Page 1

J

K

310 Series

MANUAL NO.JS310-UM-251

SignJet

Service Manual

JS310-UM-251-03-9370

Page 2

iJS310-UM-251-9370

HISTORY OF REVISIONS

No. Date issued Description of revision Page Edition

1 06.08.31 First printing All 01

2 06.12.07 Additional parts added for the parts list. 115 to 132 02

3 07.07.18 Part number of the GTC Flange Set was corrected. 130 03

Page 3

iiJS310-UM-251-9370

CONTENTS

1. Safety information

...............................................................................................................................1

1.1 Safety precautions

.................................................................................................................................1

1.2 Important Safety Information

.....................................................................................................2

1.3 Caution When Using Printer

........................................................................................................2

1.4 Guide When Using Ink

......................................................................................................................2

1.5 Choosing Printer Installation Place

........................................................................................3

1.6 Warning, Caution and Attention

...............................................................................................3

2. Technical Parameters

.......................................................................................................................5

3. Product Configuration

....................................................................................................................7

3.1 Main Unit

....................................................................................................................................................7

3.2 Accessories

.................................................................................................................................................8

3.3 Consumables

...........................................................................................................................................12

4. Basic Panel Operation

...................................................................................................................13

4.1 Menu Structure of Control Panel

............................................................................................13

4.1.1 Function description of the keys ..................................................................................................13

4.1.2 Menu structure ...................................................................................................................................14

4.2 Description of menu function

.....................................................................................................15

4.3 LCD display for normal usage

..................................................................................................21

4.3.1 LCD display during printing .......................................................................................................21

4.3.2 LCD display when printing is paused ......................................................................................21

4.3.3 System warning and error display .............................................................................................22

4.4 Printing Steps

........................................................................................................................................23

5. Assembling the Printer and the Installation Procedure

.............................25

5.1 Notes on the Installation Environment

................................................................................25

5.1.1 Installation Space ..............................................................................................................................25

Page 4

iiiJS310-UM-251-9370

5.1.2 Installation Space ..............................................................................................................................25

5.1.3 Power Supply Specifications .........................................................................................................26

5.2 Removing the Printer from its Packaging

........................................................................27

5.3 Mounting the Ink Tanks

................................................................................................................31

5.4 Mounting the Waste Ink Tanks

................................................................................................32

5.5 Connecting the Power Supplies

.................................................................................................33

5.6 Setting the Print Speed

...................................................................................................................34

5.6.1 Turning on the printer power supply ........................................................................................34

5.6.2 Setting the print head carriage speed .......................................................................................34

5.6.3 Setting the media feed speed ........................................................................................................34

5.7 Executing the Moving Test

...........................................................................................................35

6. Initial Ink Induction Procedure

..........................................................................................37

6.1 Initial Cleaning of the Ink Supply Tubes and the Sub Tanks

.............................37

6.2 Initial Cleaning of the Cleaning Solution Supply Tubes

........................................44

6.3 Print head height Adjustment

....................................................................................................46

6.4 Mounting the Print heads

.............................................................................................................47

6.5 Initial Print head Cleaning Procedure

................................................................................51

6.6 Ink Induction

.........................................................................................................................................54

7. Media Loading Procedure

.........................................................................................................57

7.1 Loading the Media

..............................................................................................................................57

7.2 Adjusting the auto feed function

..............................................................................................61

7.3 Winding the Media onto the Take-up Unit

.......................................................................63

7.4 Adjusting the auto take-up function

......................................................................................66

7.5 Setting the Media Width

................................................................................................................68

8. Print head Adjustment Procedures

.................................................................................69

