Grant VortexAir, Aerona3, VortexBlue, VTXBFAIR, HPIDAIR2 Installation And Servicing Instructions

...

Grant VortexAir

VortexBlue Oil Boiler and Aerona³ Air Source

Heat Pump Hybrid

Installation and Servicing Instructions

THESE INSTRUCTIONS SHOULD BE READ IN

CONJUNCTION WITH THE INSTALLATION AND SERVICING

INSTRUCTIONS SUPPLIED WITH THE HEAT PUMP.

UK | DOC 0110 | Rev 1.0 | November 2016

Special Text Formats

The following special text formats are used in this manual for the

purposes listed below:

!

Warning of possible human injury as a consequence of not following the instructions in the warning.

!

Caution concerning likely damage to equipment or tools as a

consequence of not following the instructions in the caution.

!

Used for emphasis or information not directly concerned with

the surrounding tex t but of impor tance to the reader.

WARNING

CAUTION

NOTE

GRANT ENGINEERING (UK) LIMITED

Hopton House, Hopton Industrial Estate, Devizes, Wiltshire, SN10 2EU

Tel: +44 (0)1380 736920 Fax: +44 (0)1380 736991

Email: info@grantuk.com www.grantuk.com

This manual is accurate at the date of printing but will be superseded and should be disregarded if specifications and/or appearances

are changed in the interests of continued product improvement. However, no responsibility of any kind for any injury, death, loss, damage

or delay however caused resulting from the use of this manual can be accepted by Grant Engineering (UK) Limited, the author or others

involved in its publication.

All good sold are subject to our official Conditions of Sale, a copy of which may be obtained on application.

© Grant Engineering (UK) Limited 2016. No part of this manual may be reproduced by any means without prior written consent.

Contents

1 Introduction 4

1.1 General 4

1.2 Outputs 4

1.3 Planning Permission 4

1.4 DNO Application 4

1.5 Servicing 4

1.6 Important Advice 5

1.7 Product Contents 5

1.8 Installation Accessories 5

1.9 Hybrid Components 6

2 Technical Data 8

2.1 Boiler Technical Data 8

2.2 Heat Pump Technical Data 8

2.3 Sealed System Data 9

2.4 Burner Settings 9

2.5 Flue Gas Analysis 9

2.6 Hybrid Dimensions 10

2.7 Clearances 12

3 Oil Storage and Supply System 13

3.1 Fuel Supply 13

3.2 Burner Oil Connection 15

3.3 Burner Components 15

4 Installation Information 16

4.1 Introduction 16

4.2 VortexAir Location 16

4.3 Preparation for Installation 16

4.4 Regulations and Standards 16

4.5 Completion 17

4.6 Before you Commission 17

4.7 Heating System Design Considerations 17

4.8 Underfloor Heating Systems 17

4.9 Pipework Materials 17

4.10 Underfloor Pipework 17

5 Installation of the Oil Boiler 18

5.1 Preparation for Installation 18

5.2 Installing the Oil Boiler - External Location 18

5.3 Installing the Oil Boiler - Internal Location 18

5.4 Boiler Only Operation 18

6 Installation of the Heat Pump 20

6.1 Preparation for Installation 20

6.2 Installing the Heat Pump - Next to 20

Oil Boiler

6.3 Installing the Heat Pump - Separate 21

from Oil Boiler

6.4 Heat Pump Parameter Settings 21

7 Installation of Heat and 22

Electricity Meters

7.1 General 22

7.2 Heat Meter 22

7.3 Electricity Meter 28

7.4 Setting up the Heat Meter 28

8 Internal Pipework 30

8.1 General 30

8.2 Meter Ready 30

11 Domestic Hot Water 38

11.1 Temperature Control 38

11.2 Legionella 39

11.3 Grant Automatic DHW Boost Kit 2 39

11.4 Grant Digital 2-Stage Cylinder Thermostat 39

12 Electrical 40

12.1 General 40

12.2 Hybrid (Boiler) Electrical Supply 40

Connection

12.3 Heating System Controls Connection 41

12.4 Heat Pump Electrical Supply Connection 42

12.5 Heat Pump Controls Connection 42

13 Flue System and Air Supply 54

13.1 Flue System 54

13.2 Air Supply 55

13.3 Balanced Flue Terminal Positions 56

13.4 Prepare the Wall - Indoor Installation only 58

13.5 Prepare the Flue - Low Level 58

14 Control Panel 60

14.1 General 60

14.2 Hybrid Controls 60

14.3 Heat and Electricity Meters 60

15 Operation 62

15.1 General 62

15.2 External Heating System Controls 62

15.3 Oil/Hybrid Switch 62

15.4 Hybrid Operation 62

15.5 Boiler Only Operation 63

16 Commissioning 64

16.1 General 64

16.2 Oil Boiler 64

16.3 Before Switching On 64

16.4 Setting the Hybrid Temperature Controls 64

16.5 Digital Temperature Controllers 65

16.6 Switching On 67

16.8 Air Adjuster Disc - 15/21kW only 67

16.9 Running the Boiler 67

16.10 Balancing the System 68

16.11 Completion 68

16.12 Heat Pump 68

17 Servicing 69

17.1 Checking before Servicing 69

17.2 Dismantling prior to Servicing 69

17.3 Cleaning the Boiler 69

17.4 Cleaning the Burner 70

18 Fault Finding 72

18.1 Burner Fault Indication 72

18.2 Burner Fault Diagnostics 72

18.3 Riello RDB BLU Fault Finding Chart 73

19 Spare Parts 74

19.1 Riello RDB BLU Burner Parts List 74

19.2 Exploded View of Riello RDB BLU Burner 75

19.3 Boiler Parts List 76

9 Condensate Disposal 32

9.1 Heat Pump Condensate Disposal 32

9.2 General Requirements 32

9.3 Connections 32

9.4 Pipework 32

9.5 External Pipework 32

9.6 Condensate Soakaway 32

9.7 Condendate Trap 33

9.8 Condensate Disposal Pipework 33

9.9 Inspection and Cleaning of Trap 34

10 Sealed Systems 36

10.1 Sealed System Requirements 36

10.2 Filling the Sealed System 37

10.3 Pressure Relief (Safety) Valve Operation 37

20 EC Declaration of Conformity 78

21 ErP 79

22 Health and Safety 80

23 Recycling and Decommissioning 81

24 Guarantee 82

Appendix A 84

Contents Page 3

1 Introduction

1.1 General

The Grant VortexAir Hybrid is a unique combination of a Grant

VortexBlue oil-fired boiler and a Grant Aerona³ inver ter driven heat

pump.

It is available in two models – HPIDAIR (15/21kW) and HPIDAIR2

(21/26kW). The outputs indicate the size of the range-rated blue

flame boiler used, either 15/21kW or 21/26kW. A 16kW Grant

Aerona³ heat pump is used in both models.

The Grant VortexAir is supplied in t wo parts, the oil boiler and the

heat pump (each on their own pallets), for connection together by

the installer on site.

It also possible to purchase the boiler only. This can be installed as

an immediate replacement for an existing boiler, with the Aerona³

HPID16 heat pump being purchased and added at a later date.

Alternatively, the boiler can simply be installed and used as a 'standalone' boiler with no heat pump fitted, if required.

Both parts of the Grant VortexAir Hybrid have are housed in a

powder coated galvanised steel weatherproof enclosure.

The Aerona³ heat pump is designed to be installed externally in a

suitable position, either against a wall or some distance away from

the property as required. Refer to Section 2.7 for guidance.

The boiler unit can be installed either:

a) Externally – located next to the heat pump

OR

b) Internally – connected through the wall to the heat pump

The Grant low level balanced flue system (Yellow system) must be

used with the VortexAir. This is supplied with the unit.

The Grant VortexAir is only suitable for use on sealed central heating

systems. Refer to Section 10.

Both models are supplied with the control panel, burner and hybrid

system pipework/valves factory fitted.

1.1.1 How it Works

The Grant VortexAir Hybrid combines the Grant Aerona³ air-to-water

inverter driven air source heat pump and the innovative VortexBlue

high-efficiency oil boiler.

The VortexAir Hybrid control system allows the Aerona³ heat pump

to operate as the primary heat source for the majority of the heating

season, thus achieving the fuel efficient and cost effective provision

of space heating.

The oil boiler will only be operated when the ambient air temperature

falls to a level where the heat pump cannot either sustain the

required flow temperature for the system, or when the heat demand

cannot be met by the heat pump at the set flow temperature.

The ambient air temperature is monitored by the air thermostat

incorporated in the control system. The two-stage air thermostat

operation allows either partial use of the boiler (to back up the heat

pump) or full operation of the boiler, under control of the boiler

thermostat controller, under the most extreme low temperature

conditions.

The air thermostat settings will vary from one installation to another.

These are critical for the correct and efficient operation of the Hybrid

unit and must be determined by using the Grant Hybrid Calculator

(available as a download at ww w.grantuk.com). The resulting values

for both the Air thermostat controller and Boiler thermostat controller

are set during commissioning. Refer to Section 12.

For further details on the operation of the Grant VortexAir Hybrid

refer to Section 15 (Operation).

1.2 Outputs

There are two models in the VortexAir range as follows:

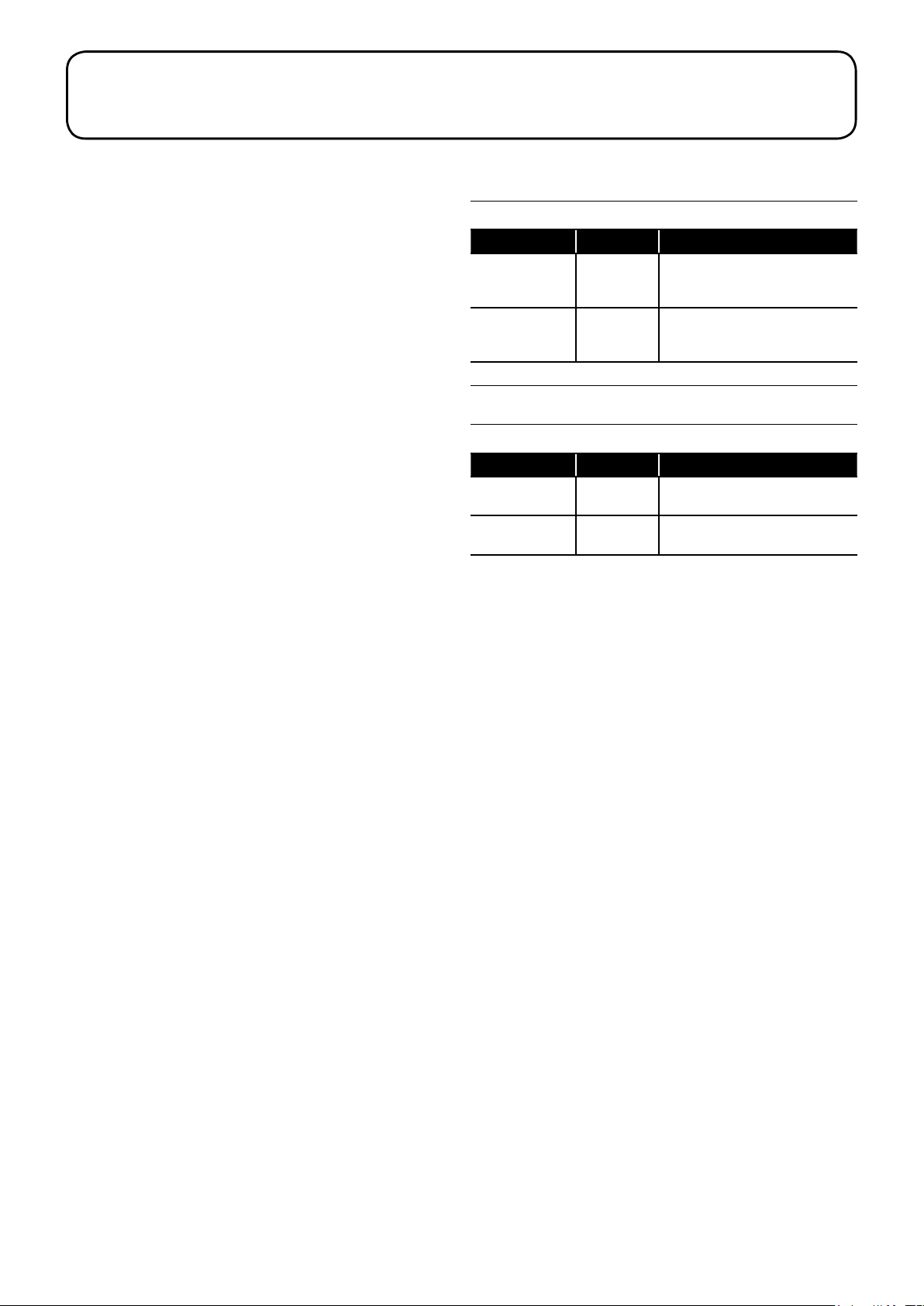

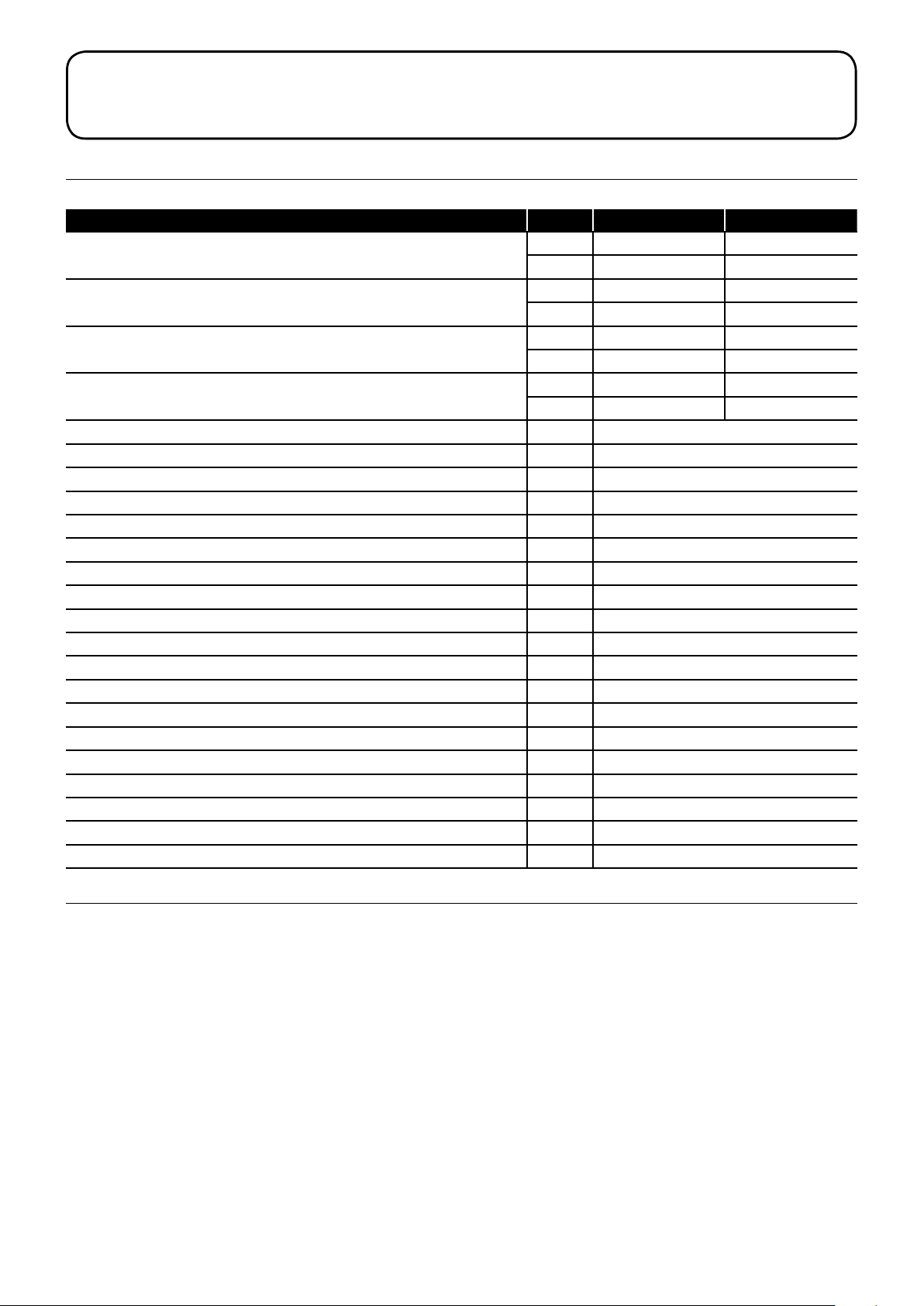

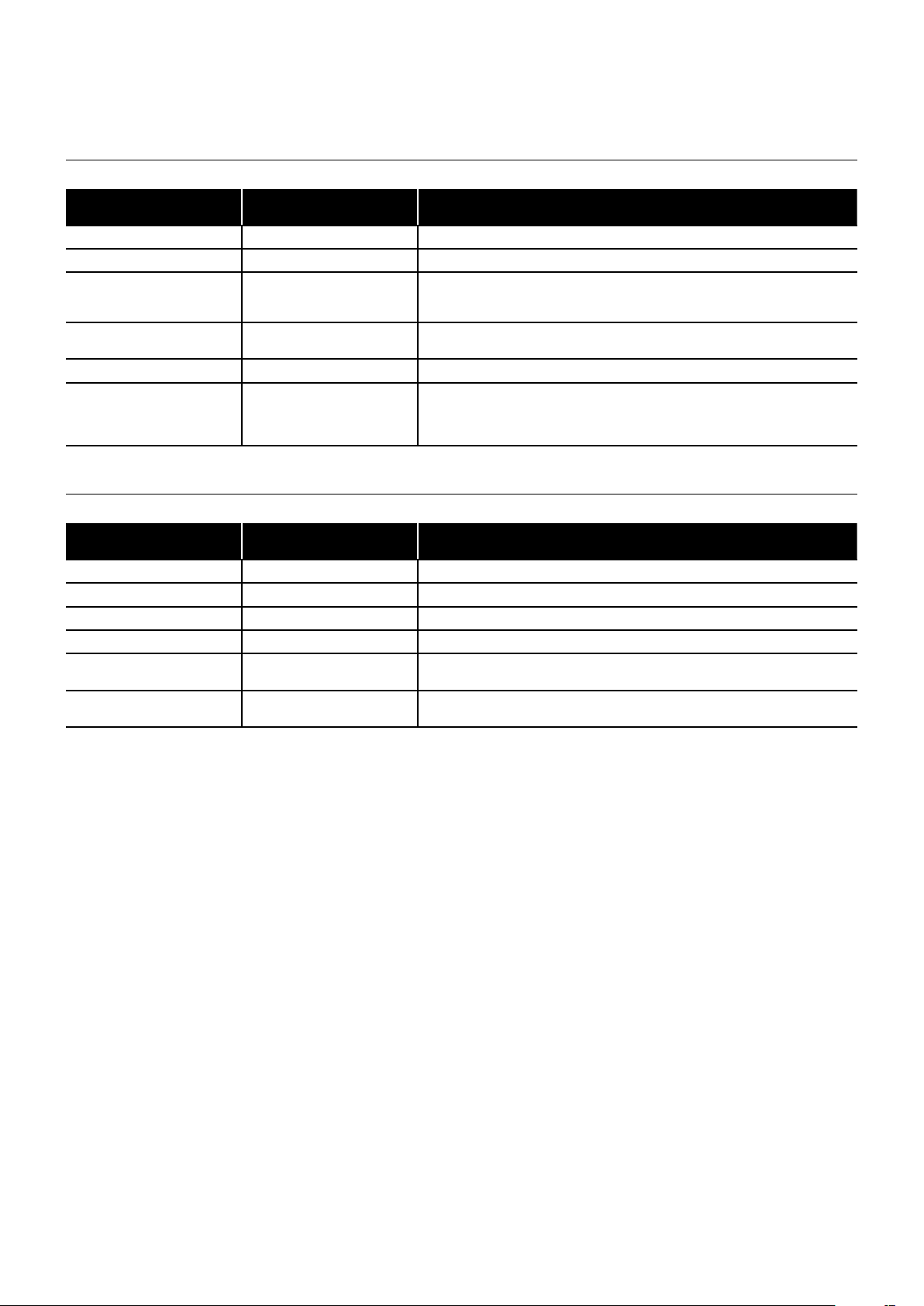

Table 1-1: Hybrid product codes

Product code Components Output

HPIDAIR

HPIDAIR2

* 7°C air and 35°C flow temperature

Boiler:

Flue:

Heat Pump:

Boiler:

Flue:

Heat Pump:

15/21kW (factory setting 21kW)

EZ90 (included)

16kW*

21/26kW (factory setting 26kW)

EZ90 (included)

16kW*

Two models of oil boiler only are also available as follows:

Table 1-2: Oil boiler product codes

Product code Components Output

VTXBFAIR

VTXBFAIR2

Boiler:

Flue:

Boiler:

Flue:

15/21kW (factory setting 21kW)

EZ90 (included)

21/26kW (factory setting 26kW)

EZ90 (included)

1.3 Planning Permission

Oil Boiler

Boiler installation is considered to be permitted development

and therefore, you do not need to apply for planning permission.

However, there are limitations:

• External flues must not exceed the highest point of a roof by

one metre or more.

• Listed buildings and property located in conser vation areas

may be subject to listed building consent and planning

permission.

• Any external flue installed on to a propert y located in a

conservation area must not be on the front of a propert y or any

part of the propert y that fronts a highway.

• Any outside building that will form part of your boiler and

heating system will have to follow the planning permission

limitations of outbuildings and extensions.

Heat Pump

The installation of a heat pump on domestic premises may

be considered to be permitted development, not needing an

application for planning permission, provided ALL the limits and

conditions listed on the Planning Portal website are met.

For further information, visit w w w.planningportal.gov.uk.

1.4 DNO Application

An application must be made to the Distribution Network Operator

(DNO) before connecting the heat pump to the mains electrical

supply. There are six DNOs operating the electrical distribution

network throughout England, Scotland and Wales and the

application must be made to the DNO covering the area concerned.

The necessary information required to make this application

(J-forms) can be downloaded from the Grant UK website (ww w.

grantuk.com), completed and then submitted to the correct DNO for

the area in question.

1.5 Servicing

It is recommended (and a requirement of the product guarantee)

that the hybrid should be regularly serviced, at least once a year

and the details entered in the Service Log by the service engineer.

Refer to Section 16 (Commissioning).

Section 1: IntroductionPage 4

1.6 Important Advice

1. It is essential that the full layout of the system is understo od

before the installation of any component is undertaken. If you

are in any doubt, please stop and seek advice from a qualified

heating engineer or from Grant UK. Please note that Grant

UK will not be able to offer specific advice about your system.

In this case, we will always refer you to seek the advice of a

qualified system designer.

2. The hybrid must be installed and commissioned in accordance

with these installation and servicing instructions. Deviations of

any kind will invalidate the guarantee and may cause an unsafe

situation to occur. Please seek advice from Grant UK if any of

these user, installation and servicing instructions cannot be

followed for whatever reason.

3. The heat pump contains high pressures and high temperatures

during normal working conditions. Care must be taken when

accessing the internal workings of the heat pump.

4. The heat pump contains an electrically driven fan which rotates

at high speed. Disconnect the heat pump from the electrical

supply before removing the top cover.

1.7 Product Contents

The VortexAir comes supplied on t wo pallets. The following items

are included:

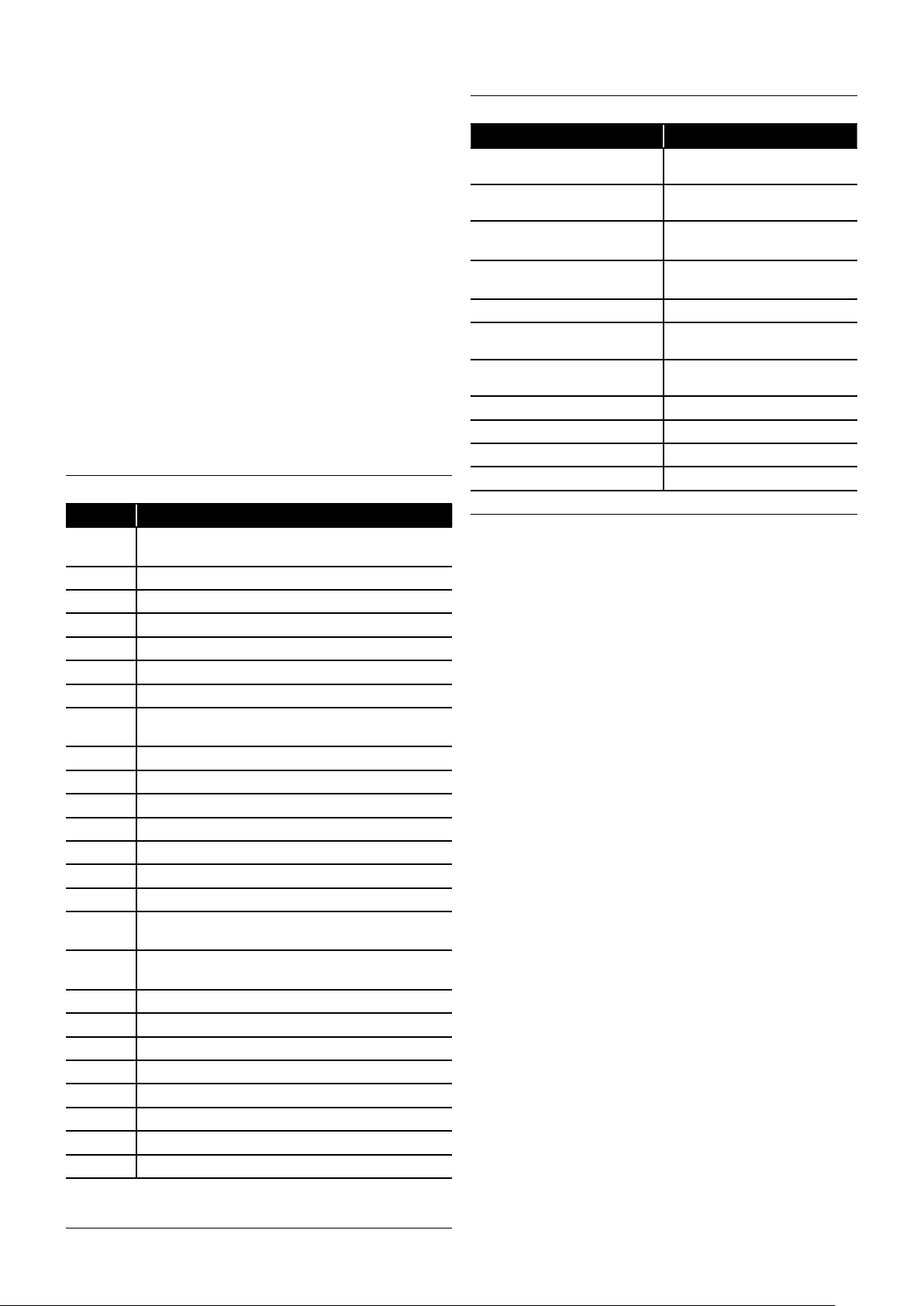

Table 1-3: Product contents

Quantity Item

1

1 Heat pump remote controller

1 Heat pump remote controller cable (length: 8 metres)

1 Heat pump condensate drain elbow

2 Flexible braided hose (1" BSP / 28 mm compression)*

2 1" x 1¼" BSP elbow

2 1" BSPM x 28mm brass tail

1

1 Joiner front cover plate

1 Joiner top cover plate

1 Lockshield valve adjustment key

1 Air adjuster disc**

1 Flexible oil hose (600 mm)

1 Oil line adaptor (

1 Oil isolator

4

1

1 Vertical flue ex tension section

1 Flue clamp bolt and nut

1 Flue bubble seal

1 Hybrid Installation and Servicing Instructions

1 Aerona³ Installation and Ser vicing Instructions

1 User Guide

1 Commissioning form

1 Energy label

* If flexible braided hoses are supplied with the heat pump, they must be

discarded.

