jumpers, web browser interface, and the Newton Control

Panel are summarized in Table 3. The parameter defaults, choices, ranges,

and resolution are provided for each function.

Table 3. Summary of 2031RDA-SM/-MM Configuration Functions

Function

Type

Input

Mode

Optic Tx Enabled or Disabled

Recall factory

defaults

1

Newton Control Panel operation for this module requires a 2000NET module running version 4.0.0 or later in the frame.

Default

Reverts to on-board

jumper settings

– See Default column

Range/Choices

Resolution

Coax or Fiber

Bypass

Auto

Auto Reclock

Manual 143M

Manual 177M

Manual 270M

Manual 360M

Manual 540M

Web Page/

Function Name

Settings/

Input pulldown

Settings/

Mode Pulldown

Settings/

Optic TX pulldown

Recall Factory Defaults

Recall Factory

Defaults

button

On-Board Jumper

Setting

J112 pins 1-2 = Electrical Input

J112 pins 2-3 = Fiber Input

J106 pins 1-2 = AUTO

J106 pin 2 only =270 Mb

J106 pins 2-3 = BYPASS

J110 pins 1-2 = Fiber Tx En

J110 pins 2-3 = Fiber Tx Dis

Newton

Control

Panel

InpSel

Mode

OpticTx

N/A N/A

1

2031RDA-SM/-MM Instruction Manual 13

Page 14

Configuration and Monitoring

Local On-board Configuration

Jumpers are provided on the module for setting the following functions in

local mode:

• Local or Local/Remote control

• Auto/270 Mb/Bypass mode

• Fiber Tx enable/disable

• Fiber Input or Electrical Input enable

Refer to Figure 6 on page 15 for jumper locations.

Local or Local/Remote Control

Set jumper J107 to LOCAL (pins 1-2) to lock out remote control or LOCAL

& REMOTE (pins 2-3) for both local and remote control.

Auto/270 Mb/Bypass

Set jumper J106 for AUTO (pins 1-2) to enable auto reclocking (for signal

data rates of 143 Mb/s, 177 Mb/s, 270 Mb/s, or 360 Mb/s), 270 Mb

reclocking only (jumper pin 2 only), or BYPASS (pins 2-3) to bypass

reclocking (for signals with data rates of 50 Mb/s to 540 Mb/s).

Fiber TX Enable/Disable

Set jumper J110 to FIBER TX EN (pins 1-2) to enable the fiber output or

FIBER TX DIS (pins 2-3) to disable the fiber output.

Fiber or Electrical Input Enable

Set jumper J112 to ELEC INPUT (pins 1-2) to enable the electrical (BNC)

input or FIBER INPUT (pins 2-3) to enable the fiber input.

14 2031RDA-SM/-MM Instruction Manual

Page 15

J107

Figure 6. Onboard Jumper Locations

Remote Control Lockout

Jumper across pins 1–2

to lock out remote control.

LOCAL

J107

LOCAL

REMOTE

Jumper across pins 2–3

&

to enable remote and

local control.

Configuration and Monitoring

J106

J110

J112

Reclocking Modes

Pins 2–3 forces bypass function.

J106

BYPASS

AUTO

Pins 2 only forces

270Mb

270 Mb/s reclock.

Pins 1–2 selects auto reclock.

Fiber Input Select/Fiber Tx Enable

FIBER

Jumper J110 pins 1-2 to enable

J110

TX DIS

the fiber TX output or pins 2-3

FIBER

to disable the fiber output.

TX EN

FIBER

Jumper J112 pins 1-2 to enable

INPUT

the electrical coax input or

ELEC

pins 2-3 to enable the fiber input.

INPUT

J112

Jumper Positions for J106

Pins 2-3

Pin 2 only

Pins 1-2

2031RDA-SM/-MM Instruction Manual 15

8318_05

Page 16

Configuration and Monitoring

Remote Configuration and Monitoring

Configuration and monitoring can be performed using a web browser GUI

interface or a networked Newton Control Panel when the 2000NET

Network Interface module is present in the video frame. Each of these

interfaces is described below.

