TM262 Menu

Covers Welch Allyn TM262 Auto Tymp

Service Manuals

WARRANTY

We, Grason-Stadler, Inc. warrant that this product is free from defects in material and

workmanship and, when properly installed and used, will perform in accordance with

applicable specifications.

meet this standard, it will be repaired, or at our option, replaced at no charge except

for transportation costs, when returned to an authorized Grason-Stadler service facility.

If field service is requested, there will be no charge for labor or material; however, there

will be a charge for travel expense at the service center’s current rate.

Changes in the product not approved in writing by

Grason-Stadler shall void this warranty. Grason-Stadler

shall not be liable for any indirect, special or

consequential damages, even if notice has been given

in advance of the possibility of such damages.

THIS WARRANTY IS IN LIEU OF ANY OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO,

MERCHANTABILITY OF FITNESS FOR A PARTICULAR

PURPOSE.

If within one year after original shipment it is found not to

NOTE

ANY IMPLIED WARRANTY OF

’

WARNING

The GSI

damage to equipment can result when a three-prong to two-prong adapter is connected

between the GSI 38 power plug and an AC outlet or extension cord. Additionally, those

GSI 38 Auto Tymps that are equipped with power transformers, use a specific

transformer (8000-0260, 800-0261, or 8000-0262) which should not be interchanged

with any other transformer or supply.

The GSI 38 is a specifically calibrated device and the periodic

which the instrument may require should be done only by an authorized Grason-Stadler

service technician.

38

is designed to be used with a hospital grade outlet. Injury to personnel or

service

1

and adjustments

PRODUCT SPECIFICATION

2

GSI 38 PRODUCT SPECIFICATIONS (RI)

CATALOG LISTINGS

1738-9700

1738-9705

1738-9706

1738-9708

1738-9710

1738-9715

1738-9716

1738-9716

1738-9720

1738-9725

1738-9726

1738-9728

1738-9730

1738-9735

1738-9736

1738-9738

GSI 38 Auto Tymp,

GSI

GSI 38 Auto Tymp,

GSI

GSI 38 Auto Tymp, V2,

GSI

GSI 38 Auto Tymp, V2, Export,

GSI 38 Auto Tymp, V2, Export, 240V

GSI 38 Auto Tymp, V3, USA

GSI

GSI 38 Auto Tymp, V3, Export,

GSI 38 Auto Tymp, V3, Export, 240V

GSI 38 Auto Tymp, V4, USA

GSI

GSI 38 Auto Tymp, V4, Export,

GSI 38 Auto Tymp, V4, Export, 240V

DESCRIPTION

38

38

38

38

38

Auto

Auto

Auto

Auto

Auto

Tymp,

Tymp,

Tymp,

Tymp,

Tymp,

Vl,

USA

Vl,

Export

Vi,

Export,

V1,,

Export,

240V

USA

V2,

Export

V3,

Export

V4,

Export

100V

100V

100V

100V

Tymp + lpsi Reflex

Tymp +

Tymp

lpsi/Contra

+Ipsi/Contra

+ Aud.

Tymp + lpsi + Aud.

Reflex

The GSI 38 is an automatic acoustic admittance and reflex measurement system with

a screening audiometer.

The instrument consists of a probe and a desk-to-base

interconnected via a cable. It is a combination of GSI 17 and GSI 37 plus acoustic

reflex testing capabilities, both ipsilateral and contralateral. The audiometric portion is

a single channel pure tone audiometer, with a pair of air-conduction earphones. Int he

tympanometric mode, the measurement of acoustic admittance is corrected for the

acoustic admittance of the external auditory meatius, and the ear canal volume is

displayed. Also a test cavity assembly is provided.

INSTRUCTION MANUAL

The GSI 38 is supplied with an instruction manual which meets the requirements of the

applicable standards.

3

STANDARDS

Acoustic Admittance Accuracy

ANSI S3.39 - 1987

Aural Acoustic Impedance and Admittance Standard Type 3

(Middle Ear)

ANSI S3.6 - 1989

IEC 1027-l 991

IS0 645

IEC 601-l

Audiometric Standard Type 4 (Audiometer)

Aural Acoustic Impedance/Admittance Type 3

Type 4 (Audiometer)

Medical Electrical Equipment General Requirements For

Safety

Designed to Meet International Standards Organization requirements fo r

Magnetic Compatibility and Safety

ACOUSTIC ADMITTANCE MEASUREMENT SYSTEM - AUTO TYMP

Probe Signals

Frequenc y:

Sound Pressure Level :

Harmonic Distortion:

226 Hz,

85.5

d B

(ANSI

<

5%

Spe c

+/-

3%

SPL ,

90

+/-

2.0

d B

SPL Max)

dB,

Measured in a 2. 0

cm3

coupler

Electro-

Acoustic Admittance Range

0.0 to 1.5

cm3 or 0.0 to 3.0

cm

3

-

selected automatically for compensated

tympanogram.

0.2 to 6.0

The 0.2 to 6.0

cm3- ECV/cavity

limits for initiating pressurization (starting test)

cm3 is the sum of the ear canal volume and the middle ear admittance.

(Full pressure sweep for 6 cc up to 7000 ft. altitude with no leak)

3

+/- 5% or

Tvmpanogram Gradient:

Pressure interval at 50% of compensated admittance

+/-

0.1 cm

whichever is greater

peak.

Pneumatic Svstem

Pressure

Pressure sweeps to at least -100 dapa if tymps complete otherwise sweeps to -400

daPa

Pressure Accuracv:

Rate of Sweep:

200

Test Time

Approximately 1

Direction of Sweep:

ACOUSTIC - REFLEX ACTIVATING STIMULUS SYSTEM

Stimulus Frequencies:

Range

daPa/sec -

(corrected for altitude): + 200 to - 400 dapa (1 dapa = 1.02 mm

water)

+/-

15% or

600

daPa/sec -

for tymp slopes

sec

(high relative tymp will take longer).

Positive to Negative

500, 1000, 2000, and 4000 Hz

+/-

10

for tymp slopes of

=,>

0.2 ml per 24

daPa

whichever is greater.

daPa

<0.2

ml per 24

daPa

+/-

Stimulus Freauencv Accuracv:

Stimulus Total Harmonic Distortion:

Stimulus

Output

IPSI:

(Time multiplexed with probe tone, 106 ms On/53 ms Off Cycle)

CONTRA:

(Steady tone, non multiplexed)

Equivalent Hearing Threshold Levels, in DB SPL

Levels:

500, 4000 Hz

1000, 2000 Hz

500, 1000, 2000 and 4000 HZ 90, 100, 110 db HL

3%

<5% measured acoustically

where speaker driving signal

80, 90, 100

85, 95, 105 dB HL

dB

HL

except at 4 khz

is measured

Transducer

TvPe

Stimulus Tone

Frequency (HZ)

Contra (Insert Phone)

(in HA-l Coupler)

IPSI

(in HA-l Coupler)

Contra (Insert Phone)

(in IEC 711 Coupler)

Rise/Fall Time:

Pressure:

Automatically set to the pressure of peak compliance - 20

5 to 10

Reflex Determination:

Test Time:

Approximately 2 -12 seconds, depending on number of test frequency

selections and if tymp only test. (four maximum)

Probe LED indicators:

Green

-

blinking: Ready to test

Green - steady: Test in progress

Orange - steady: leak or other error

Yellow - steady:

500 1000

6.0

7.0

9.5

1.0

4.5 2.0

5.5 11.5

2000

6.0

4000

3.0

3.5

15.0

msec

Minimum compliance change - 0.05

Occlusion

cm

daPa.

3

AUDIOMETER

Test Stimulus

Pure Tone

Specifications:

A pure tone is the only stimulus source for this

audiometer.

Discrete

Frequencies:

125,

250,500.750,

and8000

1000,1500,

Hz.

2000,3000,

Equivalent Hearing Threshold Levels. in dB SPL for TDH 39 Earphones:

Frequency

Reference

Frequency

Reference

Frequency

(Hz) 125 250 500

Threshold

(dB)

(Hz)

Threshold

Accuracy:

(dB) 9.0

+/-

45.0

2000

3%

Total Harmonic Distortion (From

25.5 11.5 7.5

3000

10.0

125Hz

40006000

9.5 15.5

to 3000 Hz, measured Acoustically at the

750

10001500

7.0 6.5

8000

13.0

Maximum HL, measured electrically at 4000 & 6000 Hz) < 3%.

4000,6000

6

Output Hearing Level Control

Calibrated in dB HL.

Measured in increments of 5

Ranges:

Additionally a

"+1

frequencies by IO

Accuracy

of all

125Hz -10to

500

to 6000 Hz

250

and 8000 Hz

0

dB"

Extended Range switch, which extends the Maximum HL at all

dB.

settings

of Hearing Level control:

125

to 4000 Hz

6000 to 8000 Hz

Signal

to Noise ratio (in

1/3

Octave):

(for levels less than 60 dB HL)

Tone Switch:

This electronic switch turns the stimulus signal on/off with minimal

audible distortion.

Modes:

Normal state:

Activated state:

dB

>70 dB

Stimulus Off

Stimulus On

50

dBBHL

-10to90dBB

-10to70dBB

+/-

3

dB

+/- 5

dB

HL

HL

or less than -10 dB HL

Rise/Fall Time:

20-50

msec

Measured at the -1 dB and -20 dB points on the signal envelope.

On/Off Ratio:

Above 60 dB HL

With the tone switch off, the output will be at least -10 dB below

standard reference equivalent threshold with HL setting of 60

setting:

>70

dB

dB.

Cross Channel Leakage: At HL settings of 70 dB or greater, the unwanted signal in

the non test earphone shall be at least 70 dB below the tone

in the test earphone.

Stimulus Signals

Continuous signals

Continuous FM

Pulsed

7

Signal Format

-

Continuous

Signal steady as long as present bar is depressed

Pulsed

Pulse rate:

Duty Cycle:

Rise/Fall Time:

2.5

pulses/sec

50%

20 - 50

msec

On/Off Ration (between pulses): > 20

Frequency Modulation

FM Rate:

FM deviation:

Transducers

Headset:

Insert Phone:

Output

5Hz

+/-

5%

TDH-39 Earphones with 60 ohm impedance

Audiovox Model SM-N Earphone,

impedances and voltages on back

dB

panel

Eartip, Eartip

adapter and cord.

