Page 1

2000GEN

GENLOCK TIMING MODULE

Instruction Manual

SOFTWARE VERSION 1.0.0

071817201

AUGUST 2003

Page 2

Contacting Grass Valley

Region Voice Fax Address Web Site

North America (800) 547-8949

Support: 530-478-4148

Pacific Operations +852-2585-6688

Support: 852-2585-6579

U.K., Europe, Asia, Middle East +44 1753 218 777 +44 1753 218 757

France +33 1 45 29 73 00

Germany +49 221 1791 234 +49 221 1791 235

Copyright © Thomson Broadcast and Media Solutions All rights reserved.

Grass Valley Web Site

Sales: (530) 478-3347

Support: (530) 478-3181

+852-2802-2996

Grass Valley

P.O. Box 599000

Nevada City, CA 959597900 USA

www.thomsongrassvalley.com

The www

Online User Documentation

.thomsongrassvalley.com web site offers the following:

— Current versions of product catalogs, brochures,

data sheets, ordering guides, planning guides, manuals, and release notes

in .pdf format can be downloaded.

FAQ Database

— Solutions to problems and troubleshooting efforts can be

found by searching our Frequently Asked Questions (FAQ) database.

Software Downloads

— Software updates, drivers, and patches can be down-

loaded.

2 2000GEN Instruction Manual

Page 3

Contents

2000GEN Genlock Timing Module

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Module Placement in the Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Reference Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation Indicator LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Remote Control and Monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Module Links and Configuration Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Status Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Genlock Status Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Settings Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Slot Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Locate Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Slot Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Slot Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Hardware Switch Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Slot SNMP Trap Reports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Software Update Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Power-up Diagnostics Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Module Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Index

2000GEN Instruction Manual 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Page 4

Contents

4 2000GEN Instruction Manual

Page 5

2000GEN Genlock Timing Module

Introduction

The 2000GEN Genlock Timing Module locks to reference black burst and

provides clock and pulse timing references for the applicable modules in

Kameleon Series frames.

Key features of the 2000GEN module include:

• Support for NTSC, PAL-B reference input signal,

•A low-jitter 27 MHz reference clock generator,

•A generated common reference pulse stream containing:

•Reference field pulse,

• Frame bit,

•Color-frame bit,

•AES 5 frame sequence bits,

•Differential LVDS (low voltage differential signaling) lines that distribute signals to each front module slot,

•Reference blackburst locked with burst lock PLL as default, and

•Remote control and monitoring support.

2000GEN Instruction Manual 5

Page 6

1.

2.

3.

