Page 1

Kameleon Frames

2000T1 and 2000T3 MODELS

Instruction Manual

071803902

AUGUST 2004

Page 2

Contacting Grass Valley

Region Voice Fax Address Web Site

North America (800) 547-8949

Support: 530-478-4148

Pacific Operations +852-2585-6688

Support: 852-2585-6579

U.K., Asia, Middle East +44 1753 218 777 +44 1753 218 757

France +33 1 45 29 73 00

Germany, Europe +49 6150 104 782 +49 6150 104 223

Copyright © Thomson Broadcast and Media Solutions All rights reserved.

Grass Valley Web Site

Sales: (530) 478-3347

Support: (530) 478-3181

+852-2802-2996

Grass Valley

P.O. Box 599000

Nevada City, CA 959597900 USA

www.thomsongrassvalley.com

The www

Online User Documentation

.thomsongrassvalley.com web site offers the following:

— Current versions of product catalogs, brochures,

data sheets, ordering guides, planning guides, manuals, and release notes

in .pdf format can be downloaded.

FAQ Database

— Solutions to problems and troubleshooting efforts can be

found by searching our Frequently Asked Questions (FAQ) database.

Software Downloads

— Software updates, drivers, and patches can be down-

loaded.

2Kameleon Frames Instruction Manual

Page 3

Contents

Preface

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Regulatory Notices

Certifications and Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

FCC Emission Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Canadian EMC Notice of Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

EN55022 Class A Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Canadian Certified Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Canadian Certified AC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Laser Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Laser Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Laser Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

FCC Emission Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety Summary

Safety Terms and Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Terms in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Terms on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Symbols on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Section 1 — Kameleon 2000 Series Frames

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Module Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2000 Series Frame Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Power Supply Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Monitoring and Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Genlock Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Other Frame Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2000T3 Frame Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2000T1 Frame Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Power, Cooling, and Module Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . 15

Section 2 — Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Rack Mounting the Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Module Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Rear Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Front Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Kameleon Frames Instruction Manual 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Page 4

Contents

Reference Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Frame Health Alarm Connector (2000T3 only) . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Serial Configuration Port Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Section 3 — Power Up

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Line Cord Retainer Clip. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Section 4 — Specifications

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Frame Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Section 5 — Service

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Monitoring Power Supplies and Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Fan Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4Kameleon Frames Instruction Manual

Page 5

Preface

About This Manual

This manual provides installation, configuration, operation, and safety and

regulatory information for the Newton Modular Control system rack

mount and software control panels for controlling Gecko 8900 Series and

Kameleon 2000 Series modular products.

Kameleon Frames Instruction Manual 5

Page 6

Preface

6Kameleon Frames Instruction Manual

Page 7

Regulatory Notices

Certifications and Compliances

FCC Emission Control

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

Changes or modifications not expressly approved by Grass Valley Group

can affect emission compliance and could void the user’s authority to

operate this equipment.

Canadian EMC Notice of Compliance

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’emet pas de bruits radioélectriques

dépassant les limites applicables aux appareils numeriques de la classe A

préscrites dans le Règlement sur le brouillage radioélectrique édicte par le

ministère des Communications du Canada.

EN55022 Class A Warning

For products that comply with Class A. In a domestic environment this

product may cause radio interference in which case the user may be

required to take adequate measures.

Kameleon Frames Instruction Manual 7

Page 8

Regulatory Notices

Canadian Certified Power Cords

Canadian Certified AC Adapter

Laser Compliance

Canadian approval includes the products and power cords appropriate for

use in the North America power network. All other power cords supplied

are approved for the country of use.

Canadian approval includes the AC adapters appropriate for use in the

North America power network. All other AC adapters supplied are

approved for the country of use.

Laser Safety Requirements

The device used in this product is a Class 1 certified laser product. Operating this product outside specifications or altering from its original design

may result in hazardous radiation exposure, and may be considered an act

of modifying or new manufacturing of a laser product under U.S. regulations contained in 21CFR Chapter1, subchapter J or CENELEC regulations

in HD 482 S1. People performing such an act are required by law to recertify and reidentify this product in accordance with provisions of 21CFR

subchapter J for distribution within the U.S.A., and in accordance with

CENELEC HD 482 S1 for distribution within countries using the IEC 825

standard.

Laser Safety

Laser safety in the United States is regulated by the Center for Devices and

Radiological Health (CDRH). The laser safety regulations are published in

the “Laser Product Performance Standard,” Code of Federal Regulation

(CFR), Title 21, Subchapter J.

The international Electrotechnical Commission (IEC) Standard 825, “Radiation of Laser Products, Equipment Classification, Requirements and

User’s Guide,” governs laser products outside the United States. Europe

and member nations of the European Free trade Association fall under the

jurisdiction of the Comite European de Normalization Electrotechnique

(CENELEC).

For the CDRH: The radiant power is detected trough a 7 mm aperture at a

distance of 200 mm from the source focused through a lens with a focal

length of 100 mm.

For IEC compliance: The radiant power is detected trough a 7 mm aperture

at a distance of 100 mm from the source focused through a lens with a focal

length of 100 mm.

8Kameleon Frames Instruction Manual

Page 9

FCC Emission Limits

Certification

Regulatory Notices

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) This device may no cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesirable operation. This device

has been tested and found to comply with FCC Part 15 Class B limits for a

digital device when tested with a representative laser-based fiber optical

system that complies with ANSI X3T11 Fiber Channel Standard.

Category Standard Designed/tested for compliance with:

Safety UL1950 Safety of Information Technology Equipment, including Electrical

IEC 950 Safety of Information Technology Equipment, including Electrical

CAN/CSA C22.2, No. 950-93 Safety of Information Technology Equipment, including Electrical

EN60950 Safety of Information Technology Equipment, including Electrical

Business Equipment (Second edition, 1993).

Business Equipment (Second edition, 1991).

Business Equipment.

Business Equipment.

Kameleon Frames Instruction Manual 9

Page 10

Regulatory Notices

10 Kameleon Frames Instruction Manual

Page 11

Safety Summary

Read and follow the important safety information below, noting especially

those instructions related to risk of fire, electric shock or injury to persons.

Additional specific warnings not listed here may be found throughout the

manual.

WARNING Any instructions in this manual that require opening the equipment cover

or enclosure are for use by qualified service personnel only. To reduce the

risk of electric shock, do not perform any servicing other than that contained in the operating instructions unless you are qualified to do so.

Safety Terms and Symbols

Terms in This Manual

Terms on the Product

Safety-related statements may appear in this manual in the following form:

WARNING Warning statements identify conditions or practices that may result in per-

CAUTION Caution statements identify conditions or practices that may result in damage

The following terms may appear on the product:

DANGER

the marking.

WARNING

sible as you read the marking.

sonal injury or loss of life.

to equipment or other property, or which may cause equipment crucial to

your business environment to become temporarily non-operational.

— A personal injury hazard is immediately accessible as you read

— A personal injury hazard exists but is not immediately acces-

CAUTION

Kameleon Frames Instruction Manual 11

— A hazard to property, product, and other equipment is present.