Left

Phone 130 ohm 2.5 volts rms max open circuit

Right Phone 130 ohm 2.5 volts rms max open circuit in Audiometer mode

Insert Phone <1 ohm 2.5 volts rms max open circuit

Subject response input 47 kohm pull up to 5 volts

8

DESK-TOP FRONT PANEL CONTROLS AND BACK PANEL CONNECTORS

FRONT PANEL CONTROLS

CONTROLS

Mode

Stimulus

Frequencies

Intensity

Tone on Stimulus

Extended Range

Left/Right

Recall or Page Memory

Scroll

TYMP & REFLEX

Tymp

Tymp & Reflex

Program

Ipsi, Contra or lpsi

&

Contra

500,

1K,

2K or 4KHz

Autoset

Automatically controlled

N/A

L or R (uses R phone for

contra)

Page (scrolls through

screens)

AUDIOMETER

Audiometer

Pulse, Steady or FM

Frequency Up, Down

250, 500,....or 8KHz

Rotary Knob (numeric)

dBHL

Present Press to turn on

+

10 dB

L or R

Clear

Program Mode

M- Erase Screen

M- Erase All

Save (saves program

M- Erase Screen

M- Erase All

Save

state)

Print

Print Screen

Print All

Print Screen

Print All

Paper Advance (Press to advance paper, or abort print during printing)

-

Power Switch

Subject Response

Power On Switch on Back Panel Green indicator light on Front panel.

-

Subject Response Indicator on LCD screen

9

Display

The display consists of an LCD panel which will display alpha-numeric, icons and

graphics (240 X 64 pixels). Items displayed are:

.

.

.

.

.

.

.

.

.

.

.

.

Frequencies (alpha-numeric) and Intensity (alpha-numeric) in

Tympanogram (graphics)

Ear Canal Volume (alpha-numeric)

Tymp Peak-Admittance (numeric)

Gradient (alpha-numeric)

Tymp Peak-Pressure (numeric)

Left/Right Ear (symbol)

Memory Ml to

IPSI/CONTRA

M8

(alpha-numeric)

Reflex Tracing (graphics)

Reflex with

dBHL/No

Altitude calibration or sea level calibration (icon - only in altitude calibration

mode.

.

.

Generic Error (Error Code)

Audiogram

(dBHL,

format.

Back Panel Connectors

.

.

.

.

Left/Right Earphone

Insert Earphone

Power Cord

Patient Response Switch

dBHL

Reflex (alpha-numeric)

Frequencies, cursor on frequency under test) or tabular

PRINTER

Printer:

Printed Data Format:

Used to provide a hardcopy of the test data.

Graphical area 3.75” horizontal X 6.75” vertical (Audiogram

or Tymp & Reflex for 2 ears), 51 columns/in horizontal

4 0

rows /in vertical

Choice of Audiogram or Audiotable:

Printer

Speed:

approximately 1.5 minutes to print three screens Tymp and reflex

data for each ear and audiogram for both ears.

and

3 choices of reflex printouts

10

Wallmount power supplies of various types with 5 pin DIN connections are available.

Either three prong plugs (grounded) or two prong plugs (ungrounded) are provided

depending upon the safety requirements of the country.

OR

The internal power supply, powered by AC line, 50 or 60 Hz via IEC 320 power inlet

with fuse and on/off switch on the rear panel, is also available, for the countries where

the wallmount power supplies are not available.

Two

voltage ranges are provided 200 to 250 V or 90 115 V.

+/-

Line

Voltage variation

Line

frequency range

Line

Voltage Current

Power Consumption

Line Frequency variation

Low voltage input for Wallmount power supplies 10

10 %

-

60 Hz

50

0.2 amps at 120 V or 0.1 amps at 240 V AC.

15 watts maximum while printing

+/-

5%

-

11 V DC 970

mA.

Hi Pot 3000 volts

SUPPLIED ACCESSORIES

VERSION 1

VERSION 2

VERSION 3

1738-0520

1700-l 030

1700-9622

1738-0100

1738-9600

1738-9610

(1738-0401

‘1738-0520

1700-1030

1700-9622

1700-9660

1738-0100

1738-9610

8000-0079

(1738-0402

1738-0520

1700-1030

1700-9622

1700-9660

1738-0100

1738-9600

1738-9610

8000-0175

8000-0079

(1738-0403

Wall Chart Rolled

Ass'y

Test Cavity (0.5, 2.0 and 5.0 cc)

Eartips

Package (screening)

Instruction Manual

Printer Paper (3 rolls supplied with new unit)

Kit, Grease, 0 Ring

Label Version 1 installed at factory)

Wall Chart Rolled

Ass'y

Test Cavity (0.5, 2.0 & 5.0 cc)

Eartips

Eartips

Package (screening)

Package (Contra Phone / Diagnostic)

Instruction Manual

Kit, Grease, 0 Ring

Contra Insert Phone Ass’y

Label Version 2 installed at factory)

Wall Chart Rolled

Ass’y Test Cavity (0.5, 2.0, & 5.0 cc)

Eartips

Eartips

Package (Screening)

Package (Contra Phone / Diagnostic)

Instruction Manual

Printer Paper (3 rolls supplied with new

unit)

Kit, Grease, 0 Ring

Test Headset Assembly (TDH-39)

Contra Insert Phone Ass’y

Label Version 3 installed at factory)

11

SUPPLIED ACCESSORIES CONT.

VERSION 4

1738-0520

1700-1030

1700-9622

1738-0100

1738-9600

1738-9610

8000-0175

(1738-0404

OPTIONAL ACCESSORIES

1738-9680

1738-9620

4204-0505

7874-0156

8000-0155

1738-0110

1738-9600

8000-0175

Consisting of:

Carrying Case

Dust Cover

Patch Cord

Subject Response Handswitch

Audiocups

Service Manual

Printer Paper Thermal 4” (10.16 cm wide) 5 rolls

Test Headset Ass’y TDH 39

8000-O 142

8000-0046

4204-0147 Earphone Cord Ass’y

8000-0143 Earphone Cushion

8000-0079

Consisting of:

Contra Insert Phone Ass’y

4204-0209 Cable, Coaxial

8000-0037 Earphone, Audiovox, 470 ohm

8000-0255SVC Eartip

1700-9622

Eartips

Contains:

1700-9600

Eartips Package Contra Phone / Diagnostic

Contains:

Wall Chart Rolled

Assembly Test Cavity (0.5, 2.0 & 5.0 cc)

Eartops

Package (Screening)

Instruction Manual

Printer Paper (3 rolls supplied with new unit)

Kit, Grease, 0 Ring

Test Headset Ass’y (TDH-39)

Label Version 4 installed at factory)

(1Ea.)

Head band Ass’y

Earphone, 60 ohm, plastic, TDH 39P

Modified

Package Screening

2 Ea. of

19mm,

8mm 11mm,

size

Eartips

4 Ea. of 7mm Yellow, 8mm Pink,

10mm Green, 1 mm, Pink, 12mm Yellow,

13mm Blue, 14mm Green

(1Ea.) MX41AR

6"

(1Ea.)

13mm, 15mm, 17mm,

9mm

Blue,

12

FUNCTIONAL DESCRIPTION

13

INTRODUCTION

INSTRUMENT DESCRIPTION

The

GSI

38 Auto Tymp is a versatile combination instrument which provides testing

capability for tympanometry alone, tympanometry combined with screening acoustic

reflex measurements, and screening audiometry. Four different versions are available

to meet your individual testing needs.

operation, tympanometry alone and tympanometry plus screening ipsilateral acoustic

reflex testing.

A second version permits tympanometry alone and tympanometry

combined with ipsilateral and contralateral screening acoustic reflex measurements.

The third version provides testing capability for all three test modes, i.e., tympanometry

alone, tympanometry combined with ipsilateral and contralateral screening acoustic

reflex measurements, and screening audiometry.

tympanometry alone, tympanometry combined with ipsilateral acoustic reflex screening

testing and screening audiometry. It is possible to field retrofit versions one, two and

four with the full functionality provided with version number three

original purchase.

