Grant's Automation SD series Installation Manual

INSTALLATION MANUAL

SD series 24V Sliding Gate Operators

FOR

CONTENTS

PRE-INSTALLATION CHECK LIST . . . . . . 1

TECHNICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . 1

MAXIMUM SIZE OF GATE . . . . . . . . . . . . . . . . . . . . . . . . . 2

GATE OPERATOR FREQUENCY OF USE . . . . . . . . . . . . . . . . . . 3

IMPORTANT SAFETY INSTRUCTIONS! . . . . . . . . . . . . . . . . . . . 4

TOOLS AND HARDWARE REQUIRED . . . . . . . . . . . . . . . . . . . . 5

PREPARING THE GATE . . . . . . . . . . . . . . . . . . . . . . . . . 6

GUIDE POST CLEARANCE . . . . . . . . . . . . . . . . . . . . . . . . 6

AUTOMATIC OPERATOR FITTING REQUIREMENTS . . . . . . . . . . . . . . 7

ACCESSORIES THAT CAN BE ADDED . . . . . . . . . . . . . . . . . . . 8

SAFETY PHOTOCELL 8

DIGITAL KEYPAD AND/OR INTERCOM 9

A GROUND LOOP VEHICLE DETECTOR 9

CABLING REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . 10

BASIC CABLING GUIDE 10

FULL CABLING GUIDE 10

TYPE AND SIZE OF CABLE 11

HOW IT WORKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

INSTALLATION . . . . . . . . . . . . 13

STEP 1 - INSTALL CABLING . . . . . . . . . . . . . . . . . . . . . . . 13

