Grandway FHO2000-D26, FHO2000-D35 User Manual

1

MINI OTDR

Manual

Version E0000

2

Foreword

Thank you for purchasing MINI OTDR (Optical Time Domain

Reflectometer).This user’s manual contains useful information about the

instrument’s functions and operating procedures and the handling precautions

of MINI OTDR OTDR.To ensure correct use, please read this manual

thoroughly before beginning operation.After reading the manual, keep it in a

convenient location for quick reference whenever a question arises during

operation.

Note

• The contents of this manual are subject to change without prior notice as a

result of continuing improvements to the instrument’s performance and

functions. The figures given in this manual may differ from those that actually

appear on your screen.

• Every effort has been made in the preparation of this manual to ensure the

accuracy of its contents. However, should you have any questions or find any

errors, please contact your nearest Company dealer.

• Copying or reproducing all or any part of the contents of this manual without

Company’s permission is strictly prohibited.

3

Trademark

• Microsoft, Windows, and Windows XP are either registered trademarks or

trademarks

of Microsoft Corporation in the United States and/or other countries.

• Adobe and Acrobat are trademarks of Adobe Systems Incorporated.

• For purposes of this manual, the TM and ® symbols do not accompany their

respective trademark names or registered trademark names.

• Other company and product names are trademarks or registered trademarks

of their respective holders

Version

Version 1.0 2012

4

Standard Accessary

OTDR standard accessary showed in next table.

Num.

Description

Quantity

1

Power Adapter(220V 50Hz)

1

2

Power Patchcord

1

3

Data Cable

1

4

CD

1

5

Carrying Case

1

6

Securing Strip

1

7

Manual

1

Module

OTDR optional accessary showed in next table.

Num

Module

Description

1

OTDR module

Standard

2

VFL(visual fault locator) module

Optional

3

OPM(optical power meter) module

Optional

※ All changes with standard accessary and optional accessary prices are

subject to change without notice..

5

Safety Precautions

To use the instrument safely and effectively, be sure to observe the

precautions given in the user’s manual. Not complying might

result in injury or death.

Warning

Use the Correct Power Supply

Before connecting the power cord, ensure that the source voltage matches the

rated supply voltage of the AC adapter and that it is within the maximum rated

voltage of the provided power cord.

Use the Correct Power Cord

Use only the power cord that comes with the instrument. Do not use it for other

devices.

Use the Correct AC Adapter

Use only the AC adapter specified for the instrument. Do not use it for other

devices.

Use Only the Designated Battery pack

Use only the battery pack specified for the instrument. Do not use it for other

devices.

Use only this instrument or a charger specified by Company to charge the

battery pack. If the fast charge does not finish after three hours or more, stop

charging the battery pack immediately.

To prevent the possibility of electric shock and accidents, always turn OFF the

power switch and remove the AC adapter power supply from the instrument

when replacing the battery pack.

Do not throw the battery pack into fire or apply heat to it. This can cause

dangerous explosions or spraying of the electrolytes.

Do Not Look at the Laser Light

Do not look at the laser’s direct ray, reflected ray from a mirror, or indirect ray

without the proper protective eyewear. In addition, avoid being exposed to the

laser light. It can cause blindness or damage to the eye.

Do Not Operate in an Explosive Atmosphere

Do not use the thermocouple in a location where any flammable or explosive

gas/vapor is present. Operation in such an environment constitutes a safety

hazard.

Do Not Remove Covers

The covers should be removed by Company’s qualified personnel only.

Opening the cover is dangerous, because some areas inside the instrument

6

have high voltages.

Carrying and Moving the Instrument

Remove all power cords and connection cables from the main unit before

moving the instrument. When carrying the instrument, hold it firmly by the

handle.Also, if storage media is inserted into the instrument, always remove

the storage media before carrying or moving the instrument. Never leave the

media inserted when carrying or moving. The storage media can become

damaged.

Apply Correct Signals to the Optical Connectors

Do not apply light that is —10dBm or greater to the MINI OTDR optical

Connectors.

Doing so may damage the MINI OTDR

7

Symbol

Icons on the main body or in manual

Warning: handle with care. Refer to the user’s manual or

service manual.

This symbol appears on dangerous locations on the

instrument which require special instructions for proper

handling or use. The same symbol appears in the

corresponding place in manual to identify those

instructions

Recycle

Stand-by (power)

Direct current

Hazard, radiation of laser apparatus

Comply WEEE(Waste Electrical and

Electronic Equipment ) Directive

(2002/96/EC)

8

Content

0.0Names and Functions of Parts......................................................

0.1 Panel..................................................................................................

0.2 Main Menu Interface................................................................................

0.3OTDR Module Interface............................................................................

0.4 VFL Module Interface...............................................................................

1.0Preparation.....................................................................................

1.1 Turnning on.............................................................................................

1.2 Connecting the Fiber................................................................................

2.0 Introduction of OTDR......................................................................

2.1 Purpose of Measurement................................................................................

2.2 Content of Measurement................................................................................

2.3 Analyze of Curve........................................................................................

2.4 Fundamental of OTDR..................................................................................

2.5 Event Type...............................................................................................

3.0 Setting Measurement Conditions....................................................

3.1Setting to Auto Mode..................................................................................

3.2Setting to Manual Mode.................................................................................

4.0Making Measurements.....................................................................

4.1 Averaging test mode....................................................................................

4.2 Realtime test mode.....................................................................................

4.2.1 Setting wavelength..................................................................................

4.2.2 Setting test range and pulse width..................................................................

4.3 Event List................................................................................................

4.4 Distance Measurement.................................................................................

4.5 OTDR Optimizing Tool................................................................................

4.6 Setting proper parameters..............................................................................

5.0 Expanding the Waveform and Moving the Display Area............

5.1 Switching between Event list and display window.................................................

5.2 Cursor Operation........................................................................................

5.2.1 Activating Cursor.....................................................................................

5.2.2 Moving Cursor.......................................................................................

5.3Curve Operation...........................................................................................

5.3.1Horizontal Zoom.......................................................................................

5.3.2Vertical Zoom........................................................................................

