Graphicwhizard GW Junior Service Manual

Graphic Whizard GW-Junior

Tabletop Numbering

Machine

Service Manual

21-2283 Argentia Road, Mississauga, Ontario Canada L5N 5Z2; Tel: (905) 858-7663 Fax :(905) 858-4419 Toll Free 1-8 00-265-3376

Website: www.graphicwhizard.com Email: contact@graphicwhizard

SERVICE MANUAL

VERSION 1.0

- 1 -

TABLE OF CONTENTS

Technical Highlights 3

1.0 Specifications 5

2.0 GW Junior 6

2.1 GW Junior Circuit Board Values 6

2.2 Troubleshooting 7

2.3 GW Junior Parts Diagram 7

3.0 GW 3000 Operation 8

3.1 Running a Job 8

3.2 Stopping a Job 8

3.3 Clearing a Job 9

3.4 Changing and Programming a Job 9

3.5 Error Codes 10

4.0 GW 6000 Operation 11

4.1 Running a Job 11

4.2 Stopping a Job 11

4.3 Clearing a Job 12

4.4 Changing and Programming a Job 12

4.5 Speed Control 13

4.6 GW 6000 Software Set-up and Diagnostics 13

4.7 Overview 13

4.8 Individual Items 14

4.9 GW 6000 Error Codes 17

5.0 GW 8/12000 Operation 18

5.1 Running a Job 18

5.2 Stopping a Job 20

5.3 Changing Programs 20

5.4 Programming a Job 21

5.5 The Batch Function 23

5.6 The Repeat Function 24

5.7 Motor Speed Control 24

5.8 GW 8/12000 Software Set-up and Diagnostics 25

5.9 Overview 25

5.10 Individual Items 25

5.11 GW 8/12000 Error Messages 29

6.0 Circuit Boards Layout and Diagnostics 30

6.1 GW 3/6000 Circuit 30

6.2 GW 8/12000 Circuit 31

6.3 GW 3/6/8/12000 Circuit Diagnostics 32

7.0 GW Parts List 38

8.0 Parts Diagrams 43

8.1 Feed Tray Assembly 43

8.2 Exit Tray Assembly 43

8.3 GW 3/6/8000 Operator Side 43

8.4 Electric Solenoid Drive Unit 44

8.5 Pneumatic Solenoid Drive Unit 44

8.6 Accessory Holder 45

8.7 Blade Placement on Boss Wheel 45

8.8 GW 12000 Feed Drive Components 45

8.9 GW 12000 Structural Parts Diagram 46

8.10 GW 3/6/8000 Shaft Placement 46

8.11 Conveyor Outfeed Assembly 47

- 2 -

TECHNICAL HIGHLIGHTS

Many of the benefits of our product design, construction, and materials details are not indicated in our product

literature. Obviously these details are important facts which are critical to a full understanding of our equipment

We build what we feel is the best equipment available. We take great pride and satisfaction in the knowledge that we

offer true value and performance to every customer. Our users consistently comment on the durability, ease of use

and versatility of their machines.

Their positive reactions are no accident. Listed below are the reasons.

< Feed System- we use a feed system on all our automatic machines unlike any other. The stock is fanned

forward so that the lead sheet only touches the feed tires. There is a complete lead edge retarding strip that will hold

back following sheets. We use three feed tires evenly spaced along the lead edge (the two outside tires 12" from the

edge of the stock and the third in the middle) of the page for a more consistent, straight paper feed. The pressure of

the feed tires needs only be enough that you feel a slight resistance between the stock and feed tires. This feed

system provides consistent feeding with drastically less problems of skewing, kicking, marking, scuffing and double

feeding of your stock.

< Head Driver- we are unique in the way we propel our numbering heads to the paper. We refer to it as inertia

drive. Whether using our solenoid or pneumatic drivers, there is no direct coupling of the numbering head and the

driver. The driver stroke is shorter than the head's travel to the paper. The driver has been specifically engineered to

produce rapid acceleration, impact the numbering head under inertia, and immediately release. With the inertia from

the driver, the numbering head is propelled to the paper, makes an impression on the paper and is free to return after

hitting the platen. The result is a clean and clear number. Think of it as throwing a ball against the wall and having it

bounce back rather than pushing the ball into the wall. The further benefit to this method is the reduced wear and tear

on the head frame, components, wheels etc. Resulting in longer head life.

Electronic Impression Control- microprocessor and digital control in all our models allow us to control, with

great precision, the time for which we energize our drive. This allows us to impart more or less inertia to the head

depending on how much of the stroke we energize for, thus controlling the strength of our numbering head crash.

Simply put, the longer we accelerate for, the faster we go, the harder we hit.

Solenoid Design- just look at one. The totally enclosed, tubular design creates the most efficient, complete

magnetic flux path providing the maximum energy output and optimum efficiency. The moving plunger is coated with

molybdenum disulphide, an anti friction coating used in jet airplane engines.

Numbering Head- the standard numbering head offered is an all steel numbering machine manufactured by

Reiner Gmbh & Co. in Germany. It has been our head of choice since the beginnings of our machine design ten years

ago and has proved so reliable that two of our competitors subsequently chose the same supplier's numbering head

for use in their machines.

Drive Unit Mount Assembly- thick, stiff and durable. The first of our many "never replaced due to a failure"

parts

Shafting- all the turning shafting in our products is made from a special high tensile strength steel which offers

the strength, rigidity, resistance to deflection, and a number of other critical mechanical properties normally available

only on shafting of significantly larger diameter. The shafting is supplied "centerless ground” to exacting

specifications measured at one half of one thousandth of an inch (0.0005"). Once machined to its final dimensions.

We straighten the shafting to within one thousandth over its length to ensure consistency and accuracy in perforating

scoring or slitting operations. The shafting is also plated with a very hard skin of chromium to prevent corrosion and

marking from setscrews. This shafting has proved so durable that we have never replaced a shaft on any unit

due to wear or fatigue.

Bushings- the shafts are supported in the machine and spin within oil impregnated bronze bushings. These

automatically release oil to the shafting as required. They are stressed in the unit at less than 30% of their rated load.

The bushings have proved so durable that we have not yet replaced one as failed in the field.