2000NET Module Information

Refer to the 2000NET Network Interface Module Instruction Manual for

information on the 2000NET Network Interface module and setting up and

operating the Kameleon 2000 frame network.

Newton Control Panel Configuration

A Newton Control Panel (hard or soft version) can be interfaced to the

Kameleon 2000 Series frame over the local network.

Note For Newton control of this module, the 2000NET module in the frame must

be running software version 4.0.0 or later.

Control panel access offers the following considerations for module configuration and monitoring:

• Ability to separate system level tasks from operation ones, minimizing

the potential for on-air mistakes.

• Ability to group modular products—regardless of their physical locations—into logical groups (channels) that you can easily manipulate

with user-configured knobs.

• Update software for applicable modules and assign frame and panel IP

addresses with the NetConfig Networking application.

• Recommended for real-time control of module configuration parameters, providing the fastest response time.

Note Not all module functions are available with the control panel, such as factory

default recalls. The available control panel controls for the module are listed

in Table 3 on page 13.

An example of the Newton Configurator is shown in Figure 7 on page 17.

16 2031RDA-SM/-MM Instruction Manual

Page 17

Figure 7. Newton Configurator Example

Configuration and Monitoring

Refer to the documentation that accompanies the Newton Modular Control

System for installation, configuration, and operation information.

Web Browser Interface

The web browser interface provides a graphical representation of module

configuration and monitoring.

Use of the web interface offers the following considerations:

• Provides complete access to all module status and configuration func-

tions, including factory parameter and name default recalls, slot configuration, and SNMP monitoring controls.

• Web access will require some normal network time delays for pro-

cessing of information.

• Configuration parameter changes may require pressing the

button or

become effective.

• Web interface recommended for setting up module signal and slot

names, and reporting status for SNMP and monitoring.

Refer to the Frame Status page shown in Figure 8 on page 18. The Kameleon and 2000 modules can be addressed by clicking either on a specific

module icon in the frame status display or on a module name or slot

number in the link list on the left.

Enter, upload processing time, and a manual screen refresh to

Apply

2031RDA-SM/-MM Instruction Manual 17

Page 18

Configuration and Monitoring

Note The physical appearance of the menu displays on the web pages shown in

Figure 8. 2000NET GUI

this manual represent the use of a particular platform, browser and version

of 2000NET module software. They are provided for reference only. Displays

will differ depending on the type of platform and browser you are using and

the version of the 2000NET software installed in your system. This manual

reflects 2000NET software version 3.2.2.

The Links section lists the frame and its current modules. The selected link's Status

page is first displayed and the sub-list of links for the selection is opened. The sub-list

allows you to select a particular information page for the selected device.

Content display section displays the information page

for the selected frame or module (frame slot icons are also

active links).

Refresh button for manual

update of page

8318_07

18 2031RDA-SM/-MM Instruction Manual

Page 19

2031RDA-SM/-MM Links and Web Pages

The 2000 GUI provides the following links and web pages for the

2031RDA-SM and 2031RDA-MM modules (Figure 9):

• Status – reports input and reference signal status and module informa-

tion (page 20),

• Settings – provides controls for setting input/output enables and

bypass and reclocking functions (page 22),

• Recall Factory Defaults – provides recall of factory defaults (page 24),

• Slot Config – provides a Locate Module function, Slot Identification

name and asset tag fields, and Slot Memory controls (page 25), and

• Software Update – gives information on software updating (page 27).

Figure 9. 2031RDA-SM/-MM Web Page Links

Configuration and Monitoring

Note The web page examples in this manual are shown for the 2031RDA-SM. The

web pages for the 2031RDA-MM are identical except for the Model name in

the heading or where otherwise indicated.