Page 12

Safety Summary

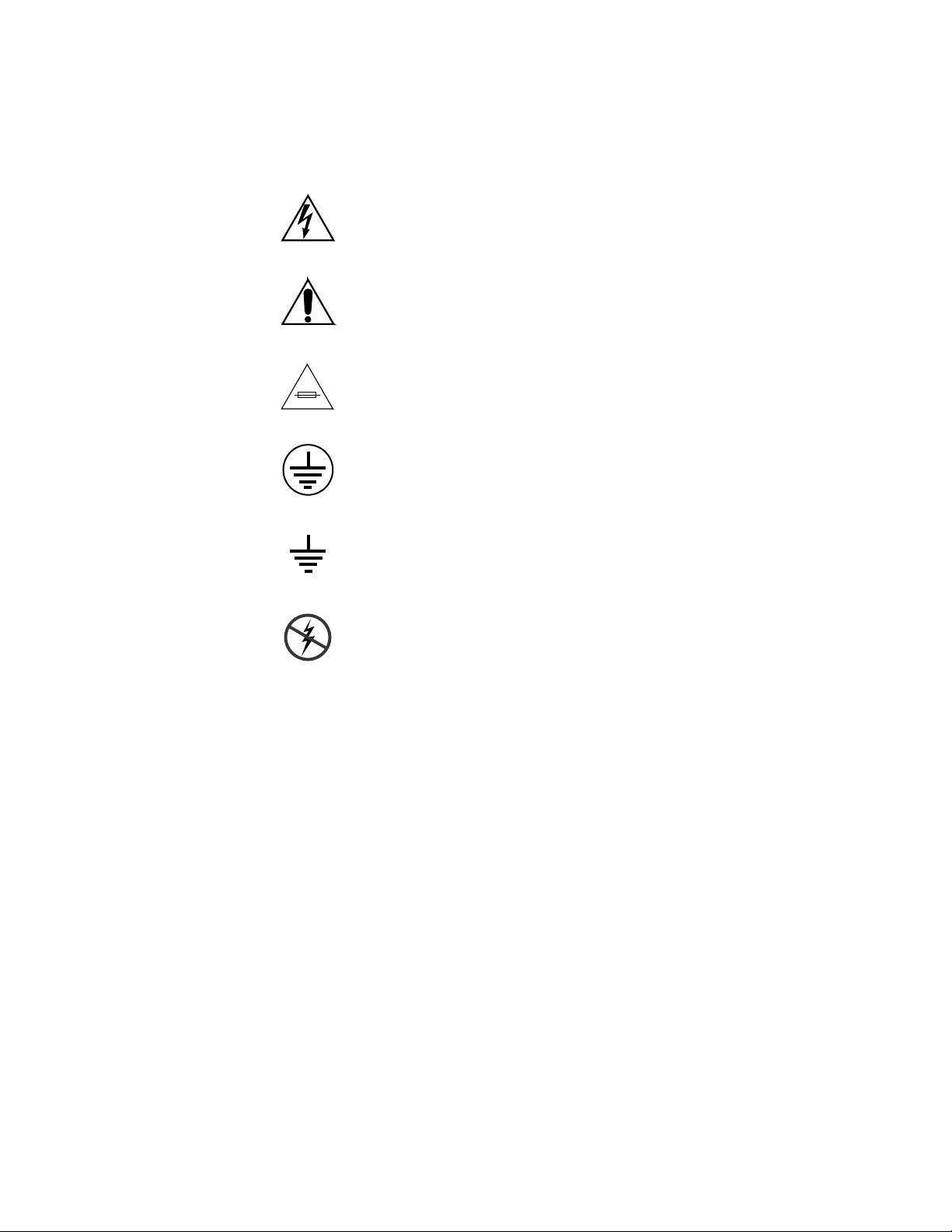

Symbols on the Product

The following symbols may appear on the product:

Indicates that dangerous high voltage is present within the

equipment enclosure that may be of sufficient magnitude to

constitute a risk of electric shock.

Indicates that user, operator or service technician should refer

to product manual(s) for important operating, maintenance,

or service instructions.

This is a prompt to note fuse rating when replacing fuse(s).

The fuse referenced in the text must be replaced with one

having the ratings indicated.

Warnings

Identifies a protective grounding terminal which must be connected to earth ground prior to making any other equipment

connections.

Identifies an external protective grounding terminal which

may be connected to earth ground as a supplement to an

internal grounding terminal.

Indicates that static sensitive components are present which

may be damaged by electrostatic discharge. Use anti-static

procedures, equipment and surfaces during servicing.

The following warning statements identify conditions or practices that can

result in personal injury or loss of life.

Dangerous voltage or current may be present

battery (if applicable) before removing protective panels, soldering, or

replacing components.

— Disconnect power and remove

Do not service alone

person capable of rendering first aid and resuscitation is present.

Remove jewelry

and other metallic objects.

Avoid exposed circuitry

circuitry when power is present.

12 Kameleon Frames Instruction Manual

— Do not internally service this product unless another

— Prior to servicing, remove jewelry such as rings, watches,

— Do not touch exposed connections, components or

Page 13

Safety Summary

Use proper power cord

this product.

Ground product

earth ground.

Operate only with covers and enclosure panels in place

product when covers or enclosure panels are removed.

Use correct fuse

product.

Use only in dry environment

Use only in non-explosive environment

explosive atmosphere.

High leakage current may be present

before connecting power.

Dual power supplies may be present

cord into a separate branch circuit employing a separate service ground.

Disconnect both power supply cords prior to servicing.

Double pole neutral fusing

— Use only the power cord supplied or specified for

— Connect the grounding conductor of the power cord to

— Do not operate this

— Use only the fuse type and rating specified for this

— Do not operate in wet or damp conditions.

— Do not operate this product in an

— Earth connection of product is essential

— Be certain to plug each power supply

— Disconnect mains power prior to servicing.

Cautions

Use proper lift points

Avoid mechanical hazards

servicing.

The following caution statements identify conditions or practices that can

result in damage to equipment or other property

Use correct power source

that applies more than the voltage specified for the product.

Use correct voltage setting

plies, before applying power ensure that the each power supply is set to

match the power source.

Provide proper ventilation

ment ventilation in accordance with installation instructions.

Use anti-static procedures

may be damaged by electrostatic discharge. Use anti-static procedures,

equipment and surfaces during servicing.

— Do not use door latches to lift or move equipment.

— Allow all rotating devices to come to a stop before

— Do not operate this product from a power source

— If this product lacks auto-ranging power sup-

— To prevent product overheating, provide equip-

— Static sensitive components are present which

Kameleon Frames Instruction Manual 13

Page 14

Safety Summary

Do not operate with suspected equipment failure

damage or equipment failure, have the equipment inspected by qualified

service personnel.

Ensure mains disconnect

of this equipment provide the means of disconnection. The socket outlet

must be installed near the equipment and must be easily accessible. Verify

that all mains power is disconnected before installing or removing power

supplies and/or options.

Route cable properly

likely to be damaged. Properly support heavy cable bundles to avoid connector damage.

Use correct power supply cords

meet all North American electrical codes. Operation of this equipment at

voltages exceeding 130 VAC requires power supply cords which comply

with NEMA configurations. International power cords, if provided, have

the approval of the country of use.

Use correct replacement battery

reduce the risk of explosion, check polarity and replace only with the same

or equivalent type recommended by manufacturer. Dispose of used batteries according to the manufacturer’s instructions.

— If mains switch is not provided, the power cord(s)

— Route power cords and other cables so that they ar not

— Power cords for this equipment, if provided,

— This product may contain batteries. To

— If you suspect product

Troubleshoot only to board level

populated with surface mount technology (SMT) components and application specific integrated circuits (ASICS). As a result, circuit board repair at

the component level is very difficult in the field, if not impossible. For warranty compliance, do not troubleshoot systems beyond the board level.

— Circuit boards in this product are densely

14 Kameleon Frames Instruction Manual

Page 15

Section

Kameleon 2000 Series Frames

Introduction

Kameleon 2000T1 and 2000T3 frame models support Kameleon multifunction and 2000 Series modules, as well as 8900 modules with the 2000A89

Adapter. These modules provide a wide range of analog and digital processing including signal distribution, format conversion, and HDTV up

and down conversion. They are designed to handle a wide variety of signal

types: HDTV, SDTV, Analog, AES, and Data. The line of Wideband Distribution Amplifiers provide an easy upgrade path from SD to HD video.

The high-bandwidth frames provide flexible I/O with each module type

installed. Front-installed modules are connected to rear I/O modules that

provide the connector type required for the application. To minimize signal

losses resulting from the higher speed HDTV signals, front-to-rear module

connections are direct rather than through the motherboard (refer to

Figure 2 on page 17).

1

The Kameleon 2000 Series features include:

•Wide bandwidth performance handling HDTV, SDTV, up and down

conversion, analog audio and video, and compressed data formats,

•Twelve media modules in a three rack unit (3 RU) 2000T3 frames or four

in the one rack unit (1 RU) 2000T1frames,

• Ethernet interface with 2000NET module installed,

•Genlock timing with 2000GEN module installed,

•Mid-plane design enabling flexible I/O,

•Hot-swappable power supplies,

• Sufficient cooling and power for any combination of modules and conditions,

•Compatibility with selected 8900 modules when using the 2000A89

adapter module, and

• Loop-through frame reference input on the 2000T3 Series frames.