- 3 -

< Framework- once again we take the stand that, enough is not enough. As with the balance of the machine,

technical testing is carried out and the results used to choose materials. In this case, we use materials rated at triple

the rated requirements. We have never experienced the failure of a frame component. We tie all the parts

together with rigid cross shafts. On our two larger models, we weld the stand out of heavy section angle rather than

making it out of stamped thin steel. The result is quieter, more solid running equipment.

< Rollers- all are solid urethane. Impervious to cleaning chemistry, chemicals in the paper (such as the ones in

carbonless paper), and whatever else may contact them. They are also capable of being machined to more precise

tolerances, are more resistant to abrasion, and quite simply last longer. While we do encounter normally expected

wear on the feed tires, the main rollers are another of our "never replaced" parts.

< Electronics- so reliable we back them for five years (see our warranty for details). Enough said

ever fails, the self-diagnostic features identify the problem and allow full details to the technician by phone. The

problem is immediately identified and correction can be carried out without requiring a service call. Exchanging the

circuit boards has also been made simple enough that a technician may not be required. Of course, with our network

of dealers across the country, help is never more than a phone call away.

< Drive Train- all drive components are metal. The main timing belt is steel reinforced. The motors are

brushless. All require no maintenance.

This listing could continue and provide you with every little detail we've sweated over while designing and building

your machine. We can (and will if you ask) tell you about gold plated contacts, idc type connectors, and a host of

other things. It's your right to know that you are getting your money's worth!

Our final word here is to tell you what we don't do. Quite simply, we don't add cosmetic features, which have no effect

on performance and add only to cost. We don't stand still and we continue to evolve the products based on

experience and field comments. We redesign with our existing customers in mind and make all future enhancements

retrofitable to the first machine we built. We don't run down our competitors and their products, we strive to stay a few

steps ahead of them. We know that if you really look you will recognize the value in our products.

We sincerely appreciate your interest and your time reading through this note.

Please contact your local dealer or us if you require any further details.

. If one

- 4 -

1.0 SPECIFICATIONS

GW Junior

Tabletop, footpedal operated numbering machine, standard forward head.

GW 3000

Programmable for a single hit per sheet per head, auto feed

numbering/perforating/scoring system, single speed of 3000 sheets per hour, maximum

of two numbering heads; optional conveyor outfeed and stand.

GW 6000

Programmable for up to 10 hits per sheet per head, auto feed

numbering/perforating/scoring system, three speeds of up to 6000 sheets per hour,

maximum of two numbering heads; optional conveyor outfeed and stand.

GW 8000

Programmable 100-job memory for up to 100 hits per sheet per head, auto feed

numbering/perforating/scoring system, batching capability, variable speeds of up to

8000 sheets per hour, maximum of four pneumatic numbering heads, optional conveyor

outfeed.

GW 12000

Programmable 100-job memory for up to 100 hits per sheet per head, auto feed

numbering/perforating/scoring system, batching capability, variable speeds of up to

12000 sheets per hour, maximum of four pneumatic numbering heads, conveyor

outfeed, optional air feed.

FinishMaster 100

Table top, autofeed perf/score/slit system, up to 10,000 sheets per hour, optional

conveyor outfeed and stand.

FinishMaster 150

Autofeed perf/score/slit system, up to 20,000 sheets per hour; optional air feed.

Paper weight: 12# - 12 point (45-250 gsm)

Paper formats: max. 18” x 18” (45 x 45 cm)

min. 3” x 5” (7.6 x 12.7 cm)

Electrical configuration:

Voltage: 90-135 VAC or

180-270 VAC

Frequency: 60 Hz or

50 Hz

Fusing: 115/250V, 3/5A

- 5 -

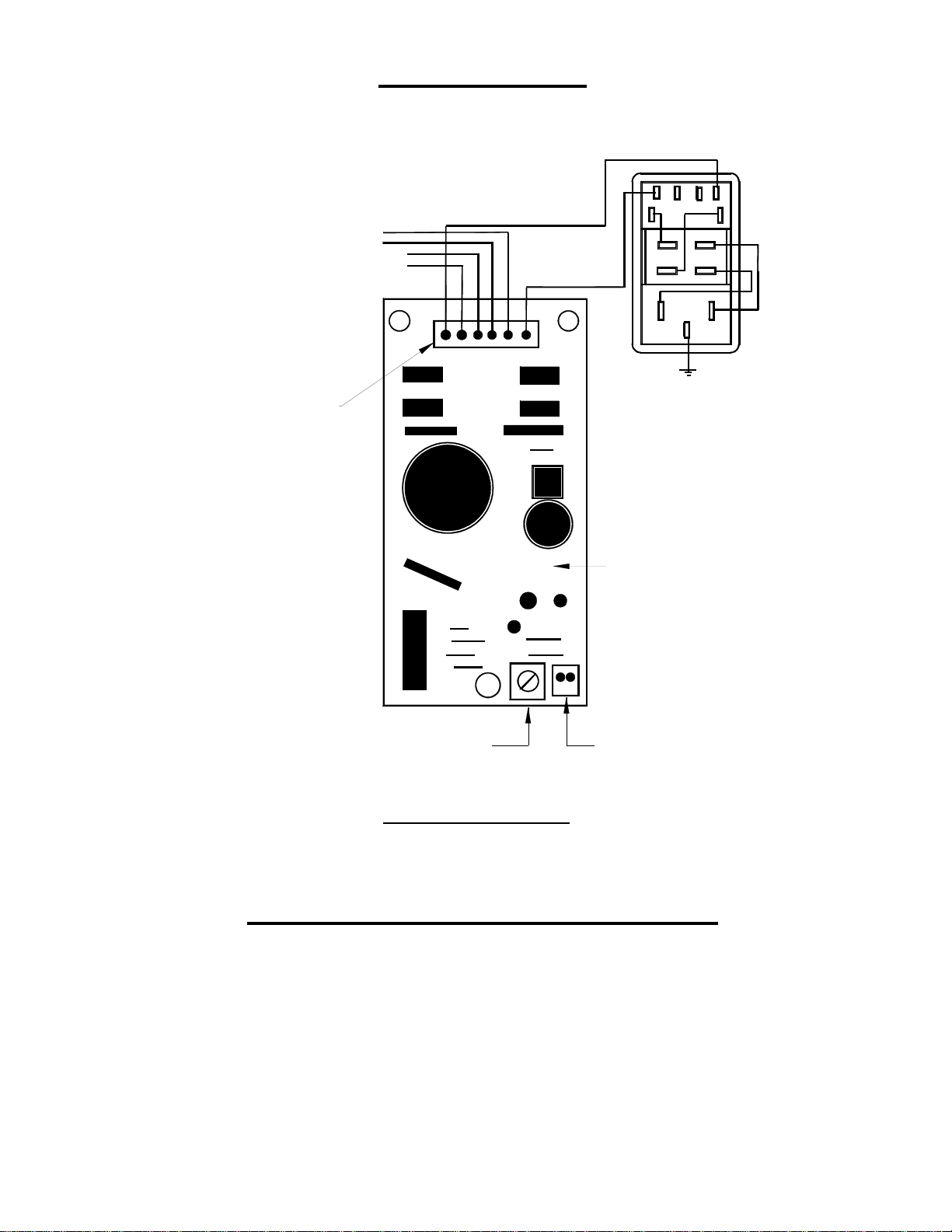

SOLENOIDS

FOOTPEDAL

6 Pin Connector

20-013-GW

2.0 GW JUNIOR

1

654

32

MODULAR SWITCH

W/FUSEHOLDER

90-062-GW

BLUE

B

R

BLUE

O

W

N

BROWN

GREEN

B

L

U

E

25-012-GW

2 Pin Impression

Impression Control

Potentiometer

Control Connector

(harness: 20-015-GW)

Model J-1 Circuit Board

2.1 GW Junior Circuit Board Values

On the Circuit Board (refer to diagram), there is a 6 Pin Main Connector (male). Numbering the

pins as follows, 6;5;4;3;2;1, from the wires you will have the following values:

1&6 -Power -you should then read the line voltage to the circuit (VAC).

2&3 -Footpedal -by pressing the footpedal, you will see the resistance change as

the line opens and closes.

4&5 -Solenoid -the solenoid resistance value will be approximately 40Ω (ohms).

On older machines, this value may range from 40 to 90Ω.

- 6 -

2.2 Troubleshooting

If you do not have a line voltage reading from pins 1&6, there is a break in the line and repairs are

required. First check the main fuse, then trace back the line for breaks.

If there is no resistance reading from the Solenoid, replacement is required of both the Solenoid and

Circuit Board. Once the Solenoid shorts, the Circuit Board will then have a short somewhere on the

real estate.

If there is no reading variation from the Footpedal, check the line for breaks. There may not be

correct contact at the Footpedal's contact point if there are no breaks in the line. Remove the two

side screws from the footpedal, but carefully because the top is sprung. The contact point will now

be exposed. There may be corrosion or dirt at the contact point. With very fine sandpaper, clean the

points reassemble and test. If after the above is performed and you still do not locate the problem,

the Footpedal may require replacement

In the bottom right of the Circuit Board is a 2 Pin Impression Control Connector. This connects to

the Impression Control on the Operating Panel. Make sure that the Impression Control is not

completely counter-clockwise, as this may close the circuit. As well, the Impression Control

Potentiometer on the circuit board is used to change the Impression Control range according to the

line voltage, and again it should not be fully counter-clockwise.

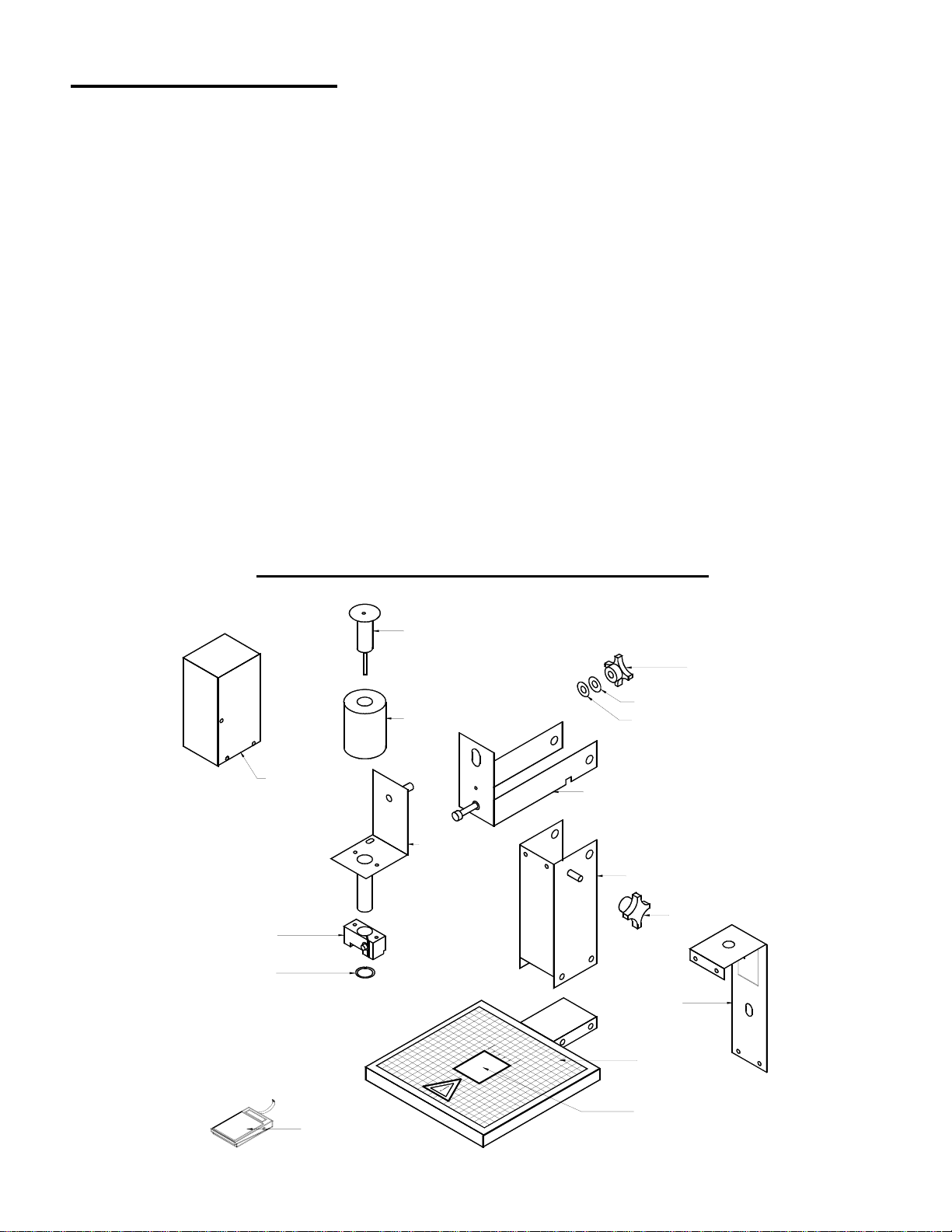

2.3 GW JUNIOR PARTS DIAGRAM

10-044-GW

10-042-GW

10-043-GW

10-053-GW

20-005-GW

10-052-GW

10-054-GW

10-011-GW

10-041-GW

25-004-GW

10-040-GW

10-040-GW

25-009-GW

20-002-GW

20-003-GW

20-010-GW

- 7 -

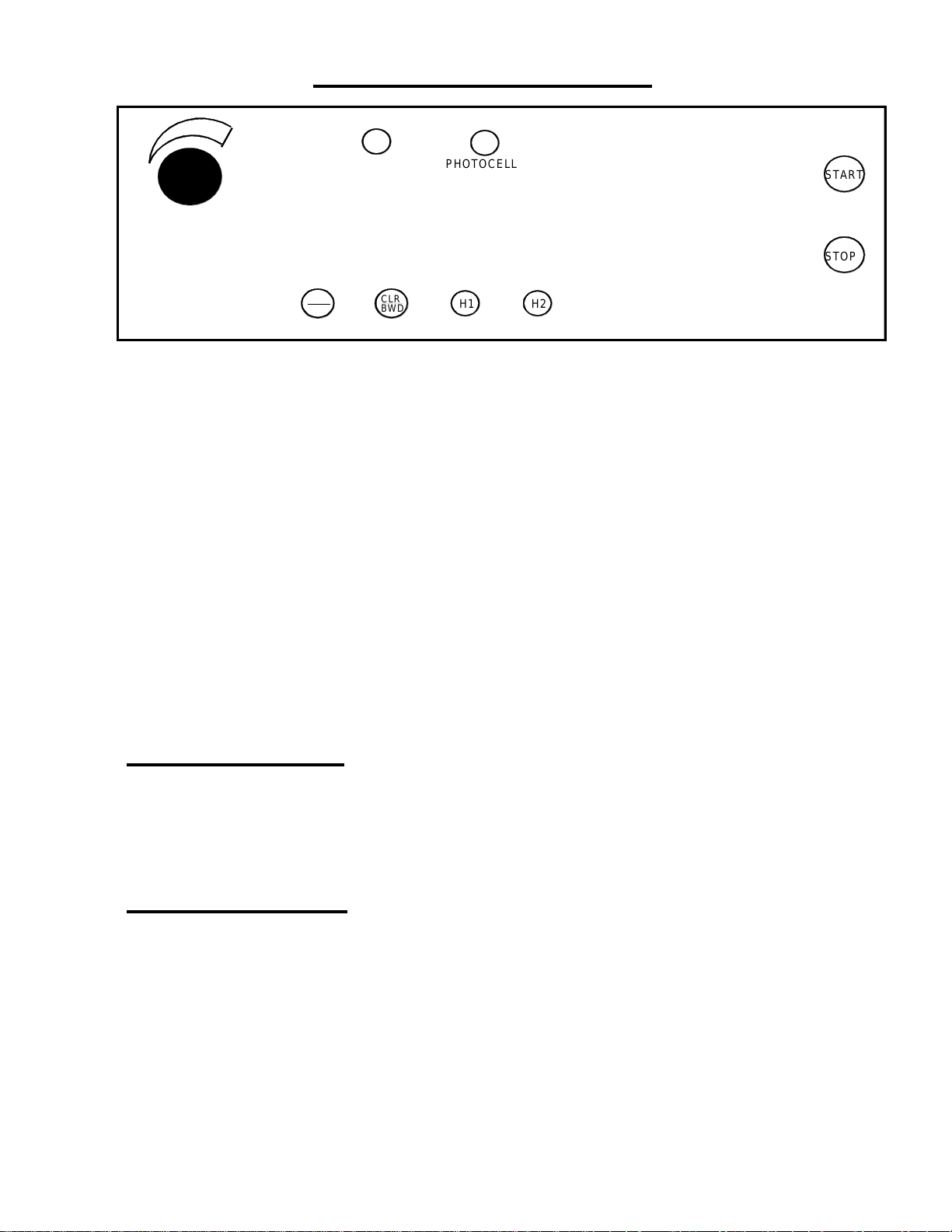

3.0 GW 3000 OPERATION

PHOTOCELL

H1

START

STOP

H2

IMPRESSION

CONTROL

SET

FWD

SAFETY

CLR

BWD

The operating keyboard is comprised of various buttons and a Impression Control which

consist of one potentiometer knobs that control the crash strength of the numbering heads, and can be

adjusted to best suit the requirements of the job. For example, you may require stronger crash

numbering for carbonless sets than for single sheet bond paper. This adjustment can be done while the

machine is stopped or running.

The four buttons under the LED display will perform whatever function is shown directly on them.

SET/FWD – Is used to set up a numbering job and incrementing the motor in a forward direction.

CLR/BWD- Is used to clear programs and increment the motor backwards.

H1- Is used to control head number one which is the head closest to the operator.

H2- Is used to control head number two which is the head furthest away from the operator.

START – Is used to start the machine.

STOP- Is used to stop the machine.

Once you have plugged the machine in, turn the on/off switch to the 'on' position. The LEDs

will flicker and then stop. The GW 3000 does systematic error checks, if it detects an error the LEDs

will remain flickering, count the number of flickers and compare with the list of all possible error

codes.

3.1 Running a Job

The machine is capable of storing a 1 job 1 hit for recall and future use. Ensure that there is

paper in the feed tray first. Pressing the 'START' button will automatically begin the program that was

previously programmed in the memory.

3.2 Stopping a Job

There are two methods of stopping the machine.

1. Once the program is running, pressing the 'STOP' button will cause the machine to finish the

stock it is currently working on, move the next stock into the starting position and then stop the

motor.

2. If you want to stop the machine while stock is still left in it, simply hold on to the stock in the

feed tray. After about one second, the machine will automatically stop (since it is no longer

seeing any new sheets). This is how it also stops when all of the stock in the feed tray is gone.

3. Pressing any of the other buttons will stop the machine defaulting the machine to its idle mode.

- 8 -

3.3 Clearing A Job

To completely clear a program from the memory insert a paper in the feed tray. Press the

SET/FWD button. The paper will then feed through and stop at 75. Press the CLR/BWD button and

hold it down, next press the H2 button and this will clear the memory of the previous job.

You can now run just a perf/score/slit job by pressing START.

3.4 Changing and Programming a Job

The following describes Mode - Program Setup operation:

• Loads a new sheet of paper, regardless if paper is already in the machine or not.

• Paper is loaded into the machine at “Setup Paper Speed” and stops at “Paper Position Stop”.

• Motor advances in single steps, or continuously at Setup Paper Speed using the <FWD> and

<BWD> keys. The motor stops when the key is released.

• Motor operation will stop while holding down either of the <FWD> and <BWD> keys once

the existing programmed hit location is reached. Another key-down <FWD> or <BWD> must

be detected before moving off of the hit position.

• Heads fire according to the current program (i.e. when the sheet reaches the hit position), or

when the <H1> and/or <H2> key is pressed.

• <H2> can only be fired once <H1> is programmed at the same hit location. <H1> must be

fired first, followed by <H2>. Pressing <H2> without having first programmed <H1> does

nothing.

• If <H1> / <H2> is pressed at a current hit position, the head to fire will be toggled ON/OFF.

Pressing <H1> toggles ON/OFF SOL1, pressing <H2> toggles ON/OFF SOL2 when SOL1 is

programmed.

• If <H1> and <H2> are both programmed at the hit position and <H1> is removed, the <H2> hit

data is automatically removed from the solenoid program.

• If a solenoid head error is reported, hit data may still be programmed and saved.

• Creation of hit data can be performed at any paper position. If the solenoid is fired at a new

position, followed by pressing the <START> key, any existing old hit data will be overwritten

and the new position and hit data saved.

• When the <START> key is pressed, the changes to the program are saved to the EEPROM, the

current sheet is ejected, and the next sheet is loaded to “Paper Position Stop”.

• If the <STOP> key is pressed, any changes made during Setup are aborted and the solenoid

program will be re-loaded from EEPROM. The exception is if a EEPROM error exists, then

the solenoid program workspace in RAM will remain intact.

1. The following are the Mode - Program Setup (solenoid program) constraints:

• There is a maximum of 1 hit position in a program.

• SOL2 can only be enabled when SOL1 hit data exists, otherwise <H2> key presses will be

ignored.

• Modification of existing hit data can only occur while at the hit position.

• The user shall not be allowed to step backward past “paper stop position”

• The perf shield shall be closed before entry to Mode - Program Setup.

• An open perf shield condition with paper loaded disables the motor and solenoid operation

until the perf shield is closed.

- 9 -

3.5 Error Codes

ERROR/BLINK

NUMBER

01 PAPER JAM

02 CH 1 OPEN

03 CH 1 SHORT

04 CH 1 HOT

05 CH 2 OPEN

06 CHANNEL 2 SHORT

07 CHANNEL 2 HOT

08 AC LINE VOLTAGE OUT OF

09 MOTOR VOLTAGE OUT OF

10 EEPROM ERROR

ERROR

CONDITION

OPERATION RANGE

RANGE

CONDITION

• Paper has lodged itself above the photocell and beneath the

reflector.

Remove paper sideways- do not pull up against the reflector.

• Dust has accumulated over the photocell.

Blast the groove below the reflector with air.

• Photocell needs readjustment.

• Head #1 is not plugged into channel #1.

• The solenoid has failed and replacement is necessary.

• Machine has been running for a while, and the solenoids

have heated up.

Turn the machine off to allow the head to cool down.

• Head #2 is not plugged into channel #2.

• The program being ran is using two heads and there is only

one drive unit.

Reprogram using Head #1.

• The solenoid has failed and replacement is necessary.

• Machine has been running for a while, and the solenoids

have heated up.

Turn the machine off to allow the head to cool down.

• Check line voltage.

• Motor has been running for a while and needs cooling down.

• MSTP board needs replacing.

• A component problem has occurred.

- 10 -

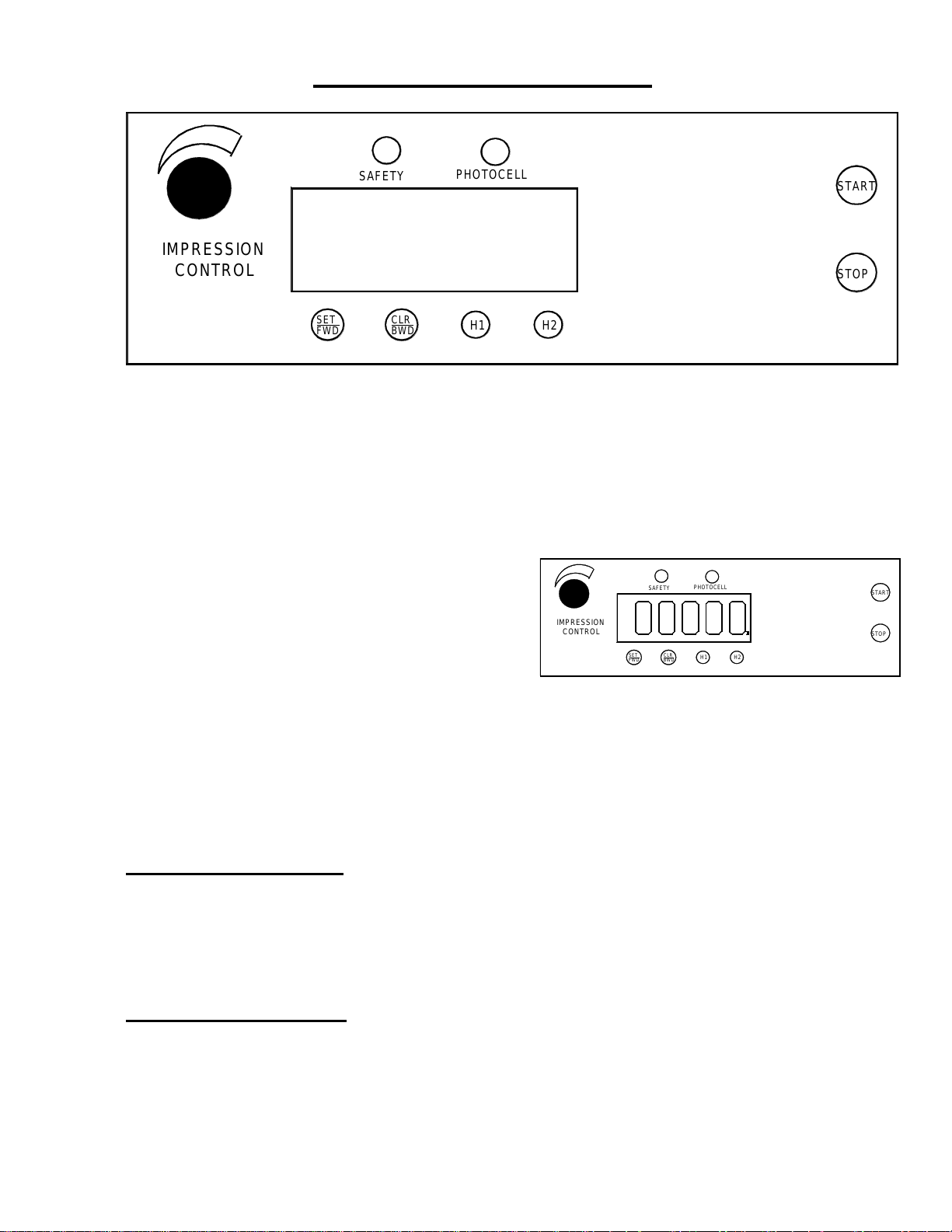

4.0 GW 6000 OPERATION

SAFETY

PHOTOCELL

START

IMPRESSION

CONTROL

SET

FWD

CLR

BWD

H1

H2

STOP

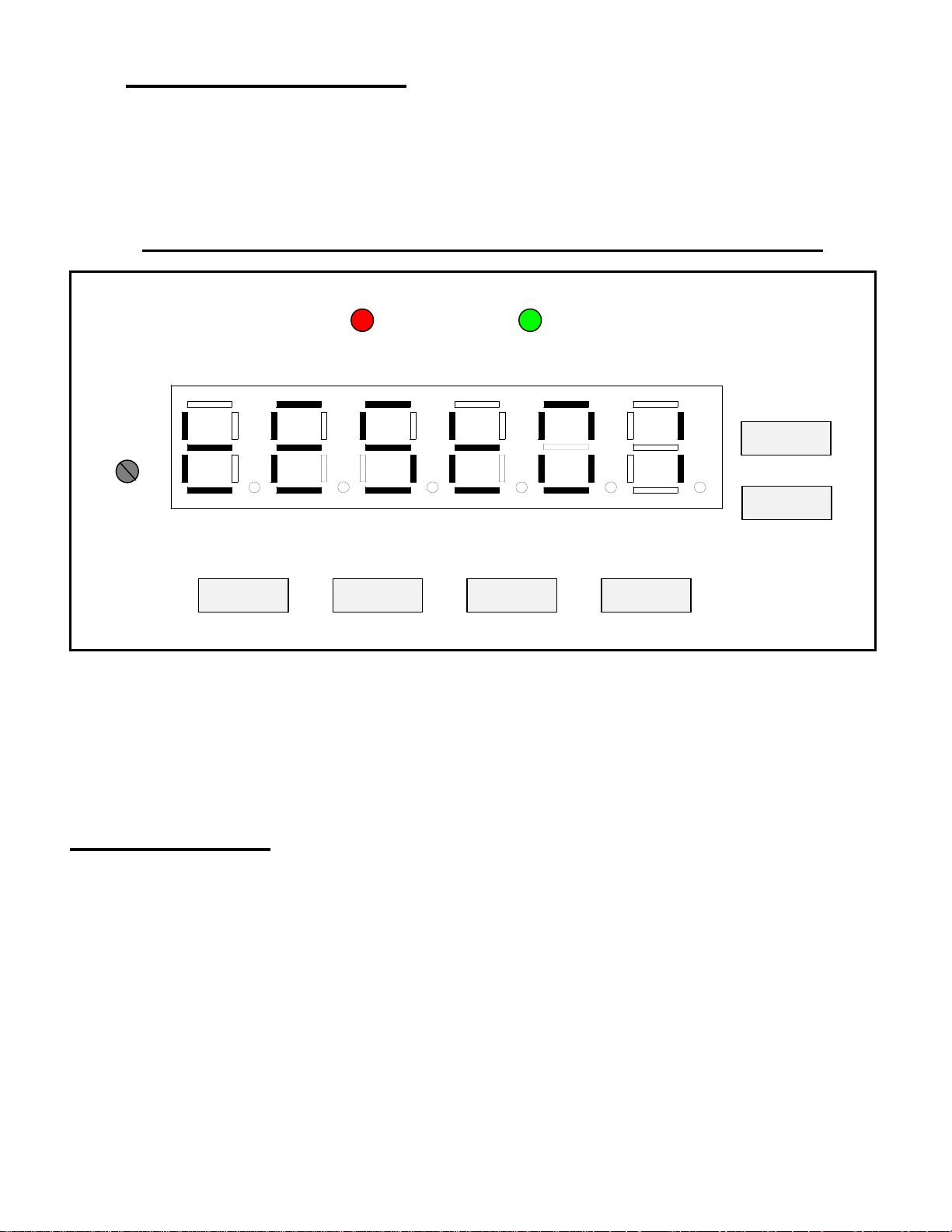

The operating keyboard is comprised of six LED segments, various buttons and a Impression

Control which consist of one potentiometer knobs that control the crash strength of the numbering

heads, and can be adjusted to best suit the requirements of the job. For example, you may require

stronger crash numbering for carbonless sets than for single sheet bond paper. This adjustment can be

done while the machine is stopped or running.

The four buttons under the LED display will perform whatever function is shown directly on

them.

SET/FWD – Is used to set up a numbering job and incrementing the motor in a forward direction.

CLR/BWD- Is used to clear programs and increment

the motor backwards.

SAFETY

PHOTOCELL

H1- Is used to control head number one which is the

head closest to the operator.

H2- Is used to control head number two which is the

head furthest away from the operator.

IMPRESSION

CONTROL

CLR

SET

FWD

H1

BWD

H2

START – Is used to start the machine.

STOP- Is used to stop the machine.

Once you have plugged the machine in, turn the on/off switch to the 'on' position. The LED

display will be blank for a second the two lights for the safety lid and photocell will light up. The

system will do a check on each LED line segment and then look like the above.

The Sprint 6000 does systematic error checks, if it detects an error it will display a numeric

value.

START

STOP

4.1 Running a Job

The machine is capable of storing a maximum of 1 job with 10 hits for recall and future use.

Ensure that there is paper in the feed tray first. Pressing the 'START' button will automatically begin

the program that was previously programmed in the memory.

4.2 Stopping a Job

There are two methods of stopping the machine.

1. Once the program is running, pressing the 'STOP' button will cause the machine to finish the

stock it is currently working on, move the next stock into the starting position and then stop the motor.

- 11 -

2. If you want to stop the machine while stock is still left in it, simply hold on to the stock in the

feed tray. After about one second, the machine will automatically stop (since it is no longer seeing

any new sheets). This is how it also stops when all of the stock in the feed tray is gone.

4.3 Clearing A Job

To completely clear a program from the memory insert a paper in the feed tray. Press the

SET/FWD button. The paper will then feed through and stop at 75. Press the CLR button and hold it

down, next press the H2 button and this will clear the memory.

4.4 Changing and Programming a Job

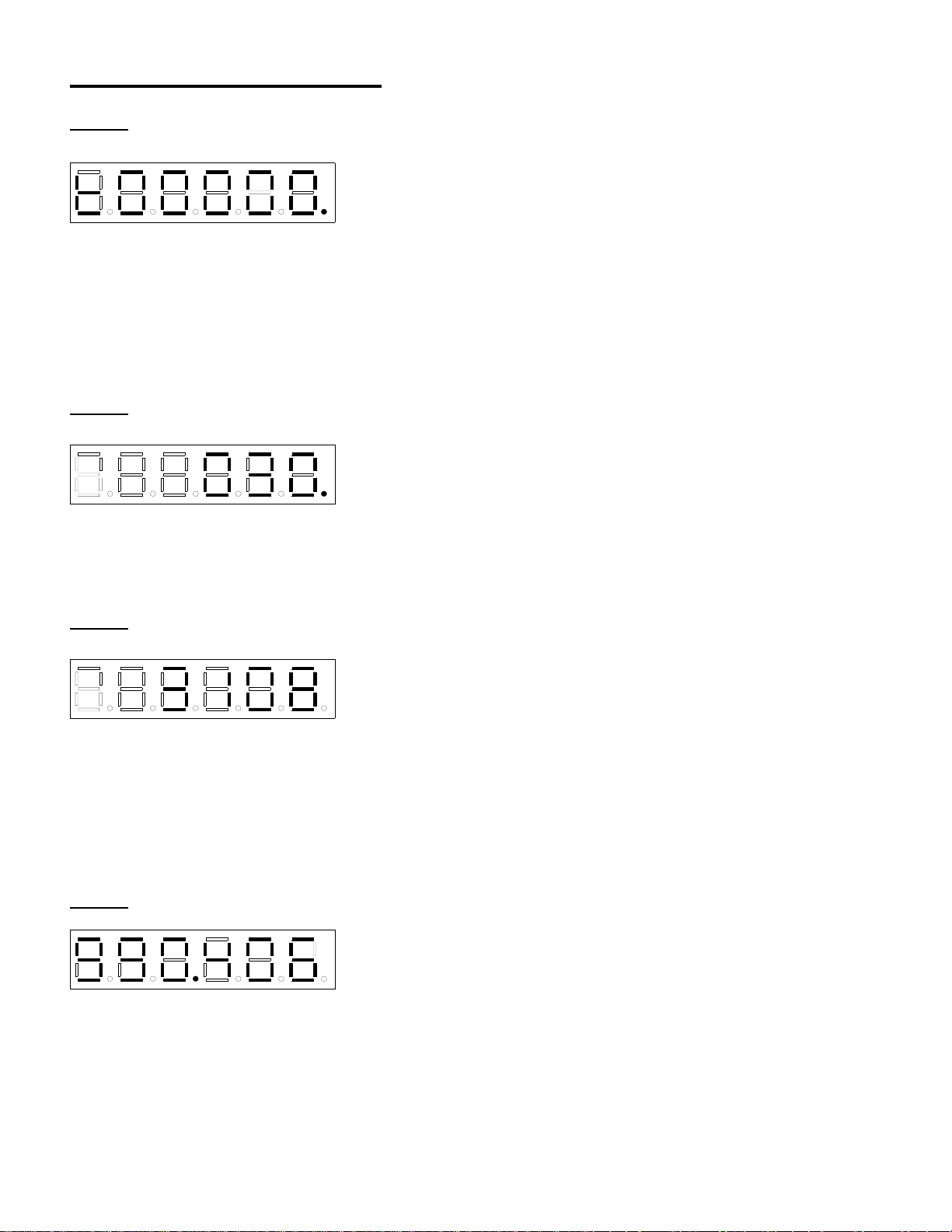

DIG 5 DIG 4 DIG 3 DIG 2 DIG 1 DIG 0

DP 5 DP 4 DP 3 DP 2 DP 1 DP 0

completely press the CLR/BWD button, while holding it down press the H2 button, you will notice DP

0 will go off, this indicates that the memory and all hits have been cancelled.

As a guide, refer to the orientation of the LED digit segments (DIG 5-0) and the Decimal point

functions (DP 5-0) in the picture.

DIG 5 – Displays “P” for Program Set-up.

DIG 4 – Displays “h” only if a hit has been programmed at the current position.

DIG 3 - DIG 0 – Current paper position in steps from the paper leading edge. In run mode they act as

paper count.

DP 5 – Indicates the motor direction On = Forward

DP 4 – If it is on it indicates all 10 hit positions are used.

DP 3 – No function.

DP 2 – Solenoid 1 – On indicates Head 1 will be fired at the current position.

DP 1 – Solenoid 2 – On indicates Head 2 will be fired at the current position.

DP 0 – Indicates a hit exists in the program.

Changing the position of a hit can be done by scrolling (SET/FWD or CLR/BWD) to where the

previous hit existed. Once there the head will fire and you will have an “h” displayed in DIG 4, the

numbers indicate the stepper count position. You will also have either DP 1 and/or DP 0 lit depending

on which numbering head was activated. Pressing Either H1 or H2 will toggle the lights off or on.

When DP 1 or DP 0 is off, it indicates there is no longer a hit programmed at that position. Now by

scrolling with the SET/FWD or CLR/BWD buttons you can reposition the number hit.

Once all is set, press START and “SAVE” will display in DIG 5-2 and the current sheet will

eject. The machine will go into the idle mode. This will show DIG 4-0 as 0’s. Any numbers on the

display will be a paper count; pressing the CLR/BWD button will clear this back to zero.

To run the job, insert paper into the feed tray and press start.

Whenever you wish to change or program a job,

insert a piece of paper into the feed tray and press

the SET/FWD button. The paper will go through

the machine and stop in front of the photocell.

The DIG 5 will have P indicating you are in the

program mode, DP 5 will light up indicating the

motor is on in the forward position, DIG 1-0 will

have 75 and DP 0 will light up indicating that a

hit exists in the program. To clear the memory

- 12 -

4.5 SPEED CONTROL

The GW 6000 is equipped with three speeds. Slow speed is the default when you first run the program.

While the program is running press ‘H1 and/or H2’ you will notice on the far-left side of the display

vertical lines. Three of these lines indicate high speed, two for medium and one for low speed.

4.6 GW 6000 SOFTWARE SET UP and DIAGNOSTICS

PERF SHIELD (RED)

DIG 4 DIG 3 DIG 2 DIG 1

PHOTOCELL (GRN)

DIG 0DIG 5

IMPRESSION

DP 5 DP 4 DP 3 DP 2 DP 1

DP 0

H2 H1 SET/FWD CLR/BWD

START

STOP

The GW 6000, performs a limited set of self-diagnostics on power up. A full set of diagnostic utilities is

accessed by a manufacturing test mode. The system indicates paper error conditions along with hardware

faults by displaying a message on the LED display during operation.

All settings are simple enough for the customer to be coached through via telephone. We however recommend

that they only be done on site, by the dealer.

4.7 OVERVIEW

Access to all settable parameters is available through the keyboard while in the main operating menu. This is

the menu display when the machine is first turned on. If you are not at this point, press ‘STOP’ as often as

required to return to the main operating menu.

When at this point press ‘STOP’ and while holding it down press ‘H1’ and ‘H2’ at the same time. The display

will read “tESt01”. The test program is one of 10 available items. Each of the others is accessible by scrolling

with the ‘SET/FWD’ or ‘CLR/BWD’ buttons and then ‘START’ will allow you to enter that specific item

number.

- 13 -

4.8 INDIVIDUAL ITEMS

tESt01

our plant using this program to burn in the circuits and weed out any other assembly or miscellaneous

problems. DP4 allows for a single hit program by pressing ‘SET/FWD’ it will come on or go off. This light is

usually off allowing for a ten hit program. DP0 is always on indicating hits existing in the default program.

Pressing the ‘CLR/BWD’ will clear the simulated paper count.

To exit this item press ‘STOP’.

tESt02

midsection of the board beside the two, four pin connectors.

To exit this item press ‘STOP’.

tESt03

this point the numbers to the left of the dot will be the actual motor voltage, and the number to the right is the

actual input line voltage reading. The motor voltage typically will be around 150V if the voltage is higher than

160V then there is a problem. In 220-volt systems the line voltage will be approximately half of the actual line

input voltage.

To exit this item press ‘STOP’.

tESt04

version.

To exit this item press ‘STOP’.

– TEST RUN

DIG 4 DIG 3 DIG 2 DIG 1

DIG 0DIG 5

When selected, this program will run the default factory program. The

motor will run, stop, start and the heads will fire simulating a standard

run. This is useful after replacing a component on the machine and

DP 5 DP 4 DP 3 DP 2 DP 1

DP 0

testing its correct installation. We run each machine for three full days in

– DISPLAY PHOTOCELL ADC

DIG 4 DIG 3 DIG 2 DIG 1

DIG 0DIG 5

This is a machine value for the photocell. The value should be

approximately 60. Making adjustment on the gray pot located on the

PSTEP board can change this value. This is the bigger board located on

DP 5 DP 4 DP 3 DP 2 DP 1

DP 0

the non-operator side of the machine. The pot is located at the top

– DISPLAY VOLTAGES

DIG 4 DIG 3 DIG 2 DIG 1

DIG 0DIG 5

This displays the motor off-line, DIG2-0 will display the line voltage (it

will be lower than the actual line voltage), DIG5-3 will read the actual

motor voltage, when off-line the voltage will read around 0. When ‘H2’

DP 5 DP 4 DP 3 DP 2 DP 1

DP 0

is pressed DP3 will light up indicating that the machine is now on-line at

– DISPLAY SOFTWARE VERSION

DIG 4 DIG 3 DIG 2 DIG 1

DIG 0DIG 5

This mode will indicate the software version dates of the ICPU software

and the MSTP software. Default on entry is the ICPU Software Version,

DP 5 DP 4 DP 3 DP 2 DP 1

indicated by DP3. Pressing ‘H2’ will display the MSTP version in

DP 0

which the DP3 will disappear and ‘H1’ will get you back to the ICPU

- 14 -

Loading...

Loading...