Shaking water bath

OLS200

Refrigerated immersion

cooler

CS200G

Operating Manual

1 Safety 2

2 Getting Started 3

2.1 Unpacking 3

2.1.1 Shaking bath - OLS200 3

2.1.2 Universal Tray 3

2.1.3 Test Tube Tray 3

2.1.4 Cooler - CS200G 3

2.1.5 Cooling coil - CW200 3

2.2 Installation 3

2.2.1 Location 3

2.2.2 for operating temperatures below ambient 3

2.2.3 for operating temperatures above 60°C 3

2.2.4 Fitting the trolley 4

2.2.5 Fitting the tray 4

2.2.6 Filling 4

2.2.8 Connection to electrical supply 4

3 Operation 5

3.1 OLS 200 5

3.1.1 Controls and indicator lamps 5

3.1.2 Setting the temperature 5

3.1.3 Shaking 6

3.1.4 Setting the overtemperature cut-out 7

3.1.5 Draining 7

3.2 CS200G 7

4 Accessories 7

4.1 Universal tray UT200 7

4.2 Plain Tray UTP 7

4.3 Tray for test tube racks TT200 8

4.4 Perforated tray for use as an ordinary unstirred bath SBT28 8

4.5 Gabled lid, stainless steel LS200 8

5 Fault diagnosis 9

6 Technical specification 10

6.1 OLS200 orbital/linear shaking bath 10

6.2 CS200G refrigerated cooler 11

7 Maintenance and service 11

7.1 OLS200 Shaking bath 11

7.2 Refrigerated cooler: CS200G 11

7.3 Replacement of fuses 12

7.3.1 OLS200 Shaker bath 12

7.3.2 Refrigerated cooler: CS200G 12

8 Guarantee 12

9 Service 12

10 Compliance 13

10.1 Disposal & WEEE 13

10.2 RoHS Directive 13

10.3 Electrical safety and Electromagnetic compatibility 13

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 1 www.grant.co.uk

1 Safety

The following symbols marked on the equipment mean:-

Caution: Read these operating instructions fully before use and pay particular attention to sections

containing this symbol

Caution: Surfaces can become hot during use.

Always observe the following safety precautions

Use only as specified by the operating instructions or the intrinsic protection may be impaired.

After transport or storage in humid conditions, dry out the unit before connecting it to the supply

voltage. During drying out the intrinsic protection may be impaired.

Connect only to a power supply with a voltage corresponding to that on the serial number label.

Connect only to power supply which provides a safety earth (ground) terminal.

Before moving, disconnect at the power supply socket. Do not remove the IEC connector.

Do not check the temperature by touch; use the temperature display or a thermometer.

To reduce the risk of eye injury during high temperature operation, use safety goggles or spectacles.

Do not touch surfaces which become hot during high temperature operation.

Ensure that the operating temperature is less than the maximum operating temperature of your

sample material.

Set the adjustable overtemperature cut-out after setting or changing the set temperature, and reset it

at monthly intervals to check that the cut-out is operating correctly.

Ensure that the mains switch is easily accessible during use.

Do not block or restrict ventilation slots.

If liquid is spilt inside the unit, disconnect it from the power supply and have it checked by a

competent person.

It is the user’s responsibility to carry out appropriate decontamination if hazardous material is spilt on

or inside the equipment.

Do not connect to a power supply or switch on before filling the tank.

Take care when topping up or draining, as the liquid in the tank may be very hot.

If the alarm lamp is illuminated do not touch the liquid or the heater, they may be very hot. Refill

carefully, a hot heater can cause a spattering of very hot water droplets and scalding steam.

Always use a lid when operating above 60°C. Take care when rising and removing the lid, it may be

hot. Steam and hot vapours can cause scalding.

Drain before moving the bath. Before draining allow the liquid to cool to below 50°C or heat to above

10°C.

Use only liquids specified in the operating instructions, within the specified temperature range. If the

alarm lamp is illuminated the liquid temperature may be above its recommended maximum: do not

inhale the vapours given off as they may be toxic; liquids should be safely discarded and replaced.

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 2 www.grant.co.uk

2 Getting Started

2.1 Unpacking

Remove the packing materials carefully, and retain for future shipment or storage.

2.1.1 Shaking bath - OLS200

The pack should contain:

shaking bath

trolley

drive magnet

drain insert (located in a clip on the rear panel of OLS200)

mains cable

these instructions.

