grandimpianti WF8 G4, WF18 G4, WF11 G4, WF22 G4 Instructions For Installation And Use Manual

INSTRUCTIONS FOR INSTALLATION AND USE

www.groupdynamics-laundry.com

sales@groupdynamics.lv

WF8 G4

WF11 G4

WF18 G4

WF22 G4

®

WASHING MACHINE

MICROPROCESSOR G400

Industrial Laundry EquipmentIndustrial Laundry Equipment

Industrial Laundry EquipmentIndustrial Laundry Equipment

grandimpiantigrandimpianti

grandimpiantigrandimpianti

grandimpianti

LAVA-WF8-11-18 G4 v.05

VIA MASIERE, 211/C

32037 - SOSPIROLO (BL)

ITALY

Industrial Laundry Equipment

INSTRUCTIONS FOR INSTALLATION AND USE

www.groupdynamics-laundry.com

sales@groupdynamics.lv

CONTENTS

Page

1) General information ...................................................................... 2

INSTRUCTIONS FOR INSTALLATION

2) Electrical connection ..................................................................... 2

3) Requirements for installation ........................................................ 3

4) Transportation and installation ..................................................... 3

INSTRUCTIONS FOR USE

5) Machine information ...................................................................... 5

6) Machine operation ......................................................................... 4

7) Safety procedures ........................................................................... 8

INSTRUCTIONS FOR MAINTENANCE

8) Special use and safety measures ................................................. 13

9) Decommissioning and dismantling ............................................. 14

Figures ............................................................................................... 15

Description of cycles ........................................................................ 17

Technical data ................................................................................... 18

Key to components ........................................................................... 19

Wiring diagrams ............................................................................... 20

1. GENERAL INFORMATION

1.1 GENERAL ADVICE

The machine must be operated by trained personnel only.

Disconnect the equipment in case of malfunction and/or faulty

operation.

During use, cleaning and maintenance it is absolutely necessary to

be sure that tools or hands never reach into the moving parts of the

appliance (motor, belts, chains and gears).

The manufacturer disclaims all liability for personal injury occurring

to users or other people while using, cleaning or servicing the

equipment.

Do not open the washing machine soap dispensers when these are

working.

The equipment was designed for the treatment of fabrics according

to the instructions provided on the labels attached to the garments.

Only use it for the treatment of clothing, household linen and

ordinary everyday-use fabrics.

Do use this equipment to treat fabrics that have been in contact with

inflammables or chemicals. If this is unavoidable, hand-wash the

items and air-dry them to let those substances evaporate completely.

The operation of any electric or electronic appliance entails

compliance with certain basic rules and in this case particularly:

- do not touch the equipment with damp or wet hands or feet;

- Do not use the equipment while barefoot.

- Do not expose the equipment to atmospheric agents like rain,

salt, salinity, etc;

- Do not allow operation of the equipment by children or disabled

without proper supervision;

- Do not smoke near the equipment or during operation;

- Do not override or by-pass safety devices.

- Do not clean the machine by spilling water directly or indirectly

over it and therefore, install far from areas in which these

events are likely to occur.

- DO NOT use the equipment if you have not been trained to do

it.

ANY USE NOT EXPLICITLY MENTIONED HERE MUST BE

CONSIDERED AS A HAZARD.

THE MANUFACTURER UNDERTAKES NO RESPONSIBILITY

FOR DAMAGE RESULTING FROM IMPROPER, INCORRECT

OR UNREASONABLE USE, OR FROM USE NOT

CONTEMPLATED IN THIS MANUAL.

.

1.2 FOREWORD

Congratulations on your selection of our equipment.

If you follow carefully the present instructions you will certainly be

satisfied with its performance and guarantee.

Be informed that, in the event of claims or remarks, the reference

text is the original one in the manufacturer's native language, that

is, the Italian version.

1.3 GUARANTEE

- The warranty is valid for twelve (12) months from the date of

purchase of the equipment or of the relevant part.

- The warranty covers the replacement of parts that may prove faulty

for manufacturing causes. It is directly enforced by the supplier.

- In-warranty labor, freight and packing costs, as well as shipping

risks must be born by the purchaser.

- The warranty is valid only if the faulty parts are sent back carriage

paid, along with the information on the model, serial number and

defect of the machine the part was assembled onto.

- The warranty does not apply to machines that were damaged by

malpractice or carelessness, misconnection, incorrect installation,

non-compliance with the instructions for assembly and use, nor

does it apply to machines that were tampered with by unauthorised

personnel. The warranty does not cover machines whose serial

number has been altered, erased, removed or is not known.

- The warranty does not cover the following items:

a) Parts subject to ordinary wear and tear like belts.

b) The diaphragm in electrical valves and rubber parts at large.

c) Electric parts like motors, coils, contactors, heating elements and

so on.

1.4 INTRODUCTION

The present booklet was formulated in a simple and rational way,

in order for the reader to become familiar with his/her equipment.

Please, read it carefully and keep it near the equipment at all times.

The advice and instructions contained in this manual cannot cover

every possible contingency. This is why it is important to keep in

mind that common sense and caution cannot be supplied by the

manufacturer along with the appliance, but must be contributed by

those in charge of its installation, maintenance and use.

Whoever operates the equipment must have read this manual

beforehand.

In case of repairs the manufacturer warmly recommends the use of

original spare parts. As for ordering these, reference is made to the

relevant paragraph at the end of this manual.

The descriptions and sketches reported in this manual do not bind

the manufacturer, who reserves the right to update them and/or

include any upgrading modification of parts and fittings at any time

and with no previous notice if this is deemed necessary for

manufacturing or commercial purposes.

INSTRUCTIONS FOR INSTALLATION

2. ELECTRIC CONNECTION

The machine must be installed by professionally qualified and

licensed personnel, in accordance with the instructions provided by

the manufacturer as well as the national and local regulations.

Incorrect installation may result in harm to persons, animals or

property. The manufacturer undertakes no responsibility for such

damage.

Make sure that power supply voltage meets the details indicated on

the rating plate of the equipment. Consider also that the maximum

allowable power voltage variation is ±10%.

2

IMPORTANT:

www.groupdynamics-laundry.com

sales@groupdynamics.lv

CONNECTING THE MACHINE TO THE EARTHING SYSTEM

IS MANDATORY.

To this purpose, the terminal block is fitted with a specific contact,

which must be connected according to the regulations in force. The

manufacturer disclaims all responsibility for damage resulting

from non-observance of this accident prevention principle.

In compliance with the latest accident prevention provisions, the

machine is provided with an external terminal for equipotential

connection.

At the beginning of the power supply line there must be an

automatic all-pole circuit breaker with settings meeting the

maximum rated input (cfr. rating plate details of the equipment).

Provide for a 20 mm cable carrier duct (outer diameter) between the

circuit breaker and the power supply inlet to the equipment. Use the

cable clamp existing at the back of the machine to introduce the

power cord and, once the cables have been connected to the terminal

board following the sequence shown on the same, stop the cable by

the plastic nut.

Caution!

These appliances are equipped with electronic control devices like

a control card and an inverter. To be CE type-approved, such

devices must include noise filters complying with EMC standards

on eddy current emission. To operate properly, these filters leak a

small current of approximately 10-15mA through the earth lead.

Therefore every machine must be fitted with its own systemprotecting residual current cutoff switch (RCD). Avoid connecting

more than one appliance, whatever their capacity or brand,

downstream of a single RCD.

THE WARRANTY DOES NOT COVER DAMAGE CAUSED

BY INCORRECT INSTALLATION.

