Page 1

JW220-06

USER’S MANUAL

MANUAL NO.JW220-UM-151

Page 2

TO ENSURE SAFE AND CORRECT USE

• To ensure the safe and correct use of your printer, read this manual thoroughly prior to

use.

• After reading this manual, store it in a safe place for reference as necessary.

• Do not allow small children to touch the printer.

• The following describes important points for safe operation. Be sure to observe them

strictly.

Conventions Used in This Manual

To ensure the safe and correct use of the printer as well as to prevent human injury and

property damage, the safety precautions provided in this manual are ranked in the three

categories described below. Be sure to gain a full understanding of the difference

between each of the categories before reading the Manual.

This category provides information that, if ignored, is highly likely

DANGER

WARNING

to cause fatal or serious injury to the operator.

This category provides information that, if ignored, is likely to

cause fatal or serious injury to the operator.

This category provides information that, if ignored, could cause

CAUTION

injury to the operator or damage to the printer.

Description of Safety Symbols

The symbol indicates information that requires careful attention (including warnings). The specific point requiring attention is

described by an illustration or text within or next to the symbol.

The symbol indicates an action that is prohibited. Such prohibited action is described by an illustration or text within or next to

the symbol.

The symbol indicates an action that must be performed. Such

imperative action is described by an illustration or text within or

next to the symbol.

i

Page 3

Safety Precautions

To ensure the safe and correct use of your printer, be sure to observe the following

points.

Installation Precautions

WARNING

Do not install the printer in the vicinity of

volatile solvents such as alcohol or thinner.

• A volatile solvent coming into contact with any of the

internal electrical components may result in a fire

hazard or electric shock.

Benzine

Thinner

Do not place objects such as those listed

below on top of the printer.

• Objects such as these coming into contact with any

of the internal electrical components may result in a

fire hazard or electric shock.

- Metallic objects such as necklaces

- Objects such as glasses, vases, houseplants, etc. that contain water or other fluids

If any of these objects does come into contact with the internal electrical components

immediately turn off the power, remove the plug from the power outlet, and either

contact the store where you purchased your printer or your nearest Graphtec representative.

CAUTION

Do not use the printer in an unstable location

such as on a slope or a location that is subject

to a lot of vibration.

• Such locations may cause the printer to tip over and

cause injuries.

Do not place heavy objects on top of the

printer.

• Such objects may tip over or fall off, causing injuries.

ii

Page 4

If the printer is mounted on its dedicated

stand, be sure to use the caster stoppers to fix

the stand in place and prevent it from moving

while the printer is being used.

• If the stand is not fixed in place, the printer may tip

over and cause injuries.

Avoid using the printer in the following loca-

tions.

• Use in such locations may result in a fire hazard or

electric shock.

- Excessively humid or dusty locations

- Locations exposed to direct sunlight

- Locations exposed to high temperatures

- Locations near flames or moisture

iii

Page 5

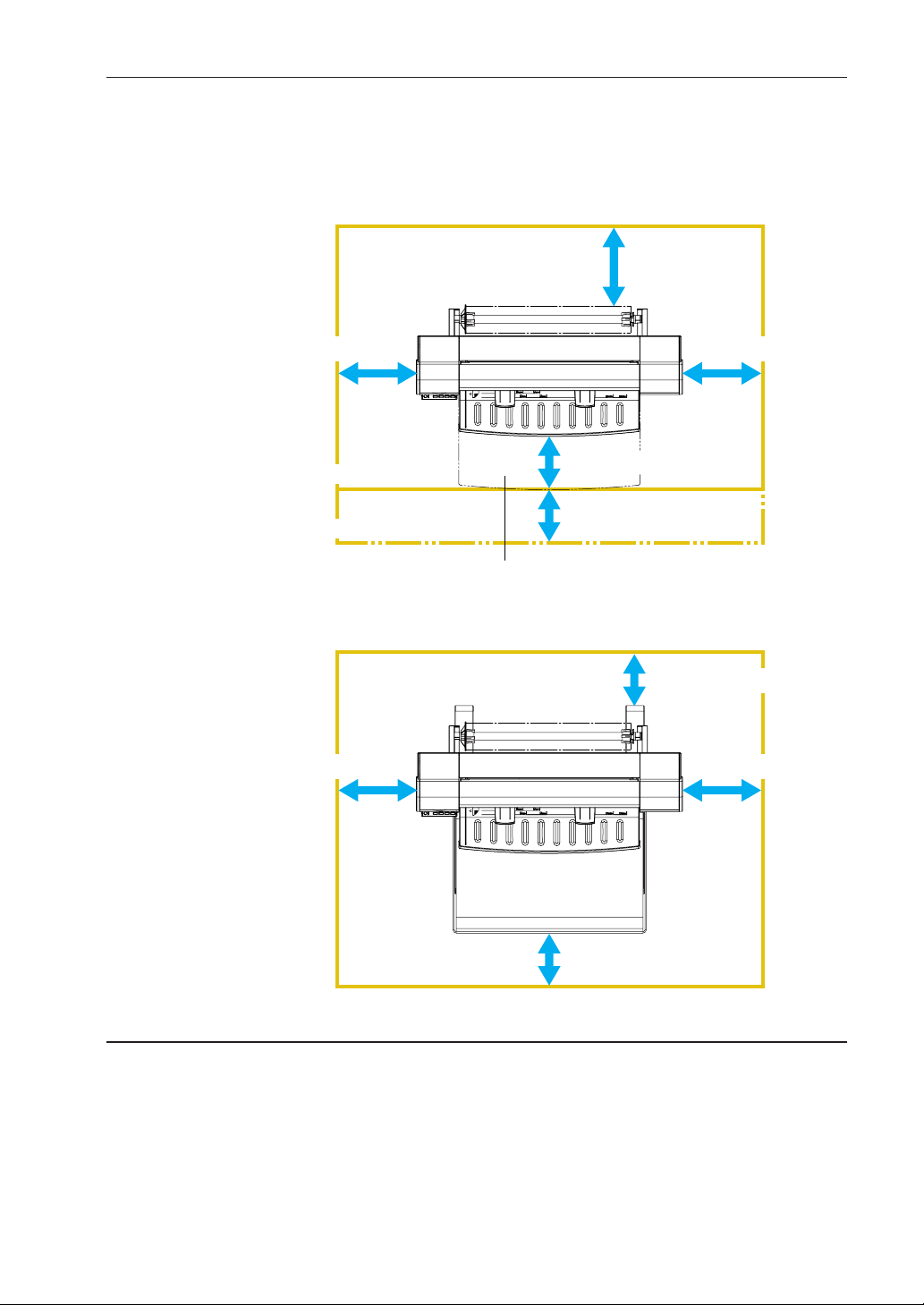

Leave plenty of space around the printer.

• Leave sufficient space for operations in front of and

behind the printer.

When using the printer on a desktop

At least 300 mm

At least 300 mm

Standard

When the paper guide table is mounted

When the A2-size paper feed cassette is mounted.

When using the printer on its optional stand

At least 300 mm

At least 300 mm

At least 200 mm

At least 200 mm

A2-size paper feed cassette

At least 200 mm

At least 300 mm

At least 200 mm

iv

Page 6

Power Supply Precautions

WARNING

Do not damage the power cable, or modify it in

any way. Moreover, do not place heavy objects

on the power cable, pull on the cable, or bend

it excessively.

• There may be current leakage from the damaged

parts, resulting in a fire hazard or electric shock.

• Do not unplug or plug in the power cable when your

hands are wet, such action may result in electric

shock.

Do not connect multiple devices to the same

power outlet.

• Use of the printer in such a condition may result in a

fire hazard or electric shock.

Do not bundle or tie-wrap the power cable.

• Use of a bundled power cable may result in a fire

hazard or electric shock.

Make sure that the power cable is firmly in-

serted into the power outlet.

• Use of a power cable when the plug is not completely inserted into the power outlet may result in a

fire hazard or electric shock.

Do not use a power cable other than the one

supplied with your printer.

• Use of a different power cable may result in a fire

hazard or electric shock.

v

Page 7

CAUTION

Do not connect the inkjet printer to a non-rated

power supply.

• Use of a different supply voltage may result in

electrical shock or a fire hazard due to current

leakage.

When disconnecting the power cable, be sure

to hold on to the plug, and not pull on the

cable itself.

• Pulling on the cable will expose the core wires, or

cause damage such as broken wires. Current

leakage from the exposed or damaged areas may

result in a fire hazard or electric shock.

As a general rule, do not use an extension

cord.

• Use of an extension cord may result in a fire hazard

or electric shock. If you must use an extension cord,

unbundle it, and make sure that the power plug is

firmly inserted into the extension cord socket.

Prohibited

Specified

rating

Make sure that the power plug can be readily

unplugged at any time, and that there are no

objects placed in its vicinity.

• Objects placed in the vicinity of the power plug will

prevent its removal in an emergency.

vi

Page 8

Be sure to ground the earth terminal.

Ground the inkjet printer

• If the cutting plotter is not grounded, the operator

could suffer an electrical shock in case of current

leakage.

• Denmark

Vigtigt ! Lederen med grøn/gul isolation må kun tilsluttes en

klemme mærket (IEC 417, No. 5019) eller (IEC 417, No. 5017).

• Norway

Apparatet må tilkoples jordet stikkontakt.

• Sweden

Apparaten skall anslutas till jordat uttag.

• Finland

Laite on liitettävä suojamaadoituskoskettimilla varustettuun pistorasiaan.

Handling Precautions

WARNING

Do not disassemble or modify the printer.

• Such actions may result in a fire hazard or electric

shock.

If the printer makes an unusual noise, gener-

ates smoke, overheats, emits a strange odor,

or otherwise functions abnormally, immedi-

ately turn off the power, remove the plug from

the power outlet, and either contact the store

where you purchased your printer or your

nearest Graphtec representative.

• Use of the printer in such a condition may result in a

fire hazard or electric shock.

Do not use flammable aerosols or similar

products in the vicinity of the printer.

