Granudos 10-S4 Operating Instructions Manual

WDT Operating instructions GRANUDOS 10 (S41C-03/10) page 1 of 21

____________________________________________________________________________

i

Series No.....................................Customer.....................................Date of delivery...................

Operating instructions GRANUDOS 10-S4

Safety Devices

1. Chlorine and acid may not be mixed together or

with other chemicals

Pay attention to the safety devices on chemical

Containers

2. Close hopper immediately after filling

3. If an adapter to a chemical container is used the

hopper must be screwed even and firmly to the

container

4. Clean environment with water if chemical was

spread

5. Only instructed personnel may work with the

GRANUDOS

6. Ensure booster pump does not run dry, always

isolate pump when backwashing.

WDT Operating instructions GRANUDOS 10 (S41C-03/10) page 2 of 21

____________________________________________________________________________

i

TABLE OF CONTENTS

page

1 Function of GRANUDOS 10-S4 2

1.1 Data, Measures, Performance 3

1.2 Dosing Assembly Chlorine 4

1.3 Dissolving System 5

1.4 Acid dosing 6

1.5 Control System GR-S41 7

1.5.1 Service elements 7

1.5.2 Operation and test programmes 7

1.5.3 Dosing performance – Dosing scheme 8

1.5.4 Diagnose 9

1.5.5 Irritations not indicated by monitoring switches 11

1.6 Filter disinfection at back wash – high chlorination 12

2 Installation 12

2.1 Tubing 12

2.2 Electrical Connection 13

3 Start 13

3.1 Check of pump 13

3.2 Deaeration of water supply tubing 13

3.3 Water level in flushing tank 13

3.4 Water flow/Suction performance of injector 13

3.5 Filling of Chlorine into the hopper 14

3.6 Providing of acid 14

3.7 Dosing Performance Adjustment 14

3.8 Dosing controlled by Auto-Controller 15

4 Maintenance 15

5 Control plate GRANUDOS-S4c 16

6 Maintenance List GRANUDOS 10/45/100 17

7 Spare parts list GRANUDOS 10-S4 18

8 Wiring diagram 19

WDT Operating instructions GRANUDOS 10 (S41C-03/10) page 3 of 21

____________________________________________________________________________

i

1 Function of GRANUDOS 10-S4

1.1 Data, Measures, Performance

The GRANUDOS 10-S4 dosing system comprises:

- polyethylene housing one piece

- filling hopper 5 kg (option 10 kg or adapter to 10 kg containers)

- calcium hypochlorite screw feed arrangement

- peristaltic acid pump

- dissolving system

Measures:

base: 60 x 50 cm

height: 80 cm

weight: 30 kg

Material:

PE, polyethylene

Booster Pump

centrifugal pump: SS - 0.3 kW, 230 Volt

supply pressure: 0,2 – 1,2 bar

counter pressure: 0 – 1,2 bar (depending on supply pressure)

water flow: app. 1000 l/h

Dosing performance ( further see para 1.5.3)