2031RDA-SM/-MM Instruction Manual 19

Page 20

Configuration and Monitoring

Status Web Page

The Status web page shows the status of the input signal(s) and the frame

Use

this

link

bus communication. Color coding of the display indicates the signal status.

In general, colors used on the frame and modules indicate:

• Green – normal operation, (Pass) or signal present, module locked.

• Red – On continuously = fault condition, flashing = internal error.

• Yellow – On continuously = active condition (configuration mode or

• Grey – not monitored, such as the Reference Signal and the Output

Information about the module, such as part number, serial number, hardware revision and software version, and Asset Tag number are given in a

read-only

The Status page for the 2031RDA-SM is illustrated in Figure 10.

Figure 10. 2031RDA-SM Status Web Page

communication), flashing in sequence = module locator function.

Signal(s) for this module.

Properties section at the bottom of the display.

20 2031RDA-SM/-MM Instruction Manual

Page 21

Configuration and Monitoring

The Status page for the 2031RDA-MM is illustrated in Figure 11.

Figure 11. 2031RDA-MM Status Web Page

2031RDA-SM/-MM Instruction Manual 21

Page 22

Configuration and Monitoring

Settings Web Page

The Settings web page (Figure 12) provides both status reporting and controls for the module.

Use

this

link

The following read-only status reports are provided:

•

•

•

•

Figure 12. Settings Web Page

Coax In – reports the presence of a signal carrier on the coax input.

Optic In – reports the presence of a signal carrier on the optic input.

Reclocker – reports the reclocking status as Locked, Unlocked, or N/A (when

set for Bypass).

Auto Rate – reports the currently detected bit rate or N/A if mode is set to

Bypass or

locked.

Unknown if mode is Auto or Auto Reclock and signal is not

22 2031RDA-SM/-MM Instruction Manual

Page 23

Configuration and Monitoring

The following parameter controls are provided on the Settings web page.

Select the

Apply button after each parameter selection.

Input

Select Coax or Fiber as the input to the module.

Mode

Set the reclocking mode to one of the following with the menu pulldown:

•

Bypass – reclocking is completely bypassed. The input signal passes

directly to the outputs without reclocking.

•

Auto – if the module detects the input signal as one of the SMPTE

standard definition rates (143 Mb/s, 177 Mb/s, 270 Mb/s,

360 Mb/s, or 540 Mb/s), it will reclock the signal at that rate. If one

of these rates is not detected, the module will not reclock the signal

(bypass the reclocker) and distribute the signal to the outputs.

•

Auto Reclock – if the module detects the input signal as one of the

SMPTE standard definition rates (143 Mb/s, 177 Mb/s, 270 Mb/s,

360 Mb/s, or 540 Mb/s), it will reclock the signal at that rate. If one

of these rates is not detected, the signal will not be reclocked and

will be passed to the output as is (corrupted).

Note This mode will not reclock/bypass DVB-ASI signals reliably. Use the Auto

mode for these signal types.

• Manual 143Mb – the module will attempt to reclock the input signal

at 143 Mb/s. If this signal rate is not detected, the signal will not be

reclocked and will be passed to the output as is (corrupted).

•

Manual 177Mb – the module will attempt to reclock the input signal

at 177 Mb/s. If this signal rate is not detected, the signal will not be

reclocked and will be passed to the output as is (corrupted).

•

Manual 270Mb – the module will attempt to reclock the input signal

at 270 Mb/s. If this signal rate is not detected, the signal will not be

reclocked and will be passed to the output as is (corrupted).

•

Manual 360Mb – the module will attempt to reclock the input signal

at 360 Mb/s. If this signal rate is not detected, the signal will not be

reclocked and will be passed to the output as is (corrupted).

•

Manual 540Mb – the module will attempt to reclock the input signal

at 540 Mb/s. If this signal rate is not detected, the signal will not be

reclocked and will be passed to the output as is (corrupted).

Optic TX

Use this control to enable or disable the optical output of the module.