• The gas contained in the spray may cause a fire

hazard or electric shock if it comes into contact with

the printer's internal electrical components.

vii

Page 9

Before moving the printer, make sure that the

power switch is in the "off" position and that

the power plug has been removed from the

power outlet.

• If the printer is moved while it is still plugged into the power outlet, the power cable may

be damaged and cause a fire hazard or electric shock.

CAUTION

Take care not to drop metallic items such as

paper clips or staples, or spill water, other

fluids or flammable solvents (alcohol, ben-

zene, thinner, etc.) inside the printer.

• Metallic items or fluids coming into contact with the

internal electrical components may result in a fire hazard or electric shock. If such items

or fluids fall or are spilled inside the printer, immediately turn off the power, remove the

power plug from the power outlet and either contact the store where you purchased the

printer or your nearest Graphtec representative.

Do not insert your hands inside the printer

during a printing operation or when paper is

being loaded.

• Moving parts inside the printer may cause injuries.

Take care not to cut your hands or other parts

of your body when handling the roll paper

cutter.

• There is a risk of cutting your fingers on the cutter

blade.

If the printer will not be used for an extended

length of time, such as at night, turn off the

power switch as a safety precaution.

viii

Page 10

Maintenance and Inspection Precautions

WARNING

Be sure to turn off the power and remove the

power plug from the power outlet before per-

forming any cleaning operations.

• Failure to do so may result in a fire hazard or electric shock. Moreover, there is a risk of injury if the

printer starts to move during a cleaning operation.

To clean the printer, use a cloth that has been

dampened with neutral detergent and then well

wrung out. Do not use volatile solvents such

as alcohol, benzene or thinner to clean the

printer.

• A volatile solvent coming into contact with any of the

internal electrical components may result in a fire

hazard or electric shock.

Benzine

Thinner

CAUTION

At least once a year, remove the power plug from the power outlet and clean

the prongs and surrounding areas.

• A build-up of dust may result in a fire hazard.

When cleaning or checking the inside of the printer, make sure that a

metallic object such as a necklace or bracelet does not come into contact

with any of the internal components.

• Such actions may result in injuries or an electric shock.

When replacing roll paper, loading paper, or removing paper that has

become jammed in the printer, take care not to cut yourself on the edges

of the paper.

• Sharp paper edges may cause injuries.

ix

Page 11

Precautions on Handling the Consumable Items

CAUTION

Do not touch any metallic parts on the print

heads after a printing operation.

• These parts will be hot, and may cause burns.

• Printing malfunctions may occur.

• There is a risk of damage from static electricity.

Do not touch the ink cartridge openings or the

head section of the print heads.

• Your fingers may become stained with ink.

• Printing malfunctions may occur.

• There is a risk of damage from static electricity.

As a safety precaution, store the print heads and ink cartridges in a location

out of the reach of small children.

• If ink is licked or ingested accidentally, consult a doctor immediately.

Do not drop or shake the print heads or ink

cartridges.

• Such actions may cause the ink to leak or spatter,

with the risk of staining your surroundings and

clothing.

• The head section may become damaged, making

the print head unusable.

Do not touch the blade of the roll paper cutter.

• You may cut your fingers on the blade.

The print heads are consumable items

• The print heads are consumable items. If printing is not performed correctly even after

the print heads have been cleaned or adjusted, replace them with new ones. See

Chapter 5, "Maintenance" for further details.

x

Page 12

Precautions to observe when removing jammed paper

• When removing paper that has become jammed inside the printer, take care not to get

ink from the paper on your clothing or hands. There is a possibility of ink adhering to

your clothing or hands.

• If paper has become jammed during a paper feed operation, do not pull too hard on

the paper to remove it. Pulling on the paper may cause it to tear, and torn paper

fragments remaining inside the printer may cause paper feed problems.

• Please refer to Section 6.4, "If the Paper Becomes Jammed" for the correct removal

procedure.

Precautions to Note When Unpacking the Printer

If the printer was stored in a location where the temperature dropped below 10 °C,

allow sufficient time for the printer to become acclimatized to room temperature (the

operating environment specification is the range from 15 °C to 30 °C) before mounting

the print heads. (We recommend that you allow at least two hours for the printer to

become acclimatized.)

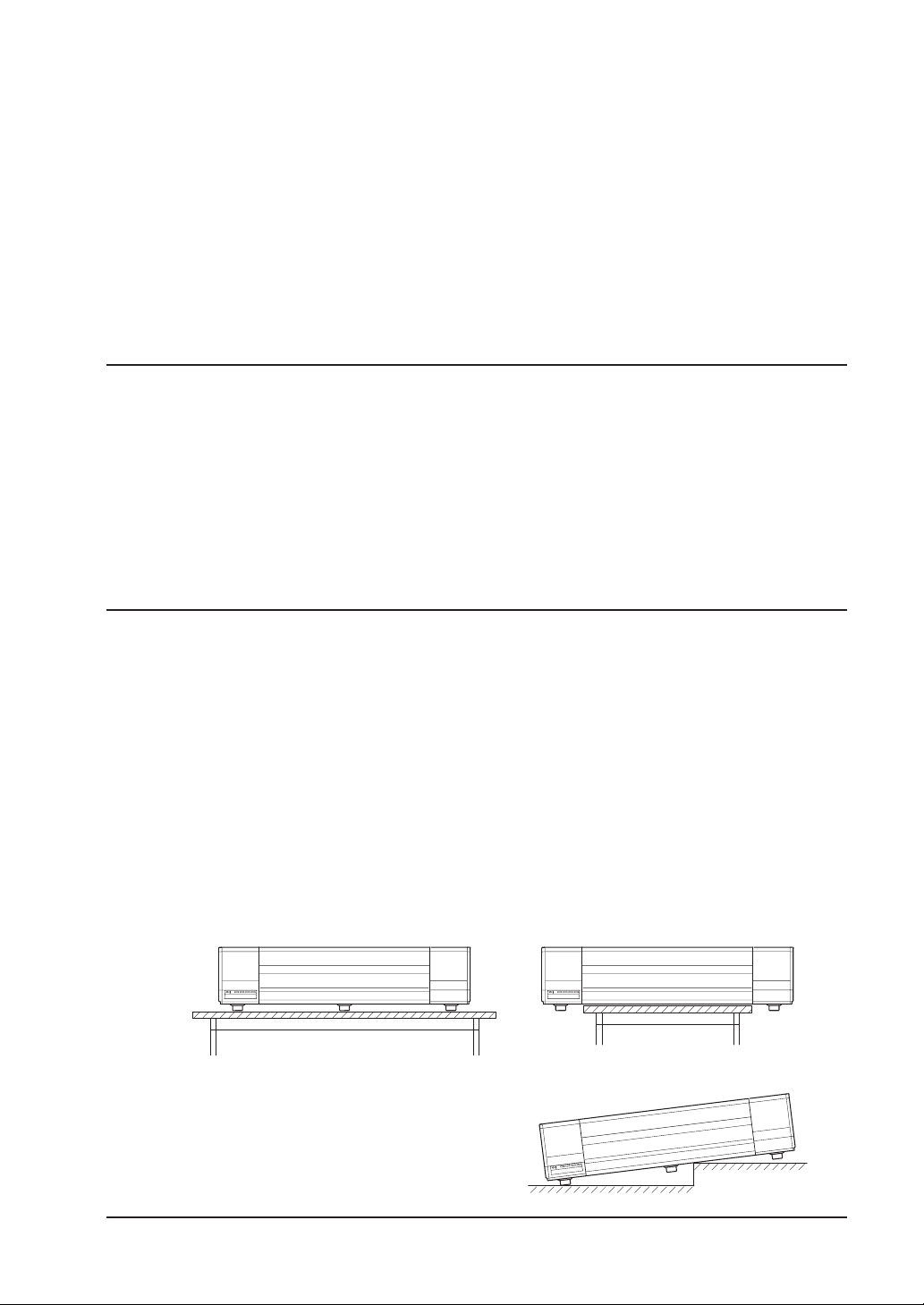

Precautions to observe when installing the printer

If the printer will be installed as a desktop model, be sure to heed the following points.

• Install the printer on a flat desk.

• Make sure that all five rubber feet are sitting on the desk.

• Do not install the printer on a stepped surface.

(Installing the printer in a location where its underside is touching another object may

cause malfunctions to occur.)

If there is no desk available for installation, mount the printer on the dedicated stand

(ST0060) that is available as an option.

Correct Incorrect

Incorrect

xi

Page 13

Precautions to observe when handling the paper

• Paper may not be fed correctly and may become jammed if the leading edge of the

roll paper is not straight or if there is adhesive from the fastening tape remaining on

the paper. Make sure that the leading edge is straight before loading the paper in the

printer.

• Paper feed problems or paper jams may occur if paper that is not Graphtec-supplied

paper is used. Be sure to use Graphtec-supplied paper.

• Depending on the storage conditions, the paper may become creased and/or the

leading edge may curl up. The use of creased or curled paper may cause paper jams.

Remove the creased or curled sections before loading the roll paper in the printer.

(If you are using a cut sheet, remove the creased section before loading the sheet in

the printer.)

Notes on the ink cartridges

Do not leave an ink cartridge that has been removed from the printer lying around for an

extended period of time. Doing so may cause ink deterioration, inferior print quality, or

clogging of the print head nozzles.

Notes on the print heads

Do not perform any unnecessary print head removal or mounting operations. Print head

removal and mounting operations should only be performed when print head replacement is required.

Be sure to observe the following points when loading paper in

the A2-size paper feed cassette

• Align the edges of the paper stack before loading it in the tray.

• Do not use paper that has been folded or creased.

• Fan the paper stack thoroughly before loading it in the tray.

If the paper is not fanned, paper jams may occur or two or more sheets may be fed at

the same time.

xii

Page 14

Notes on connecting the printer to a power outlet

Always leave the printer connected to a power outlet.

The printer periodically performs automatic maintenance operations in order to maintain

print quality.

xiii

Page 15

WARNING

Only computers or peripherals (computer input/output devices, terminals, printers, etc.)

certified as complying with the limits for a Class B digital device, pursuant to Part 15 of

the FCC Rules, may be attached to this product when this product is operated in a

residential environment. Operation with non-certified peripherals is likely to result in

interference to radio and TV.

