Grason-Stadler GSI TympStar User manual Versions 1

Grason-Stadler

®

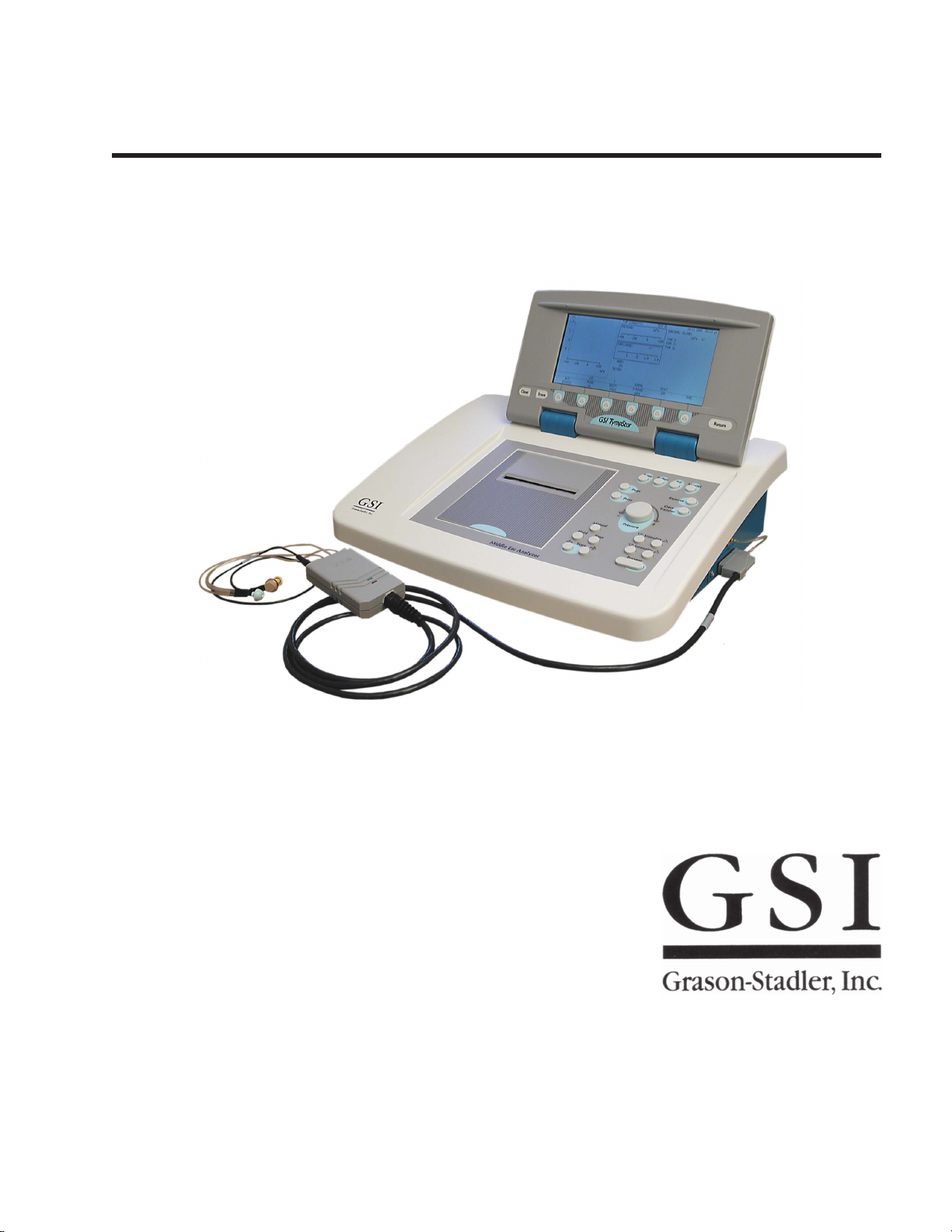

GSI TympStar Versions 1 and 2

Middle-Ear Analyzer

Reference Instruction Manual 2000-0110, Rev 1.0

Printed November, 2001

Service Manual

Grason-S tadler , Inc.

5225 V erona Road, Building #2

Madison, WI USA 53711-4495

T el: 1-603-672-0470

T oll free in the USA: 800-700-2282

Fax: 1-603-672-0487

Title: GSI TympStar Versions 1 and 2

Middle-Ear Analyzer

Service Manual

Date: November , 2001

Copyright © 2001 Grason-Stadler, Inc. All rights reserved. No part of this publication may be repro-

duced or transmitted in any form or by any means without the prior written permission of Grason-Stadler,

Inc. The information in this publication is proprietary to Grason-Stadler , Inc.

Part number: 2000-0110

Printing history: November, 2001 Fi rst p ri nti ng Rev 1.0

Grason-Stadler, Inc.

5225 V erona Road, Building #2

Madison, WI USA 53711-4495

T el: 1-603-672-0470

T oll free in the USA: 800-700-2282

Fax: 1-603-672-0487

W arranty for the GSI T ympStar V ersions 1 & 2

Grason-Stadler warrants the GSI T ympS tar Versions 1 and 2 to be free of original defects in material and

workmanship and to perform in accordance with manufacturer’s specifications for a period of one year

from the date of purchase. If this instrument or any component thereof is found to be defective or at

variance from the manufacturer’s specifications during the warranty period, Grason-Stadler will repair,

replace, or recalibrate the instrument or component at no cost to the purchaser .

This warranty only applies to instruments purchased new from Grason-Stadler or its authorized distributors or representatives. The purchaser must return the instrument directly to Grason-Stadler or an authorized GSI TympStar distributor or representative and bear the costs of shipping.

This warranty does not cover breakage or failure due to tampering, misuse, neglect, accidents, modification, or shipping, and is void if the instrument is not used in accordance with manufacturer’s recommendations or if repaired or serviced by other than Grason-Stadler or a Grason-Stadler authorized representative.

WARNING

The GSI TympStar Versions 1 and 2 are designed to be used with a hospital grade outlets.

Injury to personnel or damage to equipment can result when a three-prong adapter is connected between the instruments’s power plug and an A/C outlet or extension cord.

Accessory Hazard Warning

This IEC 601-l/CSA C22.2 No. 601.1M90 listed medical instrument should be interconnected with accessories that have proper electrical compatibility and which are listed as

conforming to Part 1: General Requirements for Safety of the UL Medical Electrical Equipment Standard UL2601-1. Connection of accessories not meeting these requirements may

result in electrical leakage currents in excess of those allowed by the standard and present a

potential electrical shock hazard to the person being tested.

User manuals

Installation, setup and operating information can be found in the Reference

Instruction Manuals:

T ympS tar Version 1: 2000-0100

T ympS tar Version 2: 2000-0120

Service personnel

Electrical safety

CMOS handling

Repair and/or bench testing of the GSI TympStar Version 1 and Version 2

instruments should be performed only by trained personnel. The following

instructions are provided primarily for use by persons who are skilled in the

repair of electronic equipment.

CAUTION

The GSI T ympS tar V ersion 1 and V ersion 2 instruments ar e

IEC 601-1/CSA appr oved; consequently if any parts ar e replaced during the repair of these units, only exact replacements should be made. Any alterations of the present electrical or mechanical construction or components will void

these safety approvals.

Many of the integrated circuits on the PC Boards are constructed of CMOS

and NMOS materials. Please observe the following precautions:

CAUTION

Failure to observe the following precautions whenever a cir cuit board or an integrated circuit package is handled can

result in damage to the GSI TympStar Version 1 or

Version 2 instrument. Please observe these precautions:

1) Place the instrument and parts on a grounded, conductive work

surface.

2) Ground yourself (with a strap having about 1 Meg-Ohm resistance)

to discharge or prevent static charges.

3) Ground the frame of any test instrument or soldering iron to be used.

4) If any circuit boards are to be stored or transported, enclose them in

conductive (antistatic) envelopes.

