Page 1

MT100

MOUNTCORDER

MANUAL NO. MT100-UM-851

Quick Start Guide

Quick Start Guide

English

Page 2

Contents

Introduction 21

To Ensure Safe and Correct Use 21

Checking the Outer Casing 21

Checking the Accessories 21

1. MT100 Part Names and Functions 22

Front 22

Rear 24

2. Installation Procedure 25

3. Connecting to an AC Power Supply 26

4. Connecting Signal Input Cables 27

5. Connecting Cables to Digital Input and Alarm Output Terminals 28

6. Precautions to Observe When Performing Measurement 29

7. Noise Countermeasures 29

8. Initial Setup 30

9. Window names and functions 31

10. Key Operation 33

11. Setting Examples 36

(Example 1) Enabling temperature measurement using thermocouples

for all the channels 36

(Example 2) Storing captured data in USB memory 37

(Example 3) Replaying captured data 38

12. Specifications 39

Page 3

21

Thank you for purchasing the MOUNTCORDER MT100.

Please read this manual and the User's Manual provided in the supplied CD-ROM thoroughly

before attempting to use your new product to ensure that you use it correctly and to its full

To promote safe and accurate use of the MT100 as well as to prevent human injury and property damage,

safety precautions provided in this manual are ranked into the five categories described below. Be sure

you understand the difference between each of the categories.

This category provides information that, if ignored, is

highly likely to cause fatal or serious injury to the operator.

This category provides information that, if ignored, is likely

to cause fatal or serious injury to the operator.

This category provides information that, if ignored, could

cause physical damage to the MT100.

After unpacking, check the MT100's outer casing before use. In particular, please check for the following:

• Surface scratches

• Other flaws such as stains or dirt

After unpacking, check that the following standard accessories are included.

Checking the Accessories

Checking the Outer Casing

DANGER

WARNING

CAUTION

Conventions Used in This Manual

٨To ensure safe and correct use of the MT100, read this Manual thoroughly before use.

٨After having read this Manual, keep it in a handy location for quick reference as needed.

٨Do not permit small children to touch the MT100.

٨The following describes important points for safe operation. Please be sure to observe them strictly.

To Ensure Safe and Correct Use

Introduction

CD-ROM: 1

Panel mount bracket: 2

Quick Start Guide: 1

Page 4

22

1. MT100 Part Names and Functions

Front

Front panel

Monitor

Control panel cover

Opening the Control Panel Cover

As shown in the following figure, hold the tab in the center of the control panel cover and pull it in the

direction indicated by an arrow to open the cover.

Operation status LED

POWER:

ON when the power is ON

START: ON during data capture

Control panel keys

Control panel cover

Page 5

23

Opening the Front Panel

Pull the part indicated by an arrow in the following figure to open the front panel.

Front panel

Power switch

USB memory terminal

Maximum Dimensions of USB Memory

The maximum dimensions of USB memory that can be attached to the MT100 are shown in the following

figure.

Front

47mm

90mm

21.5mm

13mm

8.5mm

Page 6

24

Rear

Power terminal and protective ground

terminal

USB terminal

Ethernet terminal

Power jack for the humidity sensor

External input/output

terminal

LOGIC/PULSE

EXT TRIG

ALARM

Analog signal input

terminals

Removing the Terminal Cover

While applying force in direction A, pull the cover in direction B to remove the cover.

(The external input/output terminal cover can also be removed in the same way.)

A

B

Page 7

25

ii

i

CAUTION

Installation Site

2. Installation Procedure

Install the MT100 in an indoor location where:

an instrumentation panel can be attached

For information on the panel cut dimensions, see the User's Manual in the supplied CD-ROM.

there is good ventilation

there is little mechanical vibration

the floor is level

Do not install the MT100 in a location where:

㨯 the unit is exposed to direct sunlight or near a heater.

㨯 there are excessive greasy fumes, steam, humidity, dust, corrosive gas, etc.

㨯 the unit is near an electromagnetic field source.

As the panel, use a steel sheet 2mm to 26mm in thickness. Use the panel mount brackets provided with the MT100 to attach it.

There are two panel mount brackets. Be sure to attach them in two opposite locations (up and down or left and right).