FEDERAL COMMUNICATIONS COMMISSION RADIO FRE-

QUENCY INTERFERENCE STATEMENT

"This equipment has been tested and found to comply with the limits for a Class B

digital device pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur

in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help."

xiv

Page 16

PREFACE

Thank you for choosing the Graphtec JW220-06 inkjet printer.

Please read this manual thoroughly before attempting to use your new product to

ensure that you use it safely and correctly.

Notes on this Manual

(1) No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form or by any means, without the prior written permission of

Graphtec Corporation.

(2) The product specifications and other information in this manual are subject to

change without notice.

(3) While every effort has been made to provide complete and accurate information,

please contact your sales representative or nearest Graphtec vendor if you find any

unclear or erroneous information or wish to make other comments or suggestions.

(4) Notwithstanding the stipulations in the preceding paragraph, Graphtec Corporation

assumes no liability for damages resulting from either the use of the information contained herein or the use of the product.

Registered Trademarks

All names of companies, brands, logotypes, and products appearing in this manual are

the trademarks or registered trademarks of their respective companies.

Copyright

This User's Manual is copyrighted by Graphtec Corporation.

Precautions to Observe When Transporting the Printer

Be sure to read Section 5.8, "Precautions on Transporting the Printer" before transporting the printer to another destination. Do not transport the printer as is, as there is a

possibility of the ink leaking out. If you have any questions or if anything is unclear,

please contact your sales representative or nearest Graphtec vendor.

I

Page 17

Contents

TO ENSURE SAFE AND CORRECT USE ..................................................................................... i

PREFACE ....................................................................................................................................... I

Notes on this Manual......................................................................................................... I

Registered Trademarks ..................................................................................................... I

Copyright ........................................................................................................................... I

Precautions to Observe When Transporting the Printer.................................................... I

Chapter 1 Before Using the Printer ............................................................................................. 1-1

1.1 Checking the Contents of the Package ................................................................... 1-1

1.2 Parts Names and Functions .................................................................................... 1-2

Front View ............................................................................................................... 1-2

Control panel ........................................................................................................... 1-2

Rear View................................................................................................................ 1-3

A2-size Paper Feed Cassette ................................................................................. 1-3

Chapter 2 Connection and Preparations ..................................................................................... 2-1

2.1 Attaching the Paper Guide Table ............................................................................. 2-1

2.2 Attaching the A2-size Paper Feed Cassette ............................................................ 2-1

2.3 Connecting to the Power Supply ............................................................................. 2-2

2.4 Turning the Power On and Off ................................................................................. 2-2

Turning the Power On ............................................................................................. 2-2

Turning the Power Off ............................................................................................. 2-2

2.5 Mounting the Print Heads ........................................................................................ 2-3

2.6 Mounting the Ink Cartridges .................................................................................... 2-6

2.7 Mounting the Roll Paper Cutter ............................................................................... 2-8

2.8 Connecting the Printer to a Computer ................................................................... 2-10

USB Connection.................................................................................................... 2-10

Ethernet connection (option) ................................................................................. 2-11

Chapter 3 Loading the Paper ...................................................................................................... 3-1

3.1 Usable Paper Types ................................................................................................ 3-1

Paper Types and Sizes ........................................................................................... 3-1

Print Area ................................................................................................................ 3-3

3.2 Using Roll Paper ..................................................................................................... 3-6

Loading roll paper ................................................................................................... 3-6

Removing roll paper ................................................................................................ 3-9

3.3 Using Cut Sheets .................................................................................................. 3-10

Loading cut sheets ................................................................................................ 3-10

Removing a cut sheet ........................................................................................... 3-12

II

Page 18

3.4 Using the A2-size Paper Feed Cassette ............................................................... 3-13

Attaching and removing the A2-size paper feed cassette ..................................... 3-13

Loading paper in the A2-size paper feed cassette ................................................ 3-15

Manual feeding...................................................................................................... 3-17

3.5 Using the Anti-Curling Guides ............................................................................... 3-19

Chapter 4 Printer Driver .............................................................................................................. 4-1

4.1 Printing from Windows ............................................................................................ 4-1

4.2 Canceling Printing in Windows ................................................................................ 4-3

4.3 Printer Driver Capabilities........................................................................................ 4-4

Main driver features ................................................................................................ 4-4

Compatible Operating Systems .............................................................................. 4-4

4.4 Printer Driver Functions........................................................................................... 4-5

[Base Setting] tab .................................................................................................... 4-5

[Options] tab ............................................................................................................ 4-8

[Graphics] tab ........................................................................................................ 4-10

[Color adjustment] tab ........................................................................................... 4-11

[About This Driver] tab........................................................................................... 4-12

4.5 Printer Information Button ..................................................................................... 4-13

[Data Information] tab............................................................................................ 4-13

[Printer Information] tab......................................................................................... 4-14

[Maintenance] tab.................................................................................................. 4-16

4.6 Message Displays ................................................................................................. 4-17

Chapter 5 Maintenance ............................................................................................................... 5-1

5.1 Checking the Printer Information ............................................................................. 5-1

[Printer Information] dialog screen .......................................................................... 5-1

Launching the [Printer Information] dialog screen................................................... 5-2

5.2 Replacing the Print Heads and Ink Cartridges ........................................................ 5-3

Checking the print heads and ink cartridges ........................................................... 5-3

Replacing the print heads ....................................................................................... 5-4

Replacing the ink cartridges .................................................................................... 5-8

5.3 Print Head Cleaning and Alignment ...................................................................... 5-10

Cleaning the Print Heads ...................................................................................... 5-10

Wiping the print heads .......................................................................................... 5-12

Aligning the print heads......................................................................................... 5-14

5.4 Handling the Print Heads ...................................................................................... 5-15

5.5 Replacing the Roll Paper Cutter ............................................................................ 5-16

5.6 Cleaning the Printer............................................................................................... 5-19

III

Page 19

5.7 Cleaning the Maintenance Station ........................................................................ 5-21

5.8 Transporting the Printer......................................................................................... 5-24

Attaching the various shock-absorbing packing materials .................................... 5-27

Packing the components into the packing box ...................................................... 5-27

Chapter 6 What to Do if This Happens ....................................................................................... 6-1

6.1 When an Error Message is Displayed ..................................................................... 6-1

Messages relating to paper ..................................................................................... 6-1

Messages relating to the print heads and ink cartridges ......................................... 6-2

Messages relating to the printer .............................................................................. 6-2

Messages relating to the print server connection and messages displayed during

connection monitoring ............................................................................................. 6-3

6.2 The Printer Does Not Operate Correctly ................................................................. 6-4

6.3 When Printing is not Satisfactory ............................................................................ 6-5

6.4 If the Paper Becomes Jammed ............................................................................... 6-6

Removing jammed roll paper .................................................................................. 6-6

Removing a jammed cut sheet................................................................................ 6-8

6.5 What to Do When Other Devices Cannot be Recognized..................................... 6-11

Appendix A Standard Specifications ........................................................................................... A-1

A.1 External Dimensions and Weight Standard Specifications ...................................A-1

A.2 External Dimensions and Weight When the A2-size paper feed cassette is installed

A-1

A.3 External Dimensions and Weight When the printer is mounted on a stand (ST0060:

option) .....................................................................................................................A-2

A.4 Standard Specifications ..........................................................................................A-3

Appendix B Options and Supplies............................................................................................... A-4

B.1 Options.................................................................................................................... A-4

B.2 Supplies ..................................................................................................................A-4

B.3 Cartridges for use when transporting the printer..................................................... A-5

Index .................................................................................................................................... Index-1

IV

Page 20

Chapter 1 Before Using the Printer

1.1 Checking the Contents of the Package

Check to confirm that all of the items shown below are present. If any item is missing,

promptly contact the store where you purchased your printer or your nearest Graphtec

representative.

Printer unit ···1

Power cable ···1

USB cable ···1

Print heads

(Black, color) ···1 of each

Paper guide table

(with two setscrews) ···1 set

A2-size Paper Feed Cassette ···1 set

Phillips screwdriver ···1

Ink cartridges

(Black, cyan, magenta, yellow) ···1 of each

Quick Start Guide ···1

Roll paper cutter ···1

Anti-curling guides ···2

Roll paper stocker ···1 assembly

Software package (CD-ROM) ···1

· Printer driver

· User's manual (PDF format)