Contents

Introduction ..................................1-1

General .....................................................................................................................1-1

V ersion 1...................................................................................................................1-2

Version 1 equipment connections and options.....................................................1-2

V ersion 2...................................................................................................................1-3

Version 2 equipment connections and options.....................................................1-3

The probe .................................................................................................................1-4

Instrument controls .................................................................................................1-5

Hardkeys and softkeys.........................................................................................1-5

Rotary pressure control.......................................................................................1-5

T est modes and menu navigation ..........................................................................1-5

Changing parameter settings..................................................................................1-7

Menu diagrams ........................................................................................................1-7

GSI default parameter settings...............................................................................1-7

Specifications...............................2-1

Introduction.............................................................................................................. 2-1

Standards ................................................................................................................. 2-1

V ersion 1 S pecifications...................................................2-1

Sensitivity ranges ....................................................................................................2-2

Probe signal .............................................................................................................2-2

Pneumatic System ................................................................................................... 2-3

Acoustic Reflex Activating (Stimulus) Signal.........................................................2-3

Stimulus Presentation Control................................................................................ 2-5

T emporal Specifications of Stimulus Present ation ............................................... 2-5

Environmental ..........................................................................................................2-6

Warm-Up T ime..........................................................................................................2-6

Calibration Stability..................................................................................................2 - 7

Connectors...............................................................................................................2-7

Electrical ...................................................................................................................2-8

Supplied Accessories ..............................................................................................2-9

Mechanical ...............................................................................................................2-9

Materials of manufacture ........................................................................................2-9

GSI TympStar Version 1 and Version 2 Service Manual

Contents - 1

Table of Contents

Calibration requirements......................................................................................... 2-9

V ersion 2 S pecifications.................................................2-10

Standards ............................................................................................................... 2-10

Sensitivity ranges .................................................................................................. 2-11

T emporal Latency in ARLT Mode..........................................................................2-12

Multi Frequency .....................................................................................................2-12

Probe Signal (Sinusoidal)...................................................................................... 2-12

Pneumatic System .................................................................................................2-13

Acoustic Reflex Activating (Stimulus) Signal.......................................................2-13

Click S timulus ........................................................................................................2-16

Stimulus.................................................................................................................. 2-16

Presentation Control..............................................................................................2-16

T emporal Specifications Of Stimulus Present ation ............................................ 2-17

Environmental ........................................................................................................2-17

Warm-Up Time........................................................................................................ 2-17

Calibration Stability................................................................................................2-18

Connectors.............................................................................................................2-18

Electrical .................................................................................................................2-19

Supplied Accessories ............................................................................................2-20

Mechanical .............................................................................................................2-20

Materials of manufacture ......................................................................................2-20

Calibration requirements....................................................................................... 2-20

Operation summary......................3 -1

Front panel controls ......................................................... 3-1

Hardkeys...................................................................................................................3-2

Tymp ....................................................................................................................3-2

Reflex...................................................................................................................3-2

Etf.........................................................................................................................3-2

Special .................................................................................................................3-2

Page.....................................................................................................................3-2

Print......................................................................................................................3-2

Remote.................................................................................................................3-2

Data Transfer .......................................................................................................3-2

Pressure control...................................................................................................3-2

Manual .................................................................................................................3-2

Hold......................................................................................................................3-2

Stop......................................................................................................................3-2

Start......................................................................................................................3-3

Stimulus ...............................................................................................................3-3

Intensity................................................................................................................3-3

Contents - 2

Grason-Stadler, Inc.

Table of Contents

Present.................................................................................................................3-3

LCD hardkeys...........................................................................................................3-3

Clear ....................................................................................................................3-3

Erase....................................................................................................................3-3

Return...................................................................................................................3-3

Softkeys....................................................................................................................3-3

Menus and LCD screens ................................................. 3-4

Menus .......................................................................................................................3-4

Program modes........................................................................................................ 3-5

V ersion 1 probe tone frequencies .......................................................................... 3-5

V ersion 2 probe tone frequencies .......................................................................... 3-5

V ersion 1 LCD graphic traces.................................................................................3-5

V ersion 2 LCD graphic traces.................................................................................3-5

Probe lights .............................................................................................................. 3-6

LCD screen...............................................................................................................3-6

Erasing and clearing test data................................................................................3-7

V ersion 2 External reflex test stimuli .....................................................................3-7

Paging test data .......................................................................................................3-7

V ersion 2 cursor....................................................................................................... 3-8

Printing tests............................................................................................................3-8

Preparing an external printer.................................................................................. 3-8

Setting the printer parameters..............................................................................3-9

Left column printout data....................................................................................3-10

Color or black and white .................................................................................... 3-10

Changing Instrument V ersions....................................... 3-1 1

Changing from a V ersion 2 to a Version 1 ........................................................... 3-11

Switching to V1 temporarily................................................................................3-12

Switching back to V2..........................................................................................3-12

Switching to V1 permanently..............................................................................3-12

Changing from a V ersion 1 to a Version 2 ...........................................................3-13

Obtaining a License Code..................................................................................3-14

Replacing the V1 Probe with a V2 Probe...........................................................3-15

Switching to Version 2 software .........................................................................3-16

V ersion 1 test procedures ..............................................3-17

T ymp diagnostic.....................................................................................................3-17

Manual Tymp .......................................................................................................... 3-17

T ymp screening .....................................................................................................3-18

Reflex threshold.....................................................................................................3-18

Automatic Auto Zero...........................................................................................3-18

Mark Threshold ..................................................................................................3-19

Reflex Threshold Seeking..................................................................................3-19

Reflex decay........................................................................................................... 3-20

Eustachian tube function ...................................................................................... 3-20

Pressure Swallow Test (intact TM).....................................................................3-20

GSI TympStar Version 1 and Version 2 Service Manual

Contents - 3

Table of Contents

Perforated Ear Test (Perforated TM)..................................................................3-20

Auto sequence testing ..........................................................................................3-21

Programming auto sequence tests ......................................................................3-21

V ersion 2 test procedures ..............................................3-22

T ymp diagnostic.....................................................................................................3-22

Manual tymp........................................................................................................... 3-23

T ymp screening .....................................................................................................3-23

Reflex threshold.....................................................................................................3-24

Automatic auto zero ........................................................................................... 3-25

Mark Threshold ..................................................................................................3-25

Reflex Threshold Seeking..................................................................................3-25

Reflex decay........................................................................................................... 3-26

Acoustic reflex latency test (ARLT)......................................................................3-26

Acoustic reflex sensitization (A.R. SENSI)........................................................... 3-27

Eustachian tube function ...................................................................................... 3-28

Pressure Swallow Test (intact TM).....................................................................3-28

Perforated Ear Test (Perforated TM)..................................................................3-28

Multiple frequency tympanometry (MULTIPLE Hz) ............................................. 3-29

Auto sequence testing ..........................................................................................3-30

Programming auto sequence tests ......................................................................3-31

Calibration....................................4-1

Introduction.............................................................................................................. 4-1

When to calibrate the TympStar .............................................................................4-2

Calibration requirements.........................................................................................4-2

Complete calibration sequence............................................................................4-2

Routine calibration sequence...............................................................................4-3

Preparing for calibration...................................................4-4

T ools and equipment required................................................................................4-4

Cleaning the probe and Contra phone...................................................................4-4

Probe....................................................................................................................4-4

Contra phone........................................................................................................4-5

Cal/Normal switch............................................................ 4-6

Cal Option DIP switch ......................................................4-6

Switch 1: Factory use only ................................................................................... 4-7

Switch 2: GSI/custom RTL transducer calibration..............................................4-7

Switch 3: Unused...................................................................................................4-7

Switch 4: Unused...................................................................................................4-7

Switch 5: Unused...................................................................................................4-7

Switch 6: Diagnostic mode ...................................................................................4-8

Contents - 4

Grason-Stadler, Inc.

Table of Contents

Hardware Diagnostics .............................................................................................4-8

DAC LEVELS .......................................................................................................4-9

IPSI SOURCE..................................................................................................... 4-11

IPSI ON/OFF...................................................................................................... 4-11

CONTRA SOURCE ............................................................................................ 4-11

CONTRA ON/OFF.............................................................................................4-12

MUX INPUTS .....................................................................................................4-12

PROBE/FILER....................................................................................................4-13

ROUTING........................................................................................................... 4-14

PROBE ON/OFF ................................................................................................4-15

PORTS DIAG...........................................................................................................4-15

RS-232 INT. ON/OFF .........................................................................................4-15

RS-232 INT. ON/OFF .........................................................................................4-16

PARALLEL ON/OFF ...........................................................................................4-16

MISC. DIAG .............................................................................................................4-17

CALENDAR CLOCK...........................................................................................4-18

DISPLA Y & LEDS...............................................................................................4-20

KEYS..................................................................................................................4-21

DIP SWITCHES ..................................................................................................4-22

EEPROM............................................................................................................4-22

SOFTWARE TIMER ...........................................................................................4-23

WA TCHDOG TIMER..........................................................................................4-24

ERROR LOG........................................................................................................... 4-25

Switch 7: Self-Cal..................................................................................................4-26

Switch 8: Load default calibration data...............................................................4-26

Probe serial number....................................................... 4-26

Resolving problems .......................................................4-27

Calibration procedures................................................... 4-28

Hardkeys ............................................................................................................4-28

Softkeys .............................................................................................................4-29

Printing calibration sheets..................................................................................4-30

Adjusting Cal HL and Target SPL levels.............................................................4-31

Custom transducers..............................................................................................4-32

T ransducerconnections ........................................................................................4-32

Calibration requirements....................................................................................... 4-33

Complete calibration sequence.......................................................................... 4-33

Routine calibration sequence.............................................................................4-33

T ympStar Version 1 Calibration...................................... 4-33

V ersion 1 Calibration Procedures................................... 4-34

Self-Cal ...................................................................................................................4-34

Loading default data.............................................................................................. 4-35

Contra, Ipsi and Probe tone calibration ...............................................................4-36