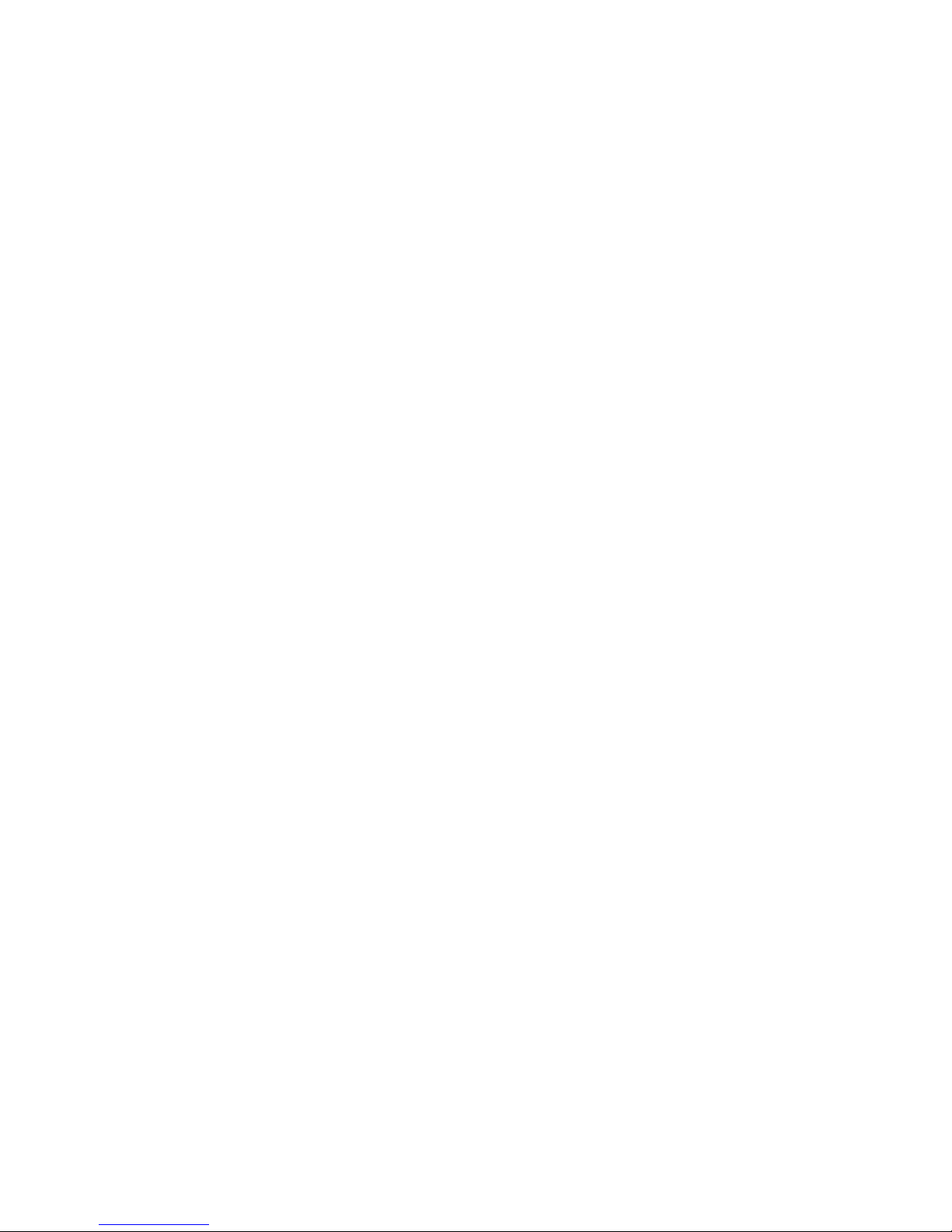

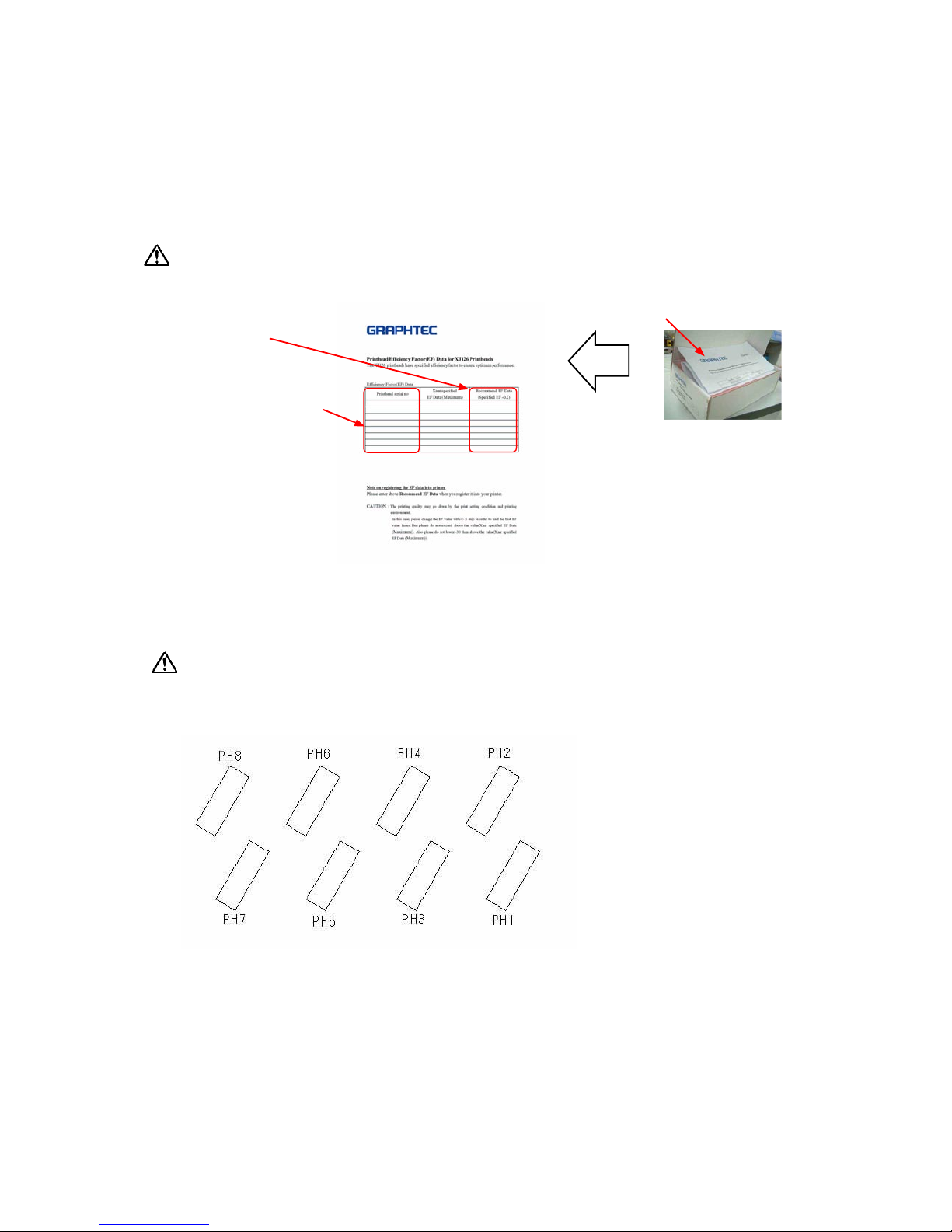

8.1 Setting the Print head Drive Voltage

....................................................................................69

Page 5

ivJS310-UM-251-9370

8.2 Installing the Printer Adjustment Utility Software “Try”

...................................70

8.3 Connecting the Print Heads

........................................................................................................72

8.4 Launching the Try Utility

.............................................................................................................73

8.5 Printing the Nozzle Check Pattern

........................................................................................74

8.6 Adjusting the Positions of Print heads of the Same Color

.....................................75

8.7 Adjusting the Positions of Print heads of a Different Color

.................................79

8.8 Media Feed Amount Compensation

......................................................................................81

8.9 Bi-directional Printing Band Adjustments

......................................................................84

9. Procedures when leaving the printer for a long time

...................................87

9.1 Dispose the ink from the printer

..............................................................................................87

9.2 Induction of the cleaning solution

...........................................................................................88

9.3 Moisturizing of print head

...........................................................................................................89

10. Procedures when you transport the printer

........................................................ 91

10.1 Dispose the cleaning solution from the printer

...........................................................91

10.2 Fixing the printhead carriage

.................................................................................................91

10.3 Discard the waste ink

....................................................................................................................92

11. Troubleshooting

.................................................................................................................................93

11.1 Printing is not performed

...........................................................................................................93

11.2 Unsatisfactory printing

................................................................................................................93

11.3 Cleaning cannot be performed

...............................................................................................96

11.4 Other problems

...................................................................................................................................97

11.5 Additional Troubleshooting

......................................................................................................98

12. Consumables

......................................................................................................................................103

13. How to use the Print head position alignment jig

....................................... 105

Page 6

vJS310-UM-251-9370

14. Ink supply system diagram

.................................................................................................107

15. Recommended print conditions

.....................................................................................109

16. Upgrading of firmware

............................................................................................................ 111

17. AC cable alteration procedure from CEE to NEMA

...............................113

18. Maintenance parts lists

...........................................................................................................115

18.1 Recommend Parts List

................................................................................................................115

18.2 Electrical part

................................................................................................................................... 116

18.3 Control panel

.....................................................................................................................................119

18.4 Main Frame

........................................................................................................................................120

18.5 Sensor part

..........................................................................................................................................122

18.6 Inkjet part

............................................................................................................................................124

18.7 Cables

......................................................................................................................................................129

18.8 Accessories

...........................................................................................................................................130

Page 7

Page 8

1. Safety information

1JS310-UM-251-9370

1. Safety information

Before use your Inkjet Digital Printer, please read following safety information carefully and pay more

attention to the cautions on the Printer.

1.1 Safety precautions

• Install over-current and over-voltage facility for printer power.

Failure to follow this guide could result in electric shock, personnel injury and fire.

• Clean the ink channels with solution matching to the used ink.

Failure to follow this guide could result in filter clog and ink channel blockage.

• Besides the ground-line for power, another unattached ground-line should be connected outdoor.

Failure to follow this guide could result in abnormal work status of printer.

• Static prevent facility should be settled on the carpet or in dry climate.

Failure to follow this guide could result in print head or other parts damage on the printer.

• Waiting for 10 minutes at least after power off to transport, connect and check the printer.

Failure to follow this guide could result in electric shock.

• Printer should be settled on flat floor and be adjusted horizontally.

Failure to follow this guide could reduce the print resolution.

• Clean the print head and ink channel with solution after long-time printing.

Failure to follow this guide could result in print head damage and ink channel clog.

• Never put hands on depend fence while the printer is working.

Failure to follow this guide could result in hand crushing.

• Never put hands into the heating board while the board is heating.

Failure to follow this guide could result in hand scald.

• Never put hands on rotating rollers while the printer is working.

Failure to follow this guide could result in hand crushing.

• Don’t open the electric tank in normal condition.

Failure to follow this guide could result in electric shock.

Page 9

1. Safety information

2JS310-UM-251-9370

1.2 Important Safety Information

• Do not block the hole on the cover.

• Do not insert any object into the Printer groove. Don’t let any kind of liquid splash into Printer.

• Only use the power supply according to the label.

• Connect all the equipment to a properly grounded socket. Avoid the socket in the same circuit with copy

machine or air conditioner.

• Avoid to using the socket controlled by the wall switch or by auto timer.

• Please keep Printer away from the latent source of electromagnetic disturbance. For example,

loudspeaker or wireless phone.

• If you use additional cable, please make sure that total amperage of the equipment connecting with

cable shall not exceed the amperage of the power supply. Moreover, the amperage of all equipment

connecting with wall socket does not exceed the amperage of the wall socket.

• Do not use damaged Electrical Power wire.

• Do not repair Printer by yourself.

• Shut off the power and ask experienced technician for help, if the following situations occur:

Power cable or plug is damaged.

Liquid splashes into printer.

Printer falls down or broken.

Printer cannot work properly or change in property.

1.3 Caution When Using Printer

• Don’t use your hand to move print head; otherwise the printer will be damaged.

• Always use power switch to turn On/off the printer. Before shutting down the Printer, do not pull out

Power Supply wire or Data Wire.

• Before moving the printer, please make sure the print head is fixed at original position.

1.4 Guide When Using Ink

• Never put the ink near open flames. Failure to follow this warning might result in fire.

• Do not swallow ink or avoid its splashes on the eye.

• If ink spills on the skin, please wash with soap and water. If ink splashes into eye, please wash with

water immediately and consult a doctor as required.

• If it is swallowed, do not try to vomit it forcefully, but see a doctor.

• Do not shake the ink cartridge in case ink leak is caused.

• After using for a certain period (generally 3 months), you should take off the ink cartridge, clean it and

dry it.

• Please keep surrounding clean when you replace a new ink container. It helps you improve printing

quality.

• Do not mix the waste ink with any other chemicals and solvent when you displace the waste ink.

Also dispose the waste ink as the industrial waste (waste oil).

Page 10

1. Safety information

3JS310-UM-251-9370

1.5 Choosing Printer Installation Place

• Put printer at a horizontal and stable place with enough space; otherwise, the Printer may not work

properly.

• Don’t leave Printer at a place where temperature and humidity change severely. Avoid direct sunlight,

strong light or heat.