· Adobe Acrobat Reader

1-1

Page 21

1.2 Parts Names and Functions

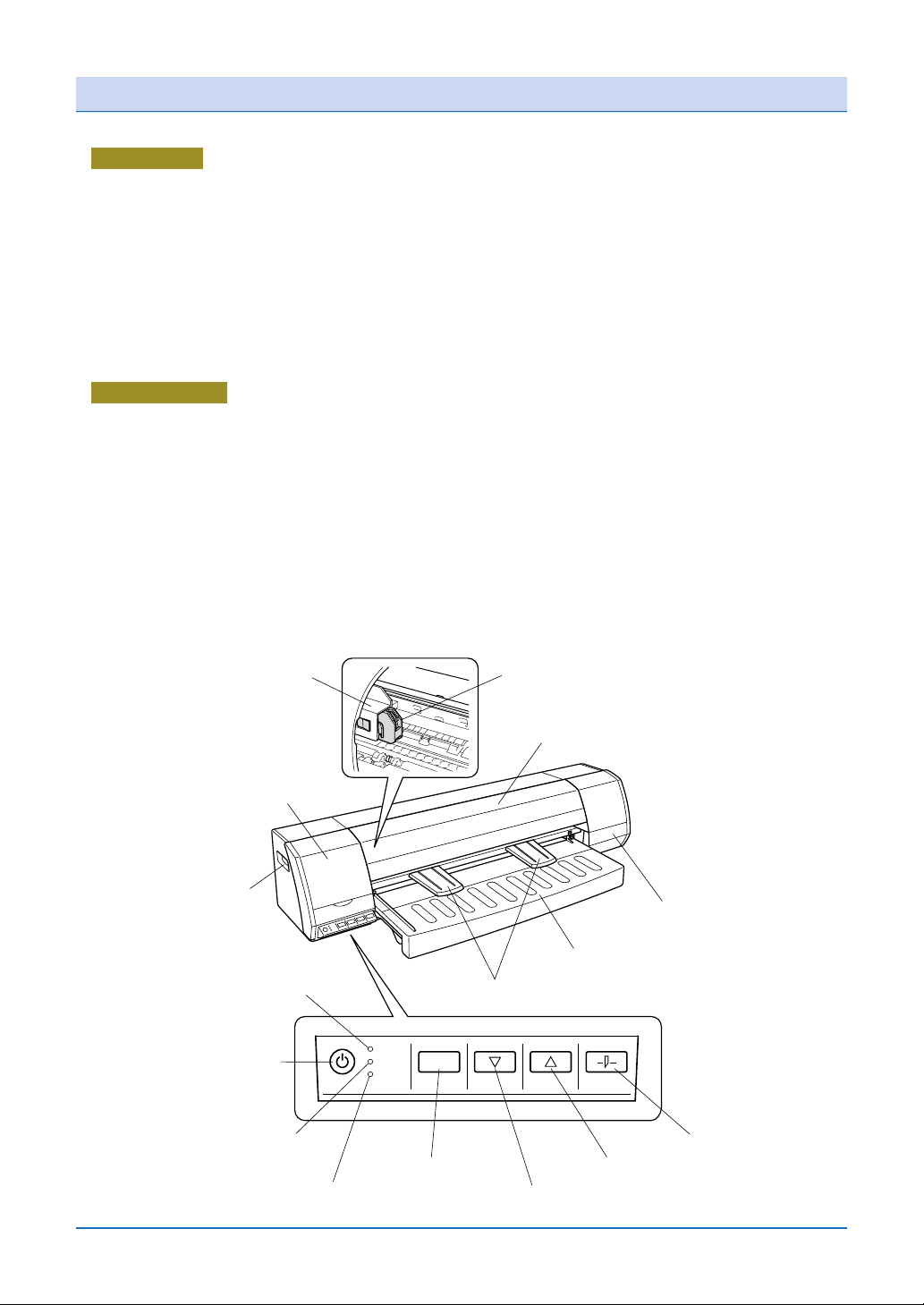

Front View

(1) Center cover ................. Used when mounting the roll paper cutter and when cleaning the inside of

the printer unit.

(2) Maintenance cover........ Used when the print heads are replaced. (Print head replacement position)

(3) Handholds ..................... These handles (located at the left and right sides of the printer) are used to

grip the printer when moving it.

(4) Anti-curling guides......... These guides are attached when thin media such as tracing paper is used.

(5) Paper guide table .......... Used for loading paper for printing.

(6) Ink cartridge cover ........ Used when mounting the ink cartridges. (Ink holder)

(7) Roll paper cutter ............ Used for cutting roll paper.

(8) Cutter holder ................. Used to mount the roll paper cutter.

Control panel

(9) [POWER] button ........... Press this button to turn the power supply to the printer on or off. The button

lights (blue) when the power supply is on.

(10) [DATA] LED ................. Flashes (green) when data is being received from the computer.

(11) [CAUTION] LED .......... Lights (orange) when the printer is out of paper.

(12) [ERROR] LED ............. Lights (red) when there is a paper jam, when the print head carrier stops, or

when some other malfunction occurs.

(13) [CANCEL] button ........ Press this button to cancel the printing operation.

(14) [FORWARD] button..... Press this button to feed the paper in the forward direction when the printer

is in standby status.

(15) [REVERSE] button ...... Press this button to feed the paper in the reverse direction when the printer

is in standby status.

(16) [PAPER CUT] button... Press this button to cut roll paper when the printer is in standby status.

(8) Cutter holder

(2) Maintenance cover

(Print head replacement position)

(3) Handholds

(10) [DATA] LED

(flashes green)

(9) [POWER] button

(lights blue)

(11) [CAUTION] LED

(lights orange)

(12) [ERROR] LED

(lights red)

(4) Anti-curling guides

DATA

CAUTION

ERROR

CANCEL FORWARD REVERSE PAPER CUT

(13) [CANCEL] button

(14) [FORWARD] button

(7) Roll paper cutter

(1) Center cover

(6) Ink cartridge cover

(Ink holder)

(5) Paper guide table

(16) [PAPER CUT] button

(15) [REVERSE] button

1-2

Page 22

Rear View

(17) Roll paper stocker .................. Used for loading roll paper for printing.

(18) Access door ........................... Open this door to remove the paper if it becomes jammed.

(19) Power inlet ............................. Used to connect the power cable.

(20) USB interface connector ........ Used to connect the USB cable.

(17) Roll paper stocker

(18) Access door

(19) Power inlet

(20) USB interface connector

A2-size Paper Feed Cassette

The A2-size paper feed cassette is designed specifically for feeding plain paper.

Cut sheets of standard-size paper, from A4-size to A2-size*1, can be loaded in the A2-size

cassette to enable automatic feeding of paper to the printer.

*1: Please note that only paper of the same size can be loaded at one time in the cassette.

The number of cut sheets that can be loaded

*2

• Plain paper (64 g/m2): approx. 100 sheets

*2: The number of sheets is a guideline only. When actually loading the paper in the

cassette, make sure that the top of the stack is below the line under the [ ]

mark printed on the stock tray.

Paper alignment levers ............ Move these levers to match the paper size and hold the paper in

place.

Stock tray ................................. Used to load cut sheets for feeding.

Paper guide table..................... Use this table when manually feeding sheets for printing.

Paper stack

height

Stock tray

Paper alignment levers

Paper guide table

1-3

Page 23

Chapter 2 Connection and Preparations

2.1 Attaching the Paper Guide Table

Firmly insert the paper guide table into the printer until it makes contact with the rear

side, and then fasten it in place with the two setscrews provided.

Paper guide table

Setscrews

Phillips screwdriver

provided with the printer

2.2 Attaching the A2-size Paper Feed Cassette

Attach the A2-size paper feed cassette, insert it fully into the printer as shown in the

diagram below. After the cassette has been inserted, gently pull on it to check that it is

firmly inserted.

Stock tray

2-1

Page 24

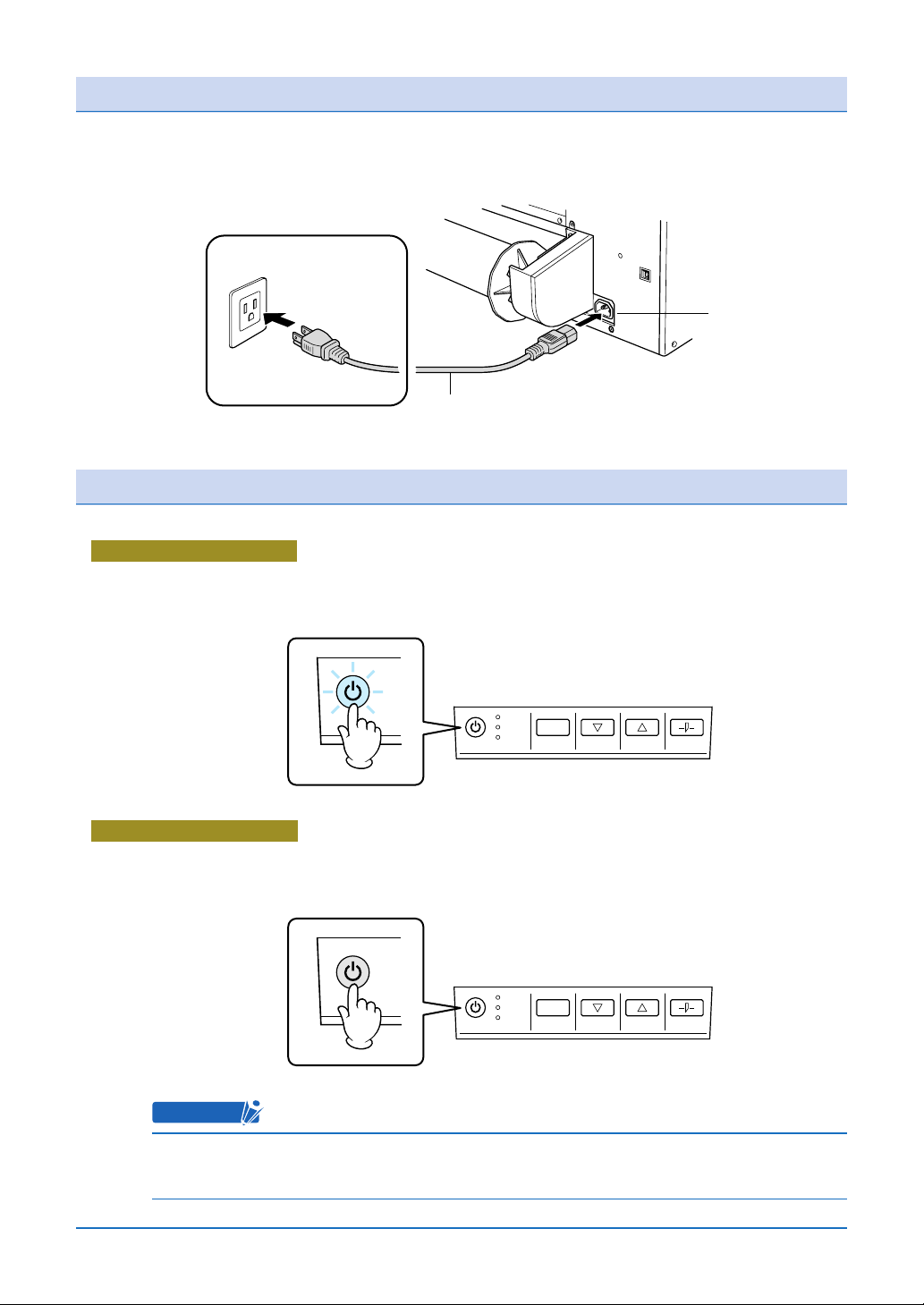

2.3 Connecting to the Power Supply

Connect one end of the power cable provided to the printer's power inlet and the other

end to an AC power outlet of the rated supply voltage.