2.1.2 Universal Tray

Tray fitted with springs for use with flasks.

2.1.3 Test Tube Tray

Tray for use with test tube racks.

2.1.4 Cooler - CS200G

Refrigerated immersion cooler, for operating temperatures down to 0°C.

2.1.5 Cooling coil - CW200

For operating temperatures at or below ambient, a Grant CW200 heat exchange coil can be used

to maintain the temperature at 2°C above the temperature of the coolant.

2.2 Installation

2.2.1 Location

Position the bath on a firm level surface with the controls facing the operator and adjust the

position of the feet so that the bath stands level. This can be done after filling with liquid to the top

of the trolley, and levelling the water against the top of the trolley as a reference. It is necessary

that the bath is level in order to achieve optimum performance.

2.2.2 for operating temperatures below ambient

The unit is insulated for use at temperatures below ambient. It is recommended that the gabled lid

is used to reduce heat gain.

To fit the cooling coil: remove the flask tray and trolley, then remove the base tray by undoing the

retaining 'N' nuts (see figures 1 and 5).

CS200G: Stand the CS200G next to the OLS 200 and position the cooling coil in the bottom of the

tank, ensuring that it lies flat, with the feed pipe at the rear.

CW200: Place the CW200 cooling coil in the bottom of the tank, ensuring that it lies flat, with the

input and output pipes at the rear.

To secure the cooling coil in position, replace the base tray and washers and tighten the four

retaining 'N' nuts (see figure 5).

Ensure that the CS200G is located so that the ventilation grilles are not less than 100mm from

any obstruction.

To use the lid: remove the slot cover and replace in the alternative position, to allow the

connecting pipe to pass through.

2.2.3 for operating temperatures above 60°C

At operating temperatures above 60°C a lid MUST be fitted. The Grant sloping stainless steel lid

directs condensate into the bath to prevent it from dripping into open flasks or tubes.

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 3 www.grant.co.uk

0 to + 5C

80% water, 20% antifreeze (inhibited ethylene glycol)

WARNING: ANTIFREEZE IS TOXIC. IT IS HARMFUL IF SWALLOWED.

READ THE SUPPLIERS’ HANDLING INSTRUCTIONS.

+5C to 99C

Water (taps or distilled). See maintenance and service section 7.

2.2.4 Fitting the trolley

Caution: The shaker uses a magnet located in the bottom of the tank. Once removed from the

bath the drive magnet produces a strong magnetic field and it should be placed in a position

where it cannot affect computer discs, cassettes, watches, etc. If your watch is susceptible to

magnetic fields, please remove it before removing or fitting the trolley. Once the trolley and drive

magnet have been fitted the stray magnetic fields are very small.

Fit the drive magnet onto the shaft in the bottom of the bath (see figures 1 and 2). Lower the

trolley into the bath, keeping it level, with the drive arm facing the front of the bath (see figure 4);

fit the drive arm pin into one of the holes on the drive magnet. See figure 1 and paragraph

3.1.3.2.2 for guidance as to which hole to select. If the drive arm is not parallel to the base of the

tank, it may be difficult to fit the pin into the hole.

2.2.5 Fitting the tray

The OLS200 shaking bath provides both linear and orbital shaking motion. Select the type of

motion you require by altering the position of the tray in the tank.

The tray is punched with a 'O' and a ' ' (see figure 3). For orbital motion, position the 'O'

nearer the front. For linear motion, position the ' ' nearer the front.

For orbital motion: tilt up the far end, locate the near end lip on the wheels nearest to you. Lower

the far end and move the trolley sideways until the pin locates in the hole in the drive arm (see

figure 4).

For linear motion: tilt up the far end, insert the near end lip between the locating strips on the

trolley (see figure 4). Lower the far end.

To remove the tray: hold both handles and keep the tray level as you lift it.

WARNING: For safety, do not remove the tray from the unit when the liquid is hot.

2.2.6 Filling

Before filling ensure that the drain pipe is not attached.

Fill the bath without the tray fitted, with approximately 9 litres of liquid. Fit the tray and adjust the

liquid level to the required immersion depth. When the liquid is level with the top of the tray the

flask immersion depth is 50mm.

DO NOT operate the bath without any liquid.

2.2.7 Specified liquids:

Do not use any other liquids without consulting Grant Instruments.