2031RDA-SM/-MM Instruction Manual 23

Page 24

Configuration and Monitoring

Recall Factory Defaults Web Page

The Recall Factory Defaults web page (Figure 13) provides a Recall Fact.

Default Button to restores the module to the default values shown in Table 3

on page 13.

Use

this

link

Figure 13. Recall Factory Defaults Web Page

24 2031RDA-SM/-MM Instruction Manual

Page 25

Use

this

link

Slot Config Web Page

Use the Slot Config web page (Figure 14 on page 26) to perform the following functions on the 2031RDA-SM/-MM module:

•

Locate Module – selecting the Flash radio button flashes the yellow

COMM LED on the front of the module so it can be located in the frame.

•

Slot Identification – You may identify the module by typing a specific

name in the

module and travels with the 2000NET module if it is moved to another

frame. Select

Configuration and Monitoring

Name field. The assigned name is stored on the 2000NET

Default to enter the factory default module name.

You may also assign a name to the input signal in the

field. Select

An asset identification of up to 16 characters may be entered in the

Tag field. This will appear on the module Status web page and in the

NetConfig inventory report.

•

Slot Memory – the slot configuration for each media module is automati-

cally saved periodically (once an hour) to the 2000NET module in that

frame. You may also select the

save the current configuration for this slot. The configuration is saved

on the 2000NET module. If the 2000NET module is removed or

powered down, the stored configurations are not saved.

When the

ration saved to this slot is saved as slot memory. When the current

module is removed and another module of the same type is installed,

the configuration saved to the 2000NET module will be downloaded to

the new module. The box must be checked before the current module

with the saved configuration is removed.

•

Frame Heath Reporting – the reporting of Slot Fault, Signal Loss, and Ref-

erence Loss can be enabled or disabled to the Frame Health connector

on the rear of the Kameleon frame by selecting or deselecting the corresponding checkbox.

Default to enter the factory default signal name.

Learn Module Config button at any time to

Restore upon Install box has been checked, the current configu-

Input Signal Name

Asset

•

Hardware Switch Controls – a read-only status report of 2000NET module

switch settings for Module Status Reporting and Asynchronous Status

Reporting (dipswitch S1 segment 7 and dipswitch S2 segment 1). These

functions must be enabled for the following Slot SNMP Trap Reports to

function.

•

Slot SNMP Trap Reports – displayed only when the SNMP Agent software

has been installed on the 2000NET module. Slot SNMP traps can be

enabled only when the hardware switches for Module Fault reporting

and Asynchronous Status reporting are in enabled on the 2000NET

module.

The enabled SNMP traps will be reported to any SNMP manager that

is identified as an SNMP Report Destination in 2000NET configuration.

Trap severity is read-only hard-coded information that is interpreted

and responded to by the SNMP Manager software configuration.

2031RDA-SM/-MM Instruction Manual 25

Page 26

Configuration and Monitoring

Figure 14. 2031RDA-SM/-MM Slot Config Web Page

26 2031RDA-SM/-MM Instruction Manual

Page 27

Use

this

link

Configuration and Monitoring

Software Update Web Page

The Software Update web page (Figure 15) indicates that module software

updates via the web or using the NetConfig networking application are not

supported. For instructions on updating to the latest software, refer first to

the 2031RDA-SM/-MM Release Notes that accompany the software

update for complete details.

Currently, the only recommended method of software updating is done

with a software kit (8900-FLOAD-CBL) that includes a CD-ROM with the

current software files and a serial cable assembly available from Grass

Valley.

Refer to the 8900-FLOAD-CBL Software Upgrade Instruction Manual in pdf

format on the CD-ROM for complete updating instructions and the

required software files for the 2031RDA-SM/-MM.

Figure 15. Software Update Web Page

2031RDA-SM/-MM Instruction Manual 27

Page 28

Status Monitoring

Status Monitoring

This section provides a summary of status monitoring and reporting for a

Kameleon 2000 Series system. It also summarizes what status items are

reported and how to enable/disable reporting of each item. There are a

number of ways to monitor status of modules, power supplies, fans and

other status items depending on the method of monitoring being used.