9

5.3.3Horizontal Shift......................................................................................

5.3.4Vertical Shift...........................................................................................

5.4Elaborating Event.........................................................................................

5.5 Switching between curves.............................................................................

5.5.1 Removing Curve(s)..................................................................................

5.6 Removing an event.....................................................................................

5.7Adding an event.........................................................................................

6.0File Operation.................................................................................

6.1Saving Curve...........................................................................................

6.2Loading Curve(s).......................................................................................

6.3Deleting Curve(s).........................................................................................

6.4Copying/Moving Curve(s).............................................................................

6.5File Setting..............................................................................................

6.6Print screen.............................................................................................

7.0Entering Characters.......................................................................

7.1 Renaming...............................................................................................

7.2 Creating Directory.....................................................................................

8.0 VFL(Visual Fault Locator) Module..............................................

9.0OPM(Optical Power Meter Module)(Optional)........................

10.0 Software Update............................................................................

11.0 Background Information on Measurements..............................

11.1 Viewing the Optical Pulse Measurement Waveform............................................

11.2 Terminology...........................................................................................

12.0 Maintenance..................................................................................

12.1Notice...................................................................................................

12.2Cleaning Tools.........................................................................................

12.3Cleaning of Optical Port.............................................................................

12.4Calibration.............................................................................................

13.0 Diagnosis Center...........................................................................

13.1 FAQ ....................................................................................................

13.2 Help information......................................................................................

14.0 Specification...................................................................................

14.1 Physical Parameter...................................................................................

10

14.2 Test Index..............................................................................................

14.3 Dimension.............................................................................................

15.0 Warranty.......................................................................................

15.1 Terms of Warranty....................................................................................

15.2 Exclusions.............................................................................................

15.3 Transportation........................................................................................

15.4 Customer Service and Support.....................................................................

11

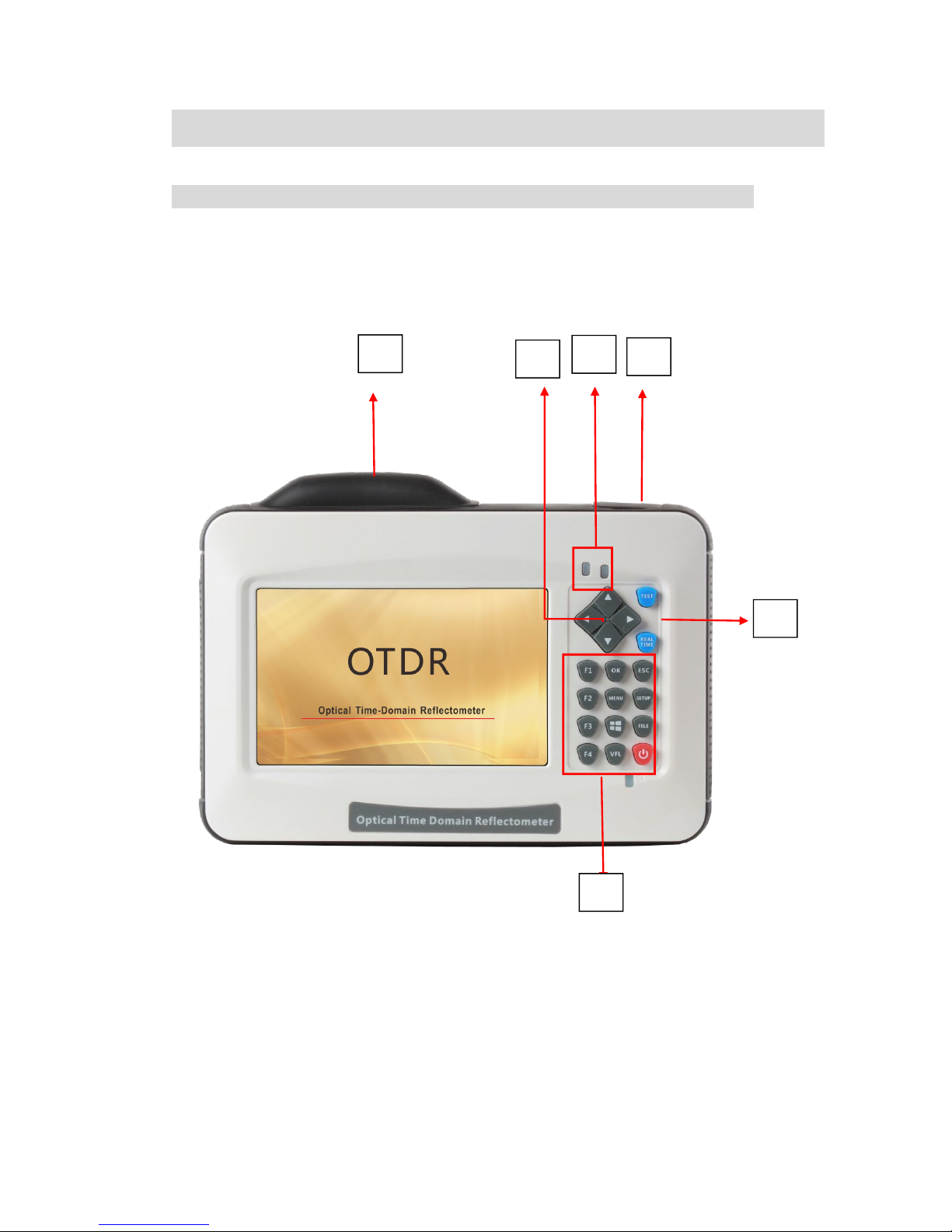

0.0 Names and Functions of Parts

0.1 Panel

I

II

III

VI

V

IV

12

Num

Name

Description

I

Port 1

Including OTDR Test port(FC/UPC)、Visual Fault

locator port(optional)×1、Power Meter port(optional)