Contra SPL Cal ..................................................................................................4-36

GSI TympStar Version 1 and Version 2 Service Manual

Contents - 5

Table of Contents

Ipsi SPL Cal ....................................................................................................... 4-37

Probe Tone SPL Cal...............................................................................................4-38

Y Cal........................................................................................................................4-39

Altitude Cal......................................................................................................... 4-39

Pressure Cal........................................................................................................... 4-41

Set ambient ........................................................................................................4-42

Set -600/400............................................................................................................4-44

Leak rate ............................................................................................................4-45

V erify Cal ................................................................................................................4-47

Diagnostic............................................................................................................... 4-49

Returning to the Normal T est Mode .....................................................................4-50

TympStar Version 2 Calibration ..................................... 4-51

Calibration requirements ...................................................................................... 4-51

Complete calibration sequence..........................................................................4-51

Routine calibration sequence .............................................................................4-51

Version 2 Calibration Procedures .................................. 4-52

Self-Cal ...................................................................................................................4-52

Loading default data...........................................................................................4-53

Contra, Ipsi and Probe tone calibration ...............................................................4-54

Contra and Ipsi Cal ............................................................................................4-54

External Input Calibration...................................................................................4-55

Click Calibration ................................................................................................. 4-55

Contra SPL Cal.......................................................................................................4-56

Ipsi Channel .......................................................................................................4-56

Contra Channel ..................................................................................................4-57

Ipsi SPL Cal ............................................................................................................4-59

Ipsi Channel .......................................................................................................4-59

Contra Channel ..................................................................................................4-60

Probe Tone SPL Cal...............................................................................................4-62

Y/B/G Cal ................................................................................................................4-64

Altitude Cal......................................................................................................... 4-64

Pressure Cal and diagnostics............................................................................... 4-66

Returning to Normal Test Mode ...........................................................................4-66

Disassembly.................................5-1

Introduction.............................................................................................................. 5-1

Disassembly Procedure................................................... 5-3

T ools Required.........................................................................................................5-3

Opening the cover ...................................................................................................5-3

Removing the analog board ...................................................................................5-4

Removing the Pump................................................................................................5-6

Contents - 6

Grason-Stadler, Inc.

Table of Contents

Removing the power supply................................................................................... 5-8

Removing the power module ................................................................................. 5-9

Fuse holder .......................................................................................................... 5-9

Removing the LCD contrast control ....................................................................5-10

Removing the printer board.................................................................................. 5-11

Removing the printer............................................................................................. 5-12

Removing the PC104 Board .................................................................................. 5-15

Removing the digital board ...................................................................................5-17

Removing the LCD or Softkeyp ad cables ............................................................ 5-20

Removing the LCD .................................................................................................5-25

Removing the LCD front panel label (sof tkey panel)...........................................5-27

Removing the instrument front panel label..........................................................5-29

Removing panel keypads.......................................................................................5-29

System Level Parts ......................6-1

General .....................................................................................................................6-1

Assembly drawings..................................................................................................6-1

Case/chassis ............................................................................................................ 6-2

Overall assembly .....................................................................................................6-4

LCD assembly ..........................................................................................................6 - 5

T op case assembly.................................................................................................. 6-6

Bottom case assembly ............................................................................................6-7

Instrument assembly ...............................................................................................6-8

Labels ....................................................................................................................... 6-9

Printer Assembly.................................................................................................... 6-11

Hardware description...................7-1

General .....................................................................................................................7-1

System boot sequence.................................................... 7-1

Pre-CP Control.........................................................................................................7-1

Main() ........................................................................................................................7-1

Set_op_mode() ........................................................................................................7-3

Tymp_sk() .................................................................................................................7-4

Interconnection diagram.................................................. 7-5

Block diagram description of assemblies .............................................................7-6

LCD assembly ..................................................................................................... 7-6

Printer...................................................................................................................7-6

Probe ...................................................................................................................7-6

GSI TympStar Version 1 and Version 2 Service Manual

Contents - 7

Table of Contents

Pump ................................................................................................................... 7-6

Digital board.........................................................................................................7-7

PC104 board........................................................................................................ 7-7

Analog board ........................................................................................................ 7-7

Power supply board..............................................................................................7-8

Printer board ........................................................................................................7-8

System assembly diagram .............................................. 7-9

Troubleshooting ...........................8-1

System power supply measurements .............................. 8-1

Power Supply (J2)....................................................................................................8-1

Power Supply (set +5VDC)...................................................................................... 8-2

Analog Board (J7) ....................................................................................................8-2

Analog Board (J6) ....................................................................................................8-2

Analog Board (J10) ..................................................................................................8-3

Digital Board (J28) ...................................................................................................8-3

Digital Board (J34) ...................................................................................................8-3

Printer Board (Full View) .........................................................................................8-4

Printer Board (J6) ....................................................................................................8-4

Printer Board (J4) ....................................................................................................8-4

Printer Board (J8) ....................................................................................................8-5

Pressure Potentiometer (Digital Board) .................................................................8-5

Error Codes .....................................................................8-6

CP Error codes ........................................................................................................8-6

SP Error codes.......................................................................................................8-16

Error Messages..............................................................8-19

LCD problem symptoms and probable causes .............. 8-22

Probe problem symptoms and probable causes............8-22

Pump problem symptoms and probable causes............8-23

Printer problem symptoms and probable causes...........8-23

Hardware Diagnostic mode............................................ 8-24

Functional description...........................................................................................8-24

Pressure A/D MUX .................................................................................................8-24

Mic. MUX.................................................................................................................8-25

Probe tone and filter mode ...................................................................................8-25

DAC levels ..............................................................................................................8-25

Routing ...................................................................................................................8-25

IPSI/CONTRA and OSC l/OSC 2 ............................................................................8-26

Contents - 8

Grason-Stadler, Inc.

Introduction

1

General

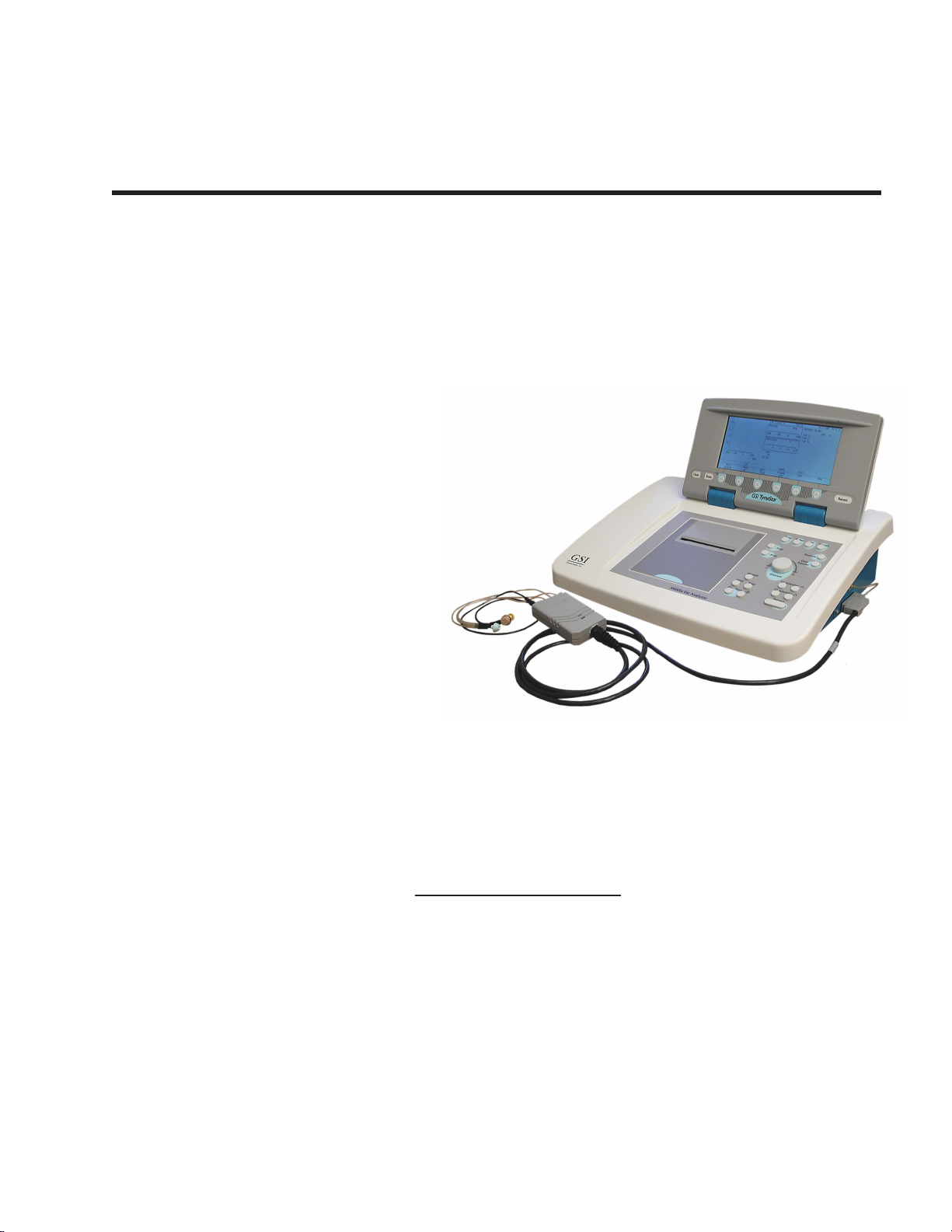

The GSI TympStar Version 1and Version 2 Middle-Ear Analyzers are technically advanced, computer-based admittance instruments designed to be used

in clinical or research settings. The TympStar builds on the sophistication,

functionality and flexibility of the GSI 33, offering unparalleled testing capabilities. It contains total capabilities for complete, manual or automatic diagnostic testing for analysis of middle ear function.