2000 Frame status will report the following items:

• Power supply health,

• Status of fans in the frame front cover,

• Temperature,

• Module health, and

• Frame bus status.

Module health status will report the following items:

• Internal module state (and state of submodule or options enabled)

including configuration errors (warning), internal faults, and normal

operation (Pass).

LEDs

• Signal input states including valid/present (pass), not present or

invalid (warning), not monitored, and not available (no signal inputs).

• Reference input states including locked/valid (pass), not

locked/invalid (warning), and not monitored.

• Signal output states with reporting functionality (reference output).

LEDs on modules in the frame and on the front of the 2000 frames indicate

status of the frame and the installed power supplies, fans in the front

covers, and modules.

When a red FAULT LED is lit on a frame front cover, the fault will also be

reported on the 2000NET or Frame Monitor module. The LEDs on the front

of these modules can then be read to determine the following fault conditions:

• Power Supply 1 and 2 health,

• Fan rotation status,

• Frame over-temperature condition,

• Frame Bus fault (2000NET only), and

• Module health bus.

28 2031RDA-SM/-MM Instruction Manual

Page 29

In general, LED colors used on the frame and modules indicate:

• Green – normal operation, (Pass) or signal present, module locked.

• Red – On continuously = fault condition, flashing = configuration error.

• Yellow – On continuously = active condition (configuration mode or

communication), flashing in sequence = module locator function.

Status LEDs for this module are described in LEDs on page 28. LEDs for the

2000NET module are described in the 2000NET Network Interface Instruction

Manual.

Frame Alarm

Connection and use of the Frame Alarm is covered in detail in the 2000NET

Network Interface Instruction Manual.

Web Browser Interface

Status Monitoring

When the 2000NET module is installed in the frame, a web browser GUI

can indicate frame and module status on the following web pages:

• Frame Status web page – reports overall frame and module status in

graphical and text formats.

• Module Status web page – shows specific input and reference signal

status to the module along with enabled options and module versions.

• A Status LED icon on each web page to report communication status

for the frame slot and acts as a link to the Status page where warnings

and faults are displayed (2000NET version 3.0 or later).

In general, graphics and text colors used indicate the following:

• Green = Pass – signal or reference present, no problems detected.

• Red = Fault – fault condition.

• Yellow = Warning – signal is absent, has errors, or is mis-configured.

• Grey = Not monitored (older 2000 module).

• White = Not present.

Status reporting for the frame is enabled or disabled with the configuration

DIP switches on the 2000NET module. Most module status reporting items

can be enabled or disabled on individual configuration web pages.

2031RDA-SM/-MM Instruction Manual 29

Page 30

Status Monitoring

SNMP Reporting

The Kameleon Series system uses the Simple Network Monitoring Protocol

(SNMP) internet standard for reporting status information to remote monitoring stations. When SNMP Agent software is installed on the 2000NET

module, enabled status reports are sent to an SNMP Manager such as the

Grass Valley’s NetCentral application.

There are both hardware and software report enable switches for each

report. Both must be enabled for the report to be sent. Software report

switches are set on the 2000NET Configuration page for the Frame, the

2000NET module, and each module slot. Refer to the 2000NET Network

Interface Instruction Manual for installation instructions.