×1 , touch pen×1 and USB A type×2

II

Port 2

Including micro-USB×1 and charging port

III

Indicator

Indicate test and power state

IV

Direction

Buttons

Move cursor, menu or files

V

Test button

Averaging Test(TEST) and Realtime Test(REALTIME)

button

VI

Button area

F1~F4: Select relative tag menu

OK: Confirm setting or enter menu

ESC: Cancel setting or enter menu

MENU: Back to main menu

SETUP:Set test parameters

FILE: File manager

VFL:visual fault locator menu

: Printscreen

:Power switch

13

0.2 Main Menu Interface

Num

Function

Description

I

Side menu

Enter relevant interface

II

Function Modules Area

Enter relevant module

III

Basic State Information Area

Display information of date ,time

and power

II

I

III

14

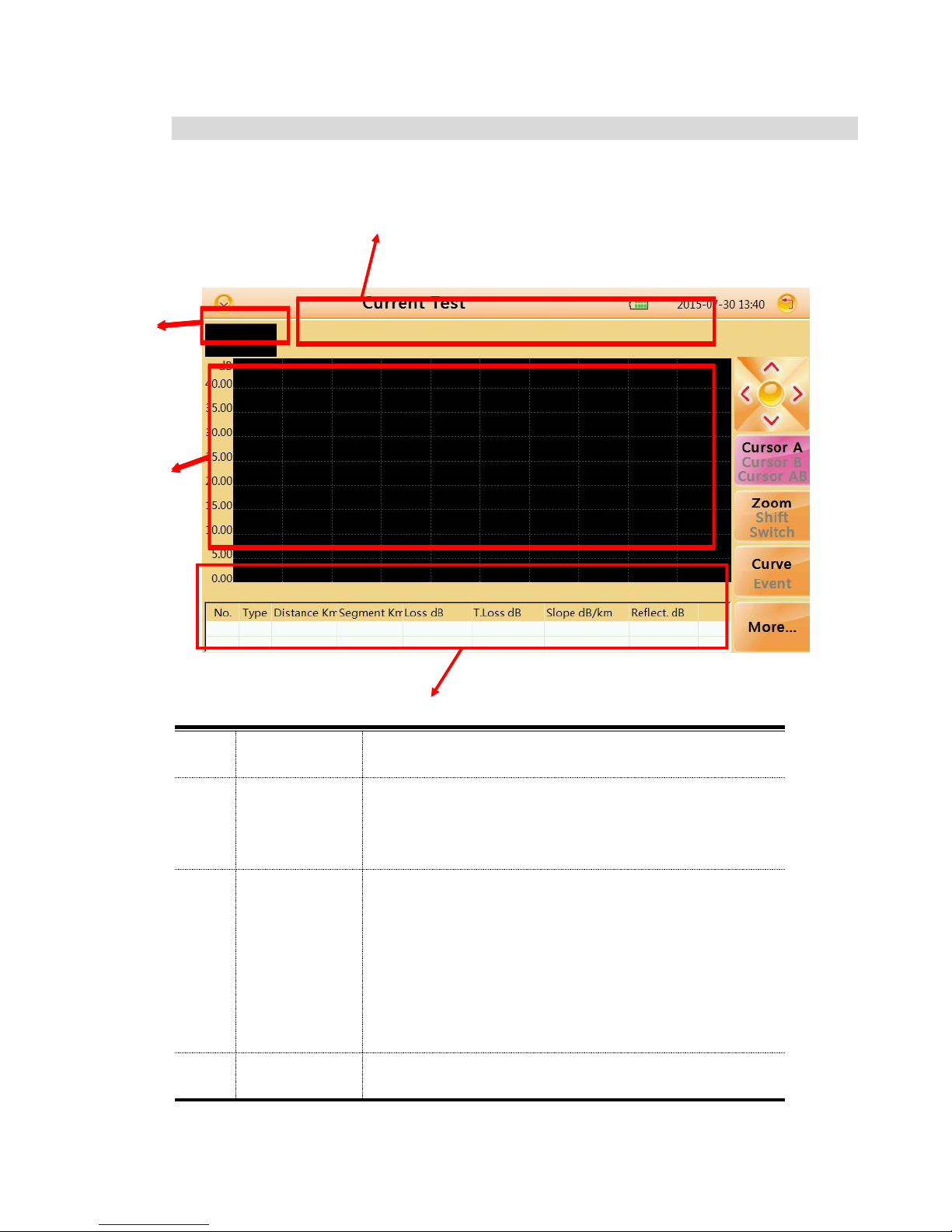

0.3 OTDR Module Interface

Num

Function

Description

I

Thumbnail of

current curve

For user's reference to the integrated curve

II

Curve

display and

operating

area

Display events and curves

III

Event list

Display event information

III

I

II

IV

I

II

15

area

including:"Type","distance(Km)","Loss(dB)","T.Los

s(dB)","Slope(dB/km)" and "Reflection(dB)"

IV

Test

condition

information

area

Display condition information of test

including"PW"(Pulse width),

"WL"(wavelength),resolution of X axis and Y

axis(dB/div),distance,averaging and total loss

from cursor A to cursor B.

