Granite Ware F0730, F0731 Instruction Manual And Users Manual

Pressure Canner

And Pressure Cooker/Steamer

Instruction Manual and User Guide

© 2013 Columbian Home Products, LLC www.columbianhp.com

2

TABLE OF CONTENTS

1. Important Safeguards……………………………………………. 3

2. Your New Pressure Canner……………………………………… 4

3. Component Part Descriptions …………………………………… 5

4. Replacement Parts………………………………………………... 7

5. Before Using Your New Pressure Canner……………………….. 8

6. Pressure Canning General Information…………………………... 8

7. Canning at Altitude: Adjustment Guide………………………….. 9

8. Using Your Pressure Canner……………………………………… 10

9. Cleaning and Maintenance………………………………………... 15

10. Model Number & Company Information…………………………. 15

11. Replacement Part Guide…………………………………………... 16

12. USDA Food Classifications & Cooking Times…………………… 17

13. Additional Recipe and Information Resources……………………. 20

3

This GraniteWare® product is a listed appliance. The following Important Safeguards

are recommended.

IMPORTANT SAFEGUARDS

When using pressure cookers, basic safety precautions should always be followed:

1. Read all instructions.

2. Do not touch hot surfaces. Use handles or knobs.

3. Close supervision is necessary when the pressure cooker is used near children.

4. Do not place the pressure cooker in a heated oven.

5. Extreme caution must be used when moving a pressure cooker containing hot liquids.

6. Do not use pressure cooker for other than intended use.

7. This appliance cooks under pressure. Improper use may result in scalding injury.

Make certain unit is properly closed before operating. See “Using Your Pressure

Canner, pages 10-14.”

8. Do not fill the unit over 2/3 full. When cooking foods that expand during cooking

such as rice or dried vegetables, do not fill the unit over 1/2 full. Over filling may

cause a risk of clogging the vent pipe and developing excess pressure. See “USDA

Food Classifications and Recommended Cooking Times, pages 18-20.”

9. Be aware that certain foods, such as applesauce, cranberries, pearl barley, oatmeal or

other cereals, split peas, noodles, macaroni, rhubarb, or spaghetti can foam, froth, and

sputter, and clog the pressure release device (steam vent). These foods should not be

cooked in a pressure cooker.

10. Always check the pressure release devices for clogging before use.

11. Do not open the pressure cooker until the unit has cooled and all internal pressure has

been released. If the handles are difficult to push apart, this indicates that the cooker

is still pressurized – do not force it open. Any pressure in the cooker can be

hazardous. See “Using Your Pressure Canner, pages 10-14.”

12. Do not use pressure cooker for pressure frying with oil.

13. When the normal operating pressure is reached, turn the heat down so all the liquid,

which creates the steam, does not evaporate.

14. SAVE THESE INSTRUCTIONS.

4

1. Adjustable 3-piece Pressure

Regulator

2. Vent Pipe

3. Back-up Safety Valves

4. Lid Gasket Sealing Ring

5. Canning Rack

6. Steamer Insert

7. Lid

8. Body

YOUR NEW PRESSURE CANNER

This GraniteWare® canner/cooker/steamer is a large capacity pressure vessel designed for

home canning your favorite fruits, vegetables, meats and poultry. Because of its hard

anodized finish – a high-end cookware feature – the canner can also be used as a pressure

cooker and steamer with outstanding results and no adverse affects on the taste or color of

your food.

The canner achieves the high temperatures required for safely processing foods through

heated water which produces steam and pressure inside the canner. The United States

Department of Agriculture (USDA) endorses the pressure canner as the only safe method for

canning meats, poultry and low-acid vegetables.

Pressure cooking is fast, healthy and cost-effective. This GraniteWare® pressure cooker

preserves flavor and nutrients, tenderizes tough cuts of meat, and cooks many foods in onethird to one-tenth the time compared to traditional methods, and it is large enough to create

family-sized meals with ease.