AC power outlet

Power cable

2.4 Turning the Power On and Off

Turning the Power On

Press the [POWER] button on the printer's control panel.

When the printer is in the power-on status, the [POWER] button lights blue.

Power inlet

DATA

CAUTION

ERROR

CANCEL FORWARD REVERSE PAPER CUT

ON

Turning the Power Off

Press the [POWER] button on the printer's control panel.

When the printer is in the power-off status, the [POWER] button LED is extinguished.

DATA

CAUTION

ERROR

CANCEL FORWARD REVERSE PAPER CUT

OFF

CHECKPOINT

After the printer has been turned off, wait at least five seconds before turning it

on again.

2-2

Page 25

2.5 Mounting the Print Heads

1. Press the printer's [POWER] button to turn on the printer.

Check that the [POWER] button LED lights blue.

ON

2. Open the maintenance cover at the left-hand side of the printer.

Maintenance cover

3. The print head carrier moves to the print head replacement position.

DATA

CAUTION

ERROR

CANCEL FORWARD REVERSE PAPER CUT

Print head carrier

4. Press down on the lock to open the joint block.

2

Lock

1

2-3

Joint block

Page 26

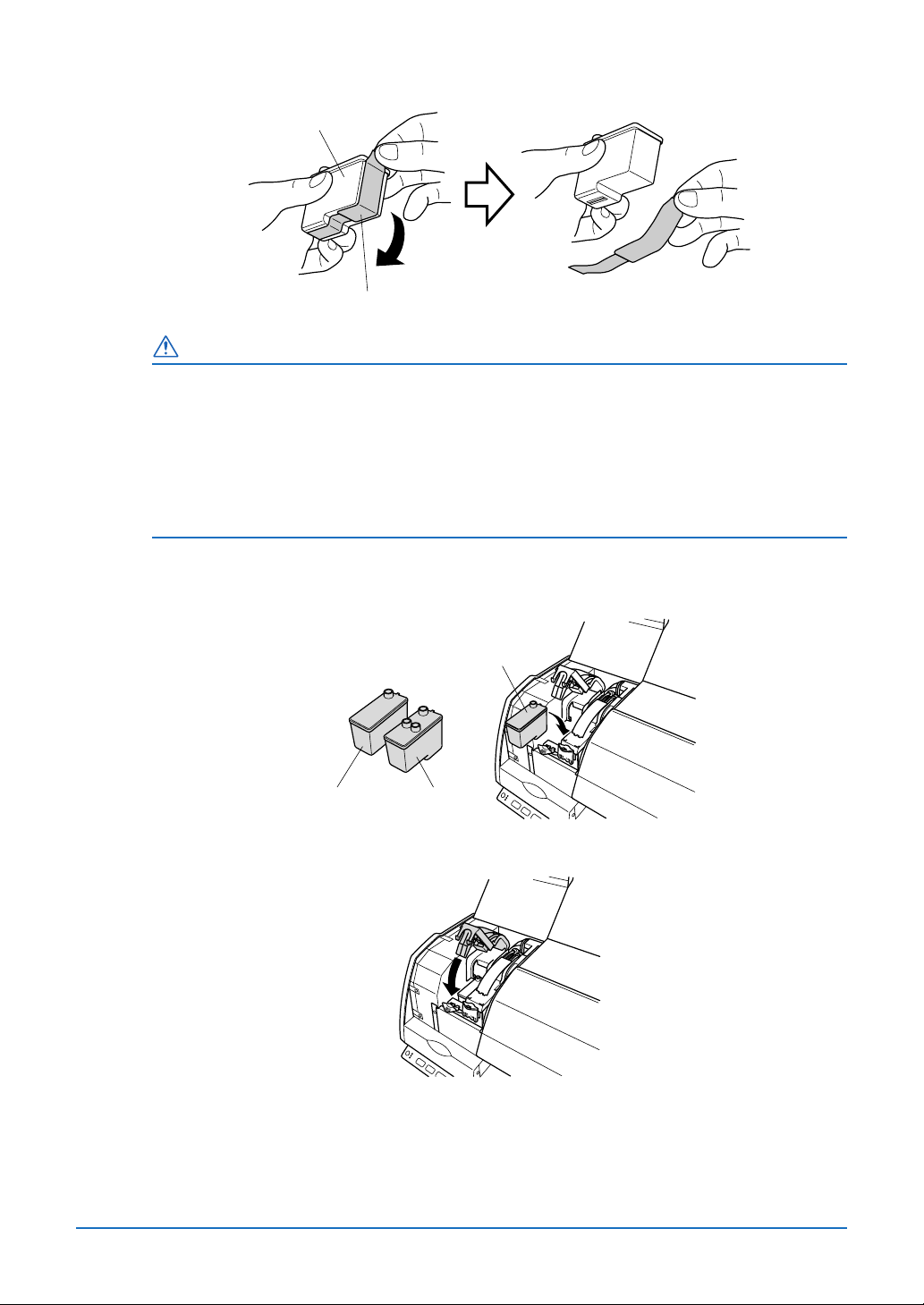

5. Prepare the print heads for mounting by removing the protective tape.

Print head

Protective tape

CAUTION

• Do not drop or shake the print head. Such actions may cause the ink to leak or

spatter, with the risk of staining your surroundings and clothing. Moreover, the

head section may become damaged, making the print head unusable.

• Do not touch the metallic parts of the print head or the print head section itself.

Such actions will adversely affect the printing. Moreover, there is a risk of

damage to the print head from static electricity.

6. Mount the print heads. Mount the black print head in the left-hand holder. Next,

mount the color print head in the right-hand holder.

Print head

(black)

Print head

(black)

Print head

(color)

7. Press down on the joint block until it makes an audible click.

2-4

Page 27

8. Gently close the maintenance cover.

2-5

Page 28

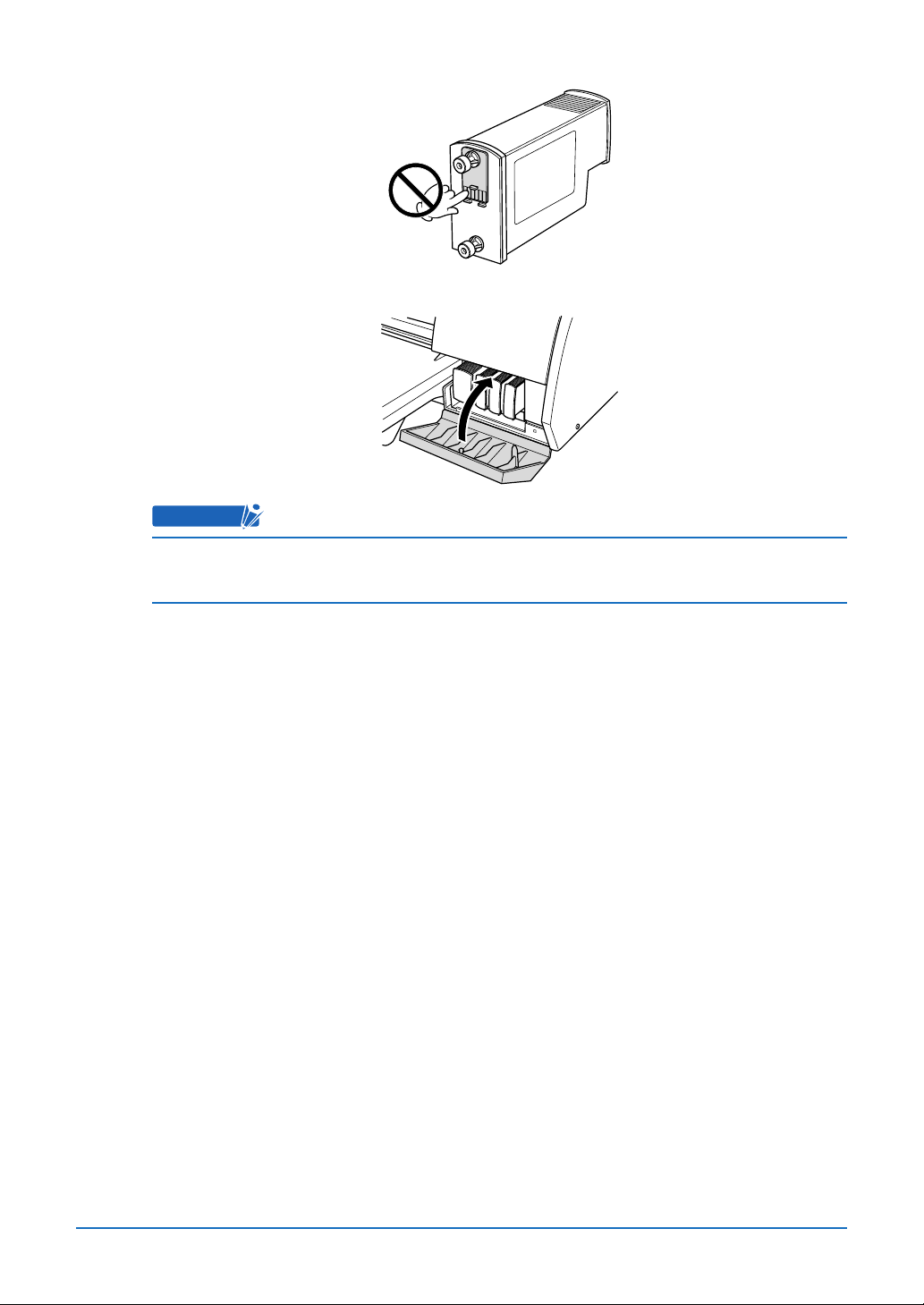

2.6 Mounting the Ink Cartridges

CHECKPOINT

• Before mounting the ink cartridges, make sure that the print heads have been

mounted.

• Perform this procedure with the printer in the power-on status. Check that the

[POWER] button is lit blue.