** For downrating the 15/21kW boiler to 15 or 16kW output.

(product codes: V TXBFAIR or VT XBFAIR2)

4-core heat pump controls cable - numbered 1 to 4

Aerona³ 16kW heat pump

(product code: HPID16)

VortexBlue oil boiler

⅜" x ¼")

Length: 1400 mm (refer to Section 12.5)

Low level standard flue kit

(product code: EZ90)

1.8 Installation Accessories

The following are available from Grant UK:

Table 1-4: Installation accessories

Product code Description

HPIDFOOT/KIT*

HPIDINSU/KIT

HPIDHEATMETER

HPIDKW/HMETER

HPIDBUFFER50 50 litre buffer vessel

GCSD2

HPDHWBK2

HPAWSSK18 Aerona³ 18 litre sealed system kit

HPAWSSK50 Aerona³ 50 litre sealed system kit

RBS35 Adaptor oil line - 3/8 x 1/4

RBS36 Flexible oil hose (900mm) - 3/8 x 1/4

* Two sets required (one for the oil boiler and one for the heat pump)

Anti-vibration mounts with fixings

(2 x 600mm)

Through wall insulation kit

(22 - 28mm flexible hoses)

Heat meter

(Refer to Section 7-2)

Electricity meter

(Refer to Section 7-3)

Digital two-stage cylinder

thermostat

Automatic domestic hot water boost

kit (timed)

Section 1: Introduction Page 5

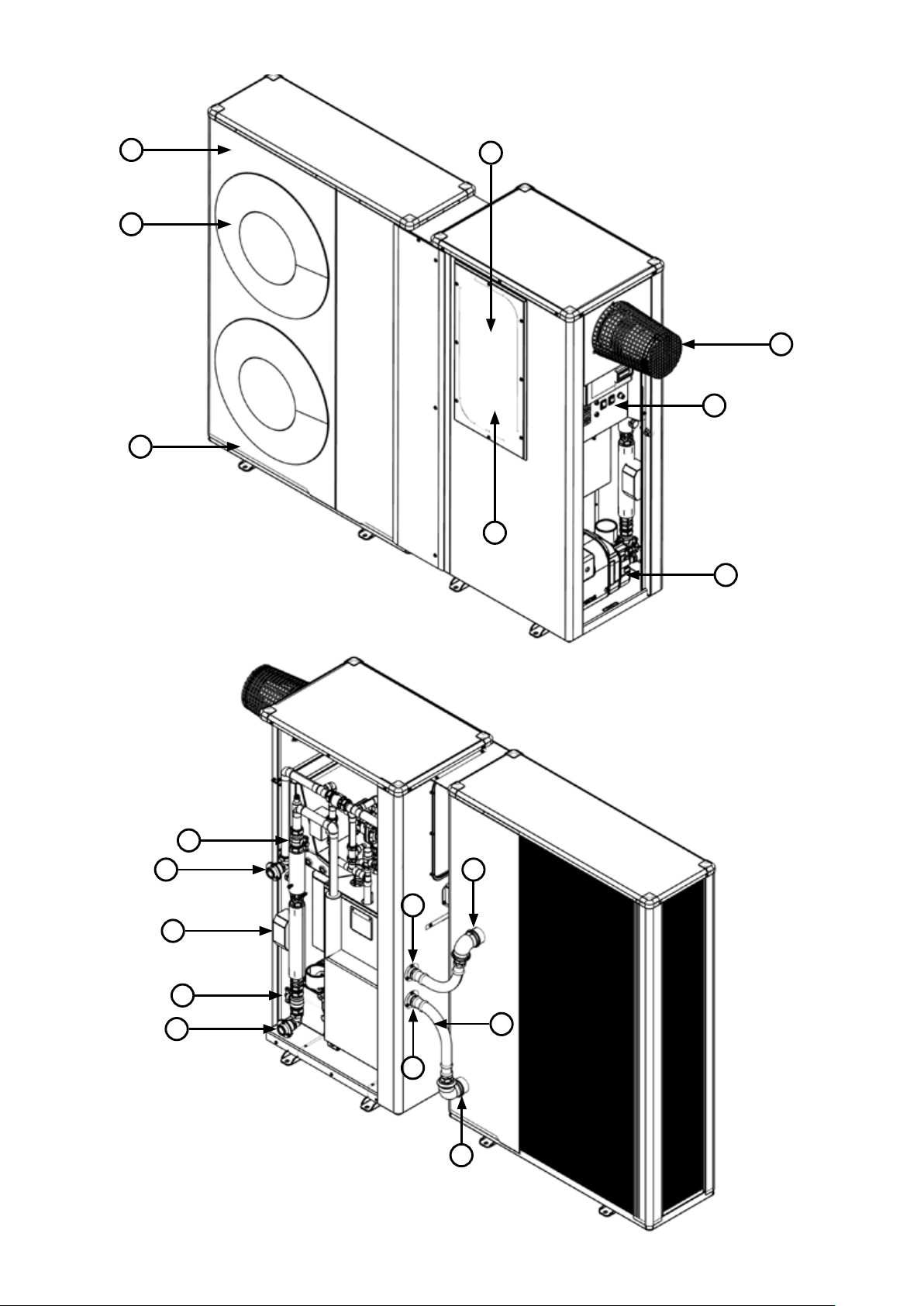

1.9 Hybrid Components

8

7

6

1

2

3

5

4

Figure 1-5: Main components - front

18

17

16

15

14

9

13

10

12

Figure 1-6: Main components - rear (oil boiler casing removed)

11

Section 1: IntroductionPage 6

13

12

21

22

19

20

Figure 1-7: Knockouts for oil lines and condensate disposal

Table 1-8: Key to main components - front

Key Item

1

2 Flue (external applications) Refer to Section 13

3 Control panel Refer to Section 10

4 Blue flame burner A Riello high-efficiency, low NOx blue flame burner with plug and socket connection

5 Pump High efficiency circulating pump

6 Anti-freezing heater Factory fitted electric heater prevents condensate in the base of the heat pump from freezing

7 Fa n

8 Air inlet Located in the left and back of the heat pump

9 Flow Refer to Section 5

10 Flexible hose

11 Return Refer to Section 5

12 Heat pump return Refer to Section 5

13 Heat pump flow Refer to Section 5

14 System return Refer to Section 5

15 Isolation valve Refer to Section 4 (if heat meter is fitted)

16 Heat meter Refer to Section 4 (if heat meter is fitted)

17 System flow Refer to Section 5

18 Isolation valve Refer to Section 4 (if heat meter is fitted)

19 Condensate trap

20 Condensate knockout

21

22 Oil line knockouts Refer to Section 3

Not shown

Front (removable) access

cover

Condensate knockout

(base - not shown)

Heat exchanger Award winning condensing heat exchanger

DC Inverter

Compressor A high-efficiency DC t win-rotary compressor to provide smooth performance and quiet operation.

Plate Heat Exchanger

(Condenser)

Circulating Pump High-efficiency DC pump speed controlled from the ASHP control PCB.

Pressure Relief Valve A 3 bar pressure relief valve is factory fitted.

Air Purge Valve (Automatic

Air Vent)

To access the heat pump wiring centre

A high-efficiency DC fan motor is used for smo oth and quiet operation. Two fans (3 blade) are fitted to the

16kW unit.

Refer to Section 9

This responds rapidly to changing conditions to provide the necessary output to meet heating demands by

varying the speed and output of the compressor, fan and circulating pump.

This reduces the on/off times of the compressor, ke eping the water temperature constant during operation

reducing the electricity consumption.

The high-efficiency plate heat exchanger is used to transfer heat to the heating system primar y circuit.

Factory fitted to assist in the removal of air from the heating primary circuit of the heat pump.

Section 1: Introduction Page 7

2 Technical Data

2.1 Boiler Technical Data

Table 2-1: Boiler technical data

Unit HPIDAIR - 15/21kW HPIDAIR2 - 21/26kW

Water content - oil boiler / heat pump (total)

Weight - oil boiler and heat pump (empty)*

Weight - oil boiler and heat pump (full)*

Maximum heat output (Kerosene)**

Heating system flow connection 1" BSP female

Heating system return connection 1" BSP female

Minimum flow rate (∆T=8°C) litres/min. 15

Condensate connection 22 mm (only connect plastic pipe)

Waterside resistance (∆T=10°C) mbar 26

Waterside resistance (∆T=20°C) mbar 9.5

Maximum static head metre 28

Minimum circulating head metre 1

Boiler thermostat range °C 65 to 78

Limit (safety) shut of f temperature °C 111 ± 3

Maximum hearth temperature °C Less than 50

Electricity supply 230/240V 1ph 50Hz fused at 5A

Burner motor power Watts 90

Absorbed motor power Watts 0.15

Starting current Amps 2.0

Running current Amps 0.85

Oil connection ¼" BSP male (on end of flexible tube)

Maximum operating pressure - sealed system bar 2.5

Maximum operating pressure - pressure relief valve bar 2.0

* Weight includes burner but excludes flue.

** Factory setting (ma ximum output). Refer to Section 2.4 for other boiler outputs.

litre 16.5 / 2.0 (18.5) 10.5 / 2.0 (12.5)

gallon 3.6 / 0.44 (4.04) 2.3 / 0.44 (2.74)

kg 270 272

lb 595 600

kg 290.2 286.5

lb 639.8 631.6

kW 21 26

Btu/h 71 694 88 764

2.2 Heat Pump Technical Data

For technical data relating to the heat pump, please refer to the Aerona³ installation and servicing instructions supplied with the heat pump.

Section 2: Technical DataPage 8

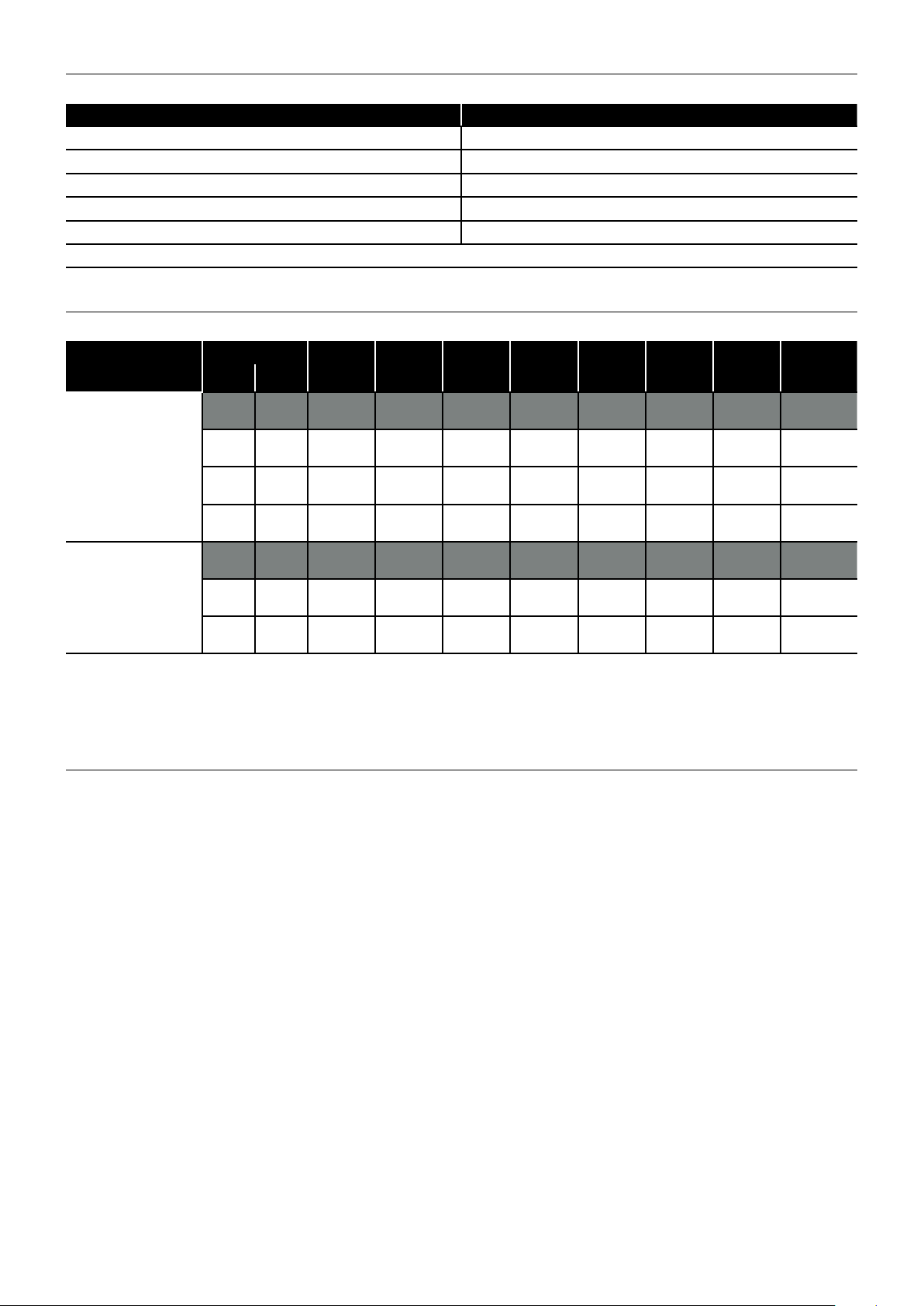

2.3 Sealed System Data

Table 2-2: Sealed system data

15/21 and 21/26kW

Heating system pressure (cold) Maximum 1.0 Minimum 0.5 bar

Operating pressure of pressure relief valve 2.5 bar

Expansion vessel size (pre-charged at 1 bar) To be selected based on the water content of the system