Operators have a choice of using GSI

preprogrammed test parameters, or programming

their own test criteria. A large liquid crystal

display (LCD) clearly displays test parameter choices and the possible alternatives. Admittance and pressure

indications are shown on the

LCD along with a

continuous digital

readout. Test status and invalid

choices are also shown

on the LCD.

Test results are displayed in real-time. The user can view the results as they

are being measured and then has the choice of printing the display or retesting

the patient. The high-speed printer generates reports in concise graphical formats that are easy to read.

This manual addresses the service requirements of the V ersion 1 and the V ersion 2

instruments, and calls attention to the differences when necessary . Please refer to

the appropriate Reference Instruction Manual for more detailed information regarding instrument installation and operation.

GSI TympStar Version 1 and Version 2 Service Manual

1 - 1

Chapter 1

V ersion 1

Version 1 equipment

connections and

options

Admittance (Y) may be measured with a probe tone frequency of 226 Hz. The

extensive battery of test mode choices include:

• Diagnostic Tympanometry

• Acoustic Reflex Threshold and Decay Measurements

• Eustachian-Tube Function Testing (Both intact and perforated eardrums)

• Screening Tympanometry/Reflex (Automatic Only)

The tympanometric measurement results are automatically

scaled and presented in equivalent ml of compliance at “Y”,

226 Hz. Sensitivity scales for the display of reflex measurement results can be selected manually . A cursor is available in all test modes for calling out

numeric positions on the X and Y

axes.

T ympStar Version 1 options that can be

connected to the rear panel include RS232

serial communication, a keyboard for entering patient information and a VGA

monitor for displaying test results. Other options offered for the TympStar

Version 1 for managing and archiving data, include:

• Internal memory for storing up to 26 test results

• Data export to an external PC via RS232 serial interface

1 - 2

Not used in TympStar

Version 1

Grason-Stadler, Inc.

Introduction

V ersion 2

Version 2 equipment

connections and

options

Admittance (Y), and its components Susceptance (B) and Conductance (G), may

be measured with probe tone frequencies of 226, 678, and 1000 Hz. The extensive

battery of test mode choices include:

• Diagnostic Tympanometry

• Acoustic Reflex Threshold and Decay Measurements

• Eustachian-Tube Function Testing (Both intact and perforated eardrums)

• Screening Tympanometry/Reflex (Automatic Only)

• Acoustic Reflex Latency Testing

• Acoustic Reflex Sensitization

• Multiple Frequency Tympanometry (250 Hz to 2000 Hz)

The tympanometric measurement results are automatically scaled and presented

in equivalent ml of compliance at “Y”, 226 Hz. All “B” and “G” measurements and measurements performed at probe tone frequencies of 678 Hz and

1000 Hz are expressed in mmhos. Sensitivity scales for the display of reflex

measurement results can be selected manually. Reflex test stimuli can be input from an external source and presented via external control. A cursor is

available in all test modes for calling out numeric positions on the X and Y

axes.

TympStar options that can be connected to the rear panel include an external

stimulus source, an external Present control, RS232 serial communication, a

keyboard for entering patient information and a VGA monitor for displaying

test results. Other options offered for the T ympS tar for managing and archiving

data, include:

• Internal memory for storing up to 26 test results

• Data export to an external PC via RS232 serial interface

Used only in TympStar

Version 2

GSI TympStar Version 1 and Version 2 Service Manual

1 - 3

Chapter 1

The probe

The innovative lightweight probe is designed for patient comfort, ease-of-seal, and

accurate test results. A wide variety of both standard and special sized eartips are

supplied with the GSI T ympStar to hermetically seal the ear canal. In addition, a set

of screening eartips is provided for screening tymp and reflex tests.

The operator has a choice of three mountings to support the probe box; the

standard lightweight shoulder mounting, standard clothes clip, or an optional

operator wrist attachment. The probe box has 2 LED’s to indicate test status.

Within the probe box there are two small loudspeakers, a microphone and a

pressure transducer . One loudspeaker delivers the probe tone to the ear canal,

while the microphone monitors the intensity of the probe tone within the ear canal.

The second loudspeaker delivers the ipsilateral (ipsi) stimuli to the ear canal.

The contralateral (contra) insert phone contains its own loudspeaker . The

pressure within the ear canal can be varied within the range of +400 daPa

to -600 daPa. At no time is it possible to exceed specified maximum

limits. Pressure can be varied automatically or manually and from nega-

tive to positive or from positive to negative values. Pressure within

the ear canal is monitored continuously in order to maintain pressure

accuracy throughout each test sequence.

1 - 4

Grason-Stadler, Inc.

Introduction

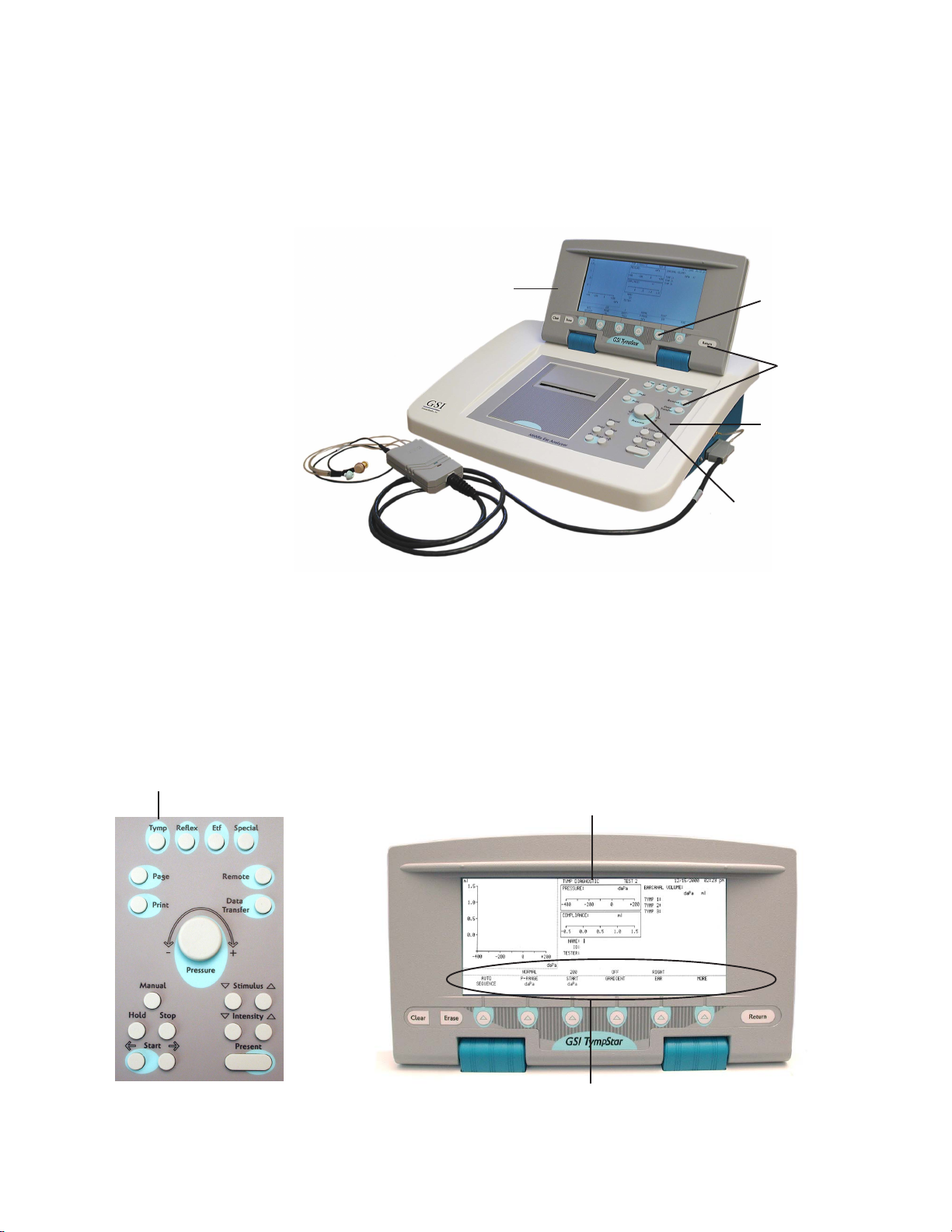

Instrument controls

Hardkeys and softkeys

A combination of hardkeys and softkeys are used to select the test modes and

parameters and to conduct tests.

