GRANULDISK GD 900 User Manual

GD 900

User manual

Art. nr 16060/ 03.2005/EN

Granuldisk AB retains the right to make technical changes to the products.

No responsibility is taken for any printing errors.

1. TECHNICAL DATA ........................................................ 6

2. INSTRUCTIONS ............................................................... 8

3. DAILY CLEANING ........................................................13

4. HACCP-documentation ...........................................15

5. TROUBLESHOOTING AND ALARMS ....... 17

Contents

EN

Declaration of Conformity

The Manufacturer:

GRANULDISK AB

Jägershillgatan 15

SE-213 75 MALMÖ, Sweden

declares that the following machinery:

The Granuldisk system GD 900

Basic conception

a) is manufactured in conformity with the Svenska Arbetarskyddsstyrelsens Författningssamling AFS1994:48. This law conforms

with the COUNCIL DIRECTIVE of 22 June 1998 concerning harmonisation of member states` legislation for machinery (the

Machinery Directive 98/37/EG), with particular reference to Annex 1 concerning the essential health and safety requirements relat

-

ing to the design and construction of the machinery.

b) is besides the provisions under a) manufactured according to the following directives: the EC Low Voltage Directive 73/23/EEC

and the EMC Directive 89/336/EEC

c) is manufactured in conformity with the following harmonised standards: EN 60204-1, EN 55014, EN 60335-2-58, EN 604391, EN 418, EN 294, EN 50081-1:1992 and EN 50082-2:1995

d) is manufactured in conformity with the following national standards and technical

specifications: ELSÄK-FS 1994:7

e) is manufactured in accordance with EN 1717 and fitted with a return flow protection of type AB with an air gap in accordance

with EN 13077.

Malmö, Sweden 01.03.2005

Signed on behalf of GRANULDISK AB

GRANULDISK AB Jägershillgatan 15

SE-213 75 MALMÖ

Telefon: 040 671 50 60

Fax: 040 21 07 21

...............................................

Per Sandberg

(Managing Director)

To the User Safety Instructions

The GD 900 is a granule potwashing machine – a potwashing machine for commercial kitchens that is designed for

washing/cleaning things like pots and pans.

This manual is your guide for the correct

installation and use of the GD 900 granule

potwashing machine.

Granuldisk AB recommends that you study

the manual thoroughly to be sure that the

machine is installed and used correctly and

safely.

Ensure that the manual is always available

during the whole life of the machine.

Granuldisk AB accepts no responsibility for

damage to the equipment or other damage

or injury caused by not following the direc

-

tions in this manual.

The plastic in the granules is approved for

use in conjunction with food.

The machine uses hot water. Avoid contact

with the skin as there is a risk for scalding.

There is a risk for slipping if granules are left

on the floor.

Formaldehyde,which is dangerous if inhaled,

may be formed if the granules catch fire.

Regarding the handling of detergent in the

manual, please see the manufacturer’s

instructions.

5

1. Technical data

6

Weight .................................................................... 685 kg filled machine

Tank volume ........................................................ 165 litres

Granule amount ................................................

16 kg

Wash power ......................................................... 10 % granule concentration

Wash water temperature ............................. 65 °C

Rinse water temperature .............................. 85 °C

Rinse water volume ......................................... 14 litres/wash programme. To obtain 3600 HUE according to ANSI/NSF

(3, 2001), 14 litres is necessary. In other cases the volume can be reduced to 5 litres.

Wash programmes ........................................... short 2 min 40 s., normal 4 min 40 s., long 6 min 40 s.

Programmes without granules are 1 minute shorter.

Time for steam reduction ............................. 1 minute

Models .................................................................... GD 900 Compact with pull-out cassette,

GD 900 Flow System with 1 trolley and 2 removable cassettes

GD 900 Freeflow System with 2 trolleys and 2 removable cassettes

Loading volume .................................................. 450 litres

Capacity ................................................................. 8 GN 1/1, 200 mm deep containers, or 16 GN 1/2, 200 mm deep containers or

the equivalent in other items to be washed

Max capacity/h (washing with granules) .... GD 900 Compact/ Flow System/ Freeflow System

115/ 122/ 144 GN 1/1

Normal capacity/h (washing with granules) .. 78/ 81/ 90 GN 1/1

Voltage** ............................................................... 400 V (normal), 3-phase, earth,

230, 415, 440 and 575 V (option), 3-phase, earth

Fuse** ..................................................................... 400 V: 40 A, 25 A for steam model

415 V: 40 A, 20 A for steam model

440 V: 40 A, 20 A for steam model

230 V: 63 A, 35 A for steam model

575 V: 25 A, 16 A for steam model

Frequency ............................................................. 50 Hz or 60 Hz

Maximum power ............................................... 21 kW

Wash tank heater element* ........................ 16 kW

Rinse tank heater element* ......................... 16 kW

Pump motors, x 2 .............................................. 2.2 kW/motor

Rinse pump .......................................................... 0.37 kW

Encapsulation class ........................................... IP 55

Hot water ............................................................. 1/2” (DN15), 55 - 65 °C, 3-7 °dH,

Note: Reverse osmosis water and distilled water must not be used.

Water pressure / flow h.w. ............................ 1-6 bar with solenoid valve open / 28 litres/minute

Cold water ............................................................ 1/2” (DN15), 3-7 °dH (refers to steam reduction)

Water pressure / flow c.w. ............................ 1-6 bar with solenoid valve open / 15 litres/minute

Detergent and rinse agent ............................ 24 and 230 VAC signals are available in separate terminal box

Recommended ventilation capacity ........ Machine without steam reduction unit: 700 m³/h

Machine with steam reduction unit: 200 m³/h

Outflow .................................................................. Pipe Ø32 mm

Drain ....................................................................... Required capacity 100 litres/minute.

