Granudos 45-S3, 45/100 Operating Instructions Manual

WDT Operating Instructions GRANUDOS 45/100 (S3 - 04/02) Page 1 of 1

_______________________________________________________________________________

Series No..........................Customer..........................................Date of delivery……….……………

Operating instructions GRANUDOS 45/100-S3

Safety Devices

1. Chlorine and acid may not be mixed together

or with other chemicals

Pay attention to the safety devices on

chemical containers

2. The dosing hopper must be screwed even

and firmly to the container

3. Ensure after changing a drum, that it is firmly

fixed in position and the securing systems are

used

4. In service the dissolving system must be

covered with the supplied cover

5. Only instructed personnel may work with the

GRANUDOS

6. Ensure booster pump does not run dry,

always isolate pump when backwashing.

WDT Operating Instructions GRANUDOS 45/100 (S3 - 04/02) Page 2 of 2

_______________________________________________________________________________

TABLE OF CONTENTS

Safety devices

Test certificate

page

1 Function of GRANUDOS 45-S3 2

1.1 Data, Measures, Performance 3

1.2 Drum carrier 3

1.3 Dosing Assembly Chlorine 4

1.4 Acid dosing 4

1.5 Dissolving System 5

1.6 Control Panel (GRD S3) 6

1.6.1 Front plate 6

1.6.2 Dosing control system 7

1.6.3 Dosing performance adjustment 7

1.6.4 Dosing by auto controller 7

2 Installation 8

2.1 Electrical Connection 8

2.2 Providing acid 8

2.3 Tubing 9

3 Start 10

3.1 Deaeration of the water supply tubing 10

3.2 Water level in flushing tank 10

3.3 Water flow/Suction performance of injector 10

3.4 Loading the chemical drum onto machine 10

3.5 Acid dosing 11

4 Irritations Diagnosis 12

4.1 Irritations indicated by red lamps/control switches 12

4.2 Irritations notmonitored/indicated by switches 13

