Page 1

303-04

USER’S MANUAL

MANUAL NO. MP303-UM-151

Page 2

TO ENSURE SAFE AND CORRECT USE

• To ensure safe and correct use of your plotter, read this Manual thoroughly before use.

• After having read this Manual, keep it in a handy location for quick reference as needed.

• Do not permit small children to touch the plotter.

• The following describes important points for safe operation. Please be sure to observe them strictly.

Conventions Used in This Manual

To promote safe and accurate use of the plotter as well as to prevent human injury and property damage,

safety precautions provided in this manual are ranked into the three categories described below. Be sure you

understand the difference between each of the categories.

DANGER

This category provides information that, if ignored, is highly likely to cause fatal or serious injury

to the operator.

WARNING

This category provides information that, if ignored, is likely to cause fatal or serious injury to the

operator.

CAUTION

This category provides information that, if ignored, could cause injury to the operator or physical damage to the plotter.

Description of Safety Symbols

The symbol indicates information that requires careful attention (which includes warnings).

The point requiring attention is described by an illustration or text within or next to the

symbol.

The symbol indicates action that is prohibited. Such prohibited action is described by an

illustration or text within or next to the symbol.

The symbol indicates action that must be performed. Such imperative action is described by

an illustration or text within or next to the symbol.

i

Page 3

Safety Precautions

y

WARNING

During a plotting operation, do not touch the Y bar,

carriage, and other moving parts.

• Such action may cause human injury.

No touching

Even when the plotter is stopped, it may suddenly

start operating if it receives data, so be sure to

keep your hands, hair, and so forth away from the

vicinity of the plotter’s moving parts such as the Y

bar and the pen carriage.

• Such action may cause human injury.

Keep away

Do not connect the plotter to a non-rated power

supply.

• Use of a different supply voltage may result in electrical shock or a fire hazard due to current leakage.

Do not disassemble or remodel the plotter.

• Such action may cause electrical shock or a fire hazard due to current leakage.

• Contact with the high-voltage parts within the plotter

may cause electrical shock.

• If the plotter requires repair, contact your sales representative or nearest vendor.

No disassembl

Do not use the plotter in a location where it will be

exposed to water, rain or snow.

• Such location may cause electrical shock or a fire

hazard due to current leakage.

Avoid water

Use prohibited

If the plotter generates smoke, is too hot, emits a

strange odor, or otherwise functions abnormally,

do not continue using it. Turn off its power and

unplug its power cable from the electrical socket.

• Use of the plotter in such status may

result in a fire hazard or electrical

shock.

Prohibited

• After confirming that smoke is no longer being generated, contact your sales

representative or nearest

vendor to request repair.

• Never try to perform repair

yourself. Repair work by inexperienced personnel is

extremely dangerous.

Beware of electrical shock

Do not allow dust or metallic matter to adhere to

the power plug.

• A dirty power plug may result in electrical shock or a

fire hazard due to current leakage.

Prohibited

Beware of electrical shock

Do not use the power cable if it is damaged.

• Use of a damaged cable may result in electrical shock

or a fire hazard due to current leakage.

• Replace the power cable with a new one.

Unplug the power

cable from the socket

ii

Page 4

Safety Precautions (Continued)

CAUTION

Do not use or store the plotter in a location exposed to direct sunlight or the direct draft of an air

conditioner or heater.

• Such location may impair the performance of the plotter.

Prohibited

Do not place any receptacle containing water or

other fluid on top of the plotter.

• Fluid falling inside the plotter may cause electrical

shock or a fire hazard due to current leakage.

Avoid water

Beware of electrical shock

When disconnecting the power cable or an interface cable, do not pull on the cable.

• Such action will damage the cable, resulting in a fire

hazard or electrical shock. Be sure to hold the power

cable’s plug or the interface cable’s connector.

Do not use or store the plotter in an excessively

dusty or humid location.

• Such location may impair the performance of the plotter.

Prohibited

Do not install, use, or store the plotter in a location subject to excessive mechanical vibration or

electrical noise.

• Such location may impair the performance of the plotter.

Prohibited

If water or foreign matter enters inside the plotter,

do not continue using it. Turn off its power and unplug its power cable from the electrical socket.

• Use of the plotter in such status may result in electrical shock or a fire hazard due to current leakage.

• Contact your sales representative or nearest vendor

to request repair.

Prohibited

Do not attempt to lubricate the plotter’s mechanisms.

• Such action may cause it to break down.

Prohibited

Unplug the power

cable from the socket

Do not clean the plotter using a volatile solvent

(such as thinner or benzene).

• Such action may impair its performance.

T

h

i

n

Prohibited

n

e

r

e

n

e

z

n

e

B

iii

Page 5

Safety Precautions (Continued)

CAUTION

Be sure to use Graphtec ink pen tips only.

• Using non-Graphtec pen tips may lower the performance or cause a malfunction or a failure.

Prohibited

Do not disassemble the ink tip.

• Such action may cause a failure.

No disassembly

Always clean the pen caps.

• Dried ink may clog the pen tip and make it unusable.

Do not put magnetic cards, magnetic tapes and

floppy disks etc. close to the pen carriage and pen

station.

• Such action may corrupt data because these parts

contain magnets.

Prohibited

Do not attach or remove the pen to/from the pen

carriage.

• Such action may cause a malfunction.

Prohibited

Clean the

pen caps

iv

Page 6

WARNING:

The United States Federal Communications Commission has specified that the following notice must be brought

to the attention of users of this product.

FEDERAL COMMUNICATIONS COMMISSION RADIO FREQUENCY

INTERFERENCE STATEMENT

NOTE : This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct the interference at

his own expense.

USE SHIELDED CABLES

To comply with FCC Class A requirements, all external data interface cables and connectors must be properly

shielded and grounded. Proper cables and connectors are available from GRAPHTEC’s authorized dealers or

manufacturers of computers or peripherals. GRAPHTEC is not responsible for any interference caused by

using cables and connectors other than those recommended or by unauthorized changes or modifications to

this equipment. Unauthorized changes or modifications could void the user’s authority to operate the equipment.

v

Page 7

Selecting a Power Cable

Be sure to refer to the following tables if you wish to use a cable other than the one supplied as an accessory.

Table 1 100 V to 120 V Power Supply Voltage Range

Supply

Plug Configuration

Plug Voltage Reference

Type Selector Standards

Settings

Power Cable

North

America

125 V

100/120 V UL498/817/62 Type SJT

10 A

Table 2 200 V to 240 V Power Supply Voltage Range

Supply

Plug Configuration

Plug Voltage Reference

Type Selector Standards

Settings

Europe CEE(7)VII

250 V 200 V IEC320

10 A CEE13

UK BS1363

250 V 200 V BS4491

5 A BS6500

ANSI C73.11 UL Listed

NEMA 5-15

CSA22.2 No.18AWG x 3

NO.42/21/49 300 V, 10 A

Power Cable

TYPE: H05VV-F

3 x 1.0 mm

TYPE: H05VV-F

3 x 1.0 mm

2

2

Australia AS3112 TYPE: OD3CFC

250 V 200 V AS3109

10 A AS3191

North

America

250 V

15 A

200 V NEMA 6-15 Type SJT

ANSI C73.20

UL 198.6 No.18AWG x 3

Switzerland SEV1011

250 V 200 V SEV1004

6 A SEV1012

3 x 1.0 mm

UL Listed

300 V, 10 A

TYPE: H05VV-F

3 x 0.75 mm

2

2

vi

Page 8

PREFACE

Thank you for purchasing the MP303-04 plotter. This pen plotter incorporates a digital servo drive to perform

plotting operations at high speed and high precision.

To ensure optimum use of its various functions, be sure to read this manual thoroughly before use.

■ Notes on the Use of This Manual

(1) All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmit-

ted.

(2) The specifications and other information in this manual are subject to change without notice.

(3) While every effort has been made to supply complete and accurate information about this product, please

address any inquiries about unclear information, possible errors, or other comments to Graphtec Corpora-

tion.

(4) Notwithstanding the preceding paragraph, Graphtec Corporation assumes no liability for damages result-

ing from the use of the information contained herein or of the product.

■ Registered Trademarks

The names of companies, logos, and products mentioned herein are registered trademarks or trademarks of

their respective companies.

■ Copyrights

All copyrights regarding this manual belong to Graphtec Corporation.

h-1

Page 9

Unpacking Your Plotter

After unpacking your plotter and before actual use, be sure to visually inspect the plotter and to confirm the

presence of all standard accessories.

■ Visual inspection

Carefully check the exterior of the plotter. If you detect a flaw or other defect, please contact the vendor where

you purchased this plotter.

■ Checking the standard accessories

Make sure that you have all the parts listed in the following table. If any part has been omitted, please contact

your vendor.

Exterior View Part Name Description Qty.

1 AC adapter SA45-3129 1

2 Cable AC cable 1

3 USB cable (1.5 m) CBL0106-1-5M 1

4

5 Plotting paper Coated paper (PL501) 5 sheets

6 Soft plastic cover For MP303-04 plotters 1

Water based KF550-S1

fiber-tip pens (

2 of black, 1 each of red, blue, green

)

1 pack

7

Paper alignment To mark positions on the writing

stickers panel for paper alignment (8 stickers)

h-2

1 sheet

Page 10

Exterior View Part Name Description Qty.