30 2031RDA-SM/-MM Instruction Manual

Page 31

Specifications

Specifications

Table 4. 2031RDA-SM/-MM Specifications

Parameter Value

Serial Digital Component Coax Input

Number and type of inputs 1 BNC

Input impedance 75 Ohm

Return loss > 15 dB from 5 MHz to 540 MHz

Signal type, auto-equalizing only 50 Mb/s to 540 Mb/s: rise/fall time – 20 to 80%, 400-800 ps,

Signal type, auto-equalizing and reclocking SMPTE 259M-1997 with the following bit rate tolerances:

Auto equalization cable lengths

(for any of the above signal types)

Input jitter tolerance ≥ 1 UI p-p from 10 Hz to 200 Hz

Serial Digital Component Fiber Input

Connector LC (1 input)

Fiber types 2031RDA-MM: multimode complying with

Wavelength 1270-1355 nm

Input power 2031RDA-MM: -28 dB (minimum) to -7.5 dB (maximum)

Signal type Same as Signal type, auto-equalizing only and Signal type,

Fiber length 2031RDA-MM: 2 kilometers minimum at 270 Mb/s

Jitter (on any specified signal type) > 0.2 UI p-p, 10 Hz to 10 MHz

Serial Digital Component Coax Outputs

Connector BNC (8 outputs)

Output impedance 75 Ω

Return loss > 15 dB from 5 MHz to 540 MHz

Signal level SDI 800 mV p-p, ± 10% maximum

Rise/fall time 400-800 ps

Output polarity Non-inverted

Output jitter < 0.2 UI p-p

signal level – 800 mV ± 10%)

143 Mb/s ± 5%

177 Mb/s ± 5%

270 Mb/s ± 5%

360 Mb/s ± 5%

ETSI TR 101 891v1.1.1 (DVB-ASI) with the following bit rate tolerance: 270 M/b/s ± 5%

SMPTE 344M-2000 with the following bit rate tolerance:

540 Mb/s± 5%

Up to 300 m of Belden 1694A cable for bit rates up to 270 Mb/s

Up to 100 m of Belden 1694A cable for bit rates > 270 Mb/s and

< 540 Mb/s

≥ 0.2 UI p-p from 200 Hz to 15 MHz

ANSI/TIA/EIA-492AAAA-A (maximum attenuation of 1.5 dB per

kilometer at 1310 nm)

2031RDA-SM: singlemode complying with

ANSI/TIA/EIA-492CAAA (maximum attenuation of 1.0 dB per kilometer at 1310 nm)

2031RDA-SM: -20 dB (minimum) to 0 dB (maximum)

auto-equalizing and relocking above

2031RDA--SM: 7 kilometers minimum at 270 Mb/s

2031RDA-SM/-MM Instruction Manual 31

Page 32

Specifications

Table 4. 2031RDA-SM/-MM Specifications - (continued)

Parameter Value

Serial Digital Component Fiber Outputs

Connector LC (1 output)

Fiber types 2031RDA-MM: multimode complying with

ANSI/TIA/EIA-492AAAA-A (maximum attenuation of 1.5 dB per

kilometer at 1310 nm)

2031RDA-SM: singlemode complying with

ANSI/TIA/EIA-492CAAA (maximum attenuation of 1.0 dB per kilometer at 1310 nm)

Wavelength 1290-1330 nm

Output power -12 to -7.5 dBm

Standard Other than LC connector, conforms to SMPTE 297-2000

Polarity Non-inverting

Output jitter < 0.2 UI

Power

Input power maximum < 6 W

Environmental

Frame temperature range See Kameleon 2000 frame specification

Operating humidity range 0 to 90% non condensing

Non-operating temperature -10 to 70 ° C

32 2031RDA-SM/-MM Instruction Manual

Page 33

Service

Power-up Diagnostics Failure

Troubleshooting

Service

The 2031RDA-SM/-MM modules make extensive use of surface-mount

technology and programmed parts to achieve compact size and adherence

to demanding technical specifications. Circuit modules should not be serviced in the field unless otherwise directed by Customer Service.

If the module has not passed self-diagnostics, do not attempt to troubleshoot. Return the unit to Grass Valley (see Module Repair).

If your module is not operating correctly, proceed as follows:

• Check frame and module power. If power is not present, check the fuse

and voltage testpoints on the module as illustrated in Figure 16.

• Check for presence and quality of input signals.

• Verify that source equipment is operating correctly.