Installation Procedure

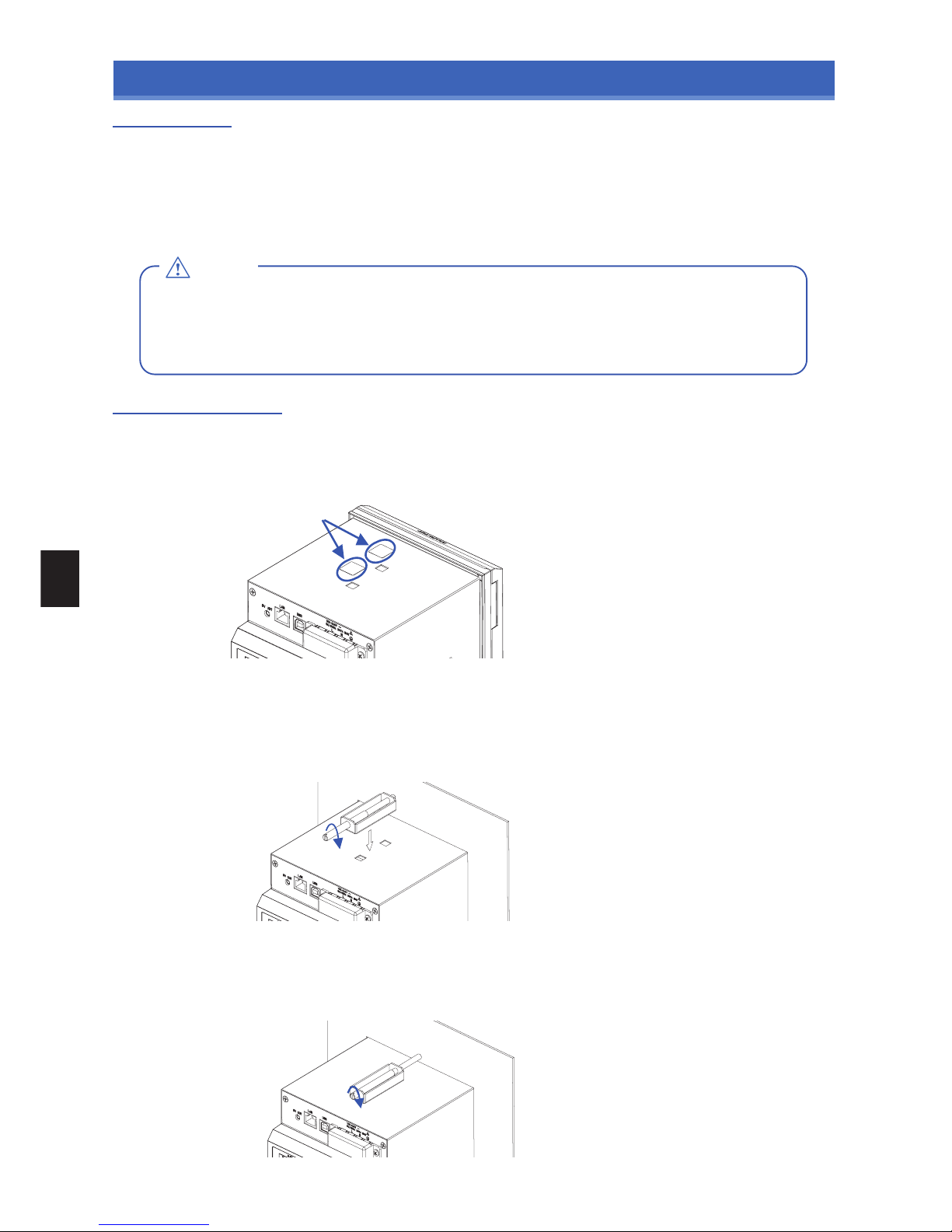

ԘޓPeel off the masking tape from the surface on which you want to attach a panel mount bracket.

ԙޓInsert the MT100 from the front side of the panel.

ԚޓAttach the MT100 to the panel using the provided mount bracket as shown in the figure below.

i. Use two mount brackets on the up and down or left and right of the case.

(Peel off the masking tape on the case that covers the holes for mount brackets beforehand.)

ii. Attach the two brackets first, then temporarily tighten mounting screws on them.

ԛޓTighten the screws to an appropriate torque.

Next, tighten the mounting screws to an appropriate torque to fix the main unit. While keeping the

main unit roughly at right angles to the panel, bring the mounting bracket into close contact with the

main unit case and tighten the mounting screws.

* The appropriate tightening torque of panel mounting screws is 10 to 12kgf/cm.