Cold water mains connection * 15 mm copper pipe

Pressure relief valve discharge connection * 15 mm copper pipe

* Provided that a Grant UK sealed system kit (listed in Table 1-4) has been used

2.4 Burner Settings

Table 2-3: Burner settings

Hybrid model

(burner type)

HPIDAIR

15/21kW

(RDB2.2 BG1 BLU)

HPIDAIR2

21/26kW

(RDB2.2 BG3 BLU)

Notes:

1. The data given above is approximate only.

2. The above settings may have to be adjusted on site for the correct operation of the burner.

3. Gas Oil and Bio Kerosene are NOT suitable for use with the Grant HybridAir

4. The flue gas temperatures given above are ± 10%.

5. When commissioning, the air damper must be adjusted to obtain the correct CO

6. * Factory settings: 15/21 - 21kW, 21/26 - 26kW

7. The installer must amend the boiler data label if the output is changed.

Heat output

(kW) (Btu/h)

* 21 * 71 650 0.60/80°ES 8.5 0 - 1 BG1 N/A 1.78 55 - 85 12.0

15 51 200 0.40/80°ES 9.0 0 - 1 BG1

16 54 600 0.40/80°ES 10.5 0 - 1 BG1

18 61 400 0.55/80°ES 8 0 - 1 BG1 N/A 1.53 50 - 80 12.0

* 26 * 88 700 0.65/80°ES 10 0 - 1 BG2 N/A 2.19 55 - 75 12.0

21 71 650 0.60/80°ES 8.5 0 - 1 BG2 N/A 1.78 45 - 65 12.0

23 78 475 0.65/80°ES 8.5 0 - 1 BG2 N/A 1.94 50 - 70 12.0

Nozzle

Oil

pressure

(bar)

Smoke

No.

Burner

head type

level.

2

Burner

head/disc

setting

Disc

setting B

Disc

setting B

Fuel

flow rate

(kg/h)

1.28 45 - 75 12.0

1.36 45 - 75 12.0

Flue gas

temp.

(°C)

CO

(%)

2

2.5 Flue Gas Analysis

To allow the boiler to be commissioned and ser viced, the boiler is supplied with a combustion test point on the front cleaning door. When

this test point is used please note the following:

• The test point is for CO2 and smoke readings only.

• The boiler efficiency and temperature must be taken from the flue test point on high level, vertical and conventional flue adaptors.

• Concentric low level flues do not contain a test point. The temperature and efficiency readings must be taken from the flue terminal.

Section 2: Technical Data Page 9

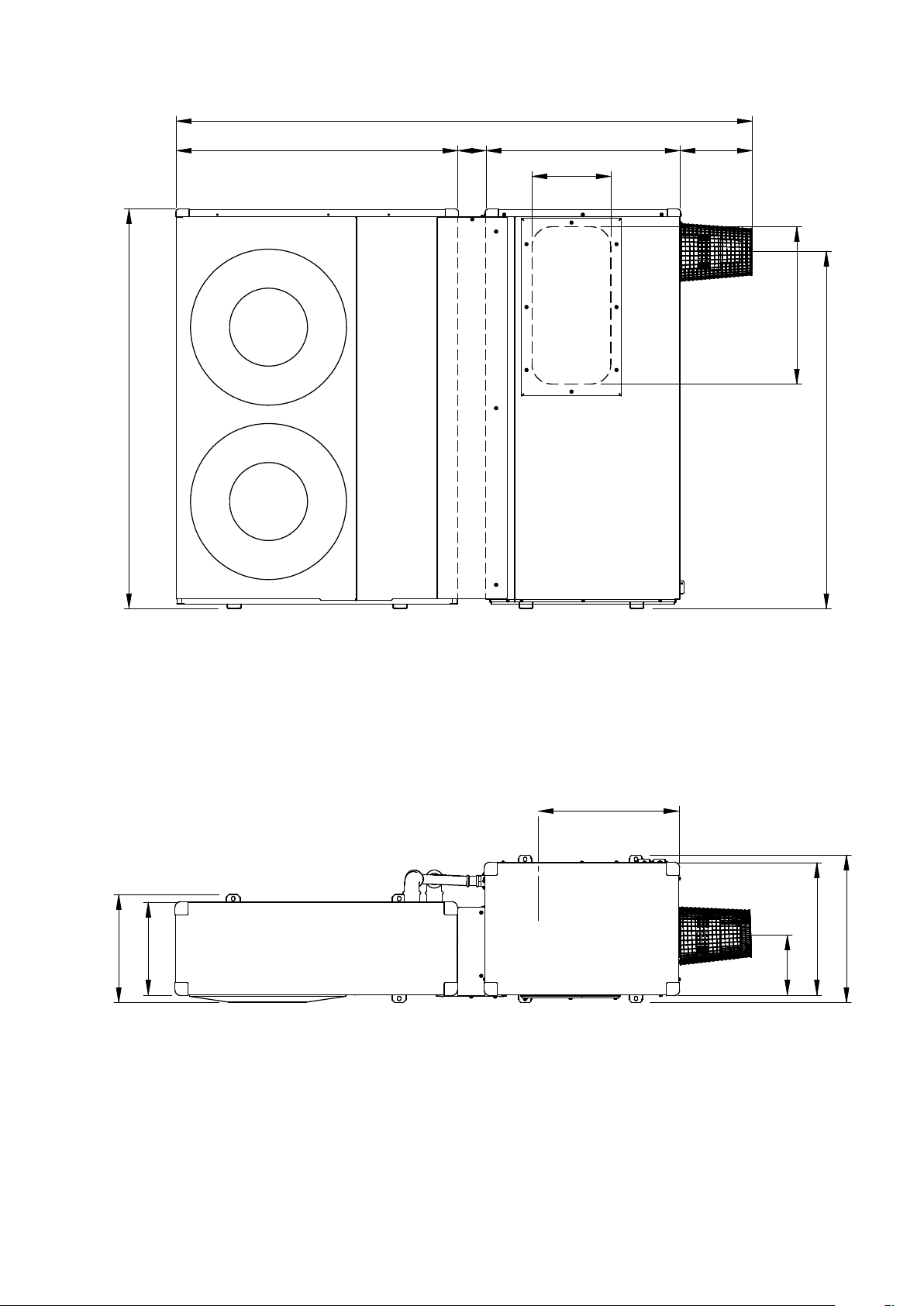

2.6 Hybrid Dimensions

2047

280

690100

257

560

1270

1000

1420

Figure 2-4: Hybrid front view

500

525

471

385

330

213

Figure 2-5: Hybrid top view

All dimensions in the diagrams are in millimetres.

Please note: all dimensions are excluding the feet (refer to Section 1.8).

For details of the heat pump only - refer to Aerona³ Installation Instructions supplied with the heat pump.

Section 2: Technical DataPage 10

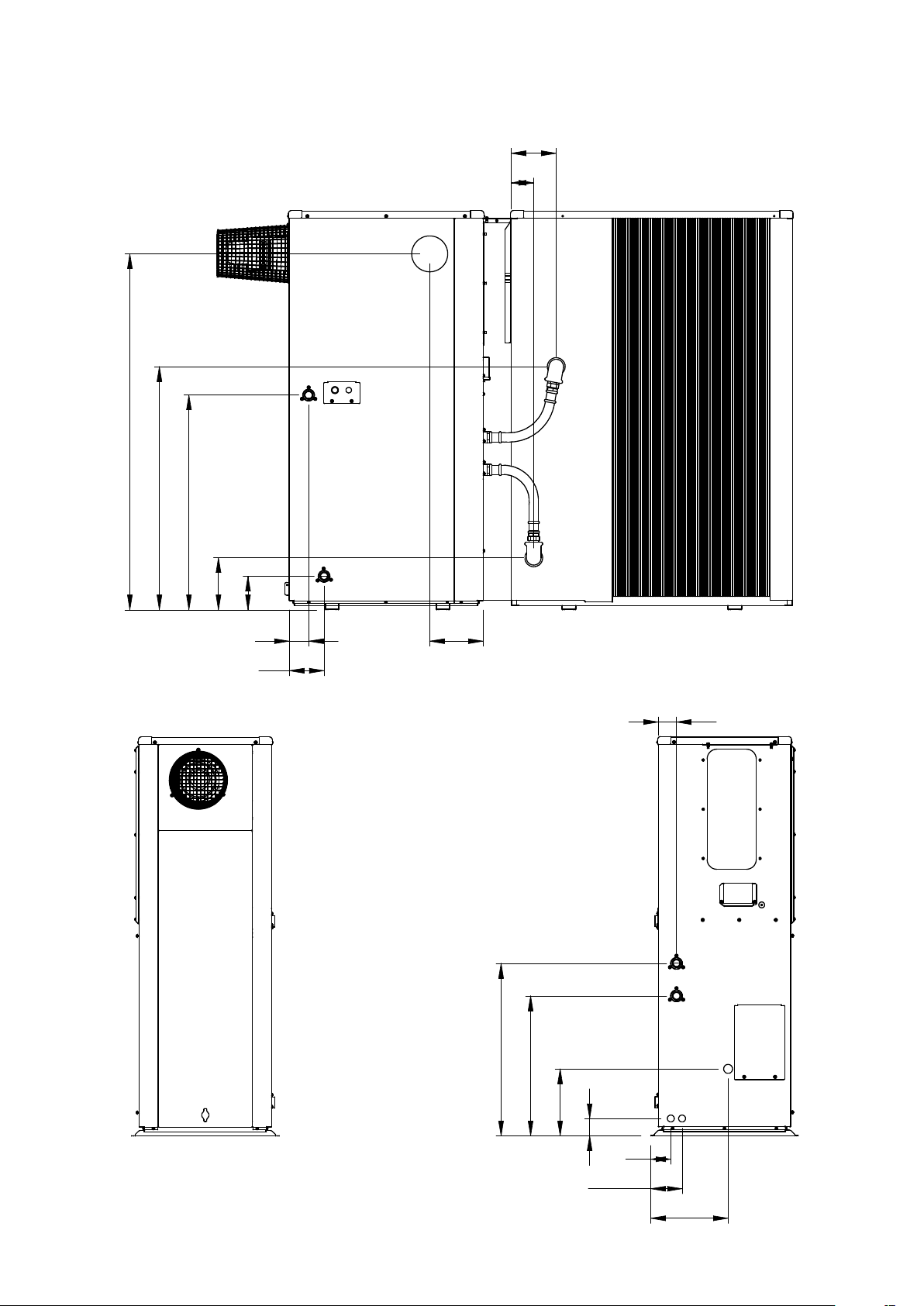

1270

160

80

865

764

185

119

69

124

190

Figure 2-6: Hybrid rear view

65

613

498

Figure 2-7: Oil boiler right hand view

Section 2: Technical Data

238

62

72

112

275

Figure 2-8: Oil boiler left hand view

Page 11

2.7 Clearances

The following minimum clearances must be used to enable the unit to be easily commissioned, serviced and maintained.

In the case of the heat pump, these will allow for adequate air flow in and out of the unit.

2.7.1 Oil Boiler and Heat Pump Installed Externally

Table 2-9: Minimum clearances required for oil boiler and heat pump installed externally

Aspect

Top (above) 300

Bottom (below)

In front of unit

Rear of unit

Left-hand side

Right-hand side (burner end) 600

Minimum clearance required

(mm)

100 This is the height of

600

300 (from rear of heat pump)

150 (from rear of oil boiler)

100

Notes

Ensure that there is adequate clearance to remove the front access panel and that the

air discharged from the heat pump will not cause a nuisance.

Ensure that there is adequate clearance to remove the access panel, the burner and

to work upon the control panel.

IMPORTANT: This distance may have to be increased in order to comply with the flue

terminal clearances. Refer to Section 13.3.

2.7.2 Oil Boiler Installed Internally

Table 2-10: Minimum clearances required for oil boiler installed internally

Aspect

Top (above) 300

Bottom (below)

In front of unit

Rear of unit

Left-hand side

Right-hand side (burner end) 600

Minimum clearance required

(mm)

N/A

600 Ensure that there is adequate clearance to remove the front access panel.

150

600

Notes

Ensure that there is adequate clearance to remove the condensate trap access panel

and condensate trap.