8 Rubber insert 8

9 Tilt stand

QuickStart Manual

10 and 1 each

Usage Precautions

11 User guide CD-ROM 1

To stand an MP303-04 plotter

at a 60° angle

2

h-3

Page 11

Special Features

The MP303-04 is an A3-format flatbed plotter that provides high performance for diverse applications at low

cost.

The MP303-04 comes with a digital-servo drive system and a 32-bit CPU, achieving a maximum plotting speed

of 700 mm/second at a mechanical resolution of 0.005 mm.

■ High-speed, high-quality plotting

A digital servo drive system and a 32-bit CPU combine to produce detailed plots with smooth curves at a

maximum plotting speed of 700 mm/s (in all directions) and a mechanical resolution of 0.005 mm.

■ Various functions ensure clearly-defined plots

A wide variety of functions come standard to ensure clearly-defined plots, including the Auto Pen Cap function

which prevents pens at the pen station from drying up when not in use and a mechanical soft-landing mechanism that extends the pen's lifetime while providing a quieter working environment. The plotting speed and pen

force most suitable for the pen type being used can be easily selected from the control panel.

■ Interface conditions are easily set

The interface mode (USB, RS-232C serial or Centronics-compatible parallel) is automatically selected when

the plotter is connected to a computer via the respective interface connector.

Even if multiple data are sent via both the Centronics and the RS-232C interfaces, the data that arrived later is

discarded and overwriting of data will not occur. In addition, as the plotter comes equipped with three preset

modes for the RS-232C interface conditions setting, most major CAD software can be used by just selecting

one of these modes.

When the MP303-04 is set to Auto RS-232C mode, you just need to send plot data from the computer; the RS232C settings are automatically selected so no bothersome settings are required.

■ Upright installation possible

To conserve space, the plotter can be mounted on a pair of stands (provided as a standard accessory) for

installation at a 60° angle.

■ Interactive operation

Various functions can be set interactively by using the panel keys according to messages and prompts appearing on the display.

■ Vector sorting function

This function speeds up plotting by minimizing the distance the pen travels in raised status from the end point of

one line to the starting point of the next line.

■ Pen sorting function

To speed up plotting by reducing the number of pen exchanges required, this function reorganizes the sequence in which plotting is performed so that each color is completely plotted before selecting the next pen.

h-4

Page 12

CONTENTS

PREFACE ........................................................................................................................ h-1

Unpacking Your Plotter ........................................................................................................................... h-2

■ Visual inspection ................................................................................................................................ h-2

■ Checking the standard accessories ................................................................................................... h-2

Special Features .................................................................................................................................... h-4

■ High-speed, high-quality plotting ................................................................................................... h-4

■ Various functions ensure clearly-defined plots .............................................................................. h-4

■ Interface conditions are easily set.................................................................................................. h-4

■ Upright installation possible ........................................................................................................... h-4

■ Interactive operation ...................................................................................................................... h-4

■ Vector sorting function ................................................................................................................... h-4

■ Pen sorting function ....................................................................................................................... h-4

1. SETTING UP YOUR PLOTTER ...................................................................................1-1

1.1 Description of Parts ....................................................................................................................... 1-1

1.2 Installation (Using the Tilt Stands) ................................................................................................. 1-4

1.3 Mounting the Pens ......................................................................................................................... 1-5

1.4 Turning the Power On .................................................................................................................... 1-7

1.5 Loading the Paper.......................................................................................................................... 1-9

1.6 Testing the Plotter ........................................................................................................................ 1-10

1.7 Connecting to Your Computer ...................................................................................................... 1-11

2. SETTING THE BASIC FUNCTIONS ...........................................................................2-1

2.1 Selecting the Command Mode ...................................................................................................... 2-2

2.2 Setting the Paper Size ................................................................................................................... 2-3

2.3 Setting the Programmable Resolution ........................................................................................... 2-4

2.4 Selecting the Sorting Mode ........................................................................................................... 2-5

2.5 Setting the Pen Speed Mode ......................................................................................................... 2-7

2.6 Setting the Pen-Up Speed Mode ................................................................................................... 2-8

2.7 Setting the Interface ....................................................................................................................... 2-9

3. PLOTTING OPERATIONS .......................................................................................... 3-1

3.1 Operating Modes ........................................................................................................................... 3-2

3.2 Setting the Pen Speed and Pen Force ........................................................................................... 3-4

3.3 Scaling and Mirror-Image Plots (P1 and P2) ................................................................................. 3-7

3.4 Moving the Origin (OFFSET) ......................................................................................................... 3-9

3.5 Raising and Lowering the Pen ..................................................................................................... 3-11

3.6 Pen Selection from the Control Panel .......................................................................................... 3-12

4. PENS AND PAPER .....................................................................................................4-1

4.1 Types and Features of Pens .......................................................................................................... 4-1

4.2 Construction and Use of Each Pen Type ....................................................................................... 4-3

4.3 Paper Features .............................................................................................................................. 4-6

4.4 Compatibility Between Pens and Paper ......................................................................................... 4-7

Page 13

5. MAINTENANCE AND TROUBLESHOOTING ............................................................5-1

5.1 Daily Maintenance ......................................................................................................................... 5-1

5.2 Storing Your Plotter ........................................................................................................................ 5-1

5.3 The Power is Turned On But the Plotter Doesn't Operate .............................................................. 5-2

5.4 After Connection to the Computer, the Plotter Operates Abnormally ............................................ 5-3

5.5 Pen Replacement is Abnormal ...................................................................................................... 5-6

5.6 Plotted Results are of Poor Quality ................................................................................................ 5-6

5.7 Problems Related to Pens and Paper ............................................................................................ 5-7

5.8 The Error Messages .................................................................................................................... 5-10

5.9 GP-GL Command Errors ............................................................................................................. 5-11

5.10 HP-GL™ Command Errors .......................................................................................................... 5-12

APPENDIX A. SUPPLIES AND OPTIONS...................................................................... A-1

A.1 Pens ............................................................................................................................................... A-1

A.2 Plotting Media ................................................................................................................................ A-2

APPENDIX B. SPECIFICATIONS ................................................................................... B-1

APPENDIX C. EXTERNAL DIMENSIONS ...................................................................... C-1

Page 14

1. SETTING UP YOUR PLOTTER

This chapter presents instructions on how to initially set up your plotter, including how to install the plotter, load

paper, mount the pens, and check the plotter's operation using the self-test.

The self-test, which you can run even if the plotter is not connected to a computer, checks whether or not the

plotter's basic functions are operating properly.

1.1 Description of Parts

Top view of the MP303-04

(1) Pen station .................. Holds pens ready for use.

(2) Control panel ............... Contains the keys used for controlling the plotter's operations.

(3) Pen carriage................ Holds the currently selected pen.

(4) Y bar ........................... This sliding bar travels left and right to move the pen carriage and enable plotting.

(5) Writing panel ............... Holds the plotting paper using an electrostatic adhesion panel.

(6) Display ........................ The MP303-04's liquid-crystal display allows functions to be set interactively.

1-1

Page 15

Side view of plotter Rear view of plotter

(7) AC inlet ....................... Plug the AC adapter into this AC line inlet.

(8) Power switch ............... This switch controls the ON/OFF status of the plotter's power supply.

(9) RS-232C connector .... To use the RS-232C serial interface, connect your computer to the plotter via this

connector.

(10) Centronics connector .. To use the Centronics-compatible parallel interface, connect your computer to the

plotter via this connector.

(11) USB connector ............ To use the USB interface, connect your computer to the plotter via this connector.

1-2

Page 16

■ The Control Panel

The features of the MP303-04's control panel and LED lamps are briefly described in the following.

MP303-04 keys

(1) POSITION keys................ Move the pen carriage in the direction indicated by each key.

These keys are also used to set functions at the display.

(2)

ENTER

(3)

PAUSE

(4)

CANCEL

(5)

MODE

(6)

CHART HOLD

(7) POWER/PROMPT lamp .. Lights when the power is turned on.

(8) PAUSE lamp..................... Lights to indicate that plotting is temporarily suspended.

(9) CHART HOLD lamp ......... Lights to indicate that the paper is being held by electrostatic adhesion.

key .................... Completes input of the function being set.

key .................... Press to temporarily stop plotting and press again to resume plotting.

key ................. To cancel a setting shown on the display, press this key instead of the

key.

key...................... Press to change the POSITION key modes.

(Pen carriage position mode ↔ Function mode)

key ....... Press to secure or release paper.

Blinks to prompt you to press the

has occurred.

ENTER

key or to inform you that an error

ENTER

1-3

Page 17

1.2 Installation (Using the Tilt Stands)

This plotter can be used in either a horizontal position or an upright position at a 60° tilt.

■ For Horizontal Use

Be sure to install the plotter on a stable, flat surface for use.

Installation space: 67 mm x 45 mm

■ Using the Tilt Stands

Mount the plotter on the tilt stands provided with this plotter by following the steps below.

(1) Insert the two hooks in each stand into the holes in the plotter's base, and then gently pull each stand

upward to securely hook the stand into the plotter.

(2) Be sure to install the stand and plotter on a stable, flat surface.

Installation space: 67 mm x 32 mm

1-4

Page 18

1.3 Mounting the Pens

■ Mounting a Pen in the Pen Station

Fit the pen's lower groove into the notched section of the pen station. Be sure to mount the pen so that its pen

cap is pressed down and its pen tip is completely inside the pen cap.

The figures below show examples of a correctly mounted pen.

A correctly mounted pen

When mounting a pen, there should be no gap between the pen station's notched section and the pen (shown

below on the left) and the pen should not be outside of its pen cap (shown below on the right). An incorrectly

mounted pen may cause unsatisfactory plotted results or plotter malfunctions.

Incorrectly mounted pen

NOTE

Whenever possible, try to consistently use the same Pen No. for a specific color. If you mount another pen

of a different color, the ink of the previous pen will adhere to the tip of the newly mounted pen and may

cause the pen to initially plot lines of mixed colors.

1-5

Page 19

■ Removing a Pen

Facing the plotter so that the pen station is on your left, remove the pen by gently pulling it out to the right and

toward you along the notched section of the pen station.

■ Using the rubber inserts for the pen caps

Your plotter is provided with eight rubber inserts for the pen caps. Each rubber insert is placed inside the pen

caps in the pen station to prevent the ink in the mounted pen from drying up. Be sure to use these rubber inserts

only when using high-speed ceramic pens, refillable ink pens, or disposable ink pens. Never use the inserts with

water-based fiber-tip pens.

When a rubber insert is placed inside a pen cap, the tip of the mounted pen will lightly touch the rubber insert,

thus better maintaining the pens' conditions than when rubber inserts are not used.

Especially when using refillable ink pens, disposable ink pens or high-speed ceramic pens, be sure to use

rubber inserts, otherwise the pen tips may dry up or drip in the caps.

Mounting the rubber inserts

Use the tweezers provided to hold the rubber insert as shown below, then place it inside a pen cap at the pen

station.

When the rubber insert is mounted, the pen tip will contact the rubber insert as shown below.

NOTE

• Whenever possible, try to consistently assign the same color pens to each Pen No. If you mount another

pen of a different color, the ink of the previous pen (which will still be on the rubber insert) will adhere to

the tip of the newly mounted pen and may cause plotting to initially be performed using a mixed color.

Also be sure to periodically wash the rubber inserts for the pen caps with water to clean off any residual

ink.

• If you will not use the plotter for a long time, be sure to remove the pens from the pen station and cap

them.

1-6

Page 20

1.4 Turning the Power On

CAUTION

(1) Check that the power switch is off (the “O” side should be down). If a pen is attached to the pen carriage,

remove the pen and return it to its position at the pen station.

(2) Plug the AC adapter into the plotter's AC inlet, then plug the other end of the cord into an electrical outlet

of the rated supply voltage.

(3) Turn on the plotter by pressing the "I" side of the power switch. The control panel's POWER lamp lights.

When the plotter is turned on, if the POWER lamp blinks, the plotter makes an abnormal noise, or it does

not function at all, immediately turn off the plotter and follow the instructions in section 5.3, “The Power is

Turned On But the Plotter Doesn't Operate.”

1-7

Page 21

(4) The plotter is initialized and the pen carriage stops at the upper right corner of the writing panel.

You are now ready to load the plotting medium.

■ Initialization

During initialization, the pen carriage moves in the sequence of the arrows shown in the figure below and the

origin for plotting is automatically set. The friction coefficients of the plotter mechanisms are also automatically

detected and adjusted.

1-8

Page 22

1.5 Loading the Paper

The MP303-04 holds paper using electrostatic adhesion.

(1) Turn on the plotter.

(2) After the plotter is initialized, the pen carriage stops at the upper right corner of the writing panel and the

prompt below is displayed.

Set

Paper!

(3) Place the sheet in the desired position on the writing panel and then press the

CHART HOLD lamp lights) to hold the sheet.

(4) If any air is trapped between the paper and writing panel, force it out with the palm of your hand. This

completes paper loading.

(5) To remove the paper from the writing panel, check that plotting is completed and then press the

CHART HOLD

upper right corner, remove the sheet.

key (the CHART HOLD lamp goes off). After the pen carriage stops at the writing panel's

CHART HOLD

key (the

1-9

Page 23

1.6 Testing the Plotter

Your plotter comes with a self-test mode, which enables the plotter to check its own functions, without necessarily being connected to the computer.

A correctly drawn test pattern signifies that all of the functions of the plotter (excluding the interface functions)

have been tested and found normal. Be sure to run this self-test before connecting the plotter to the computer.

Procedure

(1) Check that the POWER switch is off (“O”) and that pens are mounted in the pen station.

(2) Turn on the POWER switch while holding down the POSITION key.

The plotter is initialized.

The prompts below are consecutively displayed.

SelfTest

Mode

Set

Paper!

(3) After the initialization, place a sheet of paper on the writing panel.

Press the

CHART HOLD

key to secure the sheet. The prompt below is displayed.

Press

Ent key

(4) Press the

The plotter repeatedly plots the same pattern until you cancel the self-test mode.

To temporarily stop plotting, press the

To cancel the self-test mode, press the

ENTER

key to draw the self-test pattern.

PAUSE

CANCEL

Sample printout of the self test pattern

key.

key to stop plotting and then turn off the plotter.

HINT

In the above sample, the characters in parentheses following “TEST OF PLOTTER” signify the Version No.

of the plotter's ROM and the selected command set. The second line describes the currently selected

interface (RS-232C) and, if the RS-232C interface is selected, the serial interface conditions (User-1 conditions, 9600 bps, even parity, 8-bit data length, and hardwire handshaking).

1-10

Page 24

1.7 Connecting to Your Computer

The plotter can be connected to a computer via the parallel (Centronics-compatible) port, serial (RS-232C)

port, or USB port. Select which port to use according to the requirements of your application software and/or

which of your computer's interface ports are available for use.

Use a Centronics-compatible parallel cable, serial cable, or USB cable in accordance with the connection

method chosen. Obtain a Graphtec-approved interface cable that is compatible with the interface ports

(Centronics-compatible parallel and serial cables are available separately).

(1) Check to confirm that the Power switch is turned off (the “O” side is down).

(2) Connect the cable between the plotter and the computer. Make sure the connectors at the plotter and

computer ends are correctly oriented.

1-11

Page 25

2. SETTING THE BASIC FUNCTIONS

This chapter describes how to set your plotter's basic functions. Procedures for setting the following functions

are provided in this chapter.

(1) Command mode

(2) Paper size

(3) Programmable resolution

(4) Pen/Vector sorting

(5) Pen speed mode

(6) Interface conditions

■ Setting

The basic functions are set using the panel keys while observing the display. The MP303-04 comes with its

basic functions set as follows.

Baud rate : 9600 bps MP303-04 display

Handshake mode : Hardwire

Data length : 8 bits

Parity : Even

Command mode : FP-GL

Paper size : ISO A3

Programmable resolution : 0.1 mm (100 µm)

Vector/Pen sorting : ON

Pen speed mode : Manual (ignore command input specifying the pen speed)

Pen-up speed mode : NormalSp

2-1

Page 26

2.1 Selecting the Command Mode

Just as there are programming languages used for controlling the operation of a computer, there are also

programming languages that are specifically designed for use with plotters.

This plotter has three resident command sets: two sets of Graphtec commands (MP-GL and FP-GL) plus HPGL™ emulation commands that enable your plotter to emulate a Hewlett-Packard 7475A plotter. Set the command mode to match the commands used in your application program.