Peel off the masking tape.

Page 8

26

Rated power voltage

Power supply voltage range

Rated power frequency

Power frequency tolerance

Maximum power consumption

Item

100 to 240VAC

90 to 264VAC

50/60Hz

50/60Hz±2%

38VA

Specification

WARNING

3. Connecting to an AC Power Supply

No power cord is supplied with the MT100.

Be sure to use a power cord supplied with the optional desktop case (B-541).

Connecting Cables

ԘޓTurn off the power supplied to the MT100 and open the power terminal cover (transparent).

ԙޓConnect the power cord and the protective ground cord to the power terminals.

Use non-insulated solderless ring terminals (for 4mm screws) and insulation caps.

The appropriate tightening torque of screws is 12 to 14kgf/cm.

ԚޓClose the power terminal cover (transparent) and fix it with screws.

ԛޓOpen the front panel and turn on the power switch to power on the MT100.

Remove these two screws to remove the power terminal cover.

Protective ground terminal

Functional ground

terminal

Protective ground cord

Power cords

Non-insulated

solderless ring

terminals

(for 4mm screws)

Insulation caps

ޓ

ޓ

ޓ

ޓ

ޓ

ޓ

ޓ

To avoid electric shocks, check that the AC source for the power supply has been turned off.

To prevent fire, use wires or cables with a performance equivalent to or better than 600V insulated wires

(AWG 20 to 16).

Before turning on the power, be sure to connect the protective ground terminal to the ground at a

grounding resistance of 50ǡ or less.

For cables to be connected to a power supply and a protective ground terminal, use non-insulated

solderless ring terminals (for 4mm screws) inserted in insulation caps.

In the power line, provide a switch that can cut off the MT100 from the main power source (double-pole type).

As specifications of the switch, the rated steady-state current must be 1A or larger and the rated

inrush current must be 60A or larger.

Do not insert a switch or fuse in a grounding line.

Use a power supply that meets the following conditions.

Page 9

27

㨎

㨎

㧭

㧮

㨎

㨎

㨎

WARNING

CAUTION

4. Connecting Signal Input Cables

This section describes how to connect the signal input cables.

To avoid electric shocks, check that the AC source for the power supply has been turned off before connecting

A large pulling force applied to an input/output signal cable connected to the MT100 may damage a

terminal or the signal cable. Therefore, fix the wiring cords to the back of the installed panel.

To prevent fire, use signal cables with a rated temperature of 70°Cor higher.

Do not apply a voltage higher than the following values to input terminals. If you do, the MT100 may

suffer damages.

Maximum input voltage: ±60VDC

Maximum common-mode voltage: AC33Vrms or ±60VDC

Caution on Connecting Cables

Connecting Cables

ԘޓRemove the terminal cover.

ԙޓConnect signal cables to the input terminals.

The appropriate tightening torque of screws is 12 to 14kgf/cm.

Connect wires to terminals as shown in the following figure after checking them.

ԚޓReinstall the terminal cover.

Connection diagram

Direct voltage

٨Direct voltage input

٨Thermocouple input

Compensation copper wire

٨Resistance temperature detector input

٨Direct current input

Direct current

Connect input signal cables to terminals using insulated solderless terminals (for 4mm screws).

Keep the measuring circuit away from a power cable (power circuit) or a ground circuit.

If the measuring target is a noise source, refer to page 29 and take a necessary measure.

Be sure to connect a protective ground terminal to the ground at a low grounding resistance (50ǡ or less).

Be sure to attach a terminal cover when you measure temperatures using a thermocouple.

Do not use a thick wire with a high heat radiation effect when you measure a temperature using a

ޓthermocouple (a wire having a diameter of 0.65mm or less is recommended).

Avoid causing changes in the outside air temperature. In particular, turning on and off the fan near the

ޓMT100 causes significant temperature changes.

If an input cable is connected in parallel with another device, the measurement values of both the

ޓMT100 and the device may be influenced.

Do not turn on and off one of the devices during operation. The other device may be adversely

ޓinfluenced.

Page 10

28

+5V +5V

PULSE/LOGIC(n)

GND

+5V

+5V

EXT TRIG

GND

ALARM(n)

NC

COM

NO

Comparator

Comparator

WARNING

CAUTION

5. Connecting Cables to Digital Input and Alarm Output Terminals

This section describes how to connect the signal input/output cables.