Ensure that there is adequate clearance to remove the access panel, the burner and

to work upon the control panel.

anti-vibration mounts. Refer to Table 1-4.

2.7.3 Heat Pump Installed Externally

For clearances for the heat pump (only) installed externally, refer to Section 3.5.2 and Figure 3-2 of the Installation and Ser vicing Instructions

supplied with the Aerona³ unit.

Section 2: Technical DataPage 12

3 Oil Storage and Supply System

FROM PUMP

3.1 Fuel Supply

Fuel Storage

The tank should be positioned in accordance with the

recommendations given in BS 5410-1:2014, which gives details of

filling, maintenance and protection from fire.

A steel tank may be used and must be constructed to BS 7995:2010 and OFS T200.

!

A galvanised tank must NOT be used.

A plastic tank may be used and must comply with OFS T100.

!

Plastic tanks should be adequately and uniformly supported

on a smooth level sur face, across their entire base area, that

is, the area in contact with the ground.

Fuel Pipes

Fuel supply pipes should be of copper tubing with an external

diameter of at least 10 mm.

Galvanised pipe must not be used.

All pipe connections should preferably use flared fittings. Soldered

connections must not be used on oil pipes.

!

Flexible hoses must NOT be used outside the boiler casing.

A remote sensing fire valve must be installed in the fuel supply line,

with the sensing head located above the burner.

Recommendations are given in BS 5410-1:2014.

A suitable oil filter with a minimum 15µ filtration must be installed in

the oil supply line. A shut-off valve should be fitted before the filter,

to allow the filter to be serviced.

A flexible fuel line, adaptor and ¼" BSP isolation valve are supplied

loose with the boiler for the final connection to the burner. If a two

pipe system or 'Tiger Loop' type de-aerator is used, an additional

flexible fuel hose (900 mm) and 3/8" to 1/4" BSP male adaptor are

available to purchase from Grant UK (product codes: RBS35 and

RBS36).

Metal braided flexible hoses should be replaced annually when

the boiler is serviced. Long life flexible hoses should be inspected

annually and replaced at least every 60 months.

CAUTION

NOTE

CAUTION

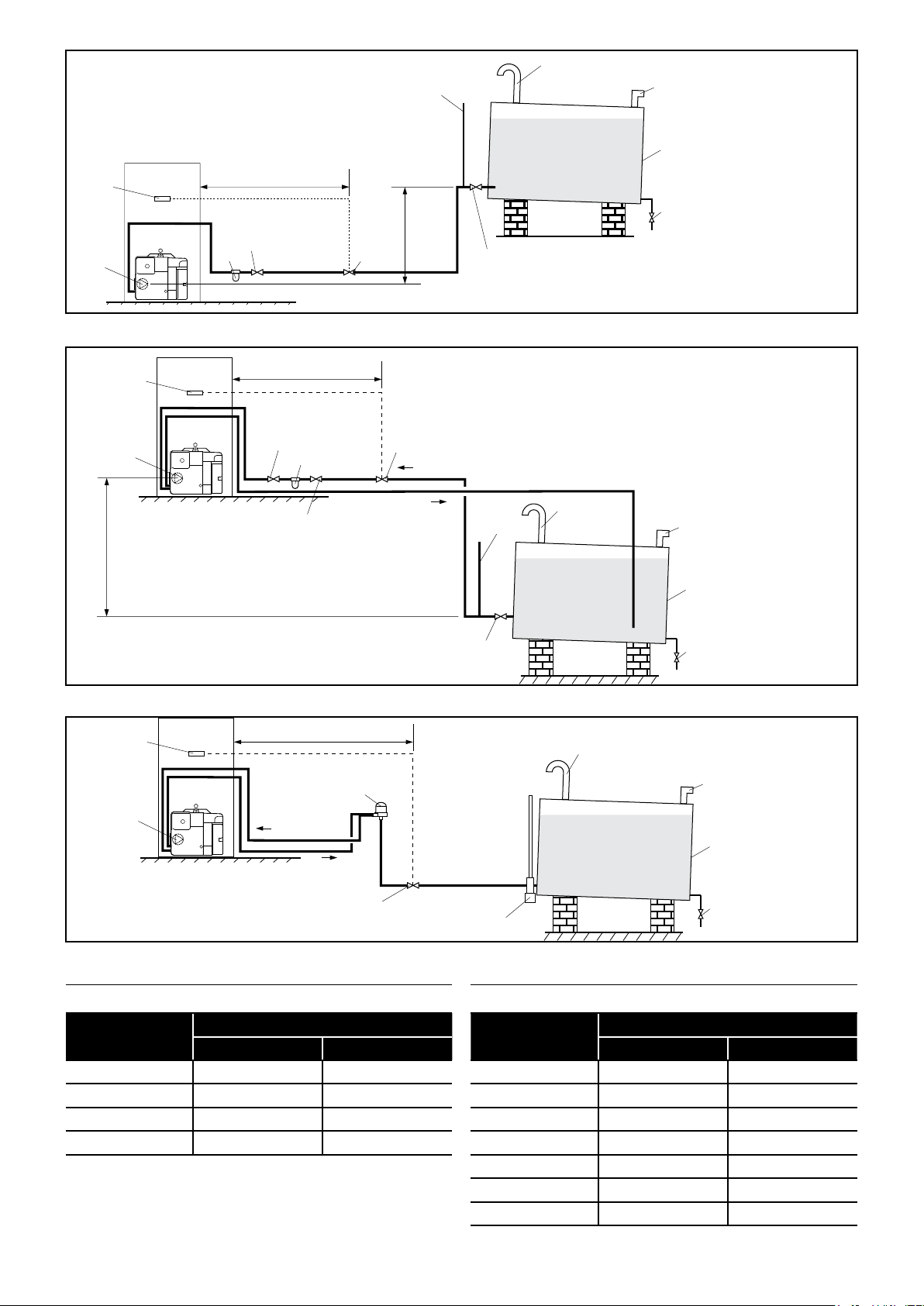

Single pipe system - (refer to Figure 3-2 and Table 3-5)

With the storage tank outlet above the burner a single pipe system

should be used. The height of the tank above the burner limits the

length of pipe run from the tank to the burner.

As supplied the burner is suitable for a single pipe system.

Two pipe system - (refer to Figure 3-3 and Table 3-6)

With the storage tank outlet below the burner, a two pipe system

should be used. The pipe runs should be as shown in Figure 3-2.

The return pipe should be the same level in the tank as the supply

pipe, both being 75 to 100 mm above the base of the tank. The pipe

ends should be a sufficient distance apart so as to prevent any

sediment disturbed by the return entering the supply pipe.

Avoid the bottom of the tank being more than 3.5 m below the

burner.

A non-return valve should be fitted in the supply pipe together with

the filter and fire valve. A non-return valve should be fitted in the

return pipe if the top of the tank is above the burner.

To be used with a t wo-pipe system, the burner must be fitted with an

additional flexible fuel hose - a flexible fuel hose (900 mm) and 3/8"

to 1/4" BSP male adaptor are available to purchase from Grant UK

(product codes: RBS35 and RBS36).

The pump vacuum should not exceed 0.4 bar. Beyond this limit gas

is released from the oil.

For guidance on installation of top outlet fuel tanks and suction oil

supply sizing, see OFTEC Technical Book 3. Available from OFTEC.

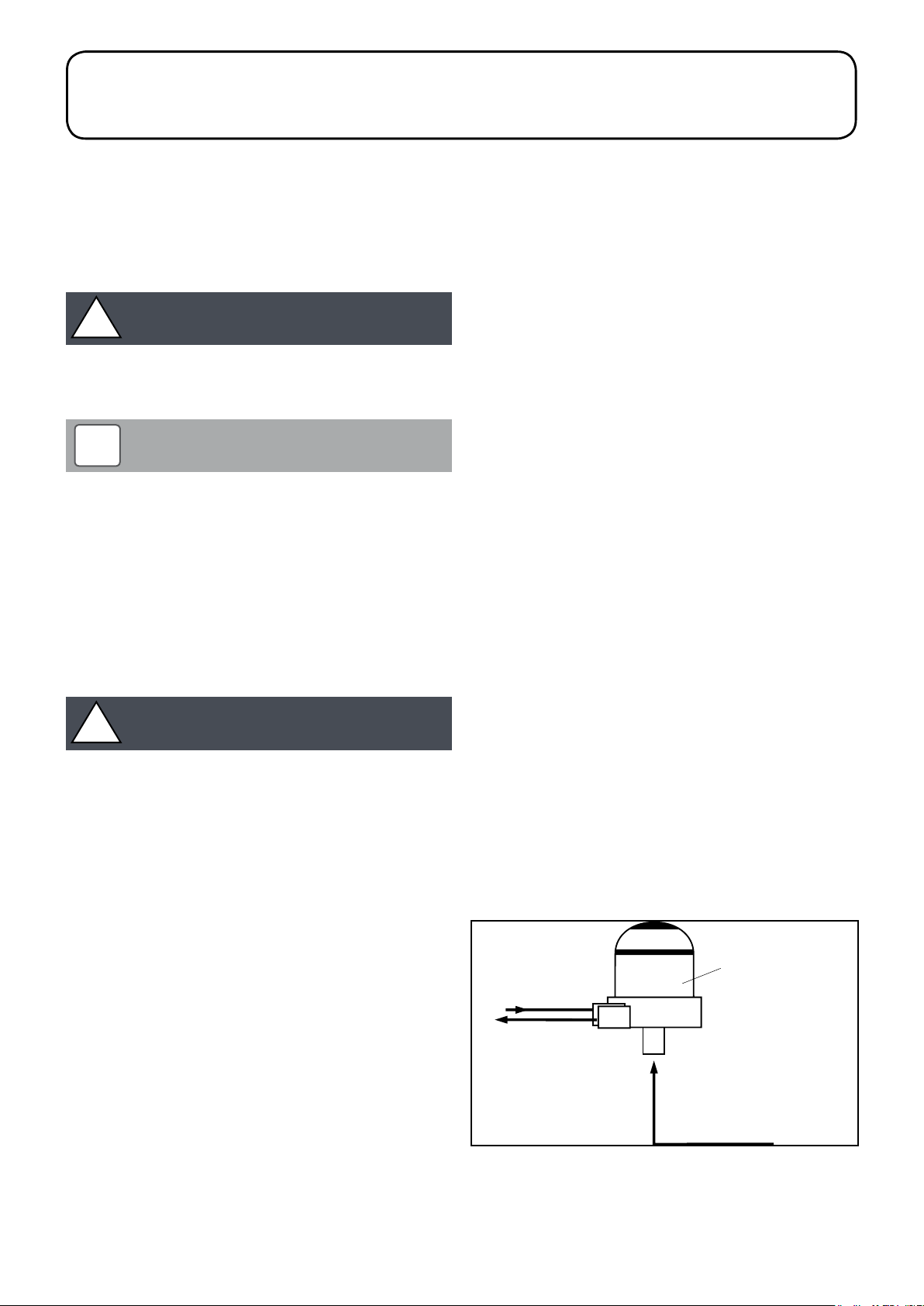

Tiger Loop system - (refer to Figure 3-1 and 3-4)

When The storage tank outlet is below the burner, an alternative to

a two pipe system can be achieved using a 'Tiger Loop' t ype oil

de-aerator. This ef fectively removes the air from the oil supply on a

single pipe lift.

The de-aerator is connected close to the boiler as a two pipe

system (omitting the non-return valve) as shown in Figure 3-3.

Refer to the manufacturers instructions supplied with the de-aerator.

The de-aerator must be mounted vertically. See Figure 3-3 and 3-4.

To be used with a de-aerator, the burner must be fitted with an

additional flexible fuel hose - a flexible fuel hose (900 mm) and 3/8"

to 1/4" BSP male adaptor are available to purchase from Grant UK

(product codes: RBS35 and RBS36).