3. REQUIREMENTS FOR INSTALLATION

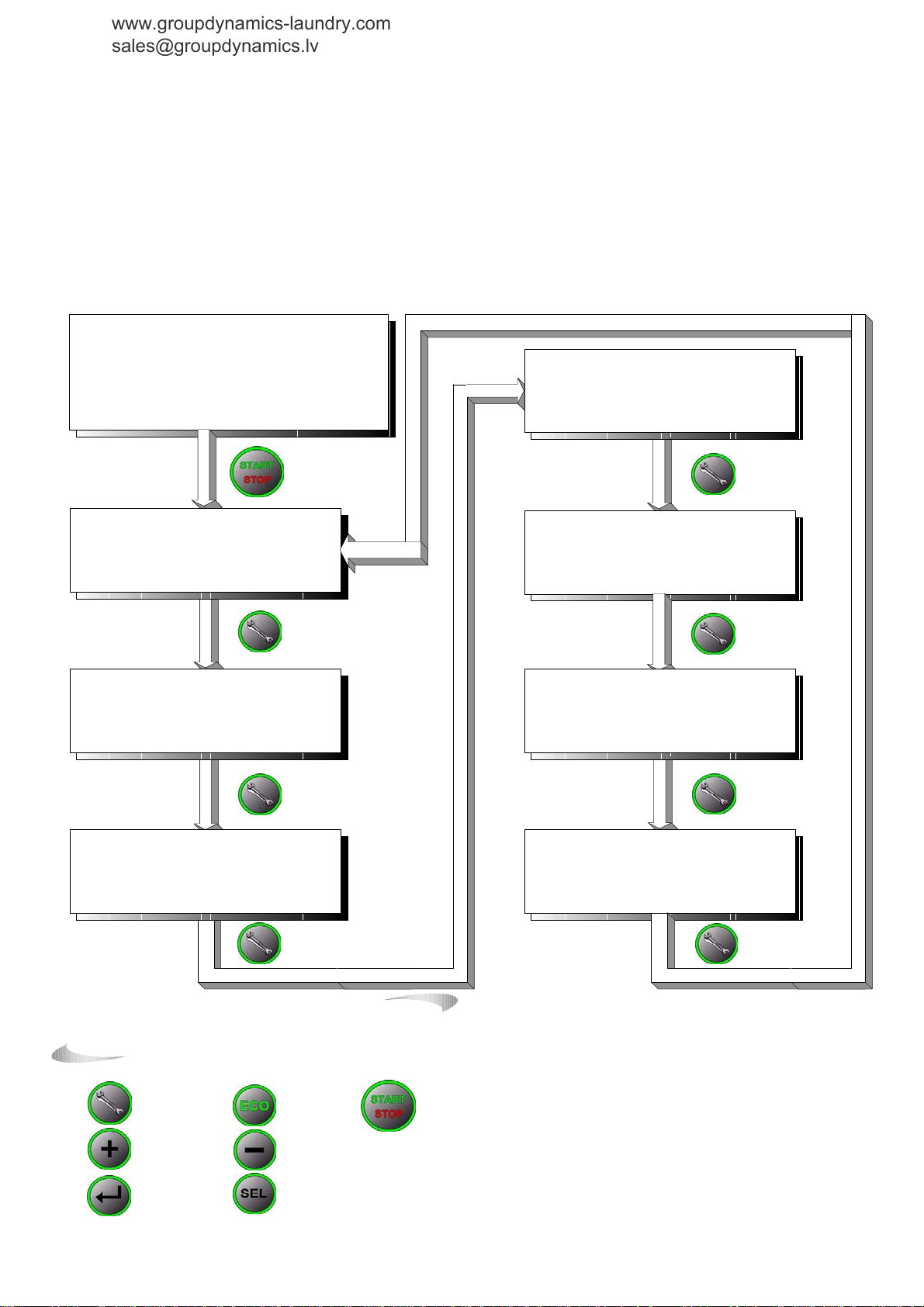

3.1 SPACE REQUIRED FOR INSTALLATION, USE AND

MAINTENANCE

The equipment requires the minimum space indicated in dimensional

figures 1 and 1a:

1) power supply line with RCBO (Residual Current Circuit Breaker

with Overcurrent Protection) at the beginning of the line*.

2) Interlocked socket including fuses and manual all-pole switch.

3) Power supply plug.

4) Shutoff taps for water inlets.

5) Grille or plate (preferred) for closing the drain trap.

6) Rubber hose for water drain (included).

7) Drain trap.

8) Circular door.

9) Hard water inlet.

10) Warm water inlet.

11) Soft water inlet.

12) Steam inlet (only for steam-heated models).

13) Cable clamp for the power supply inlet.

14) Template to be used for positioning machine-anchoring bolts.

15) 3 tubes for hard, warm and soft water intakes (included)

16) Flexible steam connection tube (included with steam-heated

models only).

17) 3/4" mechanical filter (provided with steam-heated models

only).

18) Steam supply line, pressure comprised between 4 and 6 bar; as

for consumption rates, cfr. rating plate details.

19) Steam shutoff tap (steam-heated models only).

20) 3/4" condensed water drain (only for indirect-steam models).

* The automatic circuit breaker must be in a position allowing easy

access to the operator in any EMERGENCY event.

4. HANDLING, UNPACKING AND STORING

4.1 SHIPPING AND HANDLING

To handle and/or ship the machine follow carefully the ensuing

recommendations:

Move the machine on its own pallet or on a similar platform; use a

fork lift, either manual or electric, provided it is adequate for

handling such appliances and it has the requisite lifting capacity

(cfr. technical data). Check beforehand that the equipment can

surmount any existing obstacle, like staircases, doors, etc. Do not

drag the machine by the sides or by any other part.

For shipping purposes, use only the original packaging, which

helps ensure sufficient stability during transportation.

4.2 STORING

If the equipment must be stored for a long period of time before

being put into operation, keep it inside the original package, since

this guarantees excellent protection. Also ensure that the

environmental conditions in the storehouse meet those indicated in

the next paragraphs. On the other hand, if the machine must be left

inoperative for a long period after use, be sure it is materially

disconnected from the electric supply and cover it the original

protection bag.

4.3 UNPACKING

1) Prior to accepting the machine from the carrier, check the

conditions of the packaging. If it is showing visible damage, the

machine may have been damaged too. In this case, unpack the

machine in the presence of the carrier and sign, under

reservation, the delivery slip. The manufacturer undertakes no

liability for any damage caused by transportation or improper

storage.

2) Unpack the machine with the utmost care to avoid damage. To

remove the platform, take off the screws from the inside of the

same, which are in the machine floor-fastening holes.

3) For all washing machines: open the door (cfr. next paragraphs)

and check that the following items are in the package:

- # 2 metal straps

- # 1 90° rubber elbow

- # 2 flexible pipes with ¾ ferrule

- # 1* brass strain for the steam inlet (steam-heated model only)

- # 2 flexible metal pipe

- keys to the coin box and 15 coins (only for coin-operated

versions)

- the keys to the machine's hood (only for machines featuring

a key-operated lock).

ON HIGH-SPEED WASHERS THE BRACKETS THAT

FASTEN THE TUB MUST ABSOLUTELY BE REMOVED

BEFORE MACHINE STARTUP.

4) For all ironers in the ranges with diam. 18cm, 25cm and 30cm,

install the linen-rest wood board on the respective supports

using the grub-screws and bolts as in the sticker appearing on

the roller. The head of the screw and the longer side of the board

must face upwards.

5) The packaging material (plastic bags, expanded polystyrene,

wood, cardboard, nails, etc.) represent a safety hazard and

consequently must not be left within the reach of children.

Collect and keep for further transportation or long-term storage.

Before connecting up the appliance, check that the rating plate

details match those of the existing electric line. The appliance

must only ever be used for the purposes it was explicitly

designed for.

6) For tumble dryers: check that the steam electrical valve* is in

the drum.

7) Ensure that the instruction booklet is not left in the package and

lost.

(*Steam-heated machines only).

Before connecting up the appliance, check that the rating plate

details match those of the electric line the equipment is going to be

connected to. The appliance must only ever be used for the purposes

it was explicitly designed for.

4.4 GETTING THE APPLIANCE STARTED

4.4.1 LAYOUT REQUIREMENTS

This equipment offers no positioning difficulty other than a flat,

3

level and sturdy surface. Align and level by the use of a spirit level.

www.groupdynamics-laundry.com

sales@groupdynamics.lv

For servicing purposes, it is advisable to leave a 500mm clearance

between the rear face of the machine and the wall behind.

Besides, when machines are installed in a line, leaving at least a

20mm clearance between one machine and the next is recommended.

Washing machines

Provide for a floor drain at an elevation below the machine drain,

that can be connected to the washing machine, using the supplied

elbow fitting.

CAUTION! Repeat levelling after moving the machine.

bar (0.1 MPa and 0.6 MPa).

Refer to the rating plate details.

4.7.1 FOR ALL WASHER VERSIONS

The water in the tub can be heated either directly or indirectly. In

the latter instance, a connection for the recovery of condensed water

will have to be provided for (diameter as per technical details).

If the machine is subject to ISPESL inspection, keep all ISPESL

documents in the room where the washer is lodged.

When the connection is done make sure that the piping is not

crushed or blocked.

4.4.2 ALLOWABLE AMBIENT CONDITIONS FOR PROPER

SERVICE

Let these conditions be known to direct machine users.

- TYPE OF ROOM: CLOSED

- MINIMUM TEMPERATURE: 10°C (note: when ambient

temperature is below 10°C, electronic parts may work

irregularly)

- MAXIMUM TEMPERATURE: 40°C

- RELATIVE HUMIDITY: 75% H.R.

- LIGHTING: 100 LUX (value valid for Italy; given the variety

of regulations regarding luminance in working premises, for

other national provisions, refer to the specific national codes).

4.5 FOR ALL HIGH-SPEED WASHER MODELS AND

VERSIONS: TILT SWITCH ADJUSTMENT

All high-speed washers are equipped with a device that terminates

spinning steps when severe imbalance poses a threat to the

mechanical parts composing the machine.

To reach this safety device open the machine's top cover (cfr.

relevant instructions in the manual section For the repair personnel).

This device is at the topmost point of the tub. Adjust this switch only

after the wall cutoff switch was turned off and the machine was

disconnected from the power mains.

Adjustment of this switch is reserved for the authorised and

qualified personnel.

This device consists of a microswitch that is fixed to the machine's

frame. It is is driven by a flexible rod located inside a metal window

that moves integral with the drum of the washer. When severe

vibrations occur, the window moves the rod and the safety device

trips (cfr. also alarm "E9" and alarm description).

During machine installation, after removing the transportation

brackets and with the drum empty, position the flexible rod at the

centre of the window, so that abnormal tripping of this safety device

is avoided.

For proper positioning, use the screws that fasten the support of the

microswitch and position this properly.

4.6 FOR ALL HIGH-SPEED WASHER MODELS AND

VERSIONS: WATER CONNECTION

Washers feature a warm water inlet (for approximately 60°C) and

two cold water inlets (cold and soft), ¾" and ½" in diameter (see

rating plate details for the specific model).

The incoming water pressure must be comprised between 0.5 and

5 bar (0.05 Mpa and 0.5 MPa).

Make arrangements for the distance from wall couplings not to

exceed the length of the piping attached.

If a warm water source is not available, mount a T pipe on the soft

cold water coupling and connect the warm water inlet too to the

cold-water source. As for cold and warm water consumption, refer

to the rating plate details for the specific model.

All machine water inlets must be fed water.

CAUTION! When assembly is complete, ensure that the piping is

not crushed and that water flows normally.

4.8 DRAIN CONNECTION

Make certain that the distance between the machine drain outlet

and the floor drain is not longer than the drain elbow supplied.

Water is drained through a direct-action motor-driven valve that

stays open (by gravity - no pump) when the machine is not powered.

Therefore, the floor drain must always be below the drain outlet of

the machine. The diameter of the floor drain must never be smaller

than the diameter of the hose supplied.

Drain flow rate and diameter: refer to the rating plate data for the

specific model.

CAUTION!

- The draining pipe must be able to resist a temperature of 90°C.

- Install a U-trap between the hose supplied and the drain.

- Check that the piping is not crushed or blocked.

4.9 AIR BREAK

The washing machine is equipped with an air-break device that

stops wastewater from flowing back into the drinkable water system

in the event of a depression. This device has a rear or side outlet that

may release innocuous steam during heating. Do not close or couple

the air-break outlet.

THE WARRANTY DOES NOT COVER DAMAGE CAUSED

BY INCORRECT INSTALLATION.

INSTRUCTIONS FOR USE

5. MACHINE DETAILS

5.1 MACHINE DESCRIPTION

The machine is composed of the following main parts (see fig. 2):

1) Hood under which the control circuit is lodged.

2) Soap dispenser for pre-wash and wash (foam-damping washing

powder) and for liquid conditioner (foam-damping type).

3) Circular loading/unloading door.

4) Coin-meter (on coin-operated machines only).

5) Coin box (on coin-operated machines only).

6) Drain.

7) Equipotential terminal.

8) Air break.

9) Water inlets.

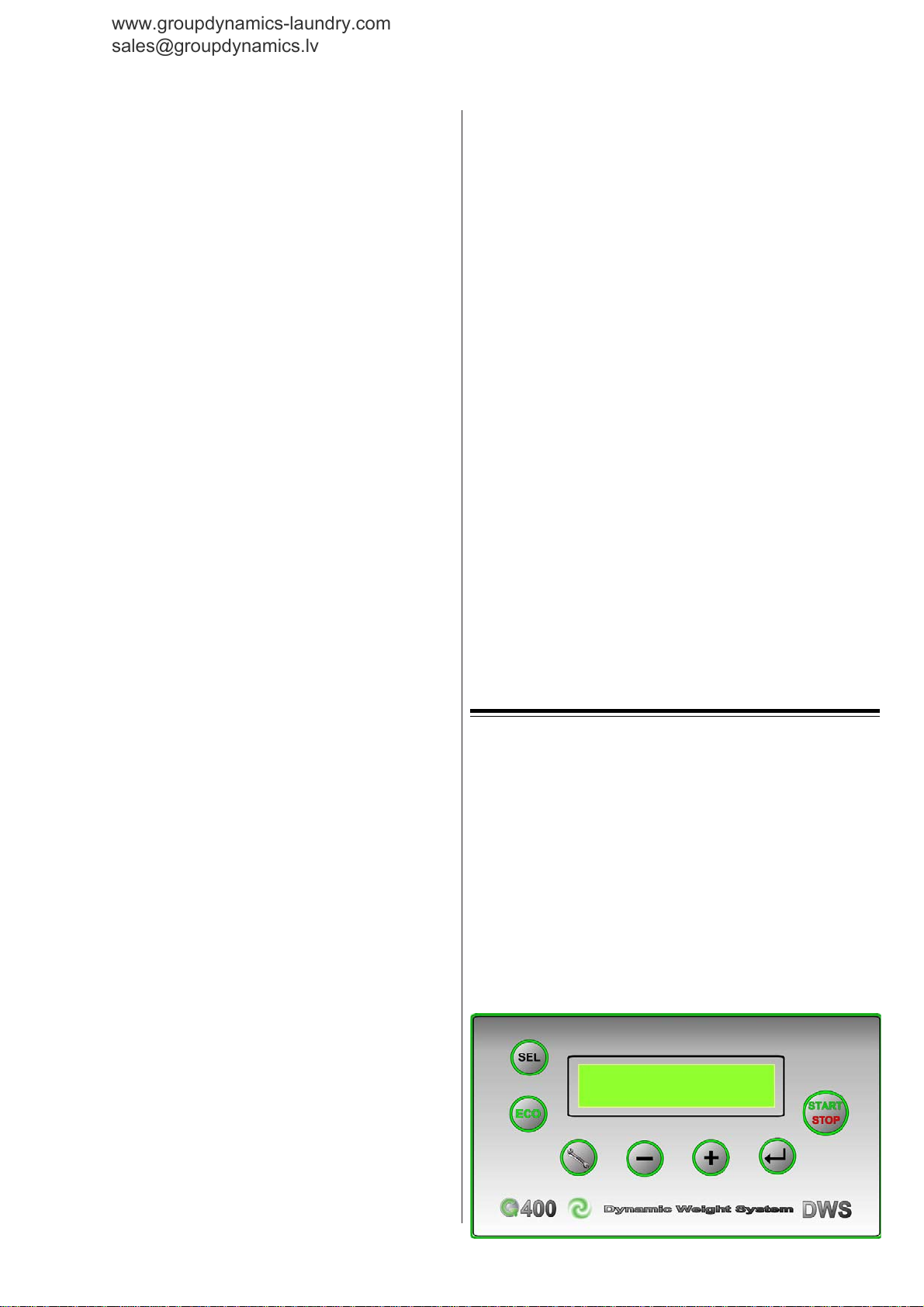

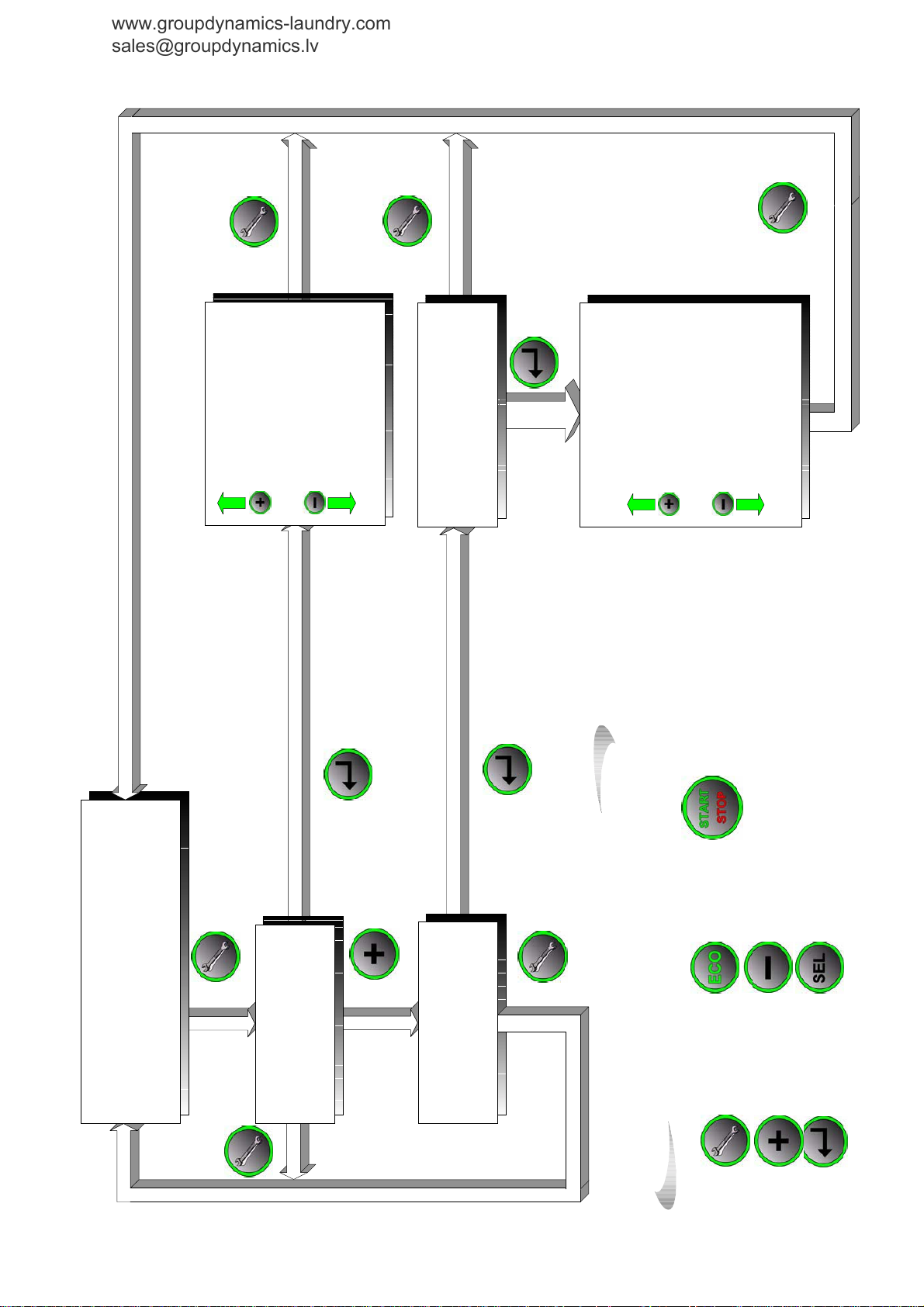

5.2 DESCRIPTION OF THE KEYPAD

4.7 STEAM CONNECTION (STEAM-HEATED

MACHINES ONLY)

The equipment features a steam inlet for saturated dry steam. Inlet

diameter depends on the machine model (cfr. technical details).

The incoming steam pressure must be comprised between 1 and 6

4

SEL: Cycle (program) selection BUTTON

www.groupdynamics-laundry.com

sales@groupdynamics.lv

ECO: ECONOMY BUTTON: to reduce water consumption by

20%. THIS DOES NOT consider the effective wash load and works

only if the "weighing" function is not featured.

!!

"

! " ENTER BUTTON: to confirm selections when programming

!!

optional parameters.

"+" PLUS PUSH BUTTON: to increase values.

"-" MINUS PUSH BUTTON: to decrease values

If the "+" and " - " buttons are pressed during operation, the machine

is put to pause. To resume operation press the START / STOP

button.

"Key tool" MODE push button: is used to enter and exit the

MACHINE PARAMETER menu and the SERVICE menu.

START / STOP: it is used to start the wash cycle. If it is held down

for longer than 5 seconds it causes the END OF THE CYCLE.

5.3 COMPLETE APPLICATION RANGE

Your washing machine was designed to wash synthetics, woolens,

cottons and linens. Choose your cycle by the appropriate button as

suggested on the labels attached to the garments to be washed.

5.4 ELECTRICAL SYSTEM DETAILS

The built-in electrical system is composed of protection and control

devices duly lodged on a plate in the top part of the machine. The

relevant diagrams and lists appear later on in this manual.

6. WASHER OPERATION

Make sure that the cold water, warm water and steam taps are open

(the latter applies only to steam-heated machines).

Turn ON the automatic overcurrent circuit breaker on the wall. If

the door is closed, the machine will then be ready to be started using

the appropriate button (START/STOP) on the front panel.

To select and start a cycle and also to program optional functions,

refer to the block diagrams later on in this manual.

Make your cycle selection following the temperature and wash

action suggested in the labels attached to the garments (see cycle

description below), sort the laundry according to the type of fabric,

load the drum and close the door.

Then fill the various dispenser bins with soap (foam-damping type)

according to cycle selection, i.e.:

A prewash compartment (when scheduled in the selected wash

cycle)

B main wash compartment

C compartment for optional conditioning agent (when scheduled

in the selected wash cycle)

D compartment for optional conditioning agent (when scheduled

in the selected wash cycle)

E compartment for optional conditioning agent (when scheduled

in the selected wash cycle)

ECONOMY FUNCTION WARNING:

This function simply reduces the amount of water and soap used

with reference to factory-foreseen amounts. NOT to be interpreted

as "half-load button".

To start the cycle, press the START / STOP push button with the

door closed: The door will automatically be locked. Cycle progress

will be shown on the control panel display unit.

Pressure on the START / STOP button also causes the timer to

commence the countdown to the end of the cycle.

Such time values are those that the machine has stored in a previous

equivalent cycles. Therefore they are not binding but represent a

mere reference.

6.1 FAST-FORWARDING AND END OF CYCLE

When a wash cycle is in progress, each pulse on the START / STOP

causes the cycle to move one step forward. If the same button is held

down for more than 5 seconds, the cycle will move straight to the

end, which will consequently cause the door to unlock.

Each time a button is pressed the machine beeps briefly. It beeps for

15 seconds at the end of the cycle.

It is however possible to stop the beeper by pressing the " - " push

button or even inhibit the beeper altogether through programming.

6.2 ALARM AND FAULT SIGNALING

When faults arise (voltage drop, supertemperature, water level

error in the drum) the equipment notifies the user by a number of

alarms that appear on the front panel DISPLAY. All alarm details

are dealt with in the "SAFETY MEASURES" chapter.

6.3 CYCLE STEPS

The control display reads the various steps, i.e.:

1) WEIGHING - The machine weighs the laundry. Weighing can

be automatic (standard) or manual. This step can only be

performed at the beginning of the cycle.

2) SOAK - Soak step underway (when scheduled).

3) PREWASH - Prewash step underway (when scheduled)

4) WASH - Wash step underway

5) RINSE - This message is read when the machine is performing

any rinsing step in the cycle.

6) SPIN - Final or intermediate spin underway

7) DISTRIBUTION - Distribution step underway

At any rate, every step is read along with a description explains the

relevant details.

When the end of the cycle is reached, the door is automatically

unlocked: then it will be possible to open the door using the handle

and pick the clean laundry.

CAUTION! Never force the door open. Open by hand only after it

has been unlocked.

At any rate, before opening the door make sure that the drum has

stopped, the water has been drained and the temperature inside the

drum is below 40°C .

Should a potential drop occur during the wash cycle, it will be

possible to open the door after about 90 sec.; in case of emergency

or defect of the door-opening device, to open the door jerk the

manual puller downwards (see fig. 2).

To reach the manual puller it is necessary to unscrew the two fixing

screws with a cross-bit screwdriver and withdraw the machine's

lower front panel. After the door has been unlocked manually, open

it using the handle as explained above and then put the panel back

in place.

6.4 CONFIGURATION OF SETTINGS

Besides the "START/STOP" and the "ECO" push-buttons, the

machine has 4 more buttons for cycle selection and special functions.

More precisely, with the door closed and before starting a cycle, the

programming mode can be entered by pressing the "MODE" pushbutton.

For further details cfr. the block-diagram attached.

WARNING: if a potential drop should occur during a programming

session, changes will not be saved and it will be necessary to repeat

the programming procedure from the beginning.

6.5 PROGRAMMIMG BY PC - OPTIONAL

Washers can also be programmed via PC through a serial port. To

this purpose the washers feature an ad-hoc RS232 serial port at the

rear (OPTIONAL).

To enable the "data transmission and reading" mode it will be

necessary to switch the washer on while holding down the "MODE"

key: the displays will read "HOST COMPUTER" only.

For further details, contact your seller or the after-sales service.

CAUTION!

Do not try to read or change machine programming, unless you

have the ad-hoc cable supplied by the manufacturer, as this could

cause severe damage to the electronic boards.

If you wish to change machine programming, contact your seller or

the after-sales service.

6.6 PROGRAMMIMG BY SMART CARD

Washers can also be programmed using a SMART CARD. As a

matter of fact, the Smart Card reader featured as standard can save

or load the machine-control firmware.

5

6.6.1 WASH PROGRAMS

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Wash cycles can only be saved and loaded (as preset) when the

machine is on, no cycle is in progress and the door is open. On

inserting the Smart Card the G400 control identifies the card:

a) Invalid card: the display will read "invalid card": remove the

card. As soon as it is removed the machine will resume

standard readings.

CYCLE SELECTION, VIEW AND START

b) Firmware card: the display will read "software card" and will

allow no action other than removing the card.

c) Correct card: the display will read "cycles card" and will offer

the user two graphic options: download the programs to the

G400 or upload them to the Smart Card. Make your selection

using the "+" and " - " keys and confirm by the key "! :

ENTER".

MACHINE AWAITS START

DISPLAY READING:

`

Program selection from P01 to P20

`

Time to cycle end: clock icon and time in hh:mm

`

Maximum temperature in the cycle

`

Cycle name

`

Door status: open or

CYCLE IN PROGRESS

DISPLAY READING:

` Program selection flashes for the first 2 minutes

` Time to end of cycle: clock icon and time countdown alternate with

name of step

` Water intake icon if applicable

` Number and name of step in progress

CYCLE IN PROGRESS

DISPLAY READING:

` Water intake icon if applicable

` Number and name of step in progress

` Temperature setting and effective temperature

` Water level setting and effective temperature

` Number of water liters taken in. OPTIONAL

CYCLE IN PROGRESS

DISPLAY READING:

` Water intake icon if applicable.

` Number and name of step in progress

`

W

arm water intake enabled YES/NO and number of liters taken in

`

Cold

water intake enabled YES/NO and number of liters taken in

`

Cold

water intake enabled YES/NO and number of liters taken in

closed

Programming and Menus

Push buttons

MODE

button

PLUS

button

ENTER

button

ECONOMY

MINUS

CYCLE

SELECTION

button

button

button

CYCLE IN PROGRESS

DISPLAY READING:

` Water intake icon if applicable

`

Number and name of step in progress.

`

Dispenser A: dispenser ON time

`

Dispenser B: dispenser ON time

`

Dispenser C: dispenser ON time

CYCLE IN PROGRESS

DISPLAY READING:

` Water intake icon if applicable

` Number and name of step in progress

`

Soap pump n°1: pump ON time

`

Soap pump n°2: pump ON time

- - - - - -

`

Soap pump n°9: pump ON time

CYCLE IN PROGRESS

DISPLAY READING:

` Water intake icon if applicable

` Number and name of step in progress

`

Motor action: to left and time countdown

`

Motor action PAUSE and time countdown

`

Motor action: to right and time countdown

`

Motor speed in RPM

CYCLE IN PROGRESS

DISPLAY READING:

` Water intake icon if applicable

` Number and name of step in progress

` Drainage delay: YES / NO

` Drain at end of step: YES/ NO

CYCLE

START/STOP

button

8

www.groupdynamics-laundry.com

sales@groupdynamics.lv

MACHINE STANDBY STATUS

MACHINE PARAMETERS

COOLING CHANGE

OVERRIDE SPINNING

OVERRIDE PREWASH CYCLE DEFERRED START

ENABLE /DISABLE BUZZER

REDUCED HEATING

DRUM ROTATION HEATING HYSTERESIS

STRUCTURE OF MENUES

VIEW COUNTDOWN TIME

START WITH H2O

ENABLE SOAP PUMPS

AUTOMATIC TARE AND LEVEL CALIBRATION

ENABLE CYCLES

MACHINE STANDBY STATUS

SERVICE EN TER PASSWORD:_ _ _ _ _ _

SEQUENCE OF BUTTONS

MACHINE STANDBY STATUS

SERVICE MENU

LANGUAGE

DEGREE TYPE SPINNING MOTOR (2° LEVEL) WEIGHT CONVERSION FACTOR (2° LIVELLO)

DRAIN TIME STANDARD WATER INTAKE

BALANCED WATER INTAKE

H2O TIME-OUT

ECONOMY FUNCTION

HEATING TABLE

MACHINE TYPE ELECTRONIC COIN-OP SETTINGS (2° LEVEL) PASSWORD

CONSUMPTION MAINTENANCE (2°LEVEL)

COMMENTS MACHINE BLOCKED

MACHINE TESTING

7

button

CYCLE

START/STOP

MACHINE ON AWAITS CYCLE START

DISPLAY READINGS:

closed

Program selection from P01 to P20

Time to the end of the cycle

Maximum temperature in the cycle

Cycle name (max 20 chars.i)

Door status:

`

`

`

`

`

MACHINE STANDBY STATUS

Programming

MACHINE PARAMETERS

MACHINE STANDBY STATUS

Programming

SERVICE MENU

ECONOMY

button

button

MINUS

button

CYCLE

selection

Push buttons

Programming and menus

MODE button

PLUS button

ENTER button

6.6.2 FIRMWARE

www.groupdynamics-laundry.com

sales@groupdynamics.lv

To save and load the firmware, insert the Smart Card when the

machine is off. When the machine is then turned on the system will

react by showing the following messages:

a) Invalid card: the display will read "invalid card": remove the

card. As soon as it is removed the machine will resume

standard readings. At this stage also the cycles card will be

considered invalid.

b) Correct card: the display will read "software card" and will

graphically inform the user that the firmware is being transferred

from the Smart Card to the G400 (firmware upgrade): Loading

the firmware from the G4 controller to the Smart Card is not

possible.

If a software card is inserted when the machine is on, the G400

control will start the card identification routine and will allow no

further action.

CAUTION!

Do not attempt to read or program the machine using SMART

CARDS other than the original one (ATM cards, credit cards, other

service cards etc.) as they will be irretrievably damaged. The

manufacturer undertakes no liability for incorrect or improper use

of the Smart Card reader on the machine.

If you need to change machine programming by this system,

contact your seller or the after-sales service.

6.7 USEFUL ADVICE

Remember that loading 80% of the rated capacity provides better

wash results.

Mind that more soap does not mean cleaner: on the contrary, using

too much washing agents leads only to unnecessary pollution. The

right amount of soap is indicated by the manufacturer according to

the hardness of the water used.

Unless specifically advised against, the use of the reduced water

and temperature cycles is warmly recommended, in order to cut

back water and energy consumption and consequently reduce cycle

length.

Before loading the drum make sure that buttons, zips, clasps and

buckles are facing inside Check that the pockets are empty.

At the end of a working day do the following:

- leave the door open;

- turn the machine off by the master switch;

- close the warm water, cold water and steam taps (the latter applies

to steam-heated machines only);

- turn the wall circuit breaker off.

6.8 THE WEIGHING FUNCTION

The washing machine is fitted with a special function that informs

the user how many kilos of laundry he/she has loaded onto the

drum. When this value is available, the machine proportions the

amount of water and detergents to the real load and not to a the

standard theoretical full-load value.

The weighing function is fully automatic: all the user has to do is

load the drum, select the desired program, close the door and push

the "START / STOP" button.

To change the weighting function from automatic to manual it is

necessary to alter the settings using a PC connection and the ad-hoc

software. Contact the technical after-sales service for further

details.

CAUTION! When the machine performs the weighing function

automatically, the weight value read NEVER appears on the

display. This occurs only when the weighing function is manual.

6.9 WASH PROGRAMS

Cycle steps are detailed in the user-friendly tables attached.

Generally speaking, the first 9 cycles feature automatic weighing,

cycle 10 rinses and spins only, and the last 9 cycles are clones of the

first nine cycles except for the weighing function, which is

DISABLED. Cycle 20 is empty (customizable). At any rate, ALL

cycles can be customized using a PC and the ad-hoc software.

Contact the technical after-sales service for further details.

CAUTION!

If the machine has been programmed via PC or optional functions

have been enabled, the cycle tables provided below do not apply.

The manufacturer reserves the right to change cycle the features or

the machine's

6.10 ADVICE

Do not leave the machine on to no purpose. TURN the master switch

OFF when the machine is not being used.

During use:

- Only open the door after the drum has come to a complete stop and

it has been drained.

- In case of a potential drop during a washing cycle, the door may

be opened after about 90 sec. In case of emergency or defect of the

door opening device, it is possible to open the door by jerking the

manual puller downwards (see fig.1). Before opening the door make

sure that the drum has come to a complete stop, that the water has

been drained and that the temperature is below 40°C.

- Before any maintenance or cleaning operation, check that the wall

circuit breaker is off and the warm water, cold water and steam taps

are closed (the latter applies to steam-heated machines only).

- Do not machine-wash fabrics that have been cleaned, dampened,

washed or stain-removed with inflammable or explosive substances.

Otherwise, hand-wash them first.

- Keep inflammable liquids far from the washing machine, in a dry

and ventilated spot, out of the reach of outsiders.

- Keep cleaning products and washing powder far from the

equipment. If possible, keep them closed in a cabinet.

- Do not hamper air inlets or heat-exchanging openings. Keep an

appropriate distance between the machine and the walls or other

objects.

7. SAFETY PROCEDURES

During operation, the machine monitors working conditions and,

in case of malfunction, displays the relevant alarm signals.

Such signals will flash on the display.

When alarms arise, some of them can be removed by switching the

machine off and then on again. These removable alarms also cause

the door to be unlocked, although 90 seconds after the alarm occurs.

To remove the alarm signal from the display unit, either switch the

machine off and then on again (to disconnect and reconnect the

card) or wait for 5 minutes: the alarm will be called off automatically

(see the specific alarm management section).

Of course, if the cause for the alarm persists, the alarm signal will

be there again even after switching the machine back on or after the

automatic reset caused by program restart (the user must press the

START/STOP push button).

7.1 PARTICULAR FEATURES OF THE "MOTOR

FAILURE" ALARM

For some alarm types involving the inverter / motor, reset may occur

automatically.

Then when an inverter alarm arises, the motor goes to idle for 90

seconds (8kg model), 120 seconds (11kg model), or 150 seconds

(18kg model). The inverter too stays "idle" during that time.

After the time indicated the machine resumes operation from the

step right after the one in which the alarm occurred.

This procedure can be repeated for 5 times maximum. Then the

program is aborted and the door is unlocked after a further 150 sec

safety time.

The alarm will stay on in the display for 300 secs. Then the machine

will reset automatically, and will be ready and waiting for a new

start to be given.

The buzzer only trips when the program is interrupted. The only

notice given all through the attempts at finishing the programmed

step is the alarm signal on the display.

8

PARAMETER CONFIGURATION

www.groupdynamics-laundry.com

sales@groupdynamics.lv

MACHINE STANDBY STATUS

MACHINE PARAMETERS

1) COOLING

2) SPINNING

3) PREWASH

4) DEFERRED START

5) BUZZER

6) HEATING

7) ENABLE CYCLES

. . . . . . .

. . . . . . . .

MACHINE PARAMETERS

1) COOLING

MACHINE PARAMETERS

2) SPINNING TIME

MACHINE PARAMETERS

3) PREWASH

MACHINE PARAMETERS

4) DEFERRED START

MACHINE PARAMETERS

5) BUZZER

MACHINE PARAMETERS

6) HEATING

MACHINE PARAMETERS

7) ENABLE CYCLES

MACHINE PARAMETERS

1) COOLING

CYCLE 01

MACHINE PARAMETERS

2) SPINNING TIME

MACHINE PARAMETERS

MACHINE PARAMETERS

4) DEFERRED START: disabled /

enabled

WHEN ENABLED, DELAY TERM CAN

BE SET.

DELAY RANGE: 00h:00min - 23h:59min

TIME STEP: 1 MINUTE

MACHINE PARAMETERS

MACHINE PARAMETERS

6) HEATING:

normal / reduced

MACHINE PARAMETERS

7) ENABLE CYCLES

CYCLE 01

CYCLE 02

CYCLE 03

. . . . .

CYCLE 20

CYCLE 02

CYCLE 03

. . . . .

CYCLE 20

CYCLE 01

CYCLE 02

CYCLE 03

. . . . .

CYCLE 20

3) PREWASH

CYCLE 01

CYCLE 02

CYCLE 03

. . . . .

CYCLE 20

5) BUZZER: YES / NO

MACHINE PARAMETERS

MACHINE PARAMETERS

1) COOLING

. . . . . .

CYCLE 02: YES / NO

. . . . . .

MACHINE PARAMETERS

2) SPINNING TIME

. . . . . .

CYCLE 03: 0 - 150%

. . . . . .

MACHINE PARAMETERS

3) PREWASH

. . . . . .

CYCLE 02: YES / NO

. . . . . .

MACHINE PARAMETERS

7) ENABLE CYCLES

. . . . . .

CYCLE 02: YES / NO

. . . . . .

9

MACHINE STANDBY STATUS

www.groupdynamics-laundry.com

sales@groupdynamics.lv

MACHINE PARAMETERS

. . . . . . .

8) DRUM MOVEMENT INTAKE/DRAIN

9) HEATING HYSTERESIS

10) PUMP LEVEL

11) START WITH H2O

12) CALIBRATION

13) VIEW CYCLE TIME

MACHINE PARAMETERS

8) DRUM MOVEMENT INTAKE/DRAIN

MACHINE PARAMETERS

9) HEATING HYSTERESIS

MACHINE PARAMETERS

10 ) PUMP LEVEL

MACHINE PARAMETERS

11) START WITH H2O

MACHINE PARAMETERS

12) CALIBRATION

MACHINE PARAMETERS

13) DISPLAY CYCLE TIME

MACHINE PARAMETERS

MACHINE PARAMETERS

8) DRUM MOVEMENT

INTAKE/DRAIN

CYCLE 01

CYCLE 02

CYCLE 03

CYCLE 20

MACHINE PARAMETERS

9) HEATING HYSTERESIS

RANGE BETWEEN 2°C AND 6°C

MACHINE PARAMETERS

10) PUMP LEVEL

PROGRAMMABLE FROM MIN.

THRESHOLD OF 4CM

MACHINE PARAMETERS

11) START WITH H2O

12) CALIBRATION

CLOSE DOOR AND PRESS START / STOP

THAT STARTS AUTOMATIC PROCEDURE

. . . . .

CYCLE 01

CYCLE 02

CYCLE 03

. . . . .

CYCLE 20

MACHINE PARAMETERS

8) DRUM MOVEMENT INTAKE/DRAIN

. . . . . .

CYCLE 02: YES / NO

. . . . . .

MACHINE PARAMETERS

11) START WITH H2O

. . . . . .

CYCLE 02: SI / NO

. . . . . .

WAIT FOR END

OF STEP

MACHINE

WAITS FOR

START

MACHINE PARAMETERS

13) DISPLAY CYCLE TIME

CYCLE 01

CYCLE 02

CYCLE 03

….CYCLE 20

MACHINE PARAMETERS

13) DISPLAY CYCLE TIME

. . . . . .

CYCLE 03: - - h: - - min.

PROGRAMMING RANGE BETWEEN 00h :

00min AND 99h : 59min

10

ALARM E1 WATER IN THE TUB

f

www.groupdynamics-laundry.com

sales@groupdynamics.lv

DISPLAY DESCRIPTION E1: WATER IN THE TUB

DESCRIPTION

BUZZER The BUZZER will not go on.

ALARM RESET

CHECKS REQUIRED

CORRECTIVE ACTION

ALARM E2 WATER INTAKE TIME EXCEEDED

DISPLAY DESCRIPTION

DESCRIPTION

BUZZER

ALARM RESET

CHECKS REQUIRED

CORRECTIVE ACTION

ALARM E3 WATER DRAIN TIME EXCEEDED

DISPLAY DESCRIPTION

DESCRIPTION

BUZZER The BUZZER will not go on.

ALARM RESET

CHECKS REQUIRED

CORRECTIVE ACTION

If the pressure switch detects a water level above 4cm

at the beginning of the cycle, this will be terminated.

The alarm can be removed by switching the machine

off and then on again.

drain condition

leve l pre ssur e-s witc h

condition of tub/pressure switch tube

Clean and inspect the drain valve.

Perform level calibration for the electronic card.

Replace the tube connecting the tub to the pressure

switch.

E2: poor water level

During a wash cycle the water failed to reach the

required level in the programmed intake time; water

intake and the wash cycle will proceed normally.

The buzzer will go on only 5 minutes after the alarm

occurred.

The alarm is automatically dismissed if the required

water level is reached in 5 minutes.

The machine will prompt the user whether to restart

the cycle or not: “START:?” if the machine failed to

reach the required level in 5 minutes.

drain condition

leve l pre ssur e switch

condition of tub/pressure switch tube

Clean and inspect the drain valve and the water intake

valves.

Perform level calibration for the electronic card.

Replace the tube connecting the tub to the pressure

switch.

E3: drainage failure

During a wash cycle, 1minute after the start o

draining the water level failed t o drop under the

minimum threshold (4cm); water draining and the wash

cycle proceed normally.

The alarm is automatically dismissed as soon as the

water level drops below the 4cm minimum threshold.

drain co ndition

leve l pre ssur e switch

cond ition of tub/p ressure swit ch tube

Clean and inspect the drain valve and the water intake

valves.

Perform level calibration for the electronic card.

Replace the tube connecting the tub to the pressure

switch.

ALARM E4 HEATING TIME EXCEEDED

DISPLAY DESCRIPTION

E4: slow heating

After the heating has worked for 20 minutes, the

DESCRIPTION

temperature failed to rise by at least X°C. The display

reads “E4: slow heating", and the cycle proceeds

normally.

BUZZER The BUZZER will not go on.

The alarm is automatically removed as soon as the

ALARM RESET

calculated threshold or the maintain (soak) time is

reached.

drain condition

CHECKS REQUIRED

level pressure swit ch

condition of tub/pressure switch tube

Condition and cleanliness of heating elements

Clean and inspect the drain valve and the water intake

valves.

Perform level calibration for the electr onic card.

CORRECTIVE ACTION

ALARM E5

DISPLAY DESCRIPTION

DESCRIPTION

BUZZER The BUZZER goes on immediately.

ALARM RESET

CHECKS REQUIRED

CORRECTIVE ACTION

ALARM E5

DISPLAY DESCRIPTION

DESCRIPTION

ALARM E6 DOOR LOCK/UNLOCK TIME EXPIRED

DISPLAY DESCRIPTION

DESCRIPTION

BUZZER The BUZZER will not go on.

ALARM RESET

CHECKS REQUIRED

CORRECTIVE ACTION

ALARM E7 DOOR FAULT ALARM

DISPLAY DESCRIPTION

DESCRIPTION

BUZZER The BUZZER goes on.

ALARM RESET

CHECKS REQUIRED

CORRECTIVE ACTION

Replace the tube connecting the tub to the pressure

switch.

Replace the faulty heating elements.

Ensure that the value entered in the SERVICE menu,

item “HEATING TIME: X°C/20minutes”, is

correct.

SUPERHEATING OR DISCONNECTED

SENSOR

E5: superheating - probe 1

At any given moment if sensor TEMP1 is not

connected or if it reads a temperature above

below 0°C,

The alarm can be removed by switching the machine

off and then on again.

Perfect condition of temperature probe: cable + sensing

element + connector.

Correct connection of the electronic card

Proper operation of heating contactor

Condition and cleanliness of heating elements

Replace the broken element with a new one.

Correct connection of the electronic card

Replace the heating contactor with a new one

Replace the faulty heating element/s.

SUPERHEATING OR DISCONNECTED

SENSOR

E5: superheating probe 2

SEE PREVIOUS ALARM: This alarm is enabled for

spe cial ve rsio ns.

E6: door failed to be locked/unlocked

If the door is not locked/unlocked within 10seconds

from the door lock/unlock command, this is

interrupted.

The alarm is removed by holding the START / STOP

button pressed until the door can be opened manually

using the procedures specific to each machine model.

The do or may have been closed incorrectly by hand.

The handle may have been forced: the lock

microswitch o r lock devices may have been damaged.

Open and close the door again and start the cycle.

Replace the faulty microswitch/es or the entire door

lock.

E7: Door fault

If there is a power drop affecting the door microswitch

MPORT or at the door-lock signal input MBLOC, the

cycle in progress is interrupted.

The machine will prompt the user whether to restart

the cycle or not: “START:?”.

If the problem persists, it will be necessary to switch

the machine off and then on again.

The handle may have been forced during the wash

cycle: the lock microswitch or lock devices may have

been damaged.

Replace the faulty microswitch/es or the entire door

lock.

the cycle will automatically be terminated.

95°C or

11

ALARM E8 LEVEL ERROR

f

www.groupdynamics-laundry.com

sales@groupdynamics.lv

DISPLAY DESCRIPTION

DESCRIPTION

E8: Level error

If a water level 10 cm above the established height is

detected, the cycle is interrupted.

BUZZER The BUZZER goes on.

When the level is back below the safet y value t he

display prompts “START ?”. The user can either try to

ALARM RESET

resume the program from same step or go to the end o

the cycle and collect the washing. The alarm can also

be removed by switching the machine off and then on

again.

working conditio n of the w ate r intake valves

CHECKS REQUIRED

leve l pressur e switch

condition of tub/pressure switch tube

Clean and inspect the water intake valves

Perform level calibration for the electr onic card

CORRECTIVE ACTION

Replace the tube connecting the tub to the pressure

switch

DO not use very foamy soap.

ALARM E9 OUT-OF-BALANCE

DISPLAY DESCRIPTION

E9: Out of balance

The tilt switch (the contact connected to MSBIL

opens) notifies that there is a mechanical hazard

involving drum movement and the weight distribution

DESCRIPTION

inside the drum. This alarm is monitored only during

spinning and weighing. The alarm appears on the

display only after the last restart attempt has failed, and

then the cycle is terminated.

BUZZER The BUZZER goes on.

ALARM RESET

This alarm is reset at the end o f the step in which it

occurred, and the door is simultaneously unlocked.

Cor rect adjustment of the tilt switch.

Correct positioning of the microswitch rod in the

mobile window.

CHECKS REQUIRED

The laundry load needs to be as homogeneous as

possible.

Vibration dampers and shock absorbers must be in

goo d condition. They must not be discharged or worn

down.

Connect t he tilt switch properly.

Position the microswitch rod properly inside the mobile

CORRECTIVE ACTION

window.

Optimize the laundry load.

Replace discharged or worn down vibration dampers

and shock absorbers.

OUT OF BALANCE OUT OF BALANCE “A”, “B” or “C”

DISPLAY DESCRIPTION

DESCRIPTION

“A”, “B” or “C” flashing on the second screen of the

spinning step (pushing the MODE button). This

reading is not available for SELFSERVICE versions.

While in the speed = distribution 1, the machine assesses

the distribution quality inside the drum, i.e. how the

laundry items are distributed.

Letter “C” stands for good distribution, letter “B” stands

for mediocre distribution, and letter “A” stands for bad

distribution.

When distribution is assessed to be type “A” final spinning

speed will automatically be reduced by 7.5%.

If distribution is type “B” or “C” maximum sp inning

speed remains unchanged.

BUZZER The B UZZER will not go on.

ALARM RESET

CHECKS REQUIRED

CORRECTIVE ACTION

AUTOMA TIC SPEED

REDUCTION

DISPLAY DESCRIPTION

DESCRIPTION

BUZZER The BUZZER will not go on.

ALARM RESET

CHECKS REQUIRED

CORRECTIVE ACTION

ALARM

This function is automatically enabled and disabled at each

spinning step.

If distribution type “C” occurs often, check that the

laundry load is as equalized as possible.

Vibration dampers and shock absorbers must be in good

condition. They must not be run down or worn out.

As a rule no corrective action is needed, other than

equalizing the laundry loa d (using it ems similar in size and

type).

LAUNDRY LOAD TOO BIG OR TOO SMALL

NONE

IF THE AUTOMATIC WEIGHING FUNCTION

HAS BEEN ENABLED, the machine weighs how heavy

the laundry load contained in the drum is, ex pressing it in

kilos.

If the drum is UNDERLOADED, i.e. the load is 40%

smaller than the rated capacity, or else if the drum is

OVERLOADED, meaning that the load is in excess of

120%, the maximum spinning speed is automatically

reduced by 8% in models for 22kg, it is reduced by 15%

in models for 1 6.5kg and by 10% in models for 7, 4kg and

9,5kg.

This function is automatically enabled and disabled at each

spinning step.

Check that the laundry load at issue falls within the

machine's working range.

As a rule no corrective action is needed, other than

equalizing the laundr y load (using items similar in size and

type), and using a load between 40% and 120% of the

machine's capacity rating.

MOTOR OVERLOAD SWITCH TRIPPED WITH

AUTORESET ALARMS

EF Motor fault

1 “

”

2 “OC Motor overcurrent”

DISPLAY DESCRIPTION

3 “OV motor overvoltage”

UV motor undervoltage

4 “

5 “OCH motor failure”

6 “ST motor failure”

These 6 alarms are read on the display. The listing

DESCRIPTION

priority is from highest to lowest. When in error

condition, the inverter awaits the automatic reset of the

G400 control.

BUZZER The BUZZER goes on.

Control G400 performs the first reset attempt and the

display prompts “START?”.

ALARM RESET

After 5 consecutive attempts the alarm stays fixed and

can only be removed by switching the machine o ff and

then on again.

The power voltage supplied to the machine must be in

CHECKS REQUIRED

the range specified in the rating plate.

The wash load MUST NOT exceed the machine’s

rated load.

Connect the appliance to a power source ensuring the

CORRECTIVE ACTION

correct voltage.

Optimize the laundry load.

”

12

ALARM

www.groupdynamics-laundry.com

sales@groupdynamics.lv

DISPLAY DESCRIPTION

DESCRIPTION

BUZZER The BUZZER goes on.

ALARM RESET

CHECKS REQUIRED

CORRECTIVE ACTION

MOTOR OVERLOAD SWITCH TRIPPED WITH

NON AUTORESET ALARMS

1 “OH inverter supertemperature”

OLi inverter overload

2 “

3 “OLM motor overload”

OLR brake overload

4 “

5 “OT motor torque overload”

inverter phase failure

6 “PH

7 “FU inverter input fuse”

OP1 communication failure

8 “

9 “OP2 communication failure”

communication failure

10 “BF

11 “OHS inverter supertemperature”

LF Inverter limit condition

12 “

13 “SHC mo tor short circuit”

These 13 alarms are read on the display as they occur

and their listing priority is the same.

There is NO inverter autoreset time.

The alarm is fixed and can only be removed by

switching the machine off and then on again. The

display will read the relevant alarm acronym and will

prompt the user to “switch off the machine”.

CAUTION! Many causes may need to be attended to

by the service personnel.

“OH inverter supertemperat ure”:

1

installation needs to meet the rating plate details.

Check that the inverter fans are clean and in good

working condition.

2 “OLi inverter overload”: Optimize the laundry

load.

3 “OLM motor overload”: Optimize the laundry

load.

4 “OLR brake overload”: Optimize the laundry load.

motor torque overload”:

5 “OT

load.

inverter phase failure”:

6 “PH

wiring.

FU Inverter input fuse

7 “

service.

communication failure”:

8 “OP1

sales service.

communication failure”:

9 “OP2

sales service.

BF communication failure

10 “

sales service.

11“ OHS inverter supertemperature” The place of

installation needs to meet the rating plate details.

Check that the inverter fans are clean and in good

working condition.

12 “12 “LF Inverter limit condition” Optimize the

laundry load.

13 “SHC mo tor short circuit” Contact the after-sales

service.

”

”

”

”

”

”

The place of

Optimize the laundry

Restore proper

”: contact the area technical

Contact the after-

Contact the after-

”: Contact the after-

INSTRUCTIONS FOR MAINTENANCE

8. INFORMATION ON SPECIAL USE AND

SAFETY MEASURES

When carrying out the first cycle, verify the following:

- Soap dispensers must stay clean.

- Perform a 90°C cycle to remove all manufacturing residues.

- The operator must be able to check soap compartments with ease.

Place a platform if necessary.

- Make certain that laundry trolleys are lower than the door's bottom

edge.

- If need be, mount appropriate bumpers to prevent trolleys from

impacting and damaging the door.

- Never open the soap compartment when the machine is being

filled with water or it is heating. Some models are standard-fitted

with a device that puts the machine to pause at once. Close the

dispenser and press the START button to begin the cycle again.

8.1 ORDINARY MAINTENANCE BY THE USER

BEFORE ANY MAINTENANCE OPERATION, CHECK THAT

THE WALL CIRCUIT BREAKER IS OFF AND THE WATER

TAPS ARE CLOSED. THE DRUM MUST BE MOTIONLESS

AND DRAINED AND THE TEMPERATURE INSIDE IT MUST

NOT EXCEED 40°C.

The machine requires no special maintenance, thanks to its

ergonomic design and to the use of very reliable, first-quality parts.

Periodically clean the external panels with a damp cloth. Never use

inflammable or abrasive products and rub in the direction of the

satin-finish.

Always keep forced-cooling slots and openings free from dust (the

fan sucks fresh air from the room), which are on the rear of the

machine, where the speed inverter is housed.

NEVER WASH THE APPLIANCE USING WATER JETS.

PRIOR TO CONNECTING POWER SUPPLY AGAIN BY THE

MAIN CIRCUIT BREAKER ON THE WALL, PUT ALL THE

PANELS REMOVED BACK IN PLACE.

8.2 EXTRAORDINARY MAINTENANCE AND

ORDERING SPARE PARTS

8.2.1 ACCESSING THE ELECTRICAL BOARD

Models for up to 22kg

To reach the electrical parts of the machine, take off the screws

fastening the soap dispenser and proceed as follows:

A) Key-locked cover : insert the keys supplied into the two locks

located at the top's rear.

Unlock the cover's front and lift it until it can be held up by the stop

rod located on the side of the machine, beside the soap dispenser.

The cover is hinged at the back of the machine and cannot be

removed altogether.

B) Cover without key-lock: take off the screws fastening the cover

to the back panel; then lift the rear part of the cover and pull it to

the front by approximately 5 cm.

7.2 MANAGEMENT OF ALARM RECORDS

The alarm records will be managed in the SERVICE, menu,

protected by a password of level 1. It will be possible to track the last

10 alarm events recorded by the G400 control. Enter this parameter

to view the sequence with the previous 10 errors, starting from the

very last, along with the step and cycle they occurred in. If the error

occurred astride two steps, the reference will be the earliest step.

Event time and date will not be stored.

Models for over 22 kg

The electrical panel has two parts: the front, which includes control

devices, and the rear, which contains the power devices and the

inverter.

A) Key-locked front cover: insert the keys supplied in the two locks

located on the machine's front and turn this downwards until it

stops against the horizontal support.

B) Cover without key-lock: remove the screws that fasten it to the

back panel and remove the rear to access the power components.

PRIOR TO CONNECTING POWER SUPPLY AGAIN BY THE

MAIN CIRCUIT BREAKER ON THE WALL, PUT ALL THE

PANELS REMOVED BACK IN PLACE.

13

8.2.2 SAFETY DEVICES

www.groupdynamics-laundry.com

sales@groupdynamics.lv

- Door closed safety microswitch cuts off power to the whole

auxiliary circuit and consequently stops the machine.

- Electronic overcurrent device (overload cutout) within the motor:

disconnects power supply in the event of coil overheating.

- Air-break system in the soap dispenser: prevents wastewater from

polluting the drinkable water system in the event of a depression.

- Normally open drain valve: enables safe door manual opening by

means of the manual puller.

- Tilt switch: avoids mechanical damage in the event of irregular

loads.

- Fuse-fitted heating elements. the electric circuit is disconnected in

case of malfunction.

8.3 PERIODIC MAINTENANCE BY TECHNICAL

PERSONNEL

All periodic maintenance operations must be carried out by the

authorized after-sales service or by qualified personnel.

BEFORE ANY MAINTENANCE OPERATION, CHECK THAT

THE WALL CIRCUIT BREAKER IS OFF AND THE WARM

WATER, COLD WATER AND STEAM TAPS ARE CLOSED

(THE LATTER APPLIES TO STEAM-HEATED MACHINES

ONLY). THE DRUM MUST BE MOTIONLESS AND DRAINED

AND THE INSIDE TEMPERATURE MUST NOT EXCEED

40°C.

Be very careful during maintenance. NEVER override or ignore

safety devices for any reason. Use only original spare parts. If doubts

should arise, contact your sales person immediately, explaining

what the fault is and indicating some information on the machine:

model and serial number (details reported on the rating plate

appearing on the rear of the machine or inside the door, where

applicable).

Monthly checks

Make certain that the filters located on the outer part of the electrical

valves are clean.

Make certain that the steam valve strain is clean (this applies to

steam-heated machines only).

Clean the soap dispenser from any soap remains.

Clean the door gasket and the tub inlet with a cloth. Always keep

forced-cooling slots and openings free from dust (the fan sucks

fresh air from the room), which are on the rear of the machine,

where the speed inverter is housed.

Yearly checks

Make certain that the floor fastening nuts are securely closed (if

applicable).

Check the wear of the belts and replace them if necessary. If more

than one of them is worn out, replace the entire set of belts.

Make sure that the safety devices are working properly (e.g. the lock

microswitch and the tilt microswitch).

Check that the screws for electrical connection are tight on the

contactors and power inlet terminal strip.

Disassemble the drain valve and clean it inside from lint.

Check that the heating elements are in perfect condition and clean

them from scale.

BEFORE TURNING THE MACHINE BACK ON BY THE

CIRCUIT BREAKER, PUT ALL THE PANELS REMOVED

BACK IN PLACE.

8.4 AUTOMATIC MAINTENANCE REQUEST

The machine saves the number of cycles it executes. After 1000

programs the machine will flash a message from cycle 1001

onwards.

More precisely, when starting a new cycle by the START/STOP

button, the machine will enable the buzzer and will flash the writing

" MAINTENANCE REQUIRED" for 10 seconds. Then it will carry

out the selected cycle normally. At every cycle, 50 cycles before

cycle 1000, the display puts out the message "MAINTENANCE IN

50 cycles" to warn the user that maintenance will be required. In this

case the buzzer will not be enabled.

When this message is displayed, request yearly maintenance.

To dismiss this reading and start the 1000 cycle count from scratch,

press the push-button "- " for at least 5 secs with the door closed.

Then the total number of cycles performed will be viewed and, if the

push button "-" is pressed again within 10 seconds, the count will

be set to zero and will be ready to start back again.

Before resetting the G400 control it will be necessary to enter a date

and a text. The control will first read the question "date: 01/01/01".

Move the cursor to the first "0". Increase or decrease the selection

as needed using keys "+" and "-" and confirm using the "! :

ENTER" key. Then the cursor will automatically move to the

second figure of the date ("1"). Proceed accordingly until the date

is complete and then press the "! : ENTER" key. The G400 control

will prompt the word "technician": enter the name of the person

who performed the maintenance.

Press the "SEL" key: the cursor will become bigger so that you can

select the letters using keys "+" and "-". Confirm by the "! :

ENTER" key. The cursor will move to the next position so that you

can select the next letter as above. The control count cannot be reset

unless these two values are entered.

This information will be stored and is available in the SERVICE

menu, MAINTENANCE entry, along with the number of cycles

performed from the last maintenance event and the total number of

cycles carried out.

8.5 IDENTIFYING AND ORDERING SPARE PARTS

To identify the codes of spare parts refer to the exploded drawings

and relevant list. Once you have identified your codes, send a

standard written order to the manufacturer, mentioning clearly

machine model, serial number, feed voltage and frequency and, of

course, including the code and description of the spare part needed.

9. MACHINE DECOMISSIONING,

DISMANTLING AND DISPOSAL

If the equipment is no longer to be used, it is advisable to

decommission it and suitably dispose of the resulting materials,

considering the advice provided in the chapter "Transportation and

installation". Please, for the sake of the environment, sort the

materials in accordance with the waste disposal provisions in force

in your country, so that they can be properly disposed of or recycled.

All the parts composing the machine can be treated as solid urban

waste, except for the metal parts, which yet are not classed among

special waste in most European countries.

9.1 INFORMATION TO USERS

Pursuant to the Italian law 151 that implements Directives 2002/

95/EC, 2002/96/EC and 2003/108/EC concerning the reduction in

the use of hazardous substances in electric and electronic apparatus,

as well as waste disposal

the crossed-out dustbin symbol on the appliance indicates the

product must be disposed of separate from other wastes once it

reaches the end of its life cycle.

The sorting for recycling purposes of this equipment when at the

end of its life cycle is organized and managed by the manufacturer.

Users willing to discard this equipment will have to contact the

manufacturer and comply with the procedures the latter has

established for sorting and recycling the machine at the end of its

life cycle. Adequate pre-sorted waste collection before subsequently

sending the appliance for recycling, treatment and environmentally

compatible disposal helps avoid possible negative effects on the

environment and health and favors the recycling of the materials

making up the appliance. Unlawful disposal of the product by the

user is punishable by the administrative sanctions the laws in force

provide for.

14

SPACE REQUIRED FOR MACHINE INSTALLATION, USE AND MAINTENANCE

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Fig. 1

5

2

3

4

15

16

6

7

22kg

835

1

2

9

11

8

4040

5050

19

18

23

17

12

10

25

21

22

24

14

800

15

MACHINE DESCRIPTION

www.groupdynamics-laundry.com

sales@groupdynamics.lv

16

Cycles 1 to 9 with initial automatic weighing

www.groupdynamics-laundry.com

sales@groupdynamics.lv

Cycles from 10 to 19 are identical to 1 to 9, except for initial automatic weighing, which is disabled.

Cycle 1: very soiled whites

For very soiled hard-wearing laundry

40°C prewash with strong wash action 40°C prewash with gentle wash action

500 rpm short spinning 500 rpm short spinning

90°C main wash with strong wash action 60°C main wash with gentle wash action

500 rpm short spinning Rinse with gentle wash action

Rinse with strong action 500 rpm short spinning

500 rpm short spinning Rinse with gentle wash action

Rinse with strong action 500 rpm short spinning

500 rpm short spinning Rinse with gentle wash action and softener int ake

Rinse with strong wash action and softener intake Short 1000 rpm spinning

Short 1000 rpm spinning

Cycle 2: soiled whites

For very soiled hard-wearing laundry

40°C prewash with strong wash action 40°C prewash with strong wash action

500 rpm short spinning 500 rpm short spinning

60°C main wash with strong wash action 40°C main wash with strong wash action

500 rpm short spinning 500 rpm short spinning

Rinse with strong action Rinse with strong action

500 rpm short spinning 500 rpm short spinning

Rinse with strong action Rinse with strong action

500 rpm short spinning 500 rpm short spinning

Rinse with strong wash action and softener intake Rinse with strong wash action and softener intake

Short 1000 rpm spinning Short 1000 rpm spinning

Cycle 3: soiled coloreds

For colored hard-wearing laundry

For very soiled hard-wearing laundry requiring

Soak

Cycle 8: soak for very soiled items

For very soiled hard-wearing laundry requiring

Cycle 6: terry cloth

For toweling items

Cycle 7: delicate soak

soaking

soaking and high-temperature washing

40°C prewash with strong wash action

500 rpm short spinning 60°C prewash with strong wash action

40°C main wash with strong wash action 500 rpm short spinning

500 rpm short spinning 90°C main wash with strong wash action

Rinse with strong action 500 rpm short spinning

500 rpm short spinning Rinse with strong action

Rinse with strong action 500 rpm short spinning

500 rpm short spinning Rinse with strong action

Rinse with strong wash action and softener intake 500 rpm short spinning

Short 1000 rpm spinning Rinse with strong wash action and softener intake

Cycle 4: delicate coloreds

For colored delicates

Cold prewash with delicate wash action

Soak

Short 1000 rpm spinning

For very soiled hard-wearing laundry requiring

Cycle 9: soak for soiled items

soaking and medium/high temperature washing

25°C main wash with gentle wash action

500 rpm short spinning

Rinse with gentle wash action

Rinse with gentle wash action

Rinse with gentle wash action and softener intake

800 rpm last spinning

Cycle 5: very delicate items

For very delicate items

Cold prewash with delicate wash action

25°C main wash with gentle wash action

Rinse with gentle wash action

Rinse with gentle wash action

Rinse with gentle wash action and softener intake

500 rpm last spinning

Soak

40°C prewash with strong wash action

500 rpm short spinning

90°C main wash with strong wash action

500 rpm short spinning

Rinse with strong action

500 rpm short spinning

Rinse with strong action

500 rpm short spinning

Rinse with strong wash action and softener intake

1000 rpm last spinning

Rinse with strong action

1000 rpm last spinning

Simple rinse followed by spinning

Cycle 10: Rinse and spin

17

TECHNICAL DATA

www.groupdynamics-laundry.com

sales@groupdynamics.lv

MODELLI WFG4 8 11 18 22 WFG4 MODELS

Capacità rapporto

Dimensione cesto

Dimensione oblò Diam. mm 290 290 410 410 Diam. Door opening

Velocità cesto r.p.m. 25÷1000 25÷1000 25÷1000 25÷860 r.p.m. Drum speed

Fattore G 74/300 74/300 91/364 83/310 Factor G

Dimensioni Larg. mm 660 660 830 900 Width Dimensions

Dimensioni

imballo dimensions

Volume m

Peso netto/lordo Kg 235/250 275/300 465/485 740/830 Kg Net/gross weight

Alimentazione Pressione KPa 300/500 (3/5 bar) Pressure Water inlet

idrica

Scarico Diam. pollici 3" 3" 3" 3" inches Drain

Consumo * 79 113 137 153

idrico

Acqua calda Lt./ciclo 18 23 40 45 Lt./cycle Hot water

Alimentazione V/ph/Hz 400/3N/50-60 V/ph/Hz Electric supply

elettrica

Potenza riscaldamento Heating power

Standard KW 6 9 12 18 KW Standard

Optional KW 4.2/9 6/12 6/9 12 KW Optional

Potenza motore KW 0.75 1.5 2.2 3 KW Motor power

Potenza totale KW 6.75 10.5 14.2 21/15 KW Total power

Fusibile A 16-20 20-32 25-40 32-63 A Fuse

Rumorosità dB (A) 55 55 58 70.6 dB (A) Noise

1:10 Kg 7.3 9.5 16.5 22 1:10 Capacity ratio

Diam. mm 530 530 650 750 Diam. Drum size

Prof. mm 330 420 500 498 Depth

Volume dm

3

73 95 165 220

Volume

Prof. mm 690 790 960 1060 Depth

Alt. mm 1070 1140 1295 1430 Height

Larg. mm 750 750 930 975 Width Packing

Prof. mm 850 930 1140 1190 Depth

Alt. mm 1240 1290 1510 1620 Height

3

0.79 0.90 1.59 1.88 m

3

Volume

Diam. pollice 3/4" 3/4" 3/4" 3/4" inch

N° entrate 3 3 3 3 3 N° w. inlets

V/ph/Hz 230/3/50-60 V/ph/Hz

Modello vapore diretto/indiretto Direct/indirect steam model

Diretto KPa 50/ 600 (0,5/6 bar) KPa Direct

Consumo Kg/h 7.2 9.5 16.5 45.8 Kg/h Consumption

Indiretto KPa 300/ 600 (3/6 bar) - KPa Indirect

Consumo Kg/h 8.64 11.4 19.8 - Kg/h Consumption

Entrata vapore Diam. pollice 3/4" inch Steam inlet

Scarico vapore ind. Diam. pollici 3/4" inches Ind. steam outlet

Fusibile A 10 10 10 16 A Fuse

* Ciclo 60°C, senza il prelavaggio e carico ottimale. * 60°C program, without pre-wash at rated capacity.

18

Key to components – Electrical board of models WF8-11-18-22G4

www.groupdynamics-laundry.com

sales@groupdynamics.lv

A power card

B power card

BALANCE tilt microswitch

c liter meter common (optional)

C soap pump power card (optional)

CP (COINPROGRAM) coin-meter programming switch (optional)

CR cycle relay (optional)