2.2.8 Connection to electrical supply

WARNING: The equipment must be earthed (grounded). It is protected by internal electrical

fuses. We strongly recommend that the power supply to any equipment for heating liquids should

include a residual-current circuit breaker (earth leakage trip).

Check that the voltage rating of the products, given on the serial number plate at the power cable

entry, is correct for your supply.

Fit the mains cable into the IEC power socket at the rear of the unit(s).

Connect the plug to the power supply socket.

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 4 www.grant.co.uk

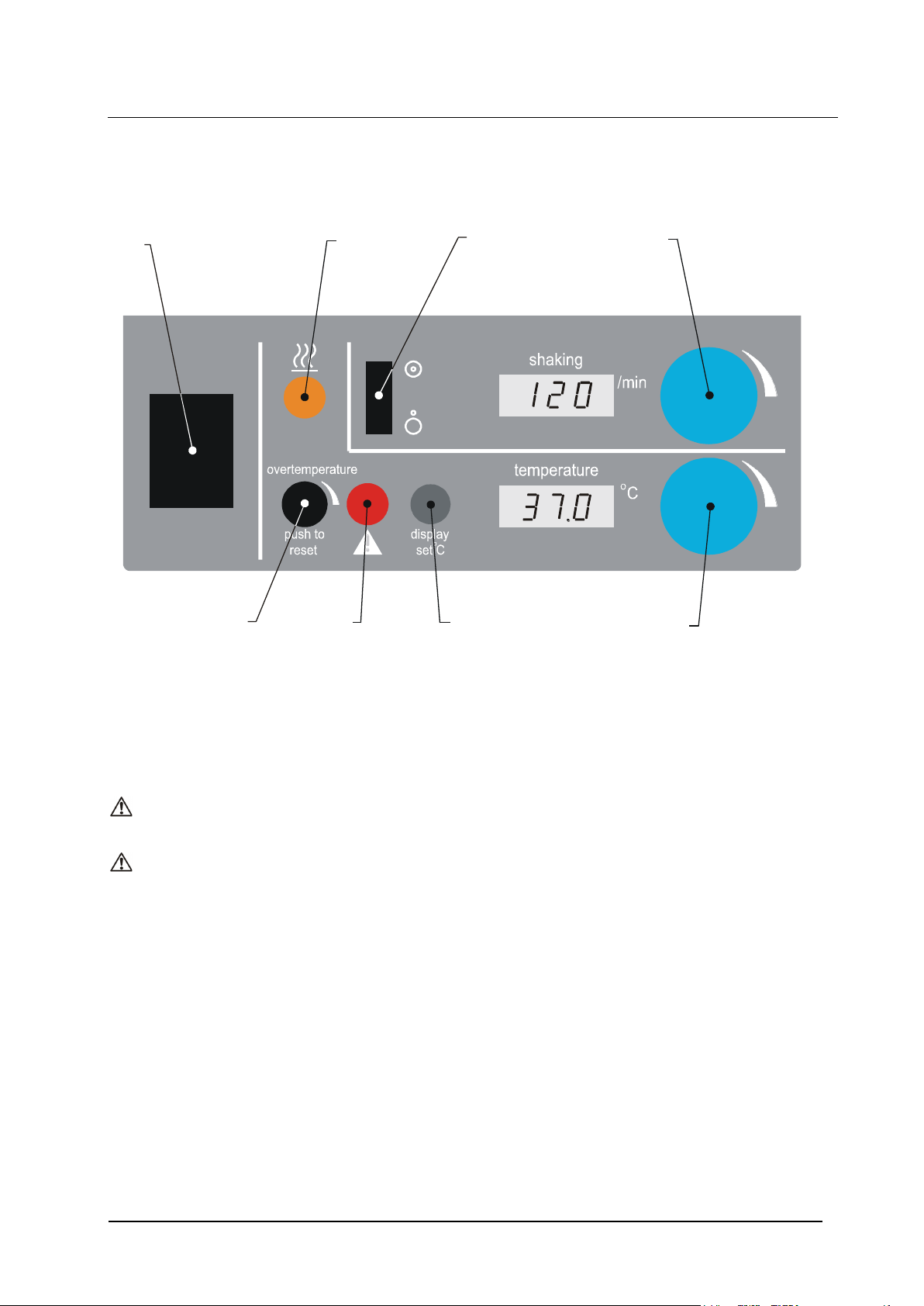

Power

Switch

Heater

Lamp

Shaking

Switch

Shaking

Knob

Temperature

Knob

Display

Set Button

Alarm

Lamp

Push to

Reset

Knob

3 Operation

3.1 OLS 200

3.1.1 Controls and indicator lamps

The temperature display normally shows the liquid temperature in C.