Installation

Installation

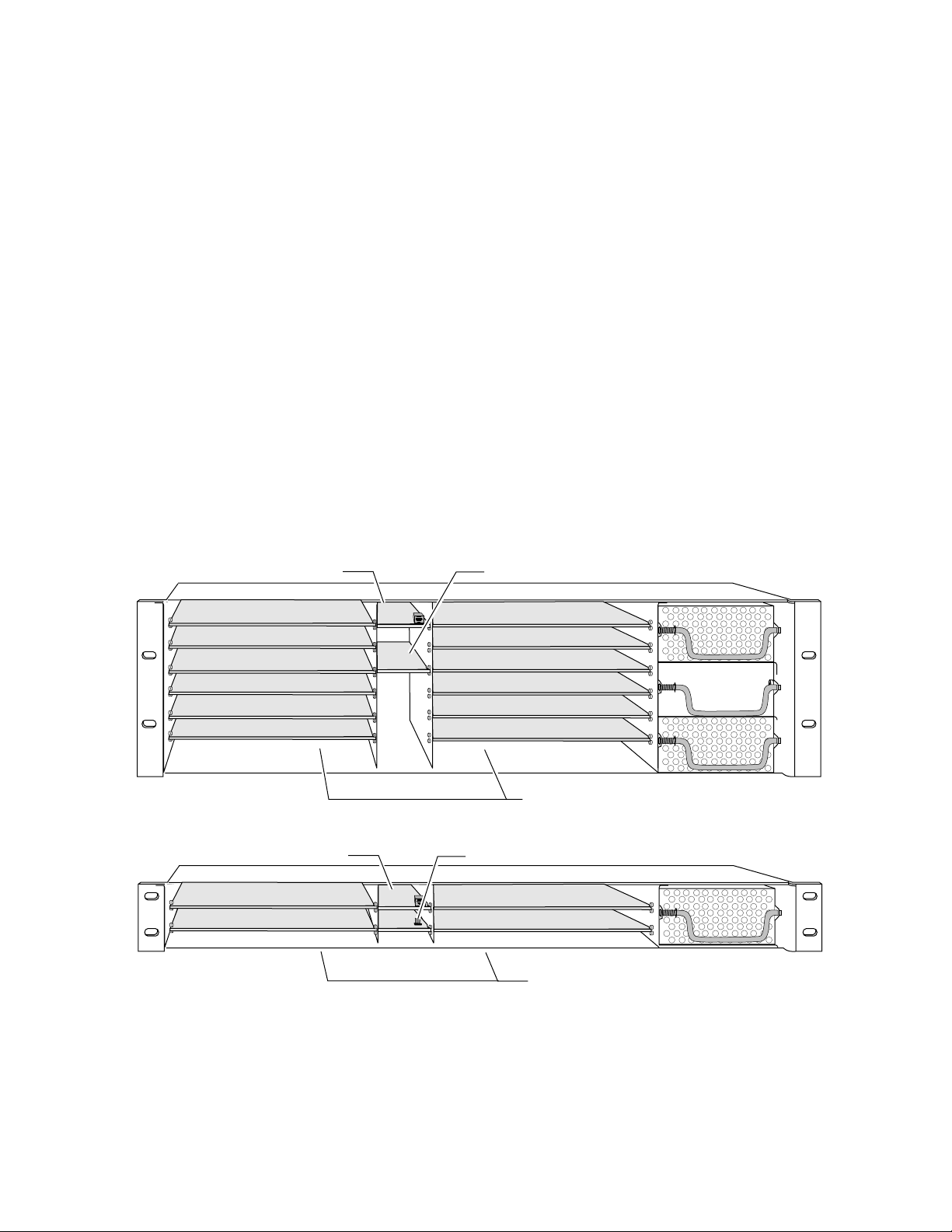

Module Placement in the Frame

The 2000GEN module can be plugged in and removed from a Kameleon

Series frame with power on. When power is applied to the module, LED

indicators reflect the initialization process (see

Power Up

on page 8).

There are six cell locations in central control module section of the 3 RU

frame to accommodate network and reference modules. The 2000GEN

module plugs into Slot 15 (see Figure 1). The 1 RU frame has two central

control module slots. Slot 6 is used for the 2000GEN module.

Install the module by inserting it into the appropriate slot of the frame.

Verify that the module connector seats properly against the midplane

connector.

3 RU Frame

1 RU Frame

Press the module ejector tab to seat the module in the slot.

Figure 1. 2000GEN Module Frame Slots

Network Slot (13)

(1)

(2)

(3)

(4)

(5)

(6)

Network Slot (5) Genlock Timing Slot (6)

(1)

(2)

(13)

(15)

(5)

(6)

Genlock Timing Slot (15)

(7)

(8)

(9)

(10)

(11)

(12)

Front Media Slots (1-12)

(3)

(4)

8172-01

8172-03

Front Media Slots (1-4)

6 2000GEN Instruction Manual

Page 7

Cabling

3 RU Frame

Cabling to the 2000GEN module is done on the BNCs on the rear of the

frame. Refer to Figure 2 for a detailed illustration of the rear connections

referenced below.

Reference Inputs

The 2000GEN will accept any of the video standards listed in the Input

specifications in Table 1 on page 17. Connect a video input to the Reference

BNC. In the 3 RU frame, terminate the looping connector if the signal is not

looped to other equipment.

