Page 1

Instruction Manual

Outdoor Microphone System Types 41AM / 41CN

Skovlytoften 33, 2840 Holte, Denmark

www.gras.dk gras@gras.dk

SOUND & VIBRATION

G R A S

...

.

Page 2

Revision 11 June 2010

LI0002

Outdoor Microphone System

Types 41AM / 41CN

Note: unless individually specied, the term “Outdoor Microphone

System” throughout this document refers to both types, i.e.

Type 41AM and Type 41CN.

Page 3

Important! any dismantling details given in this document are

addressed solely to qualied service personnel who must ensure

that the unit is rst disconnected from its power supply before pro-

ceeding.

Page 4

CONTENTS

1. Introduction and Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Available Types and Applications ......................................6

2. Main Components ................................................7

2.1 Windscreen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Microphone Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.1 Pressure Equalisation ................................................10

2.2.2 Electrostatic Actuator .................................................10

2.2.3 Microphone ........................................................10

2.2.4 Dismantling the Microphone Assembly ...................................11

3. Access to Electronics Assembly ...................................12

4. Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1 Electrostatic Actuator ..............................................14

4.1.1 Adjustment .........................................................14

4.1.2 Calibration Control Box AC0001 ........................................14

4.2 Pistonphone .....................................................15

4.2.1 Setup and adjustment ................................................16

4.3 Factory Calibration ................................................16

5. Maintenance ...................................................17

5.1 Windscreen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 Dehumidiers ....................................................17

5.3 Multi-frequency Calibration Check (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.3.1 Output Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6. Service and Repair ..............................................19

7. Specications ..................................................20

8. Circuit and Component Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Page 5

Outdoor Microphone System - Page 5

G.R.A.S. Sound & Vibration

1. Introduction and Description

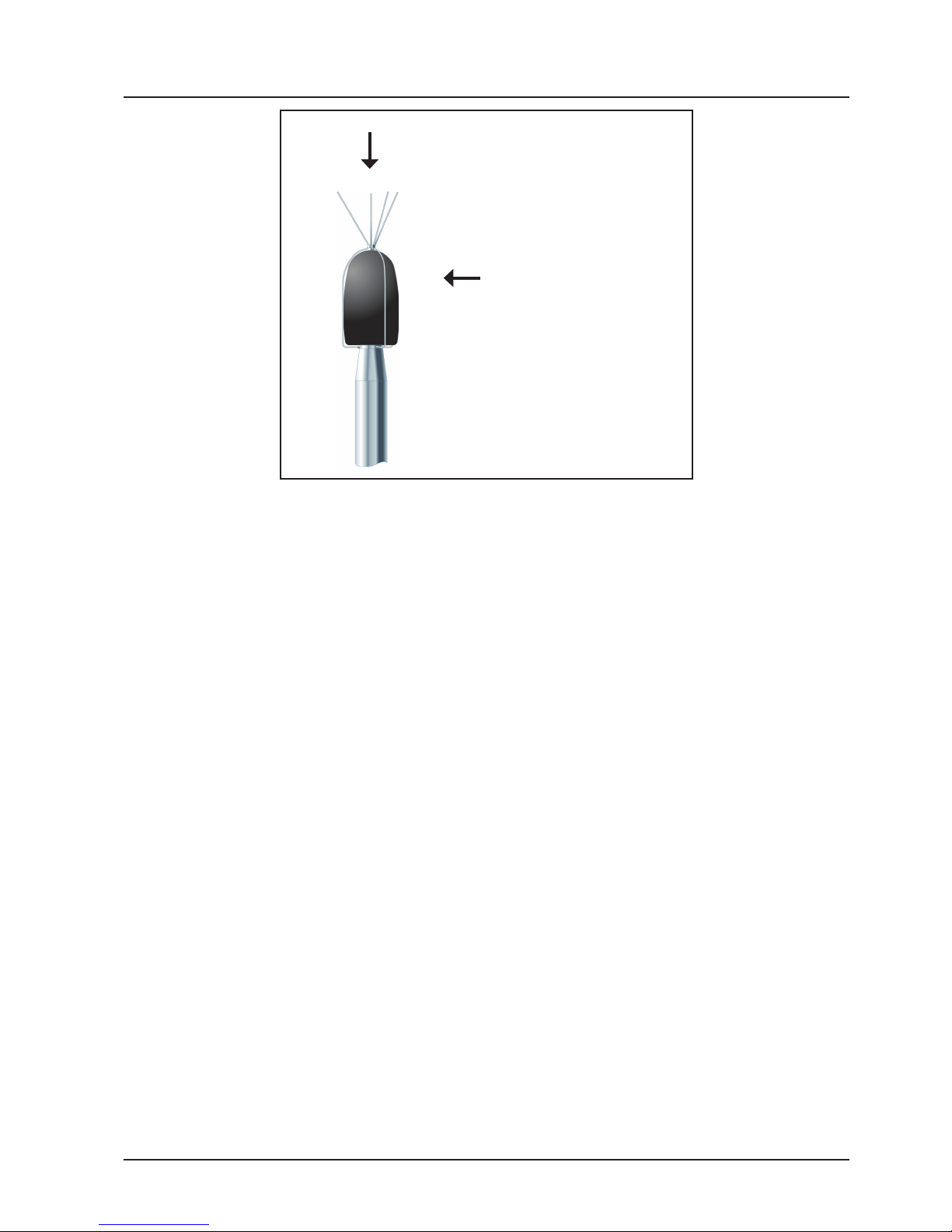

The G.R.A.S. Outdoor Microphone System (Fig. 1.1) is for outdoor use whenever trouble-free

noise monitoring is required, e.g. around airports or in communities.

It complies with IEC 651 Type 1 and ANSI S1.4 1983 Type 1 requirements and can be used with

any suitable electronic sound or vibration measurement system. It is PTB approved as part of

an IEC 651 Type 1 system.

A ½-inch precision condenser microphone and thick-lm preamplier ensure maximum stability

and performance. Both microphone and casing are made of stainless steel.

Precise in-situ calibration checks at 1000 Hz are enabled any time via a built-in electrostatic

actuator and test oscillator.

Fig. 1.1 Outdoor Microphone System

Page 6

Outdoor Microphone System - Page 6

G.R.A.S. Sound & Vibration

Fig. 1.2 Outdoor Microphone System. Types, reference

directions and applications

1.1 Available Types and Applications

There are two types of the Outdoor Microphone System, these are Type 41AM and Type 41CN.

Each has its own measurement reference direction and application, i.e.:

Type 41AM

Measurement reference direction - vertical (along axis of symmetry)

Angle of incidence - 0°

Application - monitoring airport noise

Type 41CN

Measurement reference direction - horizontal (perpendicular to axis of symmetry)

Angle of incidence - 90°

Application - monitoring community noise

See also Fig. 1.2.

Both types are almost physically identical; differing only in the type of the microphone cartridge

and rain-protection cap used. Type 41AM uses Microphone Cartridge Type 41AS and Type

41CN uses Microphone Cartridge Type 40AS.

Reference Direction

0° incidence (airport noise)

Type 41AM

Reference Direction

90° incidence (community noise)

Type 41CN

Page 7

Outdoor Microphone System - Page 7

G.R.A.S. Sound & Vibration

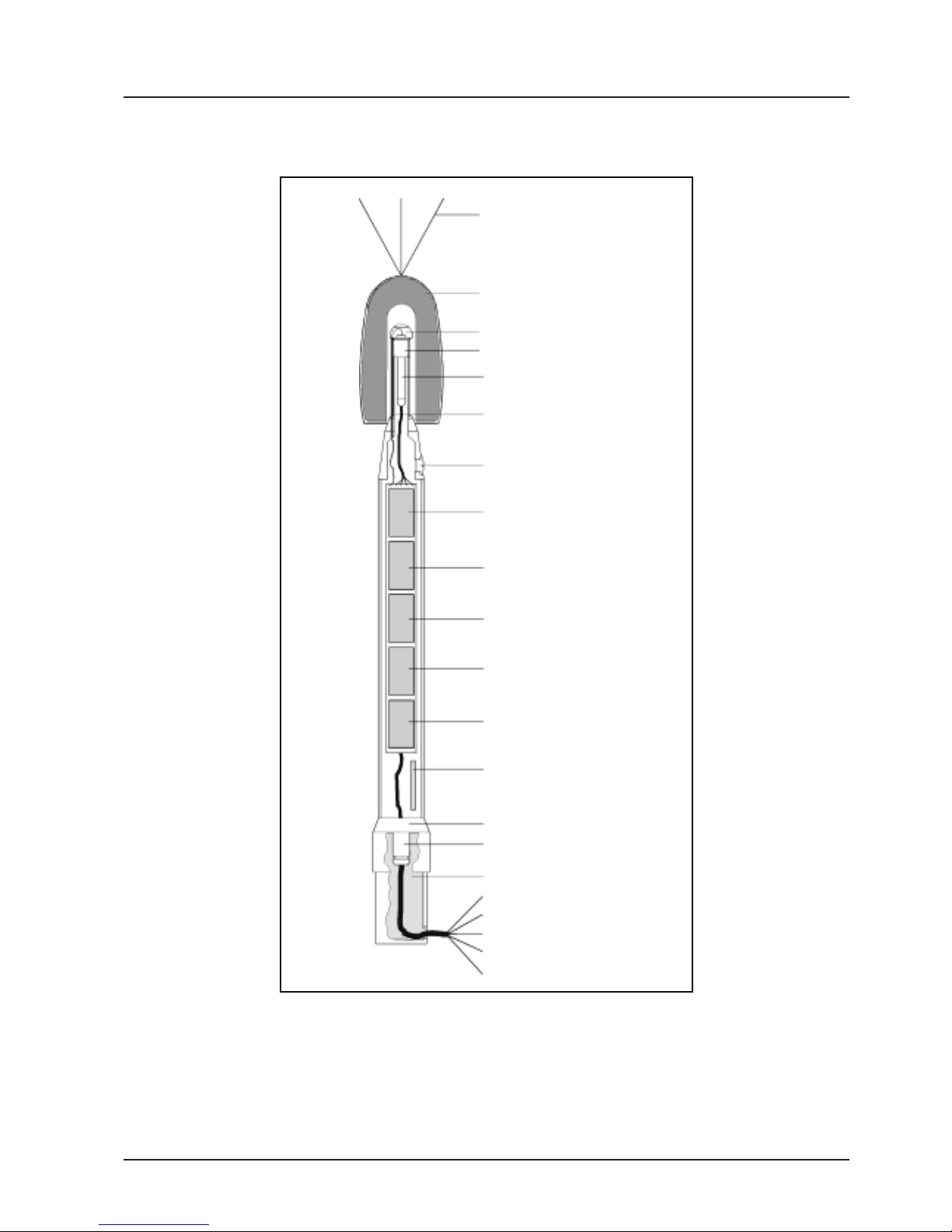

2. Main Components

The following is a brief description of the main components of the Outdoor Microphone System

(see also Fig. 2.1).

All external metal parts are made of stainless steel.

Windscreen and windscreen holder with anti-bird spikes.

Electrostatic actuator housing mounted on top of the condenser microphone.

Condenser microphone and preamplier mounted on top of the casing. The microphone

and electrostatic-actuator assembly are galvanically isolated from the system casing.

The top of the casing has an inspection window for viewing the state of the dehumidier

when the cover screw is removed.

The cylindrical casing contains the assembly of electronics and desiccator bags for absorb-

ing moisture.

The electronics include:

A switch-mode power supply for generating:

a) 200 V for microphone polarisation

b) 120 V for the microphone preamplier

And:

c) an A-weighting network

d) a circuit jumper for applying a gain of ± 20 dB to the microphone signal

A pole adaptor with a standard ISO 228/1 G 1½-in thread. Also used for the tripod adaptor

(Fig. 2.2).

The Outdoor Microphone System can be mounted on the tripod adaptor using the pole

adaptor. The cable and plug are readily led through the tripod adaptor. The tripod adaptor

is not meant for permanent outdoor installations, but for test setups in labs and short-term

outdoor surveys.

The connector is a 6-pole LEMO FFA.2S.306, which locks into a socket at the bottom of

the Outdoor Microphone System. It cannot be pulled out by its cable. It can be removed

only by pulling outwards on the knurled outer sleeve.

Page 8

Outdoor Microphone System - Page 8

G.R.A.S. Sound & Vibration

Fig. 2.1 Main components of the Outdoor Microphone

System

Anti-birds spikes

Windscreen and holder

Electrostatic actuator

½″ microphone

Preamplier

Equalisation vent

Calibration oscillator

Dehumidier inspection window

Lin. or A-weighting

Sensitivity control

0 or ±20 dB gain

Cable driver

DC - DC converter

Dehumidier

Pole adapter

LEMO connectror

12 - 18 V DC

Signal out

Test-oscillator start

Ground

Multi-freq. cal. check (optional)

Tripod adapter

Page 9

Outdoor Microphone System - Page 9

G.R.A.S. Sound & Vibration

Fig. 2.2 Left to right; tripod and pole adapters

2.1 Windscreen

This comprises a windscreen and a windscreen holder (see Fig. 2.3).

The windscreen itself is made of polyurethane foam. It reduces wind-noise to a minimum and

gives maximum rain protection. It also allows for 0 ° (Type 41AM) and 90 ° (Type 41CN) refer-

ence directions of incidence.

The windscreen holder has four anti-bird spikes to prevent birds from perching on top of the

windscreen. The centre spike prevents smaller birds from perching between the other three

spikes.

Fig. 2.3 Windscreen of the Outdoor Microphone System

2.2 Microphone Assembly

On delivery, the microphone assembly is protected by a transport tube, see Fig. 2.4. A small

hole of 0.5 mm diameter at the top end of the transport tube ensures pressure equalization

during transport. The transport tube is also used when testing for self-noise. In this case, the

hole must be sealed using a piece of tape. Remember to remove the tape after use.

When screwing the windscreen onto the microphone, apply some silicone grease (supplied) to

the thread - see Fig. 2.4). The silicone grease is waterproof and protects against rust.

Anti-birds spikes

Windscreen

Windscreen holder

Page 10

Outdoor Microphone System - Page 10

G.R.A.S. Sound & Vibration

2.2.1 Pressure Equalisation

The pressure equalisation system, which ensures that the air-pressure within the cartridge of

the condenser microphone is kept equal to the ambient atmospheric pressure, allows sufciently

rapid pressure equalisation while keeping to a minimum the exchange of air between the interior

and exterior. This also extends the working life of the dehumidier.

Pressure equalisation takes place via the 1.5 mm diameter stainless-steel tube visible on the

side of the upper cylindrical section (see Fig. 2.4). This tube is also a conduit for the signal wire

connecting the calibration oscillator with the electrostatic actuator.

2.2.2 Electrostatic Actuator

The position of the actuator relative to the microphone is maintained by a calibration ring positioned under the Teon sleeve. The calibration ring ensures the correct spacing between the

actuator and the diaphragm of the microphone.

For inspection purposes, access to the signal wire in the pressure-equalisation tube is gained

after removing the rain-protection cap (see section 2.2.4) which is held in place by a left-hand

thread mushroom-head screw. In the case of the Type 41CN, the small black plastic cone

mounted on top of the screw has to be removed rst.

2.2.3 Microphone

If the electrostatic actuator, Teon sleeve and calibration ring are removed, the microphone

can be unscrewed (see section 2.2.4). The microphone is mounted on a galvanically isolated

assembly, together with a thick-lm, high-impedance input preamplier which is miniature,

ceramic-based, and robust.

Fig. 2.4 Showing microphone assembly - note the difference between

the two rain-protection caps

Rain-protection cap and actuator

Teon sleeve

Pressure-equalisation tube

Dehumidier inspection window

Transport tube

Type 41AM

Type 41CN

Add silicone grease to this thread

Page 11

Outdoor Microphone System - Page 11

G.R.A.S. Sound & Vibration

2.2.4 Dismantling the Microphone Assembly

Dismantling the microphone assembly is rarely necessary and should be done by a qualied

technician recognised by G.R.A.S. Sound & Vibration.

First disconnect the power from the Outdoor Microphone System before proceeding. The actua-

tor voltage is 300 V.

The circled numbers refer to which part of the special tool AM0038 (Fig. 2.5) to use

1. Unscrew the windscreen

1

.

2. Remove the black cone from the top of the rain-protection cap (Type 41CN only).

3. Unscrew the mushroom-head screw holding the Teon rain-protection cap in place.

Use

2

for the Type 41AM and 3 for the Type 41CN.

Note: Left-hand thread - unscrew clockwise.

4. Remove the Teon rain-protection cap.

5. Disconnect the signal wire (with gold plated pin) from the top of the actuator housing so

that it sticks directly out of the pressure-equalisation tube.

6. Use the special key RA0087 (Fig. 2.5) to unscrew the actuator housing (right-hand thread)

and remove the spacer and insulator rings placed around the microphone capsule. Be very

careful not to damage the diaphragm of the microphone capsule.

7. The microphone capsule can now be unscrewed to gain access to the preamplier. It is

recommended to mount a protection grid (not included) on the microphone capsule before

unscrewing it.

Re-assembling is in the reverse order of the above. Don’t forget the spacer and insulator rings

otherwise the microphone diaphragm can be seriously damaged.

After re-assemby, re-calibrate the electrostatic actuator as described in section 4.1.1.

Fig. 2.5 Special tools for dismantling the Outdoor

Microphone System; left to right:

Multi-spanner

Key for dismantling actuator housing

AM0038

RA0087 (not included)

1 2

3

5

4

Page 12

Outdoor Microphone System - Page 12

G.R.A.S. Sound & Vibration

3. Access to Electronics Assembly

For access to the electronics assembly, do the following. The circled numbers refer to which part of the tool

AM0038 (Fig. 2.5) to use:

1. Unscrew the large retaining ring at the base of the

casing

4

.

Make sure that only the retaining ring turns.

4. Remove the rubber O-ring, locking washer and

nut from the LEMO socket.

This will allow the silica-gel container to pass over

the LEMO socket.

2. Pull out the socket plate.

If necessary, insert the LEMO connector in the

LEMO socket and pull out the socket plate. This

will reveal the silica-gel container.

3. Unscrew the LEMO socket nut and remove the

socket plate

5

.

Note: steps 4 and 5 are necessary only if the silica-gel

container is to be removed. Otherwise, go to step 6 if

only access to the electronics is required.

Retaining ring

Silica gell

container

Socket plate

LEMO socket

LEMO socket

nut

LEMO socket

nut

Socket plate

Nut

Washer

O-ring

LEMO socket

NutWasherO-ring

LEMO socket

Silica-gel

container

Electronic

assembly

Socket plate

1

2

3

4

Page 13

Outdoor Microphone System - Page 13

G.R.A.S. Sound & Vibration

5. Remove the silica-gel container.

At this point, the silica-gel crystals can be

removed from the container, dried off and used

again (see section 5.2).

6. Unscrew the stainless-steel casing to give access

to the electronics assembly.

If necessary, remove the screw from the dehumidier inspection window and screw the tommy

bar (AM0063) in its place if the casing is difcult

to unscrew.

Dehumidier

container

Stainless-steel casing

Electronics assembly

5

6

Page 14

Outdoor Microphone System - Page 14

G.R.A.S. Sound & Vibration

4. Calibration

4.1 Electrostatic Actuator

The Outdoor Microphone System is equipped with a built-in electrostatic actuator to enable

rapid calibration checks in-situ. The electrostatic actuator is factory adjusted to simulate a sound

level of 90 dB at a frequency of 1000 Hz on the diaphragm of the microphone (94 dB is also

available on order). The electrostatic actuator is switched on by connecting pin 1 to pin 6 on the

LEMO socket (see Fig. 5.2). This will cause a calibration signal of 500 Hz AC to be applied to

the actuator.

Warning! do not touch the actuator while the calibration signal is applied. The voltage applied

to the actuator is approximately 300 V RMS. Extreme care should be taken when handling the

circuit boards while the power is on. High voltages are present!

The 500 Hz signal creates an oscillating electrostatic eld which causes the diaphragm of the

microphone to oscillate at twice the applied frequency thus generating a reference signal of

1000 Hz. The result is a simulated sound pressure on the diaphragm of the microphone which is

directly proportional to the applied voltage and inversely proportional to the spacing between the

actuator surface and the microphone diaphragm.

It can be shown that this method of calibration relates directly to simple absolute physical

parameters.

The stability of this method ensures that the microphone calibration is consistent; therefore no

other calibration check is necessary. Electrostatic actuator calibration should be carried out at

regular intervals.

4.1.1 Adjustment

With the electrostatic actuator switched on, adjust P201 (see Fig. 8.3) to give a signal output

level of 31.6 mV.

An electrostatic-actuator calibration is referred to a Pistonphone calibration as described in section 4.2.1 and assumes that the Outdoor Microphone System has a sensitivity of 50 mV/Pa. In

turn, this means that an output level of 31.6 mV will correspond with 90 dB as simulated by the

electrostatic actuator.

A-Weighting

At this stage, the A-weighting network can also be checked as follows:

1. Move the “Jumper for response” (see Fig. 8.3) from Lin to A-w.

2. With the electrostatic actuator switched on, adjust P101 (see Fig. 8.3) to give a signal

output level which corresponds with 90 dB, i.e. 31.6 mV.

3. Move the “Jumper for response” back to the position Lin.

Position Com is not used.

4.1.2 Calibration Control Box AC0001

A useful accessory available from G.R.A.S. is the Calibration Control Box AC0001 (see

Fig. 4.1). This has a lead which plugs directly into the output socket of the Outdoor Microphone

System. The AC0001 has sockets for signal output, remote-control calibration and external

power (12 – 18 V DC, e.g. from a G.R.A.S. Mains/line Adapter AB0002/AB0003*). It also has an

on/off switch for local calibration control.

* AB0002 for 230 V AC; AB0003 for 120 V AC

Page 15

Outdoor Microphone System - Page 15

G.R.A.S. Sound & Vibration

4.2 Pistonphone

If actuator calibration results give rise to suspicion by showing abnormal variations, i.e. in

excess of 0.4 dB (temperature coefcient accounted for), after a warm-up period of at least one

hour, a Pistonphone calibration is advisable.

A calibration using a Pistonphone (or Sound Calibrator) requires rst removing the windscreen

from the Outdoor Microphone System and mounting a special adapter in its place: no other

parts need be removed.

Use Adapter RA0009

1

for Type 41AM

Use Adapter RA0041

1

for Type 41CN

Note: remove the black plastic cone from the rain-protection cap only if a Sound Calibrator

is to be used.

The RA0009/RA0041 consists of a support tube with a close-tting collar which holds together

the two halves of a split coupler. The two halves of the split coupler are engraved with a

common number to show that they are correctly matched. The correction values supplied with

each RA0009/RA0041 must be applied to the nominal value for the Pistonphone or Sound Calibrator used (+ means add, – means subtract).

When using a Pistonphone, apply any barometric correction in the normal way. The Pistonphone/Calibrator must be tted with a coupler for 1-inch microphones.

Once the windscreen has been removed, mount the adapter as follows (refer to Fig. 4.2):

Fig. 4.2 Mounting the Adapter RA0009/RA0041

1

The Adapter RA0009/RA0041 is not included with the Outdoor Microphone System Type 41AM/41CN but is available on sepa-

rate order.

Fig. 4.1 Calibration Control Box AC0001

5

2

3

4

1

Page 16

Outdoor Microphone System - Page 16

G.R.A.S. Sound & Vibration

4.2.1 Setup and adjustment

1. Screw the support tube (1), with its collar (2) on, onto the thread used by the windscreen.

If the adapter has not been used recently, the collar might stick a little and should be made

free before proceeding.

2. Assemble the two halves of the split coupler (3 and 4) around the microphone assembly

(5). It is very important for the calibration that the two halves t correctly around the microphone assembly making sure to accommodate for the thin pressure-equalisation tube.

3. Push the collar up onto the lower part of the split coupler to keep the two halves tightly

together. While doing this, press the two halves of the split coupler against the support

cylinder.

4. Mount the Pistonphone/Calibrator on top of the split coupler and switch on. It is important

for the calibration that the two halves of the split coupler are pressed against the support

cylinder to avoid faulty results. Do not turn or twist the Pistonphone/Calibrator while

mounting it or removing it because this could damage the thin pressure-equalisation tube.

5. With a pistonphone mounted and switched on, adjust P102 (see Fig. 8.3) to give a signal

output level of:

• 5 V for a nominal pistonphone signal of 134 dB.

• 1.6 V for a nominal pistonphone signal of 124 dB.

• 500 mV for a nominal pistonphone signal of 114 dB.

This will ensure that the sensitivity of the Outdoor Microphone System will be 50 mV/Pa.

A Pistonphone calibration will help in tracing any dubious results with the electrostatic-actuator

to one or more of the following:

Actuator

Actuator voltage supply

Microphone preamplier

Microphone cartridge

Actuator calibration should be carried out at regular intervals. Calibration using a Pistonphone/

Calibrator should be carried out primarily for diagnostic purposes.

4.3 Factory Calibration

The Outdoor Microphone System is a self-contained unit. The microphone polarisation voltage

is supplied internally by the system’s electronics which also supplies the 120 V needed to power

the preamplier as well as the voltages needed for the built-in actuator. This enables the system

to be calibrated to the nominal sensitivity of 50 mV/Pa as given on the calibration chart.

If a basic verication is desired in-situ, this should be carried out using the Pistonphone method

of calibration as described in section 4.2. The frequency-response of the Outdoor Microphone

System is given on the calibration chart. It can be shown that any change in frequency response

of the microphone used in Outdoor Microphone System is highly unlikely without an attendant

change in sensitivity and, hence, in the calibration level. There is no advantage in performing annual checks on the Outdoor Microphone System as long as the built-in calibration per-

forms correctly. Small deviations during warm up and cooling down periods will occur owing to

changes in the static pressure within the microphone unit.

Variations of approximately 0.4 dB will level off within half an hour, depending on the magnitude

of the variations. This is normal and should be taken as a sign of correct system performance.

If required, a timely calibration result can be used to correct the measurement of a short-term

event such as an aircraft yover.

Multi-frequency calibration check (see section 5.3) is an available option if required. It provides

a check on the frequency response and gain of the electronic circuits. It does not increase

system reliability.

Page 17

Outdoor Microphone System - Page 17

G.R.A.S. Sound & Vibration

5. Maintenance

5.1 Windscreen

The windscreen should be cleaned as and when necessary depending on the severity of local

conditions. Recommended exchange frequency is one year.

First remove the foam inner sleeve and thereafter unscrew the windscreen assembly and lift it

over the top of the microphone assembly. Pull the foam windscreen out of its holder and wash

it in clean water. Squeeze it, place it back in the holder then remount it over the microphone

assembly.

5.2 Dehumidiers

There are two dehumidiers in the form of silica-gel containers in the Outdoor Microphone

System. The one at the top can be viewed through the inspection window after removing the

screw (see Fig. 2.4). The one at the bottom is referred to in section 3, step 5 and is shown in

Fig. 5.1. Both contain silica-gel crystals. In the dry state the colour of these crystals are:

Top dehumidier: blue *

(changing to pink while absorbing moisture)

Bottom dehumidier: orange

(changing to white when absorbing moisture)

The top dehumidier is an indicator of the state of the silica-gel crystals in the bottom dehumidier. If the top dehimidier starts absorbing moisture, then its time to change/dry-off the silica-gel

crystals in the bottom dehumidier. The effect of this will also dry off the silica-gel crystals in the

top dehumidier.

There are two ways of drying off the silica-gel crystals in the bottom dehumidier.

1. Unscrew the Plexiglas lid and put the dehumidier and crystals in a standard oven (preheated to 100 °C – 120 °C) for approximately one hour.

2. Pour the silica-gel crystals onto a piece of paper and place in a microwave oven at medium

power for approximately 10 minutes.

After drying off, the colour of the crystals should have changed to dark orange. If not, repeat the

process. Next, pour the crystals back into the dehumidier and ret the lid.

A new dehumidier (GU0037) can be ordered, as well as 15 grams of replacement silica-gel

crystals (MI0013).

It is recommended that the colour of the crystals is checked at least once a year in dry climates

and twice a year in humid climates; more often in extremely humid areas or when large temperature uctuations occur.

* For environmental considerations, to be phased out and orange crystals used instead

Fig. 5.1 Silica-gel container (GU0037) used at the bottom

of the Outdoor Microphone System

Page 18

Outdoor Microphone System - Page 18

G.R.A.S. Sound & Vibration

5.3 Multi-frequency Calibration Check (Optional)

This makes use of an option which calls for an internal modication of the Outdoor Microphone

System.

This option allows an AC signal of approximately 1 V RMS to be applied to pin 4 shown in

Fig. 5.2. This signal is led to the calibration circuit for amplication and then applied to the system’s electrostatic actuator built into the rain-protection cap (see Fig. 2.4). As with the system’s

own calibration oscillator, frequency doubling will take take place.

This option is useful for checking the stability of the system’s frequency response. It is not a

measure of its free-eld frequency response.

5.3.1 Output Connections

The output connections via the LEMO socket at the base of the Outdoor Microphone System

are shown in Fig. 5.2.

Fig. 5.2 LEMO socket output connections (external view)

Page 19

Outdoor Microphone System - Page 19

G.R.A.S. Sound & Vibration

6. Service and Repair

Service and repair should be carried out only by qualied service personnel. The Outdoor

Microphone System should not be dismantled with power on because of the presence of high

voltages in its circuits.

Page 20

Outdoor Microphone System - Page 20

G.R.A.S. Sound & Vibration

7. Specications

Valid for Types 41AM/41CN at 1013 mbar, 23 °C and 50 % RH unless stated otherwise

Nominal sensitivity:

50 mV/Pa

Frequency response:

IEC 651 Type 1 and ANSI S1.4-1983 Type 1

For the applicable reference direction as shown in Fig. 1.2, re. 1000 Hz:

20 Hz - 80 Hz: ± 1dB

80 Hz - 4 kHz: ± 0.7 dB

4 kHz - 8 kHz: ± 1 dB

8 kHz - 12.5 kHz: ± 1.5 dB

12.5 kHz - 16 kHz: + 1.5 dB, – 5 dB

Dynamic range (upper limit):

>156 dB SPL (at – 20 dB setting) re. 20 µPa

Total system-noise level:

A-weighted: < 20 dB re. 20 µPa

Lin. 22.5 Hz - 22.5 kHz: < 23 dB re. 20 µPa

Output impedance:

<50 Ω

Output current:

>25 mA

Power supply:

12 - 18 V DC

Power consumption:

120 mA at 15 V

180 mA at 15 V calibrator “on”

Operating-temperature range:

– 40 °C to + 50 °C

Calibration level of electrostatic actuator:

90 dB re. 20 µPa at 1000 Hz: ± 0.2 dB at 23 °C

Actuator temp. coefcient: – 0.021 dB/ °C

Dimensions:

Casing (ext. dia.): 40 mm (1.57 in)

Length: 520 mm (20.5 in)

Pole-adapter thread: 50 mm (1.97 in) x G 1½ in (ISO 228/1)

Weight:

1.3 kg (2.8 lbs)

Page 21

Outdoor Microphone System - Page 21

G.R.A.S. Sound & Vibration

Accessories included:

Windscreen complete: AM0052

Spanner: AM0038

Transport protection cap: AM0037

Tripod adapter: AM0033

Pole adapter: AM0029

LEMO plug FFA.2S.306: AE0001

Silicone grease (7-ml tube) MI0016

Accessories available:

Pistonphone adapter: RA0009 (Type 41AM) RA0041 (Type 41CN)

Foam windscreens (5 items): AM0009

Calibration Control Box: AC0001

Extension cables:

3m: AA0003

10m: AA0002

20m: AA0001

30m: AA0017

50m: AA0004

100m: AA0015

200m: AA0016

WEEE directive:

2002/96/EC

CE marking directive:

93/68/EEC

Manufactured to conform with:

RoHS directive:

2002/95/EC

G.R.A.S. Sound & Vibration continually strives to improve the quality of our products for our customers; therefore, the

specifications and accessories are subject to change.

Page 22

Outdoor Microphone System - Page 22

G.R.A.S. Sound & Vibration

8. Circuit and Component Diagrams

Fig. 8.1 shows the circuit diagram for signal conditioning.

Fig. 8.2 shows the circuit diagram for the power supply.

Fig. 8.3 shows component placement and the location of user-serviceable jumpers and adjust-

ment potentiometers.

Page 23

Outdoor Microphone System - Page 23

G.R.A.S. Sound & Vibration

Fig. 8.1 Circuit diagram for signal conditioning

Page 24

Outdoor Microphone System - Page 24

G.R.A.S. Sound & Vibration

Fig. 8.2 Circuit diagram for power supply

Page 25

Outdoor Microphone System - Page 25

G.R.A.S. Sound & Vibration

Fig. 8.3 Showing component placement and the location of user-serviceable jumpers

and adjustment potentiometers

Jumper for gain:

0 dB* or + 20 dB

Jumper for gain:

0 dB* or – 20 dB

Jumper for response:

A-weighting or linear*

Com not used

Jumper for signal:

direct or conditioned*

* Factory settings

Potentiometer

P102

Potentiometer

P201

Potentiometer

P101

Lin

Loading...

Loading...