RETURN

SUPPL Y

TO PUMP

Tiger Loop

1/4" BSP female

connections

Section 3: Oil Storage and Supply System Page 13

SUPPL Y

FROM TANK

Figure 3-1: Tiger loop de-aeration device

Vent

Fire

valve

sensor

Pump

Filter

Figure 3-2: Single pipe system

1 m

Shut-off

valve

Fire

valve

A

Level

gauge

pipe

Fill

pipe

Fuel

storage

tank

Sludge

valve

Shut-off

valve

Fire

valve

sensor

See

Section 3.2

A

Figure 3-3: Two pipe system

Fire

valve

sensor

See

Section 3.2

1 m

Non

return

valve

Filter

Shut-off

valve

1 m

De-aeration device

e.g. Tiger Loop

See Figure 3-1

Supply

Return

Fire

valve

Return

Supply

Shut-off

valve

Level

gauge

Vent

pipe

Fill

pipe

Fuel

storage

tank

Sludge

valve

Vent

pipe

Fill

pipe

Fuel

storage

tank

Fire valve

Figure 3-4: De-aeration device system

Table 3-5: Single pipe system maximum pipe runs

Head A

(m)

0.5 10 20

1.0 20 40

1.5 40 80

2.0 60 100

Maximum pipe run (metres)

10 mm OD pipe 12 mm OD pipe

Sludge

Tankmaster

valve

Table 3-6: Two pipe system maximum pipe runs

Maximum pipe run (metres)

10 mm OD pipe 12 mm OD pipe

Head A

(m)

0 35 100

0.5 30 100

1.0 25 100

1.5 20 90

2.0 15 70

3.0 8 30

3.5 6 20

Section 3: Oil Storage and Supply SystemPage 14

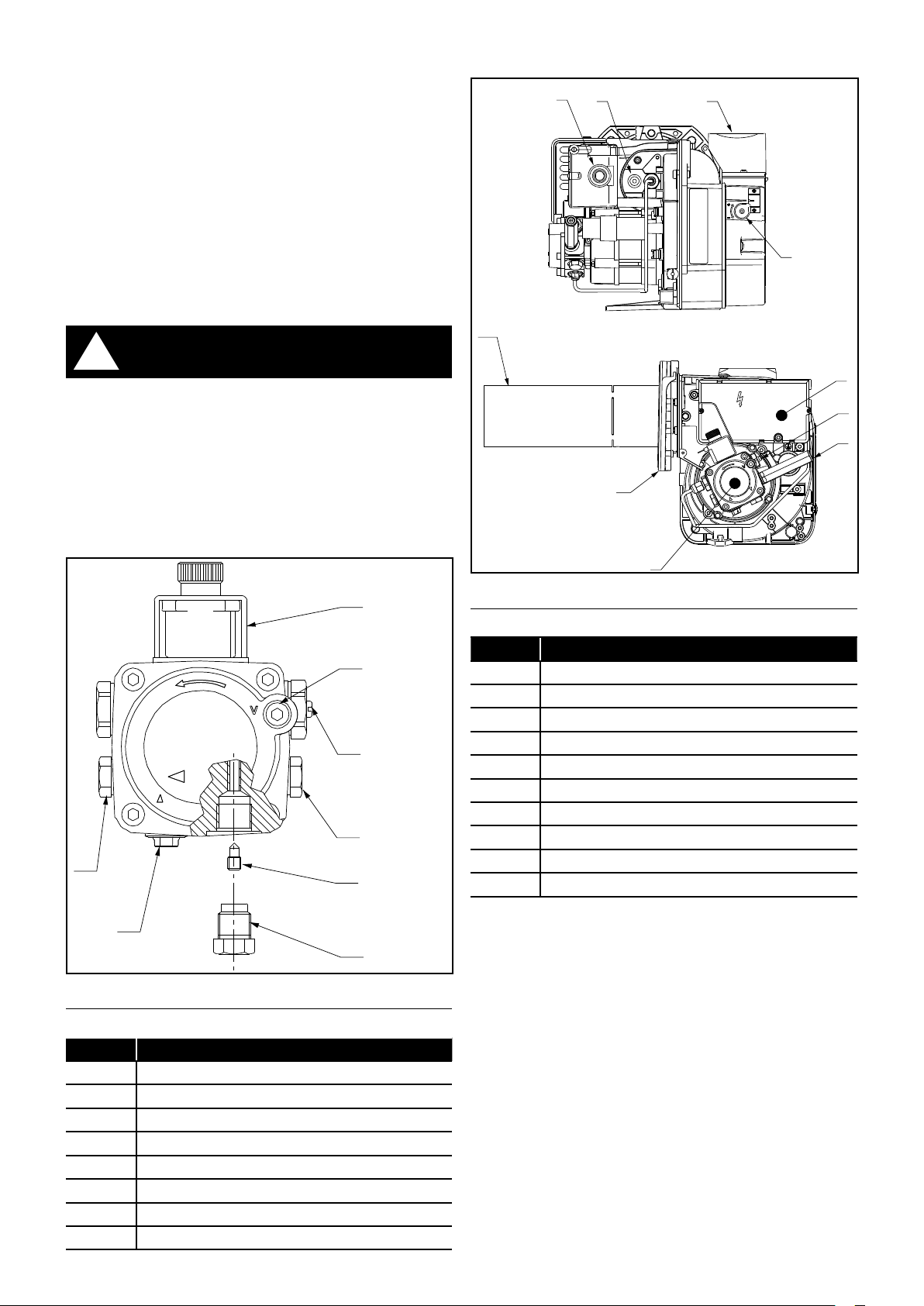

3.2 Burner Oil Connection

3

The burner fuel pump is supplied for use with a single pipe fuel

supply system. For use on a two pipe system, it is necessar y to fit

the by-pass screw, as shown in Figure 3-7, into the tapping in the

return port.

The by-pass screw is supplied in the boiler accessory pack.

1. Remove the plastic burner cover (secured by one screw).

For ease of access to the fuel pump, to fit the by-pass screw

and connect the oil lines, the burner can be removed from the

boiler. To do this, unscrew the single nut at the top of the burner

(using a 13 mm spanner) and withdraw the burner from the

boiler.

2. Remove and discard the blanking plug from the return

connection of the pump and fit the by-pass screw using an

hexagonal key.

3.3 Burner Components

9

10

6

5

!

The blanking plug supplied in the inlet (suction) port may now

be plastic and will not provide an oil tight seal when the pump

is running. Ensure that the supply from the tank is connected

to this port and that the plastic plug is discarded.

3. Connect the return oil flexible fuel hose to the pump.

4. Connect the 3/8" to 1/4" BSP adaptor to the flexible fuel hose.

Flexible fuel hoses and adaptors are available to purchase from

Grant UK. Refer to Section 1.8.

WARNING

7

6

5

4

8

3

2

7

8

4

1

Figure 3-9: Riello RDB burner components

Table 3-10: Riello RDB burner components key

Key Description

1 Oil pump

2 Digital control box

3 Reset push-button with lockout lamp

4 Flange with insulating gasket

5 Air damper adjustment screw

6 Snorkel (balanced flue) connection

7 Pump pressure adjustment screw

8 Pressure gauge port

9 UV sensor

10 Combustion head

1

2

Figure 3-7: Riello RDB pump

Table 3-8: Riello RDB pump key

Item Description

1 Inlet (suction) port

2 Return port

3 By-pass screw

4 Pressure gauge port

5 Pressure adjustment

6 Vacuum gauge port

7 Solenoid

8 Auxiliar y pressure test point

Section 3: Oil Storage and Supply System Page 15

4 Installation Information

4.1 Introduction

!

Before star ting any work on the boiler or fuel supply, please

read the Health and Safet y information given in Section 18 of

these instructions.

Before star ting any work on the heat pump, please read

the Health and Safety information given in Section 14 of the

Aerona³ installation instructions.

This section gives a general overview of the installation process with

detailed installation information given in the following sections:

• Section 5 - Installing the Oil Boiler - pages 18 to 19

• Section 6 - Installing the Heat Pump - pages 20 to 21

• Section 7 - Installing the Heat Meters (where required) - pages

22 to 29

!

It is recommended, where possible, to fit the heat meter

during the installation of the oil boiler to avoid the need to

drain the system at a later date.

WARNING

NOTE

4.2 VortexAir location

4.2.1 Selection of position

• Consider a place where the noise, air and flue discharge will

not affect neighbours.

• Consider a position protected from the wind.

• Consider an area that reflects the minimum spaces

recommended.

• Consider a place that does not obstruct the access to doors or

paths.

• The surfaces of the floor must be solid enough to suppor t the

weight of the VortexAir and minimise the transmission of noise

and vibration.

• Take preventive measures so that children cannot reach the

unit.

• Install the VortexAir in a place where it will not be inclined more

than 5°.

• When installing the VortexAir where it may exposed to strong

wind, brace it securely.

Decide the mounting position as follows:

• Install the VortexAir in a level location which can withstand the

weight of the heat pump and vibration.

• Provide the indicated space to ensure good airflow.

• Do not install the VortexAir near a source of heat, steam, or

flammable gas.

• During heating operation, condensate water flows from the heat

pump. Therefore, install the heat pump in a place where the

condensate water flow will not be obstructed.

• Do not install the heat pump where strong wind blows directly

onto the heat pump or where it is very dusty.

• Do not install the VortexAir where people pass frequently.

• Install the VortexAir in a place where it will be free from adverse

weather conditions as much as possible.

•

4.2.2 Noise Level (heat pump)

All heat pumps make a noise. Discuss the potential nuisance factor

with the end-user when considering the final position of the heat

pump. Take opening windows and doors into account. It is not

essential for the heat pump to be positioned next to a wall of the

house. Behind an out-building may be more suitable so discuss the

options with the end-user.

4.2.3 Orientation (heat pump)

The North face of the building will usually have colder ambient air

than any other side. To ensure ma ximum ef ficiency from the Grant

UK Aerona³ heat pump, position the heat pump on a warmer side. In

order of preference, site the heat pump on a South face followed by

either South East or South West, then by East or West. Only install

on a North face if there is no other alternative.

4.3 Preparation for Installation

4.3.1 Base (boiler and heat pump installed externally)

The heat pump and boiler should be installed on a flat trowelled

finished concrete base 150 mm thick. This base should extend at

least 150 mm beyond the heat pump and boiler on three sides.

To avoid bridging the DPC, leave a gap of at approximately 150 mm

between the concrete base and the wall of the house.

The VortexAir unit must be raised up from the base by approximately

100mm on suitable anti vibration mounts or blocks - two each for

the boiler and the heat pump (refer to Table 1-4).

The VortexAir can be installed either against the building or 'free

standing' some distance away from the building.

4.3.2 Base (boiler installed internally)

The boiler must stand on a firm and level surface. The boiler base

temperature is less than 50°C so no special hearth is required.

4.3.3 Clearances

The minimum clearances given in Section 2.7 must be used to

enable both the boiler and heat pump of the VortexAir to be easily

commissioned, serviced and maintained and allow adequate air

flow in and out of the heat pump.

4.4 Regulations and Standards

Installation of a Grant VortexAir must be in accordance with the

following recommendations:

• Building Regulations for England and Wales, and the Building

Standards for Scotland issued by the Department of the

Environment and any local Byelaws which you must check with

the local authority for the area.

• Model and local Water Undertaking Byelaws.

• Applicable Control of Pollution Regulations.

The following OFTEC requirements:

• OFS T100 Polythene oil storage tanks for distillate fuels.

• OFS T200 Fuel oil storage tanks and tank bunds for use with

distillate fuels, lubrication oils and waste oils.

Further information may be obtained from the OFTEC Technical

Book 3 (Installation requirements for oil storage tanks) and OFTEC

Technical Book 4 (Installation requirements for oil fired boilers).

The installation should also be in accordance with the latest edition

of the following British Standard Codes of Practice:

• BS 715 Metal flue pipes, fittings, terminals and accessories.

• BS 799:5 Oil storage tanks.

• BS 1181 Clay flue linings and flue terminals.

Section 4: Installation InformationPage 16

• BS 4543:3 Factory made insulated chimneys for oil fired

appliances.

• BS 4876 Performance requirements for oil burning appliances

• BS 5410:1 Code of Practice for oil firing appliances.

• BS 5449 Forced circulation hot water systems.

• BS 7593 Code of Practice for treatment of water in heating

systems.

• BS 7671 Requirements for electrical installations, IET Wiring

Regulations.

For a list of recommendations and regulations to the heat pump,

refer to the Installation and Servicing Instructions supplied with the

heat pump.

Grant Engineering (UK) Limited strongly recommends that

a Grant MagOne in-line magnetic filter/s (or equivalent*)

is fitted in the heating system pipework. This should be

installed and regularly serviced in accordance with the filter

manufacturer’s instructions.

* As measured by gauss. The MagOne magnetic filter has a gauss

measurement of 12000.

!

We recommend that both antifreeze and corrosion inhibitor

be used in the primary water system.

NOTE

4.5 Completion

Please ensure that the OFTEC CD/10 installation completion report

(provided with the boiler) is completed in full.

Leave the top copy with the User.

Retain the carbon copy.

Ensure that:

a. The User Information pack (supplied with the boiler) is handed

over to the Householder.

b. The householder is aware of how to use the product.

c. The householder is aware of the need to refer to the online

calculator and change the stat.

d. The product is registered for the Grant product guarantee.

4.6 Before you Commission

4.6.1 Flushing and Corrosion Protection

To avoid the danger of dir t and foreign matter entering the VortexAir

the complete heating system should be thoroughly flushed out

– both before the VortexAir is operated and then again af ter the

system has been heated and is still hot.

This is especially important where the VortexAir is installed as a

replacement for a boiler on an existing system.

In this case the system should be first flushed hot, before the old

boiler is removed and replaced by the VortexAir.

For optimum performance after installation, this VortexAir and the

central heating system must be flushed in accordance with the

guidelines given in BS 7593:2006 ‘Treatment of water in domestic

hot water central heating systems’.

This must involve the use of a proprietary cleaner, such as Sentinel

X300 or X400, or Fernox Restorer.

After flushing, a suitable thermal fluid should be used (such as

Sentinel R600) specifically designed for use in air source heat pump

installations. This provides long term protection against corrosion

and scale as well as the risk of the freezing in the ex ternal section of

the heating system (i.e. the flexible hoses, condenser and circulating

pump within the heat pump casing) in the event of power failure

during winter months.

In order to avoid bacterial growth, due to the lower system operating

temperatures, a suitable Biocide (such as Sentinel R700) should

also be used in conjunction with the thermal fluid.

Both the thermal fluid and biocide should be added to the system

water when finally filling the heating system.

Alternatively, Fernox HP5C can be used (or HP15C for greater frost

protection).

This is a suitable thermal fluid that already contains a suitable

biocide.

Full instructions on the correct use of thermal fluids and biocides are

supplied with the products, but further information can be obtained

from either ww w.sentinel-solutions.net or ww w.fernox.com.

Failure to implement the above guidelines by fully flushing the

system and using a suitable thermal fluid and biocide corrosion

inhibitor will invalidate the heat pump product guarantee.