Figure 2. 2000GEN Input Connectors

Installation

Power, frame

configuration,

& frame health

connections

1 RU Frame

Power connections

Media section

rear slots 7-12

Media section

rear slots 3-4

Reference

Loopthrough Input

1

3

J101

J102

2

4

Terminating

Reference

Input

Media section

rear slots 1-6

Media section

rear slots 1-2

8172-07

8172-06

2000GEN Instruction Manual 7

Page 8

Power Up

Power Up

Operation Indicator LEDs

The on-board LED indicators are illustrated in Figure 3. Upon power-up,

the green PWR LED should light and the yellow CONF LED should illuminate for the duration of module initialization.

After initialization, the green on-board PWR LED should light to indicate

correct power is present. Power can be measured at the indicated

testpoints.

Set the jumper at J8 to

should be off). When remote configuration is complete, the jumper can be

set to local to lock out any further changes but still allow remote monitoring of the module if desired.

Refer to Table 1 on page 9 to see a complete list of possible operating con-

ditions and the resulting indicator status.

Figure 3. LEDs and Configuration Switches

Testpoints

+5V, +3.3V, +2.5V, -5V

FAULT red

Communication (COMM) yellow

Configuration (CONF) yellow

Remote

during configuration (LOCK OUT LED

Remote control

lockout jumper, J8

(Local = Pins 1 and 2,

Remote = Pins 2 and 3)

8172-02

Remote LOCK OUT yellow

PAL M yellow

PAL B yellow

NTSC yellow

Signal Lock LOCKED green

Power OK (PWR) green

8 2000GEN Instruction Manual

Page 9

Table 1 describes the meaning of the various states for the LED indications

on the front of the module (from left to right).

Table 1. Indicator LEDs and Conditions Indicated

LED Indication Condition

Off Module functioning properly

FAULT (red)

COMM (yellow)

CONF (yellow)

PWR (green)

LOCKED (green)

NTSC (yellow)

PAL -B (yellow)

PAL-M (yellow)

LOCK OUT (yellow)

On continuously Module has detected internal fault

Long flash Selected reference signal missing

Off No activity on frame bus

Long flash Locate Module command received by the module from a remote control system

Short flash Activity present on the frame communication bus

Off Module is in normal operating mode

On continuously Module is initializing, changing operating modes or updating firmware

Off No power to module or module’s DC/DC converter failed

On continuously Normal operation, module is powered

Off Signal phase unlocked

On continuously Signal phase locked

Off NTSC mode not selected

On continuously NTSC mode selected

Off PAL-B mode not selected

On continuously PAL-B mode selected

Off PAL-M mode not selected (currently not used)

On continuously PAL-M mode selected (currently not used)

Off Jumper J8 is in the Remote position

On continuously

Jumper J8 is in the Local position, remote module configuration is locked out, monitoring is still enabled

Power Up

2000GEN Instruction Manual 9

Page 10

Remote Control and Monitoring

Remote Control and Monitoring

The 2000GEN has no on-board user configuration requirements. There is a

jumper, J8 — LOCAL/REMOTE , on the front of the module (Figure 3 on

page 8) for enabling or disabling remote control.

2000GEN control and monitoring can be performed remotely using the

2000NET interface (see Figure 4). This section describes the GUI access to

the module configuration and monitoring functions. Refer to the 2

Network Interface Module Instruction Manual

and operating the Kameleon frame network.

000NET

for information on setting up

Note

The 2000 modules can be addressed by clicking on a specific module icon

in the frame status display or on a module name or slot number in the link

list on the left.

Figure 4. 2000NET GUI

The Links section lists the frame and its current modules. The selected link's Status

page is first displayed and the sub-list of links for the selection is opened. The sub-list

allows you to select a particular information page for the selected device.

The physical appearance of the menu displays shown in this manual represent the use of a particular platform, browser and version of 2000NET

module software. They are provided for reference only. Displays will differ

depending on the type of platform and browser you are using and the version

of the 2000NET software installed in your system.

Content display section displays the information page

for the selected frame or module (frame slot icons are also

active links).