• Avoid shaking or vibrating.

• Keep sufficient room around printer for air circulation.

• Place printer nearby the wall socket, so that it is easy to connect or disconnect the power supply

1.6 Warning, Caution and Attention

Warning

Must obey in order to ensure personal safety.

Caution

Must obey in order to protect the machine.

Attention

Contain some important and useful information about operation.

Page 11

Page 12

2. Technical Parameters

5JS310-UM-251-9370

2. Technical Parameters

Product JS310-25ES JS310-18ES

Printer Technique Xaar 126 300dpi piezo head, 8 head inside

Resolution 200dpi, 400dpi

Color Quality Photo effect including 2 levels: Basic and High Quality

Max. Media Width 2530 mm

(thickness less than 1 mm)

1860 mm

(thickness less than 1 mm)

Man. Printing Width 2471 mm 1800 mm

Min. Printing Size A4 or 210 mm (thickness less than 1 mm)

Output (m2/h)

(Designed values, not from

measurement)

Mode Output (m2/h)

180 x 200 dpi 2pass 27.5

180 x 200 dpi 4-2pass 14.5

180 x 200 dpi 3pass 19.2

180 x 200 dpi 6-3pass 10.5

180 x 200 dpi 4pass 14.5

180 x 200 dpi 8-4pass 7.5

180 x 200 dpi 6pass 10.5

180 x 200 dpi 8pass 7.5

300 x 300 dpi 14.5

Display LCD display with 8 keys panel, self-diagnosis available

Ink Type Solvent based ink: C, M, Y, K and solvent based solution

Ink Supply Mode 300 ml/min auto ink supply by electric pump, volume of main tank

1000 ml/color

Ink Inspection System Auto/manual ink supply, low ink detector

Printing Driver Support many RIP drivers

Operation Platforms Multi-operation platforms (Windows 2000, XP, etc.)

Media Type Flex, vinyl, window film, polyester, etc.

Media Transmission Roll media or sheet media (bigger than A4 or 210 mm)

Media Processing Auto feeding and take-up system,

weight less than 70 kg/roll

Auto feeding and take-up system,

weight less than 40 kg/roll

Print head Height 3 mm to 5 mm above media adjustable

Pre-heater & Dry System Auto heating after electrifying, the tiptop temperature is about 40˚C

Clamp Manual adjustment media width

Print head Cleaning System Auto positive pressure cleaning

Safety System Inside safety lock with auto shutting down function

Page 13

2. Technical Parameters

6JS310-UM-251-9370

Product JS310-25ES JS310-18ES

Print Interface USB2.0 interface (Windows 2000, NT, XP, etc.)

Noise

Printing status less than 70 db / waiting status less than 40 db (ISO7779)

Printer Size (including ink tank) / Net Weight

L 3820 mm x H 1190 mm x W 890 mm / 330 Kg L 3103 mm x H 1160 mm x W 890 mm / 270 Kg

Package Size / Net Weight

L 3920 mm x H 1365 mm x W 960 mm / 470 Kg L 3220 mm x H 1365 mm x W 960 mm / 400 Kg

Input Voltage AC 200 to 240V, 50Hz/60Hz

Voltage for the Heating and Drying System

AC 200 to 240V, 50Hz/60Hz

Power (AC 220V applied) 2000W

Working Environment Temperature: 20˚C to 28˚C, Humidity: 40% to 70%

The parameters above are subject to be changed.

Page 14

3. Product Configuration

7JS310-UM-251-9370

3. Product Configuration

3.1 Main Unit

(1)

(2)

(3)

(4)

(5)

(6)

(9)

(10)

(8)

(7)

(1) LCD Control Panel

(2) Press roller control pole

(3) Ink tanks & Solution tank

(4) DRYER Power Socket

(5) Take-up Roller

(6) Cleaner

(7) Media Feeding Roller

(8) Waste Ink Tanks

(9) PRINTER Power Socket & HEATER Power Socket

(10) Media Feeding System

Page 15

3. Product Configuration

8JS310-UM-251-9370

3.2 Accessories

No. Item Q’ty Remark

1 Printhead 8 Xaar 126-300

2 Power cable 3 UL cord/250V/4 m

3 USB interface cable 1 4 m

4 Ink tank 4

5 Solution tank 1

6 Screw M4*12 8 Spare parts

7 File bag 1

8 Tool box 1

9 Software CD 1 RIP

10 Software CD

1 Utility, “Try”

11 Non-woven fabric

1 2 m

12 Sealing washer

2 Spare parts

13 Wet keeping frame

1

14 Brush

4

15 User’s Manual

1

16 Set-up Guide

2 English: 1, Spanish: 1

17 Maintenance of print head Manual

1

18 Quick Install Manual

1

19 Try Important Setup Sheet

1

20 Waste ink tank

2

21 Bracket, Waste ink tank

2

22 ø3/5 Soft tube

1 1 m, Spare part

23 ø4/6 Soft tube

1 1 m, Spare part

24 Clamp, Printhead 10

25 Inlet tube assembly

4 Tube connector for 126 printhead x 2

ø3/5 Soft tube (100 mm) x 2

ø3/5 Soft tube (200 mm)

F type 3/5 connector

Y type 3-way connector

26 Outlet tube assembly

8 Tube connector for 126 printhead

ø3/5 Soft tube (80 mm)

F type 3/5Connection cable, Printhead

connector

Cap, Connector

27 Connection cable, Printhead

8

28 Screw for printhead alignment

3

29 Flange, Take-up roller

2

30 Light bulb

1 Spare parts

31 Empty core

2 Inner diameter 3 in, Length 36 in

32 Packing list

1

33 Jig, Head height adjustment

1

34 Tube clamper

8

35 AC Plug

3 250V

36 Media Flange

2

Page 16

3. Product Configuration

9JS310-UM-251-9370

No.1 Printhead No.2 Power cable

No.3 USB interface cable No.4 Ink tanks, No.5 Solution tank

No.6 Screws, M4*12 No.7 File bag

No.8 Tool box No.9, 10 SSoftware CD

Page 17

3. Product Configuration

10JS310-UM-251-9370

No.11 Non-woven fabric No.12 Sealing washers

No.13 Wet keeping frame No.14 Brushes

No.20 Waste ink tank No.21 Bracket, Waste ink tank

No.22, 23 Ø3/5, Ø4/6 Soft tube No.24 Clamp, Printhead

Page 18

3. Product Configuration

11JS310-UM-251-9370

No.25 Inlet tube assembly No.26 Outlet tube assembly

No.27 Connection cables, Printhead No. 28 Screws for printhead alignment

No.29 Flange, Take-up roller No.30 Light bulb

No.31 Empty core No.32 Jig, Head height adjustment

Page 19

3. Product Configuration

12JS310-UM-251-9370

No.34 Tube clamper No.35 AC Plug

No.36 Media Flange

3.3 Consumables

• Ink

Eco-Friendly Solvent Eco-Friendly Solvent Pure Solvent

Black

IJ-80050Bk IJ-80100K IJ-80200K

Cyan

IJ-80050C IJ-80100C IJ-80200C

Magenta

IJ-80050M IJ-80100M IJ-80200M

Yellow

IJ-80050Y IJ-80100Y IJ-80200Y

CAUTION: Do not use non-specified inks.

• Flash solution

IJ-80050S (For IJ-80050 Ink)

IJ-80100S (For IJ-80100 Ink and IJ-80200 Ink)

Page 20

4. Basic Panel Operation

13JS310-UM-251-9370

4. Basic Panel Operation

4.1 Menu Structure of Control Panel

LCD

Function Keys

Direction Keys

4.1.1 Function description of the keys

Direction keys

(1) Operation via control panel:

UP and DOWN ARROW key: Scroll the menus for selection; reduce or increase the values on LCD.

LEFT and RIGHT ARROW key: Move the cursor position over the number string on LCD.

Function keys

(1) ONLINE:

Switch the printer online and offline / press down and hold it for several seconds to pause printing.

Waiting

Online

(2) ESC:

Cancel operation and return to up-level menu.

(3) ENTER:

Confirm and execute the operation.

(4) FUNC:

Shift to special function. Combine with LEFT ARROW key to test print when the printer is waiting.

Key combination

FUNC + LEFT ARROW key. Test print when printer is waiting.

Page 21

4. Basic Panel Operation

14JS310-UM-251-9370

Basic operation

After power on the printer, the system executes X and Y motion test and p/h test.