To avoid electric shocks, check that the AC source for the power supply has been turned off before connecting cables.

A large pulling force applied to an input/output signal cable connected to the MT100 may damage a

terminal or the signal cable. Therefore, fix the wiring cords to the back of the installed panel.

To prevent fire, use signal cables with a rated temperature of 70°C or higher.

Do not apply a voltage higher than the following values to input terminals. If you do, the MT100 may

suffer damages.

Digital signal terminal: +24VDC at the maximum

Alarm output relay terminal: 250VAC/2A, 30VDC/2A

Caution on Connecting Cables

Connecting Cables

ԘޓRemove the terminal cover.

ԙޓConnect signal cables to the input terminals.

The appropriate tightening torque of screws is 12 to 14kgf/cm.

Connect wires to terminals as shown in the following figure after checking them.

ԚޓReinstall the terminal cover.

Pulse/logic input

Trigger input

Alarm output

* When an alarm is generated, COM and NO are connected (while COM and NC are open-circuited).

Internal equivalent circuit of input/output circuit

When you connect digital input and alarm output cables, please note the following:

Use insulated solderless terminals (for 4mm screws) to connect signal cables to terminals.

Connect a protective ground terminal to the ground at a low grounding resistance (50ǡ or less).

Page 11

29

DANGER

CAUTION

Channel Switching Relay

6. Precautions to Observe When Performing Measurement

Please be sure to read the following carefully in order to prevent electric shocks or shorts.

• Do not apply voltage of AC30Vrms or 60VDC or above between the analog input section and main unit

(GND terminal), or between each analog input channel.

• Do not apply radio-frequency signals with high voltage (50KHz or above).

Input Circuit Diagram for Analog Input (Voltage, Thermocouples)

Capacitors have been incorporated into the input circuit to increase the noise elimination capability.

After voltage measurement, when the inputs have been disconnected, there will still be some electric

charge remaining. Before starting another measurement operation, short-circuit the + and - terminals to

enable self-discharge.

The MT100 has a scan system.

While in the status (open) in which signals are not input to the input terminal, measured results may be

influenced by signals from other channels.

In such a case, turn OFF the input setting or short circuit +/-.

If signals are input correctly, measured results are not influenced by other channels.

7. Noise Countermeasures

If the measurement values of the MT100 vary due to external noise, the following countermeasure is recommended.

(The effect varies depending on the noise type.)

Example 1: Connect the ground terminal of the MT100 to the ground (see the following figure).

Example 2: Connect the ground terminal of the MT100 and the ground terminal of a measurement

target (see the following figure).

Example 3: Set the filter to other setting than OFF in the AMP setup menu.

Example 4: Set a sampling interval at which the digital filter of the MT100 is effective (500ms or more).

To be connected to the

power ground

(Protective grounding)

To be connected to the chassis of the

measuring target (Functional grounding)

Page 12

30

CAUTION

8. Initial Setup

Language Setting

When you power on the MT100 for the first time after purchase, a language selection menu is displayed.

Select a language that you want to use.

The language setting can be changed later.

To change the setting later, open OTHR menu and select Language.

If you are using the MT100 for the first time, charge the internal rechargeable battery and then make the

date and time settings.

Setting the Date and Time

If the MT100 is not used for a period of approximately six months, the internal rechargeable battery may

be discharged and the date and time may revert to the initial settings. If this happens, recharge the

battery before using the MT100.

How to Recharge the Rechargeable Battery

Turn on the power switch and leave the MT100 connected for at least 24 hours.

How to Set the Date and Time

Press the MENU key, display the OTHR screen, and then set the date and time at the Date/Time Settings

sub-menu. Refer to the User's Manual in the supplied CD-ROM for more information on the setting.

Page 13

31

CAUTION

9. Window names and functions

Status display

Screen

Measurement data display

Status display

Ԙ Simplified message display

ԙ Time/DIV display Ԛ

Status display

ԛ Clock display

Ԝ

Alarm display

Displays the operation status of the MT100.

Free Running : Displayed in the start-up status or when no data is being captured.

Armed :

Displayed when the MT100 is waiting for a trigger to be issued after

measurement is started (No data is being captured).

Memory Recording :

Displayed when data is being captured to the internal memory of the MT100.

USB Drv Recording : Displayed when data is being captured to the USB memory.