16

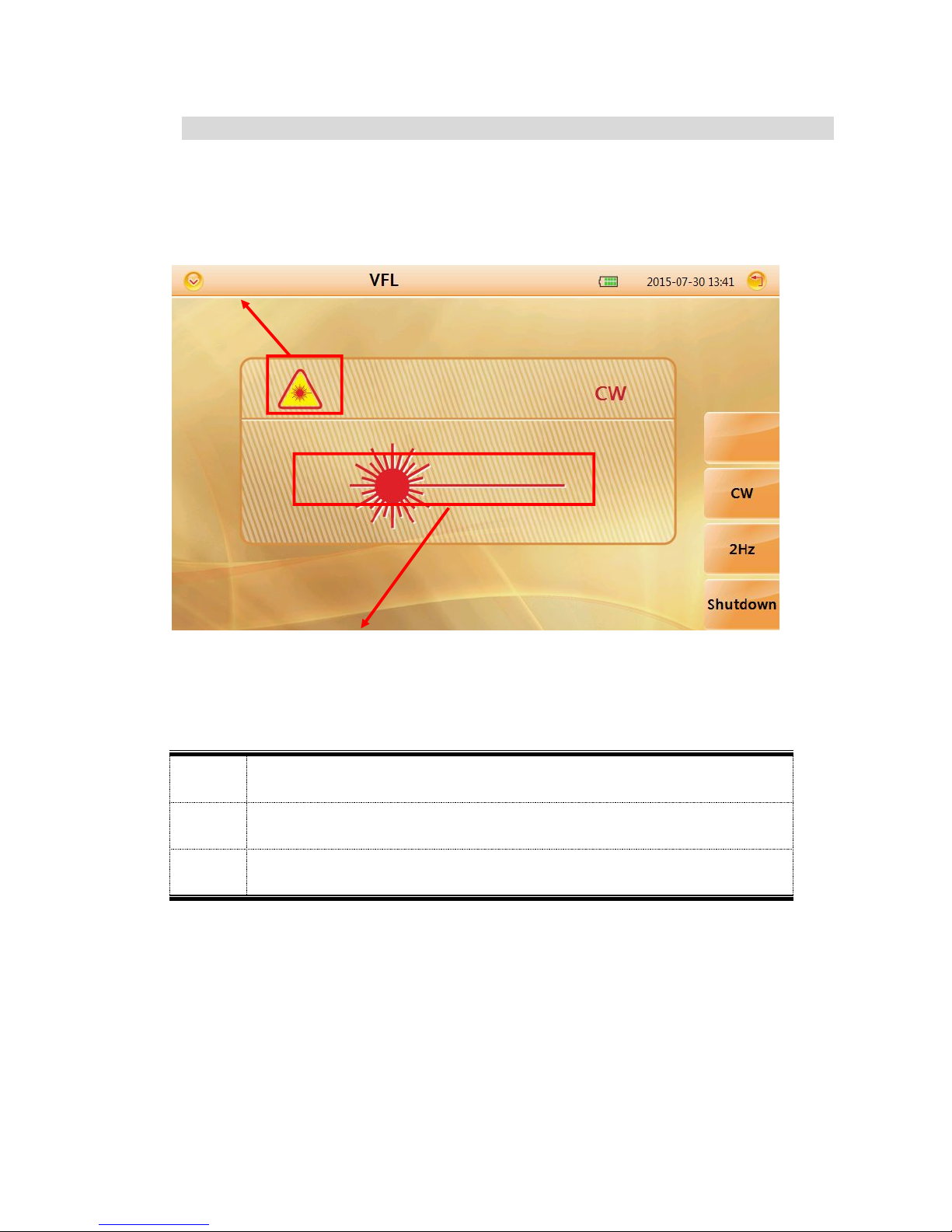

0.4 VFL Module Interface

Num.

Function

I

VFL mode indicator

II

Launching state indicator

II

I

17

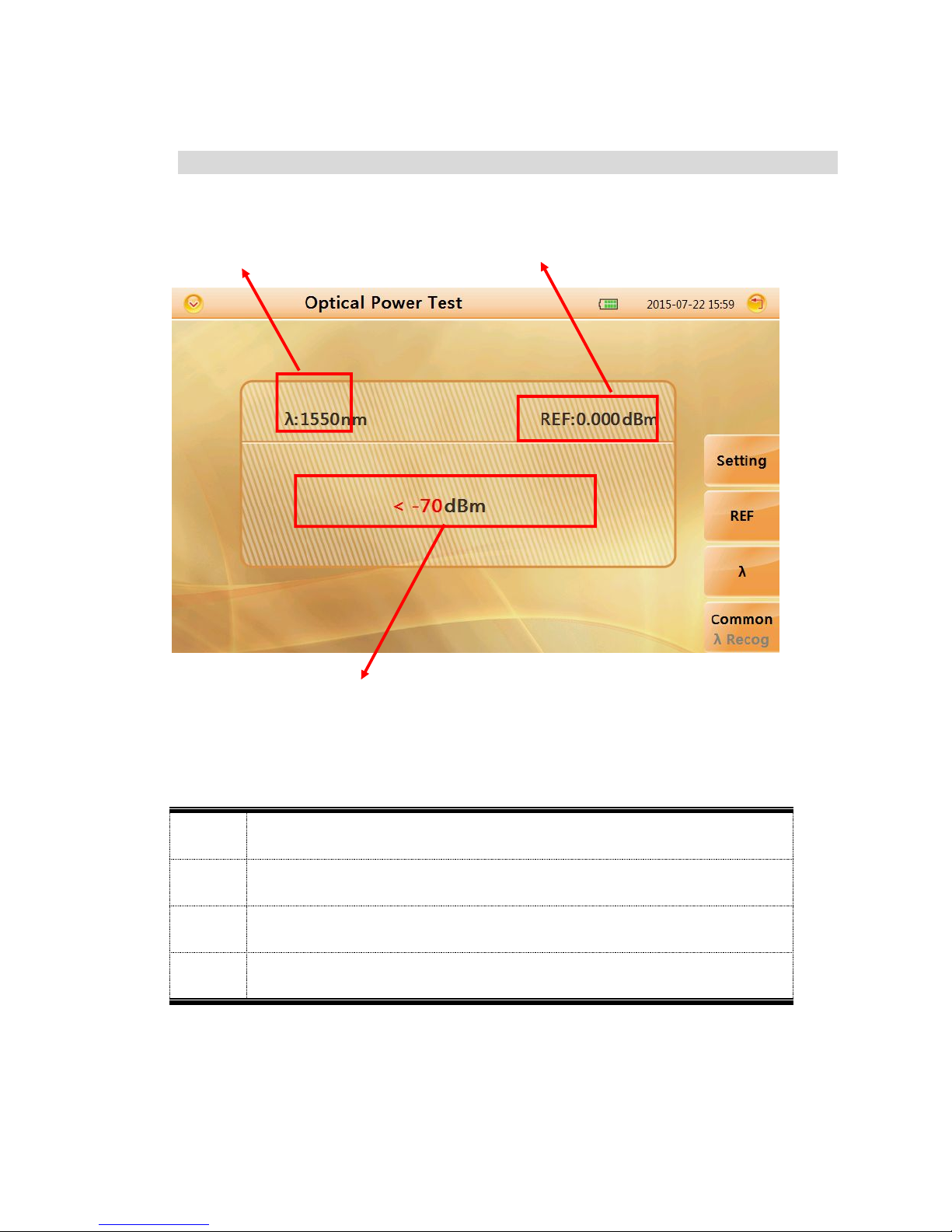

0.5 OPM Module Interface

Num.