Booting >System

>Y Motor

>X Motor

Check ->Print head

After self-test, the system moves the p/h carriage back to original position. The LCD displays printer model

and version number and then shift to basic operation menu shown as below. That stands for the printer is ready.

Menu -> 1. Ink Status +

2. Heat Status +

3. Cleaning Toll +

OFFLINE 4. Print para +

4.1.2 Menu structure

Menu structure includes main menus and sub menus. Main menus followed by “+” s have sub menus inside.

Submenus followed by “-” s have no lower level inside.

Main menu includes items as below:

-> 1. Ink Status +

2. Heat Status +

3. Cleaning Tool +

4. Print para +

5. Application +

6. Engineer Set +

Press UP and DOWN ARROW keys to scroll the menus upward and downward. Press ENTER to unwrap

submenus. For example, while the arrow points to “1. Ink Status”, press ENTER to unwrap the submenu. LCD

displays details of submenu M1 as below:

On the LCD, M1 stands for this submenu under main menu No.1. Here press ESC key, it returns the display to

main menu.

Arrow points to the first line on the LCD. Scroll the submenus by pressing UP and DOWN keys same as main

menu. The submenu followed by a “-” means has no lower submenu inside. Press ENTER key to execute the

operation. Here press ESC key, operation will be canceled.

Menu -> Ink Status

M1 Cha C M Y K cm

Rn _ _ _ _ _ _ _

OFFLINE Al _ _ _ _ _ _ _

Page 22

4. Basic Panel Operation

15JS310-UM-251-9370

4.2 Description of menu function

Main menu Submenu Function description

Ink Status

Ink Status

Ch A C M Y K c m

Rn _ _ _ _ _ _ _

Al _ _ _ _ _ _ _

Ink status displays.

The LCD display details as below:

Ink Status

Cha C M Y K cm

Rn _ _ _ _ _ _ _

Al _ _ _ _ _ _ _

Item Ch: stands for ink channels. A means all

channels;

Item Rn: displays ink supply status of

corresponding channel;

Item AL: displays ink lack alarming of

corresponding channel; Press

ENTER

to refill

ink and cancel alarming.

Heat Status

Heat Status

FH Pre P/H

Tem 00 00 00

Set 00 00 00

Heating status displays.

The LCD display details as below:

Heat Status

FH Pre P/H

Tem 00 00 00

Set 00 00 00

Item

Tem

: displays actual temperature;

Item

Set

: displays setup temperature.

Cleaning Tool

Firing

Press

ENTER

key to execute the operation,

“

Busy

” flashes on the LCD. P/Hs spray

downward to prevent nozzle clogs. The LCD

stops flashing after firing finishes.

Press

ENTER

key again to execute P/H firing

one more time if necessary.

Jam Test

Press

ENTER

key to execute the operation of

test printing.

Clean POS

Press

ENTER

key to execute the operation of

moving P/H carriage to cleaning position.

Home Post Press

ENTER

key execute the operation of

returning the P/H carriage to original position.

Auto Clean Press

ENTER

key execute the operation of

negative pressure cleaning automatically.

Page 23

4. Basic Panel Operation

16JS310-UM-251-9370

Main menu Submenu Function description

Print Para

Print Post

Number string “XXXX” flashed on the LCD.

Here press and key to move the cursor

position over the number string and press

LEFT

or

RIGHT

ARROW key to increase or

reduce the value of the flashing number. Press

ENTER

to save the number as print position.

Images and test print start from this position.

Here press key combination

FUNC

+ UP

or

DOWN

ARROW key to move the media

forward or backward; press key combination

FUNC

+

LEFT

ARROW key to move the

P/H carriage to printing position It will tell the

position set well or not. Press any key to return

the P/H carriage to original position.

Bi-dir. Adj

This function is used to adjust bi-direction

printing to ensure bi-direction printing quality.

The LCD displays details as below after

pressing

ENTER

key:

Menu -> 2BID Adjust

XXXX

OFFLINE

Press

UP

or

DOWN

ARROW key to increase

or reduce the value “

XXXX

” by 1. Press

ENTER

to save it as bi-direction compensation.

To adjust the compensation accurately, adjust

the P/Hs to an inch in TRY one by one.

Print Speed

This function is used to adjust the scan speed of

the P/H carriage. The LCD displays details as

below:

Menu -> 2Pirnt Speed

Norm

OFFLINE

Press UP or

DOWN

ARROW key to select

from the 3 options.

High

scan speed will reduce printing quality.

Low

scan speed will increase printing quality

but reduce printing speed. The suggestion is

Norm

.

Page 24

4. Basic Panel Operation

17JS310-UM-251-9370

Main menu Submenu Function description

Print Para

Feed Speed

The LCD displays details similar to Print speed.

“

Norm

” flashes as the default option.

Press UP or

DOWN

ARROW key to select

from the 3 options.

The suggestion is “

Norm

”

Firing Vol

“

XXXX

” flashes on the LCD.

Press UP or

DOWN

ARROW key to increase

or reduce the value by 1.

This value is the firing volume of P/Hs for auto

spray (that means all nozzles are unclogged).

Flash Mode

3 options altogether are ready for flash mode

selection: 0, 1 and 2.

0 stands for P/H does not flash during

printing.

1 stands for P/H flashes only once during

the whole printing.

2 stands for P/H flashes once every

forward and backward.

Press or key to select from the 3 options.

Page 25

4. Basic Panel Operation

18JS310-UM-251-9370

Main menu Submenu Function description

Print Para

PH Volt. Set

This function is used to set Voltage of P/Hs.

The LCD displays details as below:

Menu -> PH 1 Voltage

PH 2 Voltage

PH 3 Voltage

OFFLINE PH 4 Voltage

Here press

UP

or

DOWN

ARROW key to

scroll the submenu. The LCD will display

values as below:

Menu ->1 PH 1 Voltage

0099

0182

OFFLINE

The upper number is adjustable EF value of P/H

and the down number indicates voltage value of

P/H.

Press

LEFT

or

RIGHT

ARROW to move the

cursor position over the number string and press

UP

or

DOWN

ARROW key to increase or

reduce the flashing number of EF value.

The 8 P/Hs setup from 1 to 8:

PH 1 Voltage

for P/H C1;

PH 2 Voltage

for P/H C2;

PH 8 Voltage

for P/H K2.

Application

UV Lamp Power No operation.

Front Heater

“45” flashes on the LCD as default setting at the

unit of centigrade degrees. Press

UP

or

DOWN

ARROW key to increase or reduce the value of

temperature.

For normal condition, keep the default value.

Pre Heater

“40” flashes on the LCD as default setting at the

unit of centigrade degree. Press

UP

or

DOWN

ARROW key to increase or reduce the value of

temperature.

For normal condition keep the default value.

PH Heater No operation.

Page 26

4. Basic Panel Operation

19JS310-UM-251-9370

Main menu Submenu Function description

Application

Media Detect

Press

ENTER

to execute the operation, the

LCD displays OFF means the function is switch

off when the printer is waiting.

OFF

(function switch off)

Press UP or

DOWN

ARROW key to switch on

the function.

ON

(function switch on)

Pull up the press pole and then pull it down, the

LCD displays details as below:

Menu Media Detect

Star: 0000mm

Lenth: 0000mm

OFFLINE

Press

ENTER

key to start media edge

detecting. Press

ESC

to cancel the operation.

After detecting, “OK” displays means the

detecting is successful and saves the result as

print position, which should add the value of

offset set at below step. “

Error

” displays means

the detecting is failed and the value of print

position does not change.

Media Offset

“XXXX” flashes on the LCD. Press Up or

Down key to increase or reduce the value. This

value added to the value of media detecting is

saved as the value of print position.

Take Up Detect No operation.

T Neg. Pressure No operation.

Curve of ink

Select ink curves in the 12 options from 0 to 11.

LCD displays details as below:

1 2 3 4

The name of ink curve indicates as below.

1.

Xr

stands for XAAR print head.

2. 2 stands for 200 dpi print head.

3

stands for 300 dpi print head.

3. S stands for solvent based ink type.

O

stands for oil based ink type.

U

stands for UV ink type.

4. Ink name

Page 27

4. Basic Panel Operation

20JS310-UM-251-9370

Main menu Submenu Function description

Engineer Set

Clean Post No operation.

Printer Width No operation.

Moving Test

Press

ENTER

to execute the operation.

The LCD displays details as below:

Menu ->Moving Test

0000

OFFLINE

And P/H carriage moves back and forth to

simulate printing, but P/H not spray.

It’s used for mechanical test. The number on the

LCD indicates times the P/H carriage moves

back and forth.

Default Set No operation.

Y Test Speed No operation.