5 Maintenance 13

6 Wiring Diagram/Fuses 14

7 Spare parts list 15

8. Maintenance list 17

WDT Operating Instructions GRANUDOS 45/100 (S3 - 04/02) Page 3 of 3

_______________________________________________________________________________

1. Function of GRANUDOS

1.1. Data, Measures, Performance

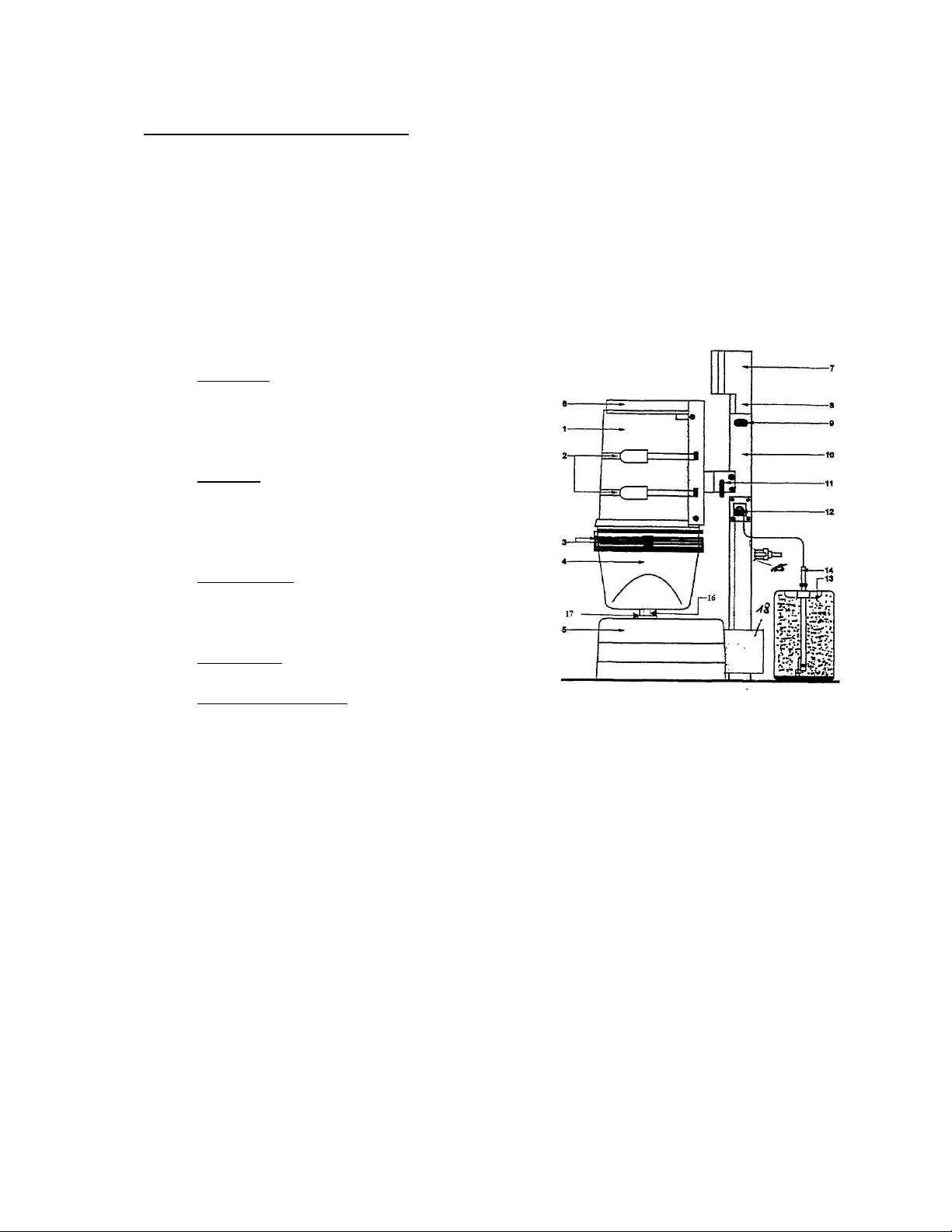

The GRANUDOS 45-S3 dosing system comprises:

- main vertical support with rotating drum carrier

assembly

- calcium hypochlorite granules metering

- acid metering equipment

- dissolving system

- control panel

Measures:

base needed: 120x70x180 cm

height: 140 cm

weight: 50 kg

material:

main vertical support and drum carrier:

steel, zinc and powder coated

other parts: PVC, PE

booster pump

centrifugal pump: 0,3 kW, 230 VAC,

supply pressure: minimum 0,2 bar

Water flow: app. 1000 l/h

Dosing Performance:

chlorine: GR 45: 1,5 kg/h. GR 100: 3 kg/h

acid: GR 45: 3 l/h, GR 100: 3 l/h

1 drum 9 type label.

2 2 clamp bands 10 vertical carrier

3 lid curl 11 locker

4 dosing hoper 12 acid pump

5 dissolving system 13 acid carboy

6 drum carrier 14 carboy lance

7 controlsystem 15 water supply with filter

8 conn. Housing 16 heated dosing nozzle

17 dust protection

18 pump cover

WDT Operating Instructions GRANUDOS 45/100 (S3 - 04/02) Page 4 of 4

_______________________________________________________________________________

1.2 The Drum Carrier

The rotating drum carrier assembly (6) is fixed to the main vertical support (10). The drum

(1) with hypochlorite is fixed on the carrier assembly (6) by 2 band clamps (2) and a

retaining belt. The dosing hopper (3) is fixed on the drum in place of the drum lid. The

carrier with the drum is then turned through 180° to the dosing position, the chemical is

dosed into the dissolving system (5) where it is fully dissolved and conveyed by a venturi to

the swimming pool.