5

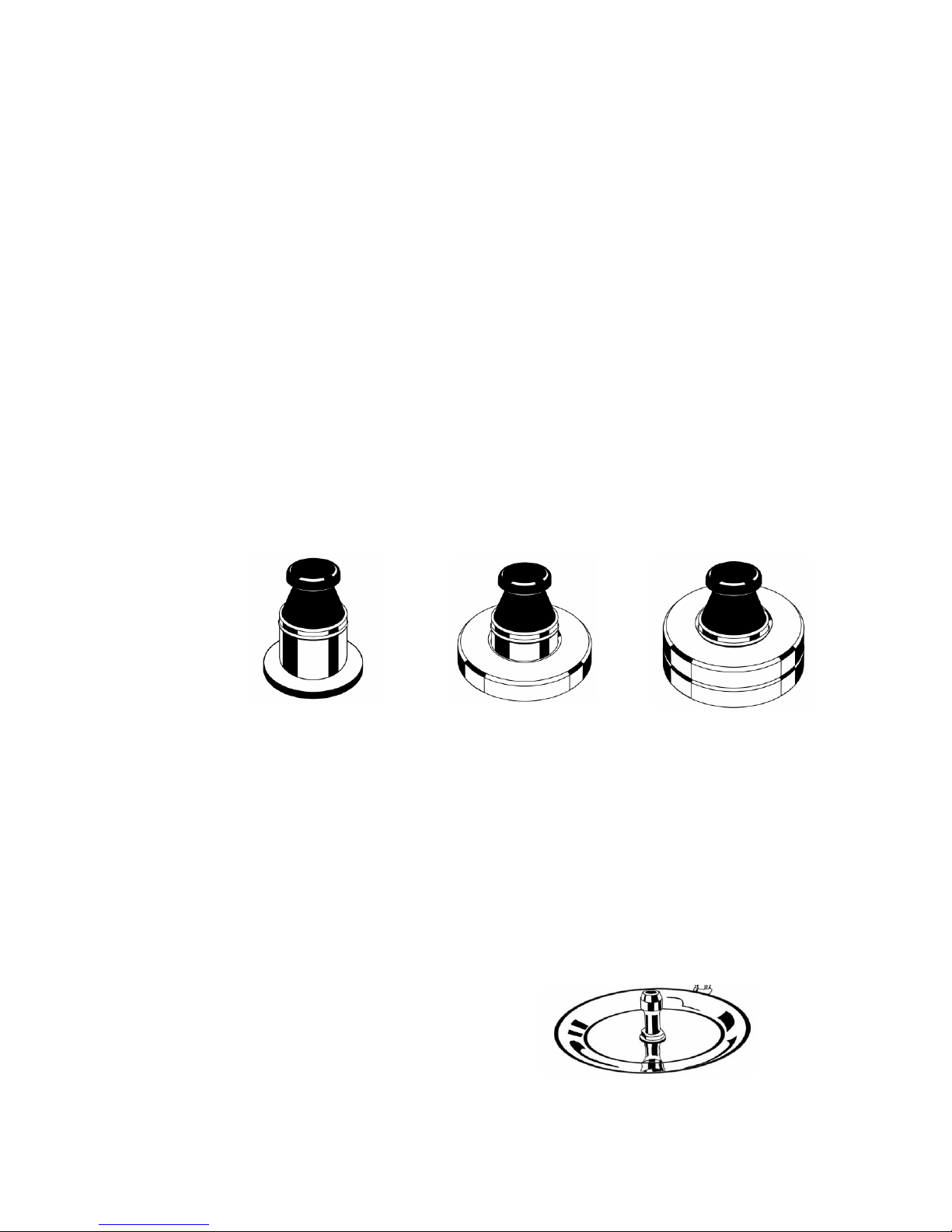

1. ADJUSTABLE 3-PIECE PRESSURE REGULATOR

The Pressure Regulator controls the pressure inside the canner. When normal

operating pressure is reached, the pressure regulator will begin to rock. Gradually

lower the heat as necessary to maintain the pressure. Correct pressure is indicated

by a consistent gentle rocking of the pressure regulator. It is normal for some

steam to be released when the proper pressure is attained.

The Pressure Regulator is calibrated for three different pressure levels measured

in pounds per square inch or psi (5 psi, 10 psi or 15 psi). The Pressure Regulator

maintains 15 psi of pressure when completely assembled with the two additional

weighted rings included.

For different pressure levels (See Canning at Altitude, page 9), the regulator can

be adjusted by removing the appropriate number of weighted rings. With both

rings removed, the regulator by itself maintains 5 psi. If 10 psi is required, add

one ring to the regulator. If 15 psi is required, add both rings to the regulator.

5 psi Pressure Regulator 10 psi Pressure Regulator 15 psi Pressure Regulator

2. VENT PIPE

The vent pipe is located in the center of the lid. Steam will pass through the vent

pipe to the Pressure Regulator. It is extremely important to keep the vent pipe

clean and unobstructed. The Pressure Regulator sits loosely on the vent pipe.

Push the Pressure Regulator downwards on the vent pipe until it clicks into place.

The Pressure Regulator will move around when in place but is secured from

lifting off by the safety catch. To remove the Pressure Regulator from the vent

pipe, hold the regulator by the black top and pull directly upwards firmly until it

passes over the safety catch. NOTE: Do not remove the Pressure Regulator

while pressure is in the vessel.