TIPS FOR RUNNING LOW VOLTAGE CABLE YOURSELF. 14

STEP 2 - FIT THE OPERATOR . . . . . . . . . . . . . . . . . . . . . . 14

POSITION OF THE OPERATOR 13

CHECK HEIGHT OF THE OPERATOR 15

RAISE THE HEIGHT OF THE OPERATOR IF NEEDED 15

FIX THE OPERATOR IN PLACE 16

MANUALLY RELEASE THE OPERATOR 16

STEP 3 - FIT THE RACK TO THE GATE . . . . . . . . . . . . . . . . . . . .17

STEP 4 - POWER OPERATOR UP . . . . . . . . . . . . . . . . . . . . . 21

WIRING DIAGRAM FOR POWER CONNECTIONS 21

CHECKING THE GATE DIRECTION 22

WIRING DIAGRAM FOR THE BATTERY 23

WIRING DIAGRAM FOR A PHOTOCELL 24

WIRING DIAGRAM FOR DIGITAL KEYPAD OR PRESS BUTTON 24

WIRING DIAGRAM FOR AN INTERCOM 25

TERMINATING GROUND LOOP VEHICLE DETECTOR 24

TERMINATING A 7-DAY TIMER, DIGITAL KEYPAD OR KEYSWITCH 25

TERMINATING AN INTERCOM 25

STEP 5 - MOTOR SETUP . . . . . . . . . . . . . . . . . . . . . . . . 26

ACTIVATING REMOTE CONTROLS 26

DEACTIVATING REMOTE CONTROLS 26

SETTING THE GATE OPEN AND CLOSE DISTANCE 26

AUTO-CLOSE DELAY 27

ADJUSTING FORCE SETTING FOR SAFETY REVERSE 27

SOFT START 27

SOFT STOP 27

MOTOR SPEED 27

PEDESTRIAN GATE OPENING 28