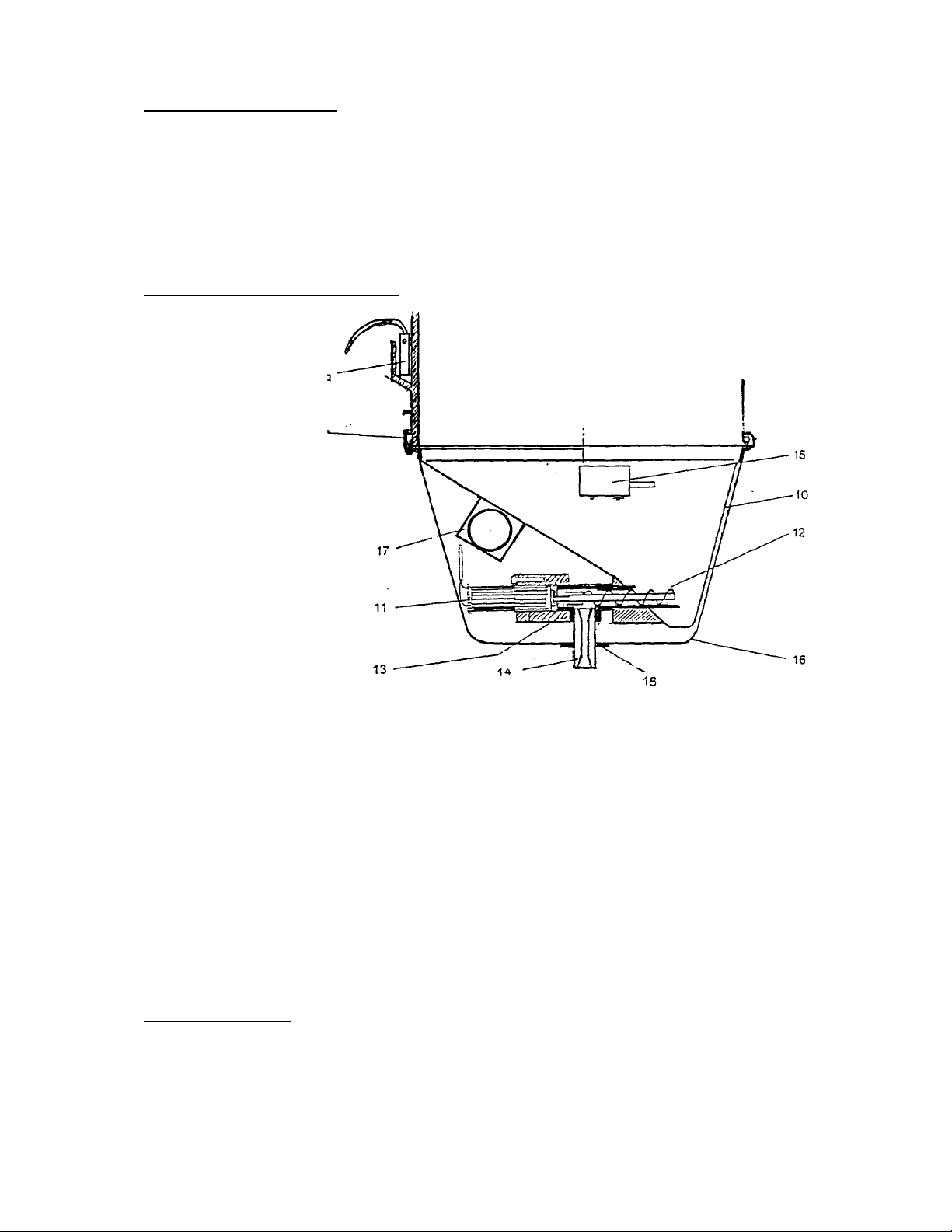

1.3 Chlorine Dosing Assembly

19

10 dosing hopper 16 hopper cover

11 dosing motor 17 knocker (option)

12 dosing screw 18 seal washer

13 motor mounting 19 dosing hopper screw ring

14 dosing nozzle heated

15 drum empty switch with adjusting screw and LED

The dosing screw (12) meters the chlorine through the heated dosing nozzle (14) to the

dissolving system. If the drum empty switch (15) is indicating, the LED 4 burns

continuously, dosing is running on,. The knocker (17, optional) gives a hit to the hopper at

each dosing motor run so supporting dosing.

Dosing performance is adjusted by 2 turning knobs at front fascia, see para starting.

1.4 Acid Dosing

The acid is dosed down in the flushing cone (23 - see next para) by the peristaltic pump

which is fitted directly right side at the vertical support. If acid level switch indicates acid

container empty, the GRANUDOS chlorine dosing is stopped too to avoid scaling.

As acid use sulphuric acid 37%. Concentrated hydrochloric acid (HCI) penetrates the pump

hose and will attack the pump rollers and further the pump

WDT Operating Instructions GRANUDOS 45/100 (S3 - 04/02) Page 5 of 5

_______________________________________________________________________________

1.5 Dissolving System

32

21

22

21a

23

29

30

26

33 34 31 20 24 25 27

2

0

20 pressure switch (optional) 27 cyclone mixing/dissolving

chamber

21 floating valve 29 level switch

22 flushing tank 30 union bush with nozzle inside

23 flushing tube 31 outlet ball valve

24 suction tube with flow control 32 water supply ball valve

25 venturi nozzle 33 fitting ¼” for test pressure gauge

26 booster pump

The supply water coming from the pool water is divided at the discharge of the booster

pump (26), one way leading to the flushing tank (22), the other branch directed to the

venturi nozzle (25), where the water is drawn out of the flushing tank together with the

dosed chemicals. The supply water flow is controlled by means of a floating valve (21) and

monitored by a flow switch (24), the latter being installed in the suction tube of the venturi.

To mix the chemicals and to ensure the complete dissolving of the hypochlorite granules a

cyclone mixing chamber (27) is fitted after the venturi. Optionally the supply water

pressure is monitored by the pressure switch (20).

WDT Operating Instructions GRANUDOS 45/100 (S3 - 04/02) Page 6 of 6

_______________________________________________________________________________

To ensure that calcium hypochlorite and acid do not come in contact with each other in the

open tank part of the dissolving assembly a sophisticated control system is installed:

- metering of the two chemicals is regulated with pauses between the metering

intervals (para 4.2 'Adjusting dosing performance').

- power supply for chlorine and acid dosing motors are connected by a relay system so

that only one of them can get power (24VDC).

- flow switch (24) , level switch (29), and optional pressure switch monitoring water

supply and flow conditions. If any non-compliance with the given limits occurs, the

dosing will be switched off.

1.6 Control Panel (GRD S3)

1.6.1 Front plate – service elements

The control board is of analogical type, one part together with the front plate. All

connectors are push type directly on the control board.

Service elements:

On connector housing below:

1 main switch on/off

1 main fuse 3,15 amp slow

On front plate:

1 select switch for dosing by auto controller or for continuous dosing

1 potentiometer knob to adjust dosing cycle from 1 – 8 minutes

2 potentiometer knobs to adjust dosing time of dosing motors chlorine and acid:

100 % = 20 seconds

2 push button switches to test dosing motors of the chemicals: if pushed, dosing is

running accordingly if no fault is indicated.

1 green lamp to indicate service

Loading...

Loading...