X Test Speed No operation.

Page 28

4. Basic Panel Operation

21JS310-UM-251-9370

4.3 LCD display for normal usage

4.3.1 LCD display during printing

Printing

TORAL: XXXX

FINISH: XXXX

ONLINE RIP READY: XXXX

Total lines for printing

Lines of RIP ready

Lines finished

The LCD displays total lines for printing, lines finished and lines of RIP ready during printing.

4.3.2 LCD display when printing is paused

P/H nozzles may be clogged during printing, so it needs cleaning.

Press and hold

ONLINE

key to pause the printing until the LCD displays “

Busy

”.

The P/H carriage returns to original position after it finishes the current line printing. The LCD displays menus

as below:

Waiting 1. Ink status

2. Heat status

3. Cleaning tool

ONLINE 4. Continuous

5. Cancel

Press UP or

DOWN

ARROW key to select “

Cleaning tool

” function in the menu and execute cleaning.

Select “

Continuous

” to continue printing or “

Cancel

” to cancel printing.

Page 29

4. Basic Panel Operation

22JS310-UM-251-9370

4.3.3 System warning and error display

1. Warning:

Warn1: UV lamp is NOT ready;

Warn2: Press pole is NOT pulled down;

Warn3: The system is executing ink refilling;

2 Error:

When one of the errors listed below occurs during printing, the printer will run normally but give alarm

for warning.

Err5: Ink refill overtime;

Err6: The safety bottle is full;

Err7: For solvent based printer: The waste ink bottle is full;

For UV printer: The safety bottle in manometer is full;

Err8: Null

Errors listed below indicate the detail for further check when self test fails

Err9: Y raster count direction differs from motion direction;

Err10: Y raster signal is NOT detected;

Err11: Y raster error too big;

Err12: Reverse count abnormal;

Err13: Self test for main board failed;

Err14: Version of assistant board NOT matches main board;

Page 30

4. Basic Panel Operation

23JS310-UM-251-9370

4.4 Printing Steps

On normal condition, the steps are as follows:

1. Power on the printer

2. Turn on the computer

Note:

It is recommended to turn on the printer before computer. Otherwise the connection may fail.

3. Load media, put down the press bar to press on media.

4. Clean the head and start the self-diagnosis till no nozzle clogging.

5. Press ONLINE.

Menu -> 1. Ink Status +

2. Heat Status +

3. Cleaning Toll +

OFFLINE 4. Print para +

OFFLINE

MODE

Offline mode Online mode

6. Trim the pattern for printing, and save it in computer.

7. Open GRAPHTEC RIP.

8. Create new file.

9. Read the pattern for printing.

10. Adjust the position, size, property, and resolution of the pattern.

11. Printer setting

(1) Select File/Printer setting. Below dialogue box shows:

(2) Select the type of printer as “GRAPHTEC Printer” and the model as “JS300-18ES”.

Page 31

4. Basic Panel Operation

24JS310-UM-251-9370

(3) Click the “Printer setting”. Set the relevant value in the following dialogue box.

a. Select the printing resolution.

b. Select BID or single direction printing. BID has higher efficiency than single direction.

Note:

The horizontal parameters, BID compensation and feeding compensation should be adjusted already

before your printing; otherwise the printing quality will be reduced.

Details of the functions above and others referred to the Sign Jet RIP Manual

12. Click “Printing Project” to print.

13. LCD displays as below when printing:

Printing

TORAL: XXXX

FINISH: XXXX

ONLINE RIP READY: XXXX

Total lines for printing

Lines of RIP ready

Lines finished

14. If clogging appears during the printing, press ONLINE for a longer time (3s) to pause printing for print head

cleaning. After cleaning, press ONLINE to go on printing.

Cleaning procedure during printing:

P/H nozzles may be clogged during printing, so it needs cleaning.

Press and hold ONLINE key to pause the printing until the LCD displays “Busy”. The P/H carriage returns to

original position after it finishes the current line printing. The LCD displays menus as below:

Waiting 1. Ink status

2. Heat status

3. Cleaning tool

ONLINE 4. Continuous

5. Cancel

Press UP or

DOWN

ARROW key to select “

3. Cleaning tool

” function in the menu and execute cleaning.

Select “

Continuous

” to continue printing or “

Cancel

” to cancel printing.

15. Press ONLINE when the printing is all finished. Then the printer is under the Offline mode.

Note:

To cancel printing operation, usually do in RIP. If you want to cancel printing directly on the printer,

press ONLINE button after the menu “printing cancel” appears in software.

Page 32

5. Assembling the Printer and the Installation Procedure

25JS310-UM-251-9370

5. Assembling the Printer and the Installation Procedure

5.1 Notes on the Installation Environment

5.1.1 Installation Space

Sufficient space must be left in front of, behind, and at both sides of the printer not only for normal operating

procedures such as the replacement of consumable, the handling of printed materials, and for ventilation, but also

for the replacement of parts in the event of a malfunction. Ensure that the space left around the printer is as shown in

the following diagram.

CAUTION:

Do not install the printer in an unsteady location such as on a rickety base or on a sloping surface.

There is a risk of injury if the printer falls or topples over.

5.1.2 Installation Space

Use the printer in the following temperature and humidity ranges.

Temperature: 20 to 28˚C

Humidity: 40 to 70% (non-condensing)

CAUTION:

If the printer is used outside the specified temperature and humidity ranges, the print quality may be

adversely affected and the printer may malfunction.

Page 33

5. Assembling the Printer and the Installation Procedure

26JS310-UM-251-9370

5.1.3 Power Supply Specifications

The power supply specifications for this printer are as follows. Make sure that the power supply used conforms to

the printer specifications.

• Printer control power supply: AC200 to 240 V, 50/60Hz

• Heater power supply: AC200 to 240 V, 50/60Hz

• Drying fan power supply: AC200 to 240 V, 50/60Hz

*Power Supply Precautions:

(1) Install the printer near a power outlet that is within easy reach.

(2) Do not connect the printer to the same power supply line that is used for noise-generating devices such as

photocopying machines, air conditioners and motors.

(3) Connect the printer to a separate power outlet. Do not connect other devices to the same power outlet.

Page 34

5. Assembling the Printer and the Installation Procedure

27JS310-UM-251-9370

5.2 Removing the Printer from its Packaging

Follow the procedure described below to unpack the printer.

(1) Remove the top panel and the four side panels.

Waste ink tanks Accessories box

Printer fastenings (8 locations)

(2) Remove the accessories box and the waste ink tanks.

Page 35

5. Assembling the Printer and the Installation Procedure

28JS310-UM-251-9370

(3) Remove the printer fastenings.

Printer fastenings (8 locations)

(4) Move the printer off the base used to hold it in place.

Use a forklift to raise the printer off the base.

Insert the forklift prongs here.

CAUTION:

Before raising the printer, align the direction of the wheels with the direction of the rectangular holes.

If they are not aligned, the wheels will catch on the edges of the holes when the printer is raised.

Page 36

5. Assembling the Printer and the Installation Procedure

29JS310-UM-251-9370

Align the direction of the wheels with the

rectangular holes before raising the printer.

CAUTION:

The printer weighs approximately 270 kg (JS310-18ES) or 330 kg (JS310-25ES). There is a risk of lower

back injury to the person(s) attempting to lift the printer. Use a forklift to move the printer.

CAUTION:

When raising the printer off the base used to hold it in place, make sure that the printer’s weight is

evenly balanced.

(5) Move the printer.

Unlock the casters, and then move the printer to its installation location.

If the installation location is on a different level or if there is a steep slope leading up to it, use a forklift or

crane to move the printer.

CAUTION:

The printer weighs approximately 270 kg (JS310-18ES) or 330 kg (JS310-25ES). There is a risk of lower

back injury to the person(s) attempting to lift the printer. Use a forklift or crane to move the printer if

the installation location is on a different level or if there is a steep slope leading up to it.

(6) Lock the casters.

Lock the casters

Page 37

5. Assembling the Printer and the Installation Procedure

30JS310-UM-251-9370

(7) Remove the plastic sheets and fastening bands.

Remove the print head carriage fastening (remove

the screws).

CAUTION:

Store the print head carriage fastening in a

safe place so as not to lose it.

Page 38

5. Assembling the Printer and the Installation Procedure

31JS310-UM-251-9370

5.3 Mounting the Ink Tanks

Follow the procedure described below to mount the four ink tanks (C, M, Y, K) and the solution tank.

(1) Remove the cap from the tip of each of the ink tubes protruding from the printer.

(2) Attach an ink tank to each of the tubes, making sure that the color of the sticker affixed to the ink tank matches

the color of the ring on the ink tube. The tube without a colored ring is the tube for the cleaning solution.

Attach the solution tank to this tube.

(3) Mount the ink tanks and the solution tank onto the printer.

Page 39

5. Assembling the Printer and the Installation Procedure

32JS310-UM-251-9370

5.4 Mounting the Waste Ink Tanks

Follow the procedure described below to mount the two waste ink tanks.

(1) Attach the waste ink tank mounting brackets to the printer.

Using the screws provided, attach one bracket to the left side and one to the right side of the printer.

(2) Connect the tubes to the waste ink tanks.

Mount the waste ink tanks on the brackets. Insert the corresponding waste liquid tubes protruding from the

printer into the opening of each waste ink tank.

CAUTION:

Store the caps that were removed from the waste ink tanks in a safe place so as not to lose them.

Page 40

5. Assembling the Printer and the Installation Procedure

33JS310-UM-251-9370

5.5 Connecting the Power Supplies

The printer is provided with three power supplies: a printer power supply, a heater power supply, and a dryer power

supply. Connect a cable to each power supples, making sure that the cable conforms to the specifications.

(1) Connect the power supply cables to the power supply connectors.

PRINTER power supply

HEATER power supply

DRYER power supply

(2) Check that all of the power supply switches are off.

Lower position

Lower position

PRINTER power supply switch HEATER power supply switch

Forward position

Middle position

DRYER power supply switch Media Feeding System switch

(3) Insert the plug of each power supply into a power outlet.

(4) Turn on the cleaner power supply.

The lower position is the ON position

for the power supply.

The upper or middle position is the

OFF position.

Page 41

5. Assembling the Printer and the Installation Procedure

34JS310-UM-251-9370

5.6 Setting the Print Speed

5.6.1 Turning on the printer power supply

When the power is turned on, the printer begins a self-test operation (the print head carriage and the feed rollers

move). When the self test has been completed, wait until the main menu is displayed on the LCD.

Since ink has not yet been supplied to the printer, a “

No Ink

” alarm will sound after several minutes have elapsed.

This alarm does not indicate a malfunction, and no action is required.

5.6.2 Setting the print head carriage speed

(1) From the main menu, select [

Print Para

] and then press the

ENTER

key.

(2) From the submenu, select [

Print Speed

] and then press the

ENTER

key.

(3) Select “

Norm

”, and then press the

ENTER

key.

(4) Return to the main menu.

5.6.3 Setting the media feed speed

(1) From the main menu, select [

Print Para

] and then press the

ENTER

key.

(2) From the submenu, select [

Feed Speed

] and then press the

ENTER

key.

(3) Select “

Norm

”, and then press the

ENTER

key.

(4) Return to the main menu.

Page 42

5. Assembling the Printer and the Installation Procedure

35JS310-UM-251-9370

5.7 Executing the Moving Test

Execute the Moving Test to ensure that the lubricating oil is spread evenly on the print head carriage rails and the

feed rollers.

• If the power is turned off, turn it on.

• Since ink has not yet been supplied to the printer, a “

No Ink

” alarm will sound after several minutes have elapsed.

This alarm does not indicate a malfunction, and no action is required.

Executing the moving test

(1) From the main menu, select [

Engineer Set

] and then press the

ENTER

key.

(2) From the submenu, select [

Moving Test

] and then press the

ENTER

key.

(3) Let the operation continue for approximately 15 minutes.

Check that there are no abnormalities during the moving test operation.

If there are any abnormalities such as an unusual noise or if the printer doesn’t operate, turn off the power

supply and contact your sales representative or nearest Graphtec vendor.

(4) End the Moving Test.

Press the

ESC

key to end the moving test. When the test has ended, return to the main menu.

• Hold down the

ESC

key until the print head carriage stops at the Home position.

Page 43

Page 44

6. Initial Ink Induction Procedure

37JS310-UM-251-9370

6. Initial Ink Induction Procedure

6.1 Initial Cleaning of the Ink Supply Tubes and the Sub Tanks

• If the power is turned off, turn it on.

• Since ink has not yet been supplied to the printer, a “

No Ink

” alarm will sound after several minutes have elapsed.

This alarm does not indicate a malfunction, and no action is required.

Moving the print head carriage to the cleaning position

(1) From the main menu, select [

Cleaning Tool

] and then press the

ENTER

key.

(2) From the submenu, select [

Clean Post

] and then press the

ENTER

key.

(3) The print head carriage moves to the cleaning position and then stops.

Checking that the clips on the sub tanks have been released

(4) Open the panel behind the cleaning position.

(5) Check that the tube clamper on each of the sub tanks is in the open position. If any of the clampers is in the

closed position, open it.

Tube clamper:

Check that the clampers for all four colors

are open.

(6) Check that all the tube caps are closed firmly.

Tube cap:

Tighten the caps using long-nose pliers.

Check that the tube caps for all five caps

are closed firmly.

Page 45

6. Initial Ink Induction Procedure

38JS310-UM-251-9370

Pouring 150 to 200 cc of cleaning solution into each ink tank

(7) Pour 150 to 200 cc of cleaning solution into each of the four ink tanks (C, M, Y, K).

• 150 to 200 cc guideline amount: The level where the filter in the ink tank is covered.

Feeding the cleaning solution to the sub tanks

(8) From the main menu, select [

Ink Status

] and then press the

ENTER

key. The “

No ink

” alarm sounds and

then stops, and the ink pump operates to feed the cleaning solution to the sub tanks.

If the “

No ink

” alarm sounds once again, from the main menu, select [

Ink Status

] and then press the

ENTER

key once more. The alarm will stop sounding when the four sub tanks (C, M, Y, K) are filled with cleaning

solution. At this time there will be no operating noise from the ink pump.

(9) Visually check that the sub tanks are sufficiently filled with cleaning solution.

The tanks should be filled up to approximately the level indicated by the white line.

(10) Turn off the printer power supply.

Page 46

6. Initial Ink Induction Procedure

39JS310-UM-251-9370

Removing the print head carriage cover and the print head protector

(11) Open the panel in front of the cleaning position.

Cleaning position cover:

Open the front panel by raising the top

half and lowering the bottom half.

(12) Remove the two screws holding the print head carriage cover, and then detach the print head carriage cover.

Print head carriage cover

Remove the screws at the left and right

sides and then detach the cover.

(13) Detach the print head protector.

Pull and then turn the knobs to detach the print head protector.

Print head protector

Knobs

Pull and then turn

about 90 degrees.

Pull and then turn

about 90 degrees.

Page 47

6. Initial Ink Induction Procedure

40JS310-UM-251-9370

Connecting the inlet tubes

(14) Open the rear panel, and then remove the two screws holding rear of the main board cover.

Main board cover

Remove the screws.

Open the rear panel.

(15) Open the front panel, and then detach the main board cover from the grooved pins.

Main board cover

Open the front panel.

(16) Remove the main board cover from the right side as shown in the below picture.

Main board cover

(17) Remove the two screws holding the fixer, and then detach the fixer.

Fixer

Remove the screws.

Page 48

6. Initial Ink Induction Procedure

41JS310-UM-251-9370

(18) Attach the four inlet tubes provided to the 3-way valves on the print head carriage.

Inlet tube

Make sure that the tubes are firmly

connected to the 3-way valve.

(19) Put the inlet tube through bottom of a board, and wire it forward as shown in the below picture.

3-way valves

PCB board

PCB fixing studs

Inlet tubes

Inlet tube Fixing plate

Rear

Front

(20) Set the 3-way valve for each ink tank to the ink supply position.

Ink tank 3-way valve

(4 valves)

Turn to the ink

supply position

(21) Turn on the printer power supply.

When the power is turned on, the printer begins a self-test operation (the print head carriage and the feed

rollers move). When the self test has been completed, wait until the main menu is displayed on the LCD.

Moving the print head carriage to the cleaning position

(22) From the main menu, select [

Cleaning Tool

] and then press the

ENTER

key.

(23) From the submenu, select [

Clean Post

] and then press the

ENTER

key.

(24) The print head carriage moves to the cleaning position and then stops.

Page 49

6. Initial Ink Induction Procedure

42JS310-UM-251-9370

Feeding the cleaning solution in the sub tanks through the inlet tubes

(25) Position the end of each inlet tube so that it faces the waste liquid slot underneath.

(26) Press the Ink button at the cleaning position to feed the cleaning solution through the inlet tubes.

Continue to feed the cleaning solution through the tubes until they are clean (approximately 20 seconds).

Ink button

CAUTION:

Take care not to get cleaning solution stains on your clothing.

Feeding out any cleaning solution remaining in the inlet tubes

(27) Press the Ink button to feed out any cleaning solution remaining in the inlet tubes. When the “

No ink

” alarm

sounds, from the main menu, select [

Ink Status

] and then press the

ENTER

key to continue the cleaning

solution removal operation.

(28) Continue feeding out the cleaning solution until the “No ink” alarm sounds once again.

(29) Turn off the printer power supply.

Page 50

6. Initial Ink Induction Procedure

43JS310-UM-251-9370

Empty out the cleaning solution from the sub tanks

CAUTION:

First of all, remove the waste ink tanks mounted in the printer, and then discard the cleaning solution

from the sub tanks into the waste ink tanks.

(30) Remove the cap from each sub tank.

If the cap is difficult to remove, use pliers or similar to grip the cap and open it.

Pliers

CAUTION:

When opening the cap, be sure to grasp

the upper corners of the tank.

(31) Empty out the cleaning solution from each sub tank.

Tilt the sub tank, and then pour the cleaning

solution into the waste ink tank positioned

underneath it.

(32) Reattach the cap on each of the sub tanks, and then leave them to dry out for at least 10 minutes.

Page 51

6. Initial Ink Induction Procedure

44JS310-UM-251-9370

6.2 Initial Cleaning of the Cleaning Solution Supply Tubes

(1) Turn on the printer power supply.

When the power is turned on, the printer begins a self-test operation (the print head carriage and the feed

rollers move). When the self test has been completed, wait until the main menu is displayed on the LCD.

• Since ink has not yet been supplied to the printer, a “

No Ink

” alarm will sound after several minutes have

elapsed. This alarm does not indicate a malfunction, and no action is required.

(2) Move the print head carriage to the cleaning position.

(a) From the main menu, select [

Cleaning Tool

] and then press the

ENTER

key.

(b) From the submenu, select [

Clean Post

] and then press the

ENTER

key.

The print head carriage will move to the cleaning position and then stop.

(3) Pour approximately 150 cc of cleaning solution into the solution tank.

(4) Set the 3-way valve for the solution tank to the supply position.

Solution tank 3-way valve

Turn to the supply position

(5) Set the 3-way valve for each ink tank to the cleaning position.

Ink tank 3-way valve

(4 valves)

Turn to the cleaning position

Page 52

6. Initial Ink Induction Procedure

45JS310-UM-251-9370

(6) Feed the cleaning solution through the inlet tubes.

(a) Position the end of each inlet tube so that it faces the waste liquid slot underneath.

(b) Press the Solution button at the cleaning position to feed the cleaning solution through the inlet tubes.

Ink button

(c) Hold down the Solution button until the cleaning solution passes through the tubes.

CAUTION:

Take care not to get cleaning solution stains on your clothing.

(7) Empty out the cleaning solution from the solution tank.

CAUTION:

First of all, remove one of the waste ink tanks mounted in the printer, and then discard the cleaning

solution from the solution tank into the waste ink tank.

(8) Feed out any cleaning solution remaining in the inlet tubes.

Press the Solution button once again to feed out any cleaning solution remaining in the inlet tubes.

Continue holding down the button until all the fluid has been removed from the tubes.

Page 53

6. Initial Ink Induction Procedure

46JS310-UM-251-9370

6.3 Print head height Adjustment

Adjust the print head height using the print head height adjustment jig.

(1) Loosen the screws holding the print head frame.

(2) Insert the print head height adjustment jig under the print head frame.

Head height adjustment Jig

(3) Adjust the print head height to the following position.

The height adjustment position

Print head Frame

• When the head protector is not attached.

(Standard)

• When a print head rubs with the media.

• When the head protector is attached.

Jig

(4) Tighten the screws holding the print head frame.

Page 54

6. Initial Ink Induction Procedure

47JS310-UM-251-9370

6.4 Mounting the Print heads

• If the print head carriage is not at the cleaning position, move it to the cleaning position.

Moving the print head carriage to the cleaning position

(a) From the main menu, select [

Cleaning Tool

] and then press the

ENTER

key.

(b) From the submenu, select [

Clean Post

] and then press the

ENTER

key.

(1) Turn off the printer power supply.

Turn off the printer power supply before mounting the print heads.

• Performing the print head mounting operation while the power supply is on may result in damage to the

printer or to the print heads. Make sure that the power supply is turned off.

(2) Mount the print heads in order from the left-hand side.

Mount the print heads in the order shown below, starting from the left-hand side. The procedure described

below is the procedure for mounting one print head. Repeat the procedure of step from (3) to (10) for all eight

print heads.

S

E

Print head mounting order

Page 55

6. Initial Ink Induction Procedure

48JS310-UM-251-9370

(3) Write down the print head mounting position and the serial number.

These will be required for a later procedure.

Print head mounting position

Outlet side

Inlet side

Serial number

(4) Attach an outlet tube and tube clamper (provided as accessories) to the print head.

Leave the tube clamper open.

Clamper

Outlet tube

Page 56

6. Initial Ink Induction Procedure

49JS310-UM-251-9370

(5) Remove the caps attached to the print head, and then insert the inlet tube and outlet tube into the print head

inlet.

Outlet tube

Inlet tube

CAUTION:

Do not mistake the color of tubes when connecting the inlet tubes.

(6) Attached to the print head clamper to the print head and the inlet tube joints.

Print head clamp

Print head clamp

Check the orientation.

(The longer dimension is the horizontal direction.)

CAUTION:

Do not touch the surface of the print head nozzles.

Page 57

6. Initial Ink Induction Procedure

50JS310-UM-251-9370

(7) Loosen the top and the left screws, and remove the right screw.

Loosen

Remove

Loosen

(8) Mount the print head, and then reattach the right screw.

(9) Tighten the top, left and right screws to fasten the print head in place.

Page 58

6. Initial Ink Induction Procedure

51JS310-UM-251-9370

6.5 Initial Print head Cleaning Procedure

A new print head contains a protecting liquid. Before using the print head, follow the procedure described below to

clean the print head.

(1) Pour cleaning solution into the solution tank.

Pour a generous amount of cleaning solution into the solution tank.

Solution tank:

Pour a generous amount of cleaning solution

into the tank, up to the level indicated by the

white line.

(2) Turn on the printer power supply.

When the power is turned on, the printer begins a self-test operation (the print head carriage and the feed

rollers move). When the self test has been completed, wait until the main menu is displayed on the LCD.

• Since ink has not yet been supplied to the printer, a “

No Ink

” alarm will sound after several minutes have

elapsed. This alarm does not indicate a malfunction, and no action is required.

(3) Move the print head carriage to the cleaning position.

(a) From the main menu, select [

Cleaning Tool

] and then press the

ENTER

key.

(b) From the submenu, select [

Clean Post

] and then press the

ENTER

key.

The print head carriage moves to the cleaning position and then stops.

(4) Check that the 3-way valve for the solution tank is set to the supply position.

• If the lever is at a different position, move it to the supply position.

Solution tank 3-way valve

Turn to the supply position

Page 59

6. Initial Ink Induction Procedure

52JS310-UM-251-9370

(5) Clean the outlet tubes.

Follow the procedure described below to clean the cyan outlet tube. Clean the magenta, yellow and black

outlet tubes in the same way.

(a) Set the lever of the 3-way valve for the cyan ink tank to the cleaning solution supply position. Set the

lever on all the other 3-way valves to the ink supply position.

Cyan ink 3-way valve only

Turn to the solution supply position

All other 3-way valves

Turn to the ink supply position

(b) Remove the cap from the one (cyan) of the outlet tubes.

Outlet tube cap

Outlet tube

(c) Position the open end of the outlet tube so that it is facing the waste liquid slot.

Waste liquid slot

(d) Press the Solution button to feed the cleaning solution through the outlet tube.

Continue to hold down the Solution button until the cleaning solution flows out of the outlet tube.

• Cleaning solution may be emitted from the print head nozzles.

CAUTION:

Take care not to get cleaning solution stains on your clothing.

(e) Reattach the outlet tube cap that was removed in Step (b), and then remove the cap from the second outlet

tube.

Page 60

6. Initial Ink Induction Procedure

53JS310-UM-251-9370

(f) Press the Solution button in the same way as described in Step (d) to feed cleaning solution through the

outlet tube. Position the open end of the outlet tube so that it is facing the waste liquid slot.

Continue to hold down the Solution button until the cleaning solution flows out of the outlet tube.

