Page 1

Graphic Whizard GW

6000 Number/Perf/

Score/Slit Machine

Instruction Manual

Page 2

6635 Kitimat Road, Unit 34; Mississauga, Ontario; Canada L5N 6J2;

Web Site: www.graphicwhizard.com

GW 6000

Reference

Manual

Tel: (905) 858-7663 Fax: (905) 858-4419 Toll Free 1-800-265-3376

Shown with optional second head & optional stand

Mississauga, Ontario L5N 6J2

Phone # (905) 858-7663 Fax # (905) 858-4419

Web Site: www.graphicwhizard.com

GRAPHIC WHIZARD

6635 Kitimat Road, Unit 34

Toll Free: 1-800-265-3376

Version 99-07

Page 3

3

Page 4

TABLE OF CONTENTS

1.0 General Operation 3

1.1 Technical Data 3

1.2 Safety Regulations 3

1.3 Cautions Concerning Machine 4

2.0 Machine Assembly 5

2.1 Feed and Exit Trays 5

2.2 Numbering Heads 6

2.3 Optional Conveyor Outfeed Plate 7

2.4 Additional Switches and Control 7

3.0 Operating Keyboard 8

3.1 Running a Job 8

3.2 Stopping a Job 8

3.3 Clearing a Program 9

3.4 Changing and Programming a Job 9

3.5 Speed Control 10

4.0 Setting Up a Job 10

4.1 Aligning the Feed Tray Guides 10

4.2 Setting Feed Tire Pressure 10

4.3 Perforating/Slitting 12

4.4 Scoring 13

4.5 Idler Wheel Holders 14

4.6 Main Rollers 14

4.7 Installing Ink Pads 14

4.8 Locating the Numbering Heads 15

4.9 Stripper Assemblies 15

4.10Setting Impression Control 15

4.11Flatness of Impression 16

4.12Exit Rollers 17

5.0 Running a Job 17

5.1 Setting the Start Number 17

5.2 Setting the Repeat Selector 17

5.3 Fanning 18

6.0 Maintenance 19

6.1 Numbering Heads 19

6.2 Machine Cleaning 19

6.3 Lubrication 20

6.4 Friction Feed 20

7.0 Troubleshooting 21

Friction Feeder 21

Print Quality 21

Registration 22

Numbering Heads 22

Error codes 24

Parts List 25

GW 6000 PARTS LIST 25

GW 6000 PARTS DIAGRAM 29

4

Page 5

1.0 GENERAL OPERATION

The GW 6000 is a numbering, perforating, scoring, and slitting system. It operates at three speeds that is

factory programmed to print 6000 sheets per hour, assuming 1 hit per page and a 15 millisecond

solenoid pulse width. The operation of the machine is controlled by a microprocessor with an LED

display and keypad interface.

The system allows for a maximum of two numbering heads, which can independently turn off or on for

a maximum of 1 job with ten hits per head that, are stored and recalled for future use. Numbering can be

done on single sheets (13# bond to 12 point card or 45 to 250 gsm paper) or multi-part carbonless forms

(up to 10 parts) while simultaneously perforating, slitting and/or scoring. The unique friction feeder

sends through one set at a time, even from the unglued side of a padded set. The pressure adjustable

feed shaft ensures consistent registration. Perforations are done between the feed and main rollers

producing a straight perforation, slit or score, avoiding tail whip. Perforating wheels are offered in a

wide range of teeth configurations and can be quickly changed using the retaining ring pliers supplied.

A photocell recognises the lead edge of the sheet and the microprocessor stops the sheet at the specific

location(s) where numbers are required. The numbering heads are electrically operated. All this, in a

compact design.

1.1 TECHNICAL DATA

Areas of use:

Paper weight: 12# - 12 point (45-250 gsm)

Paper formats: max. 18” x 18” (45 x 45 cm)

min. 3” x 5” (7.6 x 12.7 cm)

Electrical configuration:

Voltage: 90-135 VAC or

180-270 VAC

Frequency: 60 Hz or

50 Hz

Fusing: 115/230V, 3/5A

1.2 SAFETY REGULATIONS

• Before using the machine, you must read the operating instructions.

• Professionals must only eliminate damage or extraordinary malfunctions.

• Never insert your hand into the machine while it is running.

• Do not wear loose fitting clothing when working with the machine.

• Make sure that the machine stands on a level and well-ventilated positions.

5

Page 6

1.3 CAUTIONS CONCERNING MACHINE

CAUTION – The solenoids may get hot during

operation. Do not touch the solenoid case while the

machine is running and until it has been given enough

time to cool down.

CAUTION – The motor may get hot during normal

operation use. Do not touch any vicinity near motor.

CAUTION – On Electric Solenoid machines the noise levels can

be excessive and hearing protection may be required.

CAUTION – Machine should never be left unattended.

6

Page 7

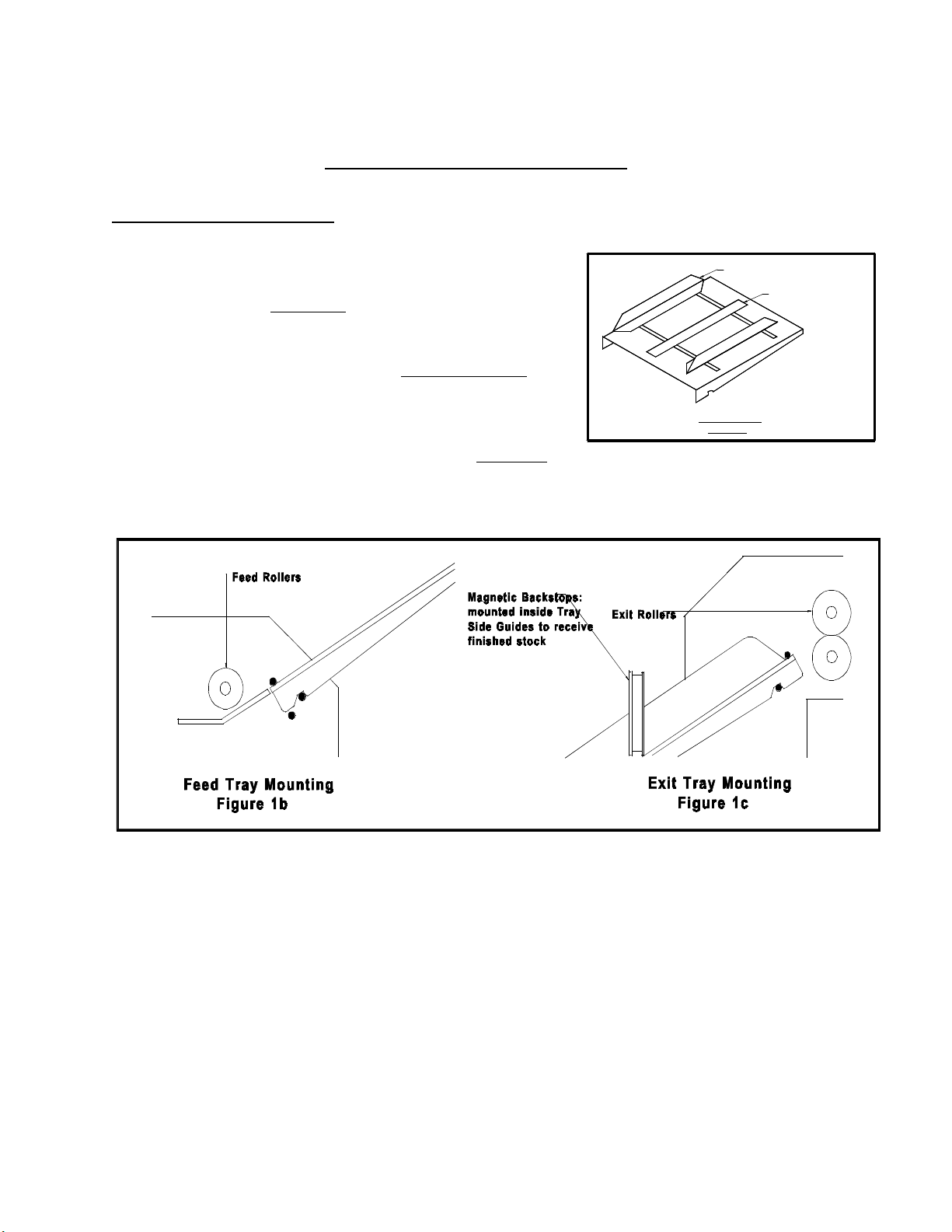

2.1 Feed and Exit Trays

2.0 MACHINE ASSEMBLY

The feed and exit tray assemblies are comprised of

four components each: the tray, two tray side guides and a

centre slot cover (see Figure 1a).

SIDE GUIDE

CENTER SLOT GUIDE

The trays sit in the machine on mounting pins inside

the machine's side frames as shown in Figure 1b and 1c. The

trays can be easily removed and stored elsewhere when not in

use.

Place the tray side guides, bottom flange towards the centre

Tray Assembly

Figure 1a

and the centre slot cover on the tray as shown in Figure 1a and

screw on the nylon wing nuts to secure the pieces on the tray. The operator side tray guide of both the

feed and exit tray should be pulled all the way over to the operator side before tightening its two wing

nuts.

Note: It is critical that the operator side tray guide be moved all the way over to the

operator side of the machine to ensure that the stock being processed through the

machine passes directly underneath the photocell. If the stock does not pass directly

underneath the photocell, the machines will not recognise sheets and the program

being run will not be initiated.

Place a pile of the stock to be processed in the feed tray and use it to align the non-operator side

tray guide to the pile. Allow a fraction of an inch so that the pile flows freely up and down the tray if

released from the top. Set the exit tray in a similar manner, although the accuracy of the non-operator

side guide position is not critical.

As a backstop to finished stock, there are two magnets included with the machine (unless

equipped with the conveyor outfeed) that are set inside the side tray guides on the exit tray. Relative

7

Page 8

position of the magnets depends on the stock being processed, but the magnets should be set such that

the stock does not slide down the exit tray too far, possibly causing sheets to get in uncollated order.

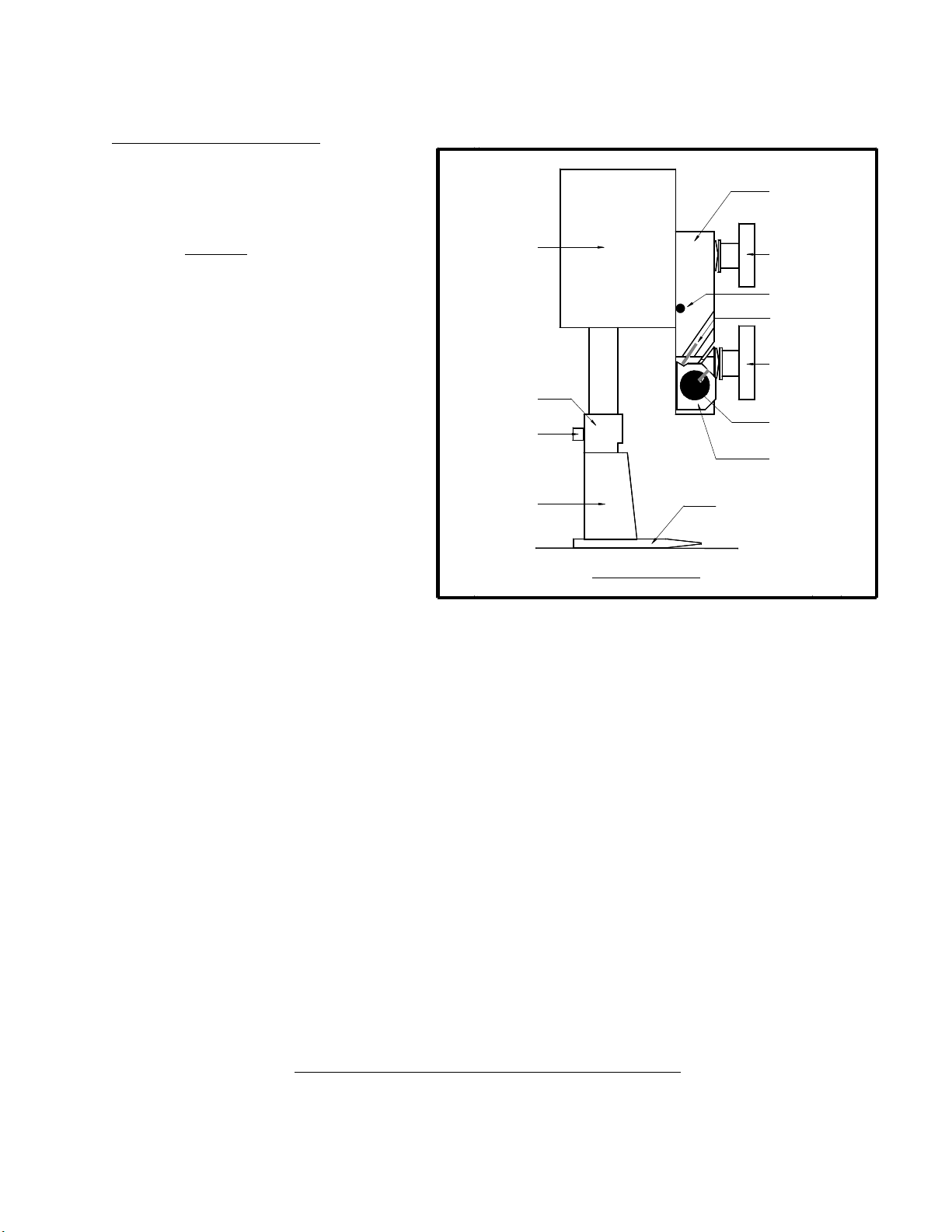

2.2 Numbering Heads

The numbering heads are already secured

to the drive unit by two screws through

the numbering head mount block as

shown in Figure 2. The drive unit is then

mounted to the drive unit mount block

using the hand knob provided. While

installing the drive unit, make sure the

screw cap on the back of the drive unit

fits in the cavity on the drive unit mount

block so that the rubber plug provides

some pressure against the screw cap. You

may have to back out the left/right pitch

screw in order to do this. Plug in the cord

from the drive unit into the appropriate

receptacle on the non-operator side cover

(closest head to the closest receptacle). If

your machine is equipped with more than

one head, by convention, the numbering

head and drive will refer to unit closest to

the operator control panel as head #1(H1)

and the other will be head #2 (H2).

Drive Unit

Numbering Head

Mount Block

Numbering Head

Rotation Lock Screw

Numbering Head

Platen

Figure 2: Numbering Heads

Drive Unit Mount Block

Hand Knob

(Left/Right Pitch)

Left/Right Pitch Screw

Forward/Back

Pitch Screw

Hand Knob

(Forward/Back Pitch)

Drive Unit Mount Shaft

Anti-Pitch Block

Change Stylus: Numbering

Head should be approx. 1/4"

from the platen, or the

thickness of a change stylus

The height of the numbering head has been factory set and it is critical to the proper performance

of the drive unit and numbering head. This distance is approximately 3" or the thickness of a numbering

wheel change stylus. However, the numbering head must be levelled to ensure that the numbering

wheels strikes the sheet square to provide a quality inked impression and a flat crash impression on

carbonless sets. This will be discussed later (Section 4.11).

The numbering heads can operate through 360Ε. This is done by loosening the numbering head

rotation screw (using the large hexdriver supplied) located on the front of the numbering head mount

block. Once the screw is loose, the head is free to rotate. Tighten the screw once the desired position is

achieved in order to prevent any movement during machine operation.

The standard numbering head is 3/16" (4.5mm) Gothic style, reverse order, 6 digits with 2 drop wheels.

The numbering head employs a pre-inked pad, which can be purchased in red or black. These ink pads

will supply you with approximately 15,000 impressions. Uninked pads may be purchased if a different

colour is required (Note: any ink used must be a non-metal corrosive one, labelled numbering machine

ink).

The numbering head comes standard with six numbering wheels (a seventh numbering wheel is

optional), the last two of which are drop wheels (this will be discussed later). The first 5 digits may be

activated automatically. The 6th (or 7th) digit must be changed manually. Also available are letter

prefix wheels (A-J; K-R; S-Z) and a µ prefix wheel. Modifications are possible with new numbering

head orders or by special order.

8

Page 9

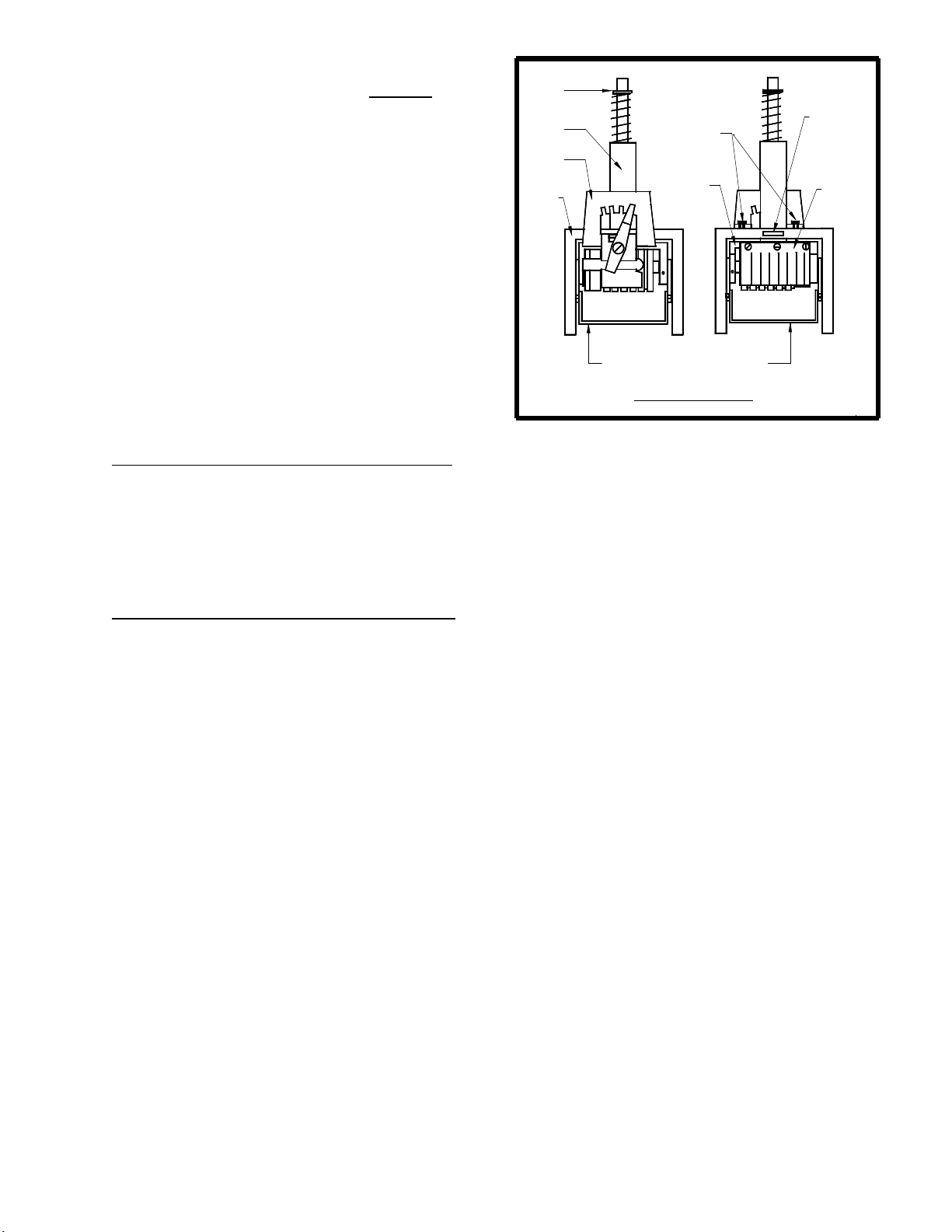

The numbering heads also have a repeat

function. The repeat selector (see Figure 3) allows a

number to be repeated from one to four times. By

leaving the repeat selector in the "0" position, the

number will not change when the head returns to the

print position. Using the "0" position prevents you

from having to re-set the starting number when you

are programming a new job (this will be discussed

C-Clip

Spring

Bushing

Repeat

Selector

Print

Head

Frame

Locking

Repeat

Selector

Adjustment

Screws

Numbering

3

2

4

Head

1

0

Frame

Tab

Comb

Spring

later). Position "1" changes the number

consecutively with each stroke and positions "2",

"3" and "4" repeat the number 2, 3 or 4 times

respectively. The repeat functions are achieved by a

mechanical ratchet action in the numbering head.

When trying to use these functions, you may have to

cycle the numbering head manually in order to

match the number of repeats on a page to the

Ink Pad Holder Mount Bracket

Figure 3: Numbering Heads

number positions on a page.

2.3

O

ptional Conveyor Outfeed Plate

The conveyor outfeed plate sits in the machine in the same fashion as the exit tray. Make sure

that the spur gears mesh and do not force the conveyor outfeed plate into position. The pile tray is

mounted on the end of the conveyor outfeed plate, with two Phillips screws and acts as a backstop for

the finished stock.

2.4

Additional Switches and Controls

The main on/off switch module is located under the feed tray on the back of the operator side

plate. This module also houses the main fuseholder and power cord.

9

Page 10

3.0 Operating Keyboard

Figure 4: OPERATING KEYBOARD

The operating keyboard is comprised of six LED segments, various buttons and a Impression

Control which consist of one potentiometer knobs that control the crash strength of the numbering

heads, and can be adjusted to best suit the requirements of the job. For example, you may require

stronger crash numbering for carbonless sets than for single sheet bond paper. This adjustment can be

done while the machine is stopped or running (see Figure 4).

The four buttons under the LED display will perform whatever function is shown directly on them.

SET/FWD - Used to set up a numbering job and incrementing the motor in a forward direction.

CLR/BWD - Used to clear programs and increment

the motor backwards.

H1 - Used to control head number one, which is the

head closest to the operator.

H2 - Used to control head number two, which is the

head furthest away from the operator.

START - Used to start the machine.

STOP - Used to stop the machine.

Once you have plugged the machine in, turn the on/off switch to the 'on' position. The LED

display will be blank for a second the two lights for the safety lid and photocell will light up. The system

will do a check on each LED line segment and then look like the above.

The GW 6000 does systematic error checks, if it detects an error it will display a numeric value.

A list of all possible error codes is listed on page 21.

3.1 Running a Job

The machine is capable of storing a maximum of 1 job with 10 hits for recall and future use.

Ensure that there is paper in the feed tray first. Pressing the 'START' button will automatically begin the

program that was previously programmed in the memory.

3.2 Stopping a Job

There are two methods of stopping the machine.

1. Once the program is running, pressing the 'STOP' button will cause the machine to finish the

stock it is currently working on, move the next stock into the starting position and then stop the motor.

2. If you want to stop the machine while stock is still left in it, simply hold on to the stock in the

feed tray. After about one second, the machine will automatically stop (since it is no longer seeing any

new sheets). This is how it also stops when all of the stock in the feed tray is gone.

10

Page 11

3.3 Clearing A Program

To completely clear a program from the memory insert a paper in the feed tray. Press the

SET/FWD button. The paper will then feed through and stop at 75. Press the CLR button and hold it

down, next press the H2 button and this will clear the memory.

3.4 Changing and Programming a Job

Whenever you wish to change or program a

job, insert a piece of paper into the feed tray

and press the SET/FWD button. The paper

will go through the machine and stop in

front of the photocell. The DIG 5 will have

P indicating you are in the program mode,

DP 5 will light up indicating the motor is on

in the forward position, DIG 1-0 will have

75 and DP 0 will light up indicating that a

hit exists in the program. To clear the memory completely press the CLR/BWD button, while holding it

down press the H2 button, you will notice DP 0 will go off, this indicates that the memory and all hits

have been cancelled.

As a guide, refer to the orientation of the LED digit segments (DIG 5-0) and the Decimal point

functions (DP 5-0) in the picture.

DIG 5 – Displays “P” for Program Set-up.

DIG 4 – Displays “h” only if a hit has been programmed at the current position.

DIG 3 - DIG 0 – Current paper position in steps from the paper leading edge. In run mode they act as

paper count.

DP 5 – Indicates the motor direction On = Forward

DP 4 – If it is on it indicates all 10 hit positions are used.

DP 3 – No function.

DP 2 – Solenoid 1 – On indicates Head 1 will be fired at the current position.

DP 1 – Solenoid 2 – On indicates Head 2 will be fired at the current position.

DP 0 – Indicates a hit exists in the program.