Refresh button for manual

refresh of page

Online Manual Link

8046-13 r1

'

10 2000GEN Instruction Manual

Page 11

To navigate to one of the device’s pages click on any of the device’s sub-list

of links. This will update the content display to the right.

Remote Control and Monitoring

Note

Using the web browser’s reload function will always return you to the

Frame Status page. To refresh a particular page, always click on that page’s

Refresh

The Online Manual Link will open a .PDF version of the appropriate

instruction manual if you have set up an Online Manual Server as

described in the 2000NET manual.

To update status, HTML pages must be manually refreshed by clicking on the

Refresh button. Changes made at the frame or from other browsers on the

network will not be displayed until the page is refreshed.

button to the right of the page name.

Module Links and Configuration Displays

The 2000 GUI provides the following links and displays for the 2000GEN

module (Figure 5):

• Status display showing overall module status,

•Genlock Status display showing genlock status,

• Settings display for configuring the module parameters,

• Slot Config display showing slot identification and status reporting,

and

• Software Update display.

The Module Configuration displays operate in the same manner for all

remote controllable 2000 modules. Refer to the 2000NET manual for more

information on these displays. Some functions listed may not be supported

by a particular module. These will be indicated as not supported.

Figure 5. 2000GEN Display Links

2000GEN Instruction Manual 11

Page 12

Remote Control and Monitoring

Status Display

Use

This

Link

The Status display (Figure 6) shows status of the input and output signal

status and module properties (part and serial number, and software, hardware and firmware version).

Figure 6. 2000GEN Status Display

Use

This

Link

Genlock Status Display

The Genlock Status display (Figure 7) shows the genlock standard selected

and lock status of the reference input and color and AES frame.

Figure 7. Genlock Status Display

12 2000GEN Instruction Manual

Page 13

Use

This

Link

Settings Display

The Settings display (Figure 8) provides controls for selecting the video

standard, the genlock mode and for making adjustments to the input

timing stream from the external reference.

The following configuration parameters are provided for the module:

Remote Control and Monitoring

•Use

Standard Select

to choose the video standard as either

NTSC

or

The input video standard is not auto-sensing.

• Set the

Genlock

nected to the reference BNC,

control to lock the module to the external reference con-

Enable

or

Free Run

(not locked to external

reference).

• Set the

Frame Offset

to shift the input timing stream by frames in reference to the input signal color framing (NTSC = 0–1, PAL-B = 0–3,

Default = 0).

• Set the

Line Offset

to shift the input timing stream by lines up to one full

frame (NTSC = 0–524, PAL-B = 0–624, Default = 0).

• Set the

Pixel Offset

to shift the input timing stream by pixels up to one full

line (NTSC = 0–857.5, PAL-B = 0–863.5, Default = 0).

• Set the

AES Frame Offset

to shift the AES marker in the timing stream by

VFrames for NTSC only (NTSC = 0–4, Default = 0). PAL-B is not adjustable (always 0).

• Select

Recall Defaults

to recall preset factory defaults for the selected stan-

dard.

Figure 8. 2000GEN Settings Display

PAL-B

.

Set video standard

Set Genlock mode

Set Line Offset

Set Frame Offset

Set Pixel Offset

Set AES Frame Offset

Recall factory defaults

2000GEN Instruction Manual 13

Page 14

Remote Control and Monitoring

Slot Configuration

The Slot Config display (Figure 9) allows you to do the following:

•Activate/deactivate the module locator function,

Use

This

Link

Locate Module

•Type a specific name for the module and the input signal, and

•Report and enable/disable SNMP reporting for the slot.

When enabled, the

CONF LEDs three times on, then a long off period, to make the module

easy to locate in the frame.

Slot Identification

In the

identifying name for the module and a name to identify the input signal.

The assigned names are stored on the 2000GEN module and travel with the

module if it is moved to another frame.