• Check cable connections.

Figure 16. Location of Module Fuse

Voltage

Test Points

125V

+24V +5V GND

J108

J108

F1

2A

Fuse: F1, 2A, 125V

TP 6

GND

GND+3.3V

8318_03

2031RDA-SM/-MM Instruction Manual 33

Page 34

Functional Description

Module Repair

If the module is still not operating correctly, replace it with a known good

spare and return the faulty module to a designated Grass Valley repair

depot. Call your Grass Valley representative for depot location.

Refer to Contacting Grass Valley at the front of this document for the Grass

Valley Customer Service Information number.

Functional Description

A block diagram of the 2031RDA-SM/-MM is shown in Figure 17.

Figure 17. 2031RDA-SM/-MM Block Diagram

J9

J8

Optical

Input

Coax

Input

2000

Frame

Bus

Input Processing

The wideband serial SD signal enters the module from rear BNC J10

(labeled In) to an input amplifier. It is then equalized for the specified cable

lengths in the equalizer circuit.

Optical

Receiver

Equalizer

On-board

Jumpers

Microprocessor

Reclocker

Front

LEDs

Bypass

Optical

Transceiver

J7

J6

Electrical

J5

J4

J3

J1

8

Coax

Outputs

Optical

Output

8318_06

34 2031RDA-SM/-MM Instruction Manual

Page 35

Microprocessor

The main functions of the microprocessor include:

• Providing remote control and monitoring capability for the module

(through ethernet),

• Communicating with equalizer IC to monitor signal present status,

• Relaying module status through on-board LEDs, and

• Configuring module components at power up.

Output Processing

Driver circuits drive each of the eight serial digital outputs to the rear BNCs

J2 through J9. These outputs are non-inverting and are in-phase with each

other.

Power Supply

Functional Description

Power is fed from +24 V rails of the frame’s switching power supply. Each

stage of the module receives its own, separate, highly regulated and filtered

power source. The power input is protected by a socketed fuse (Figure 16

on page 33).

2031RDA-SM/-MM Instruction Manual 35

Page 36

Functional Description

36 2031RDA-SM/-MM Instruction Manual

Page 37

Index

Numerics

2000 frame

status reporting

2000NET module

software requirements

8900-Fload/Bload 27

28

16

A

Asset Tag assignment 25

B

block diagram 34

C

cabling

inputs

outputs 10

circuit descriptions 34

COMM LED 11, 25

CONF (configuring) LED 11

configuration

Remote, GUI

configuration summary 13

control panel 16

10

16

D

F

FAQ database 2

FAULT LED 11

troubleshooting 28

fault table 11

Frame Health Reporting

enabling and disabling

Frame Status web page 29

frequently asked questions 2

fuse 33, 35

25

G

graphical user interface (GUI) 19

Grass Valley web site 2

I

input signal name

assigning

inputs 10

specifications 31

installation 8

25

L

Learn Module Config button 25

LEDs 11

locate module function 25

documentation online 2

Dual Optical Transmitter submodule

summary table

13

M

module health status 28

Module Status web page 29

E

enable SNMP 30

environmental 32

2031RDA-SM/-MM Instruction Manual 37

N

Newton Control Panel

2000NET software requirement

control summary table 13

13

Page 38

Index

overview 16

O

online documentation 2

outputs 10

P

PWR LED 11

R

Recall Factory Defaults web page 24

repair depot 33

report enable switches 30

S

Settings web page 22

SIG LED (rear) 11

Slot Config

hardware switch controls

slot identification 25

slot memory 25

Slot Config web page 25

SNMP reporting

enabling

overview 30

software download from web 2

Software Update web page 27

specifications 8, 31

status monitoring 28

Status web page 20

25

25

Grass Valley 2

software download 2

T

troubleshooting 33

W

web browser

overview

web site

documentation

FAQ database 2

38 2031RDA-SM/-MM Instruction Manual

17

2

Loading...

Loading...