Memory Review :

Displayed when data is being replayed from the internal memory of the MT100.

USB Drive Review : Displayed when data is being replayed from the USB memory.

ԘޓSimplified message display

ԙޓTime/DIV display

Displays the current time scale.

Displays the current date and time.

Displays the alarm output terminal status. The terminal for which an alarm has been generated has a

terminal number displayed in red.

ԚޓStatus display

USB memory status display

: (Gray) No USB memory is attached.

: (Green) USB memory is attached but not being accessed.

: (Red) USB memory is being accessed.

: (Gray) Keys are not locked. Normal operation is enabled.

: (Yellow) Keys are locked. All the keys are locked.

Refer to the User's Manual provided with the MT100 for more information on the key lock statuses.

: (Gray) Local mode. The operations on the MT100 are enabled.

: (Yellow)

Remote mode. The operations on the PC are enabled except for some operations.

Cancel the PC connection to automatically return from the remote mode to the local mode.

If the local mode is not regained, press the QUIT key.

: (Gray) Internal memory is not accessed.

: (Red) Internal memory is being accessed.

Internal memory status

Do not turn off the power of the MT100 while the USB memory or internal memory is being accessed.

If you do, data may be corrupted and you may no longer be able to access the memory.

Key lock status display

Remote mode display

ԛޓClock display

ԜޓAlarm display

<Waveform scrolling direction: Vertical>

<Waveform scrolling direction: Horizontal>

Page 14

32

<Waveform scrolling direction: Vertical >

<Waveform scrolling direction: Horizontal >

Measurement data display

ԘData capture bar

ԙDigital display

ԚPen display

ԛ

Waveform display (Present)

Ԝ

Compressed waveform display (Past)

ԝSampling interval display

ԞFile name display

Displays the position of each channel signal with the pen.

In addition, displays the trigger position and the alarm range.

ԚޓPen display

Displays measurement signals as waveforms in real time.

ԛޓWaveform display (Present)

Displays the current sampling interval.

ԝޓSampling interval display

Displays the name of the file used to capture data.

(Displayed only while data is being captured.)

ԞޓFile name display

Displays measurement signals in compressed format.

The compression rate can be set using the menu.

Refer to the User's Manual in the supplied CD-ROM for more information on the setting.

ԜޓCompressed waveform display (Past)

Displays the input value of each channel.

Use the SPAN/TRACE/POSITION key to check the setting value of each channel.

ԙޓDigital display

During data capture, indicates capturing time and the remaining capacity of the capture media.

(When the remaining capacity runs short, the display changes into orange.)

During replay, indicates information about the displayed position.

ԘޓData capture bar

Trigger level display

ޓDisplays the trigger level position and direction.

* Displays the trigger level also in horizontal scrolling.

Alarm range display

ޓDisplays the alarm position and range.

ޓAn alarm is generated when a signal enters the green area shown in the following figure.

ޓ(When an alarm is generated, the display changes into red.)

* Displays the alarm range also in horizontal scrolling.

<H> <L> <Win In> <Win Out>

Page 15

33

10. Key Operation

(1) CURSOR

(2) SPAN/TRACE/POSITION

(3) QUIT

(4) Direction Keys

(5) MENU

(6) START/STOP

(7) ENTER

(8) DISPLAY

(9) TIME/DIV

(10) REVIEW

This key has different roles according to the operation status.

During replay: This key is used to toggle between cursors A and B displayed during replay.

During free-running and data capture: When the alarm setting is “Hold generated Alarm”, the

maintained alarm is cleared.

(1) CURSOR (ALM CLR)

Pressing this key can switch the channels of the digital display area.

Used to change the settings related to waveform display during free running (when stopped), data

capture and data replay.

(2) SPAN/TRACE/POSITION

This key is primarily used for the following operations.

To cancel a setting during menu configuration.

To return to the MONITOR window when the SPAN/TRACE/POSITION window is displayed.

To cancel remote status (in which keys are disabled) through interface control.

To close the menu screen.

To quit data replay.

To return from the Digital + Calculation Display or Bar Graph Display to Waveform + Digital Display

(3) QUIT (LOCAL)

MONITOR

Displays the measurement values of each

channel.

(Default)

SPAN

Allows changing of the span value.

Channel change: keys

Span change: keys

Change range: Eight voltage levels

and six temperature levels

POSITION

Allows changing of the waveform position.

Channel change: keys

Position change: keys

Change range: Range can be

changed in units of 10%.

TRACE

Allows turning ON/OFF of the waveform

display.

Channel change: keys

Trace change: keys

Change range: ON/OFF

* Data capture is enabled even with the

OFF setting.

[SPAN/TRACE/POSITIO N] key

[SPAN/TRACE/POSITIO N] key

[SPAN/TRACE/POSITIO N] key

[SPAN/TRACE/POSITIO N] key

Page 16

34

CAUTION

This key is primarily used for the following operations.

To move a menu or setting item during menu configuration.

To move the cursor during replay.

To move the active channel in the Waveform + Digital screen ( keys).

To change the setting of SPAN/TRACE/POSITION ( keys).

(4) Direction keys

Open the settings window to capture data. Pressing this key switches the tab on the settings window.

Refer to the User's Manual in the supplied CD-ROM for more information on the setting.

(5) MENU

This key is used in the following two operations:

<Starting or Stopping Measurement>

Pressing this key during free-running starts capture.

Pressing this key during capture stops capture.

<USB Drive Mode>

In USB Drive Mode, the internal memory is recognized by the PC as external storage media.

Files on the internal memory, being recognized as a removable disk, can be easily transferred, deleted, or otherwise handled.

ԘޓUse a USB cable to connect the MT100 and a PC.

ԙޓWhile pressing the MT100 START/STOP key, turn the power ON.

ԚޓThe external storage media is recognized by the PC and data exchange becomes possible.

(The screen is shown in the following figure.)

(6) START/STOP(USB DRIVE)

This key is used to finalize setting items during menu configuration or open submenus.

(7) ENTER

AMP

DATA

TRIG

DISP

MARK

FILE

USER

I/F

OTHR

Specify input signal-related settings.

Input, range, filter, etc.

Specify miscellaneous settings.

LCD brightness, language, AC line frequency, etc.

Specify capture-related settings.

Sampling interval, file name, statistical calculation, etc.

Specify trigger and alarm settings.

Capture start and stop conditions, alarm conditions, etc.

Specify screen display settings.

Scrolling direction, waveform color, etc.

Specify mark-related settings.

Mark text setting, mark display execution, etc.

Specify file-related settings.

Setting conditions, bitmap, file operations, etc.

Specify setting conditions for each user of the MT100.

User name, user switching, etc.

Specify interface-related settings.

USB ID number, LAN IP address, etc.

To exit USB Drive Mode, turn the power off and then on.

When the MT100 is used in USB Drive Mode, no user operation

ޓis allowed, including data capturing and data replay.

Page 17

35

This key is used to switch the data display mode.

You can switch the display mode during free running (when stopped) and data capturing.

Pressing this key switches the display mode as follows:

(8) DISPLAY

Pressing this key changes the time axis display width.

The following settings are possible.

1, 2, 5, 10, 20, 30sec/DIV

1, 2, 5, 10, 20, 30min/DIV

1, 2, 5, 10, 12, 24, 72 hour/DIV

(9) TIME/DIV

This key is used to replay captured data.

(10) REVIEW

Waveform + Digital Screen

Displays waveforms and digital values.

This is the initialscreen at power-on.

Digital + Calculation Display screen

Displays digital values and calculation results in large

text.

Calculation results are added up in real time.

Refer to the User's Manual in the supplied CD-ROM

for more information on the calculation results.

Bar Graph screen

Displays measurement data in bar graphs.

Allows you to select a reference point of a bar graph.

Refer to the User's Manual in the supplied CD-ROM

for more information on the setting.

Page 18

36

11. Setting Examples

(Example 1) Enabling temperature measurement using thermocouples for all the channels

ԘޓPress the MENU key to open the AMP menu.

ԙޓUse the key to move the cursor to ALL Input.

ԚޓPress the ENTER key to select TEMP.

Ԝޓ

Press the ENTER key to select a thermocouple type.

ԝޓPress the MENU key to open the DATA menu.

ԞޓPress the key to move the cursor to Sampling.

ԟޓ

Press the ENTER key to set the sampling interval to 1s.

ԛޓPress the key to select ALL Range.

A sampling interval of 1 sec or more is recommended to improve the

efficiency of removing external noise.

Page 19

37

(Example 2) Storing captured data in USB memory

This setting allows you to store captured data with an automatically generated file name in USB memory.

* Attach the USB memory to the MT100 before making this setting.

ԘޓPress the MENU key to open the DATA menu.

ԙޓUse the key to select File Name

ޓޓand press the ENTER key.

ԚޓSelect Folder and press the ENTER key.

ԛޓUse the key to move the cursor to USB1

ޓޓand press ENTER.

ԜޓUse the key to select OK and press

ޓޓthe ENTER key.

Page 20

38

(Example 3) Replaying captured data

This section explains how to replay captured data.

ԘޓPress the REVIEW key to open the Data Replay

Source menu.

ԙޓSelect File and press the ENTER key to open the

file selection menu.

ԛޓSelect a file to be replayed and press the ENTER

key.

ԜޓMove the cursor to OK and press the ENTER key.

ԚޓPress the key to go into a folder.

Press the and keys to move the cursor and

check the measurement values.

Press the CURSOR key to switch between

Cursors A and B.

Page 21

39

12. Specifications

Standard Specifications

Interface specifications

Sampling interval

TIME/DIV

Data save functions

(internal and USB memory)

Calculation

Display modes

Message/marker function

Clock accuracy (23°C environment)

Insulation resistance

Data backup functions

Withstand voltage

Number of analog input

External input/output

PC interface

Internal memory devices

Operating environment

Power supply

Internal memory: approx. 14MB

USB memory slot (FullSpeed supported) is provided as a standard feature

100, 125, 200, 250, 500ms, 1, 2, 5, 10, 20, 30sec, 1, 2, 5, 10, 20, 30min, 1 hour

1, 2, 5, 10, 20, 30 sec/DIV, 1, 2, 5, 10, 20, 30min/DIV, 1, 2, 5, 10, 12, 24, 72 hour/DIV

Save data: Measurement data, setup data, copy of data screen

Backup function: Internal to USB memory; internal to FTP server; USB memory to FTP server

* USB memory can be removed during data capture.

Types of statistical calculation: Average value, peak value, maximum value, minimum value, RMS

Calculation between channels: Addition, subtraction, multiplication, and division; calculation of humidity from wet and dry bulb temperature (Channels 1 and 2 only)

Waveform + digital (vertical and horizontal scrolling), digital, and bar graph

Function: Records message/marker at specified timing

Number of registered messages: 8

Marker type: Arbitrary message, start/stop, trigger, alarm, power failure

Setup conditions: EEPROM; Clock: lithium secondary battery

0 to 50°C, 5 to 85%RH

Between AC input and GND: 1 minute at 2000VAC

Between alarm terminal and GND: 1 minute at 1000VAC

Between each input channel and GND: 1 minute at 350Vp-p

Between input terminals: 1 minute at 350Vp-p

AC input: 100 to 240VAC/50 to 60Hz

Terminal type: M4 screw type terminals

Description

1 unit (10 channels)

Trigger input, Logic input 4 channels or Pulse input 4 channels, Alarm output

Ethernet (10BASE-T/100BASE-TX), USB (FullSpeed supported) provided as standard features

r

0.002% (approx. 50 seconds per month)

٨

AC power consumption

H144 x W144 x D200mm

Condition

2.1kg

Equivalent to automobile parts Type 1 Category A classification

When the LCD is ON

When the screensaver is operating

Vibration-tested conditions

Weight

Other

Power consumption

1

2

* Normal status is when LCD brightness is set to MAX.

No.

IP-65 compatible (only the front panel)

38VA

30VA

Dust-proof and water-proof

External dimensions

Interface types Ethernet (10BASE-T/100BASE-TX)

USB (FullSpeed)

Ethernet functions Web server function: Displays MT100's screen image on Web browser, operation of MT100

(10BASE-T/100BASE-TX) FTP server function: Transfers and deletes files from internal memory and USB memory

FTP client function: Supports backup of data in internal and USB memory

NTP client function: Adjusts internal clock

USB functions USB drive mode: Transfers and deletes files from internal memory

Realtime data transfer speed 100 msec/10 ch maximum

Item

Input/output types • Trigger input (1 ch) • Logic input (4 ch) or Pulse input (4 ch) • Alarm output (4 ch)

* Switch between Logic and Pulse

Input specifications Maximum input voltage: 0 to +24V (single-ended ground input)

Input threshold voltage: Approx. +2.5V

Hysteresis: Approx. 0.5V (+2.5 to +3V)

Alarm output specifications

Output format: Relay contact output (NO/NC)