Figure 9. 2000GEN Slot Config Screen

Enable/disable module

locator function

Name the module slot

Slot Identification

Locate Module

Name and Input Signal Name fields, you can type an

function blinks the yellow COMM and

Name the input signal

Check box to restore saved config

when new module installed

Learn module configuration

to this slot

Read-only status of 2000NET

module hardware settings

necessary for enabling

SNMP Trap Reports

Enable/disable specific

SNMP reports for the slot

Read-only severity level

assigned to each event

14 2000GEN Instruction Manual

Page 15

Slot Memory

The slot configuration for each media module is automatically saved periodically (once an hour) to the 2000NET module in that frame. You may also

select the

ration for this slot. The configuration is saved on the 2000NET module. If

the 2000NET module is removed or powered down, the stored configurations are not saved.

Learn Module Config

Remote Control and Monitoring

button at any time to save the current configu-

When the

saved to this slot is saved as slot memory. When the current module is

removed and another module of the same type is installed, the configuration saved to the 2000NET module will be downloaded to the new module.

The box must be checked before the current module with the saved configuration is removed.

Restore upon Install

Hardware Switch Controls

This section is a read-only status report of 2000NET module switch settings

for Module Status Reporting and Asynchronous Status Reporting. These

functions must be enabled on the 2000NET module for the following Slot

SNMP Trap Reports to function.

Slot SNMP Trap Reports

This section is displayed only when the SNMP Agent software has been

installed on the 2000NET module (refer to the 2000NET Instruction Manua l

for installation instructions). Slot SNMP traps can be enabled only when

the hardware switches for Module Fault reporting and Asynchronous

Status reporting are in enabled on the 2000NET module (dipswitch S1

segment 7 and dipswitch S2 segment 1).

box has been checked, the current configuration

The enabled SNMP traps will be reported to any SNMP manager that is

identified as an SNMP Report Destination in 2000NET configuration. Trap

severity is read-only hard-coded information that is interpreted and

responded to by the SNMP Manager software configuration.

2000GEN Instruction Manual 15

Page 16

Remote Control and Monitoring

Software Update Display

The Software Update display (Figure 10) allows you to download new software versions for the module. Refer to the 2000NET manual and the Grass

Valley web site at http://www.thomsongrassvalley.com for complete

Use

This

Link

details on software downloading and new software versions.

Figure 10. 2000GEN Software Update Display

16 2000GEN Instruction Manual

Page 17

Specifications

Specifications

Table 1. 2000GEN Specifications

Parameter Value

Input

Connector type 75

Input impedance High impedance to meet return loss with terminating frame assembly

Signal type NTSC, PAL-B standard complying blackburst video

Return loss > 40 dB up to 10 MHz

Equalization None

CMRR None

Hum rejection > 40 dB on a maximum of 1 V p-p of 60 Hz hum

Input Locking Conditions

Input signal minimum S/N ratio > 40 dB

Signal level 300 mV p-p ± 6 dB of sync tip portion

SCH error range ± 45 degrees for NTSC and PAL-B

Timebase error range ± 15 ppm over temperature range

AES framing detection Meets SMPTE 318 standard

Clock Output

Signal type 27 MHz 50%, ± 10% duty cycle clock

Output impedance 100

Signal type LVDS (Low voltage differential signal)

Rise/fall time 500–1500 ps between 20–80%

Jitter < 200 ps p-p with > 60 dB input S/N ratio

Timing Pulse Output

Signal type TTL internal bus

Output polarity Positive logic

Rise/fall time 1–5 ns between 20–80%

Jitter < 2 ns

S/H timing to clock 10 ns setup/10 ns hold time, ± 2 ns tolerance

Modes of Operation

Locking modes Genlcok enable or free run (remote menu selection)

Input signal select modes NTSC, PAL-B

Delay

Power

Input power maximum < 5 W

Environmental

Frame temperature range 0 to 40 ° C

Operating humidity range 10–90% non condensing

Non-operating temperature -10 to 70 ° C

Ω

BNC

Ω

differential internal bus

Full video color frame in clock (37 ns) steps in three ranges: field/line/clock

2000GEN Instruction Manual 17

Page 18

Service

Service

Power-up Diagnostics Failure

Troubleshooting

The 2000GEN modules make extensive use of surface-mount technology

and programmed parts to achieve compact size and adherence to

demanding technical specifications. For service other than changing the

on-board fuse, circuit modules should not be serviced in the field unless

otherwise directed by Customer Service.