The machine should not be placed directly over a drain.

* Not activated simultaneously.

** For specific data for this machine, please see rating plate.

• GD 900 can also be supplied for steam heating or cold water connection.

• The machine is supplied with a 2.5-metre long electrical cable which is connected to the main switch on the wall. The main

switch is not included in the delivery.

7

2. Instructions

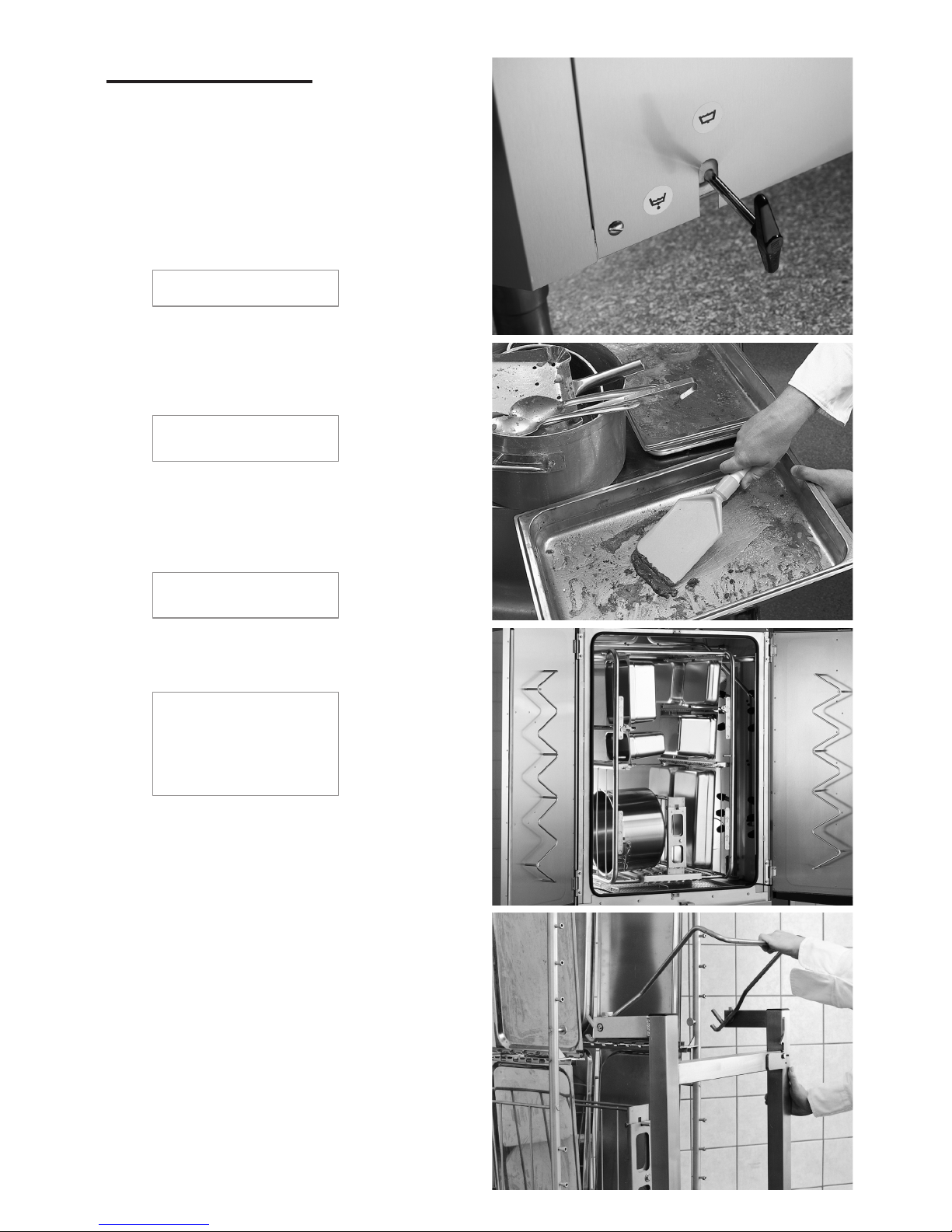

At the start of the working day

1. Pour over the granules in the wash tank.

2. Close the drain valve (Figure 1).

3. Switch on the main switch.

1

2

3

3:1

3:2

8

Filling with water

Close the doors. The message below will appear in the display:

Fill wash tank?

Press the START button. The machine will then fill with water

and heat it to the correct temperature. The programme selection

diodes flash out of sequence with the diodes for washing, with

or without granules during filling. The following message is

displayed on the machine:

XX°C XX°C

Filling the wash tank

With a hot water connection (+55 °C), filling and heating takes

20 minutes.

If the correct temperature has not been attained in the wash tank

after filling, the following message is displayed:

50°C 60°C

Heating the wash tank

When the correct temperature has been attained in the wash

tank, a preselected programme is displayed. The diodes for the

programme come on. The machine is ready for use.

65°C Standby 85°C

Normal program

with granules

Wash time: 4:10

Preparing items to be washed

Remove or scrape off extraneous waste from the items to be washed

before loading them into the machine (Figure 2).

NB! Pots should not be soaked. To avoid foaming, do not prewash

with washing-up liquid. If foaming occurs, the machine will not

clean properly.

Loading utensils

All pots shall be placed in the machine with the insides facing

the spray pipes (fig.3:1).

The GD 975 multi-cassette is supplied as standard with all

machines. There are also a number of optional extras.

Inserting and removing the cassette

GD 900 Compact: The cassette is an integral part of the machine

and can be slid halfway out of the machine (fig.3:1).

Loading...

Loading...