• There are four types of ink cartridges: black (BK), cyan (C), magenta (M) and

yellow (Y). Check their mounting positions in the ink holder in the printer, and

make sure that each cartridge is mounted correctly.

1. Open the ink cartridge cover at the right-hand side of the printer.

1

2

Ink cartridge cover

(Ink holder)

2. Align each ink cartridge with its corresponding rail on the ink holder, and then insert it

gently until it clicks into place. At this time, check the color of each ink cartridge and

make sure that it is inserted at the correct position.

Rail

Ink cartridge

Black

Cyan

Magenta

Yellow

CAUTION

• Do not touch the printed circuit board part of the ink cartridges with your fin-

gers. Such action may cause damage due to static electricity.

• Do not drop or shake the ink cartridges. Such actions may cause the ink to leak

or spatter, with the risk of staining your surroundings and clothing.

2-6

Page 29

3. When all four ink cartridges have been mounted, gently close the ink cartridge cover.

CHECKPOINT

The printer driver can be used to check the status of the print heads and the ink

cartridges. For further details, see Chapter 4, "Printer Driver".

2-7

Page 30

2.7 Mounting the Roll Paper Cutter

CAUTION

• Take care not to cut your fingers or other parts of your body on

the roll paper cutter blade.

• When mounting the roll paper cutter, do not touch any of the

internal components of the printer other than the cutter holder.

Roll paper cutter

Take care with the blade inside the cutter

Note: The roll paper cutter is a consumable item.

1. Press the printer's [POWER] button to turn off the printer.

Check that the [POWER] button LED is extinguished.

OFF

2. Open the center cover.

Center cover

DATA

CAUTION

ERROR

CANCEL FORWARD REVERSE PAPER CUT

2-8

Page 31

3. Prepare the roll paper cutter for mounting.

Remove the protective tape (with a piece of sponge attached) from the tip of the roll

paper cutter blade, taking care not to cut yourself on the blade.

Protective tape

(with sponge attached)

Take care with the blade tip

Roll paper cutter

4. Hold the roll paper cutter by its lock tab, and insert the cutter firmly into the holder.

After the roll paper cutter has been mounted, check that the lock tab's hook is engaged in the cutter holder's slot.

Lock tab

Cutter holder

Lock tab hook

5. Close the center cover to complete the roll paper cutter mounting operation.

2-9

Page 32

2.8 Connecting the Printer to a Computer

USB Connection

A USB cable is used to connect the printer to the computer, via the respective USB

interface connectors. The connectors at the computer and printer ends of the USB

cable have different shapes. Make sure that the cable is oriented correctly before

making the connection.

Computer

USB cable

USB interface connector

IMPORTANT

Make sure that the USB cable is firmly inserted into the interface connectors.

When using a USB cable, a USB driver must be installed in the computer. Do not

connect the cable before the driver has been installed.

CHECKPOINT

Please see the separate "Quick Start Guide" for the printer driver installation

procedure.

2-10

Page 33

Ethernet connection (option)

If an Ethernet print server (option) is used, the printer can be used in a network environment. Please see the user's manual provided with the Ethernet print server (option) for

the network connection settings and other details.

1. Use the two screws provided with the Ethernet adapter to attach the adapter to the

printer.

Ethernet adapter

2. Mount the Ethernet print server on the Ethernet adapter.

Print server

3. Use the USB cable to connect the printer and the print server.

Next, use the Ethernet cable to connect the print server to the network.

Print server

Ethernet cable

Connect to network

USB interface connector

USB cable

2-11

Page 34

4. Connect the AC adapter to the print server.

Print server

1

AC adapter

3

Power cable

2

2-12

Page 35

Chapter 3 Loading the Paper

3.1 Usable Paper Types

The JW220 printer can handle a wide range of paper types up to A1 size (both roll

paper and cut sheets). Select the paper type that best suits your printing application.

In addition, use of the A2-size paper feed cassette enables automatic feeding of cut

sheets (plain paper) of the same size.

Paper Types and Sizes

The paper types and sizes that can be used with the JW220 printer are shown in the

following tables.

Paper types

Roll paper

Classification Name Part Name

Plain paper

Plain paper

Coated paper

Tracing paper

Glossy paper Photo paper

Recycled paper

Recycled paper

Matte

Ecological

Thick matte

Tracing paper

JC-∗∗R-PM

JC-∗∗R-PM-R2

JC-∗∗R-RMW2-R2

JC-∗∗R-RM2

JC-∗∗R-ST2

JC-∗∗R-ST2-R2

JC-∗∗R-RCT-R2

JC-∗∗R-STM2

JC-∗∗R-TM2

JC-∗∗R-WRP2

Abbre-

*1

viation

RMW2 64

Weight

(g/m2)

PM 64

RM2 64

ST2 90

RCT 80

STM2 117

TM 75

WRP 175

Thickness

(µm)

Approx.90

Approx.92

Approx.84

Approx.114

Approx.110

Approx.153

Approx.68

Approx.180

Features

80% whiteness

80% whiteness, 70% recycled-paper content

Suitable for outputting check prints

70% whiteness, 100% recycled-paper content

Suitable for outputting check prints

Plain paper is used as the base

Suitable for outputting check prints and simple graphics

80% whiteness, 70% recycled -paper content

Suitable for outputting check prints

Plain paper is used as the base; white paper suitable for graphics

Suitable for outputting color drawings, posters, etc.

Thin type, high translucency, natural tracing paper

Fast-drying photo paper that is suitable for printing graphics

Vivid color reproduction; optimal for printing posters, etc.

Cut sheets

Abbre-

Weight

Classification Name Part Name

Plain paper

Tracing paper

Plain paper PM 64

Tracing paper

JC-∗∗L-PM-100

JC-∗∗L-TM2

*1

viation

TM 75

(g/m2)

Thickness

(µm)

Approx.90

80% whiteness

Approx.68

Thin type, high translucency, natural tracing paper

Features

*1 These part names are for Graphtec-supplied paper. The "∗∗" part of the name varies

according to the paper size selected. Please see Appendix B, "Options and Supplies" for further details.

IMPORTANT

• To obtain high quality printed results, be sure to use Graphtec-supplied paper.

• Some of the paper types may require a longer ink drying time than others.

Allow sufficient time for the ink to dry before handling the prints.

• When using plain (or recycled) paper when "Normal" is specified for the print

3-1

Page 36

quality setting and high-density (dark) printing is performed, the paper may

become wavy. If this happens, either change the print quality setting to "High

quality" or else use coated or glossy paper instead.

Paper sizes

Roll paper: The following roll paper sizes can be used.

The maximum roll diameter must be less than 100 mm, the inner core

diameter 2 inches, and the rolls outside wound (the print side is on the

outside of the roll).

Roll paper sizes (paper widths)

ISO A1 Paper width 594.0 mm

ISO A2 Paper width 420.0 mm

ISO A3 Paper width 297.0 mm

JIS B2 Paper width 515.0 mm

JIS B3 Paper width 364.0 mm

ARCH 24 Paper width 24 inch

CHECKPOINT

Please see Section 3.2, "Using Roll Paper" for details on how to load roll paper in

the printer.

Cut sheets: The following cut sheet sizes can be used.

Cut sheet sizes (paper sizes)

ISO A1 594.0 x 841.0 mm

ISO A2 420.0 x 594.0 mm

ISO A3 297.0 x 420.0 mm

ISO A4

JIS B2

JIS B3

JIS B4

210.0 x 297.0 mm

515.0 x 728.0 mm

364.0 x 515.0 mm

257.0 x 364.0 mm

CHECKPOINT

Please see Section 3.3, "Using Cut Sheets" for details on how to load cut sheets

in the printer.

3-2

Page 37

Print Area

The JW220 printer can print within the areas described below.

CAUTION

• Depending on how the paper is loaded in the printer, the margin sizes may vary

slightly.

• When the roll paper cutter is used to cut roll paper, the operating environment

may cause slight changes in the paper size (the length in the paper feed direc-

tion) to occur.

Roll paper

Printing can be performed in the area up to 5 mm from all the edges of the paper

(leading edge, trailing edge, left and right edges).

5mm

Leading edge

5mm

Paper size

Left edge

Paper feed direction

Print area Right edge

5mm

Trailing edge

5mm

3-3

Page 38

Cut sheets

Standard print area

Printing can be performed in the area up to 5 mm from the leading edge, 13 mm from

the trailing edge, and 5 mm from the left and right edges. (When "Wide" has been

selected for "Margin Settings" in the driver setting menu.)

5mm

Leading edge

5mm

Paper size

Left edge

Paper feed direction

Print area Right edge

13mm

Trailing edge

5mm

Expanded print area

Printing can be performed in the area up to 5 mm from all the edges of the paper

(leading edge, trailing edge, left and right edges). (When "Narrow" has been selected

for "Margin Settings" in the driver setting menu)

5mm

Leading edge

5mm

Paper size

Left edge

Paper feed direction

Print area Right edge

5mm

Trailing edge

5mm

3-4

Page 39

CAUTION

• With the Expanded print area, the print quality may deteriorate at the trailing

edge.

• The guaranteed area for accurate printing is the area where the margins are 5

mm for the leading edge, 13 mm for the trailing edge, and 5 mm for the left and

right edges.

3-5

Page 40

3.2 Using Roll Paper

IMPORTANT

• To obtain high quality printed results, be sure to use Graphtec-supplied paper.

• The rolls must be outside wound, with printing performed on the outer surface.

When loading a roll of paper in the printer, try to avoid touching the printing

surface directly with your hands.

Fingerprints on the printing surface will adversely affect ink adhesion.

• Take care not to cut your fingers on the edges of the paper when handling it.

• Paper may not be fed correctly and may become jammed if the leading edge of

the roll paper is not straight or if there is adhesive from the fastening tape

remaining on the paper. Make sure that the leading edge is straight before

loading the paper in the printer.

Loading roll paper

1. Press the printer's [POWER] button to turn on the printer.

Check that the [POWER] button LED lights blue.

Note: Immediately after the power is turned on, the printer performs an initialization

operation. Wait until the initialization operation has been completed before

proceeding with the paper loading operation.