Hardkeys are located on the front panel and the sides of the LCD panel and provide

fixed functions that do not change. Softkeys are located directly under the LCD and

change to support the requirements of a test session.

LCD panel

Softkey

Hardkeys

Front panel

Pressure control

Rotary pressur e

control

T est modes and menu

navigation

Tymp hardkey

A rotary pressure control is also provided to change or fine-tune pressure within the

ear canal.

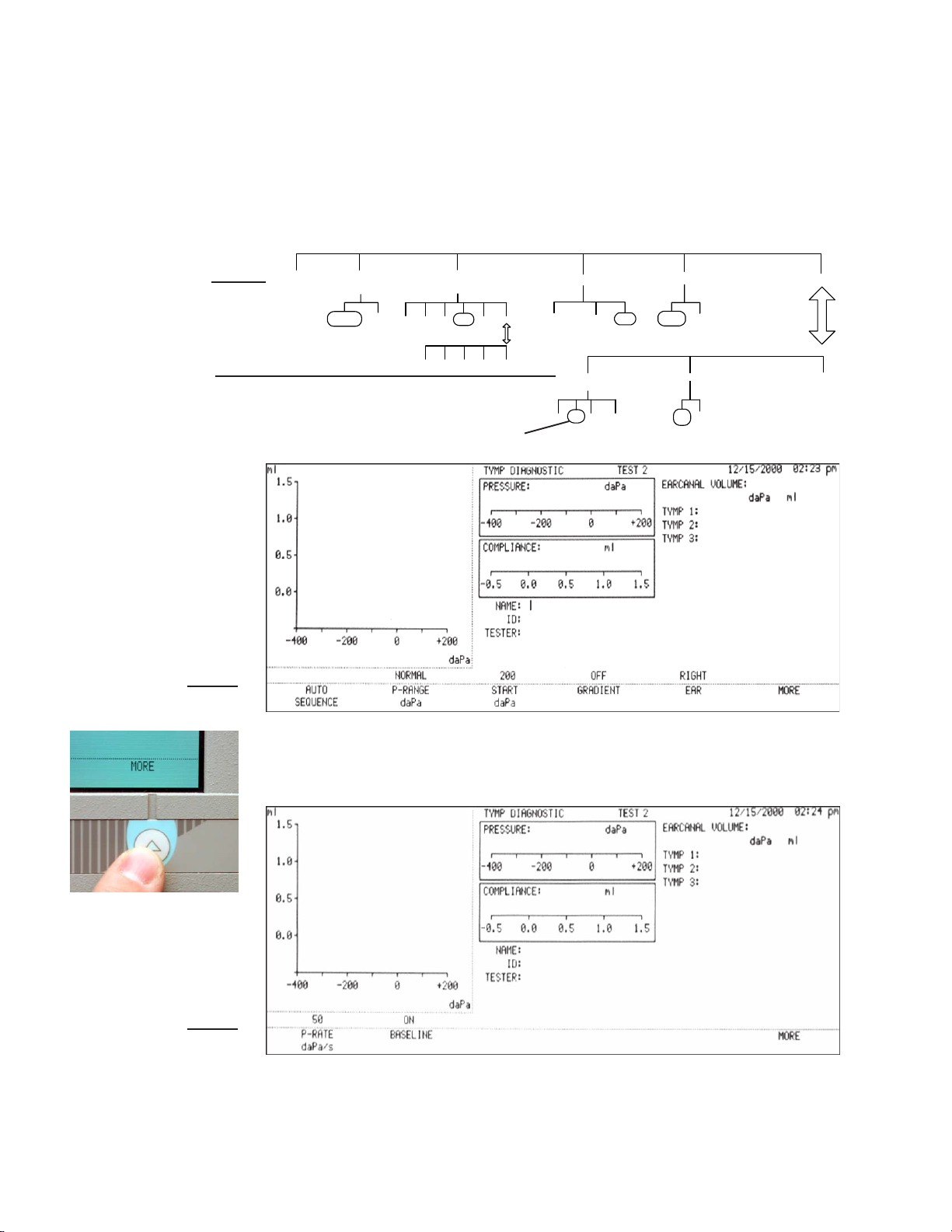

Selecting a test mode by pressing a hardkey causes the required test screen to be

displayed on the LCD with the appropriate menu of test parameters shown across

the bottom. The softkeys are then used in conjunction with a few hardkeys to

navigate through the menus and set parameter values for the selected tests. For

example, pressing the TYMP hardkey causes the T ymp Diagnostic screen to be

displayed.

Tymp Diagnostic screen

Tymp parameter menu

GSI TympStar Version 1 and Version 2 Service Manual

1 - 5

Chapter 1

Pressing the softkeys displayed across the bottom of the LCD allows the user to

navigate through the T ymp Diagnostic parameter menus diagrammed below . These

menus are from the Version 1, however , the process is the same in both versions.

GSI default softkey selections are circled on menu diagrams.

The first level of parameter menu selections includes AUTO SEQUENCE,

P-RANGE, START, GRADIENT, EAR and MORE.

First level

Second level

First level

AUTO

SEQUENCE

P-RANGE

daPa

NORMAL WIDE

START

daPa

-600 -400 -200 +200 +400 MORE

-500 -300 0 +300 MORE

Default

selection

GRADIENT

TYMP WIDTH RATIO

daPa ml

P-RATE

daPa/s

12.5 50 200 600/200

OFF

EAR

RIGHT LEFT

BASELINE

ON OFF

MORE

MORE

Second level

1 - 6

A second level of menus can be displayed by pressing the MORE softkey and

includes P-RATE, BASELINE and MORE.

The MORE softkey is used to toggle between the top and lower levels of menus

while the test screen portion above the softkeys remains unchanged.

Grason-Stadler, Inc.

Introduction

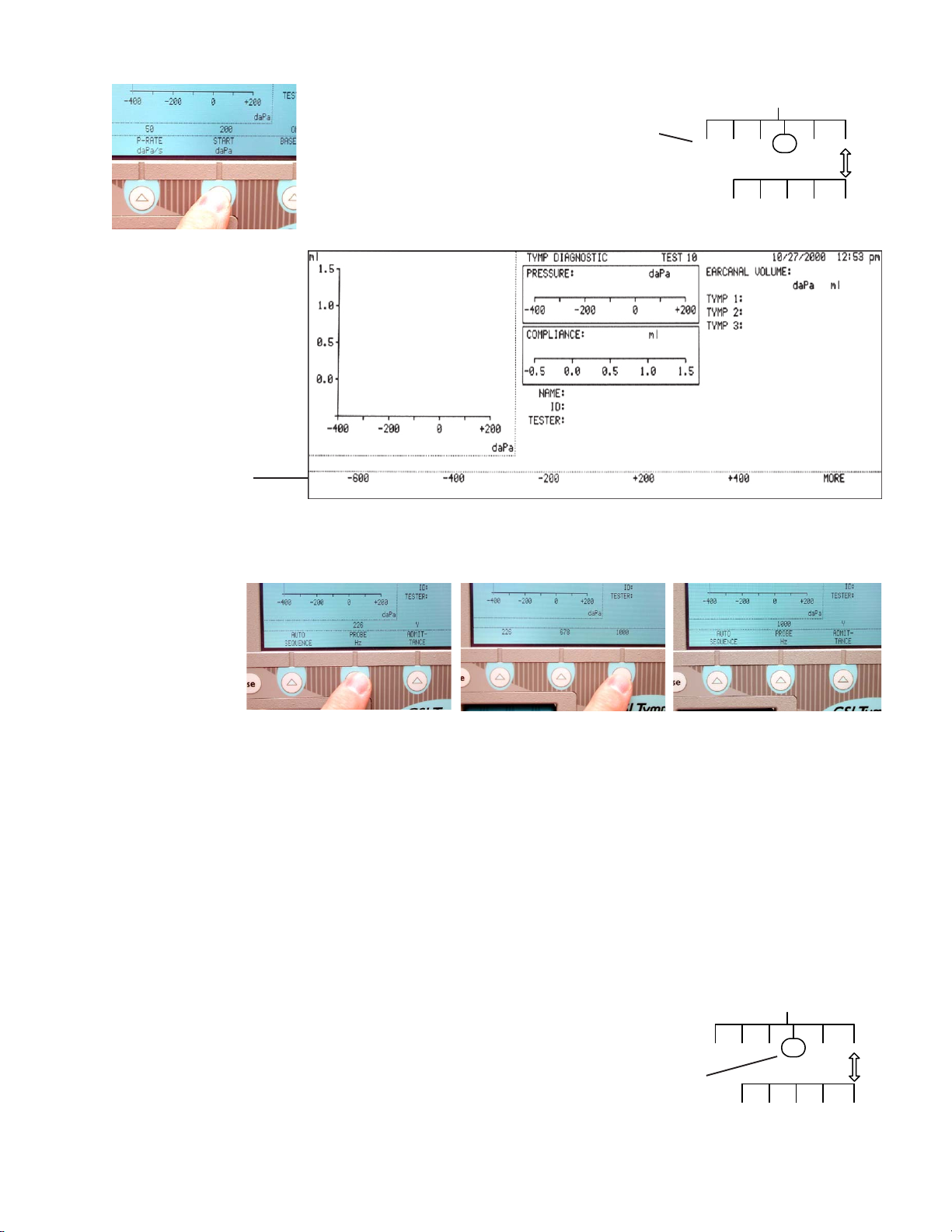

Sub-menu of

START daPa

Pressing a parameter menu softkey

causes a sub-menu of parameter

settings to be displayed. Often submenus will also contain MORE

softkey selections that provide access to additional setting alternatives.

Sub-menu of

START daPa

START

daPa

-600 -400 -200 +200 +400 MORE

-500 -300 0 +300 MORE

Changing parameter

settings

Menu diagrams

GSI default parameter settings

Settings can be changed for a selected parameter by pressing the desired softkey as

shown in this example of changing the Probe Hz from 226 to 1000.

Making the new selection returns the display to the previous menu level with the new

setting shown above the selected parameter .

If no change is desired, the display can be returned to the previous level by

pressing the RETURN hardkey .

In the manner described above, menus can be navigated and settings can be

changed for any of the test modes.

Menu structure diagrams like the diagrams shown on these pages will be used

throughout the remainder of this manual as a convenience to the user .

START

GSI default parameters are circled on

menu structure diagrams shown

throughout the remainder of this

manual.

-600 -400 -200 +200 +400 MORE

GSI default value

daPa

-500 -300 0 +300 MORE

GSI TympStar Version 1 and Version 2 Service Manual

1 - 7

Chapter 1

1 - 8

Grason-Stadler, Inc.

Specifications

2

Introduction

Detailed specifications are provided in this chapter for the T ympStar V ersion 1

and TympStar Version 2 instruments. The specifications for each instrument

can also be found in its corresponding Reference Instruction Manual.

V ersion 1 S pecifications

Standards

The GSI TympStar Version 1 meets or exceeds the following standards and

specifications for aural acoustic admittance instruments:

IEC 1027 1991-03

ANSI S3.39-1987

ANSI S3.6-1996

ANSI S3.7-1995

IEC 645-1 1992

IEC 126-1973 (also BS 6111-1981)

BS ISO 389-2 1994

Y2K Compliant

UL 2601-1 Part 1: General Requirements for Safety

CSA C22.2 No. 601.1-M90 (Canada)

CE Mark per Medical Device Directive (93/42/EEC)

European Representative:

Mr. Leo Hoogendoorn

Nicolet Biomedical GMBH

Saalackerstrasse 8

63801 Kleinostheim, Germany

T el: 011-49-6027-46980

Fax: 011-49-6027-469815

EN60601-1:1990 Safety Requirements for Medical Electrical Equipment

EN60601-1-2 Medical Electrical Equipment Emissions and Immunity

Requirements

This equipment has been tested for radio frequency emissions and has been

verified to meet Radiated and Conducted Emissions per EN 55011-1998,

Group 1, Class A and per CISPR, Class A.

GSI TympStar Version 1 and Version 2 Service Manual

2 - 1

Chapter 2

Sensitivity ranges

The following admittance measurements give maximum range at 226 Hz, Y

in ml.

Table 1: Tymp Mode

Frequency Digital Read-Out Graphical

Including Cursor Display

226 Hz -7.0 to +7.0 -1.0 to +7.0

Accuracy at 226Hz: 0.1 ml or 5%, whichever is greater .

Table 2: Reflex Mode

Frequency Digital Read-Out Graphical

Including Cursor Display

Probe signal

226 Hz -7.0 to +7.0 -0.16 to +0.80

+0.16 to -0.80

Accuracy: 226 Hz is 0.02 ml or 5%,whichever is greater.

Sinusoidal signal with the following characteristics:

Frequency: 226 Hz

Frequency accuracy: ±1%

Harmonic distortion: <2%

(Measured in an HA-1 2cc coupler)

Signal level: 85 dB SPL

(In Real Ear and in Normal Test Mode)

NOTE

The probe tone level is set to be nominally 70 dB HL.

Signal level accuracy: ±1.5 dB SPL

2 - 2

Grason-Stadler, Inc.

Specifications

Pneumatic System

Acoustic Reflex

Activating (Stimulus)

Signal

Pressure Maximum Limits: -800 daPa to +600 daPa

Programmed Pressure Ranges:

Normal: + 200 to - 400 daPa

Wide: + 400 to - 600 daPa

Pressure Accuracy: ±10% or ±10 daPa, Whichever is greater in cavities

from 0.5 cc to 5.0 cc.

Pressure Sweep Rate: 12.5 daPa/sec

50 daPa/sec

600/200 daPa/sec

Manual Sweep Rate Limit: 600 daPa/sec

Sweep Rate Accuracy: ±10%

Pressure System Leak Rate: < 1. 0 daPa/sec

(Measured at -600 and +400 daPa, while pressure servo is disabled.)

Pure T one Stimulus

Frequencies for Contra phone and for Ipsi phone with time multiplexed

stimulus. See Table 3.

Frequency Accuracy: ±1%

T otal Harmonic Distortion (Acoustically): <2%

(Measured 5 dB HL below guaranteed maximum HL)

Noise Stimulus

The uniformity of the spectrum level of acoustic pressure for the noise signal over 20

averages measured acoustically within their respective band limits will be:

±10 dB for insert or probe type earphones

±5 dB for supra-aural type earphones

Noise Band Widths:

Low Band: 125 -1600 Hz

High Band: 1600 - 4000 Hz

Broad Band: 125 - 4000 Hz (Relative to level at 1 kHz)

Band-edges accurate to within ±15%

Roll off rate: >12 dB/Octave

Stimulus Level Control

T one Stimulus: The transfer of reference equivalent threshold values are based

on the article; “Reference Threshold Levels For The ER-3A Insert Phone”, by

Laura Ann Wilber, Barbara A. Krueger and Mead C. Killion, J. Acoustic Soc.

Am. Suppl. 1, Vol. 81 Spring 1987. GSI determined the transfer data from an

IEC 711 coupler to an ANSI HA-1 coupler. Using this data, the reference

threshold values were determined for both the Ipsi and Contra insert earphones

for calibration in an ANSI HA-1 2cc coupler.

Noise Stimulus: The transfer of reference threshold values was done by GSI

using the “Threshold Determination Method”. The transfer data from an IEC

711 to an ANSI HA- 1 coupler was determined by GSI.

GSI TympStar Version 1 and Version 2 Service Manual

2 - 3

Chapter 2

Intensity levels are reduced as a function of volume at a rate of 1 dB SPL for each .1

ml. Intensity reduction begins at 1.2 ml.

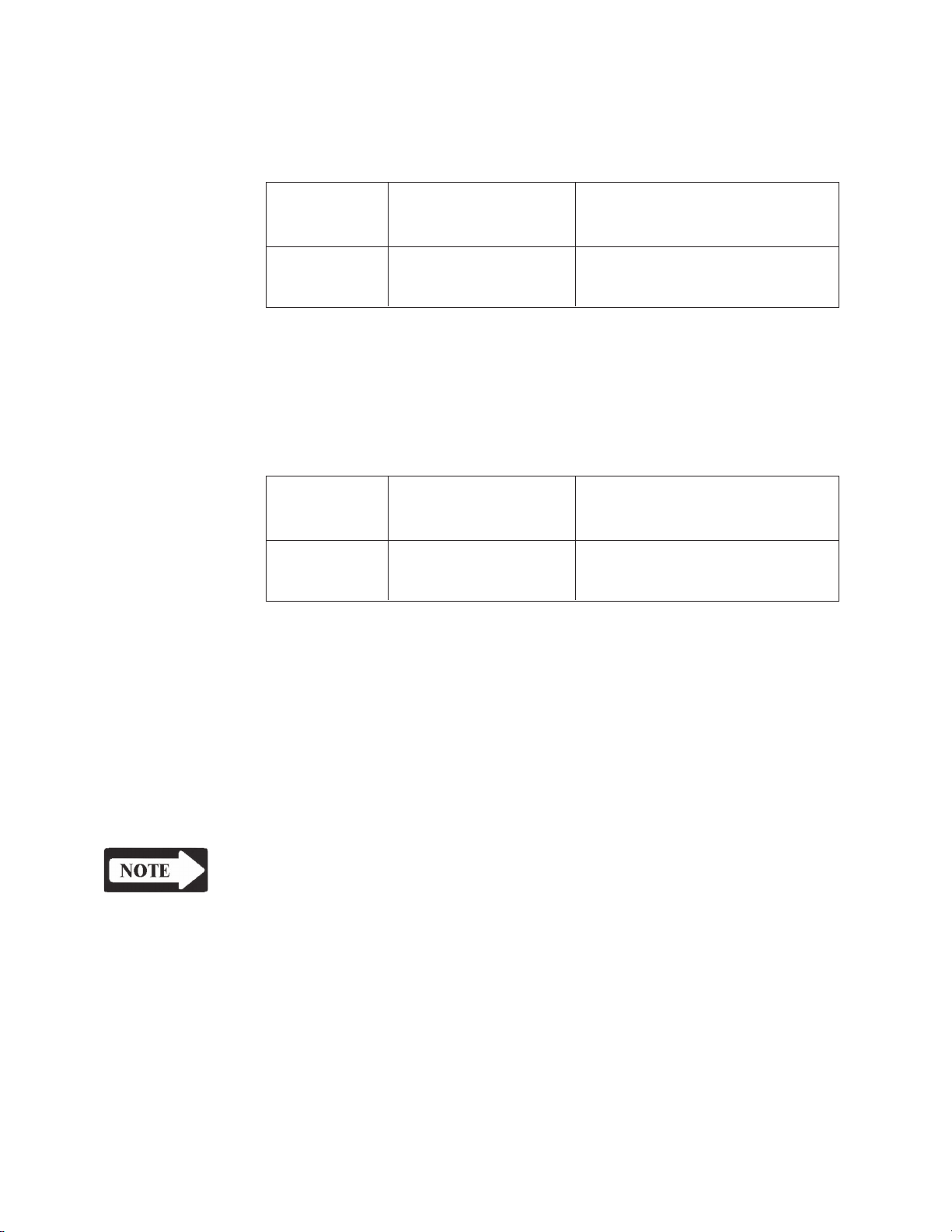

Table 3: Upper limit of HL range in Reflex Threshold Mode

110

105

Lower limit of HL range for all stimulus signals (35 dB HL).

Hearing Level Increment: 5.0 dB

Hearing Level Increment Accuracy: ±0.5 dB

Hearing Level Control Linearity: ±1.0 dB

2 - 4

Grason-Stadler, Inc.

Specifications

Stimulus

Presentation Control

Signal ON/OFF Ratio: >70 dB

OFF mode signal level: <20 dB SPL

Signal T o Noise Ratio: >70 dBA

Measured with disabled probe signal and “A” weighting for noise

measurement.

Residual noise: <25 dBA SPL

(Stimulus Present switch in OFF position)

Unwanted Acoustic Probe Signals: <60 dBA

Measured while pump is operating and probe tone is disabled. Measure it

with “A” weighted filter in “SLOW” Time mode. The noise in normal

operating mode will not effect the immittance measurement accuracy.

Signal separation between Ipsi and Contra channels; all frequencies: >70 dB

(Measured at the probes with the “ON” channel set to 90 dB)

Leaked signal: <20 dB SPL

The radiated acoustic noise from the instrument (with reflex stim off) when

measured at 1 meter from the instrument, shall be: <50 dBA

(“A” weighting and “SLOW” averaging)

T emporal Specifications of Stimulus

Presentation

Steady S tate S timulus

Initial Delay (elapsed time from present bar activation to 10% stimulus

amplitude): < 100 msec

Terminal Delay (elapsed time from present bar deactivation to 90% stimulus

amplitude): <100 msec

Rise time: 7.5 ± 2.5 msec

Fall time: 7.5 ± 2.5 msec

Multiplexed Stimulus (Used in Reflex Threshold test mode)

Period data for frequencies: 250 and 500 Hz:

Period 124 msec

Stimulus on time 44 msec

Stimulus off time 62 msec

Rise and fall time 18 msec

Period data for all other frequencies:

Period 115 msec

Stimulus on time 44 msec

Stimulus off time 53 msec

Rise and fall time 18 msec

Temporal Spec. Accuracy: ±10% or 5 msec, whichever is greater

GSI TympStar Version 1 and Version 2 Service Manual

2 - 5

Chapter 2

Environmental

Warm-Up T ime

The GSI T ympStar Version 1 meets ANSI S3.6-1996 Standards for temperature

and humidity specifications, and it meets the UL 2601-1, CSA 22.2 and IEC606011 standards for safety .

Temperature:

Storage: -40 degrees C to +75 degrees C

Operating: +15 degrees C to +35 degrees C

Humidity: 90% at 35 degrees C (non-condensing)

At room temperature; +15°C to +35°C: 10 Minutes

At room temperature; below +15°C: 1 Hour

2 - 6

Grason-Stadler, Inc.

Specifications

Calibration Stability

Connectors

All GSI T ympStar V ersion 1 specifications are met over the range of specified power

line, temperature and humidity variations.

Power Line:

Voltage Variation: ±10%

Frequency Variation: ± 5%

Power line short term variation which affects the performance of the instrument will turn off all probe and stimulus signals.

Power Rating: 120 Watts maximum

Line Voltage Range: 100 VAC to 240 VAC

Power Line Frequency Range: 50 - 60 Hz

T emperature Operating Range: +15°C to +35°C

Relative Humidity Operating Limit: 90%

Guaranteed Operating Elevation: 6000 Ft. (1800m)

STIMULUS: External Stimulus Input

(Phone Jack) Peak Voltage: 3 VAC

Input Impedance: 15,000 Ohms

PRESENT: External Present Control Input that turns the stimulus signal ON

and OFF (Phone Jack).

Voltage Range: STIM OFF:+5.0 VDC

STIM ON:0.0 v

Input Impedance: 11,000 Ohms

Contra PHONE: Output Voltage: 7 VAC

Output Impedance: 2.5 Ohms

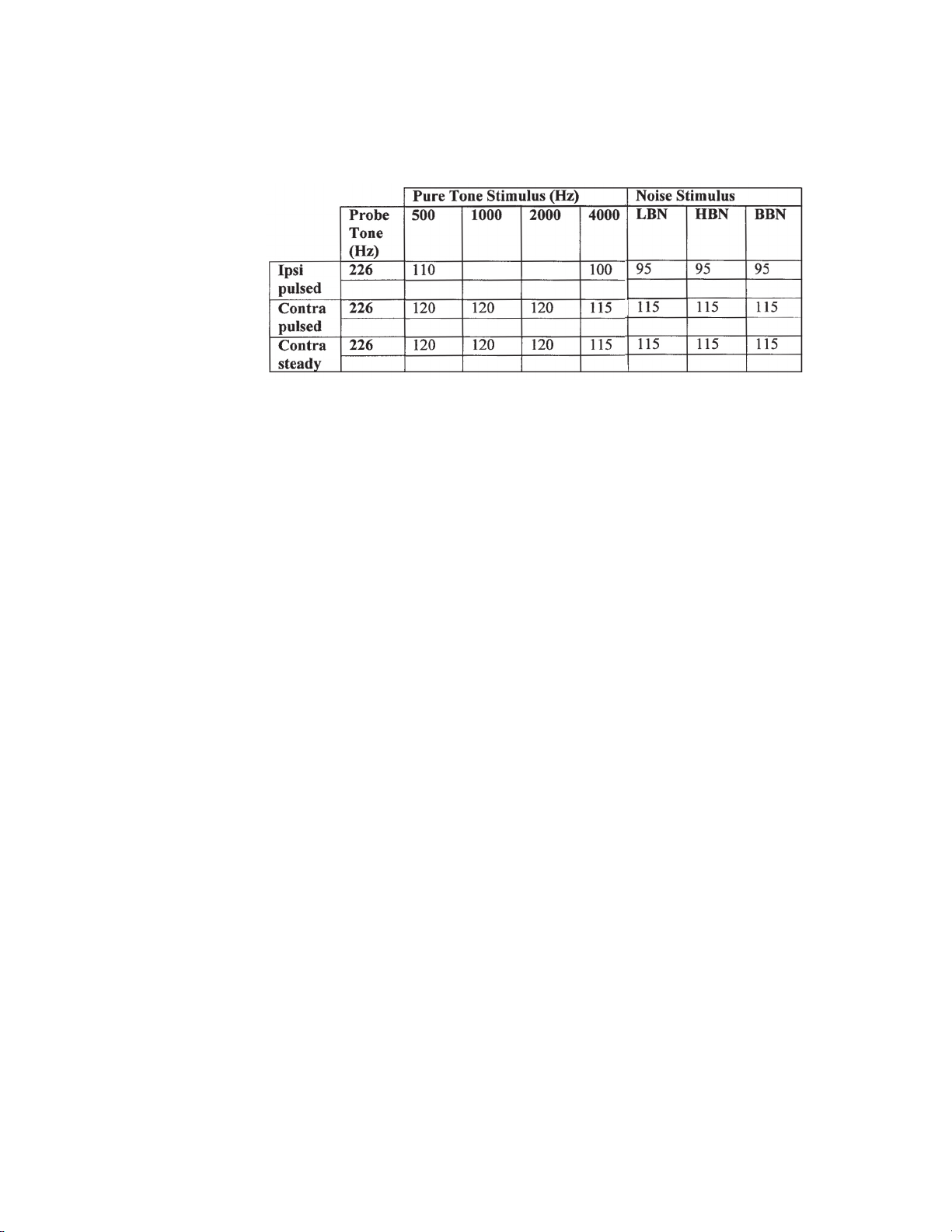

Standard 9-pin RS232C serial port for interfacing with outside computer .

RXD

CTS

TXD

RTS

Standard VGA port for external monitor .

GSI TympStar Version 1 and Version 2 Service Manual

2 - 7

Chapter 2

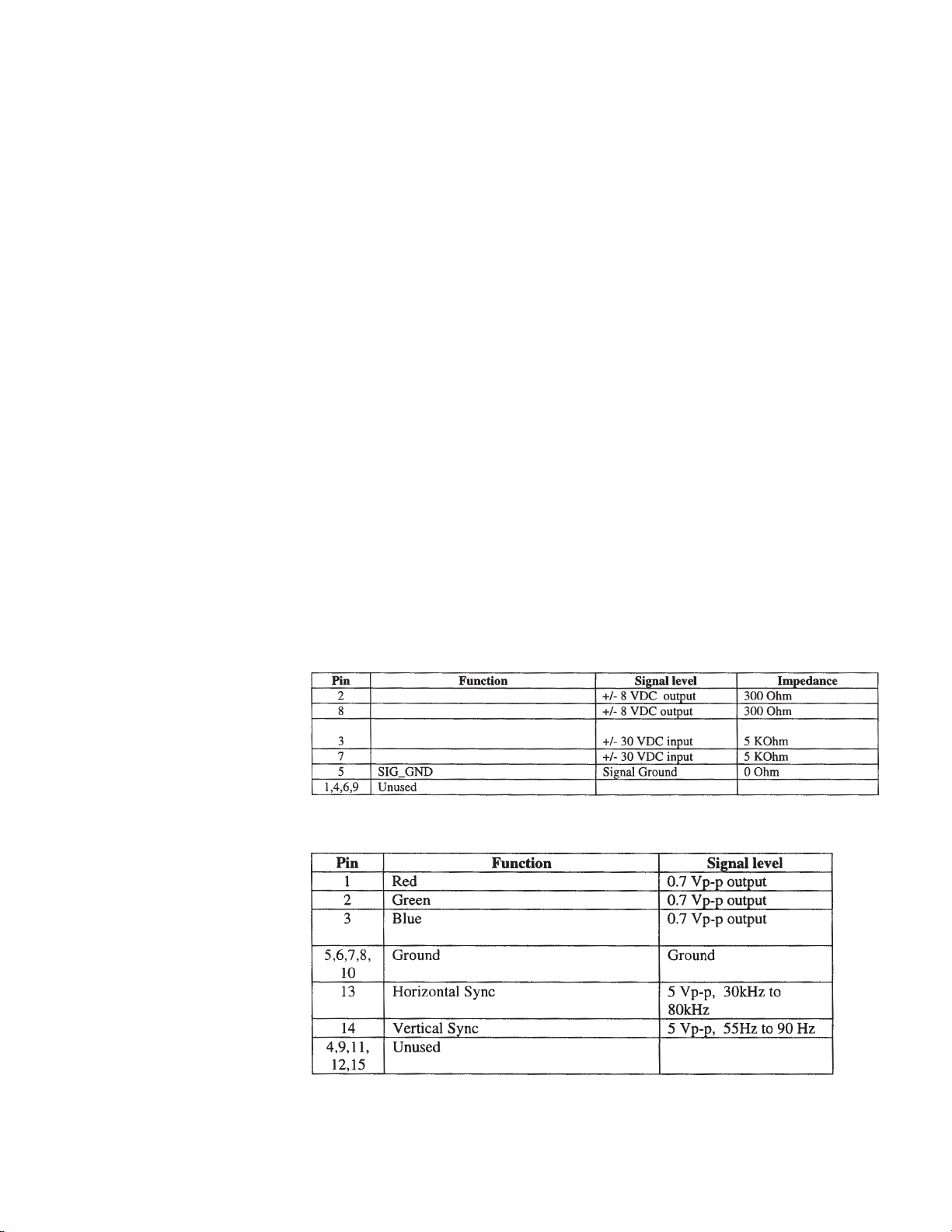

Standard PS-2 keyboard port for external Keyboard.

Standard parallel printer port for external printer .

Electrical

The following apply to the T ympStar system:

1) Class 1 Medical Equipment

2) Type B Medical Equipment

3) IPXO ingress of water (ordinary equipment)

4) Equipment not suitable for use in the presence of flammable anesthetic

mixture with air or with oxygen or nitrous oxide.

5) Mode of operation - continuous

Input Voltage: 100 – 240 VAC

Input Frequency: 50 – 60 Hz

Input Current: 3.2 A maximum

Power Consumption: 120W maximum

2 - 8

Grason-Stadler, Inc.

Specifications

Supplied Accessories

Contra insert phone GSI Part # 8000-0078

Calibration cavity (V1) GSI Part # 2000-1036

Probe cleaning kit (2 boxes) GSI Part # 2000-9610

Eartips:

1 pkg. 8 standard sizes, 4 ea. (Color coded) GSI Part # 1700-9660

1 pkg. 6 special sizes, 2 ea. GSI Part # 1700-9670

1 pkg. 6 screening sizes, 2 ea. GSI Part # 1700-9622

Reference Instruction Manual GSI Part # 2000-0100

Quick User Guide GSI Part # 2000-0108

Printer paper (2 rolls) for orders including printer GSI Part # 1700-9619

Spare set of probe tubing GSI Part # 2000-9617

Probe mount - shoulder GSI Part # 1700-9646

Probe mount - wrist GSI Part # 1700-9642

Probe mount - clothes GSI Part # 1700-9608

Printer paper, adhesive-backed

for orders including a printer GSI Part # 1770-9643

GSI TympStar dustcover GSI Part # 1700-9618

Power cord with hospital-grade plug GSI Part # 4204-0251

(USA)

Power cord part # varies depending on location

Mechanical

Materials of

manufacture

DIMENSIONS AND WEIGHT

W x D x H: 20.38 inches x 15 inches x 12.6 inches (LCD raised)

52cm x 38cm x 32cm

Height with LCD lowered - 6 inches (15cm)

Weight: 16.58 pounds, 7.53 kg

Shipping weight: 29.50 pounds, 13.38 kg

T op Case, LCD Housing

Front & Rear & Hinges: Lexan 500 w/10% Glass & 2% Blowing Agent,

UL 94V0 Rated

LCD Lense: GE HP40S -OR- Duralan II

Switches: Shincor Shin-Etsu/Novacor KE-951 U

Labels: Lexan & Polycarbonate

Softkey Panel: Mylar

Probe Cord: Polyvinyl Chloride (PVC)

Probe T op & Bottom Housings: Cycolac KJW , UL 94V0 Rated

Probe Tip: Polypropolene

Eartips: Kraton 3226

Tubing: Vinyl and Polyurethane

Calibration

requirements

GSI recommends quarterly calibration checks for the GSI T ympStar along with

annual certification. ASHA requires quarterly electro-acoustic calibration checks

and annual electro-acoustic calibration. It is good practice to perform daily biologic

checks. See Chapter 4: Calibration for complete calibration instructions.

GSI TympStar Version 1 and Version 2 Service Manual

2 - 9

Chapter 2

V ersion 2 S pecifications

Standards

The GSI T ympStar Version 2 meets or exceeds the following standards and specifications for aural acoustic admittance instruments:

IEC 1027 1991-03

ANSI S3.39-1987

ANSI S3.6-1996

ANSI S3.7-1995

IEC 645-1 1992

IEC 126-1973 (also BS 6111-1981)

BS ISO 389-2- 1994

Y2K Compliant

UL 2601-1 Part 1: General Requirements for Safety

CSA C22.2 No. 601.1-M90 (Canada)

CE Mark per Medical Device Directive (93/42/EEC)

European Representative:

Mr. Leo Hoogendoorn

Nicolet Biomedical GMBH

Saalackerstrasse 8

63801 Kleinostheim, Germany

T el: 011-49-6027-46980

Fax: 011-49-6027-469815

EN60601-1:1990 Safety Requirements for Medical Electrical Equipment

EN60601-1-2 Medical Electrical Equipment Emissions and Immunity

Requirements

This equipment has been tested for radio frequency emissions and has been

verified to meet Radiated and Conducted Emissions per EN 55011-1998,

Group 1, Class A and per CISPR, Class A.

2 - 10

Grason-Stadler, Inc.

Loading...

Loading...