6

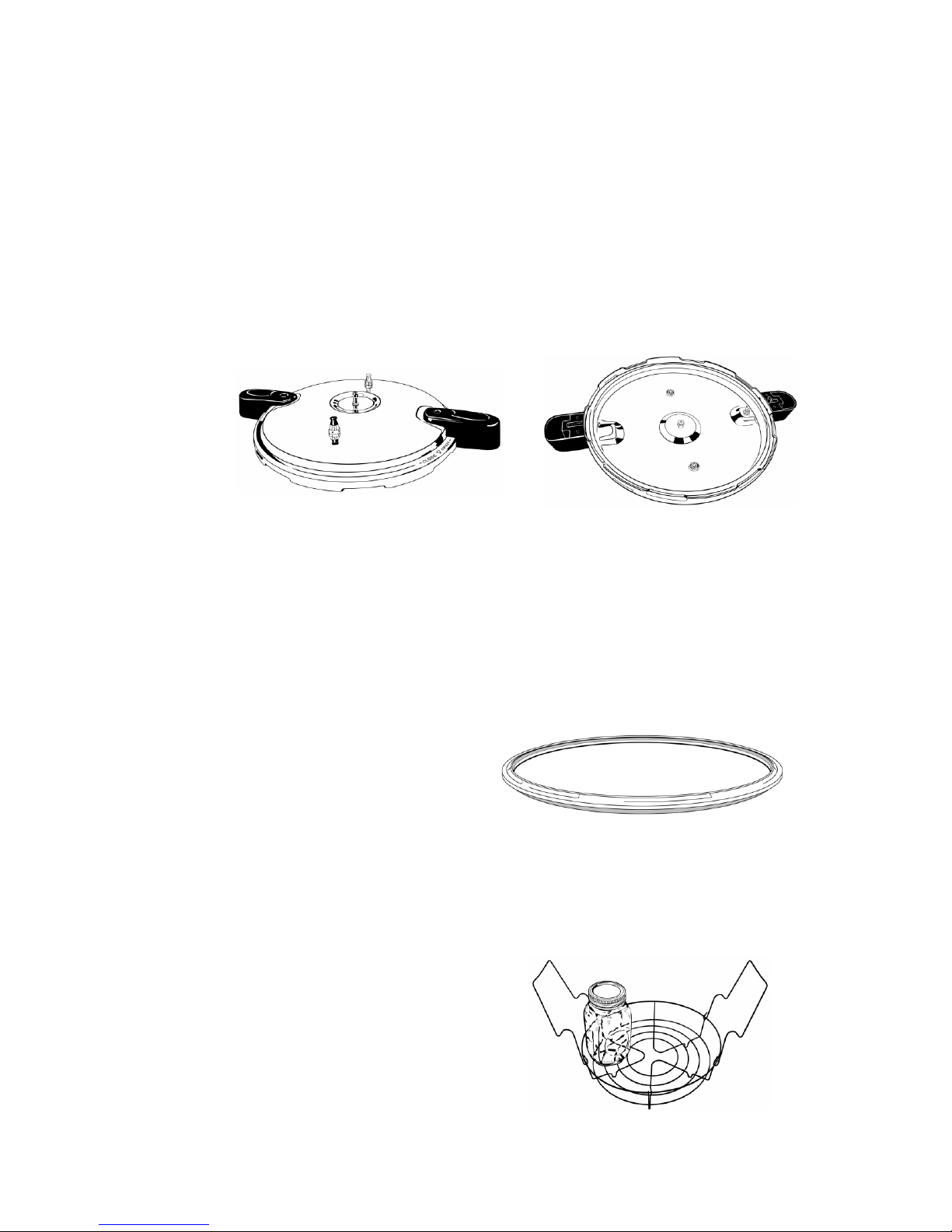

3. BACK-UP SAFETY VALVES

Two (2) additional safety valves are found on the top of the lid. One black cap

safety valve is set to go off as back-up pressure release if the main pressure

regulator fails or is clogged. The second safety valve is all metal and will exhaust

residual pressure while sounding a whistling alarm.

The valves can be removed for cleaning and inspection by loosening their nut on

the underside of the lid. Turn the nut counterclockwise (left) to loosen and

remove the valves. Be sure to replace the valves and tighten the attachment nut

by turning it clockwise (right) until secure.

4. LID GASKET SEALING RING

The lid gasket is a flexible silicone ring that fits inside the canner cover and forms

a pressure-tight seal between the body of the canner and the cover during use.

Remove the gasket sealing ring before each use and inspect it for signs of wear

and rigidity. The ring should bend easily and be free from holes or tears.

Periodic light oiling with mineral oil will keep the ring flexible. We recommend

replacing the lid sealing ring each canning season.

5. CANNING RACK

The canning rack holds jars off the bottom of the pot. Never place glass jars

directly into the canner without the rack. The rack holds 7 quart jars, 8 pint jars

or 24 half-pint jars. Lower the rack into the canner when ready to process your

food. Fold handles inward so they do not touch the canner lid.

Loading...

Loading...