Kameleon Frames Instruction Manual 15

Page 16

Section 1 — Kameleon 2000 Series Frames

Module Slots

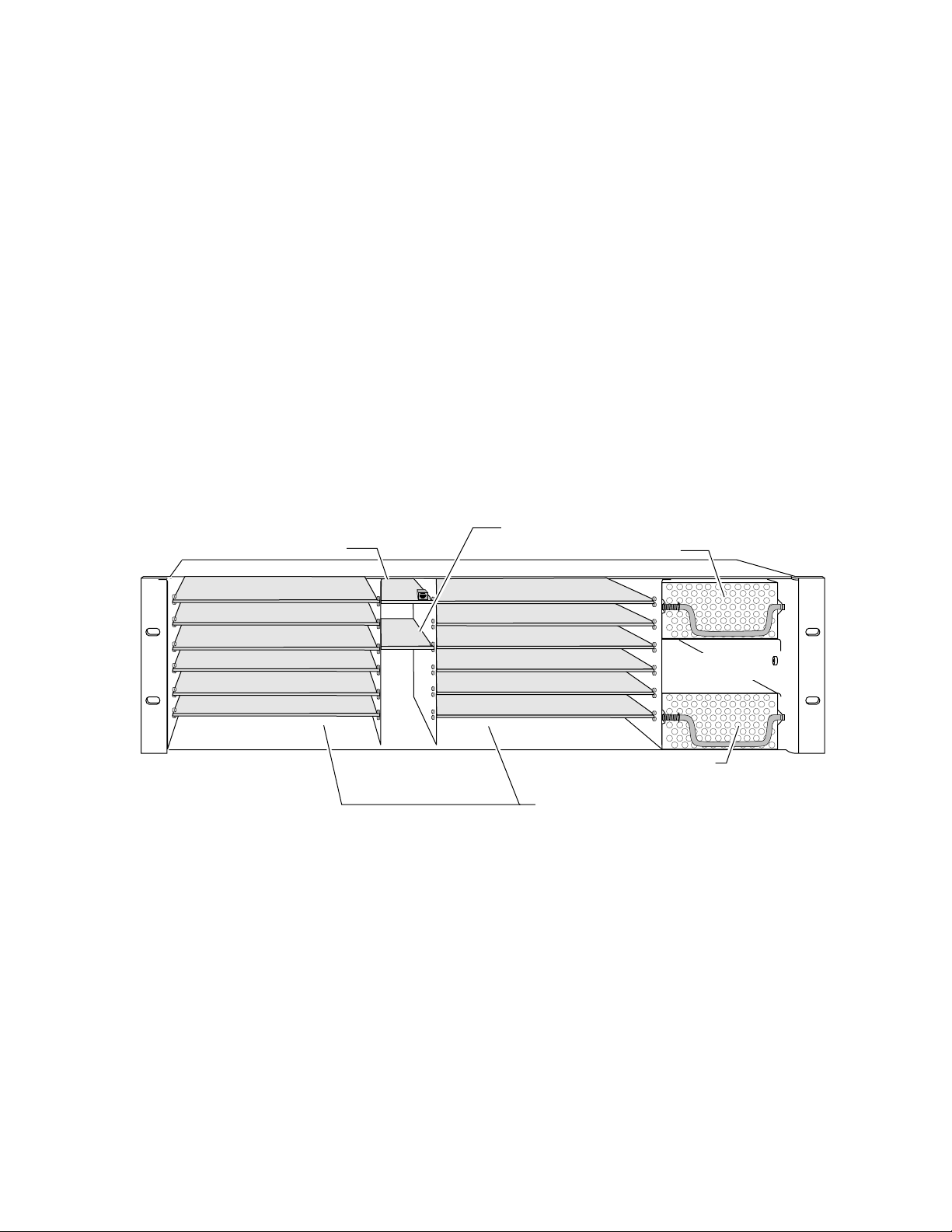

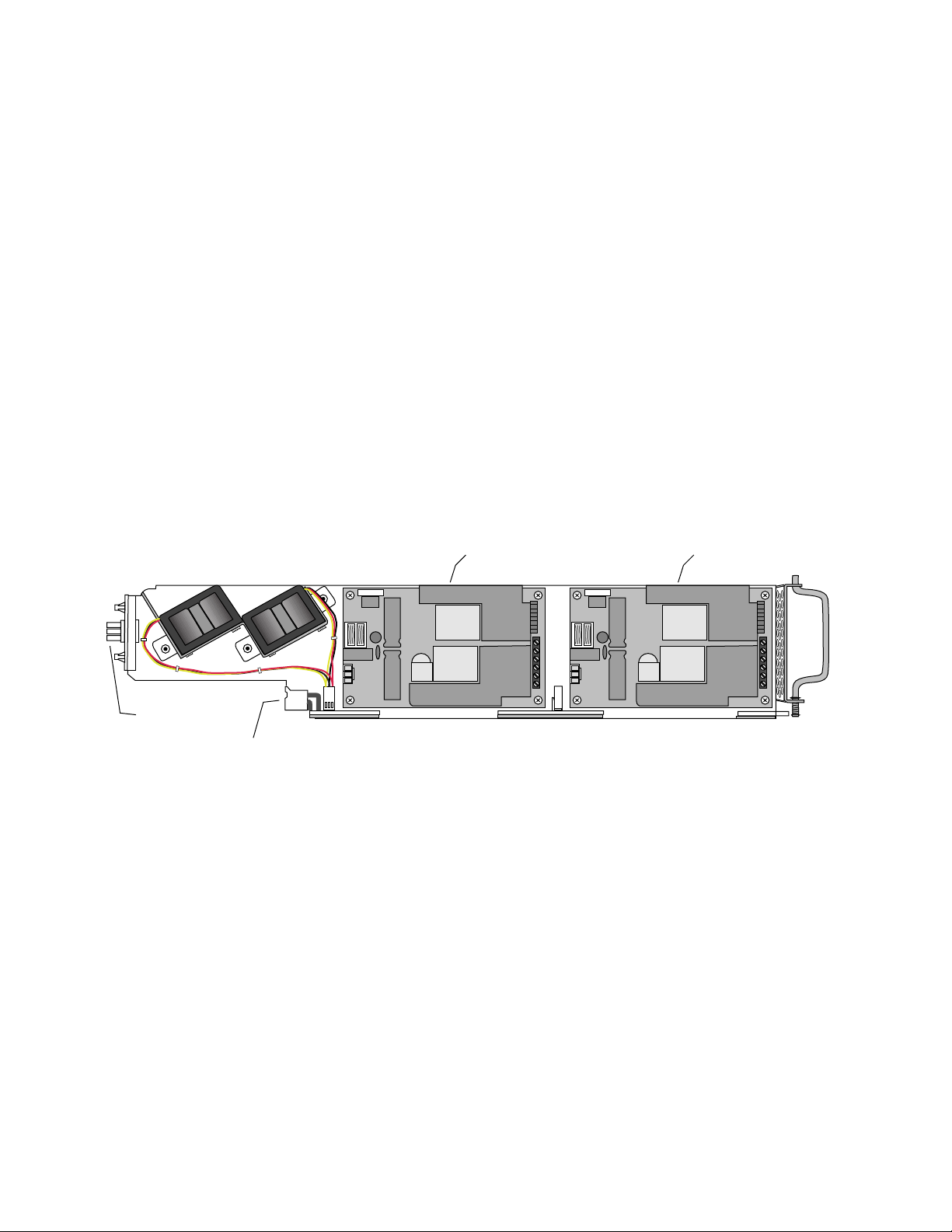

2000T3 frame model architecture allows for up to 12 media modules in the

front slots shown in Figure 1. The front modules connect to rear I/O

modules that allow selection of various connector types. The 2000T1 frame

models have four front and four rear module slots.

2000T3

Note

Some rear modules are dual height and require 2 slots. This will affect the

number of actual modules that can be installed in the frame. Refer to the specific module manual for more information.

Figure 1. 2000T3 and 2000T1 Frame Slots

Reference Distribution Slot (15)

Network Slot (13)

(1)

(2)

(3)

(4)

(5)

(6)

Network Slot (5) Power Supply Slot (7)

(13)

(15)

Main Power Supply Slot (19)

(7)

(8)

(9)

(10)

(11)

(12)

Redundant Power

Supply Slot (21)

Front Media Slots (1-12)

Slot (20)

8039-04

2000T1

(1)

(2)

(5)

(6)

(3)

(4)

Front Media Slots (1-4)

The rear slots (Figure 2) accept either passive I/O connector modules (dedicated to front modules) or standalone active rear-slot media modules. The

center section houses network and timing reference modules.