The basic version provides two modes of

Finally, the fourth version allows

after

the time of

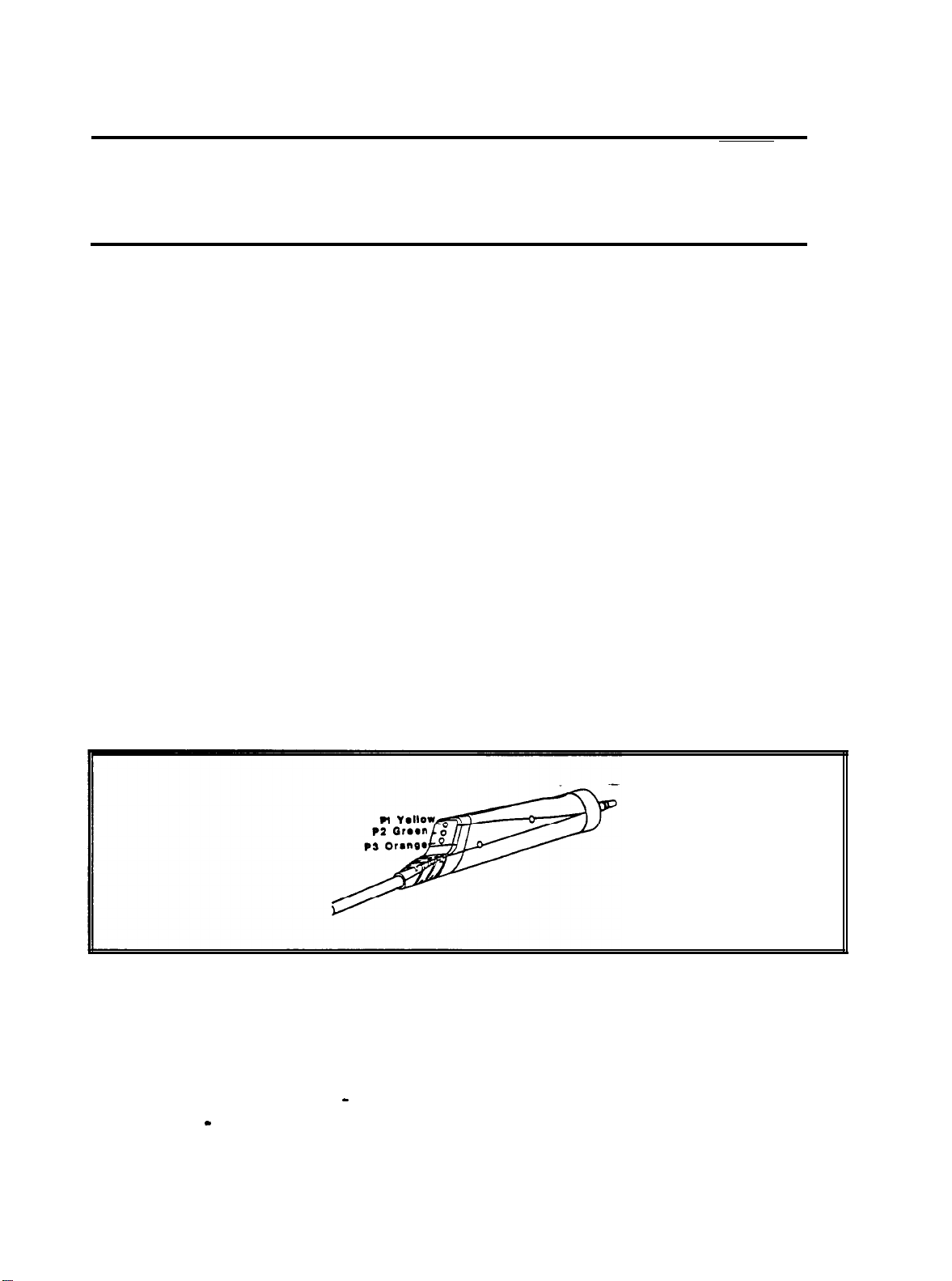

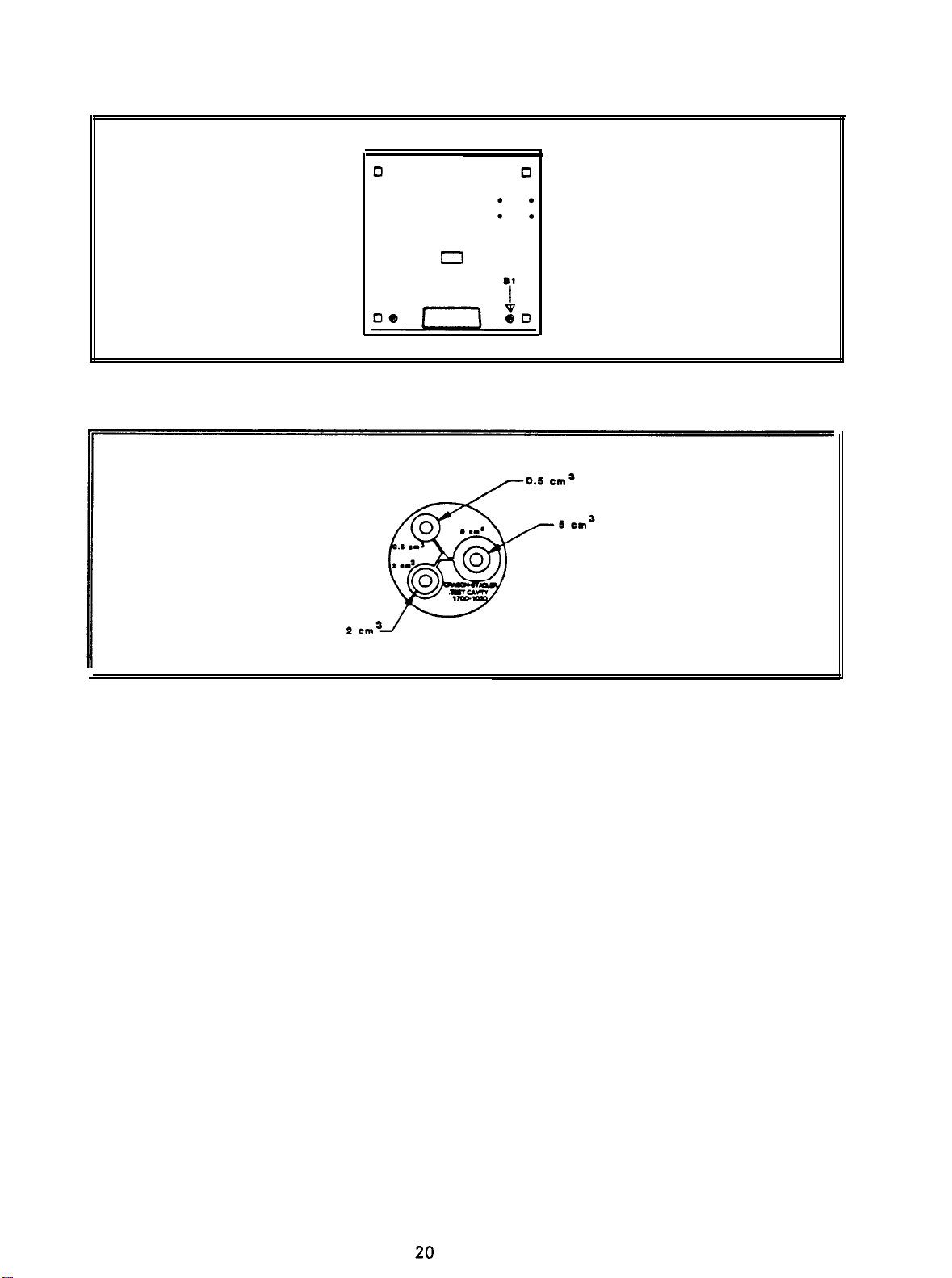

PROBE INDICATORS

The probe indicators are show in Figure

2-1

Figure 2-1: Probe Indicators

PI

Yellow:

the probe is occluded; remove the probe and inspect for cause of

occlusion

P2

Green lamp: blinking

-

GSI 38 Auto Tymps is ready to begin a Tymp; steady

green - test successfully started and in progress.

and a description follows.

P3 Orange:

a pressure leak has been detected.

14

FRONT PANEL CONTROLS AND INDICATORS

Figure 2-2: Front Panel

Fl

F2

F3

F4

F5

F6

F7

F8

Power on indicator and label: indicator is illuminated when the GSI 38 is

receiving power.

Print Screen: pushbutton used to print the currently displayed page of memory.

Print All Memory: used to print all pages of data from memory.

Paper Advance:

causes paper to feed through printer; may be used to load

paper or to provide space between printouts.

FM: used during the Audiometry mode to select a frequency modulated test

tone when the present bar is depressed; causes the letters FM to appear on the

display when selected.

Steady: used during Audiometry mode to select a continuous test tone when

present bar is depressed; causes the steady symbol to appear on the display.

Pulsed: used during Audiometry mode to select a pulsed tone when the present

bar is depressed; causes the pulsed symbol to appear on the display.

(dB

Attenuator Knob

HL): used to increase or decrease the intensity of the

test tone presented in Audiometry mode; counterclockwise rotation causes the

intensity to be lowered; clockwise rotation causes the intensity to be increased.

F9

FlO

dB:

+10

used to temporarily extend the intensity range by 10

dB;

causes a

large + sign to appear on the display indicating that the extended range has

been selected.

M+: save key; during Audiometry mode, causes the threshold information per

frequency to be saved on the display; during Program mode, causes option to

be selected; during Tymp/Reflex mode, causes frequency to be stored as a

default parameter.

15

Fll

<

and > Hz:

selecting

Selecting < causes the cursor to move the next lower frequency;

>

causes the cursor to move to the next higher frequency.

F12

F13

F14

F15

F16

F17

F18

Present Bar:

Push downward to present test signal to appropriate earphone;

release to turn test tone off.

Prog(ram):

press to select Program mode screen which lists setting available

to reflex presentation format, printout header format, audiogram vs. tabular

format, display normal box, and identify frequency range for Audiometry mode.

Aud(iometry):

press to select Audiometry mode. (Available in Versions 3 & 4

only).

TYMP:

Tymp Reflex:

R:

press to select Tympanometry only mode.

press select Tympanometty and Reflex mode.

used to identify right ear under test so that data stored in memory and/or

printed is properly identified; for Versions 3 and 4, used to select right earphone

for audiometry.

L: used to identify left ear under test so that data stored in memory and/or

printed is properly identified: for Versions 3 and 4, used to select

left

earphone

for audiometry.

F19

F20

F21

F22

F23

F24

F25

F26

F27

IPSI:

used to select an ipsilateral reflex test.

to

CONTRA: used

select a contralateral reflex test (available with Versions 2

and 3 only).

Hz

500: selects 500

as a stimulus during reflex testing.

1000: selects 1000 Hz as a stimulus during reflex testing.

2000: selects 2000 Hz as a stimulus during

as

4000: selects 4000 Hz

PAGE:

used to scroll through test results stored in memory.

a stimulus during reflex testing.

reflex

testing.

M-: used to erase currently displayed page of data from memory.

M-:

used to erase all pages of data from memory.

16

PRINTER AND DISPLAY

The printer cover can be removed to reload paper. See Figure 2-3 for location of the

printer and printer cover. Section 2-7 provides paper loading instructions.

Figure 2-3: Printer and Display

The display indicates test mode, parameters for test and test results. See Figure 2-3

for location of display. Figures 2-4 through 2-8 show the individual display format for

each test mode.

Figure 2-4: Display Format for

TYMP

Only Test

Figure 2-5:Display Format for TYMP/REFLEX Test

(Reflex

test results given as “Yes” or “No”).

17

Figure 2-6: Display for

(Reflex test results given in

TYMP/REFLEX

"dB

HL”).

Test

Figure 2-7: Display Format

(Reflex test results given in

Figure 2-8:

REAR AND BOTTOM PANEL

"dB HL"

Display Format for AUDIOMETRY

LABELS/CONNECTORS

The rear panel labels and connectors

each one follows.