Chlorine dosing motor PLG 30-35 app. 2,4 * ( 0,44**) kg/h

acid: 1,3 * ( 0,15**) l/h

* cycle time 1 minute

** cycle time 6 minutes

Fault remote indication by relay

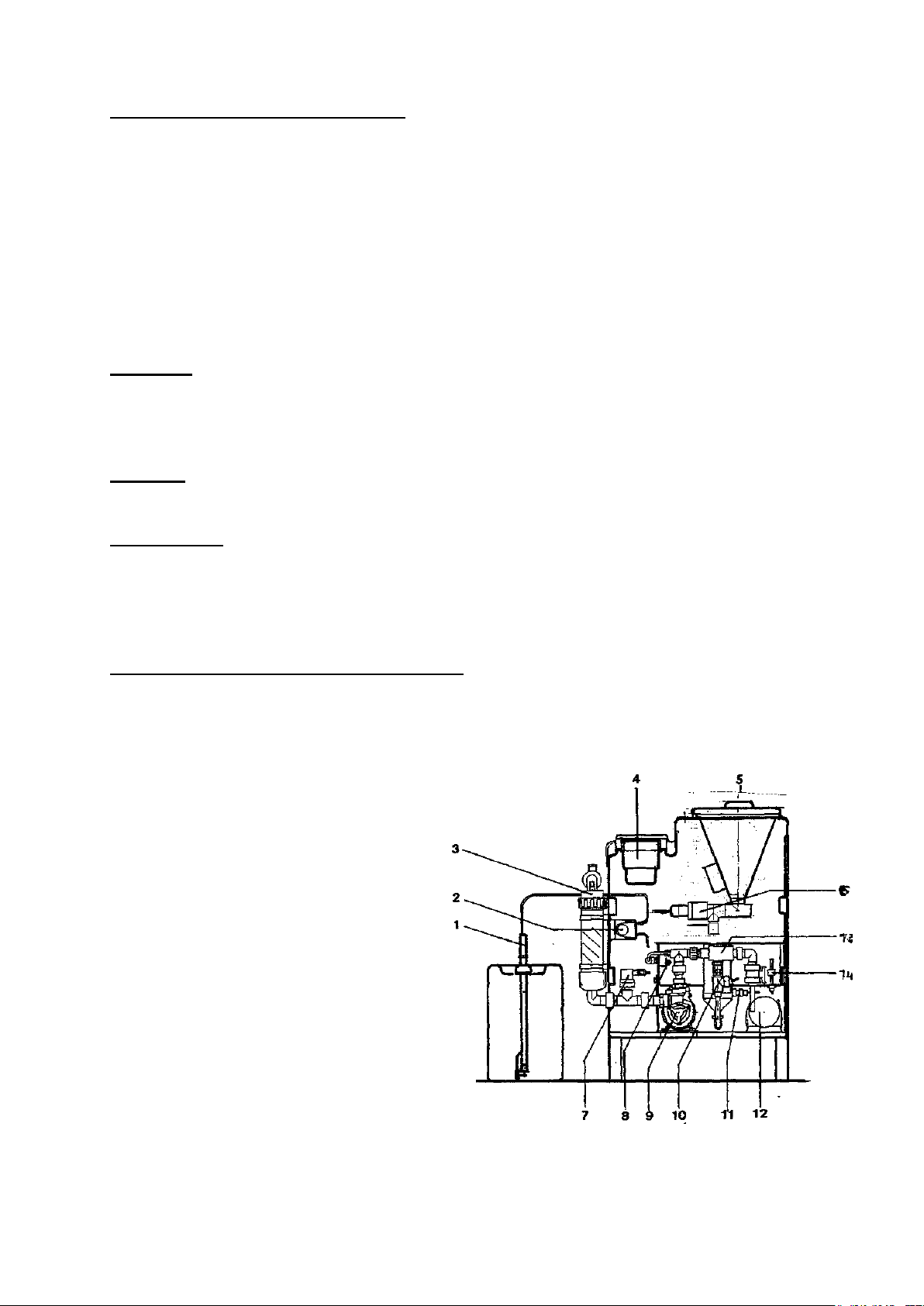

1 supply carboy lance

2 dosing pump for acid

3 strainer GR 10 complete

4 control system

5 dosing hopper

6 dosing assembly GR 10

7 pressure switch

8 floating valve d25 complete

9 booster pump

10 suction tube with flow switch

11 acid dosing valve GR

12 mixing cyclone GR 20

13 venturi complete

14 level switch GR 20

WDT Operating instructions GRANUDOS 10 (S41C-03/10) page 4 of 21

____________________________________________________________________________

i

1.2 Dosing Assembly

The dosing assembly, placed into the main housing consists of the dosing hopper (5a) and the dosing unit

with dosing motor (6a) pushed into and screwed to the motor holder (6b) the dosing

screw (6c) and the dosing nozzle which is heated preventing condensation of the warm pool water vapour.