When the display set C button is pressed the set temperature is shown.

The temperature C control knob sets the required operating temperature.

Heater lamp (orange) indicates when the heater is on. While the bath is warming up, the lamp is

on continuously. As the temperature approaches set point, the lamp starts to flash, and continues

to flash intermittently while the unit is controlling at set temperature.

Alarm lamp (red) illuminates when the overtemperature cut-out has operated.

The overtemperature push to reset knob sets the overtemperature cut-out. The cut-out

operates if the liquid temperature rises above its set temperature. When it has operated, the red

alarm lamp illuminates and the heater is switched off. The temperature of the liquid continues to

be displayed to warn of possible high temperatures.

The speed display shows shaking speed in revolutions per minute. In linear motion the number of

strokes is twice the number displayed.

The shaking/min knob sets the shaking speed.

3.1.2 Setting the temperature

The display normally shows the liquid temperature. To show the set temperature at any time,

press the display set °C button. To set the required operating temperature, push the display set

C button, whilst turning the temperature °C knob until the required temperature is indicated on

the display.

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 5 www.grant.co.uk

Flask

size ml

No. flasks

Linear

18mm stroke

Hole ‘A’

Max. speed

strokes/min

Linear

28mm stroke

Hole ‘B’

Max. speed

strokes/min

Linear

36mm stroke

Hole ‘C’

Max. speed

strokes/min

Orbital

Hole 'A'

Max. speed

rpm

1000

1

300

270

180

160 3 220

200

170

130 500

1

340

220

200

190 6 260

170

120

135 250

1

380

270

180

200

11

280

200

140

145 100 1

200

18 145 50 1 360

300

170

200

28

260

200

140

150

3.1.3 Shaking

Switch on shaking. In linear motion the number of strokes/minute is double the number displayed.

To set the required revolutions per minute, turn the shaking/min knob until the required speed is

displayed. The speed rises slowly to the set value. Following adjustment, the setting should be

checked after several minutes. Stroke length for linear movement

The stroke length in linear motion can be altered according to your requirement with a choice of

three settings. The setting can be changed by altering the position of the drive arm pin in the drive

magnet (see figure 1). Hole ‘A’ sets the stroke length at 18mm; there are three alternative

positions of hole ‘A’, any of them may be used. Hole 'B' sets the stroke length at 28 mm and Hole

'C' sets the stroke length at 36 mm. See figure 1 for identification of holes.

Orbital motion operates ONLY at 9mm radius.

Maximum speed

The maximum speed depends on number and size of flasks, liquid depth, operating temperature

and, in linear motion, stroke length. The maximum speed will need to be determined for each

individual application. To determine the maximum speed, increase the speed until the trolley

begins to move erratically or stop; switch the shaking off, turn the speed down and restart. By

repeating this procedure the speed can be fine tuned to a maximum point, just below the point at

which it de-latches. The shaking trolley is driven by a drive magnet coupled to a rotating magnet

below the tank; as the speed is increased a point is reached where the magnetic coupling de-

latches, causing the trolley either to move erratically or to stop.

Liquid depth

Maximum speed is achievable with the minimum liquid depth.

Liquid depths up to a maximum of 130mm (90mm flask immersion) can be used, but water may

splash out at high speeds, particularly with a small number of large vessels.

Flasks, stroke length

The following table gives a guide to the maximum speeds obtainable with 50mm immersion

depth, three different stroke lengths and various sizes and numbers of Erlenmeyer flasks.

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 6 www.grant.co.uk

3.1.4 Setting the overtemperature cut-out

To protect both the unit and your samples, the overtemperature cut-out should be set each time

the required operating temperature is changed. Turn the overtemperature push to reset knob

fully clockwise and press to reset. The cut-out is now set at its maximum. Allow the bath to

stabilise at the required operating temperature. Turn the control slowly anticlockwise using a

screwdriver until the red alarm lamp comes on. Press the knob and gently turn clockwise until the

alarm lamp goes out. Turn the knob anticlockwise three quarters of the way back towards the

point where the alarm lamp came on. The overtemperature cut-out is now set approximately 10°C

above the required operating temperature.