4.7 Heating System Design Considerations

To achieve the ma ximum ef ficiency possible from the Grant

VortexAir, the heating system should be designed to the following

parameters:

Radiators:

• Flow temperature 70°C, return temperature 50°C, differential

20°C

Underfloor:

• Flow temperature 50°C, return temperature 40°C, differential

10°C

Size radiators with a mean water temperature of 60°C.

Design system controls with programmable room thermostats or

use weather compensating controls to maintain return temperatures

below 55°C.

!

The boiler should not be allowed to operate with return

temperatures of less than 40°C when the system is up to

operating temperature.

The use of a pipe thermostat is recommended to control the return

temperature when using weather compensating controls.

NOTE

4.8 Underfloor Heating Systems

In underfloor systems it is essential that the return temperature must

be maintained above 40°C to prevent internal corrosion of the boiler

water jacket.

4.9 Pipework Materials

Grant VortexAir units are compatible with both copper and plastic

pipe. Where plastic pipe is used it must be of the oxygen barrier

type and be of the correct class (to BS 7291-1:2010) for the

application concerned.

!

The first metre of pipework connected to both the heating

flow and return connections of the boiler must be made in

copper.

WARNING

4.10 Underfloor Pipework

Plastic pipe may be used on underfloor systems where the plastic

pipe is fitted after the thermostatic mixing valve.

Copper tube must be used for at least the first metre of flow and

return primary pipework between the boiler and the underfloor

mixing/blending valves.

Section 4: Installation Information Page 17

5 Installation of the Oil Boiler

5.1 Preparation for Installation

1. Carefully remove the packaging from the boiler and remove it

from the transit pallet.

2. The oil supply line should be installed up to the position of the

boiler. Refer to Section 3 for details.

3. The final connection into the boiler enclosure can be made

when the boiler is in position. Using 10 mm soft copper, route

the oil line(s) into the boiler casing through the hole(s) provided

in the lower left corner of the left-hand casing panel. Refer to

Figure 1-7. Run it along the base of the enclosure (between

rear casing panel and the boiler) up to the burner located at the

right hand end of the enclosure. Refer to Section 3.2 for details

of the connection to the burner.

4. Position the boiler in the final location required, raised up from

the base by approximately 100 mm on suitable anti-vibration

mounts. This location may be either inside or outside the

building, as required.

• If the boiler is to be installed externally (next to the heat pump),

refer to Section 5.2.

• If the boiler is to be installed internally (with the heat pump

outside), refer to Section 5.3.

5.2 Installing the Oil Boiler – External location (nex t

to the heat pump)

1. With the boiler in the required position, ensure that the flue

terminal position complies with the necessary clearances.

Refer to Section 2.8.

2. Mark the wall and drill holes for the system flow and return

pipes. Refer to Figures 2-6 and 5-2 for the positions of the

pipework connections in the boiler rear panel.

3. Make the water connections as described in Section 8.4. If

access will be restricted, make any connections to the boiler

(and heat pump) before placing it in its final position.

4. Pipework should be insulated where it passes through the wall.

5. The boiler must be fitted to a sealed heating system. Refer to

Section 10 for details.

6. Ensure the requirements for the disposal of condensate as

described in Section 9 are met.

7. Connect the power supply to the hybrid control panel (in the

boiler) as described in Section 12.

8. Connect the flue system as described in Section 13.

5.3 Installing the Oil Boiler – Internal Location (with

heat pump outside)

1. With the boiler in required position, ensure that the flue terminal

position will comply with the necessary clearances. Refer to

Section 2.7.

2. Prepare the wall for the pipework and flue system. Mark the wall

and drill holes for the system flow and return pipes between the

boiler and the heat pump. Refer to Figures 2-6 and 5-2 for the

positions of the pipework connections in the boiler rear panel.

3. Mark the wall and make a hole for the flue system to pass

through. Refer to Section 13-.4 for the correct hole position.

4. Fit the flue system to the boiler as detailed in Section 12.5.

Ensure that there is an adequate air supply to the boiler if

required. Refer to Section 12.2.

5. Make the water connections as described in Section 8.4. If

access will be restricted, make any connections to the boiler

(and heat pump) before placing it in its final position.

6. The boiler must be fitted to a sealed heating system. Refer to

Section10 for details.

7. Ensure the requirements for the disposal of condensate as

described in Section 9 are met.

8. Connect the power supply to the hybrid control panel (in the

boiler) as described in Section 12

5.4 Boiler Only Operation (inside or outside

location)

5.4.1 Heat pump flow and return connections

If the boiler and heat pump are not to be installed at the same time,

but the boiler is required to operate immediately, e.g. following an

emergency boiler replacement, the boiler can be operated as a

‘stand-alone’ unit.

To do this the heat pump flow and return connections on the boiler,

located at the rear of the left side casing panel, must be connected

together.

This can be done by using 1" BSP x 28mm compression connectors,

as follows:

1. Using a suitable thread sealant or PTFE tape, screw one of the

connectors into the 1”BSPF ‘Heat Pump Flow’ connection on

the boiler.

2. Repeat the above process to fit the second connector to the

1”BSPF ‘Heat Pump Return’ connection on the boiler.

3. Make a 'U' section of 28mm Copper pipe (using either

two compression or capillary elbows). Fit this into the two

compression connections on the boiler to complete the loop

and tighten both compression fittings.

4. Insulate the connection bet ween the heat pump flow and return

connections. Even though this loop may only be a temporar y

measure, until the heat pump is installed, it MUST be insulated

using a suitable external insulation material.

5. Fill the sealed heating system as described in Section 10 of

these instructions.

6. Vent the system to remove trapped air using the manual air

vents located inside the boiler enclosure (refer to Figures 8-2

and 8-3).

Section 5: Installation of the Oil BoilerPage 18

!

WARNING

!

WARNING

If the boiler is to be used without the heat pump fitted, the

heat pump flow and return connections on the boiler MUST be

connected together, as described above, BEFORE the system

and boiler are filled with water.

5.4.2 ‘Boiler only’ controls

If the boiler is to be used as a ‘stand-alone’ unit, without the heat

pump connected, the ‘Oil/Hybrid’ switch on the Hybrid control panel

(in the boiler) MUST be set to ‘Oil’ for the boiler to operate.

Depending on the hot water controls option fitted, it may be

necessary to alter either the connections to the heating system

controls terminal block (in the hybrid control panel) in the boiler or

change the control settings for the boiler to operate to heat a hot

water cylinder. Refer to Section 11 for details of the hot water control

options and Section 12 for details of the electrical connections.

Table 5-1: Flow and return key

Item Description Item Description

1 System return (1" BSP female) 4 Return (1¼" BSP male)

2 System flow (1" BSP female) 5 Heat pump return (1" BSP female)

3 Flow (1¼" BSP male) 6 Heat pump flow (1" BSP female)

Any such changes to connections or settings MUST be

reversed when the heat pump is connected to the boiler and

operation of both together as a hybrid unit is required.

2

3

6

5

1

4

Figure 5-2: Flow and return connections

Section 5: Installation of the Oil Boiler Page 19

6 Installation of the Heat Pump

6.2 Installing the Heat Pump – Next to Oil Boiler

!

Ensure that the electrical supply to the boiler has been

isolated at the lockable isolator BEFORE commencing the

installation and connection of the heat pump.

WARNING

6.1 Preparation for Installation

• Carefully remove the packaging from the heat pump and

remove it from the transit pallet.

• Position the heat pump in the final location required, raised

up from the base by approximately 100 mm on suitable antivibration mounts.

This location may be either:

• Next to the boiler, if the boiler is installed externally. Refer

to Section 6.2

OR

• Freestanding outside, if the boiler is installed internally.

Refer to Section 6.3

!

If the boiler has been operated as a ‘stand-alone’ unit prior to

the installation of the heat pump, the loop bet ween the heat

pump flow and return connections on the boiler (as described

in Section 5.4.1) will now have to be removed to connect the

heat pump.

To avoid draining the heating system it is possible to close valves

in both the flow and return pipework within the boiler enclosure.

Referring to Figures 8-2 and 8-3, the isolation valves for the heat

meter flow sensor (13) and heat meter in the return (3) should be

closed before removing the loop bet ween the heat pump flow and

return connections on the boiler.

NOTE

(External oil boiler)

6.2.1 Electrical connections

1. Before moving heat pump into final position, remove the

wiring cover from the right hand end of the heat pump. Refer

to Section 6 of the Installation Instructions supplied with the

Aerona³ heat pump for details.

2. Remove the access panel from the front of the boiler casing.

Unscrew and remove the eight screws that secure the access

panel to the casing. Refer to Figure 12-1.

3. Working from inside the boiler enclosure, remove the internal

access cover in the left casing panel of the boiler. Slacken

off all six retaining screws. Lift the panel upwards and of f the

retaining screws using the keyhole slots.

4. Remove the t wo screws from the top lef t edge of the boiler

enclosure and fit the top spacer plate provided with the boiler.

Re-fit and tighten the screws to secure it in position on the

boiler enclosure.

5. Manoeuvre the heat pump into position such that the top

spacer plate butts against the heat pump enclosure across the

full depth of the heat pump, giving a gap between the boiler

and heat pump of 100mm.

6. Make the heat pump electrical supply connection bet ween the

heat pump electrical supply terminal block in the hybrid control

panel (in the boiler) and the electrical supply terminal block in

the Aerona³ heat pump.

Refer to Section 12 for electrical connection details. Figure 1210 shows the location of this terminal block and Figure 12-11 is

the connection diagram.

7. Make the heat pump controls connection bet ween the heat

pump controls terminal block in the hybrid control panel (in the

boiler) and the Terminal PCB in the Aerona³ heat pump.

Refer to Section 12 for electrical connection details. Figure 1212 shows the location of this terminal block and Figure 12-13 is

the connection diagram.

8. Working from both outside and through the access opening

in the left casing panel of the boiler, as required, replace

the wiring cover on the right hand end of the heat pump and

secure in place with the three fixing screws.

9. Replace the internal access cover in the lef t casing panel of the

boiler. Fit the keyhole slots onto the six retaining screws. Pull it

down and tighten the screws to secure it in position.

10. When all wiring connections have been made, re-fit the upper

cover panel at the rear of the control panel and secure it using

the two screws at the top of the cover. Refer to Figure 12-3.

11. Then replace the lower cover panel at the rear of the control

panel and secure it using the two screws. Refer to Figure 12-3.

12. Replace the access panel on the front of the boiler casing. Refit and tighten the eight screws to secure the access panel to

the casing. Refer to Figure 12-1.

Section 6: Installation of the Heat PumpPage 20

6.2.2 Pipework connections

Make the flow and return connections between the boiler and heat

pump, using the fittings provided with the boiler, as follows:

1. Using a suitable thread sealant or PTFE tape, screw one of

the two flexible hoses into the 1”BSPF ‘Heat Pump Flow’

connection on the boiler.

2. Repeat the above process to fit the second flexible hose to

the1”BSPF ‘Heat Pump Return’ connection on the boiler.

3. Using a suitable thread sealant or PTFE tape screw the

1”BSPM x 28mm tail into the 1” x 1¼” elbow. Then fit the elbow

to the flow connection (the higher of the two connections) on

the rear of the heat pump.

4. Fit the 28mm compression connection on the end of the flexible

hose from the heat pump flow connection (on to the boiler) on

to the tail fitted to the heat pump flow connection. Tighten the

compression connection.

5. It may be necessar y to adjust the angle of the elbow/tail on the

flow connection to align it with the compression connection on

the end of the flexible hose.

6. Repeat steps 4 and 5 above to connect the heat pump return

on the boiler with the flow connection on the heat pump.

7. Fill the sealed heating system as described in Section 10 of

these instructions.

8. Vent the system to remove trapped air using the manual air

vents located inside the boiler enclosure (refer to Figures 8-2

and 8-3) and also the automatic air vent in the heat pump (refer

to Section 1 of the Installation Instructions supplied with the

Aerona³ heat pump.

6.3 Installing the Heat Pump – Separate from Oil

Boiler (Internal oil boiler)

6.3.1 Electrical connections

1. Move the heat pump into the required final position. Ensure that

it does not obstruct the flue terminal and that the flue terminal

position complies with the necessary clearances. Refer to

Section 2.8.

2. Remove the wiring cover from the right hand end of the

heat pump. Refer to Section 6 of the Installation Instructions

supplied with the Aerona³ heat pump for details.

3. Remove the access panel from the front of the boiler casing.

Unscrew and remove the eight screws that secure the access

panel to the casing. Refer to Figure 12-1.

4. Make the heat pump electrical supply connection bet ween the

heat pump electrical supply terminal block in the hybrid control

panel (in the boiler) and the electrical supply terminal block in

the Aerona³ heat pump.

Refer to Section 12 for electrical connection details. Figure 1210 shows the location of this terminal block and Figure 12-11 is

the connection diagram.

5. Make the heat pump controls connection bet ween the heat

pump controls terminal block in the hybrid control panel (in the

boiler) and the Terminal PCB in the Aerona³ heat pump.

Refer to Section 12 for electrical connection details. Figure 1212 shows the location of this terminal block and Figure 12-13 is

the connection diagram.

6. Replace the wiring cover on the right hand end of the heat

pump and secure in place with the three fixing screws.

7. When all wiring connections have been made, re-fit the upper

cover panel at the rear of the control panel and secure it using

the two screws at the top of the cover. Refer to Figure 12-3.