• Cleaning solution may be emitted from the print head nozzles.

CAUTION:

Take care not to get cleaning solution stains on your clothing.

(g) Reattach the outlet tube cap to the outlet tube.

(h) Clean the magenta, yellow and black outlet tubes in the same way.

(6) Clean the print head nozzles.

(a) Set the levers on the cyan and magenta 3-way valves to the cleaning solution supply position.

(b) Set the levers on the yellow and black 3-way valves to the ink supply position.

(c) Press the Solution button to feed cleaning solution through the cyan and magenta print head nozzles.

Hold down the Solution button until the cleaning solution flows out of all four print heads.

(d) Set the levers on the yellow and black 3-way valves to the cleaning solution supply position.

(e) Set the levers on the cyan and magenta 3-way valves to the ink supply position.

(f) Press the Solution button to feed cleaning solution through the yellow and black print head nozzles.

Hold down the Solution button until the cleaning solution flows out of all four print heads.

(7) Leave the print heads in this status for 10 minutes to ensure that the protecting liquid is completely dissolved.

Leave the print heads in this status for 10 minutes.

(8) Feed out any cleaning solution remaining in the print heads.

Using the procedure described in step (6) above, feed out any remaining cleaning solution from all of the print

head nozzles.

Page 61

6. Initial Ink Induction Procedure

54JS310-UM-251-9370

6.6 Ink Induction

• If the power supply is turned off, turn it on and then move the print head carriage to the cleaning position.

• Since ink has not yet been supplied to the printer, a “

No Ink

” alarm will sound after several minutes have

elapsed. This alarm does not indicate a malfunction, and no action is required.

(1) Pour ink into the ink tanks.

Pour a generous amount of ink into each ink tank. Make sure that the ink color matches the color code label

on each of the tanks.

CAUTION:

Make sure that you do not get ink stains on your clothing.

Ink tanks

Pour a generous amount of ink into each tank, up to

the level indicated by the white line.

(2) Feed the ink to the sub tanks.

From the main menu, select [

Ink Status

] and then press the

ENTER

key.

The “

No ink

” alarm sounds and then stops, and the ink pump operate to feed the ink to the sub tanks.

If the “

No ink

” alarm sounds once again, from the main menu, select [

Ink Status

] and then press the

ENTER

key once more.

The alarm will stop sounding when the four sub tanks (C, M, Y, K) are filled with ink.

At this time there will be no operating noise from the ink pump.

(3) Visually check that the sub tanks are sufficiently filled with ink.

The tanks should be filled up to approximately the level indicated by the white line.

Page 62

6. Initial Ink Induction Procedure

55JS310-UM-251-9370

(4) Set the levers of the 3-way valves for each ink tank to the ink supply position.

Turn to the ink supply position

(5) Feed ink through the outlet tubes.

Perform the following procedure for both outlet tubes on each of the print heads.

(a) Remove the outlet tube cap.

(b) Position the open end of the outlet tube so that it is facing the waste liquid slot.

(c) Press the Ink button located at the cleaning position to feed ink through the outlet tube.

• Hold down the Ink button for approximately 10 seconds.

• Ink may be emitted from the print heads.

CAUTION:

Take care not to get ink stains on your clothing.

(d) Press the Ink button once again. When ink flows out of the outlet tube, firmly close the tube clamper.

Make sure not to allow any air to enter the outlet tube.

Close the tube clamper.

(e) Reattach the outlet tube cap, and then tighten the caps using long-nose pliers.

(f) Open the tube clamper on the outlet tube.

Page 63

6. Initial Ink Induction Procedure

56JS310-UM-251-9370

(6) Feed ink through the nozzles.

Check that all the outlet tube caps have been firmly inserted.

Press the Ink button once again to feed ink through all the nozzles.

(7) Use the brushes provided to clean the surface of all the print head nozzles.

Printing will not be performed correctly if the nozzle surfaces are wet. Use the brushes provided to wipe the

nozzles clean.

CAUTION:

If the print heads will not be used for a long period of time, attach the wet keeping frame to the print

head carriage (see “Maintenance of print head Manual”).

Page 64

7. Media Loading Procedure

57JS310-UM-251-9370

7. Media Loading Procedure

7.1 Loading the Media

(1) Mount the media on the media feeding rollers as shown in the figure below.

• Inside wound

Print side: inside

Media

Feeding roller

• Outside wound

Print side: outside

Media

Feeding roller

CAUTION:

As the media is heavy, at least two persons are required for the loading operation.

Take care not to drop the roll. Dropping the roll on your foot may result in injury.

(2) Insert the media flange into a madia roll.

Media flange

Media

Page 65

7. Media Loading Procedure

58JS310-UM-251-9370

(3) Turn the knob to the red arrow direction to fix the media flange firmly.

(4) Insert the media flange to the other side of media roll likewise.

Note: Don’t use the media flanges when the media may be bended beneath the burden of its weight.

May be wrinkled up the media by the heavy roll media.

(5) Feed the media a distance of approximately 1 m.

Use the following procedure to feed the media a distance of approximately 1 m.

(a) Set the rotation direction switch on the media feeding system.

Inside wound media: [

] direction Outside wound media: [ ] direction

Page 66

7. Media Loading Procedure

59JS310-UM-251-9370

(b) Press down the “I” (Manual) side of the selector switch on the media feeding system.

Right-hand position

(c) When the media has been fed approximately 1 m, return the selector switch to the position between the “II”

and “I” markings (the OFF position, “O” ).

Center position

(6) Load media on the platen surface.

(a) Raise the press roller control lever.

Press roller control lever

(b) Remove the screws from the flap at the rear of the printer and open the flap.

Remove these two screws and open the flap.

Page 67

7. Media Loading Procedure

60JS310-UM-251-9370

(c) Insert the leading edge of the media from the rear of the printer towards the front.

(d) Align the left edge of the media with the rear guide and front guide scales at the left of the printer,

making sure that the media is not loaded at an angle.

(e) Lower the press roller control pole to hold the media in place.

(f) Close the flap and Replace the screws to the flap at the rear of the printer.

(g) Align the media edge guards with the left and right edges of the media.

Slide each media edge guard

to approximately the position

indicated by the dotted line.

Page 68

7. Media Loading Procedure

61JS310-UM-251-9370

7.2 Adjusting the auto feed function

(1) Feed the media manually.

Press down the “I” side (Manual) of the selector switch on the media feeding system.

When the media has passed over the media sensor (or just before the media reaches the floor), return the

selector switch to the position between the “II” and “I” markings (the OFF position, “O”).

(2) Place the empty core provided on top of the media as shown in the picture below.

Empty core

(3) Use a screwdriver to turn the trimmer fully to the left for the rear media sensor.

The orange LED goes out (only the green LED remains lit).

LED

(4) Gradually return the trimmer to the right.

Stop at the position where the orange LED lights.

Page 69

7. Media Loading Procedure

62JS310-UM-251-9370

(5) Set the rotation direction switch on the media feeding system to the direction opposite to the direction set

earlier.

Inside wound media: [ ] direction Outside wound media: [ ] direction

(6) Rewind the media manually.

Set the selector switch on the media feeding system to the “I” (Manual) position, rewind the media to the

position where the orange LED does not light, and then return the selector switch to the position between the

“II” and “I” markings (the OFF position, “O”).

(7) Check that the orange LED does not light even if an object is placed behind it.

Empty core

Media

Feeding roller

Place an object here to

check the sensor.

Sensor

Check that the orange

LED does not light

even if an object is

placed behind the

sensor.

(8) Check that the media stops at the sensor after it has been fed automatically.

Set the selector switch on the media feeding system to “II” (Auto).

Left-hand position

Page 70

7. Media Loading Procedure

63JS310-UM-251-9370

7.3 Winding the Media onto the Take-up Unit

(1) Mount the take-up core flanges and the take-up core.

(a) Raise the take-up roller at the left-hand side and remove it.

Take-up roller

(b) Slide one of the flanges onto the roller and then fasten it in place at the right.

Flange

Use these two screws to

fasten the flange.

(c) Insert the take-up core onto the right flange.

Take-up core

(d) Insert the other flange into the left edge of the take-up core.

Flange

Use these two screws to

fasten the flange.

Take-up core

(e) Return the take-up roller to its original position.

Page 71

7. Media Loading Procedure

64JS310-UM-251-9370

(2) Feed the media up to the take-up roller position.

(a) Set the take-up roller selector switch to the position between the “II” and “I” markings (the OFF position,

“O”).

Center position

(b) From the main menu, select [

Print Para

] and then press the

ENTER

key.