If the module has not passed self-diagnostics, do not attempt to troubleshoot. Return the unit to Grass Valley (see Module Repair).

If your module is not operating correctly, proceed as follows:

•Check frame and module power. If power is not present, check the fuse

on the module as illustrated in Figure 11.

Module Repair

•Check for presence and quality of input signals.

•Verify that source equipment is operating correctly.

•Check cable connections.

Figure 11. Location of Module Fuse

Fuse F1

2A, 125V F

8172_05

If the module is still not operating correctly, replace it with a known good

spare and return the faulty module to a designated Grass Valley repair

depot. Call your Grass Valley representative for depot location.

Refer to Contacting Grass Valley at the front of this document for the Grass

Valley Customer Service Information number.

18 2000GEN Instruction Manual

Page 19

Functional Description

A block diagram of the 2000GEN is shown in Figure 12.

Figure 12. 2000GEN Block Diagram

Functional Description

Black Burst

Input

Input Signal path selection

Remote control/monitoring

Gain and

Clamp

Signal present, locked, signals

Inputs and Outputs

The module input accepts a PAL-B or NTSC black-burst signal from the

Reference In BNC on the rear of the Kameleon frame. The reference signal

is first processed in a clamp and gain circuit. It is then digitized and locked

in a Burst Genlock circuit before entering output logic processing. Output

phase adjustments of up to one color frame can be made to the timing

signal through the remote monitoring GUI.

A

to

D

Microcontroller

Burst

Genlock

Locking mode

Delay, Output Signal path selection

Output

Logic

Output

Drivers

12 x LVDS Clock

Bus

Timing

8172_04

The module outputs a low-jitter 27 MHz reference clock which is distributed through differential LVDS (low voltage differential signal) lines to

each front module slot. It also generates a common reference pulse timing

stream containing a reference field pulse, frame bit, color-frame bit and

AES 5 sequence bits for distribution throughout the frame.

Microcontroller

The primary purpose of the microcontroller section is to provide remote

control and monitoring capability for the 2000GEN.

2000GEN Instruction Manual 19

Page 20

Functional Description

20 2000GEN Instruction Manual

Page 21

Index

Numerics

2000NET module

hardware switch controls

manual 10, 11

SNMP Agent 15

software updating 16

B

block diagram 19

C

cabling

inputs

outputs 7

circuit descriptions 19

COMM LED 9

locate module 14

CONF (configuring) LED 9

7

D

15

G

Genlock Status display 12

Grass Valley

website

GUI 10, 11

2

I

inputs 7, 19

specifications 17

installation 6

J

jumper

Remote/Local

10

L

LEDs 8

LOCK OUT LED 9

LOCKED LED 9

documentation online

web site

E

environmental 17

2

N

network 10

NTSC LED 9

O

F

FAQ database 2

FAULT LED 9

features

key

5

frame status display 10

frame, 1 RU 6

frequently asked questions 2

fuse 18

2000GEN Instruction Manual 21

online documentation

web site

outputs 7, 19

2

P

PAL-B LED 9

PWR LED 8, 9

Page 22

Index

R

remote control displays

Genlock Status display

Settings display 13

Slot Config display 14

Software Update display 16

Status display 12

repair depot 18

12

S

Settings display 13

Slot Config display 14

slot configuration

saving

slot memory 15

SNMP 15

software download from web 2

Software Update display 16

software updating 16

specifications 6, 17

Status display 12

15

T

troubleshooting 18

W

web site

documentation

FAQ database 2

Grass Valley 2

software download 2

2

22 2000GEN Instruction Manual

Loading...

Loading...