Function

I

Power value display

II

Wavelength channel

III

Reference value

I

II

III

18

1.0 Preparation

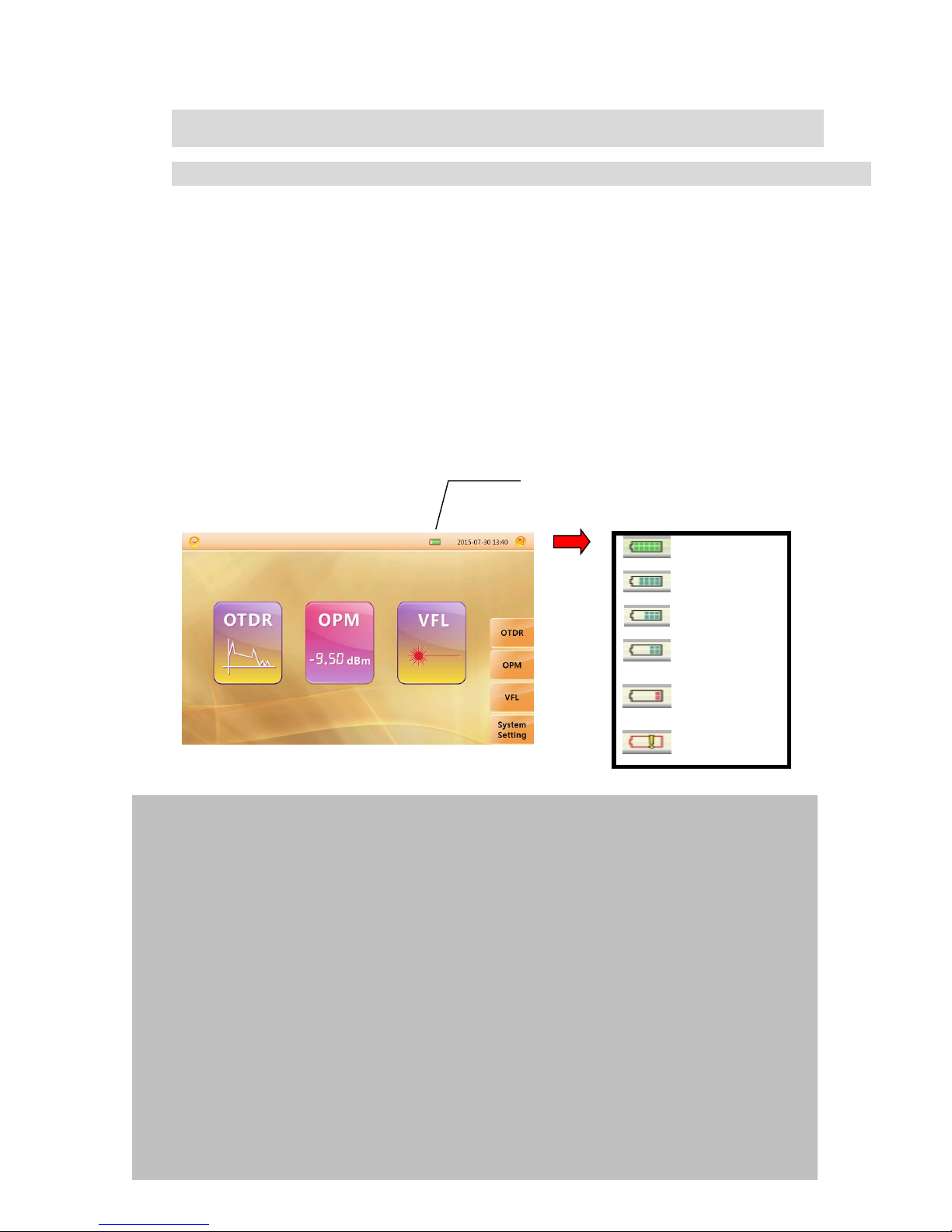

1.1 Turnning on

Press power button(>2s) to turn on OTDR, power state indicator turns

green .when power is low some warning information will display on the screen.

V

Full

80% Power

60% Power

40% Power

20% Power

Less than 20%

Launching state indicator

Green light:Proceed realtime test

Red light:Proceed averaging test

Power state indicator

Green light:Working state or fully charged

Red light:Charging state

Power Indicator

Caution

In case of low power, special icon will appear, and after that for a while MINI

OTDR will turn off automatically.

If it has not been used for an extended period of time,MINI OTDR will turn of

immediately after turned on to protect the internal battery ,please connect the AC

adapter adapter.

Proper charging temperature is: -10~50℃,high charging temperature may shorten

battery life.

Charging time is about 5 hours with power on, about 3 hours with power off.

Don't charge battery more than 8 hours.

19

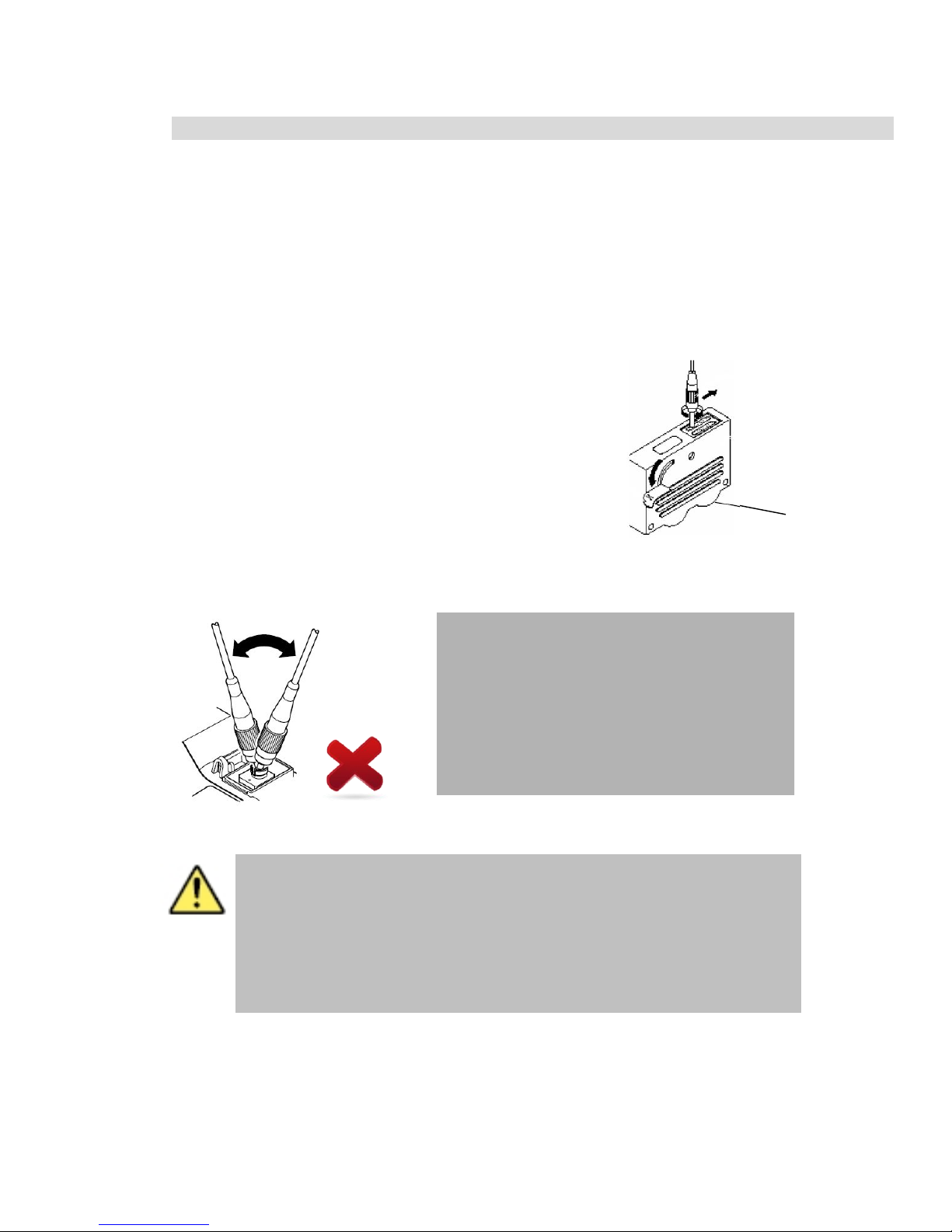

1.2 Connecting the Fiber

Before connect fiber to MINI OTDR,clean fiber end first ,the dust which on

the end of connector may damage the optical port or reduce test quality.

Procedure:

1. Put connector against the cleaner.

2. press the handle of cleaner.

3. Rub each other carefully to clean the contaminant.

4. Repeat procedure 1 and 3.

5. Open the protecting cover of optical port.

6. Insect connector into optical port carefully.

Caution

Insect connector carefully into optical

port,unproper operation may cause the

damage of optical port.

Cleaner

Warning

Before connection make sure that there is no optical signal exist

inside the fiber,any signal which is larger than -30dBm will disturb the

sampling of OTDR,even cause permanent damage of sensor.

20

2.0 Introduction of OTDR

2.1 Purpose of Measurement

OTDR shows the back-scatter light power of the optical signal relative to the

distance. With this information, the OTDR could measure a series of important

information of an optical fiber such as the quality of the line, distance of the line

and etc.

2.2 Content of Measurement

Event position----- a broken point or the end of the tested fiber

Optical attenuation coefficient of a optical fiber

Single event loss, such as the loss of a connection or a macro bending. Or

the loss of a end-to-end line on the tested optical fiber

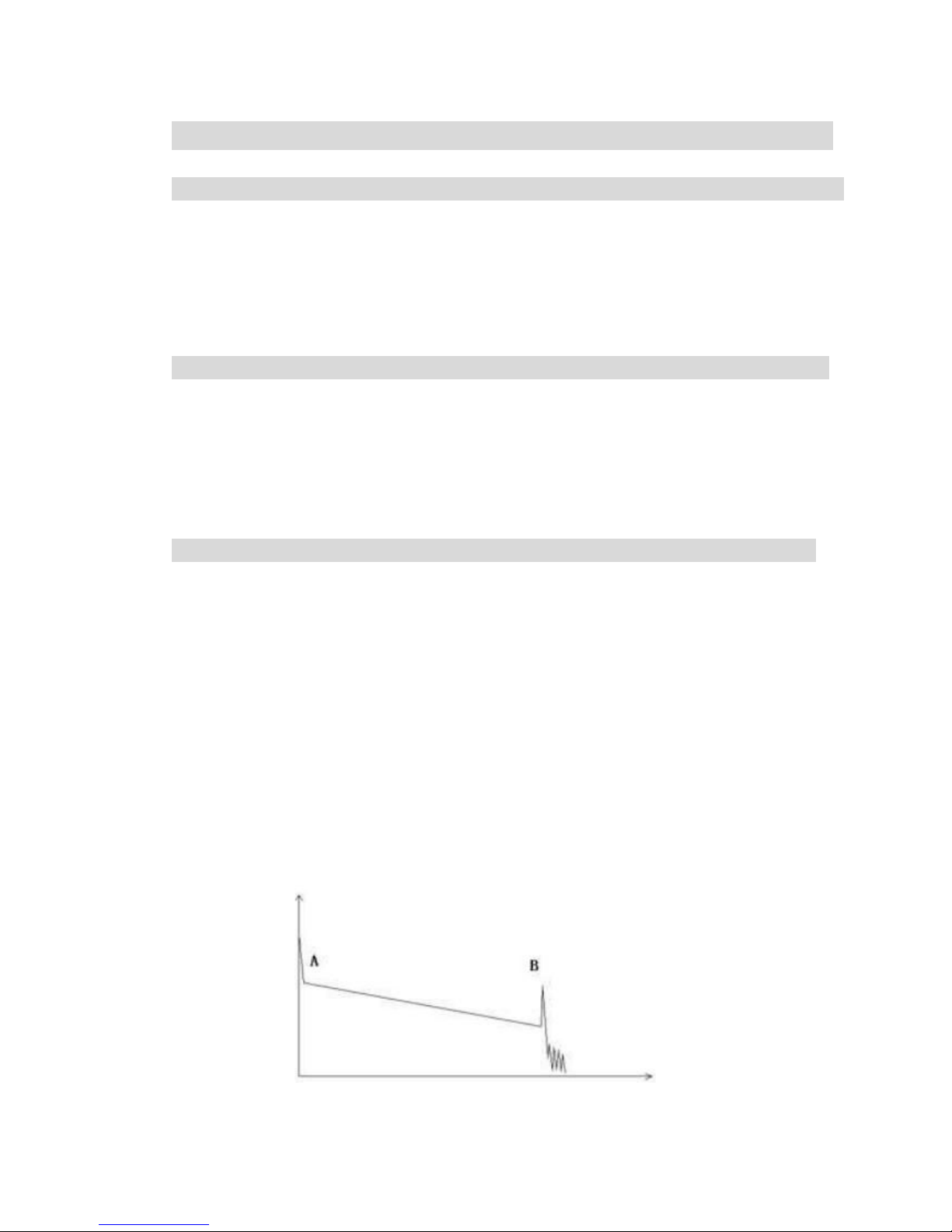

2.3 Analyze of Curve

OTDR can auto analyze a tested trace, the position process shows below:

Get the reflection events generated by connectors or mechanical splicer.

Non-reflection events(usually it is splicing points or macro bending).

End: the first point which the loss of it is over the threshold would be

scanned as the end of a trace.

Events list: event type, loss, reflection and distance.

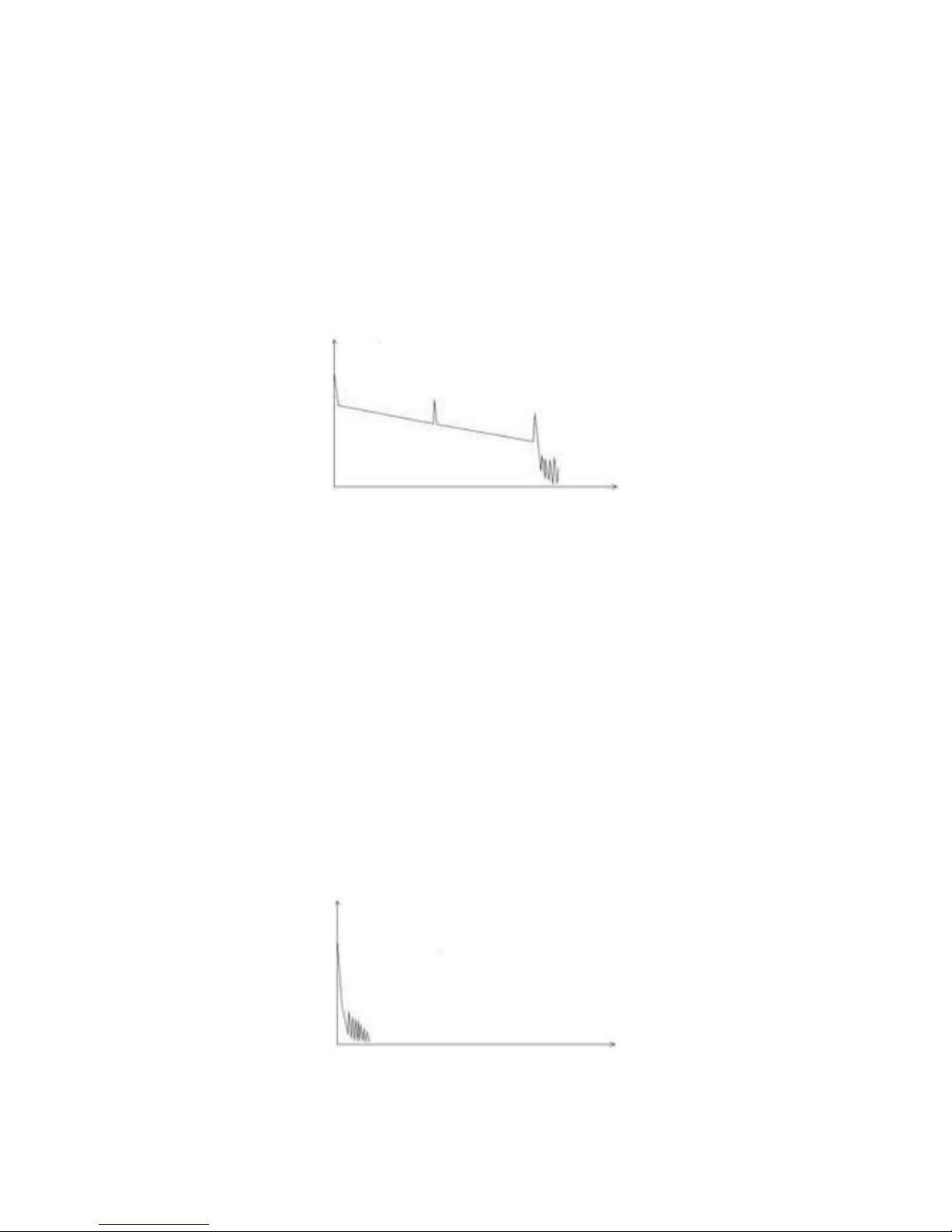

Normal Curve

21

A normal trace shows as above, the A mark is a start-peak and the B

mark is a end-reflection-peak. The tested trace is oblique, the total loss

will become bigger with the increasing of the fiber length. The total

loss(dB) divides total length is the average loss(dB/km) of a fiber.

Curve with Jumper Connected

If there is additional reflection peak in a tested trace, this may be

caused by a connection point or some other reasons. Anyway,

appearance of the reflection peak shows that the two connecting

surfaces of the connection are smooth. The smoother the connection

surfaces are, the higher the reflection peak is.

For an instance, if a broken optical line is under test, the OTDR

trace will show a broken point. After a maintenance of this line, use the

OTDR test it again, we may see a reflection peak replacing the broken

point on the OTDR trace, this shows the maintenance is done.

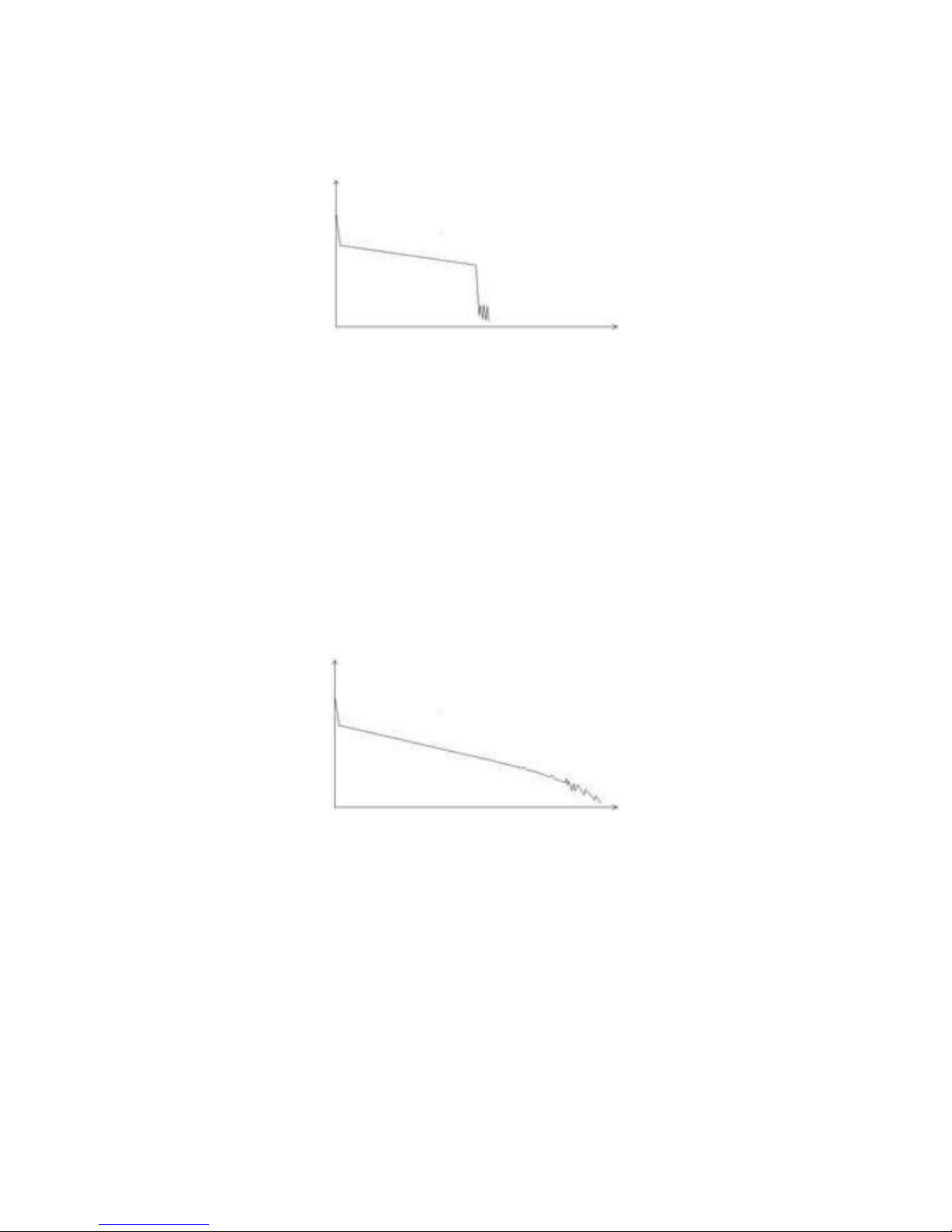

Curve with Broken Point

22

If the tested trace is just like the figure shows above, this might be

caused by several reasons like: a bad connection between the connector

and the lunching port, the optical pulse cannot be launched into the optical

fiber or a short distance broken point of the tested fiber from the initial

connection and the preset testing distance and pulse width is larger.

To fix this problem, we should:

1. Check the connection of the connector and the launching point

2. Reset the test parameters, decrease the preset distance and the

pulse width.

If the problem still exists, we could estimate:

1. The connector of the test fiber is broken or polluted.

2. The launching port on the OTDR is broken or polluted.

3. The distance of the broken point of the from the initial connection is

too close.

Curve with Non-reflective Event

There is a common phenomenon that an obvious step is on the middle of a

tested trace, it often caused by a fiber bending, fiber knot, being pressed by

something heavy or a fuse splicing point. The step means a bigger loss of a

fiber, it is also called event point. If the direction of it is downward, it could be

called non-reflection event. If the direction is upward, we can call it reflection

event.

Sometimes, the loss value could be a negative value, it does not means the

loss does not exist. It is common phenomenon called pseudo gain, it is by a

connection of two fibers with different back scatter coefficient, the scatter

coefficient of the back fiber is large than the front one's. In addition, the

different refract ratio also can cause the phenomenon. To avoid it, we could

test a fiber bi-directionally.

23

Abnormal Condition

The situation that there is no reflection peak at the end of a trace shows

above should be paid attention on. If the distance of the tested fiber is

available and the distance shown on OTDR is not equal to the original distance,

this shows that the fiber might be broken down or twisted and the bending

radius of it is over limited. The distance shown on OTDR is the position of the

fault point.

This phenomenon is often used in maintenance. If a fiber is uncertain, we

can bend a fiber and make sure the bending radius is over limited, then use

real time testing function of the OTDR to confirm the fiber.

Distance is Too long

This situation often happened in a long distance testing, caused by

under-range dynamic range of the OTDR that the energy of it can not support

a long distance transmission or caused by a under-range preset testing range

of distance or pulse width corresponding to the actual fiber length.

To avoid this situation, adjust the testing distance and the pulse bigger and

extend the sampling time.

Loading...

Loading...