TYMP/REFLEX

Test

and also shown with a “tracing”)

are shown in Figure 2-9 and a description of

18

Figure 2-9: Rear Panel

R1

R2

R3

R4

R5

R6

R7

R8

R9

Company name, address, model, serial number and country of origin.

Symbol denotes a

Type B, Class II Product per IEC 878 as referenced in IEC

601 Standard.

Symbol denotes Attention, consult accompanying documents.

Symbol indicates a service adjustment part that is intended for service personnel

use only.

Connector for handswitch. Input impedance -47 k ohm pulls up to 5 volts.

Connector for contralateral insert phone. < 1 ohm, 2.5 volts rms maximum open

circuit.

Connectors for right and left earphone. 130 ohm, 2.50 volts rms maximum open

circuit.

Label describing low input voltage and current from wall mounted power supply.

5-pin

Power Input Jack.

DIN connector for external wall mounted power supply.

RIO

Power Switch with ON/OFF indicators.

NOTE

There is a symbol on the bottom panel that indicates

entry by qualified service personnel only. This symbol

1"

is marked “B

in Figure

19

2-10

Bottom Panel.

Figure 2-10: Bottom Panel

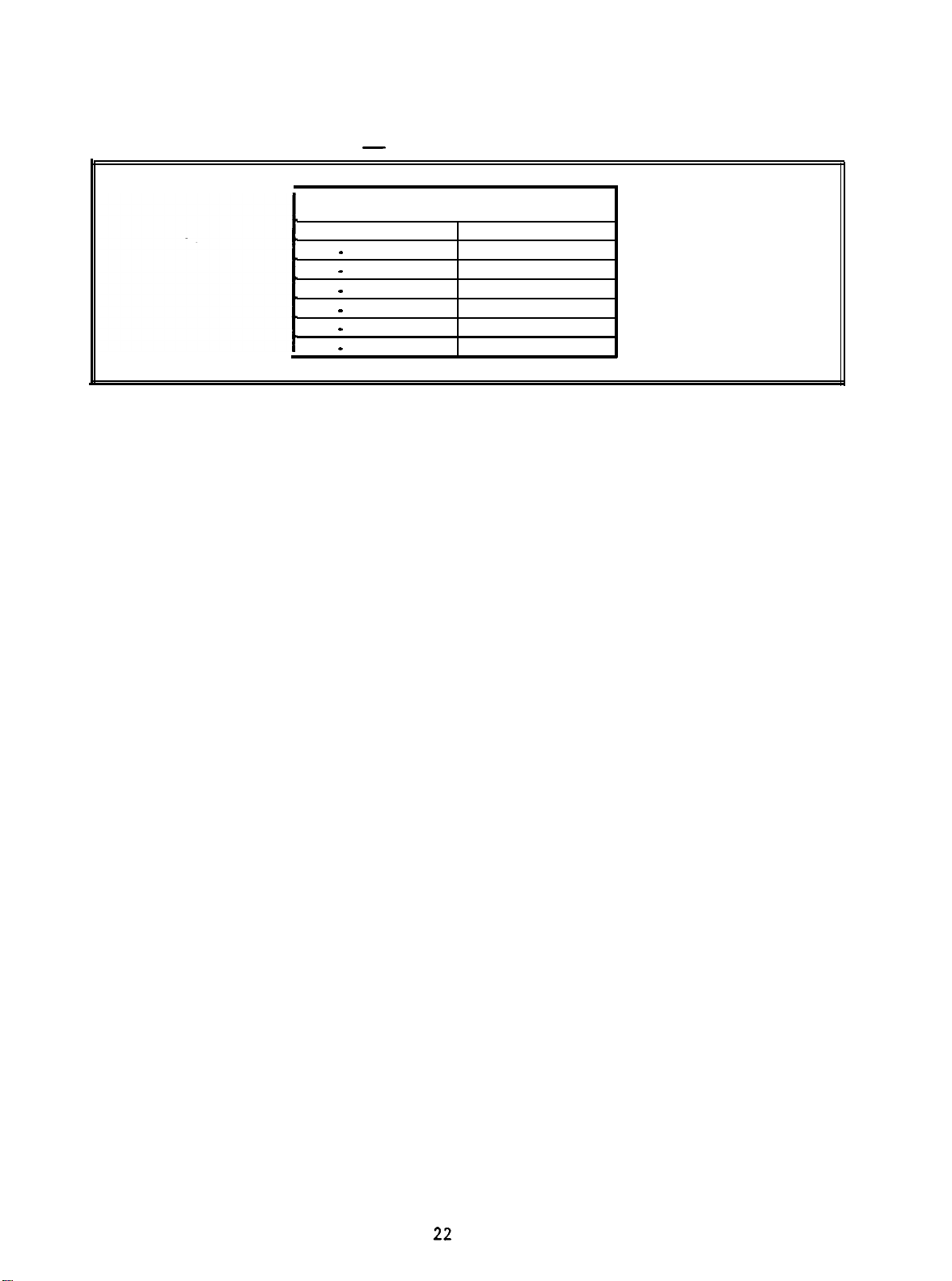

Figure 2-11: Test Cavity

PRETEST

TYMP

CHECKS

For your convenience, a test cavity is provided with your GSI 38 Auto Tymp. This test

cavity enables you to quickly verify, on a daily basis, the prober calibration of your unit.

GSI strongly recommends that you make this quick check a part of your daily routine.

TYMP CALIBRATION VERIFICATIONS

To initiate the quick check, select the Tymp only mode and insert the probe into the

0.5

cm3 opening on the test cavity. See Figure 2-l 1.

NOTE

Since the

important that the probe is inserted as quickly and as

smoothly as possible. During the calibration check, the

probe must be held carefully and without movement.

Do not place the probe on the same counter as the

instrument or any moving object during this check as

mechanical noise will be picked up by the probe and

interfere with the calibration check.

GSI

38 is designed to start automatically, it is

20

The calibration check will start automatically if the probe has been inserted into the

cavity properly. This is confirmed by the green lamp changing from blinking to a steady

condition. If the orange lamp is illuminated, the probe is not properly positioned within

the cavity so that a large pressure leak exists. If the yellow lamp is illuminated, the

probe tip has been occluded.In either case, remove the probe and wait for the blinking

green lamp. Insert the probe once again. Clean the probe tip if necessary (XXXXXX).

When the test sequence is completed, the green lamp on the probe is no longer

illuminated.

Remove the probe from the test cavity and note that the green lamp is

blinking once again. The display will indicate a flat line on the tympanogram along with

the value of the test cavity next to the letters ECV (ear canal volume) i.e., 0.5. The

letters NP will appear next to the labels

cm3

and

daPa

and three dashed lines will

appear next to the letters GR (gradient). Since the test cavity is a hard-walled cavity,

the tympanogram should be a flat line indicating that there is no mobility in the system.

The GSI 38 places the letters NP next to the

cm3 and

daPa

headers to indicate that

there is no peak compliance and, therefore, no peak pressure can be determined

during the quick check. Also, since there is no compliance peak detected, it is not

possible to calculate a gradient. Therefore, the GSI 38 displays the dashed lines when

a gradient calculation isn’t possible. Using the same sequence, place the probe in the

test cavity opening

0.5

cm3 measurement except for the value placed next to the letters ECV 2.0. If you

wish, the same sequence can be followed with the 5.0

labelled

2.0

cm3

Note that the display looks the same as with the

cm3 opening on the test cavity.

To keep a record of this test cavity calibration check, simply press the print all

pushbutton on the front panel of the GSI 38.

Since sound pressure will vary with altitude and barometric pressure, some variation

3

from the 0.5, 2.0 and 5.0 cm

readings may be observed. Your GSI 38 is carefully

calibrated at our factory which is at approximately 250 feet above sea level. If you are

located at an elevation of 1000 feet or higher, your instrument may need to be

recalibrated to account for your elevation (See Section XXXX). If is not necessary to

recalibrate for barometric pressure changes on a daily basis. Just keep in mind that

a change in barometric pressure (i.e., from low to high or high to low) will slightly affect

the test cavity readings.

ALTITUDE ADJUSTMENT

The Altitude calibration adjustment allows the instrument operator to “correct” the ear

canal volume

(ECV)

measurement and test cavity volume measurement

for variations

due to altitude. Because the GSI 38 is a pressure-sensitive device which makes

measurements relative to ambient air pressure, changes in air pressure due to weather

or altitude will affect the ECV read-out of the instrument. The slight pressure change

resulting from changing weather conditions will usually yield volume read-outs within

+/- 0.1

these cavity values by as much as 30%. These

the accuracy of the compliance measurement system in any way.

cm3

of the expected cavity value, but pressure changes due to altitude can shift

changes in pressure do not affect

However, many

instrument operators prefer that their equipment give ECV values as they would appear

at sea level. The altitude calibration mode allow the operator to adjust his/her Auto

Tymp without the services of a qualified GSI representative.