The dosing unit is screwed into the dosing hopper. The required dosing rate is adjusted at the control board

by means of a dosing cycle and dosing time – see para 1.5.

5a dosing

hopper

5b hopper

cover

6a dosing

motor

6b motor

holder

6c dosing

screw

6d heated

dosing nozzle

6e knocker

The knocker (6e) gives a stroke to the dosing hopper

wall and thus prevents clogging of the chemical.

The complete dosing assembly can be taken out of the

frame for service.

With the shown fitting systems chemical containers of 10 kg can be fitted directly to the hopper so that the

chemical must not be moved from the container to the hopper.

Fitting system to join a Fitting system to join a

10 kg container with round edge 10 kg HTH container

WDT Operating instructions GRANUDOS 10 (S41C-03/10) page 5 of 21

____________________________________________________________________________

i

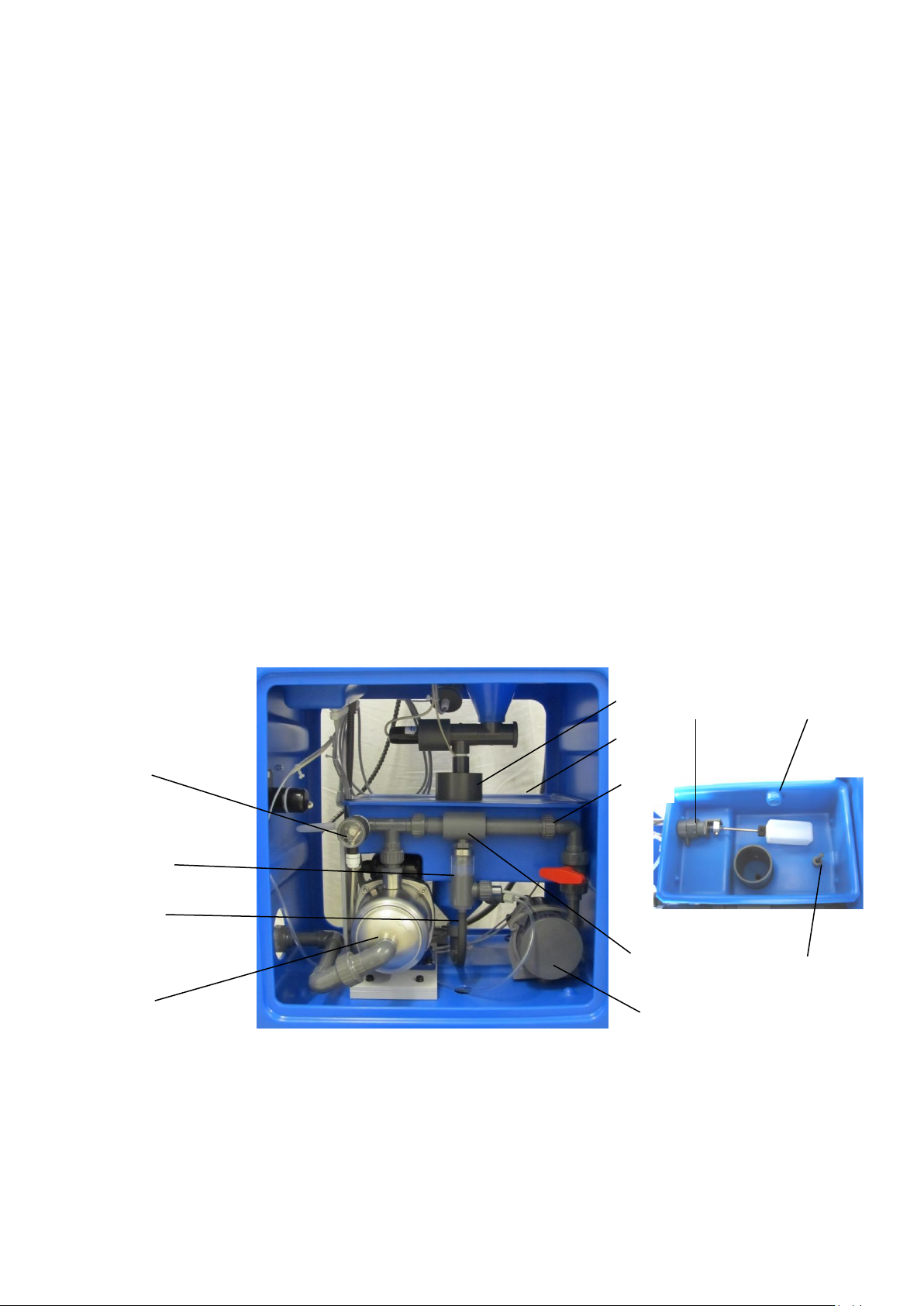

1.3 Dissolving System

The dissolving water is normally supplied from before or from behind the filter. There must be a sufficient

supply pressure to avoid dry running and/or cavitation on the booster pump, at least 0.2 bar. The

pump pressure is controlled by the pressure switch (7) fitted on top of the pump. At a pressure below the set

switch pressure by sucking air or at pressure drops the machine stopps, lamp 1 & 2 will burn. At works 1,5

bar is set.

The supply water is divided at the discharge of the booster pump (9), one way leading to the

flushing tank via the floating valve (8), the other branch directed to the venturi nozzle (13), where

the flushing water is sucked together with the dosed chemicals out of the flushing tank. A flow

switch (10), being installed in the suction tube of the venturi monitors the suction power of the

venturi. To adjust the suction to different pressure conditions an orifice washer (13c) with different

bores can be used. To mix the chemicals and to ensure the complete dissolving of the hypochlorite

granules a cyclone mixing chamber (12) is fitted after the venturi.

To ensure that calcium hypochlorite and acid do not come into contact with each other in the open

part of the dissolving assembly a sophisticated control system is installed:

- metering of the two chemicals is regulated with pauses between the metering intervals

- dosing motors of chlorine and acid are controlled by connected relays – joint dosing is

impossible

- flow switch (10 indicates if water flow to venturi falls below 150 – 200 l/h

- level switch (14) indicates water maximum or water minimum level in the flushing tank thus

supervising water supply conditions.

- 4 red lamps indicate any fault.

If any non-compliance with the given limits occurs, the chemical dosing will be stopped.

7 pressure switch 13 venturi nozzle

8 floating valve 14 orifice washer inside

9 booster pump Lo HM04 flux 15 level switch low/high

10 flow switch holder d40 with flow switch 16 lid on flushing tank

11 acid dosing valve with chlorine dust protection

12 mixing and dissolving 17 overflow to drain

chamber with PVC ball valve 18 dust prevention tube

7

8 9 10

11

12

14

13

15

16

17

18

WDT Operating instructions GRANUDOS 10 (S41C-03/10) page 6 of 21

____________________________________________________________________________

i

The flushing tank is an open system with two ways for a drain of water coming from the

circulation to the flushing tank and possibly causing an overflow at switch off times. To avoid this,

the flow switch holder as the floating valve are acting as non return valves: The floating valve

closes the inlet bore at rising level (proved up to 4 bars at test), in addition a spring loaded non

return valve is installed in the elbow fitting into the valve. The switch bobbin has a seal to close

this way. Both devices function well if the seal/diaphragm are maintained in a good shape. But as a

mechanical seal may leak after any time or by being blocked by

impurities a 100% isolation may not be guaranteed. If this is needed

for any cases, an electric valve must be installed.

1.4 Acid dosing

The acid required either for pH-control or just for cleaning of

the flushing, mixing and dosing system is metered by the

peristaltic pump to the flushing water via the dosing injector

(11). As the cleaning procedure is vital for the correct function

of the complete dosing assembly, chlorine dosing is stopped if

the level switch at the supply carboy lance indicates container

empty.

As acid use one on base of sulphuric acid (37 – 50 %),please do

not use concentrated hydrochloric acid for this job as that

penetrates the peristaltic hose and will destroy the pump head.

Diluted hydrochloric acid may be not strong enough for the

neutralisation job. Please note that using dry acid (sodium

bisulphate) 20% (= maximum concentration) is equivalent to a only

10% sulphuric acid.

Maximum dosing performance is app. 3 l/h and is set as for

chlorine. The dosing cycle set for chlorine is valid for acid too.

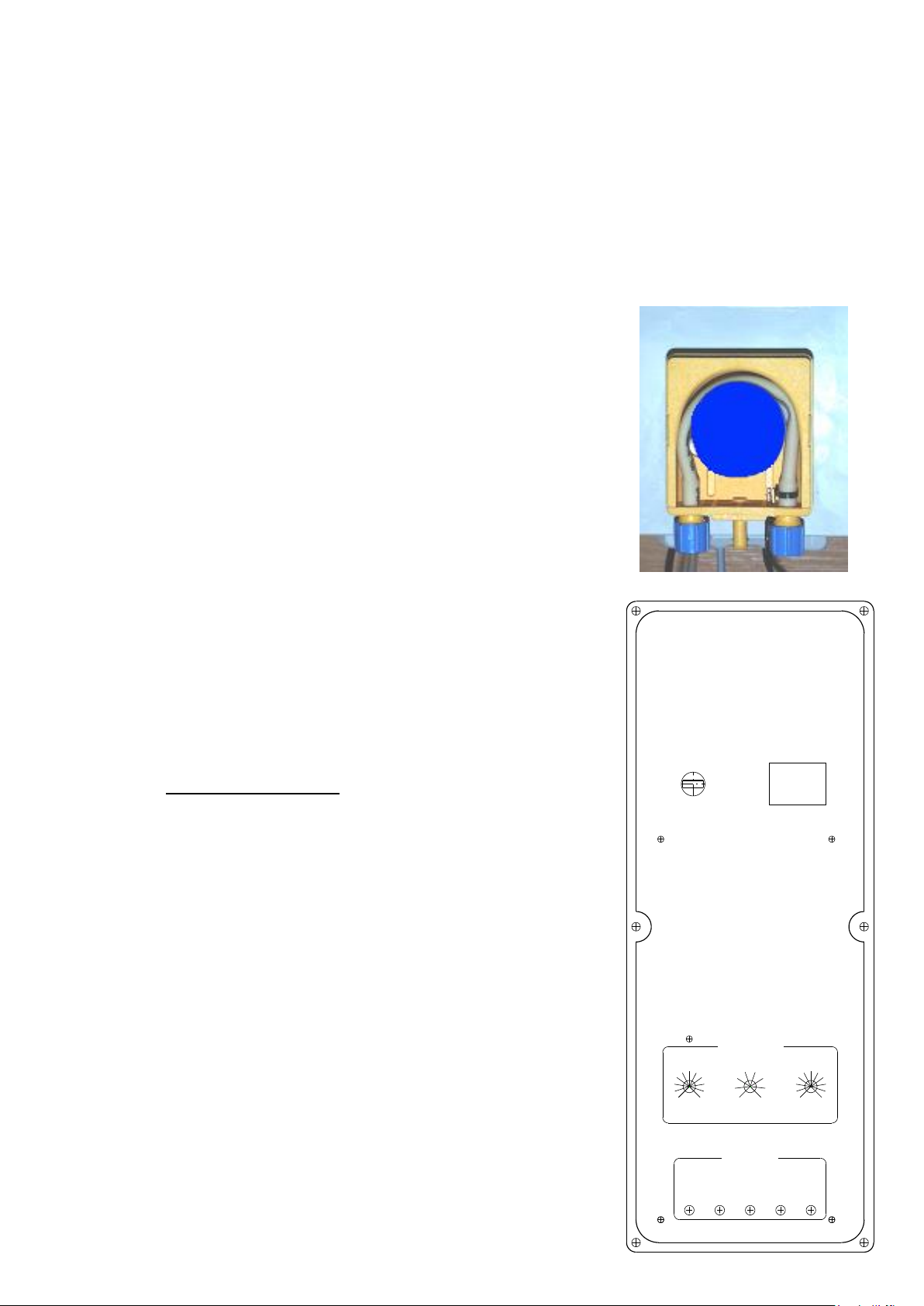

1.5 Control system S41

1.5.1 The service elements

The processor-plate S4 of the GRANUDOS is

combined with the front facsia to a unit with the

elements

- main switch on/off

- main fuse 3,15 AT

- 1 programme switch for test- and operation

programmes

- 2 knobs to adjust dosing performances 0-

100%

- 1 green lamp to show „on operation“

- 4 red lamps for fault and dosing indication

Internal elements: fuses, program switch for

alternatives in

cycles and timers

3,15 A

on / off

Diagnose

level low

pump

pressure

off

on

off

level high

suction

dos off

acid

empty

dosing

dosing

chlorine

low

Programme

Acid

Chlorine

auto

monitor.

test

chlorine

dos-off

test

knocker

off

auto

test

acid

hand

60

10

0

20

30

70

80

100

90

40

50

%

60

10

0

20

30

70

80

100

90

40

50

%

GRANUDOS

S4

WDT Operating instructions GRANUDOS 10 (S41C-03/10) page 7 of 21

____________________________________________________________________________

i

1.5.2 Operation and test programmes

By turning the programme switch there is a retention time of

2 seconds with 2 flashes of the green lamp

Auto:

Dosing control by external auto-controller free chlorine and pH-value. Dosing always within the

dosing cycle advance or at the next cycle. The cycle is to be set on 1 minute with code switch S1 on

“on”, or on 6 minutes with code switch S2 on “off”. Dosing of chlorine and acid is independent.

Auto monitor.: as „Auto“ but with dynamic time monitoring: :

When controlling the GRANUDOS dosing by an external controller the dosing performance must

be set high enough to ensure the dosing times (= dosing performance) of acid and chlorine shall not

exceed 50% of total time, the actual values are near to the set points of free chlorine and pH. If

controller output time exceeds 50% , there must be any interruption in the system:

- too high bathing load

- interruption at the dosing appliance: motor, valve

- interruption at the auto control system: hanging relay, faulty electrode etc.

The GRANUDOS controller S4 adds up all ordered dosing time (input time) that exceeds

50% of total time and stops dosing if 60 minutes excess time is reached. Indication by

flashing of all 4 red lamps.

Hand

Continuous dosing as set. dosing cycle as set on code switch S2 ”on”1 minute, “off” 6 minutes..

With the longer cycle time you get a lower dosing performance

Test chlorine:

Test chlorine dosing for 6 minutes continuously, then stop, the green lamp flashes

Can be used to test the real dosing performance.

Test acid :

Test acid dosing for 6 minutes continuously, then stop, the green lamp flashes.

Can be used to test the real dosing performance

Test knocker

Test for knocker function: the knocker hits 4 times all 2 seconds then stop, the green lamp flashes

Dos-off

Dosing switched off, the booster pump continues. Used for maintenance.

Off:

Switch off of all functions. Used if the machine is taken out of operation for a longer period.

Dosing can be switched off by an additional external switch e.g. a flow or pressure switch

Programme

Acid

Chlorine

auto

monitor.

test

chlorine

dos-off

test

knocker

off

auto

test

acid

hand

60

10

0

20

30

70

80

100

90

40

50

%

60

10

0

20

30

70

80

100

90

40

50

%

Loading...

Loading...