INSTALLING THE SOLAR PANEL . . . . . . . . . . . . . . . . . . . . 30

WHAT HAPPENS IF THERE IS A POWER CUT? . . . . . . . . . . . . . . 31

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . 32

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1

PRE-INSTALLATION CHECK LIST

TECHNICAL SPECIFICATIONS

ELECTRICAL

Power Supply SD-240, SD-LVC, SD-LVH: 240VAC 50Hz

Power Supply SD-SOL: Solar Panel

Electronic Controller: Micro-controller based

Gate Obstruction Detection: Over Current

Safety Barrier: Photocell

Operating distance of remote controls 50m or more

Remote control buttons: Open, Stop, Close, Ped open

Open and close limit type: Encoder and Magnetic SW

Auto-close time: 0 to 99 seconds

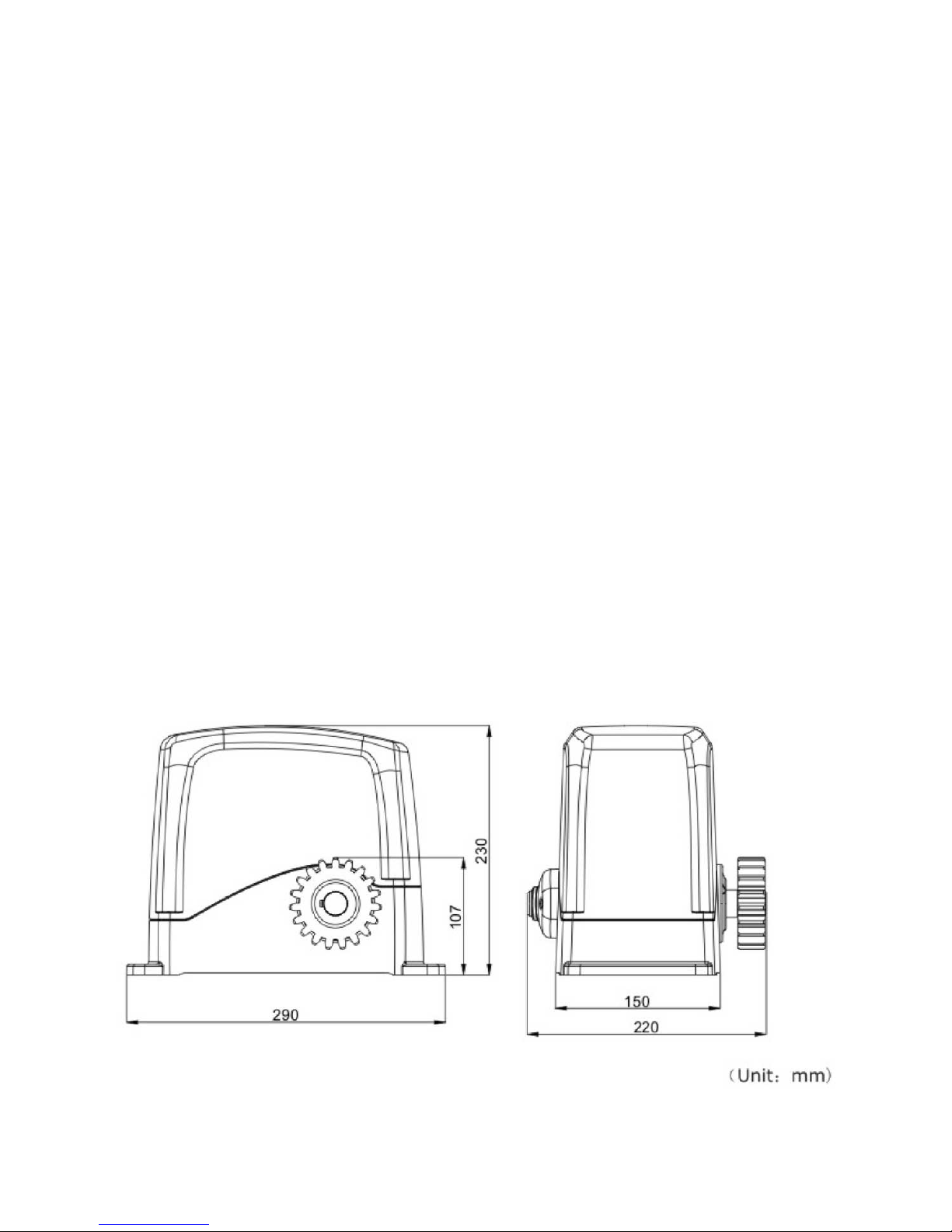

MECHANICAL

Max. gate weight: 800kg

Gate Operating Speed: 22cm/second

Packing Size: 40 x 30 x 18.5cm

Noise: less than 65db

IP Rating: IP57

Working Temperature: -15

O

C to 55OC

2

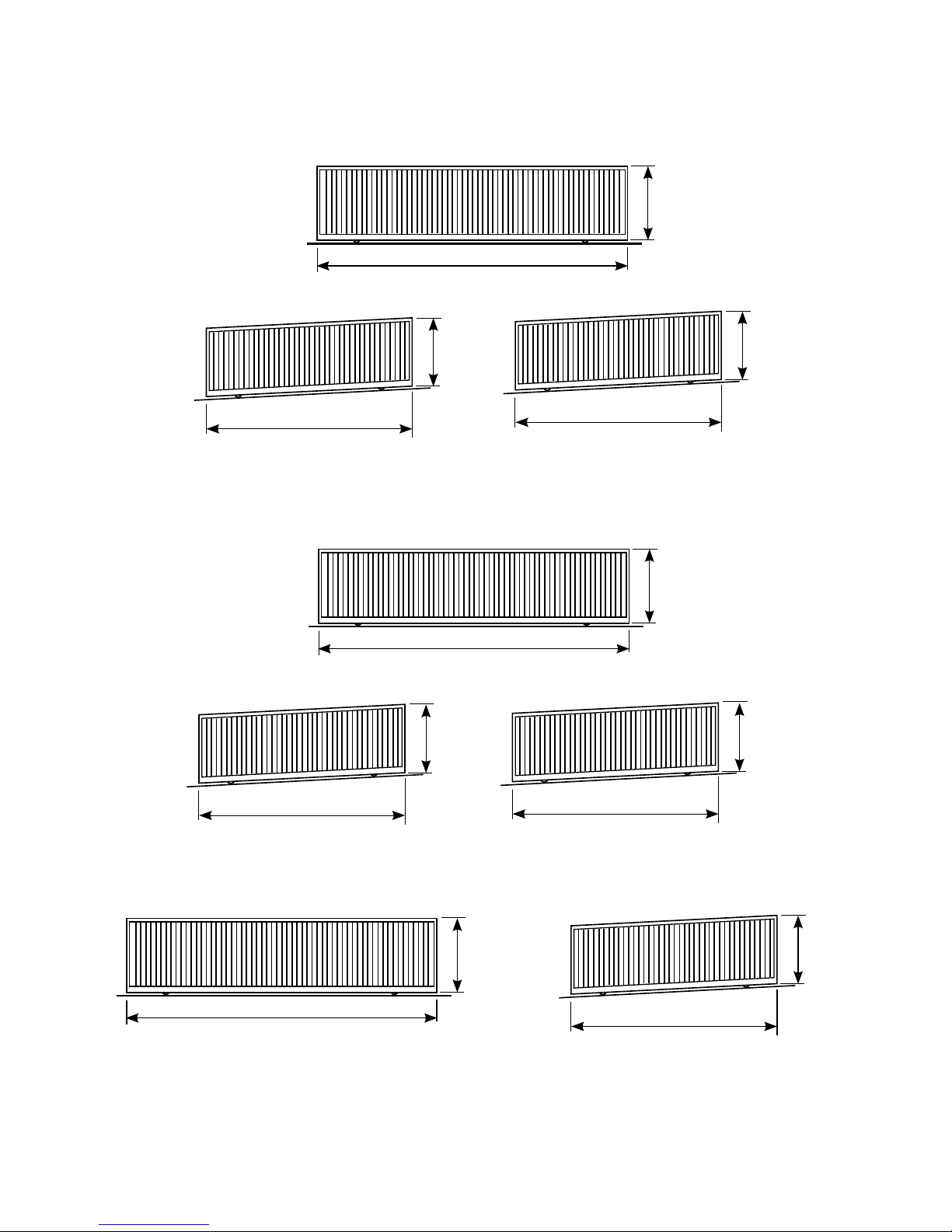

MAXIMUM SIZE OF GATE FOR THE SD-240, SD-LVH AND SD-SOL OPERATORS

FOR SD-LVC REDUCE THIS BY 40%

to 20m Wide

2m High

to 6m Wide

1.8m High

300mm rise

For Aluminium Gates with vertical bars or Chain Link Gates:

to 10m Wide

2m High

to 6m Wide

1.8m High

200mm rise

For Galvanised Steel Gates with vertical bars, Aluminium Gates with Slats

or 16mm thick pine palings:

to 6m Wide

2m High

4m Wide

1.8m High

100mm rise

For Heavy Galvanised Steel Gates or Gates with Hardwood Cladding:

to 3m Wide

1.8m High

500mm rise

to 3m Wide

1.8m High

400mm rise

3

GATE OPERATOR FREQUENCY OF USE

This Gate Operator is rated for RESIDENTIAL AND LIGHT INDUSTRIAL USE

ONLY, which is a maximum of Five Households or Ten Carpark spaces for a

commercial building. Any more than this and the life span of the operator can

be reduced.

The warrantee does not cover wear and tear due to average use of more

than 60 operations per day.

If higher frequency of use is required consider using an industrial sliding gate

operator rated for continuous use. Gates that have a lot of users are more likely

to be struck by a vehicle so need to be a robust industrial grade operator.

Battery Back Up System

If a Battery Back Up is used the 24V 7Ah battery takes over if the mains power

fails. It will provide up to 200 operations over a couple of days or last a week

or so if not used.

Battery Conditioning During Normal Use

During normal use when the motor starts up it draws power from the battery,

which keeps it conditioned for reliable operation as batteries need to be used

regularly for them to work properly.

Low Voltage Power Cable

The Battery Conditioning arrangment also allows the power transformer to be

away from the gate and Low Voltage Power Cable only run to the gate. This is

because any current that is too high for the low voltage cable is taken up by the

battery. This means that the operator must have a battery connected before

it will work properly with Low Voltage cabling.

Solar Powered

Run from the Battery during normal use, which is charged from a solar panel.

The 14Ah battery supplied will run for up to 12 to 24 operations per day depending on the weight of the gate for 10 cloudy days in a row. A 20Watt Solar panel

will charge the battery from flat in two days of full sun. If you are in an area that

doesn’t get a lot of sun you may need to add extra solar panels and batteries,

which are available as extra’s.

4

IMPORTANT SAFETY INSTRUCTIONS!

CONSIDERING THE GENERAL PUBLIC:

When Installing an Automatic Gate that will be entered from a public road

way, make sure the Gate is placed far enough from the road to prevent trafc

congestion.

The Gate must be installed in a location that provides adequate clearance

between it and adjacent structures when opening and closing to reduce risk of

entrapment.

Install the Gate Operator on the inside of the property and fence line. DO NOT

install an opener on the outside of the gate where the public has access to it.

The Gate and Gate Operator must comply with any applicable local council

regulations.

CONSIDERING THE USERS:

If using the Auto-close feature it is highly recommended that a Point to Point

Photo Electric Safety Beam (Photocell) is installed to prevent the gate closing

on any vehicle using the gate.

It is also recommended that a seperate small side gate is used for pedestrians

particularly if there will be children, disabled or elderly people using the gate.

If push buttons, key switches or Digital Keypads are installed, they should be

within sight of the gate but not placed so the user will be tempted to reach

through the gate to activate the gate operator.

USER AWARENESS:

It is important to make sure everyone that will be using the gate is aware of the

following dangers associated with automatic Gates: do not contact any part of

the gate or walk in the path of the gate while it is moving. Never let children

play with the gate controls. Do not attempt to “beat the gate” while it is closing.

This is extremely dangerous.

In the event you sell the property, make sure the new owners have a copy of

these instructions. If you lose the instructions they can be downloaded from:

www.grantsautomation.com.au.