21

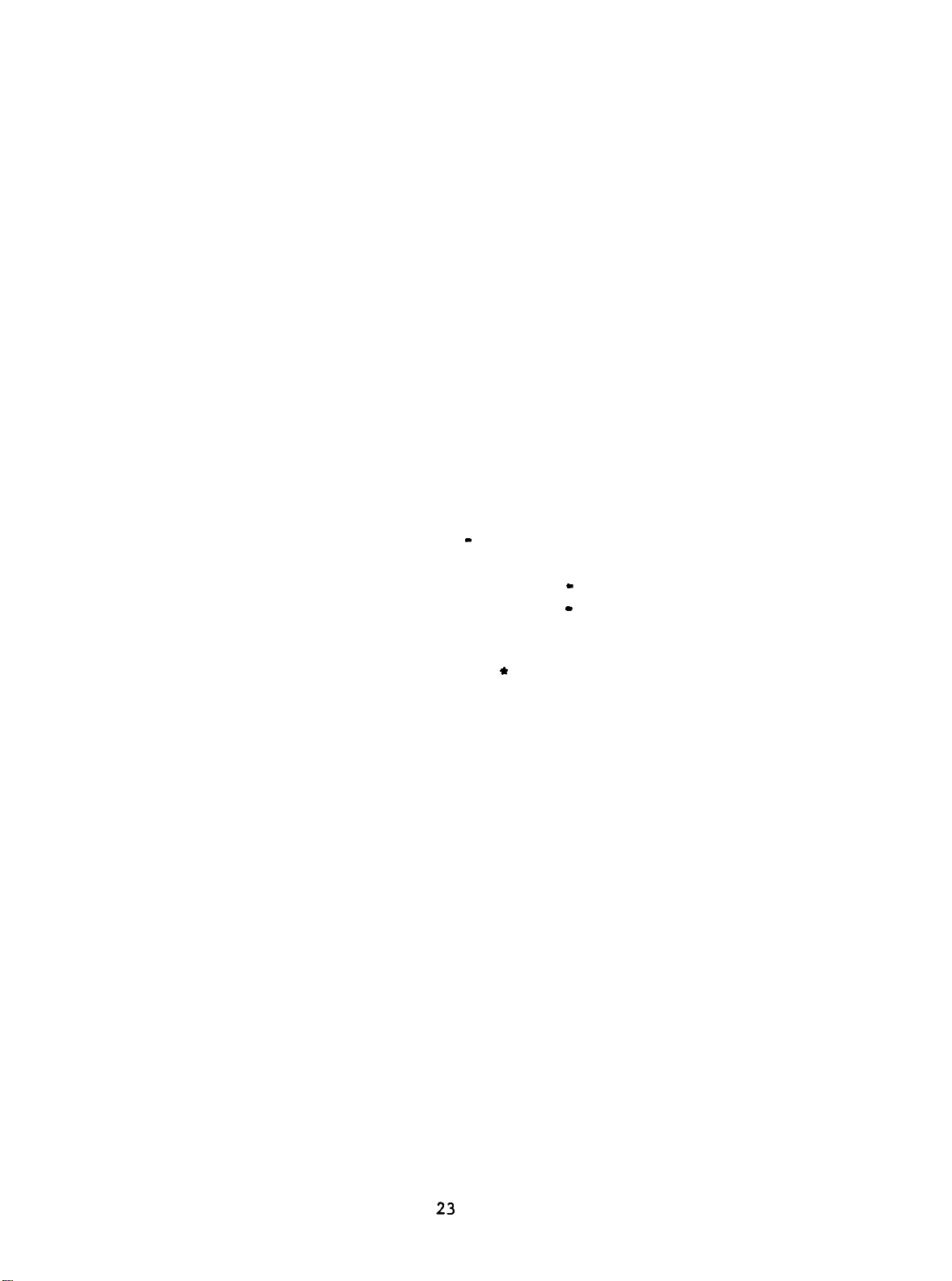

TABLE 2-1 Altitude Correction

-

ALTITUDE CORRECTION

Altitude (ft)

0

-

1,500

2,000-3,500

4,000- 6.000

6.500- 7.600

6.600- 6.000 24+/-

6.500-10,000

---

20

2.1

2.2

2.3

2.5

Altitude

+/-

0.1

+/-

0.1

+/-

0.1

0.1

+/-

0.1

Table (cm3)

The altitude calibration mode can only be entered when the

GSI

38 is powered up from

its “off’ state while the program mode pushbutton, PROG is depressed. Hold the

PROG pushbutton for approximately five seconds.

STEP 1

When entering the altitude mode the display will read as follow:

Altitude Mode

ECV 2.0

cm3 9.99

Standard

(E71) is displayed in the bottom right corner of the display until the probe is in the 2.0

cm3 cavity.

STEP 2

Place the probe into the

2.0cm3 cavity provided with the instrument and check

cm

3

value against the altitude correction table for accuracy.

STEP 3

If the measured volume is not within the published table value

+/-

.1cc, then the

operator should exit the altitude mode by pressing the PROGRAM MODE pushbutton

and contact field service. Providing the measured volume agrees with the published

table

With

+/-

.1cc, the operator may proceed with the altitude adjustment.

STEP 4

the probe still in the 2.0

cm3 cavity, select the page pushbutton to enter the

custom calibration mode. Custom will appear on the fourth line of the display.

22

STEP 5

3

The value now displayed in the c m

to the current altitude.

If the value displayed is 2.0 cc then the volume is adjusted to

the current site. If the value is not 2.0 cc

display area is the volume measured and adjusted

+/- .1,

then press the SAVE pushbutton M+

to customize the volume measurement to the current altitude. The measured volume

should now read 2.0 cc.

STEP 6

To exit the altitude mode press the PROG pushbutton to return to normal mode.

PROGRAM MODE

To enter the program mode, select the

PROGram

pushbutton located on the front

panel. The following screen appears the first time you enter the Program mode after

you receive your GSI 38 from the factory. (in other words, there are the default settings

used at the factory during production).

Program Mode

l

Reflex HL + Curve

Reflex HL only Print - Aud Table

Reflex Yes/No l Normal Box ASHA

* Pm Header GSI

Pm Header Off

Pm Header Custom Aud Range Narrow

Note that these selections. fall into

five

-

User Selections

l Print - Audiogram

Normal Box Off

* Aud Range Normal

different groups of controls:

Reflex format for printer

Print header format

Audiometric test result format

Status of normal box

Audiogram frequency range

The default setting for each group of controls has an asterisk

(*)

before it so that it is

easy to scan the settings selected for each group.

REFLEX FORMAT

Reflex test results can be displayed and printed in three different ways: reflex dB HL

dB

plus curve; reflex

dB

reflex

HL plus curve. This means that all reflex test results will appear on the

HL only; or reflex yes/no. The default setting for this grouping is

display and the printout with the following information.

23

NOTE

If you

the square cursor next to the asterisk

Header custom and press M+ to cause the line

appear

display.The word SAVED will appear at the lower tight

margin indicating that the custom header is still

selected.

had previous/y entered a custom header, position

(*)

in front of Pm

cursor

to

at the left-hand margin along the bottom of the

To move the cursor from the left-hand margin without inserting a letter or number,

select the character which represents a space (i.e., rotate the knob one position to right

of the letter A). Use the > Hz pushbutton to move over to the next character position.

Repeat this sequence until the cursor is moved over to the desired start position for the

first character to appear in your header.

Rotate the

dB

HL knob to select the

appropriate characters to spell out the desired header. After selecting each character,

use the > Hz pushbutton to move over to the next character position. Once all of the

header characters have been added, press the M+ pushbutton to save your header in

memory. The word SAVED will appear on the right-hand margin indicating that you

header is now saved. The square cursor will reappear next to Pm Header Custom.

It is now possible to exit the program mode or to sequence on the next user selection.

To exit the program mode, press the pushbutton labeled PROG. Enter a single test

result and select print screen to see how the custom header looks.

AUDIOMETRIC FORMAT DURING PRINTING

The audiometric test results can be printed out in an audiogram format (PRINT

-

AUDIOGRAM) or in a tabular format (PRINT - AUD TABLE). The default setting for

this function is the audiogram format.

NOTE

When a specific frequency is deselected for testing, the

result will be

frequency.

threshold exists at that untested frequency.

Move the < or > Hz pushbutton

AUD TABLE.

Next, select the M+ pushbutton to save this format as the new default

parameter. Note that the

a break in the audiogram line at that

This eliminates the assumption that a

to

position the cursor in front of the description

word

SAVED appears in the lower right-hand comer of the

PRINT-

display to indicate that this new setting has been saved. With PRINT-AUD TABLE

selected, all audiometric test results will appear in a table with the frequency range

typed horizontally along the top of the table followed by two lines of test data. The test

results for the right ear will appear next to the letter R and below each frequency

tested. Similarly, the test results from the left ear will follow below the right ear results.

24

This setting (PRINT-AUD) selects the format for the

printout only. An audiogram always appears on the

screen while in this mode.

NORMAL BOX FORMAT

NOTE

It is possible to have the normal box, as described by

tympanogram screen and printout. The boundaries for this normal box are -150

to

+100 daPa

and 0.2

cm3 to 1.4

cm3.

ASHA,

appear on the

daPa

NOTE

A compliance value of 7.5

automatically turn off the

ASHA

cm3 or greater will

normal box.

The normal box is the default setting. To deselect this normal box, move the square

cursor with either the < or > Hz so that it is placed in front of the words Normal Box Off.

While the cursor is in this position, select the M+ pushbutton to save this feature as the

new default setting. Note that the word SAVED appears in the lower right-hand margin.

This message assures you that the normal box ill not appear on the tymp screen or

printout.

AUDIOGRAM RANGE

All eleven frequencies are available during audiometry or the range can be abbreviated

to eight frequencies.

The default setting is Aud Range Normal. To select the

abbreviated frequency range, position the square cursor in front of the feature Aud

Range Narrow. Press the M+ pushbutton to save this narrow range for audiometric

testing. Note that the word SAVED will appear in the lower right-hand margin and the

asterisk now appears in front of the narrow range selection. The normal range of

frequencies include 125 Hz through 8000 Hz. The narrow range of frequencies

includes 500 Hz through 6000 Hz. Please note that in the Aud mode, if the narrow

range is selected, the < and > Hz pushbuttons will allow you to scroll through this

abbreviated frequency range only. Both the screen and printout will still be

labelled

with the full range of frequencies. i.e., 125 Hz through 8000 Hz.

EXIT PROGRAM MODE

Exit the program mode by selecting the PROG pushbutton. Note that you return to the

test mode which was operational prior to entering the program mode.

25

TEST IN MEMORY

The Tymp and TympReflex test results

.

test sequence

ends.

Audiometric test

are automatically stored in memory when the

results are stored in memory when the M+

pushbutton is pressed a total of eight memory locations are available with the GSI 38.

Each test result is assigned a memory location number in order of sequence obtained

starting with Ml and continuing up to M8.

To review the individual test results, press the PAGE pushbutton. Note that the screen

contains the appropriate format for each test type stored (e.g., tympanogram or

audiogram). The memory number is located in the upper right-hand corner of each

screen.

If, for example, only five tests were stored in memory, only five memory

locations can be scanned. The memory can be scanned a page at a time by pressing

the PAGE pushbutton once and observing the results. The entire memory can be

scrolled through by holding the PAGE pushbutton down continuously.

MEMORY ERASE

If there is a particular test result that you wish to delete before printing, PAGE to this

test result and press the M- pushbutton. This causes that particular test result to be

erased from memory. The erase mode is accessed when the operator selects a test

to erase and presses the M- pushbutton. The LCD displays a blank screen for erased

memories with the memory location number located at the top right corner. Upon exit

form the erase mode the stored memories reshuffle and replace the empty memory

with the remaining tests in the order in which they were run. The erase mode will be

exited once the operator presses the PRINT ALL or ERASE ALL pushbuttons or any

pushbutton that would normally begin the setup of a new test. Please note that when

the erase mode is entered, a current audiogram is no longer accessible to change or

to store new HL values.

*

NOTE

The instrument is programmed to default to the right ear

dB

at 0

audiometric test.

and 1000 Hz upon selection of a new

If you should wish to erase all tests from memory, press the M-(ERASE ALL)

pushbutton. (For example, the test results have been printed and you wish to test

another person).

NOTE

Be certain that you wish to remove all tests from

M--

memory before pressing the

the erasure

pushbutton!

occurs

immediately upon pressing the

26

pushbutton because

M--

PRINTING TEST RESULTS

The printout will begin with a header if it is selected during the program mode (i.e.,

GSI

38 or a custom header designed by you). The next two lines contain space for entering

the individuals name and the test date. This is followed by the test results in the order

that they were obtained/selected.

Either a single test can be printed from memory or the entire group of tests in memory

can be printed. To print a single test from memory, use the PAGE pushbutton to arrive

at the desired test result to print.

Once this test is displayed, press the PRINT

SCREEN pushbutton.

To print all tests in memory, simply select the PRINT ALL pushbutton. When

PRINT ALL

is pressed and two audiogram tests are stored in memory, they will combine

under the following conditions. There must be one left test and one right test

sequentially stored in memory. A left and right audiometric pair of tests will not be

combined if they are separated in the memory by a tymp test. Therefore, when tests

are erased, the resorting could cause a change in left, right or right, left combined when

PRINT ALL is selected. Prior to selecting PRINT ALL the operator should scroll

through the tests in memory to determine where the audiometric tests are located. This

will help the operator to avoid combining tests from different patients.

27

CIRCUIT THEORY

28

The Microprocessors

GSI

The

38 operation is controlled by two

MC68HC1 1E1

microcontrollers. The

microcontrollers have an 8 bit CPU and additional built in peripheral devices. It was

designed using HCMOS technology which combines smaller size and higher speeds

with the lower power and high noise immunity of CMOS. On chip

bytes of

RAM

and 512 bytes

of EEPROM. The built in peripheral functions include:

memory includes 512

An eight

channel/8

bit analog to digital convertor

A 16 bit timer system

bit

An 8

pulse accumulator circuit

A real time interrupt circuit

Parallel input/output ports

A computer operating properly (COP) watch dog system which protects against

software failures.

A serial peripheral interface (SPI)

A serial communications interface (SCI)

Power saving wait and stop modes

The many functions incorporated by the microcontroller helps to reduce board space

requirements and the need for additional support

circuitry.

The audio microprocessor (U34) is the master of the system and has control over the

tymp microprocessor (U7) which functions

as a slave.

THE AUDIO MICROPROCESSOR CONTROLS THE FOLLOWING FUNCTIONS:

Communication

to the

Tymp

Microprocessor: Asynchronous serial communications

data is transmitted and received using the processors built in serial communications

interface. The interface is located within port D of the microprocessor. PDO is the

receive data (ARXD) line and

PD1

is the transmit data (ATXD) line. The bi-directional

communication allows the transfer of information, test results, parameters and control

functions to occur between the two processors.

Display Drive Information: Display information to and from the liquid crystal display

(LCD) display board RAM is latched via the bi-directional latch (U29). After the

information is loaded into the LCD board RAM the display board drives the associated

pixels and the audioprocessor is free to perform other tasks. The display area is 240

pixels wide by 64 pixels high.

Monitoring of the Switch Matrix Kevs:

The processor routinely checks the status of

the front panel keys for a change in state. The key panel switch inputs buffers U26,

U27, U28 and U31 are read every 24 msec.

processor executes the commands associated with the key function. The

(extended range) key and the reflex control keys (Ipsi, Contra, 500,

If a switch change has occurred the

+10dB

1K, 2K,

4K) are

active toggle controls (ie., push on/push off).

29

Monitoring of the Switch Matrix Keys Continued:

The present bar, subject response switch, frequency up/down key, paper advance key,

and page key all function as press and hold controls where the corresponding function

is active only as long as the control is pressed. Single action controls include the mode

control keys (Prog, Aud, Tymp,

routing keys

(L,R),

memory control keys (Page, M-, M-), and the printer control keys

Tymp/Reflex)

tone type keys (FM, Steady, Pulsed),

(Print Screen, Print All, Paper Advance).

Normal/Calibration

Mode Switch: The slide switch is monitored by the processor thru

the switch input buffer U31. It is utilized for entry to the calibration and diagnostic

modes.

Switches: Dip switches 1 thru 4 are connected directly to the microprocessor

Dip

A/D

convertor. Dip switches 5 thru 8 are connected to the switch input buffer U31. These

dip switch selections are read or processed upon entry to the calibration mode. When

calibration mode is selected the dip switch status is verified and processed according

to the individual selections. Any change in the dip switch status after entry to the

calibration mode will be ignored by the processor.

Hearing

Level Control

(HL):

The hearing level control dial is connected to a 36

position 2 bit encoder (RE1) located on the HL Board. The encoder output from the HL

board is connected to port A of the audio processor. In the audiometer mode this

rotary knob selects the stimulus hearing level based on the relative position change of

the knob from the previous hearing level selection.

30

Pure Tone Stimulus

The Audio microprocessor controls the frequency generator for the associated Left

Earphone, Right Earphone, Ipsilateral, or Contralateral outputs. The foundation of the

pure tone stimulus generator is a Programmable Timer (U24). Output 0

square wave with a

50/50

duty cycle equal to the selected front panel frequency. Out 1

(SQWIN)

is a

(SCFCLK) is a square wave that is either fifty or one hundred times greater than the front

panel frequency and is used to set the band pass of the switched capacitor filter.

Out 2

is tied back to the micro controller IRQ and is used as an interrupt for the microprocessor

)

so that it can update the COP (computer operating properly

The

SQWIN

and minus

signal is a 0 to 5 volt square wave which is level shifted by (U44) to a plus

5

volt square wave. The signal then passes through an anti

eliminates high frequency harmonics and “rounds” the edges of the sine wave.

circuit.

-

aliasing filter that

The signal

then passes through the switched capacitor filter (U49) which reduces harmonics and other

noise. This is the process that produces the clean sine wave product.

Attenuator and +

The attenuator

10dB

Range Extender

(U56)

is a Voltage Controlled Amplifier

(VCA).

This device has

amplification gain but most of its dynamic range is used as an attenuator. The total range

of the attenuator is 112 dB The output of the attenuator may be set to any level within this

range by adjusting the DC voltage present at the EC line pin 3. This input pin is connected

to a Digital to Analog Convertor

(DAC/U53)

that controls the output level of the attenuator.

Calibration of the output levels is accomplished by storing a Hearing Level to Sound

Pressure Level value, per frequency and transducer, in a look up table in EEPROM. This

information is then latched (U25) to the DAC that drives the attenuator to the appropriate

output level.

+10 Range Extender may be selected any time that the hearing level is within 1

The resolution or step size is controllable to within a .5 dB increment. The

0dB

of the

maximum non-extended hearing level for all frequencies. This selection allows an

additional

+10dB

of range above the normal maximum hearing level limit. After the

attenuator but before the routing of the signal to the left or right earphone is the 1 0dB gain

or attenuator circuit. The control line (+1 ODB) that selects the extended range (U51) is

enabled or disabled by the latch

Output Routing

Control

(U20).

The output of the attenuator

Amplifier

(U52),

or the lpsi / Probe Tone

(ATTENOUT)

is routed to either the Left amplifier

Speaker Amplifier

(U66).

When contra is selected

(U48)

Right

the output is routed through the right output amplifier and is then switched to the contra

phone by the routing relay

allows the output to be disabled or shut off to conserve power.

K1.

The output amplifiers have a special control line (pin 1) that

Thispower saving feature

also eliminates any unwanted noise from a non selected output.

31

.

unction I Control

The test results are printed using a thermal print head printer on paper that is

112mm

wide. When the print function is selected the processor starts building a graphical bit

mapped image of the printout in the Audio RAM (U32). The printout is formatted as

specified by the selections made in the program mode and stored in EEPROM. Before

printing takes place the A/D port E of the micro controller measures the ambient

temperature and adds it to the calibrated Dot on time stored in EEPROM. This routine

assures consistent print quality regardless of the ambient temperature or the print head

resistance.

The serial print data is transferred from the RAM through port D of the micro controller to

&

the serial to parallel convertor (U19). The dot drivers (U16

U19

sink the current through the associated print head dot element. Information for the

U17) that are connected to

print head motor driver (U15) and the paper feed motor driver (U14) is received from the

micro controller port A. The latch (U13) assures that the print head dot drivers are off

when the print head motor is inactive or when the paper feed motor is advanced. The

printer has a built in switch that is closed when the print head is returned to the home

position.

During the power up initialization and after each print out the print head motor

is returned to the home position. The printer also has independent power supplies used

for the print head

(U38/

V

+5P)

and the print motors

(U39/

+VM). The +VM power supply

is also connected to the left right routing relay Kl.

32

The Tymp

.

Microp

rocessor controls the

following

functions:

Communication to the Audio

transmitted and received using the processors built in serial communications interface.

The interface is located within port D of the microprocessor.

line

(TRXD)

communication allows the transfer of information, test results, parameters, and control

functions to occur between the two processors.