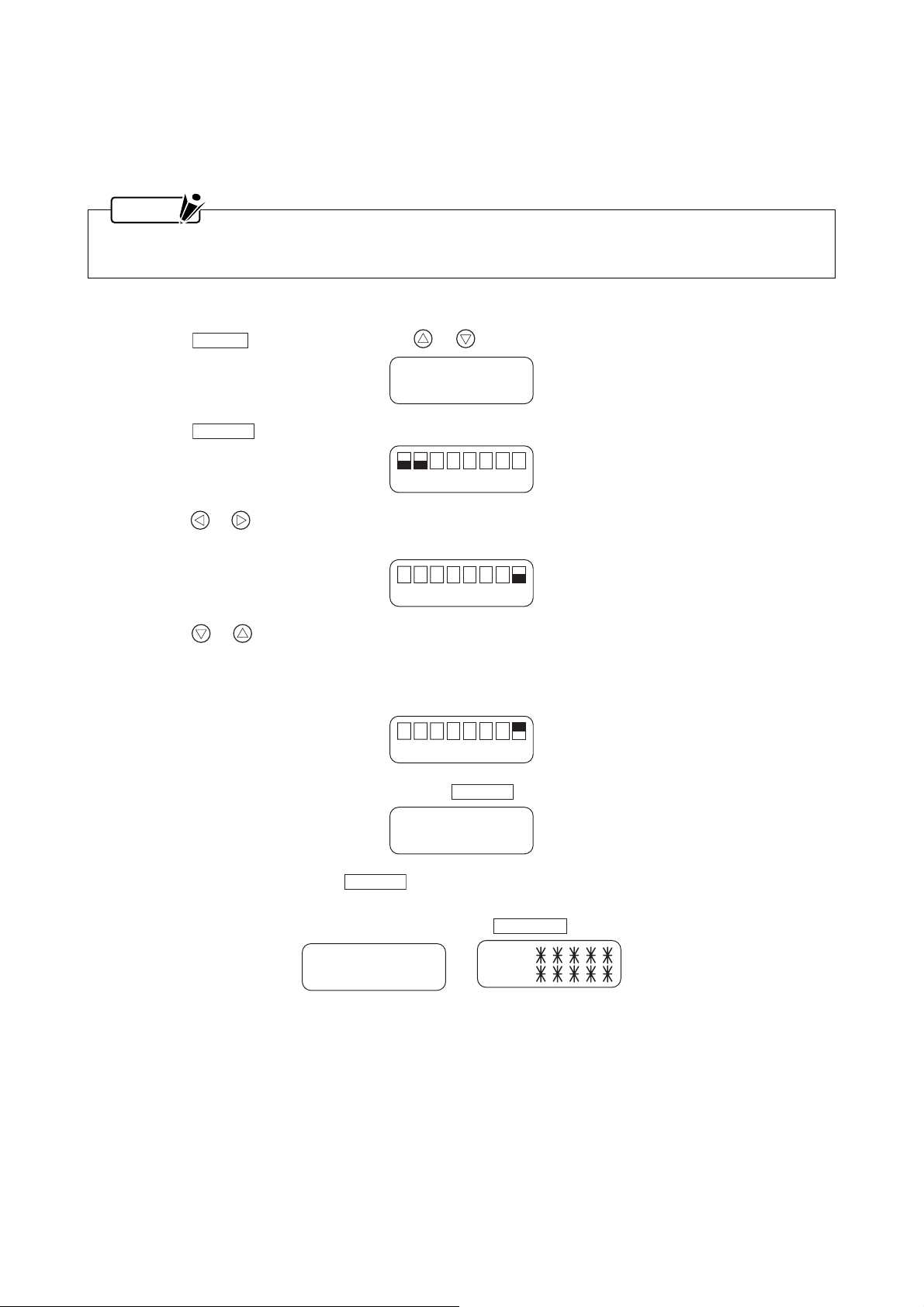

(1) Press the

MODE

key and then press the or key to display the message below.

Setup

DipSW.

(2) Press the

mand mode (in this example, FP-GL).

ENTER

key to display the command selection menu that shows the currently selected com-

FP-GL

(3) Each time the or key is pressed, the command mode setting changes in the sequence shown below

(the bits which affect command mode selection blink).

MP-GL

HP-GL

------

(4) When the desired mode is displayed, press the

ENTER

Reset?

ENTorCAN

(5) If the setting is correct, press the

to take effect. To cancel the setting and return to Step (1), press the

ENTER

ReadyReady

key. Pressing the key resets the plotter to allow your new setting

X=

or

Y=

key. The prompt below appears.

CANCEL

key.

2-2

Page 27

2.2 Setting the Paper Size

Set the paper size to match the plotting medium to be used.

(1) Press the

MODE

key and then press the or key to display the message below.

Setup

DipSW.

(2) Press the

appears).

(3) Press the or key to display the paper size menu and the currently selected paper size (in this

example, ISO A3).

ENTER

key to display the command selection menu (the currently selected command mode

(command mode)

ISO A3

(4) Each time the or key is pressed, the paper size setting changes in the sequence shown below (the

bits which affect the paper size setting blink).

ANSI B

ISO A4

Expand

(5) When the desired size is displayed, press the

Reset?

ENTorCAN

(6) If the setting is correct, press the

to take effect.

To cancel the setting and return to Step (1), press the

ENTER

key. Pressing the key resets the plotter to allow your new setting

ReadyReady

ENTER

X=

or

Y=

key. The prompt below appears.

CANCEL

key.

2-3

Page 28

2.3 Setting the Programmable Resolution

When the command mode is set to Graphtec's GP-GL commands (MP-GL or FP-GL), the programmable resolution of the plotter, which determines the minimum distance the pen moves when the numeric value 1 is sent

from the computer, can be set to either 0.1 mm or 0.025 mm (100 or 25 µm).

(1) Press the

MODE

key and then press the or key to display the message below.

Setup

DipSW.

(2) Press the

displayed).

(3) Press the or key until the “Step” menu is displayed. In this example, 100 mm (0.1 mm) is the

currently selected resolution.

ENTER

key to display the command selection menu (the currently selected command mode is

(command mode)

Step 100

(4) Press the or key to switch the programmable resolution between 100 µm and 25 µm (the bit which

affects the resolution setting blinks).

Step 25

(5) When the desired resolution is displayed, press the

ENTER

key. The prompt below appears.

Reset?

ENTorCAN

(6) If the setting is correct, press the

to take effect.

To cancel the setting and return to Step (1), press the

ENTER

ReadyReady

key. Pressing the key resets the plotter to allow your new setting

key.

or

CANCEL

X=

Y=

This setting becomes effective when the command mode is set to GP-GL commands.

When the command mode is HP-GL™ commands, even if the resolution is set to 0.1 mm, 0.025 mm will be

automatically selected.

2-4

Page 29

2.4 Selecting the Sorting Mode

The MP303-04 comes equipped with a sorting function that controls the on/off status of both pen sorting and

vector sorting.

■ Pen sorting

To speed up plotting by reducing the number of pen exchanges required, this function reorganizes the sequence in which plotting is performed so that each color is completely plotted before selecting the next pen.

■ Vector sorting

This function speeds up plotting by minimizing the distance the pen travels in raised status from the end point of

one line to the starting point of the next line.

HINT

If plotting is performed with sorting mode enabled, the sequence in which lines are plotted or pens are

exchanged will be changed. When you wish to perform plotting in the exact sequence specified in your

application program, turn off the sorting function.

■ Procedure

Enable or disable the sorting function as described below.

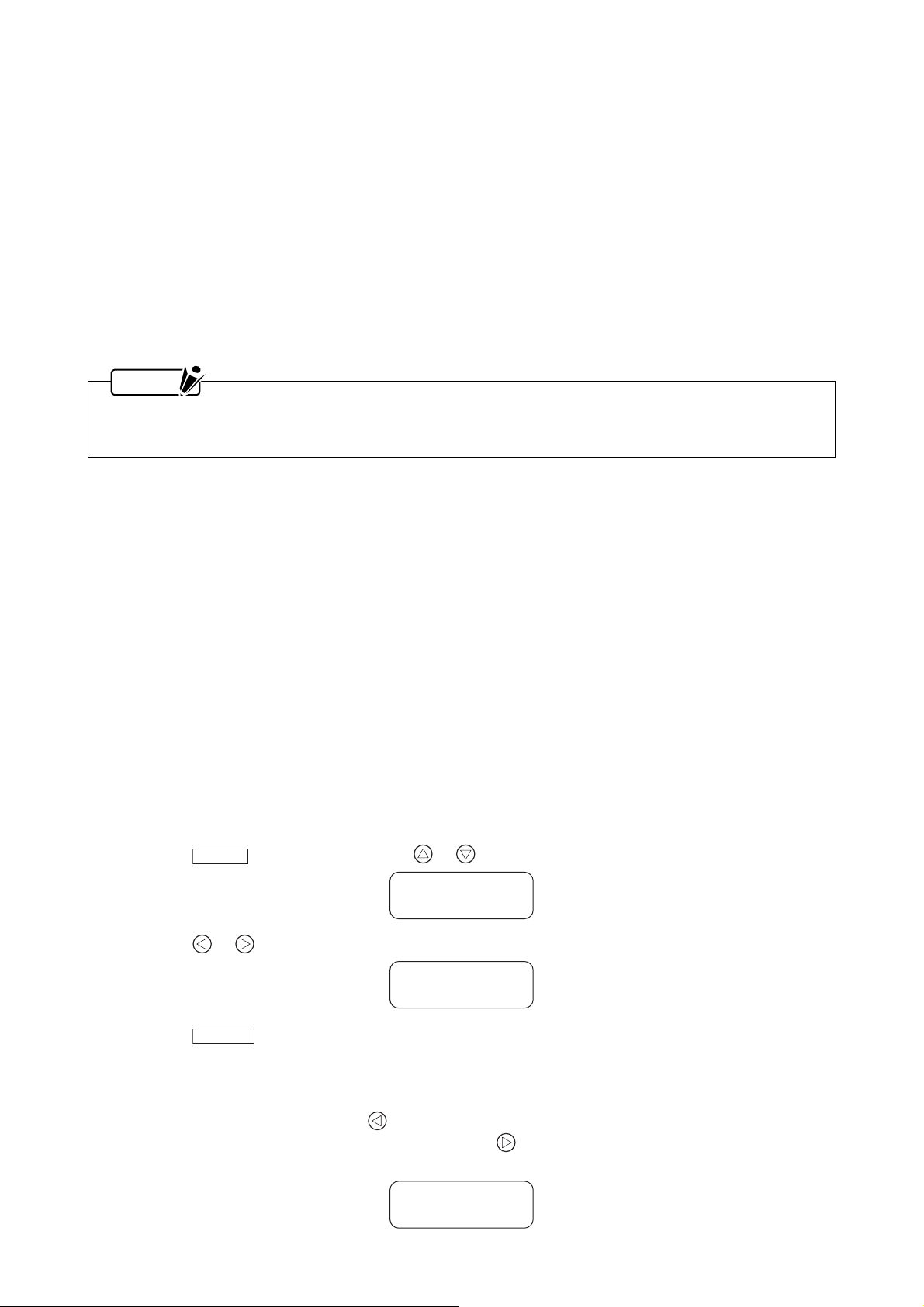

(1) Press the

MODE

key and then press the or key to display the message below.

Setup

DipSW.

(2) Press the

displayed).

(3) Press the or key until the “Sort” menu is displayed. In this example, pen sorting and vector sorting

are currently enabled.

ENTER

key to display the command selection menu (the currently selected command mode is

(command mode)

Sort On

(4) Press the or key to switch the Sorting mode between On and Off (the bit which affects the sorting

setting blinks).

Sort On : Enables pen sorting and vector sorting.

Sort Off : Disables pen sorting and vector sorting.

Sort Off

(5) When the desired status is displayed, press the

Reset?

ENTorCAN

ENTER

2-5

key. The prompt below appears.

Page 30

(6) If the setting is correct, press the

to take effect.

To cancel the setting and return to Step (1), press the

ENTER

key. Pressing the key resets the plotter to allow your new setting

CANCEL

key.

ReadyReady

or

X=

Y=

2-6

Page 31

2.5 Setting the Pen Speed Mode

The pen speed mode can be set to Manual or Program mode.

Program mode: Command input specifying the pen speed will override the pen speed setting that was manually

selected at the plotter's control panel.

Manual mode : The pen speed setting that was manually selected at the control panel remains effective and

command input specifying the pen speed will be ignored.

■ Procedure

(1) Press the

MODE

key and then press the or key to display the message below.

Setup

DipSW.

(2) Press the

displayed).

(3) Press the or key until the “Speed” menu is displayed. In this example, the pen speed mode is

currently set to M (Manual).

ENTER

key to display the command selection menu (the currently selected command mode is

(command mode)

Speed M

(4) Press the or key to switch the pen speed mode between M and P (the bit which affects the pen

speed mode setting blinks).

Speed M : Selects “Manual” pen speed mode.

Speed P : Selects “Program” pen speed mode.

Speed P

(5) When the desired status is displayed, press the

ENTER

key. The prompt below appears.

Reset?

ENTorCAN

(6) If the setting is correct, press the

to take effect.

To cancel the setting and return to Step (1), press the

ENTER

key. Pressing the key resets the plotter to allow your new setting

ReadyReady

or

2-7

CANCEL

X=

Y=

key.

Page 32

2.6 Setting the Pen-Up Speed Mode

The pen in the raised status can be moved at the maximum speed of both the X and Y axes. Thus, plotting that

includes a lot of diagonal movement takes less time.

NOTE

This function is less effective for plotting that does not include much pen-raised movement.

■ Procedure

(1) Press the

MODE

key and then press the or key to display the message below.

Setup

DipSW.

(2) Press the

ENTER

key to display the command selection menu.

FP-GL

(3) Press the or key until the Pen-up speed mode menu is displayed. In this example, the Pen-up speed

mode is currently set to NormalSp (normal speed).

NormalSp

(4) Press the or key to switch the Pen-Up speed mode between HiSpeed and NormalSp (the bit which

affects the Pen-Up speed mode setting blinks).

HiSpeed : Selects high speed mode.

NormalSp : Selects normal speed mode.

HiSpeed

(5) When the desired status is displayed, press the

ENTER

key. The prompt below appears.

Reset?

ENTorCAN

(6) If the setting is correct, press the

to take effect.

To cancel the setting and return to Step (1), press the

ENTER

key. Pressing the key resets the plotter to allow your new setting

ReadyReady

or

2-8

CANCEL

X=

Y=

key.

Page 33

2.7 Setting the Interface

CAUTION

This plotter is provided with three types of interfaces for connection to a computer: a USB interface, a Centronicscompatible parallel interface and an RS-232C serial interface.

■ Setting the USB Interface

When using the USB interface to transfer data, you must have the driver that supports the USB port installed on

the computer (a USB cable is supplied with the plotter). For information on installing the USB driver, refer to the

explanation in the supplied CD-ROM.

On the plotter, simply set the command mode and the programmable resolution (when a GP-GL command set

is selected).

Compatible OS:

Windows 98/Me, Windows 2000 Professional, Windows XP

NOTE

Windows 3.1, Windows 95 and Windows NT do not support USB.

In the following cases, the plotter may not operate properly:

• When connected to a USB hub or an add-on USB card.

• When used with a self-made computer or an altered computer.

• When operated with other than the supplied driver.

Do not disconnect/connect the USB cable in the following cases:

• While installing the USB driver onto the computer.

• When the computer or the plotter are initializing.

• While the computer is transmitting data to the plotter.

Do not disconnect the USB cable within a 5-second period after connecting it.

Do not connect multiple plotters to a single computer using the USB interface.

■ Centronics-compatible parallel interface

When using the plotter by connecting via the Centronics interface, just connect a cable. No interface settings

are required.

2-9

Page 34

■ Setting the RS-232C Interface Conditions

This plotter can retain six different combinations of RS-232C interface conditions in its internal memory, three of

which can be revised to best suit your application.

Your plotter comes with the conditions of each RS-232C interface mode set to the following settings.

RS mode Interface conditions

RS-1 9600 bps, even parity, 7 bits, Xon/Xoff handshaking

RS-2 9600 bps, no parity, 8 bits, hardwire handshaking

RS-3 9600 bps, odd parity, 8 bits, Xon/Xoff handshaking

USER-1 9600 bps, even parity, 8 bits, hardwire handshaking

USER-2 9600 bps, odd parity, 8 bits, Xon/Xoff handshaking

AUTO 9600 bps, odd parity, 7 bits, hardwire handshaking

NOTE

You can change the settings of the USER-1, USER-2, and AUTO modes, but those of RS-1 through RS-3

cannot be altered.

When you receive your plotter, its functions are set as follows (the RS mode is set to USER-1).

Baud rate : 9600 bps

Handshake mode : Hardwire

Data length : 8 bits

Parity : Even

Command mode : FP-GL

Paper size : ISO A3

Programmable resolution : 0.1 mm (100 µm)

Pen/Vector sorting : On

Pen speed mode : Manual (the pen speed set at the plotter's panel overrides any command

input specifying the pen speed)

Pen-up speed mode : NormalSp

Selecting the RS Mode

To automatically connect to the computer (AUTO mode), to revise the interface conditions of AUTO mode, or to

manually select one of the five other manual modes (USER-1, USER-2, RS-1, RS-2, RS-3), follow the steps

below.

(1) Press the

MODE

key and then press the or key to display the message below.

Setup

DipSW.

(2) Press the or key to display the message below.

Setup

RS232C

(3) Press the

(4) The prompt below appears.

If you wish to manually select one of the five manual RS modes and/or change the settings of USER-1,

USER-2, or AUTO mode, press the key.

To connect to the computer in AUTO mode, press the key and then skip to Step (5) of “When AUTO

Mode is Selected” on page 2-12.

ENTER

key to enable selection of an RS-232C interface mode.

Setting?

Man Auto

2-10

Page 35

Manually Selecting or Changing the Interface Conditions

(5) Pressing the key displays the currently selected interface conditions as shown below.

User-1

96-E8-H

(6) Press the (or ) key to consecutively cycle the display forward (or backward) through the currently

selected interface conditions in the six RS modes.

You can change the settings of USER-1, USER-2, or AUTO while the current settings of the respective

mode are being displayed.

Press the or key to select the interface condition you wish to change (the selected condition blinks).

User-1

96-E8-H

RS-3

96-O8-X

User-2

96-O8-X

RS-2

96-N8-H

Auto

96-O7-H

RS-1

96-E7-X

NOTE

If you wish to cancel your revisions, press the

After selecting the target condition, press the or key to change its setting as shown below.

CANCEL

User-1

192-E8-H

96-O7-X

48 N

24

12

key before proceeding to Step (7).

192 19200 bps baud rate

96 9600 bps baud rate

48 4800 bps baud rate

24 2400 bps baud rate

12 1200 bps baud rate

E Even parity

O Odd parity

N No parity check

8 8-bit data length

7 7-bit data length

H Hardwire handshaking

X Xon/Xoff handshaking

E ENQ/ACK handshaking (HP-GL™ mode only)

(7) Check that the displayed interface conditions of the selected RS mode are correct, then press the

key. The message below is briefly displayed.

ENTER

Setting

OK !

(8) The message below reappears with the characters in the lower row blinking.

Press the

MODE

key to exit the Setup mode.

Setup

RS232C

NOTE

If you wish to connect to the computer in AUTO mode after changing the AUTO mode's interface conditions,

return to Steps (1) through (4) on the previous page and then skip to Step (5) below.

2-11

Page 36

When AUTO Mode is Selected

Setting?

Man Auto

(5) Pressing the key displays the prompt below

Send plot data to the plotter from the computer while this prompt is displayed.

(If the

PAUSE

key is pressed (in local mode), it is automatically reset.)

Send

Data !

(6) If the AUTO mode interface conditions retained in the plotter's internal memory have not been changed,

the plotter displays the current settings followed by the “Online” message to indicate that the plotter can

begin receiving and plotting data from the computer.

OK !

< 96-E8>

Online

(7) If the AUTO mode interface conditions retained in the plotter's internal memory have been changed, the

plotter reads and then briefly displays the new settings, and then displays the “Online” message when it

can begin receiving and plotting data from the computer

OK !

< 96-E8>

(8) If the prompt below appears, stop sending data to the plotter and then press the

ENTER

key.

Retry !

PressEnt

(9) When the plotter recognizes the new settings, the plotter enters Ready mode and the message below

appears. When data is resent from the computer, the plotter enters Online mode and can begin receiving

and plotting data from the computer.

X=

Y=

If the "Ready" Message doesn't Appear after Step (8)

(9) If the plotter doesn't recognize the new settings, the message below appears.

Error!

PressEnt

(10) Press the

Send data to the plotter from the computer while this prompt is displayed.

ENTER

key to display the prompt below and enable the plotter to read the new settings again.

Send

Data !

2-12

Page 37

(11) When the plotter recognizes the new settings, the message below appears briefly. The plotter then enters

Online mode and can begin receiving and plotting data.

OK !

< 96-E8>

(12) If the prompt below appears, stop sending data to the plotter from the computer and then press the

ENTER

key.

Retry !

PressEnt

(13) When the plotter recognizes the new settings, the plotter enters Ready mode and the message below

appears. When data is resent from the computer, the plotter enters Online mode and can begin receiving

and plotting data from the computer.

ReadyReady

■ Precautions on Using AUTO Mode

• When AUTO mode is selected, the plotter may not recognize the selected interface conditions in some

cases. If the AUTO mode interface conditions are not recognized after several retries, manually select

USER-1 or USER-2 mode and set that mode to the desired interface conditions.

• If you wish to exit AUTO mode while the plotter is awaiting data from the computer, either press the

key or reset the plotter (by concurrently pressing the

• If the plotter receives data via the Centronics or USB interface while it is awaiting data via the RS-232C

interface in AUTO mode, the plotter becomes unavailable to receive data for AUTO mode properly. In such

cases, immediately start over from powering on again.

• In AUTO mode, the plotter recognizes all of the currently selected RS-232C interface conditions except for

the handshaking mode. After the plotter reads the AUTO mode settings, if plot data is omitted or inaccurately reproduced during plotting, select USER-1 or USER-2 mode and set the desired handshaking method.

• Do not use AUTO mode if your application program contains a READ command that requests the plotter to

return information about its status, model number, etc. Because the plotter cannot respond to READ commands in AUTO mode, sending a READ command to the plotter causes program execution at the computer

to freeze.

• Only the RS-232C interface conditions can be set for AUTO mode. If you do not correctly set the command

mode and programmable resolution before beginning to plot, a command error may occur or the resulting

plot may not fit correctly into the effective plot area of the paper loaded on the plotter. Before you start

plotting, be sure to also set the command mode and programmable resolution.

ENTER

and keys).

MODE

2-13

Page 38

3. PLOTTING OPERATIONS

This chapter describes how to perform the plotting operations that can be selected at the plotter's control panel.

■ Functions

(1) Moving the pen carriage

Press the POSITION key corresponding to the direction in you wish to move the pen carriage.

(2) Raising/lowering the pen

The pen can be raised or lowered using a displayed menu.

(3) Setting the pen force

The pen force can be switched between HIGH and LOW using a displayed menu.

(4) Setting the pen speed

The pen speed can be set in a range of 1 cm/s to 70 cm/s in 1 cm/s increments using a displayed menu.

(5) Moving the coordinate system's origin

The origin is set using a displayed menu.

(6) Resetting the plotter

Press the

reset the plotter to the status it initially assumes when it is turned on.

(7) Clearing the plotter's internal memory

Press the

clear any data remaining in the plotter's buffer memory.

The following functions are selected interactively using panel keys while viewing a displayed menu.

• Manual pen selection

• Setting of P1 and P2 points

• Setting of RS-232C interface conditions

PAUSE

PAUSE

A pen can be manually selected for retrieval by the pen carriage.

The P1 and P2 points can be set to perform scaling or to plot a mirror image of the plot data.

Three combinations of RS-232C interface conditions can be set to suit different applications.

key and while the PAUSE lamp is lit, press the and

key and while the PAUSE lamp is lit, press the and

ENTER

ENTER

keys concurrently to

keys concurrently to

3-1

Page 39

3.1 Operating Modes

The plotter has five operating modes.

Ready In Ready mode, the plotter is simply waiting for plot data from the computer. It is loaded

with paper and is ready to receive data from the computer.

Online While the plotter is online, it is receiving and plotting data sent from the computer.

Pause If the

PAUS E

key is pressed during a plotting operation, the plotter temporarily sus-

pends plotting and enters Pause mode.

Chart Hold OFF Until the paper is secured, plotting is not performed even if data is sent from the com-

puter.

Setup This mode is assumed by pressing the

PAUS E

key.

The figure below shows a block diagram of the relationship between the various operating modes.

CHART HOLD is off.

Plotting is suspended

until the paper is

secured.

CHART HOLD key

Online

The plotter is

receiving and

plotting data.

Plotting

Receipt of

data

Ready

The plotter is ready to

receive data.

PAU S E

key

Setup mode

(plotting is suspended)

MODE

key

PAUSE

key

Pause

Plotting is

suspended until

Pause mode is

cancelled.

3-2

Page 40

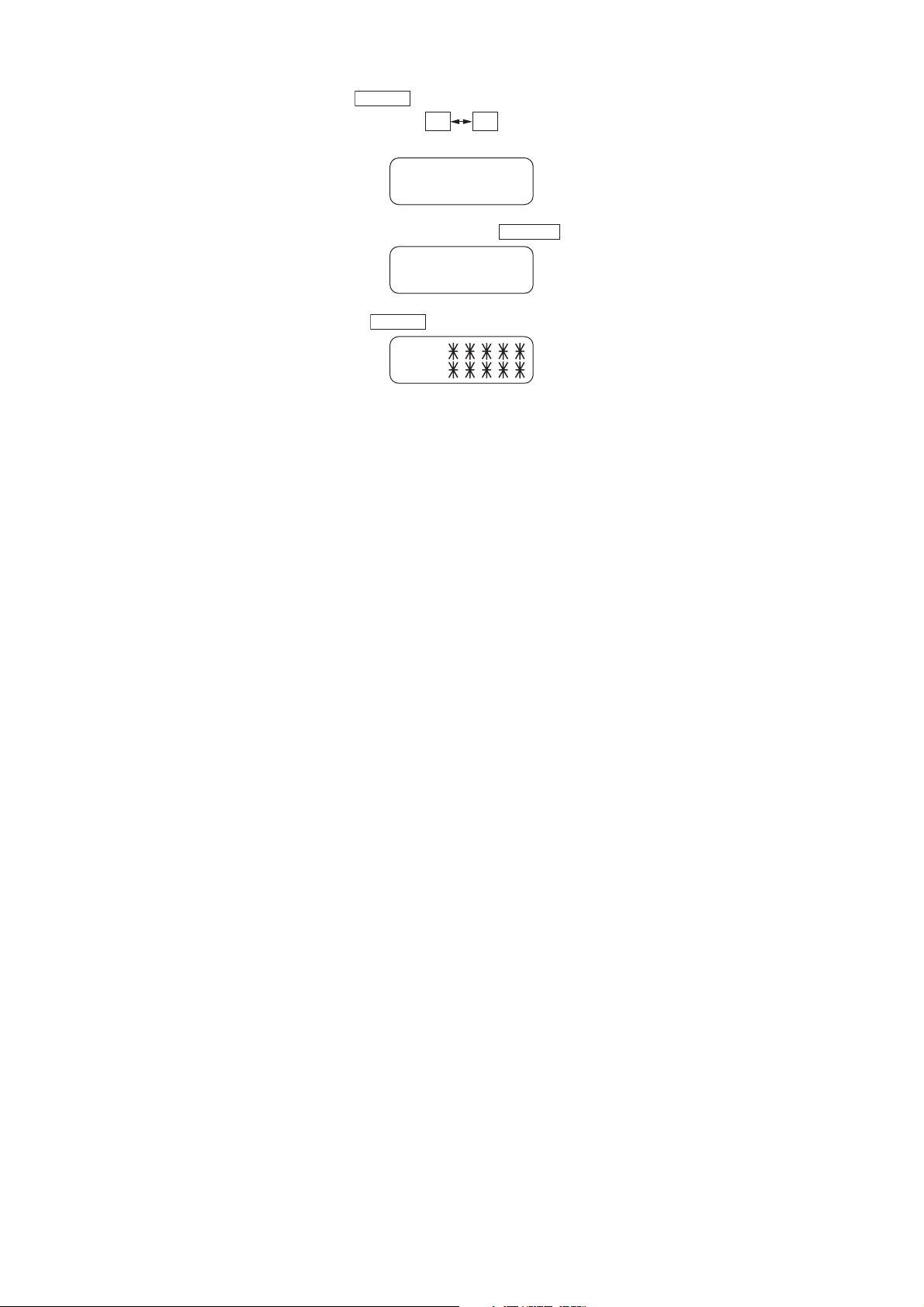

MP303-04 Menu Tree

Pen Type

W.Fiber

ENTER ENTER

Pen Type

Ceramic

No.=ALL

Sp70,FoH

ENTER

Raise the pen. Lower the pen.

ENTER

Ready

Pen Type

D.Ink

ENTER

SetPoint

P1

Pen

Up Down

Pen No.

12345678

Setup

DipSW

X=

or

Y=

MODE

Pen Type

R.Ink

SetPointP2SetPoint

X=

Y=

ENTER

ENTER

ENTER

Pen Type

Manual

ENTER

Offset

ENTERENTER

Select the Pen No. using the and

keys, and press the key

ENTER

to save the selection.

Setup

RS232C

ENTER

FP-GL ISO A3

MP-GL ISO A4

HP-GL

ENTER

ANSI B

Expand

Step 100 Sort On Speed P NormalSP

Step 25 Sort Off Speed M HiSpeed

ENTER ENTER ENTER

ENTER

ENTER

Setting?

Man Auto

User-1

192-E8-H

96-07-X

48 N

24

12

User-2

96-08-X

RS-3

96-08-X

Auto

96-07-H

RS-2

96-N8-H

RS-1

96-E7-X

Select the User No. using the and keys.

On the selected user display, the transfer speed

can be changed by pressing the and keys,

and then by pressing the and keys, the

parity, data length and handshake can be

selected. Finally, press the key to save

ENTER

the setting.

3-3

Page 41

3.2 Setting the Pen Speed and Pen Force

The actual pen speed and pen force vary with the combination of pen and paper types being used and with the

complexity of the plot being produced. To obtain the best plot quality, set the pen speed and pen force to suit the

pen type being used.

The pen force (HIGH or LOW) and the pen speed (1 to 70 cm/s in 1 cm/s increments) can be set using displayed

menus. If you wish your panel setting for the pen speed to override any command input specifying the pen

speed, be sure to set the pen speed mode to “Manual” (see section 2.5, “Setting the Pen Speed Mode”).

The pen force and pen speed are set from displayed menus.

You can either automatically select preset pen force and pen speed settings by specifying the pen type or

manually set the pen force and pen speed (in 1 cm/s increments) for individual pen numbers.

With either method, the pen force can be set to H (HIGH) or L (LOW), whereas the pen speed can be set in a

range of 1 to 70 cm/s.

■ Setting the Pen Speed/Force by Pen Type

This method lets you automatically select predetermined settings for the pen speed and pen force by simply

specifying the pen type. In this case, the same settings will apply to all pen numbers.

The table below lists the pen speed and pen force presets that correspond to each pen type.

Pen type Display Pen speed Pen force

Water-based fiber-tip W.Fiber 70 cm/s H

Refillable ink R.Ink 10 cm/s L

Disposable ink D.Ink 20 cm/s L

High-speed ceramic Ceramic 10 cm/s L

■ Procedure

(1) With the plotter in Ready mode (the coordinates of the current pen position are displayed), press the

MODE

The currently selected pen type is displayed.

key.

Pen Type

W.Fiber

(2) If you wish to change the pen type, press the or key to cycle through the available choices as shown

below. While the pen type is being selected, the pen type being displayed blinks.

W.Fiber

Manual Ceramic

R.Ink

D.Ink

3-4

Page 42

(3) When the desired pen type is displayed, press the

ENTER

key. The message below appears briefly.

Speed

OK!

(4) Finally, the currently selected pen type is displayed (in this case, water-based fiber-tip pens).

Pen Type

W.Fiber

(5) To return to Ready mode, press the

MODE

key.

X=

Y=

■ Setting the Pen Speed/Force for Individual Pen Nos.

This method lets you set the pen speed in a range of 1 to 70 cm/s in 1 cm/s increments for each pen number.

The pen force can be switched between H (HIGH) and L (LOW).

■ Procedure

(1) With the plotter in Ready mode (the coordinates of the current pen position are displayed), press the

MODE

key. The currently selected pen type is displayed.

Pen Type

W.Fiber

(2) To set the pen speed and pen force for individual pen numbers, press the or key until the display

below appears.

Pen Type

Manual

(3) To select the pen number, press the or key to cycle through the available choices as shown below.

Select “ALL” to set the same pen speed and pen force for all pen numbers.

ALL 1 2 3

8765

4

No.=ALL

Sp70,FoH

(4) To select the pen speed, press the or key to cycle through the available range of 1 to 70 cm/s.

706968321

No.=ALL

Sp70,FoH

3-5

Page 43

(5) To select the pen force, press the

MODE

key to switch between (HIGH) and (LOW).

No.=ALL

Sp70,FoH

LH

(6) When all of the displayed settings are correct, press the

Speed

OK!

(7) To return to Ready mode, press the

MODE

key.

X=

Y=

ENTER

key. The message below appears briefly.

3-6

Page 44

3.3 Scaling and Mirror-Image Plots (P1 and P2)

When your plotter is turned on, the P1 and P2 points are respectively set to the lower left and upper right left

corners of the effective plot area of the selected paper size.

This function lets you change the coordinate positions of P1 and P2 so that the plotted image is scaled (enlarged or condensed) to fit within the quadrilateral defined by P1 and P2. To plot a mirror-image of a plot, reverse

the P1 and P2 positions. Note that the method for scaling a plot differs with the command mode. In a GP-GL

mode (FP-GL or MP-GL), a plot is scaled by using a displayed menu to specify the coordinate positions of the

P1 and P2 points. To scale plot data in HP-GL™ emulation mode, specify the P1 and P2 points and then specify

the user-coordinate system by inputting the SC command from your computer.

After moving the P1 and P2 points in either command mode, their default values can be restored by inputting

such commands as IP, IN, or DF.

The steps below describe how to consecutively set the P1 and P2 points.

■ Procedure

(1) With the plotter in Ready mode, press the

The currently displayed pen type appears.

Pen Type

W.Fiber

MODE

key.

(2) To set the P1 position, press the or key until the display below appears.

SetPoint

P1

(If you wish to skip to the P2 setting, press the or key to switch the display from the P1 menu to the

P2 menu.)

When the desired menu is displayed, press the

(3) The pen carriage moves to the current P1 position and the current coordinates are displayed (“X=” and

“Y=” blink).

The actual coordinate position can be set by using the POSITION keys or by direct numeric input. Proceed

to Step (4) of the method you wish to use.

ENTER

key.

X=

Y=

■ Using the POSITION Keys

(4) Move the pen carriage to the desired position by pressing the keys.

The coordinates of the pen carriage's position are displayed while “X=” and “Y=” continue to blink.

Skip to Step (5).

3-7

Page 45

■ Direct numeric input

(4) Press the

Use the or key to move to the column you wish to change (the selected column blinks).

To switch between + and –, press the or key. To set a numeral, press the or key until the

desired numeral is displayed.

MODE

key to permit the P1 position to be selected by numeric input of the coordinates.

X=+00000

Y=+00000

X=+00300

Y=+00000

(5) When the desired position of P1 is displayed, press the

To cancel the setting, press the

When the

set.

To set the P2 position, repeat Steps (4) and (5).

ENTER

key is pressed, the message below briefly appears and then the P2 position can be

CANCEL

key instead of the

ENTER

key.

ENTER

key.

P1

OK!

SetPoint

P2

(6) When both the P1 and P2 points are set to the desired positions, press the

mode.

MODE

key to return to Ready

NOTE

If the Sort mode is set to ON, the P1 or P2 point cannot be set from the control panel. Though the pen

carriage moves to the currently selected P1 or P2 point in Step (3), you will not be able to proceed to Steps

(4) through (6).

Scaling Plotting a mirror-image

3-8

Page 46

3.4 Moving the Origin (OFFSET)

Set the Offset when you wish to move the programmed origin of plotting.

Plotter's writing panel

Effective plot area

New origin

Original origin

In a GP-GL mode, moving the programmed origin does not change the effective plot area because the LL

(Lower Left) point remains in its original position as shown in the example above.

In HP-GL™ mode, even if you specify a new origin, the origin may not actually be moved when using certain

application programs (that include, for example, the SC command to specify the user-coordinate system).

■ Procedure

NOTE

When the Sort mode is set to ON, the origin cannot be moved from the control panel. Though the pen

carriage moves to the currently selected origin in Step (4), you will not be able to proceed to Steps (5)

through (7).

(1) With the plotter in Ready mode, press the

(2) Press the or key until the display below appears.

MODE

key.

SetPoint

P1

(3) Press the or key until the display below appears.

SetPoint

Offset

(4) When the

nates of the current origin are displayed (“X=” and “Y=” blink).

ENTER

key is pressed, the pen carriage moves to the current origin position and the coordi-

X=+00000

Y=+00000

The actual coordinate position can be set by using the POSITION keys or by direct numeric input. Proceed to

Step (5) of the method you wish to use.

3-9

Page 47

■ Using the POSITION Keys

(5) Move the pen carriage to the desired position by pressing the keys.

The coordinates of the pen carriage's position are displayed while “X=” and “Y=” continue to blink.

Skip to Step (6).

X=+01000

Y=+01000

■ Direct numeric input

(5) Press the

Use the or key to move to the column you wish to change (the selected column blinks).

To switch between + and –, press the or key. To set a numeral, press the or key until the

desired numeral is displayed.

MODE

key to permit the new origin position to be selected by numeric input of the coordinates.

X=+00000

Y=+00000

X=+00300

Y=+00000

(6) When the desired origin position is displayed, press the

CANCEL

When the

key instead of the

ENTER

key is pressed, the message below briefly appears.

ENTER

key.

Offset

OK!

(7) When the message below appears, press the

MODE

key to return to Ready mode.

X=

Y=

ENTER

key. To cancel the setting, press the

3-10

Page 48

3.5 Raising and Lowering the Pen

Depending on the current status of the pen being held at the pen carriage, this function either lowers the pen if

it is raised or raises it if it is lowered.

■ Procedure

(1) With the plotter in Ready mode, press the

Press the or key until the menu below appears.

To raise the pen (Pen Up), press the key.

To lower the pen (Pen Down), press the key.

Pen

Up Down

MODE

key.

(2) Press the

MODE

key to return to Ready mode.

X=

Y=

3-11

Page 49

3.6 Pen Selection from the Control Panel

■ Procedure

(1) With the plotter in Ready mode, press the

Press the or key until the menu below appears.

MODE

Pen No.

12345678

The currently selected Pen No. blinks, so press the or key to consecutively cycle through the Pen

Nos. until the desired Pen No. blinks. When the desired Pen No. blinks, press the

carriage retrieves the selected pen.

If no Pen No. is selected, all the Pen Nos. blink.

key.

ENTER

key. The pen

(2) After the pen exchange operation is completed, press the

MODE

key to return to Ready mode.

X=

Y=

NOTE

When the Sort mode is set to ON, the pen cannot be manually selected. Though the currently selected Pen

No. blinks in Step (1), a Pen No. cannot be selected by using the or key.

3-12

Page 50

4. PENS AND PAPER

This chapter describes the types and features of the pens and paper that can be used with the plotter as well as

how each type should be used.

The type of pen and paper you will use should be selected on the basis of your application and the compatibility

between pen and paper types. If the selected pen and paper are not compatible, the ink may not be properly

absorbed by the paper or may not flow evenly. To achieve optimum performance from your plotter, make sure

you thoroughly understand the features of each type of pen and paper.

4.1 Types and Features of Pens

■ Pens suitable for drafting

High-speed ceramic pen (

Refillable ink pen (KD110 series) • A choice of line widths (0.2, 0.3, 0.5 mm).

Disposable ink pen (SD500 series) • Line width can be selected: 0.2, 0.3, 0.5, or 0.7 mm.

HC500P series

) • A choice of line widths (0.2, 0.3, 0.5, or 0.7 mm).

• Maximum pen speed: 20 cm/second

• These disposable-type ceramic pens are easier to use than

refillable ink pens.

• Suitable for detailed diagrams.

• Maximum pen speed: 10 cm/second

• Special care must be taken during use, cleaning, storage,

and other handling.

• An ink pen plunger (PHP32-INK) is required.

• Suitable for detailed drafting.

• Easier to use than refillable ink pens; the ink reservoir and

ink pen tip are disposable.

• Maximum pen speed: 20 cm/second

• An ink pen plunger (PHP32-INK) is required.

■ Pens suitable for graphs, illustrations, and tables

Water-based fiber-tip pen (

KF550 series

) • Width of plotted line: approx. 0.3 to 0.7 mm.

• Maximum pen speed: 70 cm/s.

• Easiest to use of all the pen types.

• Note that the plotted line becomes wider during use because

the pen's tip is made of fiber.

4-1

Page 51

■ Maximum plotting life and maximum pen speed

Pen type Line width (mm) Maximum plotting life Maximum pen speed

High-speed ceramic pens 0.2 approx. 1200 m 20 cm/s

0.3 approx. 850 m 20 cm/s

0.5 approx. 500 m 20 cm/s

0.7 approx. 350 m 20 cm/s

Refillable ink pen 0.2, 0.3, 0.5 10 cm/s

Disposable ink pens 0.2 approx. 1500 m 20 cm/s

0.3 approx. 880 m 20 cm/s

0.5 approx. 460 m 20 cm/s

0.7 approx. 380 m 20 cm/s

Water-based fiber-tip pens 0.3 to 0.7 approx. 600 m 70 cm/s

NOTE

The maximum plotting life of each pen type varies with the type of paper being used.

4-2

Page 52

4.2 Construction and Use of Each Pen Type

■ Water-based fiber-tip pens

The figure above shows the construction of a fiber-tip pen. When it is not in use, its pen tip must be capped.

NOTE

The fiber-tip pens are disposable pens, so do not attempt to refill their ink supply.

■ High-speed ceramic pens

High-speed ceramic pens

• Note that the high-speed ceramic pens (HC500P series) cannot be used for polyester films.

• Use the rubber inserts for the pen caps in the pen station to prevent the pen tip from drying up or dripping.

NOTE

The high-speed ceramic pens are disposable pens, so do not attempt to refill their ink supply.

The pens can be used with the pen speed set up to 20 cm/s.

4-3

Page 53

■ Ink pen plunger (PHP32-INK)

PHP32-INK ink pen plunger

The ink pen plunger shown above is required to assemble refillable ink pens and disposable ink pens as

indicated below.

Pen type Required parts of PHP32-INK

Refillable ink pen Plunger B, Plunger A, Ink reservoir D, and Cap E.

SD disposable ink pen Plunger A and Plunger C.

■ Refillable ink pens

Refillable ink pen

How to use the refillable ink pen

(1) Screw the KD series ink pen tip into plunger B as far as it will go. (The ink pen tip's case is designed to be

held for screwing in the pen tip.)

(2) Fill ink reservoir D with ink, then insert it into plunger B.

(3) To draw ink to the pen tip, hold the pen with its tip downward and gently tap ink reservoir D until the ink

flows down to the pen tip as shown in the figure.

(4) Try writing on a piece of paper. If the ink does not flow out at all or runs out while you are writing, repeat

Step (3).

(5) Finally, screw plunger B into plunger A.

(6) After use, unscrew plunger A from plunger B, attach cap E, and then store the pen with its tip pointing

upward.

(7) If the ink does not flow smoothly during later use, gently tap the bottom of ink reservoir D several times on

top of a table or desk. (To avoid splattering ink from the pen tip, be sure to tap the ink reservoir gently.)

(8) Use the rubber inserts for the pen caps in the pen station to prevent the pen tip from drying up or dripping.

NOTE

After using the pen, always disassemble it, wash its components in water, and then wipe them dry.

4-4

Page 54

■ SD500 series disposable ink pens

NOTE

The SD500 series disposable ink pens cannot be used on polyester film.

SD series disposable ink pen

How to use the SD500 series disposable ink pen

(1) Insert the SD ink pen tip into the tip of the SD ink reservoir. Next, use the SD cap to screw on the SD ink

pen tip as shown in the figure.

(2) To draw ink to the pen tip, hold the pen with its tip downward and gently shake the SD ink reservoir up and

down.

(3) Try writing on a piece of paper. If the ink does not flow out at all or runs out while you are writing, repeat

Step (2).

(4) Next, screw plunger C into plunger A.

(5) Finally, screw the SD ink reservoir into plunger A and plunger C.

(6) After use, unscrew the SD ink reservoir from plunger A and plunger C, attach the SD cap, then store the

pen with its pen tip pointing upward.

(7) If the ink does not flow smoothly during later use, gently tap the bottom of the SD ink reservoir several

times on top of a table or desk. (To avoid splattering ink from the pen tip, be sure to tap the ink reservoir

gently.)

(8) Use the rubber inserts for the pen caps in the pen station to prevent the pen tip from drying up or dripping.

4-5

Page 55

4.3 Paper Features

Paper Type Features

Measurement paper (SP325) • Paper size is minimally affected by fluctuations in humidity.

• Minimal ink smears.

• Wet-copying is possible to some degree.

• Writing quality somewhat degenerates at high-speed plotting.

Coated paper (PL501) • Good ink adhesion because the paper surface is smooth.

• Plotted results look good due to paper's whiteness.

• Paper size is somewhat affected by fluctuations in humidity

(more so than measurement paper).

• Not suitable for use with refillable ink pens, disposable ink

pens and high-speed ceramic pens because its ink absorption

speed is slightly slower than that of other paper.

Tracing paper (PL507) • Plotted results can be wet-copied.

• Paper size is considerably affected by fluctuations in humidity.

Polyester film (PL524) • Plotted results can be clearly wet-copied.

• Fluctuations in humidity have practically no effect on the paper