Note: When the cut-out has operated, the bath needs to cool to below the set temperature before

the cut-out can be reset. Push the knob to reset the cut-out.

3.1.5 Draining

Allow the liquid to cool to below 60°C before draining. The drain connector is positioned on the

rear panel. The drain insert is fitted into a clip on the rear panel next to the drain connector.

Connect a suitable pipe to the drain insert. Place the end of the pipe over a drain or in a container.

Push the drain insert into the drain connector. The liquid will now drain from the bath. To remove,

press the button and pull out the insert. Replace in the clip.

3.2 CS200G

The mains (power) switch is on the rear of the unit.

Switch on at the rear. Always ensure that the bath is switched on to provide temperature control,

and that shaking is switched on at low temperatures, to prevent the formation of ice.

Do not switch on if:

- the temperature of the liquid in the bath is above 40°C

- the cooler has been tilted by more than 25° during the past six hours

- the interval since switching off the cooling system is less than 10 minutes

4 Accessories

4.1 Universal tray UT200

The universal tray accommodates a wide variety of vessels. The configuration of the springs can

be altered to accommodate the maximum number of each size of Erlenmeyer flask as follows:

Figure

45 x 25 ml flasks 6

28 x 50 ml flasks 7

18 x 100 ml flasks 8

11 x 250 ml flasks 9

6 x 500 ml flasks 10

3 x 1000 ml flasks 11

Springs may be removed to accommodate awkward shaped vessels, for example boxes for

hybridisations.

There are two rows of holes in the long sides. The upper set should be used for high vessels and

the lower set for vessels up to about 50mm tall. Select the spring configuration which best suits

the application.

To change spring positions, slide out the retaining rod, place the end of the spring into the

required hole and refit the rod.

4.2 Plain Tray UTP

Universal tray without springs.

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 7 www.grant.co.uk

4.3 Tray for test tube racks TT200

The tray accommodates up to five test tube racks as follows:

H1 test tube racks:

H1-10 rack holds 48 x 10 mm tubes

H1-13 rack holds 44 x 13 mm tubes

H1-16 rack holds 24 x 16 mm tubes

HI-19 rack holds 21 x 19 mm tubes

H1-25 rack holds 12 x 25 mm tubes

H1-30 rack holds 10 x 30 mm tubes

4.4 Perforated tray for use as an ordinary unstirred bath SBT28

Remove the trolley leaving the drive magnet in position, and fit the SBT28 perforated tray to

provide a platform on which vessels or racks can be placed.

4.5 Gabled lid, stainless steel LS200

To use the lid with a cooler, remove the slot cover and replace it in the alternative position, to

allow the connecting pipe to pass through.

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 8 www.grant.co.uk

Symptom

Possible Cause

Action required

Unit does not operate

Unit not switched on

Switch on

Unit not plugged into power

supply

Plug in, switch on

Power supply failure

Check that other electrical appliances

on the same circuit are working

Fuse blown in unit or in plug (UK

units only)

Check and replace - see 7.3.1.

Alarm lamp on

Overtemperature cut-out has

operated

Reset the cut-out and check the

settings as described in 3.1.4.

If the cut-out operates again or cannot

be reset, have the unit checked by a

competent person

Temperature does not

rise when expected

Set temperature is lower than

liquid temperature

Check set temperature

Set temperature is too close to

ambient

Raise set temperature, or use cooler

Temperature control circuit fault

Have unit checked by a competent

person

Temperature continues

to rise when not

expected

OR

heater lamp on

Set temperature is higher than

liquid temperature

Temperature control circuit fault

Check setting

Have unit checked by a competent

person

Trolley not shaking shaking display zero

Shaking not switched on

Switch on

Trolley not shaking speed display not zero

Incorrectly fitted trolley

Check fitting of trolley

Speed too high

Reduce speed

No display or speed

incorrect

Speed control circuit fault

Have unit checked by a competent

person

Speed reduces

Trolley has scaled up

Immerse in descaler, or clean - see 7.1

5 Fault diagnosis

Whilst it is not possible to cover all fault conditions, the following procedures provide guidance for

solving simple faults which can occur in normal operation. The operator should not attempt to cure

internal faults, but should return the unit for service to Grant Instruments' Service department or

their distributor in other countries.

Before starting this procedure set power and shaking switches OFF.

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 9 www.grant.co.uk

Temperature range

0 to 99°C

Stability (DIN 58966)

± 0.1°C

Uniformity

± 0.1°C

Temperature setting/display

digital/LED

Display resolution

0.1

Shaking speed range

20 to 200 rpm

40 to 360 strokes/min

Linear - stroke length

18, 28, 36 mm

Orbital radius

9mm

Shaking speed setting/display

digital/LED

Display resolution

1

Heater power

230V – 1450VA

115V – 1200VA

Power rating

230V – 1500VA

115V – 1250VA

Tank dimensions l/w/d

505/300/200 mm

Shaking tray area

375/235 mm

Flask immersion min./max.

0/90 mm

Liquid depth, in the tank

40mm to 130mm

Overall dimensions l/w/d

555/325/300 mm

Mass

15kg

Heat up time from 25°C to 70°C

32 minutes

with water and the lid on

Safety: overtemperature/

adjustable cut-out

low liquid level

Supply voltage range

230V 10% @

50/60Hz

120V 10% @

50/60Hz

6 Technical specification

This equipment is designed for indoor use in laboratory conditions, with room temperature

between 5°C and 40°C, and 80% relative humidity up to 31°C. Performance figures apply in

ambient temperature between 10°C and 35°C.

Installation category II (Transient voltages). Pollution degree 2 in accordance with IEC 664. For

operation at altitudes up to 2000 metres.

As Grant Instruments is committed to a continuous programme of improvement, specifications

may be changed without notice.

6.1 OLS200 orbital/linear shaking bath

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 10 www.grant.co.uk

Power consumption

500VA

Cooler extraction @ 20°C

200 W

@ 0°C

100 W

6.2 CS200G refrigerated cooler

Refrigerated cooler for use in liquids between 0° and 40°C.

Immersed material: the cooling coil is nickel-plated copper.

Supply voltage: 230V 10% @ 50/60Hz

Size: 475/320/255

Mass: 21Kg

7 Maintenance and service

7.1 OLS200 Shaking bath

All Grant laboratory products are designed to comply with IEC1010-1 and can be flash tested.

Some are fitted with radio frequency interference suppressors, so it is recommended that only a

d.c. test is performed.

The overtemperature cut-out should be checked periodically by turning the overtemperature

push to reset knob anticlockwise until the alarm lamp comes on. The cut-out should then be re-

set and set-up again (see 3.1.7) If the alarm lamp fails to light with the knob turned fully

anticlockwise the unit should be checked by a competent person.

To ensure free running of the trolley keep the liquid and the bath clean and free from scale. From

time to time remove the tray and trolley and the drive magnet. Clean the trolley wheels and the

centre of the tank where the wheels run, with warm soapy water to remove all scale and grit. Also

clean the magnet and its housing. Be careful not to damage the magnet.

The base tray and the bottom of the tank can be cleaned by removing the base tray from the tank.

To remove: undo and remove the nuts, followed by the washers and the base tray. To replace:

relocate on the four screw heads and fix in position by replacing the four washers and nuts.

If the bath is used with water and is to be left unused for longer than a couple of days, drain the

water, remove the drive magnet and dry out its housing. This will prevent the possibility of

corrosion which can occur with distilled or deionised water and some tap water, even to the high

grades of stainless steel used in the manufacture of the bath, and unwanted scale building up

around the drive magnet.

When used with water under certain conditions, algal growth can occur which can be mistaken for

rust. It can be cleaned out by washing with warm soapy water.

Cleaning: external surfaces can be wiped clean using a damp cloth and if necessary a mild

detergent.

No other routine maintenance is required.

7.2 Refrigerated cooler: CS200G

Cleaning: external surfaces can be wiped clean using a damp cloth and if necessary a mild

detergent.

Dust on the refrigeration condenser

Cooling power will be reduced if the fins behind the front grille become clogged with dust.

Examine monthly and, if necessary, call a competent person to take off the cover and remove the

dust.

The flexible hose to the cooling coil should be checked periodically for wear or damage.

No other routine maintenance is required.

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 11 www.grant.co.uk

7.3 Replacement of fuses

WARNING: Before removing the cover, isolate from the mains power supply.

Only a competent person should change fuses.

7.3.1 OLS200 Shaker bath

First disconnect the mains cable from the power supply, then remove the socket end from the

plug in the back of the bath. Drain the bath. Press down the fuse drawer catch (see figure 12).

Pull out the fuse drawer, replace the fuse with the correct type, and replace the fuse holder.

The fuses are Littelfuse 3AB 314 series, fast-acting, high breaking current (max breaking current

at least 750 A); dimensions are 1.25 inch long, 0.25 inch diameter. Replace fuses only by the

same type and rating.

230V units – 10A (250V)

120V units – 15A (250V)

7.3.2 Refrigerated cooler: CS200G

First disconnect the mains cable from the power supply, then remove the socket end from the

plug in the back of the unit. Press down the fuse drawer catch (see figure 12).

Pull out the fuse drawer, replace the fuse with the correct type, and replace the fuse holder.

The fuses are 1.25 x 0.25 inch ceramic quick acting, rated:

230V units – 10A (250V)

120V units – 20A (250V)

8 Guarantee

When used in laboratory conditions and according to these instructions, this equipment is

guaranteed for three years against faulty materials or workmanship.

9 Service

For service, return for repair to our Service Department in the UK or, in other countries, to our

distributor.

Service Address:

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 12 www.grant.co.uk

Grant Instruments (Cambridge) Ltd.,

Service Department,

Shepreth,

Cambridgeshire

SG8 6GB

England

Tel: +44 (0) 1763 260811

Fax: +44 (0) 1763 262410

10 Compliance

10.1 Disposal & WEEE

Grant Instruments complies fully with the Waste Electrical & Electronic Equipment (WEEE)

regulations 2006. We are a member of the B2B compliance scheme (Scheme Approval Number

WEE/MP3338PT/SCH), which handle our WEEE obligations on our behalf. Grant

Instruments have been issued with a unique registration number by the Environmental Agency,

this reference number is WEE/GA0048TZ.

For information regarding WEEE collections in the UK please contact our B2B

Compliance Scheme directly on 01691 676 124

For other countries please contact your equipment supplier.

For General WEEE information please visit: www.b2bcompliance.org.uk

10.2 RoHS Directive

This unit contains refrigerant gas, which must NOT be discharged to the atmosphere. At the end

of the unit's working life EITHER have the gas removed safely by using refrigerant recovery

equipment OR return the unit to us for disposal.

10.3 Electrical safety and Electromagnetic compatibility

All the products covered by this manual comply with the requirements of the EU RoHS Directive

(Directive 2002/95/EC). This means the products are free of Lead and other hazardous

substances covered by the directive.

All the products covered by this manual comply with the requirements of the Low Voltage Directive

(2006/95/EC) for Electrical safety and the EMC directive (2004/108/EC) for Electromagnetic

compatibility. See the Declaration of Conformity on the inside back page

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 13 www.grant.co.uk

Front

Figure 1

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 14 www.grant.co.uk

Figure 2

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 15 www.grant.co.uk

Front

Figure 3

Figure 4

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 16 www.grant.co.uk

Front

Front

Figure 5

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 17 www.grant.co.uk

Figure 6

Layout of springs and flasks

For 45 off 25ml flasks

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 18 www.grant.co.uk

Figure 7

Layout of springs and flasks

For 28 off 50ml flasks

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 19 www.grant.co.uk

Figure 8

Layout of springs and flasks

For 18 off 100ml flasks

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 20 www.grant.co.uk

Figure 9

Layout of springs and flasks

For 11 off 250ml flasks

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 21 www.grant.co.uk

Figure 10

Layout of springs and flasks

For 6 off 500ml flasks

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 22 www.grant.co.uk

Figure 11

Layout of springs and flasks

For 3 off 1000ml flasks

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 23 www.grant.co.uk

FUSE DRAWER PUSH LEVER UP TO

RELEASE FUSE

DRAWER

Figure 12

Replacement of mains fuses on rear panel

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 24 www.grant.co.uk

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 25 www.grant.co.uk

OLS200, CSG200 15214 Ver 9 - January 2010 57U

Operating Manual Page 26 www.grant.co.uk

Grant Instruments

(Cambridge) Ltd

Shepreth

Cambridgeshire

SG8 6GB

England

Tel: +44 (0) 1763 260811

Fax: +44 (0) 1763 262410

Email: labsales@grant.co.uk

www.grant.co.uk

Printed in England OLS200,CS200G/15214

Loading...

Loading...