2. Check the direction in which the paper is wound, and then slide the roll onto the

stocker shaft. At this time, slide the roll along the shaft until its right edge (as shown

in the figure) fits onto the flange. Next, firmly insert the stopper so that it fits into the

core at the other end of the roll.

Roll paper

Stocker shaft

Stopper

FlangeStopper

Roll paper

CAUTION

If the paper edges are not flush with the core at the sides of the roll, printing will

3-6

Page 41

not be performed correctly. Make sure that that the paper edges at both the left

and right sides of the roll are flush with the core.

The roll paper edges are

flush with the core

Roll paper

Roll paper edges

3. Check that the access door is closed.

If it is open, close it.

Access door

The roll paper edges are

not flush with the core

Roll paper Roll paper core

Uneven roll paper take-up

4. Insert the roll paper stocker holding the roll into the stocker holders, making sure that

the flange is at the right.

Flange

Stocker holders

5. Pull a length of paper out from the roll, making sure that the left and right sides are

pulled out evenly. Next, while making sure that there is no slack in the roll, place

your hands on the areas indicated by a black circle (●) in the figure below and guide

the leading edge of the paper into the paper feed slot until it contacts the feed rollers

inside the printer.

A "beep" sound is emitted, and the roll paper is loaded automatically.

3-7

Page 42

Paper feed slot

CAUTION

• Make sure that the left and right sides of the roll paper are pulled out evenly. If

the roll paper is loaded at an angle, the skew detection function will cause the

[ERROR] LED (red) on the control panel to light.

If the [ERROR] LED lights (red), follow the procedure described below to pull

the roll paper out toward the rear of the printer and then reload it.

Procedure

(1) Hold the roll paper that has been inserted into the paper feed slot at the left

and right edges, and pull it gently back toward the rear of the plotter (the side

with the roll paper stocker).

(2) Rotate the roll paper stocker toward the rear, and, while making sure that the

right edge touches the flange, wind the paper back onto the roll. At this time,

make sure that the left and right edges of the roll paper are flush with the

core.

(3) Press the [CANCEL] button on the control panel, and check that the [ERROR]

LED (red) is extinguished.

(4) Pull a length of paper out from the roll, making sure that the left and right

sides are pulled out evenly, and then insert the leading edge into the paper

feed slot once again.

• If the leading edge is cut on an angle, remove the roll paper stocker from the

printer, remove the roll from the stocker, and then trim the leading edge so that

it is parallel with the stocker.

6. The roll paper stops automatically at the printing position, and the printer is now

ready to print.

CHECKPOINT

• Make sure that there is no slack in the paper. If there is any slack, rotate the roll

paper stocker toward the rear to take up the slack, making sure that the right

edge is in contact with the flange.

3-8

Page 43

Removing roll paper

1. Press the printer's [POWER] button to turn on the printer.

Check that the [POWER] button LED lights blue.

Note: Immediately after the power is turned on, the printer performs an initialization

operation. Wait until the initialization operation has been completed before

proceeding with the paper removal operation.

2. Press the [REVERSE] button on the control panel to feed the paper toward the rear

of the printer.

REVERSE

3. Rotate the roll paper stocker in the reverse direction to take up the paper. Next,

remove the roll paper stocker from the stocker holders.

3-9

Page 44

3.3 Using Cut Sheets

IMPORTANT

• To obtain high quality printed results, be sure to use Graphtec-supplied paper.

• Load cut sheets with the printing surface face-down. When loading a cut sheet

in the printer, try to avoid touching the printing surface directly with your

hands.

Fingerprints on the printing surface will adversely affect ink adhesion.

• Take care not to cut yourself on the edges of the paper when handling it.

• Load cut sheets individually.

Loading cut sheets

1. Press the printer's [POWER] button to turn on the printer.

Check that the [POWER] button LED lights blue.

2. Check the orientation of the cut sheet, making sure that the printing surface is facedown, and then align the left edge of the sheet with the paper guide on the paper

guide table. Next, while lightly holding down the sheet, insert its leading edge into the

paper feed slot until it contacts the feed rollers inside the printer. A "beep" sound is

emitted, and the cut sheet is loaded automatically.

3-10

Page 45

Paper feed slot

Paper guide

The loading and printing directions of

standard-size printing paper

A4 size

A3 size

A2 size

A1 size

Push forward

Paper guide table

Printing paper

Printing surface

Insertion direction

Feed rollers

Cut sheet loading direction

Cut sheet

Beep

Cut sheet

A "beep" sound is emitted when

the cut sheet is inserted in the printer.

3. The cut sheet stops automatically at the printing position, and the printer is now

ready to print.

3-11

When the sheet is inserted a little further,

it is automatically fed and loaded.

Page 46

Removing a cut sheet

1. Press the printer's [POWER] button to turn on the printer.

Check that the [POWER] button LED lights blue.

2. Press the [FORWARD] button on the control panel to feed the sheet in the forward

direction.

FORWARD

3-12

Page 47

3.4 Using the A2-size Paper Feed Cassette

The A2-size paper feed cassette is designed specifically for feeding plain paper.

Cut sheets of standard-size paper, from A4-size to A2-size*, can be loaded in the A2size cassette to enable automatic feeding of paper to the printer.

* Please note that only paper of the same size can be loaded at one time in the cas-

sette.

The number of cut sheets that can be loaded

Paper type

Plain paper

(64 g/m

2

Loadable number

of sheets

Approx.

)

100 sheets

The number of sheets is a guideline only.

When actually loading the paper in the cassette,

make sure that the top of the stack is below the

line under the [ MAX ] mark printed on the

stock tray.

Remarks

CAUTION

• Plain paper is the only type of paper that can be loaded in the A2-size paper

cassette. When using cut sheets of tracing or other thin paper, load each sheet

manually on the cassette's paper feed table.

• Be sure to observe the following points when loading paper in the A2-size paper

feed cassette:

* Align the edges of the paper stack before loading it in the tray.

* Do not use paper that has been folded or creased.

* Fan the paper stack thoroughly before loading it in the tray.

If the paper is not fanned, paper jams may occur or two or more sheets may

be fed at the same time.

Attaching and removing the A2-size paper feed cassette

Attaching the cassette

1. Unfasten the two setscrews used to attach the paper guide table to the printer, and

then remove the paper guide table.

Phillips screwdriver

provided with the printer

Setscrew

3-13

Page 48

2. Attach the A2-size paper feed cassette at the location from which the paper guide

table was removed. To attach the A2-size paper feed cassette, insert it fully into the

printer as shown in the diagram below. After the cassette has been inserted, gently

pull on it to check that it is firmly inserted.

Stock tray

Removing the cassette

Grasp the cassette at both sides, raise it slightly and then pull it out toward you.

CAUTION

• Check that the A2-size paper feed cassette has been mounted correctly. Incor-

rect mounting may result in a paper jam or incorrect feeding of the paper.

• When using the printer with the A2-size paper feed cassette attached, make sure

that the printer is installed in a stable location. Moreover, make sure that the

feet on the printer and on the cassette are all positioned on the desk surface.

• When moving the printer, be sure to remove the A2-size paper feed cassette

first. Moving the printer with the cassette still attached will place an undue load

on the cassette. Moreover, if the cassette falls out of the printer, there is a risk

of a malfunction or injury.

3-14

Page 49

Loading paper in the A2-size paper feed cassette

1. Lift up the paper guide table, and remove it from the cassette.

Feed guide

CAUTION

A feed guide is attached to the underside of the paper guide table.

Take care not to touch this feed guide.

Paper guide table

2. Check that the printing surface is face-down, and then insert the stack of printing

paper (standard-size plain paper) in the stock tray. Check that the orientation of the

paper is correct, and that the stack is not too high. Align the stack's left edge with the

stock tray's left edge, and its top edge with the tray's innermost edge. Next, move the

paper alignment levers to match the paper size, and to hold the stack in place to

prevent it from shifting.

Note: Be sure to load the paper so that the printing surface is face-down.

3-15

Page 50

Paper stack height

Align with the left and innermost edges

Printing surface

Printing paper

(Standard-size paper)

Paper alignment levers

The loading and printing directions of

standard-size printing paper

A4 size

A3 size

A2 size

Insertion direction

3. Attach the paper guide table.

IMPORTANT

Make sure that the paper guide table is attached correctly. (Check that the protru-

sion at the left underside of the tray is correctly fitted into the cutout at the left

side of the stock tray).

Incorrect attachment of the paper guide table may result in a paper jam or in

incorrect feeding of the paper.

Protrusion

Cutout

3-16

Page 51

Manual feeding

Paper can still be fed into the printer manually even if the A2-size paper feed cassette

has been installed. In this case, paper that is fed manually is given priority. Insert sheets

for manual feeding one at a time.

IMPORTANT

• To obtain high quality printed results, be sure to use Graphtec-supplied paper.

• Make sure that the printing surface of the paper for manual feeding is face-

down. When loading the paper, try to avoid touching the printing surface di-

rectly with your hands.

Fingerprints on the printing surface will adversely affect ink adhesion.

• Take care not to cut your fingers on the edges of the paper.

• When using the manual paper feed function to perform printing, set the number

of sheets for printing to "1" in the printer driver. If the number of sheets has

been set to a multiple number, the paper loaded in the cassette will be used for

printing the second and subsequent sheets.

1. Press the printer's [POWER] button to turn on the printer.

Check that the [POWER] button LED lights blue.

Note: Immediately after the power is turned on, the printer performs an initialization

operation. Wait until the initialization operation has been completed before

proceeding with the paper loading operation.

2. Check the orientation of the sheet and that the printing surface is face-down, and

then align the left edge of the sheet with the paper guide on the paper guide table.

Next, while lightly holding down the sheet, insert its leading edge into the paper feed

slot until it contacts the feed rollers inside the printer.

A "beep" sound is emitted, and the cut sheet is loaded automatically.

3-17

Page 52

Paper feed slot

Push forward

Printing paper

Printing surface

Paper guide

The loading and printing directions of

standard-size printing paper

A4 size

A3 size

Insertion direction

A2 size

A1 size

Feed rollers

Cut sheet

loading direction

Cut sheet

Beep

Cut sheet

A "beep" sound is emitted when

the cut sheet is inserted in the printer.