8. Then replace the lower cover panel at the rear of the control

panel and secure it using the two screws. Refer to Figure 12-3.

9. Replace the access panel on the front of the boiler casing. Refit and tighten the eight screws to secure the access panel to

the casing. Refer to Figure 12-1.

6.3.2 Pipework connections

Make the flow and return connections between the boiler and heat

pump, using the fittings provided with the boiler, as follows:

1. Using a suitable thread sealant or PTFE tape screw one of

the 1” x 1¼” elbows (supplied with the boiler) on to the flow

connection (the higher of the two connections) on the rear of

the heat pump.

2. Repeat the same process for the return connection (the lower

of the two connections) on the rear of the heat pump.

3. Using a suitable thread sealant or PTFE tape, screw the

1”BSPM thread on one of the two flexible hoses (supplied with

the boiler) into the elbow on the heat pump flow connection.

4. Connect the other end of this flexible hose to the flow pipe from

the boiler using the 28mm compression connection.

5. Repeat the above process to fit the second flexible hose

between the elbow on the heat pump return connection and

the return pipe to the boiler.

6. It may be necessar y to adjust the angle of the elbows on the

heat pump flow and return connections to align it with the end

of the flexible hoses.

7. Fill the sealed heating system as described in Section 10 of

these instructions.

8. Vent the system to remove trapped air using the manual air

vents located inside the boiler enclosure (refer to Figures 8-2

and 8-3) and also the automatic air vent in the heat pump (refer

to Section 1 of the Installation Instructions supplied with the

Aerona³ heat pump.

6.4 Heat Pump Parameter Settings

When connected to the boiler as part of the VortexAir Hybrid unit,

some of the Control Parameter factory default settings must be

changed. Refer to Section 15.11 of these Installation Instructions for

details of the Control Parameters to be re-set.

Also, refer to Section 9 of the Installation Instructions supplied with

the Aerona³ heat pump for guidance on how to access and change

the Control Parameters.

Section 6: Installation of the Heat Pump Page 21

7 Installation of Heat and Electricity

Meters

7.1 General

As not all installations will require a heat meter and electricity

meter, the Grant VortexAir Hybrid is supplied without any meters

fitted. Usually only installations receiving a Renewable Heat

Incentive (RHI) payment will require both these meters to be

fitted.

Both meters are available as accessories from Grant UK for onsite fitting by the installer:

• Heat meter (Grant product code: HPIDMETER)

• Electricit y meter (Grant product code: HPIDKW/HMETER)

!

When required, only the meters supplied by Grant UK (as

listed above) must be used with the Grant VortexAir hybrid.

In accordance with MCS metering requirements, the Grant

VortexAir Hybrid is supplied ‘meter ready’ to allow both the heat

meter and electricity meter to be easily fitted when required, as

follows:

• The necessary temperature sensor points and valved

sections are incorporated in the pipework (inside the boiler

casing) for installation of the flow meter and temperature

sensors of the heat meter.

• A purpose made (DIN rail) mounting and housing is

provided for both the heat meter integrator unit and the

electricity meter.

• A 1A fused power supply for the heat meter is provided

within the meter housing.

• The incoming power to the heat pump is located inside the

meter housing for connection to the electricity meter.

NOTE

Electricity

meter

Heat

meter

Figure 7-1: Location of integrator meter when fitted

b) Flow meter (fluid oscillator flow sensor)

This measures the flow of water in the primary circuit when

the heat pump is operating. This flow rate can be displayed,

if required, on the integrator screen.

The flow meter is installed in the heating return pipe to the

heat pump. Refer to Figure 7-2. For details of how to install

the flow meter refer to Section 7.2.1.

7.2 Heat Meter

When correctly installed, this heat meter will measure and record the

heat produced by the heat pump only.

7.2.1 Description

The Sontex Superstatic 440 heat meter, supplied by Grant for

use with the Grant VortexAir Hybrid, consists of the following

components:

a) Integrator unit (Supercal 531)

This calculates the heat produced by the heat pump from

the information provided by the flow meter and the two

temperature sensors (see below). The heat produced by the

heat pump, along with the flow and return water temperatures,

can be displayed on the integrator screen if required.

Refer to Section 7.4 (or the Instructions supplied with the

heat meter kit) for guidance on how to access the information

available on the integrator screen.

When fitted, the integrator unit is located in a purpose made

housing immediately above the control panel. Refer to Figure

7-1.

Figure 7-2: Heating return pipework

c) Return temperature sensor

This measures the return water temperature. This

temperature can be displayed, if required, on the integrator

screen.

The sensor is fitted in a ‘dry pocket’ (supplied with the heat

meter kit) that is installed in a tapping located in the return

pipe to the heat pump (just above the flow meter). Refer to

Figure 7-2.

For details of how to install the return temperature sensor

refer to Section 7.2.5.

d) Flow temperature sensor

This measures the flow water temperature. This temperature

can be displayed, if required, on the integrator screen.

The sensor is fitted in a ‘dry pocket’ (supplied with the heat

Section 7: Installation of Heat and Electricity MetersPage 22

meter kit) which is installed in a tapping located in the flow

pipe from the heat pump. Refer to Figure 7-3.

For details of how to install the flow temperature sensor

refer to Section 7.2.6.

!

The two temperature sensors supplied with the heat meter

are a matched pair. They must both be used together, and

not replaced by any other sensor(s), as the sensors supplied

have been calibrated with the heat meter. The sensor cables

MUST NOT be either shortened or extended as this will affect

the measuring accuracy of the heat meter. They should run

independently of power cables to limit interference.

Figure 7-3: Sensor and pocket

WARNING

Figure 7-5: Kit contents (flow and return sensor coiled together)

7.2.3 Fitting the Integrator unit

To fit the flow meter integrator unit, use the following procedure:

1. Remove the top panel of the VortexAir boiler. To do so,

unscrew and remove the 10 screws around the four sides of

the top casing panel. Lift the top panel up and off the boiler

casing.

2. To access the control panel remove the boiler/burner

access panel on the right hand side of the boiler casing.

Turn the handle at the bottom clockwise to release the

catch. Pull the panel forwards at the bottom and remove it

from the boiler. Refer to Figure 7-6.

7.2.2 Kit Contents

Before fitting the heat meter, check that you have all the necessary

components, as follows (refer to Figure 7-4):

Table 7-4: Kit contents

Quantity Item

1

1

2

2

2

2

(not shown)

1

1

3

(not shown)

1

(not shown)

1

(not shown)

Sontex Superstatic flow meter DN25 G1¼”

(qp 3.5m³/hr)

Sontex Supercal 531 integrator

1¼”Union nut

1”BSP Union tail

Fibre washers

1” BSPM x 28mm compression connector

Pt500 flow temperature sensor (red tag)

Pt500 return temperature sensor (blue tag)

Sticker seals

(refer to Section 7.2.8)

Calibration report

(to be left with the end user following installation)

Sontex installation instructions

(to be left with the end user following installation)

Figure 7-6: Removal of boiler access panel

3. Remove the upper panel on the right hand side of the

boiler casing. Unscrew and remove the two panel retaining

screws (accessed from inside casing), lift the panel straight

up to disengage the two tags from their slots and remove

the panel from the boiler casing. Refer to Figure 7-7.

Section 7: Installation of Heat and Electricity Meters Page 23

6. Take the integrator unit and press in the four clips (two on each

side of the integrator unit) to release the front and carefully pull

it forwards to remove it from the rear section of the unit.

7. Pull out the tab on the rear of the LCD display to star t the clock.

Refer to Figure 7-14.

8. Push back and pull up the white plastic tab visible above the

top edge of the integrator (rear section) to open the DIN rail

clip on the back . Locate the rear section of the integrator unit

onto the DIN rail (at the left hand end of the rail) with the row of

cable grommets at the bottom.

9. Fully push the tab back down and check that the rear section of

the integrator unit us securely attached to the DIN rail.

7.2.4 Fitting the flow meter

Figure 7-7: Removal of upper side casing panel

4. Remove both the meter housing and cover (located

immediately above the control panel) from the boiler.

Unscrew the four screws (two on either side of the cover).

The meter housing and cover will come away together from

the boiler. Refer to Figure 7-8. Keep the four screws as they

will be required to re-fit the retaining bracket.

!

Whilst the flow meter and temperature sensors are best fitted

before the heating system is filled with water, they can be

fitted after filling if necessary.

To fit the flow meter use the following procedure:

1. Locate the removable section of pipe in the return to the

heat pump. Refer to Figure 7-9.

!

If the heating system has already been filled with water

ensure that the valves located both above and below this

section of pipe are CLOSED before removing the pipe.

NOTE

CAUTION

Figure 7-8: Removal of meter retaining bracket and cover

5. Cut the retaining cable ties and move the heat meter and

heat pump power supply cables to one side to gain access

to the DIN rail located behind the meter housing. Refer to

Figure 7-9.

Figure 7-9: Meter housing and DIN rail (with cover removed)

Figure 7-10: Location of removable pipe section

2. Unscrew the compression nuts at both the upper and

lower ends of the removable pipe section. Refer to Figure

7-10. Carefully lift the upper section of pipe just enough to

remove the pipe with the fittings attached at each end.

3. Remove the compression nut and olive from the 28mm

compression x 1”BSPF fitting (supplied with the heat meter)

and connect the fitting to the compression nut (just above

the lower isolating valve). Refer to Figure 7-10.

4. Using a suitable sealant or PTFE tape, fit one of the 1”BSP

threaded tails (provided with the flow meter) into the 1”

BSP socket. Ensure that the union nut is fitted on the tail

BEFORE it is screwed into the socket.

5. Repeat steps 3 and 4 above to fit the other 1”BSP threaded

tail and union nut (provided with the flow meter) into the

vacant upper 1” BSP socket. Refer to Figure 7-10.

Section 7: Installation of Heat and Electricity MetersPage 24

7.

Cable colours: R = Red, W = White, G = Green, Br = Brown, Bk = Black, Bl = Blue, G/Y = Green/yellow

Carefully route the cable from the flow meter through one

of the grommets in the side of the lower part of the control

panel and up to the integrator unit, installed immediately

above the control panel fascia.

8. The connection terminals are located towards the bottom

of the rear section of the integrator unit. Pierce the cable

grommet located in the lower face of the integrator unit

(below terminals 9, 10 and 11) and pass the flow meter

cable through.

9. The flow meter must be connected to terminals 10, 11 and

9 on the terminal block inside the Integrator unit, as follows:

• White wire – terminal 10

• Green wire – terminal 11

• Brown wire – terminal 9

Figure 7-11: Fitting of flow meter connections

6. Using the two fibre washers (provided with the flow meter),

fit the flowmeter between the joint faces of the upper and

lower tails and tighten the union nuts. Refer to Figure 7-12.

!

Ensure that the flow meter is installed such that the arrows on

the body of the unit are pointing UPWARDS.

Return temperature

sensor

Lower isolating valve

NOTE

Upper isolating valve

Return temperature

sensor pocket

!

Ensure that the metal ferrule (at the end of the flow meter

cable) is securely trapped under the metal cable clamp to

ground the flow meter cable. Refer to Figure 7-13 (integrator

connection diagram).

!

In order to comply with the Measuring Instruments Directive

(MID) 2004/22/EU the flow meter cable MUST NOT be

shortened. Any excess cable should be gathered up (coiled

up) in a suitable location, i.e. where it will not restrict access

to any component (valve, pump, etc.) within the boiler casing.

They should run independently of power cables to limit

interference.

NOTE

NOTE

Figure 7-12: Flow meter fitted

1 2 3 4 10 11 50 51 52 53 16 17 18 24 259

R W R W WGBr

Flow

temp

sensor

(Red)

Cable must be grounded by trapping the metal ferrule under the cable clamp.

Figure 7-13: Integrator connection diagram

Return

temp

sensor

(Blue)

Flow

meter

L N

Bk Bl

230V 50Hz 1ph

1A fused supply

G/Y

Section 7: Installation of Heat and Electricity Meters Page 25

7.2.5 Fitting the return temperature sensor

7.2.6 Fitting the flow temperature sensor

!

The return temperature sensor MUST be fitted in return

sensor pocket, as described below, and not fitted to (or on)

the return pipe in any other way.

To fit the return temperature sensor, use the following procedure:

1. Locate the return temperature sensor point on the return pipe

above the flow meter. Refer to Figure 7-12.

!

If the heating system has already been filled with water

ensure that the valves located both above and below this

section of pipe are CLOSED before removing the plug from

the sensor point.

Unscrew the plug from the temperature sensor point.

2.

3. Using a suitable sealant or PTFE tape, fit one of the t wo

temperature sensor pockets provided into the sensor point and

tighten, but only enough to achieve a seal.

4. Slacken of f the small clamp screw on the sensor pocket and fit

the stainless steel sensor fully into the sensor pocket. To ensure

the best operation of the temperature sensor (and heat meter),

first inject some heat conducting grease (not provided) into the

sensor pocket before inserting the sensor.

The sensor MUST be fitted fully into the pocket as far as it will

go. Then tighten the small clamp screw to secure the sensor

into the pocket. DO NOT OVERTIGHTEN!

5. Carefully route the cable from the return temperature sensor

through the same grommet as the flow meter cable (in the side

of the lower part of the control panel) and up to the integrator

unit, installed immediately above the control panel fascia.

6. Pierce the cable grommet located in the lower face of the

integrator unit (below terminals 3 and 4) and pass the flow

meter cable through.

7. The return temperature sensor must be connected to terminals

3 and 4 on the terminal block inside the Integrator unit, as

follows: