GRANULDISK Granule Gastro, Granule Combi User Manual

Granule Gastro®

User manual

Art.no E

N16235201104

GRANULDISK AB retains the right to make technical changes to the products.

No responsibility is taken for any printing errors.

www.granuldisk.com Tel. +46 40 671 50 60

Contents

Declaration of Conformity 5

1 General Description and Safety 7

1.1 To the user 7

1.2 Safety regulations 7

1.3 Technical data 8

2Operating 11

3 Daily cleaning 23

3.1 Collecting and cleaning PowerGranules 23

3.2 Cleaning inside the tank 25

3.3 Replacement of cleaned items 26

3.4 Over night and at longer stoppages 26

3.5 GD Memo™ 27

4 HACCP Hygiene and Operation

Documentation

29

5 Troubleshooting and alarms 31

6Notes 35

3

Declaration of Conformity

The Manufacturer:

GRANULDISK AB

Jägershillgatan 15

SE-213 75 MALMÖ, Sweden

declares that the following machinery:

TheGRANULDISKsystemGranuleGastro®.

Granule Gastro® is a Granule potwashing machine – a potwashing machine for commercial

kitchens that is designed for washing wares like pots and pans.

Basic conception

a. the equipment, to which the CE Mark h as been affixed, complies with the Machinery

Directive, 2006/42/EC.

b. is besides the provisions under a) manufactured according to the following directives:

the EC Low Voltage Directive 2006/95/EC and the EMC Directive 2004/108/EC

c. is manufactured in conformity with the following harmonised standards: EN

60204-1:2006, EN 55014-1, EN 60335-2-58, EN 60439-1, EN 55022, EN ISO

13850:2008, EN ISO 13857:2008, EN 61000-6-3 and EN 61000-6-2

d. is manufactured in accordance with EN 1717 and fitted with a type AB back flow

protection device with airgap in accordance with EN 13077:2008.

Malmö, Sweden 11.02.2011

Signed on behalf of

GRANULDISK AB

GRANULDISK AB

Jägershillgatan 15

213 75 MALMÖ

Phone: 040 671 50 60

Fax: 040 21 07 21

Peter Schön

President

Rev. 2011-04 5

Declaration of Conformity

1 General Description and

Safety

1.1 To the user

Granule Gastro® is a Granule pot washing machine – a pot washing machine for commercial

kitchens that is designed for washing pots and pans.

This manual is your guide for the correct installation and use of the Granule Gastro® pot

washing machine.

GRANULDISK recommends that you study the manual thoroughly to be sure that the machine

is installed and used correctly and safely.

Ensure that the manual is always available during the whole life of the machine.

GRANULDISK accepts no responsibility for damage to the equipment or other damage or

injury caused by not following the directions in this manual.

1.2 Safety regulations

The machine uses hot water. Avoid contact with the skin as there is a risk for scalding!

The plastic in the Granules is approved for use in conjunction with food.

There is a risk of slipping if Granules are left on the floor.

Formaldehyde, which is dangerous if inhaled, may be formed if the Granules catch fire.

Regarding thehandling of detergent in the manual, please see the manufacturer’sinstructions.

Always lock the hoo d in its upper position with the safety pin when daily cleaning is carried out.

Rev. 2011-04 7

1.3 Technical data 1 General Description and Safety

1.3 Technical data

Weight ............................. 413 kg (filled machine), 320 kg (empty machine)

Externaldimensions ............... 2400 (± 25) x 850 x 1002 mm (H x W x D) for more

details see Installation drawing

Tank volume ............ ........... 83 litres

Granuleamount ......... ........... 8 kg

Washwatertemperature .......... 65 °C

Rinse water temperature .......... 85 °C

WashprogramswGranules ....... Eco: 2 min

Short: 3 min, 10 sec (30 sec longer with steam

reduction)

Normal 5 min, 10 sec (30 sec longer with steam

reduction)

Washprogramsw/oGranules ..... Eco: 2 min

Short:2min,40sec

Normal: 4 min, 40 sec

Rinse water volume ................ 4 litres/ECO program

8 litres/short, normal program

To achieve 3600 HUE according to NSF/ANSI 3 - 2007,

8litresisnecessary.

Capacity ............................ 6 GN 1/1, 65 mm deep or 3 GN 1/1 200 mm and 3 GN

65 mm, or equivalent in other items

Loading volume .................... 190 litres (Ø 650 mm x H 570 mm)

Design .............................. Round rotatingstainless steel basket

Voltage** .......................... 400 V (standard); 3-phase, earth

230, 415 V (option); 3-phase, earth

Fuse** ........................ ..... 400, 415 V: 25 A (cold water option 32 A)

230 V: 40 A

Frequency .......................... 50 Hz

Maximum power ................... 11.9 kW(cold water option16.9 kW)

Washpumpmotor ................. 2.6 kW

Rinse pump motor ................. 0.37 kW

Washtankelement* ............... 9 kW (cold water option 14kW)

Rinse tank element* ............... 9 kW(cold water option 14 kW)

Encapsulationclass ................ IP55

Sound pressure level ISO 11203 .. 67.7 dB(A)

Hot water ............... ........... ½”(DN15), 55-65°C,3-10°dH

NB! Reverse osmosis water and totally softened water

must not be used.