Changing the position of a hit can be done by scrolling (SET/FWD or CLR/BWD) to where the

previous hit existed. Once there the head will fire and you will have an “h” displayed in DIG 4, the

numbers indicate the stepper count position. You will also have either DP 1 and/or DP 0 lit depending

on which numbering head was activated. Pressing Either H1 or H2 will toggle the lights off or on. When

DP 1 or DP 0 is off, it indicates there is no longer a hit programmed at that position. Now by scrolling

with the SET/FWD or CLR/BWD buttons you can reposition the number hit.

Once all is set, press START and “SAVE” will display in DIG 5-2 and the current sheet will

eject. The machine will go into the idle mode. This will show DIG 4-0 as 0’s. Any numbers on the

display will be a paper count; pressing the CLR/BWD button will clear this back to zero.

To run the job, insert paper into the feed tray and press start.

3.5 SPEED CONTROL

11

Page 12

The GW 6000 is equipped with three speeds. Slow speed is the default when you first run the program.

While the program is running press ‘H1 and/or H2’ will increase and/or decrease the speed, indicated by

the vertical lines you will notice on the far-left side of the display vertical lines. Three of these lines

indicate high speed, two for medium and one for low speed.

4.0

Setting up a Job

To set up the machine for a specific job, a few items must be adjusted depending on the specific

stock being run, the number of heads being used and the number of perforations, slits or scores required.

In order to keep it simple, adjustments required will be discussed from the feed end of the machine to

the exit.

4.1 Aligning the Feed Tray Guides

As previously mentioned, the operator side tray guide should be seated all the way to the

operator side. This will ensure that the stock passes directly underneath the photocell, allowing the

program being run to initiate. With a pile of the stock placed in the tray, align the non-operator side tray

guide with the pile. Allow a fraction of an inch so that the pile flows freely down the tray if released

from the top.

Move the center slot cover so that it is in the middle of the two side tray guides and tighten the

wing nuts.

It is very important that the stock enter the machine, square, to ensure that all perfs are square

and straight. To test for square feeding, place a piece of stock in the feed tray and align the lead edge

with a straight edge within the machine (such as the straight edge of the feed platen, or the edge of the

first shaft in the machine). Now, check that the operator side feed tray guide is parallel to the close edge

of the paper for squareness.

4.2 Setting Feed Tire Pressure

The friction feed system used in automatic Graphic Whizard machines is unique. It utilises three

top feed tires to feed sheets through with a consistent pull along the full lead edge of the sheet, and a

continuous width sheet retarder (the strip of fine sandpaper on the feed platen) to separate sheets and

prevent double feeding.

Once the feed tray and side tray guides have been assembled according to the sheet width

required, you may locate the feed tires along the feed shaft. For proper sheet feeding, the position of the

three feed tires along the width of the sheet is also important. Loosen the setscrews of the feed tire hubs

using the small hexdriver provided in the accessory kit. Slide the feed tire hubs along the feed shaft,

setting the two outer tires at about 12" in from the outside edges of the stock. The third, middle feed tire

is simply centred. Keep the three setscrews of the feed tire hubs in line on the feed shaft. Tighten all

setscrews (see Figure 5).

12

Page 13

If a feed tire is set too close to the edge of the sheet, its feeding efficiency will be affected by

variances in the stock such as sheet curl and inconsistent glue thickness on multiple padded forms.

Improper setting of the feed tires can cause random skewing problems.

Warning: All feed and exit tires, and

perf/score/slit boss wheels use setscrews

to secure their positions. When

tightening setscrews, do not over-tighten

them. This may scar the metal shafts

and inhibit the free sliding movement of

the feed tire hubs or perf/score/slit boss

wheels.

To ensure consistent, trouble-free feeding,

the feed tire pressures must be set as loose as

possible. The feed tires should never contact

H2

H1

SAFETY

>><<

PHOTOCELL

F1

F2

REP

SET

BAT

UP

ESC

1

7

4

0

ACC

98

65

32

START

STOP

the retarder strip! Our design allows for no

double feeding with substantially reduced feed

pressure than the typical friction feed system. The

gap between the feed tires and the feed platen

should be just less than the thickness of the stock

being used. Remember that we are retarding the

full lead edge of the next sheet or set. When

setting the feed tire pressures, you should have the

sense that the feed tires are just touching the

paper. It is better to set the feed tire pressure to the

Figure 5: Correct Tire Placement

minimum pressure required to prevent double

feeding. The remedy to correct double feeding is

to turn down the both feed tire pressure adjusting

screws a χth turn until consistent feeding is achieved. If the feed tire pressure is too much, you will

possibly mark or pull apart forms.

EXIT TIRES

FEED TIRES

Adjustments for feed tire

pressure are made with the feed

tire pressure adjusting screws

(see Figure 6). It is

recommended to place two

sheets of the stock in the feed

tray with the feed tire pressure

set loosely. Hold the two sheets

in your hand with one sheet

ahead of the other. Place the

leading edge of the first sheet

under the feed tires. Slowly

tighten the feed tire pressure

adjusting screws while jiggling

the pages back and forth. The

correct setting is achieved when the second page is no longer able to run under the feed tires.

13

Page 14

All three feed tires should be adjusted to the same pressure setting to minimise skewing. To

check that all the feed tires are adjusted to the same pressure, tear a strip off the stock being run and pass

it under each feed tire separately. You should sense the same amount of drag under each feed tire. A

tighter feed tire pressure on one side of the sheet will cause faster feeding of that side of the sheet (the

sheet will skew or twist towards the feed tire with tighter pressure). To prevent this skewing, reduce

pressure on the side of the feed tire shaft where you encounter more drag with a counter-clockwise, χth

of the feed tire pressure adjusting screw and increase pressure on the other side by a clockwise, χth of

that feed tire pressure adjusting screw. These adjustments should cause a change in the overall balance

of pressure from the three feed tires without affecting the total feed tire pressure.

When you have the feed tire pressure set properly, you can then tighten down the white nylon

thumbnuts to ensure the setting will be maintained.

Note: The only time the feed is too loose is if double feeding occurs (which the machine will detect

and the message "PAPER TOO LONG" will appear on the LCD display). If the feed

is too tight, the feed tires will try to pull only the top sheet off a set. If this occurs,

loosen the feed tire pressure a little on both feed tire pressure adjusting screws evenly

until this no longer happens.

With the GW 6000, carbonless sets feed best from a non-glued edge! Glue thickens the set and

can cause waves on the edge, while the unglued edges tend to be more consistently flat.

Advisory: It may require several attempts to get used to this sheet-feed technique,

and it is recommended that you practice a few numbering jobs with

scrap paper. However, some initial trial and error experimentation will

allow you to develop long-term benefits in efficiency.

4.3 Perforating/Slitting

Perforating, slitting and/or scoring can be performed with or without any numbering. As

previously mentioned, if no

numbering is desired, program '00' has

been set aside for this task. The

perforator blades are available with 2,

4, 6, 8 and 12 teeth per inch as well as

Microperf. The blades can be easily

interchanged using the ring pliers

supplied with the machine.

Remove the accessory holder

(see Figure 7) from the machine.

Simply remove the retaining clip from

the blade hub and pop off the blade.

Place the new blade on the blade hub

and put the retaining clip back on.

Ensure that the retaining clip sits

completely in the groove in the blade

hub in order to prevent any movement of the blade.

14

Page 15

Using the small hexdriver, move the bottom boss wheel to the approximate location of the

desired perforation or slit. (Note: Keep all of the setscrews of the boss wheel in line on the shaft.)

Move the accessory holder to the position desired where the perf/slit blade will ride on the flat surface

of the boss wheel (see Figure 8) and tighten the position locking set screw into the keyway of the square

shaft (using the large hexdriver). Since you can control the depth of a perf/slit, it is critical that you

locate your perf/slit wheel to the flat of the boss wheel. Tighten the pressure adjustment screw located

on the top of the accessory holder and turn the handwheel at the same time. When the perf/slit blade

turns with the handwheel, test a few sheets. Continue to make adjustments until the desired perforation

depth is obtained.

To ensure a straight perforation, score or slit, run a few sheets through the machine. Using a

straight edge, check if the perforation line is straight. If not, you may not have the main tires placed

evenly across the sheet with one tire on the non-operator side. Next, flip the first inch of the lead edge of

the sheet over and check to see if the perforation lines up. If it doesn't, double check that there is no

excess play in the tray side guides and that the operator side tray guide of the feed tray is over to the

operator side as much as possible. You may not be feeding the sheet into the machine, square. To ensure

that the sheet is running through the machine square, you can feed a sheet into the machine using the

handwheel and align the lead edge of the sheet with a straight edge in the machine (such as the edge of

the bottom boss shaft). To adjust the squareness of feed, you can move the front or back of the operator

side tray guide on the feed tray to make sure the sheet travels through the machine square. If you adjust

the operator side tray guide, you must adjust the non-operator side tray guide as well. Run a few more

sheets through and check the sheet again. Continue until the perforation lines up. Now, take the lead

edge of the sheet and fold it over to the last inch of the sheet. Again, you are checking to see that the

perforation lines up. If it does not line up, again check that the perforation itself is straight. If not, check

the main rollers for equal distribution over the sheet and also check that the feed tires have equal

pressure along the sheet. The feed pressure adjustment screws dictate the paper travel. The general rule

to remember is that a perforation runs away from a tighter tire. If the perforation runs towards the nonoperator side, then loosen the operator screw by an χth of a turn and tighten the non-operator side by an

χth of a turn. Vice versa for a perforation that skews towards the operator side. Make adjustment to the

exit rollers in the same way you make adjustments to the main rollers if the perf starts straight and then

tails off. If the perforation is straight but the perforation does not line up, you may still not be feeding

the sheet through square.

Whether perforating or slitting, place one of the strippers close to the cut. The new cut in the

sheet can often cause the sheet to curl up and can cause a jam otherwise.

4.4 Scoring

Setting up a score is similar to perforating or slitting although the scoring blade will run in the

groove of the bottom boss wheel. With a score, it is more critical to control the depth of the blade,

because this controls the depth of your score. When lining up the blade and groove of the boss wheel, do

not tighten the boss wheel until you have run the score blade into the groove using the handwheel. Once

you have the blade and boss wheel lined up you can adjust the depth of the score and run some test

sheets, adjusting the depth of the score until you are satisfied. Making adjustments for a straight score

are done in the same manner as a perf/slit (as discussed in Section 4.3).

4.5 Idler Wheel Holders

On the same-keyed shaft that the accessory holders are mounted on, for your perf/score/slit

operation, there are two idler wheel holders. These holders, if possible should be mounted about 1 to 12"

from the outside edges of the stock being run. As the stock leaves the feed tires, it will then be

perfed/scored or slit. The idler wheel holders' purpose is to equalise the force along the stock as it passes

15

Page 16

through this section, so you do not encounter any skew, which you may encounter if you only had a

perf/score/slit wheel contacting the paper before going through the main rollers.

4.6 Main Rollers

The main rollers are comprised of a bottom solid roller with 6 and 4 adjustable rollers on top.

The top rollers are mounted on a spring-loaded shaft, to maintain pressure down to the bottom solid

roller. The adjustable top rollers must be distributed along the shaft so that there is a roller on each end

of the shaft, with the remainder distributed along the shaft. To ensure proper transport, a majority of the

rollers should be on the stock, but do not load all rollers to one end of the shaft where you may

encounter stock skew.

4.7 Installing Ink Pads

Loosen the large, star-shaped, lower knob on the drive-unit mount block and swivel the drive

unit up. This will allow you better access to the numbering head itself. Slide the repeat selector, on the

numbering head, over to the "0" position (see Figure 3 if you are unfamiliar with the components of the

numbering head). Pull down the numbering wheel frame, the ink pad mount plate swings away giving

you better access to the ink pad and exposes the numbering wheels. Now press in the locking tab which

sticks out from the top of the head frame. When you pull the numbering wheel frame down far enough,

the locking tab will drop into a groove on the numbering head shaft and hold the head in this position. If

you pull the numbering wheel frame too far down, the repeat selector may jam the head. Simply pull

the numbering wheel frame further down and press the repeat selector out of the way.

Remove an inkpad from its package (provided in the accessory kit) and grasp the two plastic

fingers on the back of the ink pad holder. Before inserting the inkpad, you must first condition the pad.

Because the pad is felt it may have swollen with ink and be thicker than need be. If inserted on the

numbering head, an inkpad with a swollen felt could cause the number wheels to get too much ink and

create splattering or fat images. To condition the inkpad, use a piece of coated stock (because it is less

absorbent) and place the inkpad on the coated stock, felt side down. Press down hard on the inkpad to

compress the felt. You can then soak up the excess ink with the pad. Once the pad is conditioned, you

gently squeeze the plastic fingers inwards on the back of the ink pad holder and slide it into the groove

on the ink pad holder plate, with the ink-reservoir side of the pad sliding in first. Release the tabs and

the holder.

4.8 Locating the Numbering Heads

To move the drive unit into the lateral position required, loosen the large star-shaped knob near

the bottom of the drive unit mount block (refer to Figure 2). Loosen the setscrew in the anti-pitch block

using the large hexdriver. This will allow you to slide the drive unit across the width of the machine.

You may now move the drive unit to the location desired. Bring the anti-pitch block over to and against

the drive unit. Now tighten the large star-shaped knob and set screw in the anti-pitch block to lock the

drive unit in place.

The anti-pitch block and drive unit mount block act together when locating a number position. If

the number position is slightly off, you can loosen one of the blocks and move it over the appropriate

distance, using the fastened block as a reference point. Also, when going to replace the inkpad, you may

move the drive unit aside, leaving the anti-pitch block in position as a reference when you wish to

continue the job.

16

Page 17

To turn the numbering head so that it prints the number in the correct rotation, first loosen the

rotation lock screw on the numbering head mount block, just above the numbering head. The numbering

head will then be free to rotate to the desired orientation.

When satisfied, be sure that the head has been returned to the print position and all knobs have

been tightened.

Once you have the numbering head in the correct physical position, program the job. It is advised that

you run a few test sheets to check the strength and quality of the crash impression.

4.9 Stripper Assemblies

Each machine is supplied with a minimum of 3 stripper assemblies. Their purpose is to keep the

stock flat as it runs through the machine and to ensure that the stock does not catch on the numbering

head. The stripper blocks are to be mounted on the keyed square shaft, pointing down, and the same

shaft that the accessory holders are mounted on. They should normally be located close to the

numbering head but not underneath the numbering wheels (this can damage the numbering wheels!) or

close to where a perf/score/slit is being performed.

If you experience double images when numbering, it is possible that the stripper pressure is not

enough to keep the stock flat for the crash and the stock is bouncing, allowing a second image to occur.

If this occurs, simply bend the strippers down to create more pressure on the paper.

4.10 Setting Impression Control

After setting up the machine and then programming a job (Section 3.4), test sheets will have to

be run to verify you are getting the correct impression, in other words: number sequence; crash strength;

level impression; etc.

he Impression Control Dials, located on the control panel regulate the strength of the crash.

Simply turn the dial clockwise if more impression is required for multi-part carbonless work. Check the

bottom carbonless copies of the form to see if the impression strength is adequate. If the maximum

setting is not adequate, contact your dealer.

Reminder:Carbonless impressions are created as a development process

similar to developing a photograph. The numbering image will

continue to darken for a full twenty-four hours but will reach about

80% of its full colour in about twenty minutes. Ink chemistry, offset

powder and a number of other factors can affect both the time and the

extent of the image. Your fresh impressions will be lighter than you

want but trust them to darken. What you want to achieve is an even,

level impression with minimal or no embossing of the stock.

If making a number of impressions on the same sheet, you may have to turn up the Impression

Control to ensure a consistent crash from hit to hit. With the electric solenoid drive for the numbering

heads, jobs requiring multiple hits on a page require more work from the solenoids. A natural

consequence of an electric solenoid working more often is that the coil heats up, giving the solenoid

greater resistance to the electrical impulse. When this happens, the consequence is that the hits will get

lighter. By increasing the Impression Control, you can overcome the greater resistance the solenoid will

develop against the electrical impulse. Watching the job in progress, you will also find that the longer

17

Page 18

the job, there will be a need to increase the Impression Control to maintain a consistent hit over the

whole job.

4.11 Flatness of Impression

It is best to check for the flatness of the impression on the bottom crash copy from a carbonless

set. The inked impression will not adequately show whether the impression is truly flat while the

bottom crash impression shows this quite well. Make some test impressions on carbonless, verify the

flatness of the crash impression and follow the proceeding instructions.

To adjust for an uneven side to side impression (i.e. if the impression is too light or too heavy across the

machine), determine in which direction the numbering head must pivot to flatten the crash (consult

Figure 9a, which is viewed from the non-operator side of the machine). For adjustment '1' to pitch the

numbering head away from the non-operator side, loosen the top hand knob on the drive unit mount

block and turn the left/right pitch screw counter clockwise. Similarly, turn the left/right pitch screw

clockwise for adjustment '2'. To adjust for an

uneven top to bottom impression, determine

in which direction the numbering head must

pivot to flatten the crash (consult Figure 9b).

Adjustments for forward/backward pitch are

made by first loosening the bottom hand

knob on the drive unit mount block and

turning the forward/back pitch screw in the

appropriate direction. After adjusting, number

another carbonless set and make necessary

adjustments until the numbering head creates

an equal impression along the whole number.

4.12 Exit Rollers

The exit rollers are comprised of a bottom roller and four adjustable rollers on top. The top

rollers are mounted on a spring-loaded shaft to maintain pressure down on the bottom solid roller. The

adjustable top rollers must be distributed along the shaft so that there is a roller on each end of the shaft,

with the remainder distributed along the shaft. To ensure proper transport, at least 2 rollers should be on

the stock, but do not load all rollers to one end of the shaft where you may encounter stock skew.

Since the exit rollers follow the numbering head positions, make sure that an exit roller does not

fall behind a numbering head, where you can possible track ink, producing ghost images down the sheet.

5.0 RUNNING A JOB

5.1 Setting the Starting Number

In order to set the starting number on the numbering head, you will have to pivot the drive unit

back to get clear access to the numbering wheels. Pull down the numbering wheel frame and push in the

locking tab to engage and lock the numbering head with the numbering wheels exposed.

18

Page 19

Each individual numbering wheel can be rotated to the appropriate starting number using the

change stick provided in the accessory kit. Remember that the standard head counts backwards so the

number that you set to start the job on will be the last number required.

If you do not require all the digits to print (ie. 0097 is desired instead of 000097), the last two

numbering wheels can be dropped from profile and locked down. To do this, rotate the numbering wheel

to the "9" position. Turn the wheel slightly past this position while also pushing down on the "9".

When the correct position is reached, the "9" will drop below type height. To restore a dropped wheel to

its regular print position, simply rotate the wheel in the regular direction and it will "pop" out of its

sunken position and back into regular print position.

Once your number has been set, and the inkpad has been installed (see Section 4.7), set the

repeat selector to "0". Now, pull the numbering wheel frame downward to release the locking tab.

Gently release the numbering wheel frame and allow it to return to its rest position. [Caution: the

numbering wheel frame is spring loaded. Once you release the locking tab, the numbering wheel frame

will spring back quickly. Please make sure that you keep your fingers clear of the inner workings of the

numbering head] If you pull the numbering wheel frame down too far and it locks, refer to Section 4.4.

If you do not return the numbering wheel frame to its rest position, the numbering head will not operate

when the machine is running, since it is already at the end of its available stroke-length. Now you can

pivot the drive unit back to the print position and re-tighten the large knob.

It is advised to set the repeat selector to '0' while running a few test sheets so that the starting

number does not change. When you are ready to start your numbering job, then change the repeat

selector to the action desired.

5.2 Setting the Repeat Selector

The numbering heads can be set to repeat a number continuously ("0"), change with every crash

("1"), or change after a number of crashes (ie. "2, 3, or 4"). This setting will depend on the type of job

required. The repeat selectors is clearly in view on the front of the numbering head and requires no

special tools to be changed (see Figure 3 ). Remember, for 2x, 3x and 4x repeat action, you may need to

run a couple of test sheets to ensure these actions match your numbering sequence, since the numbering

head is a mechanical process separate from the number position programming.

If the repeat sequence does not match the numbering sequence on your stock, you may need to

manually engage the numbering head. Push down on the numbering wheel frame as many times as it

takes to complete the repeat action, counting where the sequence was on your last test sheet.

Example: Repeat action desired is a three time action. After running a test sheet,

'9 9 8' is printed. The numbering head is in mid-sequence and to correct,

push down on the numbering wheel frame twice to complete the repeat

action. Test another sheet and the sequence printed now is '9 9 7'.

The final feeding concern is the fanning of the stock. This procedure may also take some practice, and

in particular when fanning carbonless sets across the un-glued edge. The following steps should be used

in order to fan the pile:

5.3 Fanning

1)

Hold the paper as shown in Figure 10.

19

Page 20

2) Lower your left hand while holding on to the pile firmly with your right hand.

3) Hold the pile tight with your left hand and loosely with the right.

4) Return the left hand to its original position.

5) Repeat steps 1 through 4 until adequate fanning is obtained.

Try fanning while holding the stack in a vertical, upright position, with the glued edge resting on

a table. This will maintain a flat, straight edge. When loading a fanned stack into the feed tires, hold

the back end of the stack up high (at approximately a 30 degree angle, relative to the feed tray) so that

the lead edge slips under the feed tires (see Figure 11). Then, gently lower the stack onto the feed tray.

Before starting the machine, rotate the handwheel one half turn and watch that the first sheet of the stack

advances correctly, while the second sheet beneath it should be retarded from feeding into the machine.

The efficiency of the feeding can be improved by increasing the spacing between the sheets of your

fanned stack. Begin with small stacks (10 to 20 sheets) and build up to larger stacks as you become

more confident with your fanning.

Once you have mastered the art of fanning, you can progress to back-feeding to provide

continuous feeding and uninterrupted operation. To feed while the unit is operating, fan a stack and,

while holding it in your right hand, carefully

grasp the bottom set of the feeding stack with

your left hand. Raise the back edge of this

bottom set, thus slightly raising the back of the

feeding stack, and slide the new stack under it.

Release the new stack into the feed tray, letting

it slide down under the feeding stack. Lower

and release the back edge of the bottom set so

that the stacks now sit together. This backfeeding procedure should be done while there

is still sufficient stock in the feed tray to allow

for the time needed to prepare and insert the

new stack.

6.0 Maintenance

The Sprint 6000 is designed to be

trouble-free through years of use. Only minor

maintenance operations are required to keep it

running like new.

6.1 Numbering Heads

With use, the numbering heads will acquire a coat of old ink, paper dust, etc. and therefore

periodic cleaning is necessary. The minimum frequency of numbering head cleaning is once a month or

when changing over colors. Detach the numbering head by removing the two setscrews on the

numbering head mount block, using the larger hexdriver provided (see Figure 12). The head may then

be cleaned with a petroleum based spray lubricant (such as WD-40 or Sprayaway RD-90) and a small

brush (ie. an old toothbrush). Spray and soak the number wheels thoroughly. Take care to keep the

spray away from the rest of the machine. Brush the wheels and then rotate them in order to clean

every digit. Spray the numbering wheels a final time to rinse out the ink or dust. After cleaning, allow

20

Page 21

the head to dry completely (ie. leave it standing overnight) or blow it dry with compressed air. Wipe the

head and reinstall.

Important: Do not use solvents. Solvents will strip out the lubricants from the head,

allow corrosion and impair the correct functioning of the print head.

6.2 Machine Cleaning

After each job, or midway through a very large job, clean the feed tires. You can use warm water

to clean off paper dust or drying powder, or blanket wash or alcohol if there is ink on the feed tires. Any

type of rubber roller rejuvenator is also good to clean the feed tires, the rejuvenator will also soften the

rubber. This will prevent glazing of the rubber. Brand new tires will require extra cleaning for the first

job or two until the rubber beds in.

In addition, always watch that paper dust or dirt does not block the photocell sensor eyes. The “green”

light on the control panel marked “PHOTOCELL” can verify correct photocell operation. If dirty,

simply wipe the photocell sensor eyes but do not use solvents. Either use a cotton swab or blow clean

with compressed air.

Ensure that the trays and guides are clean.

6.3 Lubrication

The Sprint 6000 utilises ten oil-impregnated bronze bushings to support all shafts. An occasional

drop of light machine oil will maintain their lubricating qualities. Wipe off any excess oil to avoid

spoiling a job.

6.4 Friction Feed

Over time, the rubber components of the feed tires may wear or harden. Use a rubber roller

rejuvenator occasionally to soften the rubber. Other than the feed tires, another important element of the

friction feed system is the full lead edge-retarding strip. The abrasive agent on the retarding strip

prevents sheets from double feeding. As the abrasive agent wears, you will encounter more double feeds

and when you see the green backing of the retarding strip you must replace it. To replace the retarding

strip for the feed, adjust the feed shaft to its highest position. Using a scribe or sharp edge, etch into the

feed platen where the retarding strip ends (you will use this scribed mark as a reference point when you

apply the new retarding strip). Peel off the old retarding strip(you may need a knife or razor) and

remove any old adhesive with alcohol. Replace with a new self-adhesive retarding strip. Make sure that

there is some of the retarding strip surface under the feed tires to ensure proper operation.

21

Page 22

7.0 TROUBLESHOOTING

SYMPTOM SOLUTION

Friction Feeder

Double-Feeding Adjust feed tires down by an χ turn (feed is too loose); if the

retarding strip is glazed or worn (you can see the green

backing), replace retarding strip (see Section 6.4)

Creasing, marking, Adjust feed tires up by an χ turn (feed is too tight)

or sets pulled apart

Kicking, turning Balance adjustment on feed shaft required (one side is too

tight); adjust feed tray guides closer together to eliminate

side to side play (see Section 4.1 & 4.2 for adjustment

instructions).

Not feeding paper Feed may be too lose in which case, multiple sheets are

jammed under the feed tires, check adjustment; if feed tires

are smooth or glazed, clean, rejuvenate or replace; open

feed tray guides (set too tight to paper width and pinching

stock)

Print Quality

Uneven crash Adjust for crash flatness (see Section 4.11)

impression

Faint colour or uneven Replace ink pad. (see Section 4.7)

colour impression

Excessive inking Clean head (see Section 6.1); condition ink pad (see

Section 4.7) or replace leaking ink pad.

22

Page 23

Too heavy (embossing) Adjust Impression Control dial. (see Section 4.10);

or too light a crash check platen pad, if there is excessive wear, the

platen pad may require replacing.

Ink spreading, smudging Numbering machine ink is mineral oil with pigment.

or not drying The oil is absorbed by the paper leaving the pigment

behind as the image. On slick or glossy stocks, the supplied

inkpad will not work effectively. Non-corrosive ink must

be used as a substitute (such as fountain pen ink). An

important factor with alternative inks is that the numbering

heads be cleaned immediately after a job has been run.

Registration

Inconsistent number Check that the photocell is clear of any obstacles (see

location (poor number Section 6.2); if the number location seems to 'float',

registration) the feed tray guides may be too loose allowing sheets to

skew as they feed (this will be seen more often with

number locations closer to the non-operator side, furthest

away from where the sheet passes the photocell; if numbers

occur all over the place, the photocell may require

readjustment (it is too sensitive, mis-registering the lead

edge of the sheet)

Perf/score/slit line With a straight edge, check that the perf/score/slit is

skewing straight. If straight, the stock is not feeding square and

the feed tray guides may need adjusting to ensure the

stock enters square into the machine. If the perf/score/

slit line is not straight but is bowed or has a tail whip,

the rollers on the main shaft and/or the exit shaft may

not be evenly balanced along the shaft, causing

uneven pressure on one side of the stock. This causes

a skew and the rollers must be evenly spaced across

the shaft. A bowed line usually indicates the rollers on

the main shaft are uneven, and a tail whip usually

means the rollers on the exit shaft are uneven.

Numbering Heads

The numbering heads creating an impression are a mechanical process separate from

the programming of the machine. If encountering problems with the correct operation

of the numbering head, such as numbering wheels not turning, numbers partially

printing, numbering wheels turning out of sequence, etc. the repeat selector or other

23

Page 24

components may be out of alignment (refer to Figure 4). Being a mechanical process,

alignment of the individual parts is very important. Remove the numbering head from

the machine. Pressing down on the numbering head shaft, you will see the numbering

head frame slide down the print head frame. While this happens, the ink pad holder

mount bracket will swing away, exposing the numbering wheels (see Figure D).

The numbering wheels and repeat action ratchet wheels are mounted on a keyed

shaft inside the numbering head frame. The wheels are then held in place, and

refrained from spinning by the retaining pawls, which are forced to the numbering

wheel flats by the comb spring. The retaining pawls must be aligned with the flats of

the numbering wheels, or what looks like in between the numbering wheels. The comb

spring must also apply a constant pressure against the retaining pawls. Consequently

this alignment not in effect is that the numbering wheels may spin freely, causing

partial impression or random numbering sequences.

Like the retaining pawls, the changeover pawls of the repeat selector must also be

aligned to the flats of the numbering wheels. When an impression is made, the

numbering wheel frame is propelled down the print head frame. The ink pad holder

mount bracket swings away, the repeat selector is pushed back from the numbering

wheels and the numbering wheels are then exposed to make their impression on the

stock. After reaching the bottom of its stroke, the numbering wheel frame then returns

to the top position. As this happens, the repeat selector's changeover pawls once again

come into contact with the numbering wheel flats. Depending upon the action or

sequence in place, the repeat pawl may only interact with one of the repeat action

ratchet wheels before the changeover pawls interact with the .numbering wheel flats.

In most instances, the longest changeover pawl comes into contact with the flat of the

unit wheel flat to change it over. After a "0" has been printed, there will be more

changeover pawls changing more numbering wheels. When this happens, you may

find the next impression, with a "9" as the last digit, printing lightly. This can be

overcome by increasing the Impression Control to provide a stronger pulse to turn

over more wheels. If you are encountering problems where numbers are not turning

over, numbers are printed out of sequence, etc., then the problem may be that the

changeover pawls of the repeat selector are not aligned with the flats of the

numbering wheels.

The repeat selector is mounted

on the print head frame by the

two repeat selector adjustment

screws. The repeat selector must

be mounted to the print head

frame squarely. If not, the

changeover pawls will not engage

the flats of the numbering wheels

square, in this case some of the

changeover pawls can not change

their numbering wheels. Visually,

check that the changeover pawls

24

Page 25

are riding in-between the numbering wheels, centred on their flats. If not, the whole

repeat selector may be moved to the proper position by loosening the repeat selector

adjustment screws. Lastly, the changeover pawls must be parallel to each other.

Error Codes

Group Condition Error

Paper Handing Errors 01 PAPER JAM

05 MSTP PAPER ERROR REPORTED IS UNDEFINED

03 PAPER TO LONG

02-04, 06-09 Reserved

Solenoid Errors 10 CH1 OPEN

11 CH1 SHORT

12 CH1 HOT

13 CH2 OPEN

14 CH2 SHORT

15 CH2 HOT

16 CH1 2 HEADS

17 CH2 2 HEADS

18 NO SOLENOID BOARD ATTACHED

19 LOW VOLTAGE SOLENOID BOARD ATTACHED

20 SOLENOID TIMEOUT

21 SOLENOID BOARD TYPE INCONSISTENT (BETWEEN MSTP AND ICPU)

22 SOLENOID ADC LIMITS ARE INCONSISTENT (BETWEEN MSTP AND ICPU)

23-28 Reserved

29 MSTP REPORTED UNKNOWN SOLENOID ERROR

Motor Errors 30 MOTOR RUN TIMEOUT

31 MOTOR TURN ON/OFF TIMEOUT

32-39 Reserved

EEPROM Errors 40 UNABLE TO READ FROM EEPROM

41 UNABLE TO WRITE TO EEPROM

42 CRC INVALID FOR EEPROM PROGRAMMABLE PARAMETERS

43 CHECKSUM INVALID FOR EEPROM SOLENOID PROGRAM

44 TESTING FAILED DURING TEST/RE-FORMAT EEPROM

45 EEPROM VERSION FORMAT ID# DOES NOT MATCH SOFTWARE

44-49 Reserved

Memory Errors 50 RAM SELF-TEST READ/WRITE FAILURE

51 CHECKSUM INVALID FOR RAM SOLENOID PROGRAM

52 CRC INVALID FOR RAM PROGRAMMABLE PARAMETERS

53 SETUP MODE SOLENOID PROGRAM HIT INDEX OUT OF RANGE

54 SOLENOID PROGRAM NUMBER IS CORRUPT

55-59 Reserved

Hardware Errors 60 AC LINE VOLTAGE OUT OF OPERATION RANGE

61 MOTOR VOLTAGE OUT OF OPERATION RANGE

62-69 Reserved

SCI Errors 70 ICPU SCI RECEIVE TIMEOUT ERROR

71 ICPU SCI RECEIVE OVERFLOW ERROR

72 ICPU SCI TRANSMIT TIMEOUT ERROR

73 ICPU SCI INVALID ACK RECEIVED

74 ICPU SCI CORRUPTED MESSAGE RECEIVED

75 ICPU SCI TRANSMIT ABORTED

25

Page 26

76 ICPU SCI WATING PERIOD FOR MSTP MESSAGE EXPIRED

77 ICPU SCI INVALID MESSAGE TYPE RECEIVED

80 MSTP SCI RECEIVE TIMEOUT ERROR

81 MSTP SCI RECEIVE OVERFLOW ERROR

82 MSTP SCI TRANSMIT TIMEOUT ERROR

83 MSTP SCI INVALID ACK RECEIVED

84 MSTP SCI INVALID COMMAND RECEIVED

85 MSTP RECEIVE OVERRUN ERROR

86 MSTP RECEIVE FRAMING ERROR

77-79, 87-88 Reserved

89 MSTP SCI ERROR REPORTED IS UNDEFINED

Miscellaneous 90 MSTP ERROR REPORTED IS UNDEFINED

GW 6000 PARTS LIST

PART NO. 6K DESCRIPTION

10-001-GW X Black, Preinked Pad w/holder

10-002-GW X Black, Preinked Pad w/holder

10-003-GW X Uninked pad w/holder

10-004-GW X Felt Insert

10-005-GW X Red Ink, 4 oz. bottle

10-006-GW X Black Ink, 4 oz. bottle

10-007-GW X Changestick

10-008-GW X 3/32" Hexdriver

10-009-GW X 5/32" Hexdriver

10-010-GW X Ring Pliers

10-011-GW X ¾" Snap Ring

10-012-GW X Reverse Numbering Head (6 digits, 2 drop)

10-013-GW X Forward Numbering Head (6 digits, 5 drop)

10-014-GW X Condensed Reverse Numbering Head (8 digits, 4 drop)

10-015-GW X Date Stamp Head (month/day/year)

10-016-GW X 5/8" Wave Washer

10-017-GW X Feed Tray

10-018-GW X Feed Tray Side Guides

10-019-GW X Feed Tray Slot Cover

10-020-GW X Locking Wingnuts

10-021-GW X Feed Platen Retarding Strip

10-022-GW X Feed Shaft Adjust Screw

10-023-GW X Locking Thumbnut

10-024-GW X Roller Tire (feed/main/exit)

10-025-GW X Roller Hub

10-026-GW X Roller Shaft

10-027-GW X 3/8 " Set Screw Collar

10-028-GW X Shaft Bushing

10-029-GW X Feed Shaft Bushing w/Spring

10-030-GW X Shaft Bushing w/Spring

10-031-GW X Solid Bottom Roller

10-032-GW X Main Platen Crash Pad

10-033-GW X Main Platen

10-034-GW X Main Platen Grommets

10-035-GW X Main Platen Mount Brackets

26

Page 27

10-040-GW X Hand Knob

10-041-GW X 5/16" Disc Spring

10-042-GW X 5/16" Flat Washer

10-043-GW X Solenoid w/plunger

10-044-GW X Solenoid plunger

10-053-GW X Drive Unit Cover

10-054-GW X Print Head Mount Block

10-055-GW X Exit Tray

10-056-GW X Magnetic Tray Side Guides

10-057-GW X Magnets (2)

10-058-GW X Handwheel

10-059-GW X 120V Modular Line Cord

10-066-GW X 5A, 250V Slow Blow Fuse

10-068-GW X Impression Control Dial Knob

10-071-GW X ½ “ Cord Strain Relief

10-084-GW X Accessory Holder w/12 TPI perf blade

10-085-GW X Accessory Holder Adjust Screw

10-086-GW X Blade Mount Hub w/bearing

10-088-GW X Accessory Holder w/idler wheel

10-089-GW X Idler Wheel Tire

10-090-GW X Boss Wheel

10-091-GW X 2 TPI Perf. Blade

10-092-GW X 4 TPI Perf. Blade

10-093-GW X 6 TPI Perf. Blade

10-094-GW X 8 TPI Perf. Blade

10-095-GW X 12 TPI Perf. Blade

10-096-GW X Microperf (42 TPI) Blade

10-097-GW X Microperf (72 TPI) Blade

10-098-GW X Slit Blade

10-099-GW X Score Blade

10-100-GW X Narrow Score Blade

10-101-GW X Double Score (1/4 " separation) w/Holder & Boss

15-005-GW X Red Quick Drying Ink, 2 oz. Bottle

15-006-GW X Black Quick Drying Ink, 2 oz. Bottle

15-036-GW X ¾ “ Keyed Drive Unit Mount Shaft

15-037-GW X Anti-Pitch Block

15-038-GW X 5/16” Dogged Set Screws

15-039-GW X Drive Unit Mount Block (left/right pitch control)

15-052-GW X Solenoid Mount Angle w/tube (left/right pitch)

15-072-GW X Complete Drive Unit

15-073-GW X Complete Drive Unit w/Reverse #ing Head

30-025-GW X Large Clutch Feed Pulley /12k

30-037-GW X Rubber Foot

40-003-GW X Timing Pulley- 18XL037X3/8

40-103-GW X Timing Pulley- 18XL037X1/2

50-007-GW X Main Structure Shaft

50-008-GW X Feed Platen/8000

50-009-GW X Shaft Adjust Blocks

50-011-GW X Drive Unit Mount Shaft Bracket

50-014-GW X Boss Wheel Shaft

50-019-GW X Cross Shaft

50-020-GW X Exit Rollers Safety Shield

50-021-GW X Timing Belt- 220XL037

50-022-GW X Belt Tensioner

27

Page 28

50-023-GW X 1 ¾ “ Feed Pulley

50-033-GW X Fan Guard

50-035-GW OP Stand/8000

50-037-GW OP Regular Caster Wheel

50-038-GW OP Locking Caster Wheel

90-001-GW X Non-Operator Side Plate

90-002-GW X Operator Side Plate

90-003-GW X Non-Operator Side Cover w/guard

90-004-GW X Operator Side Cover

90-005-GW X Stepper Motor

90-006-GW X Motor Ferrite Bead

90-007-GW X Motor Guard

90-009-GW X Metal Display Panel

90-010-GW X Main Bottom Roller

90-011-GW X Photocell Reflector

90-012-GW X Accessory Holder Mount Shaft

90-013-GW X Stripper Assembly

90-015-GW X Safety Shield w/hinge & actuator /3/6/8k

90-016-GW X Safety Switch w/harness /3/6/8k

90-024-GW X O-Ring Feed Drive Belt/3/6/8k

90-028-GW X HV Voltage Solenoid Board 3/6k

90-028-GW-X X HV Voltage Solenoid Board 3/6k: Exchange

90-031-GW X Low Profile Tie Mounts

90-032-GW X 12V Cooling Fan

90-054-GW X Print Head Mount Screws

90-055-GW X Print Head Rotation Screw

90-059-GW X 220V Line Cord

90-060-GW X MSTP Board 120V Connector

90-061-GW X MSTP Board 220V Connector

90-062-GW X Modular Switch w/fuseholder

90-063-GW X Line Filter

90-064-GW X Filter to MSTP Board Cable

90-065-GW X Board Mount Stand-Off

90-067-GW X Photocell Assembly

90-069-GW X Solenoid Connection: Board to Female Terminal

90-082-GW X Wire Transfer Tube

90-083-GW X Drive Shaft Bearing

90-084-GW X Drive Shaft Bearing w/Spring

90-085-GW X Plastic Electrical Guard

92-025-GW X MSTP Board

92-025-GW-X X MSTP Board: Exchange

92-026-GW X MSTP Chip

92-027-GW X ICPU EPROM

92-028-GW X HV Voltage Solenoid Board

92-028-GW-X X HV Voltage Solenoid Board: Exchange

92-029-GW X ICPU Display Board

92-029-GW-X X ICPU Display Board: Exchange

92-030-GW X Red Screen Cover

92-034-GW X Display Board Label/6k

94-003-GW X Non-Operator Side Cover w/guard

28

Page 29

GW 6000 PARTS DIAGRAM

29

Loading...

Loading...