Page 1

GL840

USER’S MANUAL

MANUAL NO.GL840-UM-152

Page 2

Page 3

To Ensure Safe and Correct Use

To Ensure Safe and Correct Use

To ensure safe and correct use of the GL840, read this manual thoroughly before use.

•

After having read this manual, keep it in a handy location for quick reference as needed.

•

Do not permit small children to touch the GL840.

•

The following describes important points for safe operation. Please be sure to observe them strictly.

•

Conventions Used in This Manual

To promote safe and accurate use of the GL840 as well as to prevent human injury and property damage,

safety precautions provided in this manual are ranked into the ve categories described below. Be sure you

understand the difference between each of the categories.

This category provides information that, if ignored, is

DANGER

highly likely to cause fatal or serious injury to the operator.

WARNING

CAUTION

HIGH

TEMPERATURE

ELECTRICAL

SHOCK

Description of Safety Symbols

The symbol indicates information that requires careful

attention (including warnings). The specic point requiring

attention is described by an illustration or text within or next to

the symbol.

This category provides information that, if ignored, is

likely to cause fatal or serious injury to the operator.

This category provides information that, if ignored, could

cause physical damage to the GL840.

This category provides information that, if ignored, is

likely to cause burns or other injury to the operator due to

contact with high temperature.

This category provides information that, if ignored, is

likely to expose the operator to electrical shock.

The symbol indicates an action that is prohibited. Such

prohibited action is described by an illustration or text within or

next to the symbol.

The symbol indicates an action that must be performed.

Such imperative action is described by an illustration or text

within or next to the symbol.

i

Page 4

Safety Precautions

Safety Precautions

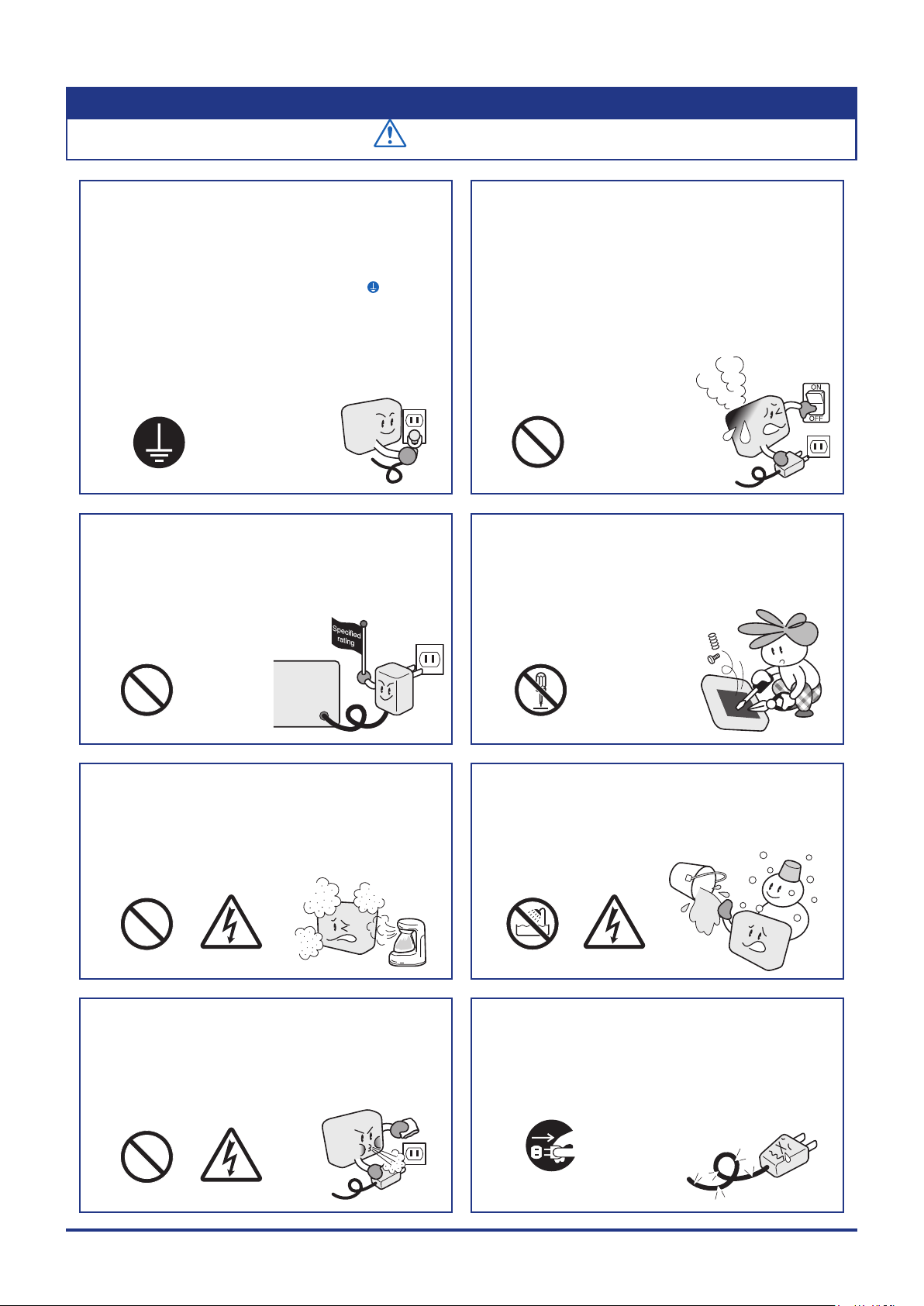

WARNING

Be sure to securely connect the GL840’s power cord.

After checking that the power switch is turned off, connect

•

the power cord’s female plug to the GL840 and then

connect its male plug into the electrical socket.

Before running the GL840 using a DC power supply, be

•

sure to ground the protective ground terminal ( ) to avoid

electrical shock and fire hazards. For grounding, use a

ground wire with a diameter of at least 0.75 mm2. When

using the GL840 in an environment where grounding is

not possible, ensure that the voltage to be measured is no

greater than 50 V (DC or rms).

Ground the Machine Use prohibited

Before turning on the GL840, ensure that the electric

socket’s supply voltage conforms to the GL840’s

power rating.

Use of a different supply voltage may cause damage to the

•

GL840 or a fire hazard due to electrical

shock or current leakage.

If the GL840 generates smoke, is too hot, emits a

strange odor, or otherwise functions abnormally,

turn off its power and unplug its power cord from the

electrical socket.

Use of the GL840 in such status may result in a fire hazard

•

or electrical shock.

After checking that smoke is no longer being generated,

•

contact your sales representative or nearest Graphtec

vendor to request repair.

Never try to perform repair yourself.

•

Repair work by inexperienced

personnel is extremely dangerous.

Never disassemble or remodel the GL840.

Such action may cause a fire hazard due to electric shock

•

or current leakage.

Contact with a high-voltage component inside the GL840

•

may cause electric shock.

If repair is required, contact your

•

sales representative or nearest

Graphtec vendor.

Use prohibited No disassembly

Avoid using the GL840 in extremely dusty or humid

places.

Such use may cause a fire hazard due to electrical shock or

•

current leakage.

Use prohibited

Prevent dust or metallic matter from adhering to the

power supply connector.

Adhesion of foreign matter may cause a fire hazard due to

•

electrical shock or current leakage.

Watch out for

electrical shock

Avoid using the GL840 in places where it may be

exposed to water such as bathrooms, locations

exposed to wind and rain, and so on.

An electrical shock or fire may be caused due to current

•

leakage.

Avoid water

Never use a damaged power cord.

Use of a damaged cord may result in a fire hazard due to

•

electrical shock.

If the cord becomes damaged, order a new one to replace

•

it.

Watch out for

electrical shock

Use prohibited

Watch out for

electrical shock

Unplug the power

cord from the socket

ii

Page 5

Safety Precautions

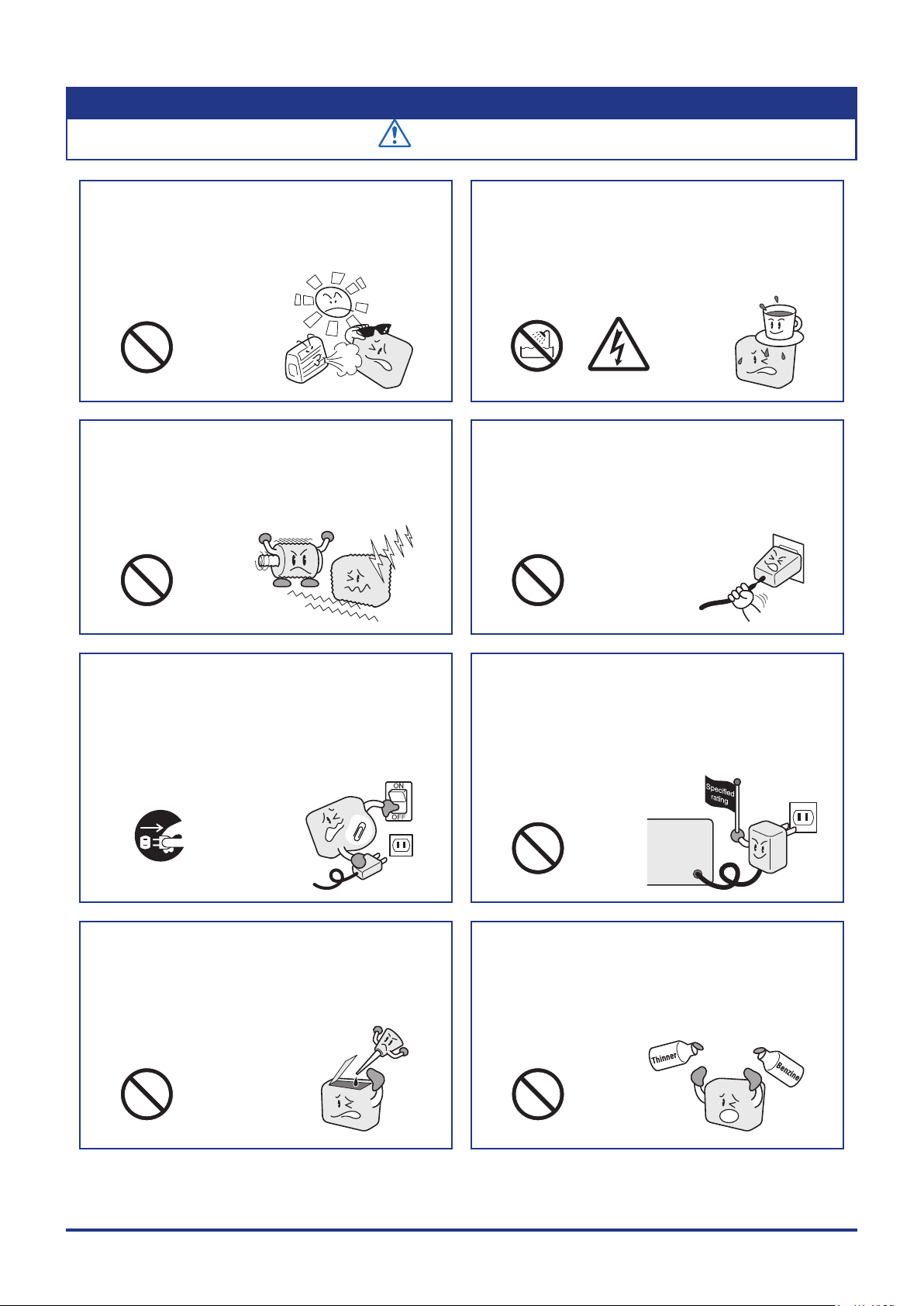

CAUTION

Safety Precautions

Do not use or store the GL840 in a location exposed to

direct sunlight or the direct draft of an air conditioner

or he ate r.

Such location may impair the GL840’s performance.

•

Use prohibited

Do not use the GL840 in a location subject to

excessive mechanical vibration or electrical noise.

Such location may impair the GL840’s performance.

•

Use prohibited Use prohibited

Do not place coffee cups or other receptacles

containing uid on the GL840.

Fluid spilling inside the GL840 may cause a fire hazard due

•

to electrical shock or current leakage.

To insert or disconnect the power cord or a signal

input cable, grasp the power cord’s plug or the signal

input cable’s connector.

Pulling the cord/cable itself damages the cord/cable,

•

resulting in a fire hazard or electrical shock.

Avoid water

Watch out for

electrical shock

If uid or foreign matters enters inside the GL840,

turn off the power switch and disconnect the power

cord from the electrical socket.

Use in such status may cause a fire hazard due to electrical

•

shock or current leakage.

Contact your sales representative or nearest Graphtec

•

vendor to request repair.

Unplug the power

cord from the socket

Do not attempt to lubricate the GL840’s mechanisms.

Such action may cause the GL840 to break down.

•

Do not input voltage that exceeds the permissible

input voltage range that is specied on the GL840’s

label.

Exceeding the specified voltage input range may cause

•

electrical shock or a fire hazard.

Use prohibited

Never clean the GL840 using a volatile solvent (such

as thinner or benzine).

Such action may impair the GL840’s performance.

•

Clean off any soiled areas using a soft dry cloth.

•

Use prohibited Use prohibited

iii

Page 6

Safety Precautions

Strict observance

Strict observance

Safety Precautions

CAUTION

When using the wireless LAN (when option is

installed), please note the following:

If you have an implantable pacemaker or implantable

•

defibrillator installed, radio signals from the device may have

an effect on the operation of your implantable pacemaker or

implantable defibrillator.

When using the wireless LAN (when option is

installed), please note the following:

Turn off the device in places where wireless radio signal

•

use is restricted, such as on aircrafts and in hospitals. The

device can have an effect on electronic devices, medical

devices, etc., and may cause malfunctions.

Use prohibited

When using the wireless LAN (when option is

installed) in a medical establishment, please note the

following rules:

Please turn off the power of this product in hospital wards.

•

Each medical institution has its own usage prohibitions in

•

various areas. Be sure to follow these.

When using the wireless LAN (when option is

installed), please note the following:

In the event that the device has an effect on automatic

•

electronic devices such as cars or elevators, immediately

turn off the GL840.

Use prohibited

Do not use the device in any way not specied in this

manual. There is a danger that protective provisions

will have not been put in place.

Use prohibited

This GL840 is not meant for use with lifesaving devices or devices with mission-critical high reliability or

high safety requirements (medical devices, aerospace devices, shipping devices, nuclear power devices,

etc.). In the event that this GL840 causes injury or property damage when used under these circumstances,

the maker assumes absolutely no responsibility and is not liable.

The module connection terminal is for use only with

separately sold sensors and modules. Do not connect

any other devices. Doing so may damage the GL840.

Use prohibited

iv

Page 7

Introduction

Introduction

Thank you for purchasing the GL840 midi LOGGER.

Please read this manual thoroughly before attempting to use your new product to ensure that you use it correctly

and to its full potential.

Notes on Use

Be sure to read all of the following notes before attempting to use the GL840 midi LOGGER.

1. Note on the CE Marking

The GL840 midi LOGGER complies with the following standards.

• EN 61326-1 Class A standard based on the EMC directive (2014/30/EU)

• EN 61010-1:2010 3rd standard based on the LVD directive (2014/35/ EU)

• EN 301 489-17/-1, EN 300 328 standards based on the R&TTE directive (1999/5/EC)

Although the GL840 complies with the above-mentioned standards, be sure to use it correctly in accordance

with the instructions and notes provided in this manual.

Moreover, use of the GL840 by incorrect procedures may result in damage to the GL840 or may invalidate its

safeguards. Please conrm all of its notes regarding use and other related information to ensure correct use.

2. Warning

This is a Class A product according to the EMC directive. In a domestic environment, this product may cause

radio interference or may be affected by radio interference to the extent that proper measurement cannot be

performed.

3. Notes on Radio Law

When using the GL840 midi LOGGER in the wireless LAN (when option is installed), please note the

following:

Do not remove the technical standards compliance label. Do not use the device if it does not have a label

on it.

This GL840 uses the 2.4GHz frequency band.

The following devices and transmitters use the same frequencies and should not be used near this GL840:

• Microwave ovens

• Pacemakers and other industrial, science, and medical devices

• Radio transmitters used in mobile body identication devices on factory production lines, etc. (transmitters

requiring licensing)

• Specied low-power radio transmitters (transmitters not requiring licensing)

Communications may become slower or impossible due to radio interference.

The signal may be weak or communications may become slower or impossible depending on the

circumstances this GL840 is used in. Take particular note of steel-reinforced, metal, concrete, and other

structural materials that can inhibit radio waves.

I

Page 8

Introduction

This GL840 is meant for use in Japan, the US, and Europe. It has not been certied for use under any other

country’s radio laws.

The following are each region’s certication marks.

Japan

US

Europe..........CE Mark

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1)This device may not cause harmful interference, and (2)this device must accept any interference received,

including interference that may cause undesired operation.

FCC CAUTION

Change or modications not expressly approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

This transmitter must not be co-located or operated in conjunction with any other antenna or transmitter.

4. Notes for Safe Operation

(1) Be sure to use the Graphtec-supplied AC adapter. In environments where there is a lot of noise or where

the power supply is unstable, we recommend that you ground the GL840.

(2) When a high-voltage signal cable has been connected to the main unit’s analog signal input terminal,

avoid touching the leads of the input terminal’s signal cable to prevent electrical shock due to high voltage.

(3) Ensure that the GL840’s power source is positioned so that it can easily be disconnected.

(4) When connecting the high voltage signal line to the analog signal input terminal using the 4ch voltage/

temperature terminal on the separately sold module (GS-4VT), avoid touching the leads of the input

terminal’s signal line to prevent electrical shock due to high voltage.

Contains FCC ID: ANSBP3591

5. Notes on Functions and Performance

(1) Be sure to connect the main unit to an AC or DC power supply that conforms to the rated range.

Connection to a non-rated power supply may cause the main unit to overheat and break down.

(2) Do not block the vent on the main unit.

Continued operation with the vent blocked may cause the main unit to overheat and break down.

(3) To avoid malfunctions and other damage, avoid using the GL840 in the following locations.

• Places exposed to high temperature and/or high humidity, such as in direct sunlight or near

heatingequipment.

(Allowable temperature range: 0 to 45°C (0 to 40°C when a battery pack is mounted, 15 to 35°C when

battery is being charged), Allowable humidity range: 5 to 85%R.H., non-condensing)

• Locations subject to excessive salt spray or heavy fumes from corrosive gas or solvents.

• Excessively dusty locations.

II

Page 9

Introduction

• Locations subject to strong vibrations or shock.

• Locations subject to surge voltages and/or electromagnetic interference.

(4) If the main unit becomes soiled, wipe it off using a soft, dry cloth. Use of organic solvents (such as thinner

or benzene) causes deterioration and discoloration of the outer casing.

(5) Do not use the GL840 in the vicinity of other devices which are susceptible to electromagnetic

interference.

(6) Measured results may not conform to the stated specications if the GL840 is used in an environment

which is subject to strong electromagnetic interference.

(7) Insofar as possible, position the GL840 input signal cables away from any other cables which are likely to

be affected by electromagnetic interference.

(8) For stabilized measurement, allow the GL840 to warm up for at least 30 minutes after turning it on.

(9) When you want to use in combination of the Petit LOGGER GL100-WL (separately sold) and various

modules (such as GS sensor and terminal / adapter), please refer to the GL100 User’s Manual.

When using in combination described above, please be careful to the operating environment because

•

the environmental conditions of the GL840 midi LOGGER are applied.

It may cause abnormal operation or damage.

• Allowable temperature range: 0 to 45°C, Allowable humidity range: 5 to 85%R.H, non-condensing.

(0 to 40°C when battery-powered / 15 to 35°C when charging)

When using temperature and humidity sensor (GS-TH) and the GL840 at the same time, the

operating environment of GL840 is applied.

Temperature and Humidity Sensor (GS-TH):

•

• Humidity sensors measure the change in dielectric capacity of water adsorption. As a result, humidity

from organic materials such as ne particles or exhaust gas may have an effect on the sensor. Use

in environments with large quantities of these organic materials may lead to signicant measurement

inaccuracies.

CO2 Sensor (GS-CO2 ):

•

• Because exhaled CO2 may have an effect on the sensor readings, do not use the sensor to take

measurements near the face.Additionally, should air ow to the sensor be blocked, it will result in

inaccurate readings, so be sure to keep vent holes open.

Illumination / Ultraviolet Sensor (GS-LXUV):

•

• When measuring illumination or ultraviolet light that can have harmful effects on the eyes or skin, be

sure to use protective eyewear, shielding, etc.

• If the sensor becomes dirty, it may affect measurements, so wipe it with a soft cloth when it becomes

dirty.

• Take care to avoid cracking the sensor when handling it. If the sensor is damaged or cracked it may

affect measurements, so replace the sensor.

Others

•

• Depending on the usage and operating environment of Temperature and Humidity Sensor (GSTH), CO2 Sensor (GS-CO2), and Illumination / Ultraviolet sensor (GS-LXUV), it is recommended to

replace periodically the sensor with new one because the sensor performance may be deteriorated.

• When connecting the GS-3AT (3-axis accelerometer) module to the GL840 midi LOGGER, please

note that IP54 standard is not satised.

III

Page 10

Introduction

Notes on the Use of This Manual

(1) All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form or by any means, without the prior written permission of Graphtec Corporation.

(2) The specications and other information in this manual are subject to change without notice.

(3) While every effort has been made to supply complete and accurate information about this product, please

address any inquiries about unclear information, possible errors, or other comments to your sales representative

or nearest Graphtec vendor.

(4) Notwithstanding the preceding paragraph, Graphtec Corporation assumes no liability for damages resulting

from the use of the information contained herein or of the product.

About Registered Trademarks

Microsoft and Windows are registered trademarks or trademarks of Microsoft Corporation in the U.S. and

elsewhere.

Other company names and product names included in this manual are registered trademarks or trademarks of

their respective companies.

Copyright

All copyrights regarding this manual belong to Graphtec Corporation.

IV

Page 11

CONTENTS

To Ensure Safe and Correct Use ................................................i

Safety Precautions ...........................................................ii

Introduction .................................................................I

Notes on Use .................................................................I

Notes on the Use of This Manual ............................................... IV

About Registered Trademarks .................................................. IV

Copyright .................................................................. IV

CHAPTER 1 General Description

1.1 Overview .............................................................1-2

1.2 Features .............................................................1-2

1.3 Operating Environment .................................................1-3

Ambient Operating Conditions ................................................. 1-3

Warming-up Before Use ..................................................... 1-3

Conguration When in Use ................................................... 1-4

1.4 Notes on Temperature Measurement .....................................1-5

CONTENTS

1.5 Notes on Using the Monitor .............................................1-5

1.6 Changing the Display Language .........................................1-5

CHAPTER 2 Checks and Preparation

2.1 Checking the Outer Casing ..............................................2-2

2.2 Checking the Accessories ..............................................2-2

2.3 Nomenclature and Functions ............................................2-3

2.4 Connecting the Power Cable and Turning on the Power ..................... 2-4

2.5 Connecting the Signal Input Cables ..................................... 2-6

2.6 Logic Alarm Cable Connection and Functions ..............................2-8

2.7 Mounting the SD Memory Card .........................................2 -11

2.8 Installing the Wireless LAN Unit (B-568: Option) ...........................2-14

2.9 Connecting to a PC ...................................................2-16

2.10 Using the Battery Pack (B-569 : Option) ..................................2-19

2.11 Connecting the Humidity Sensor (Optional) ...............................2-21

2.12 Mounting and Removing the Standard Terminal and

Withstand high-voltage high-precision Terminal

...............................................2-22

2.13 Mounting the Extension Terminal Base (Optional) and

Extension Terminal Cable (Optional)

2.13.1 Mounting the extension terminal base ...................................... 2-24

2.13.2 Mounting multiple extension terminals ..................................... 2-26

2.14 Precautions to Observe When Performing Measurement ....................2-30

2.15 Noise Countermeasures ...............................................2-34

2.16 Connecting the Temperature and Humidity Sensor (GS-TH) (Optional)

.........................................................2-24

..........2-35

C-1

Page 12

CONTENTS

2.17 Connecting the 3-axis Acceleration / Temperature Sensor (GS-3AT) (Optional) .2-36

2.18 Connecting the 4ch Voltage / Temperature Terminal (GS-4VT) (Optional) ......2-37

2.19 Connecting the 4ch Thermistor Terminal (GS-4TSR) (Optional) .............. 2-40

2.20 Connecting the Illumination / Ultraviolet Sensor (GD-LXUV) (Optional) ....... 2-43

2.21 Connecting the CO2 Sensor (GS-CO2) (Optional) ......................... 2-44

2.22 Connecting the Adapter for AC Current Sensor (GS-DPA-AC) (Optional) ...... 2-45

2.23 Connecting the Branch Adapter for GS (GS-DPA) (Optional) .................2-47

2.24 When Fixing the GL840 Body .......................................... 2-50

2.25 Setting the Date and Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-51

CHAPTER 3 Settings and Measurement

3.1 Window names and functions ...........................................3-2

3.2 Key Operation ....................................................... 3-8

3.3 Operation Modes .....................................................3-17

3.4 Setting Menus .......................................................3-21

(1) AMP settings ............................................................ 3-21

(2) DATA settings ...........................................................3-45

(3) TRIG settings ...........................................................3-50

(4) Interface settings ........................................................3-56

(5 ) WLAN setting ..........................................................3-61

(6) OTHER settings ......................................................... 3-69

(7) FILE menu ............................................................. 3 -73

(8) File box ................................................................3-77

(9) Text input ..............................................................3-79

(10) Data replay menu .......................................................3-80

(11) Integrated bar graph display ...............................................3-84

(12) NAVI menu ............................................................3-88

(13) Quick setting ........................................................... 3-90

(14) To cancel key lock by password ............................................ 3-91

3.5 WEB Server Function ................................................ 3-92

3.6 List of Error Codes .................................................. 3-96

CHAPTER 4 Specication

4.1 Standard Specications ................................................4-2

Standard Specications ...................................................... 4-2

Memory devices ............................................................ 4-3

PC I/F .................................................................... 4-3

Monitor ................................................................... 4-3

Standard terminal input section (GL840-M and B-564) ..............................4-4

Withstand high-Voltage high-precision terminal input section (GL840-WV: B-565) ........ 4-6

4.2 Function Specications ............................................... 4-8

Function Specications ...................................................... 4-8

Trigger/Alarm Functions ...................................................... 4-8

External Input/Output Functions ............................................... 4-9

C-2

Page 13

CONTENTS

4.3 Accessories/Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 -10

Control Software .......................................................... 4-10

Accessories .............................................................. 4-10

Wireless Unit B-568 (Option) ................................................. 4-10

Battery Pack B-569 (Option) ..................................................4 -11

Humidity Sensor B-530 (Option) ...............................................4-11

List of Options ............................................................ 4-12

4.4 External Dimensions ..................................................4-13

INDEX ..............................................I-1

C-3

Page 14

Page 15

CHAPTER 1 General Description

CHAPTER 1 General Description

This chapter provides a general description of the GL840 and its features.

PRODUCT SUMMARY

1.1 Overview

1.2 Fe atures

1.3 Operating Environment

1.4 Notes on Temperature Measurement

1.5 Notes on Using the Monitor

1.6 Changing the Display Language

1-1

Page 16

CHAPTER 1 General Description

1.1 Overview

The GL840 is a compact, lightweight, multi-CH, and multi-purpose data logger with a 7-inch color display.

20CH measurements are available with the standard terminal or Withstand high-voltage high-precision

terminal, and 200CH measurements are available with the extension terminal base. In addition, when

connecting various modules, the voltage, temperature and humidity as well as the acceleration, AC current,

CO2, and illuminance / ultraviolet etc. can be measured.

The GL840 is compatible with the SD memory card. The high-capacity measurement data can be saved in

the SD memory card that has various storage capacities.

For the PC interface, as USB and Ethernet is included as standard, system conguration according to use

is possible. As the Ethernet function is equipped with both WEB server and FTP server functions, remote

supervision and data transfer are also possible. In addition, when the wireless LAN and Petit LOGGER

GL100-WL are combined by installing the wireless unit, the multipurpose remote measurement is also

possible.

1.2 Features

Input

Adoption of a pluggable M3 screw type input terminal facilitates wiring.

•

20CH measurements are supported by the standard terminal or Withstand high-voltage high-precision

•

terminal, and 200CH measurements are supported by the extension terminal base.

When using the Graphtec’s GS series and terminal / adapter, the acceleration, AC current, CO2, and

•

illuminance / ultraviolet measurements are also possible.

Because that standard terminal and Withstand high-voltage high-precision terminal have a whole CH

•

isolated, the different standard signals can be measured at the same time. In addition, when using the

Withstand high-voltage high-precision terminal, the measure environmental conditions of high withstand

voltage can be applied.

Display & Operation

With the GL840’s high-resolution 7-inch TFT color liquid crystal display, you can conrm the waveforms of

•

measured data and each channel’s settings at a glance.

Easy operation is achieved through a straightforward menu structure and key allocation which resembles

•

mobile phones.

Data Capture

Data is directly saved to the large SD memory card (Standard accessory: 4GByte).

•

There two mounting slots for the SD memory card, and long-term measurement can be performed while

•

backing up the data.

* When the optional wireless LAN unit is installed, the SD memory card cannot be inserted into the SD

CARD2 slot.

Because disk image can be used for the SD memory card , multiple data can be saved.

•

The new ring memory capture function maintains latest data even after capturing for a long term. (You

•

need to set how long you want to keep data.)

For voltage, temperature and humidity measurements, data can be captured at sampling rates of up to

•

10 msec per channel by using fewer measuring channels. (Temperature measurement can be done at

sampling rates of 100 msec and higher.)

The GL840 is equipped with the relay recording function, and 2GByte or more data can be saved by

•

switching the to the other le without data missing. (When the capacity of one le reaches 2GByte, the le

is switched.)

1-2

Page 17

CHAPTER 1 General Description

Data Control & Processing

The application software provided lets you set conditions and monitor data on a PC.

•

The USB drive mode function enables the SD memory card to be recognized as an external drive by the

•

PC.

(Connect the GL840 to the PC and turn on the GL840 power while holding down the [START] key.)

The WEB server function enables control and monitoring from a remote location without using dedicated

•

software

The FTP client function enables backup of measurement data to the FTP server.

•

The NTP client function enables synchronization of the time with the NTP server.

•

When optional wireless LAN unit is installed, the data capture can be performed remotely by controlling

•

the G L10 0 -WL .

1.3 Operating Environment

This section explains the operating environment for the GL840.

Ambient Operating Conditions

(1) Ambient temperature and humidity (the GL840 must be operated within the following ranges.)

• Temperature range: 0 to 45°C (0 to 40°C when a battery pack is mounted, 15 to 35°C when battery is

being charged)

• Humidity range: 5 to 85%R.H.

(2) Environment (do not use in the following locations.)

• A Location such as being exposed to direct sunlight

• Locations exposed to salty air, corrosive gases, or organic solvents

• Dusty locations

• Locations subject to vibration or impact

• Locations subject to voltage surge or electromagnetic interference such as lightning or electric furnaces

(3) Installation category (over-voltage category)

• The GL840 belongs to Installation Category II dened in IEC60664-1.

• Never use the GL840 for Installation Category III or IV.

(4) Measurement category

• The standard terminals on the GL840 are not used for Measurement Category II, III, and IV.

• The Withstand high-voltage high-precision terminal for the GL840 belongs to Category II. However, it is

not available for Category III or IV.

•If condensation occurs...

Condensation occurs in the form of water droplets on the device surfaces and interior when the GL840

is moved from a cold to a warm location. Using the GL840 with condensation will cause malfunctioning.

Wait until the condensation has disappeared before turning on the power.

Warming-up Before Use

The GL840 should be allowed to warm up with the power turned on for approximately 30 minutes to ensure

that it operates according to the specied performance.

1-3

Page 18

CHAPTER 1 General Description

Conguration When in Use

Do not use the GL840 standing upright or at an angle. It must always be laid at.

<Usage Conguration>

Do not block the air vent on the GL840, as this will cause malfunctioning.

Measurement accuracy may not be satisfactory if the system is used in a condition other than described

above.

1-4

Page 19

CHAPTER 1 General Description

1.4 Notes on Temperature Measurement

Please observe the following precautions when performing temperature measurement.

Do not block the air vents. Always provide a space of at least 30 cm on all sides of the GL840.

•

For stabilized temperature measurement, allow the GL840 to warm up for at least 30 minutes after turning

•

it on.

Exposure of the input terminals to direct drafts, direct sunlight, or abrupt changes in temperature may

•

impair the equilibrium of the input parts and result in measurement errors. To measure temperature in

such an environment, take appropriate countermeasures such as changing the installation site of the

GL840.

To conduct measurement in noisy environments, connect the GL840’s GND terminal to ground (Refer to

•

“2.15 Noise Countermeasures”.).

If measured values uctuate due to noise, set to a slower sampling speed (Refer to “(2) DATA setting” in “3.4

•

Setting Menus”.).

1.5 Notes on Using the Monitor

The monitor is an LCD display unit, and so the display will vary depending on the operating environment.

If the screen saver function is used, it will operate and clear the screen if no operations are performed

during the preset time. If the screen saver operates, press any key to restore the display.

Condensation may form on the LCD screen if the GL840 is moved from a cold to a warm location. If this

•

occurs, wait until the LCD screen warms up to room temperature.

The LCD screen is manufactured to extremely high precision. Black dots may appear, or red, blue, and

•

green dots may not disappear. Likewise, streaks may appear when viewed from certain angles. These

phenomena are due to the LCD screen construction, and are not signs of a fault.

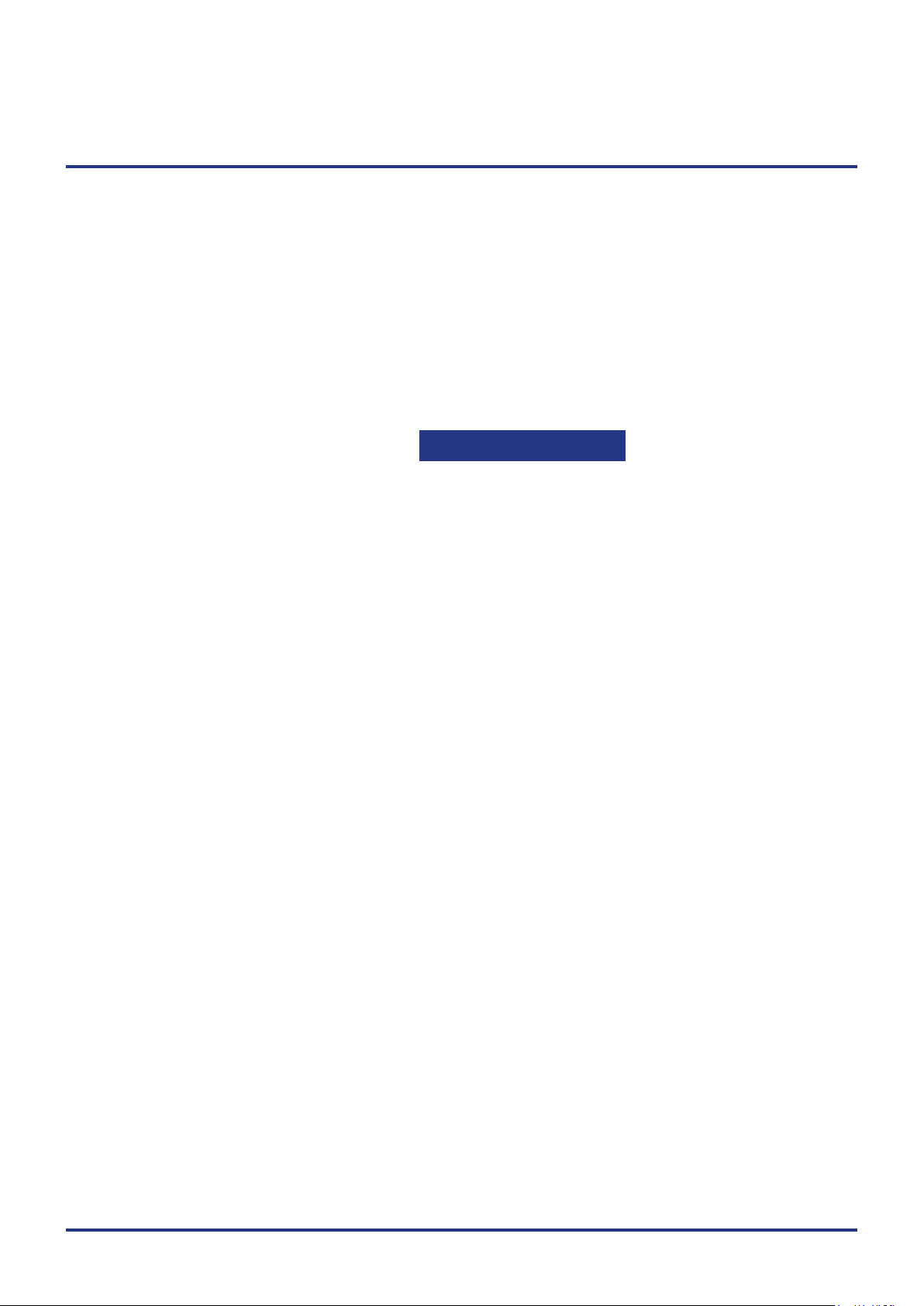

1.6 Changing the Display Language

You can choose the language displayed on the screen. The default display language is set to English when

the GL840 is shipped overseas. To change the display language, see the instructions in "OTHER:Language".

1-5

Page 20

Page 21

CHAPTER 2 Checks and Preparation

CHAPTER 2 Checks and Preparation

This chapter explains how to check the main module's external casing and accessories, and how to prepare the

main module for operation.

PRODUCT SUMMARY

2.1 Checking the Outer Casing

2.2 Checking the Accessories

2.3 Nomenclature and Functions

2.4

2.5 Connecting the Signal Input Cables

2.6 Logic Alarm Cable Connection and Functions

2.7 Mounting the SD Memory Card

2.8 Installing the Wireless LAN Unit (B-568: Option)

2.9 Connecting to a PC

2.10 Using the Battery Pack (B-569 : Option)

2.11 Connecting the Humidity Sensor (Optional)

2.12

2.13

2.14

2.15 Noise Countermeasures

2.16

2.17

2.18

2.19

2.20

2.21 Connecting the CO2 Sensor (GS-CO2) (Optional)

2.22

2.23

2.24 When Fixing the GL840 Body

2.25 Setting the Date and Time

Connecting the Power Cable and Turning on the Power

Mounting and Removing the Standard Terminal and Withstand

high-voltage high-precision Terminal

Mounting the Extension Terminal Base (Optional) and

Extension Terminal Cable (Optional)

Precautions to Observe When Performing Measurement

Connecting the Temperature and Humidity Sensor (GS-TH) (Optional)

Connecting the 3-axis Acceleration / Temperature Sensor (GS3AT) (Optional)

Connecting the 4ch Voltage / Temperature Terminal

(GS-4VT) (Optional)

Connecting the 4ch Thermistor Terminal (GS-4TSR) (Optional)

Connecting the Illumination / Ultraviolet Sensor (GD-LXUV)

(Optional)

Connecting the Adapter for AC Current Sensor (GS-DPAAC) (Optional)

Connecting the Branch Adapter for GS (GS-DPA) (Optional)

2-1

Page 22

CHAPTER 2 Checks and Preparation

2.1 Checking the Outer Casing

After unpacking, check the GL840's outer casing before use. In particular, please check for the following:

Surface scratches

•

Other aws such as stains or dirt

•

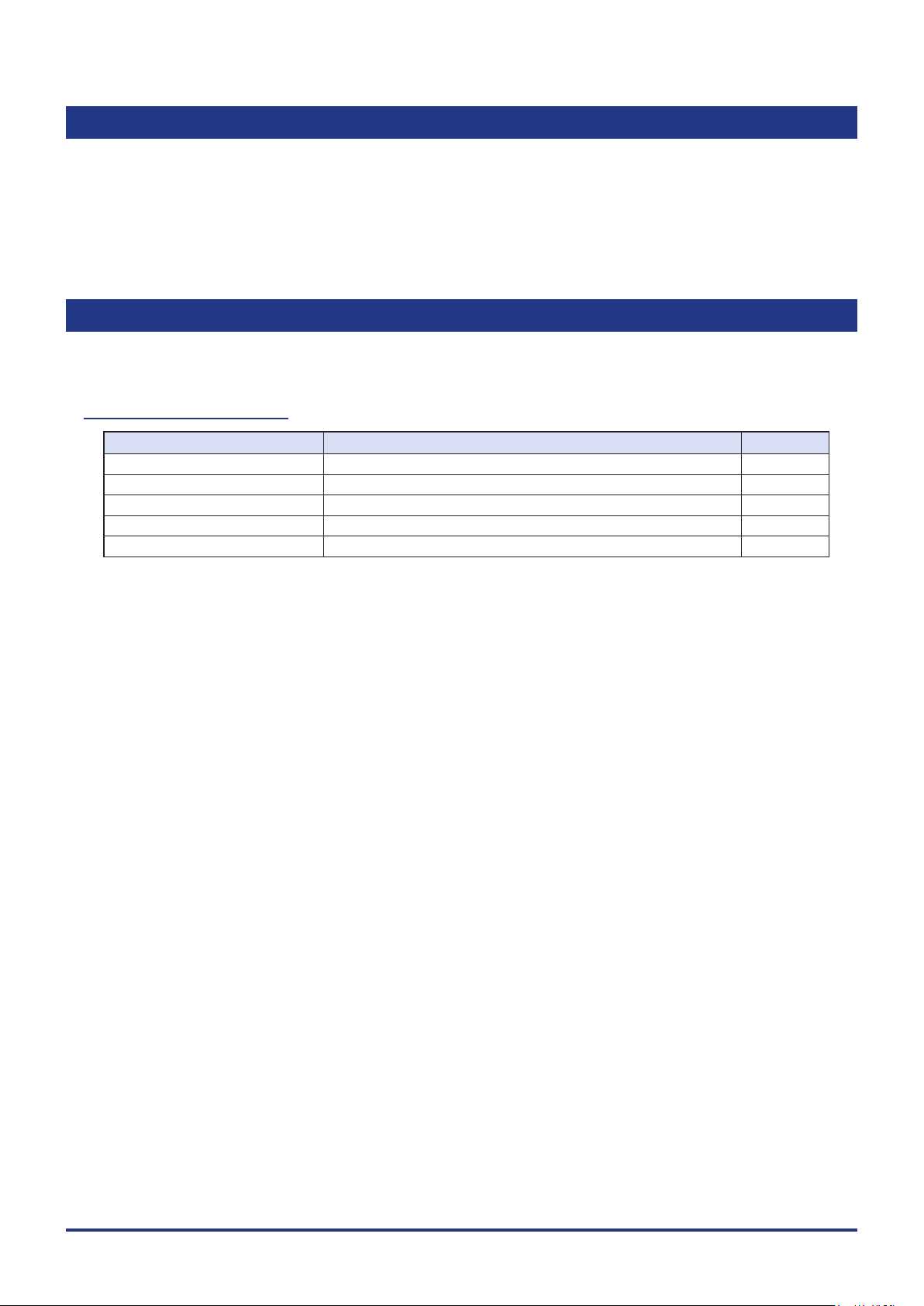

2.2 Checking the Accessories

After unpacking, check that the following standard accessories are included.

Standard Accessories

Item Remarks Quantity

Quick Start Guide GL840-UM-85x 1

SD memory card 4GByte (The card is inserted into the slot with shipment.) 1

CD-ROM User's Manual, Application software 1

AC cable/AC adapter 100 to 240 VAC, 50/60 Hz 1

Ferrite core Used to attach to the USB cable. 1

2-2

Page 23

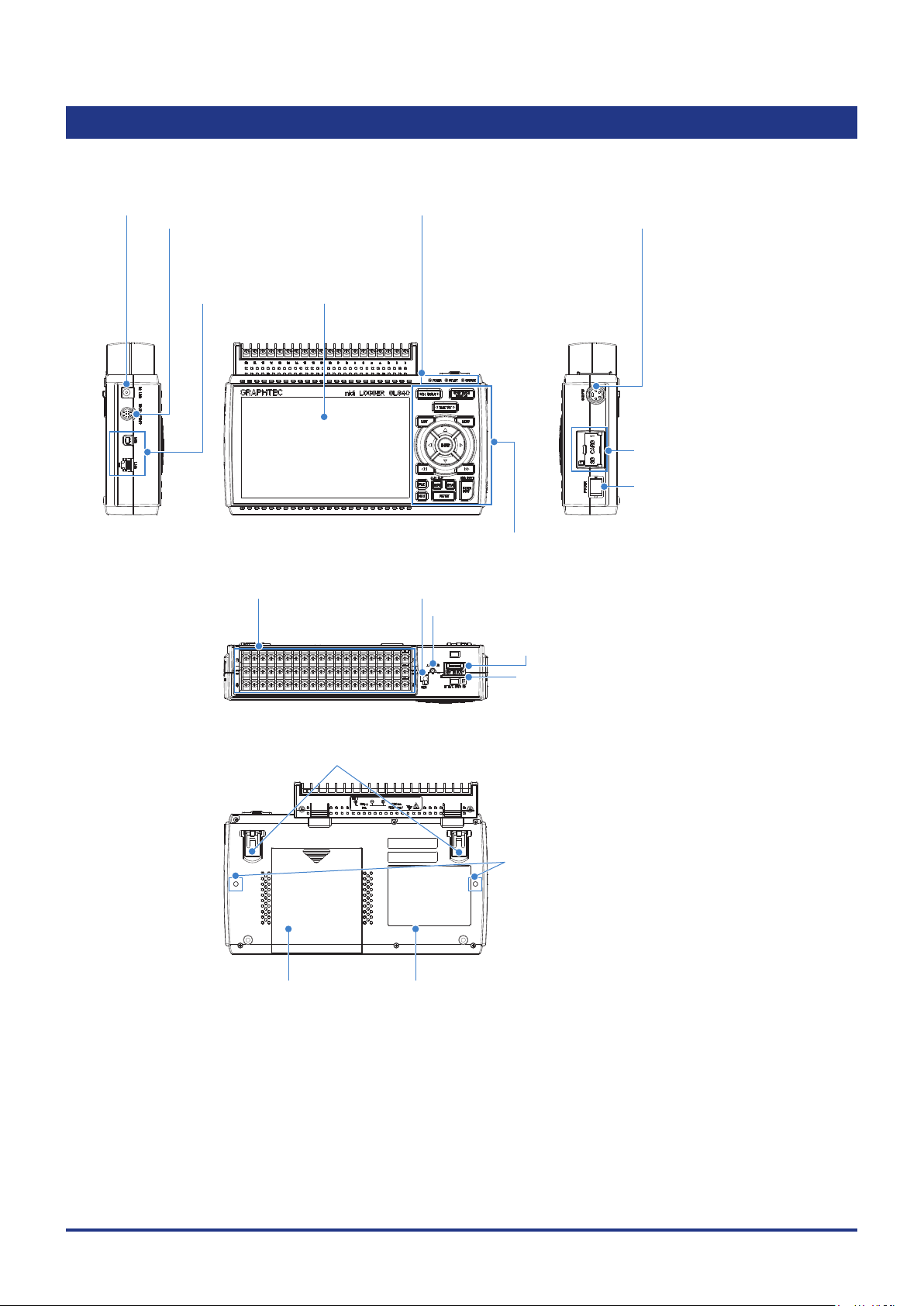

2.3 Nomenclature and Functions

This section describes the names and function of parts of the GL840.

CHAPTER 2 Checks and Preparation

External input/output terminals

• LOGIC/PULSE

• EXT TRIG/SAMP LE

• ALARM

Input /output cable for GL (Cable is the option B-513)

PC interface terminals

• USB

• LAN

Monitor

Analog signal input terminals

• Stand ard te rminal ( B-5 64)

• Withstand high-Voltage

high-precision terminal (B-565)

Operation status LEDAC adapter jack

• POWER ON when t he powe r is ON

Blinki ng while a ccessing to th e

SD mem ory card

• START ON during da ta capture

• CHARGE ON while the ba tter y is char ging

Control panel keys

GND terminal

Power jack for humidity sensor

Humidi ty sen sor (Opt ion: whe n using the B-530)

Wireless LAN conne ction terminal

Wirel ess uni t (Option: when using the B -568)

SD CARD2

GS sensor and terminal /

adapter connection terminal

(Optio n: when us ing

• Temperature an d humidi ty sen sor

• 4ch voltage/temperature terminal

• 3-a xis acc eler ation /te mper ature s ensor

• 4ch the rmistor terminal

• Adapter for AC current sensor

• CO2 sensor

• Illumination/ultraviolet sensor

• Branch adapt er for GS .)

SD CARD1

Power switch

Tilt foot

Two battery pack c an be ins talle d

(Batt ery pa ck is the o ption B -56 9)

Module xing screw

LabelBattery cover

2-3

Page 24

CHAPTER 2 Checks and Preparation

2.4 Connecting the Power Cable and Turning on the Power

This section describes how to connect the power cable and turn on the power. The connection method will

vary depending on the type of power supply used.

Connecting to an AC Power Supply

Use the AC cable and AC adapter that are provided as accessories.

Be sure to use the AC adapter that is supplied as a standard accessory.

(1) Plug the AC cable into the AC adapter.

AC adapter

AC cable

(2) Connect the output side of the AC adapter to the connector on the GL840.

AC adapter cable

(3) Using the at-blade screwdriver, press against the minus (-) button above the GND terminal, while

connecting the grounding cable to the GL840.

Connect the other end of the cable to ground.

(4) Plug the AC cable into the mains power outlet.

(5) Press the power switch on the GL840 to the ON side to turn on the power.

Always connect the GND terminal and refer to the safety precautions.

The GL840 must be grounded even when connected to other devices and sharing a common ground level.

2-4

Page 25

CHAPTER 2 Checks and Preparation

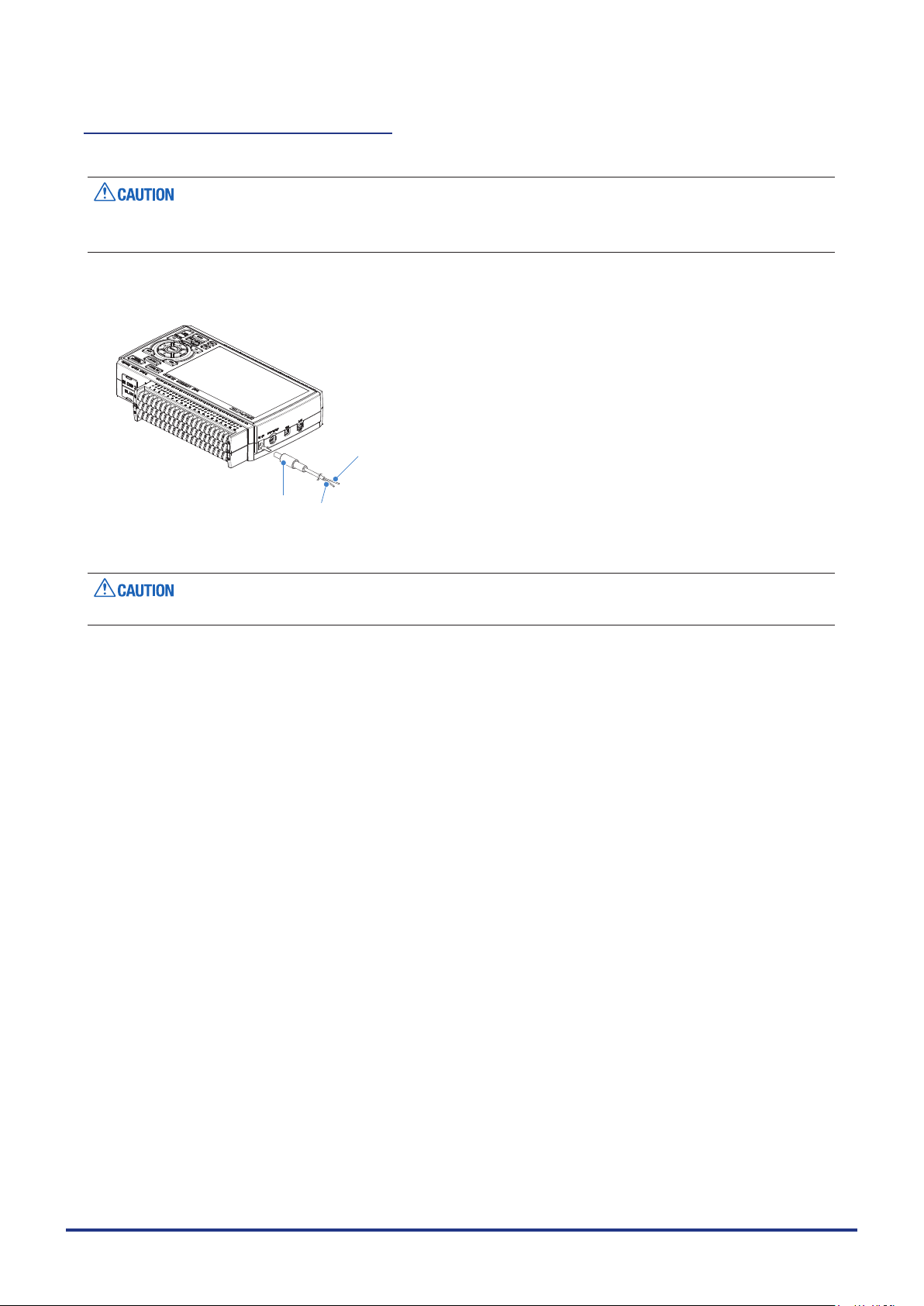

Connecting to a DC Power Supply

Use the optional DC drive cable (B-514).

Use a power supply within the 8.5 to 26.4 VDC range.

•

For DC drive cable, please be sure to use the B-514.

•

(1) Congure the tip of the DC drive cable (B-514: 2m) to enable it to be connected to the DC power supply.

(2) Connect the DC output side to the power supply connector on the GL840.

Shielded le ad (- side)

DC drive cable

(B-514: Option)

(3) Connect the DC input side to the DC power supply.

Be sure to check the polarity of the wire tips when performing wiring.

(4) Press the power switch on the GL840 to the ON side to turn on the power.

White (+ side)

2-5

Page 26

CHAPTER 2 Checks and Preparation

+

+

2.5 Connecting the Signal Input Cables

This section describes how to connect the signal input cables.

During wiring, conrm that the signal's supply source is turned OFF to prevent electrical shocks.

Also, position the GL840 input cable away from any power lines and ground cables.

Terminal Conguration and Signal Types

Terminal assignment of standard terminal and Withstand high-voltage high-precision terminal is common.

CH1 CH20

+

-

b

Connection diagram

DC voltage input Thermocouple input

Voltage input

-

Resistance temperature detector input Current input

A

B

b

Lead wire resistance should be 10Ω or

less per wire, three wires need to be

same length.

+

-

b

DC current

-

Compensationcopper wire

+

-

Shunt resister

Ex: The current is converted to the voltage in the shunt register.

For 4 to 20mA curre nt input, installing 250 ohms (0.1%)

resister for converting 1 to 5V.

* 250 ohms shunt re gister is the option B5 51.

+ .....................................High-voltage terminal (terminal for high-voltage input signals)

- ......................................Low-voltage terminal (terminal for low-voltage input signals)

b .....................................Dedicated terminal when connecting resistance temperature detector

* Resistance temperature detector input terminals A (+) and B (-) are isolated within each channel.

Terminal b is shorted within all channels.

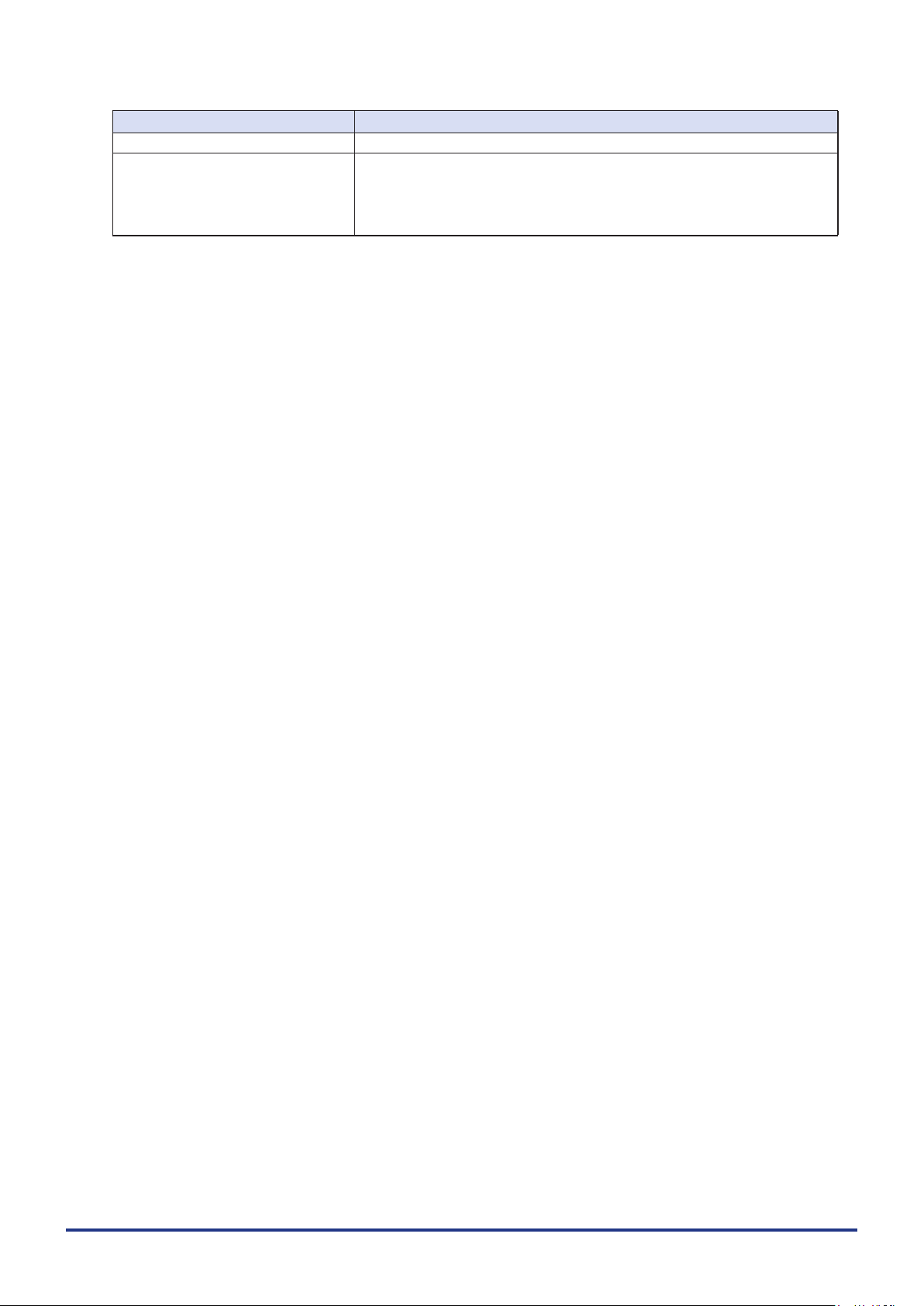

Item Description

Input conguration Isolated input, scanning

Measurement range 20, 50, 100, 200, 500 mV/F.S.; 1, 2, 5, 10, 20, 50, 100 V/F.S.; 1-5V

Thermocouples K, J, E, T, R, S, B, N, W (WRe 5-26)

Resistance temperature detector Pt100, JPt100, Pt1000 (IEC751)

2-6

Page 27

CHAPTER 2 Checks and Preparation

Item Description

A/D resolution 16-bit (Effective resolution: Approx. 1/40,000 of the +/- range)

Filter Off, 2, 5, 10, 20, 40

Filter operation is on a moving average basis.

The average value of the set sampling count is used.

If the sample interval exceeds 30 seconds, the average value of data

obtained in a sub-sample (30 seconds) is used.

2-7

Page 28

CHAPTER 2 Checks and Preparation

2.6 Logic Alarm Cable Connection and Functions

This section describes how to connect the logic alarm cables.

During wiring, conrm that the signal's supply source is turned OFF to prevent electrical shocks.

Also, position the GL840 input cable away from any power lines and ground cables.

The Input/output cable for GL (B-513: Option) enables logic/pulse input, external trigger input, and alarm

signal output.

Connect the Input/out put cable for GL (B-513: Option) to the external input/output terminal as shown below.

Input /output cable for GL

(B-513: Option)

Logic/Pulse Input Specications

Item Description

Number of input channels 4

Input voltage range 0 to +24V max. (single-ended ground input)

Threshold level Approx. +2.5V

Hysteresis Approx. 0.5 V (+2.5 to +3 V)

* Switch between logic and pulse input.

Trigger Input/External Sampling Input Specications

Item Description

Number of input channels 1

Input voltage range 0 to +24V max. (single-ended ground input)

Threshold level Approx. +2.5V

Hysteresis Approx. 0.5 V (+2.5 to +3 V)

Alarm Output Specications

Item Description

Number of Output channels 4

Output format Open collector output

+5 V, 10 KΩ pull-up resistance

* See the next page for details on alarm output

When the power is turned OFF or ON, the GL840 temporarily becomes the alarm state.

2-8

Page 29

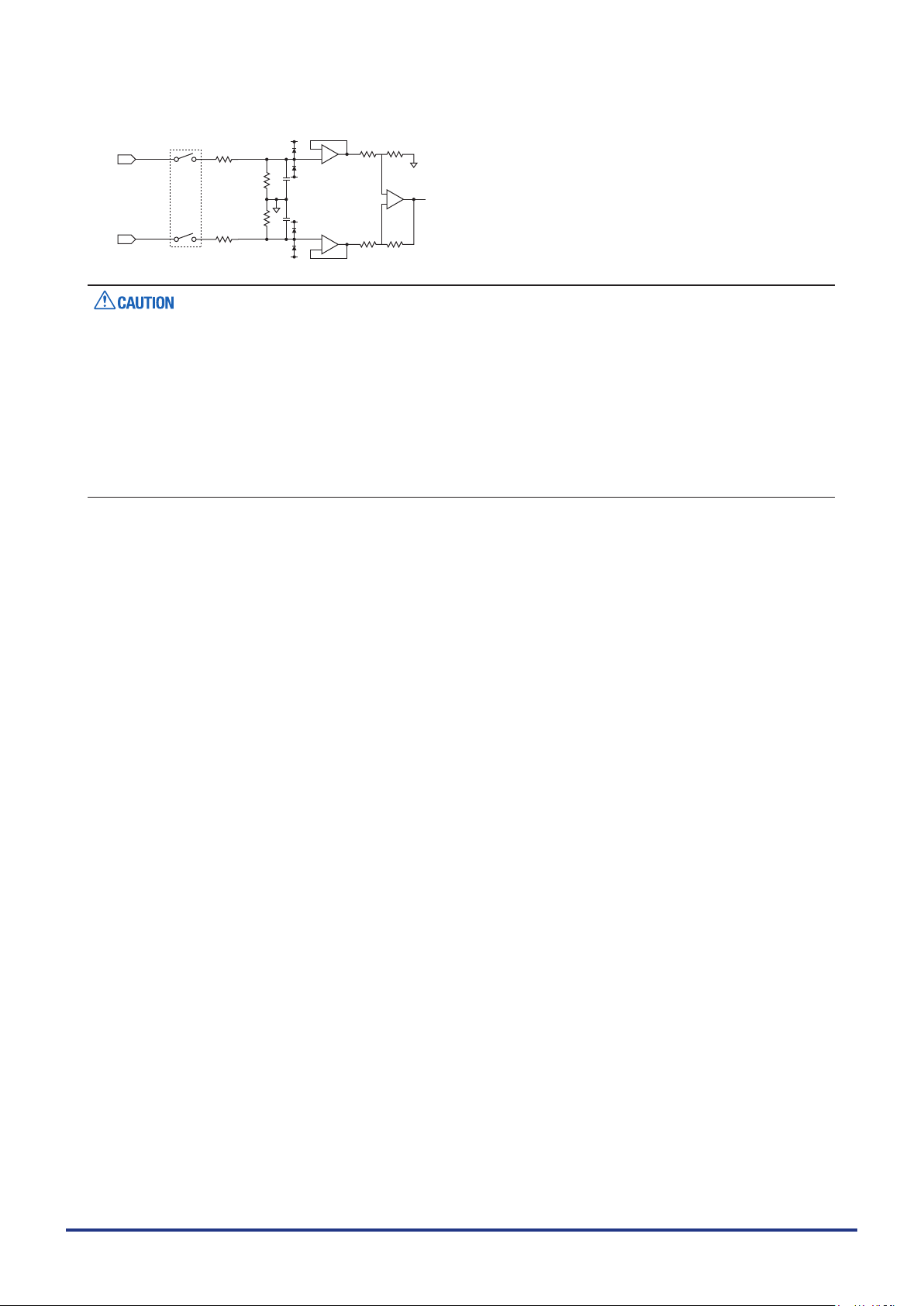

Internal equivalent circuit of I/O circuit

Alarm output

•

+5 V

Maxim um ratings of the transi stor for alarm ou tput

VCEO (Coll ector-em itte r voltag e) : 30 V

IC (Coll ector current) : 0.5A

PC (Collector d issipation) : 0.2W

* The maximum ratings mu st not be exceed ed.

CHAPTER 2 Checks and Preparation

10K Ω

2SC2411K

Logic/pulse input

•

LOGIC/PULSE

GND

Example of external connection

ALARM

Load

GND

+5 V +5V

10 K Ω

68 K Ω

22 0 K Ω

Required for a n induc tive

load such as a rel ay

DC

(5 to 24V)

Comparator

Trigger input /external sampling input

•

+5 V

10 K Ω

TRIGGER/SAMPLE

GND

68 K Ω

+5 V

Comparator

22 0 K Ω

0.01μ F

2-9

Page 30

CHAPTER 2 Checks and Preparation

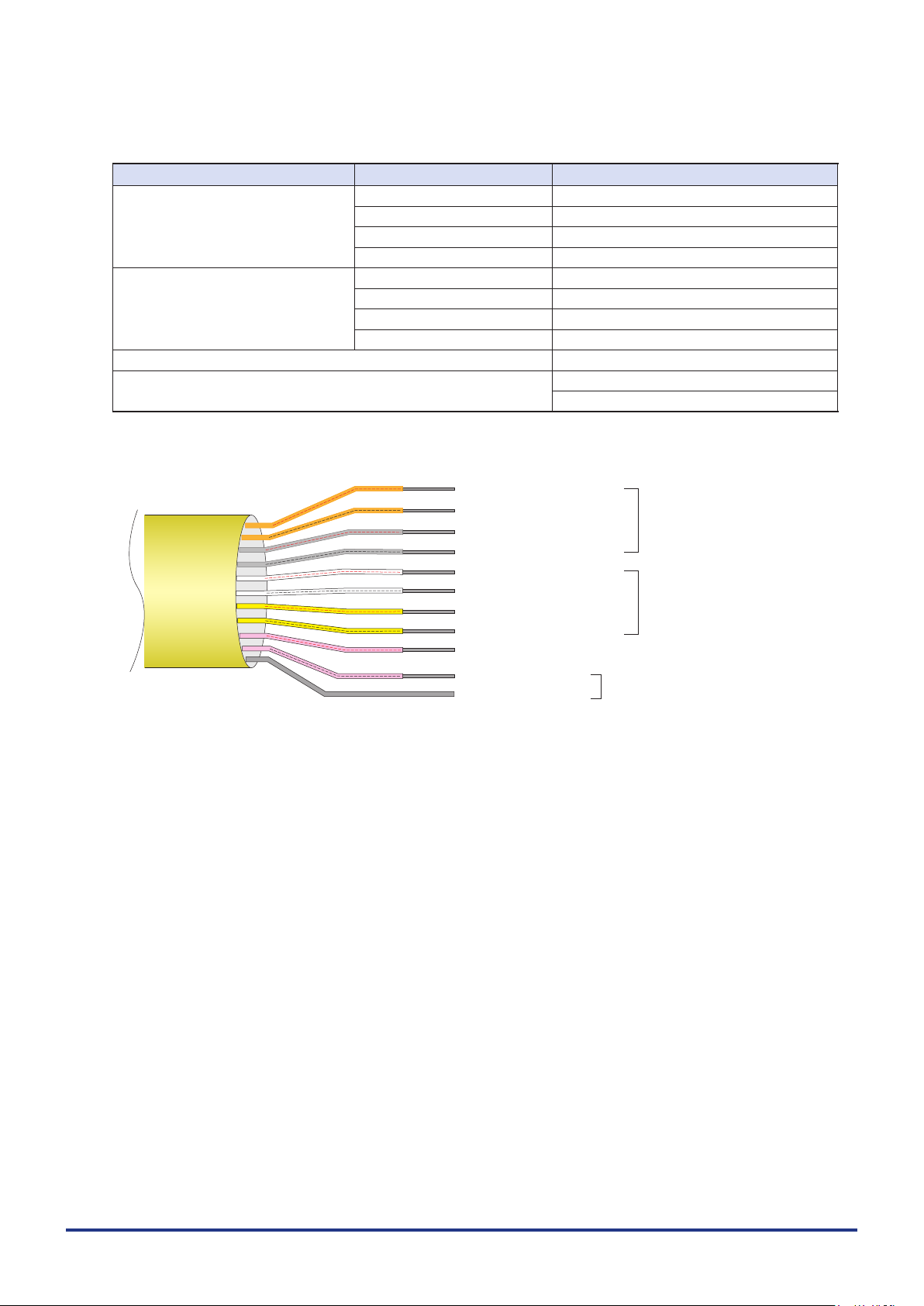

Wiring

Cable tips are bare tips. Perform wiring for the necessary functions.

Signal Name Channel Number Wire Color

Logic/Pulse Input 1 Orange with red dotted line

Alarm output 1 White with red dotted line

Trigger input/sampling input Pink with red dotted line

GND Pink with black dotted line

* Switch between logic and pulse.

2 Orange with black dotted line

3 Grey with red dotted line

4 Grey with black dotted line

2 White with black dotted line

3 Yellow with red dotted line

4 Yellow with black dotted

Shielded

Orange with red dotted line : 1

Orange with black dotted line : 2

Grey with red dotted line : 3

Grey with black dotted line : 4

White with red dotted line : 1

White with black dotted line : 2

Yellow with red dotted line : 3

Yellow with black dotted line : 4

Pink with red dotted line : Trigger input/sampling input

Pink with black dotted line

Shielded

Logic/Pulse input

Alarm output

GND

2-10

Page 31

CHAPTER 2 Checks and Preparation

2.7 Mounting the SD Memory Card

The GL840 can save the measurement data directly to the SD memory card.

One SD memory card has been inserted as standard into the SD CARD1 slot. Please make sure that the SD

•

memory card is inserted. If the SD memory card is not inserted, the data cannot be captured.

When the SD memory card is inserted, make sure that the card is not locked. If locked, the data cannot be

•

captured.

Please do not remove the SD memory card while accessing to the SD memory card (Device Access display

•

is displayed in "red" and POWER LED is blinking.). The captured data may be damaged.

How to insert the SD memory card (SD CARD1 slot)

Insert the SD memory card into the SD CARD1 slot.

(1) Open the SD CARD1 protective cover.

Protective cover

(2) Insert the SD memory card until it clicks and is locked.

* Make sure that the SD memory card is not locked.

SD memory card

Lock

SD CARD

x GB

* Make sure that the SD memory card

is not locked.

2-11

Page 32

CHAPTER 2 Checks and Preparation

(3) Close the SD CARD1 protective cover.

Protective cover

How to remove the SD memory card (SD CARD1 slot)

(1) Make sure that the SD memory card displayed on the screen is green, and then remove it.

(2) Open the SD CARD1 protective cover.

(3) The SD memory card is unlocked by pushing gently the SD memory card. Then, remove the SD memory

card.

The SD CARD1 is displayed in red while accessing to the SD memory card (Device Access display is

displayed in "red" and POWER LED is blinking.). Remove the SD memory card only when the SD CARD1 is

displayed in green.

How to insert the SD memory card (SD CARD2 slot)

Insert the SD memory card into the SD CARD2 slot.

When the optional wireless LAN unit is installed, the SD memory card cannot be inserted.

(1) Remove the SD CARD2 protective cover.

2-12

Protective cover

Page 33

CHAPTER 2 Checks and Preparation

(2) Insert the SD memory card until it clicks and is locked.

* Make sure that the SD memory card is not locked.

Lock

SD CARD

x GB

* Make sure that the SD memory card

is not locked.

SD memory card

(3) Insert and close the protective cover into the upper hole and lower hole for the SD CARD2 protective

cover.

Protective cover

How to remove the SD memory card (SD CARD2 slot)

(1) Make sure that the SD memory card displayed on the screen is green, and then remove it.

(2) Open the SD CARD2 protective cover.

(3) The SD memory card is unlocked by pushing gently the SD memory card. Then, remove the SD memory

card.

The SD CARD2 is displayed in red while accessing to the SD memory card (Device Access display is

displayed in "red" and POWER LED is blinking.). Remove the SD memory card only when the SD CARD2 is

displayed in green.

2-13

Page 34

CHAPTER 2 Checks and Preparation

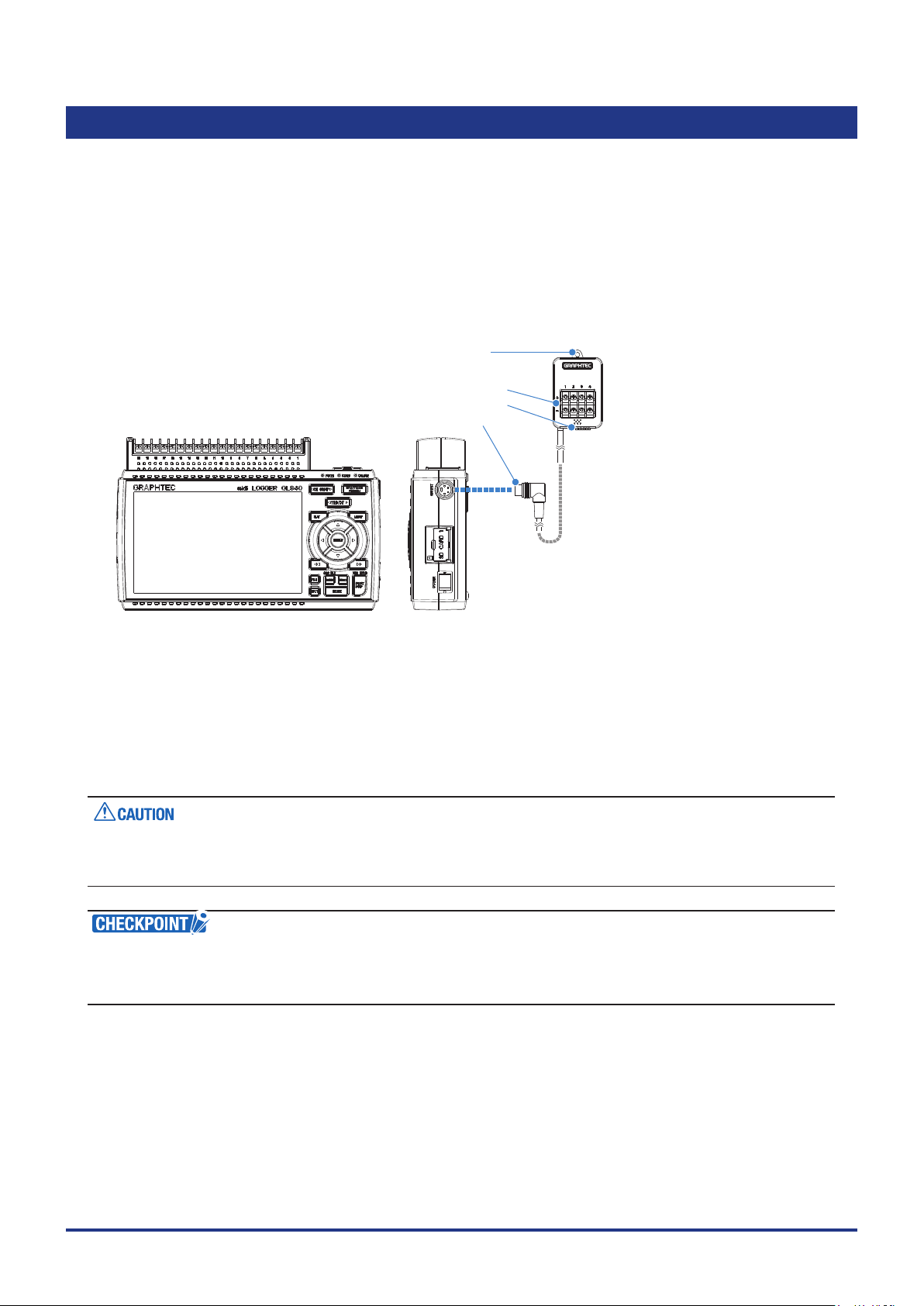

2.8 Installing the Wireless LAN Unit (B-568: Option)

To connect the GL840 to the wireless LAN, insert the wireless LAN unit in the SD CARD2 slot.

When the SD memory card has been inserted into the SD CARD2 slot, please remove the SD memory card.

•

When the wireless LAN unit has been inserted, the SD memory card cannot be inserted into the SD CARD2

•

slot.

When inserting the wireless LAN unit, please make sure that the power is turned OFF and then install the

•

unit.

When using the wireless LAN, please check the "3. Notes on Radio Law" in the “Notes on Use” described

•

above.

How to insert the wireless LAN unit

Insert the wireless LAN unit into the SD CARD2 slot.

Wireless LAN unit

(Option: B-568)

(1) Turn OFF the GL840’s power.

(2) Remove the SD CARD2 protective cover.

* Please keep so as not to lose the SD CARD2 protective cover.

Protective cover

(3) When the SD memory card has been inserted, remove the SD memory card.

* The SD memory card is unlocked by pushing gently the SD memory card. Then, remove the SD

memory card.

2-14

Lock

SD CARD

x GB

SD memory card

Page 35

CHAPTER 2 Checks and Preparation

(4) Align the wireless LAN unit to the wireless unit terminal and the wireless unit xed guide and then insert

the wireless LAN unit until the unit is locked.

Wireless LAN unit

When the wireless LAN unit has been inserted, please be careful when handling so as not to hit and drop.

Removing the wireless LAN unit

Turn OFF the power and then remove the wireless LAN unit.

(1) Push the lock part on the wireless LAN unit to unlock, and then remove it.

Lock part

(2) After removing it, mount the SD CARD protective cover to protect the connectors.

Protective cover

2-15

Page 36

CHAPTER 2 Checks and Preparation

2.9 Connecting to a PC

Use the USB or LAN Interface to connect the GL840 to a PC.

Connection Using a USB Cable

(1) This GL840 complies with the EMC Directive in the state when the supplied ferrite core is attached to the

USB cable.

To connect to the PC with the USB cable, attach the supplied ferrite core to the USB cable as shown in

the following gure.

USB cable

(2) Connect between the GL840 and PC with the USB cable.

The USB connector is adjacent to the LAN connector. Make sure the cable is inserted into the correct

conne cto r.

Ferrite core (Supplie d item)Lock part

USB cable

If the USB cable is used, the USB driver must be installed in your PC. Please refer to “USB Driver

Installation Manual” in the supplied CD-ROM for the installation procedure.

Use the cable with A and B connectors to connect the GL840 to a PC.

•

A connector B connector

2-16

Page 37

LAN Connection

Use a LAN cable to connect the GL840 to a PC.

LAN cable

Cable Types

• Use a crossing cable when connecting directly to a PC, without using a hub.

CHAPTER 2 Checks and Preparation

LAN cable (crossing)

PC GL840

• Use a straight cable when using a hub.

PC

LAN cable (straight) LAN cable (straight)

GL840GL840

2-17

Page 38

CHAPTER 2 Checks and Preparation

Connection to the wireless LAN

Insert the wireless LAN unit (optional). For the insertion, refer to “2.8 Installing the Wireless LAN Unit (B-568:

Option)”.

1. Access point (operating as a base unit):

When connecting the GL840 to the GL100-WL (up to 5 units) or PC/Smartphone via the wireless LAN,

the following devices and the operating environment are required.

• PC and Smartphone which can connect to the wireless LAN

Wireless connection

PC: Child unit

GL1 00

Smartphone: Child unit

Wireless connection

GL84 0: Base unit

Wireless connection

When the GL100-WL is connected through the wireless LAN, the PC cannot be connected to the GL840

through the wireless LAN.

2. Stations (operating as a child unit):

When connecting to the commercially available wireless LAN base unit and controlling multiple GL840s

from PC, the following devices and the operating environment are required.

• PC and Smartphone which can connect to the wireless LAN with the dedicated software

• Wireless LAN base unit (equipped with the functions of Wi-Fi authenticated wireless LAN base unit.)

• Internet environment for Internet connection (Internet provider’s contracts and mobile carrier’s

contracts)

• Internet connection and e-mail send/receive environment (Internet provider and Web mail, etc.) when

sending/receiving e-mail.

2-18

PC: Child unit

Smartphone: Child unit

Wireless connection

Wire-line connection

Base unit

Wireless connection Wireless connection

Wireless connection

GL84 0: Child unit

GL84 0: Child unit

Page 39

CHAPTER 2 Checks and Preparation

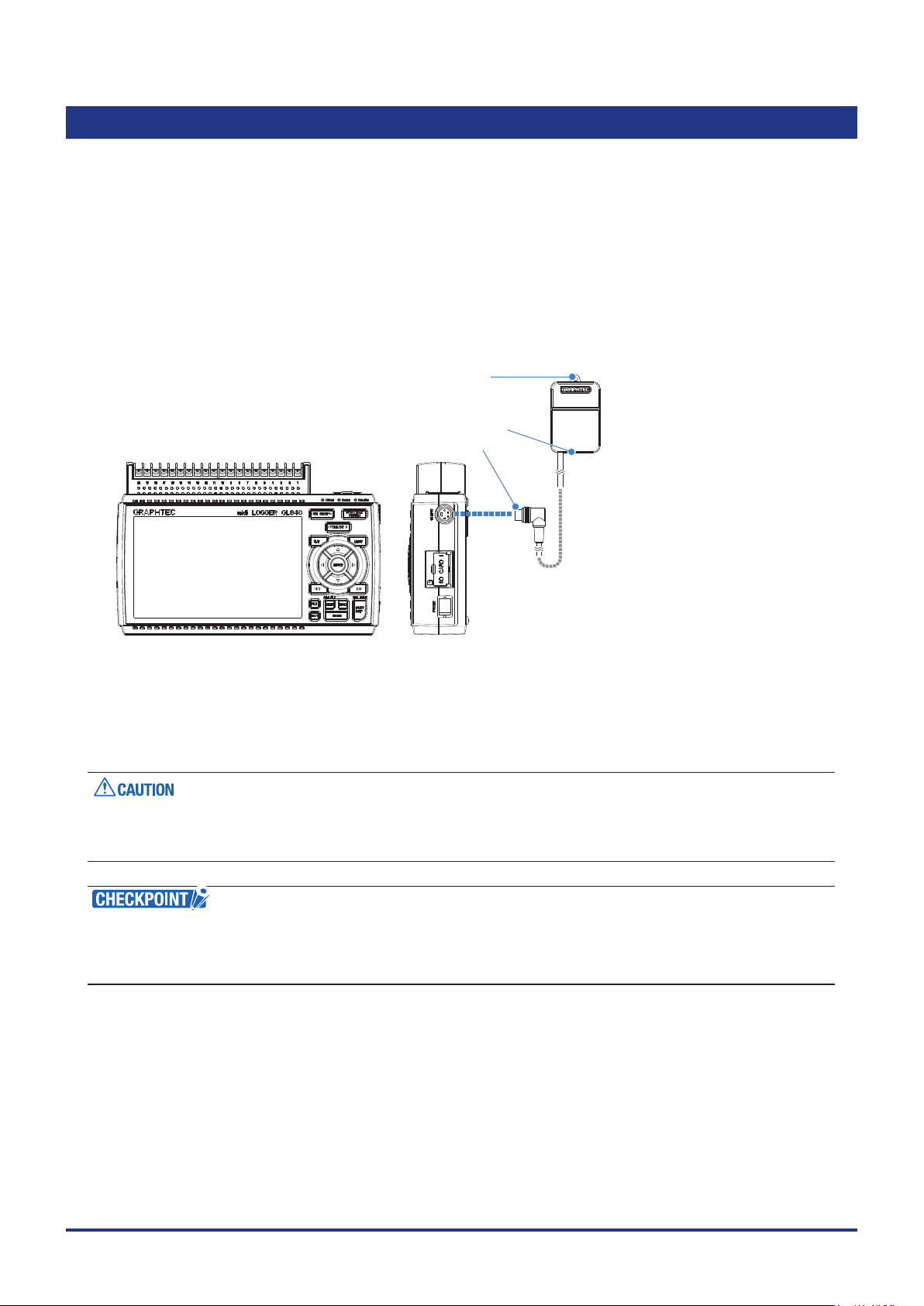

2.10 Using the Battery Pack (B-569 : Option)

The B-569 (optional) is the only battery type that can be used with the GL840.

•

Refer to the specications (Page 4-11) for information on the battery run time.

•

The operating temperature ranges of the GL840 with a battery pack mounted are as follows:

•

Running on battery : 0 to 40°C

Battery being charged : 15 to 35°C

Mounting the Battery Pack

(1) While lightly pushing the grip of the battery cover, slid the cover in the direction indicated by the arrow.

Grip

(2) Attach the battery pack (B-569).

12

Battery pack

Either one or two battery packs can be attached.

•

To connect one pack, connect to either one of the connectors.

•

Attaching two battery packs allows longer operational time.

•

When attaching two battery packs, make sure the battery levels are equivalent.

•

Do not use a new battery with an old battery at the same time.

•

When attaching two battery packs, make sure the remaining amount are same.

•

If you are not sure about the amount, charge each battery and then attach full-charged two battery packs.

•

2-19

Page 40

CHAPTER 2 Checks and Preparation

(3) Attach the battery cover.

Charging the Battery

Expected time required for charging:

Battery pack x 1: approx. 5 hours

•

Battery pack x 2: approx. 10 hours

•

The battery pack is charged by mounting it in the GL840, attaching AC adapter to the GL840.

(1) Mount the battery pack in the GL840 (see "Mounting the Battery Pack" in the previous page for the

mounting procedure.).

(2)

Turn on the power to the GL840. (Please see "2.4 Connecting the Power Cable and Turning on the Power").

(3) The CHARGE LED lights.

CHARGE LED

GL840 is equipped with a temperature monitor function which starts automatic charging as soon as

•

it is cooled down. Therefore, depending on the internal temperature, charging may not be performed

immediately.

The operating temperature range during charge is from 15 to 35°C.

•

When charging is attempted while the power is ON, charging may not be performed immediately even if

•

the temperature environment conforms to the specication. In such a case, set the Screen Saver settings

to ON or perform charging while the power is OFF.

During the data is saved to the SD memory card, when the battery capacity is lower, the le is closed

•

automatically.

When using with the AC adapter, the GL840 is automatically battery-powered in case of power outage.

•

During the power is supplied directly from the DC power without using the AC adapter, when the DC

•

voltage is 16V or less, the battery charge is disabled.

The running time depends on the operating environment.

•

When the empty battery is charged in the GL220/820/900, the charging in about 80 -90% will stop. Once

disconnect and connect the AC adapter, or remove and insert the battery pack. The battery pack charging

is started in order to charge up to 100%. (It depends on the remaining capacity.)

2-20

Page 41

CHAPTER 2 Checks and Preparation

2.11 Connecting the Humidity Sensor (Optional)

Connect the + and - lead wires of the humidity sensor (the B-530: Option) to the desired terminals, and then

insert the round connector into the 5V OUT connector on the GL840.

Brown

Humidity Sensor

White

Connected to the 5V OUT

terminal.

Humidity sensor

(B-530: Option)

Do not use the sensor in a strong electrolyte envronment. Measured results may not satisfy to the stated.

•

The optional humidity sensor power BOX (B-542) is required to use 2 to 10 humidity sensors.

•

5V OUT terminal on the GL840 is available for only one humidity sensor.

•

+

-

2-21

Page 42

CHAPTER 2 Checks and Preparation

2.12

Mounting and Removing the Standard Terminal and Withstand high-voltage high-precision Terminal

The mounting and removing procedure of the standard terminal and Withstand high-voltage high-precision

terminal is described blow.

When mounting or removing the standard terminal or Withstand high-voltage high-precision terminal,

please make sure that the GL840’s power is turned OFF.

To Re move

Pull out the terminal in the direction of the arrow while pressing the lock portions (2 places) at the bottom of

the standard terminal or the Withstand high-voltage high-precision terminal.

(1) Press the two lock portions in the direction indicated by arrows.

Lock portion

Pull out

Terminal unit

(2) Pull the terminal unit out towards the direction indicated by the arrow.

Pull the terminal unit out as shown in the following gure.

Top

2-22

2

1

Bottom

Page 43

CHAPTER 2 Checks and Preparation

To Mo unt

Insert the lock tabs at the top of the standard terminal or the Withstand high-voltage high-precision terminal

into the slots of the GL840, and push in the terminal until the lock tabs at the bottom of the terminal are

securely locked.

Slot

(1) Insert tabs at the top of the terminal unit into the slots.

Insert

(2) Press the terminal unit in the direction shown until it is securely locked.

Press

Press

If the terminal unit that comes with the standard GL800 is mounted on the GL840, the temperature

•

measurement accuracy may not meet the specications.

If the terminal unit that comes with the standard GL820 is mounted on the GL840, the temperature

•

measurement accuracy may not meet the specications.

The standard terminal and Withstand high-voltage high-precision terminal specications are different.

•

Please check the specications when using them.

The Withstand high-voltage high-precision terminal is not available for the GL800 and GL820.

•

2-23

Page 44

CHAPTER 2 Checks and Preparation

2.13

Mounting the Extension Terminal Base (Optional) and Extension Terminal Cable (Optional)

2.13.1 Mounting the extension terminal base

Mount the extension terminal base set as shown below.

When mounting the extension terminal base on the GL840, please make sure that the GL840’s power is

turned OFF.

Prepare the sold separately extension terminal base and the extension terminal connection cable.

B-566 Extension Terminal Base

Extension terminal base: 1 unit Connection plate: 1 pc. M4 x 6 at-head screw: 4 pcs.

B-567 Extension terminal connection cable (Select from two types of cables)

Extension terminal connection cable

(50 cm: B-567- 05): 1 pc.

Extension terminal connection cable

(2 m: B-567-20): 1 pc.

To Mo unt

(1) Remove the standard terminal or Withstand high-voltage high-precision terminal mounted on the GL840.

(2) Insert the lock tabs at the top of the terminal into the slots of the extension terminal base, and press the

terminal until the lock tabs at the bottom of the terminal are securely locked.

Insert

Press

2-24

* When installing the Withstand high-

voltage high-precision terminal

(B-565),please push it while pulling

to the front.

Page 45

CHAPTER 2 Checks and Preparation

(3) Connect the extension terminal connection cable to the extension terminal base.

* Insert the extension terminal connection cable until the cable is securely locked.

* Connect in accordance with the connector shape.

Extension terminal connection cable

(4) Connect one end of the extension terminal connection cable to the terminal connector on the GL840.

* Insert the extension terminal connection cable until the cable is securely locked.

Extension terminal connection cable

When one terminal unit (20ch) is mounted, the connecting plate and at-head screw are not used.

How to Remove the expansion terminal connection cable

•

Lock release lever

When you want to remove the expansion terminal connection cable from the GL840 or extension terminal

base, please note the following.

Always press the both sides of the lock release lever and pull out straightly in a state where the lock is

•

released.

Please do not forcibly remove or do not pull out in a state where the lock is not released by pressing only

•

the one side of the lock release lever.

It may cause a connection failure of connector, please be careful when you remove it.

2-25

Page 46

CHAPTER 2 Checks and Preparation

2.13.2 Mounting multiple extension terminals

The mounting procedure of the multiple extension terminal set is described.

Make sure the GL840’s power is OFF when mounting the extension terminals on the GL840.

Prepare the sold separately extension terminal base and extension terminal connection cable.

B-566 Extension terminal base

Prepare the number of extension terminal bases that is equal to the number that the standard terminal or the

Withstand high-voltage high-precision terminal is added.

B-567 Extension terminal connection cable (Select from two types of cables)

Prepare one of the two types of extension terminal connection cables (50 cm: B-567-05 or 2 m: B-567-20).

Also, when you want to connect away between the extension terminal bases, the required number of the

extension terminal bases must be prepared.

When direct-connecting the extension terminal bases

(1) Connect the extension terminal base unit connectors as shown below.

* Please direct-connect to the protruding parts carefully.

Please direct-connect the extension terminal bases carefully so as not to bend the protruding parts next to

•

the connector.

Please handle the connection plate in a horizontal state Until the connection plate is xed.

•

(2) Fix the connection plate using attached screws.

* Recommended screw torque: 14 kgf/cm

M4 x 6 at he ad screws

2-26

Connection plate

Page 47

CHAPTER 2 Checks and Preparation

(3) Connect the extension terminal connection cable to the extension terminal base.

* Insert the cable connector until it is securely locked.

* Connect in accordance with the connector shape.

Extension terminal connection cable

(4) Connect one end of the extension terminal connection cable to the GL840.

* Insert the cable connector until it is securely locked.

Extension terminal connection cable

Do not touch.

While the signal is input to the direct-connected terminal, please do not touch the connector pins and

the protruding part next to the connector.

How to Remove the expansion terminal connection cable

•

Lock release lever

When you want to remove the expansion terminal connection cable from the GL840 or extension terminal

base, please note the following.

Always press the both sides of the lock release lever and pull out straightly in a state where the lock is

•

released.

Please do not forcibly remove or do not pull out in a state where the lock is not released by pressing only

•

the one side of the lock release lever.

It may cause a connection failure of connector, please be careful when you remove it.

2-27

Page 48

CHAPTER 2 Checks and Preparation

When adding the extension terminal bases

Unit 10 (CH 181 to 20 0)

Unit 2 (CH 21 to 4 0)

Unit 1 (CH 1 to 20)

When the terminals are added, please connect continuously them without disconnected terminals. If there

•

is a disconnected terminal, subsequent terminals are not recognized.

When the combination of the standard terminal and Withstand high-voltage high-precision terminal is

•

used, the withstand voltage specication of standard terminal is applied.

When the terminal of the GL800 or the GL820 is used, or the combination of the GL800 and the GL820 is

•

used, the temperature measurement accuracy may not satisfy the specication.

The Withstand high-voltage high-precision terminal is not available for the GL800 and GL820.

•

When direct-connecting with extension terminal connection cable

(1) Connect between the extension terminal bases with the extension terminal connection cable.

* Insert the extension terminal connection cable until the cable is securely locked.

* Connect in accordance with the connector shape.

Unit 2 (CH21 to CH40)

Extension terminal

connection cable

Unit 1 (CH1 to CH20)

2-28

Page 49

CHAPTER 2 Checks and Preparation

(2) Connect each between the extension terminal bases with the extension terminal connection cable.

* Insert the extension terminal connection cable until the cable is securely locked.

Install the extension terminal bases in a stable location and be careful not to fall.

Unit 2 (CH21 to CH40)

Unit 1 (CH1 to CH20)

Extension terminal connection cable

(3) Connect one end of the extension terminal connection cable to the GL840.

* Insert the extension terminal connection cable until the cable is securely locked.

Extension terminal connection cable

Do not touch.

While the signal is input to the direct-connected terminal, please do not touch the connector pins and

•

terminal next to the connector.

When removing the extension terminal connection cable from the GL840 or the extension terminal base,

•

please note the following:

• Please always pull out straightly in a state where the both sides of the lock release lever are pushed.

• Please do not forcibly remove or do not pull out in a state where only the one side of the lock release

lever is pushed.

It may cause a connection failure of connector, please be careful when you remove it.

When the extension terminal cable is used, it becomes susceptible to noise.

•

If the cable is affected by the noise, please slow down the sampling speed.

When the terminals are added, please connect continuously them without disconnected terminals. If there

•

is a disconnected terminal, subsequent terminals are not recognized.

When the combination of the standard terminal and Withstand high-voltage high-precision terminal is

•

used, the withstand voltage specication of standard terminal is applied.

When the terminal of the GL800 or the GL820 is used, or the combination of the GL800 and the GL820 is

•

used, the temperature measurement accuracy may not meet the specication.

The Withstand high-voltage high-precision terminal is not available for the GL800 and GL820.

•

2-29

Page 50

CHAPTER 2 Checks and Preparation

B

2.14 Precautions to Observe When Performing Measurement

When using the standard terminal (GL840-M and B-564)

Please be sure to read the following carefully in order to prevent electric shocks or shorts.

If a voltage exceeding the specied value is input to the analog input section, the semiconductor relay

•

used in the input section is damaged. Please do not input the voltage exceeding the specied value even

for a moment.

Do not apply radio-frequency signals with high voltage (50 KHz or above).

•

Be sure to use only the AC adapter provided as a standard accessory. The rated power supply range for

•

the adapter is 100 to 240 VAC, and the rated frequency is 50/60 Hz. Do not use any other voltages.

Maximum input voltage

•

If a voltage exceeding the specied value is input, the semiconductor relay in the input section will be

damaged. Never input a voltage exceeding the specied value even for a moment.

* This applies to all the channels even if channel extension is used.

< Between +/– terminals (A) >

• Maximum input voltage : 60Vp-p (Range of 20mV to 2V)

110Vp-p (Range of 5V to 100V)

<Between input terminal/input terminal (B) >

Maximum input voltage : 60Vp-p

Withstand voltage : 350 Vp-p at 1 minute

<Between input terminal/GND (C) >

Maximum input voltage : 60Vp-p

Withstand voltage : 350 Vp-p at 1 minute

C

-

-

+

-

+

+

GND

A

2-30

Page 51

Input Circuit Diagram for Analog Input (Voltage, Thermocouples)

•

CHAPTER 2 Checks and Preparation

+

-

Channel Switching Relay

50Ω

500kΩ

500kΩ

50Ω

0.05μF

0.05μF

Capacitors have been incorporated into the input circuit to increase the noise elimination capability.

After voltage measurement, when the inputs have been disconnected, there will still be some electric

charge remaining.

Before starting another measurement operation, short-circuit the + and - terminals to enable self-

discharge.

The GL840 has a scan system.

While in the status (open) in which signals are not input to the input terminal, measured results may be

inuenced by signals from other channels. In such a case, turn OFF the input setting or short circuit +/-.

If signals are input correctly, measured results are not inuenced by other channels.

2-31

Page 52

CHAPTER 2 Checks and Preparation

When using the Withstand high-voltage high-precision terminal (GL840-WV and B-565)

Please be sure to read the following carefully in order to prevent electric shocks or shorts.

If a voltage exceeding the specied value is input to the analog input section, the semiconductor relay

•

used in the input section is damaged. Please do not input the voltage exceeding the specied value even

for a moment.

Do not apply radio-frequency signals with high voltage (50 KHz or above).

•

Be sure to use only the AC adapter provided as a standard accessory. The rated power supply range for

•

the adapter is 100 to 240 VAC, and the rated frequency is 50/60 Hz. Do not use any other voltages.

When the standard terminal and Withstand high-voltage high-precision terminal is mixed with the

•

extension terminal base, maximum input voltage and withstand voltage conforms to the voltage of the

standard terminal.

Maximum input voltage

•

If a voltage exceeding the specied value is input, the semiconductor relay in the input section will be

damaged. Never input a voltage exceeding the specied value even for a moment.

* This applies to all the channels even if channel extension is used.

< Between +/– terminals (A) >

• Maximum input voltage : 60Vp-p (Range of 20mV to 2V)

110Vp-p (Range of 5V to 100V)

<Between input terminal/input terminal (B) >

Maximum input voltage : 600Vp-p

Withstand voltage : 600 Vp-p

<Between input terminal/GND (C) >

Maximum input voltage : 300Vp-p

Withstand voltage : 2300VACrms at 1 minute

B

C

-

-

+

-

+

+

GND

A

2-32

Page 53

Input Circuit Diagram for Analog Input (Voltage, Thermocouples)

•

CHAPTER 2 Checks and Preparation

+

-

50Ω

500kΩ

500kΩ

50Ω

0.05μF

0.05μF

Capacitors have been incorporated into the input circuit to increase the noise elimination capability.

After voltage measurement, when the inputs have been disconnected, there will still be some electric

charge remaining.

Before starting another measurement operation, short-circuit the + and - terminals to enable self-

discharge.

The GL840 has a scan system.

While in the status (open) in which signals are not input to the input terminal, measured results may be

inuenced by signals from other channels.In such a case, turn OFF the input setting or short circuit +/-.

If signals are input correctly, measured results are not inuenced by other channels.

2-33

Page 54

CHAPTER 2 Checks and Preparation

2.15 Noise Countermeasures

Be sure to connect the chassis GND of the measurement object.

•

It may become effective by ensuring that the chassis GND wire of the measurement object is connected

to a good ground.

Measurement object

Thermocouple Input terminals

Z3

Connect the signal chassis GND to the measurement device chassis ground.

•

Use a short, thick lead to connect the chassis GND of the measurement object to the GL840’ chassis

GND. It will become even more effective if the ground potentials are the same.

Measurement device chassis

GND GND

R1

R2

GL840

GL840

+

Vin

-

Z1 Z2

Noise countermeasures

•

If measured values uctuate due to extraneous noise, conduct the following countermeasures.

(Results may differ according to noise type.)

Ex 1 : Connect the GL840’s GND to ground.

Ex 2 : Connect GL840’s GND to measurement object’s GND.

Ex 3 : In the AMP settings menu, set lter to any setting other than “OFF”.

Ex 4 : Set the sampling interval which enables GL840’s digital lter.

Use the “OTHER” menu to set the commercial power frequency you use.

Refer to "3.4 Setting Menus" for details.

2-34

Page 55

CHAPTER 2 Checks and Preparation

2.16

For the specications of the temperature and humidity sensor, refer to the Instruction Manual supplied in the

sensor.

The connecting procedure between the GL840 and temperature and humidity sensor is described.

• Turn Off the GL840’s power.

• Connect rmly the temperature and humidity sensor’s connector to the GL840's GS sensor and terminal /