Page 1

Low temperature

circulator

LTC4

Operating Manual

Page 2

Grant Instruments, based near Cambridge, England is a world leader in the

manufacture and design of equipment for sample preparation, scientific analysis, data

acquisition and data analysis providing solutions to the global scientific and industrial

markets.

Standards Compliance and Quality

Grants’ brand and reputation are based around quality, reliability and accuracy. We

ensure our products stringently meet all necessary international safety standards.

We pay particular attention to the safety testing of products and remain at the forefront of

the product safety standard for laboratory equipment IEC 61010-1. The company is

committed to operating its safety test laboratory in accordance with the requirements of

ISO 17025.

Grant operates a Quality Management System that complies with the requirements of BS

EN ISO 9001:2008.

Beyond compliance to the standard, Grant is committed to continually improving in

everything we do; with particular emphasis on understanding what matters to our

customers and suppliers, and designing our systems and work to meet their needs.

If you have any feedback on Grant’s products or services we would like to hear from you.

Please send all feedback to:

Quality Manager

Grant Instruments (Cambridge) Ltd

Shepreth

Cambridgeshire

SG8 6GB

UK

Tel: +44 (0) 1763 260 811

Fax: +44 (0) 1763 262 410

E-mail: feedback@grantinstruments.com

Page 3

Contents

Contents 2

1.0 Use of products 4

2.0 How to use this operating manual 4

3.0 Safety information 4

3.1 Safety compliance 4

3.2 Safety symbols 4

3.3 Safety warnings 5

4.0 Operating instructions 6

4.1 Unpacking instructions 6

4.2 Fitting the controller to the Refrigeration unit 6

4.3 Recommended liquids 6

4.4 Installation 8

4.5 Electrical supply 8

5.0 Operating procedures 9

5.1 Operation 9

5.1.1 Liquid level 9

5.1.2 Operation above 60°C 9

5.1.3 Setting the over-temperature thermostat 9

5.1.4 Using the control unit pump 10

5.1.5 Using the switch over relay ouput 10

5.1.6 Emptying the LTC4 11

5.1.7 Setting up and switching on 11

5.2 Using the LTC4 12

5.2.1 Product description, control unit 12

5.2.2 Product description, user interface and controls 12

5.2.3 Product desciption, rear panel connections 13

5.2.4 Communications ports 13

5.2.5 Switched relay port 13

5.2.6 External probe input 13

5.2.7 Product description, refrigeration unit front panel (grille removed) 14

5.2.8 Product description, refrigeration, rear panels 15

5.2.9 Display. Explanation of home screen icons. 15

5.2.10 Setting the control temperature 15

5.2.11 Running a bath preset 16

5.2.12 Running a countdown timer 16

5.2.13 Running a program 17

5.2.14 Activating standby mode 17

5.2.15 Accessing the settings menu 18

5.3 Viewing, editing and saving settings 19

5.3.1 Configuring a preset 19

5.3.2 Selecting a liquid type 20

5.3.3 Selecting a temperature probe type 21

5.3.4 Configuring high and low temperature alarms 22

5.3.5 Setting the buzzer volume level 25

5.3.6 Selecting a language 25

5.3.7 Relay test and configuration 26

5.4 Completing a calibration 27

5.4.1 Restoring factory calibration settings 29

6.0 Technical specifications 30

6.1 Operating conditions 30

6.2 Electrical details 30

6.3 Specification 30

7.0 Technical Tips 31

LTC4 31115 V1

Operating Manual Page 2

www.grantinstruments.com

Page 4

7.1 Which water should you use in your LTC4 tank? 31

7.2 How to prevent rust in LTC4 tanks 31

7.3 How to prevent algae and bacteria? 32

8.0 Warranty information 32

9.0 Maintenance and service 32

9.1 Routine maintenance 32

9.2 Cleaning 32

9.3 Fuses 33

9.5 Routine safety tests 33

9.6 Service 34

10.0 Optional accessories 34

10.1 Alternative pump 34

11.0 Troubleshooting 35

12.0 Contact Grant Instruments 38

13.0 Compliance 38

Notes 39

31115 V1 LTC4

Page 3 Operating Manual

www.grantinstruments.com

Page 5

1.0 Use of products

Caution: Surfaces and heat transfer liquid can be hot during and after use.

Read this manual before using the bath.

Important safety warning.

The following products are covered by this operating manual:

LTC4 & LTC4L

The products listed above low temperature circulators designed for indoor laboratory use

by a professional user.

The LTC4 consists of a TX150 immersion thermostat combined with an R4 refrigeration

unit, with insulated hoses and clips to allow circulation of temperature control fluids to

external equipment.

2.0 How to use this operating manual

This operating manual will allow you to unpack, set-up and operate the R unit correctly

and safely. Important safety information, symbols and warnings are listed below and

should be read carefully. Section 4 gives information about how to unpack and install the

product correctly. Section 5 gives provides operating information for the LTC4. Product

technical specifications and tips are provided in sections 6 and 7. The warranty for this

product is for THREE YEARS and is detailed in section 8 and should be registered by

completing the on-line registration form at www.grantinstruments.com.

If there is a technical matter that this operating manual does not address, or any other

question concerning this product, please contact Grant Instruments or your local

distributor, who will be able to provide any additional information.

3.0 Safety information

3.1 Safety compliance

The LTC4 meets the requirements of international safety standard IEC 61010: Safety

requirements for electrical equipment for measurement, control, and laboratory use.

3.2 Safety symbols

The symbols below are marked on the equipment and throughout this manual to indicate:

LTC4 31115 V1

Operating Manual Page 4

www.grantinstruments.com

Page 6

3.3 Safety warnings

Read the whole of these instructions. Safety may be impaired if they are not

followed.

Only use liquids specified in these operating instructions, within the specified

temperature range. If the alarm lamp is illuminated the liquid temperature may

be above its recommended maximum. Do not inhale the vapours given off as

they may be toxic. Liquids should be safely discarded and replaced.

Do not use the R series unit with flammable heat transfer liquids.

Do not use the R series unit to heat any sample material that could cause a fire

or any other kind of hazard.

Do not use the equipment in an area where there are aggressive or explosive

chemical mixtures.

If a potentially hazardous liquid is spilt onto or inside the equipment, disconnect

it from the power supply and have it checked by a competent person.

Before moving, disconnect from the mains power supply

It is the user’s responsibility to carry out appropriate decontamination if

hazardous material is spilt on the equipment.

If the alarm lamp is illuminated do not touch the liquid or the tank base, they

may be very hot. Refill carefully, a hot heater can cause a spattering of very hot

water droplets and scalding steam.

Do not touch surfaces which become hot during high temperature operation.