Note

In the 2000T3 frame, center slots 14, 16, 17, and 18 are not functional. Even

though some versions of the frame have board-edge guides for these slots,

they should not be used.

16 Kameleon Frames Instruction Manual

8039-21

Page 17

Mid-frame

motherboard

with power and

communication buses

Figure 2. 2000T3 Frame Rear and Interior View

Front-rear module

direct connection

cutout

Module Slots

Open frame area

for front-rear module

direct connection

Six rear

module slots

Network

and reference

input connections

Six rear

module slots

8039-03

An optional redundant power supply (2000PS) can be installed in the

2000T3 frames in addition to a fan sled for providing cooling requirements.

The 2000 frame mid-frame motherboard provides intermodule connectivity.

A 2000 frame can house selected 8900 Series modules by using the 2000A89

adapter module. Refer to the 2000A89 Instruction Manual for a list of supported 8900 modules.

Kameleon Frames Instruction Manual 17

Page 18

Section 1 — Kameleon 2000 Series Frames

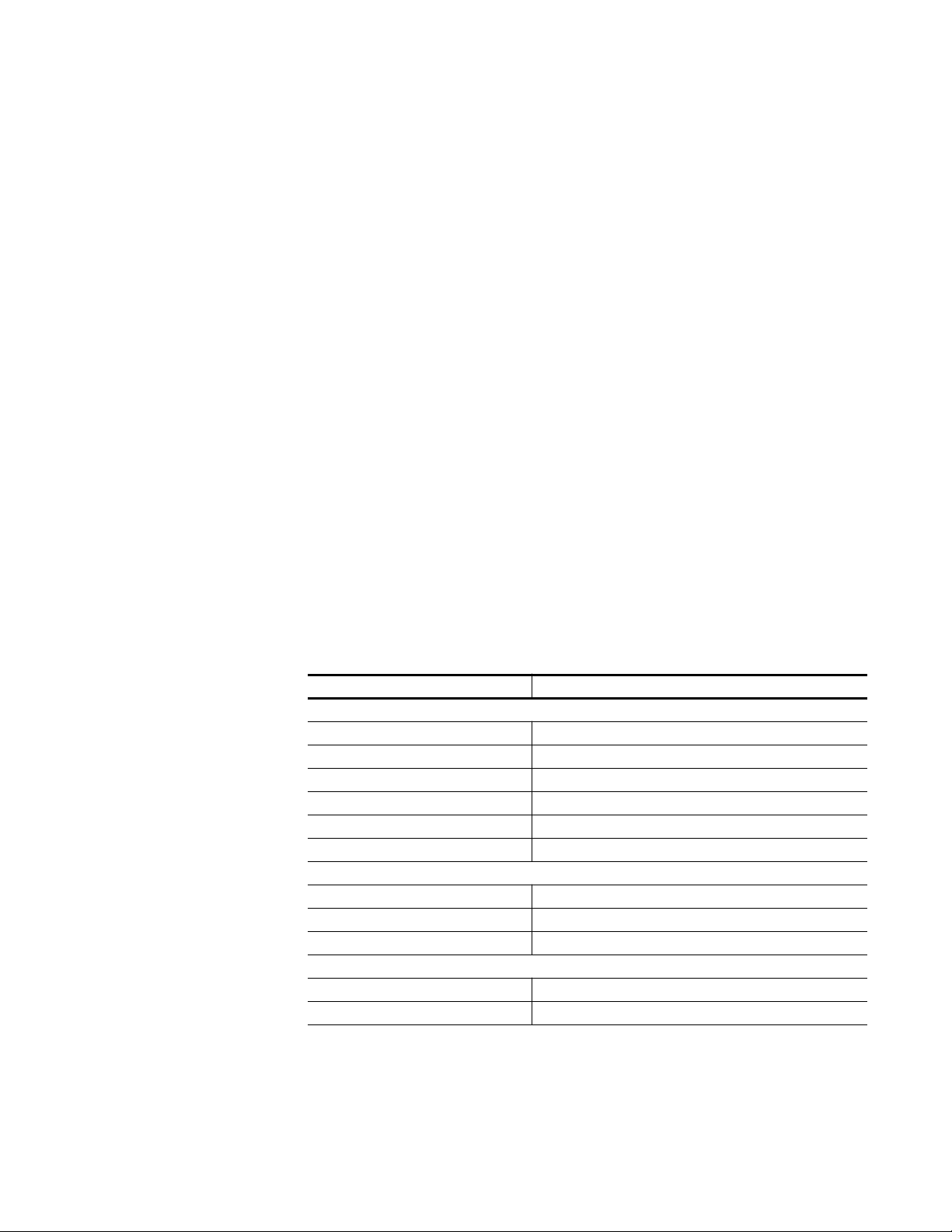

2000 Series Frame Options

A number of options can be ordered for 2000T1 and 2000T3 frames.

Table 1 contains model numbers and descriptions for the 2000T1 and

2000T3 frames and frame options.

Table 1. 2000 Series Frames and Frame Options

Model Number Description

2000T1D 1 RU frame with dual redundant 130W power supply

2000T1DN 1 RU frame with dual redundant 130W p/s and 2000NET module

2000T1DNG 1 RU frame with dual redundant 130W p/s, 2000NET and 2000GEN module

2000T3 3 RU frame with single 240W power supply

2000T3N 3 RU frame with single 240W p/s and 2000NET module

2000T3NG 3 RU frame with single 240W p/s, 2000NET and 2000GEN module

2000FAN Fan sled for 3RU frame (required for >150 W frame loading

2000EMI Blank rear covers for both 1 RU and 3 RU frames

2000PS Replacement or redundant 240W power supply for 2000T3 frames

2000PS1 Replacement dual redundant 130W power supply for 2000T1 frames

2000NET

2000GEN

2000A89 8900 Module Adapter

Network Interface Module for Ethernet I/F required for Newton control panel,

adds frame sync functionality, web browser and remote control.

Genlock module for 1 RU and 3 RU frames, required for Kameleon KAM-AV

and KAM-SD modules

Power Supply Options

The 2000 Series module power usage varies greatly from less complex

analog to higher complexity digital circuitry. To handle these power

requirements, the 2000T1 and 2000T3 model frame power supply options

include:

• Spare or replacement 130 Watt dual redundant power supplies for the

2000T1 frames (2000PS1D),

•Redundant 240 Watt power supply for the 2000T3 frame (2000PS), and

• Fan sled containing two fans for cooling the 2000T3 frame in applications where installed modules require > 150W of power (2000FAN).

18 Kameleon Frames Instruction Manual

Page 19

2000 Series Frame Options

Up to two optional

fan modules can

be installed.

Each slot

(19, 20, 21)

can accept

a fan module.

Power Supply

Slot 19

Power Supply

Slot 21

Slot 20

8039-05

When the 2000T3 Series frame is loaded with modules that require

greater than 150 Watts of power and only one power supply sled is

installed, a fan module is required for adequate cooling. The 2000FAN

sled normally resides between the two power supply slots shown in

Figure 3. If extra cooling is desired and the frame operates on only one

power supply sled, a second fan sled can be placed in either power

supply slot. Refer to Power, Cooling, and Module Capacity on page 22.

Figure 3. T3 Frame Fan Module Slot

Monitoring and Control

The 2000 Series frame offers extensive control and monitoring capability

when the 2000 Network Interface Module option (2000NET) is added.

The 2000NET Network Interface Module supports the frame connections

for:

• Frame Health alarm relay (2000T3 frames only),

• Frame network configuration serial port, and

• Ethernet 10Base-T connection for Grass Valley Modular Control and

The 2000NET module also provides DIP switches for enabling and disabling alarms, and LED indicators for quick diagnostics of alarm conditions related to temperature, power supply health, frame bus

communications and module error reporting. For detailed information on

the 2000NET module and GUI refer to the 2000NET Network Interface

Module Instruction Manual available on-line.

Monitoring System (web browser-based GUI) and Newton Control

System.

Kameleon Frames Instruction Manual 19

Page 20

Section 1 — Kameleon 2000 Series Frames

Genlock Timing

A 2000GEN Genlock Timing module is available for providing clock and

pulse timing references from a reference black burst for distribution to the

2000T1 and 2000T3 frame modules (2000GEN). This module is required for

frames with Kameleon KAM-AV, KAM-SD, KAM-HD, and KAM-XM

modules installed. The 2000GEN module can be ordered separately or

comes with the 2000T1DNG or 2000T3NG model frames.

Other Frame Options

Other frame options include:

• 2000A89 adapter for installing Gecko 8900 modules in the 2000 frames,

and

• 2000EMI blank plates can be ordered for installing in unused frame

positions for both the 2000T1 and 2000T3 frames.

20 Kameleon Frames Instruction Manual

Page 21

2000T3 Frame Connections

The rear of the 2000T3 frame provides twelve rear media or passive I/O

module slots that support various combinations of connectors for

input/output functions. Specific input/output functions are determined

by the module type installed (see Figure 4). Some rear modules require two

slots. 2000EMI blanks can be installed in unused cell locations.

Figure 4. 2000T3 Module I/O Connectors

2000T3 Frame Connections

Power, frame

configuration,

& frame health

connections

Power,

Frame Configuration,

and Frame Health

Connectors

Media section

rear slots 7-12

Network

and reference

input connections

Media section

rear slots 1-6

8039-02

The power/configuration/GPI section of the frame (Figure 5) provides AC

power plug connections and two DB9 connectors for Network Configuration (J101) and Frame Health alarm relay (J103).

The network and reference connection section provides Ethernet RJ-45 connector (J104), and loop-through reference input BNCs (J106 and J107).

Figure 5. 2000T3 Power/Communication Connectors

J1

SER 1

CONFIG

SER 3

GPI

J101

J2

J103

8039-13

GND

Kameleon Frames Instruction Manual 21

Page 22

Section 1 — Kameleon 2000 Series Frames

2000T1 Frame Connections

The rear of the 2000T1 frame provides four rear media or passive I/O

module slots that support various combinations of connectors for

input/output functions. Specific input/output functions are determined

by the module type installed (see Figure 6). Some modules require two

slots. 2000EMI blanks can be installed in unused cell locations.

Figure 6. 2000T1 Module I/O Connectors

1

3

J101

J102

2

4

Power connections

Media section

rear slots 3-4

(with 2000EMI blank)

Network

and reference

input connections

The power section of the frame provides:

• AC power plug connections and cord retention clip.

The network and reference connection section provides:

• Ethernet RJ-45 connector (J101), and

•Reference input BNC (J102) internally terminated into 75 Ω.

Power, Cooling, and Module Capacity

The 2000T3 frame and the optional fan module provide a great deal of flexibility in the type of modules that can be installed. The frame can support

both conventional low power analog DAs and higher power serial digital

modules with all modules performing to their full specifications.

Media section

rear slots 1-2

8039-20r1

Note The maximum number of modules shown reflects the cooling capacity of the

power supply/fan configuration rather than the power capacity of the power

supplies. Module capacity figures assume no other media modules are in the

frame.

22 Kameleon Frames Instruction Manual

Page 23

Power, Cooling, and Module Capacity

Table 2 provides maximum power usage per module slot for adequate

cooling in the frame. Frame, power supply and fan configurations are

described for the 2000T3 and the 2000T1 frames with 2000NET, 2000GEN,

and front media modules.

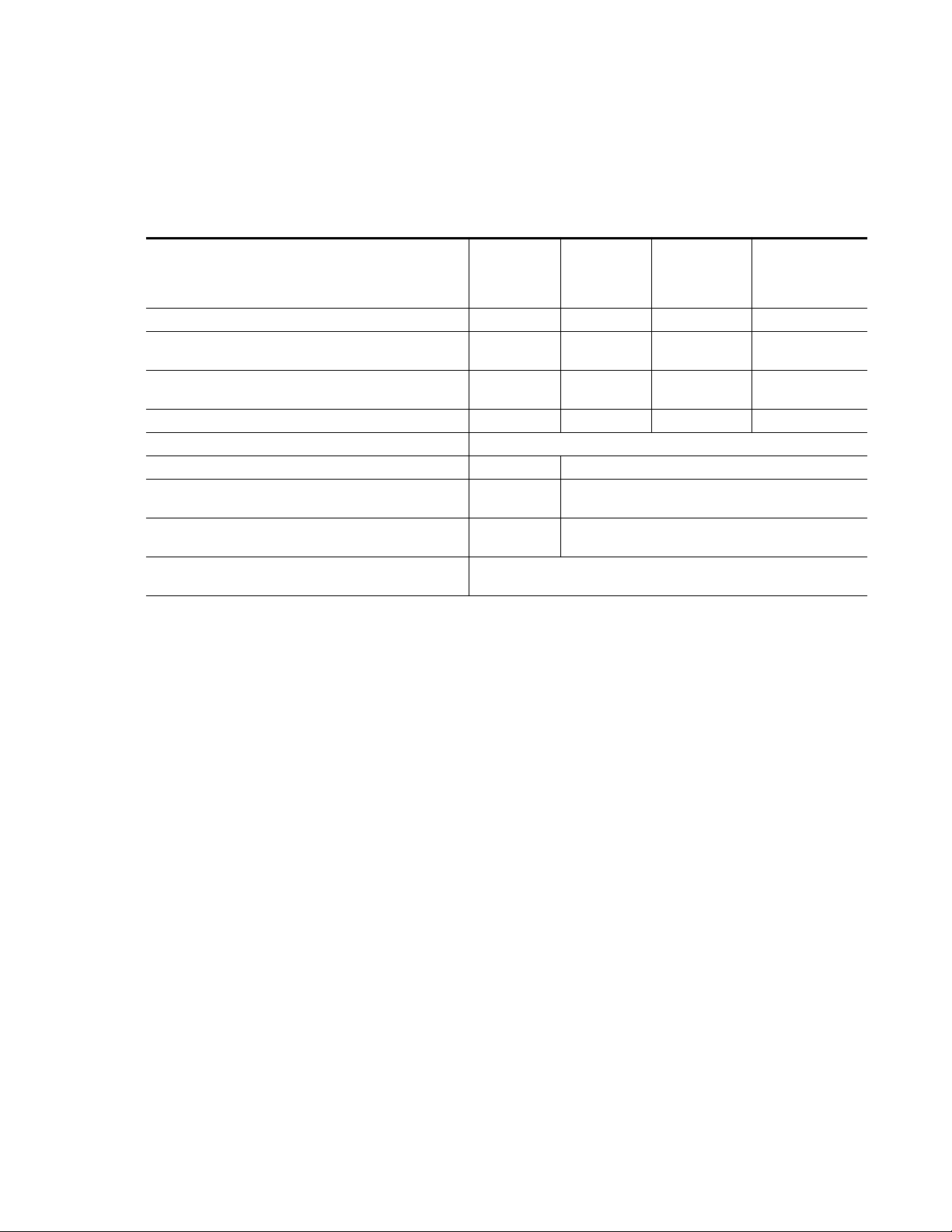

Table 2. Power, Cooling, and Module Capacity of 2000 Frames

Capacity Calculated

Power (W) 95 W 165 W 212 W 240W

Recommended maximum power per front module to ensure ade-

quate cooling

Recommended maximum power per rear module to ensure ade-

quate cooling

Recommended maximum slot power to ensure adequate cooling 20 W 12 W 17.5 W 17.5 W

Power supply load dissipated by power supply sled 4.6 W (fans)

Power supply load dissipated by fan module N/A 4.6 W

Recommended maximum 2000NET module slot power to ensure

adequate cooling

Recommended maximum2000GEN module slot power to ensure

adequate cooling

Recommended maximum front media module slot power to

ensure adequate cooling

2000T1with

Dual Power

Supply Sled

16 W 12 W 17.5 W 16 W

8 W 6 W 8 W 8 W

5 W 5 W

5 W 5 W

Refer to specific module instruction manual for power usage and maximum recommended modules per frame.

2000T3 with

Single Power

Supply Sled

2000T3 with

Two Power

Supply Sleds

2000T3 with

Single Power

Supply Sled and a

Fan Assembly

Kameleon Frames Instruction Manual 23

Page 24

Section 1 — Kameleon 2000 Series Frames

24 Kameleon Frames Instruction Manual

Page 25

Installation

Introduction

This section contains information about:

•Rack mounting the frame,

•Module installation,

•Monitoring frame health, and

• Serial configuration port connection.

After carefully unpacking this equipment, check the box for power cords

and other hardware, and examine the equipment for damage. Any damage

should be promptly reported to the carrier.

Section 2

The frames are designed to mount in a standard 19-inch equipment rack

and require a depth of 21.5 inches (546 mm) plus cabling space. The 2000T3

frame requires a vertical space of 5.25 inches (134 mm). The one rack unit

2000T1 frame requires 1.75 inches (44.45 mm) of vertical space.

Kameleon Frames Instruction Manual 25

Page 26

Section 2 — Installation

Rack Mounting the Frame

Use the rear support hardware to help support the weight of the frame.

Refer to Figure 7 while following these steps to install either the 2000T3 or

2000T1 frame (3 RU 2000T3 frame shown). You will need rack mount

screws to fit the front and rear rack rails.

1. Remove and discard the existing pan-head machine screw on each side

of the frame.

Note The 2000T1 frame uses this screw location (on the power supply side) for

attaching a ground cable. See Grounding on page 27.

2. Attach the frame support plates to each side of the 2000 frame using

three 10 mm machine screws (provided) on each side.

3. Secure the rear rack plates to the rack at the appropriate locations using

customer-supplied rack mounting screws.

4. Lift the frame into the rack and slide the frame support plates into the

open slots of the rack plates.

5. Secure the frame front to the equipment rack using four

customer-supplied rack mounting screws.

Figure 7. Frame Support and Rack Mounting (one side shown)

Remove and discard

the existing support

screw

10 mm machine

screws provided

Rear rack plate

Frame

support

plate

8039 -11

26 Kameleon Frames Instruction Manual

Page 27

Grounding

Rack Mounting the Frame

The 2000T3 frame provides a frame grounding post below the AC plug

receptacles. To ground the 1 RU 2000T1 frame, remove the existing pan

head screw on the power supply side of the frame (see Figure 8) and attach

a ground cable using a 10 mm machine screw (provided with rear frame

support hardware). The ground cable may be installed with the rear

support plate as shown or directly to the frame if the support option is not

used.

Figure 8. Grounding the 2000T1 Frame

Existing support screw is replaced

with a pan-head screw included in

the frame support package

Frame rear support plate

Ground cable

(user-supplied, place on

power supply side of frame)

8039 -23

Kameleon Frames Instruction Manual 27

Page 28

Section 2 — Installation

Power Supplies

Network Slot (13)

There are two types of 2000 Series power supplies — one for use in the 3 RU

2000T3 frame (model 2000PS) and one for use in the 1 RU 2000T1 frame

(model 2000PS1D).

CAUTION Check the label at the power supply connector end to verify the type of supply

before installing it in the frame. Keying is used to prevent the insertion of the

wrong supply. Damage to the power supply and frame can result from forcing

the wrong supply into the frame.

Power supplies are shipped separately and should be installed after the

frame is in the equipment rack. In the 2000T3 frame, the top and bottom

frame slots (19 and 21) on the right side are allocated for 2000PS power

supply sleds (see Figure 9). The 2000PS sled is keyed for use in the 2000T3

frame only. If the frame has only one power supply sled, it should reside in

slot 19 for maximum cooling. Up to two optional fan modules can be

installed in slots 19, 20, or 21. All three slots will accept a fan module.

Figure 9. 2000 Series Frame

Reference Distribution Slot (15)

Main Power Supply Slot (19)

(1)

(2)

(3)

(4)

(5)

(6)

(13)

(15)

(7)

(8)

(9)

(10)

(11)

(12)

Redundant Power

Supply Slot (21)

Front Media Slots (1-12)

Slot (20)

The 1 RU 2000T1 frame uses the single supply sled 2000PS1D containing a

primary and redundant power module. This supply is keyed for insertion

into the 2000T1 frame only.

To install a power supply:

1. Remove the frame front cover.

2. Slide the supply sled into the desired slot holding the spring tensioned

locking handle to the left (see Figure 10 on page 29).

8039-04

3. Lock the supply in place. The handle locking pins slide into the slot in

the side of the frame.

28 Kameleon Frames Instruction Manual

Page 29

Module Installation

Figure 10. Power Supply Locking Pin

Module Installation

There are twelve front slot and twelve rear slot locations in the 2000T3

frame to accommodate either analog or digital modules (refer to Figure 9

on page 28). The 1 RU 2000T1 holds four front and four rear modules (see

Figure 11). If a front slot module is installed, an appropriate rear connector

module must be installed in the associated rear slot.

8039-10

Power

supply

locking

slot

Note Some rear modules are dual height and require 2 slots. This will affect the

number of actual modules that can be installed in the frame. Refer to the specific module manual for more information.

Input and output configuration is determined by the design of the module

installed. Refer to the appropriate module instruction manual for

input/output configuration information for specific modules.

In the 2000T3 frame, the top slot of the center section (slot 13) is dedicated

to the 2000NET Network Interface Module. The 2000T1 slot #5 accepts the

2000NET module. This module provides intraframe and network communication and monitoring including the alarm reporting. For additional

information concerning monitoring and control, refer to the 2000NET

Network Interface Module Instruction Manual.

Note Center slots 14, 16, 17, and 18 are not used in the 2000T3 frame. Even

though some versions of the frame have board-edge guides for these slots,

they should not be used.

Figure 11. 2000T1 Frame Front

Network Slot (5) Power Supply Slot (7)

(1)

(2)

(5)

(6)

(3)

(4)

8039-21

Front Media Slots (1-4)

Kameleon Frames Instruction Manual 29

Page 30

Section 2 — Installation

Rear Modules

When installing a front and rear media module pair, the rear module

should be installed first. When a front slot active module is installed, it

requires a passive connector module in the associated rear module slot. The

passive rear module allows flexibility in selection of I/O connectors.

Note Connector configuration overlays are available for many 2000 modules that

use the standard Coax Passive Rear Module (Coax PRM) with ten BNC connectors. These overlays are found at the back of the module instruction

manual.

Figure 12 illustrates a passive rear connector module. The installation pro-

cedure is the same for active and passive rear modules.

Figure 12. Typical 2000 Series Rear Module Installation

Board edge guides

2000 frame (rear view)

(both sides)

Rear alignment

post and receptacle

2000 Rear module

Screw lock

(both sides)

To install a rear module, follow these steps:

1. Hold the module component side up. Insert the right edge of the

module between the right side board edge guides and slide the module

into the frame until the left edge enters the left guides.

2. Slide the module in and verify that the module connector seats

properly against the backplane.

3. Press the outside edges of the rear connector plate to fully seat the

module. Use a crosshead screwdriver to tighten the captive screws at

each side.

8039-15

30 Kameleon Frames Instruction Manual

Page 31

Front Modules

Module Installation

Figure 13 illustrates a front media module installation.

Figure 13. Typical 2000 Series Front Module Installation

2000 Frame (front view)

Alignment post and receptacle

Board edge

guides

Board edge

guides

8039-16

2000

To install a front module in the frame, follow these steps:

1. Hold the module component side up. Insert the left edge of the module

between the left side board edge guides and slide the module into the

frame until the right edge enters the right guides.

2. Verify that the module connector seats properly against the backplane

and the rear module connector.

Note If the rear module is a dual height version, make sure the front module is

inserted in the correct slot to meet the rear connectors.

3. Press the ejector tabs to seat the module in place.

Kameleon Frames Instruction Manual 31

Page 32

Section 2 — Installation

Reference Inputs

The 2000T3 frame’s Reference input (see Figure 14) uses loop-through connectors.

Figure 14. Frame Loop-though Reference Input

Power, frame

configuration,

& frame health

connections

Media section

rear slots 7-12

Network

and reference

input connections

Media section

rear slots 1-6

8039-02

If not used for looping, the loop-through input should be externally terminated. The recommended termination for serial digital signals is CANARE

BCP-TA (or equivalent).

Performance of looping inputs to equipment other than Grass Valley

equipment has not been verified; monitor signal quality carefully when

configuring such a system.

In the 2000T1 frame, the Reference input is a single BNC that is internally

terminated into 75Ω.

For more information about the reference input, see the 2000GEN Module

Instruction Manual.

Figure 15. 2000T1 Reference Input

1

3

J101

J102

2

4

Power connections

Media section

rear slots 3-4

(with 2000EMI blank)

Network

and reference

input connections

Media section

rear slots 1-2

32 Kameleon Frames Instruction Manual

8039-20r1

Page 33

Frame Health Alarm Connector (2000T3 only)

The frame health alarm provides a relay closure that will act as an alarm

trigger for a user-supplied alarm circuit. The relay is accessed through connector J103 SER3/GPI shown in Figure 16.

The frame health alarm responds to conditions enabled on the 2000NET

Network Interface module with DIP switches S1 and S2 as given in Table 3.

This information from the module is also available over the network to an

SNMP monitoring system as described in detail in the 2000NET Instruction

Manual.

Figure 16. Frame Health Alarm Connector Location

J1

Module Installation

Power,

Frame Configuration,

and Frame Health

Connectors

S1 Segment Left Position (open) Right Position (closed)

1 PS1 fault reporting enabled PS1 fault reporting disabled

2 PS2 fault reporting enabled PS2 fault reporting disabled

3 PS3 fault reporting enabled PS3 fault reporting disabled

4 PS4 fault reporting enabled PS4 fault reporting disabled

5 (Currently not used)

6 Fan fault reporting enabled Fan fault reporting disabled

7 Module fault reporting enabled Module fault reporting disabled

8 Frame Bus fault reporting enabled Frame Bus fault reporting disabled

S2 Segment Left Position (open) Right Position (closed)

1 Asynchronous Status Enabled (enabled alarms are reported over SNMP) SNMP Reporting is disabled except for Over Temp alarm

2 Net module remote control enabled Net module remote control disabled

3 (Currently not used)

4 Frame remote control enabled Frame remote control disabled

5-8 (Currently not used)

SER 1

CONFIG

J101

J2

Table 3. 2000NET Configuration DIP Switches, S1 and S2

GND

SER 3

GPI

J103

8039-13

Kameleon Frames Instruction Manual 33

Page 34

Section 2 — Installation

A number of frames can be coupled together as one alarm circuit. Refer to

Figure 17 for a typical alarm circuit interconnect diagram.

Up to 20 Frames

Figure 17. Frame Health Alarm Relay Connections

Last Frame

J103

J103

First Frame

J103

Health Alarm Circuit

To pin 8

To pin 9

470 Ω

4.7 kΩ

4.7 kΩ

330 Ω

Pin 8

Pin 9

J103

+5V

2N4126

(or equivalent)

Normally

open relay

Alarm

LED

8039-14

Serial Configuration Port Connection

On the 2000T3 frame, the female DB9 connector J101 is used to connect a

computer running terminal emulation to initially configure the frame for

networking. The 2000NET Network Interface Module is required to

support this connection. In the 2000T1 frame, the RJ-45 connector on the

front of the 2000NET is used for this function. Refer to the 2000NET

Network Interface Module Instruction Manual for details.

34 Kameleon Frames Instruction Manual

Page 35

Power Up

Introduction

This section contains information about:

• Power Connections

•Applying Power

CAUTION Verify that the power supplies are fully seated in their slots. The handle

Section 3

locking pins slide into a locking slot in the side of the frame (see Figure 18).

Figure 18. Power Supply Locking Pin

8039-10

Power

supply

locking

slot

Kameleon Frames Instruction Manual 35

Page 36

Section 3 — Power Up

Power Connections

The 2000 Series frames and optional redundant power supplies are shipped

with the proper power cords for 120V or 240V operation. Line voltage

selection is not required for this power supply. The power cord connector

type shipped is determined by the shipment’s destination.

For each power supply installed, AC power is fed through a line cord to a

socket (J1 and J2) on the rear of the frame (see Figure 19, 2000T3 frame

shown).

Figure 19. AC Power Connectors

J1

Power,

Frame Configuration,

and Frame Health

Connectors

SER 1

CONFIG

J101

J2

GND

SER 3

GPI

J103

8039-13

Note For the most effective use of redundant power, ensure that each power supply

cord is plugged into a separate branch circuit.

36 Kameleon Frames Instruction Manual

Page 37

Line Cord Retainer Clip

To help prevent accidental loss of power, the AC line cord is held in place

by a retainer clip (see Figure 20). The 2000T1 frame uses a double cord

retainer clip.

Figure 20. Cord Retainer Clips

Power Connections

Double

retainer

clip for

2000T1

Single

retainer clip

for 2000T3

Screw cap

8039 -17

To properly install the line cord, follow these steps:

1. Ensure that the retainer clip is inserted properly into the holes of the

screw caps.

2. Lift the retainer clip and plug the power cord into the receptacle.

3. Drop the retainer clip onto the power cord so the plug cannot be pulled

from its receptacle.

Kameleon Frames Instruction Manual 37

Page 38

Section 3 — Power Up

Applying Power

PS 1 Green OK LED

PS 1 Voltage test pad

PS 2 Voltage test pad

PS 2 Green OK LED

Upon applying power to the frame, verify that the green power LEDs for

each power supply sled are illuminated. Each power supply sled has a

power LED for each of its supplies (PS 1 and PS 2).

If the frame has a fan module and a 2000NET module installed, check the

red FAULT LED on the front cover. It should go off if the fans are operating

correctly and no other frame faults are detected by the 2000NET module.

Note The Fault LED is on while the 2000NET module is booting. It may take up to

45 seconds to extinguish.

The power supply LEDs may require several seconds to display correct

status after power is applied.

Figure 21. Power Indicator LEDs and Test Pads (2000T3 frame shown)

Power Supply

Redundant

Supply

8039-08

Other indicator LEDs can be viewed on the optional 2000NET module with

the front cover removed. If you have a 2000NET module installed in the

frame, see the 2000NET Network Interface Module Instruction Manual for

indicator details.

38 Kameleon Frames Instruction Manual

Page 39

SpeciÞcations

Introduction

This section discusses specifications for the 2000 Series frames and the

2000PS and 2000PS1D power supplies. Refer to the module instruction

manual for the specifications for the 2000NET Network Interface Module

or a specific media module.

Frame Specifications

Section 4

See Table 4 for a list of the 2000 Series frame specifications. Specifications

are subject to change without prior notice.

Table 4. 2000 Series Frame Specifications

Parameter Value

Frame Health Alarm Relay (2000T3 only)

Connector type DB9 9-pin female (pins 8 and 9))

Maximum current 1 A

Maximum voltage 28 V

Contact resistance 100 mΩ typical

Open state Frame status good

Closed state Fault or no power to the frame

2000T3 Front Cover Indicators

Upper power supply PS 1 & PS 2 Green LEDs — Both ON indicates correct operation

Lower power supply PS 1 & PS 2 Green LEDs — Both ON indicates correct operation

Fault (requires 2000NET module) Red LED — ON indicates an error or failure

2000T1 Front Cover Indicators

Power supply PS 1 & PS 2 Green LEDs — Both ON indicates correct operation

Fault (requires 2000NET module) Red LED — ON indicates an error or failure

Kameleon Frames Instruction Manual 39

Page 40

Section 4 — Specifications

Table 4. 2000 Series Frame Specifications - (continued)

Parameter Value

Operating Conditions

Operating temperature range 0 to 40 degrees C

Non-operating temperature range -10 to +70 degrees C

Humidity Up to 90% non-condensing

Mechanical

Height 2000T3 – 3RU, 5.25 inches (133.0 mm)

2000T1 – 1RU, 1.75 inches (44.45 mm)

Width 19 inches (483 mm)

Depth 21 inches (533 mm)

2000T3 weight with no modules 1 power supply – 26 lb (11.8 kg)

2 power supplies – 28.5 lb (12.9 kg)

2000T1 weight with no modules 15.5 lb (7.0 kg)

Power

Inputs Two independent AC inputs

Connector type IEC with cord retention

Agency Compliance

UL 1950

EN60950

CSA-C22.2 NO. 950-93

IEC950

40 Kameleon Frames Instruction Manual

Page 41

Power Supply

Power Supply

See Table 5 for a list of power supply specifications. Specifications are

subject to change without prior notice.

Table 5. 2000PS Power Supply Specifications

Parameter Value

Inputs

Voltage range 90 to 132 V, 180 to 264 V, single phase

Frequency 47 Hz to 63 Hz

Input power 240 W maximum

Line current max. load 6.6 A with power to both power supplies on the sled

Inrush current Maximum 40 A at 264 VAC at cold start

Outputs

Voltage/current +23.75 V @ 9.17 A

Load range 0.0 to 9.17 A for +24 V

Load/line regulation ± 1% for loads from nominal to maximum

.3% varying line voltage from 90 to 132 VAC and 180 to 264 VAC at full

load.

Over voltage protection Limit at 30 V ±2 V

Overshoot Less than 3%

Power factor correction Complies with EN61000-3-2 Class D

Table 6. 2000PS1D Power Supply Specifications

Parameter Value

Inputs

Voltage range 90 to 132 V, 180 to 264 V, single phase

Frequency 47 Hz to 63 Hz

Input power 130 W maximum

Line current max. load

Inrush current Maximum 40 A at 264 VAC at cold start

Outputs

Voltage/current +23.75 V @ 5.4 A

Load range 0.0 to 5.4 A for +24 V

Load/line regulation ± 1% for loads from nominal to maximum

Over voltage protection Limit at 30 V ±2 V

Overshoot Less than 3%

Power factor correction Complies with EN61000-3-2 Class D

Kameleon Frames Instruction Manual 41

Page 42

Section 4 — Specifications

42 Kameleon Frames Instruction Manual

Page 43

Service

Introduction

Section 5

This section contains general frame service information concerning:

• Power supply monitoring and troubleshooting,

• Power supply and fan replacement, and

•Maintenance.

For specific module service information, refer to the individual module

manuals.

CAUTION Servicing equipment which is still under warranty may result in that warranty

being void. Contact your Grass Valley distributor or Grass Valley Customer

Support before servicing.

WARNING Failure to disconnect power before servicing equipment may result in

severe shock or burns. Be sure to disconnect the power cord(s) before servicing the equipment.

Kameleon Frames Instruction Manual 43

Page 44

Section 5 — Service

Power Supplies

The Grass Valley 2000 Series Power Supply sleds are designed to carry two

24V power supplies. The two supplies are load-sharing in the 2000T3 and

redundant in the 2000T1 frame. In the 3 RU 2000T3 frame, a second power

supply sled can be added for redundancy. The 2000PSD1 supply for the

1 RU 2000T1 frame is a dual redundant supply.

Line voltage selection is not required for the 2000 Series power supplies.

They adjust automatically to accept between 90 to 132 V or 180 to 264 VAC

through the AC line cord connected to the rear of the frame. The supply

delivers regulated +24 VDC to each module installed in the frame. One

power supply is capable of powering a full frame of modules. When a

redundant power supply sled is installed in a 2000T3 frame, internal isolation diodes ensure automatic power supply backup.

The power supply sled with two power supplies and cooling fans is illustrated in Figure 22. The 2000PSD1 sled is keyed to insert in the 2000T1

frame only. The 2000PS sled is keyed to insert in the 2000T3 frame only.

AC input

connector

DC output

and monitor

connector

Figure 22. Power Supply module

Power Supply PS 2

Power Supply PS 1

8039-06

44 Kameleon Frames Instruction Manual

Page 45

Monitoring Power Supplies and Fans

If the 2000NET Network Interface Module is installed, power supply and

fan monitoring is available through the frame health relay (2000T3 frame

only) and the remote control and monitoring system (GUI).

CAUTION Always verify that the power supplies are fully seated in their slots. The

locking pin on the supply handle should lock into the hole on the side of the

frame (see Figure 23).

Power Supplies

Figure 23. Power Supply Locking Pin

8039-10

Power

supply

locking

slot

Troubleshooting

Use the following sequence of simple checks in the event of problems with

your 2000 Series power supply. If the problem cannot be determined,

contact your Grass Valley distributor or the Grass Valley Customer Support.

CAUTION Equipment may contain static-sensitive components. Use properly grounded

test equipment and work only in static protected areas to avoid damage.

1. Check Associated Equipment.

Before proceeding with troubleshooting, check that the equipment

connected to the 2000 Series frame is operating correctly. Check all

input signals to the frame to be sure they are present; make sure cables

are not defective and are properly connected.

2. Check Power.

Check the LEDs on the power supply front panel. The two green LEDs

should be illuminated when power is applied. If not, check that the

power cable is connected to a source of power. Verify whether there is

power available at the power main. If any LED still does not light, use

a voltmeter to verify that the +24V is truly not present at the associated

testpoint (checking for a failed LED). If the voltage does not register on

the testpoint (see Figure 24), replace the power supply with a

known-good supply.

Kameleon Frames Instruction Manual 45

Page 46

Section 5 — Service

PS 1 Green OK LED

PS 1 Voltage test pad

PS 2 Voltage test pad

PS 2 Green OK LED

Redundant

Supply

Figure 24. Power Supply Voltage Testpoints

Power Supply

8039-08

3. Check Control Settings.

If there is any question about the correct function or operation of any

control, refer to the appropriate module manual. If proper control

settings do not help, go on to the next check.

4. Module Exchange.

If spare modules are available, module exchange is the most efficient

method of localizing a problem. This is especially true if you are not

familiar with the internal operation of the 2000 Series or its modules.

5. Visual Checks.

Visually check modules in which the trouble appears to be located.

Many problems can be located by visible indication, such as connectors

not seated or loose cables.

6. Check Voltages.

Begin by looking at the block diagrams located in each module manual.

This will provide a quick understanding of the module. Use an

oscilloscope or voltmeter to check that the voltages are correct.

46 Kameleon Frames Instruction Manual

Page 47

Fan Replacement

A fan failure is reported through the 2000NET module (if present) to the

Health Alarm Relay (2000T3 frame only) as a simple alarm closure. Using

the GUI you can select the frame status display to see Fan Status and click

on the suspect power supply sled to see which fan is reporting a failure (see

the 2000NET Network Interface Module Instruction Manual for details).

If a fan needs to be replaced, contact Grass Valley Customer Support to

order the appropriate replacement fan. To install a new fan, refer to

Figure 25 while performing the following:

1. Remove the frame front cover and slide the power supply sled out.

CAUTION Do not leave the 2000T3 front cover off the frame for extended periods when

2. Remove the appropriate connector (J4 or J3) from the power

3. Remove the fan assembly bracket by removing the three hex nuts and

Fan Replacement

the frame is powered.

distribution board.

interior star washers and lifting both fans from the sled.

4. Remove the two crosshead retainer screws from the corners of the fan

bracket for the defective fan.

5. Install the replacement fan, replace the fan assembly, and re-connect the

fan lead wires.

6. Install the power supply module in the frame and replace the front

cover.

Figure 25. Fan Replacement

Hex nut and star washer (3 places)

Fan #2

Fan #1

8039-07

Mounting

Screws

Mounting

Screws

Fan Connectors

J4 (top) and J3

Kameleon Frames Instruction Manual 47

Page 48

Section 5 — Service

Maintenance

Each of the 2000 Series frames has a filter located on the inside of the front

cover. This filter should be cleaned as needed. The filter is easily removed

by pulling it straight out of the cover. The keying of the cutouts in the filter

maintains the proper front/back orientation. Use a vacuum on the front

side of the cover to remove dust. If it becomes necessary to replace the filter,

you can order a replacement from Grass Valley Customer Support.

48 Kameleon Frames Instruction Manual

Page 49

Index

Numerics

2000GEN module

description

2000NET module

description

A

AC power 21, 22

alarm 21

alarm circuit 34

alarms

disabling

applying power 38

B

BNCs 21, 22

branch circuit 36

19

20

19

F

fan filter 48

fan replacement 47

FAQ database 2

filter replacement 48

frame connections 21

Frame Health Alarm

description

Frame Monitor Module 33

frequently asked questions 2

33

G

Grass Valley web site 2

ground 27

H

health alarm 34

C

capacity 23

connector

alarm

21

cooling 19, 23

cord retainer 37

D

DB-9 connector 21

disabling alarms 19

documentation online 2

dual height rear modules 16, 29

E

equipment rack 25

ethernet 21, 22

I

input/output configuration 29

installation

frame rack mounting

modules 29

power supplies 28

26

J

J101 33

L

line cord 36

line voltage 36

loop-through reference input 32

Kameleon Frames Instruction Manual 49

Page 50

Index

M

maintenance 48

media module capacity 23

N

Network Interface Module 29

O

online documentation 2

options

frame

18

power supply 18

P

power 23, 40

power requirements 18

power supplies

description

installation 28

28

T

termination 32

troubleshooting 45

W

web site documentation 2

web site FAQ database 2

web site Grass Valley 2

web site software download 2

R

reference inputs

cabling

relay 34

replacement fan 47

retainer clip 37

RJ-45 connector 34

RS-232 22

32

S

serial configuration port 34

service information 43

sled

fan

19

power supply 19

software download from web 2

specifications 39

frame 39

power supply 41

50 Kameleon Frames Instruction Manual

Loading...

Loading...