3. The cut sheet stops automatically at the printing position, and the printer is now

ready to print.

When the sheet is inserted a little further,

it is automatically fed and loaded.

3-18

Page 53

3.5 Using the Anti-Curling Guides

If the paper used for printing is thin and curls up, attach the anti-curling guides before

starting the printing operation. Insert the anti-curling guides into the holes provided on

the printer, and then slide them to the right to lock them in place.

IMPORTANT

Be sure to attach the anti-curling guides when using thin paper such as tracing

paper. If printing is performed without the guides attached, there is a risk of the

leading edge being caught up in the paper feed slot at the front of the printer.

Anti-curling guides

3-19

Page 54

Chapter 4 Printer Driver

A printer driver is required to send data from the computer to the printer.

Be sure to install the OPS670 printer driver in the computer used to send data to your

printer for printing.

The OPS670 printer driver is compatible with the following Windows operating systems:

Windows XP, Windows 2000,

Windows Millennium Edition (Me), Windows 98 Second Edition (SE)

Note: Please see the separate "Quick Start Guide" for the OPS670 driver installation

procedure.

4.1 Printing from Windows

To print from a Windows application, follow the procedure described below.

IMPORTANT

When executing a printing operation from the computer, insofar as possible close

all the other applications that are not being used. If other applications are left

open, there is a risk that computer processing will slow down, affecting the

transfer of data for printing and causing a deterioration in the printing quality.

1. Select "Print" from the [File] menu in your application software.

2. Check that the Graphtec JW220-06 printer driver is displayed in the [Select Printer]

screen.Next, specify the "Number of copies" for "Page Range".

Note: The parameters displayed in the [Print] dialog screen may vary depending on

the application software used.

4-1

Page 55

Make other settings as required. Open the Printer Settings screen from the driver's

Properties dialog screen (click the "Preferences" button to open the Printer Settings

screen), and use the [Base Setting], [Options] and [Graphics] tabs to make settings

such as the paper type and feed method, and the print quality. For further details, see

Section 4.4, "Printer Driver Functions".

3. Click the [Print] button to start printing.

4-2

Page 56

4.2 Canceling Printing in Windows

To cancel printing, follow the procedure described below.

1. Open the Graphtec JW220-06 printer driver icon from the [Printers] folder.

2. Select the print job that you want to cancel, and then select [Cancel] from the [Document] menu. Check that the print job is deleted.

Print job

3. If the printer continues to process the print job and the DATA LED (green) is flashing,

press the [CANCEL] button.

DATA

CAUTION

ERROR

CANCEL FORWARD REVERSE PAPER CUT

4. If the print job still cannot be cancelled by performing the operations described

above, press the [POWER] button to turn off the power supply to the printer. Wait for

at least five seconds, and then turn the power on again.

4-3

Page 57

4.3 Printer Driver Capabilities

The easy-to-use OPS670 printer driver enables high quality printing of a wide range of

data, from monochrome and color CAD drawings through to images such as photographs.

Moreover, the driver continuously monitors the printer status, displaying print head

information via the printer information dialog screen, as well as various messages, on

your computer's screen.

Main driver features

• Enables the drawing of black single-color line segments and various types of line

segment settings (line width. line pitch, etc.) that are necessary for the output of CAD

drawings.

• The printer status can be checked at the Printer Information dialog screen.

• [Data Information] tab:

Click this tab to display a list of the printer driver settings.

• [Printer Information] tab:

Click this tab to display print head and ink cartridge information. Click the [Refresh]

button to display the most recent printer information.

• [Maintenance] tab:

Click this tab to perform print head cleaning and alignment.

• Message display:

Displays the printer status when an error has occurred, or when a job is being

output.

Compatible Operating Systems

The OPS670 printer driver is compatible with the following Windows operating systems:

Windows XP, Windows 2000,

Windows Millennium Edition (Me), Windows 98 Second Edition (SE)

4-4

Page 58

4.4 Printer Driver Functions

Note: The Windows XP environment is used for the screens in the explanations.

[Base Setting] tab

Use this tab to make basic printer-related settings such as Print quality, Paper Source,

and Paper Size.

Paper Source

Paper Size

Print Area

Margin

Orientation

Use this parameter to specify the printer's paper source.

Select either "Roll Paper" or "Cut Sheet".

Make sure that the paper loaded in the printer (roll paper or cut sheet) is

the same as the setting specified in the driver.

Use this parameter to specify the size of the paper that will actually be

used for printing.

Either select a standard paper size or specify your desired paper size.

For long-length prints or other special applications where there is no

The actual printing or output area is displayed here.

The displayed size represents the print size after the print margins have

been subtracted.

Use this parameter to specify the print margins (the areas where printing

cannot be performed). If "Roll Paper" has been specified for "Paper

Source", this parameter is displayed in gray and the margins are a fixed

size.

• Roll Paper Leading: trailing, and left/right edges: All 5 mm

If "Cut Sheet" was selected for the paper source, select either "Narrow" or

"Wide".

• Cut Sheet (Narrow): Leading, trailing, and left/right edges: All 5 mm

• Cut Sheet (Wide): Leading edge: 5 mm, trailing edge: 13 mm,

left/right edges: 5 mm

Select the orientation to suit the direction in which the paper is loaded.

Use the drawing of the printer at the left of the screen to check the

orientation.

4-5

Page 59

90 Rotated

Mirror

Print quality

Paper type

Color/

Mono mode

Use these parameters to print the image rotated 90 degrees or as a mirror

image.

Use the direction of the "F" symbol in the drawing of the printer at the left of

the screen to check the rotation.

Use this parameter to specify the print quality.

Select from "High-speed", "Normal", and "High quality"

• High-speed: The printing speed takes priority.

This setting is suitable for check printing.

• Normal: Printing is performed at normal speed and quality.

• High quality: The printing quality takes priority.

The slower the print speed, the higher the printing quality.

Use this parameter to specify the paper type that you plan to use. For

optimal results, make sure that the paper type selected matches the paper

that is loaded in the printer.

Use this parameter to specify monochrome or color printing, and the type

of application.

Select from "Color drawing", "Color graphic", "Monochrome drawing", and

"Monochrome graphic".

• "Color drawing", "Monochrome drawing"

Use these settings when outputting CAD drawings, text data, and so

forth.

• "Color graphic", "Monochrome graphic".

Use these settings when outputting data with a lot of solid-fill areas, such

as photos or computer graphics data.

Speed

Precedence

Copies

Printer

Information

Restore

Defaults

Use this parameter to specify the printing speed.

Speed Precedence

The print quality takes precedence. However, the printing speed is slow.

To give even more priority to the print quality, select [Base Setting] tab

>"Print quality" > "High quality".

Speed precedence

The printing speed takes precedence. However, depending on the

content, the printing quality may be a little coarse.

To give even more priority to the printing speed, select [Base Setting]

tab >"Print quality" > "High-speed".

The "Speed Precedence" parameter can only be specified for the

following setting conditions.

• "Print quality" > "Normal"

• "Paper type" > "Plain"

• "Color/Mono mode" >"Monochrome drawing"

Use this parameter to specify the number of copies to be printed.

Click the [Printer Information] button to open the [Printer Information] dialog

screen.

The Printer Information] dialog screen is used to display information

relating to the print heads and ink, as well as to perform printer

maintenance.

For further details, see Section 4.5, "Printer Information Button".

Click the [Restore Defaults] button to return all the [Base Setting] tab

settings to their default values.

4-6

Page 60

IMPORTANT

Notes on the printer driver settings and the printing quality.

If "Speed Precedence" has been selected as shown in <Printer driver setting

"Speed Precedence"> below, depending on the type of data and the paper used,

the printing may be a little uneven in places.

<Printer driver setting "Speed Precedence">

• [Base Setting] tab > "Print quality" > "High-speed"

• [Base Setting] tab > "Speed precedence" > "Checkbox checked"

In these cases, since speed takes precedence during printing, the printing quality

may be a little coarse, making it suitable for check prints only.

To even out the printing, make the "Speed Precedence" settings shown below

and then perform printing.

<Printer driver setting "Speed Precedence">

• [Base Setting] tab > "Print quality" > "High quality" or "Normal"

• [Base Setting] tab > "Speed precedence" > "Checkbox unchecked"

If satisfactory image quality cannot be obtained even after making the above

settings, perform print head*1 and maintenance station*2 cleaning.

If the printer is used as is, there is a risk of shortening the life of the print heads.

Do not continue to use the printer in this status.

*1 Print head cleaning

(See Section 5.3, "Print Head Cleaning and Alignment" in this manual.)

*2 Maintenance station cleaning

(See Section 5.7, "Cleaning the Maintenance Station" in this manual.)

4-7

Page 61

[Options] tab

Use this tab to make settings such as Scaling and Offset, and to select whether or not

to cut the paper after printing.

Use this parameter to specify the scaling ratio.

Printing is normally performed at the 100% setting.

Scaling

The Scaling setting can be made in the 25 to 400% range, in 1% units.

Examples

To enlarge an A2-size image to A1-size, specify 141%.

To reduce an A1-size image to A2 size, specify 70%.

Offset

Paper cut

Drying Time

Distance

adjustment

Use this parameter to move the printing origin.

If a check is inserted in the "Offset" checkbox, the new origin position can

be specified by entering values in the X and Y directions, in 0.1-mm

increments.

Use this parameter to select whether or not to perform cutting of the paper

after a printing operation. Select either "Perform cut" or "No cut".

This parameter can only be specified when the paper source is "Roll

Paper".

Use this parameter to specify the length of time between data output

operations.

Use this parameter to adjust the distance in the paper feed direction.

If the paper type, thickness or other factors cause a discrepancy in the

paper feed distance to occur, enter a corrective value.

The corrective value can be set in the range from -3.00% to +3.00%, in

increments of 0.01%.

Example

If a 1 m (1000 mm) line segment is printed as 995 mm, set a corrective