31115 V1 LTC4

Page 5 Operating Manual

www.grantinstruments.com

Page 7

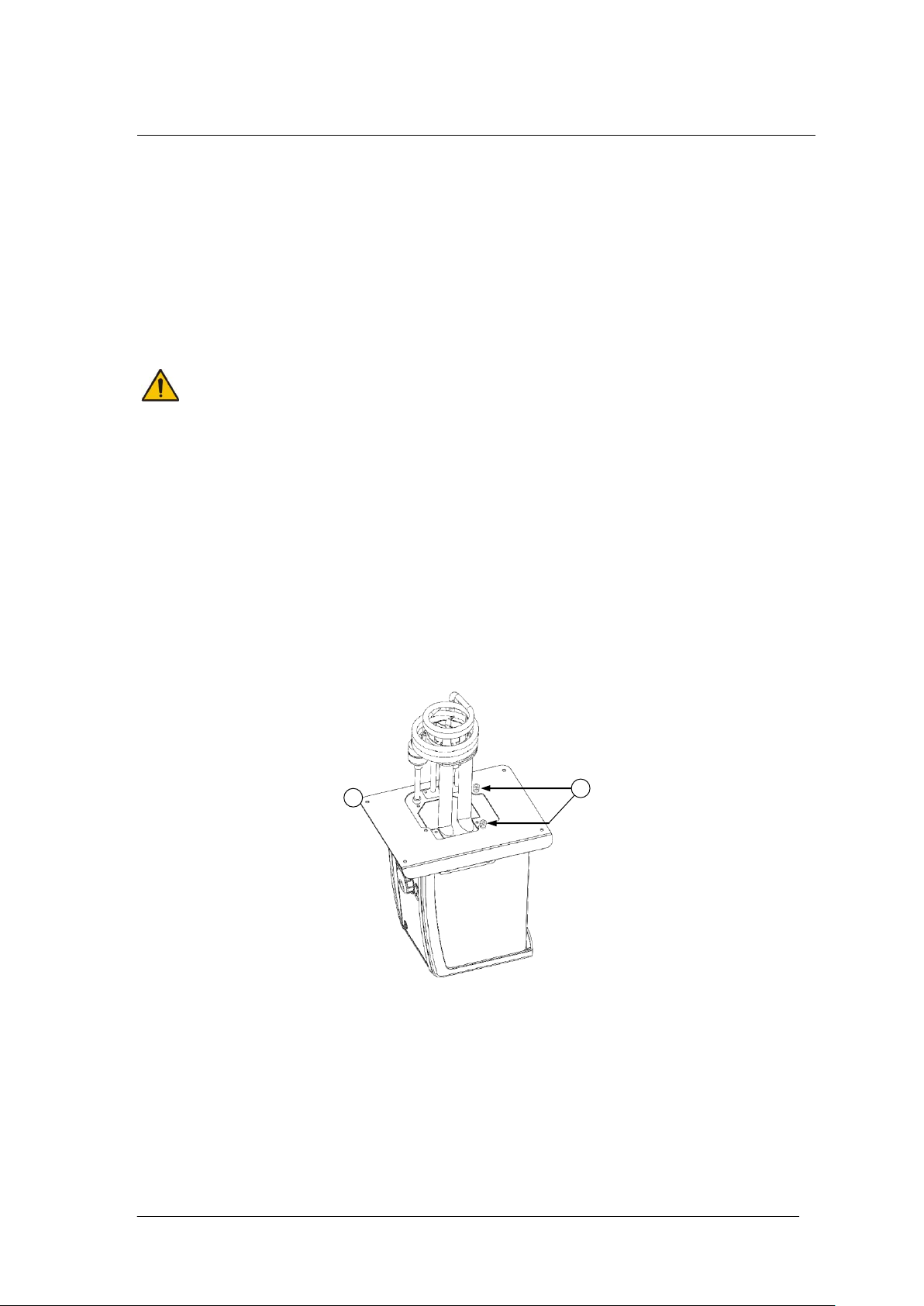

4.0 Operating instructions

The LTC weighs 39.5kg . Take necessary precautions when moving and lifting.

2

1

4.1 Unpacking instructions

Standard equipment includes:

LTC4 low temperature circulator

Pump connector kit

4 x Jubilee clips

6m of insulated hose

Mains cord

Operating manual

Remove packing materials carefully and retain them for future shipment or storage of the

equipment.

4.2 Fitting the controller to the Refrigeration unit

The TX150 unit can be fitted in two orientations on the LTC4 unit facing over the tank

opening or outwards

1. Remove the bridge plate from the LTC4 unit tank by unscrewing the four black thumb

screws.

2. Fit the Optima unit through the hole in the bridge plate and align using the locating

threads. Secure using the retaining nuts. Hand tighten only.

3. Re-attach the bridge plate onto the R unit, using the retained black thumb screws.

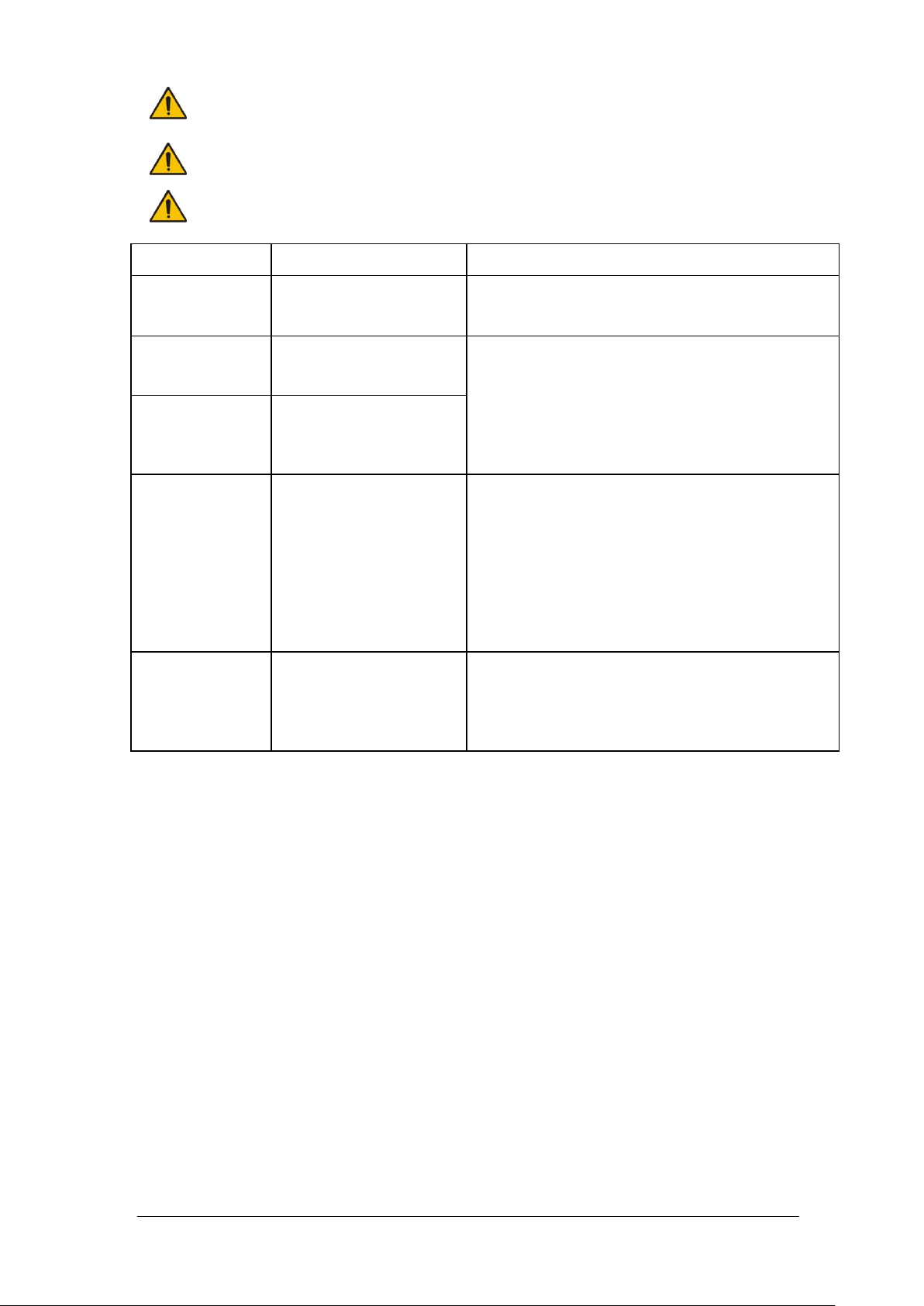

4.3 Recommended liquids

The following table lists the recommended liquids for different temperature ranges.

Always ensure the liquid used is safe and suitable for your working temperature. If using

non-recommended heat transfer liquids, it is the responsibility of the user to conduct an

assessment to ensure the intended fluid is compatible with the LTC4. If in doubt please

contact the Grant technical support team.

LTC4 31115 V1

Operating Manual Page 6

www.grantinstruments.com

Page 8

To ensure protection the overtemperature cut-out must be set appropriately for

the heat transfer liquid selected (see table below).

If using non-recommended heat transfer liquids it is important to set the overtemperature cut-out to a value no higher than 25°C below the fire point of the

liquid.

Use fume extraction when using silicone fluids at elevated temperatures

Temp range

Recommended liquid

Comments

-50°C to 50°C

Silicone oil – low

viscosity

Bayer silicone M3. Follow the manufacturer’s

instructions. For safe disposal consult your

local regulations.

-30°C to 30°C

50% water, 50%

antifreeze (inhibited

ethylene glycol)

WARNING: Ethylene glycol is toxic – follow the

manufacturer’s instructions.

For safe disposal consult your local

regulations.

Use a lid to reduce the dilution of the mixture

caused by condensing water vapour from the

air, and to maintain the cool down rate.

0°C to 30°C

80% water, 20%

antifreeze (inhibited

ethylene glycol)

5°C to 99.9°C

Water*

Water can be used but care should be taken

above 60°C as hot vapour can be dangerous.

Use a lid or polypropylene spheres above

60°C to ensure good performance & reduce

evaporation.

At temperatures approaching 99°C the

temperature performance will be affected due

to localised boiling.

The units should not be used to boil water.

70°C to 120°C

Silicone fluid

Viscosity ~20cs

Flash point ≥230°C

Fire Point ≥280°C

Dow Corning DC200/20 silicone fluid is a

suitable liquid – follow the manufacturer’s

instructions.

For safe disposal consult your local

regulations.

* See section 7.1 for further details

31115 V1 LTC4

Page 7 Operating Manual

www.grantinstruments.com

Page 9

4.4 Installation

Place the unit a level, non-combustible surface. Ensure that the mains plug and

the switch at the rear of the unit are easily accessible.

If the equipment has been transported or stored in cold or humid conditions,

condensation may form inside it. If that could have happened, allow time (at

least 2 hours at room temperature) for the condensation to evaporate before

using the equipment.

Do not block or restrict ventilation slots.

Do not connect to a power supply or switch on before filling the tank.

Drain before moving the unit. Before draining allow the liquid to cool below

50˚C.

Do not touch the condenser fins, they are sharp and may cause injury.

Connect the LTC4 to a grounded (earthed) electrical power supply with voltage

and frequency within the range specified on the serial number plate.

The LTC4 must only be connected to the mains using the mains cord supplied

or one with an identical rating (see section 9.4)

Ensure the mains switch and isolating device (power supply connector) are

easily accessible during use.

After transportation, let the unit stand in its intended working position for six hours. This

is to allow the oil to drain to the bottom of the compressor. This is normal procedure for

refrigeration compressors. Allow at least 100mm clearance from obstructions on all

sides so that there is free air flow through the unit, from the front to the back (this also

has the advantage that air is not blowing directly out of the sides onto instruments next to

the LTC4).

4.5 Electrical supply

LTC4 31115 V1

Operating Manual Page 8

www.grantinstruments.com

Page 10

5.0 Operating procedures

Take care when lifting and removing the lid as it may be hot. Steam and hot

vapours can cause scalding.

5.1 Operation

5.1.1 Liquid level

Fill the tank to an appropriate level with a liquid suitable for your working temperature;

see section 4.3 for liquid options. Allow for thermal expansion and contraction of the

liquid during operation and for any liquid in external circulation paths. If using liquids that

can evaporate then periodic checking and refilling should be completed. The low level

float switch will alarm if the liquid level drops below the minimum required level and the

unit will switch off the heater and stop temperature control.

5.1.2 Operation above 60°C

A lid or polypropylene spheres must be used above 60°C to maintain temperature control

and to ensure that the bath fluid temperature reaches the set point. They will save

energy by preventing excessive evaporation and reduce the frequency that the bath

needs to be refilled.

5.1.3 Setting the over-temperature thermostat

An over-temperature cut-out dial with a temperature scale is located at the top right of the

unit. The over-temperature probe independently monitors the bath temperature and

switches the heater off if it goes above the cut-out threshold.

Coarse setting of the over-temperature thermostat

Rotate the temperature cut-out dial in line with the marked scale to the desired setting.

This should be higher than the set temperature to avoid operating the cut-out before the

set temperature has been reached.

If the alarm is triggered the sounder can be silenced by pressing either the F or S button

once. To continue to use the TX150/TXF200, let the bath liquid cool by at least 5°C,

either naturally or by replacing the liquid, switch the unit off, wait 10 seconds and switch it

on again to clear the alarm. To avoid nuisance tripping the trip point needs to be set at

least 5°C above the desired control temperature.

Alternative setting of the over-temperature thermostat

Rotate the temperature cut-out dial to maximum (or at least a value above the level

required) and configure the set temperature to the cut-out level required. Leave the bath

to reach the set temperature and stabilise for at least 5 minutes. Turn the cut-out dial

slowly anticlockwise until an over-temperature fault is displayed on screen and the alarm

sounds continuously. This gives an over-temperature trip point at the set temperature.

The audible alarm can be cancelled by pressing either the F or S button once.

To continue to use the TX150/TXF200, let the bath liquid cool by at least 5°C, either

naturally or by replacing the liquid, switch the unit off, wait 10 seconds and switch it on

again to clear the alarm. To avoid nuisance tripping the trip point needs to be set at least

5°C above the desired control temperature.

31115 V1 LTC4

Page 9 Operating Manual

www.grantinstruments.com

Page 11

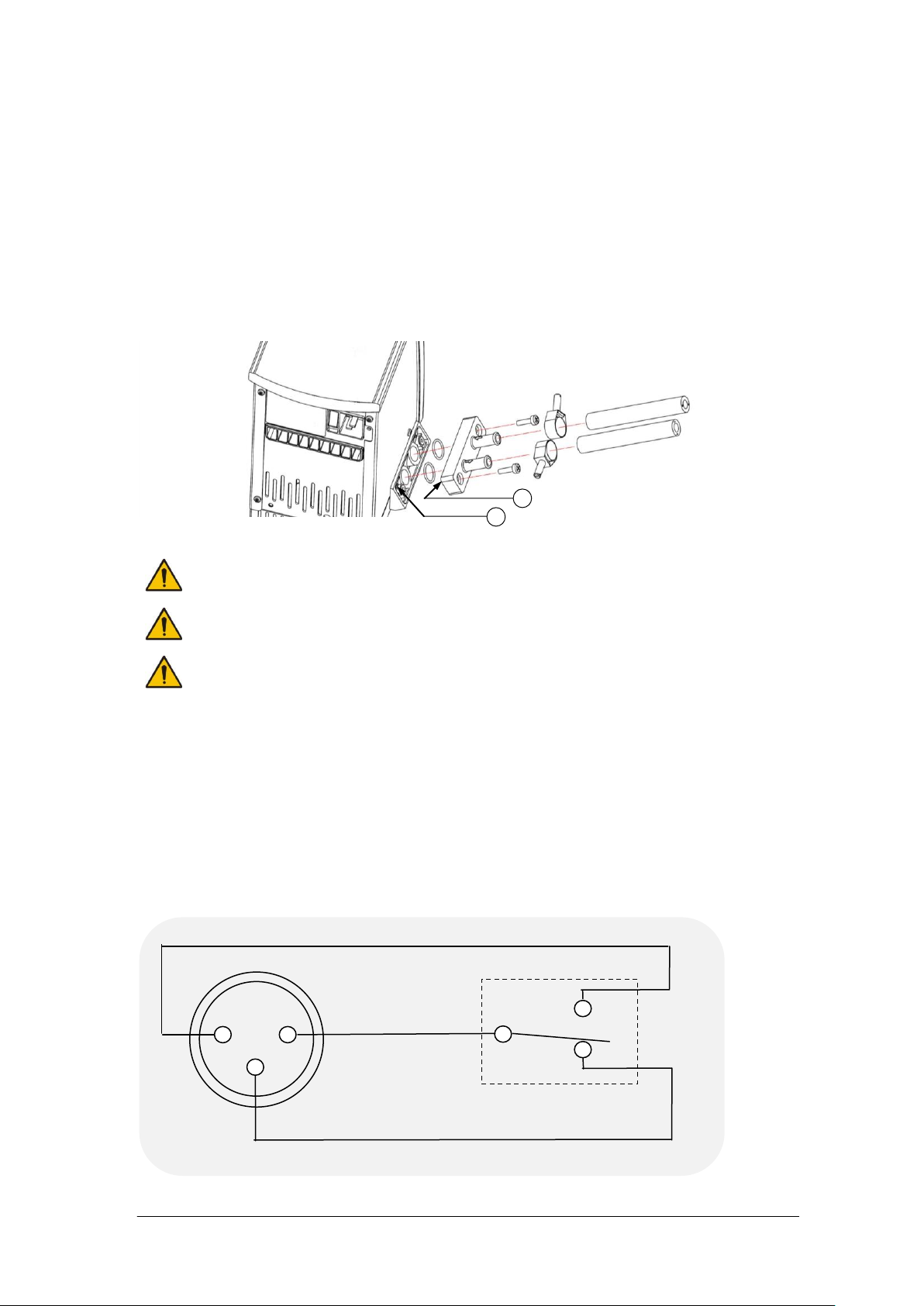

5.1.4 Using the control unit pump

Always use pump connectors and hoses that are suitable for the operating

temperature and liquid used. Check the pipe connections are secure.

Never disconnect any pipes or hoses while they contain very hot or very cold

liquids or while the LTC4 unit is pumping.

Never use silicone oil with silicone tubing.

3 2 1

Normally Closed

Normally Open

Common

Rear

Panel

connector

Relay

B

A

The LTC4 allows liquid to be pumped around a closed external system (not open to the

atmosphere). It cannot be used for circulation through an external open tank. The pump

is fitted with a blanking plate as standard. Fit a pump connector plate as shown below.

Ensure o-rings are located in the grooves, use silicone grease to hold the o-rings in

place. Note: the blanking/connector plates have a locating hole (see A below) to assist

correct alignment onto the pump moulding. It is important to verify the hole is aligned with

the corresponding locating pin (see B below) on the pump moulding. Failure to do so will

result in a leaking connection. Retain the blanking plate for refitting when the pump is no

longer required.

Pumping heat transfer liquid around an external system can lead to hazards that are

outside the control of Grant Instruments. It is essential that the user conducts a risk

assessment of the entire equipment installation to ensure that correctly rated materials

have been used throughout and that the system can be used safely.

5.1.5 Using the switch over relay ouput

An internal relay provides switch over contacts that can be used to control external

equipment. The pin connections on the rear panel 3 pin circular connector are:

LTC4 31115 V1

Operating Manual Page 10

www.grantinstruments.com

Page 12

For the connecting cable use a mating XLR style connector such as the NC3FXX

The relay is rated 24Vac or dc at 2A; to prevent injury or equipment damage,

do not connect to greater voltages or attempt to switch greater currents.

Voltages as low as 22Vac can be hazardous in locations where wetting of the

skin can occur. When making up cable to connect your equipment to the relay

connector, on the TX150/TXF200, make sure that the insulation system used is

adequate to provide protection against the voltages output by your equipment

for switching by the relay.

Always use the correct size cable with correct class of insulation for the voltage

being switched. If in doubt contact the technical support team at Grant.

Allow the liquid temperature to fall below 50˚C before emptying.

Ensure all hoses are connected securely. Liquid will begin pumping

immediately once LTC4 is switched on.

manufactured by Neutrik AG

The switch over contacts are rated at 24V AC or DC 2A maximum.

5.1.6 Emptying the LTC4

The R unit tank should be emptied to a safe level prior to moving. A drain tap is included

on R2, R3, R4 & R5 units to allow convenient emptying. See section 5.2.3 for full details.

5.1.7 Setting up and switching on

Follow instructions in section 5.1.3 to attach the pump connector plate and insulated

hose. Before filling and switching on, attach the open end of the hose to the application,

taking care to note the inlet and outlet.

Add the appropriate working liquid to the bath to at least the minimum recommended fill

level such that the float level switch is fully raised.

The control unit is connected directly to the mains supply with the IEC cable supplied

with the unit (230V units only).

Connect the refridgeration unit directly to the mains using the IEC cable provided).

Switch on the LTC4 control unit using the power switch on the rear. The motor will start

immediately and the buzzer will sound while the unit starts up. Switch on the

refrigeration unit using the power switch on the front of the unit. The LTC4 will start to

control at the set temperature

31115 V1 LTC4

Page 11 Operating Manual

www.grantinstruments.com

Page 13

5.2 Using the LTC4

Over-temperature dial

Full colour display

Select button

Main dial

Float switch

Heater coils

Pump outlet plate

Function button

5.2.1 Product description, control unit

5.2.2 Product description, user interface and controls

The TX150 features a full colour graphic display, a main dial and two buttons F and S.

All functions (setting temperature, pump speed, countdown timer, presets, programs

settings and standby mode) can be configured from the home screen. Navigation around

the home screen is achieved by rotating the main dial which moves a white curser to

highlight function icons. Pressing the S button whilst the icon is highlighted will change

the colour of the curser to red, make the icon active and allow changes to be made, or in

the case of the settings icon, further menus to be displayed.

The primary function of the F button is to exit functions and menus. If F is pressed when

in the home screen whilst the cursor is white the settings menu is displayed

LTC4 31115 V1

Operating Manual Page 12

www.grantinstruments.com

Page 14

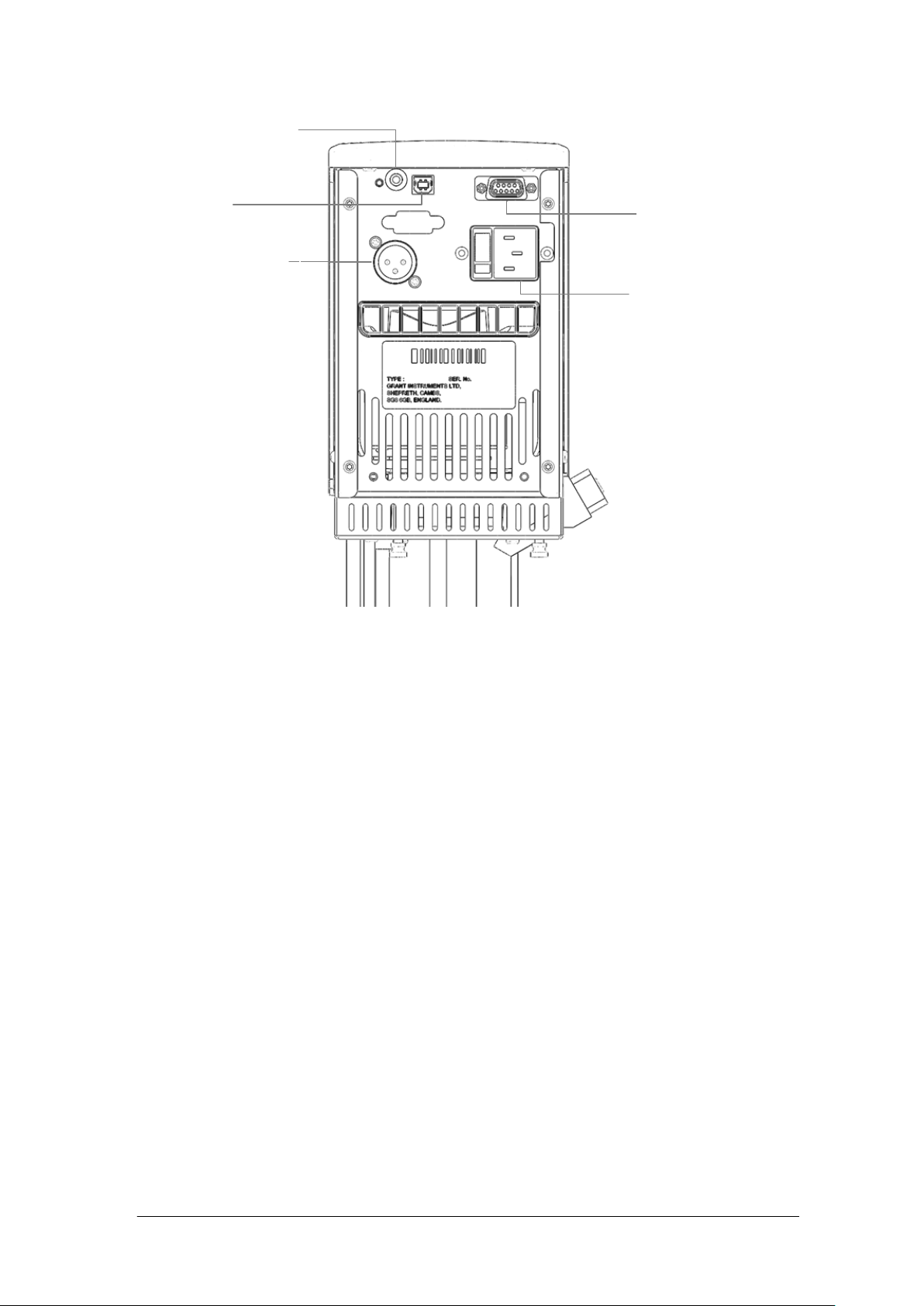

5.2.3 Product desciption, rear panel connections

RS232 communcations

port

Mains power input

USB port

Switched relay port

External probe input

5.2.4 Communications ports

The TX150 and TXF200 provide a RS232 and a USB data port for communication with a

PC running Grant Labwise™ software. Labwise™ provides the abilty to remotely

configure, control, monitor programs as well as log program temperature data.

Only use a RS232 cable supplied by Grant instruments.

The USB cable is a Type A to Type B style

5.2.5 Switched relay port

An internal relay provides switch over contacts that can be used to control external

equipment. See Section 5.1.5 for details of the relay contacts and connector type.

5.2.6 External probe input

For connecting an external PT1000 thermocouple temperature probe available from

Grant instruments

31115 V1 LTC4

Page 13 Operating Manual

www.grantinstruments.com

Page 15

5.2.7 Product description, refrigeration unit front panel (grille removed)

Power switch

Over temperature protection reset

Freezing protection, 5˚C switch

Drain port

Drain insert

Condenser fins

The over temperature protection reset: protects the unit from overheating by the over

temperature cut-out. This will be actuated when the working fluid is raised above

between 110°C and 120°C. The unit can be reset by waiting for the liquid to cool below

100°C, then unscrewing the black cap and pushing in the revealed button.

The freezing protection switch uses a low temperature thermostat to ensure the working

fluid never drops below 5°C. With the switch in the depressed/in position the cooling will

be switched off by a low temperature protecting thermostat. If water is used in the bath

this will prevent it from freezing. In the out/off position the thermostat is bypassed

allowing the unit to run at temperatures below 5°C.

The drain port and insert allow convenient emptying of the refrigeration bath. To drain

the unit first remove the drain insert from the holder and connect a suitable length of

hosing with a bore of 12.7mm (½’') to the drain insert. Have the non connected end of

tubing in a receptacle, suitable for the liquid to be drained. Push the drain insert into the

drain port and let the liquid drain. To release the drain insert push down the grey button

on the drain body and extract the drain insert. Liquid to be drained should not be below

10°C or above 50°C.

LTC4 31115 V1

Operating Manual Page 14

www.grantinstruments.com

Page 16

5.2.8 Product description, refrigeration, rear panels

1. Rotate the dial until the set temperature icon is

highlighted, press the S button.

2. Rotate the dial to set the desired temperature.

If no key is pressed for 10 seconds or if F is

pressed, the set temperature icon is no longer

active and will remain at its original value.

3. Press S to store the requested value.

If the temperature selected is higher than the

:

.

°c

.

°c

:

.

°c

Settings

Standby

Actual temperature

External probe

Program

Preset

Countdown timer

Communication

Relay

Heater on

indicator (high

power)

Set temperature

Pump speed

(TXF200 only)

.

°c

Communications lead

fuse & socket

Power supply for

accessory pumps

Mains inlet

220-240V unit

Communications lead

fuse & socket

Power supply for

accessory pumps

Mains inlet

110-120V unit

Main fuses

5.2.9 Display. Explanation of home screen icons.

5.2.10 Setting the control temperature

31115 V1 LTC4

Page 15 Operating Manual

www.grantinstruments.com

Page 17

current liquid temperature the heater will switch

on and the heater icon will be displayed.

5.2.11 Running a bath preset

1. Rotate the dial until the preset icon is

highlighted, press the S button.

2. Rotate the dial to select the desired preset 1, 2

or 3, press S to run the preset.

The preset will automatically start as soon as S

is pressed.

If no key is pressed for 10 seconds or if F is

pressed the preset icon is no longer active and

will remain at its original value.

1. Rotate the dial until the countdown timer icon is

highlighted, press the S button.

The countdown timer will display the last

countdown time set.

If no key is pressed for 10 seconds or if F is

pressed the countdown timer setting is no longer

active and will remain at its original value.

2. Rotate the dial to set the desired countdown

time, press S to store.

The countdown timer will begin counting down

from the set time. At the end of the countdown

timer period a buzzer will sound. This can be

cancelled by pressing F or S.

:

.

°c

.

°c

:

.

°c

.

°c

Each TX150/TXF200 contains three presets which can be configured to different set

temperatures and in the case of the TXF200 the pump speed can additionally be

configured. This allows the bath to be conveniently run at frequently used temperatures

and pump speeds. See section 5.3.1 for information on preset configuration.

Preset temperatures and set temperatures are limited to the model type and the liquid

selection. The TX150 settable range is between -50°C and 150°C increasing to between

-50°C and 200°C for the TXF200

5.2.12 Running a countdown timer

The countdown timer on the TX150/TXF200 can be set in the range of 1 minute to 99

hours. The countdown timer will sound a buzzer at the end of a countdown period. See

section 5.3.2 for information on configuring countdown timer expiry actions.

To cancel an active countdown timer:

1. Rotate the dial until the countdown timer icon is highlighted, press the S button.

2. Press the F button to cancel the countdown timer.

The countdown timer is stopped.

LTC4 31115 V1

Operating Manual Page 16

www.grantinstruments.com

Page 18

5.2.13 Running a program

1. Rotate the dial until the program icon is

highlighted, press the S button.

If no key is pressed for 10 seconds or if F is

pressed, the program icon is no longer active and

will remain at its original value.

2. Rotate the dial until program 1 is displayed. By

default the TX150 will display program “–“

indicating that no program is selected. Press S to

select the program.

The selected program will start. The display will

show the target temperature of the first segment

and the countdown timer will indicate the duration

of the program remaining. Whilst a program is

running only the Standby icon can be selected.

At the end of a program the buzzer will sound, this

can be cancelled by pressing F or S.

:

.

°c

.

°c

The TX150 has the capability to run automatic temperature profiles called programs.

The TX150 has the capacity to store 1 program containing 30 individual temperature/time

segments.The TXF150 can only be configured and edited using Grant Labwise™

software When a program is running icon access is limited to the standby and program

functions

To stop a program

1. Rotate the dial until the program icon is highlighted, press the S button.

If no key is pressed for 10 seconds or if F is pressed, the program icon is no longer

active and will remain at its original value and the program will continue to run.

2. Rotate the dial until the “–“ is displayed, press S to select

The program will stop. The display will remain at the set temperature reached when

the program was stopped, the countdown timer will stop at the remaining time and

the pump speed will display the last speed set.

5.2.14 Activating standby mode

In standby mode the TX150 is still powered, however key functions (heating, pump,

countdown timer and programs) are switched off. In standby mode access is limited to

the settings menu, enabling the functions such as alarms and programs to be configured

while the unit is not operating.

Note. When entering standby mode the pump will remain on for 5 minutes to allow

internal cooling to continue.

If a countdown timer has been set or a program is running before activating standby

mode they will be terminated.

31115 V1 LTC4

Page 17 Operating Manual

www.grantinstruments.com

Page 19

1. Rotate the dial until the standby icon is

highlighted, press the S button.

The temperature and countdown timer values

are no longer displayed.

2. To resume operation, rotate the dial until the

standby icon is highlighted, press the S button.

The display returns to the home screen and the

TX150 resumes operation at the last

temperature and pump speed set.

1. Rotate the dial until the settings icon is

highlighted, press the S button.

The settings menu is displayed, with presets

highlighted at the top of the list.

Shortcut to settings menu. Pressing F whilst in

the home screen when the cursor is white will

automatically display the settings menu

2. Rotate the dial to scroll up and down the list, until

the desired setting is highlighted, press the S

button to select. The desired settings menu is

displayed.

Pressing F returns to the home screen without

making changes.

.

°c

Presets

Settings

Liquid

Probe

Alarms

:

.

°c

.

°c

:

.

°c

.

°c

:

.

°c

.

°c

5.2.15 Accessing the settings menu

The settings menu provides access to the following settings screens:

preset selection and definition, program selection and definition, liquid type, probe

(internal or external), alarms, buzzer level and language. Section 5.3 provides detailed

information on viewing, editing and saving settings.

LTC4 31115 V1

Operating Manual Page 18

www.grantinstruments.com

Page 20

5.3 Viewing, editing and saving settings

1. Rotate the dial until the settings icon is highlighted,

press the S button.

Pressing F returns to the home screen without

making changes.

2. Rotate the dial to scroll up and down the list, until

preset is highlighted, press the S to select.

Pressing F returns to the settings screen without

making changes.

3. Rotate the dial to display preset icon 1, 2 or 3,

press S to select.

4. Temperature is highlighted, press the S button.

Rotate the dial to define the temperature. Press S

to set.

Pressing F restores the original preset temperature

with temperature highlighted.

Pressing F restores the original preset pump speed

with pump speed highlighted.

To save the temperature and pump speed

configuration, rotate the dial to highlight save and

press S

The display returns to the settings menu screen.

Repeat procedure to configure presets 2 and 3

5. Press F to return to the home screen.

.

°c

Temperature

Preset

Save

°c

.

.

°c

Presets

Settings

Liquid

Probe

Alarms

.

°c

Presets

Settings

Liquid

Probe

Alarms

:

.

°c

.

°c

5.3.1 Configuring a preset

31115 V1 LTC4

Page 19 Operating Manual

www.grantinstruments.com

Page 21

5.3.2 Selecting a liquid type

Liquid

Set temperature range

Water

0°C to 100°C

Water-Glycol

*-30°C to 50°C

Low Temp Oil

-50°C to 50°C

High Temp Oil

†

70°C to 150°C (TXF150)

¥

70°C to 200°C (TXF200)

1. Rotate the dial until the settings icon is

highlighted, press the S button.

2. Rotate the dial to scroll up and down the list until

liquid is highlighted, press S to select.

Liquid options are displayed.

3. Rotate the dial to scroll through the liquid options,

press S to save the selection.

The display returns to the settings screen.

4. Press F to return to the home screen.

.

°c

Presets

Settings

Liquid

Probe

Alarms

Water

.

°c

Presets

Settings

Liquid

Probe

Alarms

:

.

°c

.

°c

The liquid type determines the limits of the set temperature range.

Selection of the liquid types below changes the settable temperature range as follows:

* Water-Glycol (50% water, 50% antifreeze (inhibited ethylene glycol)

†

High Temp Oil (silicone fluid with the following characteristics: viscosity 20 centistokes,

flash point ≥230°C, fire point ≥280°C).

¥

High Temp Oil (silicone fluid with the following characteristics: viscosity 50 centistokes,

flash point ≥285°C, fire point ≥340°C). See section 4.3 for full description of

recommended bath liquids.

LTC4 31115 V1

Operating Manual Page 20

www.grantinstruments.com

Page 22

5.3.3 Selecting a temperature probe type

1. Rotate the dial until the settings icon is

highlighted, press the S button.

2. Rotate the dial to scroll up and down the list until

probe is highlighted, press S to select.

Probe options are displayed

3. Rotate the dial to scroll through the probe types

(external or internal), press S to save the

selection

The display returns to the settings screen.

The external probe icon will be displayed on the

home screen

4. Press F to return to the home screen.

.

°c

Probe

Settings

Alarms

Buzzer

Language

Internal

.

°c

Probe

Settings

Alarms

Buzzer

Language

:

.

°c

.

°c

The bath temperature can be controlled using an internal or external temperature probe.

31115 V1 LTC4

Page 21 Operating Manual

www.grantinstruments.com

Page 23

5.3.4 Configuring high and low temperature alarms

Liquid temp

Time

5

10

15

Temp

Alarm

Value -20˚C

Set temp -10˚C

Low temperature fixed alarm.

Liquid temp

Set

temperature

Deviation

5°C

Temp

Time

5

10

15

High temperature deviation alarm.

Alarm value

There are three functions in the alarm menu.

1. A high alarm function, which causes an alarm condition when the bath

temperature goes higher than the alarm value. The alarm value can be set as a

fixed temperature above the set temperature or a deviation offset value above the

set temperature. Below is an example of a high temperature deviation alarm,

where the deviation value has been set to 5˚C.

2. A low alarm function, when the bath temperature goes lower than the alarm

value. The alarm value can be set as a fixed temperature below the set

temperature or a deviation offset value below the set temperature. Below is an

example of a low temperature fixed alarm, where the fixed temperature value has

been set to -20˚C.

3. A hold-off time can be entered, which is a user adjustable time of between 0 and

LTC4 31115 V1

Operating Manual Page 22

21mins for which the alarms remain muted after either button has been pressed

to acknowledge an alarm condition. If the bath returns to the value such that the

alarm level is not exceeded the alarm will cancel. However, if the temperature

remains outside the alarm level the alarm condition will re-occur after this hold-off

time.

www.grantinstruments.com

Page 24

1. Rotate the dial until the settings icon is highlighted,

press the S button.

2. Rotate the dial to scroll up and down the list until

alarms are highlighted, press S to select.

3. High alarm mode is highlighted, press S to

select.

4. Rotate the dial to select fixed temp, deviation or

disabled. Press S to select.

The high alarm screen is displayed

.

°c

High Alarm mode

Alarm Settings

Low Alarm mode

Save

Fixed Temp

Disabled

Holdoff mm:ss

.

°c

Probe

Settings

Alarms

Buzzer

Language

:

.

°c

.

°c

Liquid temp

Set point

temp

Temp

Time

5

10

15

Hold off time.

Alarm value

0

Hold off period 8 mins

Alarm acknowledged

2

Each alarm can be programmed to latch, activate an audible buzzer and a relay. Alarms

are cancelled by pressing the F or S button or if an alarm condition has been removed.

31115 V1 LTC4

Page 23 Operating Manual

www.grantinstruments.com

Page 25

5. Temperature is highlighted, press S to select.

6. Rotate the dial to define the temperature value,

press S to set.

7. Rotate the dial to highlight latching, press S to

select.

8. Rotating the dial will display on/off, press S to

select.

When latching is on, a temperature alarm

continues unless acknowledged by the user even

if the temperature comes back in range

9. Rotate the dial to highlight relay, press S to select.

10. Rotating the dial will display on/off, press S to

select.

11. Rotate the dial to select buzzer, press S to select.

12. Rotating the dial will display on/off, press S to

select.

13. Rotate the dial to save, press S. The display

returns to the alarm settings screen. The

procedure can be repeated to configure a

deviation alarm and for the low alarm function.

14. Rotate the dial to highlight holdoff, press S to

select.

15. Rotate the dial to select a holdoff time (over a

range of 5 to 600 seconds), press S to select.

Rotate the dial to save, press S to save all

settings.

The display will return to the settings menu

16. Press F to return to the home screen

.

°c

High Alarm mode

Alarm Settings

Low Alarm mode

Save

Fixed Temp

Disabled

Holdoff (s)

.

°c

Temperature

Latching

High Alarm

Off

°c

.

On

Relay

Buzzer

On

Save

LTC4 31115 V1

Operating Manual Page 24

www.grantinstruments.com

Page 26

5.3.5 Setting the buzzer volume level

1. Rotate the dial until the settings icon is

highlighted, press the S button.

2. Rotate the dial to scroll up and down the list until

buzzer is highlighted, press S to select.

Volume options are displayed.

3. Rotate the dial to scroll through the volume levels

(low, medium and high and off), press S to save

the selection.

The display returns to the settings screen.

4. Press F to return to the home screen.

1. Rotate the dial until the settings icon is

highlighted, press the S button.

:

.

°c

.

°c

.

°c

Probe

Settings

Alarms

Buzzer

Language

Low

.

°c

Probe

Settings

Alarms

Buzzer

Language

:

.

°c

.

°c

Three buzzer volume levels are available, low, medium and high and off.

5.3.6 Selecting a language

Five language options are available, English, French, German, Italian and Spanish.

31115 V1 LTC4

Page 25 Operating Manual

www.grantinstruments.com

Page 27

2. Rotate the dial to scroll up and down the list until

language is highlighted, press S to select.

Language options are displayed.

3. Rotate the dial to scroll through the language

options (English, French, German, Italian and

Spanish) press S to save the selection.

The display returns to the settings screen.

4. Press F to return to the home screen.

1. Rotate the dial until the settings icon is

highlighted, press the S button.

2. Rotate the dial to scroll up and down the list until

relay is highlighted, press S to select.

Relay options are displayed

.

°c

Alarms

Settings

Buzzer

Language

Relay

:

.

°c

.

°c

.

°c

Probe

Settings

Alarms

Buzzer

Language

English

.

°c

Probe

Settings

Alarms

Buzzer

Language

5.3.7 Relay test and configuration

The TX150 and TXF200 can be configured to switch a relay in the program function.

This function can be tested manually outside the program function by following the

instructions below.

LTC4 31115 V1

Operating Manual Page 26

www.grantinstruments.com

Page 28

3. Rotate the dial to toggle between on/off, press S

to save the selection.

The display returns to the settings screen.

4. Press F to return to the home screen.

User recorded

Temperature

Measured

Temperature

t3

t4

t2

t1

T4

T3

T2

T1

.

°c

Alarms

Settings

Buzzer

Language

Relay

On

5.4 Completing a calibration

The TX150 allows up to five temperature points to be calibrated. The calibration menu

can be accessed by simultaneously pressing the F and S buttons for 3 seconds

The calibration temperatures are constrained by the temperature limits of the liquid type

setting. Calibration should be carried out using a traceable reference thermometer with

an accuracy of at least 0.1°C. This thermometer should be held securely in the centre of

the bath or vessel.

Two factory defined calibration points (20˚C and 70˚C) already exist and are displayed in

the calibrate probe menu, these may be recalibrated if required and up to a further three

calibration points added. Calibration points should be chosen to be at critical

experimental temperatures where accuracy is important or at the extremes of the working

range of used temperatures.

The TX150 calculates the temperature at any point using calculated values that pass

through each calibration point. This ensures precision at all critical experimental

temperatures throughout the range in use. In the example below, 4 calibration points

have been used.

31115 V1 LTC4

Page 27 Operating Manual

www.grantinstruments.com

Page 29

Calibration points must be a minimum of 5˚C apart and there must be at least 20˚C

1. Press the F and S buttons simultaneously for 3

seconds.

The calibrate probe menu displays the factory

defined calibration points and the current

temperature of the bath in the top right corner of

the screen.

2. Rotate the dial to highlight add point, press S to

select.

The calibrate point menu is displayed. If an

external probe has been selected the external

probe icon will be displayed in the top left corner.

Otherwise the settings icon will be displayed when

calibrating the internal probe.

3. Rotate the dial to highlight measured

temperature. Press S to select

4. Rotate the dial until the temperature being shown

on the calibrated thermometer is displayed on

screen. Press S to save the value.

5. Rotate the dial to highlight save, press S to select.

The display returns to the calibrate probe screen.

6. Press F to return to the home screen

Further calibration points can be added by

repeating steps 2 to 5.

Calibration points can be deleted by selecting

delete in the calibrate point screen.

.

°c

Measured Temperature

Calibrate Point

°c

.

Save

Delete

.

°c

Point 19.86 c

Calibrate Probe

Point 70.04 c

Add Point

Restore Factory

between the highest and lowest points. Any points added that do not match these criteria

will not be accepted by the unit.

Once set, calibration points can be changed or deleted but a minimum of 2 points must

remain.

Prior to calibration, ensure the probe type to be calibrated is selected, (internal or

external); the bath is set to the desired temperature and has been stable at the

temperature for at least 5 minutes.

LTC4 31115 V1

Operating Manual Page 28

www.grantinstruments.com

Page 30

5.4.1 Restoring factory calibration settings

1. Press the F and S buttons simultaneously for 3

seconds.

2. Rotate the dial to highlight restore factory, press

S to select.

Yes/No are displayed.

3. Rotate the dial to toggle to yes, press S to select.

Factory calibration values are restored.

4. Press F to return to the home screen

.

°c

Point 19.86 c

Calibrate Probe

Point 70.04 c

Add Point

Restore Factory

Yes

If the thermometer value is entered before the bath temperature is completely stable the

calibration could be poor and liquid temperature readings will be incorrect. If the

TX150/TXF200 is not in accordance with the thermometer following calibration then it

may not have been successful and the unit should be reset, using the restore factory

settings function.

31115 V1 LTC4

Page 29 Operating Manual

www.grantinstruments.com

Page 31

6.0 Technical specifications

Ambient temperature range

5 to 40°C

Altitude above sea level

Up to 2,000m (6,500ft)

Operating environment

Indoor use only

Maximum relative humidity

80% RH up to 31°C decreasing to 50% RH at 40°C

Specification

LTC4

LTC4L

Typical cooling power at an

ambient of 20°C

@ 20°C

900W

@ 0°C

500W

@ -10°C

300W

@ -20°C

180W

@ -30˚C

40W

Heater power

1.8kW

1.5kW

Stability (DIN 12876)

±0.1°C

Uniformity (DIN 12876)

±0.1°C

Settable temperature range

-50°C to 150°C

Working temperature range

-30°C to 100°

Refrigerant charge R134a

500gm

Tank capacity

20L

Top opening

230/305mm

Liquid depth min/max

80/140mm

Drain

Yes

Max pump head pressure

310mBar

Max pump flow rate

18l/min

Switchable refrigeration

Yes

Safety 100°C limit

Cut-out

Safety freezing protection

5°C thermostat & switch

Safety (high pressure)

27 Bar

Max current consumption

9A Tx150,

3.7A R unit

12.5A-TX150,

6.8 R unit

6.1 Operating conditions

6.2 Electrical details

Mains supply: 230V @ 50Hz or 120V @ 60Hz

Pollution degree: 2

Installation category: II

Mains supply voltage fluctuations are not to exceed ±10% of the nominal supply voltage.

6.3 Specification

LTC4 31115 V1

Operating Manual Page 30

www.grantinstruments.com

Page 32

7.0 Technical Tips

7.1 Which water should you use in your LTC4 tank?

For the long-term reliability of the equipment it is important to use oxygenated water that

is free from ions and minerals that can cause corrosion of stainless steel. We

recommend the use of distilled water and de-ionised water from modern ion exchange

systems that do not use salt back flushing to regenerate the ion-exchange cartridges.

Stainless steel is protected from corrosion by a layer of chromium oxide. If the layer is

damaged, oxygen present in water can reform the oxide layer. If the water is still or deoxygenated, and the oxide layer is damaged, ions can corrode the stainless steel tank. If

a water bath has been unused for some time, or water boiled, we recommend changing

to fresh distilled water or correct de-ionised water.

Water normally contains calcium or magnesium ions. De-ionised water has most ions

removed as indicated by its conductivity level; the purer the water the lower the

conductivity. It is important to use only de-ionised water from an ion exchange system

with replaceable cartridges. Do not use de-ionised water generated from an ionexchange system that incorporates a salt back-flush system to regenerate the ionexchange resin as this can leave sodium ions that are very corrosive to stainless steel.

7.2 How to prevent rust in LTC4 tanks

Most Grant tanks, as well as immersed parts, are made from type 304 stainless steel, an

extremely versatile general purpose grade of stainless steel. It is the excellent forming

characteristic that has made this grade dominant in the manufacture of laboratory and

industrial water baths, as well as domestic sinks and saucepans. Type 304 stainless

steel is highly suitable for applications where hygiene is important; it exhibits good heat

resistance and excellent resistance to corrosion.

However, despite resistance to general surface corrosion, stainless steel is susceptible to

specific types of corrosion, in particular pitting (small pin hole style corrosion) and stress

corrosion cracking. It can also undergo general corrosion in specific environments, such

as one containing hydrochloric or sulphuric acids.

Stainless steel is protected by its high content of alloying elements, primarily chromium

and nickel. Chromium is the most important with respect to corrosion resistance,

although the nickel assists in allowing the chromium to do its job. The chromium forms an

oxide layer on the surface of the steel, which inhibits further oxidation. This layer adheres

extremely well to the metal substrate, but it is essential that it remains intact, and must be

protected from various forms of damage.

If the surface chromium oxide layer becomes damaged, oxygen present in water can

partially reform the oxide layer, so it is advisable to ensure that water is always fresh and

well oxygenated. Baths that will be out of use for an extended period should be emptied,

and all moisture should be wiped from the bottom of the tank.

In some cases a brown layer may appear on the surface of a stainless steel tank. In most

of these cases this is not rust, but it may be a surface deposit of minerals from the local

water supply, or ferrous particles or salts that have fallen into the tank. These surface

deposits can usually be removed by using a household cleaner such as Duraglit or Silvo

metal polish.

31115 V1 LTC4

Page 31 Operating Manual

www.grantinstruments.com

Page 33

7.3 How to prevent algae and bacteria?

Water baths provide the ideal environment for the growth of micro-organisms. If left

uncontrolled the growth of these organisms can result in a range of serious problems and

health risks from pathogenic bacteria.

The growth of algae on the surface of parts will cause biofouling which can reduce

performance.

Micro-organisms that produce acidic metabolic by-products can cause bio-corrosion by

depolarisation of metal surfaces.

There are a number of biocides available on the market.

8.0 Warranty information

When used in laboratory conditions according to this manual, this product is guaranteed

for THREE YEARS against faulty materials or workmanship.

Extended warranty for years four and five can be purchased by contacting our sales

department at labsales@grantinstruments.com.

9.0 Maintenance and service

9.1 Routine maintenance

The over-temperature cut-out on the control unit should be checked periodically by

turning the over-temperature dial with a screwdriver anticlockwise until the alarm lamp

comes on. The control unit will also sound a buzzer and “Cut” will be shown on the

display. The over-temperature dial should then be turned to the maximum setting without

the alarm cancelling. The control unit should be powered off and back on to confirm that

the cut-out can be reset correctly. If the alarm lamp fails to light when the value indicated

on the over-temperature dial is more than 10°C below the current temperature as

indicated by the main display, then the unit should be checked by a competent person.

The float liquid level protection should also be checked periodically by lowering the level

of liquid in the bath and noting that the unit cuts out with the top turn of the heater still

immersed in the liquid.

When hoses are fitted to the pump they should be inspected periodically and replaced as

necessary to avoid hose failure.

No other routine maintenance is required.

9.2 Cleaning

Regular maintenance of the LTC4 unit is important to allow the unit to perform to its

specification and is required for warranty validity.

The removable grille of the refrigeration unit enables easy access to the condenser for

cleaning. Cooling power will be reduced if the fins become clogged with dust. The

condenser fins (see section 5.2.3) should be examined monthly and, if necessary, use a

vacuum cleaner nozzle and soft brush to remove the dust.

LTC4 31115 V1

Operating Manual Page 32

www.grantinstruments.com

Page 34

De-scaling products may be toxic and manufacturer’s instructions should

always be followed

R unit

Fuse rating

R4

5AT

R4L

10AT

Clean the outside of the equipment with a damp cloth, using water only. Do not use

chemical cleaning agents. Before using any other cleaning or decontamination method,

check with Grant Instruments or your local representative to make sure that the proposed

method will not damage the equipment. Scale on immersed parts can be removed using

chemical de-scaling products designed for use on equipment that has metal parts.

9.3 Fuses

The control unit fuses are internal and should not need to be replaced. Please contact

the Grant Instruments service department if the unit has a fuse fault.

The refrigeration unit has externally accessible fuses that can be changed by a qualified

technician. Disconnect the unit from the power supply socket. Remove the IEC power

plug from the rear of the unit. Press down the fuse drawer catch and pull out. Check

fuses and if necessary replace. Push the fuse drawer back in until fully engaged and

replace the IEC plug.

Replacement fuses must be 1.25” x 0.25” anti surge ceramic type with the rating defined

in the following table:

Fuse replacement should only be carried out by a competent person.

9.4 Replacing the mains cord

Any replacement mains cords used for the control unit or refrigeration unit must meet the

same specification as the one originally supplied to maintain the safety of the unit.

All 230V mains cables must have the following markings; <HAR>, HO5VV-F 3Gx1mm2

70°C for the R unit and <HAR>, HO5VV-F 3Gx1mm2 90°C for the TX150 and be rated to

carry 10A. The mains plug and IEC connector must carry approvals from a European

certification body (e.g. BSI, VDE or equivalent).

The LTC4L (120V) refrigeration units have fixed mains cords which should not be

replaced.

9.5 Routine safety tests

If routine tests are to be made, we recommend a test of the integrity of the protective

earth conductor and an insulation test at 500V DC. Routine flash tests are not

recommended for any electrical equipment, because repeated high voltage tests degrade

insulation materials.

31115 V1 LTC4

Page 33 Operating Manual

www.grantinstruments.com

Page 35

9.6 Service

Pump Product

Description

VTP1

Max head pressure: 1000mBar

Max flow rate: 9 L/min

VTP2

Max head pressure: 1700mBar

Max flow rate 12 L/min

17928

Pump lid for LTC4

If service is required, switch off the unit and contact Grant Instruments or your local

representative for repairs.

Please note, all returned units must be accompanied by a Return Materials Authorisation

(RMA) number, obtainable by contacting the Grant service department (details below).

Service Department

Grant Instruments (Cambridge) Ltd

Shepreth

Cambridgeshire

SG8 6GB

UK

Tel: +44 (0) 1763 260 811

Fax: +44 (0) 1763 262 410

E-mail: labservice@grantinstruments.com

10.0 Optional accessories

10.1 Alternative pump

A pump comes as standard on the TX150 unit. If greater head (pressure) is required

you can choose from two accessory pumps and the appropriate pump lid. Add L to

pump part numbers for 120V (60Hz) versions. See the Grant website at

www.grantinstruments.com for full technical specifications.

A full listing of product accessories and options is available in the Grant Scientific

Reference Catalogue (a copy of which is available upon request) and on the Grant

website at www.grantinstruments.com.

LTC4 31115 V1

Operating Manual Page 34

www.grantinstruments.com

Page 36

Symptom

Possible cause

Action required

Unit fails to cool

Compressor

overheated causing

internal overtemperature

thermostat to operate

Wait for compressor to cool, when thermostat

will reset and compressor will switch on again.

Unit failing to

cool below 5°C

Freezing protection

switch is on and is

preventing further

cooling

Switch off freezing protection (see section

5.2.7).

Unit not cooling

at higher

temperatures

Over temperature

protection switch has

tripped

Refrigeration unit may have temperatures in

excess of 100°C. Leave the unit to cool and

reset (see section 5.2.7)

Cooling

performance

reduced

Condenser fins

clogged

Carry out routine cleaning (see section 9.2)

Temp continues

to rise when not

expected

Set temp is higher

than liquid temp

Check that the bath set temperature is correct

(see section 5.2.10).

Set temperature

too restricted

Liquid type set does

not allow required set

point

Change to different liquid type (see section

5.3.2).

Temperature

does not rise

when expected

Set temp is lower

than liquid temp

Check that the bath set temperature is correct

(see section 5.2.10).

Display shows

“High

Temperature

Alarm”

High temperature

warning alarm has

tripped

Check that the bath set temperature is correct

(see section 5.2.10).

Check that high temperature alarm is correct

(section 5.3.4).

Check that the liquid level in the bath is

adequate (see section 5.1.1 for minimum fill

levels).

11.0 Troubleshooting

31115 V1 LTC4

Page 35 Operating Manual

www.grantinstruments.com

Page 37

Symptom

Possible cause

Action required

Display shows

“Low

Temperature

Alarm”

Low temperature

warning alarm has

tripped

Check that the bath set temperature is correct

(see section 5.2.10).

Check that low temperature alarm is correct

(section 5.3.4).

Check that the liquid level in the bath is

adequate

Unit showing

erratic

temperatures

Calibration values not

set correctly

Restore the factory calibration settings (see

section 5.4.1) then re-calibrate if required (see

section 5.4).

New calibration

point is not

saved

Incorrect calibration

value

The temperature calibration point is less than

20°C from an existing calibration point – choose

a higher temperature (see section 5.4).

The measured liquid temperature is more than

5°C away from selected calibration

temperature.

Only the

Standby icon

can be

highlighted

Unit is in standby

mode

Highlight and Select the Standby icon and

Press “S” to exit Standby mode.

Icons can be

highlighted but

not selected

Program running

Wait until program has finished or stop program

Select a program

number but icon

changes to “–“

Program not setup

Set-up and download a program using Grant

Labwise software

Stirrer motor not

rotating

Unit is in Standby

Mode

Stirring propeller or

pump impeller is

obstructed

Faulty motor

Highlight the Standby Icon on the control

screen and press S button to return to normal

operation

Clear obstruction.

Have a competent person check the motor or

contact Grant.

Display shows

“Over

temperature

Alarm”.

Over-temperature

cut-out has operated

Check the set temperature is correct and that

the over-temperature cut-out temperature is set

at least 5°C above the set temperature (see

section 5.2.6 for setting instructions).

If the over-temperature cut-out temperature is

correctly set but the unit still shows a “Over

temperature Alarm” then the unit has an internal

fault and must be repaired before it is used

again.

LTC4 31115 V1

Operating Manual Page 36

www.grantinstruments.com

Page 38

Symptom

Possible cause

Action required

Display shows

“Low liquid

Alarm”

Liquid level has

dropped below

minimum level

Check that the liquid level in the bath is

adequate

Display shows

“Internal

temperature

probe Fault”

Faulty temperature

probe

Have a competent person check the probe for

an open or short circuit fault or contact Grant.

Display shows

“Internal/External

Temp Diff Too

Big”

There is a

temperature

difference of more

than 5 degrees

between the internal

and external probe

Check the external probe is properly connected

at the rear panel.

Check the external probe is correctly positioned

in the bath liquid and circulation is not

restricted.

If the external probe is not required, select the

internal probe using the Settings menu

Display shows

“OverheatingPower reduced ”

Heating water at or

near to boiling

without lid

Heating very large

volumes of liquid with

large thermal losses

Add a lid to reduce thermal losses and leave

unit running with the “Overheating” warning

present. If the alarm has not cleared within 1

hour contact Grant.

Add measures to reduce thermal losses and

leave unit running with the “Overheating”

warning present. If the alarm has not cleared

within 1 hour contact Grant.

Display shows

“Service required

01”

Faulty fuse(s), relay

or heater element

Have a competent person check the product or

contact Grant.

Display shows

“Service required

02”

Pump or propellor is

obstructed

Faulty motor

Remove obstruction.

Have a competent person check the product or

contact Grant

Display shows

“Cross-check

Failure”

PCB fault

Have a competent person check the product or

contact Grant.

For any other errors or service requests, please contact Grant Instruments service

department.

31115 V1 LTC4

Page 37 Operating Manual

www.grantinstruments.com

Page 39

12.0 Contact Grant Instruments

At Grant we are continuously trying to improve the performance we offer our customers.

If you have any feedback on Grant’s products or services we would like to hear from you.

Please send all feedback to:

Quality Manager

Grant Instruments (Cambridge) Ltd

Shepreth

Cambridgeshire

SG8 6GB

UK

Tel: +44 (0) 1763 260 811

Fax: +44 (0) 1763 262 410

E-mail: feedback@grantinstruments.com

13.0 Compliance

WEEE directive

Grant Instruments complies fully with the Waste Electrical & Electronic Equipment

(WEEE) regulations 2006. We are a member of the B2B compliance scheme (Scheme

Approval Number WEE/MP3338PT/SCH), which handle our WEEE obligations on our

behalf. Grant Instruments have been issued with a unique registration number by the

Environmental Agency, this reference number is WEE/GA0048TZ.

For information regarding WEEE collections in the UK please contact our B2B

Compliance Scheme directly on 01691 676 124.

For other countries please contact your equipment supplier.

For General WEEE information please visit: www.b2bcompliance.org.uk

RoHS directive

All the products covered by this manual comply with the requirements of the RoHS

Directive (Directive 2002/95/EC).

Electrical safety and electromagnetic compatibility

All the products covered by this manual comply with the requirements of the Low Voltage

Directive (2006/95/EC) for electrical safety and the EMC directive (2004/108/EC) for

electromagnetic compatibility. See the Declaration of Conformity on the inside back

page.

LTC4 31115 V1

Operating Manual Page 38

www.grantinstruments.com

Page 40

Notes

31115 V1 LTC4

Page 39 Operating Manual

www.grantinstruments.com

Page 41

LTC4 31115 V1

Operating Manual Page 40

www.grantinstruments.com

Page 42

31115 V1 LTC4

Page 41 Operating Manual

www.grantinstruments.com

Page 43

LTC4 31115 V1

Operating Manual Page 42

www.grantinstruments.com

Page 44

Grant Instruments

(Cambridge) Ltd

Shepreth

Cambridgeshire

SG8 6GB

UK

Tel: +44 (0) 1763 260811

Fax: +44 (0) 1763 262410

Email: labsales@grantinstruments.com

www.grantinstruments.com

Printed in England – LTC4/31115/V1 /DMN B96 /Sept 2012

Loading...

Loading...