Pump Drive Control: The

a piston, and an infra photo eye/detector pair. After power-up (during the instrument

initialization period) and at the end of a test the pump piston is returned to the home

position. The home position (HOME) is determined by a state transition of the infra red

photo detector of the pump assembly which is monitored by the Tymp microprocessor

(U7) A/D input PE4 (pin 44). The pump motor coils are driven by the motor driver (U37)

which is clocked by the pump drive timer (U21). The timer controls the step rate of the

pump assembly which varies with the pressure sweep rate. The pump sweeps at a rate

of 600

to 200

probe is removed from the ear canal. When the probe is removed from the ear canal the

pump returns to the home position.

Monitoring

monitored by the Tymp Microprocessor (U7) A/D input PE6 (pin 48).

Pressure calibration mode the CMOS Switch

pressure transducer circuit so that the input voltage at the

gain adjustment places the pressure transducer output at ambient or zero pressure in the

optimum operating range for the A/D convertor. When the ambient gain has been

established the processor will set the switches to the stored values at all times. The

pressure span calibration

microprocessor as a software offset.

daPa/sec

and

daPa/sec.

of the Pressure Transducer Output ; The pressure Transducer output is

PD1

is the Tymp transmit data line (TTXD). The bidirectional

until the slope of the tympanogram is sensed then the sweep rate slows

If a leak is detected during the pump sweep the pump stops until the

(+200/-400)

Microprocessor; Asynchronous communications data is

PDO is the Tymp receive data

Pump assembly consists of a DC step motor, an air reservoir,

In the Ambient

(U64)

is used to adjust the gain of the

A/D

is equal to 1.5 vdc. This

is controlled by the technician and is stored by the

;

Probe Tone Oscillator (226 Hz) and Speaker Drive

generated by the Microprocessor (U7) Internal Timer System (Port A). This produces a

226 Hz Square wave at PA3 of the Tymp Microprocessor (U7 pin 31). The Square wave

level or gain

switches select the appropriate output levels based on controls from the microprocessor.

The output levels or switch settings are determined by the calibration data and the external

volume as measured by the probe microphone. The appropriate level is then routed

through a 226 Hz band pass filter (U61). The signal is then routed to the Probe Tone / lpsi

speaker amp (U66).

Microphone

ear canal must be filtered to remove as much unwanted signal as possible. This filtering

is

determined by the CMOS switch settings of (U45 and (U46). These

Input level Monitoring ; The microphone signals that are measured in the

33

The Probe tone Frequency is

is performed by the 226 Hz band pass filter (U65). The filtered RMS microphone signal

rectified

is

is

level adjusted (U59) by the Microprocessor to establish an optimum operating range for

to a dc level for input to the Microprocessor A/D convertor.

This filtered signal

the system during the tymp sweep or reflex testing.

34

CALIBRATION

35

EQUIPMENT REQUIRED FOR CALIBRATION

TYPE 1 SOUND LEVEL METER

ARTIFICIAL EAR

2 cc COUPLER (GSI #1700-2005 OR B&K #DB0138)

9A

(6 cc) COUPLER OR B&K ARTIFICIAL EAR (B&K #4153)

MANOMETER

VOLTMETER (RMS)

FREQUENCY COUNTER

1700-l 030 TEST CAVITY

SMALL STANDARD (SLOTTED) SCREWDRIVER

SMALL PHILLIPS (CROSS) SCREWDRIVER

36

CALIBRATION PROCEDURE

CONFIG.

Confiq.

mode of operation and once programmed should never change. If a new

microprocessor is installed in location XU7 or

programmed. To program the

JP1

and JP3 then power up the unit. Almost immediately after power up the unit will

display

previously installed jumpers. The

DEFAULT DATA LOADING: Durina routine calibration it is not

Default Data.

set of calibration values into EEPROM. Also, if a new microprocessor has been

installed the Default Data loads critical power-up information that the processor requires

for operation into EEPROM. When a new microprocessor or

installed Default Data should be loaded. Load Default Data by setting Dip Switch

positions 6, 7, and 8 to the “ON” position. Set the

then power up the unit. At power-up the display should indicate the unit model and

version number (GSI 38 Version X), the

(Tymp/Reflex

XXX), and the Default Parameters which are currently being loaded into EEPROM

(Loading Audiometer Defautts, Loading Programmed Defautts, or Loading

Defaults). When the Default Data Loading sequence is complete the display will update

to the Main Calibration Mode Menu. At this point Dip Switches 6, 7, and 8 should be

returned to their normally OFF position.

REGISTER: Durinq routine Calibration it is not

Register.

Config.

Programming the

Register Programmed. At this point power down and remove the

Defautt Data Loading

Rev XXX), the Audiometer Software Revision Number (Audiometer Rev

Config.

Config.

Config.

allows

Register establishes the microprocessors

XU34

Register install temporary jumpers (shorts) on

Register is now programmed.

the

technician

Cal/Norm

Tymp/Reflex

necessary

its

Config.

to quickly store an

Switch to the Cal Mode,

Software Revision Number

to

program

Register must be

necessary

Auto/Tymp

to

averaged

Board is

Tymp/Reflex

the

load

The technician may also load an individual set of Default Data by first setting the

desired Dip Switch to the ON position then setting the Cal/Norm Switch to the Cal

Mode position.Dip Switch assignments are as follows:

Dip Switch

6

7

8

Function

Tymp/Reflex

Audiometer Defaults

Programmed Defaults

Defaults

37

Location Loaded

Tymp EEPROM

Audio EEPROM

Audio EEPROM

‘..

NTERING

THE CALIBRATION MODE DIRECTLY (ROUTINE CALIBRATION)

1)

2)

3)

Verify that Dip Switches 6, 7, and 8 are in the OFF position.

Power up the unit.

Slide the Cal/Normal Switch to the Cal Mode position. The display should

appear as follows:

7

CALIBRATION MODES

l

ATTEN

XDUCER

MAX CAL

STIM

CAL

PRINT HEAD CAL

CUSTOM RTL CAL

PROBE

TONE/MIC

CAL

COMPLIANCE CAL

PRESSURE CAL

38

AUDIOMETER CALIBRATION

ATTENUATOR MAXIMUM OUTPUT CALIBRATION: During routine calibration it

should not be necessary to calibrate the Attenuator Maximum Output. However, if

Audiometer Default Data has been loaded then the Attenuator Maximum Output

must be calibrated.

the

1)

2)

3)

4)

5)

Connect the right phone output unloaded

Use the

ATTEN

Press the Present Bar

(The Tone Indicator

Use the

the dB HL knob until the output level for currently display frequency is within the

minimum/maximum values listed in the following table. When the desired output

level has been reached store the value by pressing the pi Key. Repeat

all frequencies.

!=I

MAX CAL

p/

Hz

Hz

Frequencv

125

250

500

750

1000

1500

2000

3000

4000

6000

8000

[c]

F)

Keys to position the cursor on the 38 display at the

position.

Key

to enter the

0

to lock on the tone.

*

should now be present on the display.

to select the desired frequency for calibration.

(Hz)

.

to

an RMS Meter.

ATTEN

MAX CAL Mode.

Minimum - Maximum

2.05-2.30

2.05-2.30

2.33

-

2.5

1.69-1.9

2.28-2.5 vrms

2.28 -

2.55 -

2.28 -

2.55 -

2.28-2.50

2.28 -

2.5

2.70

2.50 vrms

2.70 vrms

2.50 vrms

vrms

vrms

vrms

vrms

vrms

vrrns

vrms

Adjust

for

After all frequencies have been calibrated press the

Calibration Mode Menu.

39

v]

Key to the Main

AUDIOMETER

Use

1)

the a IHz[m IKeys

STIM CAL.

SPL OUTPUT LEVEL CALIBRATION

to position

the cursor on the

38

display at XDUCER

2)

Press

the

I=]

Key to

enter the XDUCER

STIM

CAL

MODE.

The display should now indicate:

XDUCER

STIM

CAL

40.0

125

dB

Hz

NOTE: Tone Bar is OFF

or Inactive

R

40.0

125 Hz

R

dB

Indicates the Current Hearing Level (HL) selected.

Indicates the Current Frequency (Hz) selected.

Indicates the Current Transducer selected.

Indicates a Steady Tone Presentation

The Tone Bar is active in this mode and serves a dual function. When the Tone Bar

as

is OFF or inactive the current hearing level is displayed

When the Tone Bar is pressed ON or active the stim on indicator

the display and the 40.0

dB

(HL) indicator will update

to

shown above.

will appear on

*

the ANSI Standard Reference

Threshold Level (RTL) measured in Sound Pressure Level (SPL) for the selected

frequency and hearing level.

Example:

40.0 dB (HL) at 125 Hz (Freq) will update to 85.0 dB SPL

when the Tone Bar is depressed.

Given:

Therefore:

The ANSI Standard (RTL) correction value for 125 Hz at 0 HL is

dB

equal to 45.0

At 40 dB HL which

Hz

125

will equal 85.0 dB SPL.

SPL.

is

For 125 Hz

ANSI Standard RTL for 0 dB HL

(+)40

dB HL

dB

40

HL

.

40 dB SPL higher that 0 dB HL the output for

=

=

=

40

45.0 dB SPL

(+)40.0 dB

85.0 dB SPL

SPL

For 8

KHz

When calibrating using a Sound Level Meter (SLM) it is important to add or subtract the

appropriate microphone correction.

manufacturer or calibration facility should supply the microphone’s frequency response

curve.

response by using a piston phone or similar standard device. Below is an example of

a microphone frequency response curve.

MICROPHONE

CALIBRATION

ANSI Standard RTL for 0. dB HL

(+)60 dB

dB

60.

HL

HL

=

=

=

13.0 dB SPL

(+)

60.0 dB SPL

73.0 dB SPL

When the microphones are calibrated the

The microphone is then calibrated to the SLM which has a flat frequency

l

CHART

5

dB

+1

0

-1

-5

Provo,

Utah

-10

. .._,..., .q , , ,

I

-15

20 Hz 50 1DO

.,-_i..,

! I. ._ ! i, _

.I 11 1

._,‘_.,.., 1,. __, _,._ ,

200 ' 500

1K

2K

5K

10K

--1-\I--s’

20K

50K

The curve shows that the microphone response is flat between 20 Hz and 1.5 KHz,

KHz

high between 2

as

an example when a standard force is applied to the surface of this microphone its

dB

output is 1

1 dB to our expected value. Our formula for determining the proper calibration

add

high. Therefore, when calibrating 4

and 6

KHz,

and low at frequencies 8 KHz or greater. Using 4 KHz

KHz

using this microphone we must

level for 4 KHz is as follows:

100k'

200K

. 41

4

KHz

ANSI Standard RTL for

Reference HL for Calibration

(+)80. dB

(+) or (-) Microphone Correction

0. dB HL

NA.