5

TOOLS AND HARDWARE REQUIRED

YOU MAY ALSO NEED THESE ITEMS BEFORE INSTALLATION

For Battery Powered Systems and systems with accessories added Low

Voltage Cable is required between the Transformer and the Gate operator

see “Cabling Requirements” for more information.

You may also need conduit, which is available from Electrical trade

suppliers and hardware stores.

For Mains Powered Systems you will need a mains power point mounted on a

free standing post in front of the gate next to the automatic operator. Check with

local regulations before installing a mains voltage power point yourself, you may

need a registered electrician to do this for you.

THE TOOLS YOU’LL NEED INCLUDE:

A basic set of hand tools will be needed including: side cutters, pliers, wire

strippers, a range of phillips head screw drivers, a small flat head screw driver

for terminal block screws and a socket set.

You’ll also need a tape measure, marking pen, an elecric drill with hammer

action and variable speed control, a 10mm hammer drill bit and socket bit for

10mm or 3/8” tek screws. An angle grinder is also handy although a hacksaw

will do if you don’t have one.

If you intend on doing you own low voltage cabling a pair of conduit cutters

are handy although a hacksaw can also be used. If you wish to run cabling

across the driveway you will need either a 230mm angle grinder with masonary

grinding disc or a hand held concrete cutter. You can hire these if necessary.

If you’ll be running cabling across a lawn or garden you’ll need a spade and

mattock for digging a low trench. If it’s a long run then a small trench digger can

be hired to do the job.

6

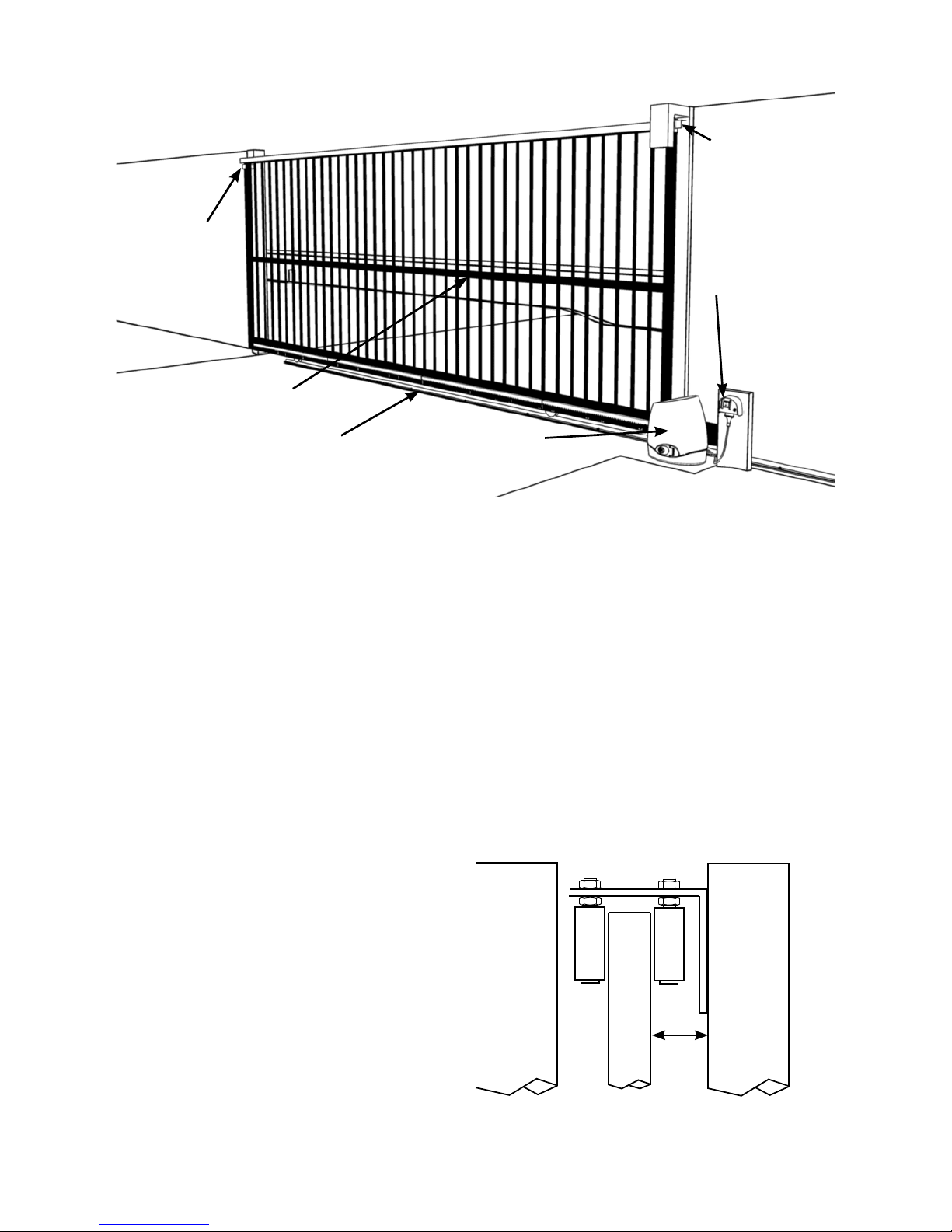

Make sure that the gate has been properly installed, is straight and slides freely

throughout its entire length without any grabbing from the guides or track any

where along the gate. The GATE TRACK MUST BE IN A STRAIGHT LINE

any sudden dips or rises may prevent the gate operator from working properly.

Repair or replace all worn or damaged gate hardware prior to installation. Gate

posts less than 150mm wide should be made from steel not timber. Replace

posts where necessary. A freely moving gate will require less force to operate

and will enhance the performance of the operator and give a long working life.

The operator should be well drained and not be submersed in water or have

water running past it in heavy rain.

Keeper to be

aligned to the

gate correctly

Guide must

move easily for

entire length of

gate.

Gate Operator on a

level concrete pad

Gate Track must be Straight,

gate should NOT run or catch

on the track.

Power Point (if

used) on free

standing post in

front of the gate

Gate must be Straight

not twisted or bowed.

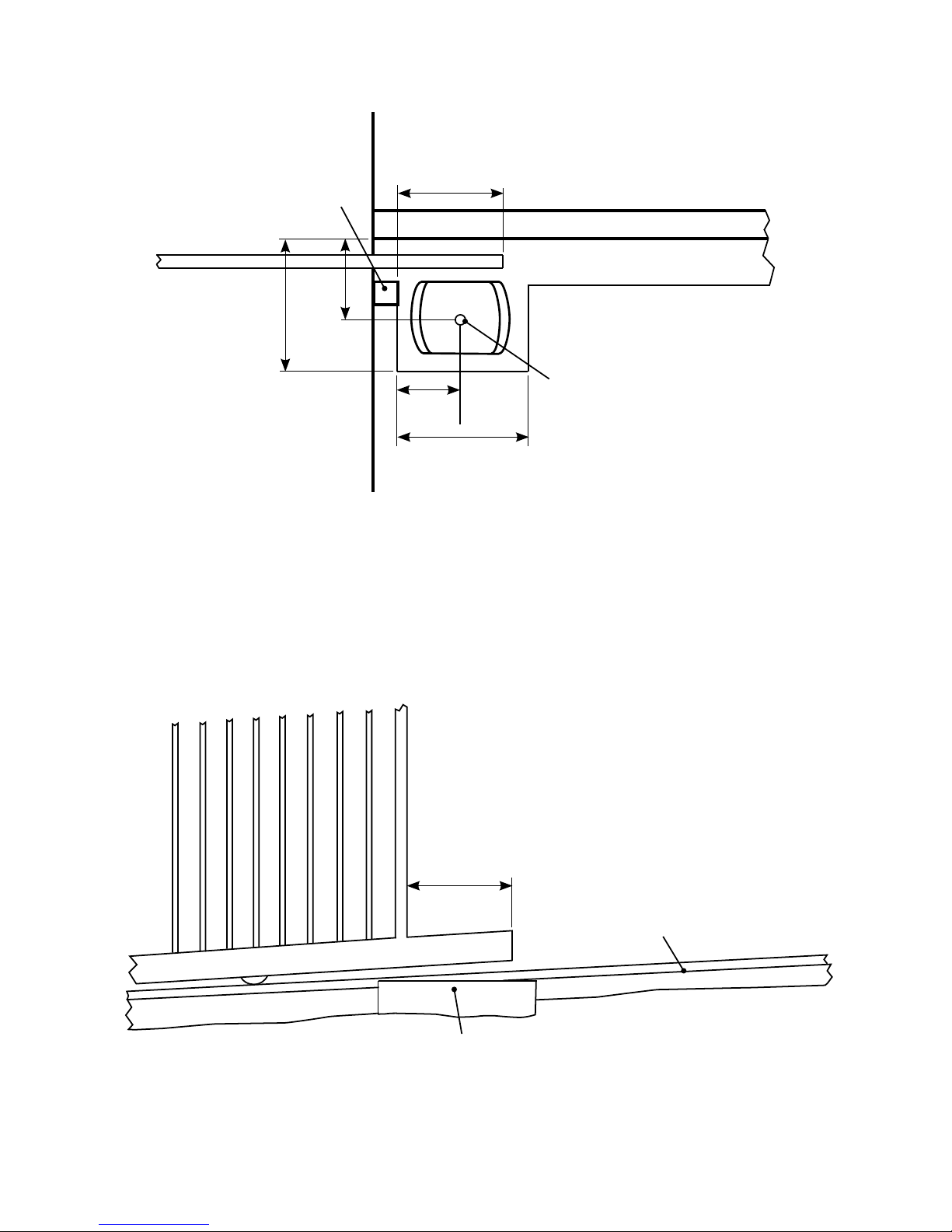

GUIDE POST CLEARANCE

Gate

Front

Fence or

Wall

Rear

Guide Post

if used

60mm

If using a guide post behind a gate

allow at least 60mm clearance for

the Rack. If the guide is fitted to the

front Fence or Wall the clearence

has no effect so long as the Gate

does not contact it at all.

Open

Hard Stop

required

to set gate

open limit

PREPARING THE GATE

7

The Gate Operator requires a level concrete pad to mount on. Even if the driveway is sloping the

concrete pad for the Operator MUST BE LEVEL!. The concrete pad should be no less than 100mm

thick and after concrete is poured must be given a week or so to harden before the operator is

installed.

If the Gate Operator power is to be hard wired it’s a good idea to place a piece of conduit into the

concrete pad, during installation, for the power cabling later on.

AUTOMATIC OPERATOR FITTING REQUIREMENTS

DRIVEWAY

Gate

Operator

FRONT FENCE/WALL

CONCRETE FOOTING AND PAD

Concrete

Pad

400mm

Concrete Pad

400mm

GATE

Guide

Post if used

Conduit for Power Cable to

come out of concrete pad here

if Power is Hardwired.

250mm

200mm

Extra Gate Length

for Automatic

Operator

300mm

PLAN VIEW

LAWN OR GARDEN

DRIVEWAY

Extra Gate

Length for

Automatic

Operator

need only be the

bottom rail

Concrete Pad must be level

even if gate track isn’t

GATE

Gate track and footing must

be straight but can be on a

gentle slope

FRONT VIEW

DRIVEWAY

LAWN OR GARDEN

Concrete Pad must be well

drained and not ever be sitting

in water even after heavy rain

8

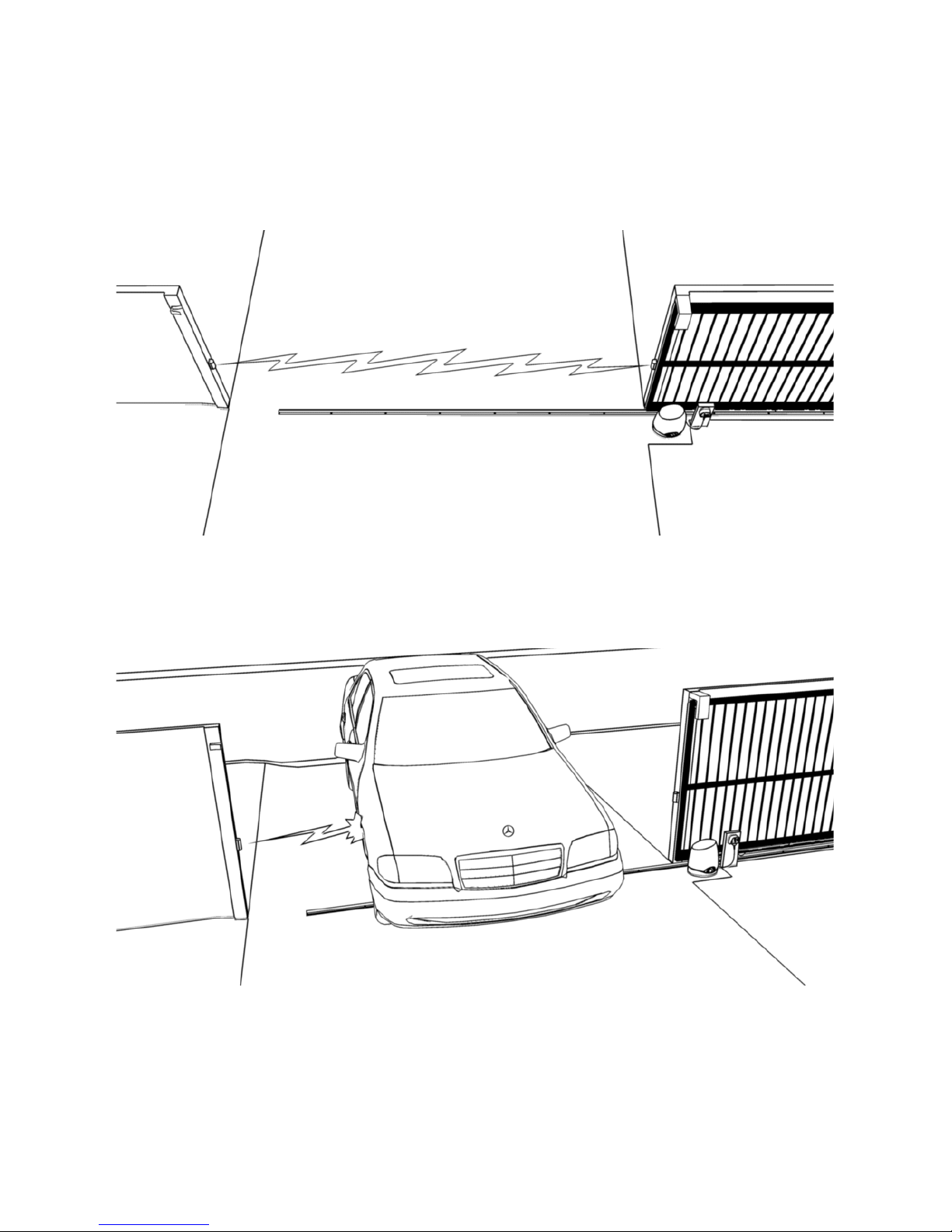

SAFETY PHOTOCELL

Photocells are a safety device that prevent the gate from closing on a vehicle.

They are highly recommended if using the Auto-close feature, as the gate

may close at any time.

A Photocell consists of an Invisible Low Power Infrared point to point Beam

Transmitted from one side of a gate to the other. REFLECTOR BEAMS are

NOT recommended for outdoors.

A Photocell prevents a Gate from Closing on a car

If the Photocell’s beam is interrupted by a vehicle, the gate won’t close.

ACCESSORIES THAT CAN BE ADDED

Loading...

Loading...