Water pressure/flow h.w. ..... ..... 1-6 bar, 15litres per min

Cold water ......................... ½” (DN15), 3-10°dH

Water pressure / fl

ow c.w. ........

1-6 bar, 15 litres

per min (3-6 bar when steam

reduction option is fitted)

8 Rev. 2011-04

1 General Description and Safety 1.3 Technical data

Recommended ventilation

capacity ............................ 500 m³/h(without steam reduction)

150 m³/h (with steam reduction)

Outflow ............................. Pipe Ø 32 mm

Drain ............................... Required capacity100l/min. The machineshould not

be placed directly above the drain.

* Not in use simultaneously

** For specific data regarding de live red machines, please see machine rating plate

NOTE

The Granule Gastro® is supplied w ith a 2 metres long electric cable to be

connected to an approved supply disconnecting device on the wall. The

supply disconnecting device is not included in the delivery.

Rev. 2011-04 9

1.3 Technical data 1 General Description and Safety

2Operating

Start up

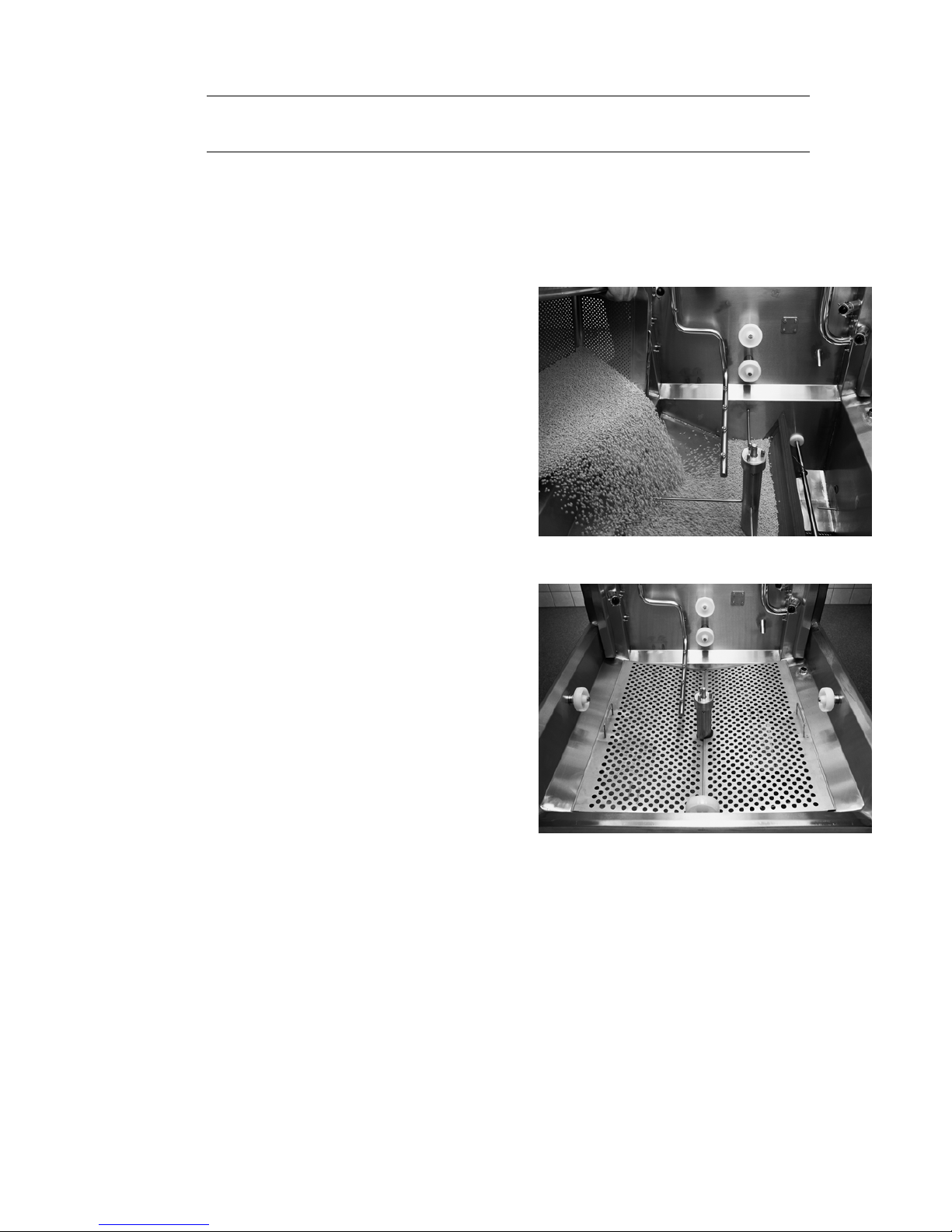

1.

Empty the Granule Collector with

PowerGranules into the left part of the

wash tank. Basket wheel and tank grid

andneedtobetakenout(Figure 1

Granule filling).

Figure 1: Granule filling

2.

Place the tw o tank grids in position

(Figure 2 Tank grids). Put the left one in

first and then the right one, so that they

overlap.

Figure 2: Tank grids

Rev. 2011-04 11

Loading...

Loading...