Rated: 250VAC/2A

Item Description

Item

Description

Digital input specifications

Between AC input and GND: 20Mǡ or higher (500VDC)

Between alarm terminal and GND: 50Mǡ or higher (500VDC)

Between each input channel and GND: 50Mǡ or higher (500VDC)

Page 22

40

Input unit specifications:

Item Description

Number of input channels

Input terminal type

Input method

Scan speed

Measurement

ranges

Voltage

Temperature

Humidity

Measurement

accuracy*1

(23°C

r5°C㧕

Voltage

Temperature

10 ch

M4 screw type terminals

Photo MOS relay scanning system

All channels isolated, balanced input

0.1s/10 ch maximum

20, 50, 100, 200, 500mV; 1, 2, 5, 10, 20, 50V; 1-5 V F.S.

0 to 100% (voltage 0V to 1V scaling conversion) *with B-530 (option)

0.1% of F.S.

٨Thermocouple

*2

Type Measurement Temperature Range Measurement Accuracy

Reference contact compensation accuracy

R/S

B

K

E

T

J

N

W

r5.2°C

r3.0°C

r(0.05% of rdg +2.0°C)

r(0.05% of rdg +2.0°C)

r3.5

r(0.05% of rdg +2.0°C)

r(0.05% of rdg +2.0°C)

r(0.05% of rdg +1.0°C)

r(0.05% of rdg +2.0°C)

r(0.05% of rdg +1.0°C)

r(0.1% of rdg +1.5°C)

r(0.1% of rdg +0.5°C)

r2.7°C

r1.7°C

r(0.05% of rdg +1.0°C)

r(0.1% of rdg +1.0°C)

r(0.1% of rdg +1.5°C)

r0.5°C

٨Resistance temperature detector

Type Measurement AccuracyApplied current Measurement Temperature Range

Pt100 -200 to 850°C (FS=1050°C)

JPt100 -200 to 500°C (FS=700°C)

Pt1000 -200 to 500°C (FS=700°C)

1mA r(0.05% of rdg +0.5°C)

1mA

0.2mA

r(0.05% of rdg +0.5°C)

r(0.05% of rdg +0.5°C)

Reference contact compensation accuracy

A/D converter

Temperature coefficient

Input resistance

Allowable signal source resistance

Maximum permissible

input voltage

Withstand voltage

Insulation resistance

Common mode rejection ratio

Noise

Filter

Internal/External switching

16 bits (out of which 14 bits are internally acknowledged)

Gain: 0.01% of F.S./°C

Between +/– terminals: 60Vp-p

Between input terminal/input terminal: 60Vp-p

Between input terminal/GND: 60Vp-p

Between input terminal/input terminal: 1 minute at 350Vp-p

Between input terminal/GND: 1 minute at 350Vp-p

At least 48dB (with +/– terminals shorted)

Off, 2, 5, 10, 20, 40

Filter operation is on a moving average basis.

The average value of the set sampling count is used.

*1

When 30 minutes or more

ޓhave elapsed after power

ޓwas switched on

Sampling 1s

Filter ON (10)

GND connected

0 ҇Ts ҇ 100

100 㧨 Ts ҇300

R: 300 㧨 Ts ҇ 1600

S: 300 㧨 Ts ҇ 1760

400 ҇ Ts ҇ 600

600 㧨 Ts ҇ 1820

㧙200 ҇ Ts ҇ 㧙100

㧙100 㧨 Ts ҇ 1370

㧙200 ҇ Ts ҇ 㧙100

㧙100 㧨 Ts ҇ 800

㧙200 ҇ Ts ҇ 㧙100

㧙100 㧨 Ts ҇ 400

㧙200 ҇ Ts ҇ 㧙100

㧙100 㧨 Ts ҇ 100

100 㧨 Ts ҇ 110 0

0 ҇ Ts ҇ 1300

0 ҇ Ts ҇ 2000

Thermocouples: K, J, E, T, R, S, B, N, W (WRe5-26)

Resistance temperature detector: Pt100, JPt100, Pt1000 (IEC751)

1Mǡ r5%

Within 300ǡ

Between input terminal/GND: At least 50Mǡ (at 500VDC)

At least 90dB (50/60Hz; signal source 300ǡ or less)

*2: Thermocouple diameters T: 0.32Ǿ , others: 0.65Ǿ

Loading...

Loading...