80.

dB

=

HL

=

HL

=

(+)80.0 dB

(+)

9.5 dB SPL

SPL

1.0 dB SPL

90.5 dB SPL

The following table contains the ANSI Standard Reference Threshold Levels

RTL's

at

0 HL for each frequency when using TDH-39P earphones.

Frequency (Hz)

ANSI Standardd

Measured

in dB SPL

RTL

125

45.0 25.5

Standard Reference Threshold Levels re:

250

11.5

500 750 1000 1500

7.5

20pPa

7.0 6.5

for

Telephonics

2000 3000

9.0

10.0

TDH-39P earphones

4000

0.5

as measured on the National Bureau of Standards 9-A coupler. Reference ANSI S3.6

6000 8000

15.5 13.0

-

1989, ISO 389 - 1975 Standards.

Grason-Stadler has made an effort to minimize calibration time by defaulting the

Reference HL Levels for Calibration to maintain an expected SPL Calibration Level of

between 85 and 95 dB SPL. The Default HL Levels are as follows:

Frequency

Default HL

(Hz)

125 250 500 750 1000 1500

40

60 80 80 80 80

2000 3000

80 80 80 80 60

4000

6000

8000

Because the 38 automatically adds the ANSI RTL and reference HL values on the

display (when the Tone Bar, is active) the technician needs only to add or subtract

the appropriate microphone correction to the displayed value when calibrating.

3)

4)

5)

Connect the right ear phone to the Sound Level Meter Artificial Ear.

Press (TONE BAR\ the display will update from the selected hearing level to

the ANSI Standard RTL value for calibration and the

appear).

indicator will

m+

Adjust the HL knob until the SPL Level measured on the SLM for the selected

frequency and transducer equals the value indicated on the 38 display (+ or

’

-

Microphone Correction).

6)

7)

Press

Repeat for all frequencies, right phone, left phone, ipsi and contra by

theIF

Key to store the data in memory.

selecting the appropriate key on the 38 front panel.

NOTE: Both left phone and right phone must be calibrated.

-

8)

When finished press the

Menu.

vl

Key to return to the Main Calibration Mode

CUSTOM RTL CAL

This mode is used primarily if a customer wants to calibrate using transducers other

than TDH-39P earphones. This mode allows the technician to program different

RTL values to be displayed when calibrating using the XDUCER

Once programmed, the Custom RTL values will be displayed each time the

XDUCER

dB

63.5

Audiometry Mode is selected to indicate to the customer that Custom RTL values

have been programmed. To return to the ANSI Standard Values and extinguish the

#

sign, the technician must load Audiometry Default Calibration Data.

1)

STIM

CAL MODE is entered. The range of allowable

A # sign will appear next to the dB HL indicator on the display when

Use

theF]Hz]=]Keys

display.

to position the cursor at Custom RTL Cal on the

STIM

CAL MODE.

RTL's

is -5 dB to

2)

3)

4)

5)

6)

7)

NOTE:

PROBE

Press the

Press

Adjust the dB HL dial to achieve the desired RTL value.

Store the value into memory by pressing the m Key.

Repeat for all desired frequencies.

Press

Use

Mode

IFZF]

thewlHz[c]Keys

the

]w]

Adjusting the Custom RTL values has no effect on the earphone

output level. After storing the Custom

must calibrate to the appropriate levels using the XDUCER

CAL MODE.

TONE/MIC

theI=] HzF]Key

position.

CAL

Key to enter the Custom RTL Cal Mode.

to select the desired frequency.

Key to return to the Main Calibration Menu.

RTL's

to position the cursor at the Probe

the technician

Tone/Mic

STIM

Cal

2)

Press the ) PROG 1 Key to enter Probe Tone/Mic Cal Mode. The display will

update to the following “flashing” display.

PROBE

ECV

At this point place the probe in the 2 cc coupler on the Sound Level Meter.

TONE/MIC

SLM

CAL 1.1

43

3)

Press the

m

Key and the display will stop flashing.

4)

5)

6)

Use the dB HL dial to adjust the Probe Tone Level to 85.5 dB SPL

dB).

At this point the Probe Tone

226 Hz

Press the

(+/-

6 Hz).

LM+f

Key to store the data in memory. The display will update to

Frequency

may be verified. It should equal

the following ‘Washing” display.

j:l’:,‘““““*“‘I

.

At this

Press the

point

place the probe in the 2 cc test cavity.

m

Key to start the microphone calibration process. The display

will update to the following steady state display.

**I

(+/-

0.9

After a few seconds the SAVED indicator will extinguish and the 1.2

will change to 1.3. When the cycle is complete the display

following “flashing” display.

7)

,

Press the

~

-

COMPLIANCE CAL

1)

Use the

F]

Mode position.

2)

Press the

[=I

update to the following “flashing” display.

Hz

will update to the

Key to return to the Main Calibration Mode Menu.

-

LqKeys

to position the cursor

Key to enter the Compliance

at the Compliance Cal

Cal Model The display will

indicator

44

COMPLIANCE CAL 2.1

ECV 0.5

3

cm

3)

4)

Place the probe into the 0.5 cc calibration cavity then press the

[M+I

Key to

start the 0.5 cc calibration. The display will stop flashing and remain in steady

state to indicate that calibration is in progress.

NOTE: If the wrong cavity size is used the display will indicate E74 in the lower

right hand corner. After approximately 5 seconds the ERROR MESSAGE will

extinguish and the calibration process may be continued by placing the probe

into 0.5 cc cavity and then pressing the

[WI

Key.

When the 0.5 cc calibration is complete the display will update to the following

“flashing” display.

COMPLIANCE CAL 2.2

ECV 2.0

3

cm

At this point place the probe into the 2.0 cc test cavity.

Press the

PI

Key to start the 2.0 cc calibration. The display will stop flashing

and remain in steady state to indicate that calibration is in progress.

NOTE: If the wrong cavity size is used the display will indicate E74 in the lower

right hand corner.

After approximately 5 seconds the ERROR

MESSAGE

extinguish and the calibration process may be continued by placing the probe

into the 2.0 cc cavity and then pressing the

m]

Key.

When the 2.0 cc calibration process is complete the display will update to the

following steady state display.

COMPLIANCE CAL 2.3

ECV 2.0

cm3

X.XX

X.XX

is equal to the current volume measurement.

.

45

The calibration of compliance measuring devices is affected by air density. As

the air gets thinner, the volume measurement in a

hardwall

cavity increases.

Therefore, as you go up in altitude, barometric pressure decreases making the

hardwall

cavity appear larger than it is.The GSI 38 allows the flexibility to

display the real altitude effect or to correct the ear canal measurements relative

to sea level.

A)

If the customer prefers to correct the ear canal volumes relative to sea

level then adjust

2.00 After adjusting to the desired level store the value by pressing

the

]m

compliance calibration process is complete.

B)

If the customer prefers uncorrected ear canal volumes (actual at altitude

measurements) then adjust the

value indicates the appropriate volume measurement for the customer site

elevation according to the following altitude table.

Altitude

(ft)

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

7000

7500

8000

8500

9000

9500

10000

Barometric Pressure

(mm

thep]HzlF]

Keys until the cm3 XXX value equals

Key. The display will start “flashing” indicating that the

i-1

Hz

[Fj

Keys until the cm’ XXX

Expected Volume Reading

Hg)

759.97

746.51

733.04

719.84

706.63

693.93

681.23

668.78

656.34

644.40

632.46

620.78

609.09

598.00

588.00

578.00

568.00

555.00

544.00

533.00

522.00

*

at Altitude (cc)

2.00

2.01

2.03

2.05

2.07

2.09

2.11

2.13

2.15

2.17

2.20

2.22

2.25

2.27

2.30

2.34

2.37 2.4~0.1

2.40

2.44

2.49 2.520.1

2.54

Calibration Volume

at

Altitude

(cc)

2.0

2.020.1

2.020.1

2.020.1

2.120.1

2.120.1

2.120.1

2.120.1

2.2zo.q

2.220.1

2.220.1

2.220.1

2.220.1

2.3~O.q

2.3~0.1

2.320.1

2.4~0.1

2.4~0.1

2.520.1

5)

Press the

]M+j

Key to store the customer altitude volume measurement. The

display will start “flashing” indicating that the Compliance Calibration process is

complete.

Press the

m]

Key to return to the Main Calibration Mode Menu.

46

PRESSURE CAL

1)

2)

3)

Use the

Press the

update to the following “flashing” display.

At this point make sure that the probe tip is in open air.

Press

Pressure Calibration is complete the display will update to the following “flashing”

display.

[~~Hz~~~

I-1

I

1

M+ 1 Key to start the Ambient Pressure Calibration.

Keys to position the

Key

to enter the Pressure

‘PRESSURE CAL

ECV OPEN

A/D

daPa

cursorr

at the Pressure Cal position.

Cal Mode. The display will

3.1

When the

Ambient

.

PRESSURE

ECV MANOMETER

A/D

XXXX

daPa

-200

CAL

3.2

4)

5)

6)

At this point connect the probe tip to a manometer.

NOTE: Manometer internal volume must be less than 5 cc’s.

Press the

Use the

to -200

Press the

saved will appear in the lower right hand corner of the display. After 3 to 5

seconds the saved indicator will be extinguished and the display will update to

a steady state display as follows.

At this point verify that the leak rate is less than 2

Press the

manometer reading is within &15%) of the pressure value indicated on the 38

display.

Press the

-1

IzIHz

daPa &15%)

wi

1-1

Ver

/=I

Key. At this point the pump will pressurize to -200

[=I

Key to store the -200